A pipe plugging method for condenser titanium pipe

A technology of condenser and titanium tube, applied in the field of steam turbine, can solve the problems of poor sealing quality of titanium tube, check the tightness of sealing of titanium tube, etc., to ensure the quality and tightness of sealing, reduce pressure, and be easy to operate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

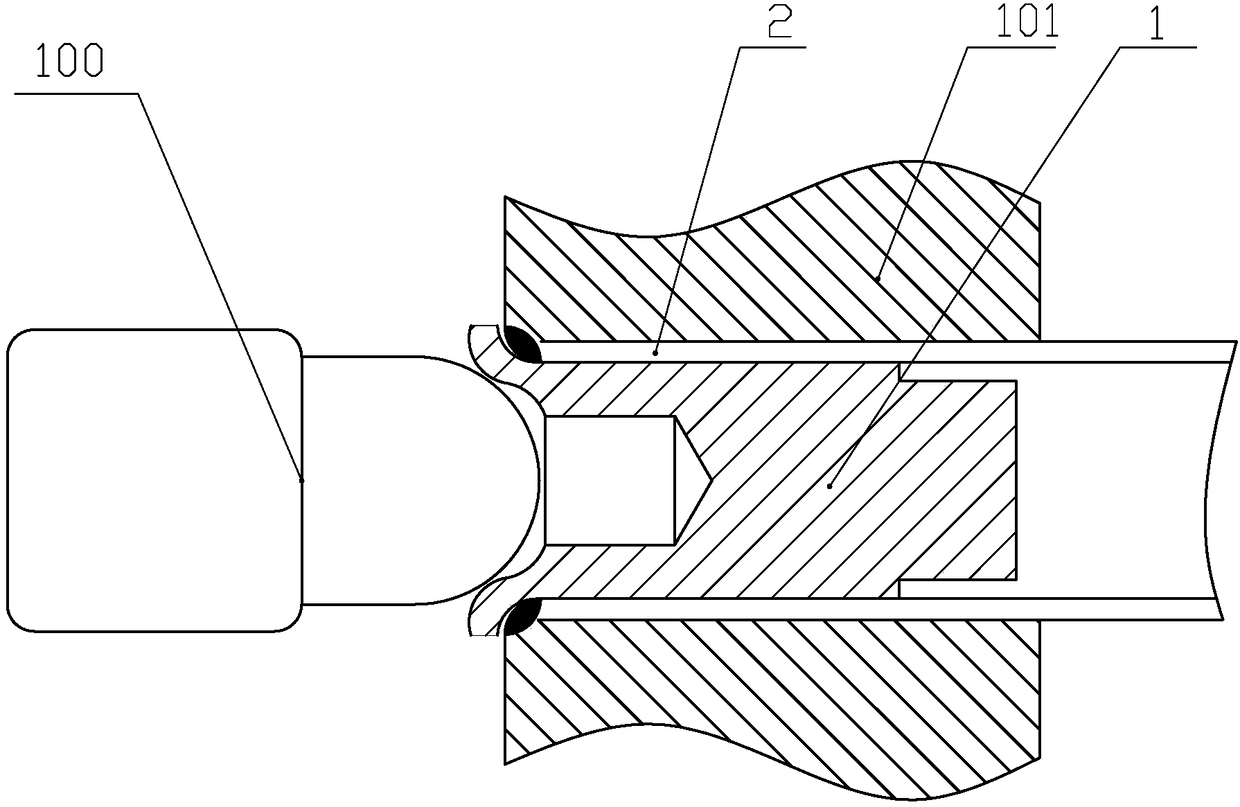

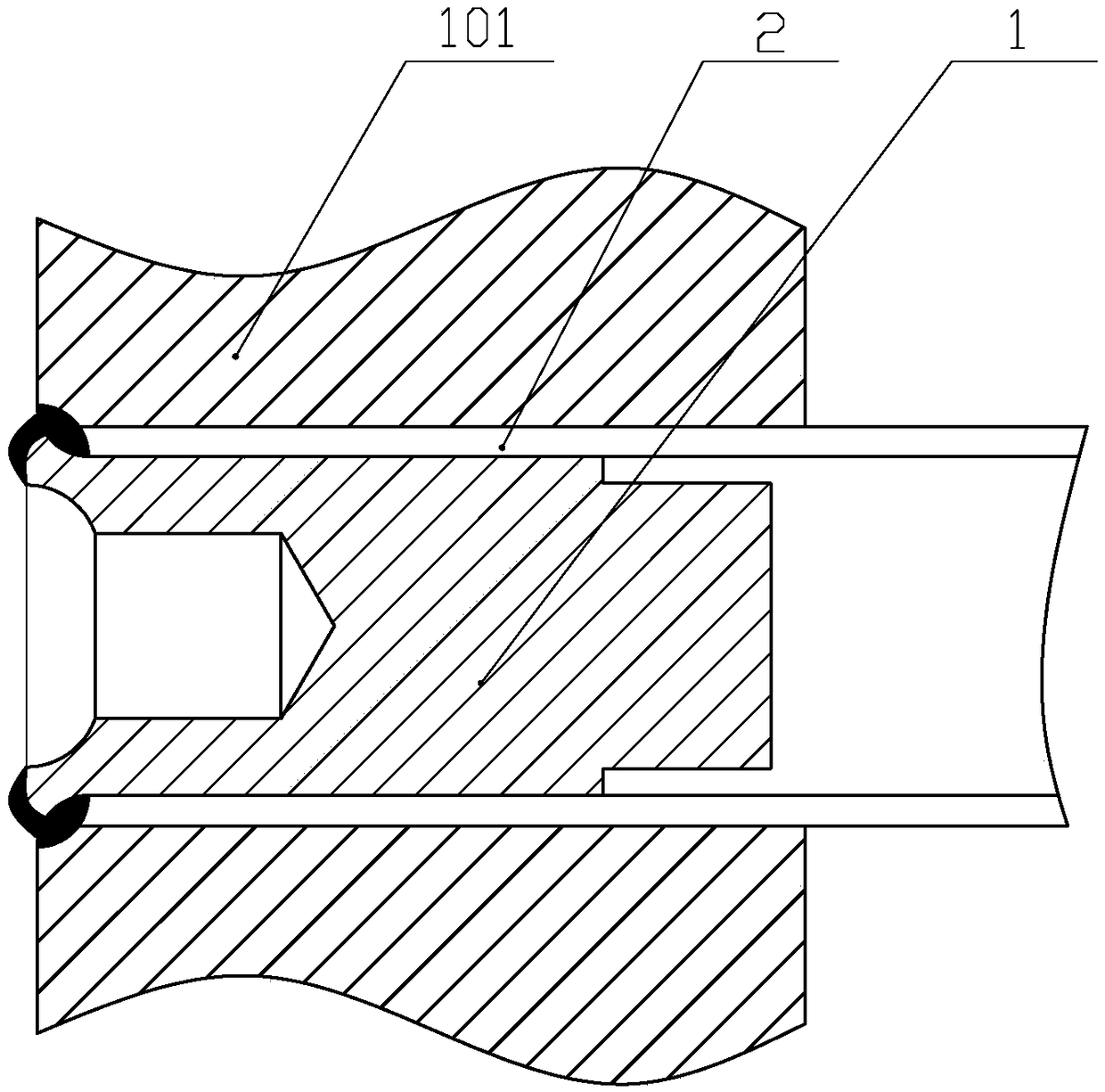

[0017] Specific implementation mode one: combine Figure 1 to Figure 4 Illustrate this embodiment, a kind of pipe plugging method that is used for condenser titanium tube of this embodiment, the steps are as follows:

[0018] 1. Use all-titanium tube plug 1 to block the nozzles at both ends of titanium tube 2;

[0019] 2. Use the manual tungsten argon arc welding process to seal and weld the full titanium tube plug 1 and the titanium tube 2 nozzle at both ends of the titanium tube 2 respectively;

[0020] 3. Use a vacuum foaming leak detection device to check the tightness of the weld.

[0021] By adopting the tube plugging method provided by the present invention, the titanium tube 2 of the condenser with leakage can be blocked in time.

[0022] After the titanium tube 2 of the condenser of the nuclear power plant leaks, the leaking titanium tube 2 of the condenser can be blocked and the quality of the plugged tube can be ensured, the leakage source of the condenser can be ...

specific Embodiment approach 2

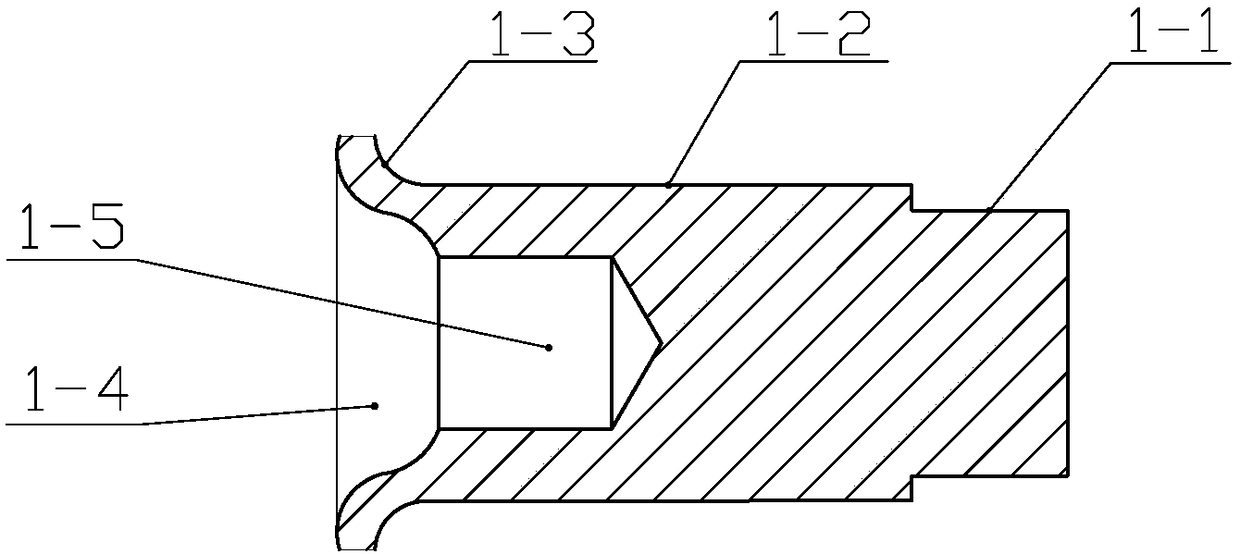

[0024] Specific implementation mode two: combination Figure 1 ~ Figure 3 To illustrate this embodiment, the all-titanium pipe plug 1 includes a guide section 1-1, a sealing section 1-2 and a limiting section 1-3, and the guiding section 1-1 and the limiting section 1-3 are respectively fixed on the sealing section At both ends of 1-2, the guide section 1-1 is in clearance fit with the inner hole of the titanium tube 2, the sealing section 1-2 is in interference fit with the inner hole of the titanium tube 2, and the limiting section 1-3 is located at the end of the titanium tube 2. In such a design, the guide section 1-1 plays a guiding role when the full titanium tube plug 1 is inserted into the tube hole of the titanium tube 2, the sealing section 1-2 has an interference fit with the tube hole of the titanium tube 2 to ensure sealing, and the limiting section 1- 3 After the all-titanium tube plug 1 is inserted into the hole of the titanium tube 2, it acts as a limiter. Oth...

specific Embodiment approach 3

[0025] Specific implementation mode three: combination Figure 1 ~ Figure 3 To illustrate this embodiment, one end of the all-titanium pipe plug 1 is provided with a groove 1-4, and the bottom end of the groove 1-4 is provided with a blind hole 1-5, and the diameter of the blind hole 1-5 is smaller than that of the groove 1-5. 4 in diameter. In such a design, after inserting the guide section 1-1 of the all-titanium tube plug 1 into the titanium tube 2, use the punch 100 to hit the bottom of the groove 1-4, thereby driving the all-titanium tube plug 1 into the hole of the titanium tube 2 Inside, the sealing section 1-2 is interference-fitted with the inner hole of the titanium tube 2, and the blind hole 1-5 plays a guiding role when the punch hits the all-titanium tube plug to ensure that the all-titanium tube plug is evenly stressed. Other compositions and connections are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com