Simple blast hole plugging device for bench blasting and application method of simple blast hole plugging device

A plugging device and step blasting technology, which is applied in blasting and other directions, can solve the problems of explosive energy waste, shot blasting, and explosive rejection of explosives, and achieve the effects of improving energy utilization, ensuring plugging quality, and prolonging action time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments, and the content of the present invention is not limited to the following embodiments.

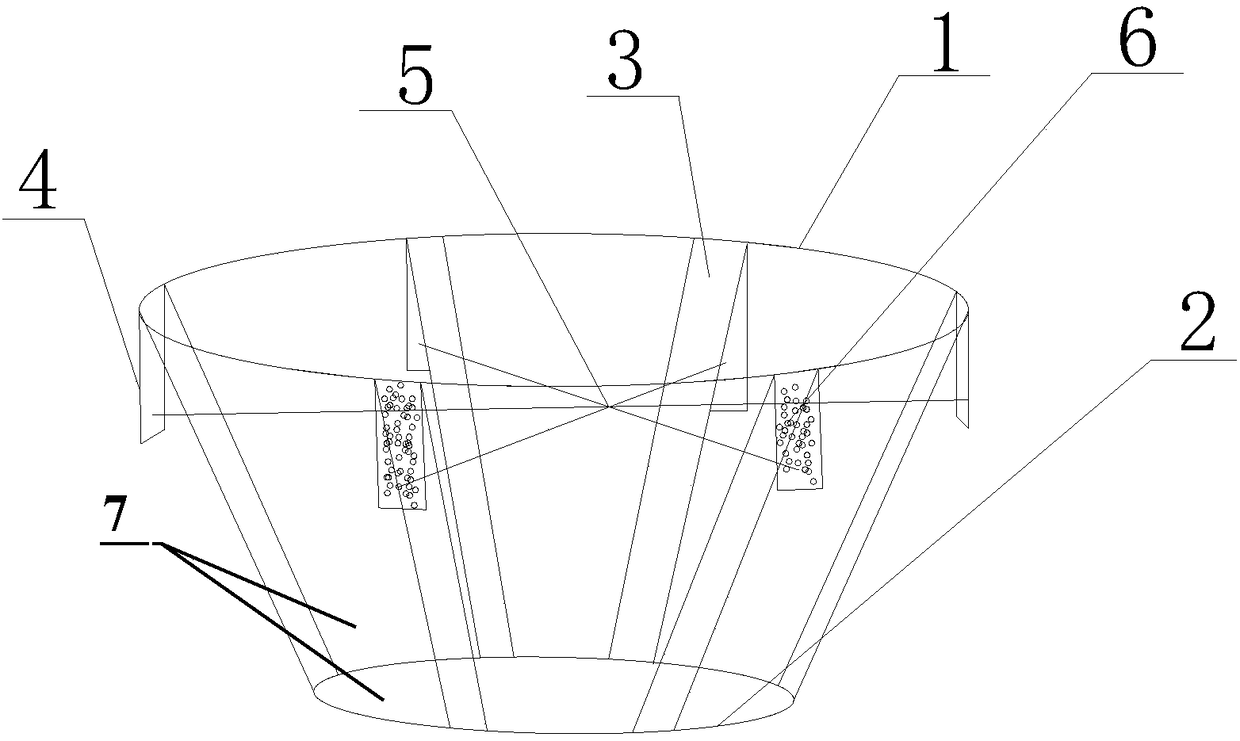

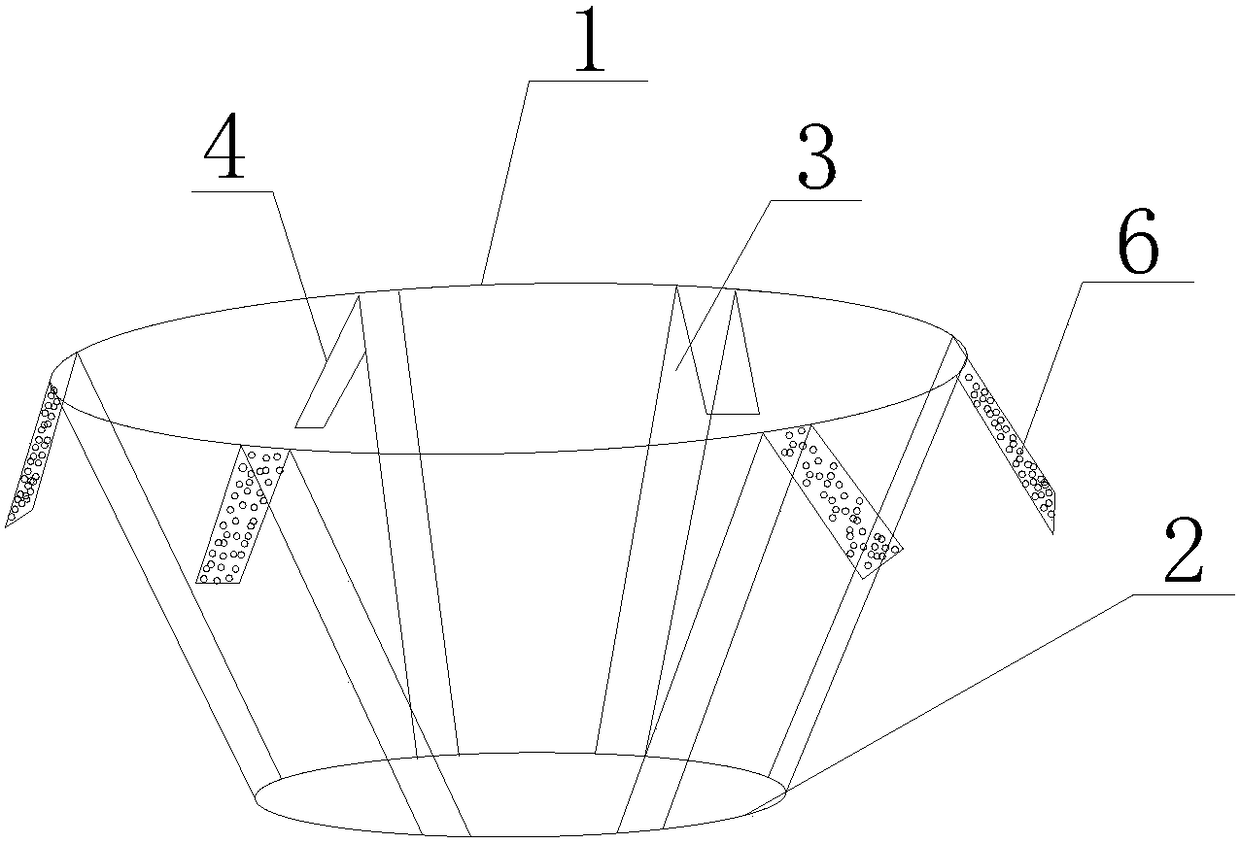

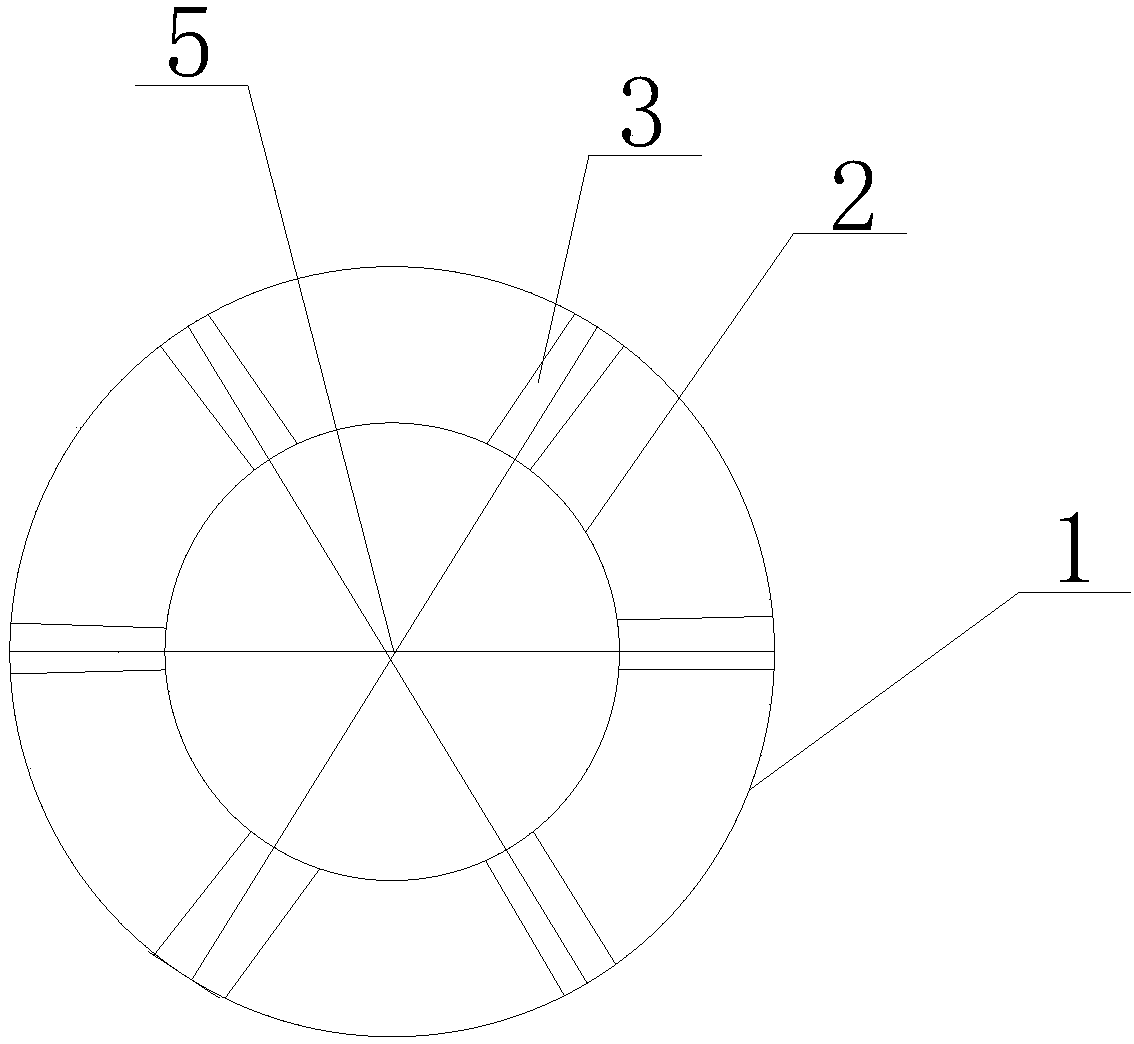

[0026] see Figure 1 to Figure 5 , a simple plugging device for step blasting, mainly composed of a large ring 1, a small ring 2, a connecting piece 3, a film 7, an elastic piece 4, a chisel 6, and a string 5, and is characterized in that: The large ring 1 and the small ring 2 are hinged by six connecting pieces 3, and the six connecting pieces 3 are symmetrically distributed on the ring, and the film 7 covers the small ring 2 to the large ring 1 and is fixed on the large ring. On the ring 1, one end of the six elastic pieces 4 is fixed on the big ring 1, at the same position as the connecting piece 3, and has a certain angle with the big ring 1, and the other end is a free end, and the six The diameter of the circle formed by the free ends of the elastic sheet 4 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com