Additive metering system and metering method of cement concrete stirring device

A technology of cement concrete and mixing equipment, applied in the field of metering system, can solve the problems of inability to compare and calibrate the load cell and digital flowmeter, unable to use the weight of flowing liquid, etc., to ensure the stability and accuracy of measurement, reduce overshoot, Guaranteed accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

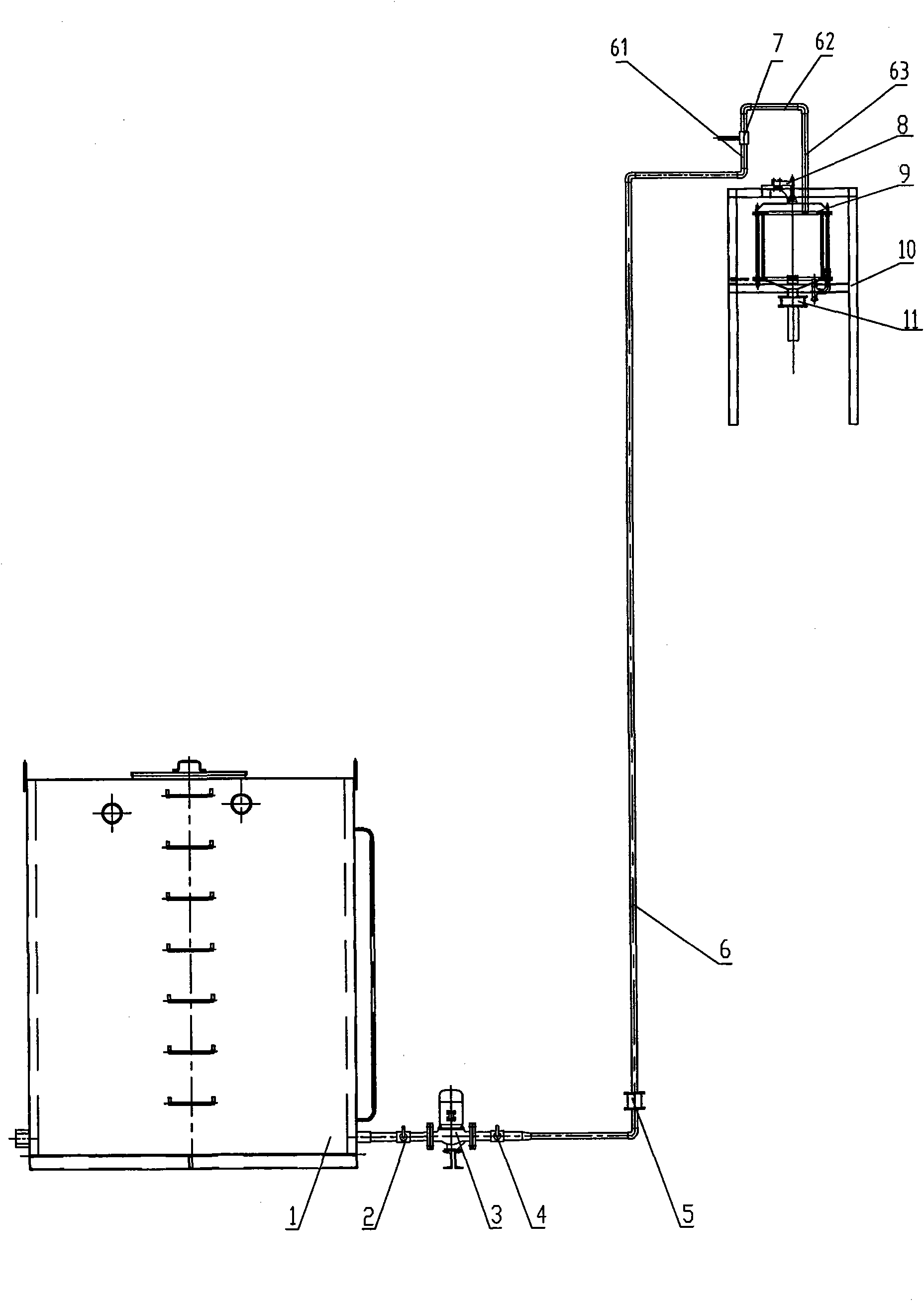

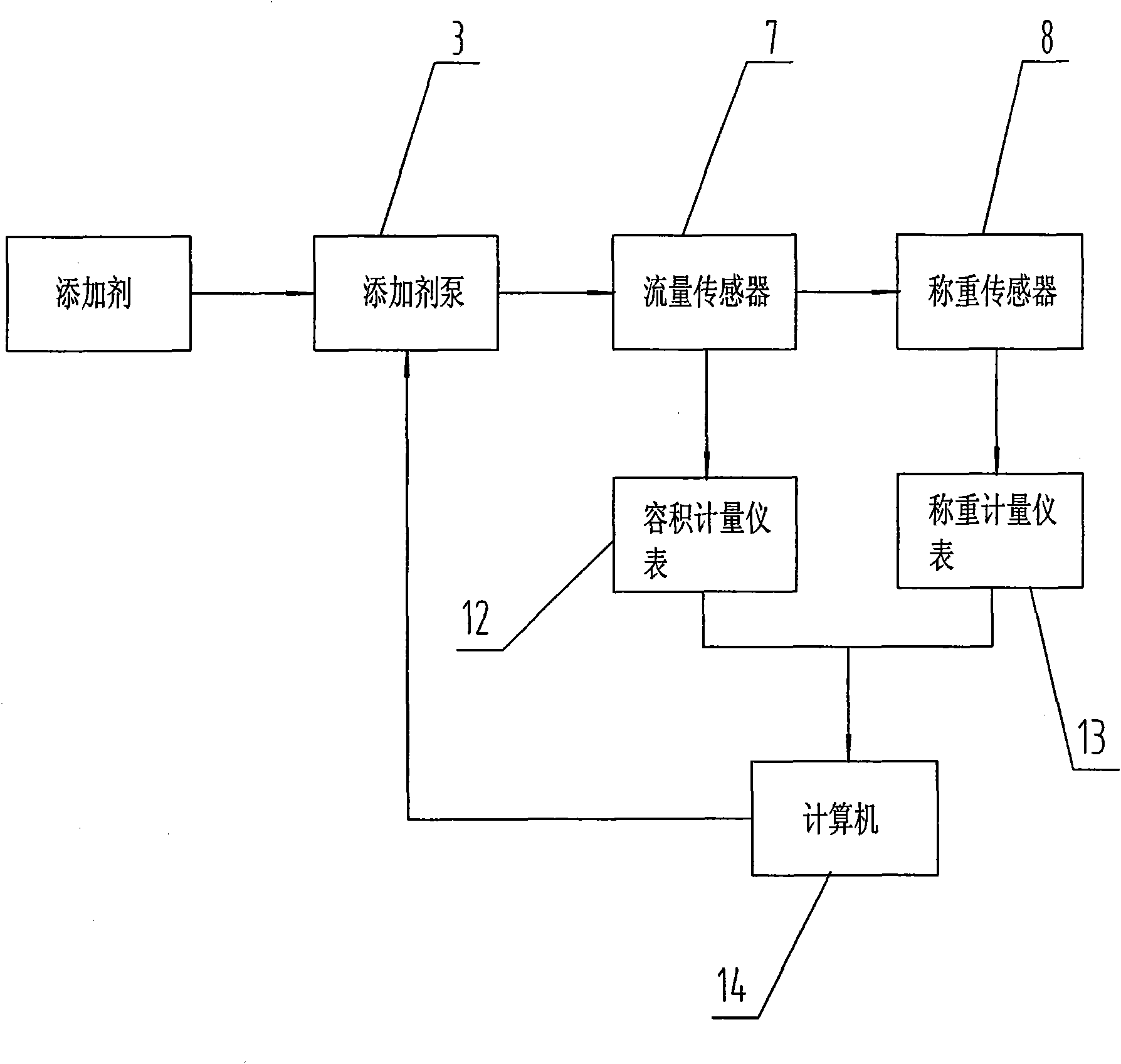

[0021] Such as figure 1 As shown, the present invention includes an additive liquid storage tank 1, a ball valve A2, an additive pump 3, a ball valve B4, a check valve 5, a flow sensor 7, a load cell 8, an additive weighing tank 9, a weighing bracket 10, and a pneumatic butterfly valve 11 , the output end of the additive liquid storage tank 1 is connected to the ball valve A2, the additive pump 3, the ball valve B4, the check valve 5, and the flow sensor 7 in sequence through the pipeline 6, and the end of the pipeline 6 is connected to the input end of the additive weighing tank 9 , the output end of the additive weighing tank 9 is connected to the discharging pneumatic disc valve 11 , the load cell 8 is connected to the additive weighing tank 9 , and the additive weighing tank 9 is supported in the weighing tank bracket 10 . The pipeline 6 connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com