Patents

Literature

42results about How to "Guarantee the quality of plugging" patented technology

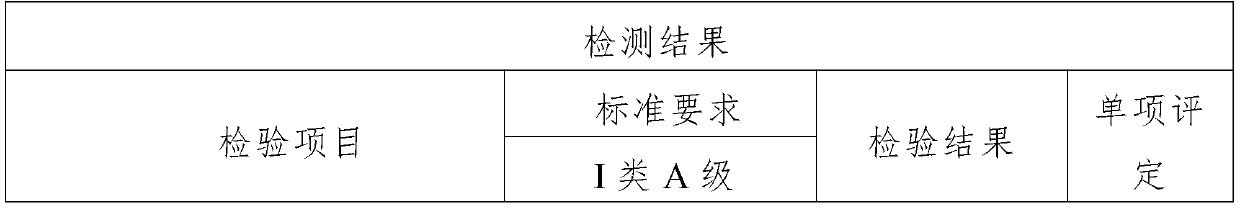

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

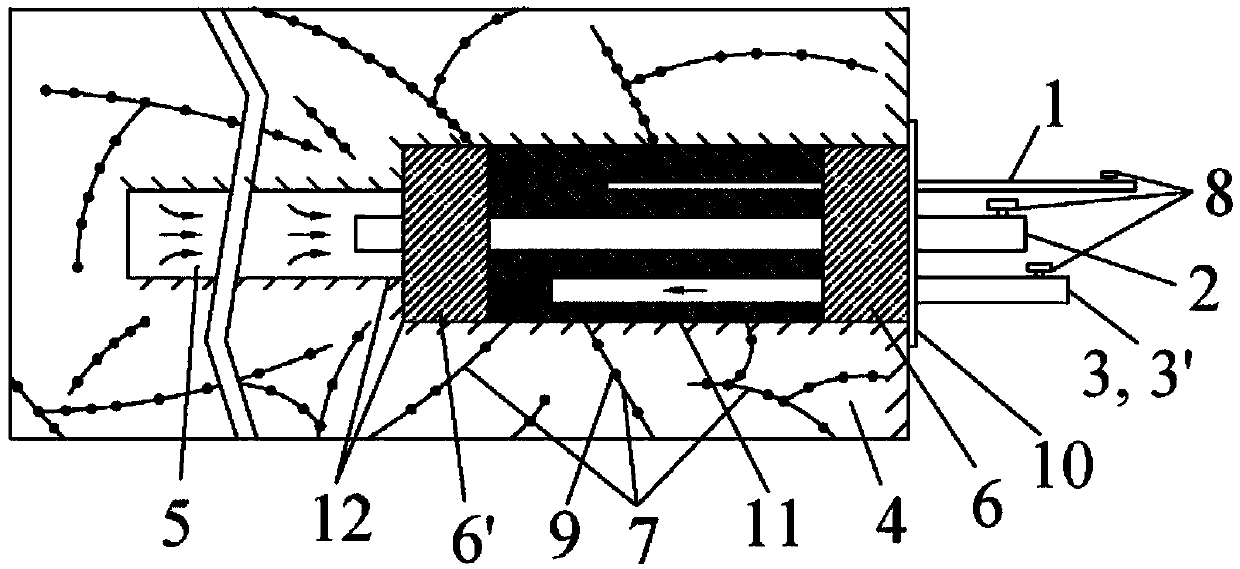

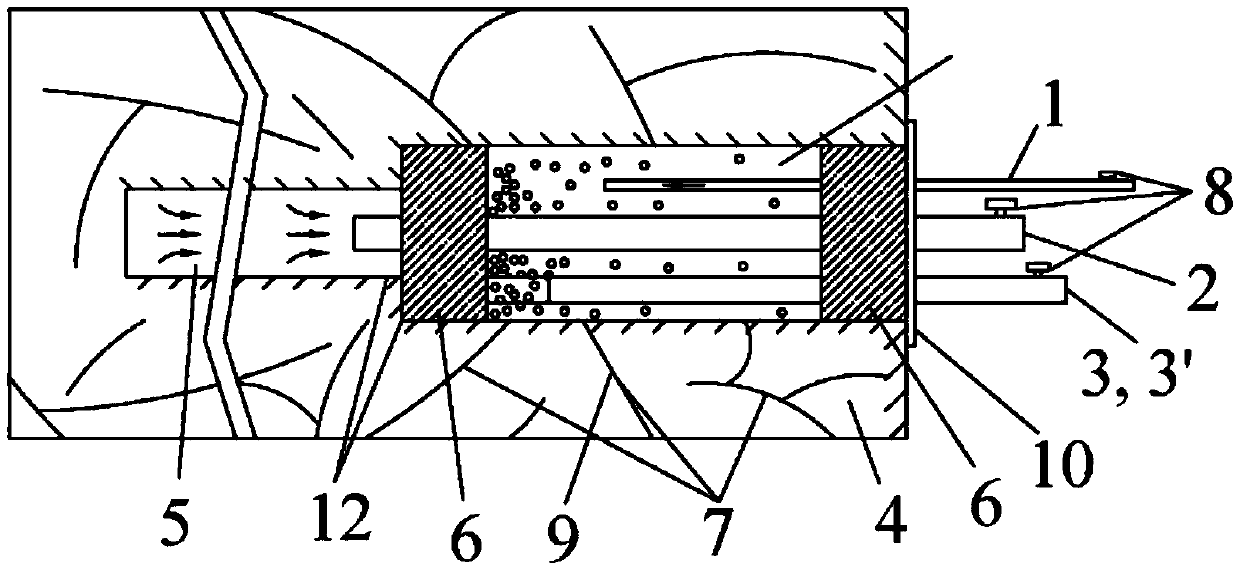

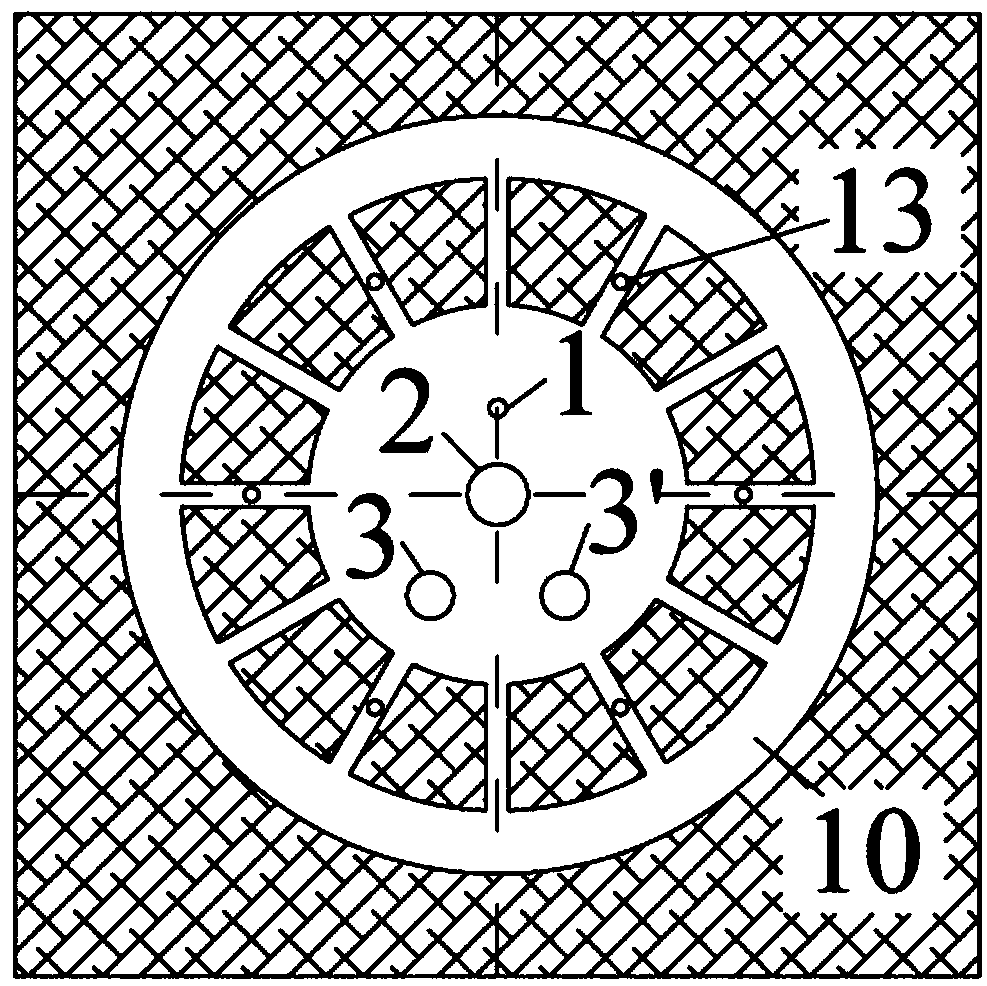

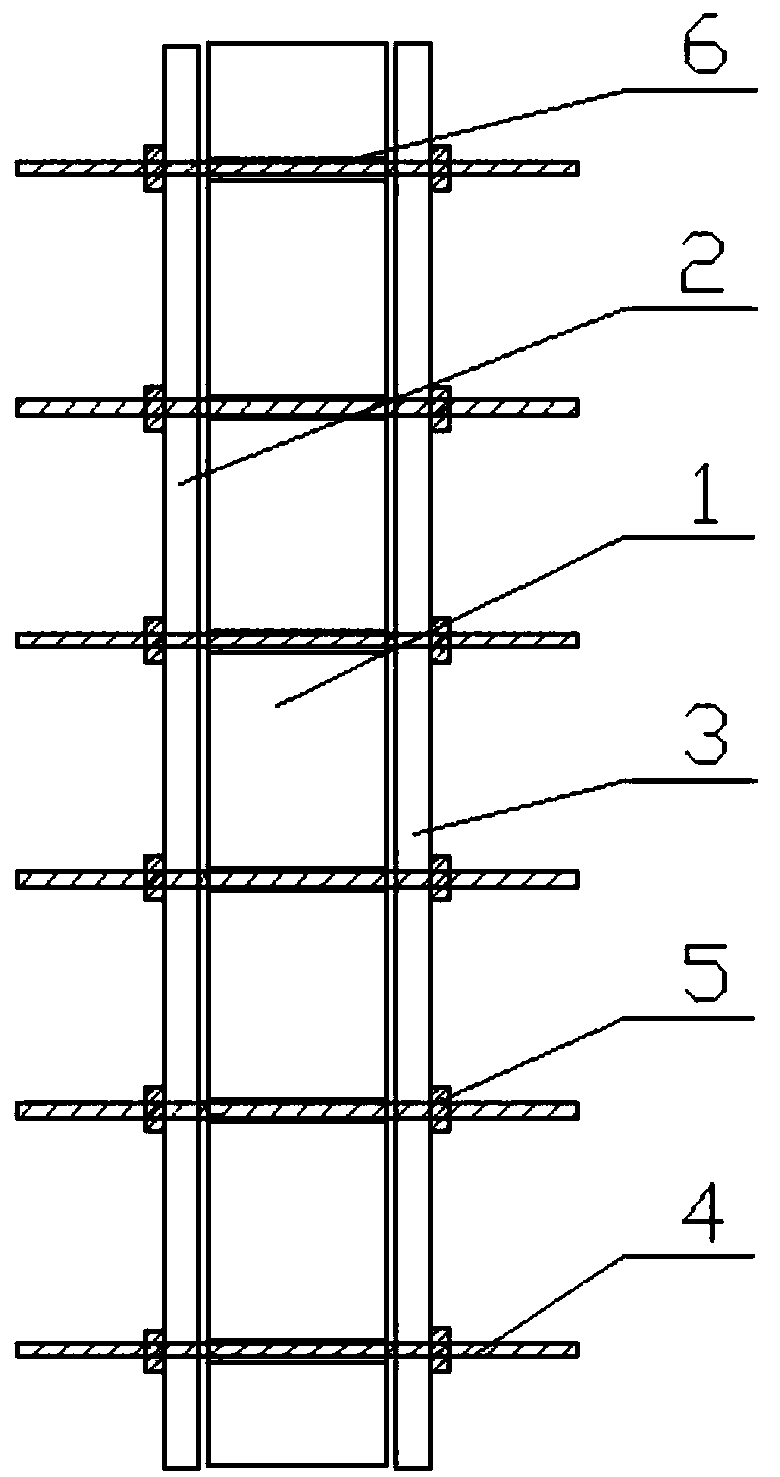

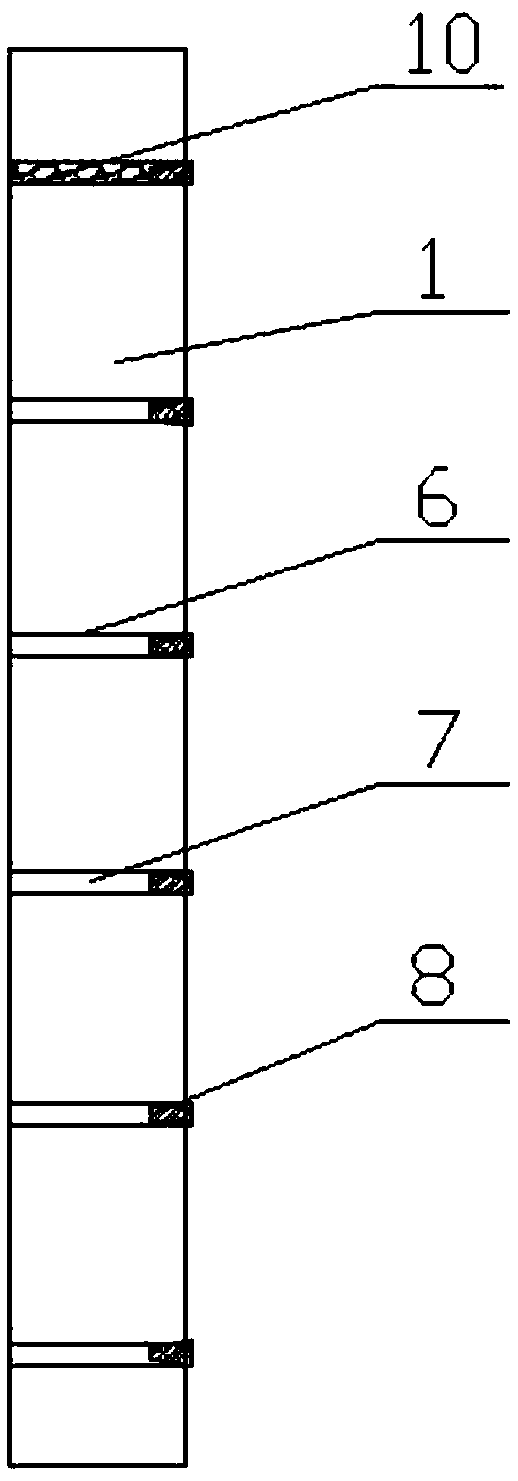

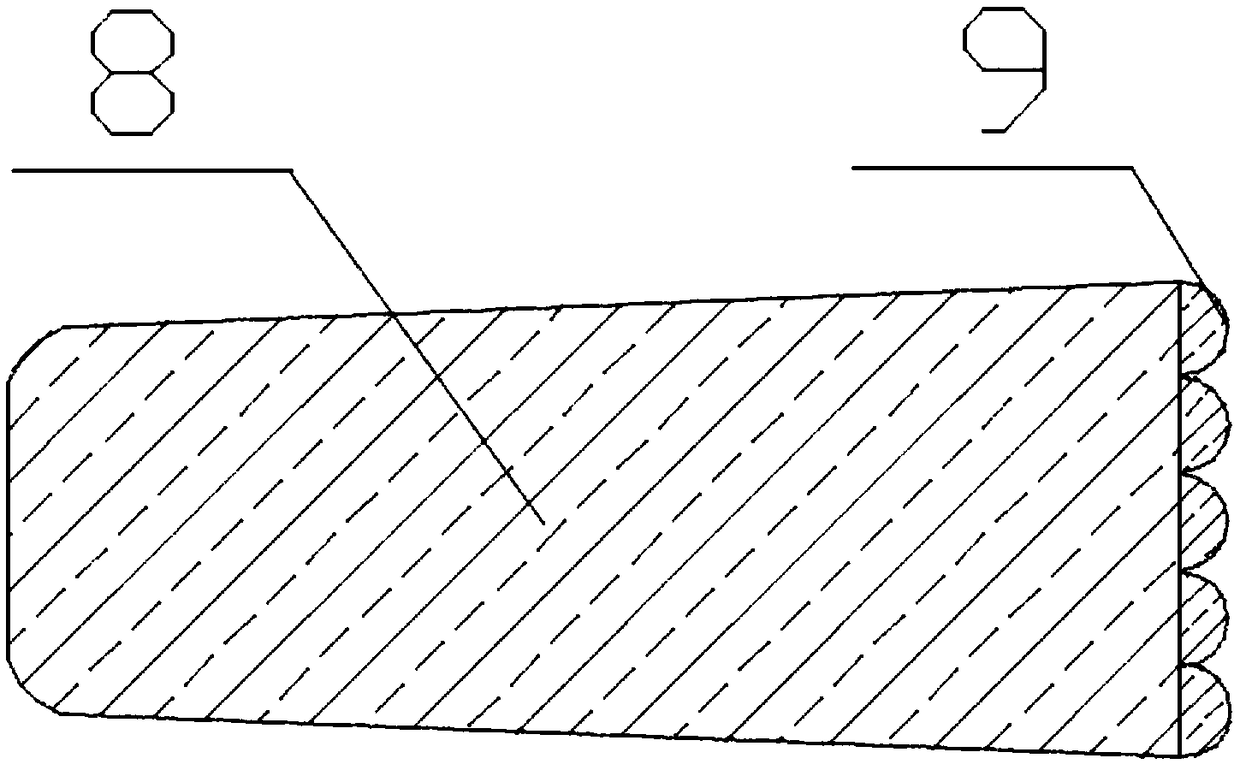

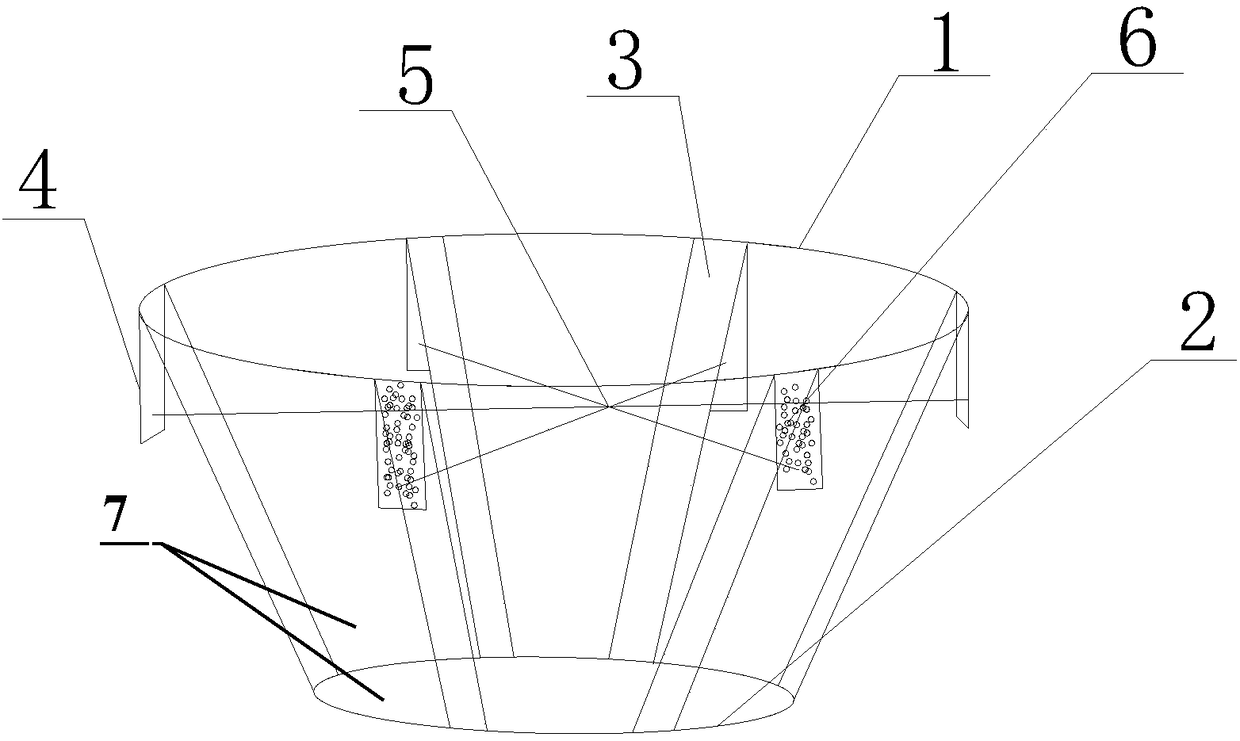

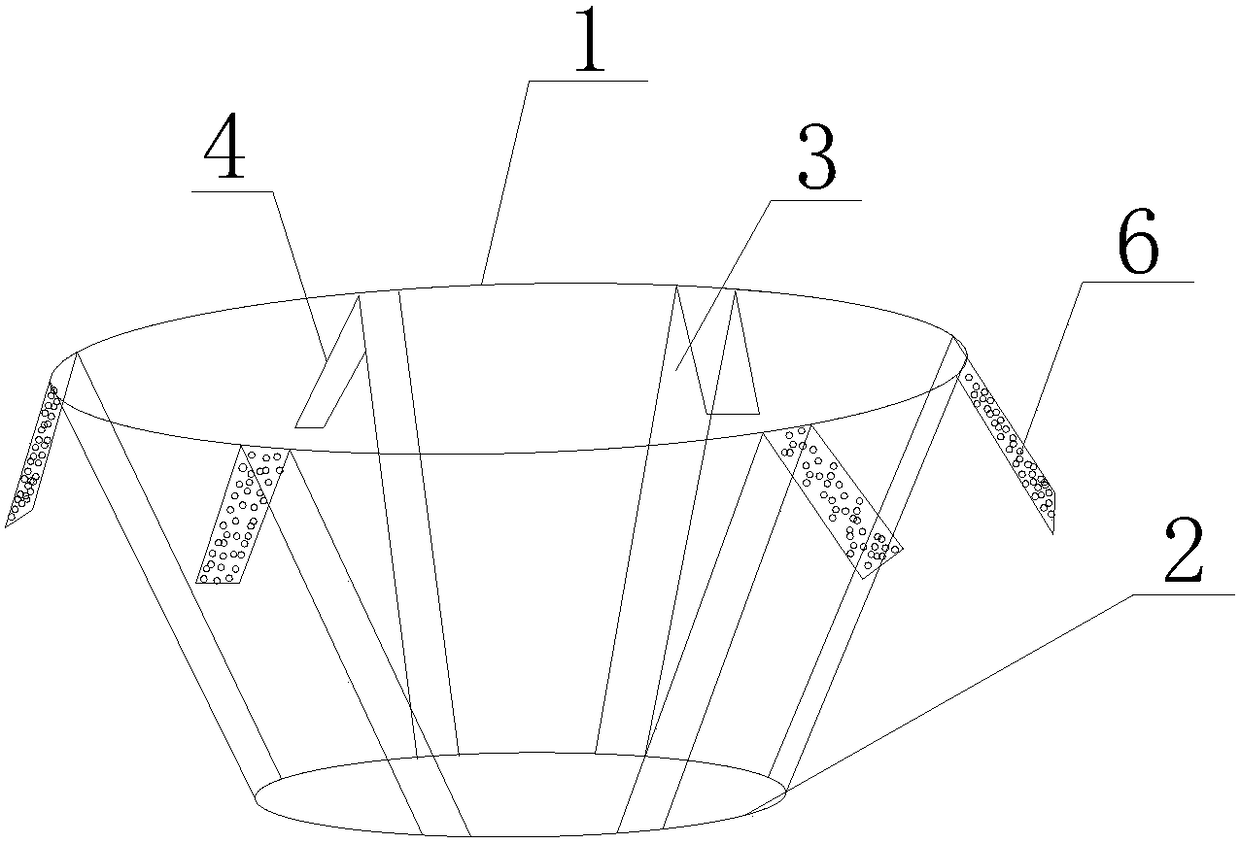

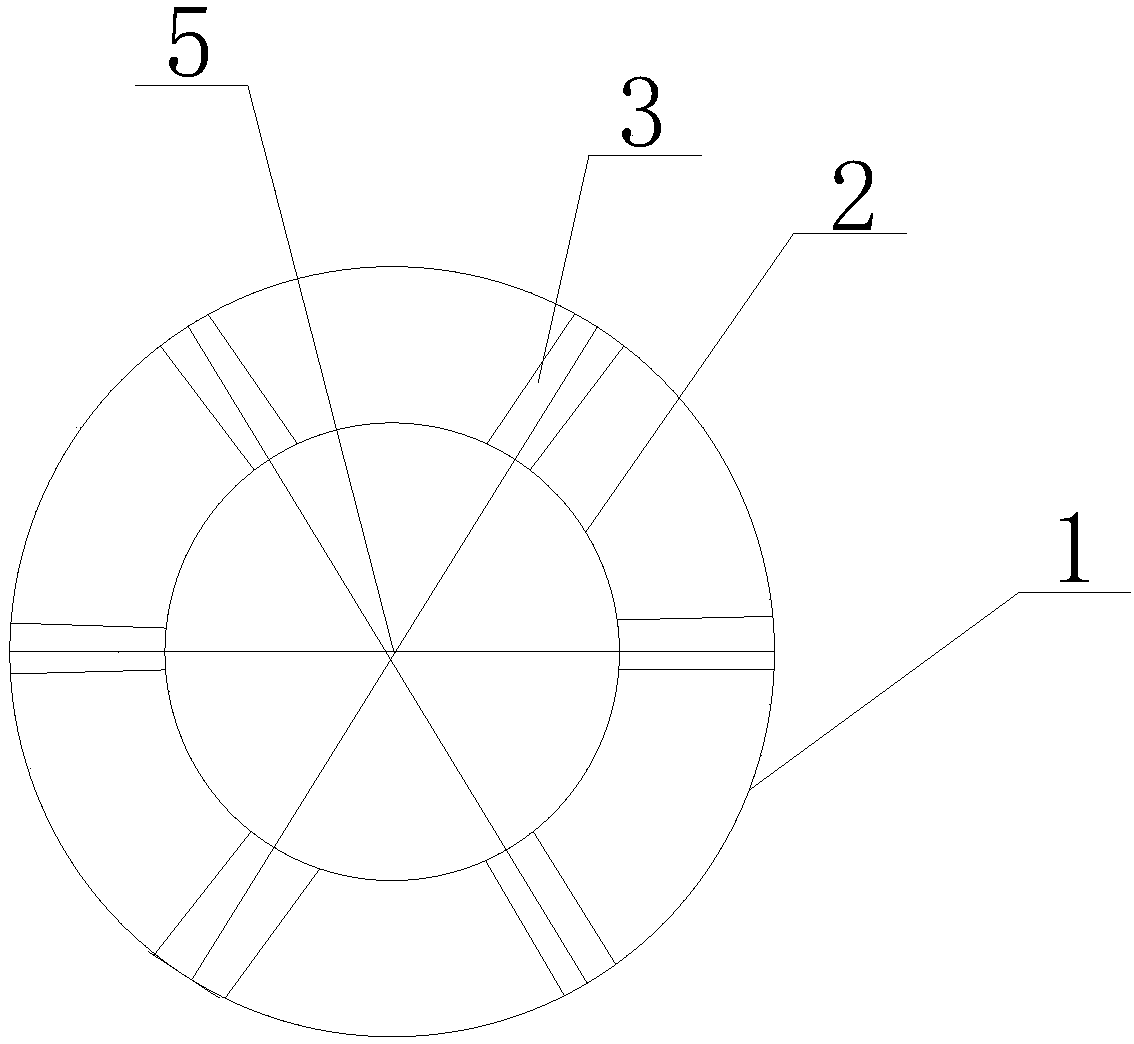

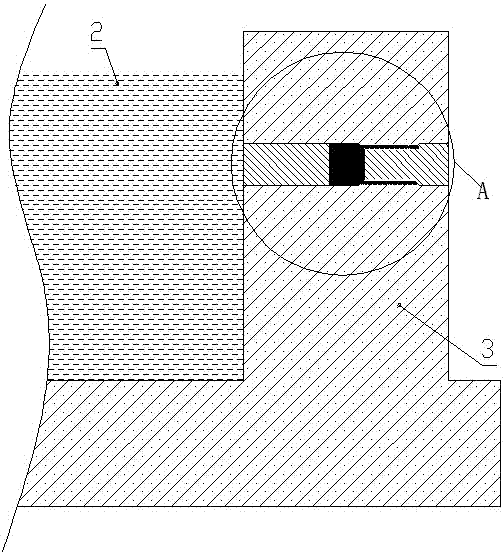

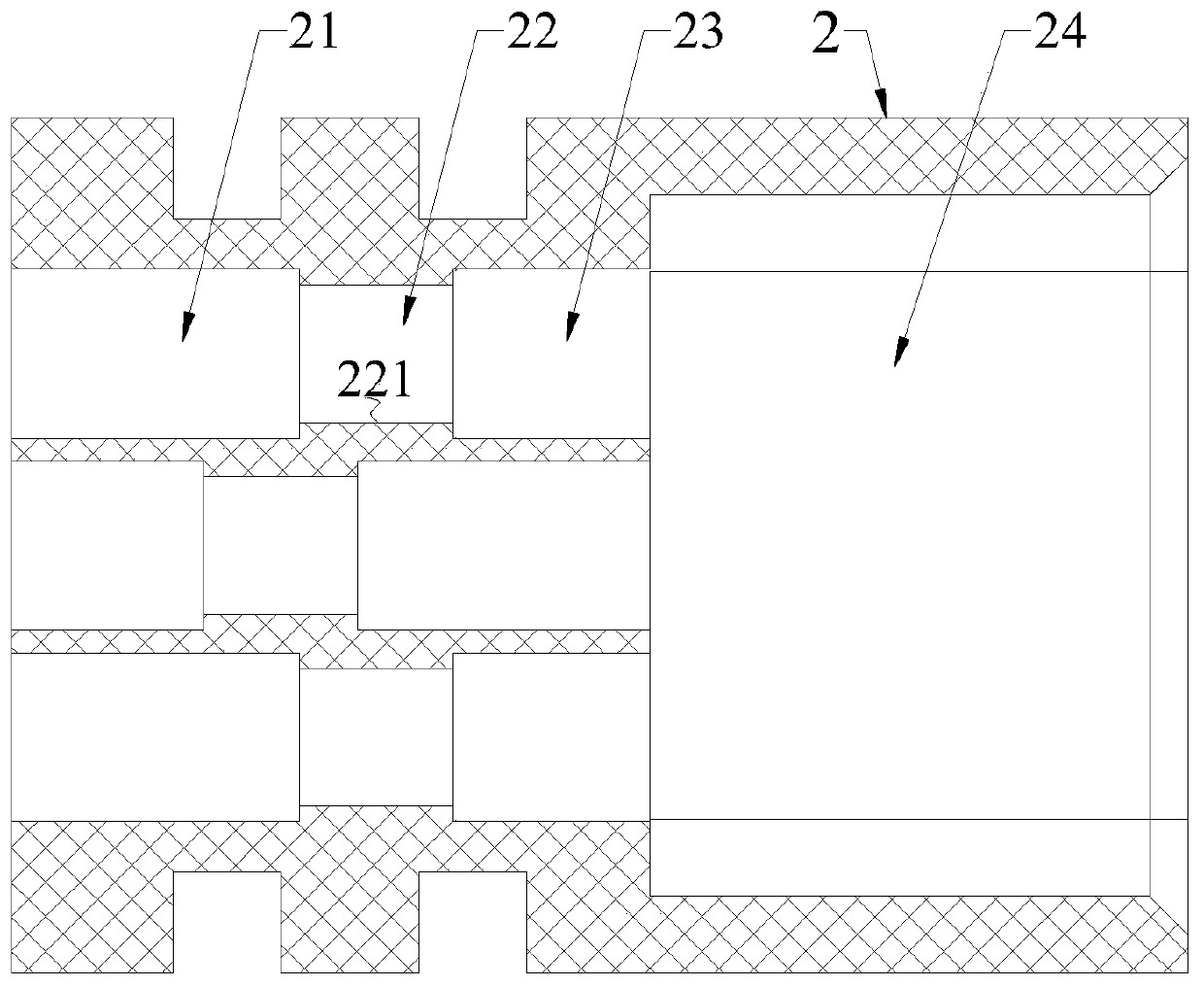

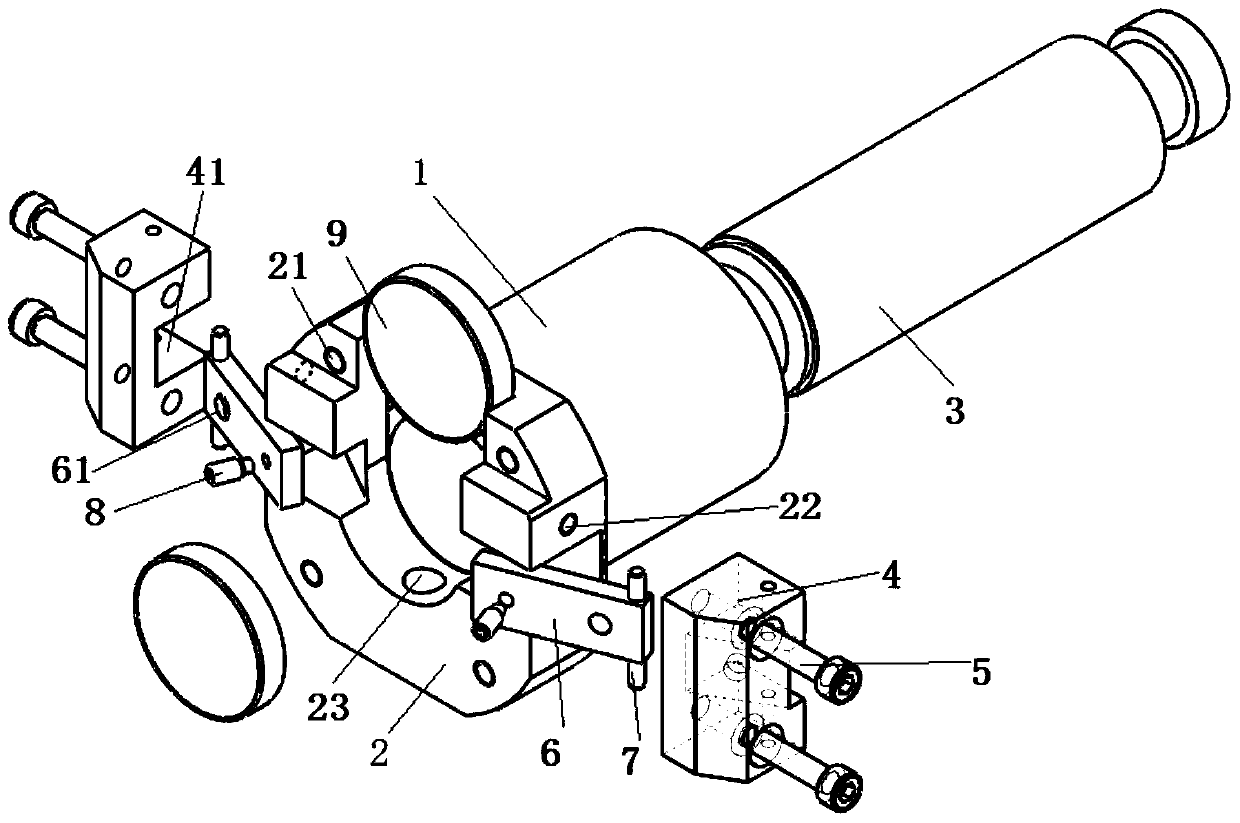

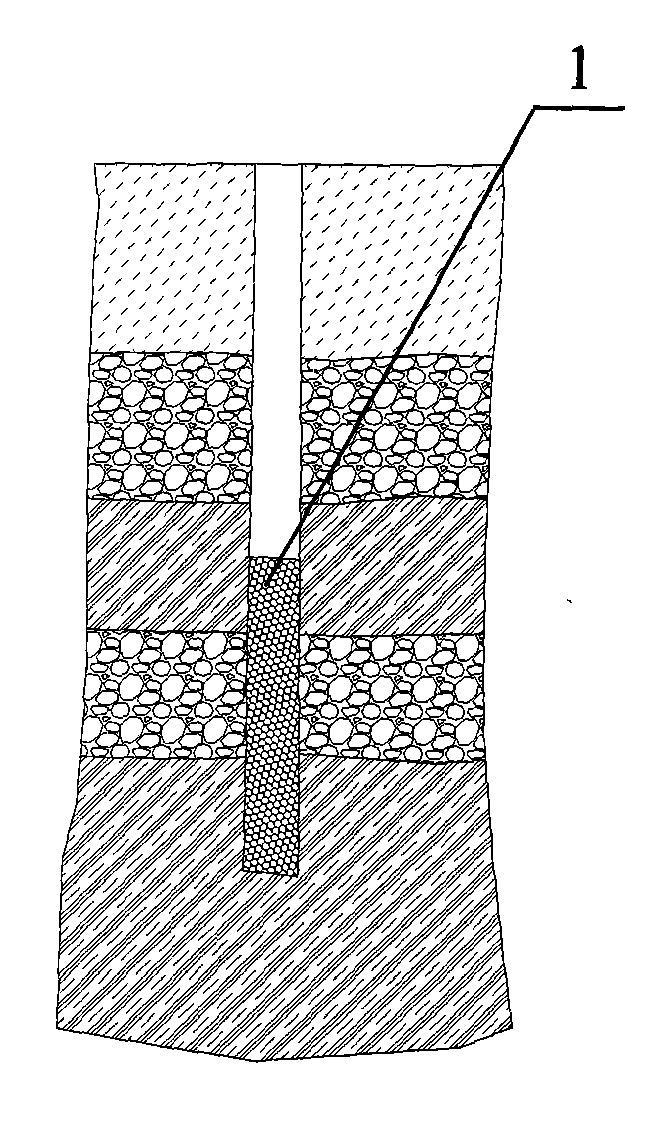

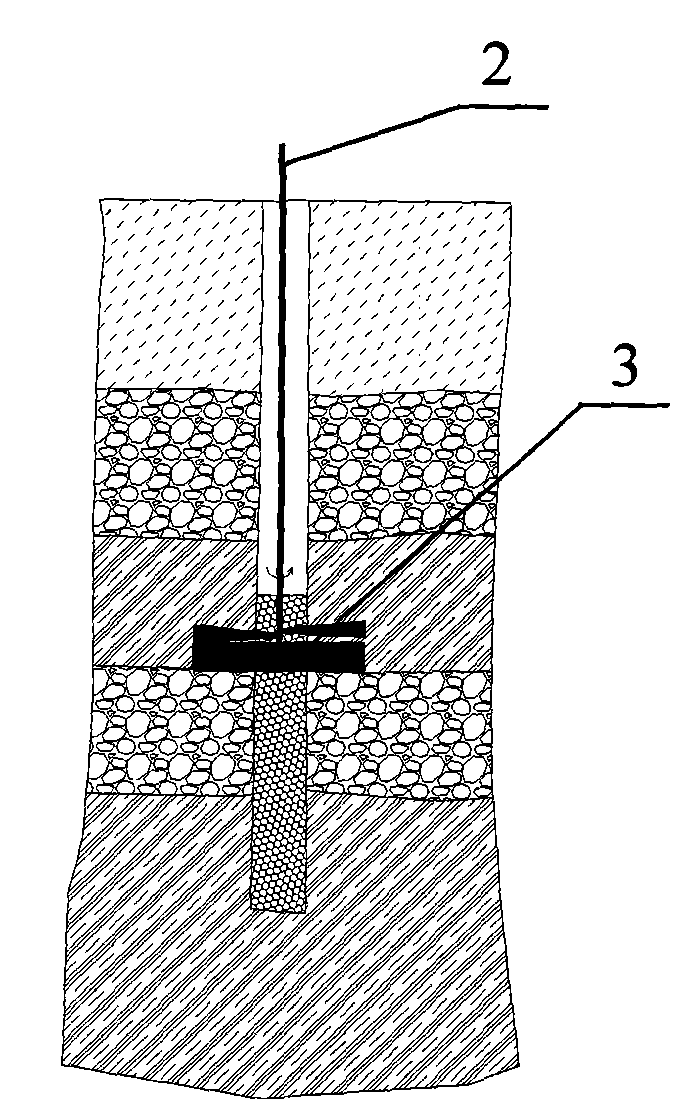

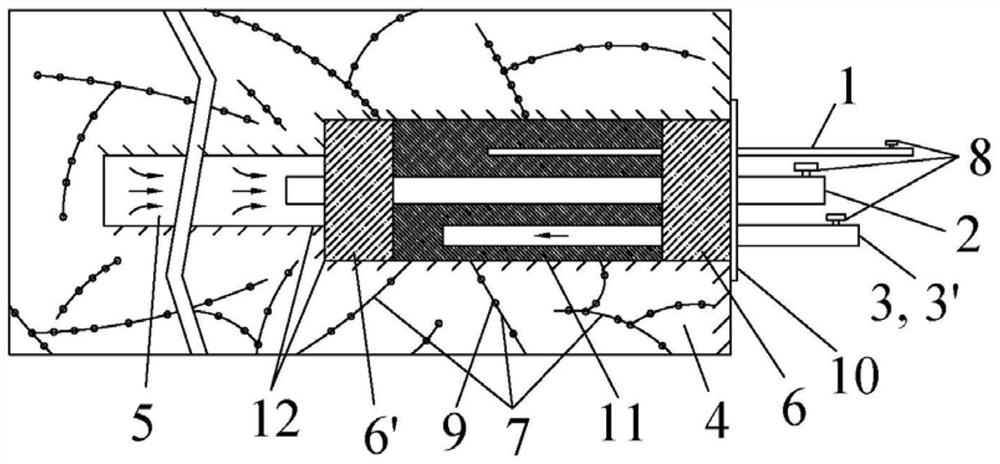

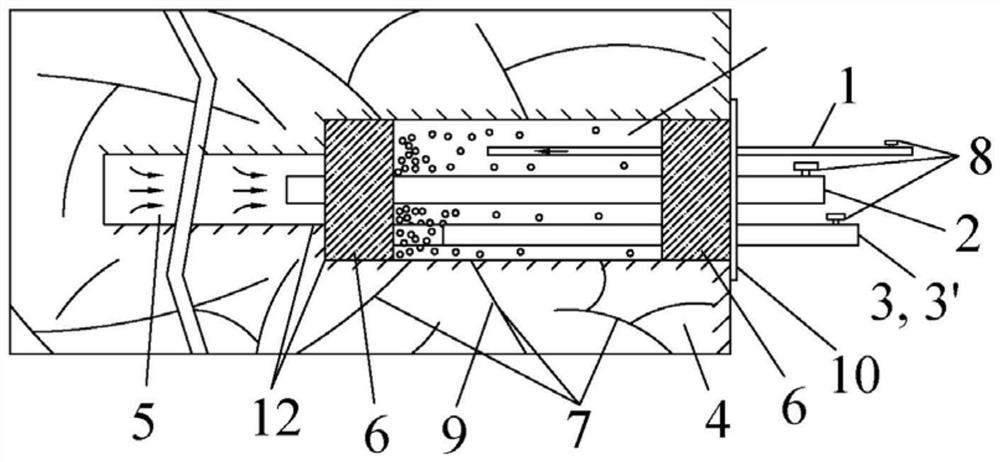

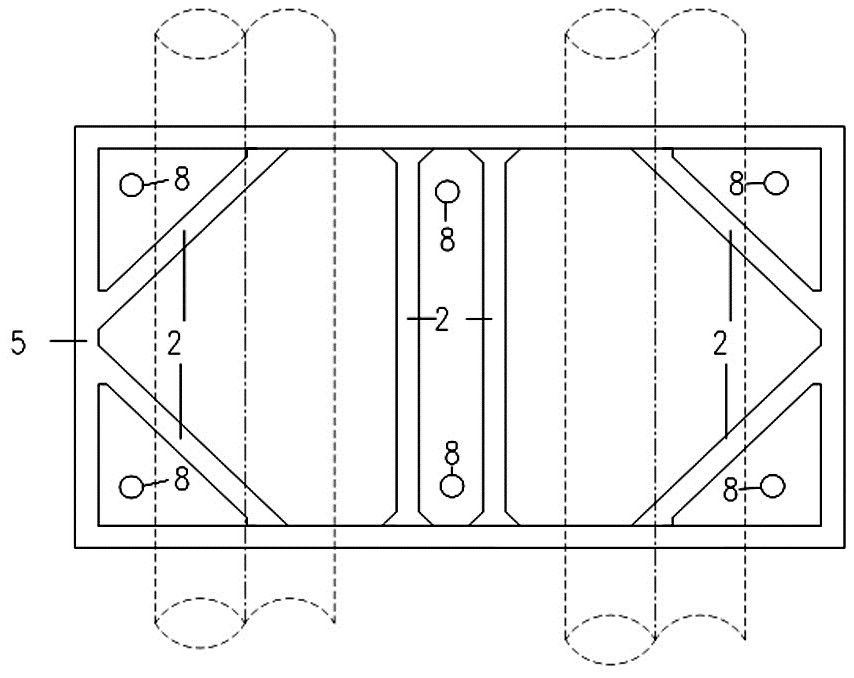

Powder particle-high-pressure grouting crack packing gas extraction drilling and sealing device and method

ActiveCN109577908AImprove radial stabilityEasy to storeFluid removalGas removalPack materialEngineering

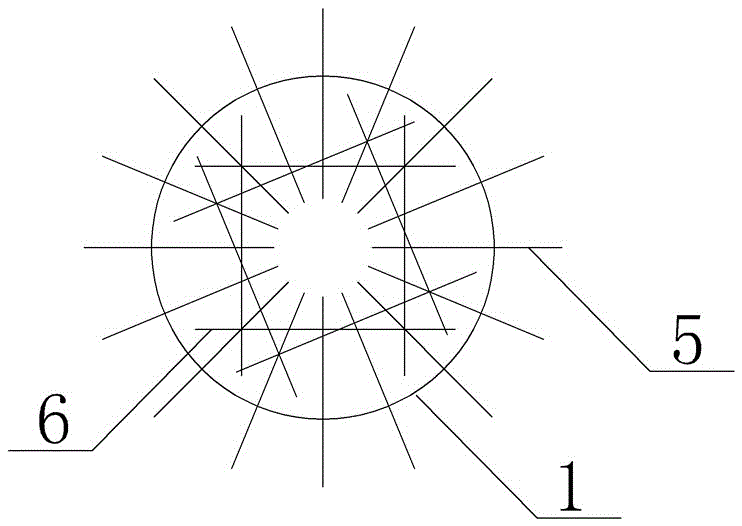

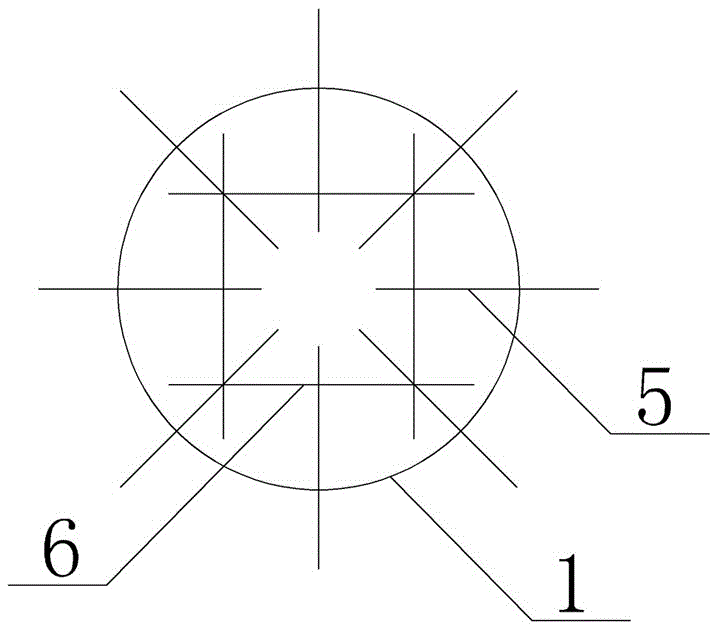

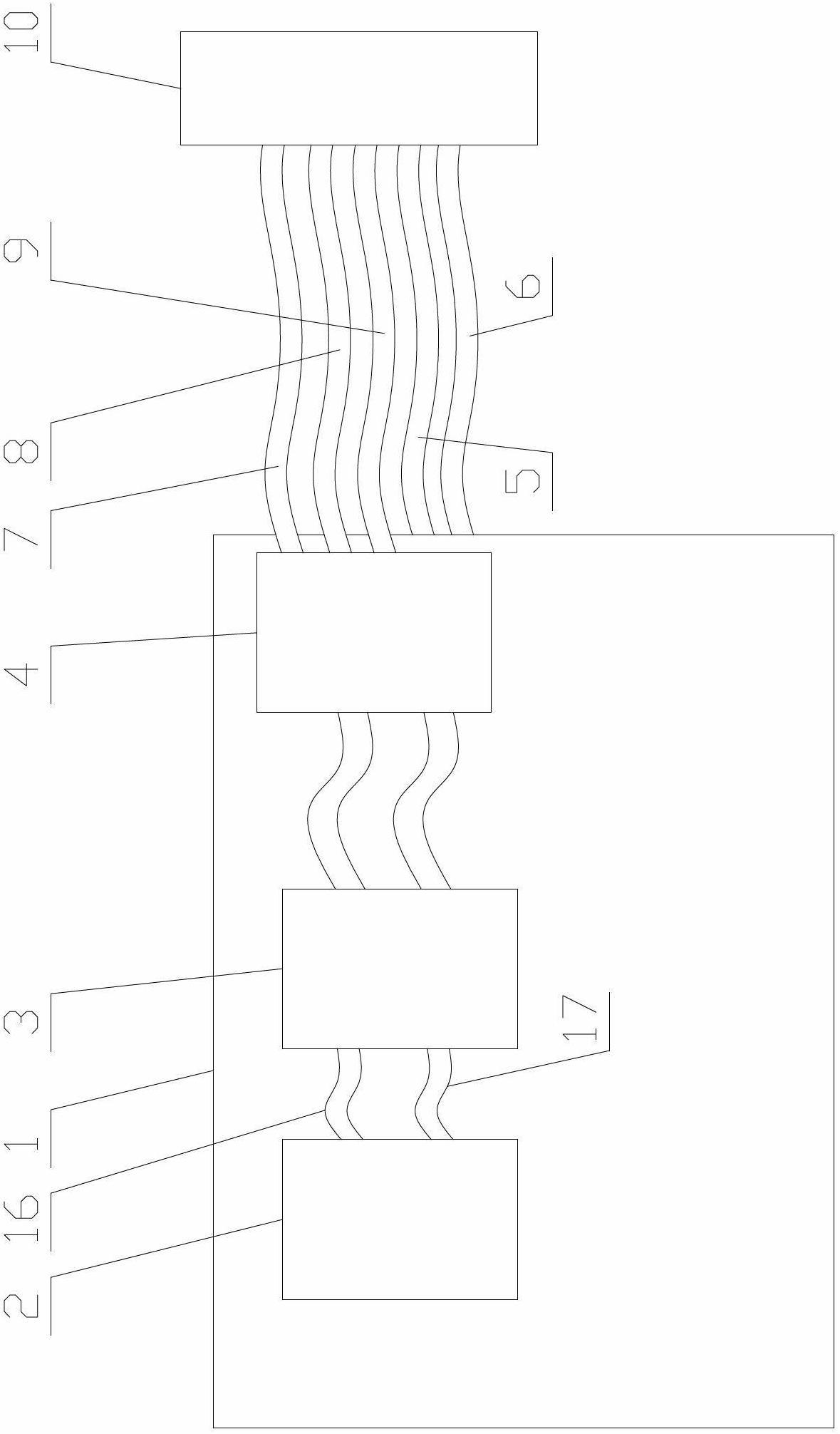

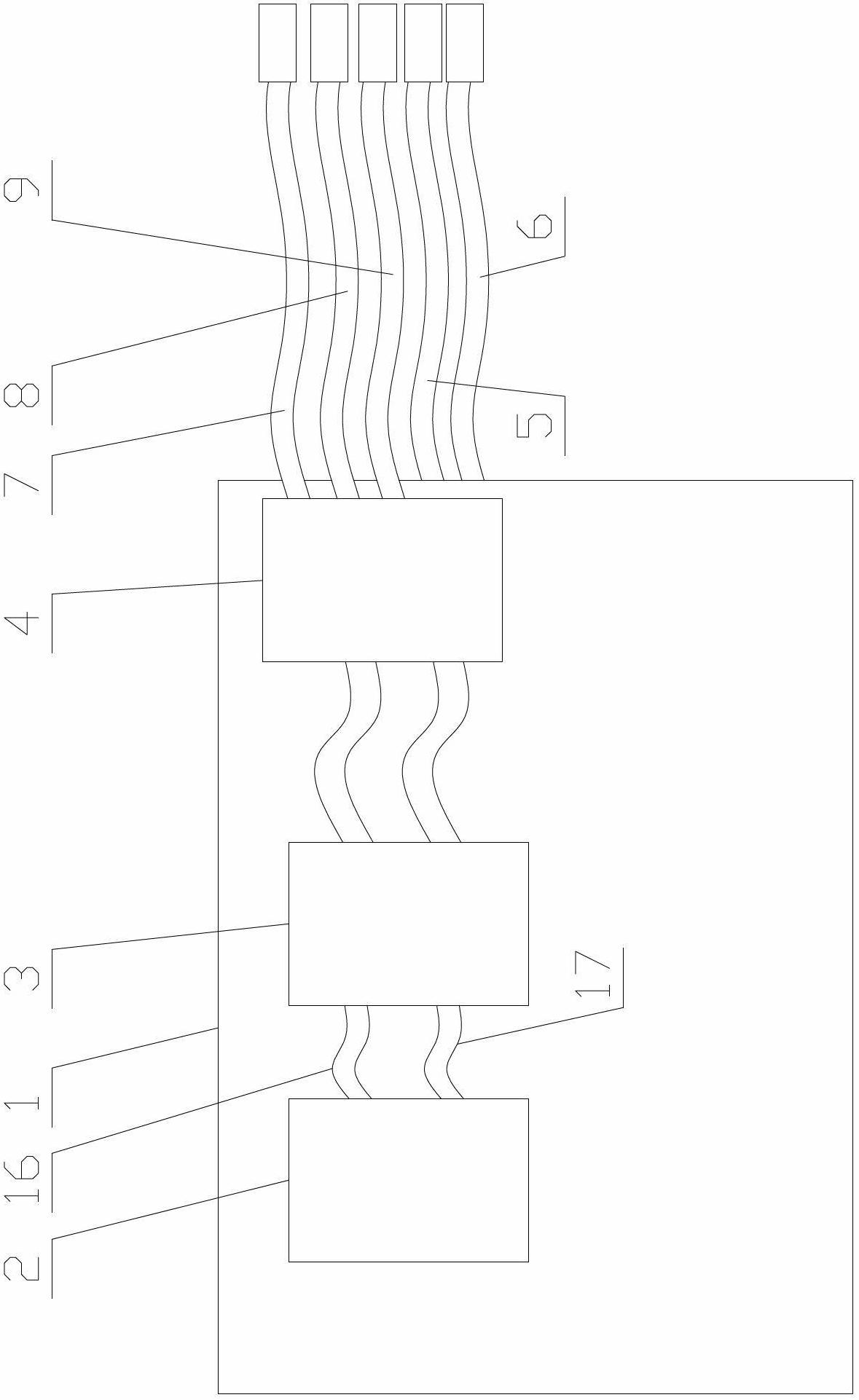

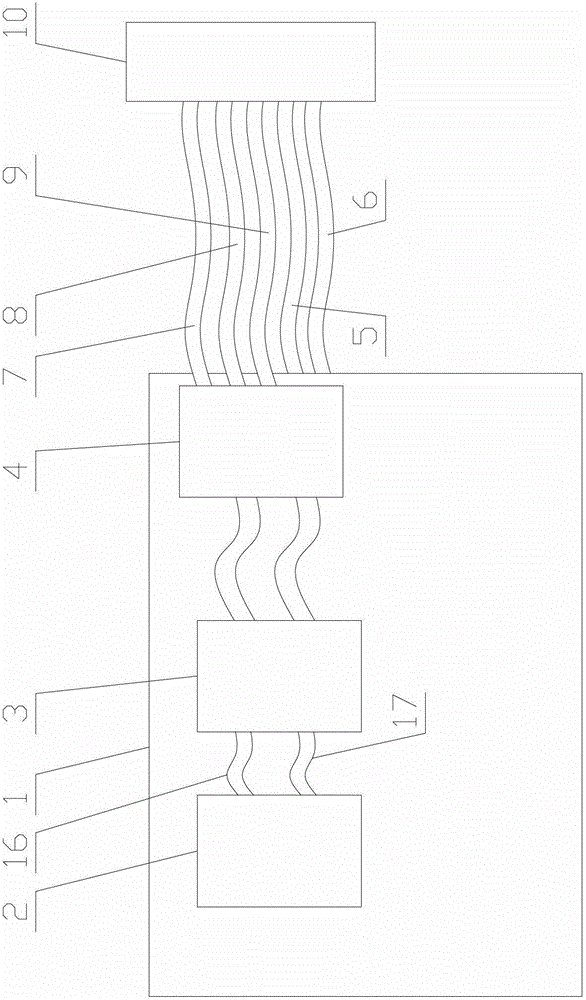

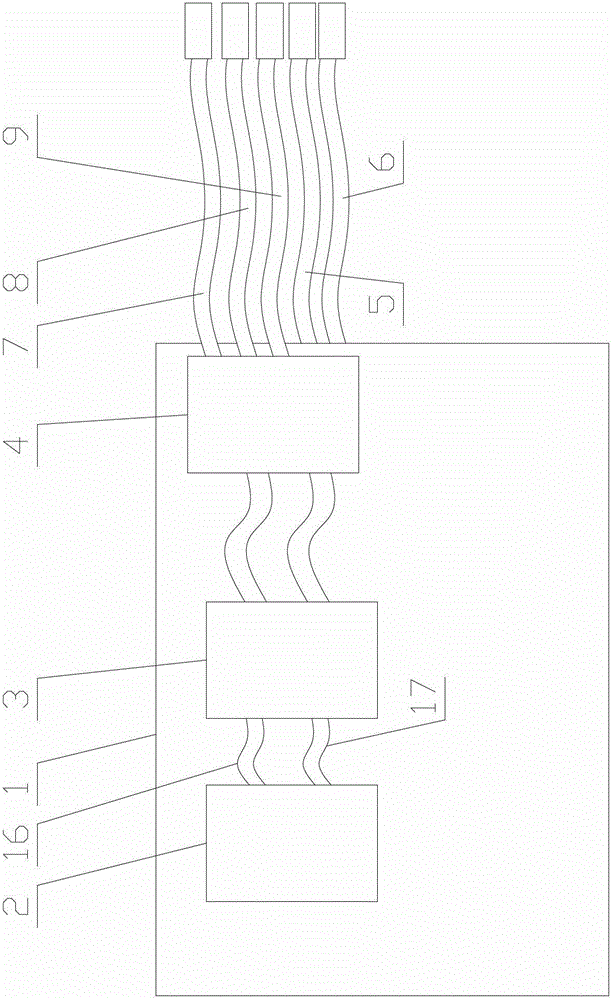

The invention provides a powder particle-high-pressure grouting crack packing gas extraction drilling and sealing device and method. The powder particle-high-pressure grouting crack packing gas extraction drilling and sealing device and method is applicable to underground coal mines. The powder particle-high-pressure grouting crack packing gas extraction drilling and sealing device comprises an outer bag and an inner bag, wherein the rear of the outer bag is provided with a fixing unit on a gas extraction pipe; the inner bag is provided with a screen pipe, a bag grouting pipe and a grouting pipe which penetrate through the fixing unit, the tail portions of the screen pipe, the bag grouting pipe and the grouting pipe are arranged at the rear of the outer bag, and the tail ends of the screenpipe, the bag grouting pipe and the grouting pipe are provided with valves; quick lime powder coerced by carbon dioxide is guided into the space among packing materials via the screen pipe to block fractures around a drilled hole through reaction products; cement mortar is filled in by the grouting pipe to achieve the aim of packing cracks and actively supporting the drilled hole. Therefore, thepowder particle-high-pressure grouting crack packing gas extraction drilling and sealing device can effectively reduce the influence of mining damage, prolong the effectively extraction period of drilling gas extraction, increase the concentration of extracted gas, maintain stability of the drilled hole, significantly improve the coal seam gas extracting effects and ensure safety of underground workers.

Owner:CHINA UNIV OF MINING & TECH

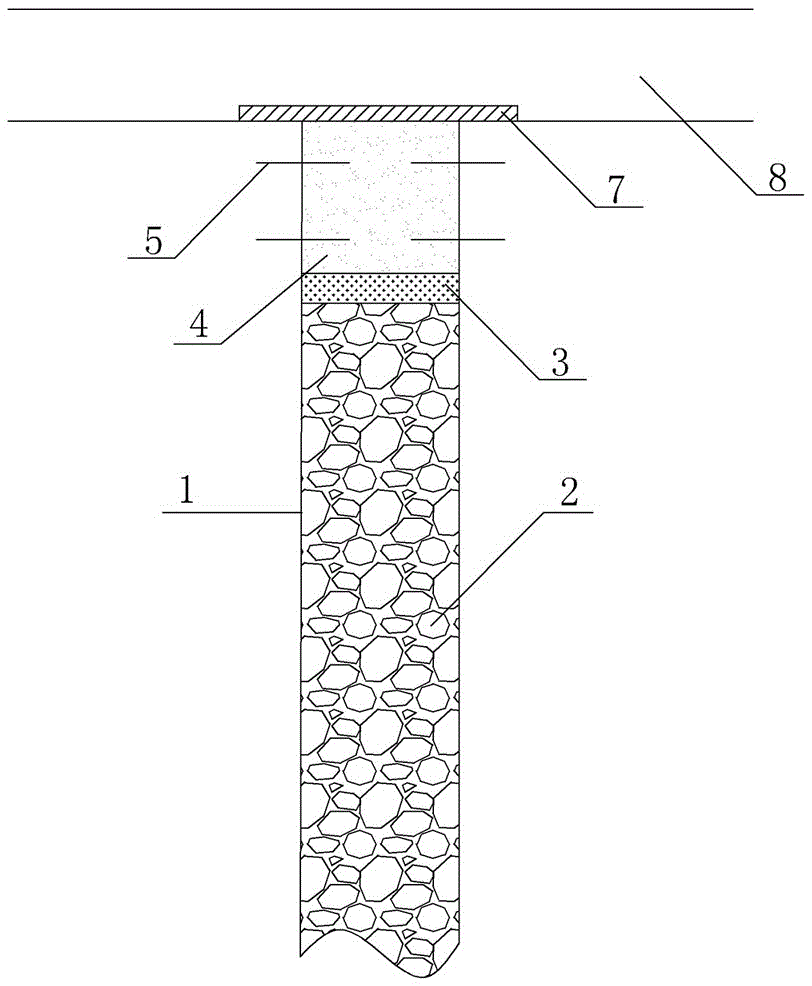

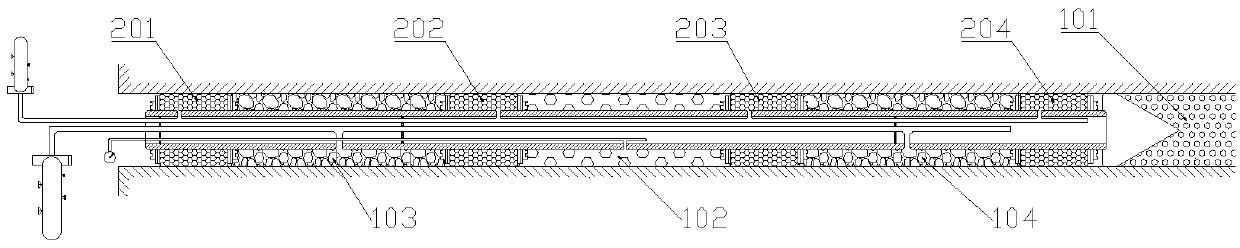

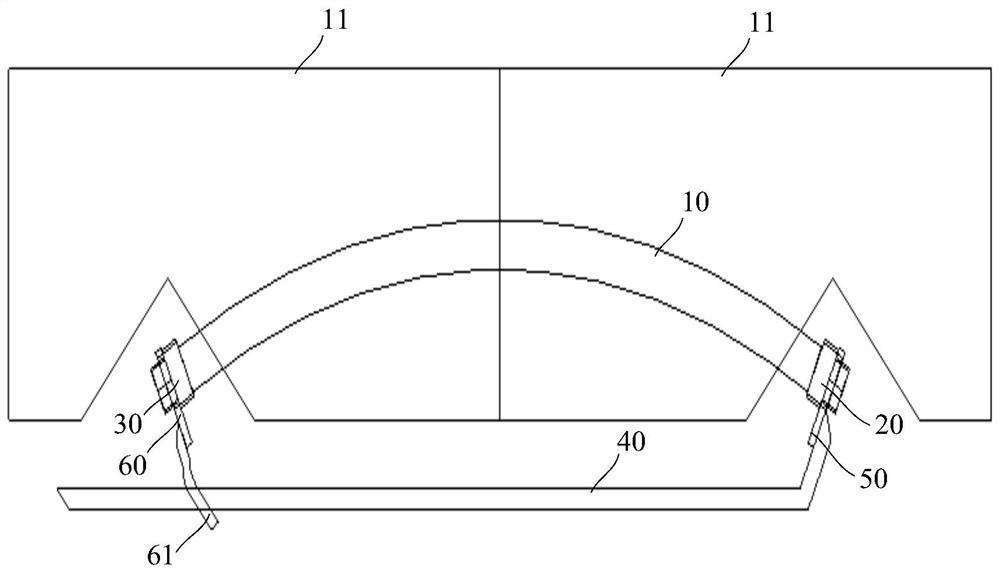

Method for calking exploratory hole by intermittent high-pressure rotary jet grouting

InactiveCN101560764ALow costGuarantee the quality of pluggingSoil preservationSoil qualityHigh pressure

The invention discloses a method for calking an exploratory hole by intermittent high-pressure rotary jet grouting, which comprises the following steps: (a) determining the depth of the exploratory hole, the soil quality and the thickness of various soil layers of the exploratory hole, and the groundwater level burial depth; (b) determining the position of confined aquifer and the position with severe collapse in the exploratory hole as reinforced regions, and taking the position positioned outside the reinforced regions in the exploratory hole as a backfill air-drying clay mud ball region; and (c) treating the reinforced regions and the backfill air-drying clay mud ball region determined in the step (b) from the bottom to the top of the exploratory hole respectively until the exploratory hole is calked to the ground surface. The method adopts rotary jet grouting on confined aquifer roof plates exposed by the exploratory hole and the regions with severe collapse and still adopts a calking method of clay ball backfill compaction in other regions, so that the method can guarantee the calking quality, avoid the water burst phenomenon, and greatly save the engineering manufacturing cost.

Owner:TIANJIN UNIV

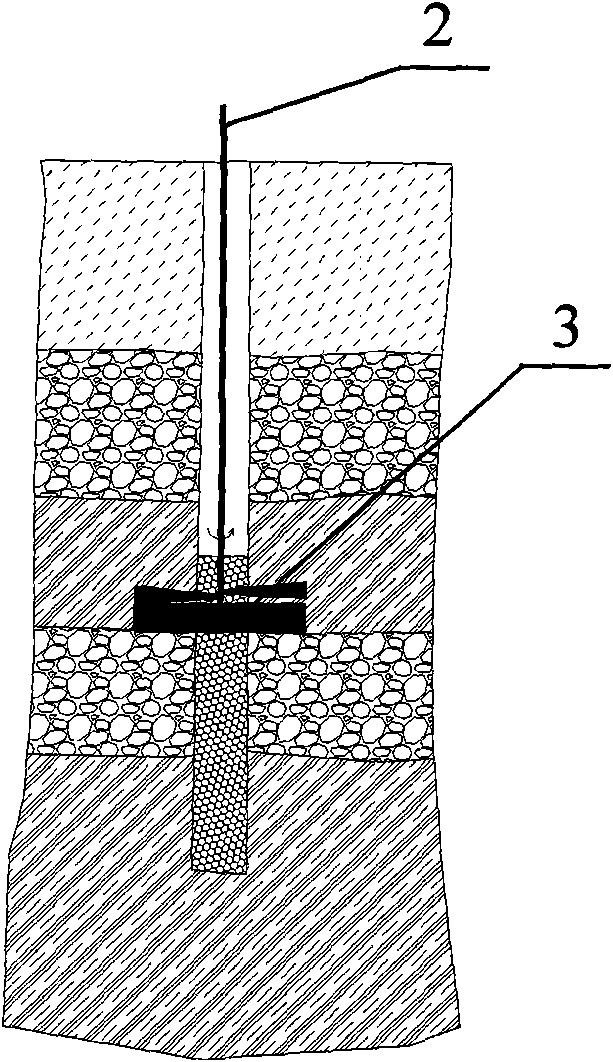

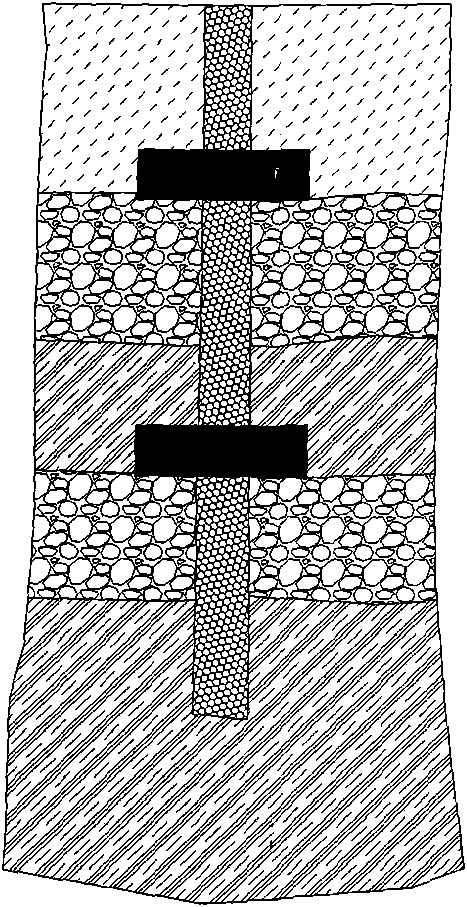

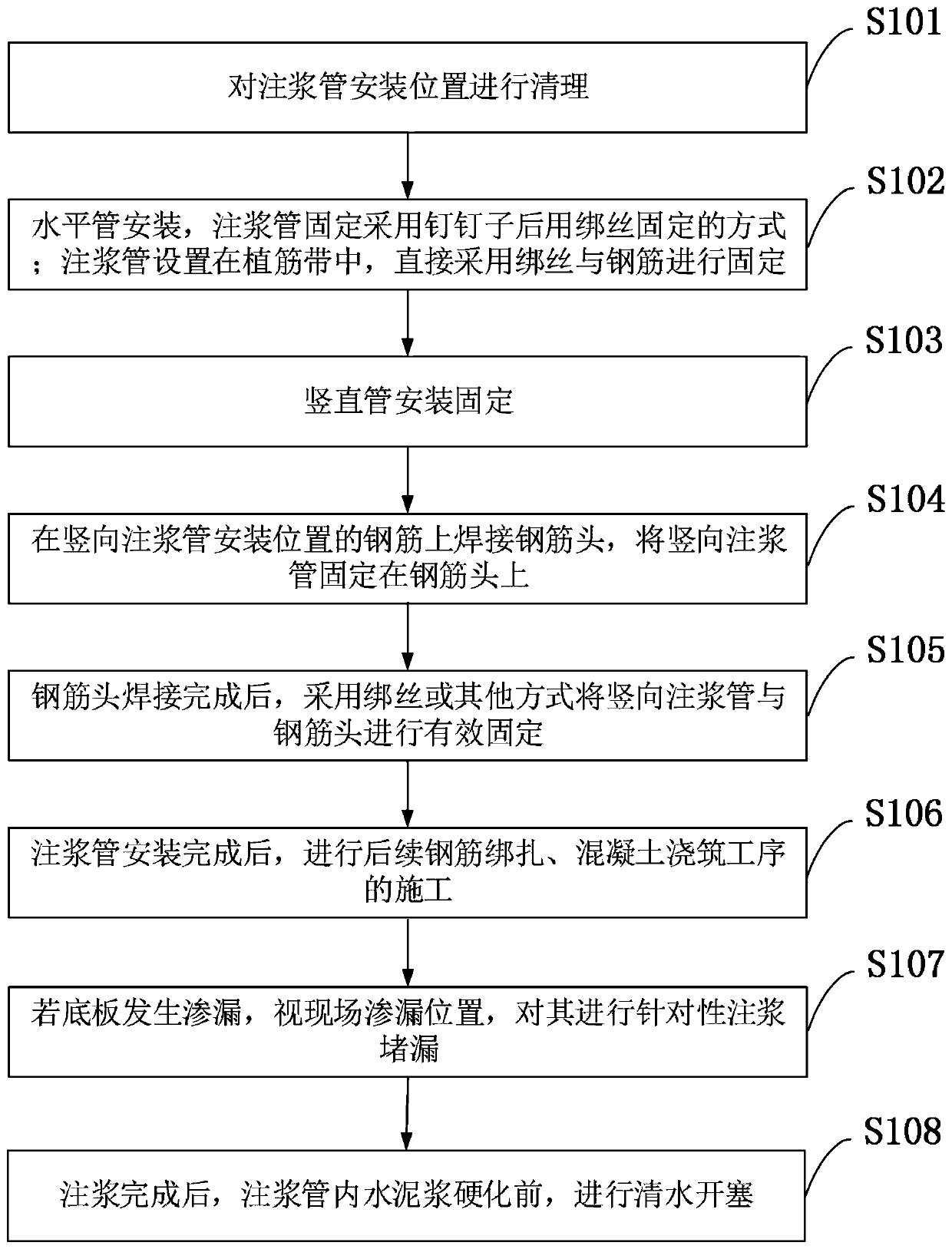

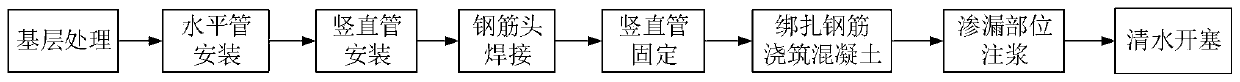

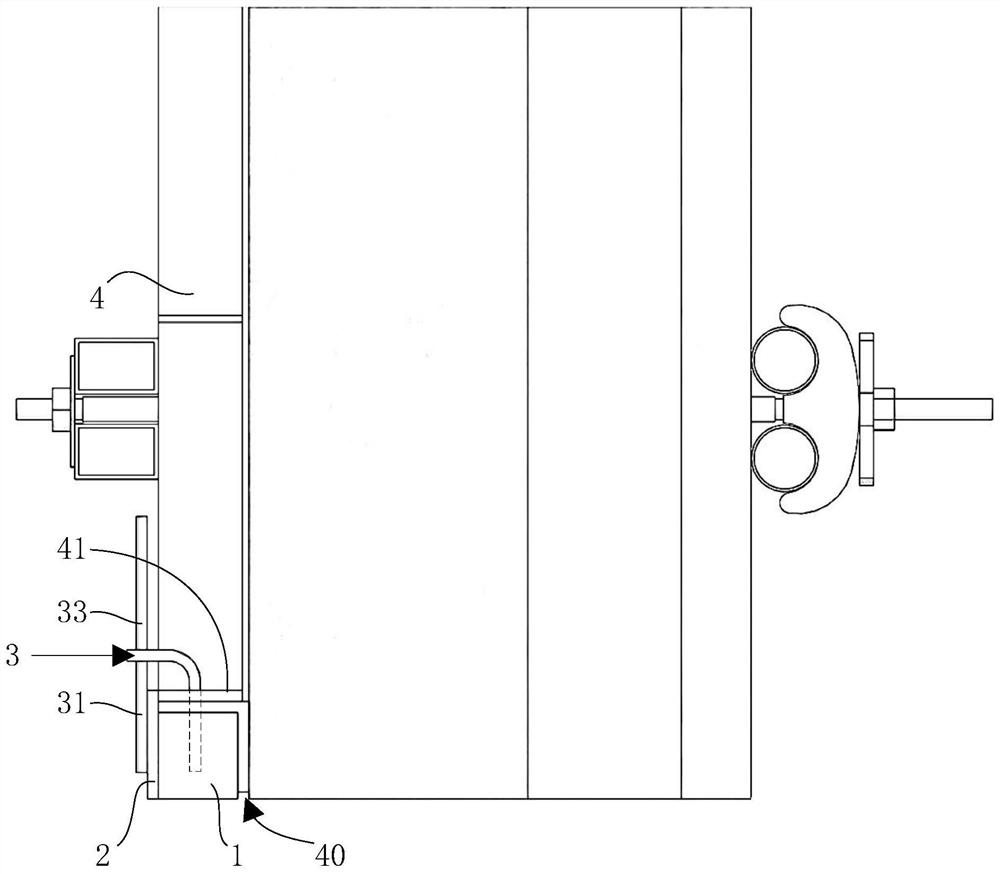

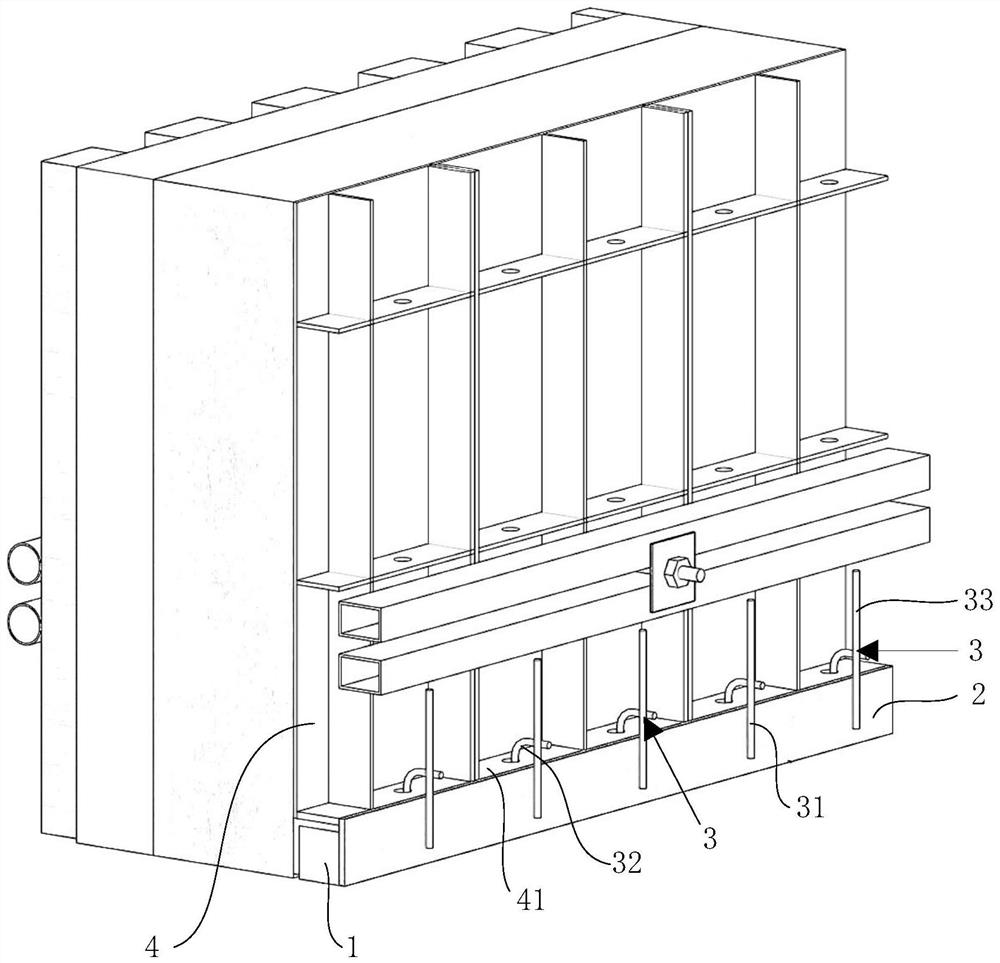

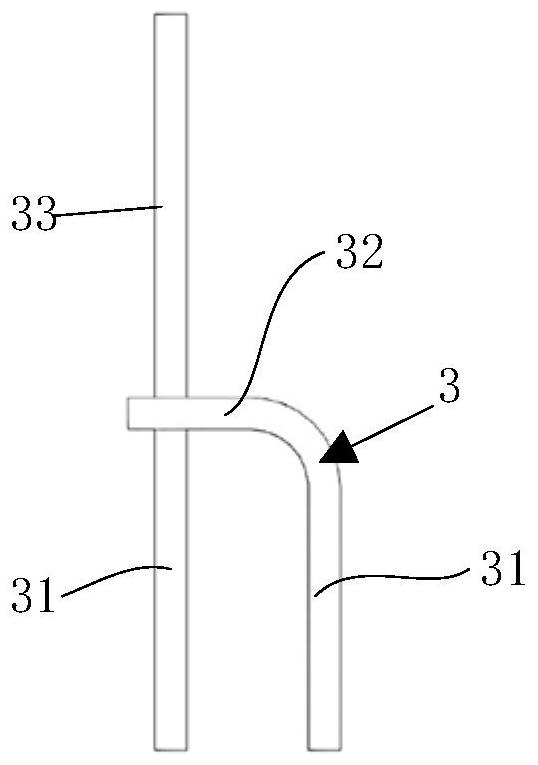

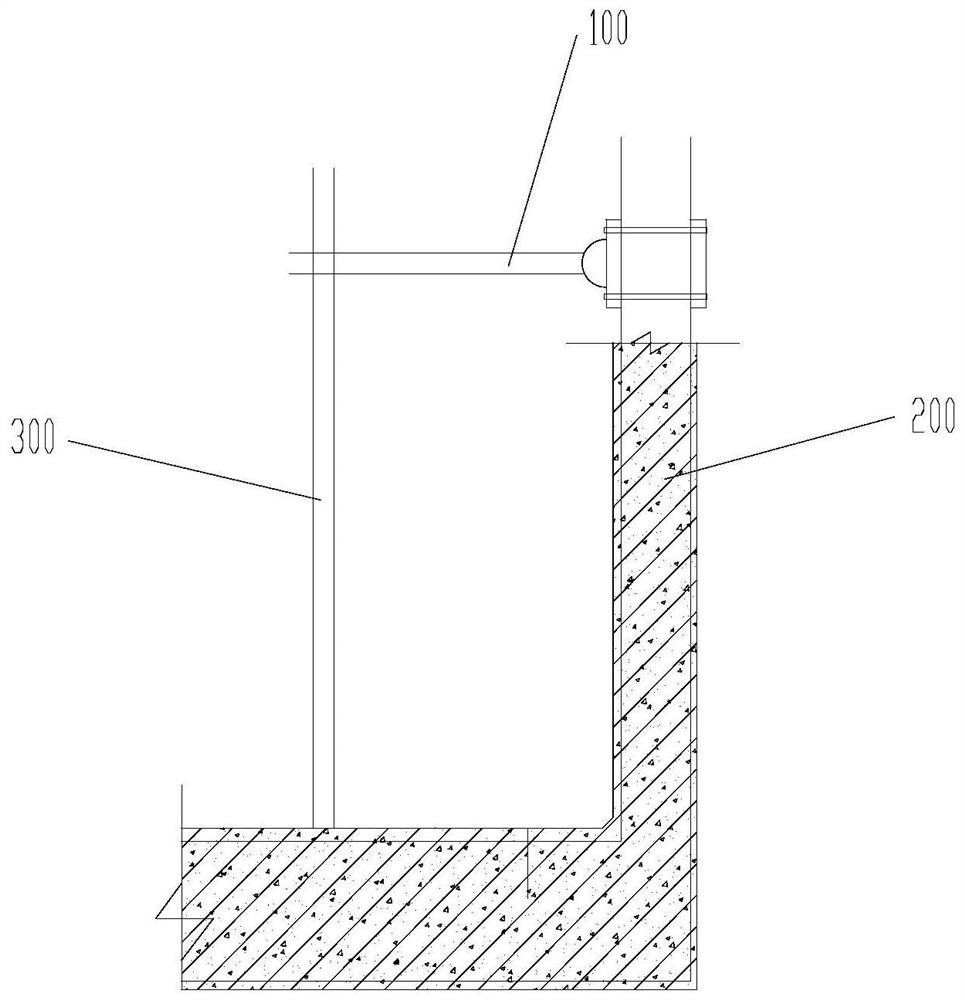

Anti-leakage construction method for foundation bottom plate, and building construction platform

InactiveCN109853629AAchieve the purpose of repeated useGuarantee the quality of pluggingArtificial islandsProtective foundationStructure of the EarthPlastic materials

The invention belongs to the technical field of building construction, and discloses an anti-leakage construction method for a foundation bottom plate, and a building construction platform; before thebottom plate is poured, a horizontal grouting pipe is pre-embedded in a joint part of the bottom plate and an exterior wall, and then a vertical grouting mouth is left and placed on the upper portionof the foundation bottom plate; and leakage occurs on the bottom plate, grouting is performed on the inside of a reserved grouting mouth of a leakage part, after grout reaches the inside of the horizontal grouting pipe, the grout is grouted into a gap between the bottom plate and the exterior wall for plugging. After the grouting is completed, before cement slurry in the grouting pipe is hardened, a plug is opened with clean water, so that when the leakage occurs again in a later stage, the grouting can be performed again to achieve a purpose of repeated usage. Materials of the method and theplatform are plastic materials, are light and easy to fix, construction is performed before a reinforcing steel bar is bound, and a normal construction period is not completely affected; and the grouting pipe is simple in structure and low in cost, and economic benefit is good compared with other grouting leaking stoppage manners. If the leakage occurs on the bottom plate, the method performs targeted grouting and leaking stoppage, and is good in plugging effect.

Owner:ZHONGTIAN CONSTR GROUP

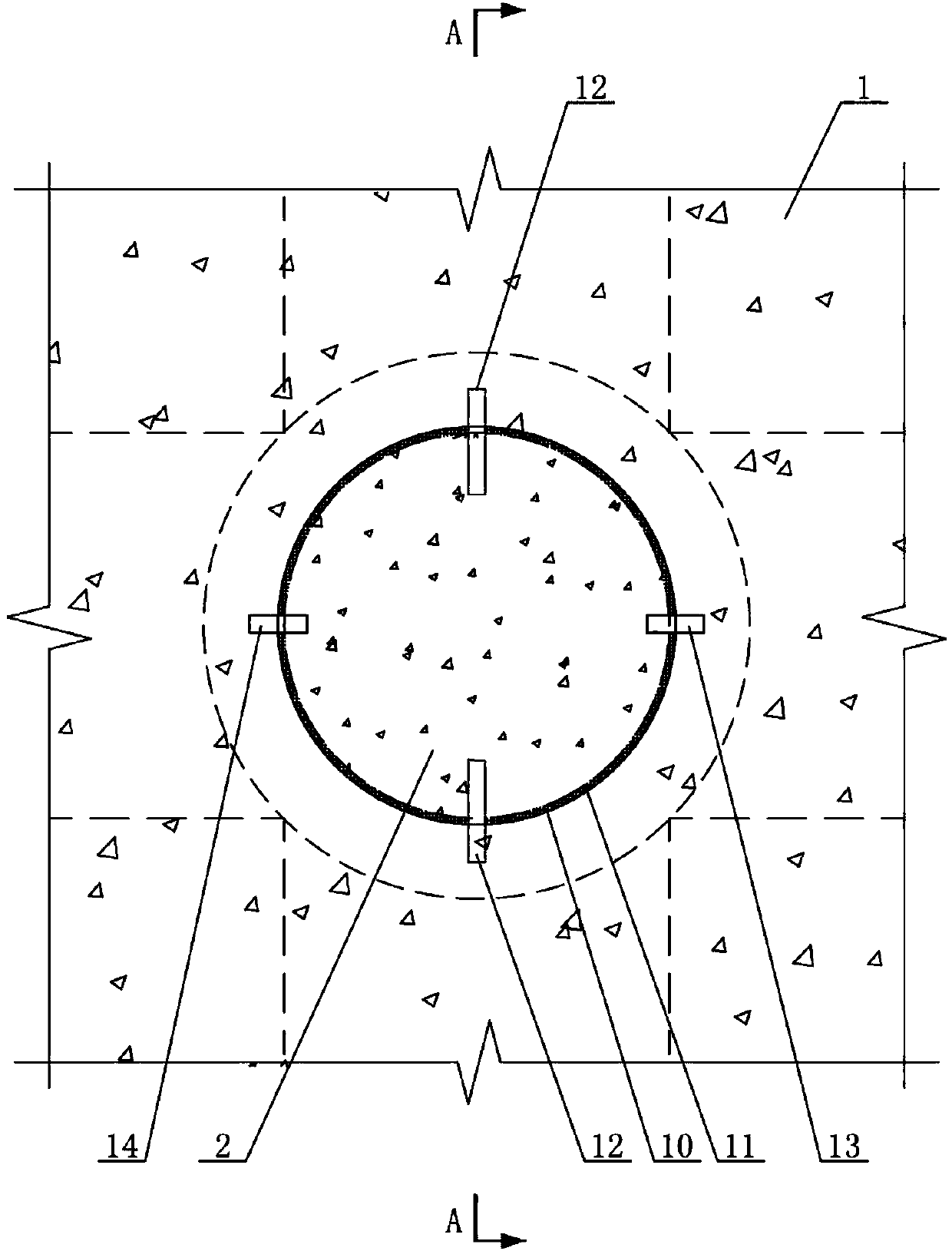

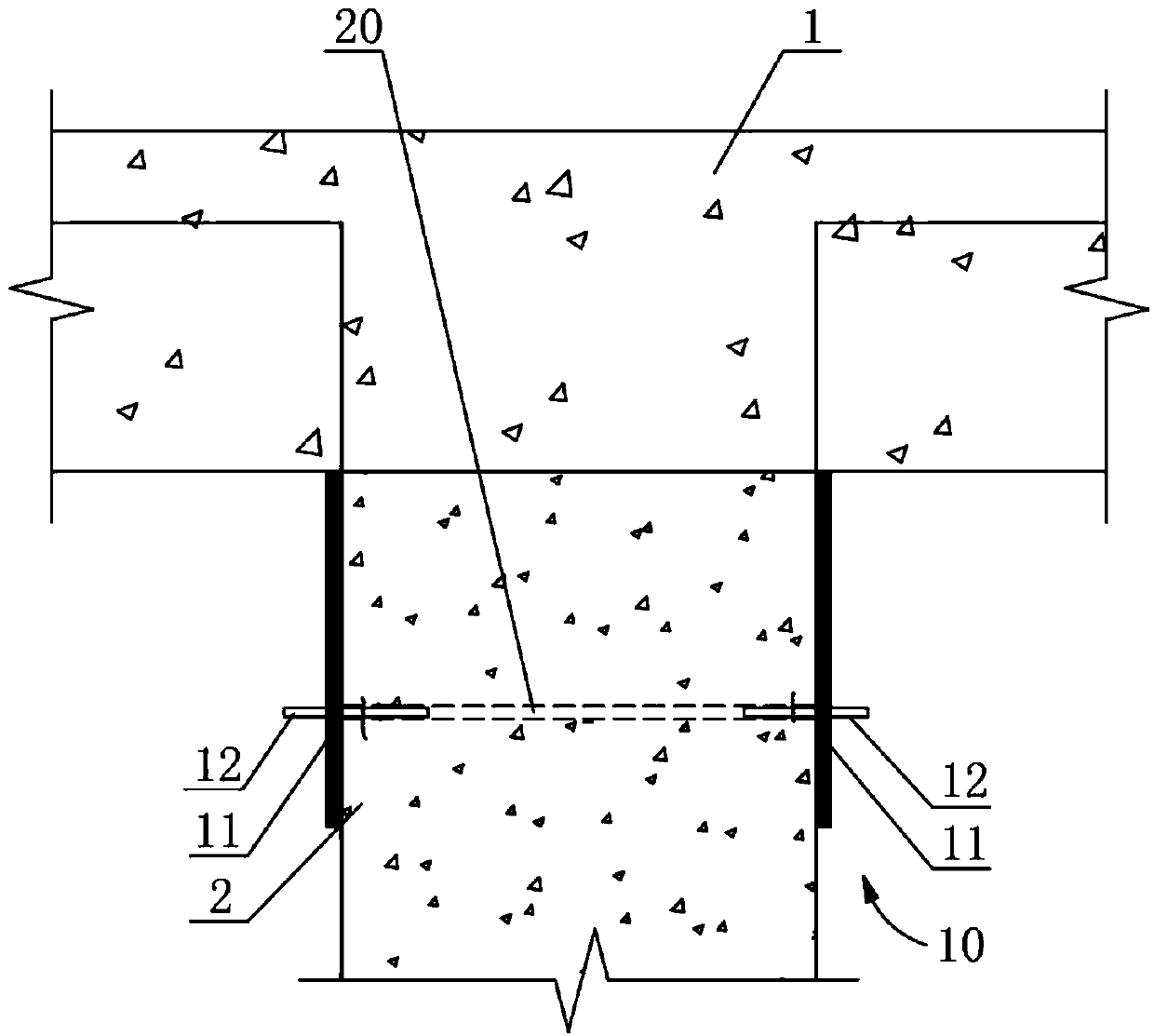

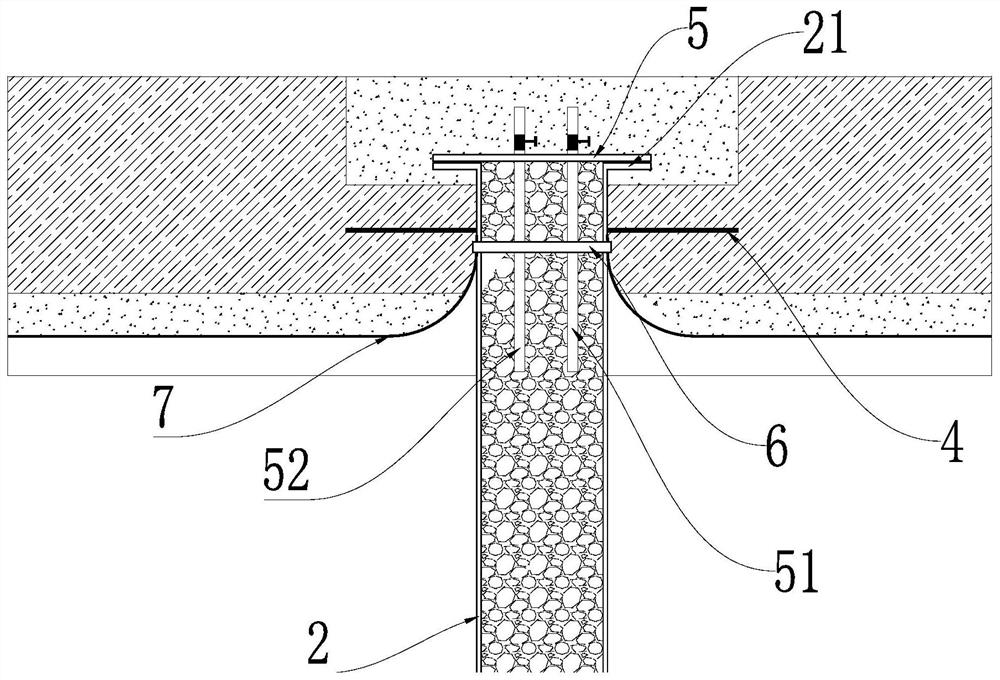

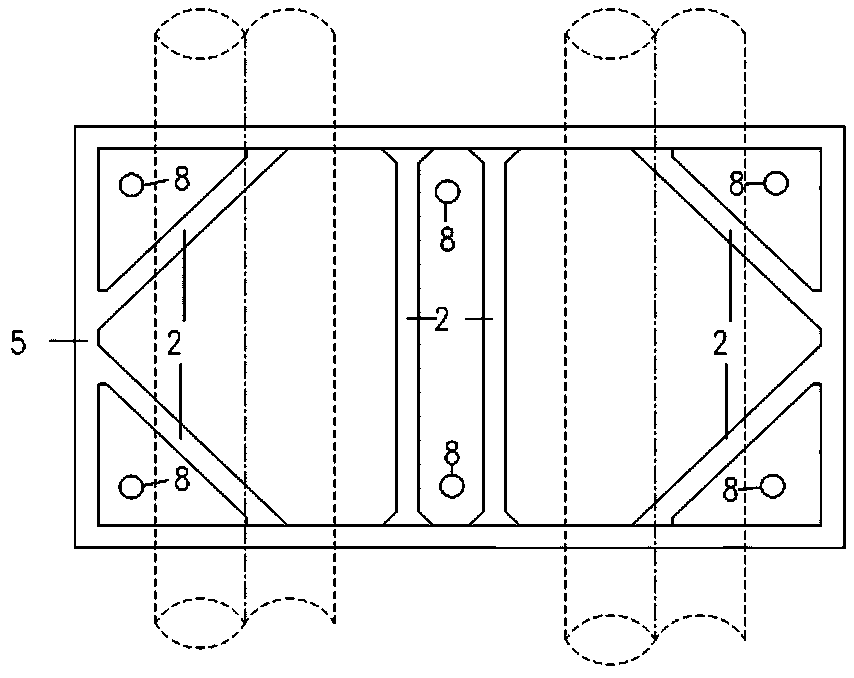

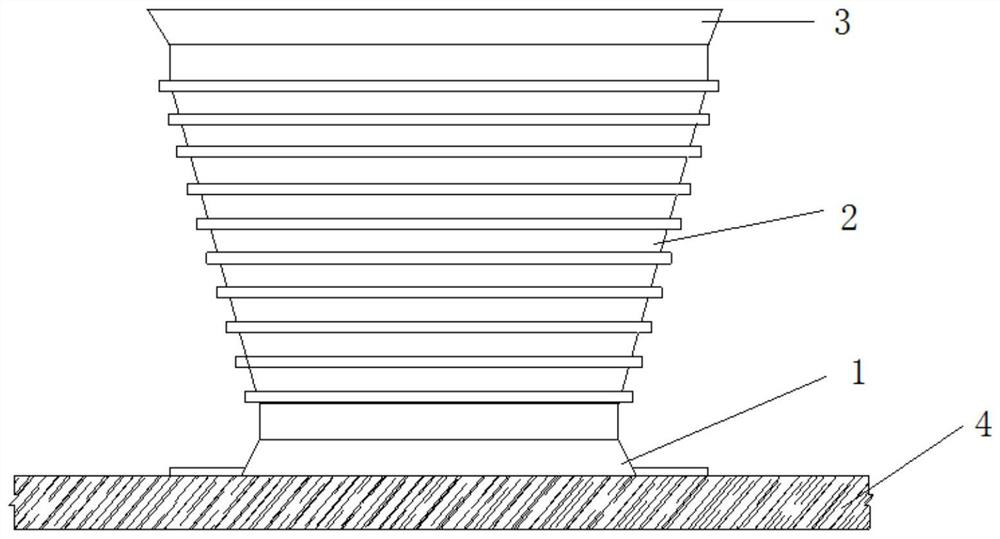

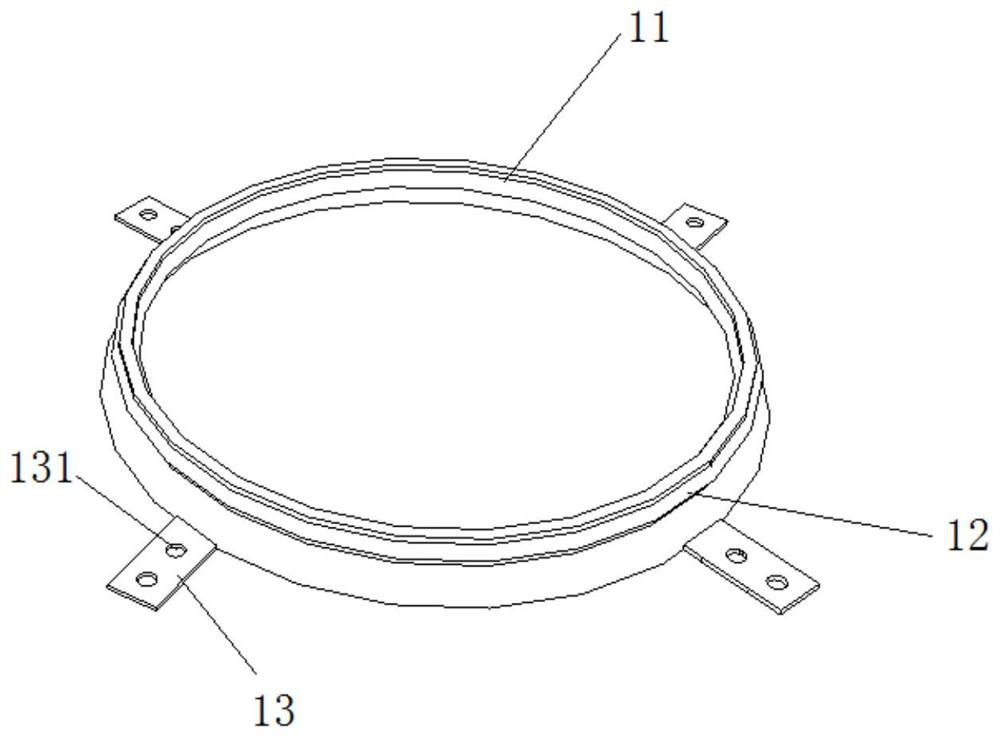

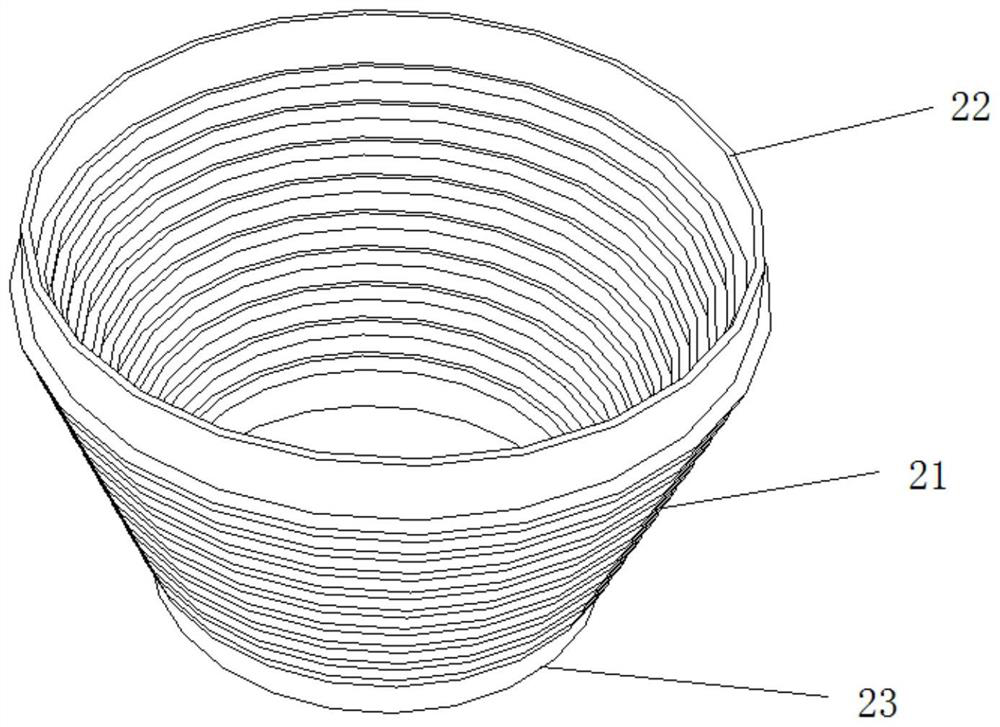

Device and method for joint treatment between vertical structure and horizontal structure

The invention provides a device and method for joint treatment between a vertical structure and a horizontal structure and relates to the technical field of site preparation of building materials or building components. The problem that in existing reverse construction method gradation pouring cylinder construction, a joint at the position of a junction surface between a beam plate and a cylinder is difficult to process, and engineering quality is influenced is solved. The joint treatment device comprises an annular formwork module capable of densely covering the outer side of the joint, at least one grouting pipe and a slurry outlet pipe, wherein the at least one grouting pipe and the slurry outlet pipe are respectively arranged on the annular formwork module. The grouting pipes and the slurry outlet pipe penetrate through and are fixedly connected to a side wall of the annular formwork module. The joint treatment method comprises a first step of providing the joint treatment device; a second step of clearing the outer surface of the vertical structure and blocking the edge of the joint; a third step of mounting the joint treatment device, assembling the annular formwork module to enable annular formwork module to tightly wrap the joint, and enabling one end of the grouting pipe and one end of the slurry outlet pipe which penetrate through the annular formwork module to be towards a cavity where the joint is located; and a fourth step of injecting concrete through the grouting pipe to block the joint.

Owner:NO 2 CONSTR GRP CO LTD OF SHANGHAI CONSTR GRP

Plugging method for dewatering well in foundation pit

The invention discloses a plugging method for a dewatering well in a foundation pit. The plugging method comprises the following steps that S1, the position of the dewatering well is selected, and a steel pipe is inserted to serve as the well wall of the dewatering well; S2, a water stop ring is welded to the neck of the steel pipe, and a connecting ring is welded to the top of the steel pipe; S3, a waterproof coiled material is arranged on the outer wall of the steel pipe and extends from the well bottom to the position below the water stop ring; S4, a water stop copper bar clamp is arranged below the water stop ring and used for clamping the waterproof coiled material; S5, bottom plates are laid on the two sides of the foundation pit and the two sides of the dewatering well, reserved plugging positions are arranged on the bottom plates, and steel pipes are arranged in the reserved plugging positions; S6, water pumps are placed in the steel pipes, water is cooled to the position 50cm below the lowest point of the foundation pit, and after a basement structure is completed, dewatering is stopped; S7, the water pumps are withdrawn, the dewatering well is filled with gravel, and a well lid with holes is additionally sealed on the connecting ring; and S8, grouting is conducted along the holes in the well lid. Underground confined water is plugged while pressure relief is conducted, the plugging quality is ensured, multiple waterproof measures are taken, and leakage of the structural bottom plates is avoided.

Owner:CHINA MCC5 GROUP CORP

Construction method for split bolt hole plugging

InactiveCN111779145AGuarantee the quality of pluggingReduce the hidden danger of water seepageAuxillary members of forms/shuttering/falseworksBuilding material handlingArchitectural engineeringMechanical engineering

The invention discloses a construction method for split bolt hole plugging. The construction method comprises the following steps of: S1: cleaning a hole: cleaning a split bolt hole on a shear wall, i.e., utilizing a hair brush to remove laitance and residues in the hole, and removing residual mortar around the hole to keep the inner wall of each bolt hole clean; and S2: removing a PVC (polyvinylchloride) pipe: adopting chiseling and expanding processing on the end part of the hole, removing the exposed PVC pipe by a scraper knife, and after cleaning is finished, cleaning the residual mortararound the hole by the hairbrush. According to the construction method, through a way that an antiseptic wooden plug and inner expansive grout are cooperated for plugging, a traditional end grout andinternal foaming plugging technology is replaced, hole plugging quality is guaranteed, the problems that cracking and falling are likely to happen can be effectively reduced, a hidden danger that an exterior wall is likely to generate water seepage in a later stage can be reduced, and construction quality is improved. In a plugging construction process, a special machine is adopted to replace a manual foaming way, so that construction efficiency is high, construction speed is high, and meanwhile, a manpower burden is lightened.

Owner:THE FOURTH OF CHINA EIGHTH ENG BUREAU

Method for sealing high-rise shear wall external wall upstream face pulling screw holes

InactiveCN109339440AReduce leakageEasy to implementAuxillary members of forms/shuttering/falseworksWall shearEngineering

The invention provides a method for sealing high-rise shear wall external wall upstream face pulling screw holes. PVC plastic conical plugs are additionally arranged, the PVC plastic conical plugs areused in the external wall shear wall pulling screw holes and inserted into the pulling screw external holes for sealing, then a foaming filler is injected from the positions, located on the inner side of a shear wall, of the pulling screw holes, and then the shear wall pulling screw holes are sealed by means of combination of inside and outside. It is ensured that the outer ends of the pulling screw holes are tightly filled with the tail ends of the PVC plastic conical plugs and the tail ends of the PVC plastic conical plugs are completely attached to a shear wall external wall, and meanwhile, conical plug anti-slip layers can effectively adhere to cement mortar. The method for sealing the high-rise shear wall external wall upstream face pulling screw holes is simple to implement and convenient to operate, leakage situation due to the high-rise external wall is greatly reduced, the maintenance cost is reduced, the construction quality is improved, and the method solves the problem ofexternal wall seepage due to poor sealing of the pulling screw holes, rough and uneven external wall ends of the pulling screw holes or aging of foaming materials caused by a conventional screw hole sealing method.

Owner:CHINA MCC17 GRP

Chute descending segment plugging method and structure for effectively improving stability

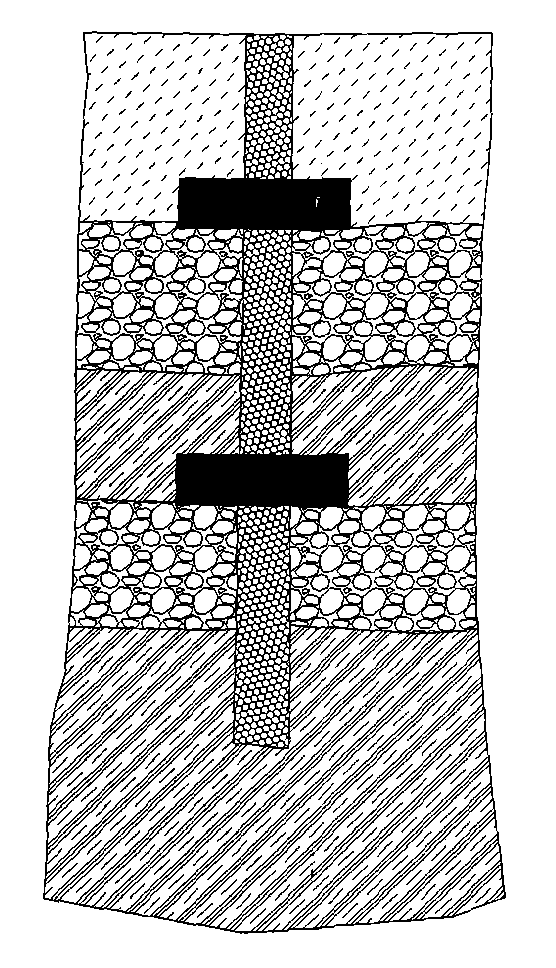

ActiveCN106761913AImprove stabilityImprove securityMaterial fill-upAnchoring boltsPumice dustIsolation layer

The invention discloses a chute descending segment plugging method and structure for effectively improving stability. The method includes the steps: 1) scaling an opening and the periphery of a chute, knocking rocks by a crowbar, prying the rocks with toneless and unclear sound by the crowbar, cleaning pumice stones and ensuring a safe construction environment without hidden danger; 2) filling the chute with ores, leveling the filling ores and laying an isolation layer; 3) setting anchor rods: forming anchor holes in the side wall of the chute between the isolation layer and the opening of the chute, inserting anchoring agents and the anchor rods into the anchor holes together, setting two layers of anchor rods on the side wall of the chute in a horizontally annular manner and embedding latticed strengthening steel into the anchor rods; 4) plugging the chute: pouring concrete into the chute within the range from the isolation layer to the opening of the chute, covering the chute with geotextile and performing maintenance after concrete pouring, finally, capping an ore plate completely covering the opening of the chute at the opening of the chute, and finishing plugging the chute.

Owner:YUXI DAHONGSHAN MINING

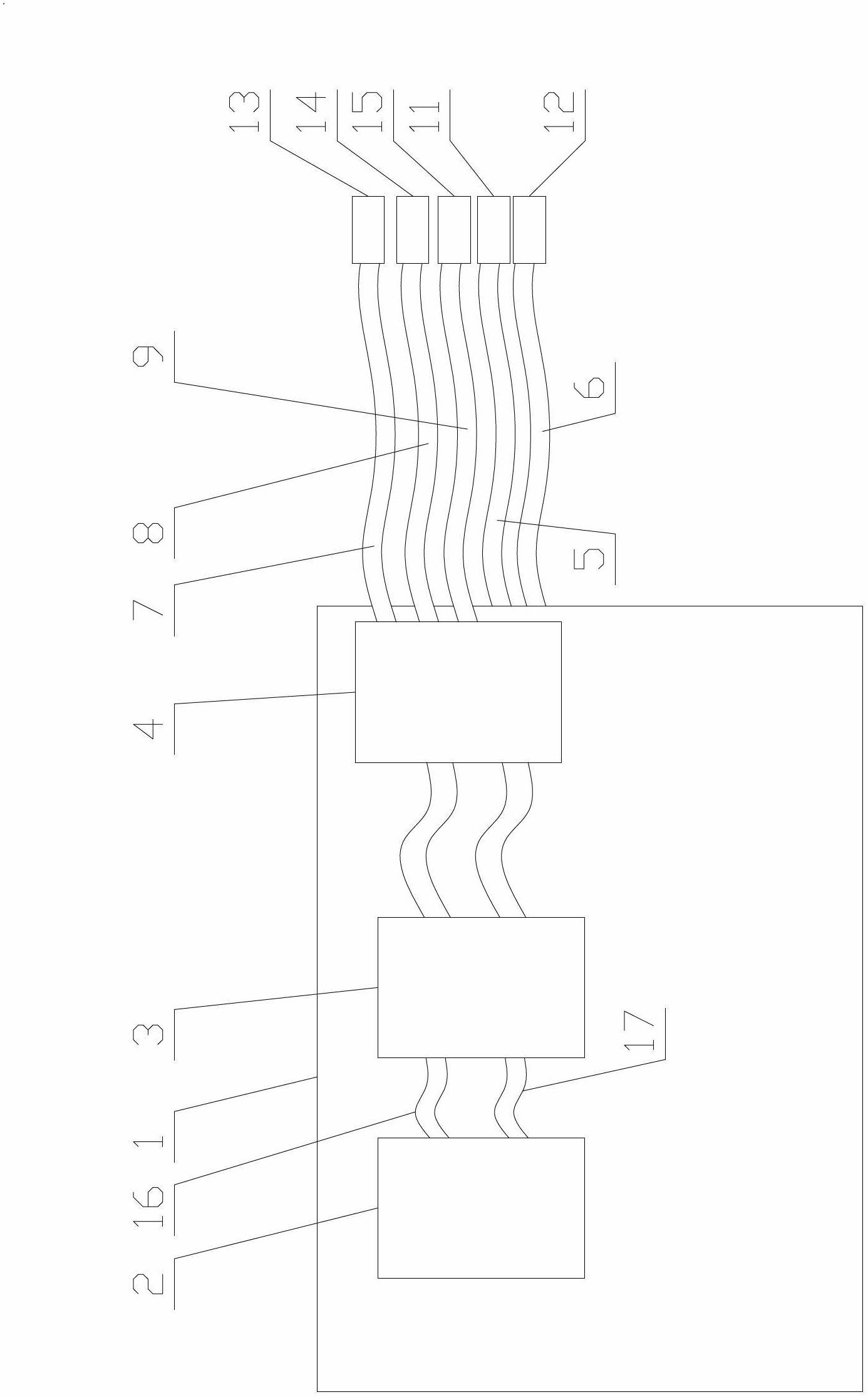

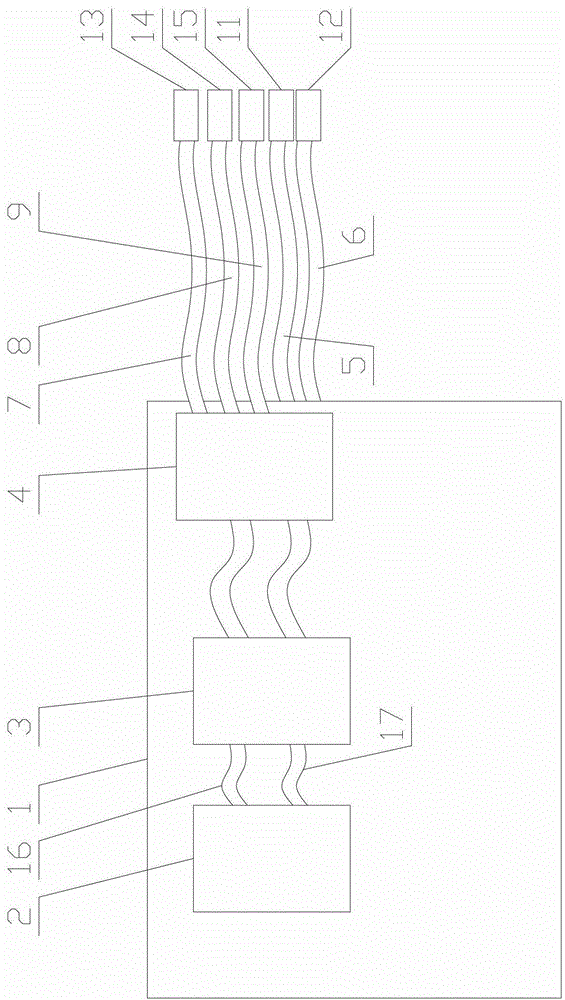

Ultralow-temperature refrigerator electric cabinet provided with patch-cord misplug prevention function

ActiveCN102650490AQuick plugRequirements for realizing quick plug-inDomestic cooling apparatusLighting and heating apparatusTransformerAssembly line

The invention discloses an ultralow-temperature refrigerator electric cabinet provided with a patch-cord misplug prevention function. A relay, a transformer, an alternating-current contact and a computer board are mounted in an electric cabinet body, and are connected through a plurality of internal connection wires; a plurality of external connection wires are arranged inside the electric cabinet body, and extend out from the electric cabinet body; and the external connection wires are connected with a quick plug and are distinguished by using wires with different colors. Rapid plugging for assembly line production is realized by matching the external connection wires with the rapid plugging, and the plugging quality is ensured. Meanwhile, the wires are distinguished by using the different colors, so that the production plugging, the future maintenance, and the wire examination in the maintenance are more convenient.

Owner:QINGDAO HAIER BIOMEDICAL CO LTD

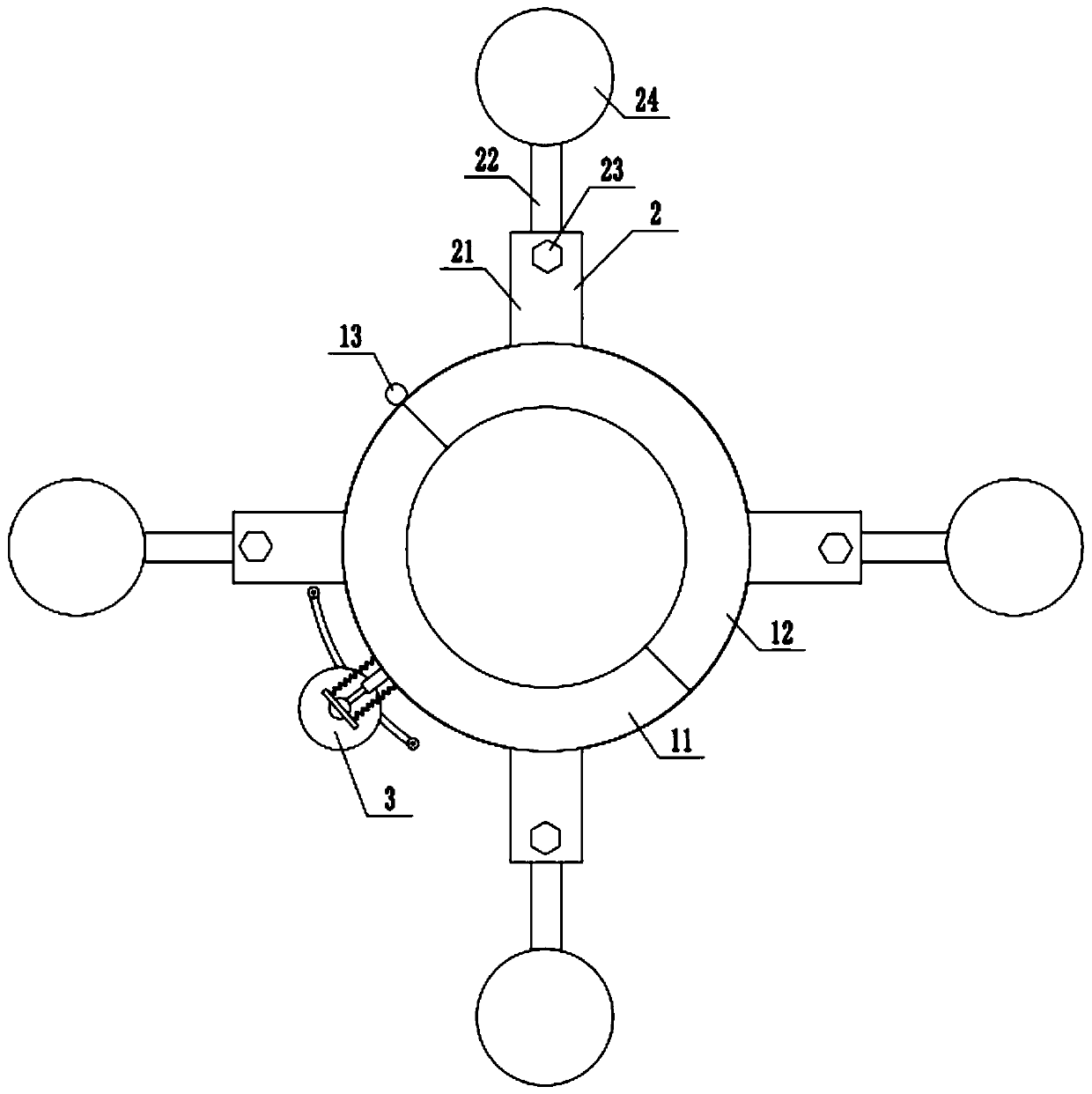

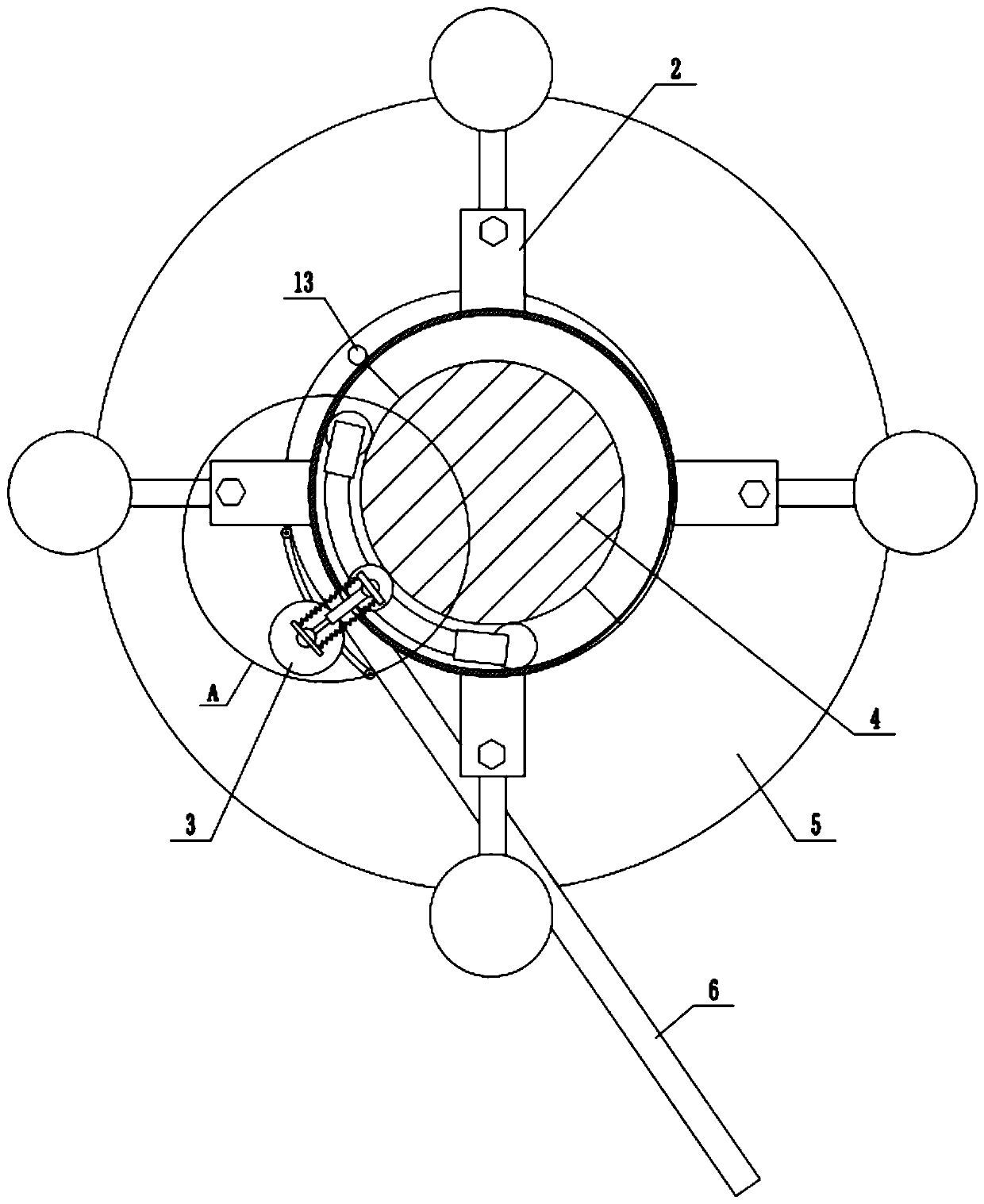

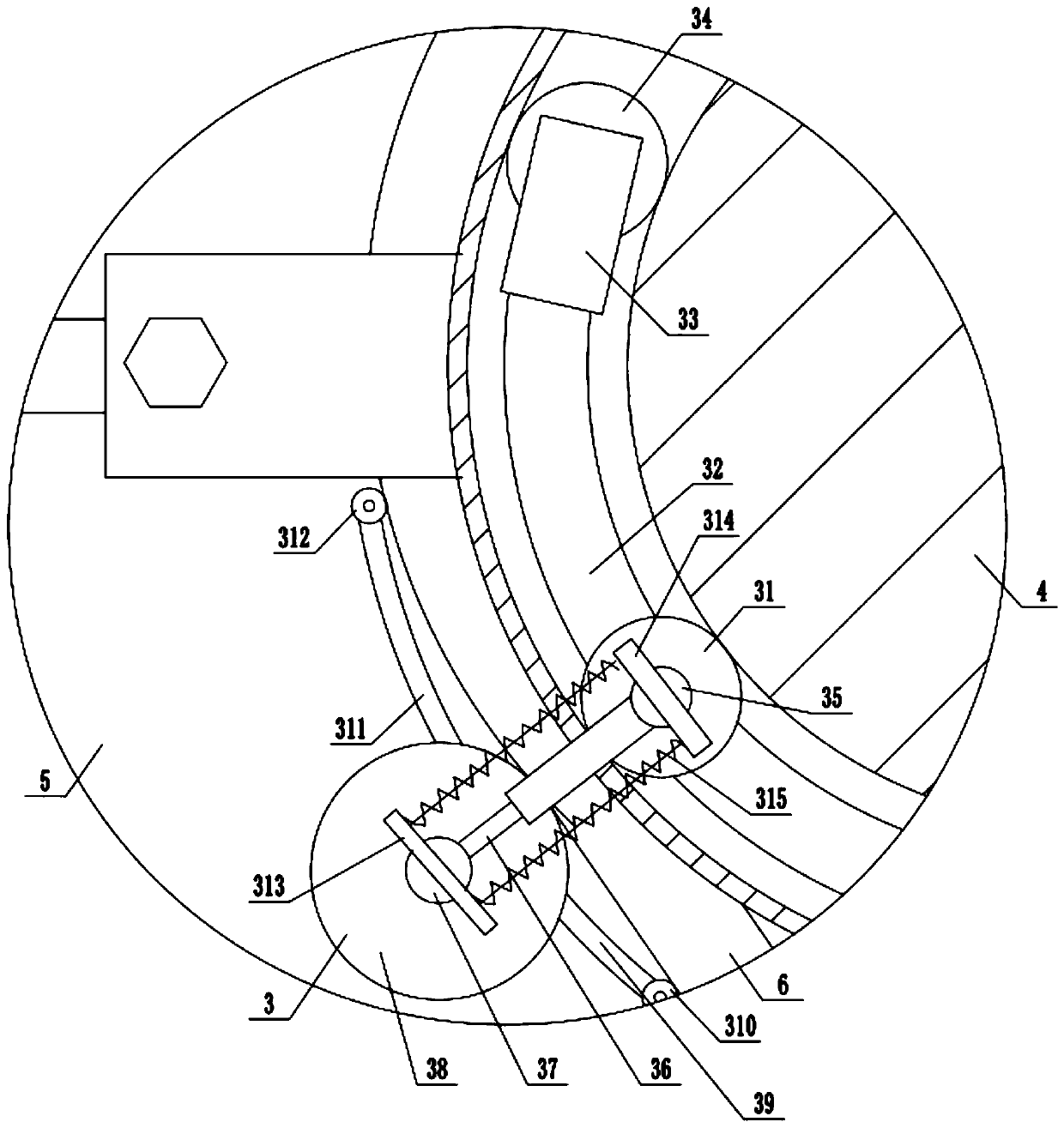

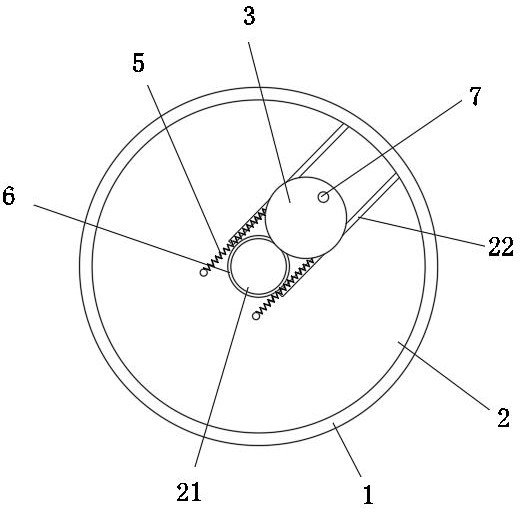

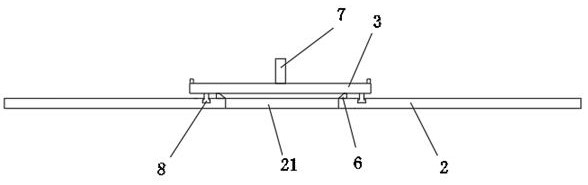

Special mold for plugging fireproof mud in cable holes

ActiveCN110752537AHard to extendSolve aestheticsCable installation apparatusFire - disastersEngineering

The invention provides a special mold for plugging fireproof mud in cable holes, and relates to the field of electrical equipment. The special mold comprises a left half ring and a right half ring, wherein the left half ring and the right half ring are connected together; a rotating ring is arranged on a cylinder body surrounded by the left half ring and the right half ring; a plurality of telescopic fixing mechanisms are annularly arranged on the rotating ring; and a heating plugging mechanism is mounted on the cylinder body. According to the special mold, the fireproof mud plugging process is changed from manually repeated splicing into mechanical auxiliary plugging forming, the process is fast and convenient, the thickness of the fireproof mud is consistent, the technological level is improved, the plugging quality of holes is guaranteed, the problems that the fireproof mud is difficult to extend at low temperature and the manual splicing process is unsightly are thoroughly solved,and the past operation process is changed. The short circuit accidents caused by fire and small animals are completely eradicated.

Owner:国网山东省电力公司昌乐县供电公司 +1

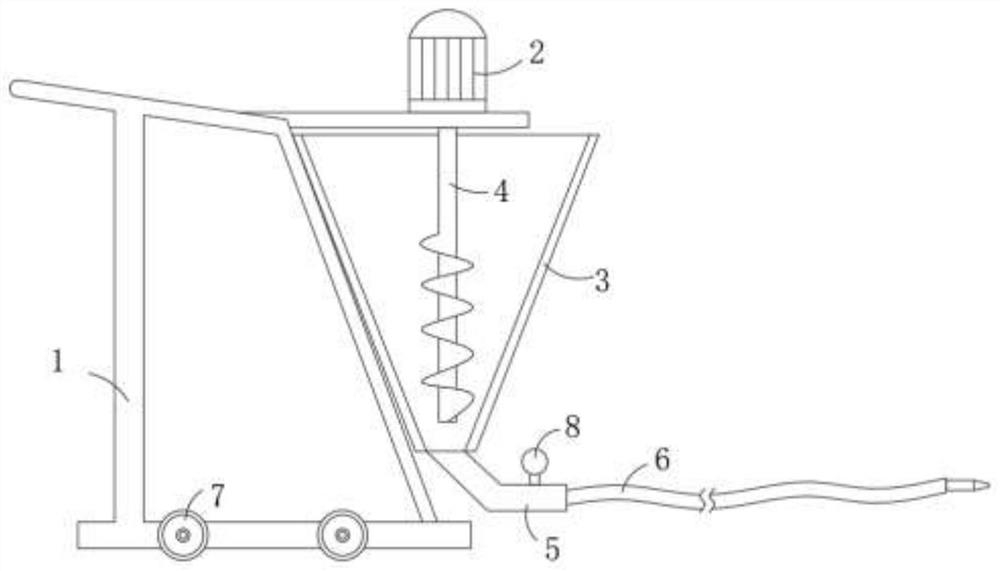

Simple blast hole plugging device for bench blasting and application method of simple blast hole plugging device

PendingCN108413824ASolve the difficulty of blockingMeet the design lengthBlastingEngineeringMechanical engineering

The invention relates to the technical field of blast hole plugging for bench blasting and particularly relates to a simple blast hole plugging device for bench blasting. The simple blast hole plugging device is characterized in that one end of each of six elastic plates is fixed to a large circular ring; the diameter of a circle defined by the other free ends of the six elastic plates is larger than the diameter of the large circular ring; a string is tensioned to make the elastic plates be in a pressed state, and at the moment the diameter of the circle defined by the free ends of the elastic plates is the same as the diameter of the large circular ring; when a lifting hook rod with scales is used for hooking the string so that the string can be put at a designed plugging position of a blast hole, the string is cut off to release the free ends of the pressed elastic plates; chiseling nails attached to elastic plates make close contact with the wall of the blast hole; and subsequentlystemming is put into the blast hole to implement the plugging. The simple blast hole plugging device provided by the invention is simple in structure and convenient to use, solves the difficulty of blocking of a vertical blast hole, can precisely meet the designed length of a plugging section of the blast hole, guarantees the plugging quality of the blast hole, improves the energy utilization rate of explosives and improves the blasting effect.

Owner:GUIZHOU HIGHWAY ENG GRP +1

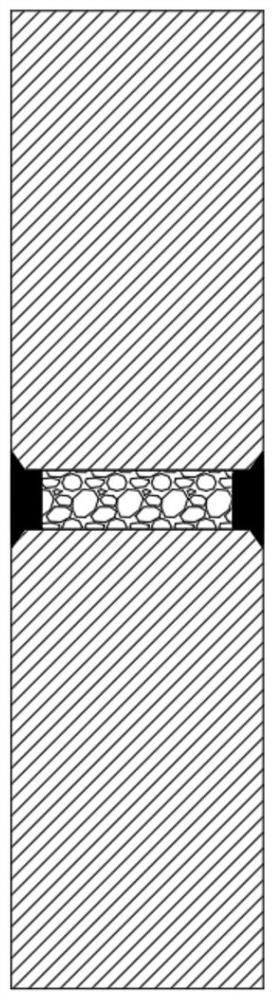

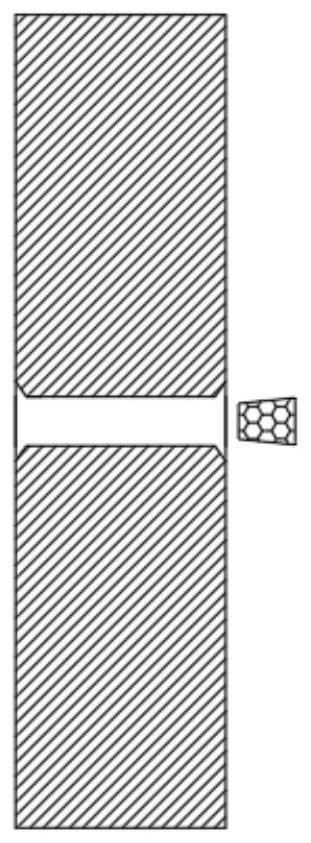

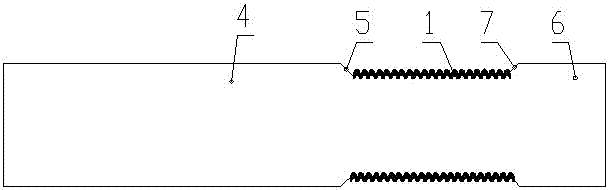

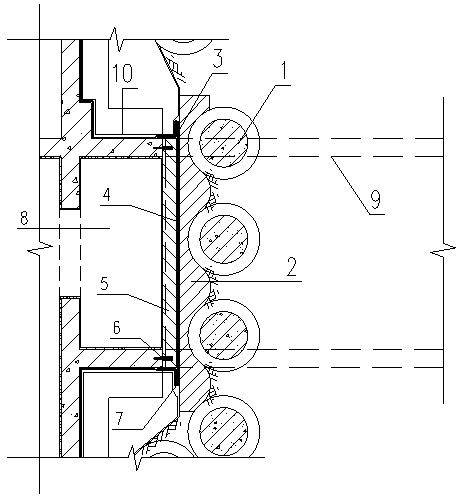

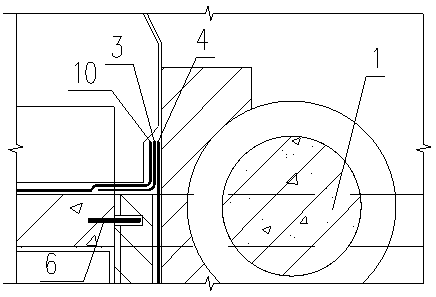

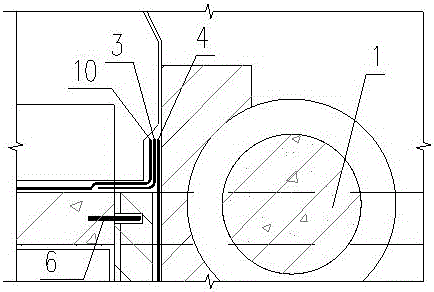

Thin-walled concrete tie screw waterstop structure and process

ActiveCN107246148ASimple structureIncreased durabilityAuxillary members of forms/shuttering/falseworksThin walledHydraulic pressure

The invention discloses a thin-walled concrete tie screw waterstop structure, comprising a plastic bellows arranged in a thin-walled concrete tie screw hole; the part of the tie screw hole in front of the plastic bellows is a front reamed hole, the part of the tie screw hole in rear of the plastic bellows is provided with a rear reamed hole, the tail end of the front reamed hole is provided with a water-swellable waterstop plug, and all the front reamed hole, the rear reamed hole and the plastic bellows are sealed with grout. The invention also discloses a construction method of the thin-walled concrete tie screw waterstop structure; the construction method comprises the steps of first, mounting a plastic bellows sleeve and tie screws; second, pouring, and removing forms; third, reaming; fourth, mounting the water-swellable waterstop plug; fifth, filling with grout; sixth, adding a water-swellable waterstop lug to the backwater side in case of underground water. The thin-walled concrete tie screw waterstop structure has high hydraulic pressure resistance, high structural tightness and durability, and good convenience of construction.

Owner:河南省水利第一工程局集团有限公司

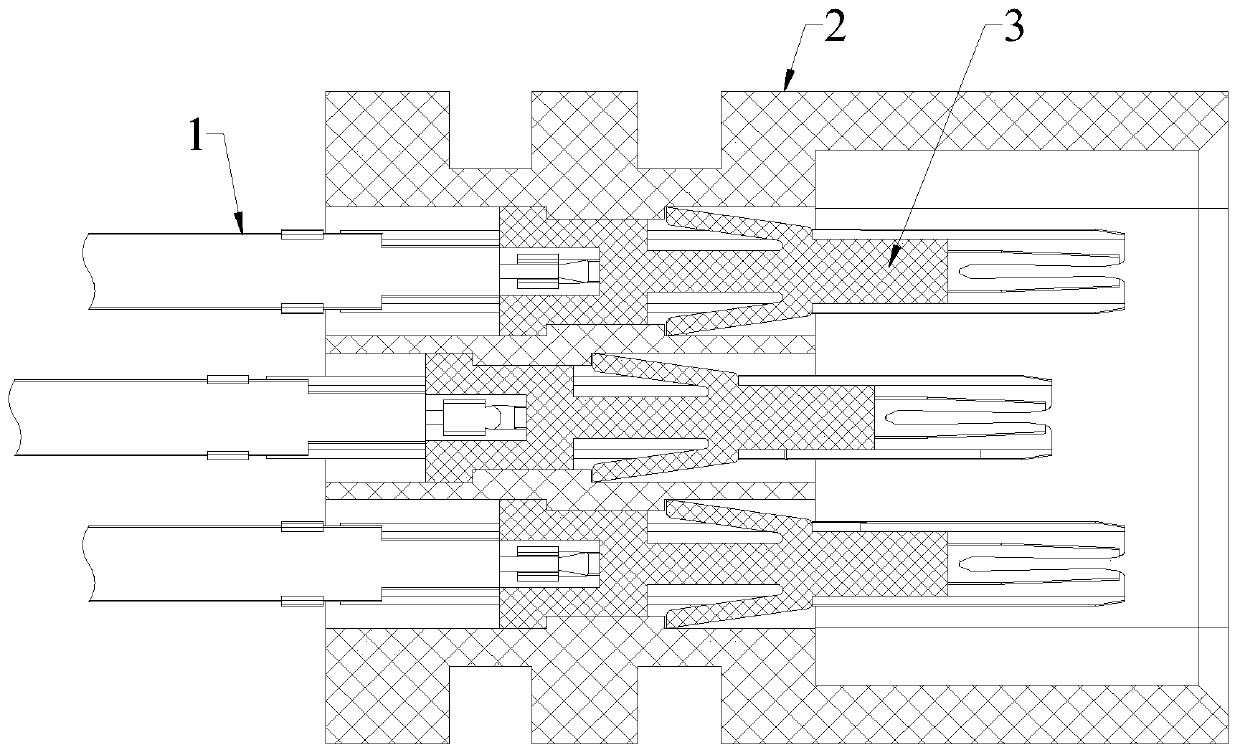

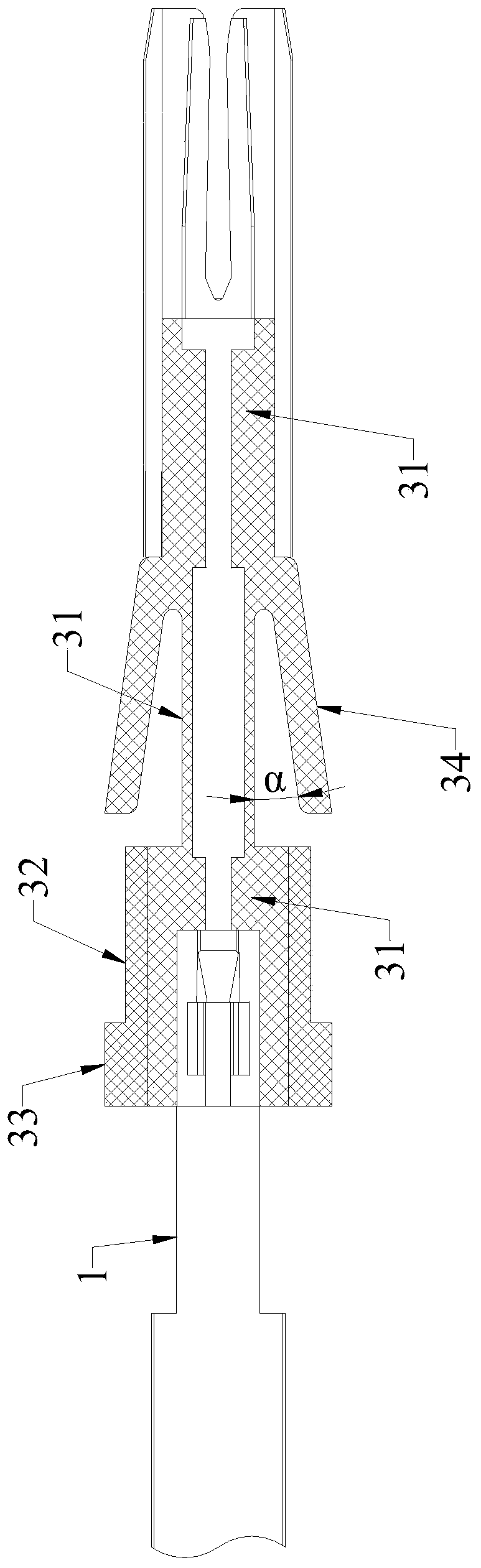

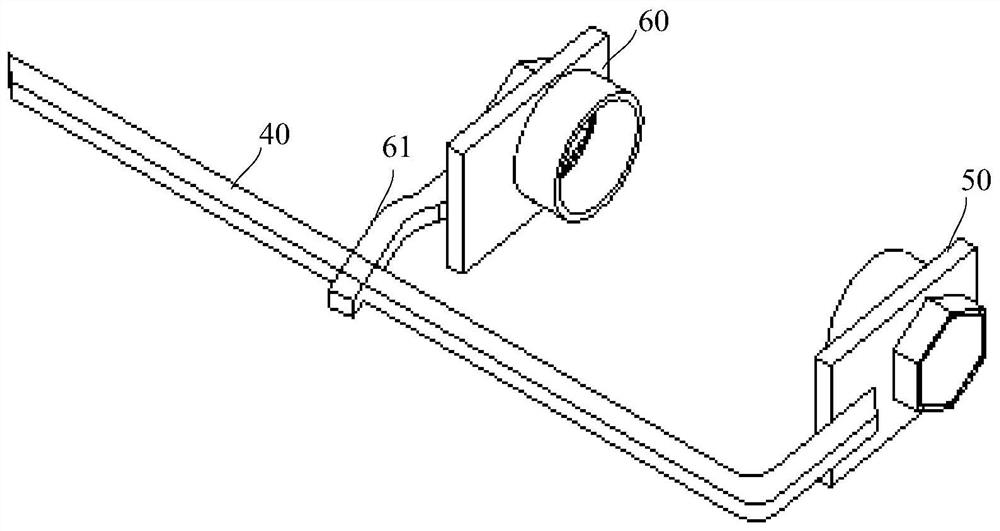

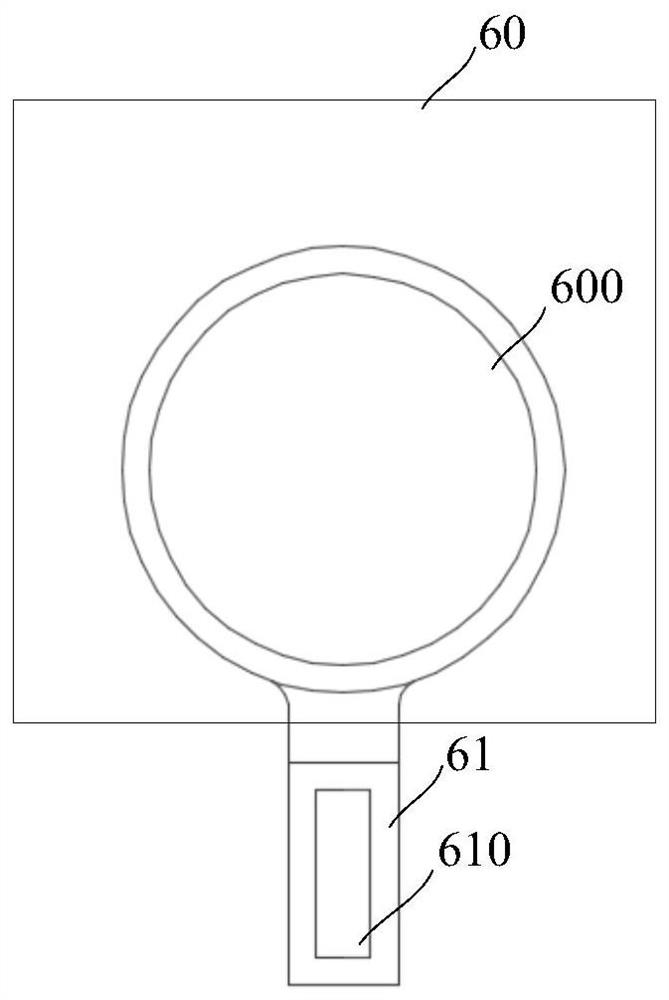

Radio frequency coaxial connector fixing device

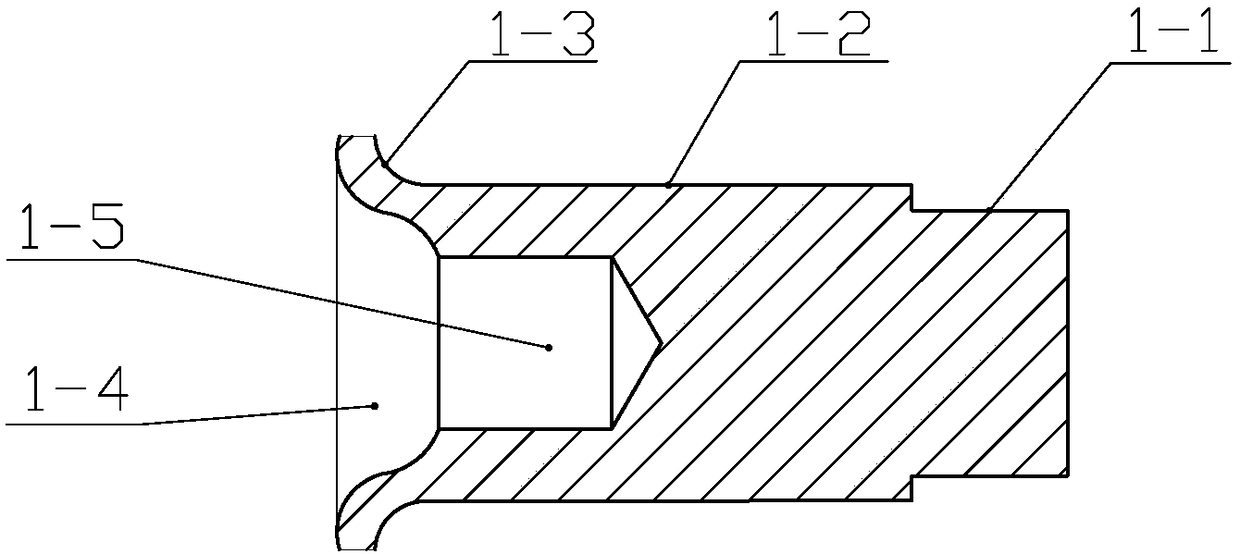

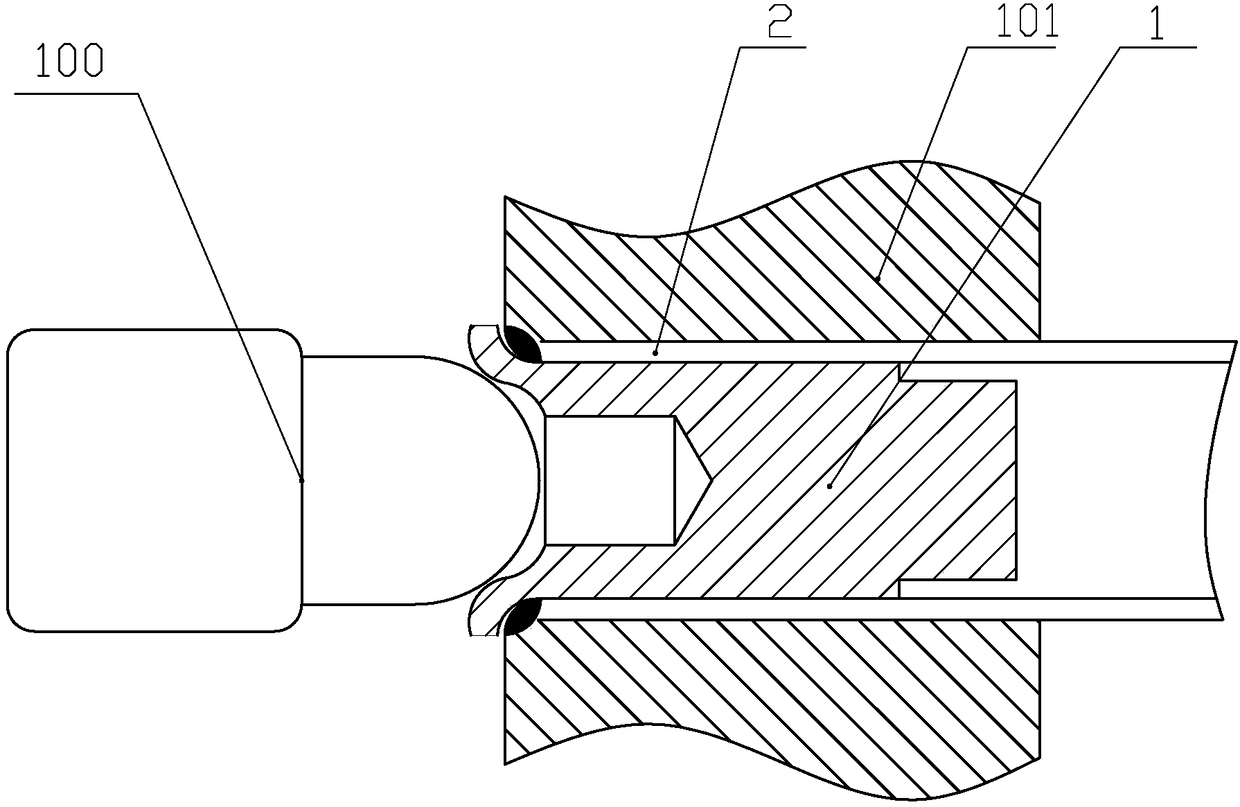

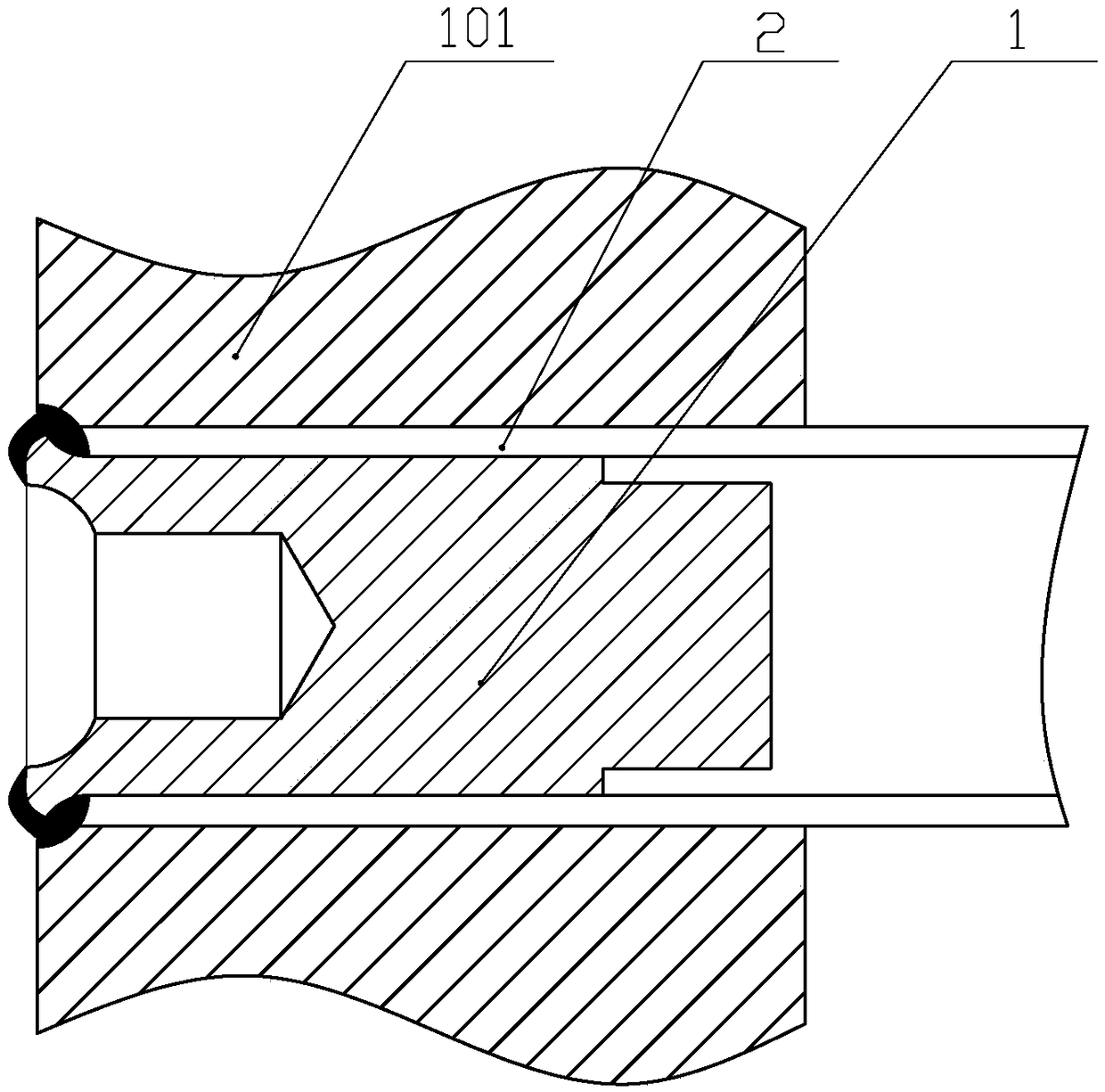

PendingCN110265819AGuarantee the quality of pluggingSimple structureCoupling device detailsTwo-part coupling devicesAcute angleRadio frequency

The invention relates to a radio frequency coaxial connector fixing device, which comprises a fixing plug and a columnar fixing socket. The fixing plug includes an insulating tube which sleeves a radio frequency coaxial connector. Multiple elastic pieces are arranged outside the middle section of the insulating tube. The angle between the lengthwise direction of the elastic pieces and the lengthwise direction of the insulating tube is alpha, which is an acute angle. Multiple raised plates are arranged at the rear section of the insulating tube. A raised block is arranged on the outer side of the tail end of each raised plate. Hole channels for installing the radio frequency coaxial connector are arranged at the head end of the fixing socket. Each hole channel includes a first installation hole for entry and exit of the raised blocks, a second installation hole for entry and exit of the raised plates and a third installation hole adapting to the elastic pieces. A fourth installation hole is arranged at the tail end of the fixing socket. The radio frequency coaxial connector fixing device is simple in structure and easy to use. After the fixing plug and the fixing socket are connected by plugging, the fixing plug and the fixing socket are locked. The fixing plug and the fixing socket cannot be easily separated, and the quality of plugging is high.

Owner:SHANGHAI AEROSPACE SCI & IND ELECTRIC APPLIANCE RES INST

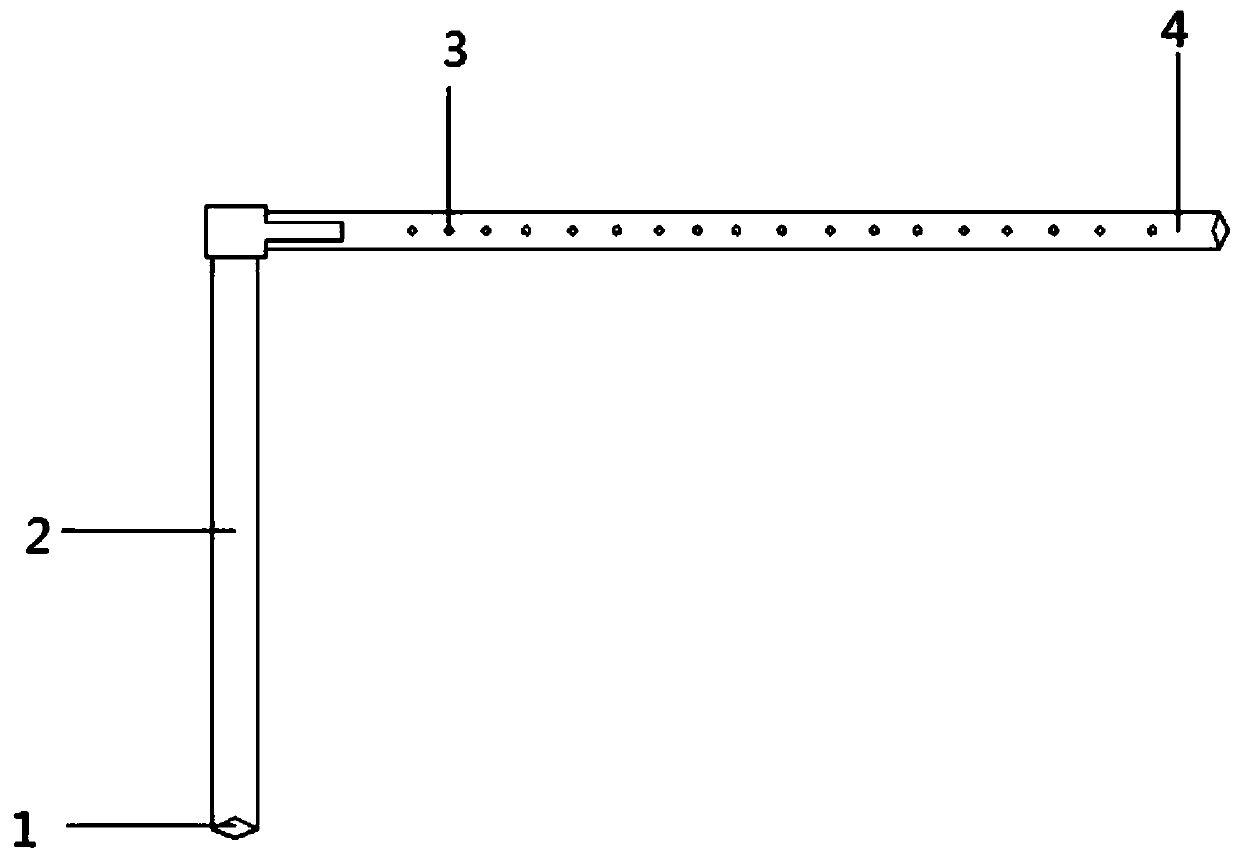

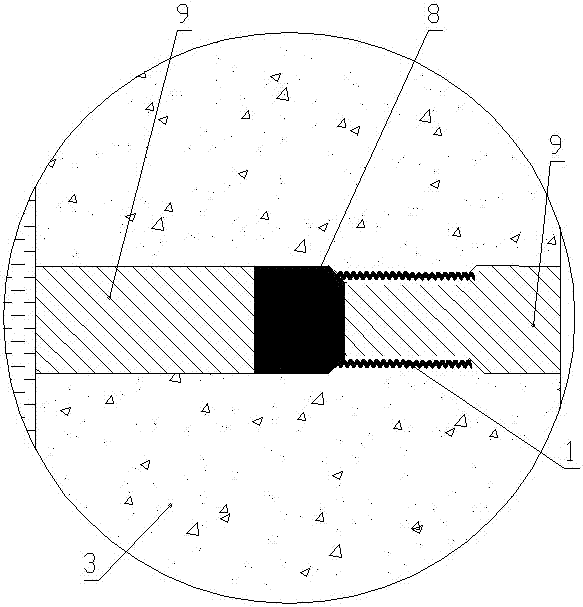

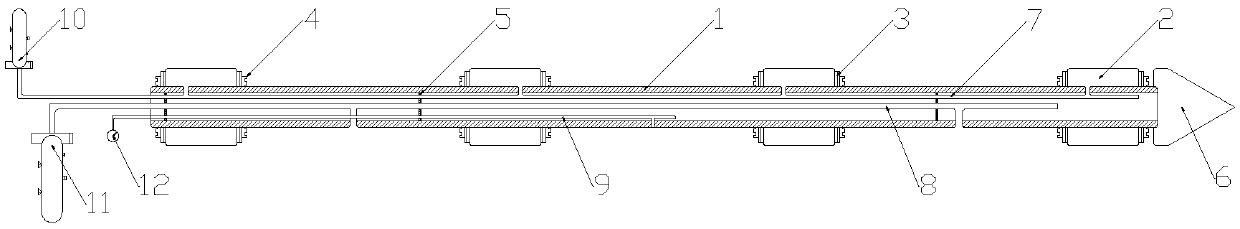

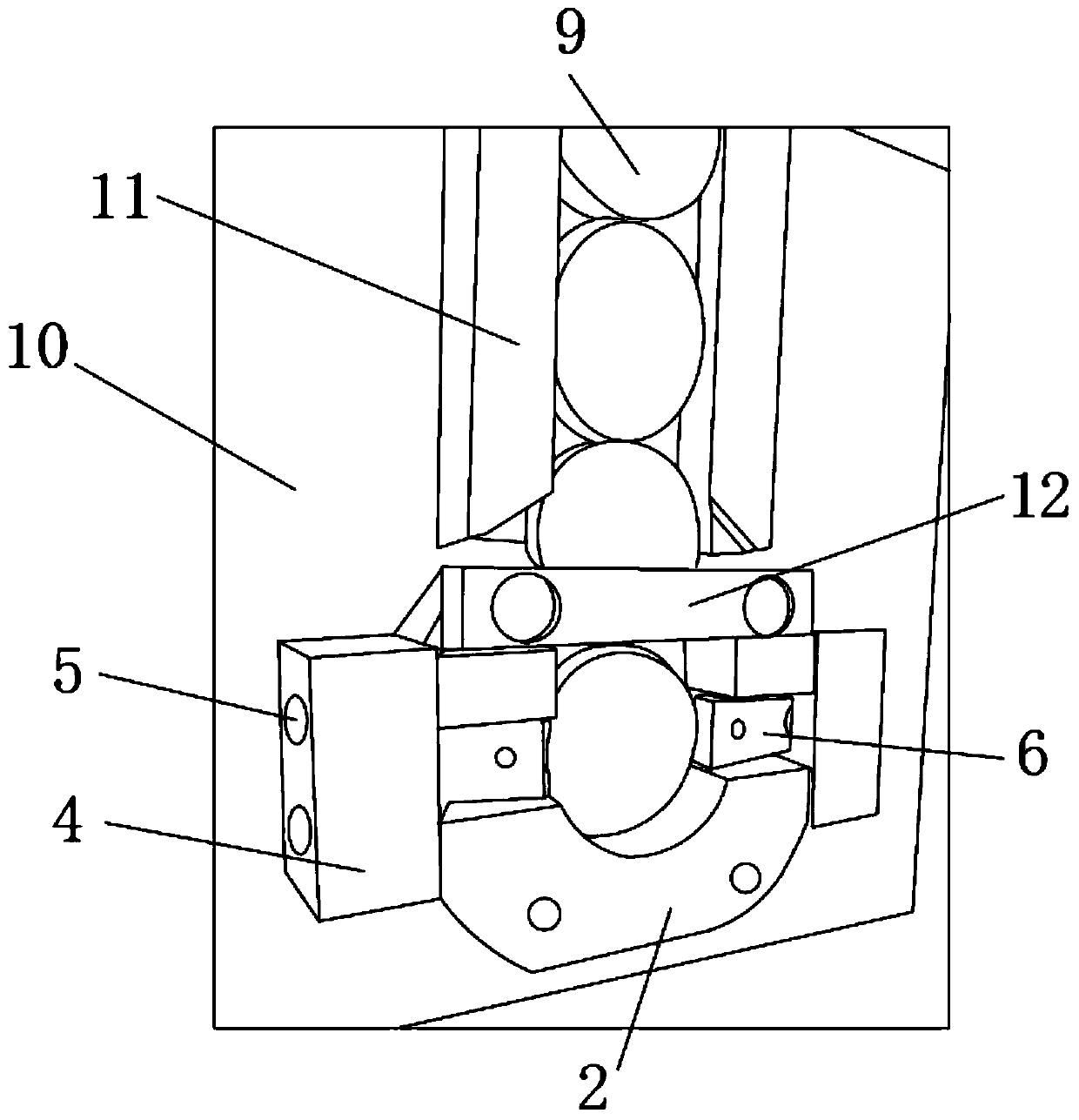

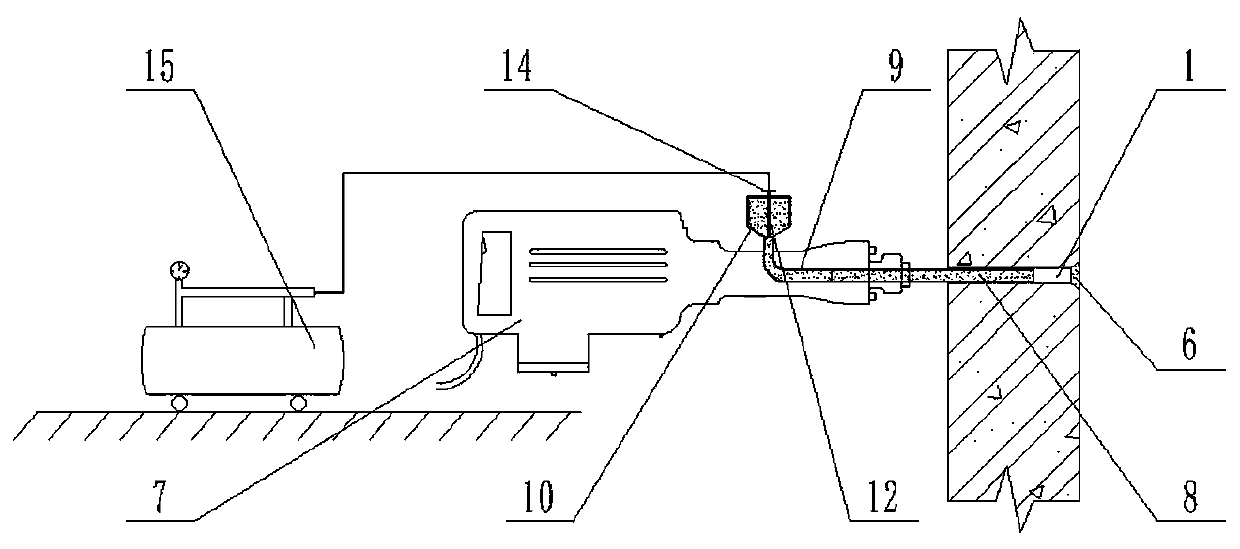

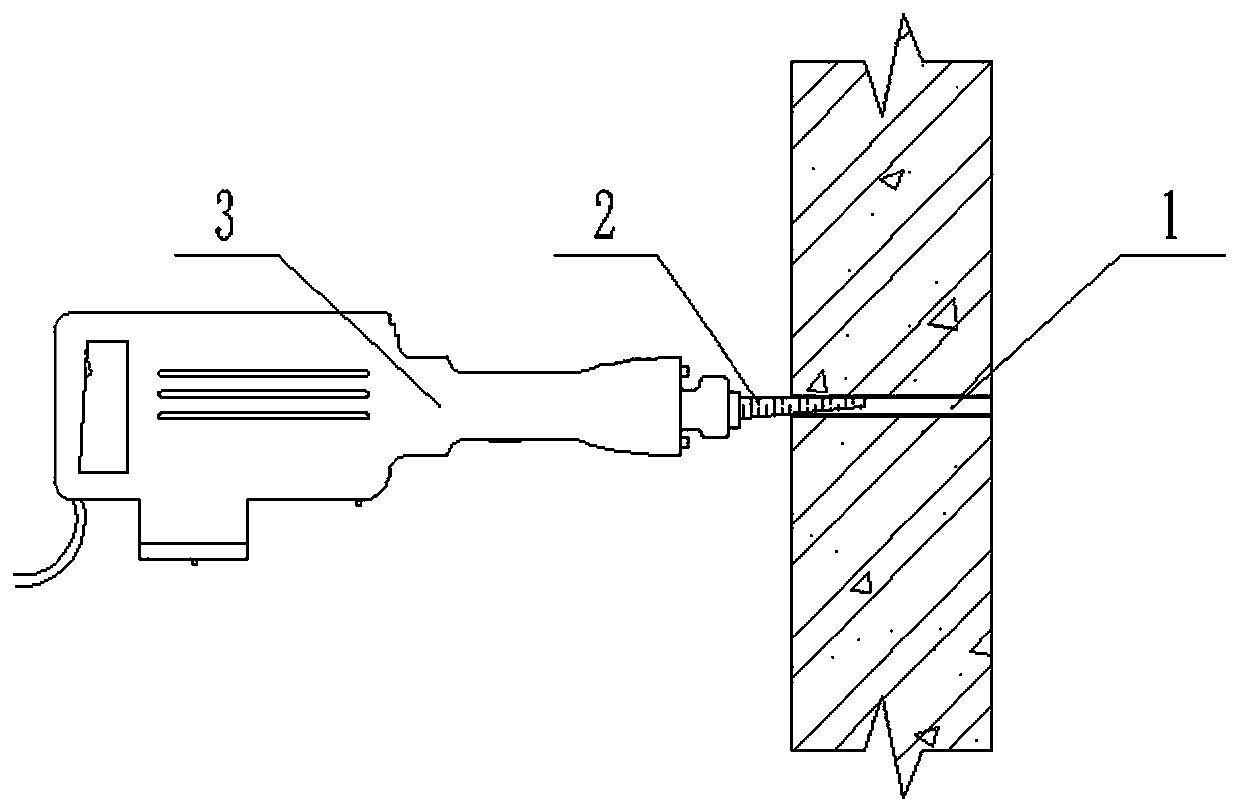

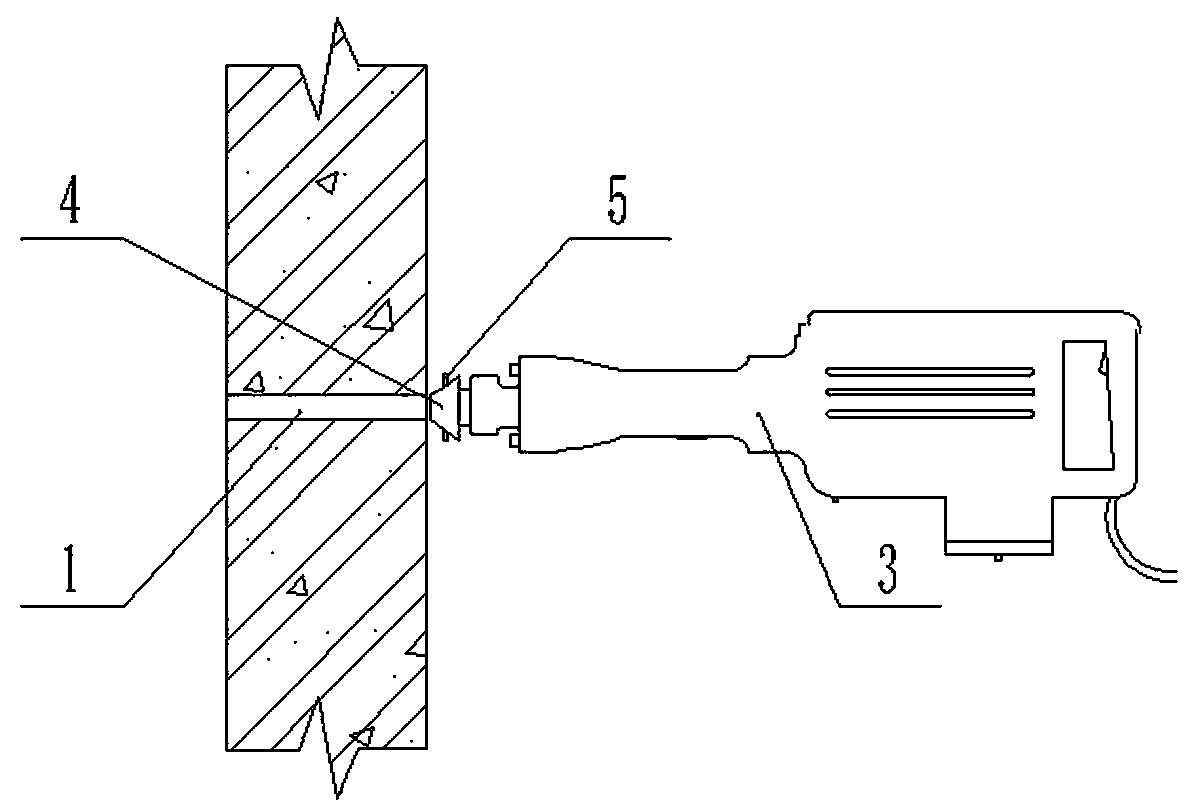

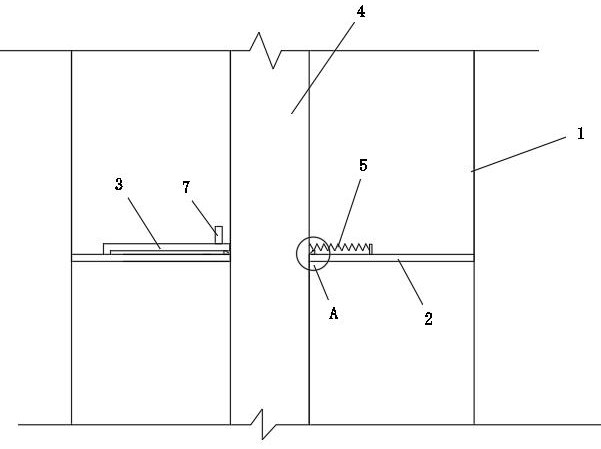

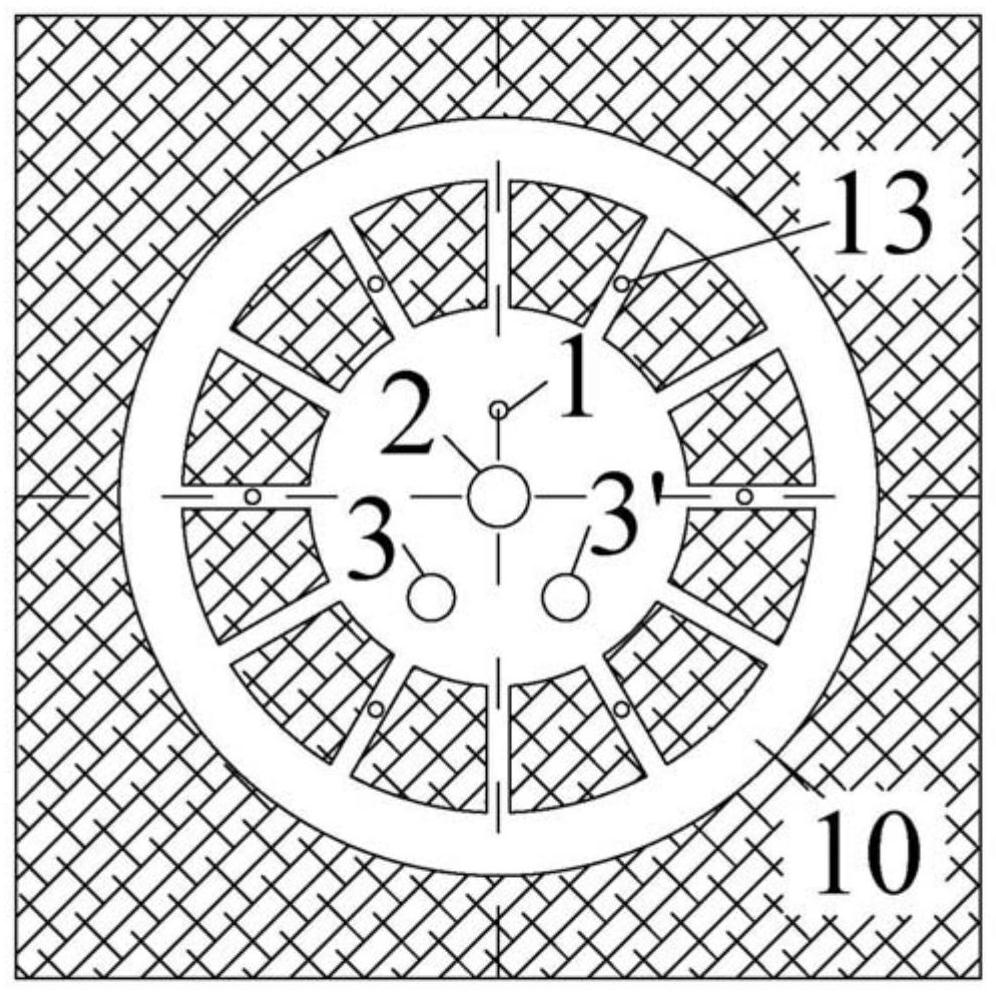

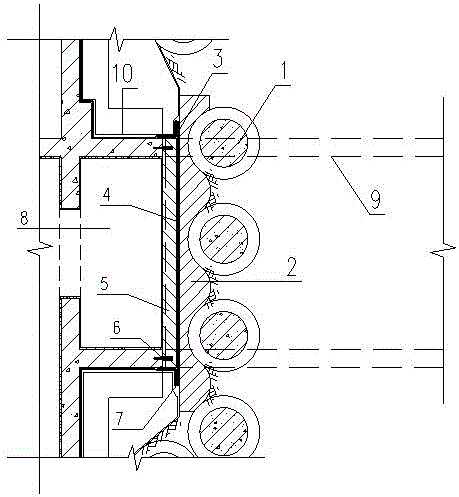

Coal mine underground water guiding borehole packer

PendingCN109630061AGuarantee the quality of pluggingPermanently blockedSurveySealing/packingSlurryHydrology

The invention discloses a coal mine underground water guiding borehole packer. The coal mine underground water guiding borehole packer comprises a hollow pipe body, polyurethane pipes, circular metalgaskets, fastening nuts, a pipe fixing ring, a guiding head, an injecting pipe, a grouting pipe, a water pipe, a liquid pressurizing device, a slurry pressurizing device and a water pressure gauge, wherein the guiding head is fixed to the front end of the hollow pipe body through a thread, the four polyurethane pipes are fixed on the hollow pipe body through the circular metal gaskets and the fastening nuts, the injecting pipe, the grouting pipe and the water pipe are located in the hollow pipe body, the injecting pipe is externally connected with the liquid pressurizing device, the grouting pipe is externally connected with the slurry pressurizing device, and the water pipe is externally connected with the water pressure gauge. The coal mine underground water guiding borehole packer is provided for the shortage of existing coal mine underground borehole plugging equipment, combines temporary sealing with permanent sealing to improve the quality of borehole plugging, and can display the water pressure change in a borehole in real time to provide early warning for coal mine permeation.

Owner:ANHUI UNIV OF SCI & TECH

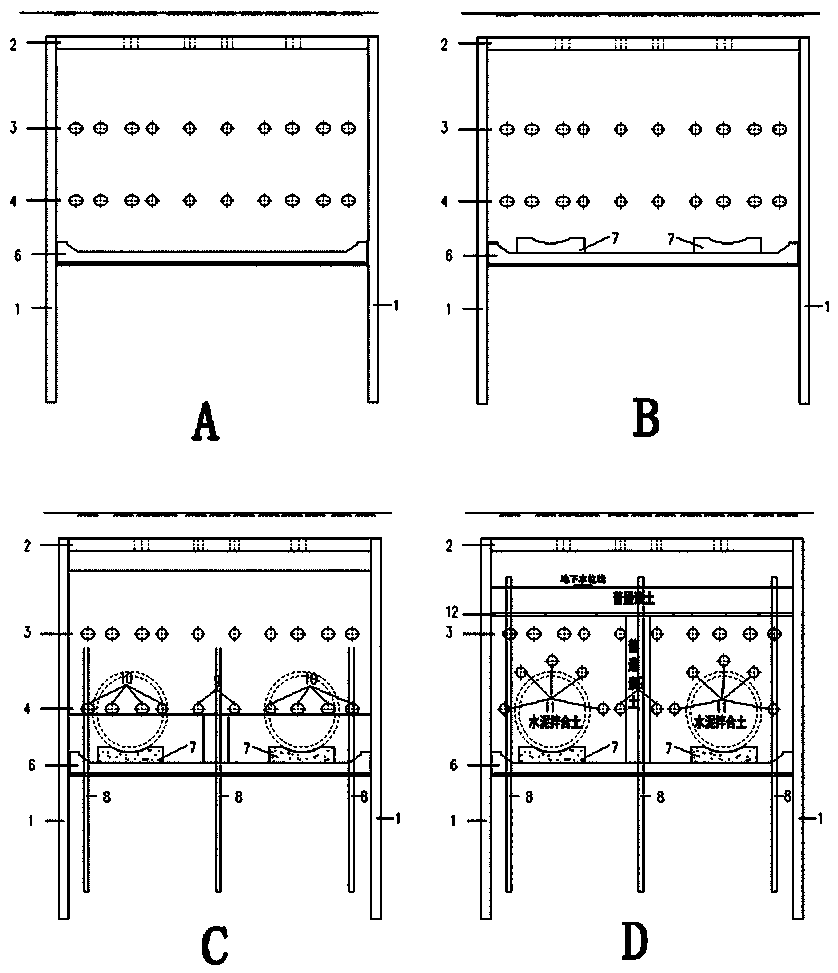

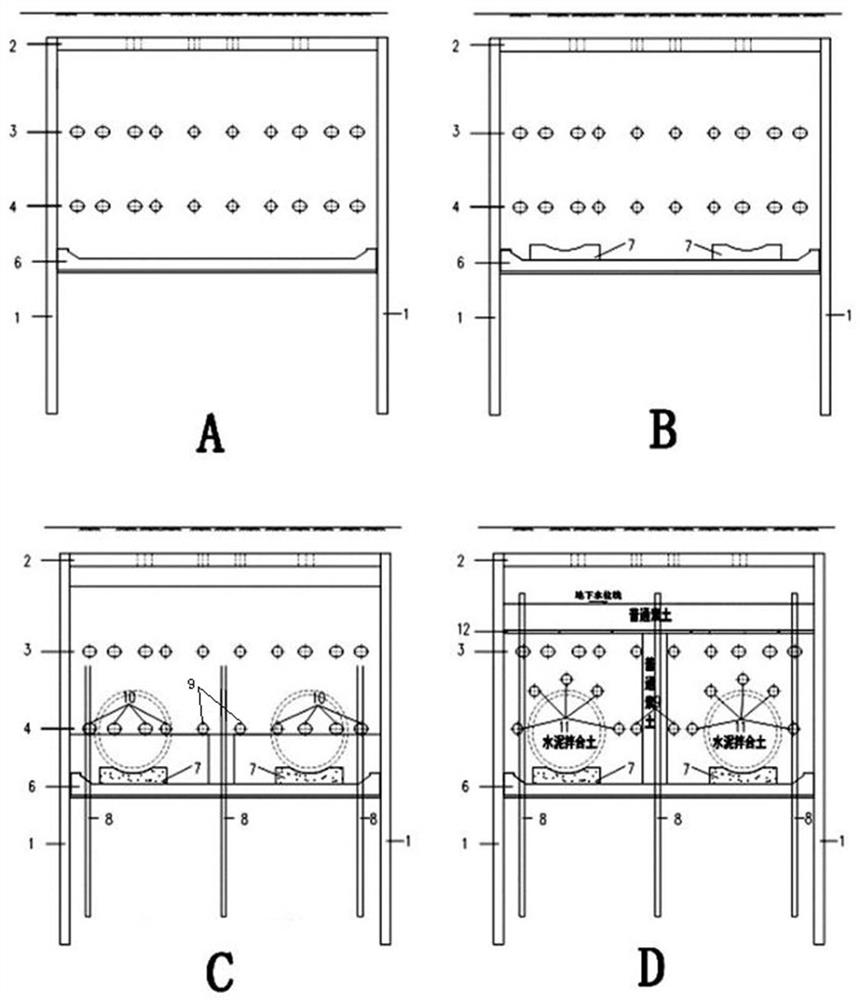

Shield interval piston vent backfilling and station passing construction method

ActiveCN109577998AAvoid receiving multiple timesReduce riskUnderground chambersTunnel liningReinforced concreteWater table

The invention relates to the technical field of metro construction, particularly to a shield interval piston vent backfilling and station passing construction method. The shield interval piston vent backfilling and station passing construction method comprises, after bottom plates of an interval piston vent are constructed, arranging steel supports circumferentially outside a shield range, backfilling modified soil, arranging reinforced concrete sealing plates into the backfilled soil, backfilling soil to reach the underground water level and the like to increase the support stiffness inside the piston vent, balance pressure of water and soil inside and outside pits and ensure structural stability of a foundation pit support; when a shield tunneling machine is passing by, strengthening synchronous grouting for secondary grouting of an out-tunnel sixth ring, and re-grouting the seepage parts of the foundation pit support during backfilled water excavation to seal joints of the foundation pit support and the seams between a tunnel entrance and the foundation pit support and further to ensure subsequent construction safety. The shield interval piston vent backfilling and station passing construction method effectively solves the contradiction between limited construction periods and lagged piston vent construction, avoids the risks of multiple starting and receiving the shield tunneling machine passing through the piston vent, and has the advantages of being reasonable in process, safe, reliable, capable of avoiding stopping of the shield tunneling machine and effectively shortening the construction period and the like.

Owner:CHINA RAILWAY 12TH BUREAU GRP +1

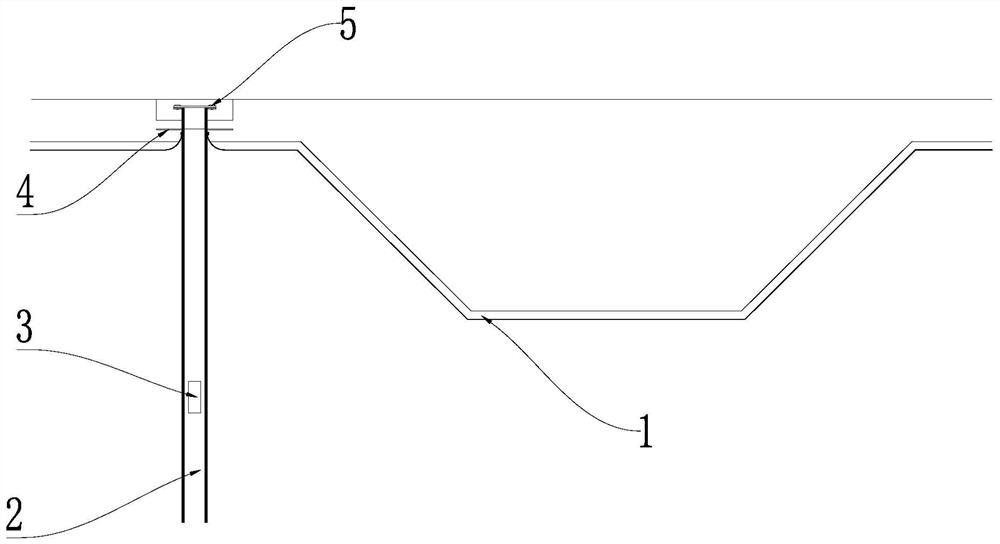

Floor paying-off hole pre-embedding device and construction method thereof

PendingCN112031412AEasy to plug inReduce labor intensityForms/shuttering/falseworksFloor slabConstruction engineering

The invention provides a floor paying-off hole pre-embedding device and a construction method thereof. The floor paying-off hole pre-embedding device comprises a base assembly, a pre-embedding part and a buckling cover, wherein the base assembly comprises a base body and a base sealing ring; the base body is fixed to a formwork; the base body is sleeved with the base sealing ring; the pre-embedding part is inserted into an upper opening of the base sealing ring; the pre-embedding part is provided with multiple layers of groove water stop wing rings; the buckling cover covers the pre-embeddingpart. The floor paying-off hole pre-embedding device and the construction method thereof have the beneficial effects that a paying-off hole is convenient to block, chiseling is not needed, the labor intensity of workers is lowered, the labor cost is reduced, and meanwhile the hidden danger of leakage after blocking is effectively avoided.

Owner:MCC TIANGONG GROUP

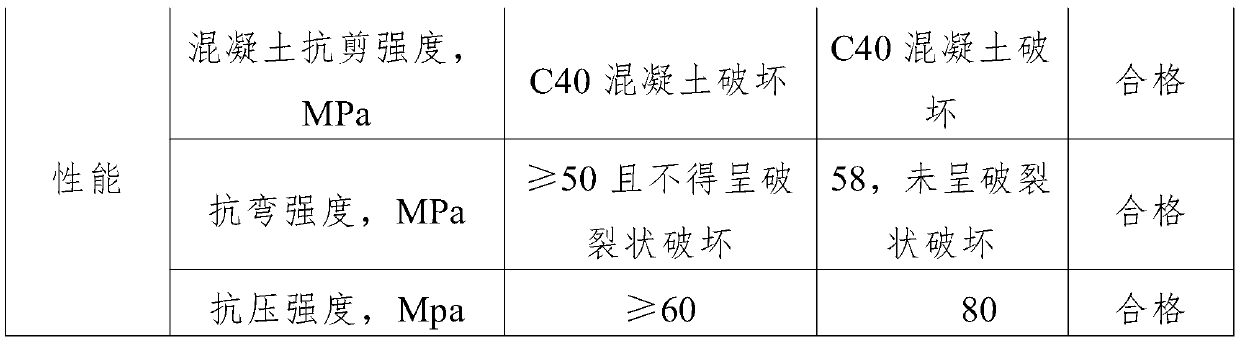

Steel-encasing strengthening plugging material in low-temperature environment

The invention belongs to the technical field of civil engineering structure reinforcement, and particularly relates to a steel-encasing strengthening plugging material in a low-temperature environment, wherein the material comprises a first composition and a second composition according to a part ratio of 3:1, the first composition is sand, and the second composition comprises, by mass, an epoxy resin, a toughening agent, a coupling agent, a curing agent, silicon micro-powder, alumina clinker, sodium carbonate and quick lime. According to the present invention, the steel-encasing strengtheningplugging material has characteristics of substantially reduced curing time under a low-temperature condition, significantly reduced fluidity and good viscosity, can ensure the plugging quality, and can solve the problem of incapability of steel-encasing strengthening construction in a low-temperature environment, wherein the hardness of the material after curing can meet the construction requirement.

Owner:NORTHEASTERN UNIV

An electric control box for an ultra-low temperature freezer with the function of preventing wrong plugging of plug wires

ActiveCN102650490BQuick plugRequirements for realizing quick plug-inDomestic cooling apparatusLighting and heating apparatusUltra Low Temperature FreezerTransformer

Owner:QINGDAO HAIER BIOMEDICAL CO LTD

Rapid plugging device and plugging method for plate seams of aluminum formworks

PendingCN114278088AQuality assuranceGuarantee the quality of pluggingAuxillary members of forms/shuttering/falseworksMechanical engineeringFloor level

The invention discloses a rapid plugging device and a plugging method for an aluminum formwork plate seam, a stiffening flange is formed on the outer side of an aluminum formwork, a gap is formed between the stiffening flange and a floor plate, the device comprises a plugging strip, a sealing strip, a sealing strip and a sealing strip, the plugging strip is embedded in the gap and attached to the outer side of the aluminum formwork, and the sealing strip is embedded in the gap and attached to the outer side of the aluminum formwork; the pressing plate is arranged outside the gap, the lower portion of the pressing plate is attached to the plugging strip, and the upper portion of the pressing plate is attached to the side, away from the aluminum formwork, of the stiffening flange plate; two clamping rods which are oppositely arranged are formed at the bottoms of the clamping and fixing assemblies, one clamping rod is detachably installed on the stiffening flange, the other clamping rod abuts against the outer side of the pressing plate in a pressing mode, and the clamping and fixing assemblies are arranged in the length direction of the stiffening flange at intervals. The problem that construction waste is easily generated in a traditional blocking mode of the slab joint between the bottom of the vertical aluminum formwork of the concrete shear wall and the floor support plate is solved.

Owner:中建八局天津建设工程有限公司

A pipe plugging method for condenser titanium pipe

ActiveCN106270960BConvenient welding operationQuality assuranceArc welding apparatusFluid-tightness measurementUnit operationTitanium

A pipe-blocking method for a titanium pipe of a steam condenser belongs to the technical field of steam turbines. The method solves the problems that the titanium pipe blocking quality is low and the titanium pipe blocking tightness cannot be checked before unit operation in the existing pipe-blocking technology for the titanium pipe of the steam condenser. The pipe-blocking method for the titanium pipe of the steam condenser comprises the following steps: 1, blocking the pipe orifices at the two ends of the titanium pipe by full-titanium pipe plugs; 2, performing seal welding on the full-titanium pipe plugs and the titanium pipe orifices at the two ends of the titanium pipe respectively by a manual argon tungsten arc welding process; and 3, performing airtightness detection on weld joints by a vacuum foaming leak detection device. The pipe-blocking method is used for blocking the titanium pipe.

Owner:HARBIN TURBINE +1

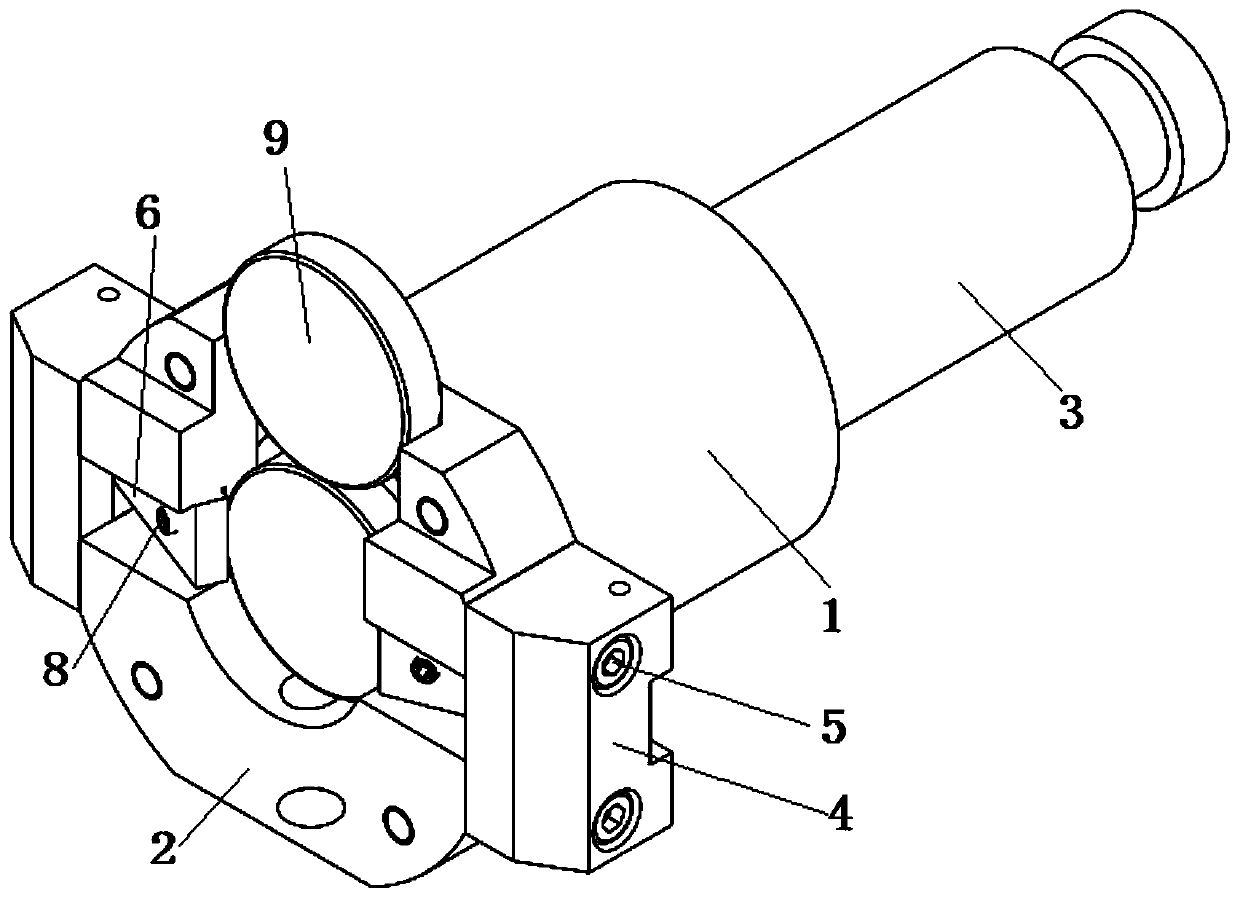

A bowl-shaped plug press-fitting device for engine cylinder block and cylinder head

The invention discloses a bowl-shaped plug press-fitting device for engine cylinder block and cylinder head, which is characterized in that it includes a base body, the front end of the base body is provided with a base end cover installed on a machine tool, and the base end Bowl-shaped plug gates for controlling the position of the bowl-shaped plug are provided on both sides of the cover, and a pressing rod for pushing out the bowl-shaped plug located at the front end for press-fitting is provided in the base body. The bowl-shaped plug press-fitting device used for engine cylinder block and cylinder head of the present invention has simple structure, convenient use, low maintenance cost, good versatility, ensures the quality of press-fit and plugging of sand outlet holes, improves the plugging efficiency, and has better performance. application prospects.

Owner:CHERY AUTOMOBILE CO LTD

Method for calking exploratory hole by intermittent high-pressure rotary jet grouting

InactiveCN101560764BLow costGuarantee the quality of pluggingSoil preservationSoil scienceStructural engineering

Owner:TIANJIN UNIV

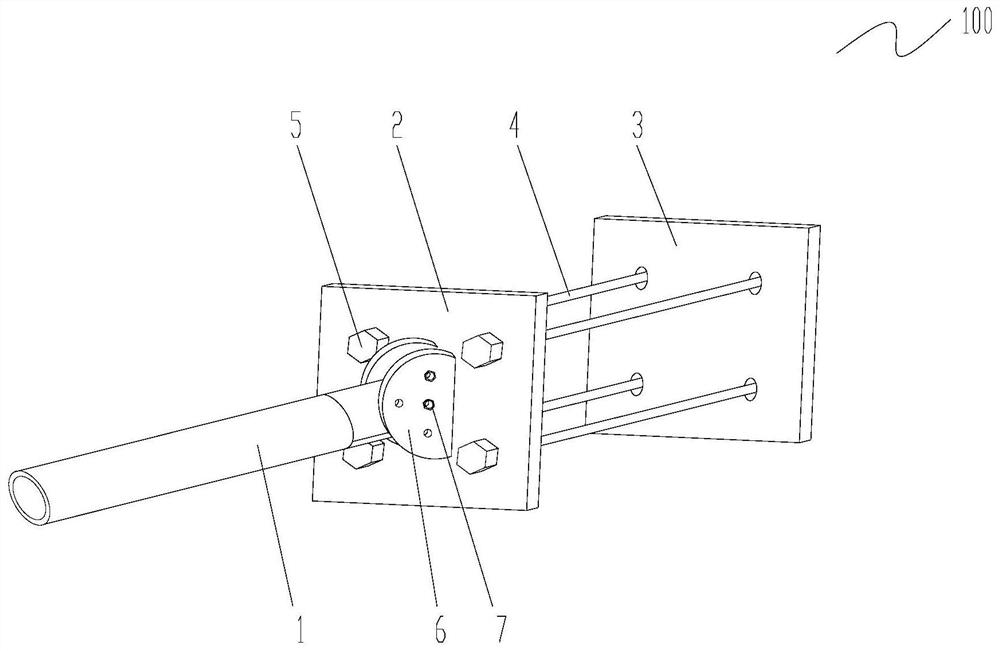

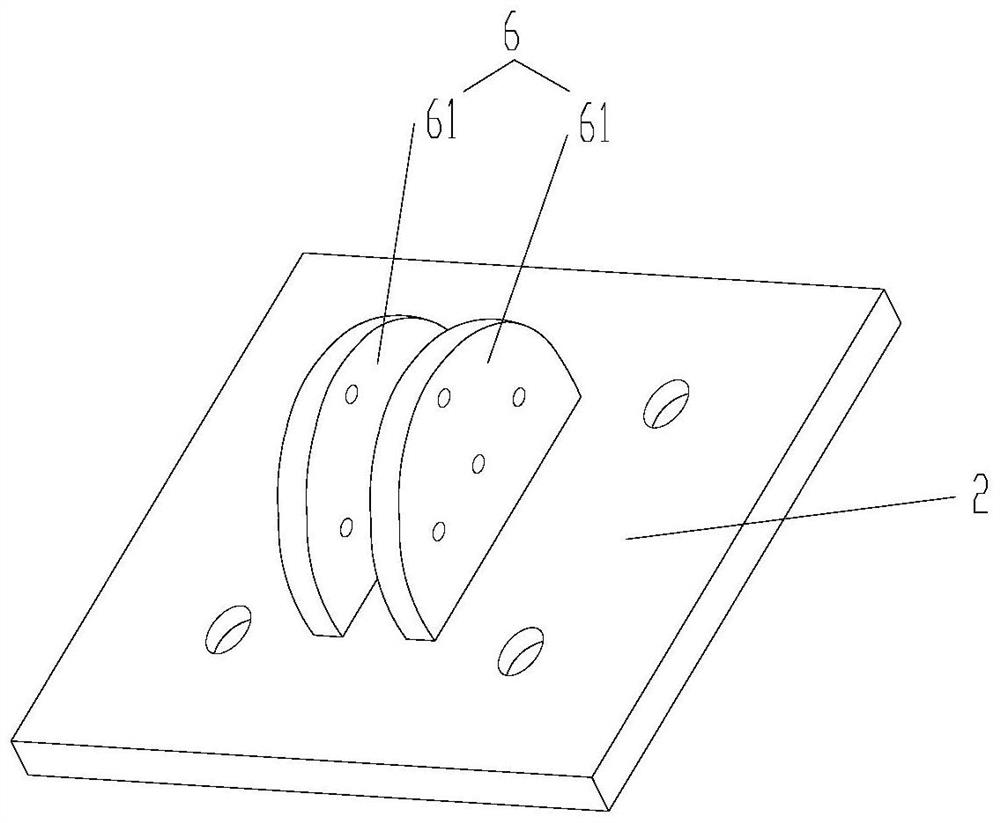

External scaffold wall connecting piece and using method thereof

The invention discloses an external scaffold wall connecting piece and a using method thereof. The external scaffold wall connecting piece is arranged between a wall body and a frame body of an external scaffold, and comprises a wall connecting rod, a first baffle, a second baffle and a plurality of lengthened screws. The plate face of the first baffle and the plate face of the second baffle are arranged in a spaced mode and used for abutting against the outer side surface and the inner side surface of the wall body correspondingly. The lengthened screws can be arranged in corresponding through holes formed in the wall body in a penetrating mode, and the two ends of each lengthened screw penetrate out of the first baffle and the second baffle correspondingly and are in threaded connection with nuts. A connecting piece is fixedly arranged on the side face, back on to the second baffle, of the first baffle. One end of the wall connecting rod is detachably and fixedly connected with the connecting piece, and the other end of the wall connecting rod is used for being detachably and fixedly connected with the frame body. According to the external scaffold wall connecting piece, construction is convenient, the number of external scaffold components pre-buried in a wall body structure can be effectively decreased, damage to the wall body is reduced, dismounting is convenient, and all the components can be used repeatedly.

Owner:MCC CAPITAL ENGINEERING & RESEARCH

A high-efficiency shear wall bolt hole sealing method

ActiveCN107237511BGuarantee the quality of pluggingDosage controlBuilding repairsThermal bridgeEngineering

The invention particularly relates to an efficient blocking method for shear wall through-wall bolt holes. The problems, existing in current shear wall through-wall bolt hole blocking, that time and energy are wasted, mortar is wasted seriously, repairing is difficult, and leakage hidden trouble and thermal bridge phenomenon are prone to occur are solved. The efficient blocking method for the shear wall through-wall bolt holes comprises the following steps that a, bolt holes are formed after concrete pouring of a shear wall is finished; b, a wooden wedge drilling pipe is selected and installed on a percussion drill I to drill, and a PVC pipe is taken out; c, a frustum-shaped alloy bit is selected and installed on the percussion drill I, and a flare opening is formed in the external end of the bolt holes; d, glue is applied, and a prefabricated mortar block is fixed to the external end of the bolt holes; e, when grouting is conducted, interfacial agents are centrifugally sprayed on the inner wall of the bolt holes, then expansive cement mortar is sprayed on the surfaces of the interfacial agents and is extruded to the center of the front end of the bolt holes; and f, the inner end of an outer wall is padded manually until compact is achieved. According to the efficient blocking method for the shear wall through-wall bolt holes, constructing efficiency is improved, and meanwhile, occurrence of leakage hidden trouble and thermal bridge phenomenon are thoroughly avoided.

Owner:DATONG TAIRUI GRP CONSTR

Dewatering well self-plugging device and mounting method thereof

ActiveCN114182746AReduce the difficulty of plugging constructionGuarantee the quality of pluggingGeothermal energy generationFoundation engineeringPipeMechanical engineering

The invention discloses a dewatering well self-plugging device and a mounting method thereof. The dewatering well self-plugging device comprises a plugging plate, a plugging piece and an elastic device. A pipe passing hole is formed in the middle of the plug. The blocking piece is movably arranged on the blocking plate and has a first state for blocking the pipe passing hole and a second state for opening the pipe passing hole. When the plugging piece is in the second state, the elastic device is in a stretching state, and when the plugging piece is in the first state, the elastic device is in an elastic reset state. When the self-plugging device for the dewatering well is used, the plugging plate and the plugging piece automatically and completely plug the whole inner pipe opening of the well pipe body, a first water stopping measure is formed, and after water stored in the dewatering pipe is pumped, concrete pouring or other plugging measures are conducted on the interior of the dewatering pipe; and the blocking construction difficulty caused by too large underground water pressure can be effectively reduced, and the blocking quality is guaranteed.

Owner:BEIJING CONSTR ENG GRP CO LTD

A powder particle-high grouting pressure sealing device and method for gas drainage drilling and sealing cracks

ActiveCN109577908BImprove radial stabilityEasy to storeFluid removalGas removalEngineeringPack material

The invention provides a powder particle-high-pressure grouting crack packing gas extraction drilling and sealing device and method. The powder particle-high-pressure grouting crack packing gas extraction drilling and sealing device and method is applicable to underground coal mines. The powder particle-high-pressure grouting crack packing gas extraction drilling and sealing device comprises an outer bag and an inner bag, wherein the rear of the outer bag is provided with a fixing unit on a gas extraction pipe; the inner bag is provided with a screen pipe, a bag grouting pipe and a grouting pipe which penetrate through the fixing unit, the tail portions of the screen pipe, the bag grouting pipe and the grouting pipe are arranged at the rear of the outer bag, and the tail ends of the screenpipe, the bag grouting pipe and the grouting pipe are provided with valves; quick lime powder coerced by carbon dioxide is guided into the space among packing materials via the screen pipe to block fractures around a drilled hole through reaction products; cement mortar is filled in by the grouting pipe to achieve the aim of packing cracks and actively supporting the drilled hole. Therefore, thepowder particle-high-pressure grouting crack packing gas extraction drilling and sealing device can effectively reduce the influence of mining damage, prolong the effectively extraction period of drilling gas extraction, increase the concentration of extracted gas, maintain stability of the drilled hole, significantly improve the coal seam gas extracting effects and ensure safety of underground workers.

Owner:CHINA UNIV OF MINING & TECH

A construction method for backfilling the piston air duct in the shield section

ActiveCN109577998BEnsure safetyAvoid constructionUnderground chambersTunnel liningReinforced concreteShield tunneling

The invention relates to the technical field of metro construction, particularly to a shield interval piston vent backfilling and station passing construction method. The shield interval piston vent backfilling and station passing construction method comprises, after bottom plates of an interval piston vent are constructed, arranging steel supports circumferentially outside a shield range, backfilling modified soil, arranging reinforced concrete sealing plates into the backfilled soil, backfilling soil to reach the underground water level and the like to increase the support stiffness inside the piston vent, balance pressure of water and soil inside and outside pits and ensure structural stability of a foundation pit support; when a shield tunneling machine is passing by, strengthening synchronous grouting for secondary grouting of an out-tunnel sixth ring, and re-grouting the seepage parts of the foundation pit support during backfilled water excavation to seal joints of the foundation pit support and the seams between a tunnel entrance and the foundation pit support and further to ensure subsequent construction safety. The shield interval piston vent backfilling and station passing construction method effectively solves the contradiction between limited construction periods and lagged piston vent construction, avoids the risks of multiple starting and receiving the shield tunneling machine passing through the piston vent, and has the advantages of being reasonable in process, safe, reliable, capable of avoiding stopping of the shield tunneling machine and effectively shortening the construction period and the like.

Owner:CHINA RAILWAY 12TH BUREAU GRP +1

Hand hole plugging device for segment bolt and construction method thereof

ActiveCN113073996BPrevent movementGuarantee the quality of pluggingUnderground chambersTunnel liningStructural engineering

Owner:中建八局轨道交通建设有限公司

A construction method for sealing and waterproofing of basement access openings

The invention provides a blockage and waterproof construction method of a basement external channel port. The method comprises such steps as underground foundation pit treatment, building and plastering of foundation pit side wall surfaces, waterproof coiled material pavement on the foundation pit side wall surfaces, building blockage of protection walls and inner side decoration construction of the protection walls. The method solves the defect of limited operation surface under traditional construction technological conditions, adjusts measures to local conditions, fully uses support piling structures in a traditional foundation pit as support structures, saves blocked structural walls, and meanwhile, applies the prepavement water prevention technology generally used for baseplate water prevention to vertical wall surfaces; and the channel blockage and waterproof construction method with simple operation, improvement of the working efficiency and good waterproof effect is provided.

Owner:CHINA FIRST METALLURGICAL GROUP

Blockage and waterproof construction method of basement external channel port

ActiveCN106592597ALow costInnovative ideasProtective foundationCellarsBasementArchitectural engineering

The invention provides a blockage and waterproof construction method of a basement external channel port. The method comprises such steps as underground foundation pit treatment, building and plastering of foundation pit side wall surfaces, waterproof coiled material pavement on the foundation pit side wall surfaces, building blockage of protection walls and inner side decoration construction of the protection walls. The method solves the defect of limited operation surface under traditional construction technological conditions, adjusts measures to local conditions, fully uses support piling structures in a traditional foundation pit as support structures, saves blocked structural walls, and meanwhile, applies the prepavement water prevention technology generally used for baseplate water prevention to vertical wall surfaces; and the channel blockage and waterproof construction method with simple operation, improvement of the working efficiency and good waterproof effect is provided.

Owner:CHINA FIRST METALLURGICAL GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com