Chute descending segment plugging method and structure for effectively improving stability

A stable, well-sliding technology, which is applied in earth-moving drilling, filling, safety devices, etc., can solve the problems of increasing the difficulty of ore beneficiation, the pressure of beneficiation equipment, the easy fall of construction personnel, and the inability to act as a safety block. Overall fall or collapse, improved firmness and safety, easy removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

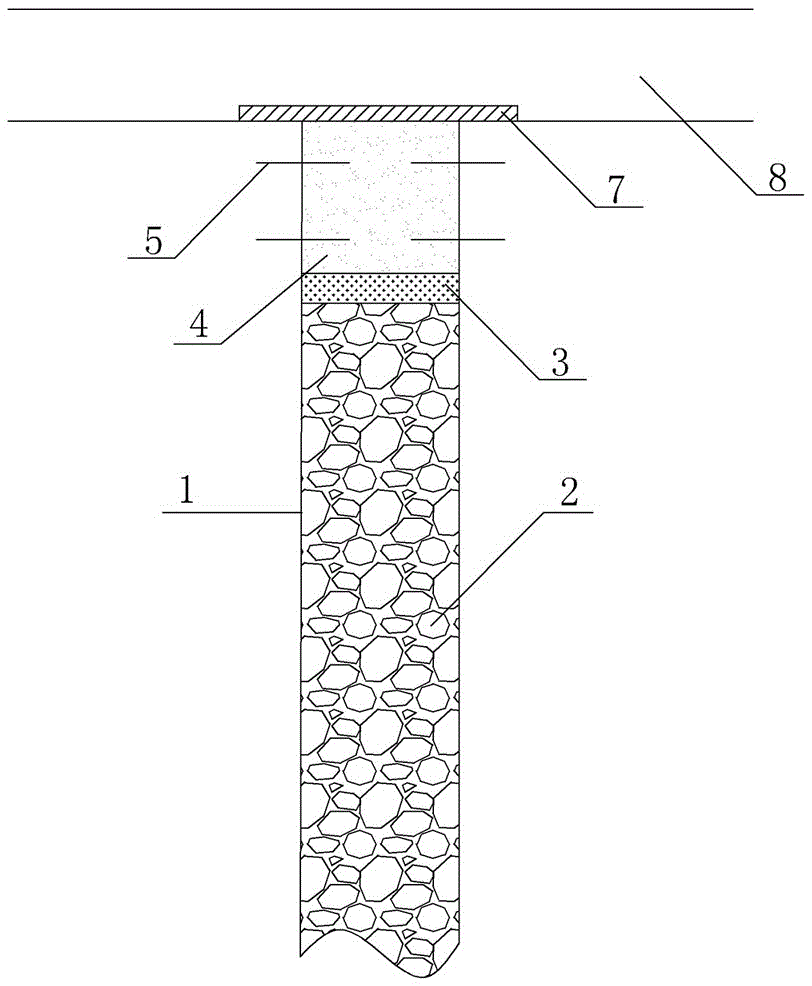

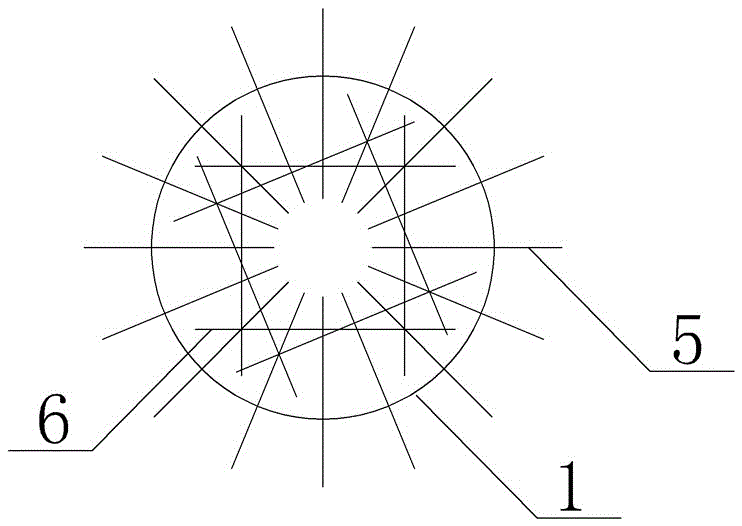

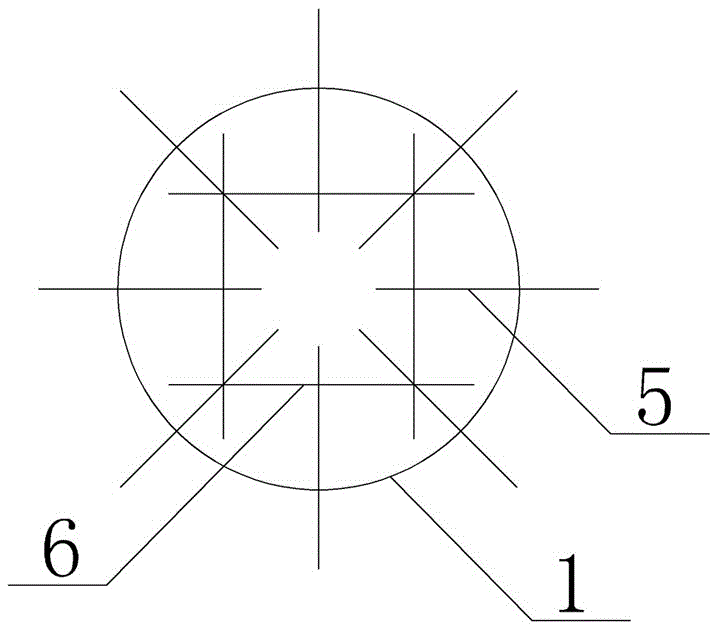

[0040]1) Prying: First, prying the mouth of the chute and the surroundings of the chute to be blocked in the descending section, tapping the rock with a crowbar, and prying off the rock with a dull and not crisp sound, so as to clean the pumice and ensure a safe and sound construction environment. Hidden dangers; 2) Ore filling in the chute: fill the chute with ore whose particle size does not exceed 1 / 8 of the diameter of the chute to 1.5m below the wellhead, level the filled ore, and lay a 0.1m cotton isolation layer; 3) Install anchor rods : An anchor hole with a depth of 0.7m is opened on the side wall of the chute between the isolation layer and the mouth of the chute, and the anchoring agent and the anchor rod are inserted into the anchor hole together. The length of the anchor rod is 1.5m, and the diameter is 20mm. On the side wall of the chute, there are two layers arranged in a horizontal ring, and there are four anchor rods in both layers. The distance between the two...

Embodiment 2

[0043] 1) Prying: First, prying the mouth of the chute and the surroundings of the chute to be blocked in the descending section, tapping the rock with a crowbar, and prying off the rock with a dull and not crisp sound, so as to clean the pumice and ensure a safe and sound construction environment. Hidden dangers; 2) Ore filling of the chute: fill the chute with ore whose particle size does not exceed 1 / 8 of the diameter of the chute to 5m below the wellhead, level the filled ore, and lay a 0.3m cotton isolation layer; 3) Install anchor rods: An anchor hole with a depth of 1.5m is opened on the side wall of the chute between the isolation layer and the mouth of the chute, and the anchoring agent and the anchor rod are inserted into the anchor hole together. The length of the anchor rod is 3m and the diameter is 20mm. There are two layers of horizontal circular rings on the side wall, and there are 20 anchor rods in both layers. The distance between the two layers of anchor rods...

Embodiment 3

[0046] 1) Prying: First, prying the mouth of the chute and the surroundings of the chute to be blocked in the descending section, tapping the rock with a crowbar, and prying off the rock with a dull and not crisp sound, so as to clean the pumice and ensure a safe and sound construction environment. Hidden dangers; 2) Ore filling of the chute: fill the chute with ore whose particle size does not exceed 1 / 8 of the diameter of the chute to 3m below the wellhead, level the filled ore, and lay a 0.2m cotton isolation layer; 3) Set the anchor rod: Open an anchor hole with a depth of 1m on the side wall of the chute between the isolation layer and the mouth of the chute, insert the anchoring agent and the anchor rod into the anchor hole, the length of the anchor rod is 2m, the diameter is 20mm, and the anchor rod is on the side of the chute There are two layers of horizontal circular rings on the wall, and 12 anchor rods are arranged on each layer. The distance between the two layers ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com