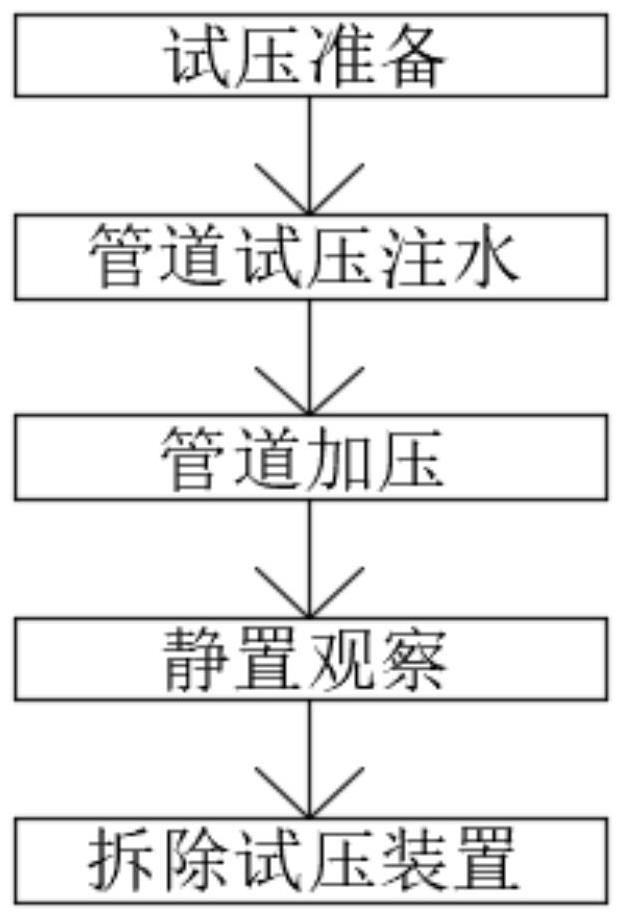

Water supply pipeline pressure test process

A technology for water supply pipes and water pipes, which is applied in the field of water pressure safety detection, which can solve the problems of water users' safety hazards, accumulation, lack of pipe cleaning, etc., and achieve the effect of rapid construction and installation, ensuring accuracy, and facilitating construction and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] See figure 1 , A water supply pipe test process, including the following steps

[0033] Step 1, the test pressure is prepared, according to the construction drawings, the pipeline is divided into several sections according to the system partition, and the segmentation partition is subjected to a separate test, and the test device is mounted on the pipeline assembly of the test pressure;

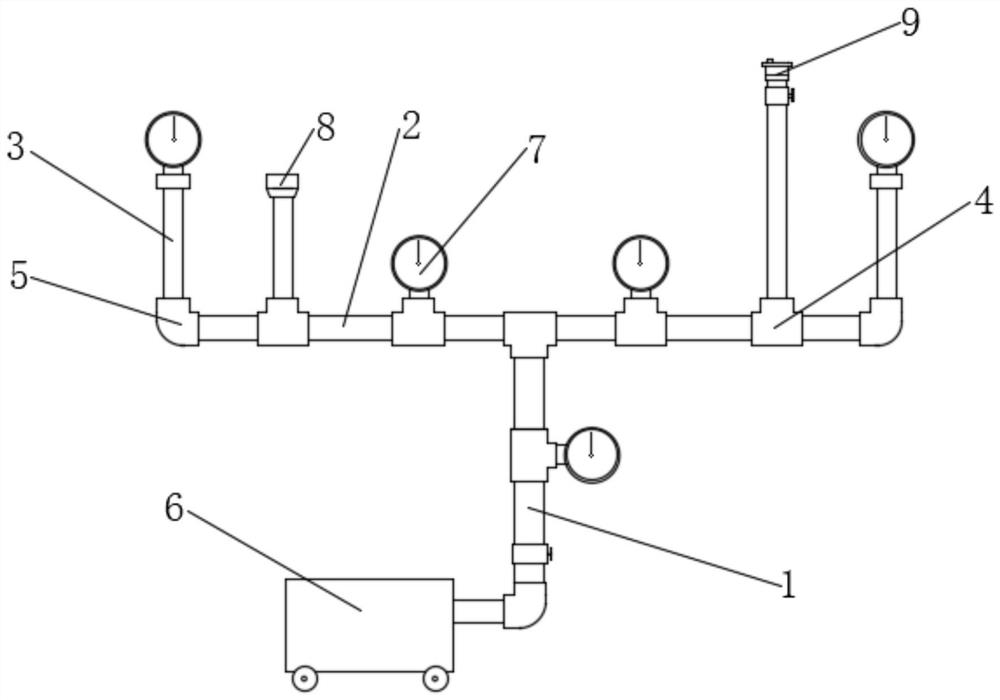

[0034] The pipe assembly is configured by the main water pipe 1, the split pipe 2, and the branch water pipe 3, which communicate with the split pipe 2 through the three-way connector 4, and several supports are connected to the split pipe 2. The road water pipe 3 is connected to the branch water pipe 2 at both ends, and the remaining the branch water pipe 3 is in communication with the binary water pipe 2 through the three-way connector 4.

[0035] The test device is configured by a pressure toner 7 attached to the body and performs pressure value monitored by an electric trial pump 6 con...

Embodiment 2

[0044] See Figure 2 ~ 4 , A water supply pipe test process, including

[0045] The pipe assembly is configured by the main road water pipe 1, the split pipe 2, and the branch water pipe 3. The water pipe 3 is connected to the branch water pipe 2 at both ends, and the remaining support pipe 3 is in communication with the binary water pipe 2 through the three-way connector 4.

[0046]The test device is configured by an electric pressing pump 6 connected to the main water pipe 1 inlet end, and is mounted on the pressure Table 7 monitored on the body and the pressure value monitored;

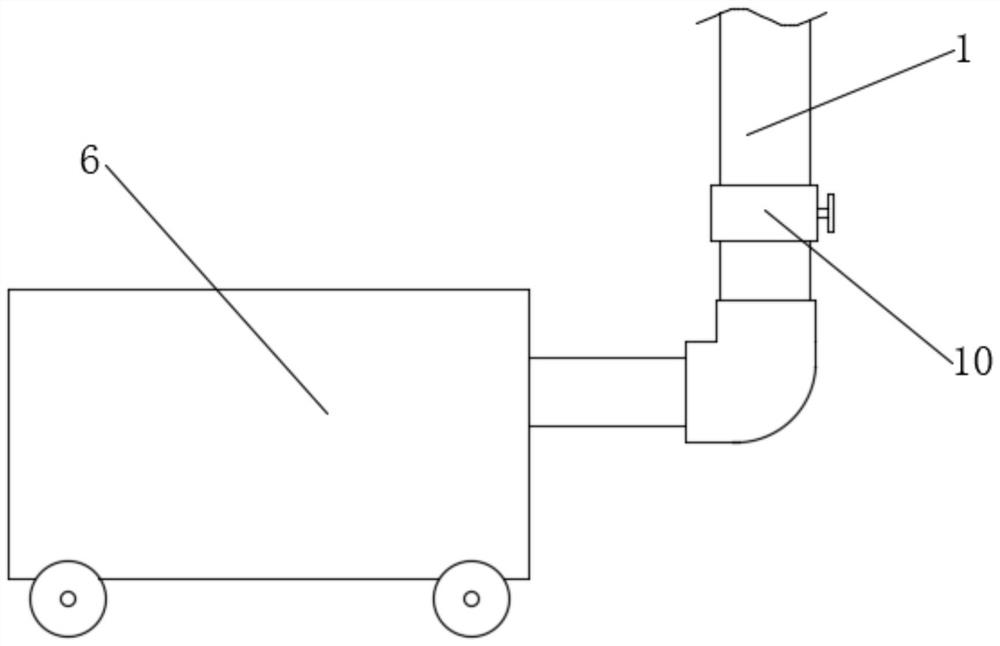

[0047] In an embodiment of the present invention, the water supply end of the main water pipe 1 is located at the bottom of the segmented conduit assembly, and the main road water pipe 1 inlet is installed at the mouth of the connected electric test pump 6. The shut-off valve 10 allows water to be slowly carried out from the bottom, thereby ensuring that each of the pipes within the pipe assembly is fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com