Method for calking exploratory hole by intermittent high-pressure rotary jet grouting

A high-pressure rotary spraying and grouting technology, which is applied in the fields of soil protection, construction, and infrastructure engineering, etc., can solve problems such as difficulty in ensuring the quality of plugging, and achieve the effect of saving engineering cost, low cost, and ensuring plugging quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

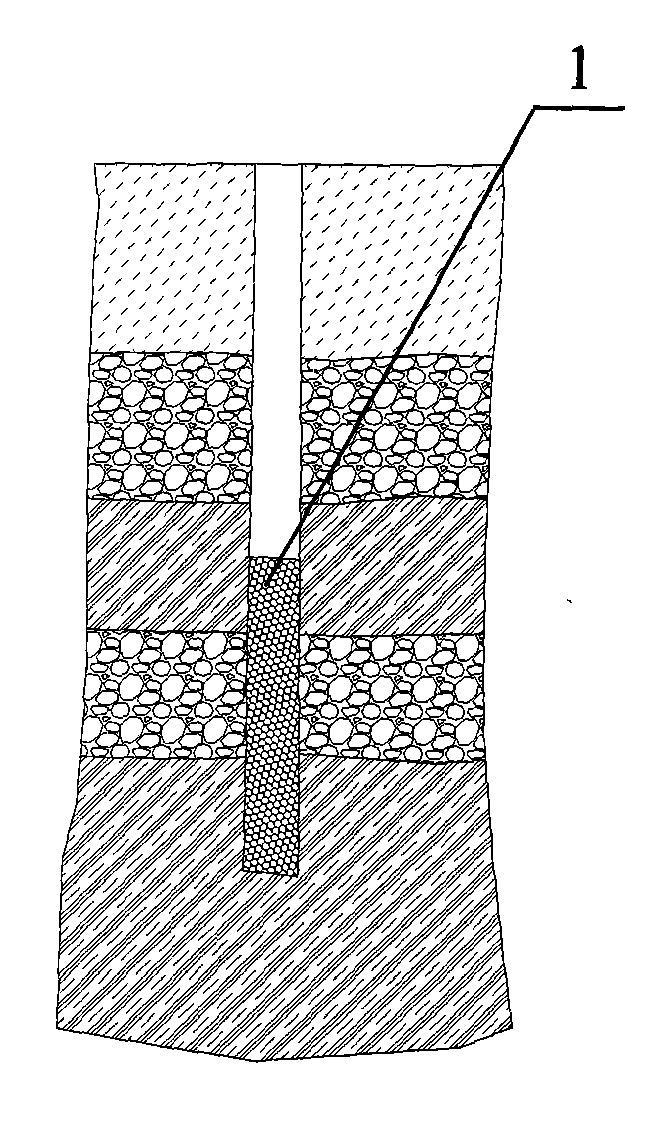

Embodiment 1

[0023] The foundation pit project of a subway station is 190.0m long and 20.7m wide. It is constructed by the open cut method. The supporting structure is ground connection wall and inner support. The depth of the foundation pit is 14.070m. Five survey holes were left in the pit, and the survey holes revealed the silt confined aquifer at the bottom of the pit at 5-7m. The water head of the confined aquifer is buried at a depth of about 1m, which poses a risk of inrush for the excavation of the foundation pit. Poorly sealed survey holes are the safety weak points that cause inrush accidents in foundation pit engineering. In order to eliminate the potential safety hazards in inrush, 5 survey holes in the pit were re-sealed before the design of precipitation. According to the geotechnical engineering investigation report, it is judged that there is a confined aquifer with a thickness of about 2-4m below the pit bottom 5-7m, so the high-pressure rotary jet grouting reinforcement te...

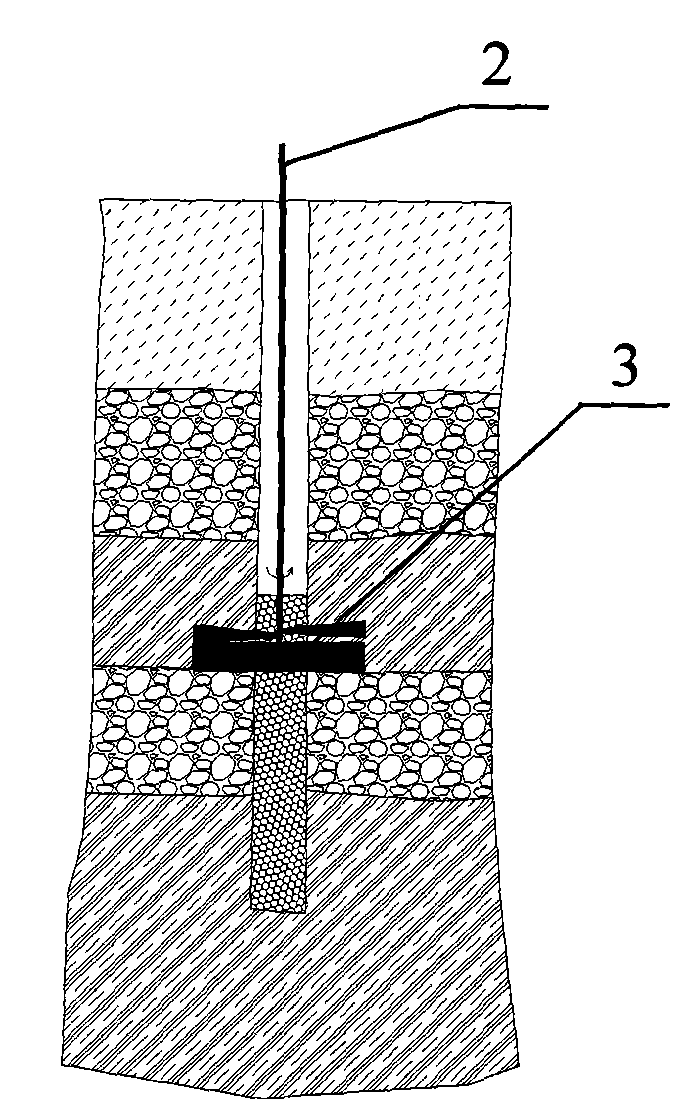

Embodiment 2

[0025] The excavation area of a large-scale transportation hub foundation pit project is 20,000 m 2 , the excavation depth is 32.5m, and the construction is carried out by cover-excavation method. The preliminary engineering survey needs to leave 23 exploration holes in the excavation range of the foundation pit. These holes will connect various aquifers within the excavation range of the foundation pit, which will pose a potential threat to the safety of the foundation pit project, and the project uses It is extremely difficult to take emergency remedial measures in the event of a sudden dangerous situation due to the construction method of cover and excavation. After the exploration work of the exploratory hole is completed, the top of the two silt confined aquifers at the buried depth of 41-45m and 21-24m respectively and the bottom of the foundation pit at the buried depth of 32.5m exposed by the exploratory hole shall be reinforced by high-pressure jet grouting Three d...

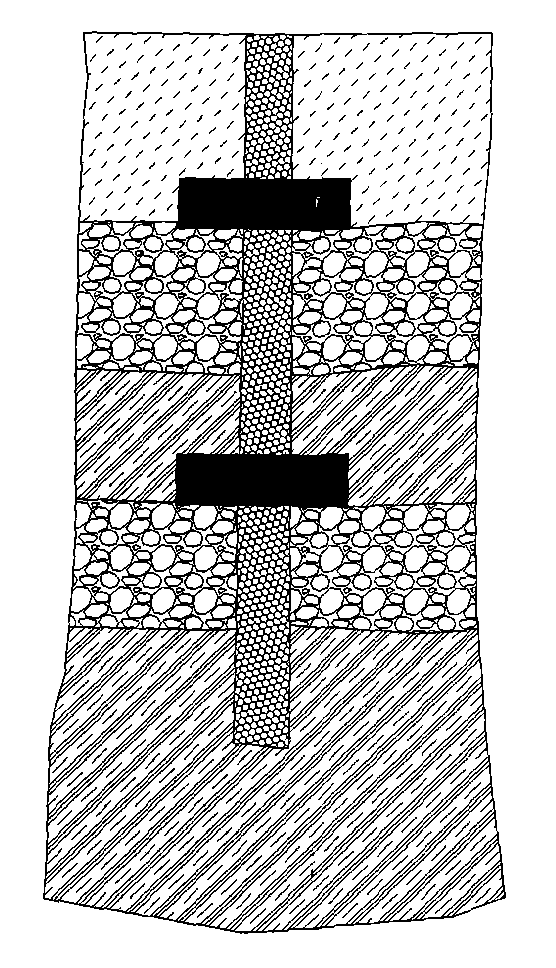

Embodiment 3

[0027] A foundation pit project has a depth of 12.6m and an excavation area of 15,000m 2, using the open-cut method, threatened by the inrush of a silt confined aquifer that is widely distributed below the pit bottom 7m and about 3m thick, 5 of the 18 survey holes in the pit have serious hole collapse at the bottom of the pit. The length of the collapsed hole ranges from 1 to 2 meters. For each survey hole that has not collapsed, three disk-shaped reinforcements with a diameter of 2.0m and a height of 0.3m are formed at a depth of 19 meters by using high-pressure jet grouting reinforcement technology, and the distance between the disk-shaped reinforcements is 2.0 meters. The remaining space in the hole is backfilled with air-dried clay balls with a diameter of 23mm and compacted in layers. For the five reconnaissance holes where collapsed holes occurred, a short column with a diameter of 2.0 m and a height of 1.5 m was formed between the top and bottom of the collapsed posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com