Patents

Literature

43results about How to "Make sure full" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

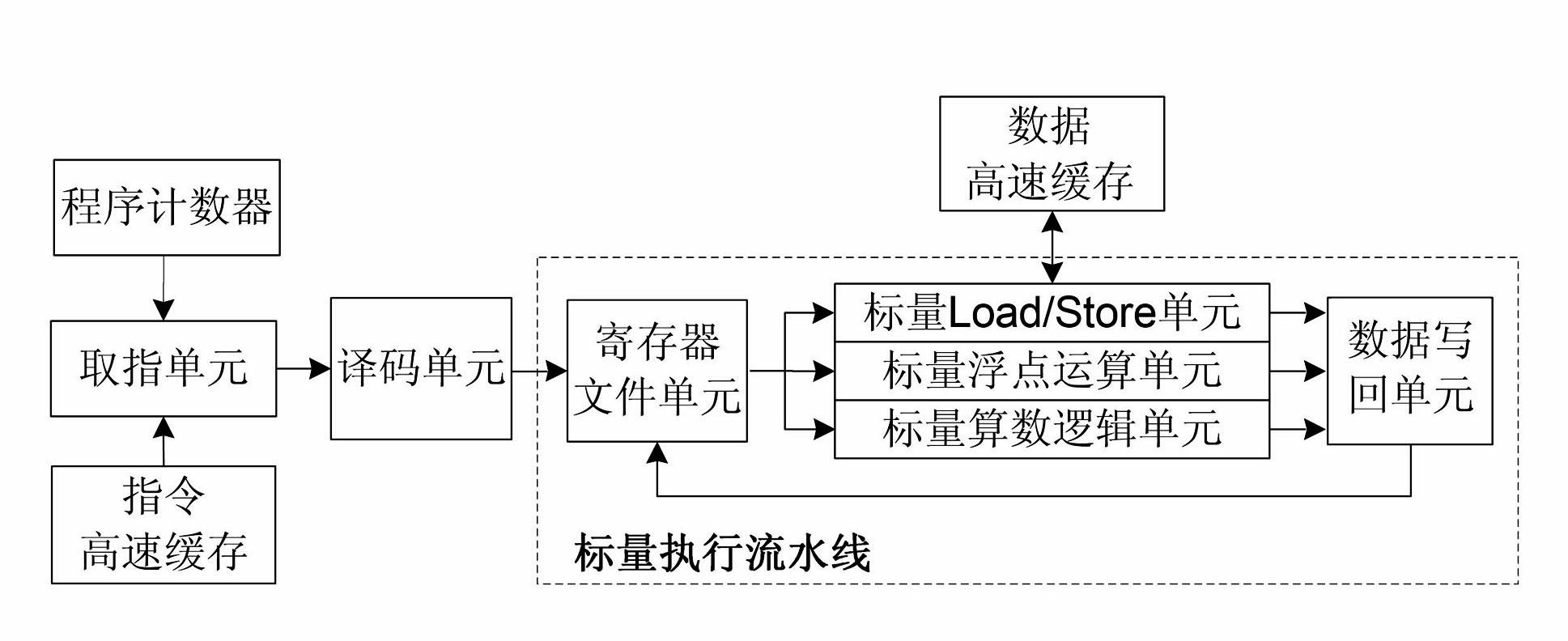

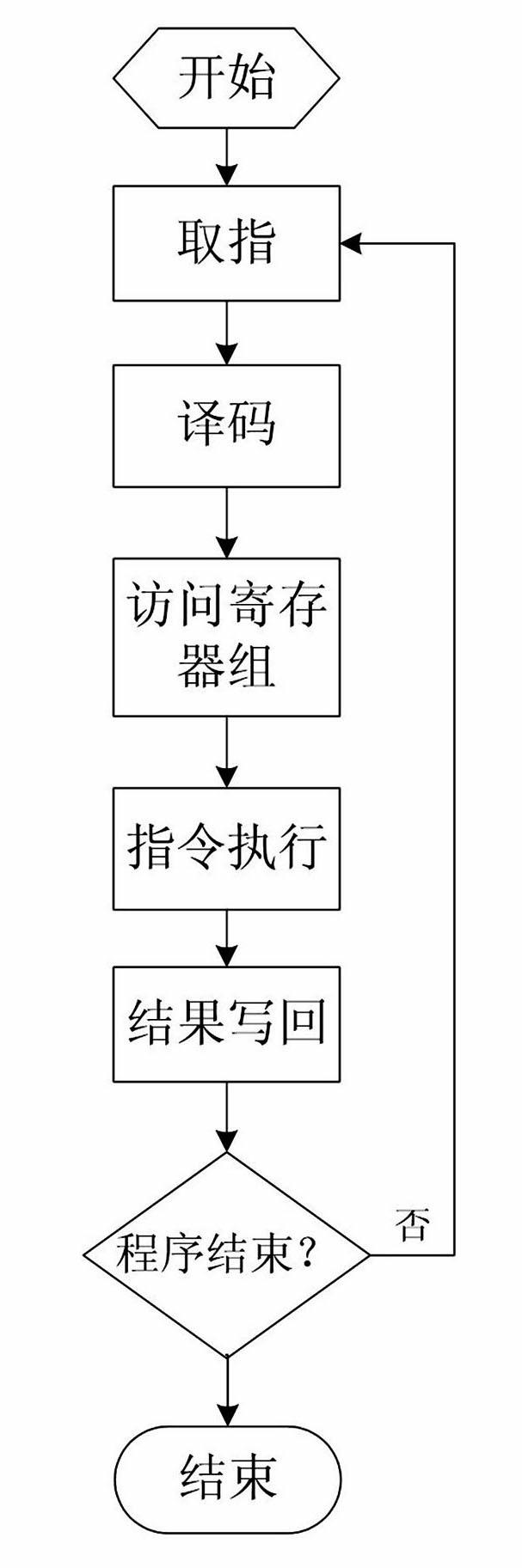

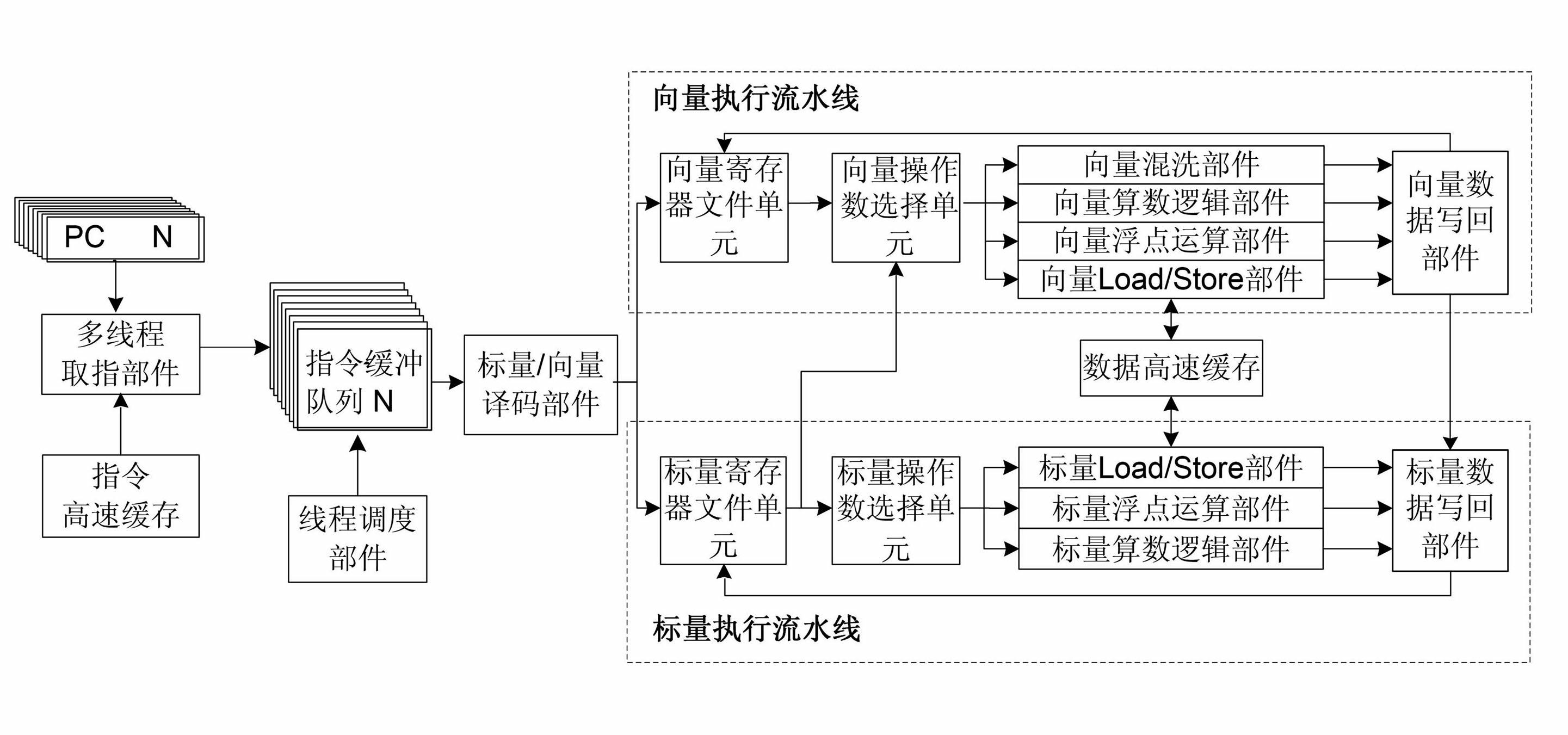

Vector crossing multithread processing method and vector crossing multithread microprocessor

InactiveCN102156637AImprove peak performanceGive full play to computing powerMultiprogramming arrangementsConcurrent instruction executionHardware structureThread scheduling

The invention discloses a vector crossing multithread processing method and a vector crossing multithread microprocessor. The processing method comprises the following steps: using a multithread instruction-acquiring part to choose a vector thread from N vector threads for reading an instruction and storing the read instruction to a corresponding instruction buffer array of the vector thread; using a thread scheduling part to choose an instruction buffer array from N instruction buffer arrays and taking out an instruction from the instruction buffer array for the purpose of decoding; and sending a decoded instruction to a vector executing streamline or scalar executing streamline so as to execute. The method can be realized by using hardware structure by the vector crossing multithread microprocessor. The method and the microprocessor provided by the invention have the advantages that the vector processing technique and multithread technique are combined, the hardware structure is simple, the operation capability is strong, the compatibility and expansibility are excellent, and the like.

Owner:NAT UNIV OF DEFENSE TECH

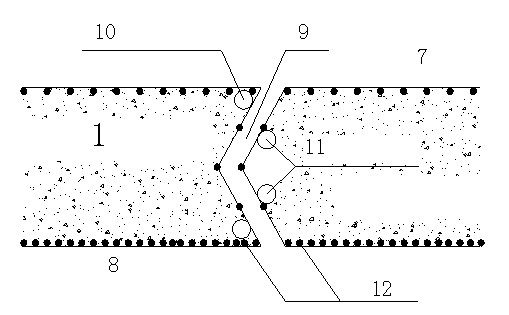

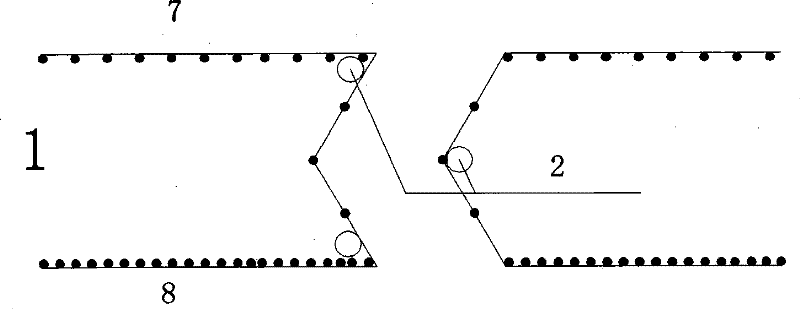

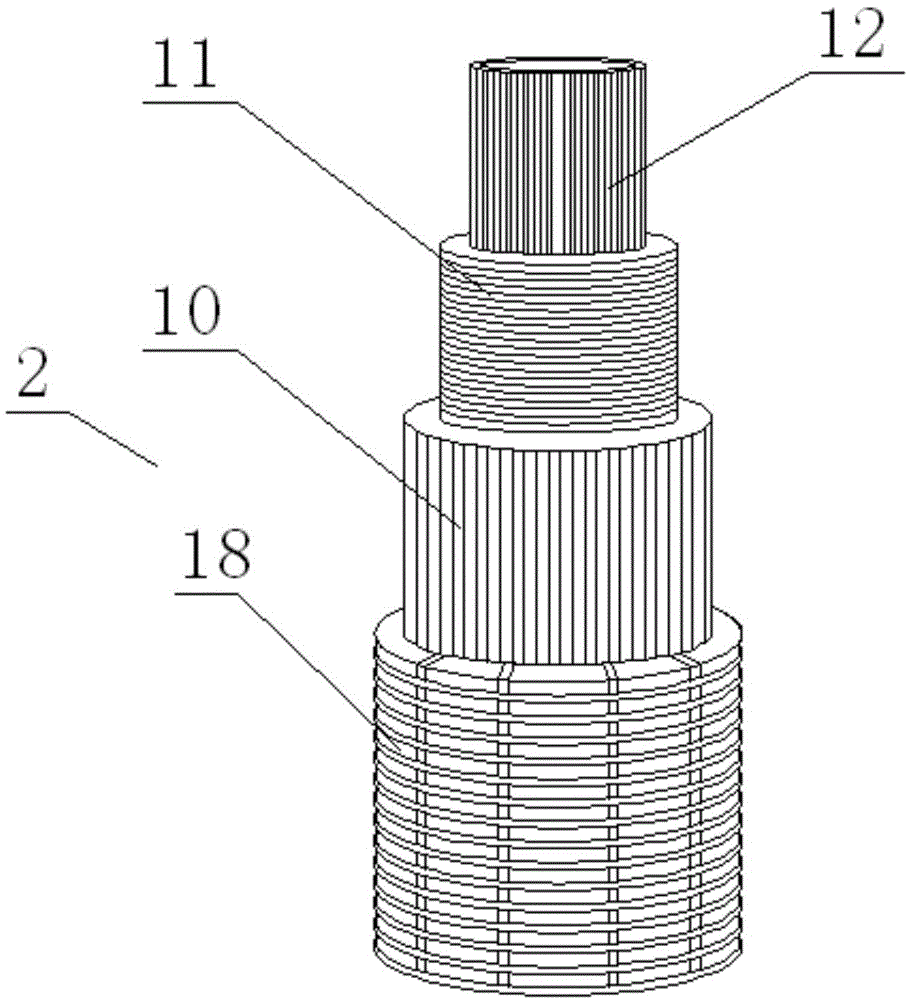

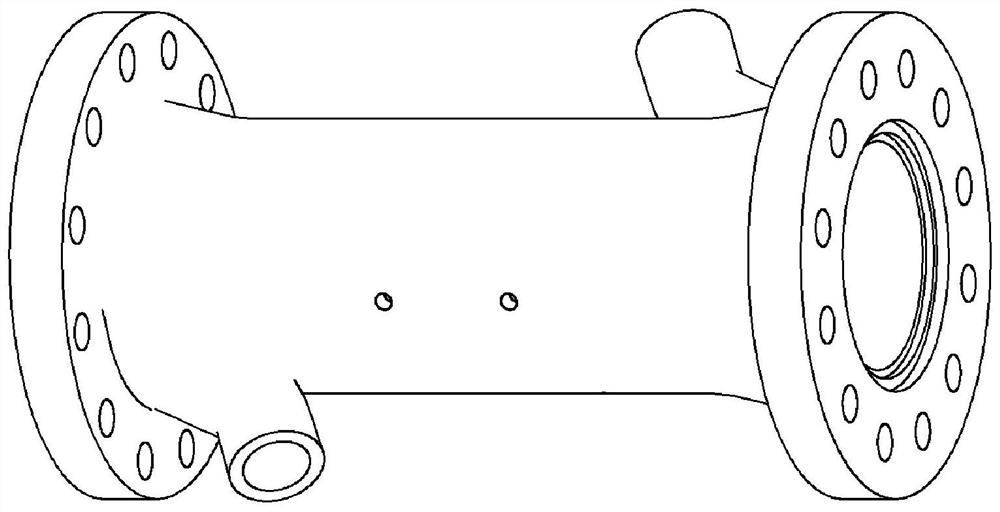

Liquid division slip casting reinforcing method for subsurface structure construction joints

InactiveCN102002950APrevent leakageImprove compactnessArtificial islandsUnderwater structuresWater leakageStructural engineering

The invention discloses a liquid division slip casting reinforcing method for subsurface structure construction joints, mainly aiming at the problems that as the subsurface structure construction is severely influenced by ground water, the peripheral structure leaks water, the material strength is reduced, the structure integrity is poor and the like. A purpose-made grouting pipe is arranged at the construction joint of a structure connector with weak stress in the process of subsurface structure peripheral construction, and the liquid division slip casting reinforcing operation is performed based on a designated method, thus making up for the defects of poor rigidity and poor waterproof effect at the construction joint of the subsurface structure preferably. The method in the invention has good grouting effect and high grouting success rate, can effectively improve the strength and the integrality of the subsurface structure, and reduce the leakage of the construction joint of the subsurface structure.

Owner:SOUTHEAST UNIV +1

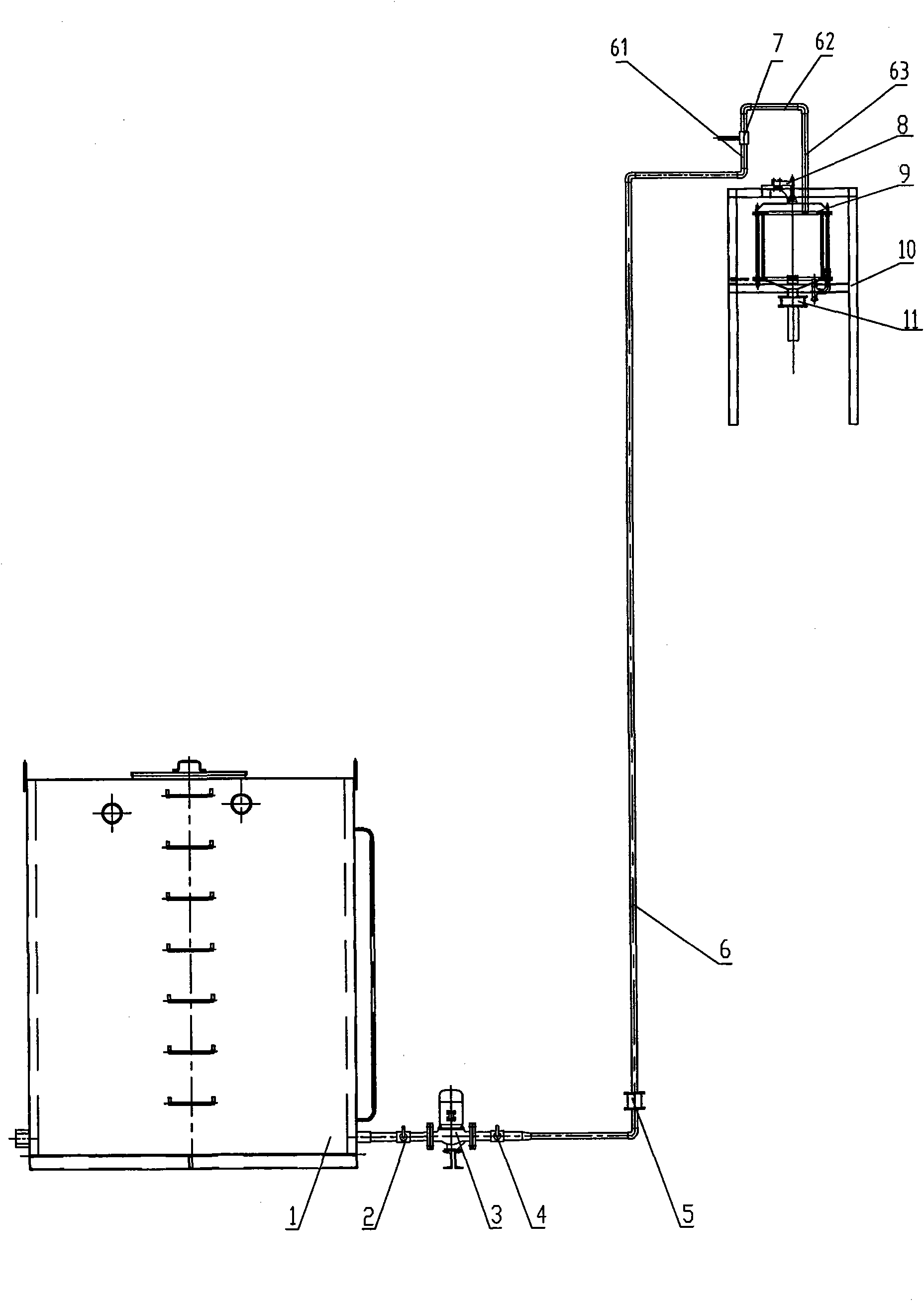

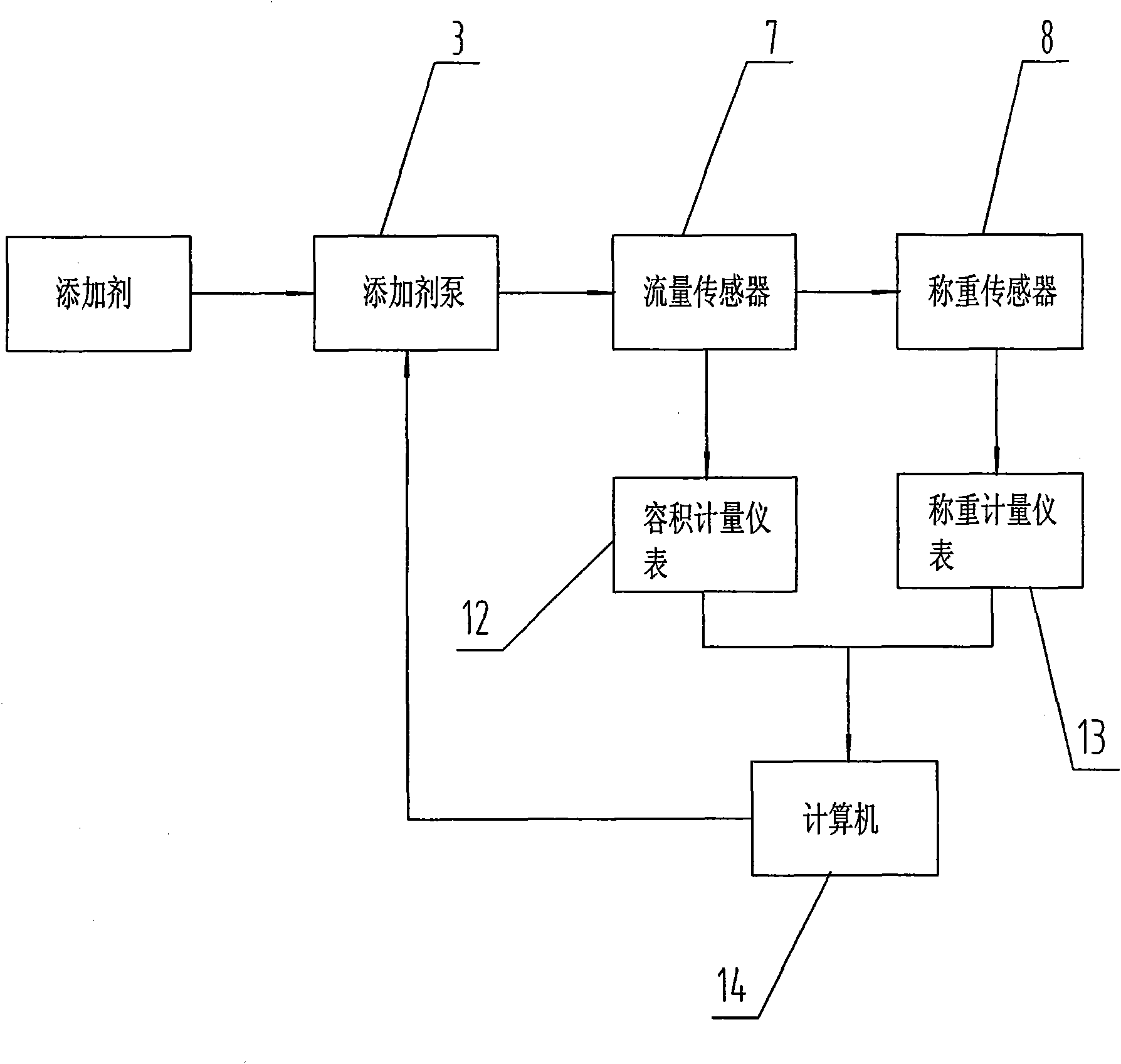

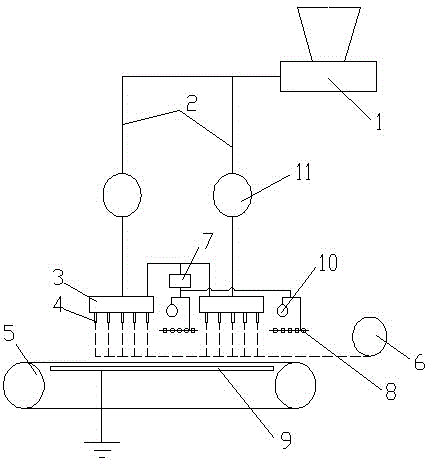

Additive metering system and metering method of cement concrete stirring device

InactiveCN101659087AOvercoming the Defects of Inaccurate Weighing and Measurement ResultsGuaranteed accuracyLiquid ingredients supply apparatusAutomatic controlControl system

The invention discloses an additive metering system and a metering method of a cement concrete stirring device, the additive metering system comprises an additive liquid storage tank, a ball valve, anadditive pump, a check valve, a flow sensor, a weighing sensor, an additive weighing tank, a support of the weighing tank and a discharge pneumatic butterfly valve, and a control system is constituted by a flowmeter, a weighing instrument and a computer. The additive metering adopts the method which combines the volumetric metering with the electronic weighing metering, the two metering results are simultaneously inputted into the computer for carrying out comparison, when any metering result achieves the set value of ingredients within the set error range, the additive pump is closed. The metering method adopts the method which combines the volumetric metering with the electronic weighing metering, when the pneumatic butterfly valve below the weighing tank is not closed tightly or otherfaults occur in the system, the computer carries out the comparison treatment on output values of the volumetric metering and the electronic weighing metering, thereby automatically controlling the opening and the closing of the additive pump and further ensuring the precision of the actual amount of the ingredients of the additive.

Owner:中外合资江苏华通动力重工有限公司

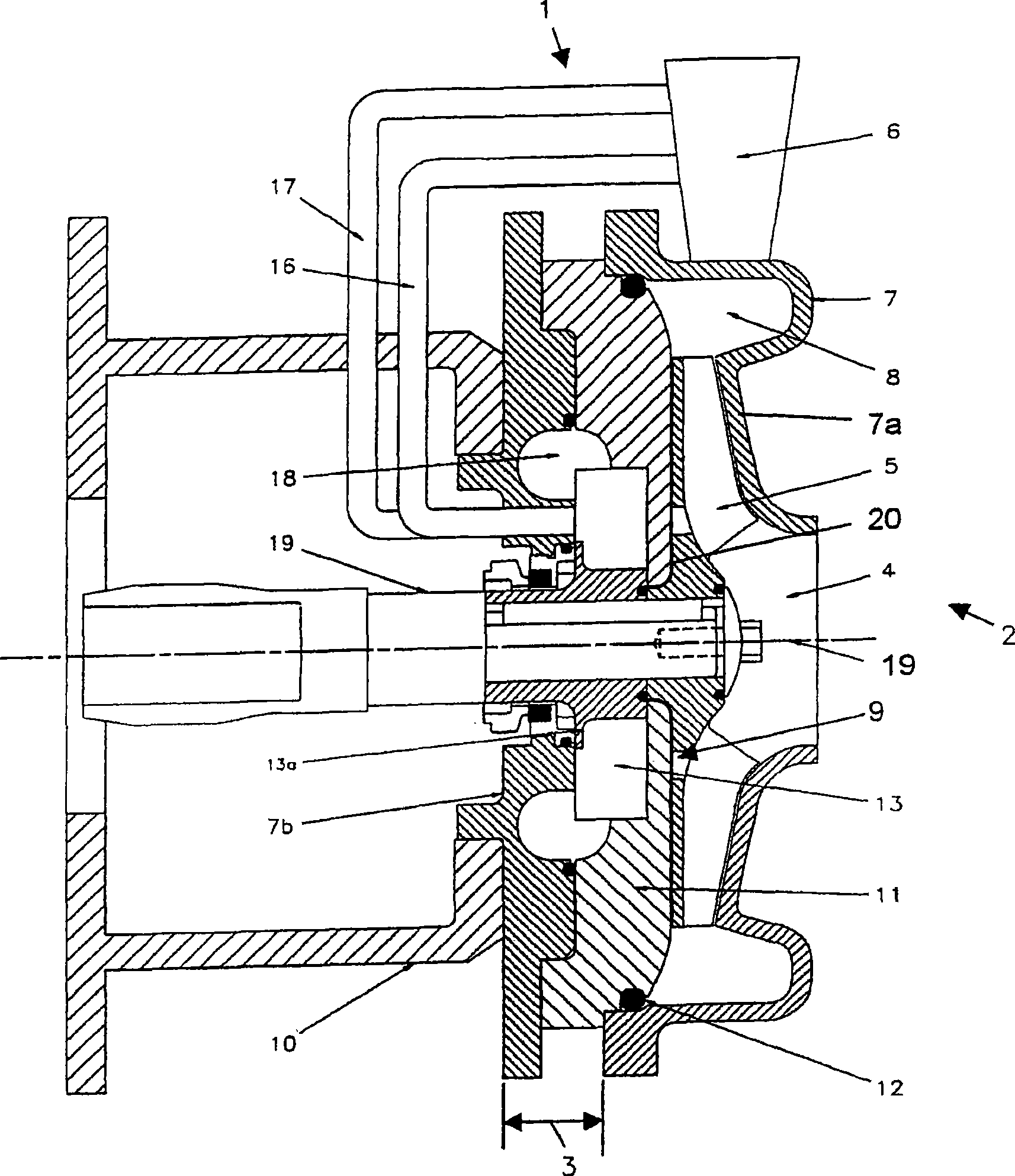

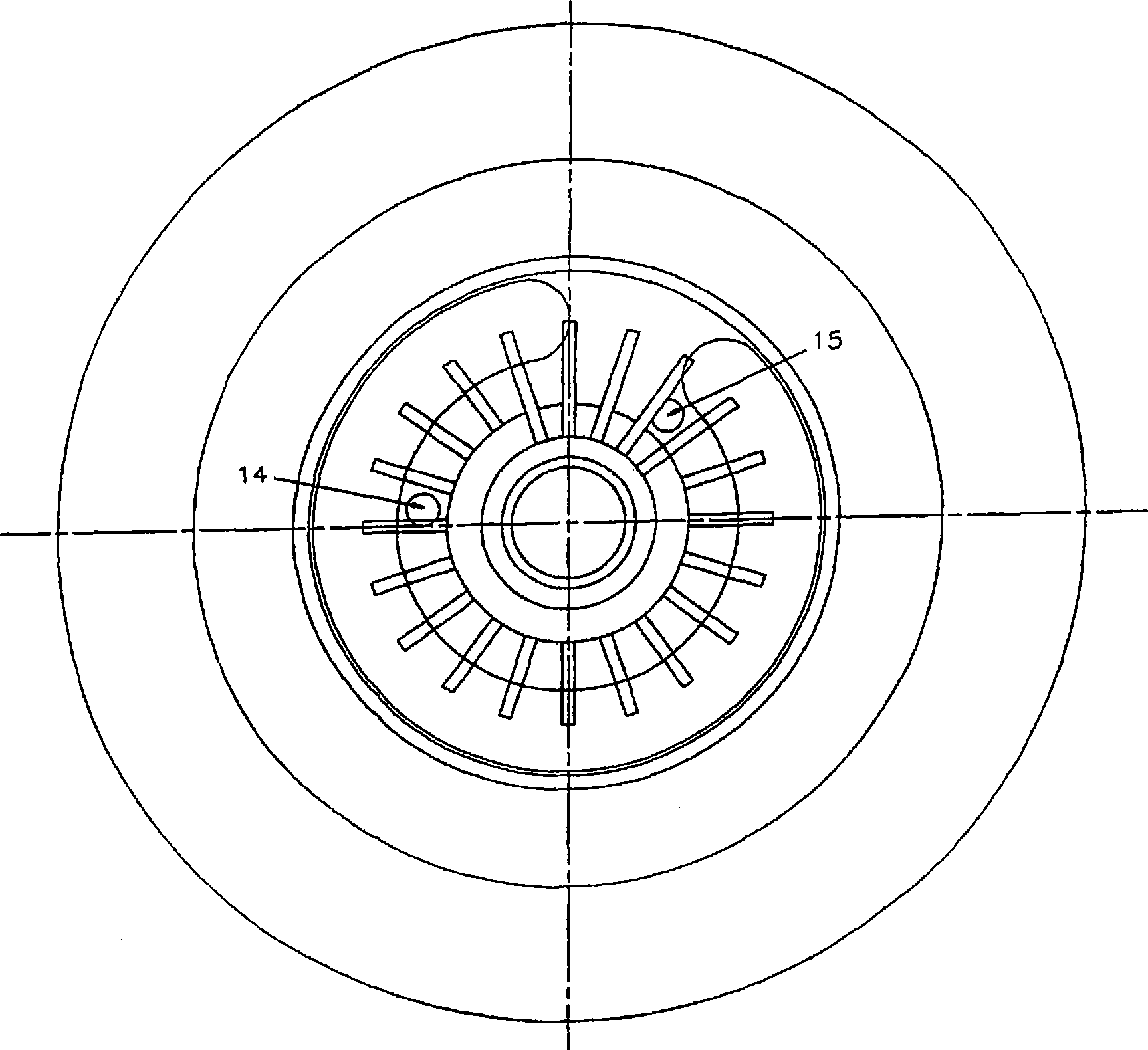

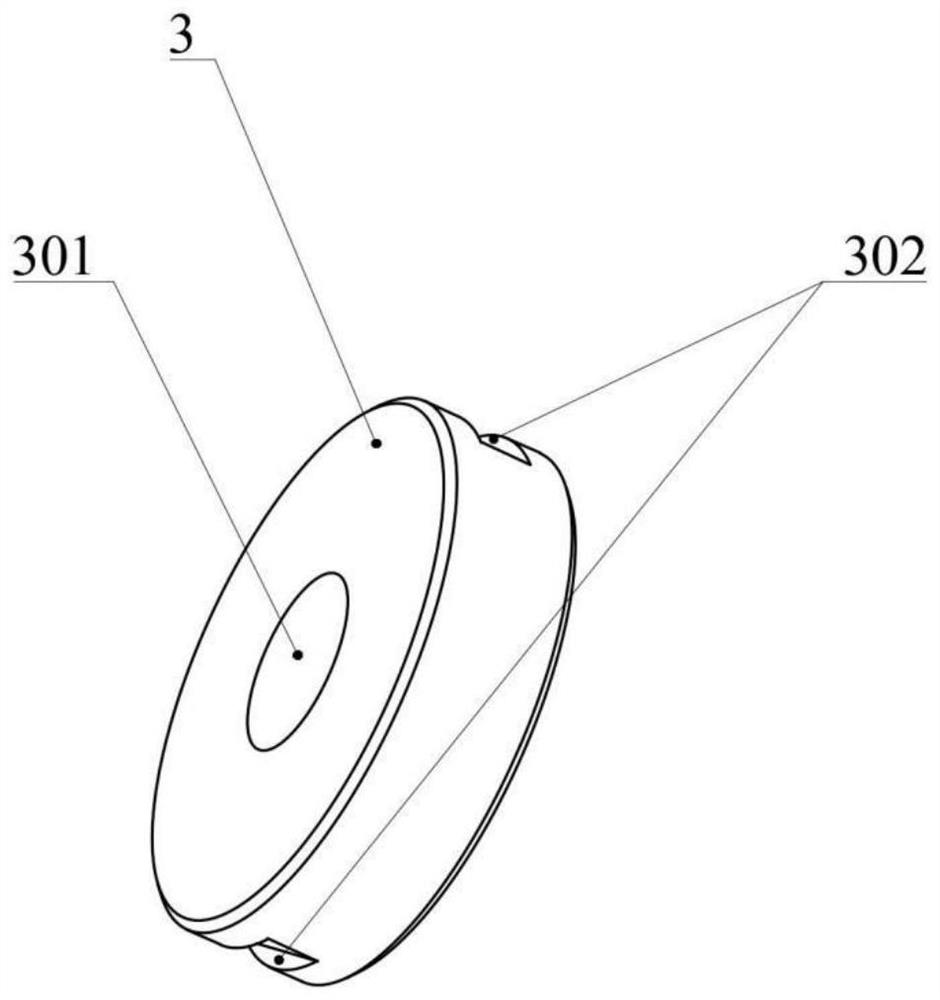

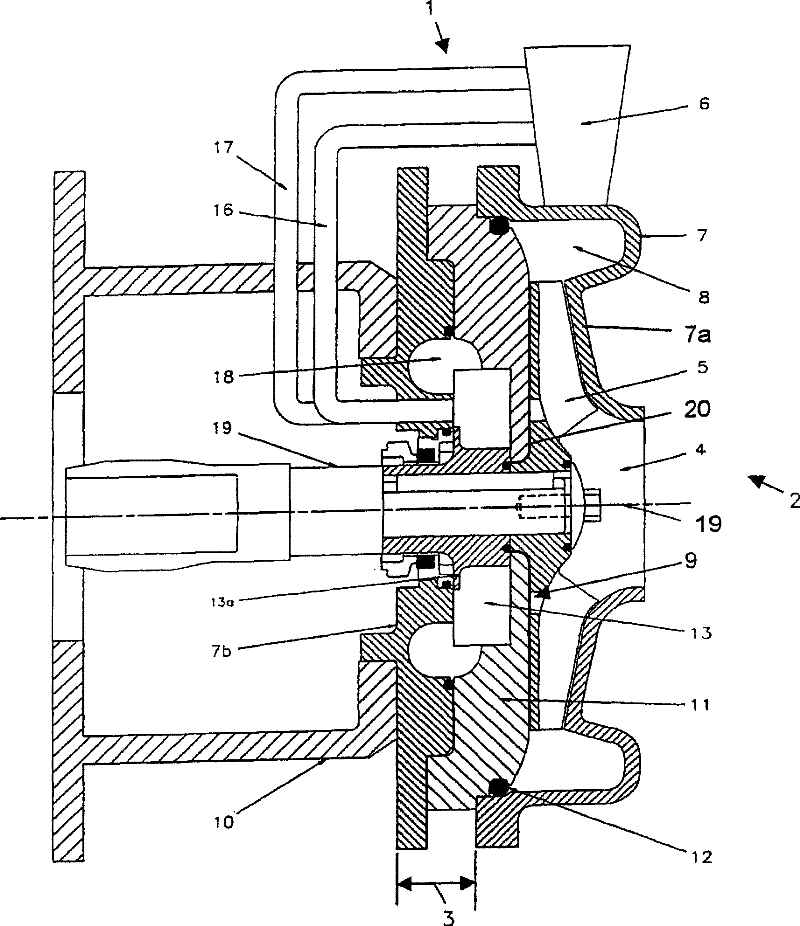

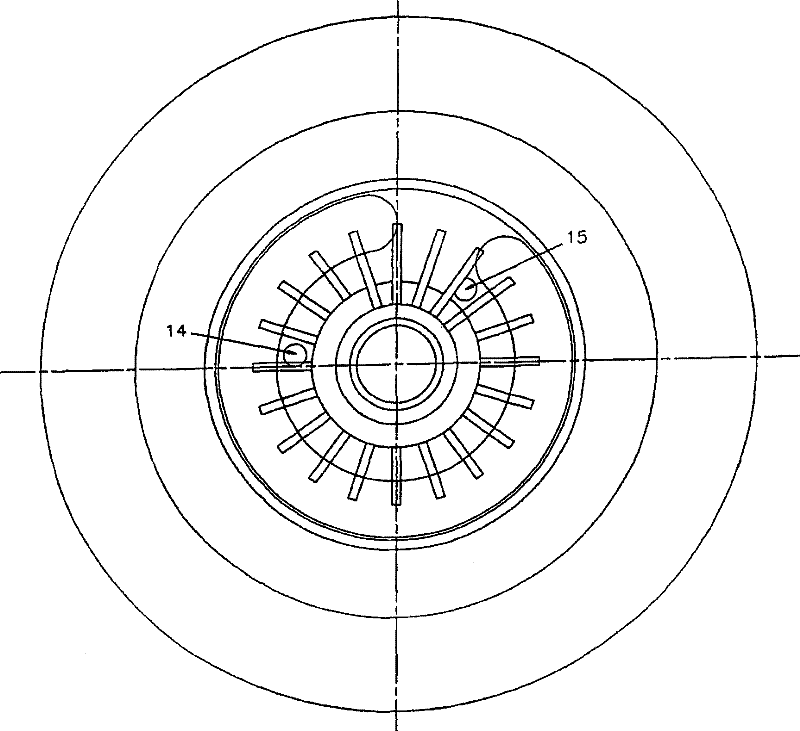

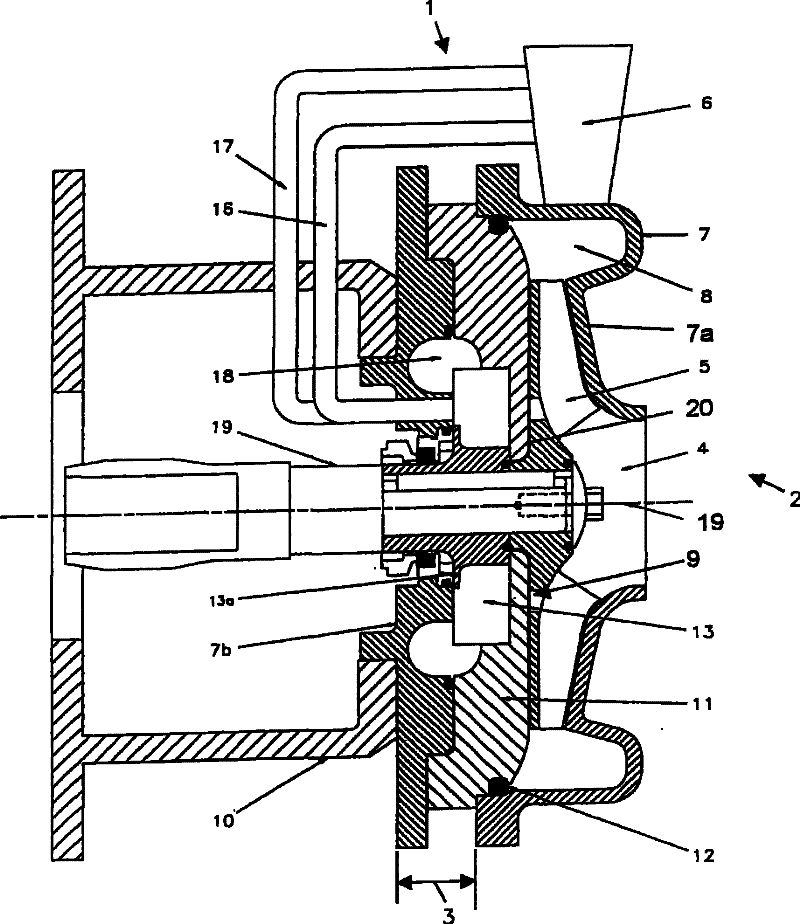

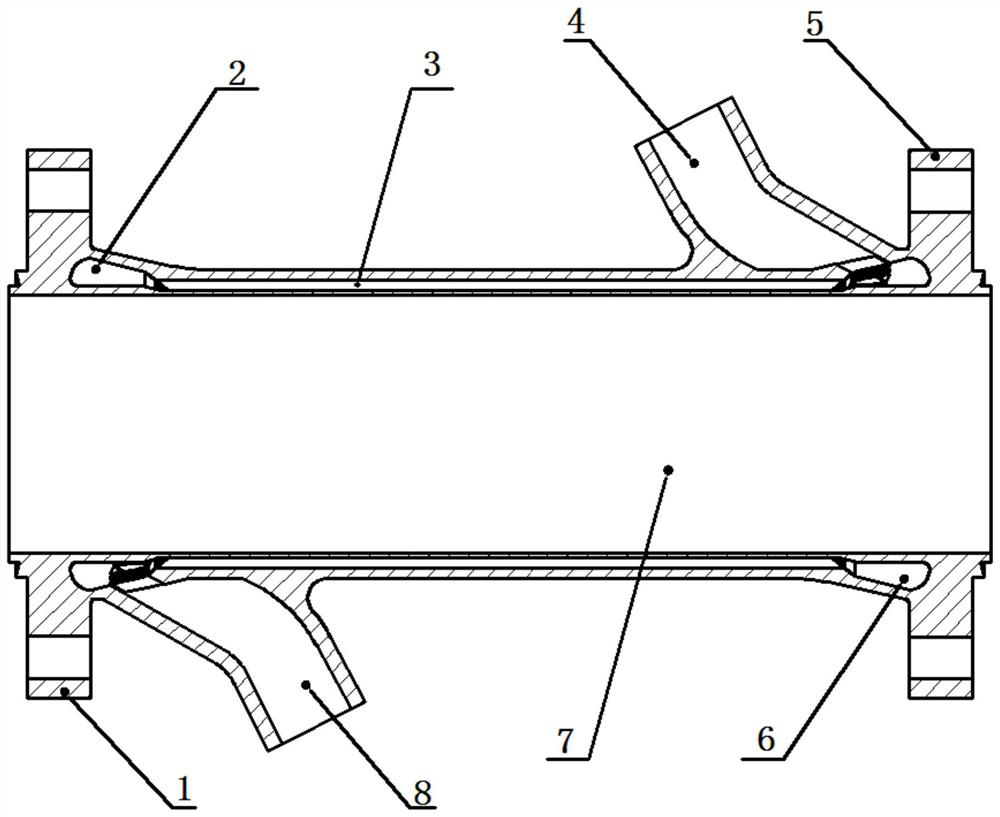

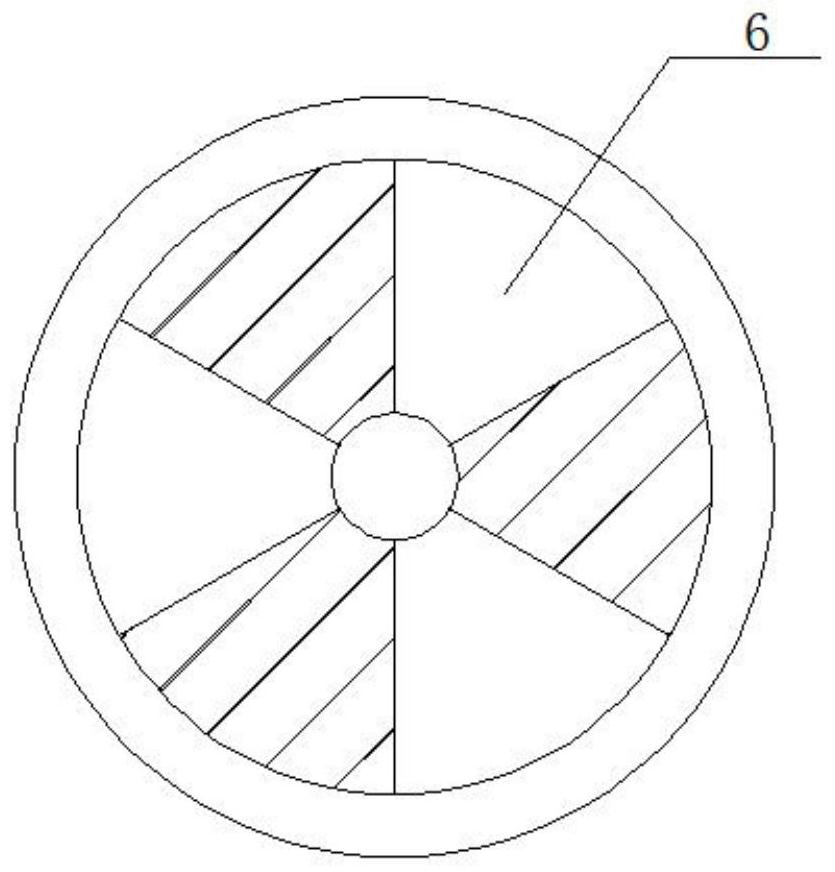

Self-ventilating centrifugal pump

InactiveCN101400896AExhaustSimple structurePriming pumpNon-positive displacement fluid enginesEngineeringVacuum pump

In order to specify a centrifugal pump (1) having a centrifugal pump outlet space (6) and a centrifugal pump suction space (4) and also having an additional ventilation pump (3), which is preferably embodied as a vacuum pump, with a ventilation pump inlet (14) and a ventilation pump outlet (15), which centrifugal pump (1) is of particularly simple construction and which, if required, can be automatically ventilated without complex mechanical switching processes, it is proposed that both the ventilation pump inlet (14) and also the ventilation pump outlet (15) are in each case connected by means of a connecting line (16, 17) to the centrifugal pump outlet space (6) so as to form an auxiliary line.

Owner:阿尔法·拉瓦尔科灵联合股份有限公司

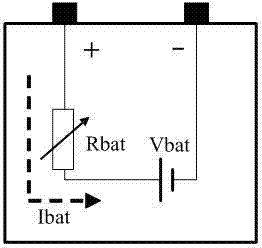

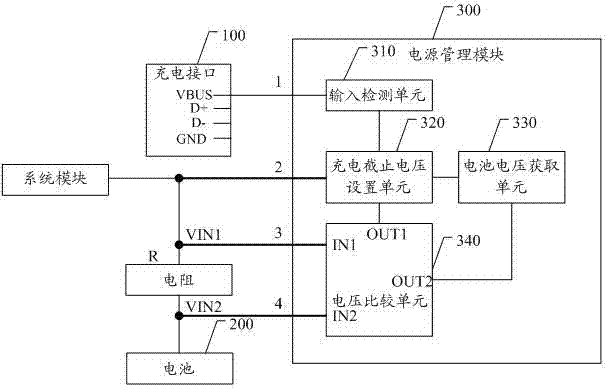

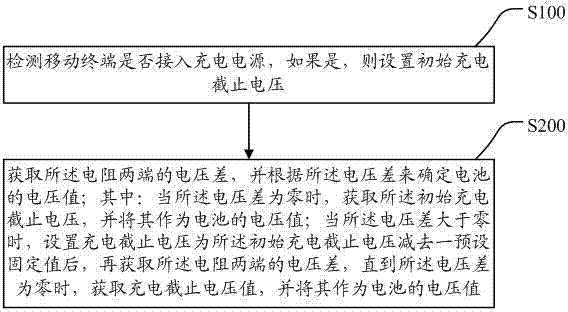

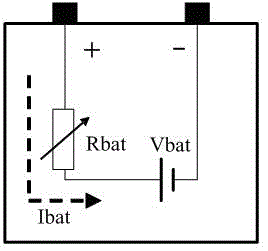

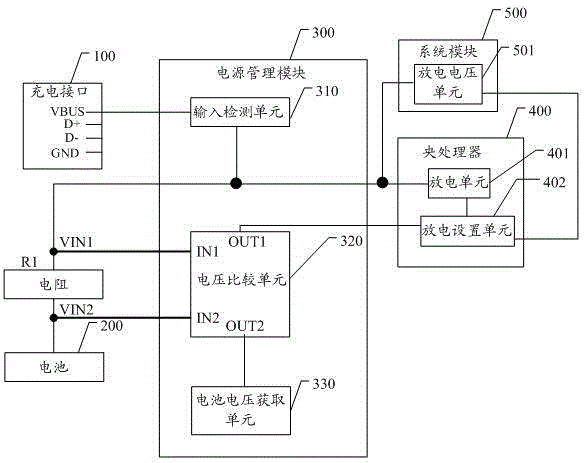

Terminal capable of accurately obtaining battery voltage in charging process and battery voltage obtaining method

ActiveCN103616551AMake sure fullStable chargingCurrent/voltage measurementElectrical batteryPower management

The invention discloses a terminal capable of accurately obtaining battery voltage in the charging process and a battery voltage obtaining method. The device comprises a charging port, a battery, a resistor and a power management module. The first end of the power management module is connected with the charging port. The second end and the third end of the power management module are connected with one end of the resistor and a system module of the mobile terminal. The fourth end of the power management module is connected with the other end of the resistor and an anode of the battery. The power management module is used for setting the initial charging cut-off voltage, obtaining the voltage difference at the two ends of the resistor when the battery is charged, and determining the voltage value of the battery according to the voltage difference. When the battery is charged, the actual voltage of the battery can be accurately obtained, then the real electric quantity of the battery is obtained and displayed to users, the users can know the electric quantity of the battery, and when the terminal is charged, whether the battery is fully charged can be accurately known, so that charging of the battery is stable and accurate.

Owner:威海高新园区运营管理有限公司

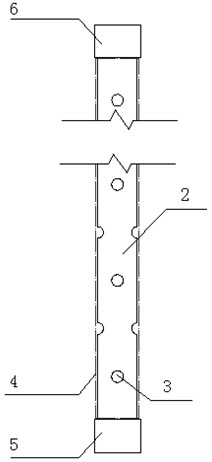

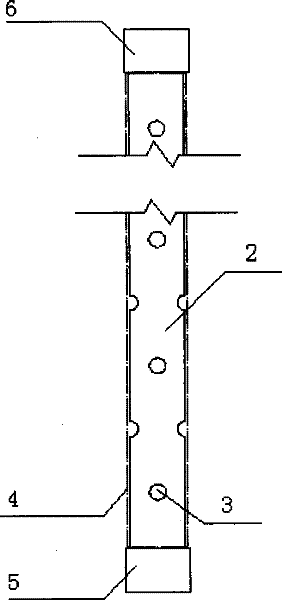

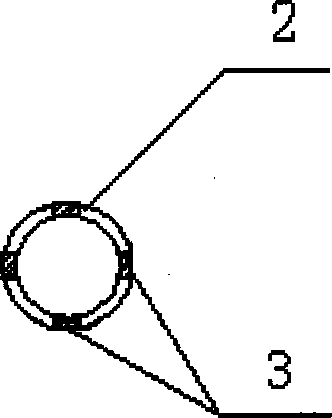

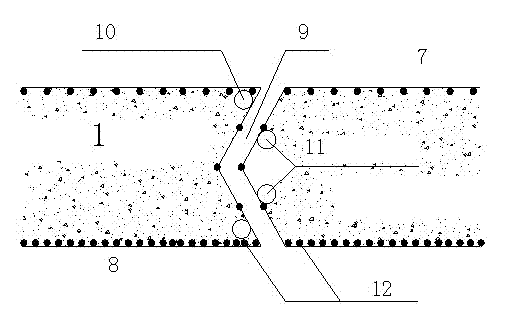

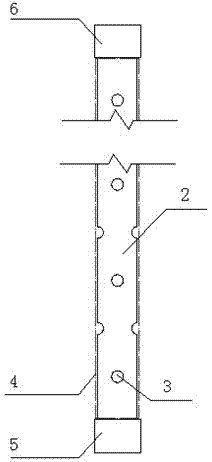

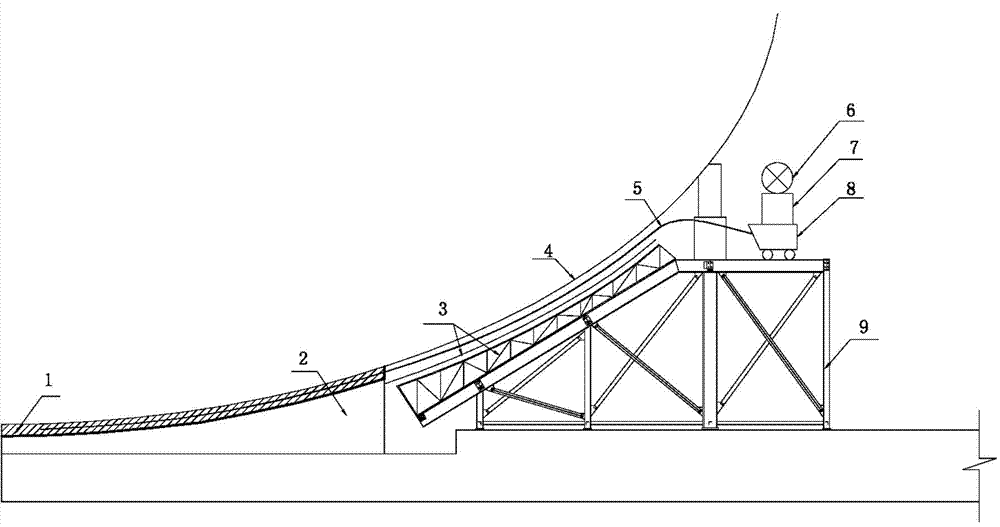

Post-grouting reinforcement construction method for flexible joints of ground-connected walls

InactiveCN102296617ARich sourcesNo pollution in the processExcavationsBulkheads/pilesSlurry wallPorous sheet

The post-grouting reinforcement construction method of the flexible joint of the ground connection wall is the construction technology of the ground connection wall of the subway foundation pit engineering. Grouting pipe (2): Place the porous grouting pipe at the end of the reinforcement cage, and tie it together with the reinforcement cage with iron wire, or weld it on the reinforcement cage with electric welding, and lower it together with the reinforcement cage; there are three porous grouting pipes, They are respectively installed at the ends of steel cages of two underground diaphragm walls, one grouting pipe is installed on both sides of the end of one underground diaphragm wall, and one grouting pipe is arranged in the middle of the end of the other underground diaphragm wall; when the underground diaphragm wall The concrete of the wall reaches more than 70% of the design strength. Before final setting, a high-pressure pump is used to inject reinforcing cement slurry into the wall through a porous grouting pipe. The invention has good grouting effect and high grouting success rate, can effectively improve the integrity of the ground connection wall and reduce the leakage problem of the flexible joint of the ground connection wall.

Owner:SOUTHEAST UNIV

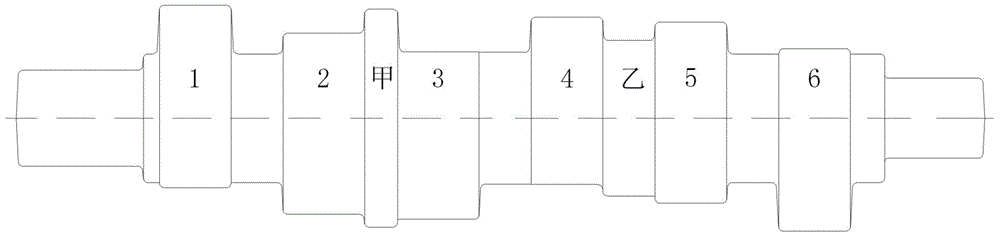

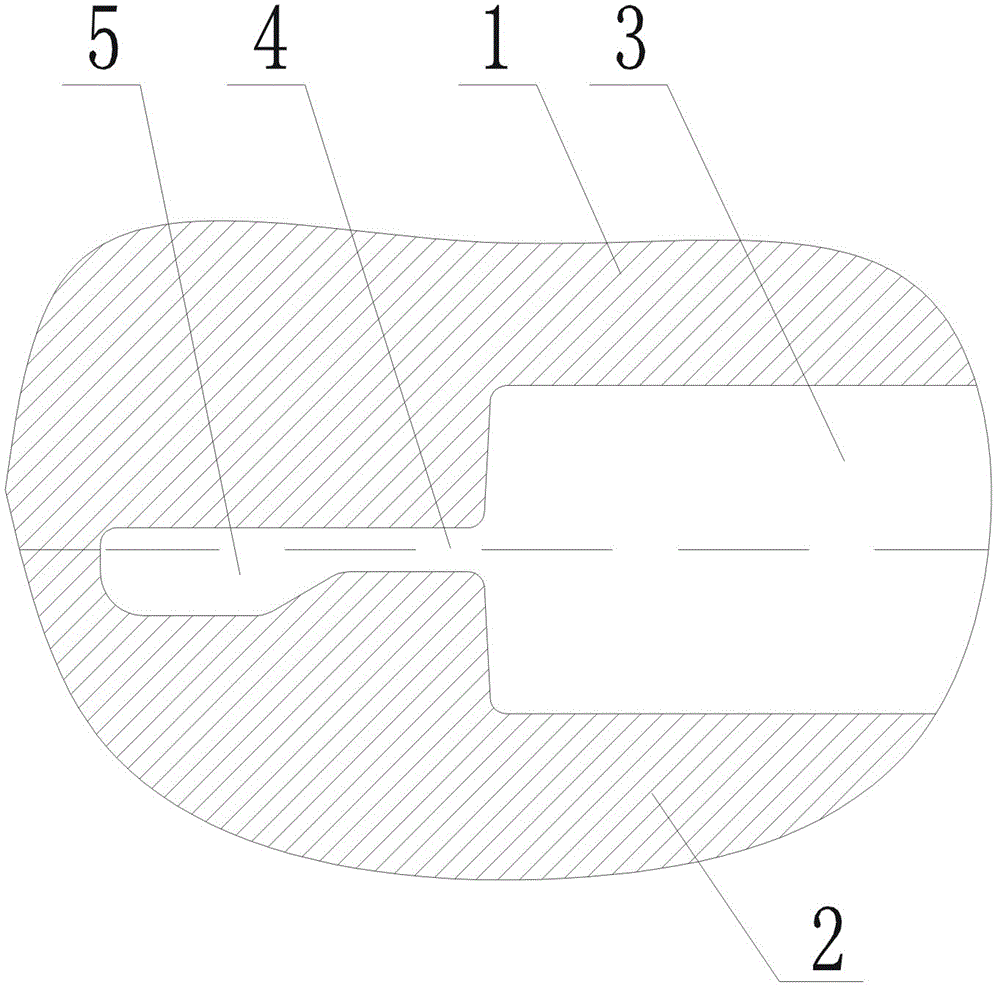

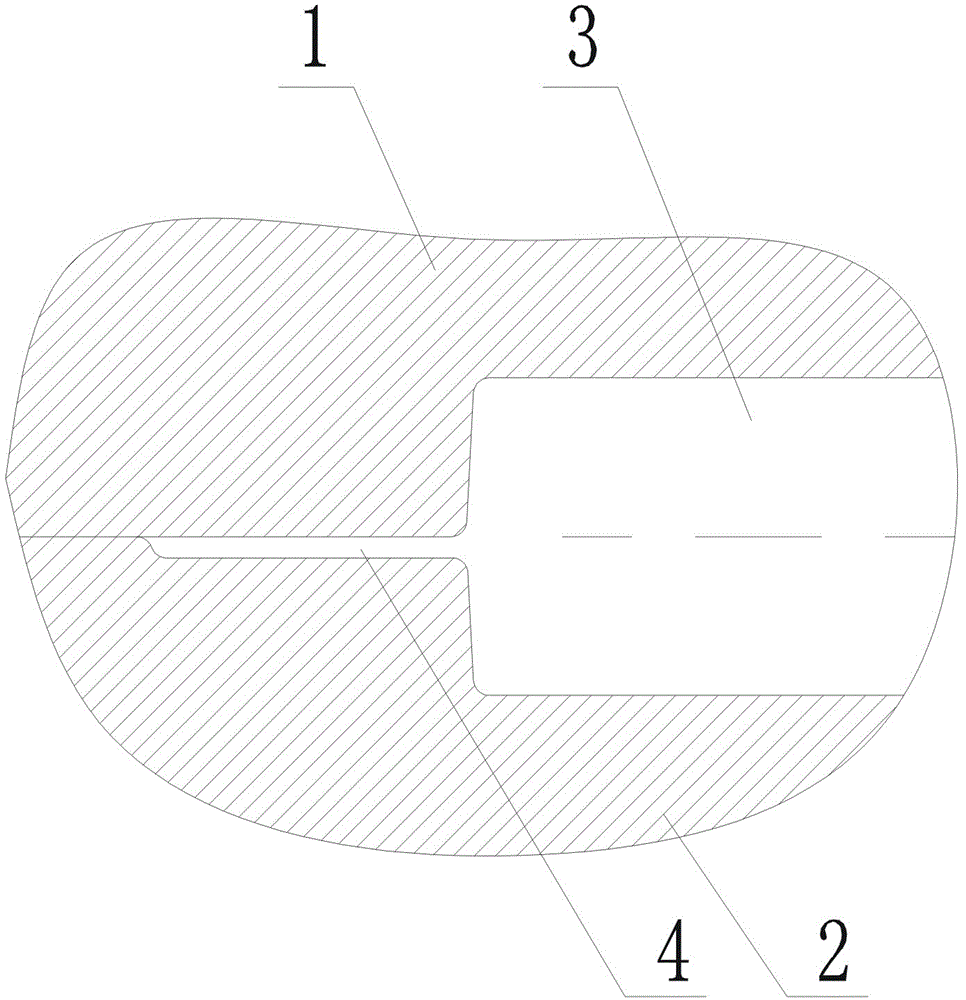

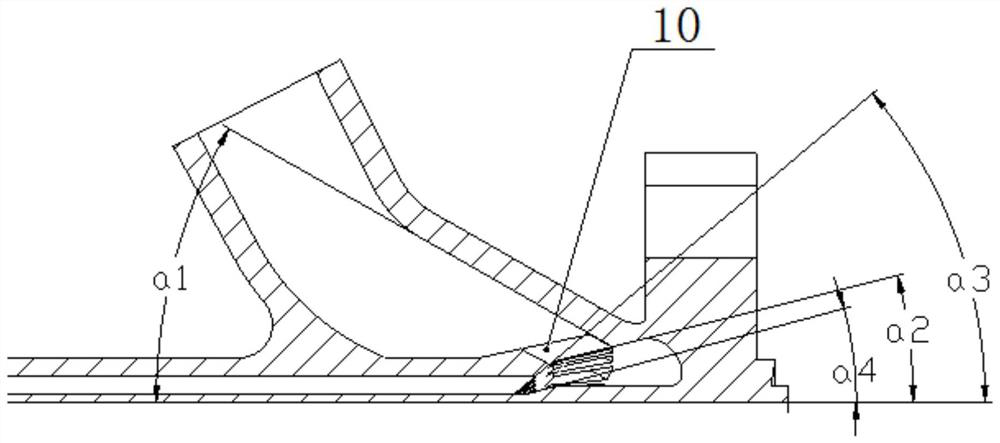

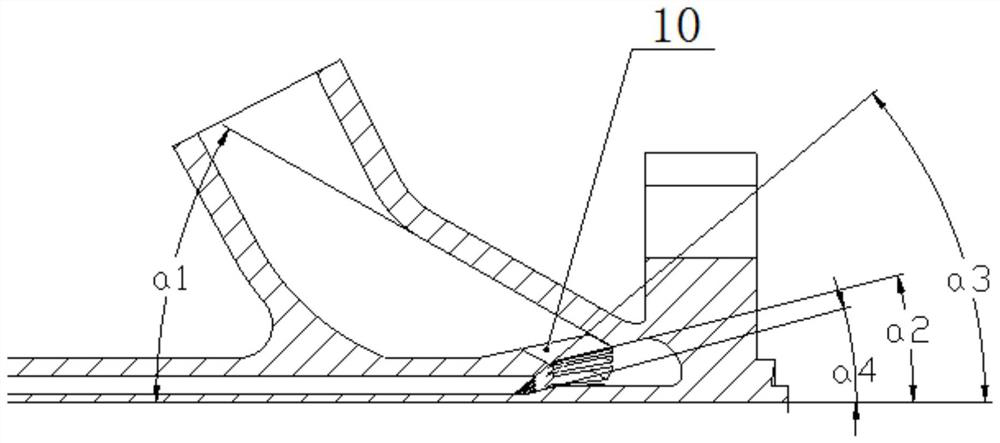

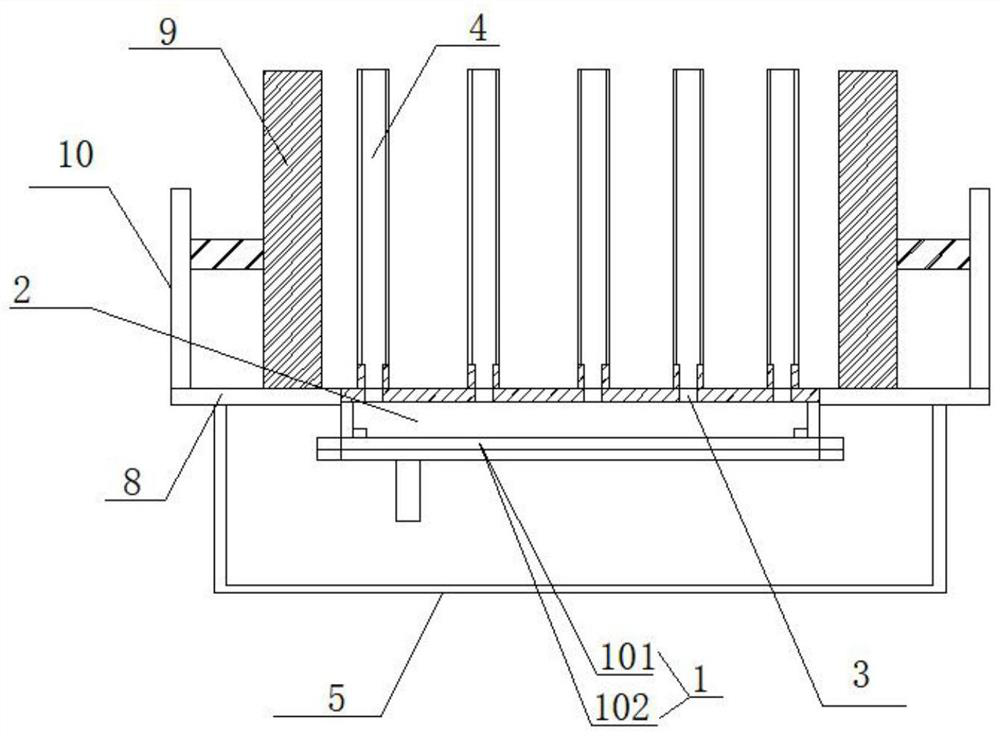

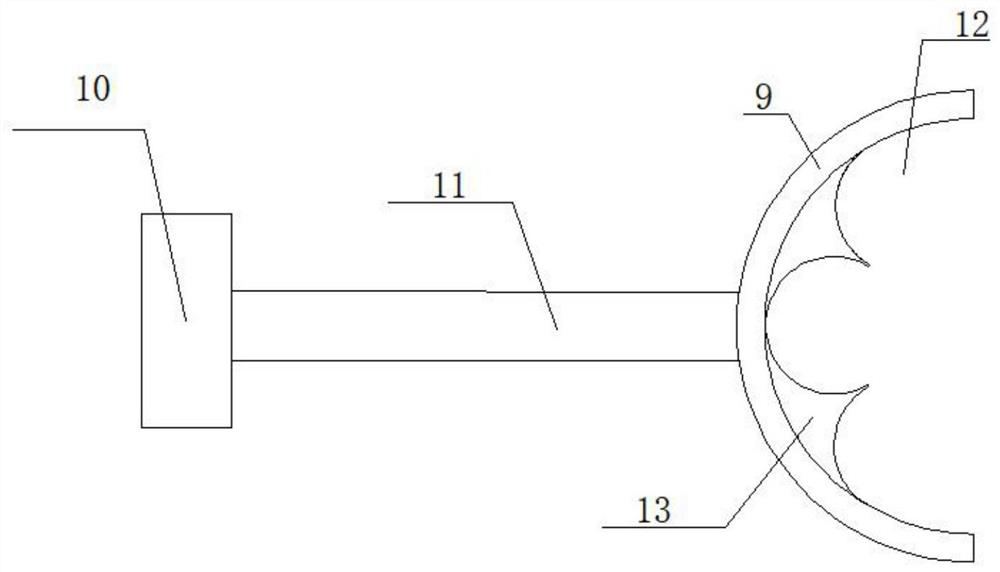

Camshaft machining process and forging die

ActiveCN106363124AIncrease resistanceMake sure fullForging/hammering/pressing machinesEngine componentsCamMachining process

The invention provides a camshaft machining process. The camshaft machining process includes the following steps: A, mold making, wherein a mold having a mold cavity and a flash groove is made, the shape of the mold cavity is same as the exterior shape of a camshaft forging, and the flash groove only has a flash bridge portion; B, the choice of materials, wherein the specification of a selected billet material is determined according to the following two points: 1) the cross-sectional area of the billet material is greater than that of a central shaft portion of a camshaft and less than that of a cam portion of the camshaft; 2) sufficient clearance should be formed between the outer circumference surface of the billet material and the widest portion of the mold cavity, so as to ensure that the billet material has a larger axial flow in a length direction when forged. The invention further provides a forging die for camshaft machining. The forging die comprises an upper die, a lower die and a die cavity, flash groove is formed in the periphery of the die cavity and only has a flash bridge portion; by adopting the technical proposal, the production efficiency and the material utilization rate can be improved, and the product quality can be ensured.

Owner:湖南高致精工机械有限公司

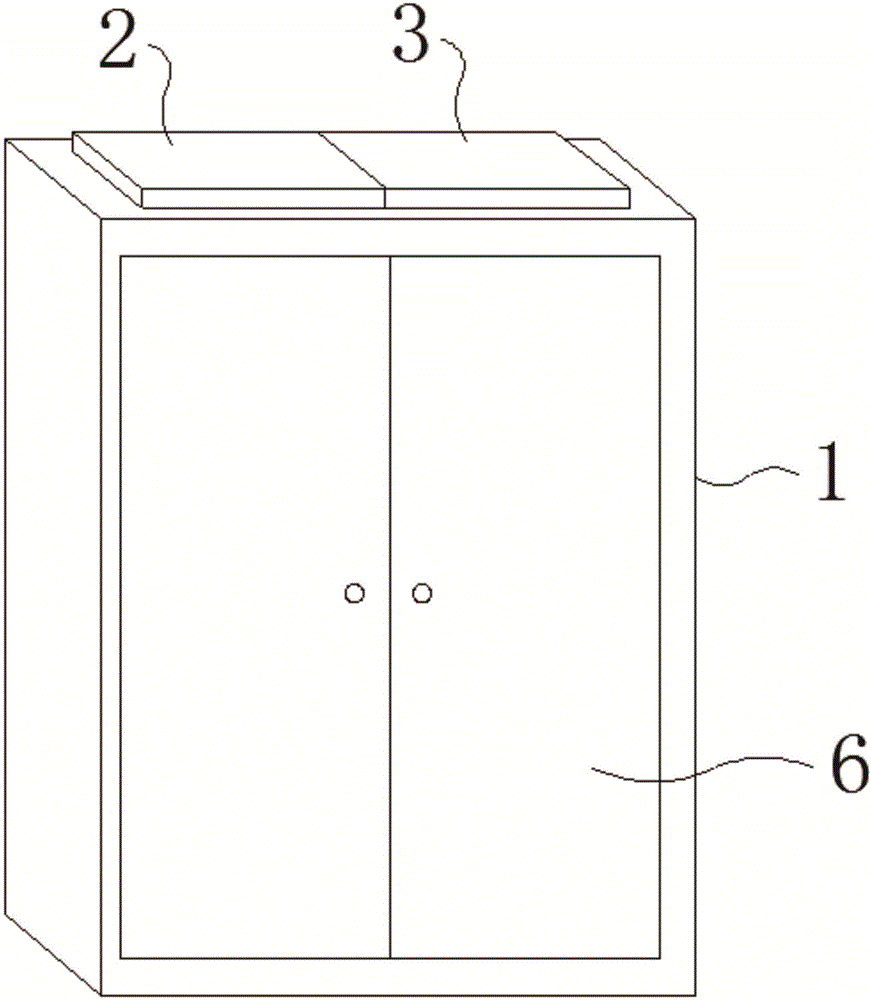

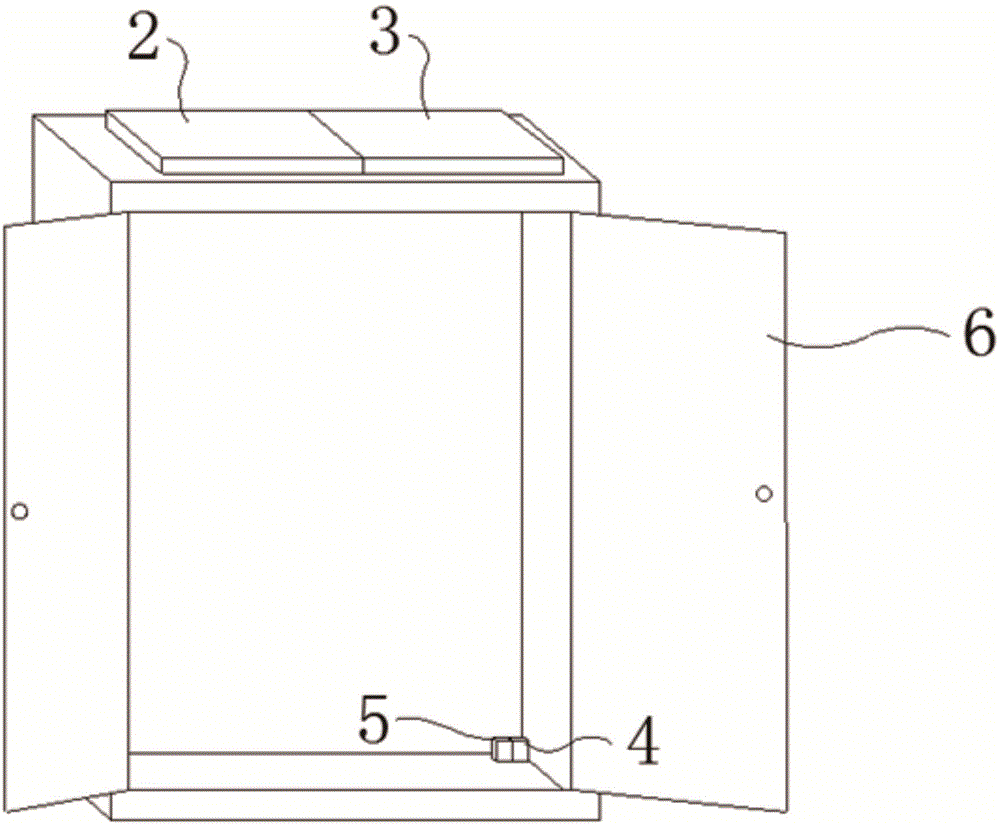

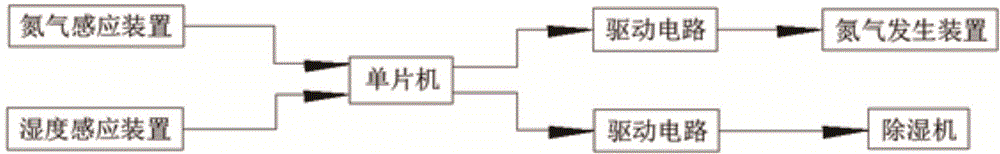

Intelligent storage cabinet

InactiveCN105620922AMake sure fullSensing nitrogen contentShock-sensitive articlesMicrocontrollerMicrocomputer

The invention relates to an intelligent storage cabinet. The intelligent storage cabinet comprises a cabinet body, a nitrogen generation device, a single-chip microcomputer, driving circuits, nitrogen induction devices, humidity induction devices and a dehumidifier. The cabinet body is provided with a sealing door which can seal the storage cabinet. The nitrogen generation device and the dehumidifier are both arranged at the upper end of the cabinet body. The nitrogen induction devices and the humidity induction devices are all arranged in the cabinet body. The single-chip microcomputer is connected with the driving circuits. The number of the driving circuits is two, and the two driving circuits are connected with the nitrogen generation device and the dehumidifier through circuits correspondingly. Compared with a storage cabinet in the prior art, the intelligent storage cabinet has the advantages that the sealing performance is good, the intelligent storage cabinet can be filled with nitrogen automatically for protection, and a dehumidification effect can be achieved.

Owner:李自甲

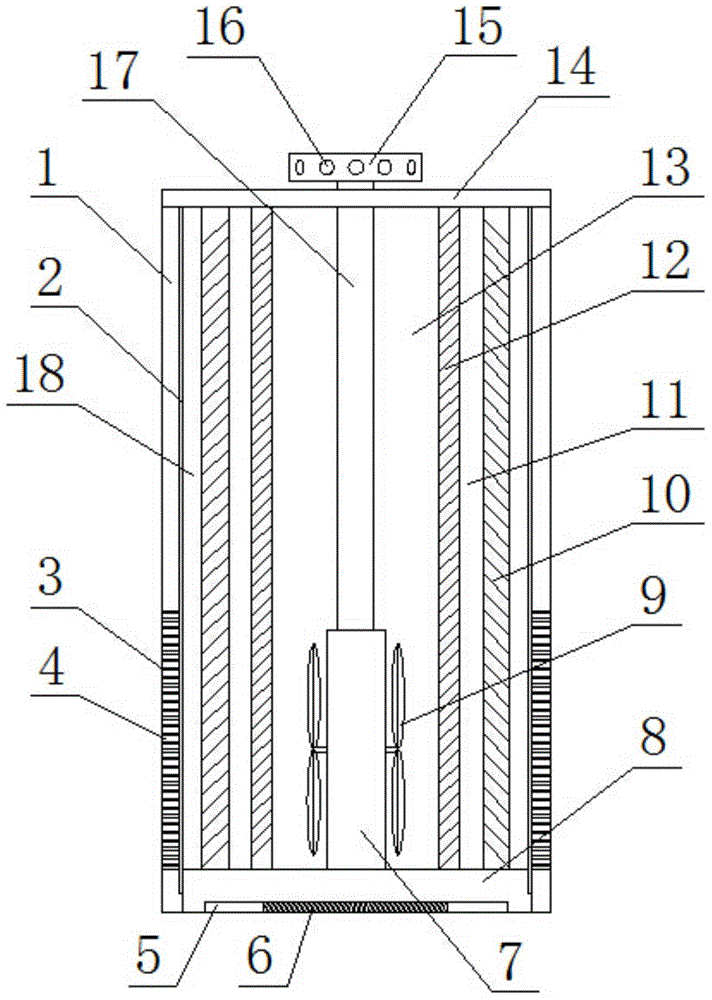

Air micro-nano particles-filtering and purifying device

ActiveCN104801140AImprove air qualityExpand the filter rangeCombination devicesMicro nanoManufacturing cost reduction

The invention discloses an air micro-nano particles-filtering and purifying device. The device comprises an upper cover, a housing body, a filtration device arranged in the housing body, an air blower, a rotating air-outlet device and a base, wherein the housing body adopts a cylindrical form; the upper cover is arranged at the upper part of the housing body; an air inlet zone is arranged at the lower part of the housing body; the filtration device is arranged inside the housing body; a purification chamber is arranged inside the filtration device; the base is arranged at the bottom of the purification chamber; the air blower is arranged on the inner side of the purification chamber; a groove is formed in the lower surface of the base; a foldable handle is arranged inside the groove; the foldable handle is fixedly connected with the rotating air-outlet device arranged above the upper cover through a rotating shaft on the air blower. The device is simple and compact in structure and easy to operate and can effectively remove the pollutants in air; the device is low in power consumption and saves electric energy; with high purification efficiency, the device can realize air purification without using various catalysts, so as to significantly reduce production cost; the device is wide in application range.

Owner:ZHONGSHAN JINCHENG PLASTIC PROD CO LTD

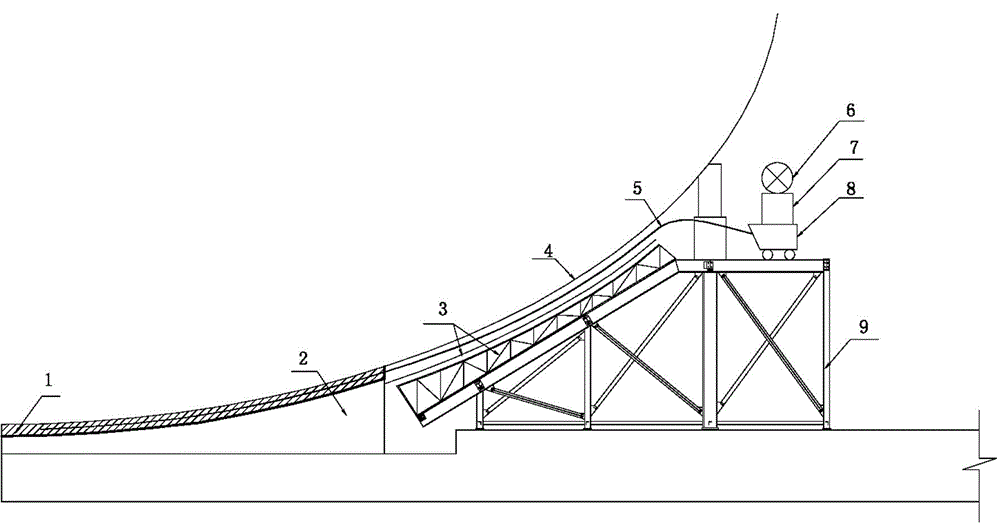

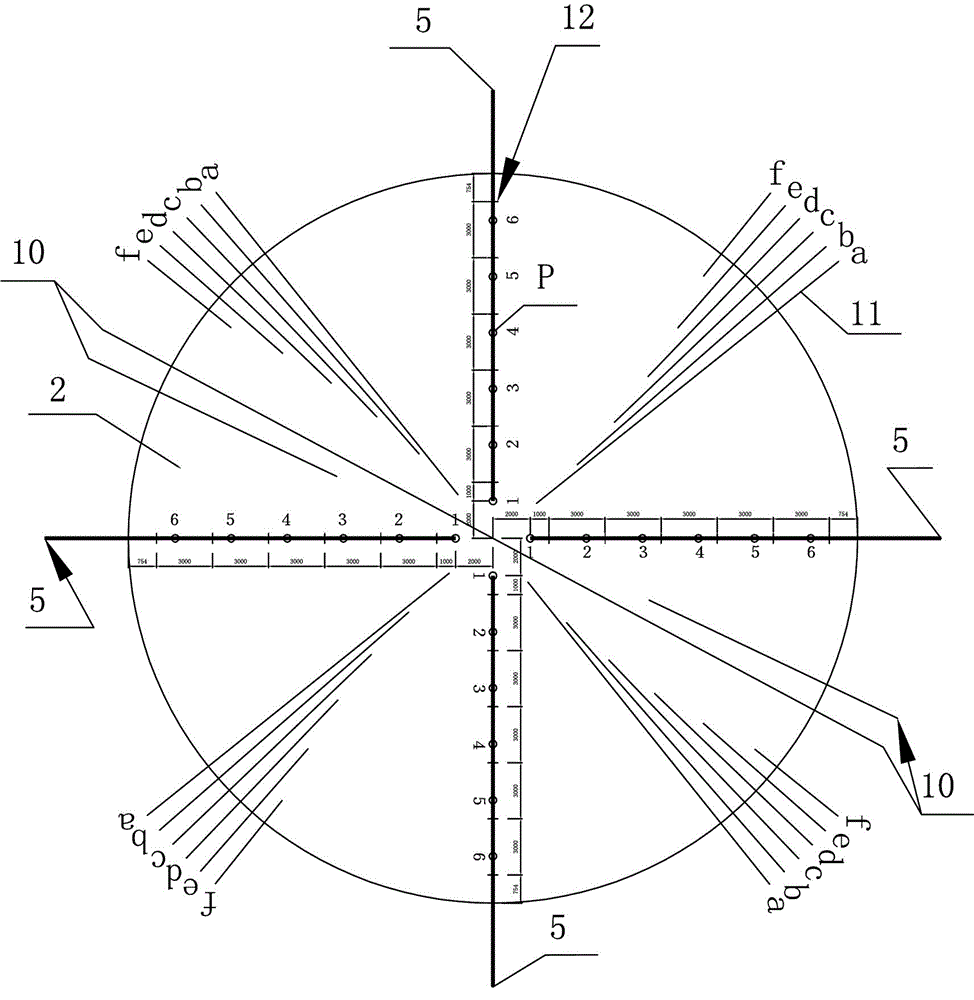

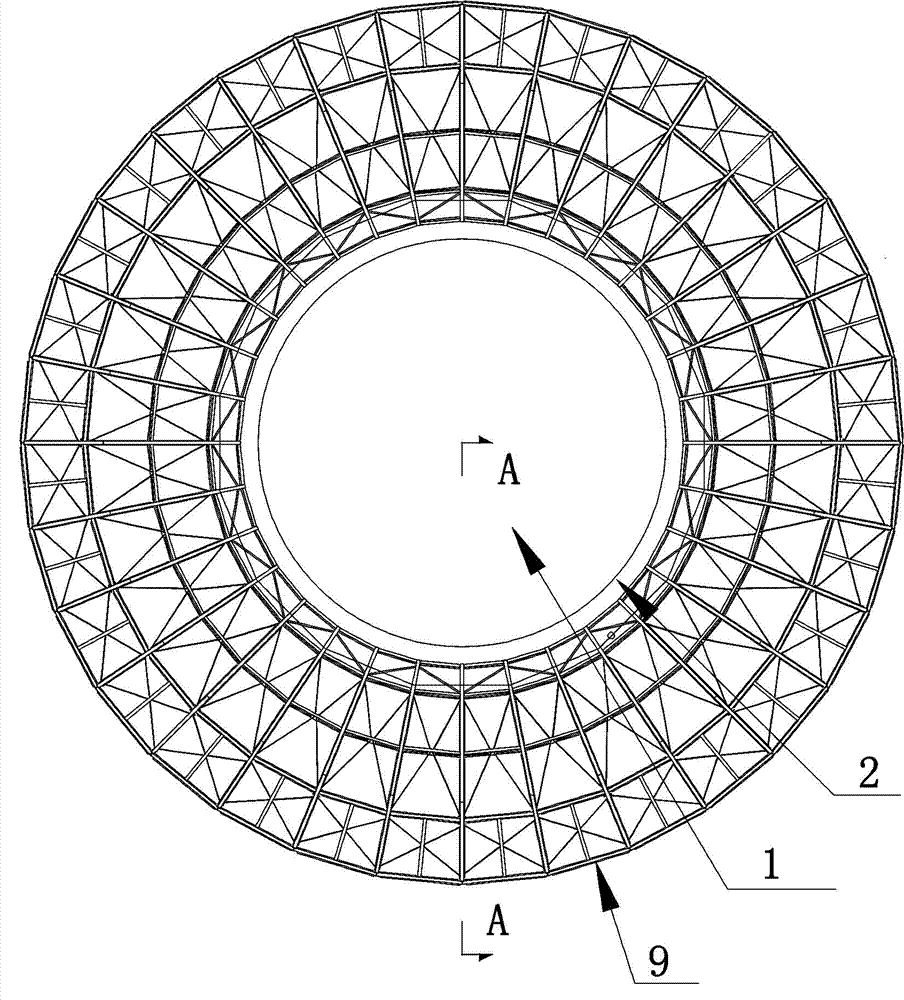

Mine dust removing apparatus and mine dust removing method

ActiveCN105233597APrevent cross flowAvoid secondary pollutionUsing liquid separation agentGas pipelineWater pipe

The present invention discloses a mine dust removing apparatus and a mine dust removing method. The mine dust removing apparatus comprises a mineral conveying unit and a water vapor atomizing unit, wherein the mineral conveying unit comprises a high position conveyor, a first sealing soft curtain, a breaking inlet rolling channel, a breaking device, a mineral outlet, a connection rolling channel, a second sealing soft curtain and a low position conveyor, the high position conveyor, the first sealing soft curtain, the breaking inlet rolling channel, the breaking device, the mineral outlet, the connection rolling channel, the second sealing soft curtain and the low position conveyor are sequentially connected, the water vapor atomizing unit comprises a pressure gas source, a pressure water source, a spraying controller and four gas-water atomizing nozzles, one end of the spraying controller is connected to the pressure gas source and the pressure water source, the other end is connected to the four gas-water atomizing nozzles through a pressure gas pipeline and a pressure water pipeline, the two gas-water atomizing nozzles are arranged on the upper end of the breaking inlet rolling channel, the spraying direction is along the mineral conveying direction, the other two gas-water atomizing nozzles are arranged on the lower end of the connection rolling channel, and the spraying direction is opposite to the mineral conveying direction. With the apparatus and the method of the present invention, the problems of not strong practicality and easy secondary pollution formation of the existing dust removing apparatus and the existing dust removing method can be effectively solved, and advantages of simpleness, reliability, environmental pollution avoiding and the like are provided.

Owner:HUAZHONG UNIV OF SCI & TECH

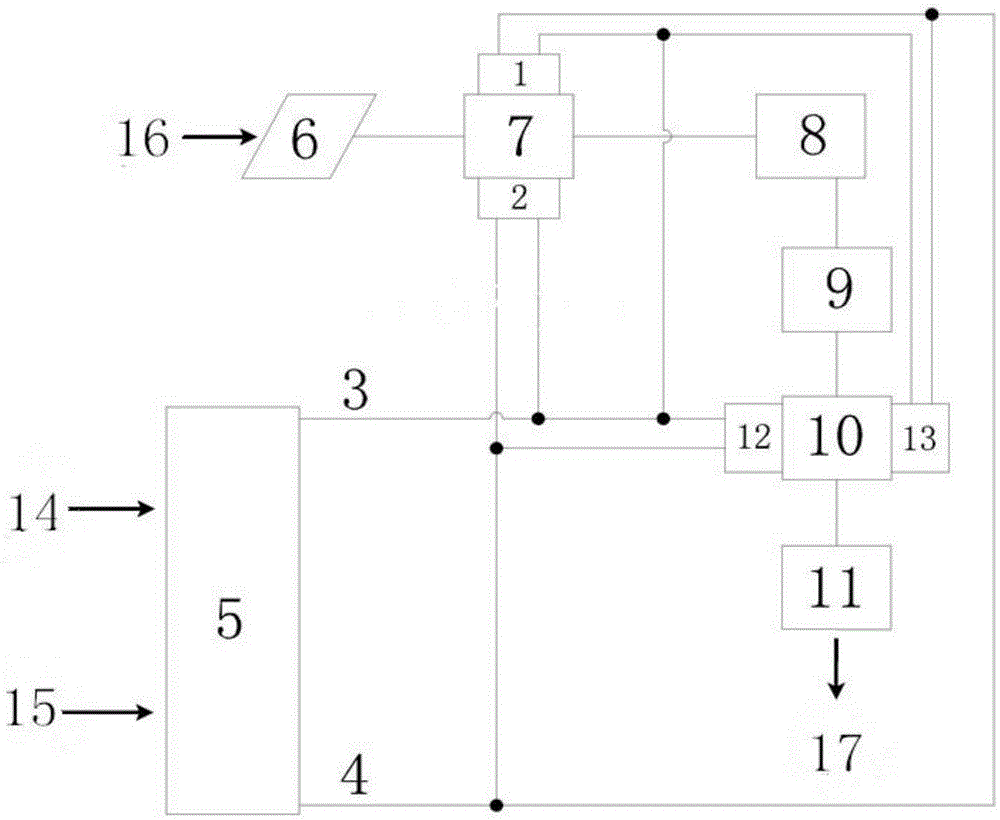

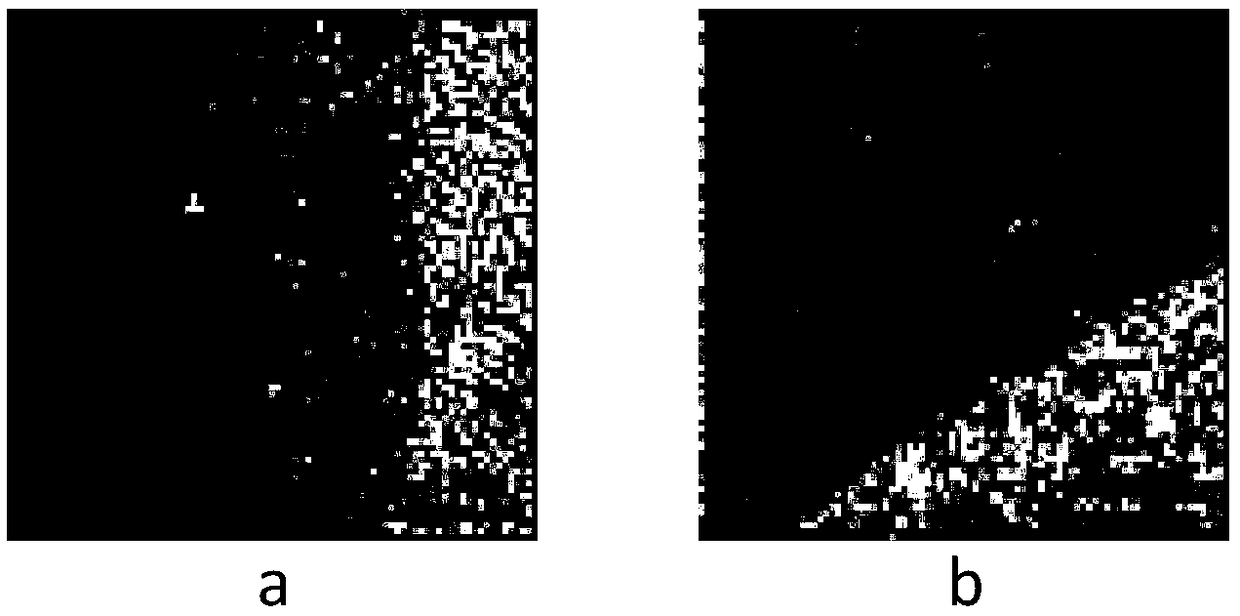

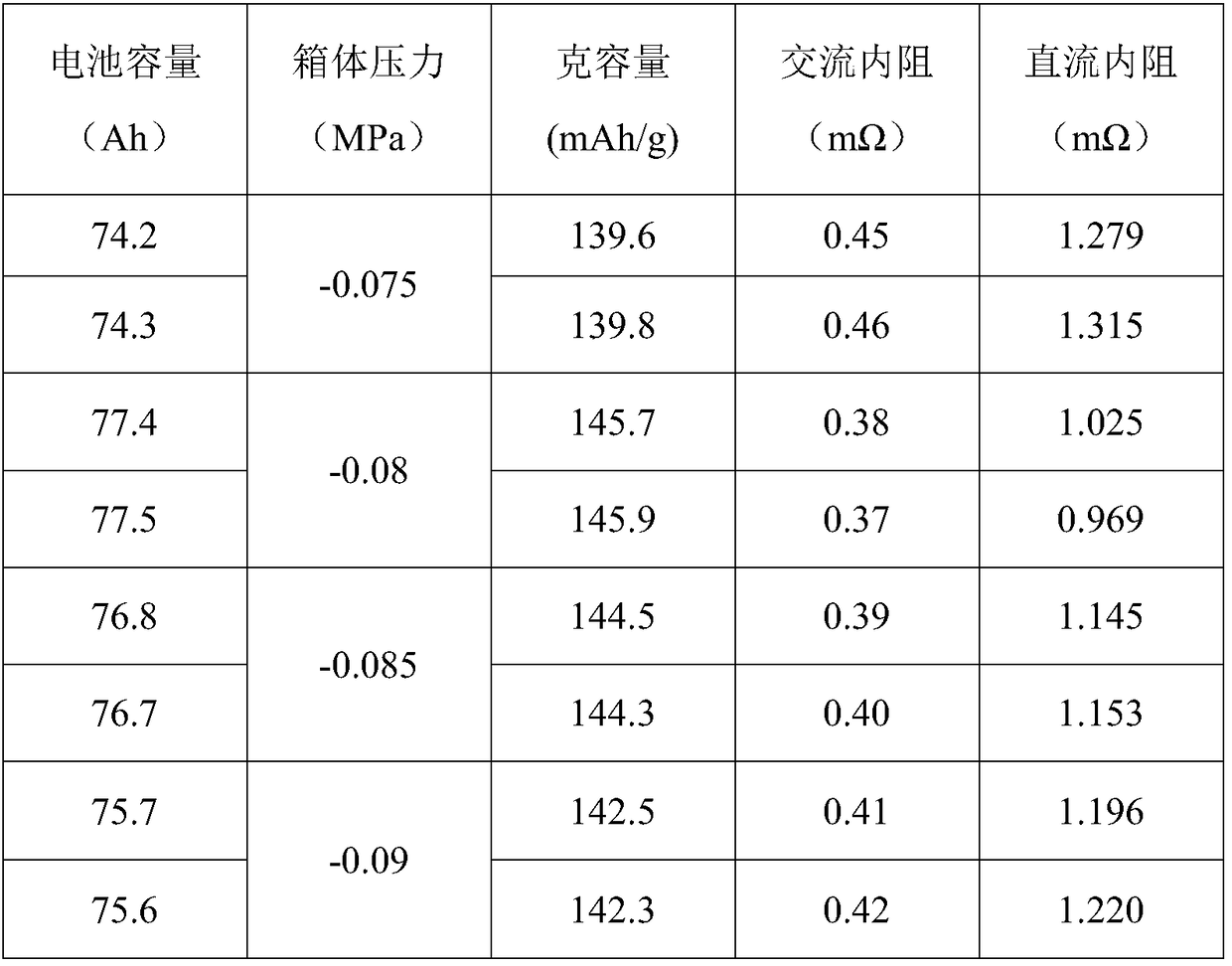

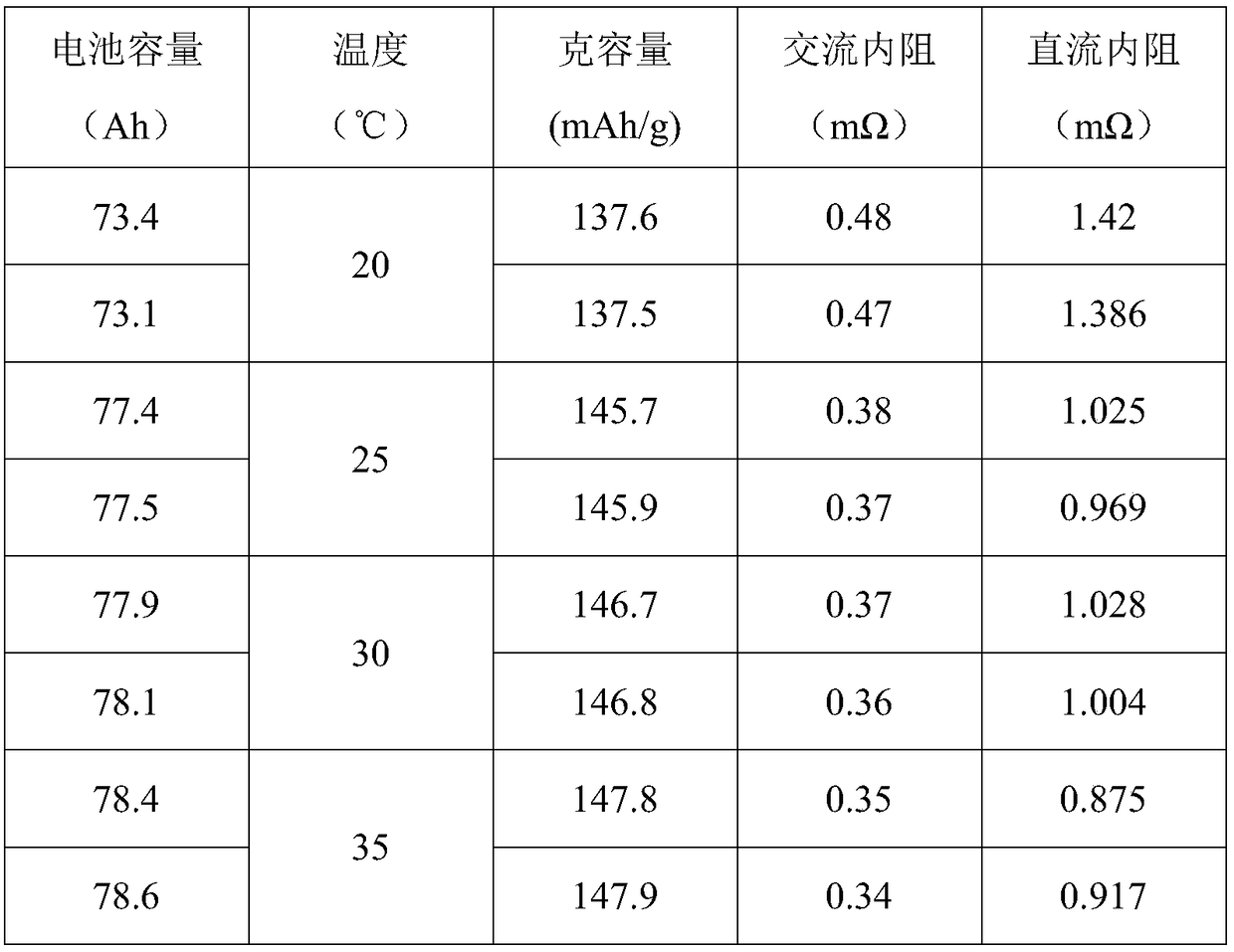

Isobaric formation method for lithium ion battery

InactiveCN108923072AReduce sucking volumeReduce DC internal resistanceFinal product manufactureSecondary cells charging/dischargingInternal resistanceLiquid storage tank

The invention relates to the field of lithium ion battery manufacturing, in particular to an isobaric formation method for a lithium ion battery. The method comprises the following steps that (1) thebattery to be formed is placed into a formation box, inert gas is introduced for 15 minutes, a sealing plug is pulled out, a liquid storage tank is additionally arranged above a liquid injection portof the battery and is open; (2) an inert gas inlet valve is closed, vacuumizing is carried out to reach -0.075 MPa to -0.09 MPa, a vacuum valve is closed, and heating is carried out to increase the temperature in the box to 20-35 DEG C; (3) the formation step is set and started; and (4) after formation is finished, the inert gas is introduced, and the liquid injection port of the battery is plugged with the sealing plug. According to the method, an isobaric formation technology is adopted, so that the sucking-back amount of electrolyte in the formation process can be decreased, in addition, gas generated in a battery cell in the formation process can be removed in time, the periphery of the battery cell is fully filled with the electrolyte, polarization caused by the concentration difference of lithium ions is reduced, so that a thin and dense SEI film is formed on the surface of a negative electrode, the direct current internal resistance and the alternating current internal resistance of the battery are reduced, the discharge capacity is improved, and therefore the capacity per gramme of the battery is improved.

Owner:HEFEI HENGNENG NEW ENERGY TECH

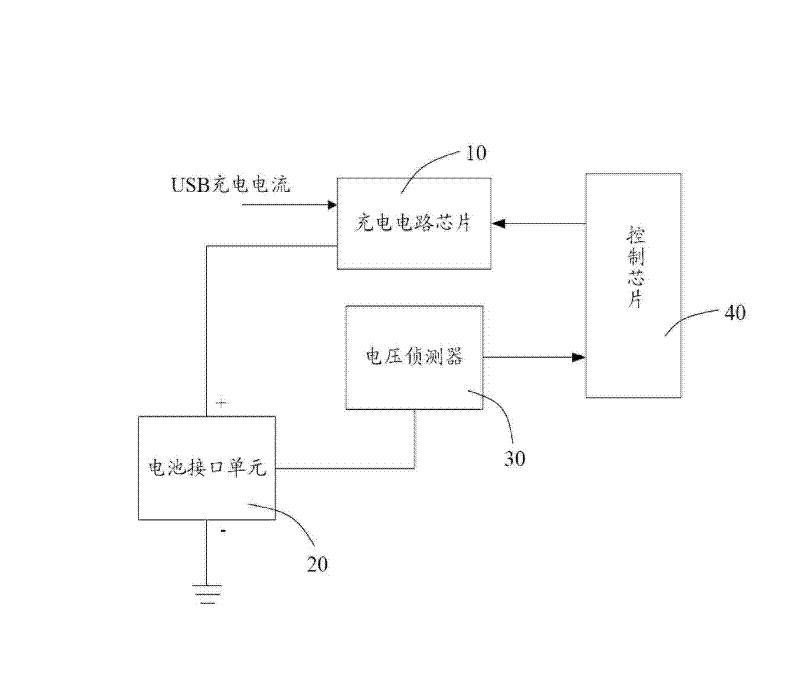

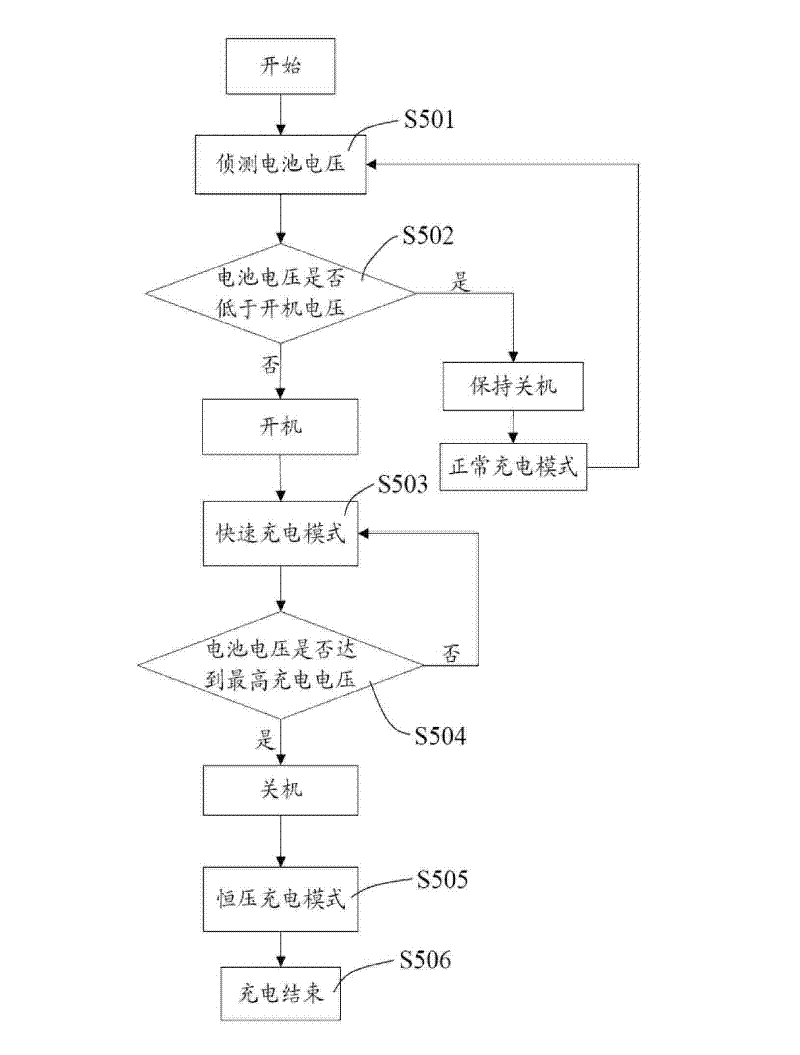

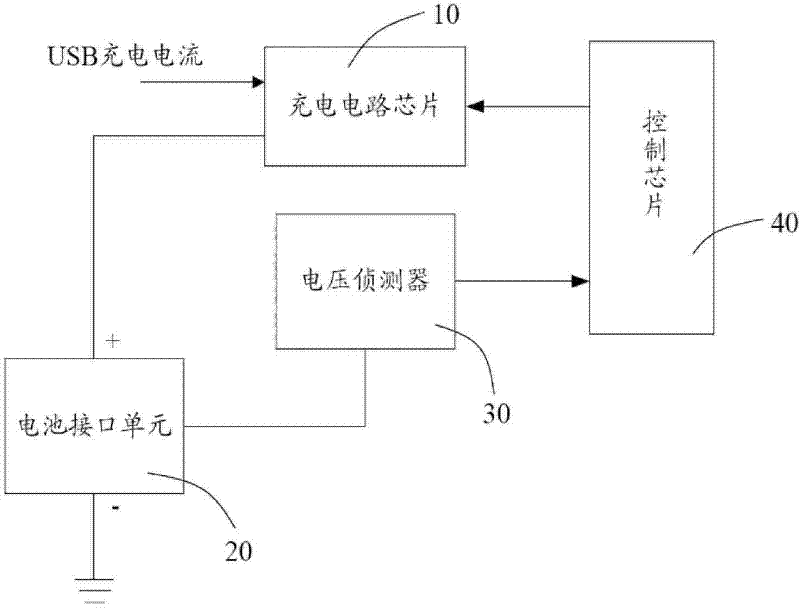

Device and method for charging USB

InactiveCN101546918BMake sure the battery is fully chargedMake sure fullBatteries circuit arrangementsSecondary cells charging/dischargingElectricityElectrical battery

The invention relates to a USB charging device arranged in an electric device for charging rechargeable batteries of the electric device. The USB charging device comprises a charging circuit chip, a battery interface unit which is connected with the charging circuit chip, a voltage detector and a control chip. The charging circuit chip is internally provided with charging circuits of different charging modes for selecting charging circuits according to charging commands so as to switch the charging modes. A positive pole end of the battery interface unit is connected with the charging circuit chip, and a negative pole end is grounded. A positive pole and a negative pole of the charging battery are respectively arranged in the battery interface unit corresponding to the positive pole end and the negative pole end of the battery interface unit. The voltage detector is used for detecting the battery voltage in the battery interface unit and feeding back the battery voltage information to the control chip. The control chip is used for sending a corresponding charging command according to the battery voltage information of the voltage detector so s to switch charging modes and simultaneously sending out power-on and power-off commands to the electric device by matching with corresponding charging modes.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

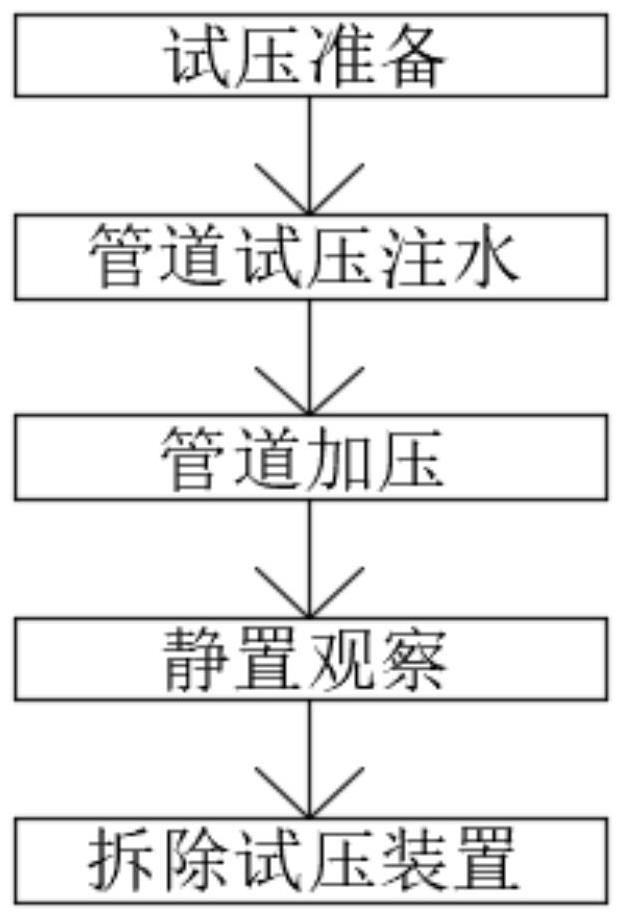

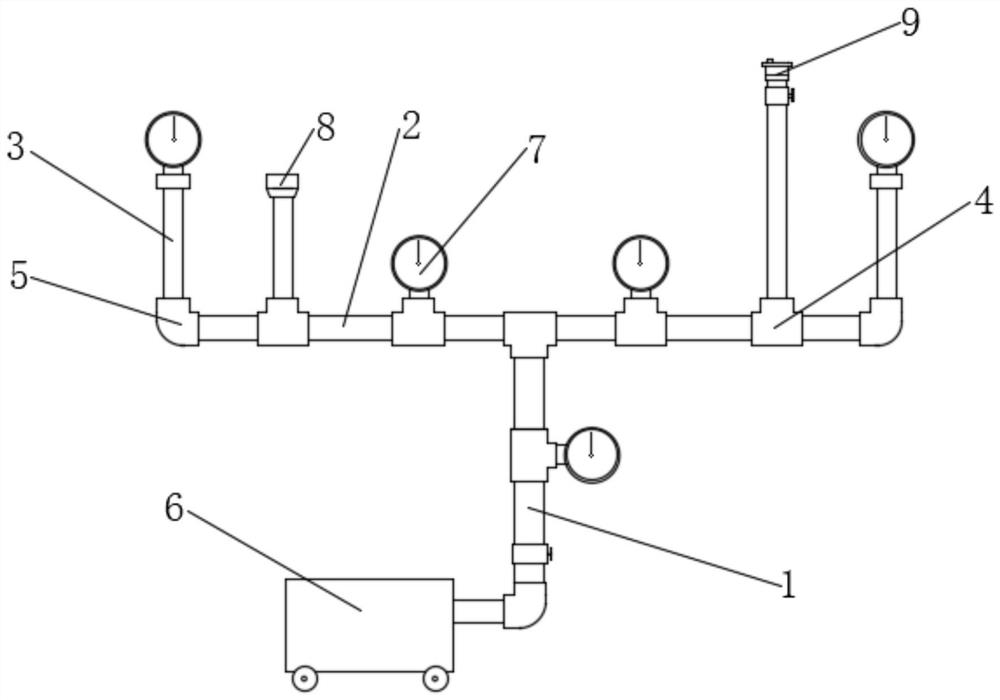

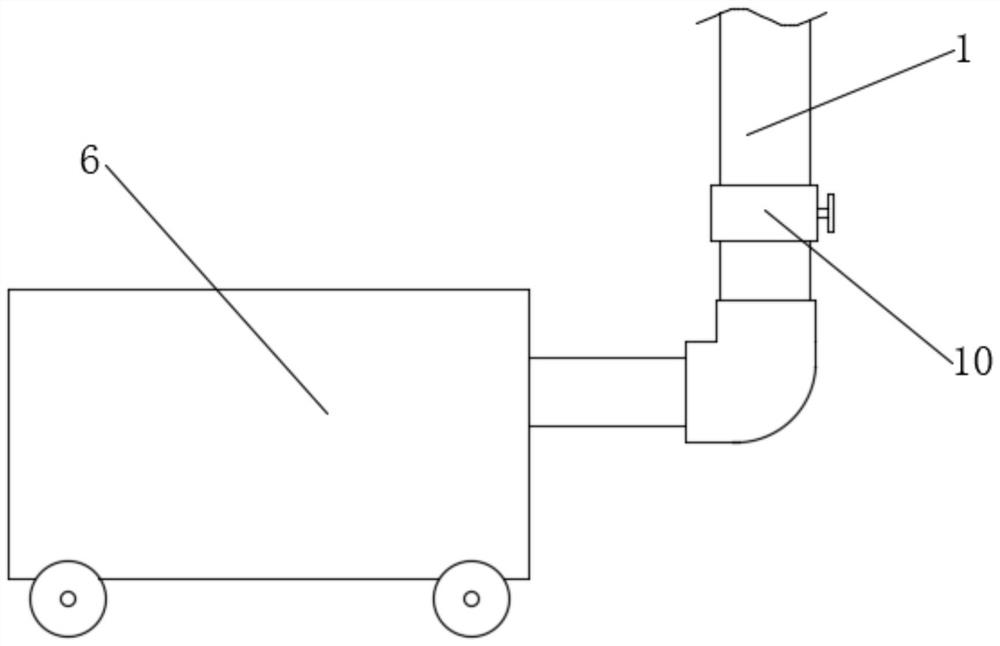

Water supply pipeline pressure test process

PendingCN114354099AEasy to plug inMake sure fullMeasurement of fluid loss/gain rateWater conservationExhaust valveWater flow

The invention discloses a water supply pipeline pressure test process. The process comprises the steps of pressure test preparation, pipeline pressure test water injection, pipeline pressurization, standing observation and pressure test device dismounting. The pipeline assembly has the beneficial effects that the pressure gauges are installed on the main water pipe, the branch water pipes and the branch water pipes correspondingly so that the pressure values of all the pipelines of the whole pipeline assembly can be monitored, the accuracy of the monitored pressure values can be ensured, connecting pieces used for being connected with the pressure gauges do not need to be additionally installed on the pipelines, and rapid construction and installation are facilitated; the exhaust valve is installed at the water outlet end of the branch water pipe with the highest horizontal height, the stop valve is installed at the position of a pipe opening connected with the exhaust valve, air in the pipeline assembly can be exhausted in the water injection process, meanwhile, when water flows out of the exhaust valve, it is indicated that the pipeline assembly is filled with water, and then the branch water pipe can be plugged through the stop valve. And water injection cleaning is carried out on the pipeline assembly after pressure testing, and it is ensured that residual objects in the pipeline are cleaned up so that the pipeline can be delivered to a user for use.

Owner:中铁建设集团机电安装有限公司 +1

Gas pipeline integrated with cooling channel

ActiveCN112253334AMeet the requirements of one-time moldingSimple processRocket engine plantsButt weldingQuality control

In order to solve the technical problems that an existing gas pipeline with a cooling structure is long in machining period, complex in procedure, high in cost, difficult in quality consistency control and low in integration level, the invention provides a gas pipeline integrated with a cooling channel. The cooling channel is integrated in the side wall of a gas channel, so that the process is simplified, and the integration level of the product is improved. The structure design oriented to a 3D printing process is adopted, a cooling working medium inlet pipe connector, a cooling working medium inlet liquid collecting cavity, a cooling channel and the like and the gas pipeline are integrally designed without supports, the structure can meet the requirement for integral one-time forming ofthe 3D printing technology, and multiple machine frame, brazing, butt welding and other working procedures in traditional process links are not needed. Product machining and turnover periods are greatly shortened, product consistency, connection strength and rigidity are good, quality control is more effective, and development cost is greatly reduced.

Owner:XIAN AEROSPACE PROPULSION INST

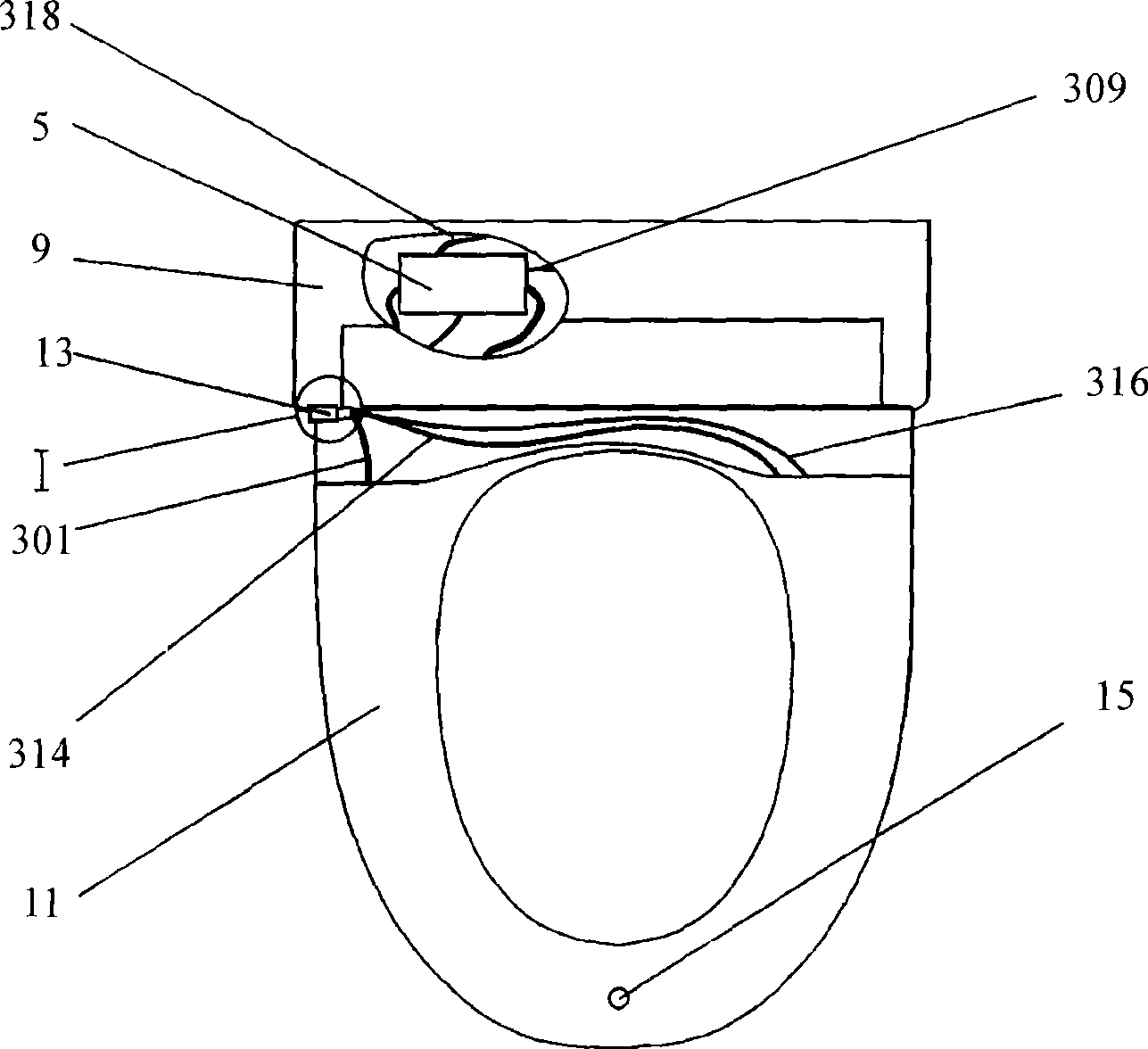

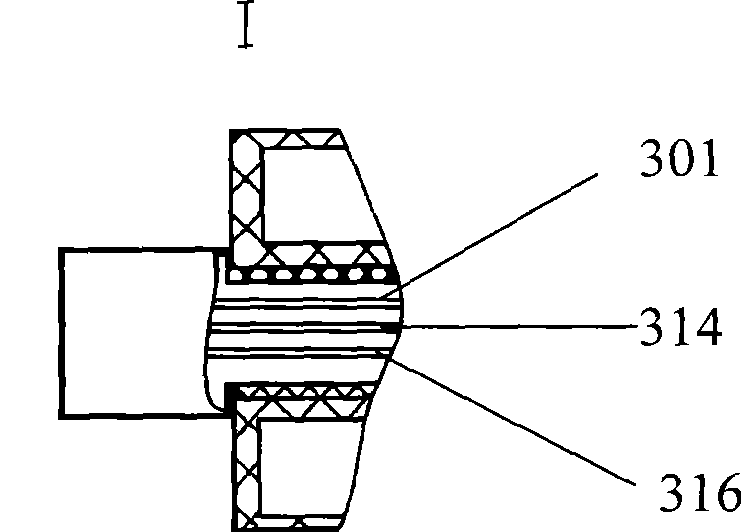

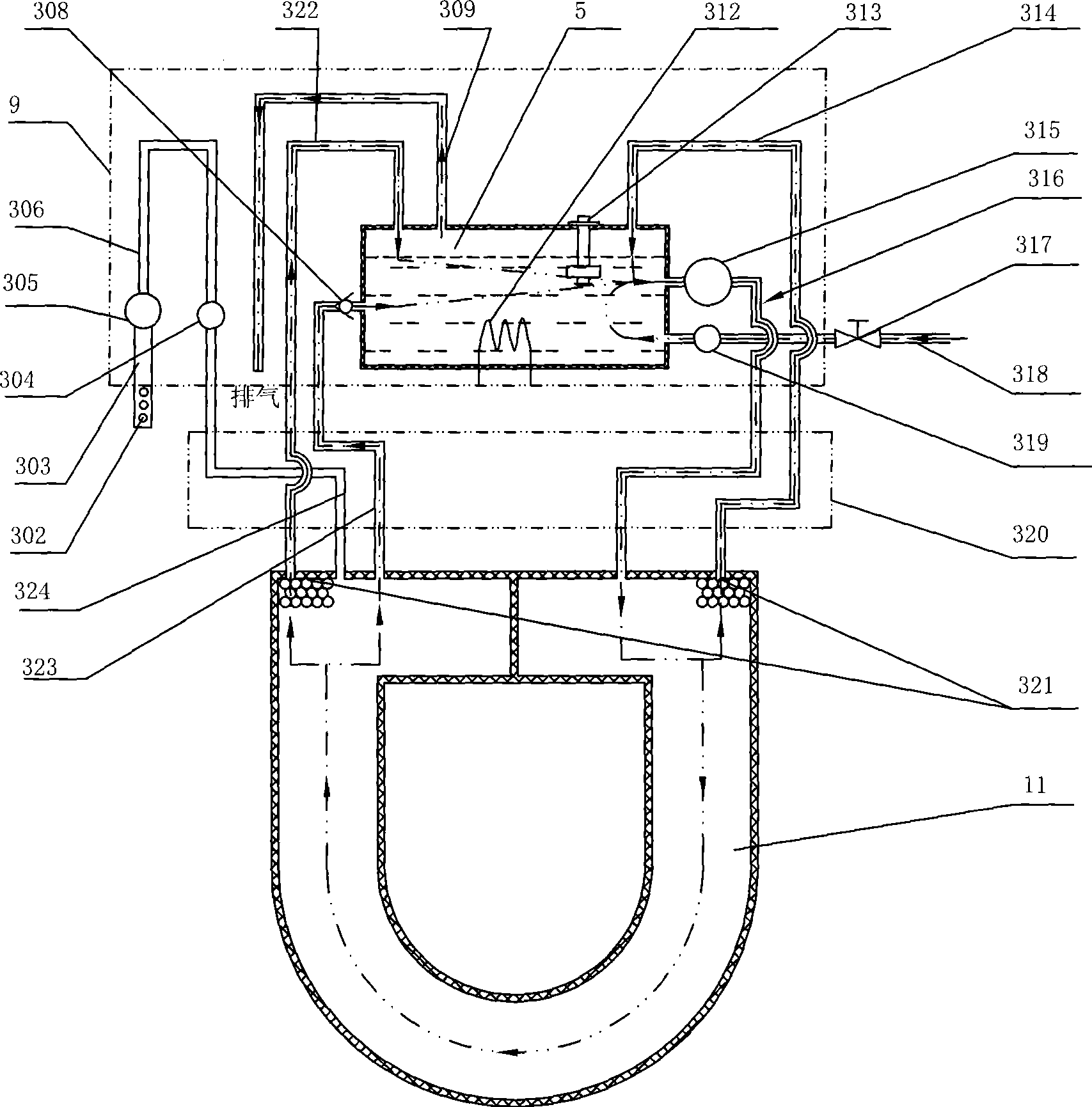

Rinsing type sanitary equipment

ActiveCN101403239BQuick exclusionEffective volumeBathroom coversLavatory sanitoryWarm waterWater spray

The invention discloses a wash-off sanitary appliance which comprises: a sanitary appliance core provided with a controlling device, a minute extension heating water tank positioned in the sanitary appliance core, an extended water tank positioned outside the sanitary appliance core, a first vent-pipe of the extended water tank with one end being communicated with the extended water tank and positioned in a water inlet region in the extend water tank while the other end being communicated with the heating water tank, a flow pipe, a return pipe and a vent pipe of the extended water tank which are communicated with the extended water tank, a water spray system and a heating water tank. As the vent pipes is arranged at the water inlet and the water outlet of the extended water tank respectively, the bubbles gathered in the extended water tank can be excluded, thus ensuring that the seat ring of extended water tank is filled with warm water so as to keep the warmth of the surface of the seat ring; further more, the volume of the extended water tank can be fully utilized.

Owner:HANYU GRP CO LTD

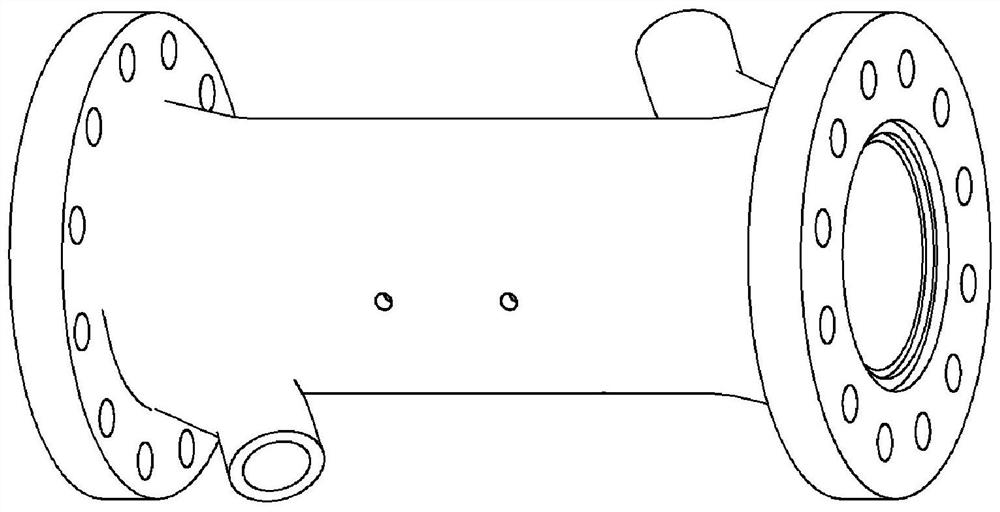

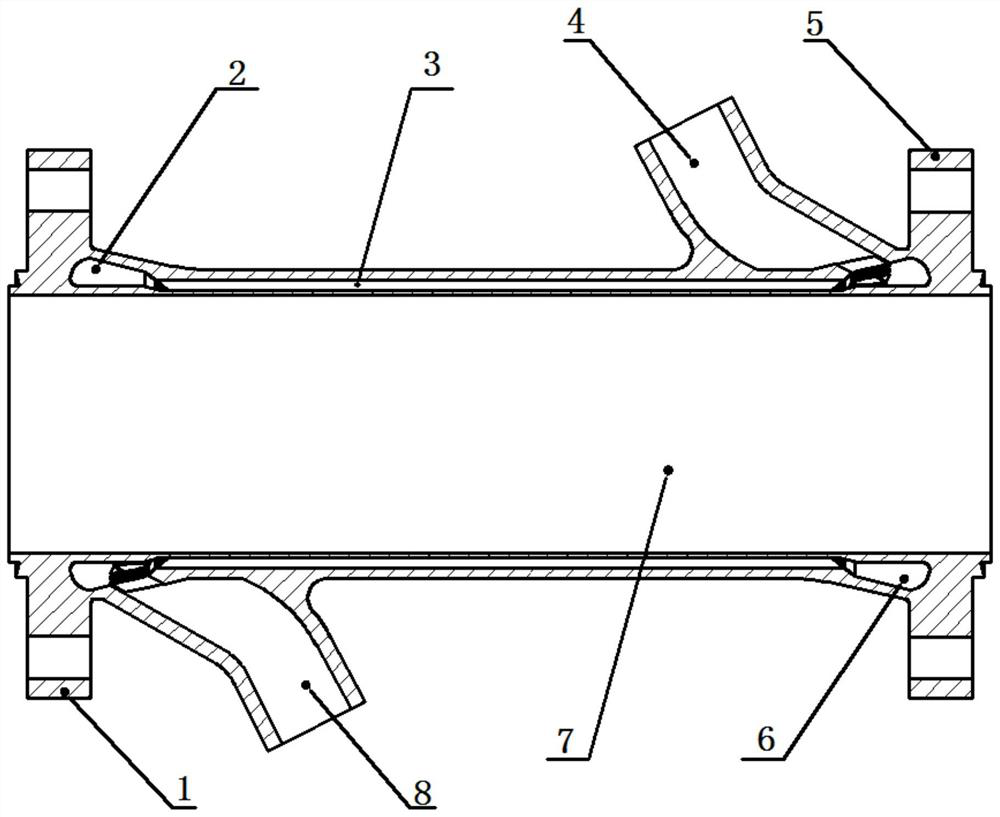

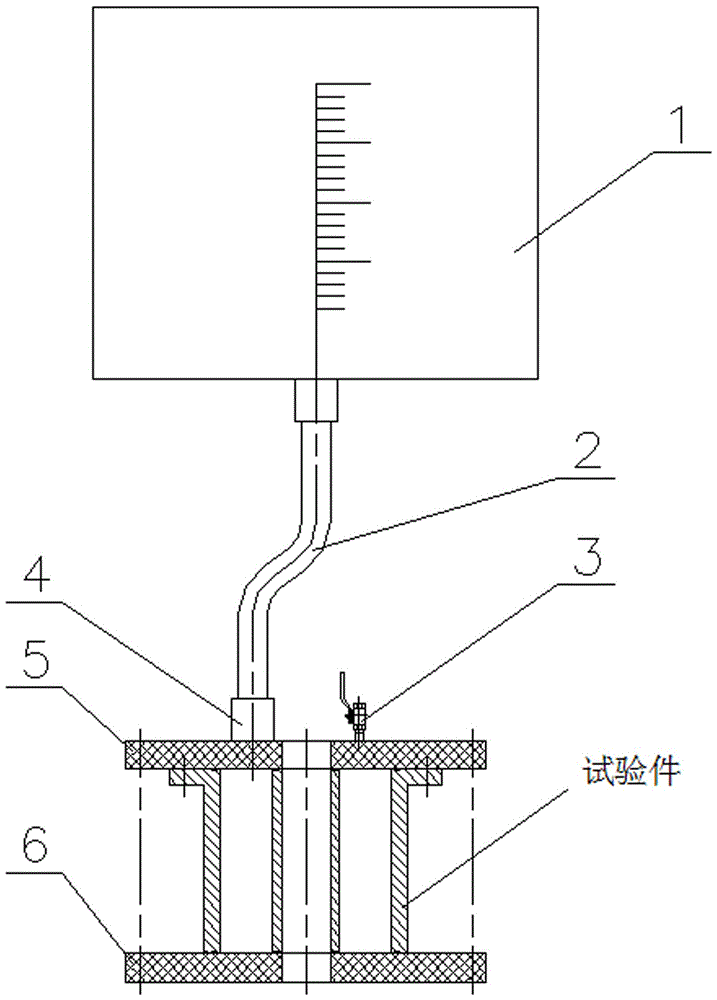

Space curved surface section area measurement device

The invention relates to a measurement device and particularly relates to a space curved surface section area measurement device. The device comprises a metering water tank, a connecting pipe, an exhausting valve, a quick-release coupling, an upper pressing plate and a lower pressing plate, wherein a test piece is clamped through the upper pressing plate and the lower pressing plate; the exhausting valve is mounted on the upper pressing plate; the metering water tank is connected with the connecting pipe; the connecting pipe and the upper pressing plate are connected through the quick-release coupling; scale lines are formed in the metering water tank; the metering water tank is used for metering the volume of water entering a test piece chamber, so that the section area of the test piece is calculated; the metering water tank is connected with the upper pressing plate through adopting the quick-release coupling so that water loss is not caused; and the exhausting valve is connected with the upper pressing plate and exhausting is carried out so that the test piece chamber is filled with the water. The space curved surface section area measurement device provided by the invention is reasonable in design, compact in structure, simple in operation and small in occupied space.

Owner:HARBIN GUANGHAN POWER TRANSMISSION

Liquid division slip casting reinforcing method for subsurface structure construction joints

InactiveCN102002950BPrevent leakageImprove compactnessArtificial islandsUnderwater structuresLeaking waterUltimate tensile strength

The invention discloses a liquid division slip casting reinforcing method for subsurface structure construction joints, mainly aiming at the problems that as the subsurface structure construction is severely influenced by ground water, the peripheral structure leaks water, the material strength is reduced, the structure integrity is poor and the like. A purpose-made grouting pipe is arranged at the construction joint of a structure connector with weak stress in the process of subsurface structure peripheral construction, and the liquid division slip casting reinforcing operation is performed based on a designated method, thus making up for the defects of poor rigidity and poor waterproof effect at the construction joint of the subsurface structure preferably. The method in the invention has good grouting effect and high grouting success rate, can effectively improve the strength and the integrality of the subsurface structure, and reduce the leakage of the construction joint of the subsurface structure.

Owner:SOUTHEAST UNIV +1

A kind of coating containing porous filler and its preparation method and use method

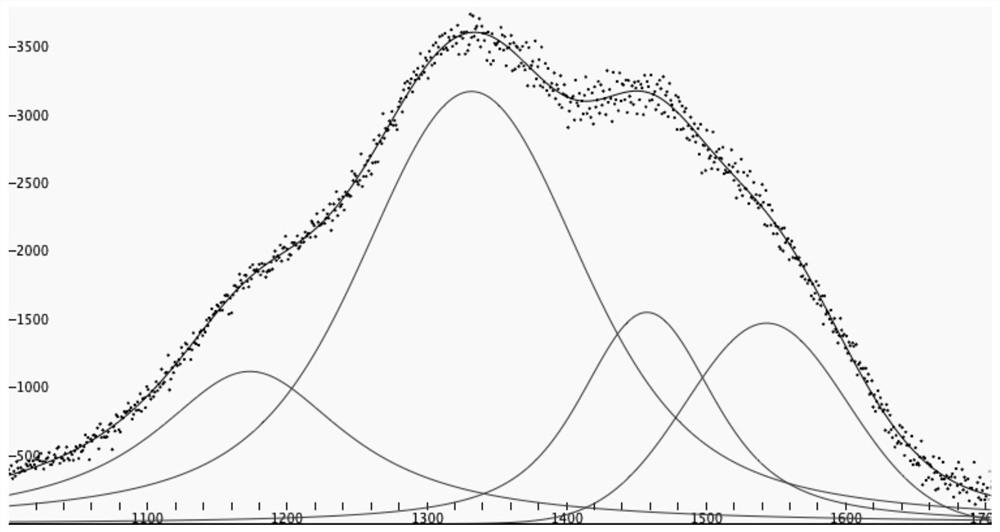

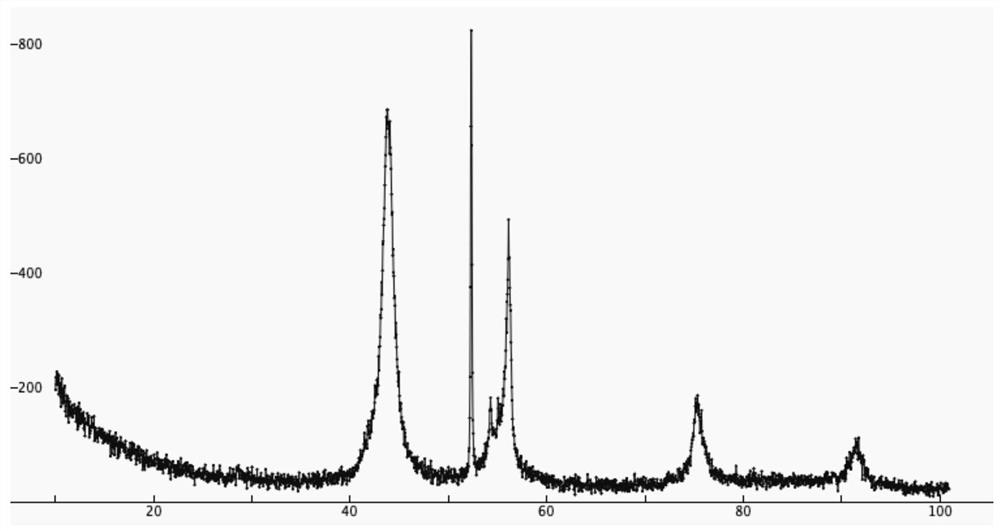

ActiveCN111944353BLow densityHigh porosityLiquid surface applicatorsEmulsion paintsCarbon nitrideGraphite

The invention discloses a coating containing porous fillers, a preparation method and a using method thereof, and belongs to the technical field of coatings. After fully absorbing water, the porous silica gel particles supporting the graphite phase carbon nitride are added to the finished paint, and adjusted to an appropriate concentration to obtain a paint containing a porous filler. The method has mild preparation conditions, simple process, cheap raw materials and good repeatability, and solves the problems that the pore structure of the filler is easily blocked in the coating and the spray method causes the filler to be in weak contact with the coating. The prepared coating containing porous fillers has strong adsorption performance and degradation performance for haze. When in use, the coating surface is first coated with primer, and then coated with a coating containing porous fillers, which can effectively absorb VOCs in the air and inhibit the formation of haze from the source.

Owner:西安凡星生物科技有限责任公司

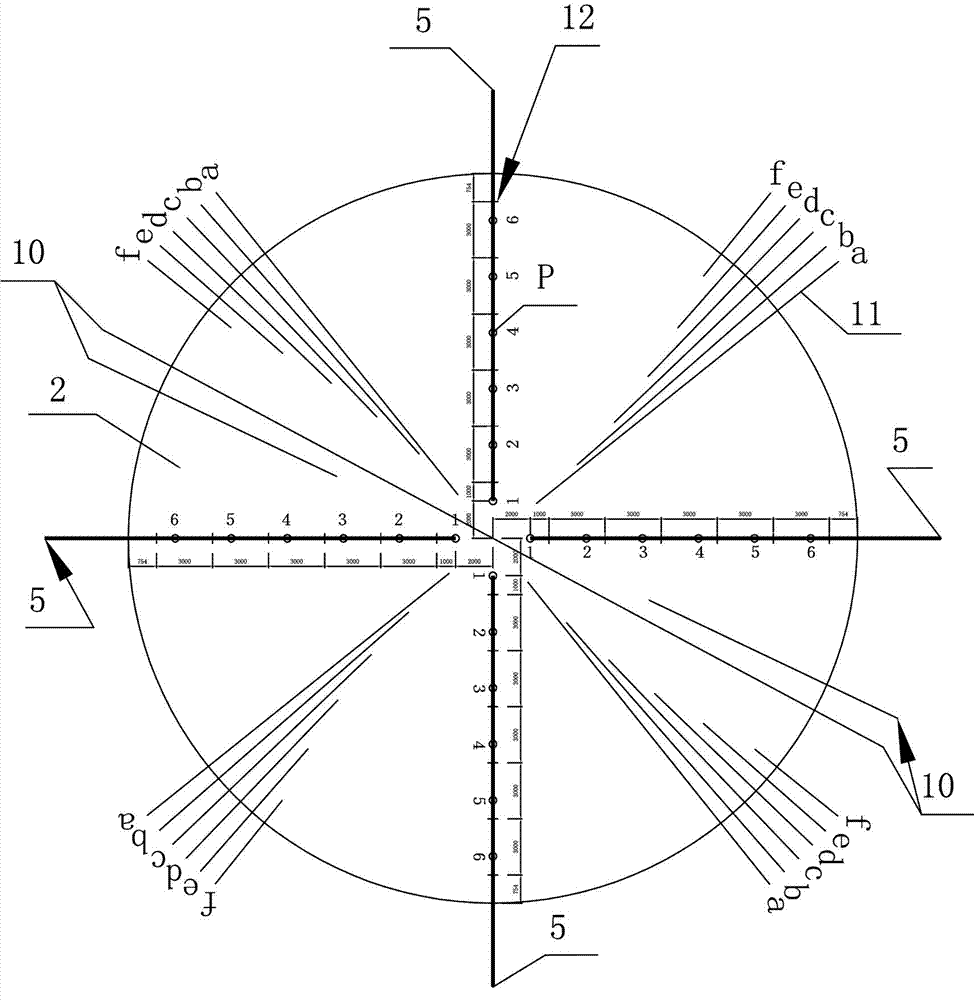

Construction method for performing pressure grouting in interlayer space between A layer concrete and CV bottom head of reactor building foundation of nuclear island

ActiveCN102900085BInhibition of segregationAvoid cloggingFoundation engineeringSlurryStructural engineering

A construction method for performing pressure grouting in an interlayer space mainly comprises the following steps of: treating the foundation course; distributing grouting pipes, a water absorption pipe and a liquid level monitor lead of a liquid level monitor: placing a grouting-region overhead space and taking a space between the overhead space and the foundation course as a grouting region; connecting each grouting pipe with a slurry making system; humidifying foundation course; lubricating the grouting pipes; grouting, and the like. The construction method for performing pressure grouting in the interlayer space is characterized in that the pipe lubrication operation is performed on the grouting pipes by means of a pipe lubricating material before the grouting, and a wet sliding layer is formed in the grouting pipes by means of a fine material in the pipe lubricating material, thereby reducing the flow resistance of grouting liquid in the grouting pipes, preventing the grouting material separation and the grouting pipe blockage and guaranteeing the smooth grouting operation; the pressure grouting is employed to ensure that the space of the whole grouting region is full of a grouting material; the liquid level monitor is matched with the grouting pipes and controls the grouting pipes to be located under the grouting liquid level all the time, so that the grouting pipes are controlled to accurately move to a specified grouting site; and therefore, the grouting quality is ensured and the grouting efficiency is improved.

Owner:CHINA NUCLEAR IND 22ND CONSTR

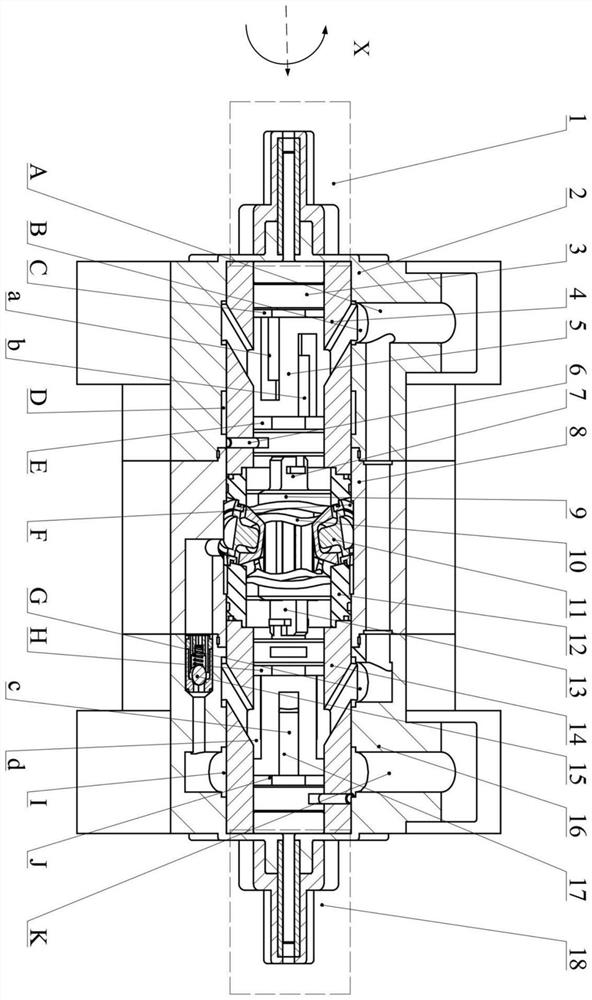

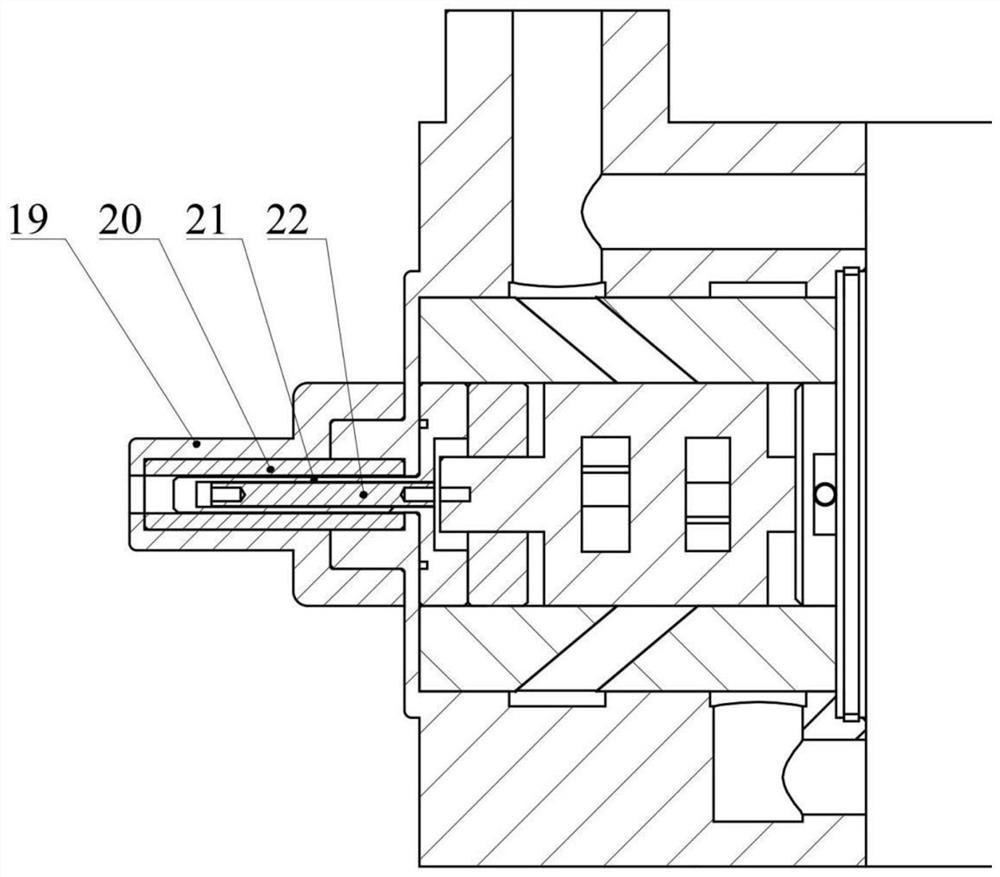

A stacked roll double-connected two-dimensional piston dynamic flowmeter

ActiveCN113324606BReal-time readingImprove linearityContracting/expanding measuring chambersVolume variation compensation/correction apparatusControl engineeringControl theory

The invention discloses a stacking and rolling double-connected two-dimensional piston type dynamic flowmeter. The left housing is provided with a liquid inlet, the right housing is provided with a liquid outlet, the left housing is provided with a left metering unit, and the right housing is provided with a liquid inlet. There is a right metering unit in the body, and the left housing is fed and drained through the left metering unit, and the right housing is fed and drained through the right metering unit; the left metering unit includes a left piston, and the right metering unit includes a right metering unit. The piston, the left piston and the right piston are connected through a stacked roller transmission that allows the left piston and the right piston to keep synchronous rotation and relatively independent axial movement; the left piston is connected to a left speed sensor for detecting the axial speed of the left piston Assemblies, the right piston is connected with the right speed sensor assembly for detecting the axial speed of the right piston; the central processing unit calculates the flow rate according to the left speed signal and the right speed signal; the present invention uses the speed sensor to measure the flow rate, and the output signal and the flow rate The signal is directly proportional, with high linearity and high response frequency.

Owner:ZHEJIANG UNIV OF TECH

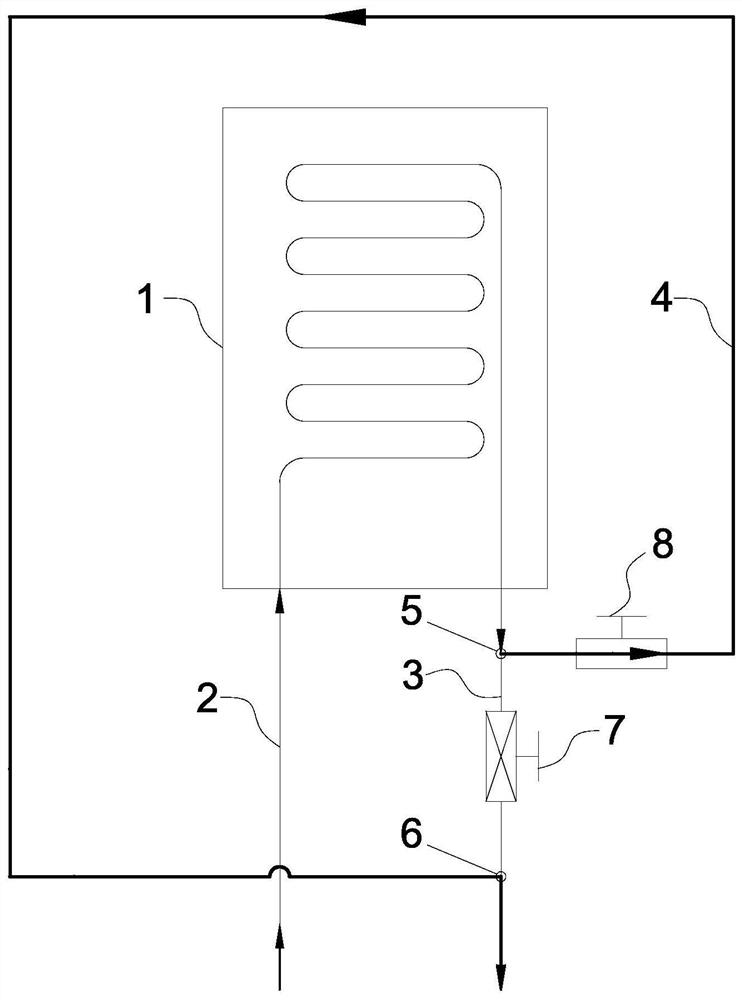

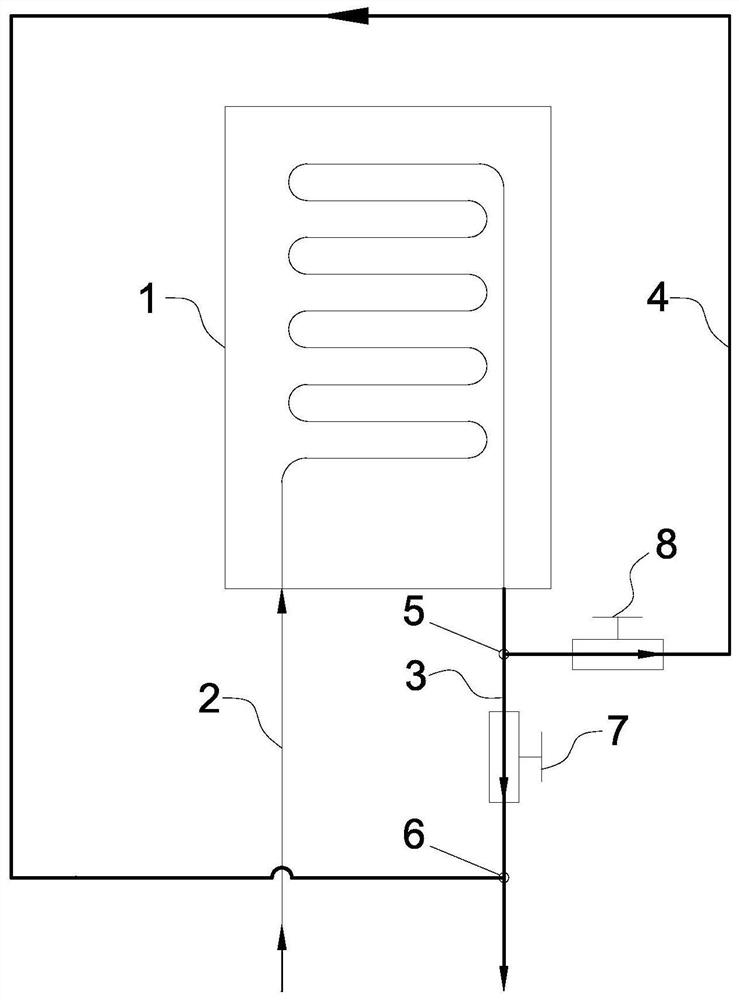

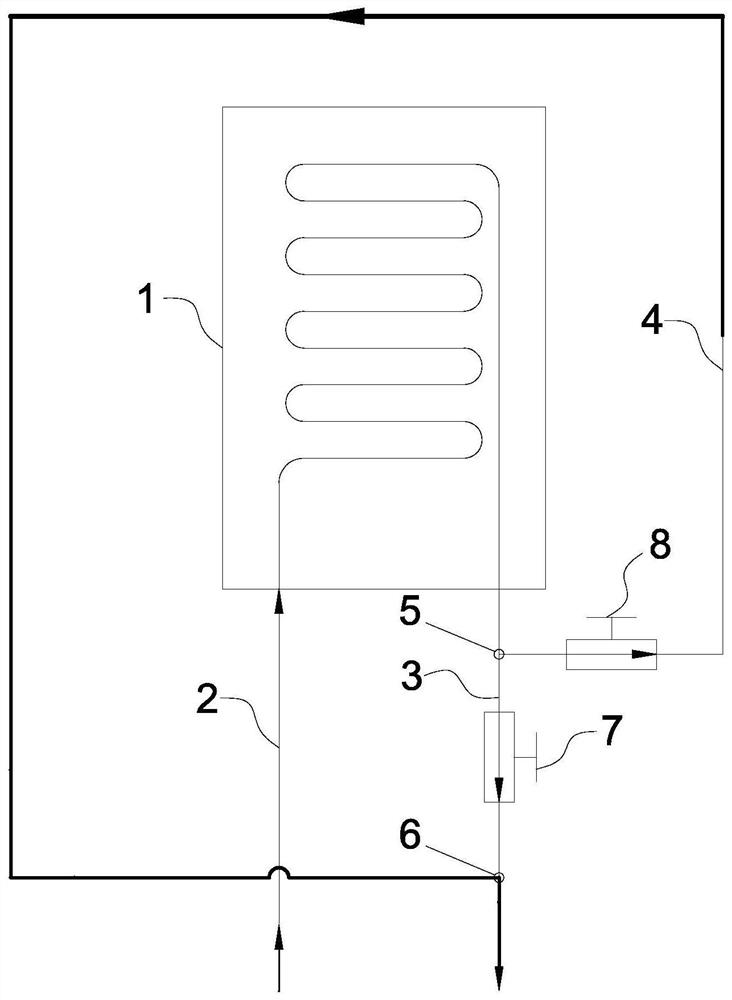

Gas-fired water heater with water outlet at constant temperature and method for realizing constant temperature of water outlet

The invention discloses a gas water heater with constant temperature outlet water and a method for realizing constant water outlet temperature. The gas water heater includes a heater, a water inlet pipe connected to the water inlet end of the heater, and a water outlet pipe connected to the water outlet end of the heater; An intermediate water storage pipe, one end of the intermediate water storage pipe is connected to the water outlet pipe of the heater through a first connection point, and the other end is connected to the water outlet pipe through a second connection point; In the direction of water flow in the water pipe, the first connection point, the first valve and the second connection point are sequentially arranged on the water outlet pipe; the end of the intermediate water storage pipe corresponding to the first connection point is provided with a second valve. After the hot water valve is opened again, the gas water heater can keep delivering hot water all the time, and there will be no "surprise" phenomenon of cold water, which greatly improves the comfort of bathing.

Owner:佛山市史麦斯卫厨电器有限公司

Self-ventilating centrifugal pump

InactiveCN101400896BExhaustSimple structurePriming pumpNon-positive displacement fluid enginesEngineeringVacuum pump

Owner:阿尔法·拉瓦尔科灵联合股份有限公司

Efficient low-resistance air filter material preparation device

ActiveCN104088084AEfficient injectionIncrease the injection depthArtificial thread manufacturing machinesFilament/thread formingFiberAir filter

The invention discloses an efficient low-resistance air filter material preparation device. The efficient low-resistance air filter material preparation device is characterized by comprising a fiber extrusion device, filament jetting devices, a web curtain receiving device, a bias voltage electrostatic charging device and a winding device. The bias voltage electrostatic charging device is used for enabling charge particles generated by a charging electrode to be quickly injected into a material under the effect of a high-voltage electric field generated by a bias voltage electrode. Meanwhile, due to existing of the bias voltage electrode, the utilization efficiency of the charge particles is improved, and the injection depth of charges is improved. A plurality of sets of filament jetting devices and the bias voltage electrostatic charging device are used, so that the inside of a thick material can also receive effective charge injection, and it is ensured that the entire space of the material and the surface of fiber are filled with charges. The bias voltage electrostatic charging device is placed on the rear portion of the movement party of the falling point of a filament jetting die opening, so that charges are quickly injected into the fiber when the fiber is not completely solidified, the fiber is subjected to the effect of the bias voltage electric field at the same time, part of electrons inside the fiber are made to move and be solidified, and the fiber is made to have polarity.

Owner:JIANGSU LIYANG NEW MATERIALS CO LTD

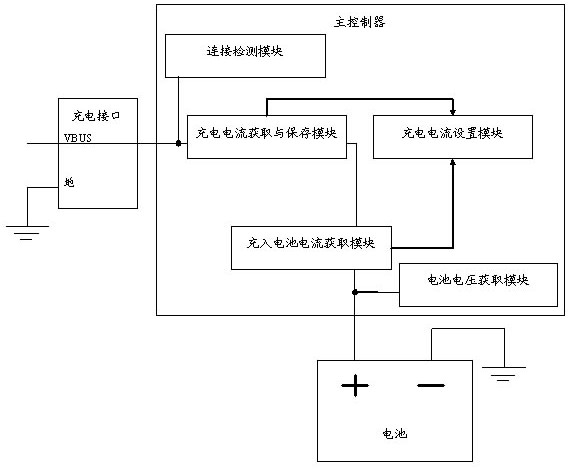

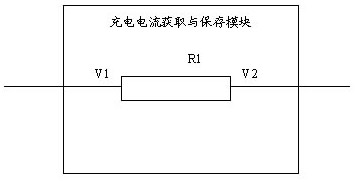

System and method for setting charging current based on battery voltage obtained by mobile terminal

ActiveCN106772092BAccurate chargesStable chargingElectrical testingElectric powerCharge currentComputational physics

The invention discloses a charging current setting system and a charging current setting method for acquiring a cell voltage based on a mobile terminal. The method comprises the following steps: detecting whether the mobile terminal accesses a charging power supply, and if so, recording a set charging current as I1; when an instruction for precisely acquiring the cell voltage is received, accruing a current I2 currently charged into a cell, and setting the charging current as I1-I2; and reading a cell voltage V1, and then setting the charging current as I1. When the current charged into the cell is zero, the cell voltage is acquired, so that the actual voltage of the cell can be precisely acquired, the real electric quantity of the cell is obtained and is displayed to a user, and the user can know the electric quantity of the cell; and when the terminal is charged, the cell can be fully charged, so that the charging of the cell is relatively stable and precise.

Owner:HUIZHOU TCL MOBILE COMM CO LTD

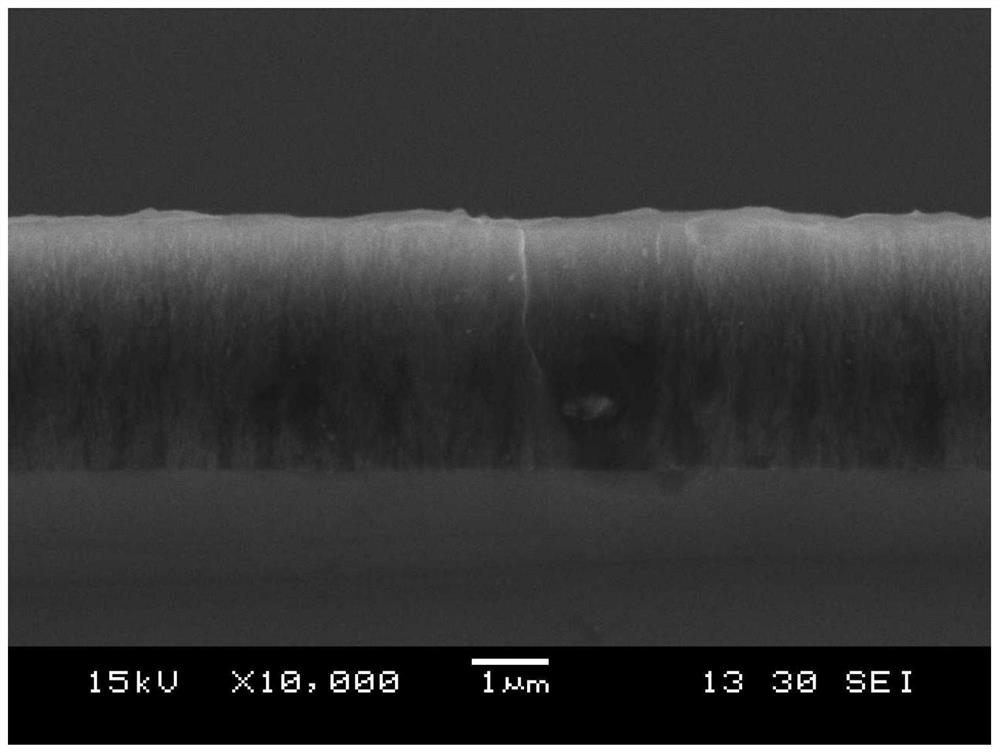

Method for preparing ultra-nano diamond film

ActiveCN112281136AFacilitate depositionImprove production efficiencyChemical vapor deposition coatingThin membraneDiamond thin film

The invention provides a method for preparing an ultra-nano diamond film, and relates to the field of diamond films. The method for preparing the ultra-nano diamond film includes the following steps of substrate treatment, substrate cleaning and film deposition. The whole method for preparing the ultra-nano diamond film is simple in process and high in preparation efficiency, and compared with a traditional preparation method, the method has the advantages that the temperature required by film deposition is reduced, so that the method can be more conveniently applied to industry and is convenient to use.

Owner:曾一

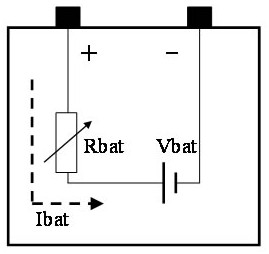

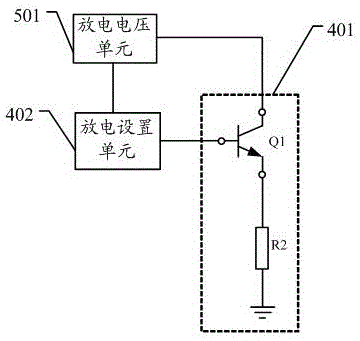

Terminal and method for accurately obtaining battery voltage by discharging during charging

ActiveCN103633705BAccurately obtain the actual voltageStable chargingBatteries circuit arrangementsSecondary cellsElectrical batteryTerminal voltage

The invention discloses a terminal and method of precisely acquiring battery voltage by discharging during charging. The terminal comprises a charge interface, a battery, a resistor, a power management module and a central processing unit. The power management module is used for notifying the central processing unit to set zero initial discharge current when detecting battery charging, acquiring a voltage difference of ends of the resistor, and judging whether or not current flows by the resistor according to the voltage difference; when no current flows by the resistor, the power management module directly acquires voltage of a battery; when current flows by the resistor, the power management module notifies the central processing unit to amplify the discharge current before acquiring the voltage difference of the ends of the resistor and judging whether or not the current flows by the resistor, and only when no current flows by the resistor, the power management module acquires the voltage of the battery. The terminal and the method have the advantages that no flow is enabled to flow by the internal resistor of the battery by means of discharging during battery charging, actual voltage of the battery can be obtained accurately, and true electric quantity of the battery can be obtained and displayed to users.

Owner:威海神舟信息技术研究院有限公司

Coating containing porous filler as well as preparation method and use method thereof

ActiveCN111944353ALow densityHigh porosityLiquid surface applicatorsEmulsion paintsCarbon nitrideGraphite

The invention discloses a coating containing a porous filler as well as a preparation method and a use method of the coating, and belongs to the technical field of coatings. The preparation method comprises: completely absorbing water from the porous silicon dioxide gel particles loaded with the graphite phase carbon nitride, adding the porous silicon dioxide gel particles into the finished product coating, and adjusting the coating to a proper concentration to obtain the coating containing the porous filler. The method has the advantages of mild preparation conditions, simple process, cheap raw materials and good repeatability, and solves the problems that the pore structure of the filler is easily blocked in the paint and the filler and the coating are not firmly contacted due to a spraying method. The prepared coating containing the porous filler has very strong adsorption performance and degradation performance on haze. When in use, the coating surface is firstly coated with the primer and then coated with the coating containing the porous filler, so that VOCs in the air can be effectively adsorbed, and the formation of haze is inhibited from the source.

Owner:西安凡星生物科技有限责任公司

Construction method for performing pressure grouting in interlayer space

ActiveCN102900085ALow flow resistancePrevent segregationFoundation engineeringPressure groutingLubrication

A construction method for performing pressure grouting in an interlayer space mainly comprises the following steps of: treating the foundation course; distributing grouting pipes, a water absorption pipe and a liquid level monitor lead of a liquid level monitor: placing a grouting-region overhead space and taking a space between the overhead space and the foundation course as a grouting region; connecting each grouting pipe with a slurry making system; humidifying foundation course; lubricating the grouting pipes; grouting, and the like. The construction method for performing pressure grouting in the interlayer space is characterized in that the pipe lubrication operation is performed on the grouting pipes by means of a pipe lubricating material before the grouting, and a wet sliding layer is formed in the grouting pipes by means of a fine material in the pipe lubricating material, thereby reducing the flow resistance of grouting liquid in the grouting pipes, preventing the grouting material separation and the grouting pipe blockage and guaranteeing the smooth grouting operation; the pressure grouting is employed to ensure that the space of the whole grouting region is full of a grouting material; the liquid level monitor is matched with the grouting pipes and controls the grouting pipes to be located under the grouting liquid level all the time, so that the grouting pipes are controlled to accurately move to a specified grouting site; and therefore, the grouting quality is ensured and the grouting efficiency is improved.

Owner:CHINA NUCLEAR IND 22ND CONSTR

A gas pipeline with integrated cooling channel

ActiveCN112253334BMeet the requirements of one-time moldingSimple processRocket engine plantsButt weldingConsistency control

In order to solve the technical problems of long processing period, complex process, high cost, difficulty in quality consistency control and low integration degree of the existing gas pipeline with cooling structure, the present invention proposes a gas pipeline with integrated cooling channel. The invention integrates the cooling channel in the side wall of the gas channel, which simplifies the process and improves the integration of the product; adopts the structural design oriented to the 3D printing process, and realizes the cooling working medium inlet pipe joint and the cooling working medium inlet liquid collection chamber , cooling channels, etc., and the overall unsupported design of the gas pipeline, this structure can meet the overall one-time molding requirements of 3D printing technology, without the need for multi-channel racks, brazing, butt welding and other procedures in the traditional process, product processing and turnover cycle It is greatly shortened, the product consistency and connection strength and stiffness are better, the quality control is more effective, and the development cost is greatly reduced.

Owner:XIAN AEROSPACE PROPULSION INST

Production process of yarn-dyed fabric

PendingCN113668162AMake sure fullImprove dyeing efficiencyFibre typesTextile treatment machine arrangementsPolyesterYarn

The invention relates to the technical field of textile fabrics, in particular to a production process of a yarn-dyed fabric. The production process comprises the following steps of S1, conducting cheese dyeing: raw yarn preparation, yarn bobbin loosening, dyeing, dehydration, drying, rewinding, warping, sizing, gray yarn inspection, singeing, desizing, mercerizing, sizing, preshrinking and finish inspection, wherein the sizing speed is 40m / min, the sizing percentage fluctuation is within the range of + / -1%, and a sizing agent formula adopted in the sizing process comprises 85 parts of starch, 3 parts of polyacrylic acid sizing agent, 2 parts of polyester cotton sizing aid, 0.01 part of starch viscosity reducer and water; S2, weaving: winding a qualified cheese on a warp beam through a warping machine, wrapping with the sizing agent, drafting, and weaving through a loom; and S3, conducting gray fabric inspection. According to the production process of the yarn-dyed fabric provided by the invention, a yarn bobbin is extruded discontinuously by adopting a dye liquor inlet adjusting mechanism, so that all positions of the yarn bobbin are filled with dye liquor, and the dyeing efficiency of the yarn bobbin is improved.

Owner:江苏盈润纺织科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com