Roof panel assembly and construction method thereof

A construction method and technology of roof panels, applied to roofs, building components, buildings, etc., can solve problems affecting roof construction quality, long construction time, and high construction costs, so as to save hoisting costs, reduce construction difficulty, and avoid potential safety hazards Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below, the present invention will be further described in conjunction with the accompanying drawings and specific implementation methods. It should be noted that, under the premise of not conflicting, the various embodiments described below or the technical features can be combined arbitrarily to form new embodiments. .

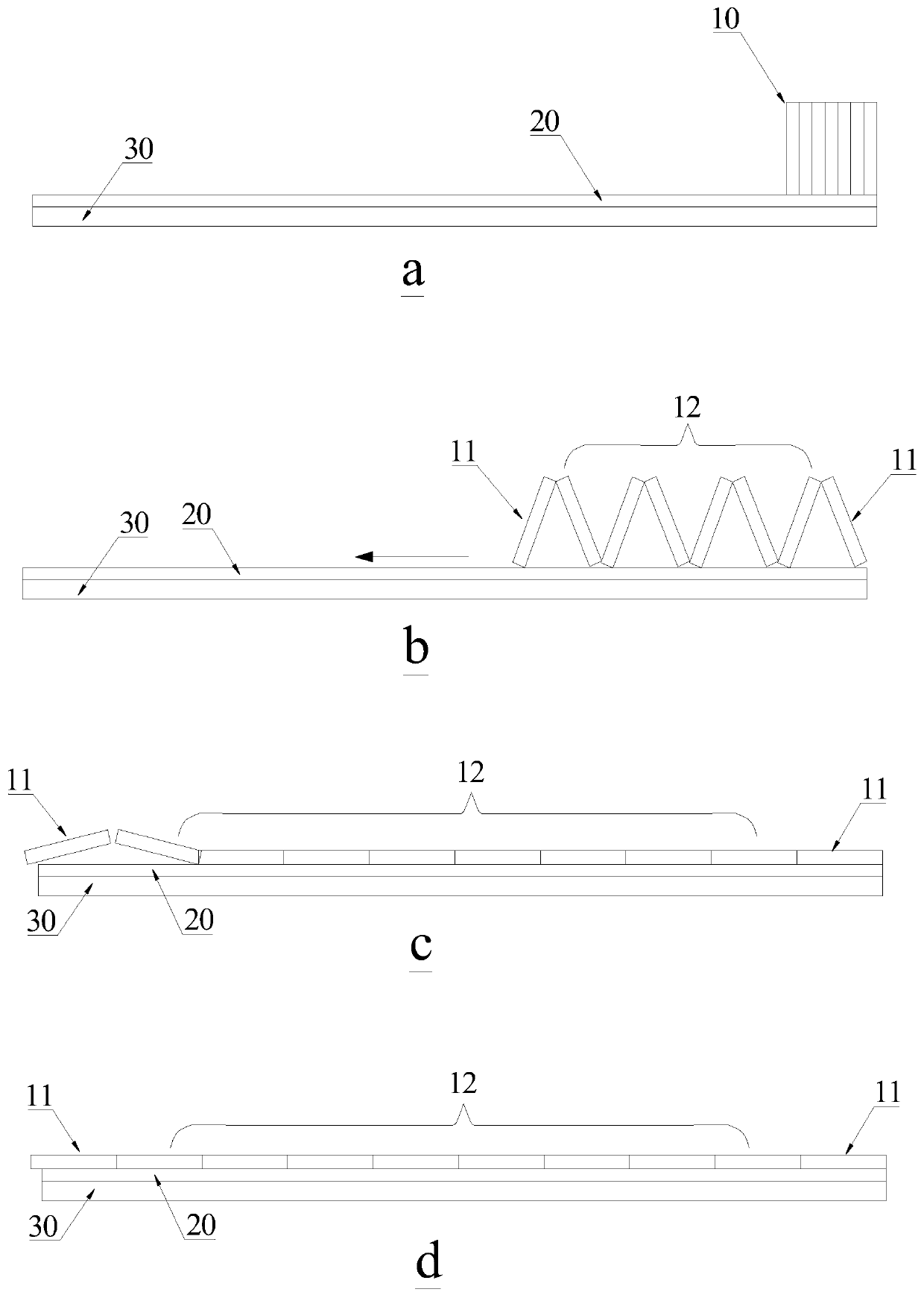

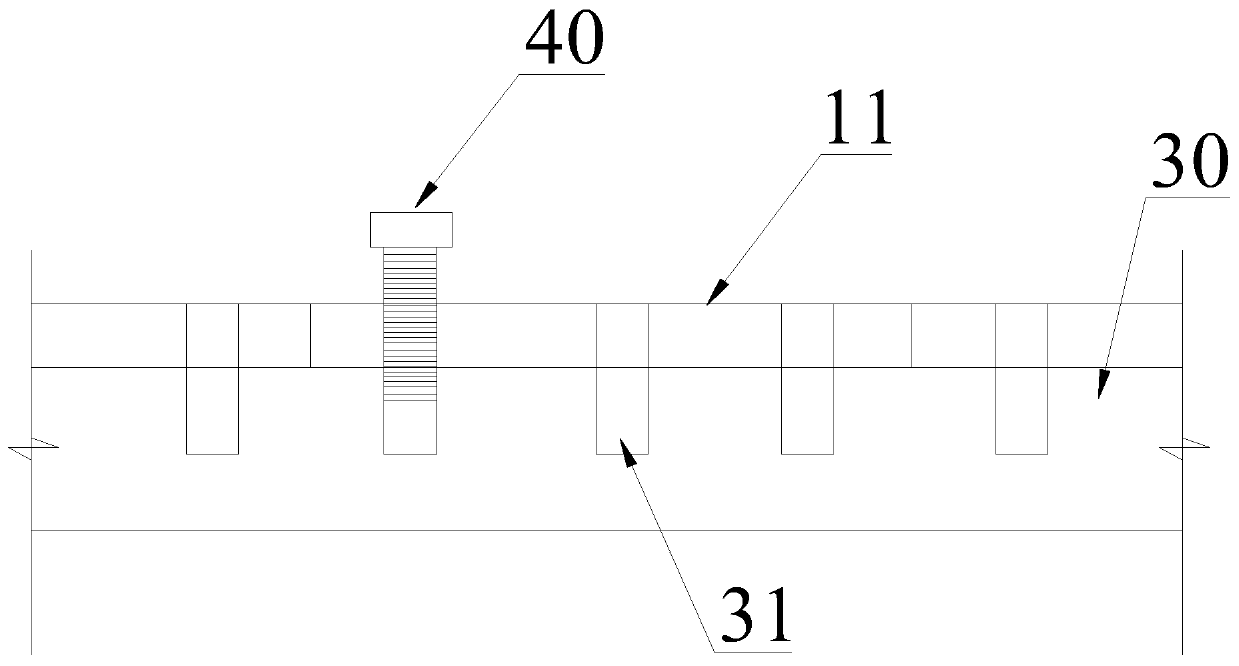

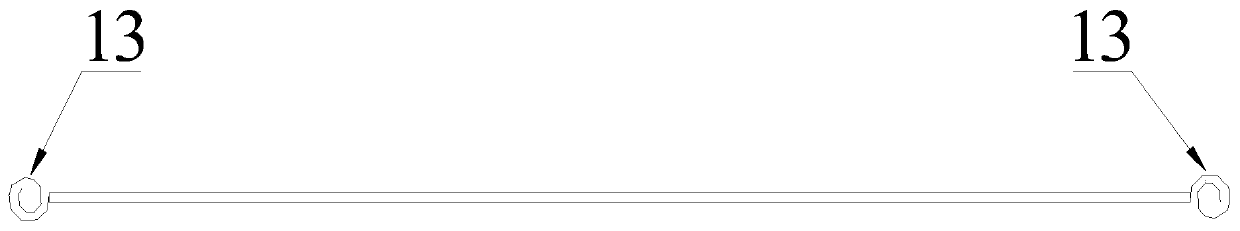

[0027] The invention discloses a roof panel assembly 10 and a construction method thereof, which can be used for roof panel installation of a steel structure factory building. refer to figure 1 This kind of roof panel assembly 10 is used for laying and fixing on the roof steel beam 30, and includes several roof panels in the form of a single piece, wherein the roof panel includes a first roof panel 11 and a second roof panel 12, the first roof panel The panel 11 is the roof panel at both ends of the roof panel assembly 10, and the second roof panel 12 is the roof panel between the two first layer panels, specifically, the two pieces at the head and en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com