Construction method for performing pressure grouting in interlayer space

A technology of pressure grouting and construction method, which is applied in the direction of basic structure engineering and construction, which can solve the problems of grouting pipe blockage, poor potential energy, and difficulty in filling the grouting space, so as to reduce flow resistance, improve grouting efficiency, and ensure grouting quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0035] General implementation of the present invention is as follows:

[0036] A construction method for pressure grouting in an interlayer space, comprising the following steps:

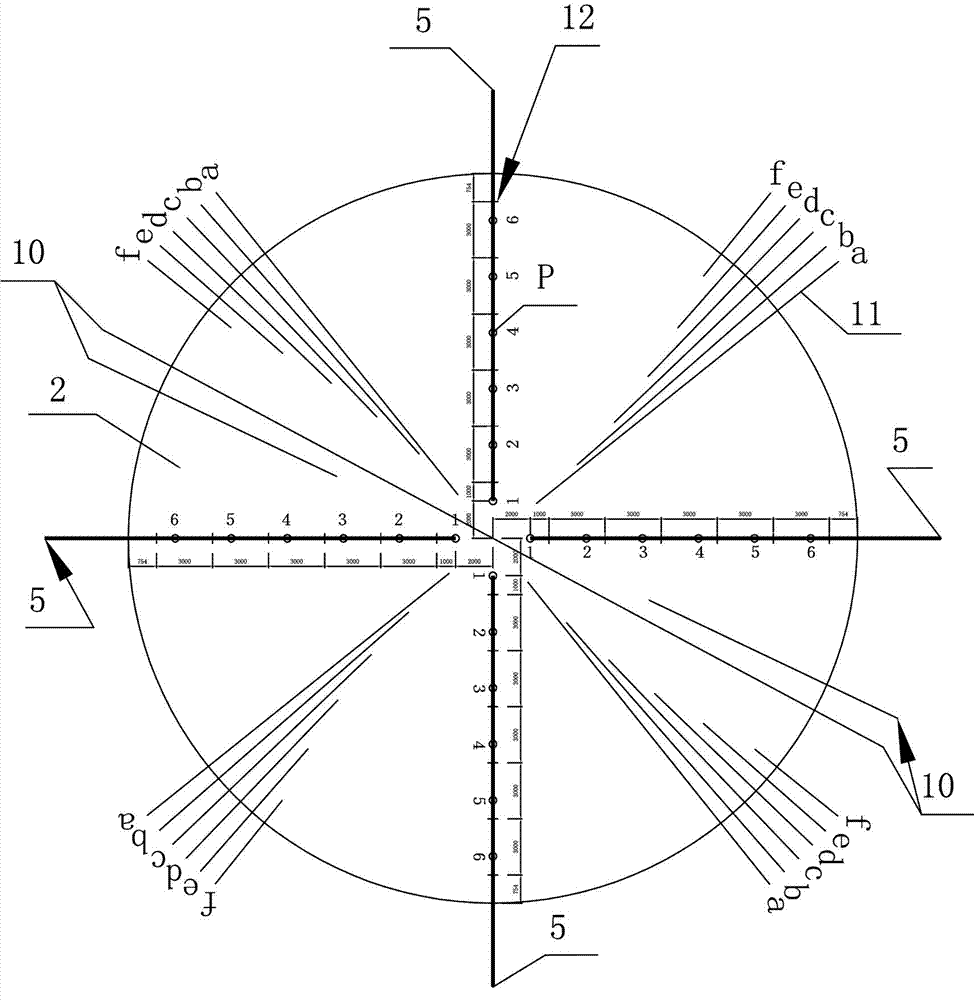

[0037] (1) Base treatment: Chisel the base, and the chisel direction is radial to form drainage grooves;

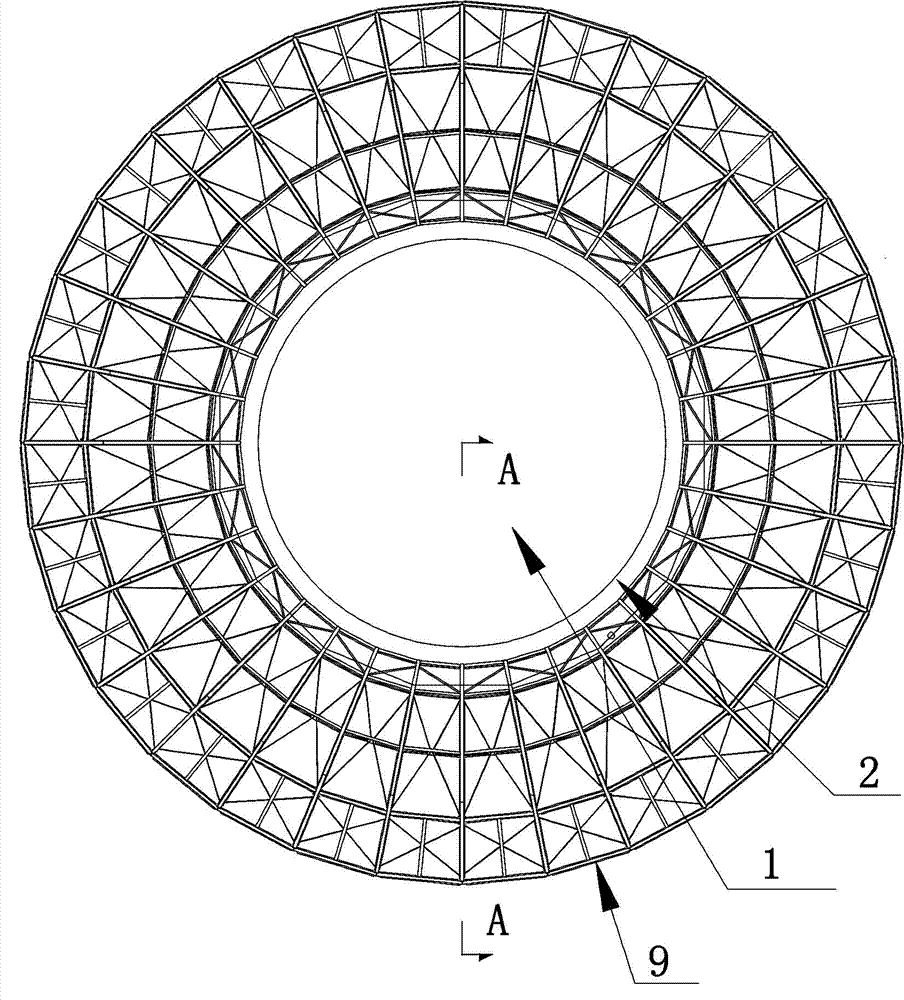

[0038] (2) Arrangement of grouting pipes, water suction pipes, and wires of liquid level monitors for liquid level monitors: evenly arrange multiple grouting pipes on the surface of the foundation after the roughening treatment, and the grouting pipes are fixed on the surface of the foundation by pipe clips; Multiple water suction pipes are arranged on the surface of the foundation; at the same time, multiple wires of liquid level monitors of different lengths are arranged between the grouting pipes;

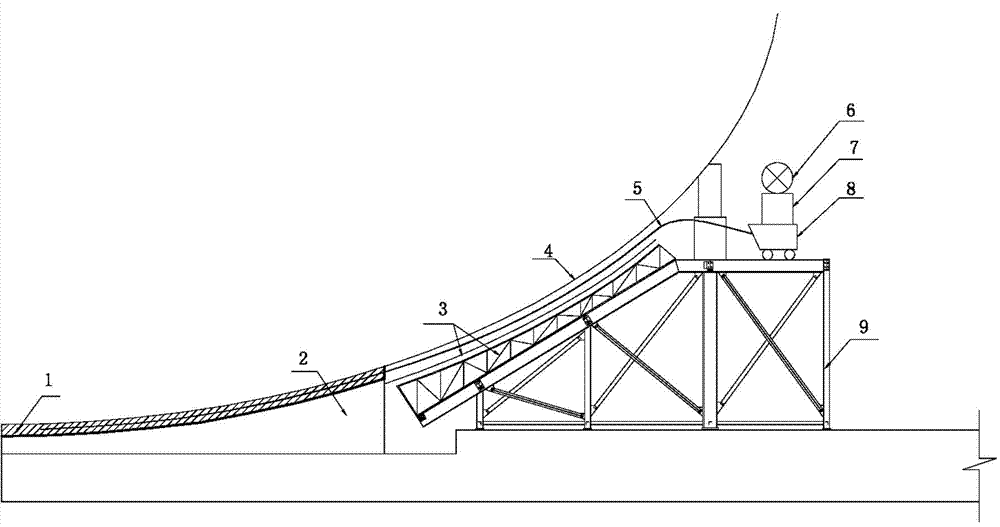

[0039] (3) Place the grouting area to cover the overhead layer, and the space formed between the overhead layer and the base layer is the grouting area;

[0040] (4) Each grouting pipe is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com