Thin-walled concrete tie screw waterstop structure and process

A concrete, thin-walled technology, applied in building construction, on-site preparation of building components, connection of formwork/template/work frame, etc. problems such as low strength, to achieve the effect of improving the ability to resist the water pressure on the upstream surface, high structural tightness and durability, and improving the impermeability strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

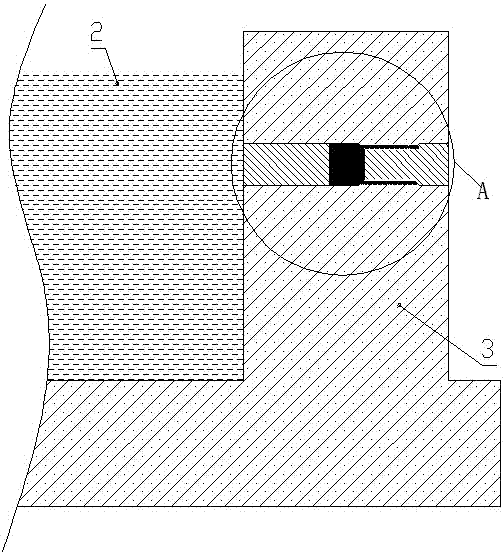

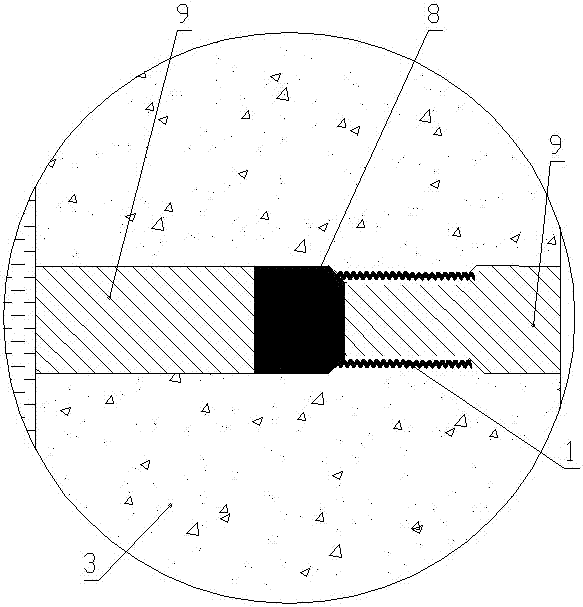

[0038] figure 1 and figure 2 The water at the thin-walled concrete structure 3 is indicated by the middle symbol 2.

[0039] Such as Figure 1 to Figure 5 As shown, the thin-walled concrete anti-screw water-stop structure of the present invention includes a plastic bellows 1 arranged in the thin-walled concrete anti-screw hole; shape.

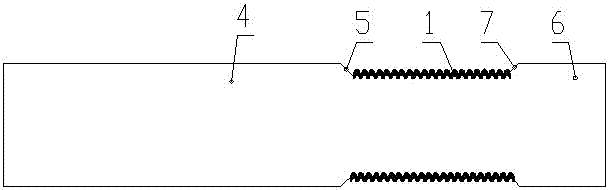

[0040] Taking the water-facing surface as the forward direction, the pull screw hole in front of the plastic corrugated pipe 1 is set as the front reaming section 4, the diameter of the front reaming section 4 is larger than the diameter of the plastic corrugated pipe 1 and the rear end of the front reaming section 4 is set There is a front contraction hole segment 5 with a large front and a small rear. The diameter of the rear end of the front contraction hole segment 5 is the same as the outer diameter of the plastic bellows 1 and communicates with the plastic bellows 1 correspondingly; The inner diameters of the screw holes are the same...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com