Method for sealing high-rise shear wall external wall upstream face pulling screw holes

A technology for pulling the screw and facing the water surface, which is used in the connection parts of the formwork/formwork/work frame, the preparation of building components on site, construction, etc. , the pull screw hole is not tightly plugged, etc., to achieve the effect of reducing maintenance costs, shortening project time, and improving construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

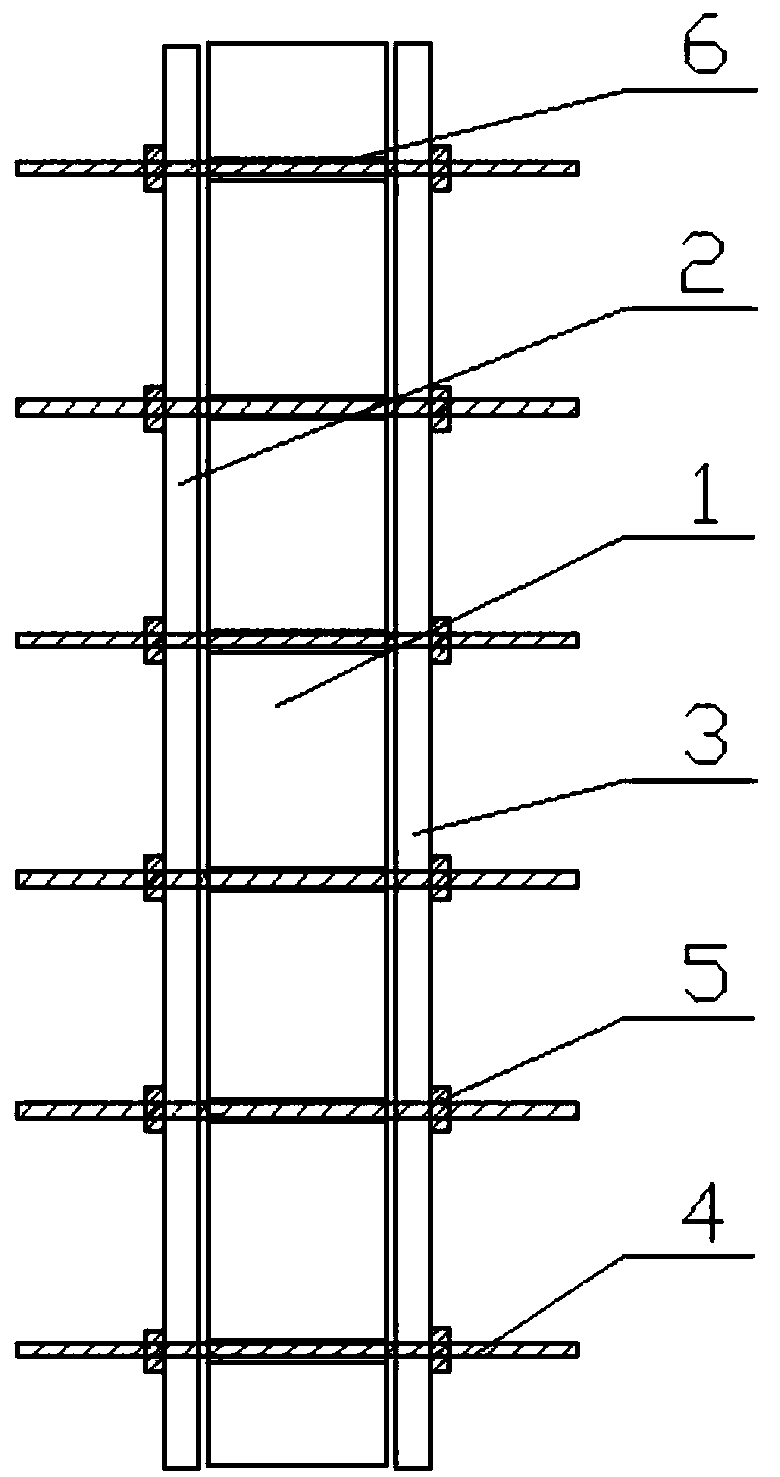

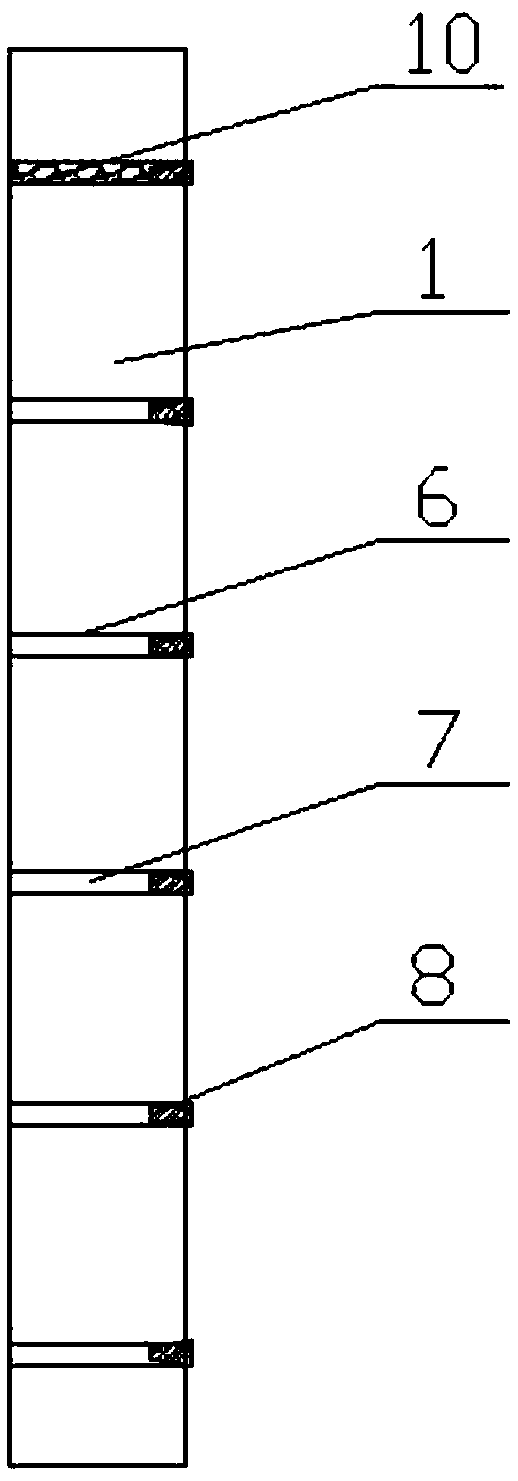

[0030] like figure 1 The shown shear wall formwork and the pull screw, including shear wall plate 1, inner wall plate 2, outer formwork 3, pull screw 4, lock nut 5 and plastic sleeve 6;

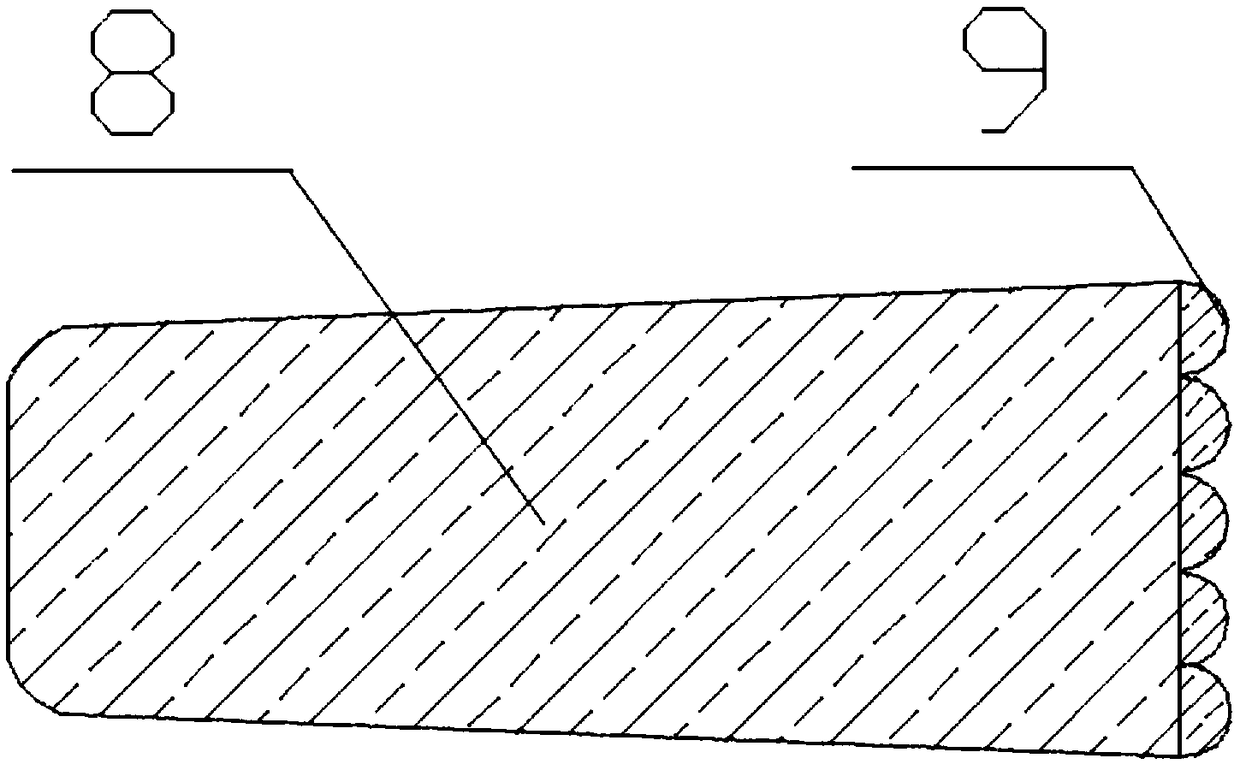

[0031] Among them, the shear wall panel 1 is a concrete structure; the inner formwork 2 is the inner support formwork during the pouring construction of the shear wall panel 1; the outer formwork 3 is the outer support wall panel during the pouring construction of the shear wall panel 1; The screw 4 is provided with an external thread, and the pulling screw 4 penetrates through the shear wall panel 1, the inner wall panel 2 and the outer wall panel 3, and the two ends of the pulling screw 4 are threadedly connected with a locking nut 5; The pitch is consistent with the pitch of the paired screw 4. During operation, the position and spacing of the template are fixed by connecting the two ends of the paired screw 4; the plastic sleeve 6 is sleeved on the outside of the paired screw 4, and the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com