Floor paying-off hole pre-embedding device and construction method thereof

A pre-embedded device and floor slab technology, applied in the field preparation of formwork/formwork/work frame, building components, construction, etc., can solve the problems of difficult quality control, high labor intensity, hidden danger of leakage, etc., to reduce labor cost, reduce labor intensity, and avoid leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

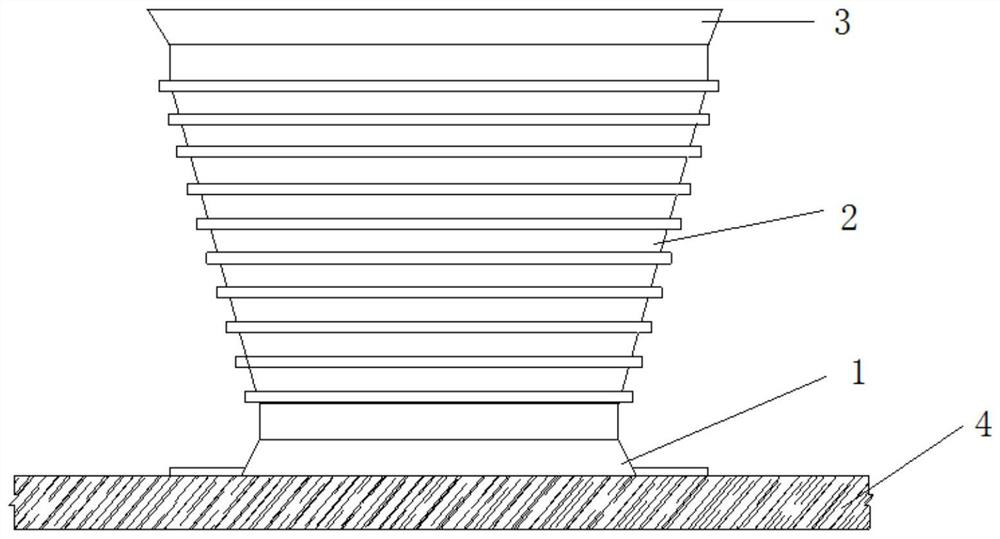

[0044] figure 1 It is a schematic diagram of the structure when this embodiment is used, such as figure 1 As shown, this embodiment provides a pre-embedded device for a floor release hole, including a base assembly 1, a pre-embedded part 2 and a buckle cover 3, wherein:

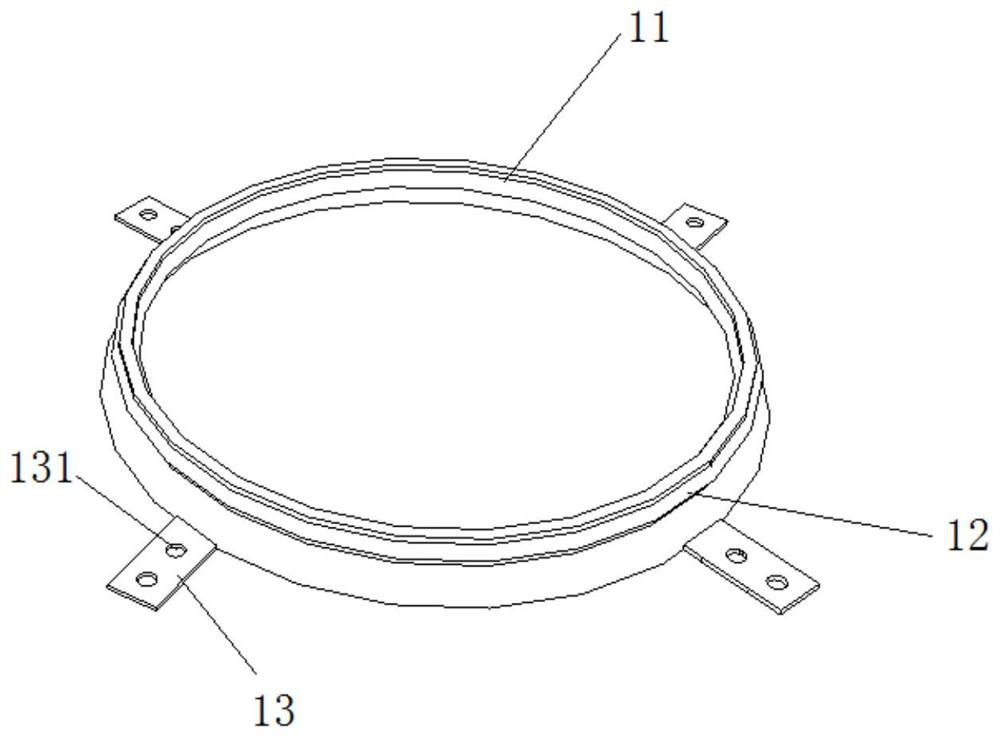

[0045] figure 2 is a schematic diagram of the structure of the base, such as figure 2 As shown, the base assembly 1 includes a base body 11 and a base sealing ring 12. The base body 11 is fixed on the template 4, and the base sealing ring 12 is sleeved on the base body 11. In this embodiment, the base sealing ring 12 is a rubber ring. Good sealing effect;

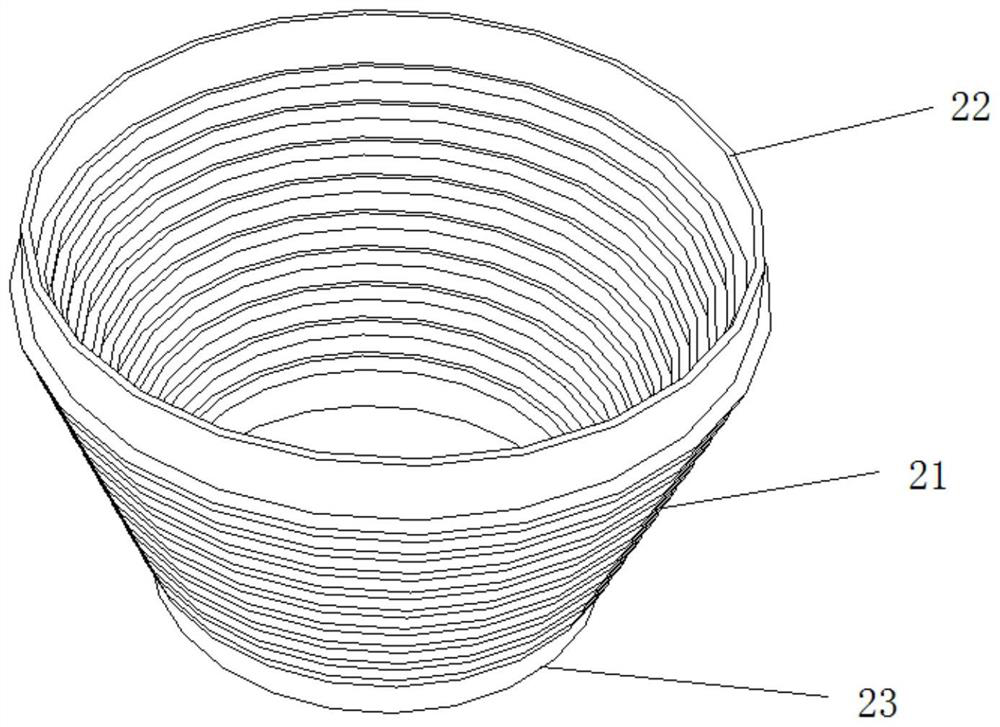

[0046] The embedded part 2 is socketed at the top of the sealing ring 12 of the base, and the embedded part 2 is provided with a multi-layer groove water stop ring 24; the button cover 3 is set on the embedded part 2.

[0047] When the floor formwork is supported, this pre-embedded device is used to facilitate the plugging of the set-out hole without...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com