Efficient blocking method for shear wall through-wall bolt holes

A technology of through-wall bolts and shear walls, applied in building maintenance, construction, building construction, etc., can solve problems such as time-consuming and labor-intensive, mortar waste, difficulty in repairing, etc., achieving low operating skills requirements, saving costs, and preventing leakage. hidden effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

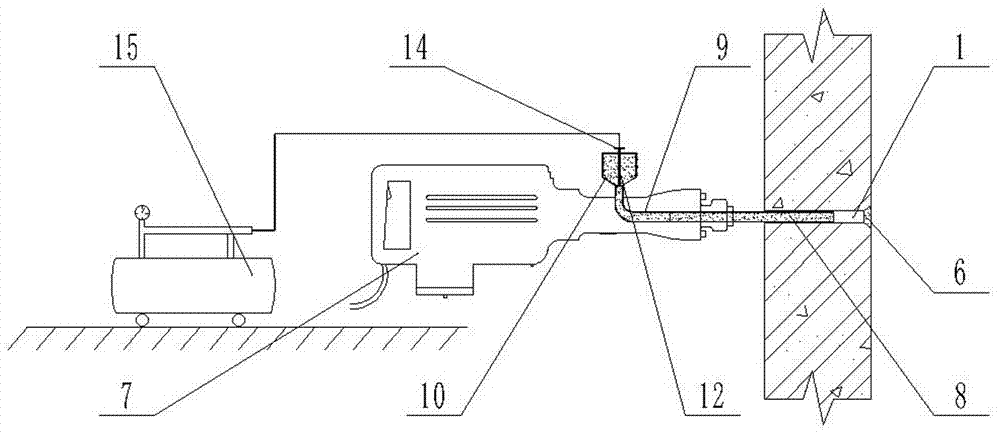

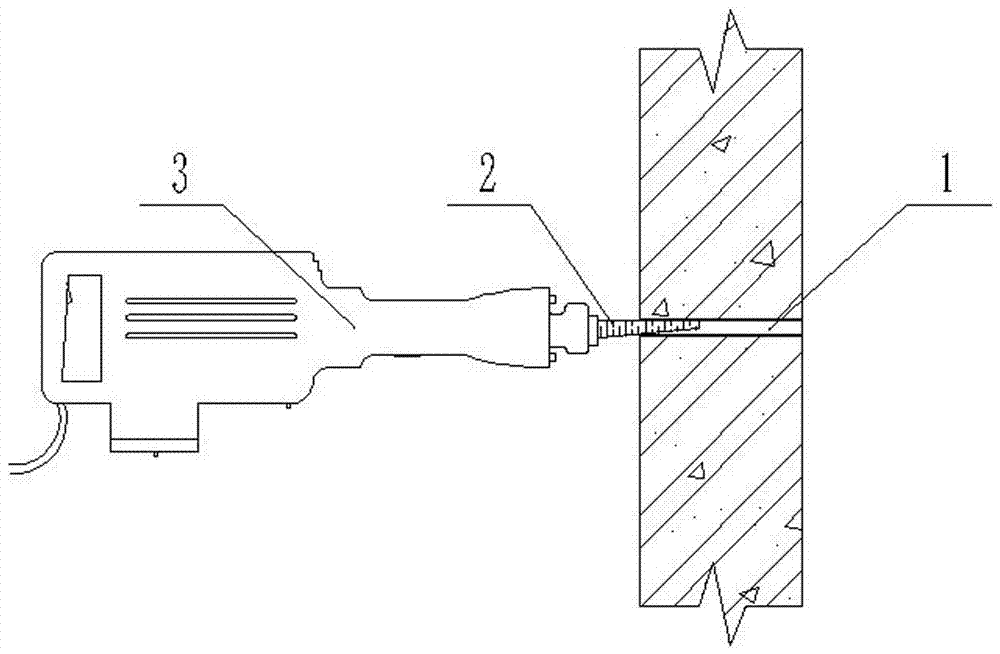

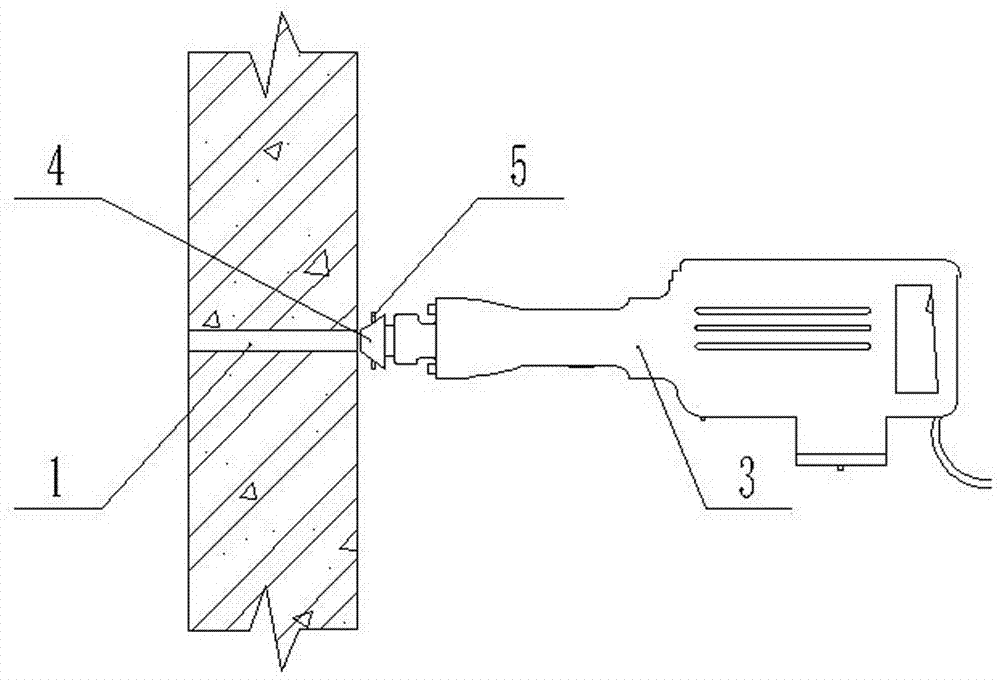

[0013] A high-efficiency method for plugging holes of through-wall bolts in a shear wall, which adopts the following steps: a. After the concrete of the shear wall is poured and reaches the form removal strength, the formwork is removed and the through-wall bolts are taken out to form a bolt hole 1 with a PVC pipe; b. 1. Select the wooden wedge drill rod 2 and install it on the impact drill I3, start the impact drill I3, and the wooden wedge drill rod 2 gradually drills into the bolt hole 1. When the PVC pipe is found to be loose, turn off the switch of the impact drill I3 and remove the PVC pipe from the Take out in the bolt hole 1; c, after the concrete reaches a certain strength, select the frustum-shaped alloy drill bit 4 to be installed on the impact drill I3, and the retaining wall snap ring 5 is fixed on the conical surface of the frustum-shaped alloy drill bit 4, and then Turn on the impact drill I3, and drill the bolt hole 1 at the outer end of the outer wall. When the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com