A bowl-shaped plug press-fitting device for engine cylinder block and cylinder head

A technology of engine cylinder block and press-fitting device, which is applied in the direction of metal processing equipment, metal processing, manufacturing tools, etc., and can solve problems such as pressure inclination, bowl-shaped plug leakage pressure, and multi-pressure, so as to achieve convenience in use and ensure the quality of plugging , the effect of good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manner of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings.

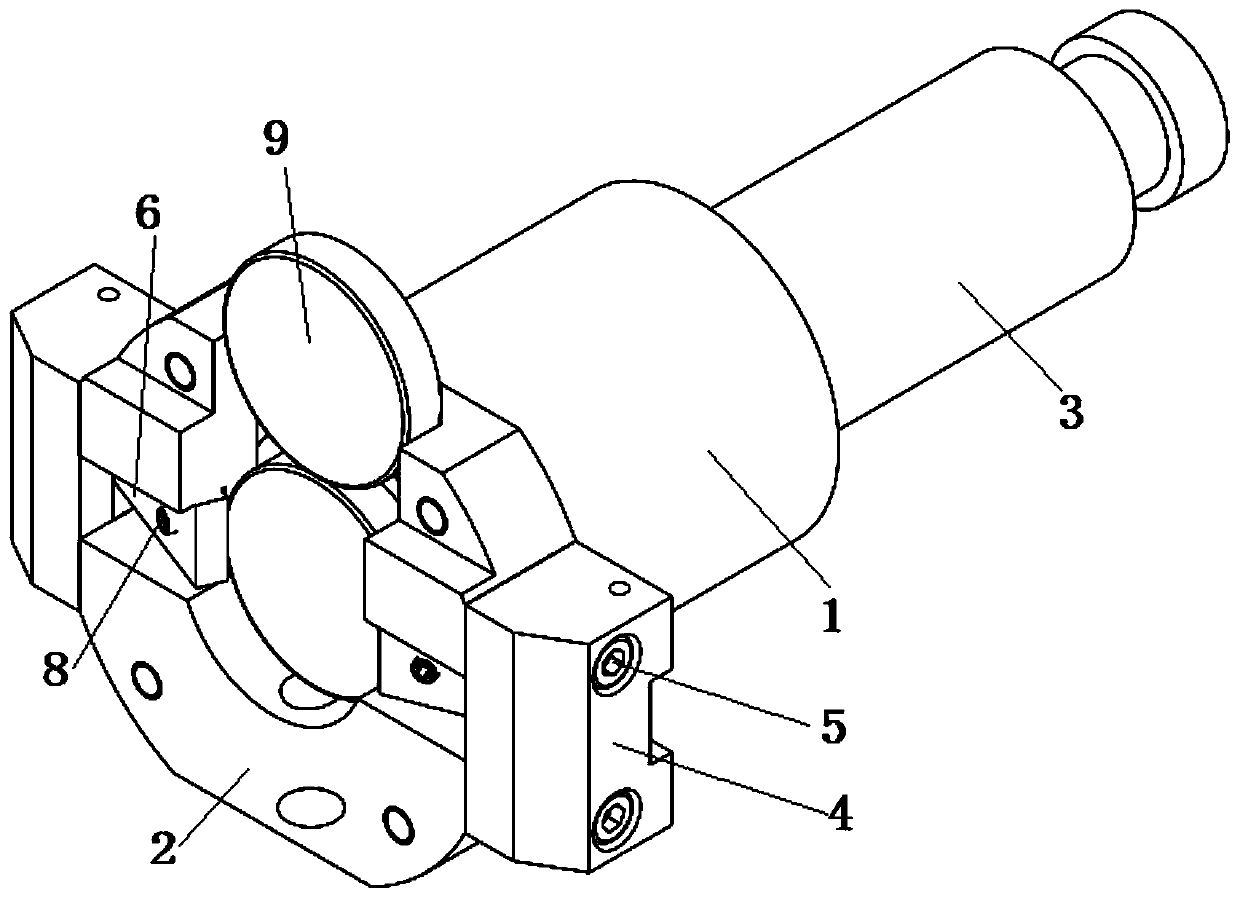

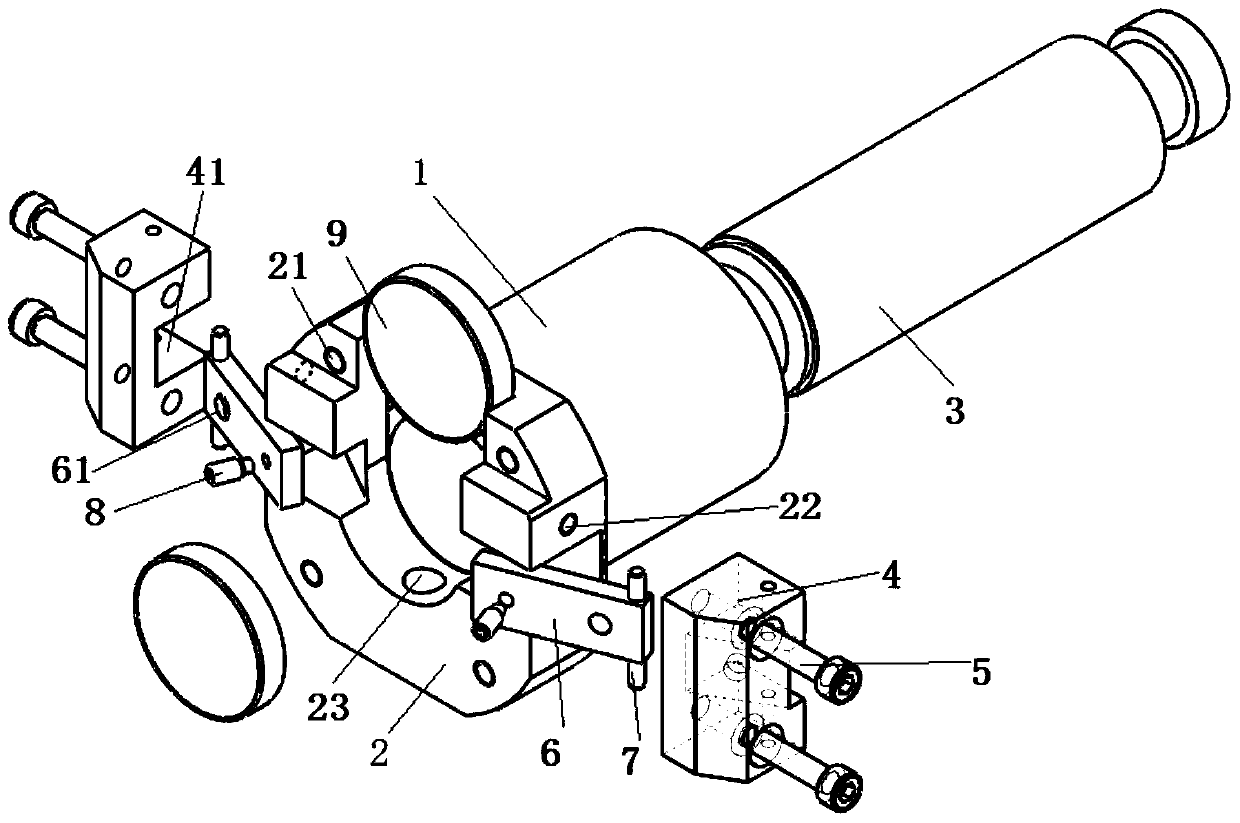

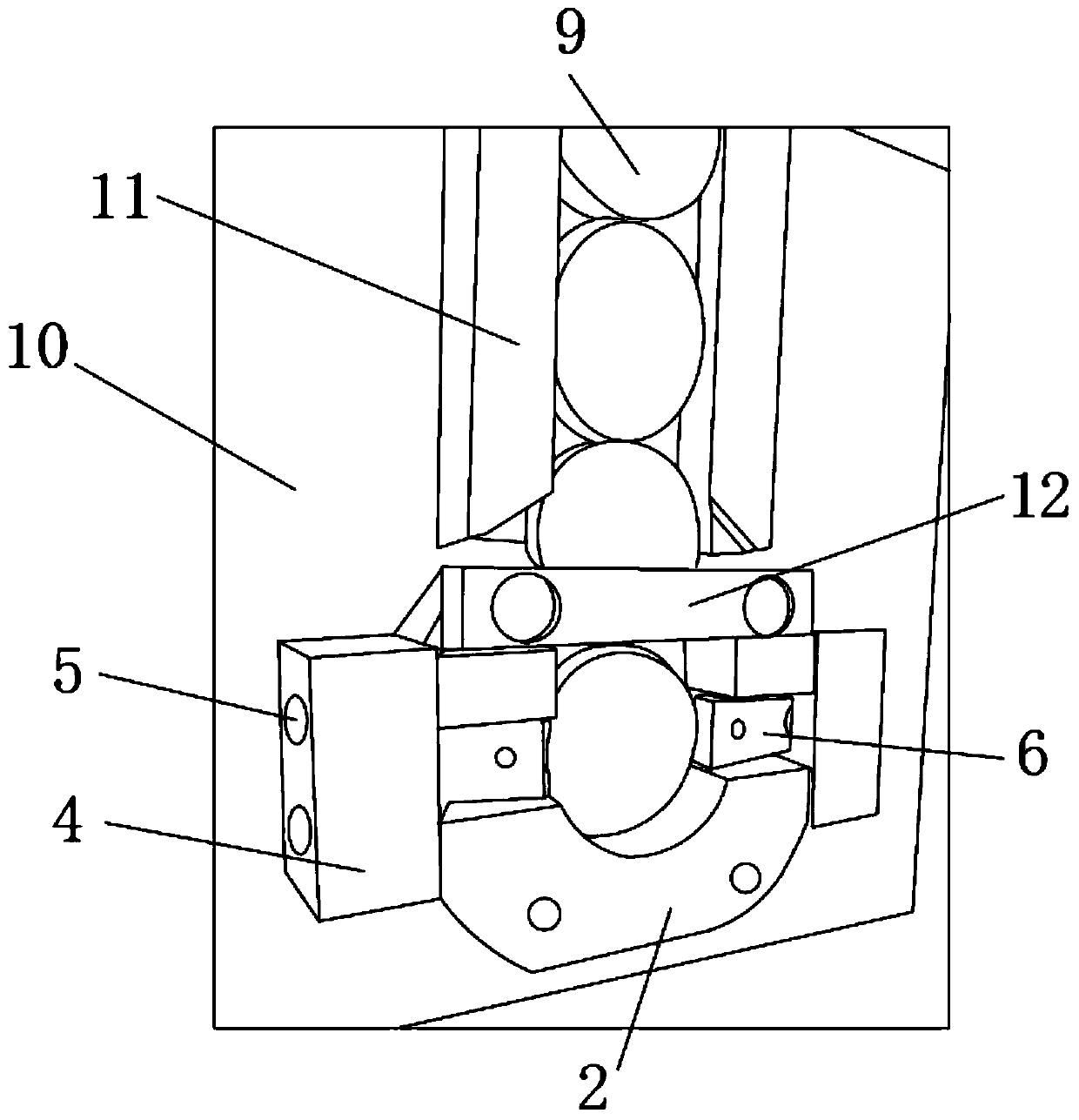

[0022] This present invention is used for engine cylinder head bowl type plug press-fitting device, as figure 1 , 2 , 3, including the base body 1, the front end of the base body 1 is provided with a base end cover 2 installed on the machine tool 10, and both sides of the base end cover 2 are provided with a bowl-shaped plug door 6 for controlling the position of the bowl-shaped plug 9 , the base body 1 is provided with a pressing rod 3 for pushing out the bowl-shaped plug 9 arranged at the front end for press-fitting.

[0023] In the present invention, side fixing blocks 4 are also provided on both sides of the base end cover 2, such as figure 2 As shown, the side fixing block 4 is connected and fixed in the side fixing block mounting hole 22 provided on the base end cover 2 through the mou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com