A powder particle-high grouting pressure sealing device and method for gas drainage drilling and sealing cracks

A powder particle and gas extraction technology, which is applied in the direction of gas discharge, safety devices, sealing/seal, etc., can solve the problems of rigidity, connectivity, and not being able to play an active support role well, so as to reduce redevelopment , ensuring safety and prolonging the effective extraction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

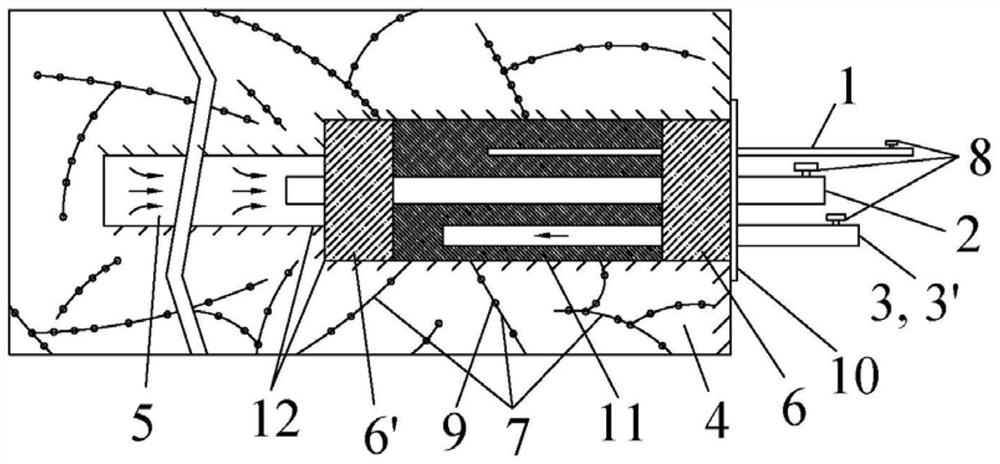

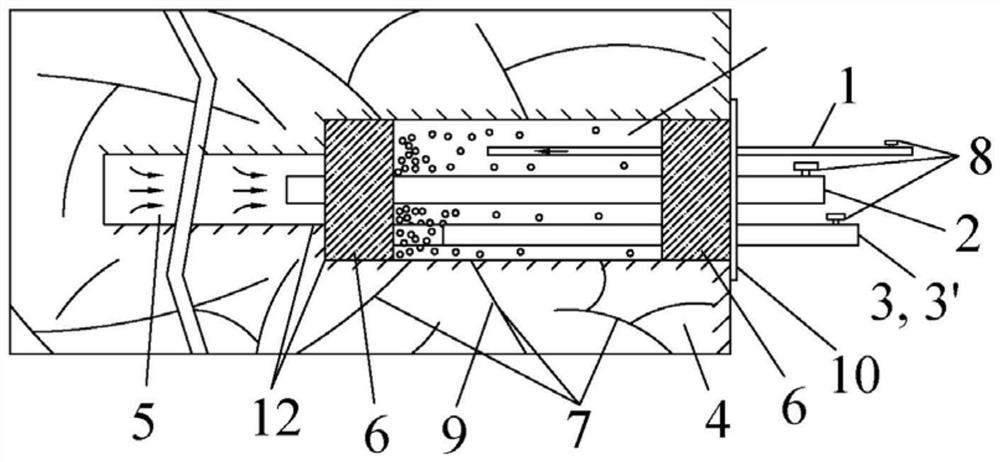

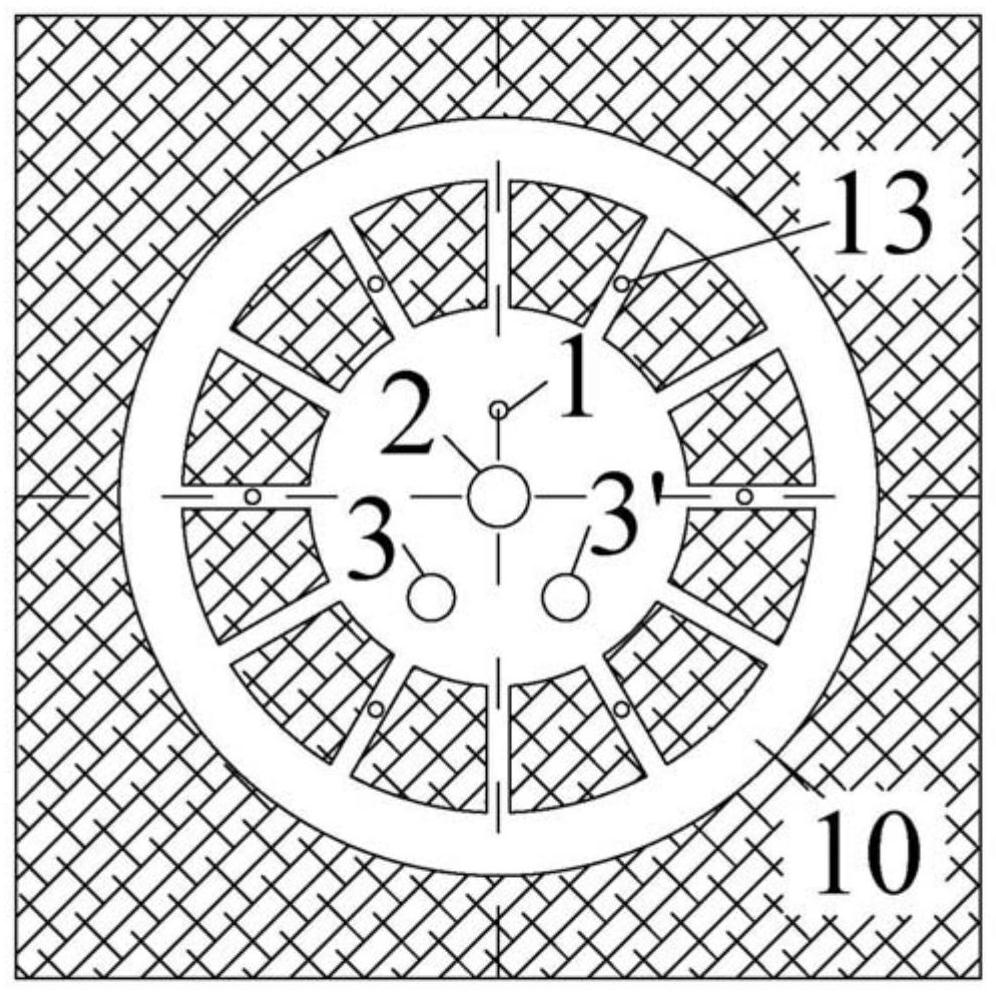

[0040] by attaching figure 1 And attached figure 2 To further describe the embodiment in combination, the implementation steps include:

[0041] 1) According to the mechanical characteristics of the area where the drilled hole 5 is located, determine the sealing depth, and drill holes in the rock (coal) wall 4 towards the coal seam; Drill holes (100mm) about 1 / 3 larger to form a step area 13, and use airflow to clean and dry the drill holes 5 after drilling.

[0042] 2) Bind the outer bladder 6 and the inner bladder 6' on the extraction pipe 2, connect the two bladders with the bladder grouting pipe 3, and send the connected bladder into the borehole together with other pipelines , wherein the inner bladder 6' is located at the step area 12, the radial stability is guaranteed by the step 12, and the outer bladder 6 is located at the orifice; a fixing member 10 is installed at the orifice to limit the radial displacement of the outer bladder 6 at the orifice; The grouting p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com