Patents

Literature

36results about How to "Reduce liquid flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

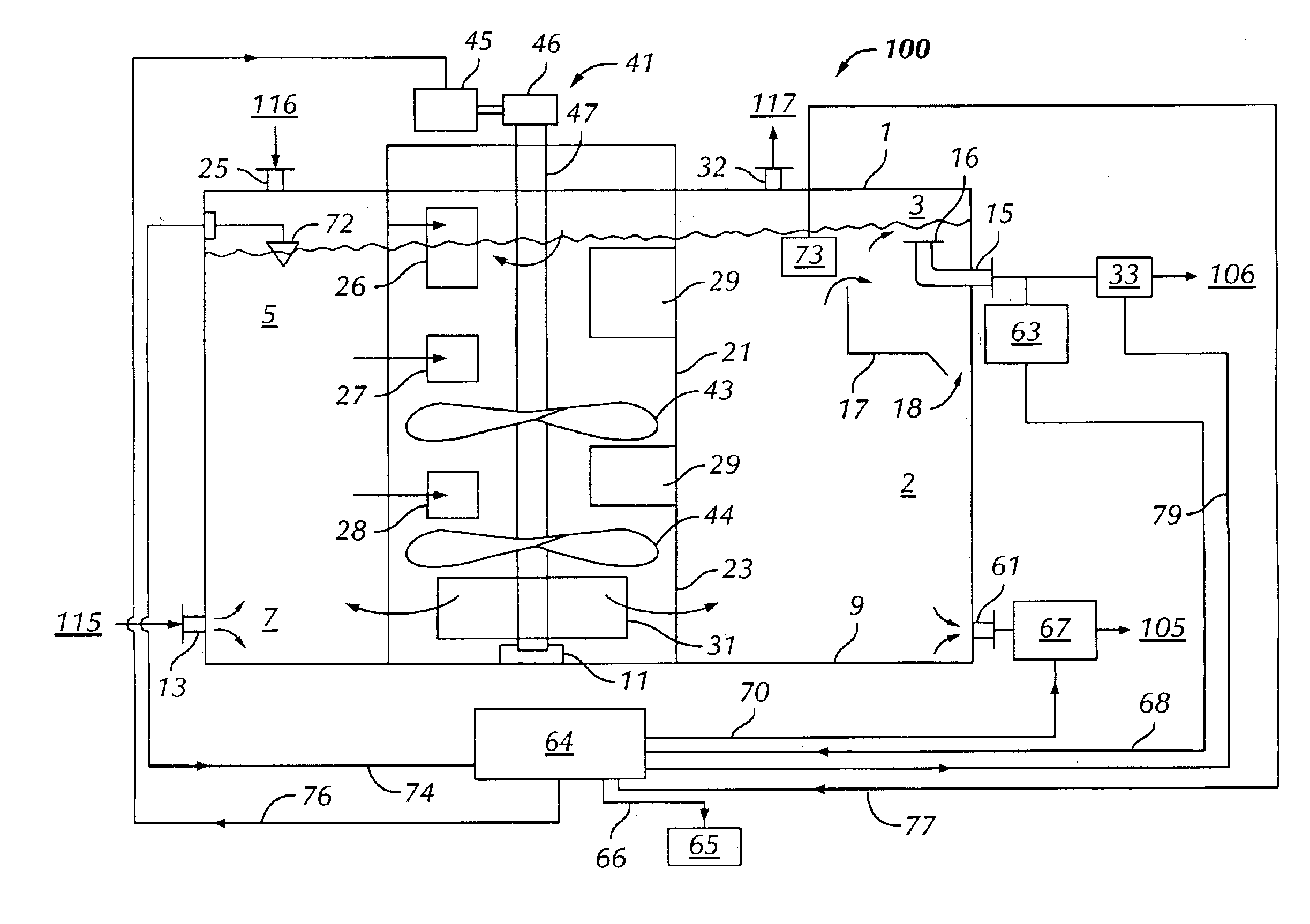

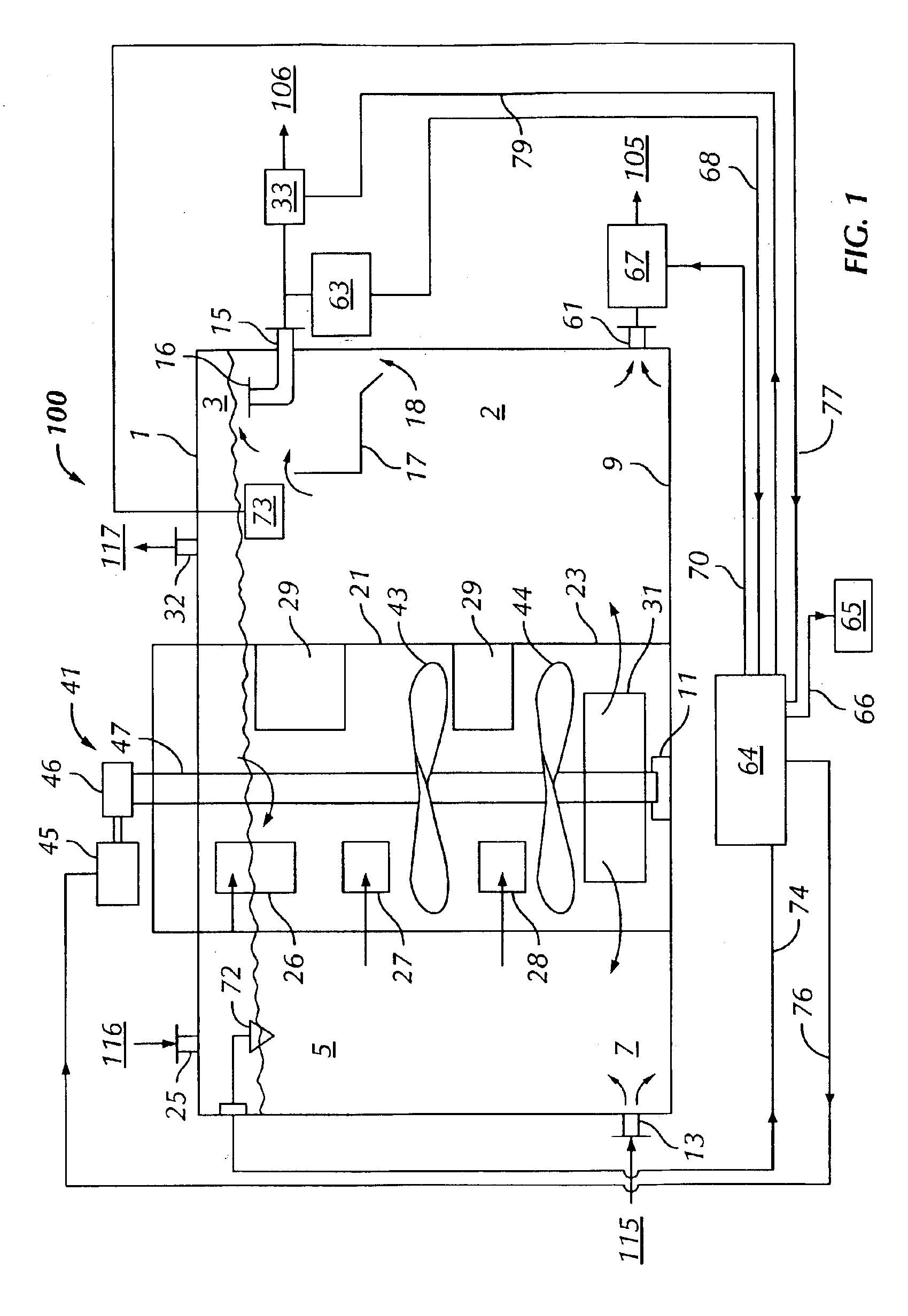

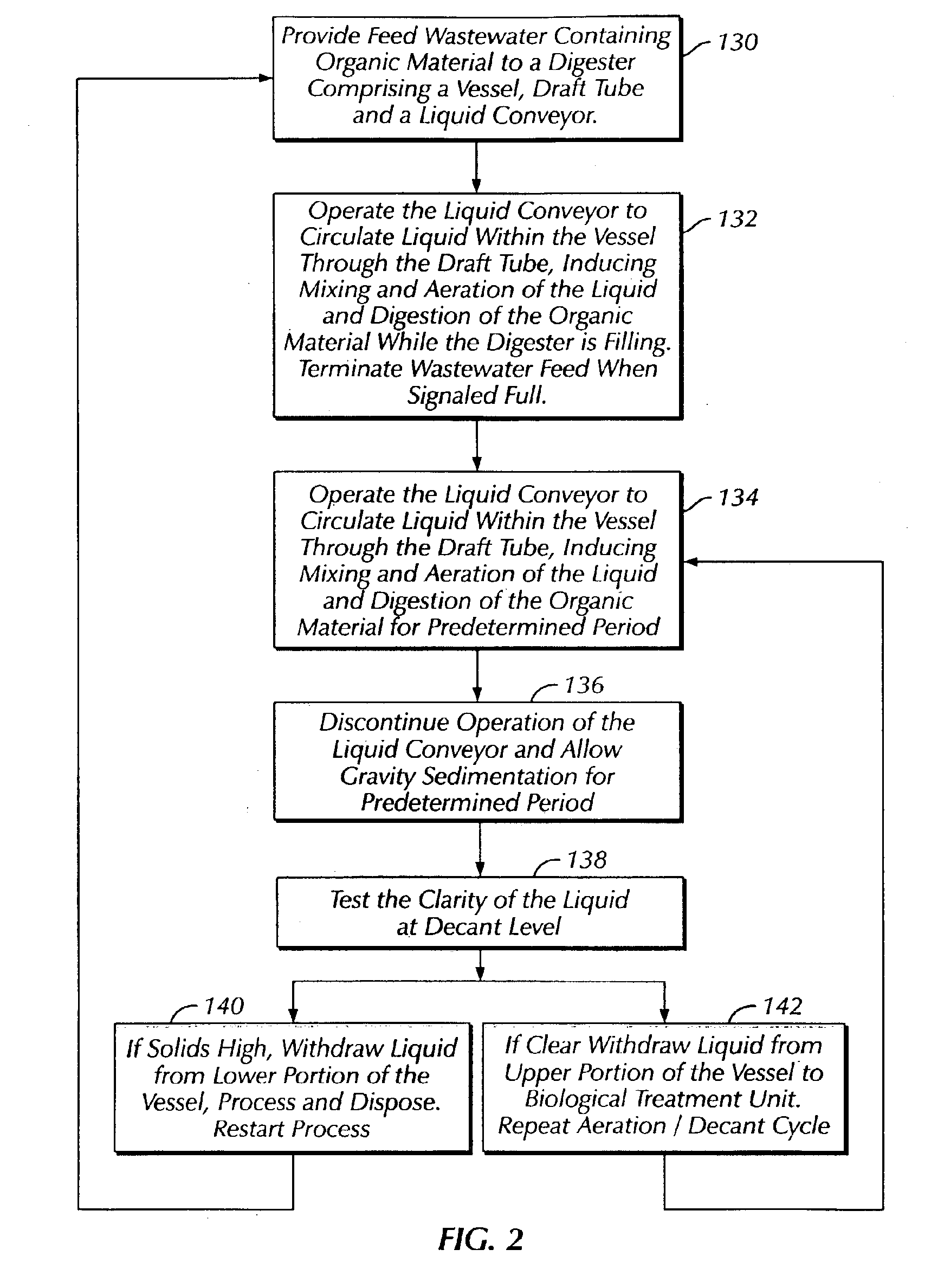

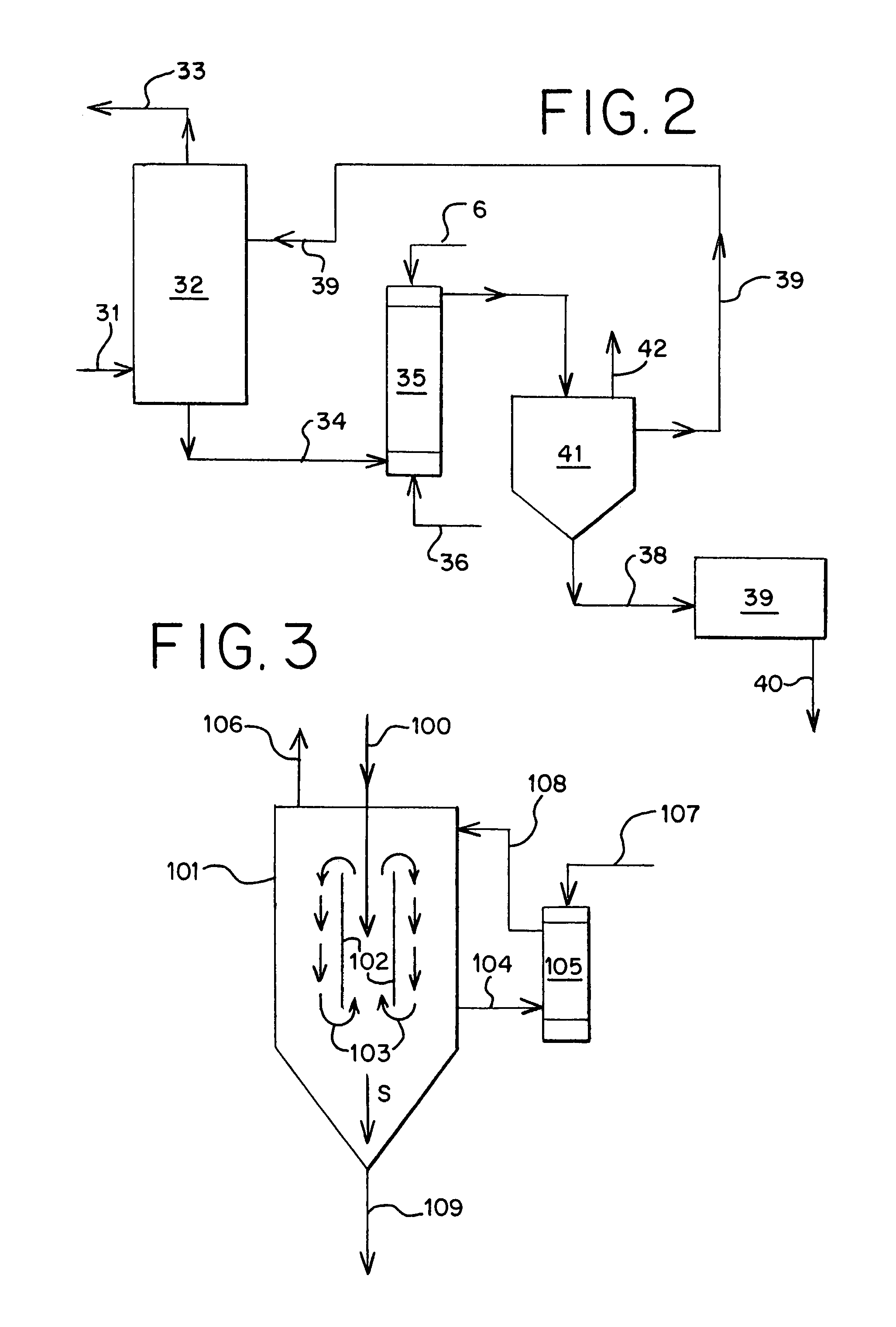

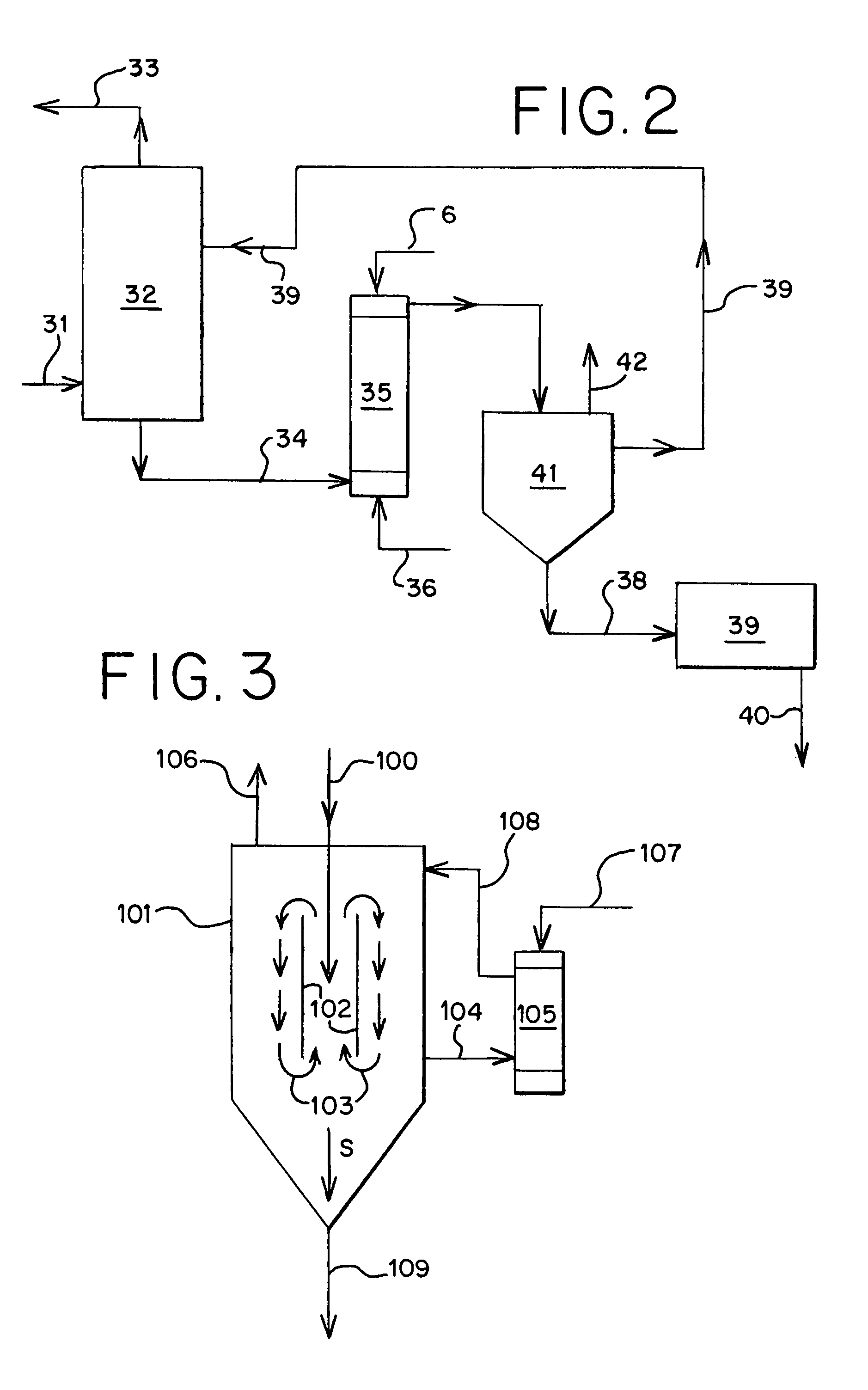

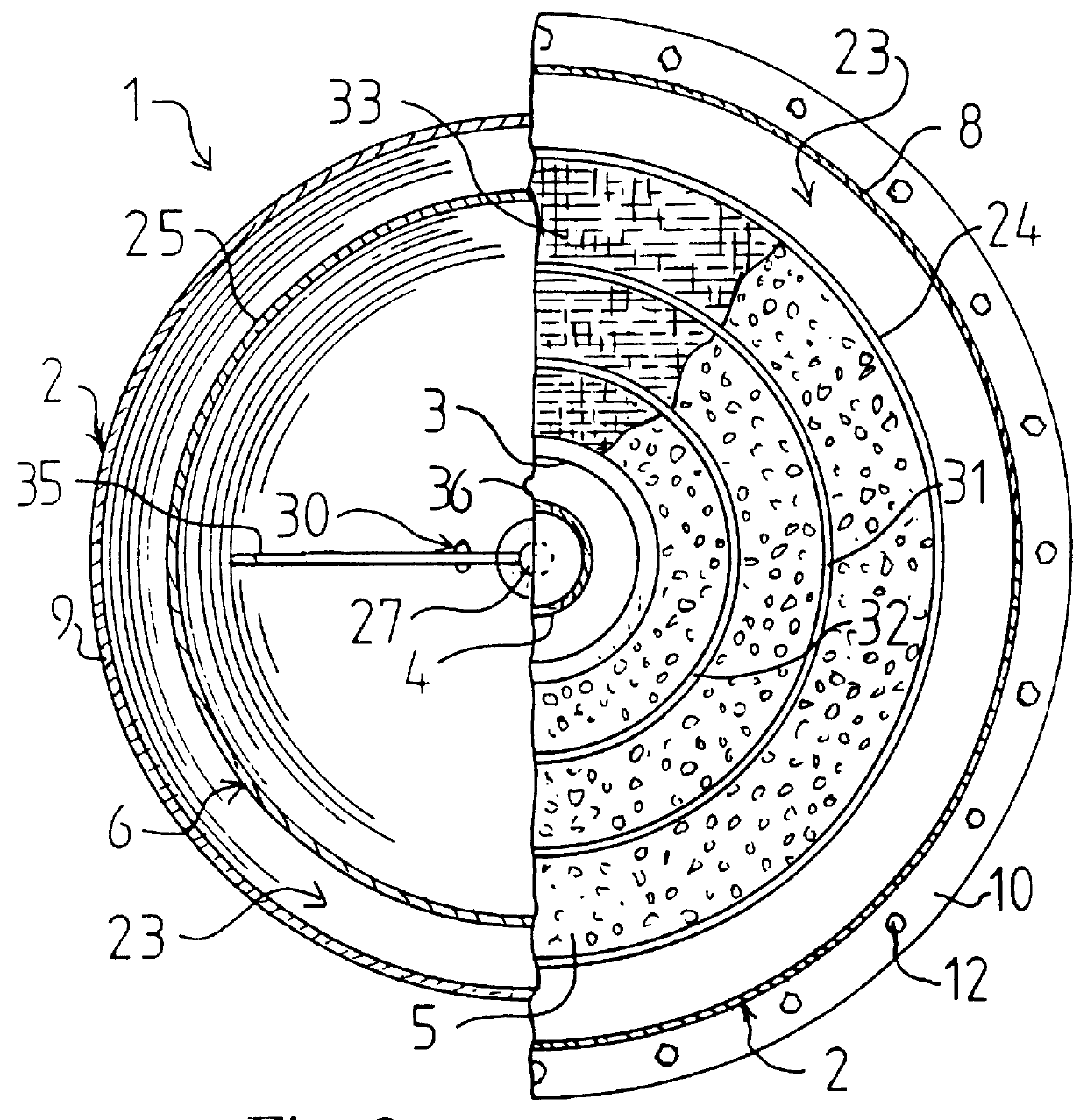

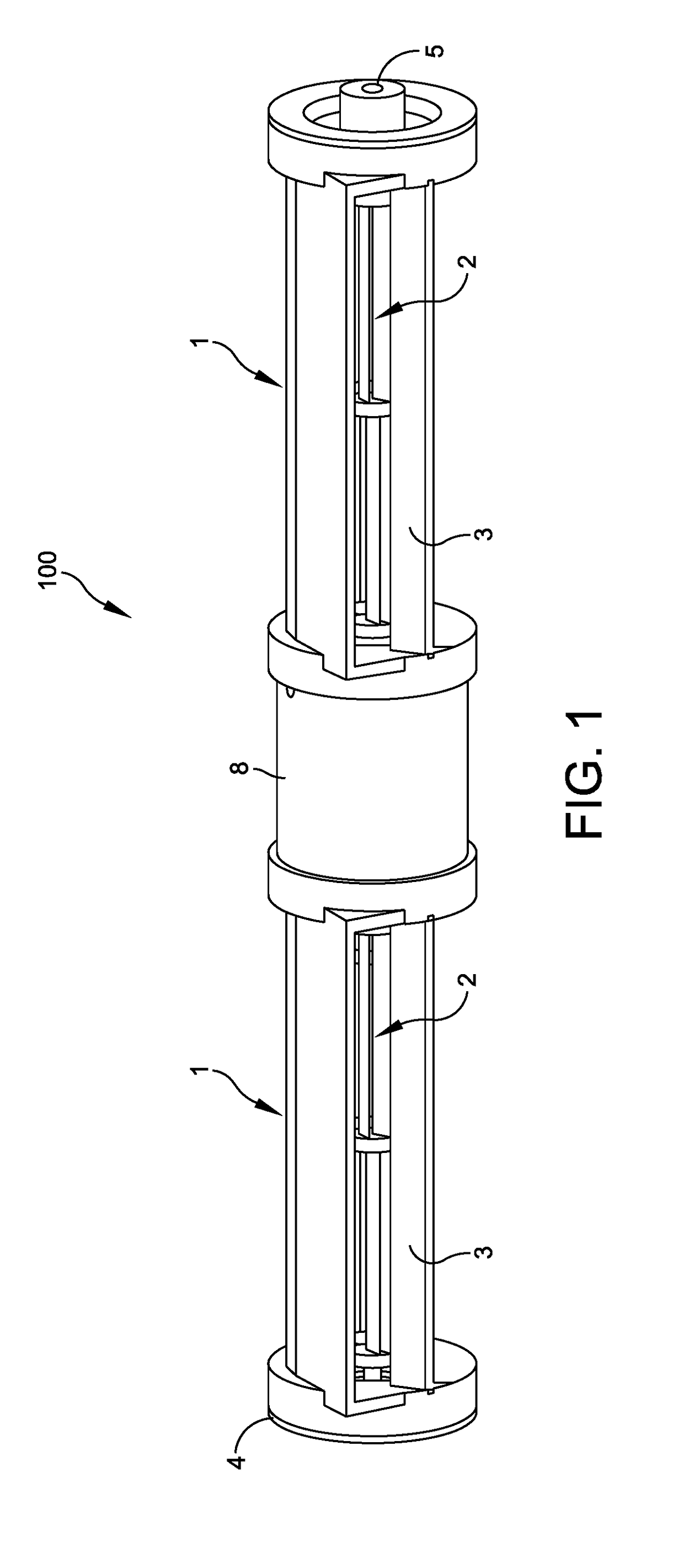

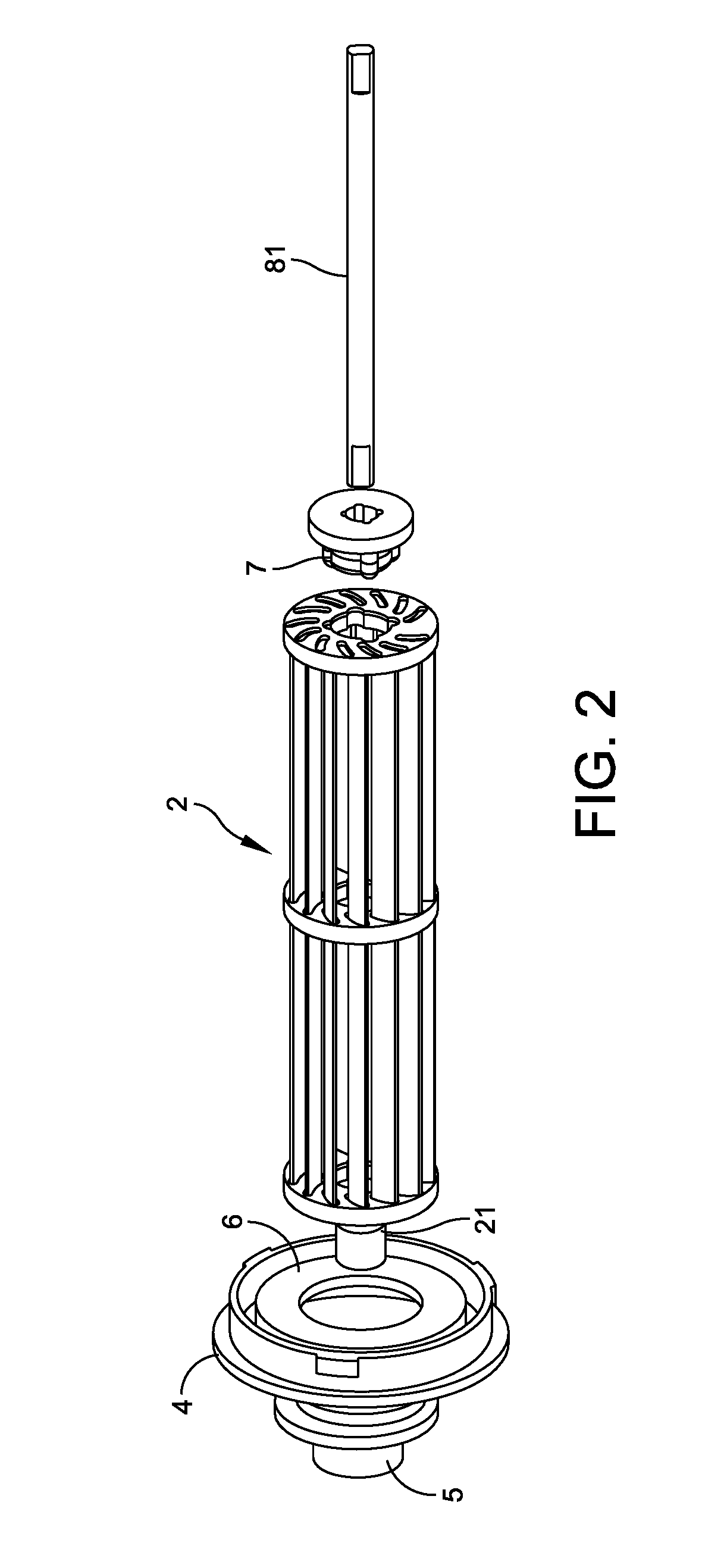

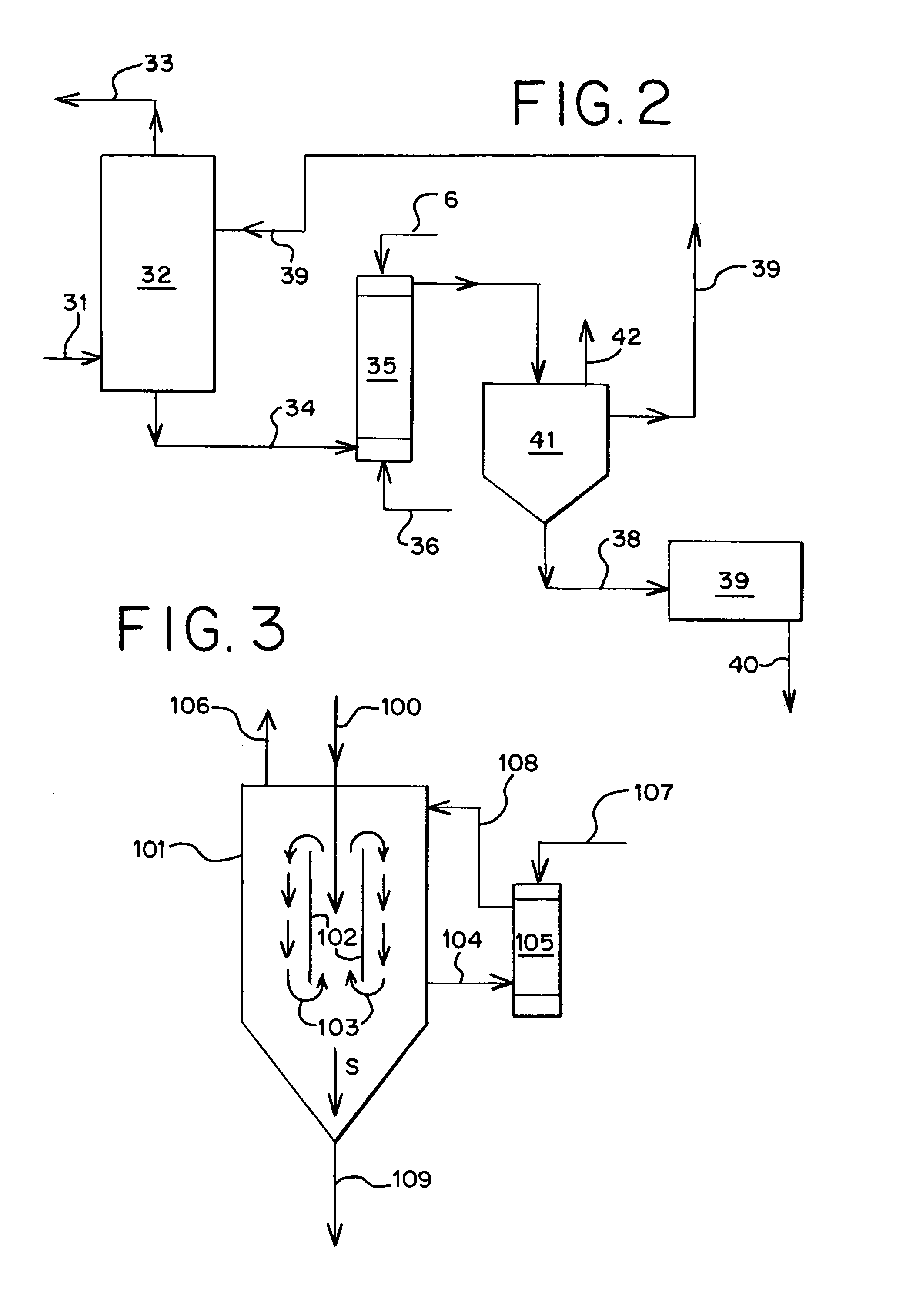

Sludge digestion methods and apparatus

InactiveUS6869534B2Large depthPrevent exitWater treatment parameter controlTreatment using aerobic processesWater treatment systemSludge

The invention relates to an aerobic wastewater digestion unit useful for degrading organic material dissolved or suspended in a wastewater stream. The wastewater is fed to a vessel, wherein it is circulated by a liquid conveyor between the vessel and a downwardly-directed tube. Expulsion of fluid from the tube into the lower portion of the vessel agitates the liquid in the vessel and disperses into the liquid air that has been entrained in the liquid in the tube. The digester can be operated using varying liquid levels, and is amenable to batch, semi-batch, and continuous operation. The digester is suitable for use in combination with other components of wastewater treatment systems, and can be included as a module in modular wastewater treatment systems.

Owner:BRENTWOOD INDS

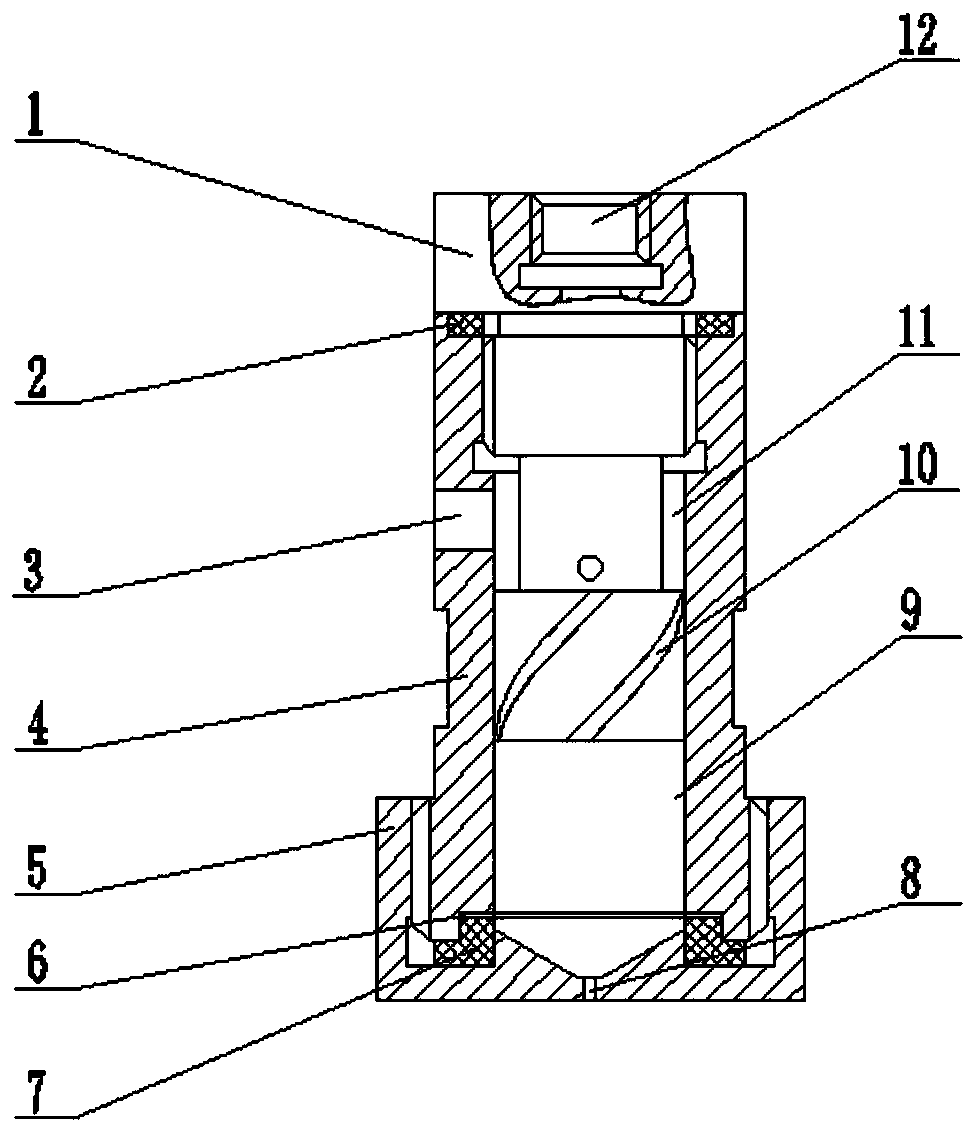

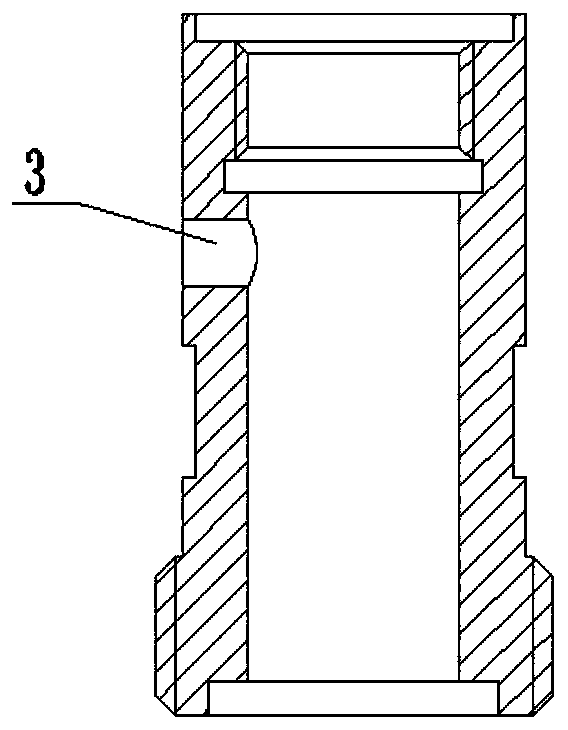

Bubble atomizing nozzle and adjusting method of bubble atomizing nozzle

The invention relates to a bubble atomizing nozzle and an adjusting method of the bubble atomizing nozzle. The bubble atomizing nozzle comprises a multi-channel air intake structure consisting of two or more layers of sealing rings, or an external part of an air intake structure of a swirl groove, and an external part having a diffusion conical spray hole, a jackscrew hole and an air-liquid inlet quick mounting joint, wherein the internal part is directly inserted in the external part to assemble the nozzle; the internal part and the external part are sealed by an O-shaped rubber ring and fixed by a jackscrew; and a space between the internal part and the external part is a mixing chamber. The flowing resistance of the internal part is lower, so that the pressure of the mixing chamber can be kept in a higher range, and the atomizing efficiency of the nozzle is higher; a bubble flow formed in the air-liquid two-phase mixing process in the mixing chamber is uniform and stable, so that the stable atomizing effect is realized under the low-air-liquid mass flow ratio (between 0.07-0.1); and the working pressure is low, and the liquid flow is low, so that the stable atomization can be kept under the liquid flow of 3.5-6.0 kg / h and the absolute air-liquid inlet pressure of 0.36-0.40 MPa. The bubble atomizing nozzle is applied to such fields as chemical engineering, motive power and heating and ventilation.

Owner:HEBEI UNIV OF TECH +1

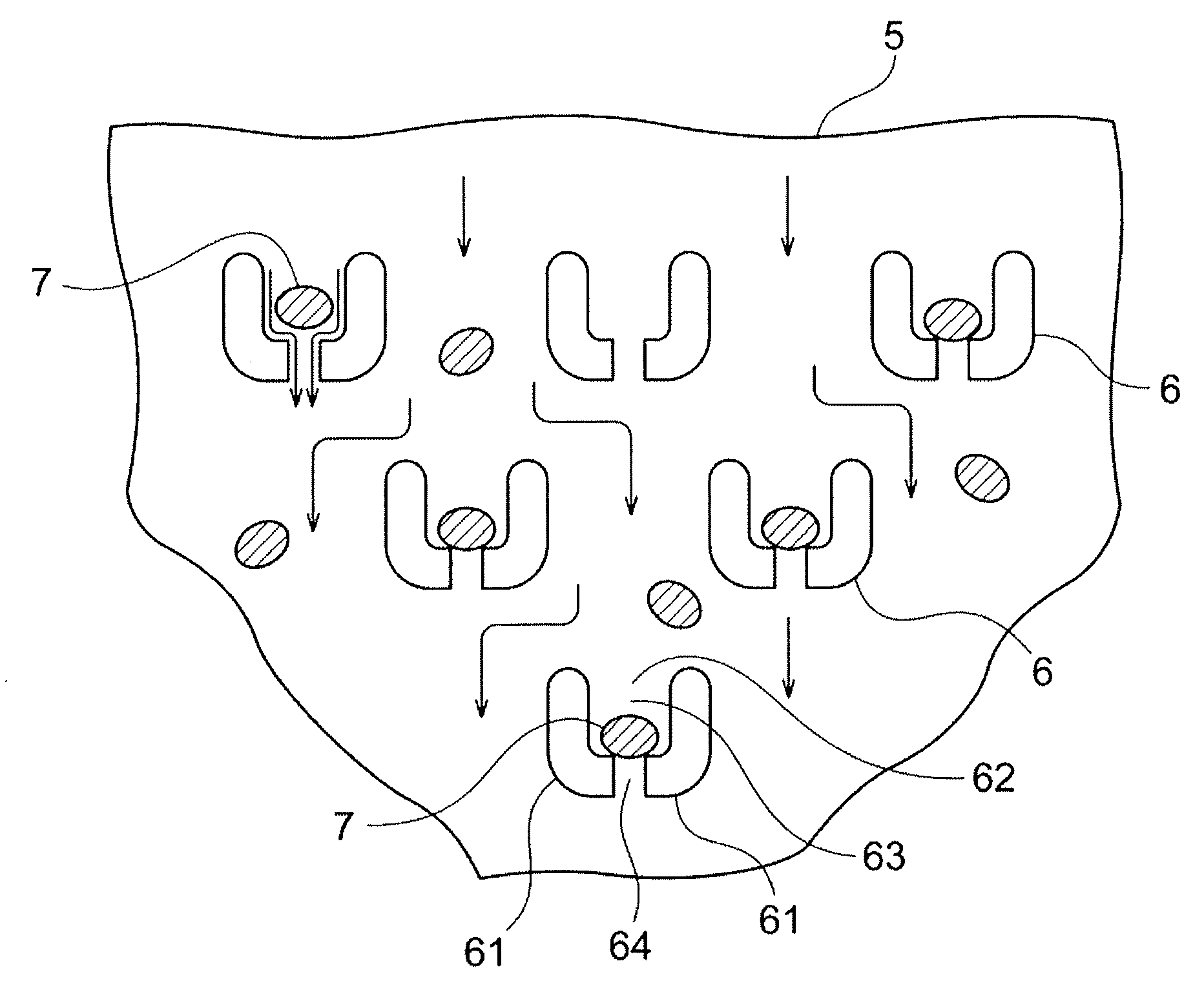

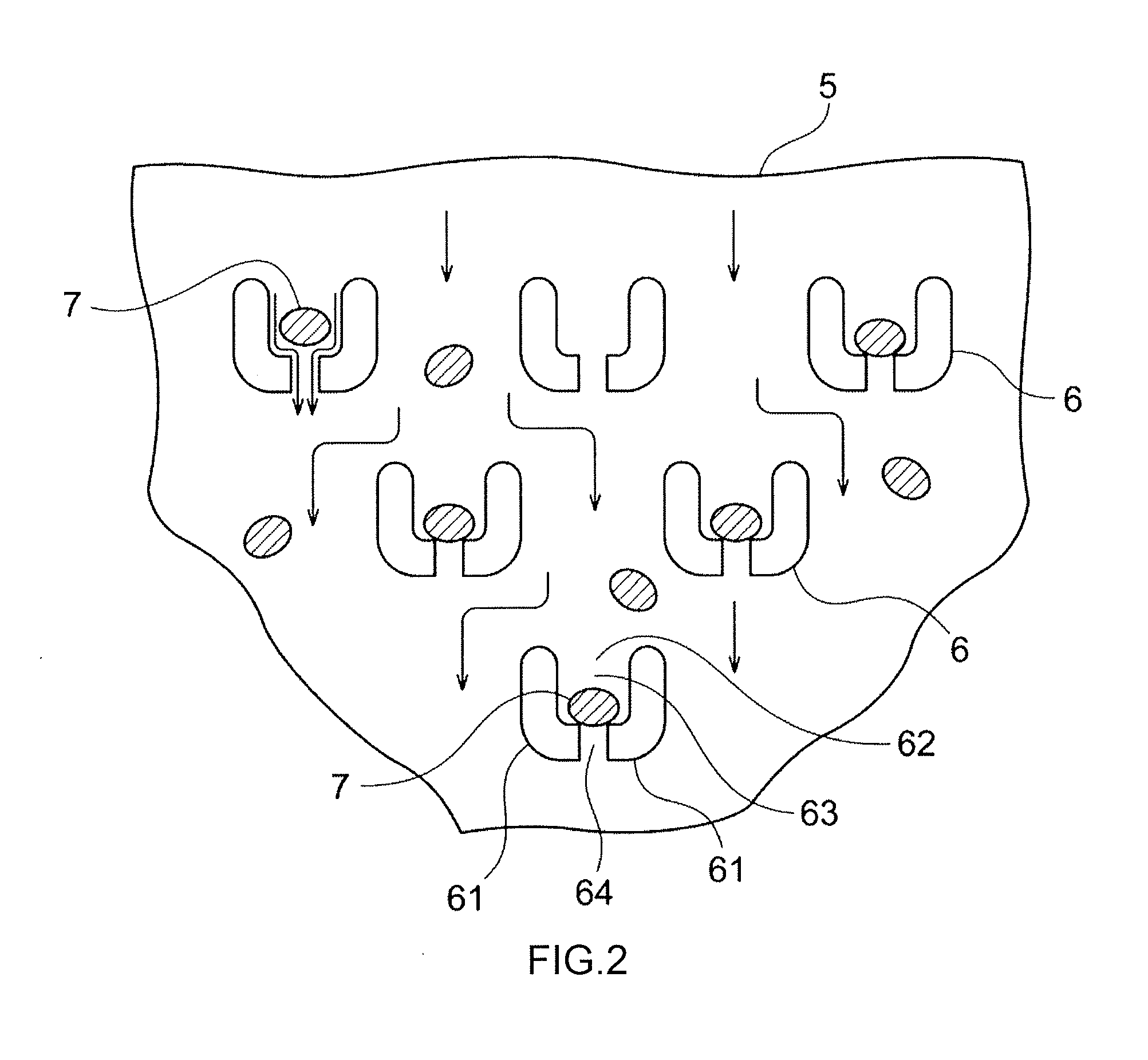

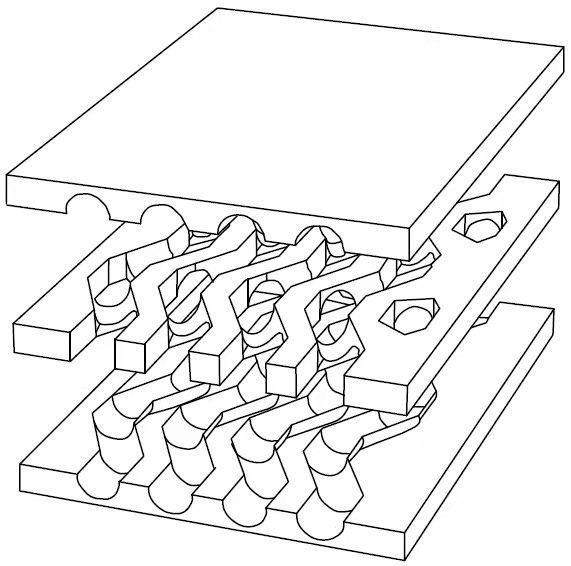

Device having solid-liquid separation function, micro-tas device, and solid-liquid separation method

InactiveUS20120261356A1Increase chanceEasy to manufactureSemi-permeable membranesSamplingSolid massTrapping

In a device having a solid-liquid separation function, a solid-liquid mixture is introduced through a lid inlet formed in a lid, a separation portion for solid-liquid separation is formed in a groove portion, and solid trapping portions are arranged in the separation portion. Each solid trapping portion is formed of a partition wall and includes an inlet portion, an accommodating portion which accommodates one or more solids that have entered through the inlet portion, and an opening portion which is formed on a downstream side of the accommodating portion and prevents the solid having a fixed size or larger from passing therethrough. A width of a region of the separation portion where the solid trapping portions are formed is narrow on a downstream side compared to on an upstream side.

Owner:JOSHO GAKUEN EDUCATIONAL FOUND

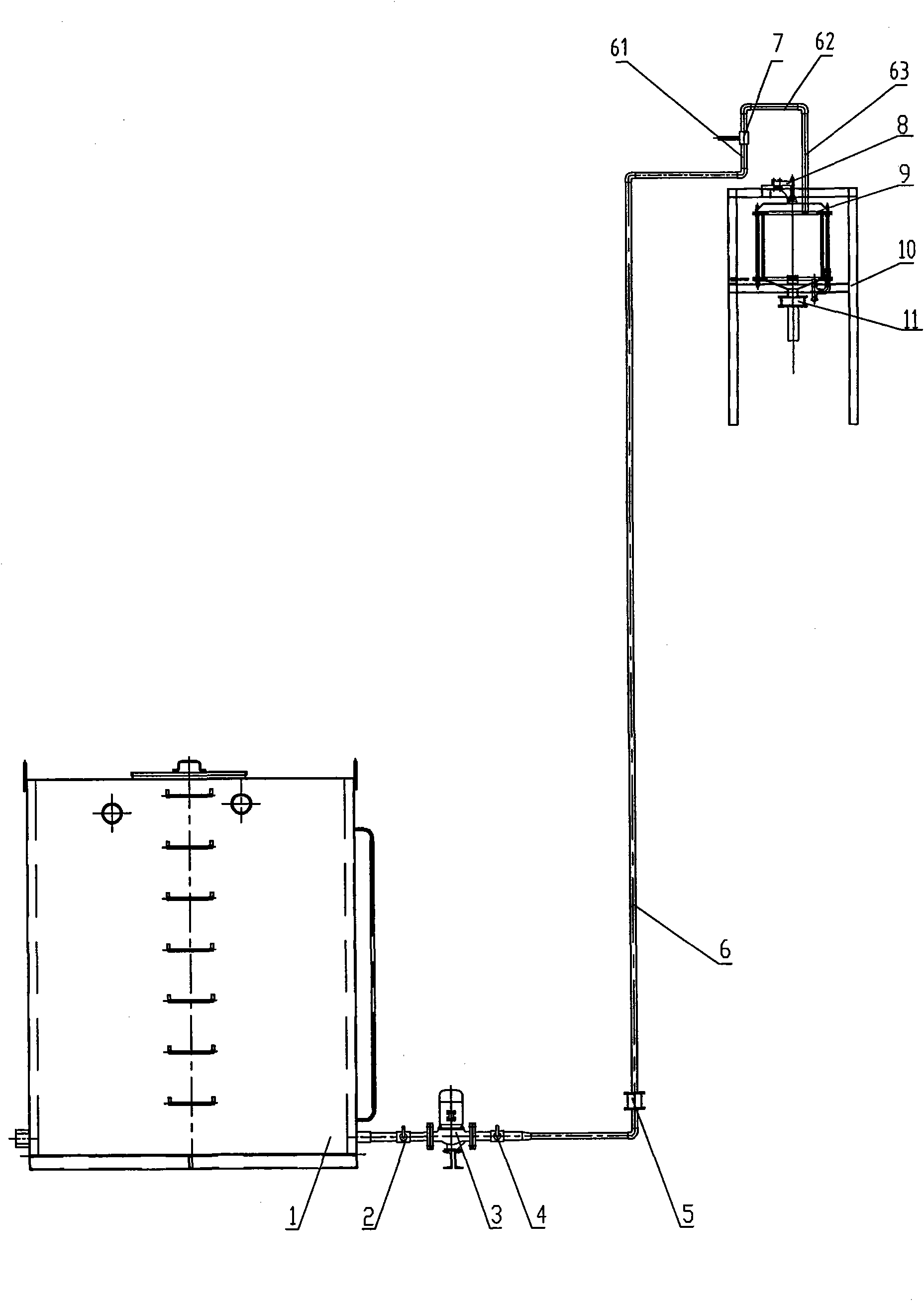

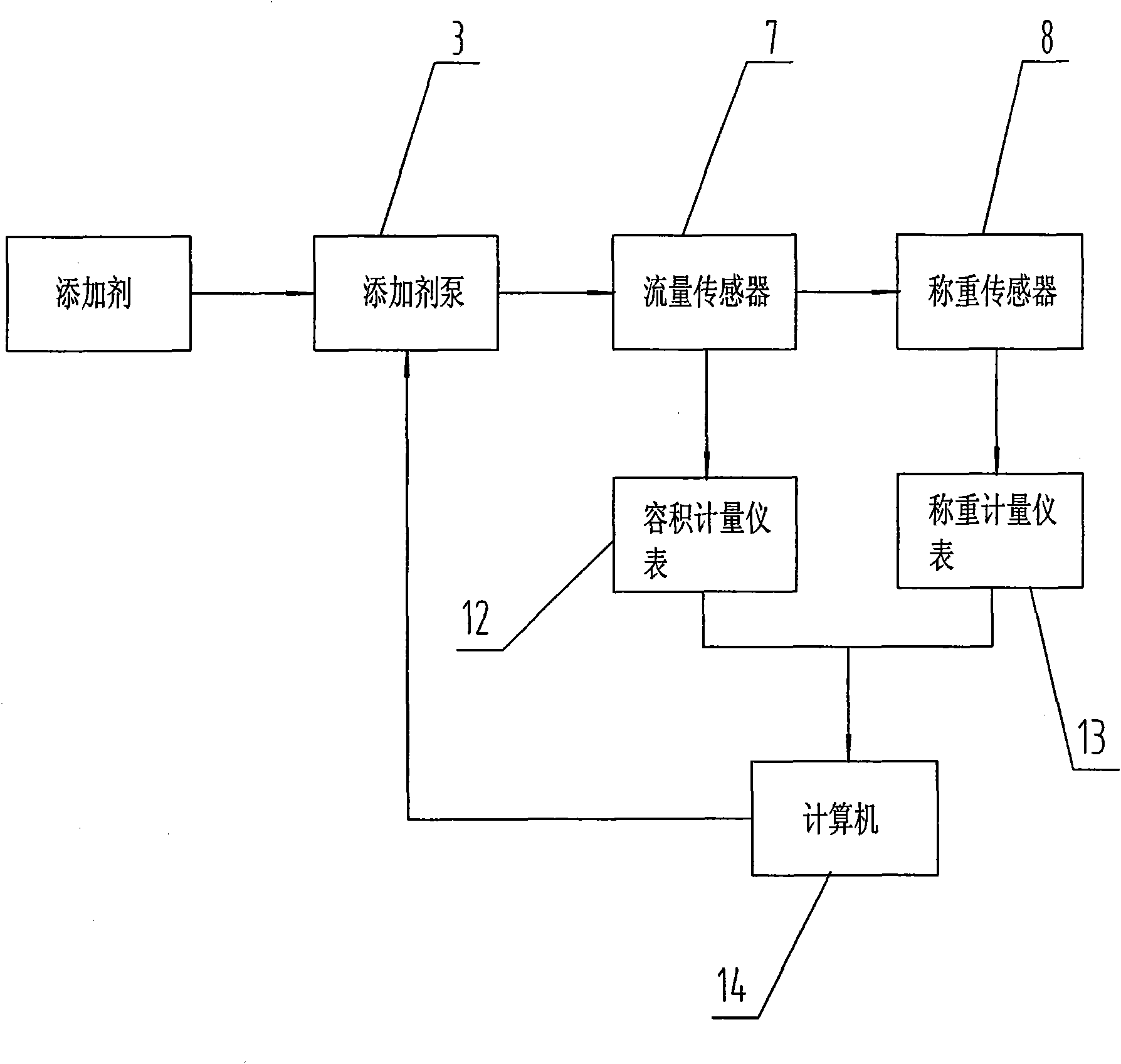

Additive metering system and metering method of cement concrete stirring device

InactiveCN101659087AOvercoming the Defects of Inaccurate Weighing and Measurement ResultsGuaranteed accuracyLiquid ingredients supply apparatusAutomatic controlControl system

The invention discloses an additive metering system and a metering method of a cement concrete stirring device, the additive metering system comprises an additive liquid storage tank, a ball valve, anadditive pump, a check valve, a flow sensor, a weighing sensor, an additive weighing tank, a support of the weighing tank and a discharge pneumatic butterfly valve, and a control system is constituted by a flowmeter, a weighing instrument and a computer. The additive metering adopts the method which combines the volumetric metering with the electronic weighing metering, the two metering results are simultaneously inputted into the computer for carrying out comparison, when any metering result achieves the set value of ingredients within the set error range, the additive pump is closed. The metering method adopts the method which combines the volumetric metering with the electronic weighing metering, when the pneumatic butterfly valve below the weighing tank is not closed tightly or otherfaults occur in the system, the computer carries out the comparison treatment on output values of the volumetric metering and the electronic weighing metering, thereby automatically controlling the opening and the closing of the additive pump and further ensuring the precision of the actual amount of the ingredients of the additive.

Owner:中外合资江苏华通动力重工有限公司

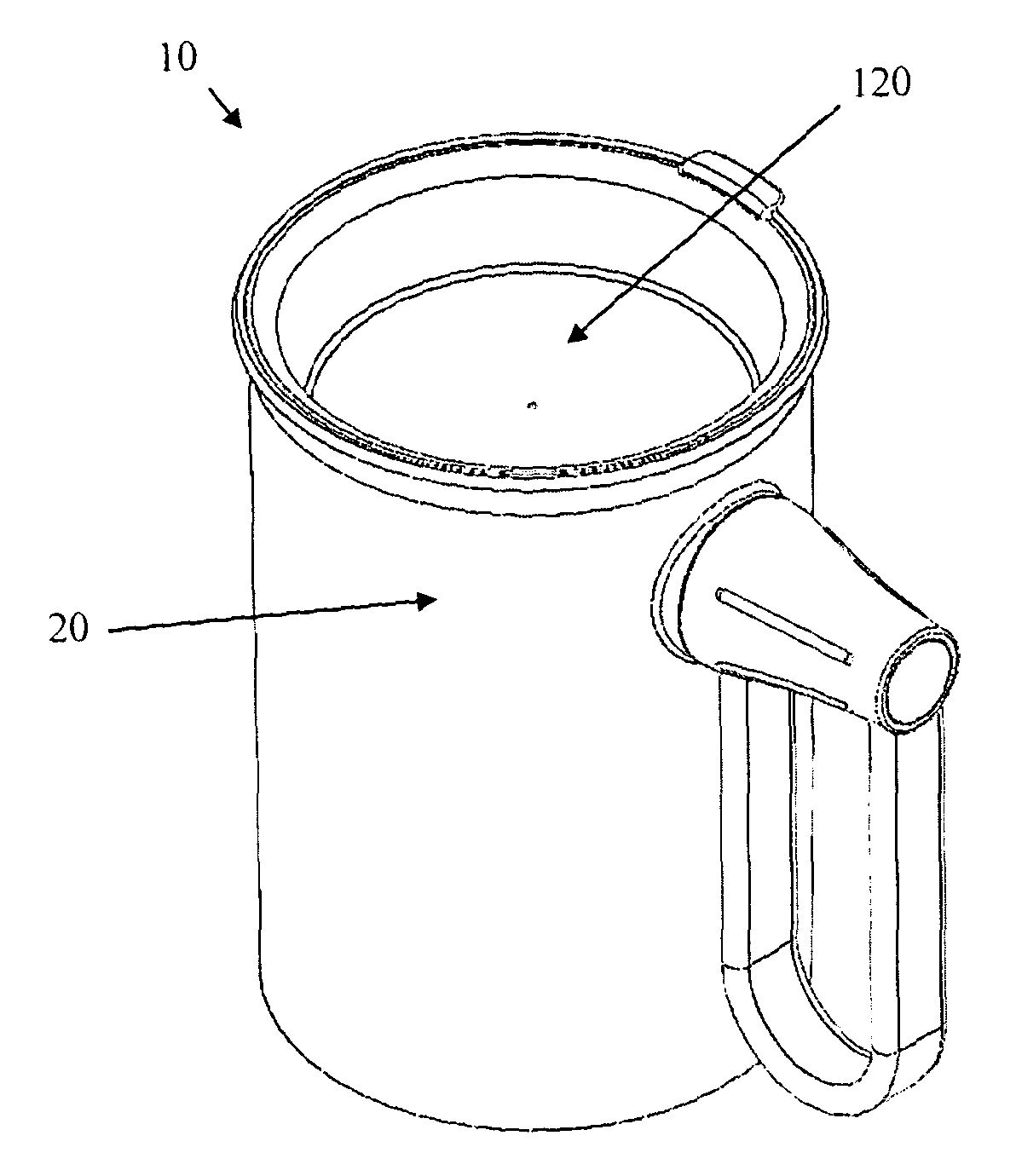

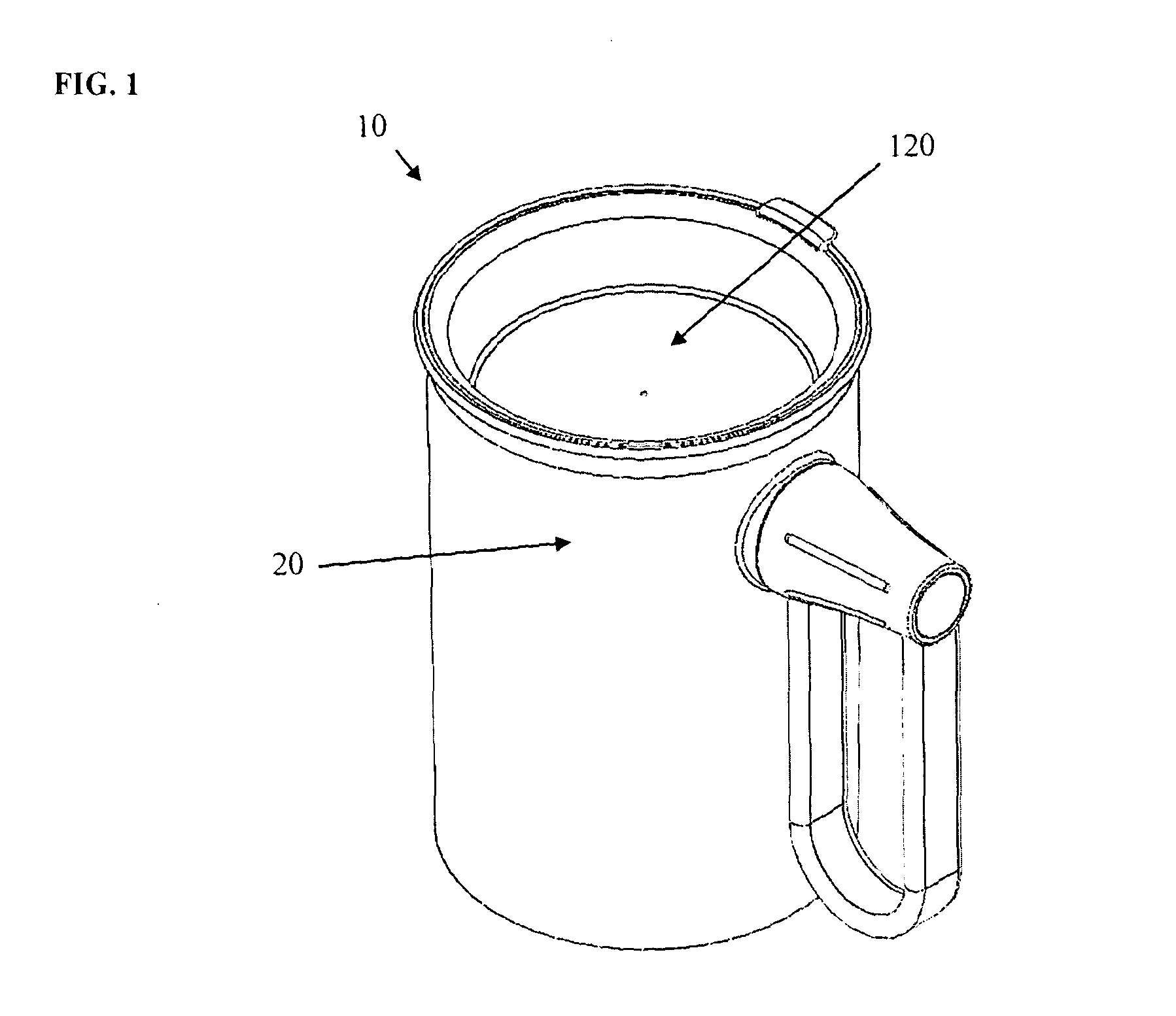

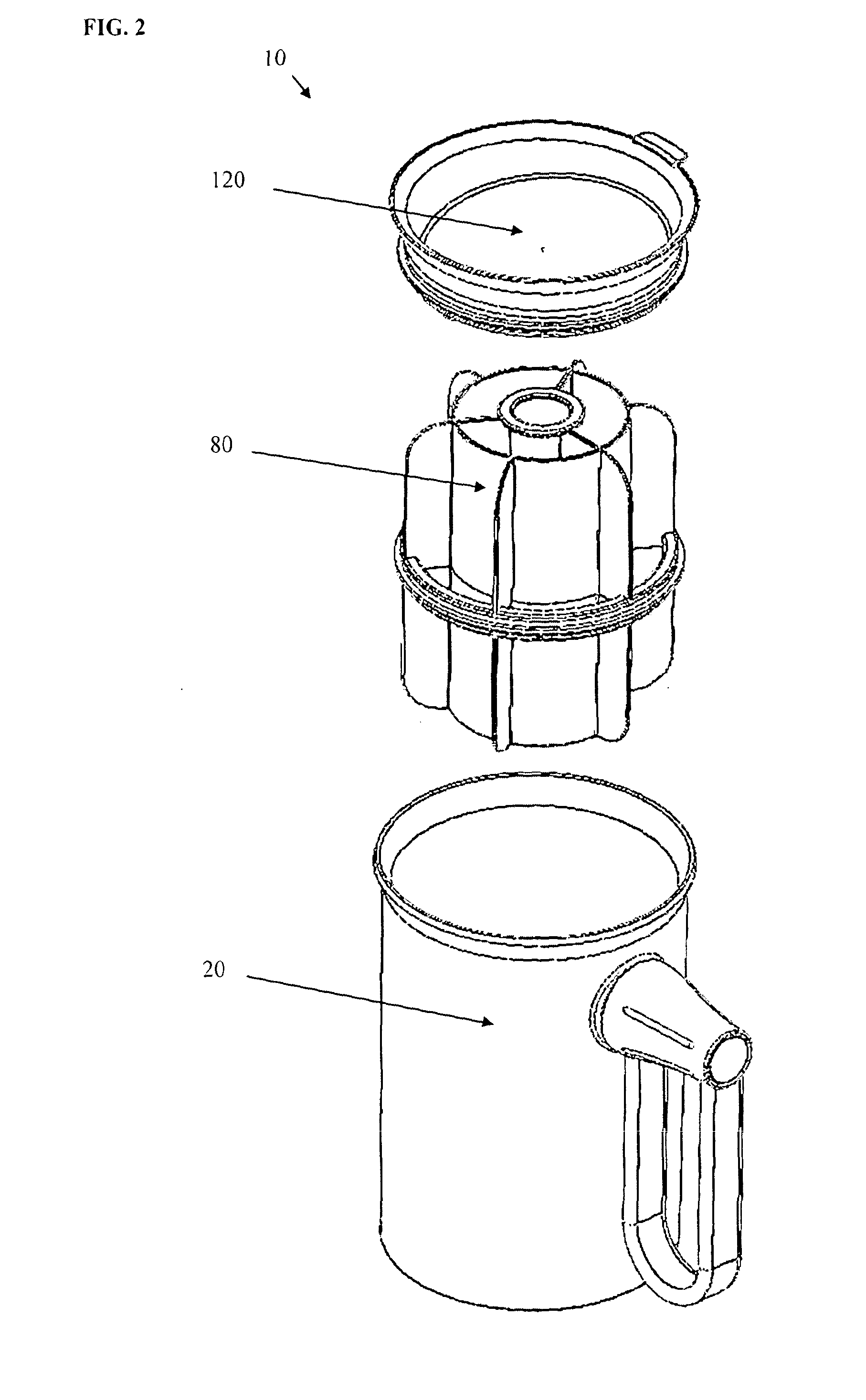

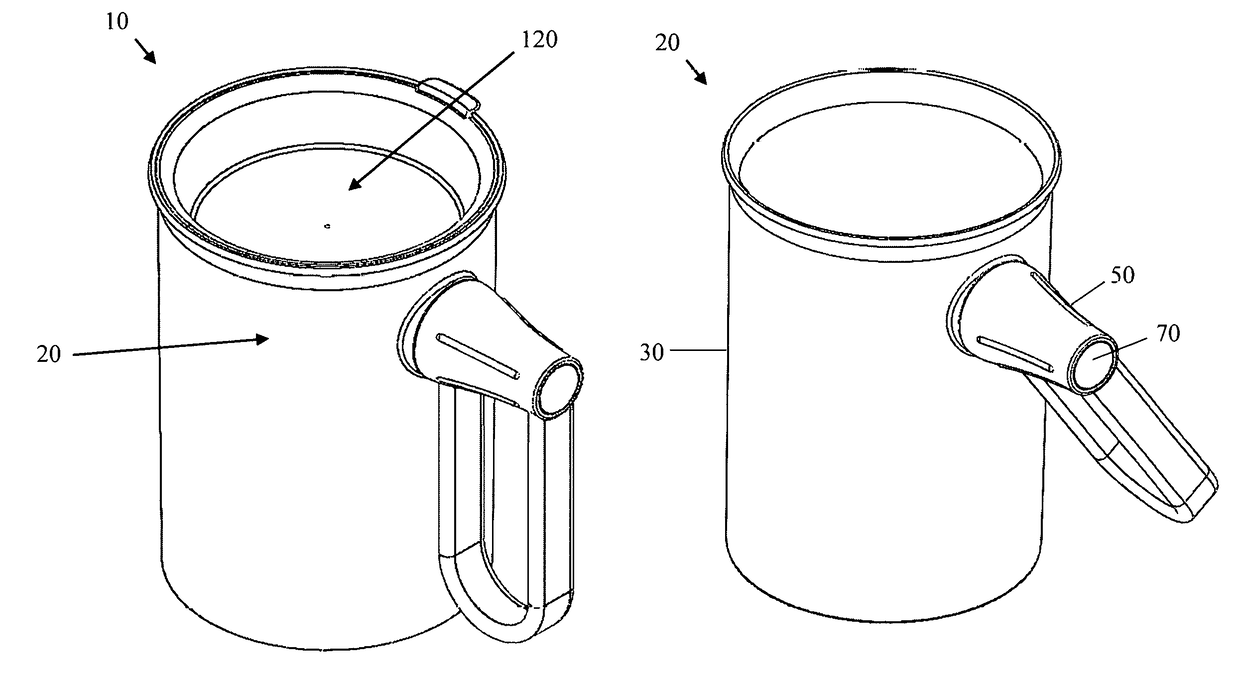

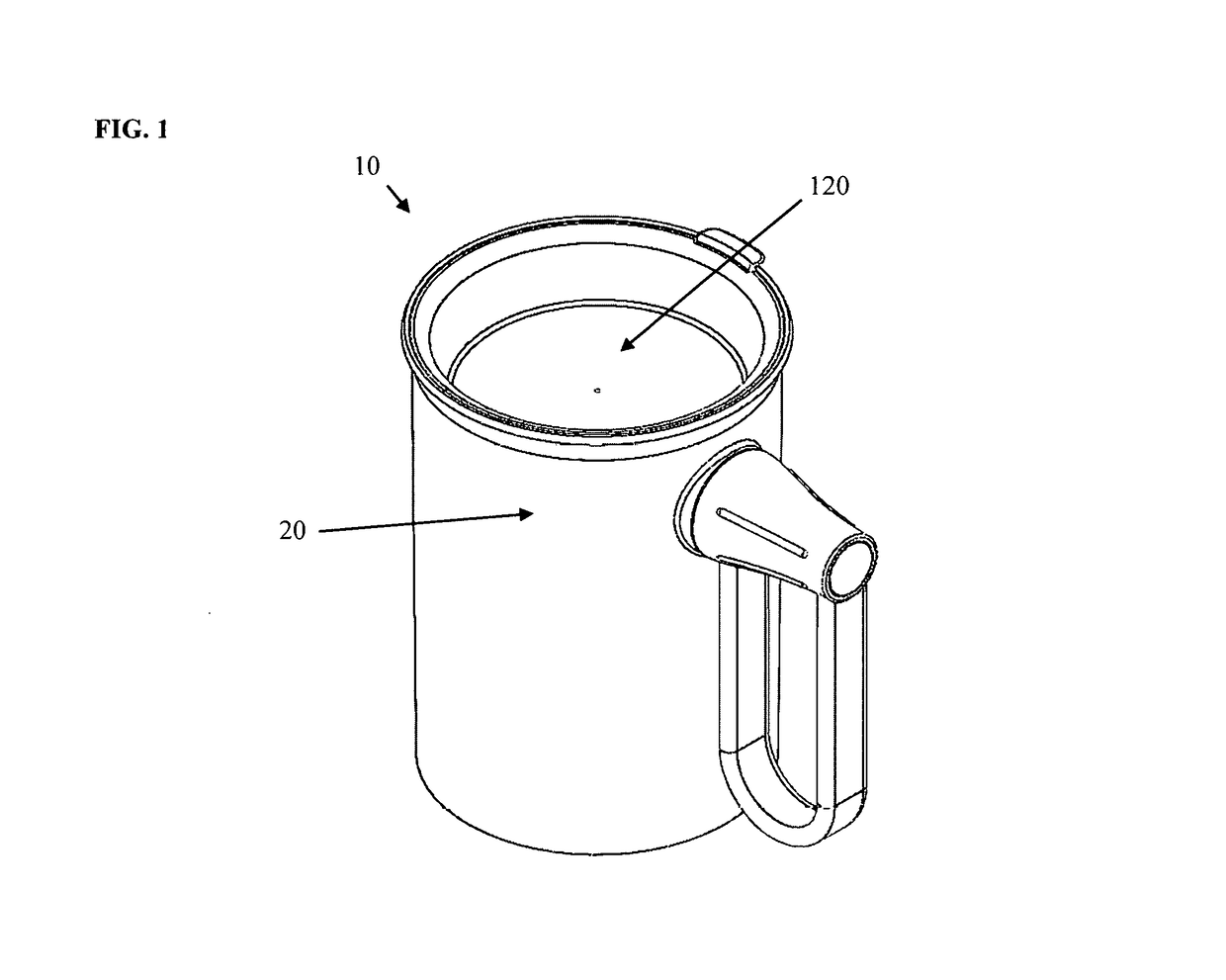

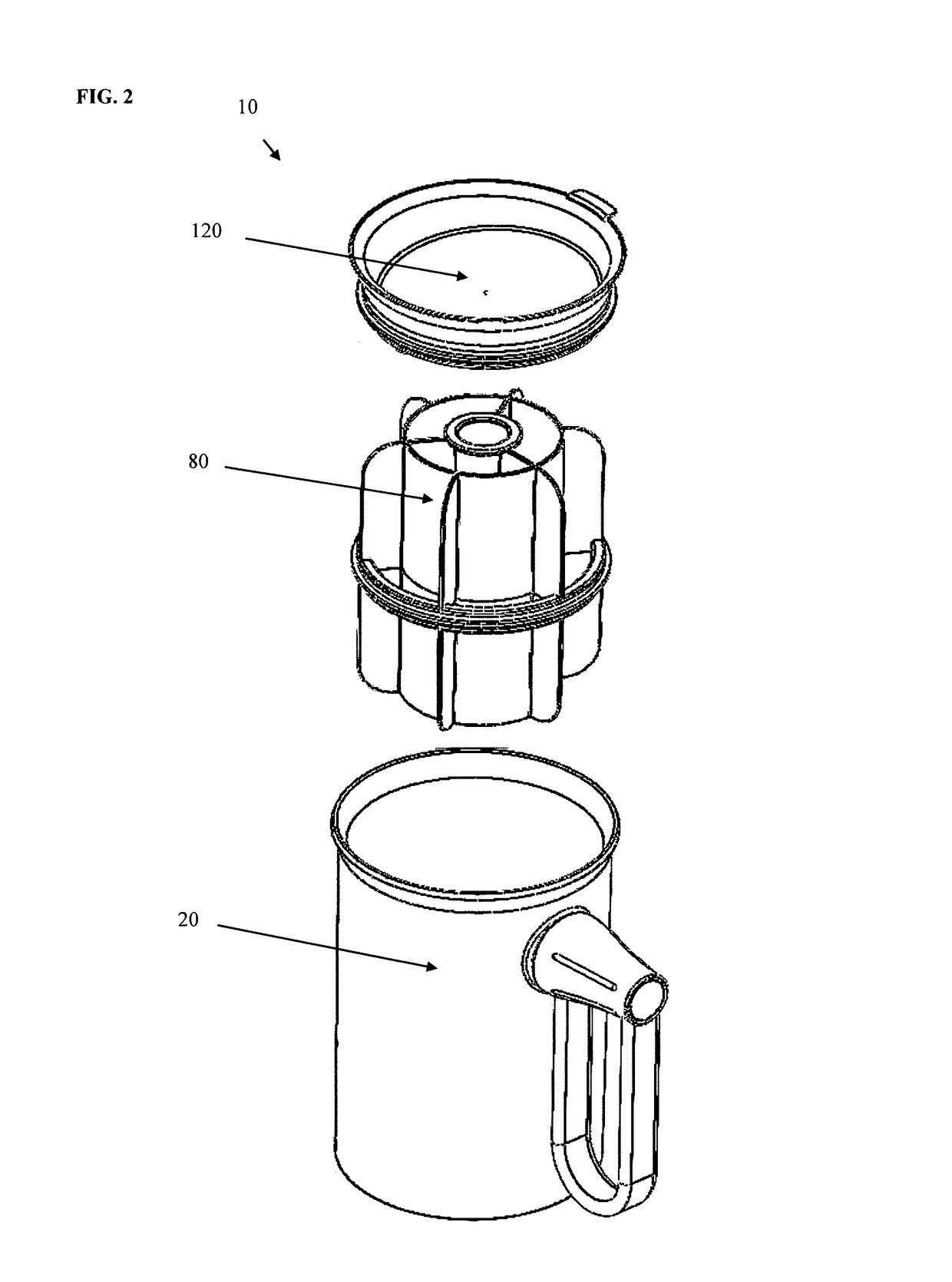

Liquid-dispensing container with single gimbal mechanism

A household liquid-dispensing container such as a drinking vessel or a jug comprising a vessel (30) that is configured to hold a liquid and that has a base (37) on which it can stand, an opening (39) and at least one side (38); and a handle (50) that is configured to be held by a user and that is attached to a side of the vessel (38) by a joint that forms a single gimbal between the handle (50) and the vessel (30) and that allows the handle (50) to pivot about a single axis (21) that extends directly above the centre of gravity of the vessel (30) when the vessel base (37) is standing on a horizontal surface: an optional baffle assembly (80) to reduce sloshing; and a lid (120).

Owner:PEACOCK CHRISTOPHER JAMES

Liquid-dispensing container with single gimbal mechanism

A household liquid-dispensing container such as a drinking vessel or a jug comprising a vessel (30) that is configured to hold a liquid and that has a base (37) on which it can stand, an opening (39) and at least one side (38); and a handle (50) that is configured to be held by a user and that is attached to a side of the vessel (38) by a joint that forms a single gimbal between the handle (50) and the vessel (30) and that allows the handle (50) to pivot about a single axis (21) that extends directly above the center of gravity of the vessel (30) when the vessel base (37) is standing on a horizontal surface; an optional baffle assembly (80) to reduce sloshing; and a lid (120).

Owner:PEACOCK CHRISTOPHER JAMES

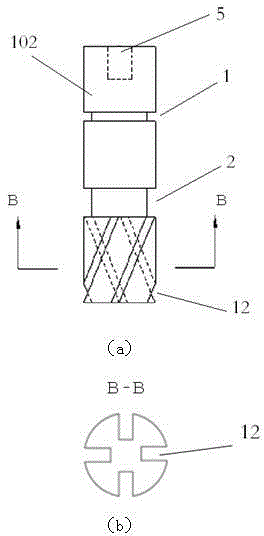

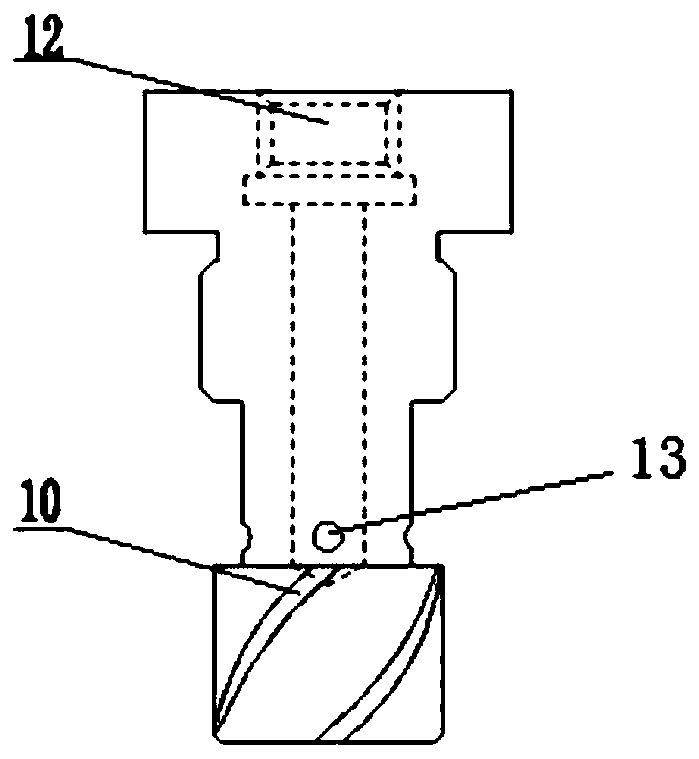

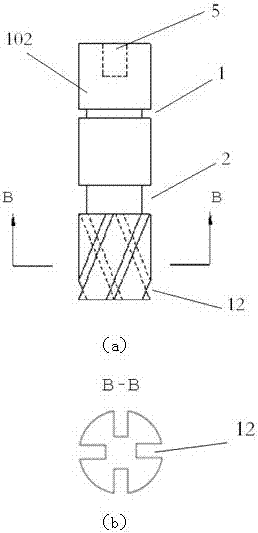

Novel atomizing nozzle based on bubble cutting

PendingCN110449283ASmall diameterImprove atomization qualityLiquid spraying apparatusEngineeringMixing chamber

The invention provides a novel atomizing nozzle based on bubble cutting. The novel atomizing nozzle comprises an internal assembly and an external assembly, wherein closed space formed by the internalassembly and the external assembly constitutes a mixing chamber of the nozzle, the internal assembly comprises an inner core and a bubble divider, the external assembly comprises a casing and a sprayhead, a first air inlet hole is formed in the top of the inner core, an external thread is formed at the upper part of the inner core below the first air inlet hole, multiple second air inlet holes are formed in the inner core below the external thread, and swirling grooves are formed in the inner core located below the second air inlet holes; the casing is a hollow opening round tube, an internal thread at the upper part of the casing is tightly connected with the external thread on the inner core through a sealing structure, a liquid inlet hole is formed in the side surface of the casing, and an external thread is formed at the lower part of the casing; an internal thread is formed at the upper part of the spray head, a spray hole is formed in the central position of the closed end of the spray head, the bubble divider is mounted in a hollow cavity in the lower part of the casing, and the casing and the bubble divider are tightly connected with the spray head through a sealing structure. The novel atomizing nozzle has higher atomizing quality, and the average diameter of particles is smaller and more uniform.

Owner:HEBEI UNIV OF TECH

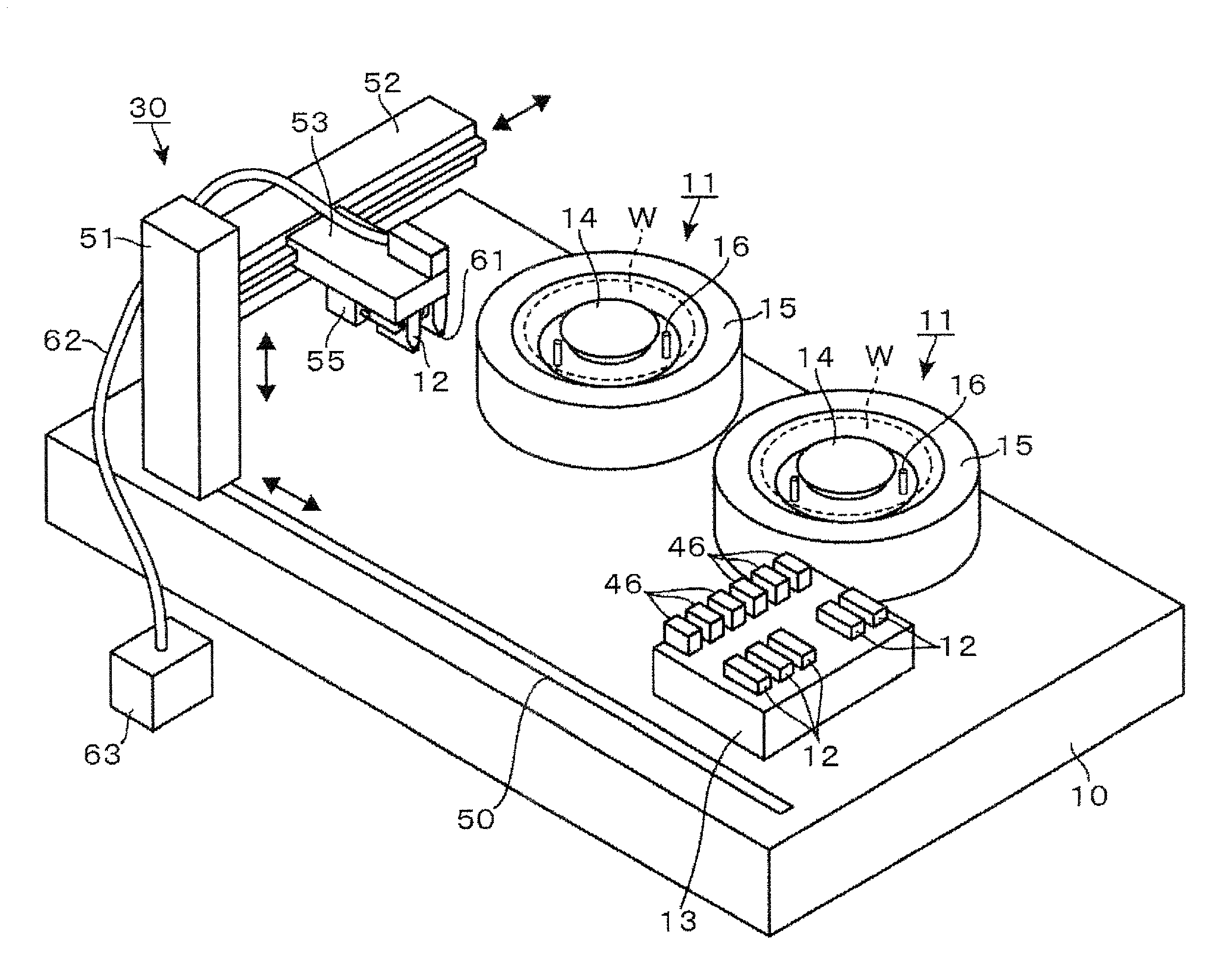

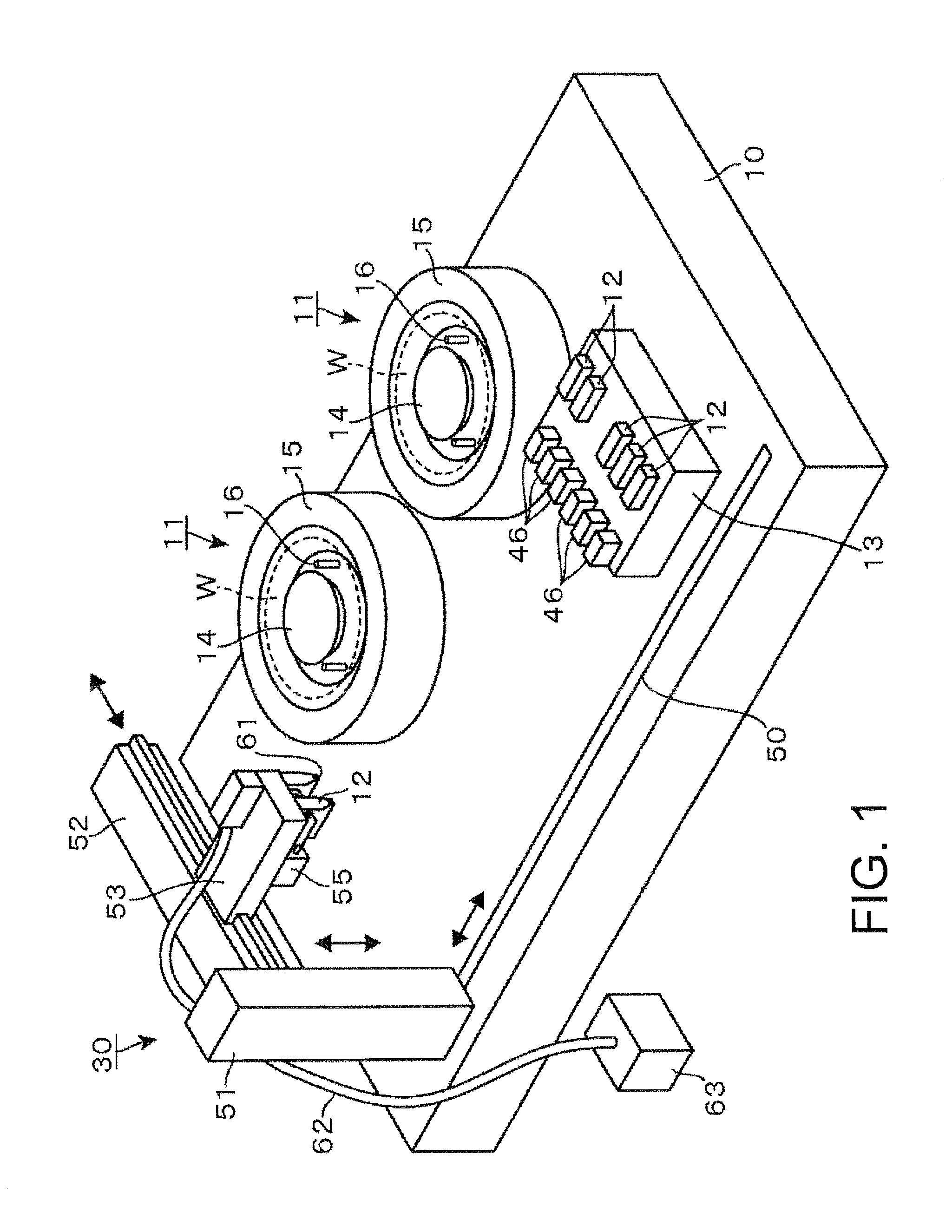

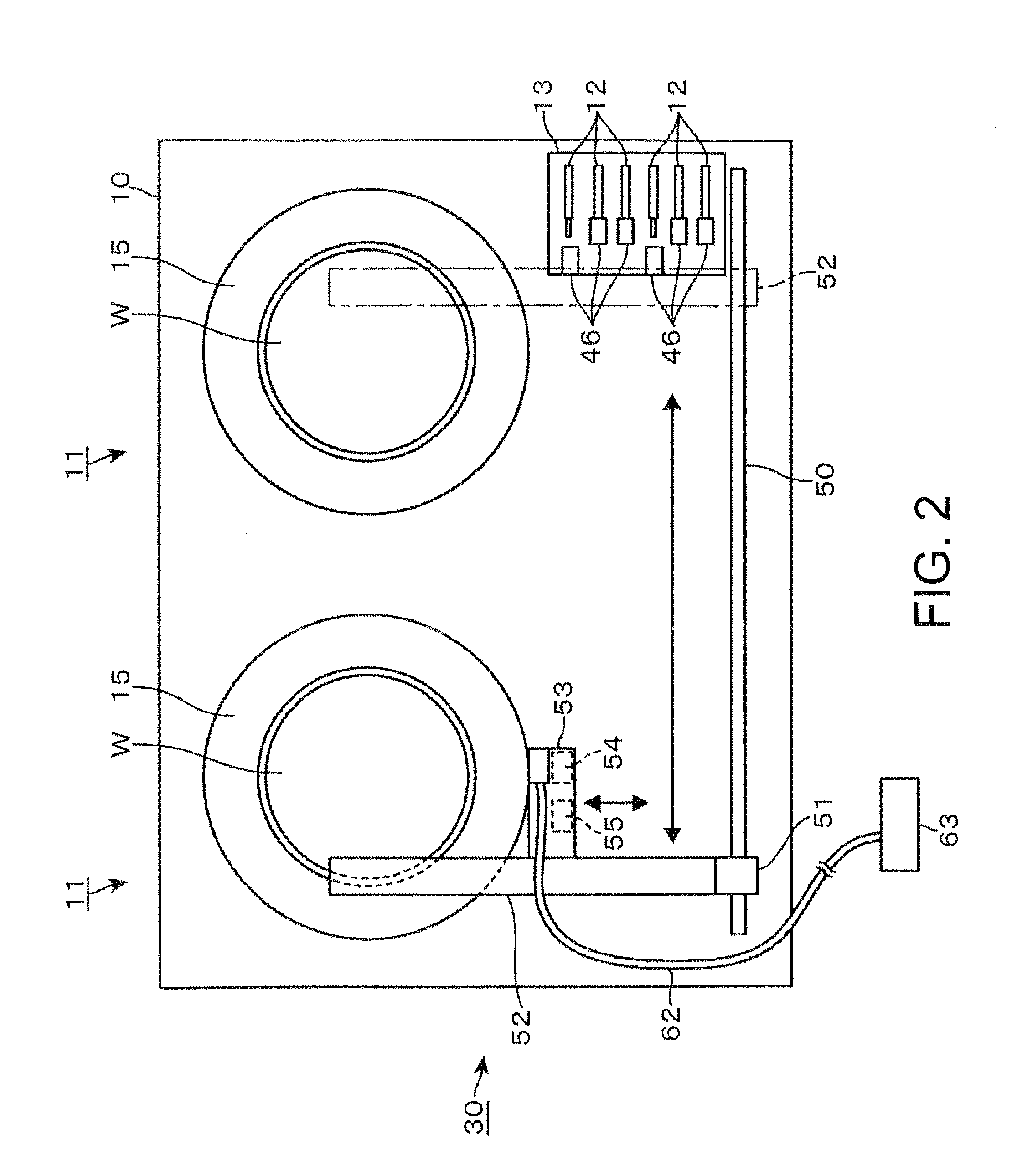

Liquid supplying apparatus

InactiveUS20150165458A1Less pressure lossReduce liquid flowLiquid surface applicatorsSemiconductor/solid-state device manufacturingEnvironmental engineering

An embodiment of a liquid supplying apparatus for supplying a processing liquid to a process object includes: a processing liquid cartridge including: a reservoir chamber for storing the processing liquid; an ejecting port for ejecting the processing liquid stored in the reservoir chamber; a pusher unit for pushing the processing liquid stored in the reservoir chamber outward through the ejecting port; and a replenishing port for replenishing the processing liquid into the reservoir chamber; a standby unit having a standby area where the processing liquid cartridge is standing-by; a transport mechanism that transports the processing liquid cartridge between the standby unit and a location where the processing liquid cartridge supplies the processing liquid to the process object; and an actuating mechanism provided in the transport mechanism that drives the pusher unit to push the processing liquid stored in the reservoir chamber.

Owner:TOKYO ELECTRON LTD

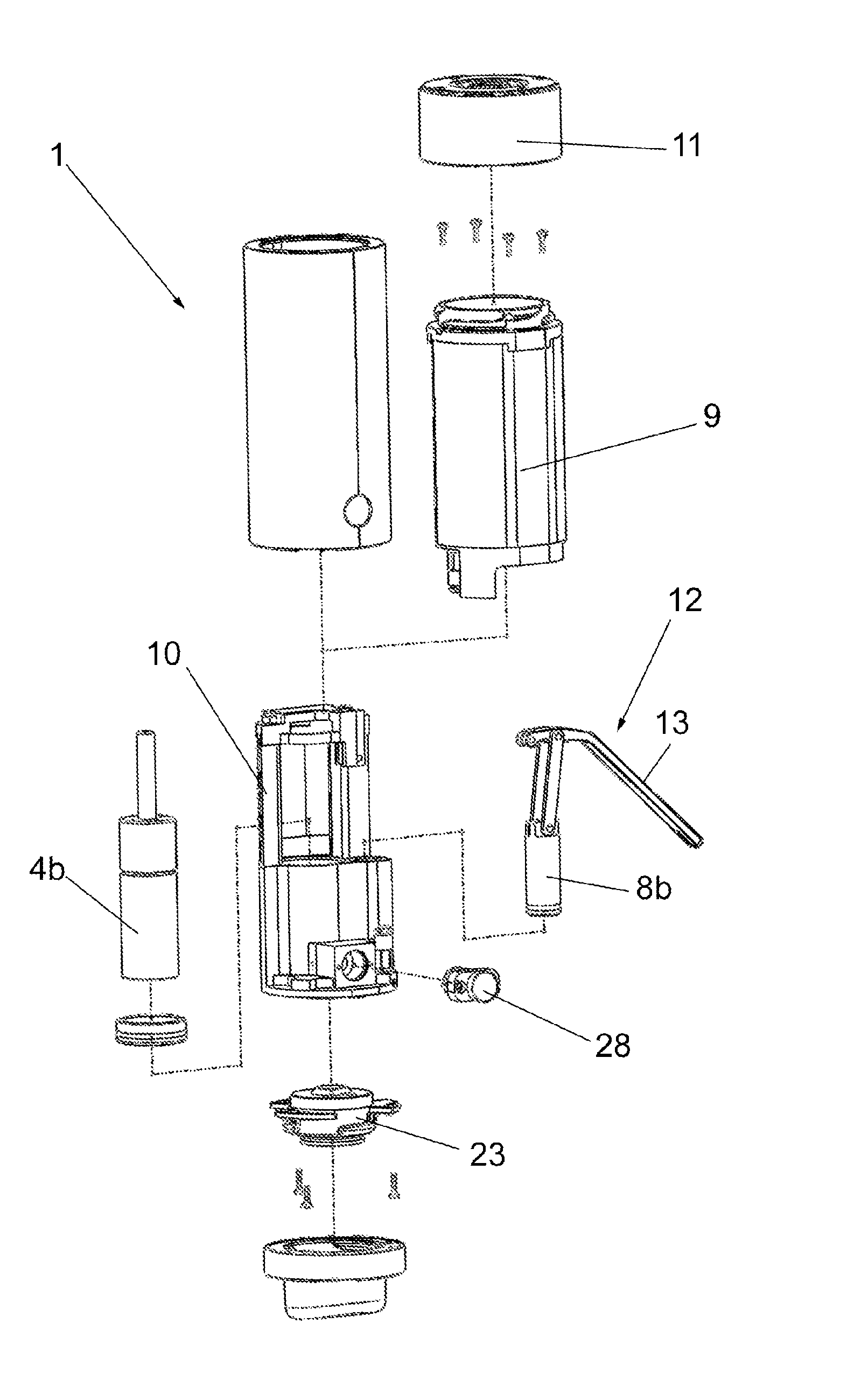

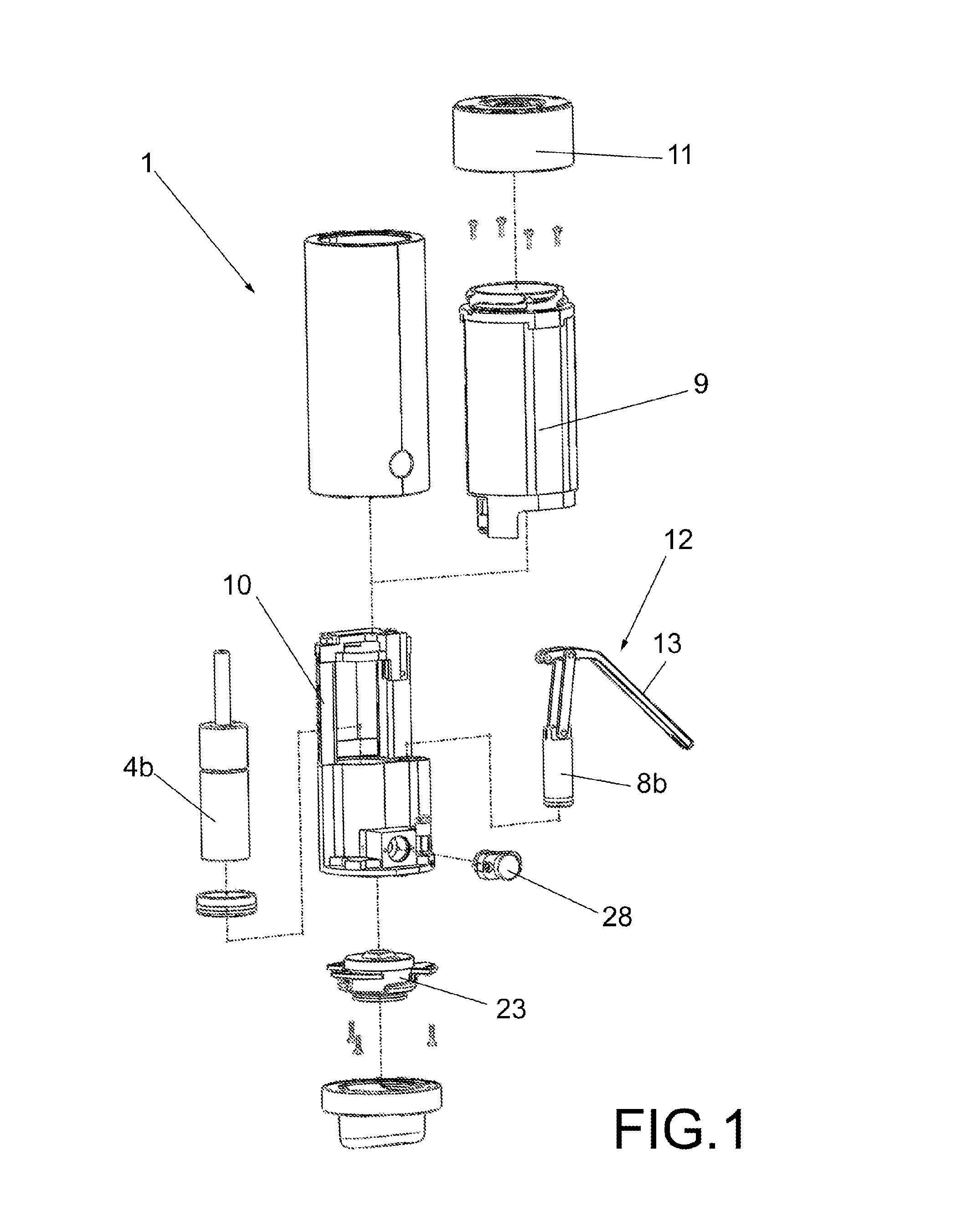

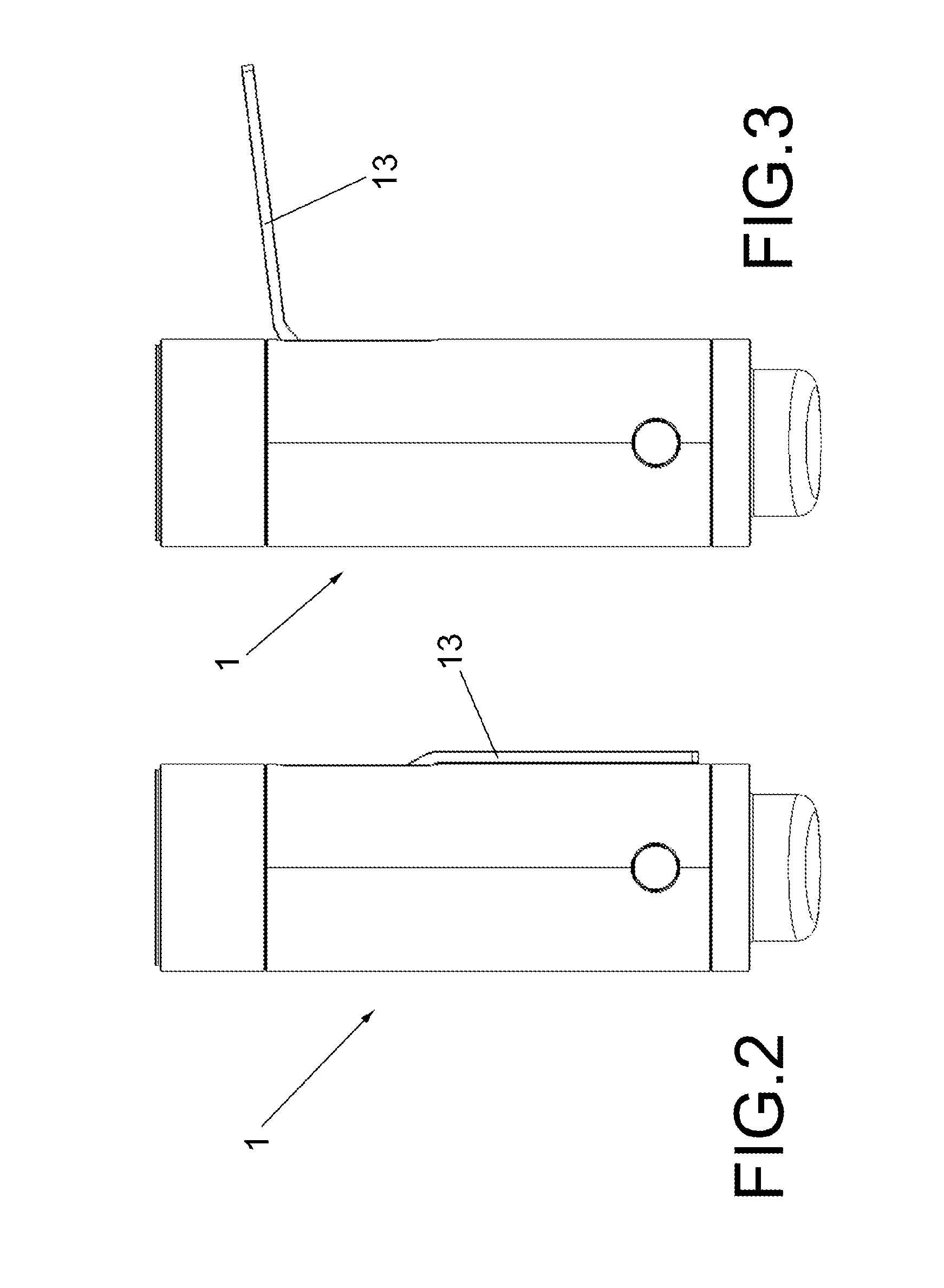

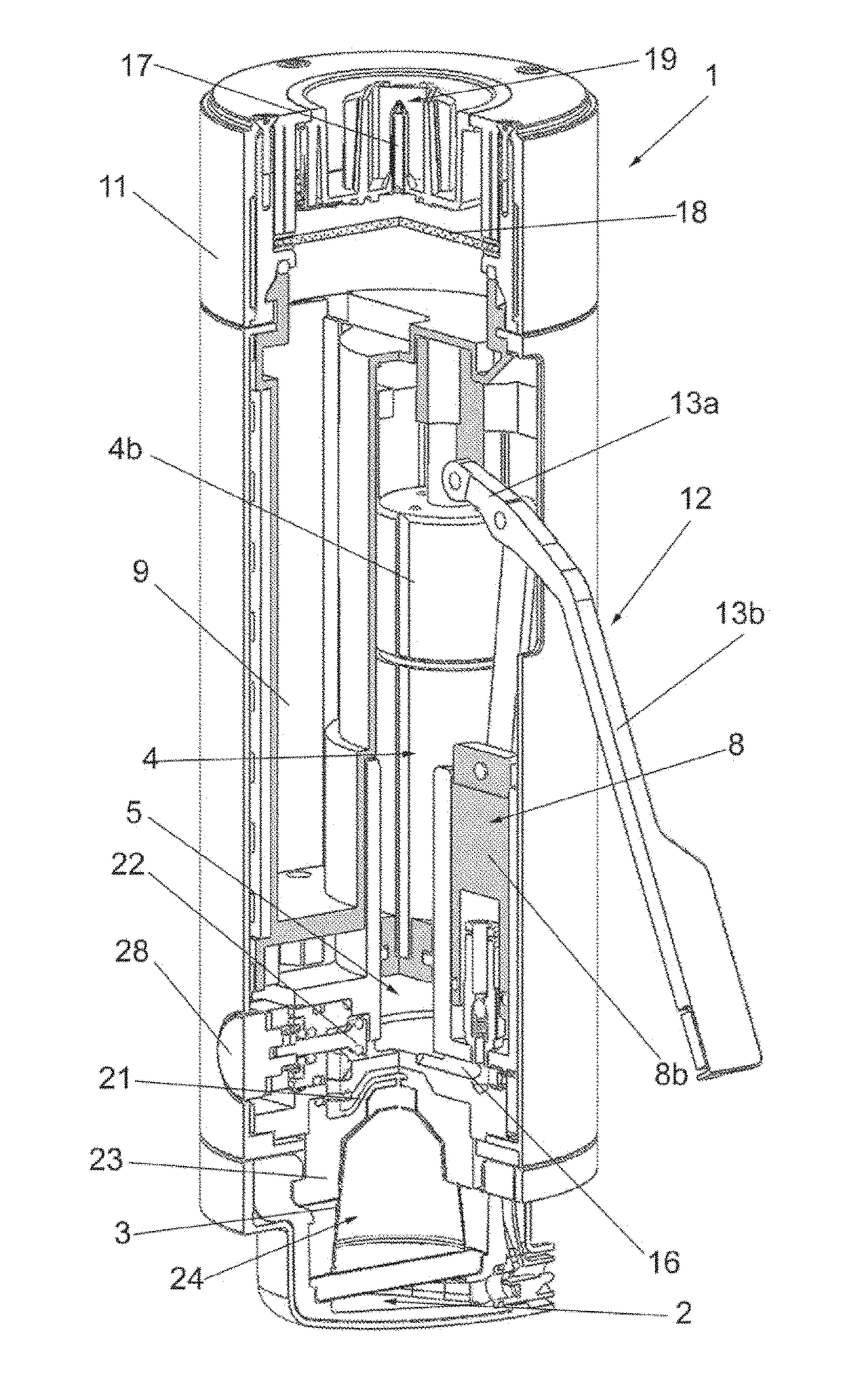

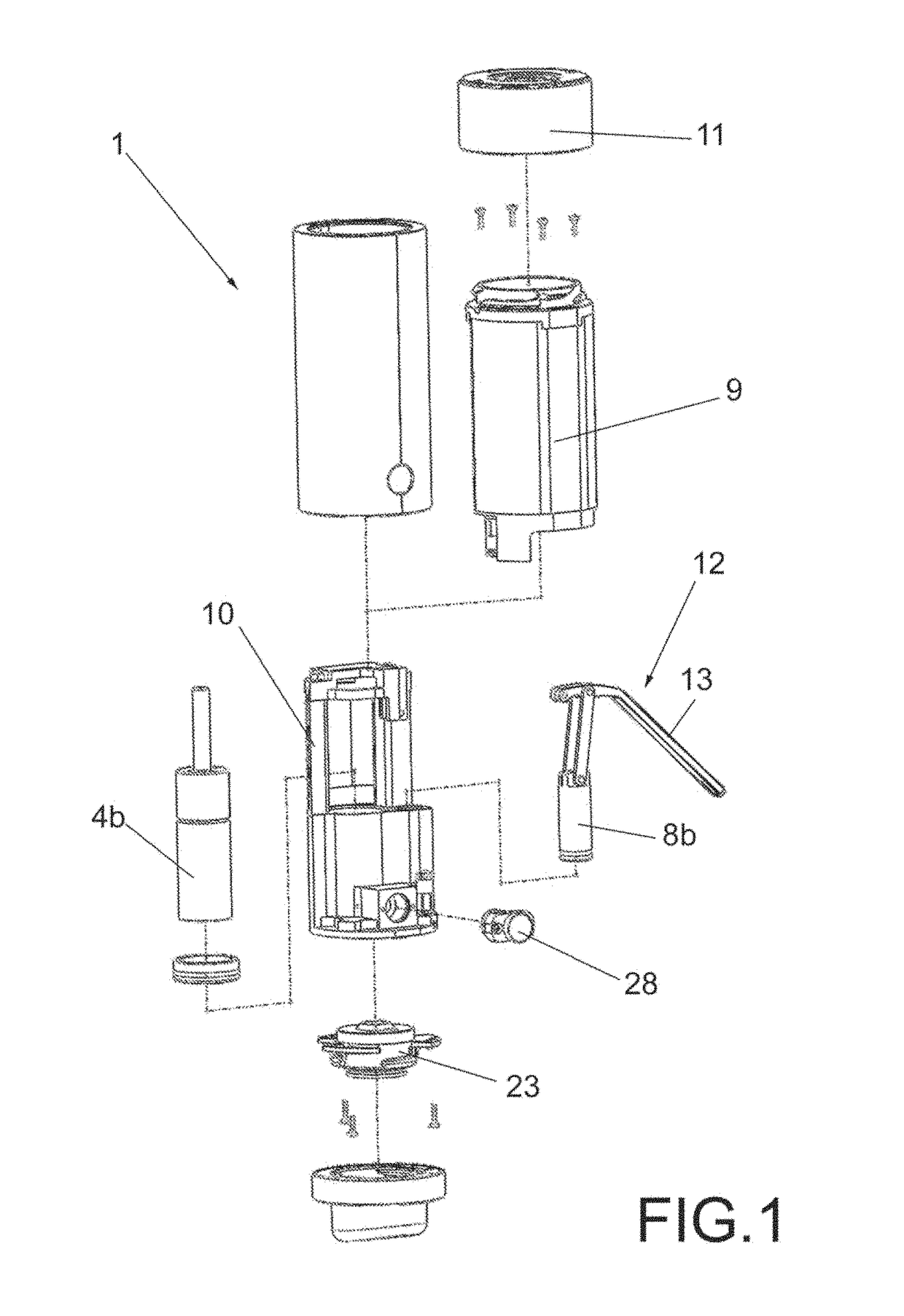

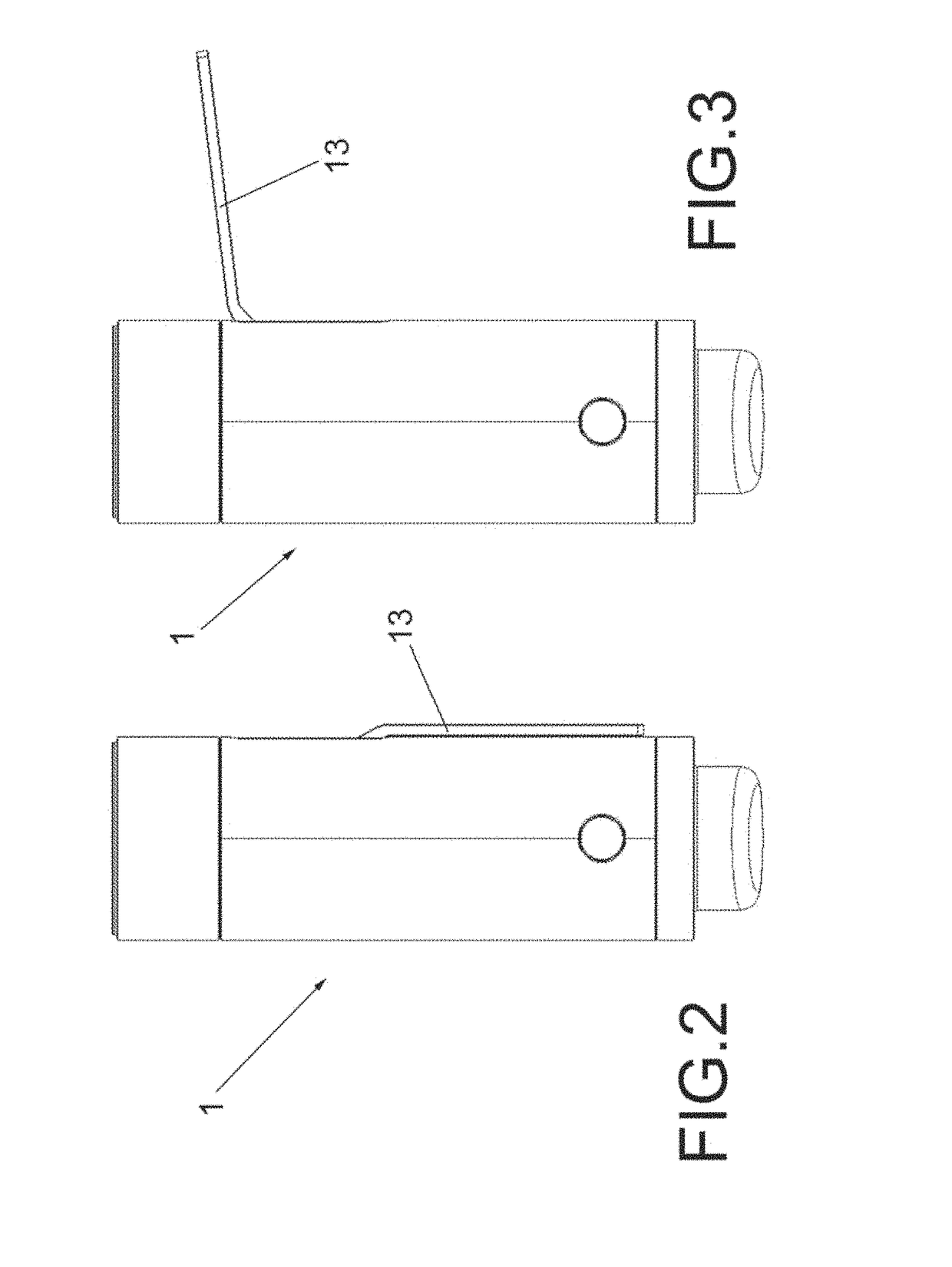

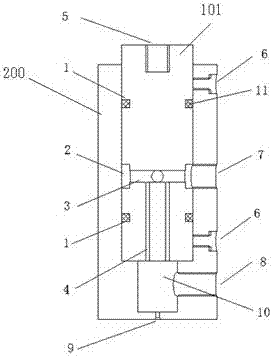

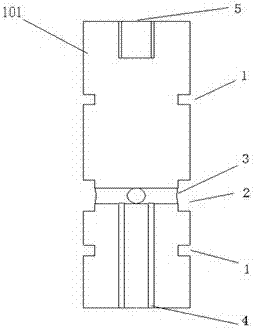

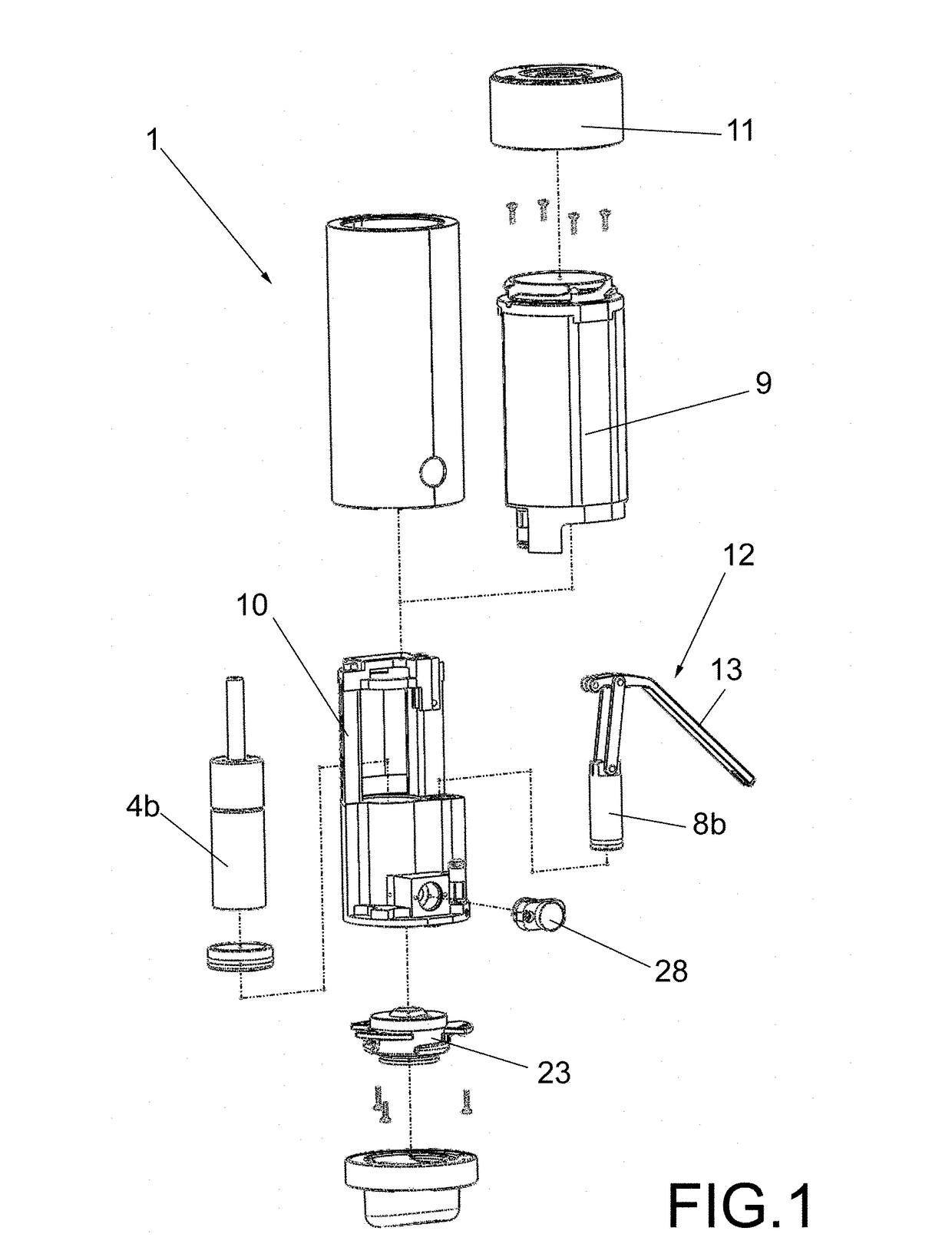

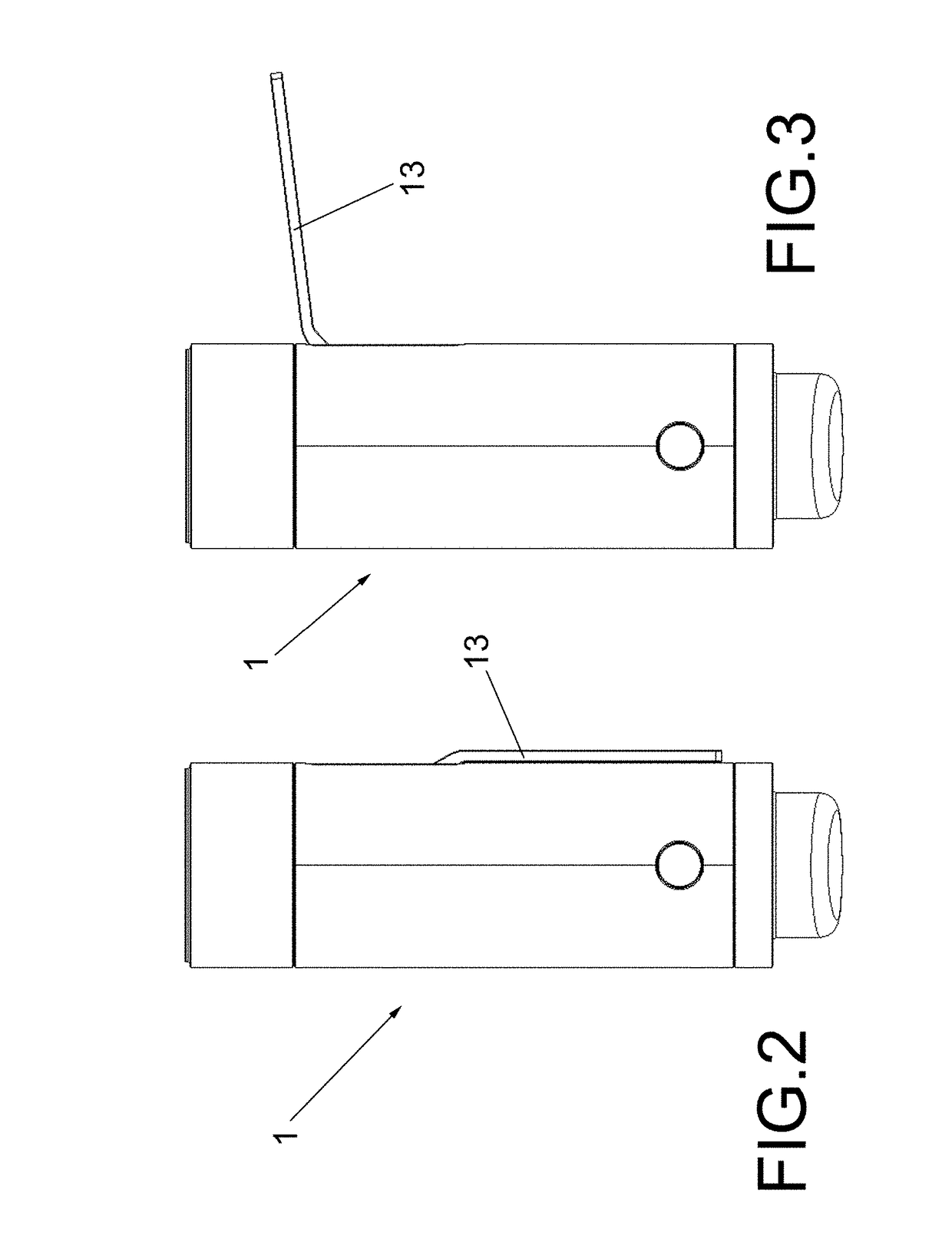

Machine for preparing a drink and method for preparing a drink using such a machine

InactiveUS20150327712A1Guaranteed continuous supplyShorten speedBeverage vesselsFood preparationEngineeringMechanical engineering

It comprises an infusion chamber (2) for housing a dose of product and means for supplying a liquid under pressure to said infusion chamber, said supply means comprising a hydraulic accumulator device (4a, 4b) susceptible of storing under pressure a liquid from liquid injection means (8, 8a, 8b, 9, 25) of said machine (1, 1′), characterised in that said liquid injection means (8, 8a, 8b, 9, 25) and said hydraulic accumulator device (4a, 4b) are configured and disposed interconnected to the infusion chamber (2), so that a first fraction of injected liquid is susceptible of being stored under pressure in a cavity (5) of said accumulator device (4a, 4b), while a second fraction of the injected liquid is simultaneously distributed or supplied to the exterior through the infusion chamber (2) of the machine (1, 1′), allowing said accumulator device (4a, 4b) to store a fraction of liquid configured to ensure the continuous supply of a certain flow (Qc) during a predetermined beverage preparation time or distribution time (te). The process comprises the steps of retracting the distribution cylinder (4a) piston (4b) or an element of said accumulator device to its active position through the injection of a liquid from an independent storage reservoir (9), and simultaneously supplying the liquid injected under pressure.

Owner:MINIMMA ESPRESSO

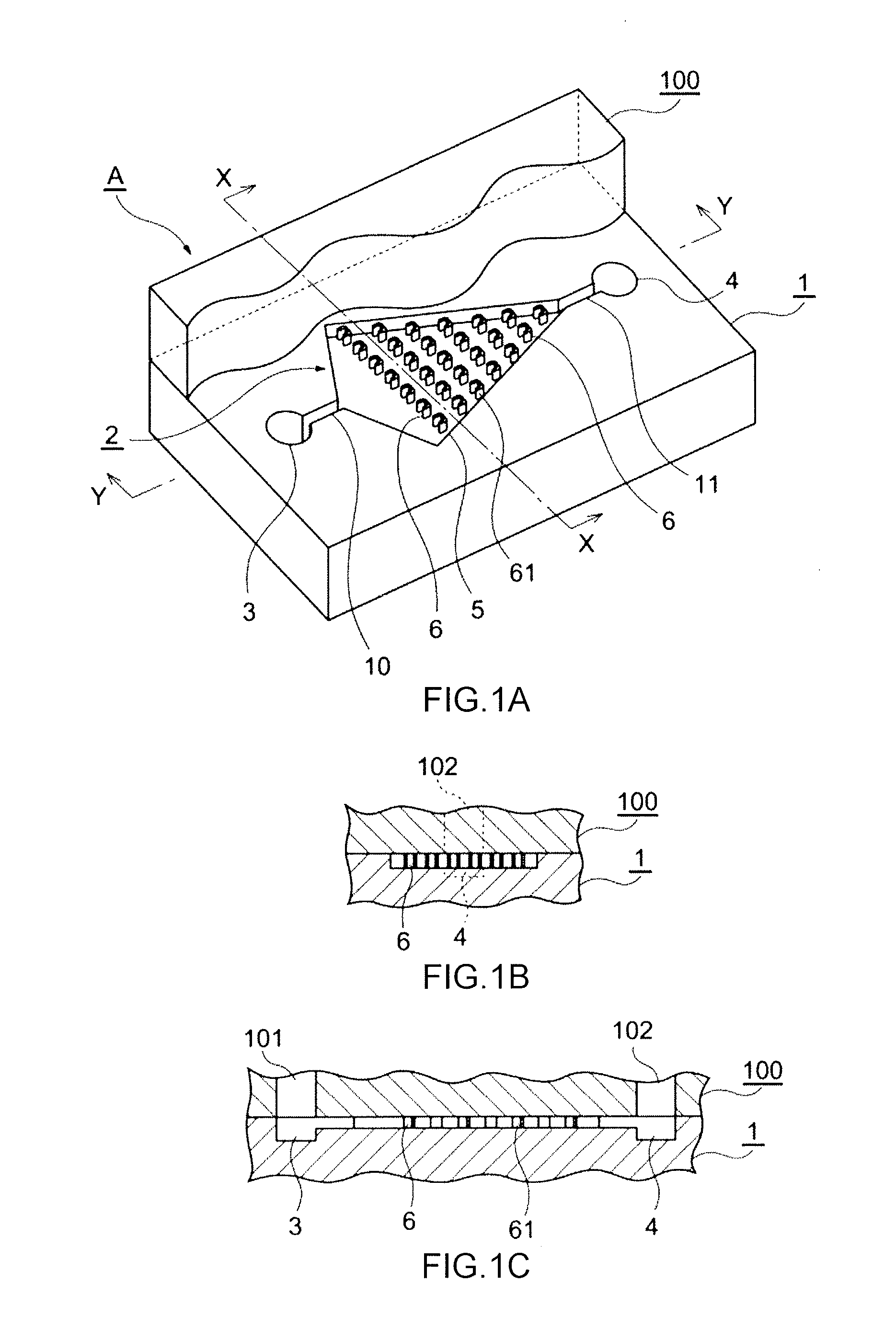

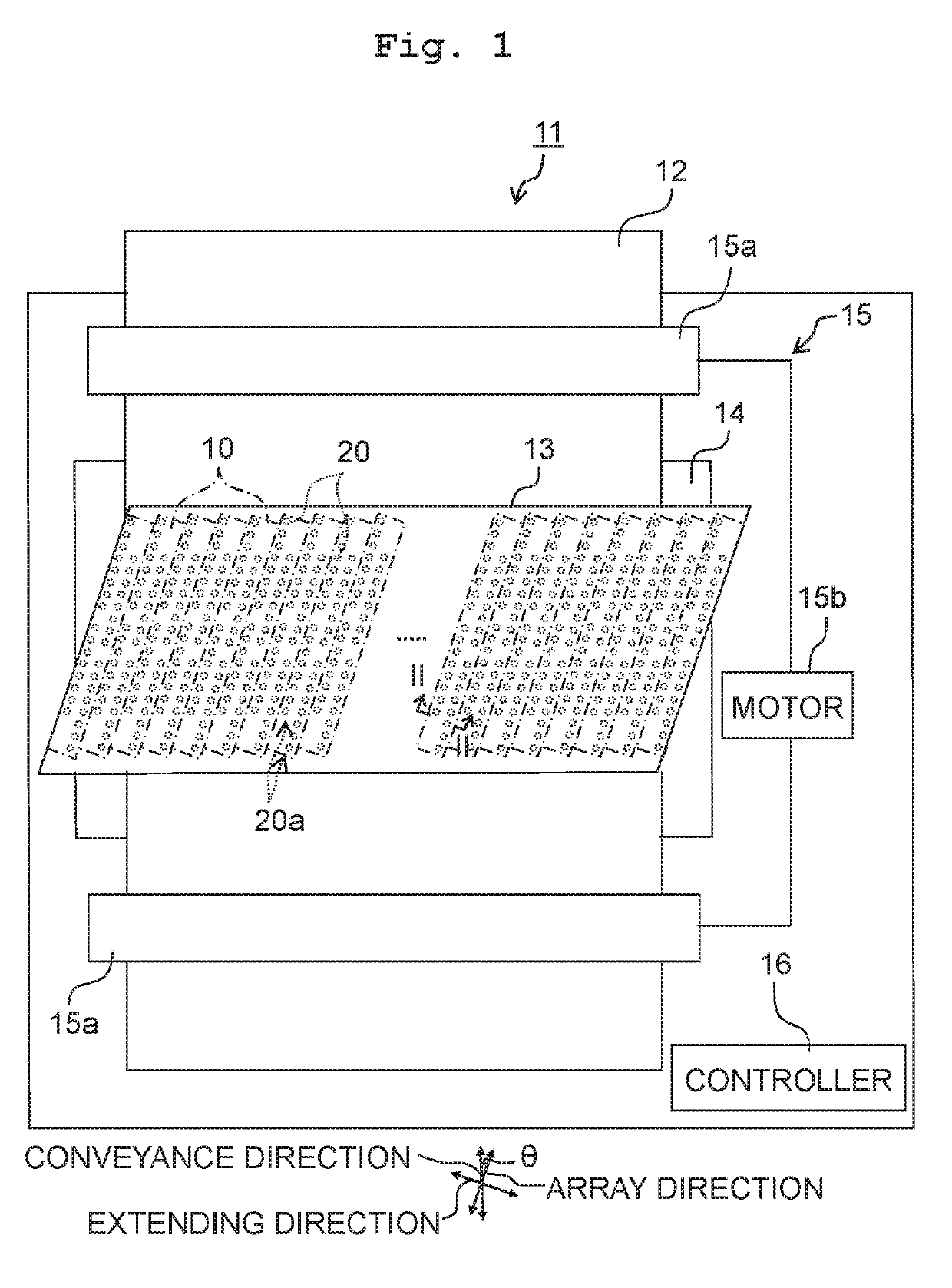

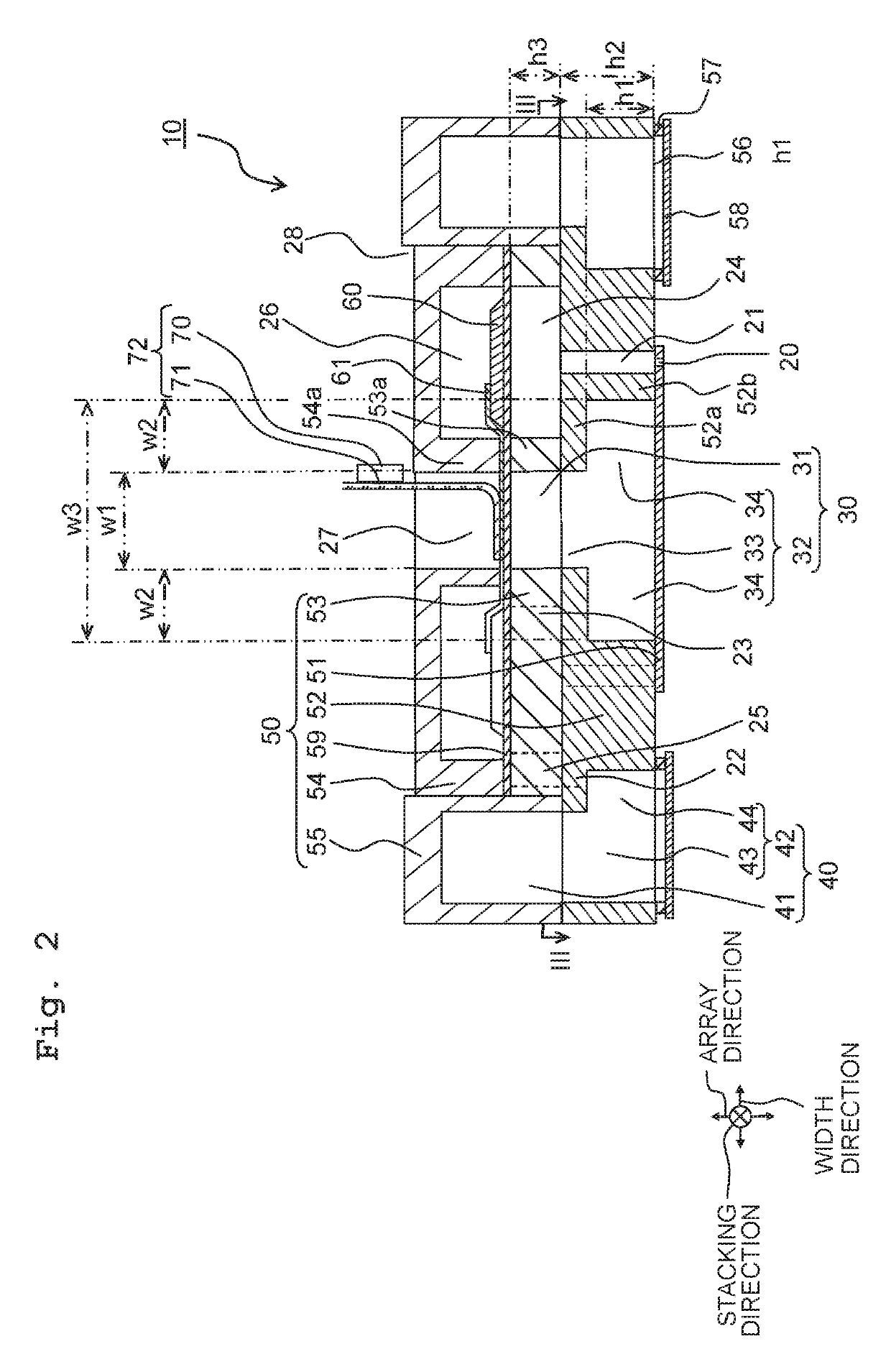

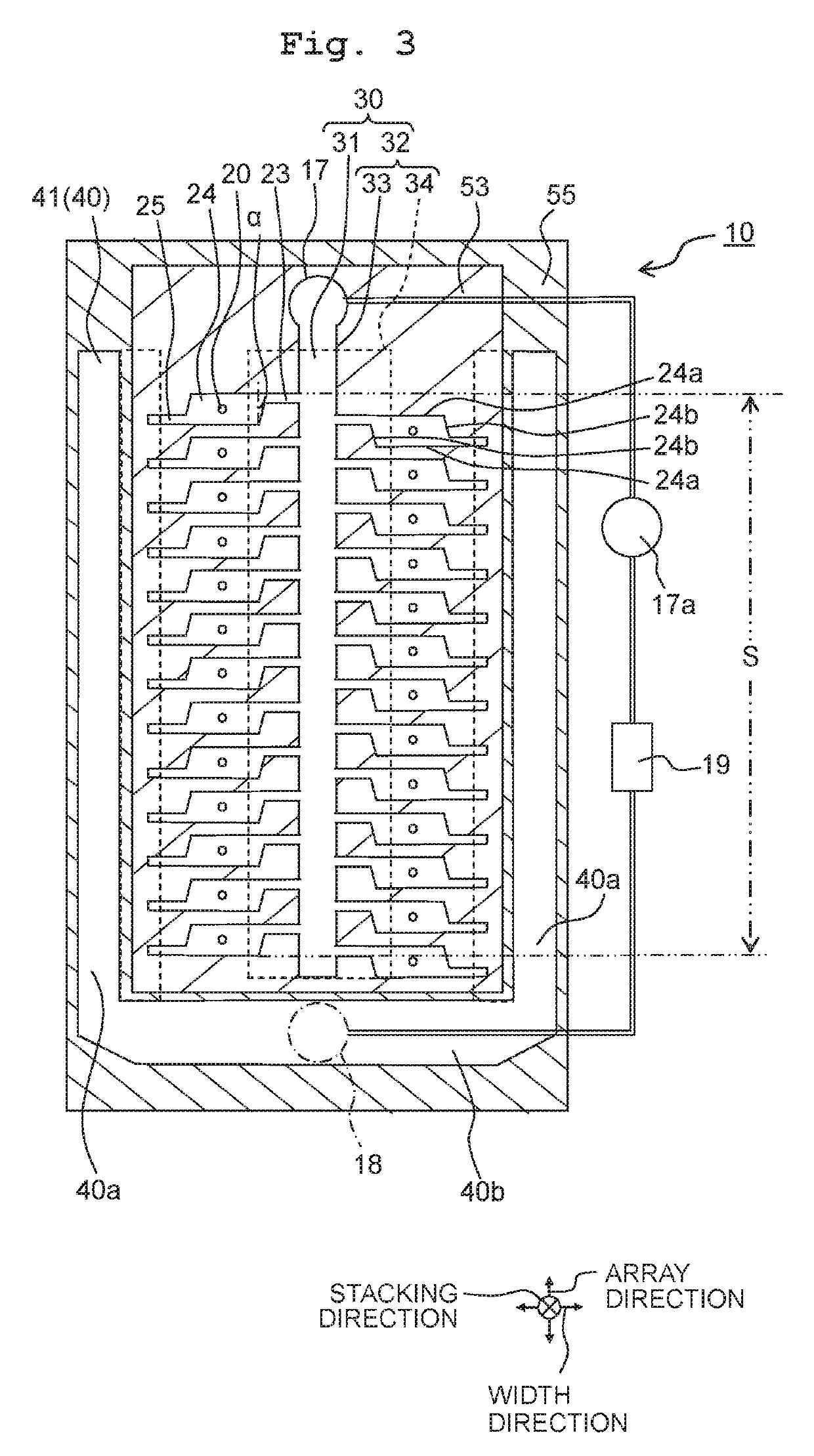

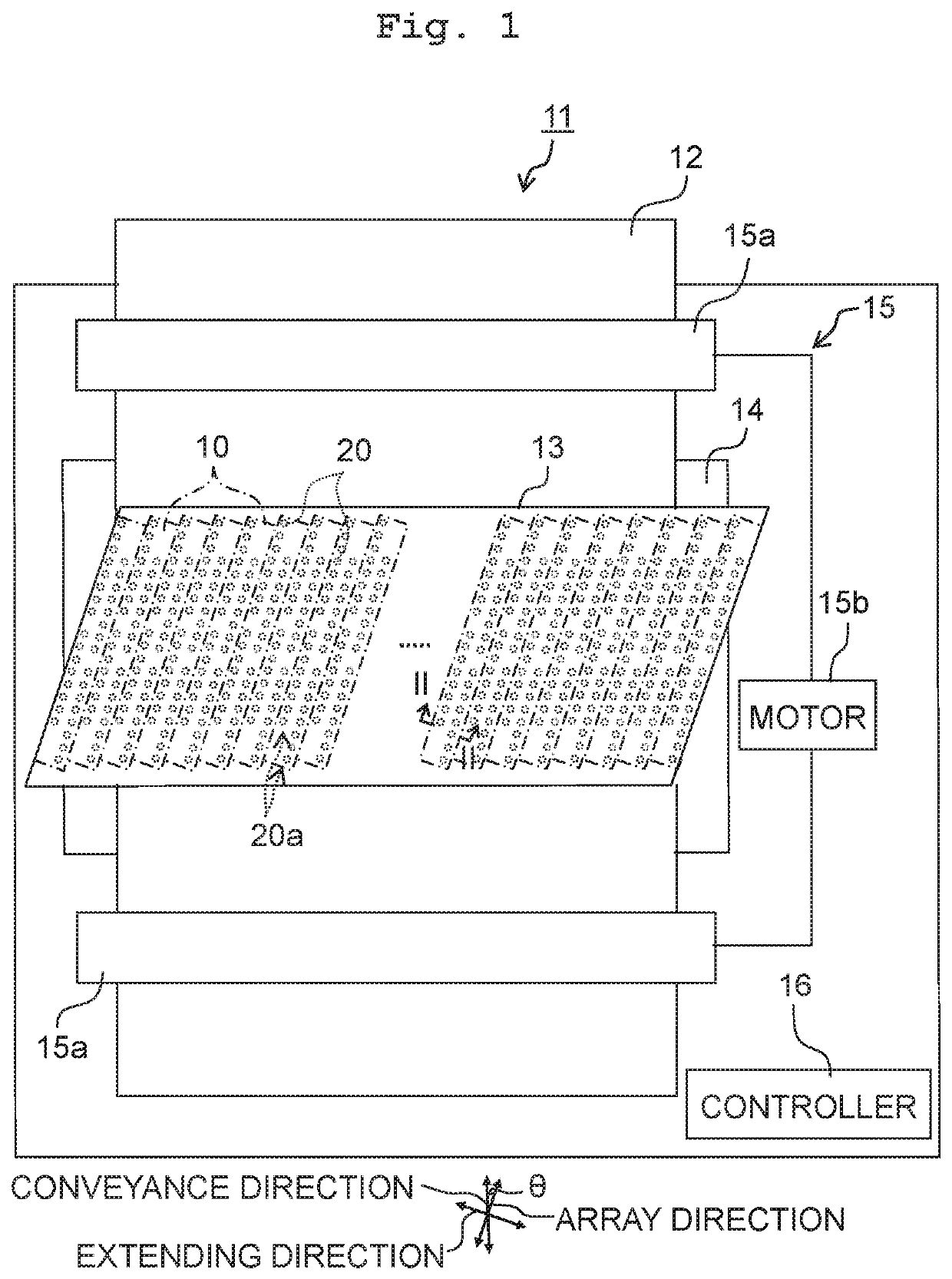

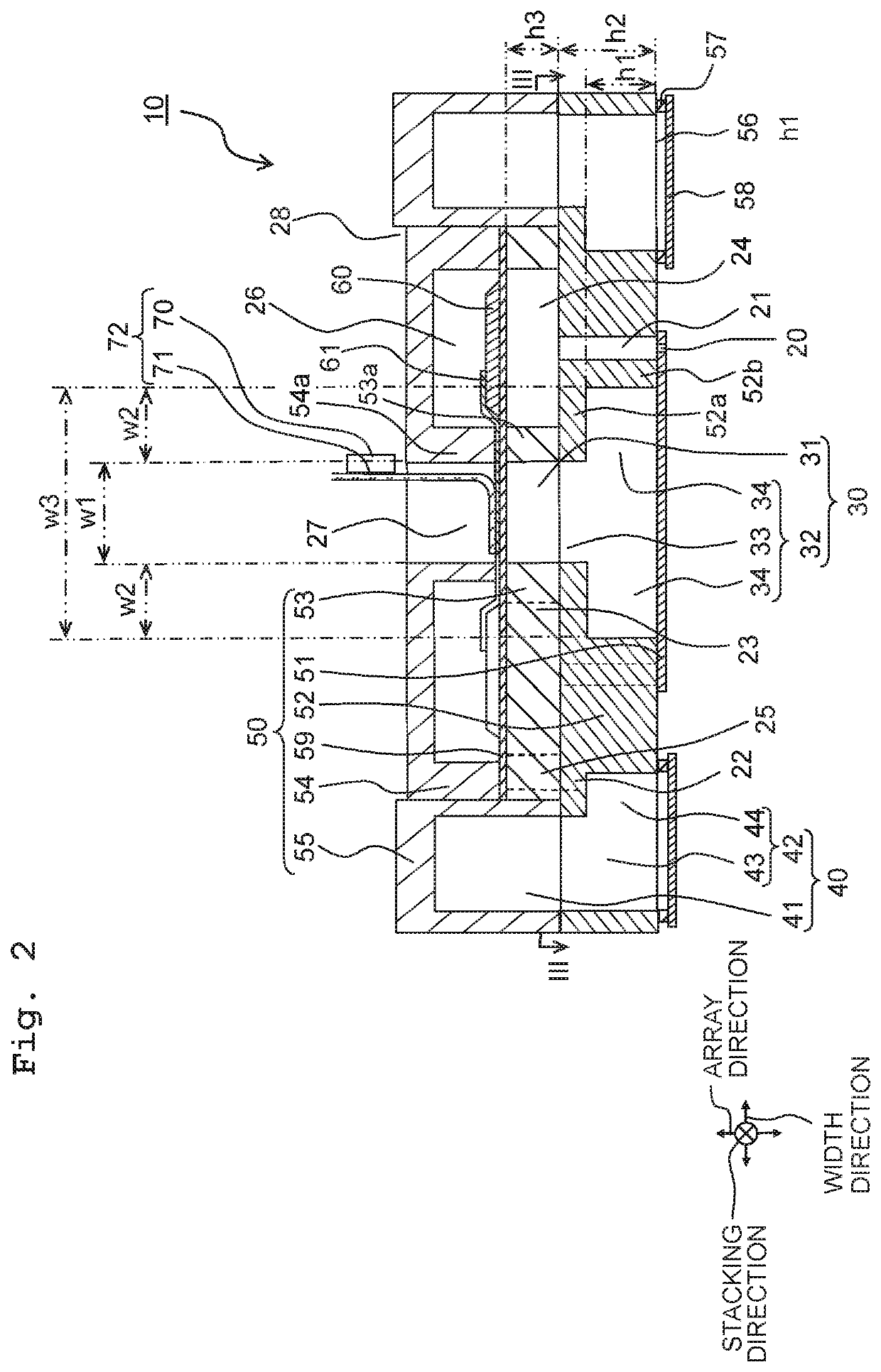

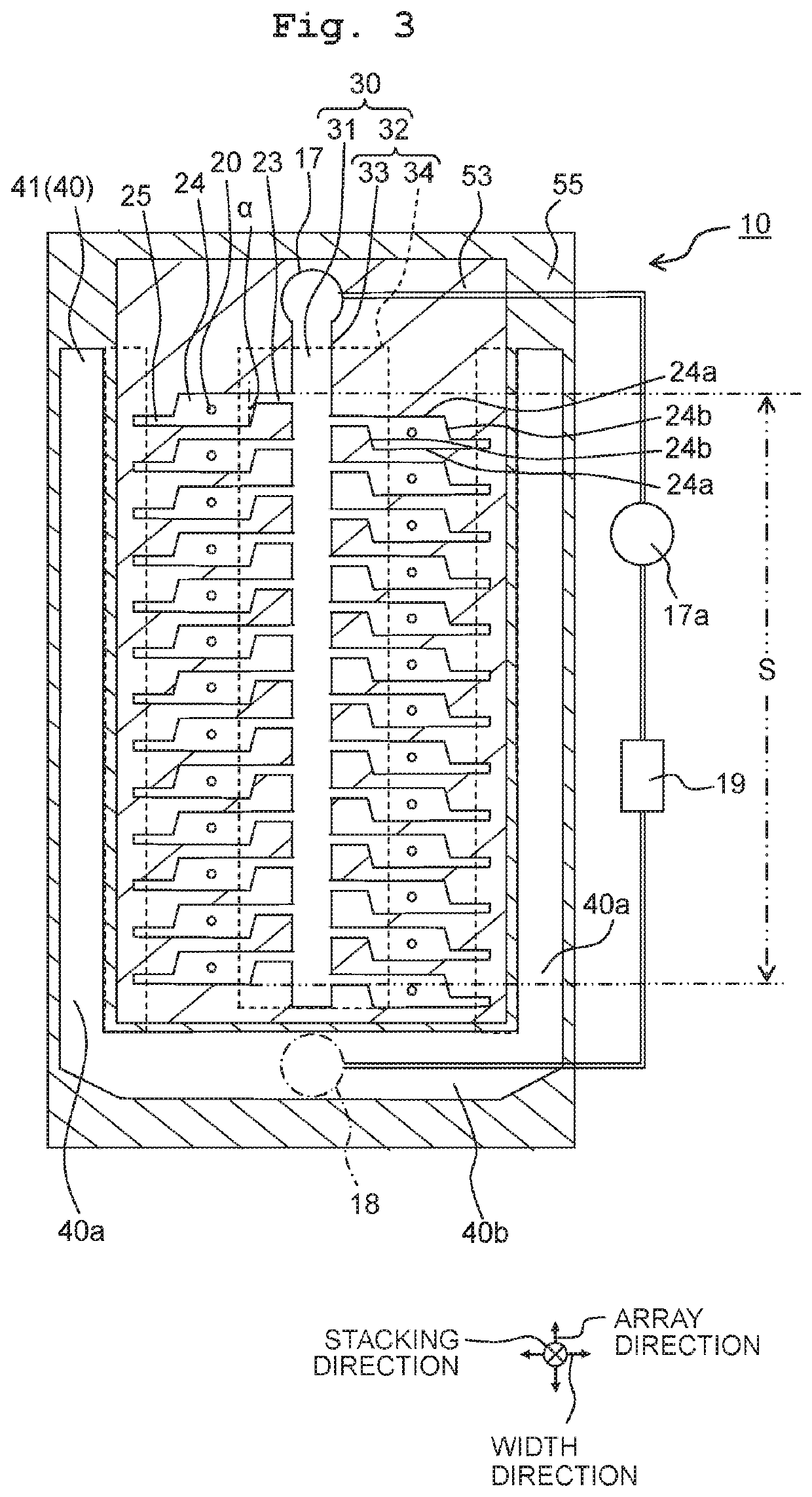

Liquid Discharge Head

ActiveUS20190283418A1Reduce resistanceReduced resistance differenceInking apparatusExpansion jointElectrical and Electronics engineering

There is provided a liquid discharge head including: a communication plate formed with a descender connected to a nozzle, a pressure chamber plate including a plurality of pressure chambers aligning in an array direction, a piezoelectric element, and a discharge common channel. The discharge common channel extends in the array direction, is connected to the plurality of pressure chambers, and has a first discharge portion and a second discharge portion. The discharge common channel is configured to discharge liquid toward one side in the array direction. The second discharge portion includes an expansion portion to expand beyond the first discharge portion in a width direction orthogonal to the stacking direction and to the array direction.

Owner:BROTHER KOGYO KK

Oxidizer and oxidation process for a desulphurization process

ActiveUS7344682B1Small apertureReduce tensionCombination devicesExhaust apparatusOxygenOxidizing agent

An improved oxidizer for liquid reduction-oxidation desulphurization processes uses a hollow fiber membrane contactor. A pressurized, oxygen containing gas stream is introduced into the interior of the hollow fiber membrane while a liquid reduction-oxidation catalyst solution contacts the exterior of the membrane. Oxygen diffuses through the membrane into the liquid reduction-oxidation catalyst solution whereby the solution is oxidized and can be recycled for further us in a desulphurization process.

Owner:MERICHEM CO

Oxidizer and oxidation process for a desulphurization process

ActiveUS7279148B1Small apertureReduce tensionOrganic-compounds/hydrides/coordination-complexes catalystsDispersed particle separationOxygenOxidizing agent

An improved oxidizer for liquid reduction-oxidation desulphurization processes uses a hollow fiber membrane contactor. A pressurized, oxygen containing gas stream is introduced into the interior of the hollow fiber membrane while a liquid reduction-oxidation catalyst solution contacts the exterior of the membrane. Oxygen diffuses through the membrane into the liquid reduction-oxidation catalyst solution whereby the solution is oxidized and can be recycled for further use in a desulphurization process.

Owner:MERICHEM CO

Machine for preparing a drink and method for preparing a drink using such a machine

InactiveUS9883765B2Guaranteed continuous supplyShorten speedBeverage vesselsCoffee extractionEngineeringMechanical engineering

It comprises an infusion chamber (2) for housing a dose of product and means for supplying a liquid under pressure to said infusion chamber, said supply means comprising a hydraulic accumulator device (4a, 4b) susceptible of storing under pressure a liquid from liquid injection means (8, 8a, 8b, 9, 25) of said machine (1, 1′), characterised in that said liquid injection means (8, 8a, 8b, 9, 25) and said hydraulic accumulator device (4a, 4b) are configured and disposed interconnected to the infusion chamber (2), so that a first fraction of injected liquid is susceptible of being stored under pressure in a cavity (5) of said accumulator device (4a, 4b), while a second fraction of the injected liquid is simultaneously distributed or supplied to the exterior through the infusion chamber (2) of the machine (1, 1′), allowing said accumulator device (4a, 4b) to store a fraction of liquid configured to ensure the continuous supply of a certain flow (Qc) during a predetermined beverage preparation time or distribution time (te). The process comprises the steps of retracting the distribution cylinder (4a) piston (4b) or an element of said accumulator device to its active position through the injection of a liquid from an independent storage reservoir (9), and simultaneously supplying the liquid injected under pressure.

Owner:MINIMMA ESPRESSO

Liquid discharge head

There is provided a liquid discharge head including: a communication plate formed with a descender connected to a nozzle, a pressure chamber plate including a plurality of pressure chambers aligning in an array direction, a piezoelectric element, and a discharge common channel. The discharge common channel extends in the array direction, is connected to the plurality of pressure chambers, and has a first discharge portion and a second discharge portion. The discharge common channel is configured to discharge liquid toward one side in the array direction. The second discharge portion includes an expansion portion to expand beyond the first discharge portion in a width direction orthogonal to the stacking direction and to the array direction.

Owner:BROTHER KOGYO KK

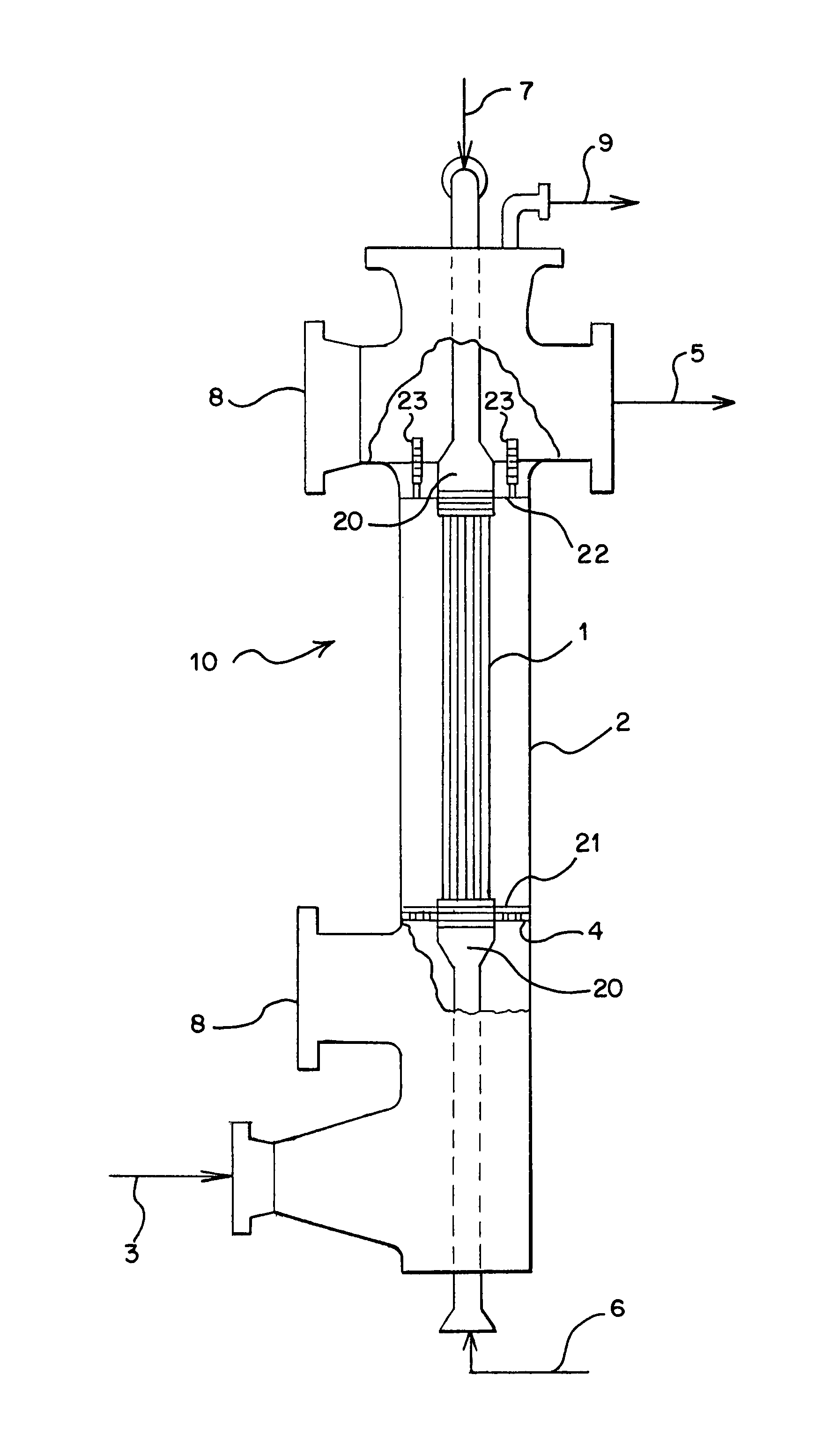

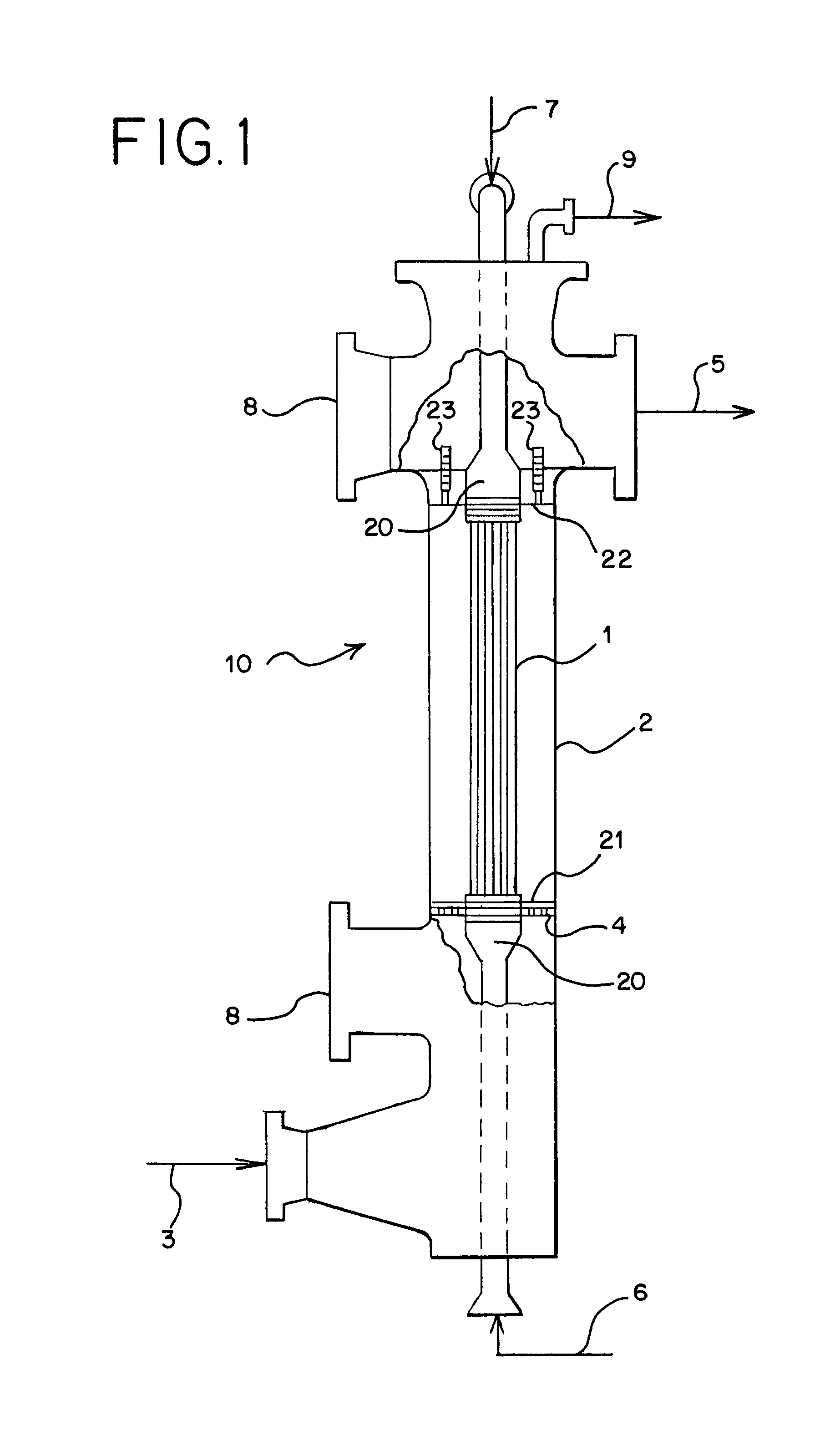

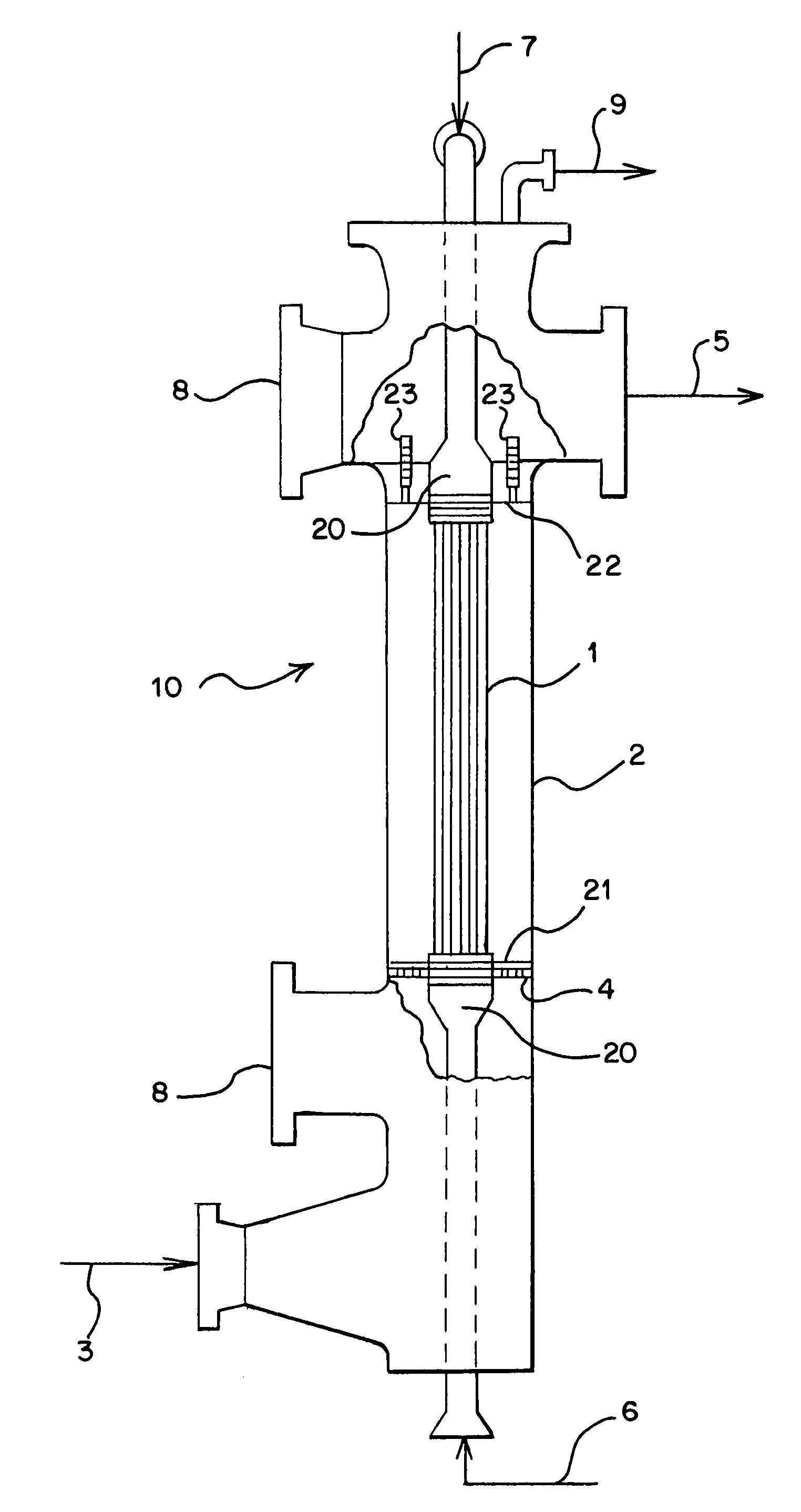

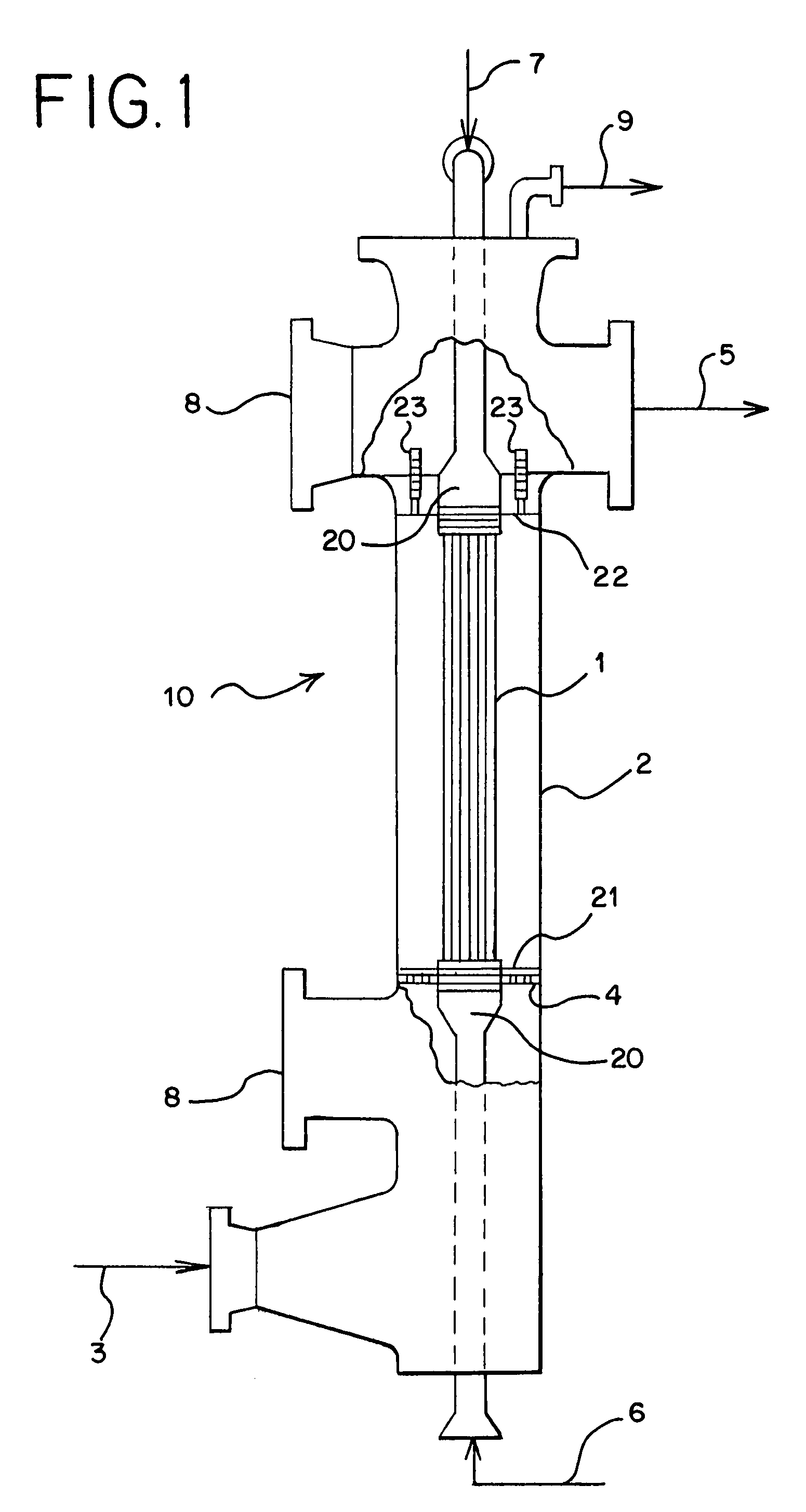

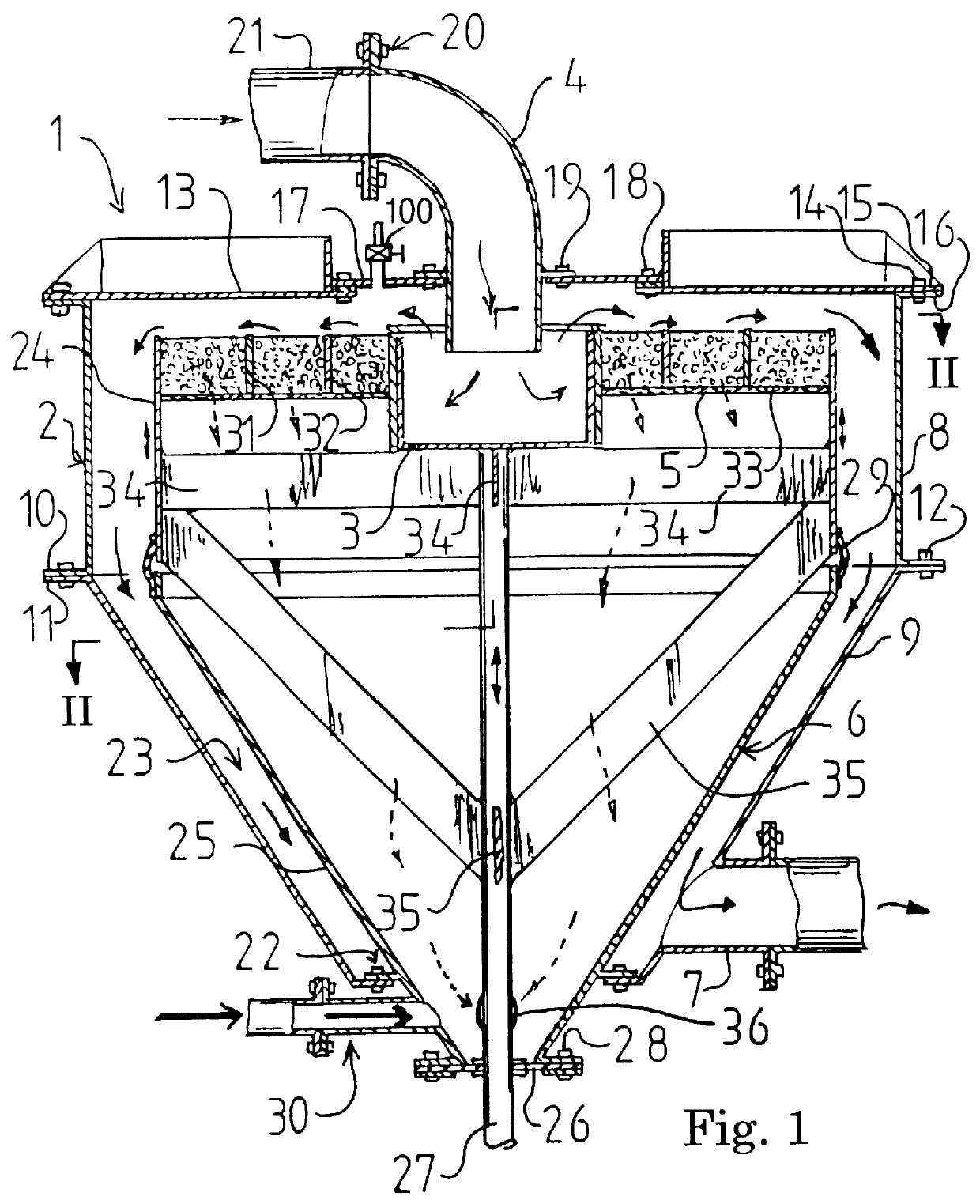

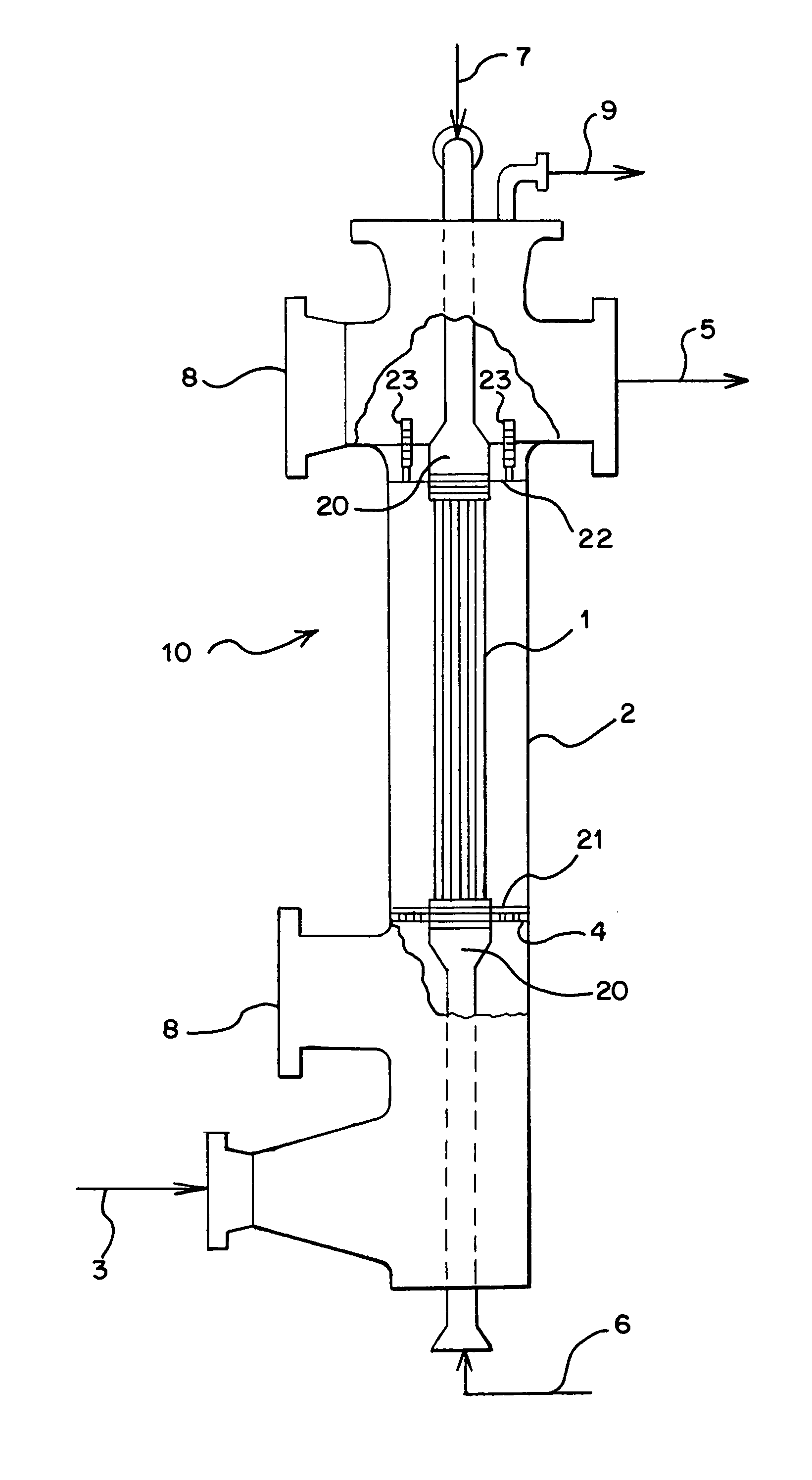

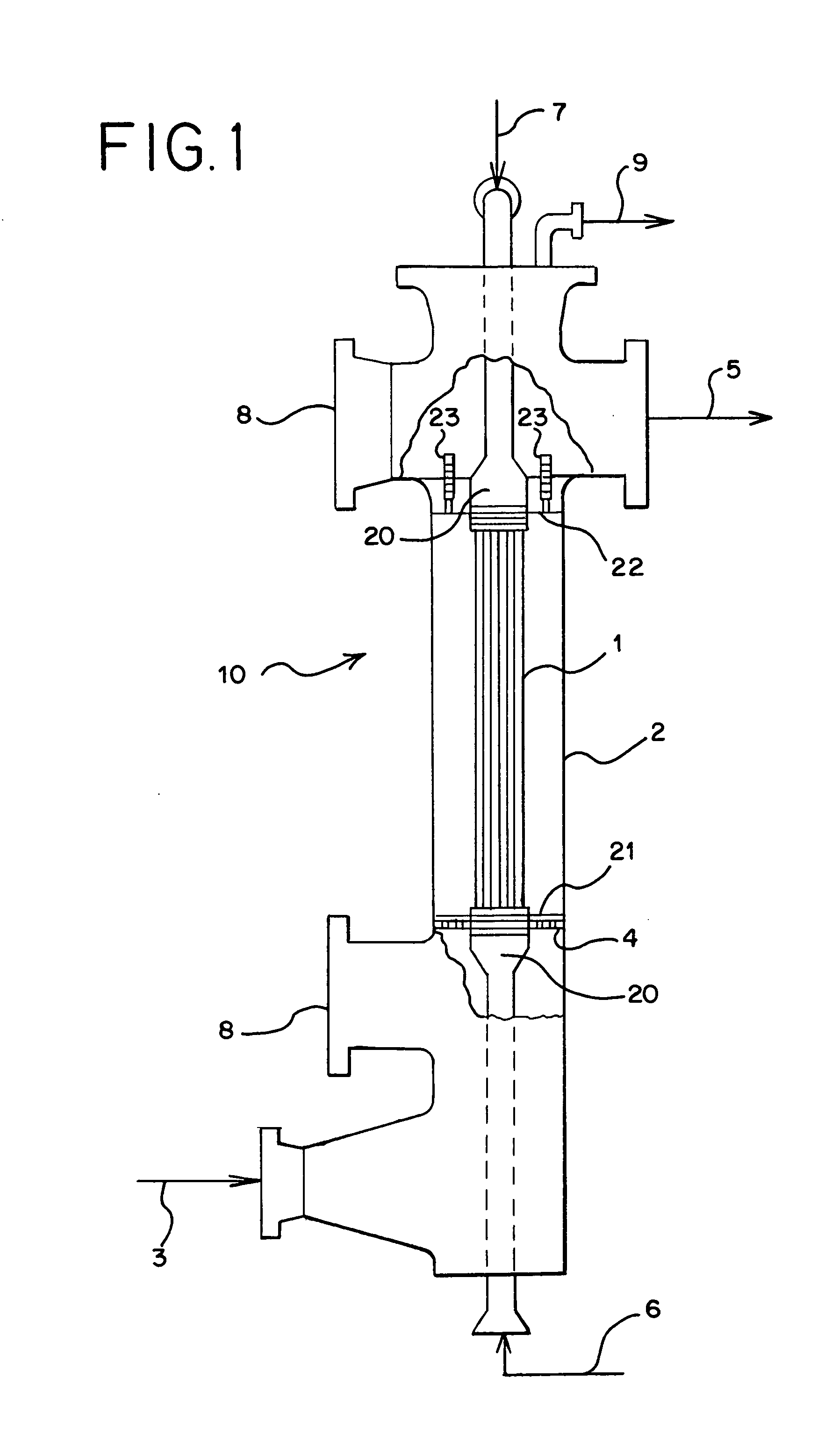

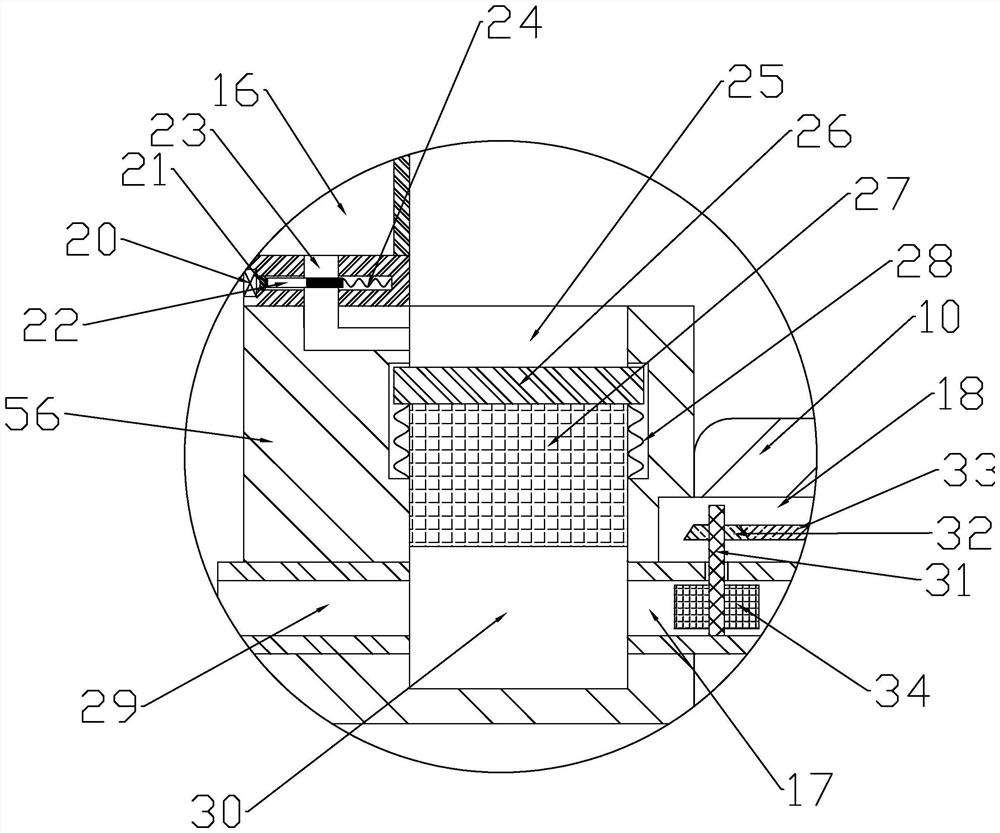

Separator for separating particles from a slurry

InactiveUS6079567ASuitable for useEasy to separateGas current separationWater/sewage treatmentParticulatesSlurry

PCT No. PCT / AU95 / 00137 Sec. 371 Date Jul. 15, 1998 Sec. 102(e) Date Jul. 15, 1998 PCT Filed Mar. 15, 1995 PCT Pub. No. WO95 / 26232 PCT Pub. Date Oct. 5, 1995A separator (1) for separating dense particulates from slurry includes a sealed housing (2) enclosing a submerged screen bed (33) which allows dense particulates to fall into a hutch (6) from which they may be discharged. The housing has a slurry inlet (4) arranged to deliver slurry to a sump (3) which directs slurry to flow radially over the bed. An annular cavity (23) formed between the housing and bed receives tailings flowing off of the top of the bed. An outlet (7) from the annular cavity allows discharge of the tailings, and a liquid inlet (30) to the hutch provides an upward flow of liquid through the bed. The bed is agitated to assist passage of dense particulates.

Owner:GRAY ALEXANDER HAMILTON

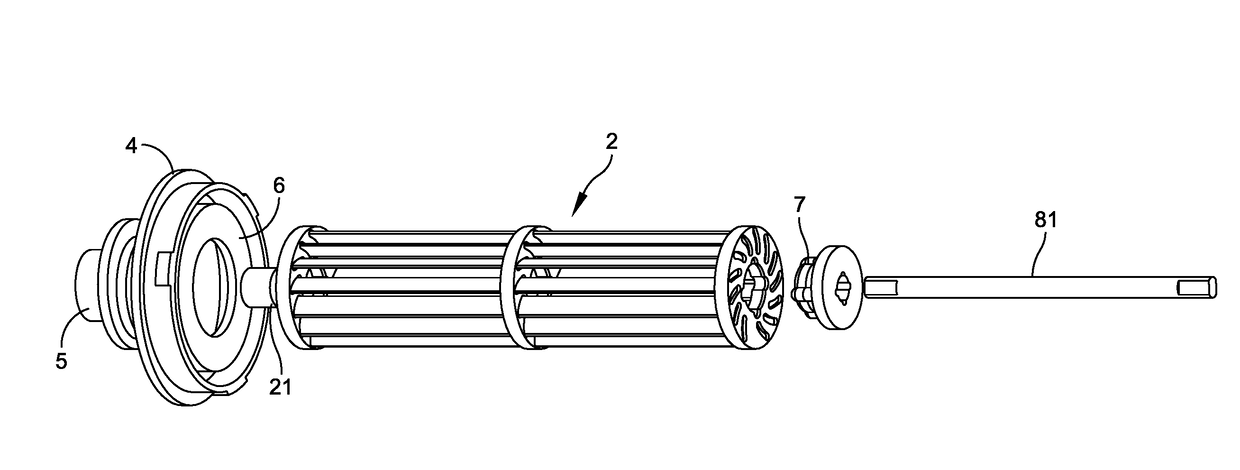

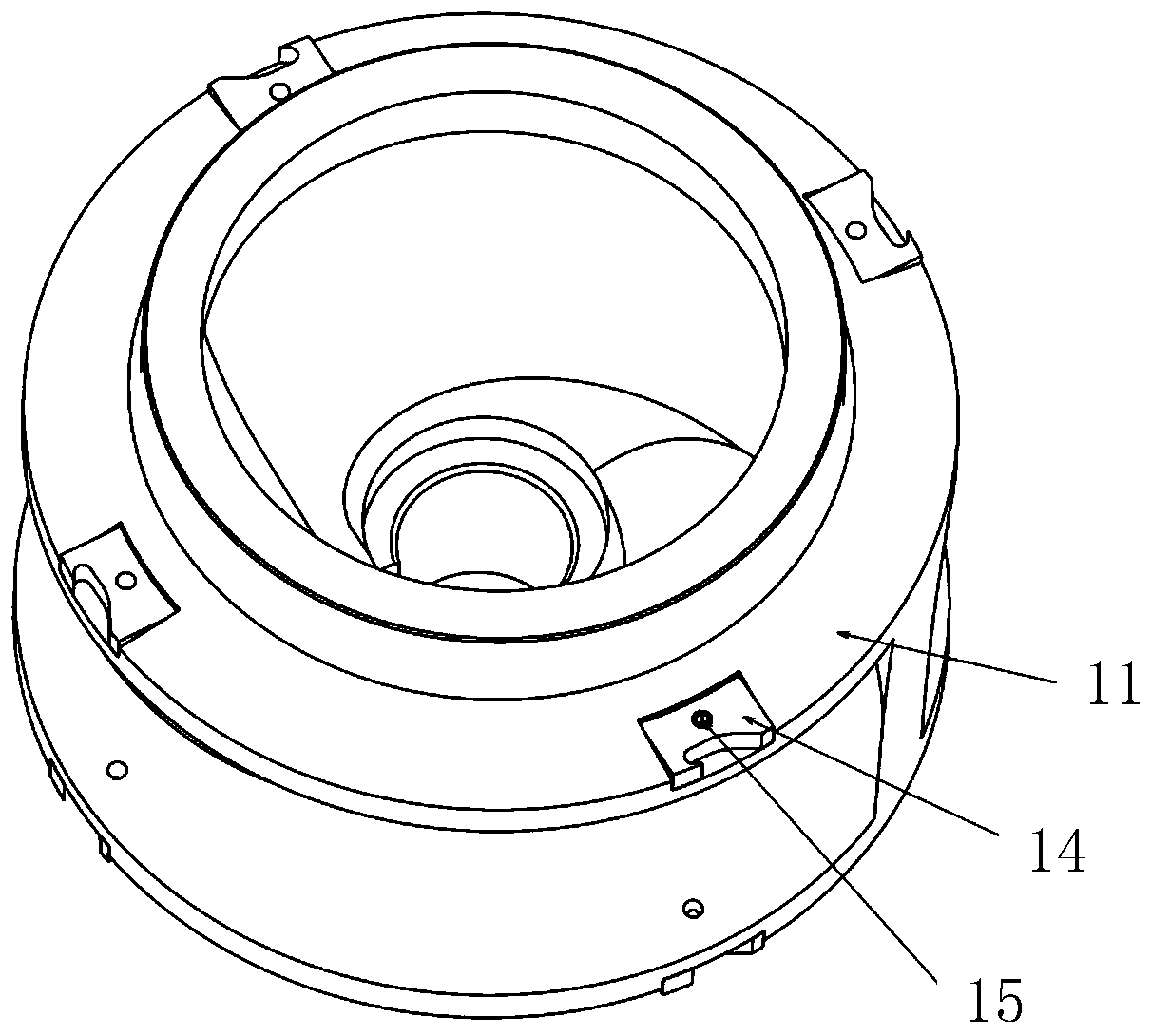

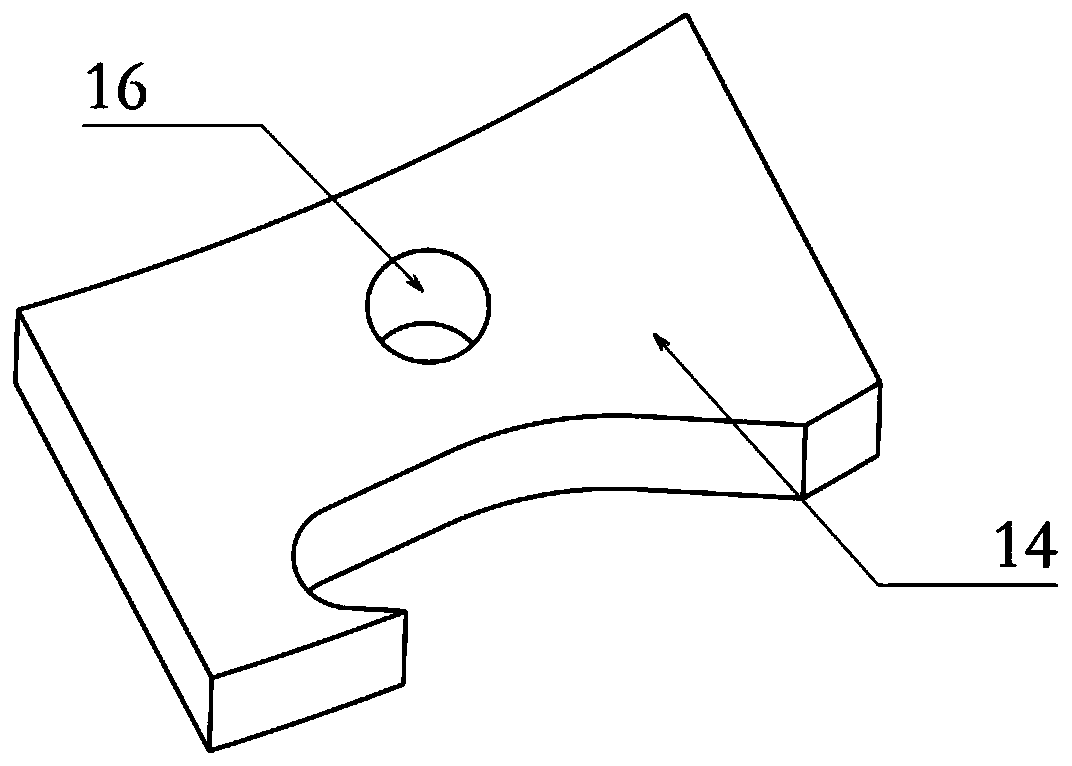

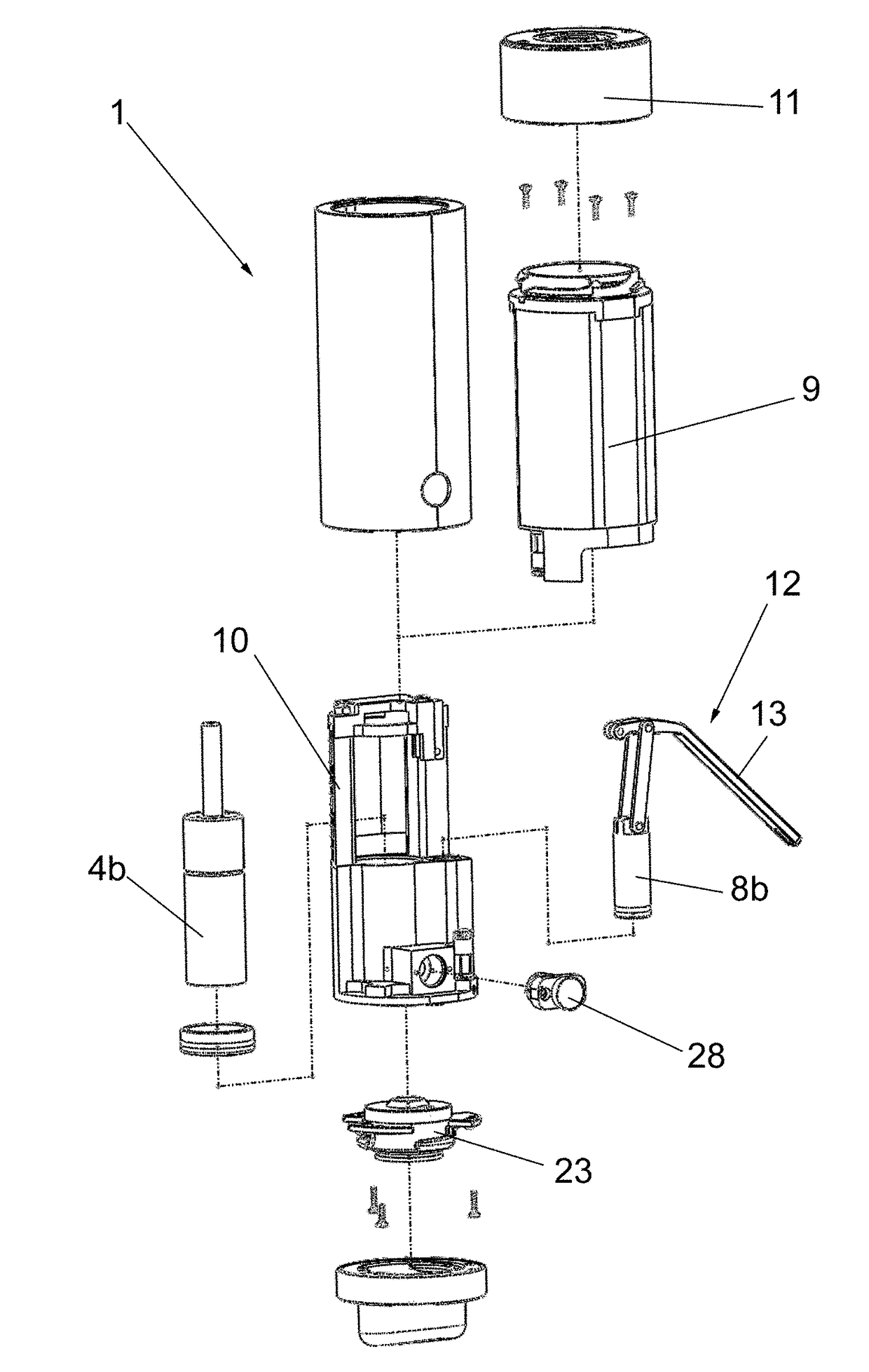

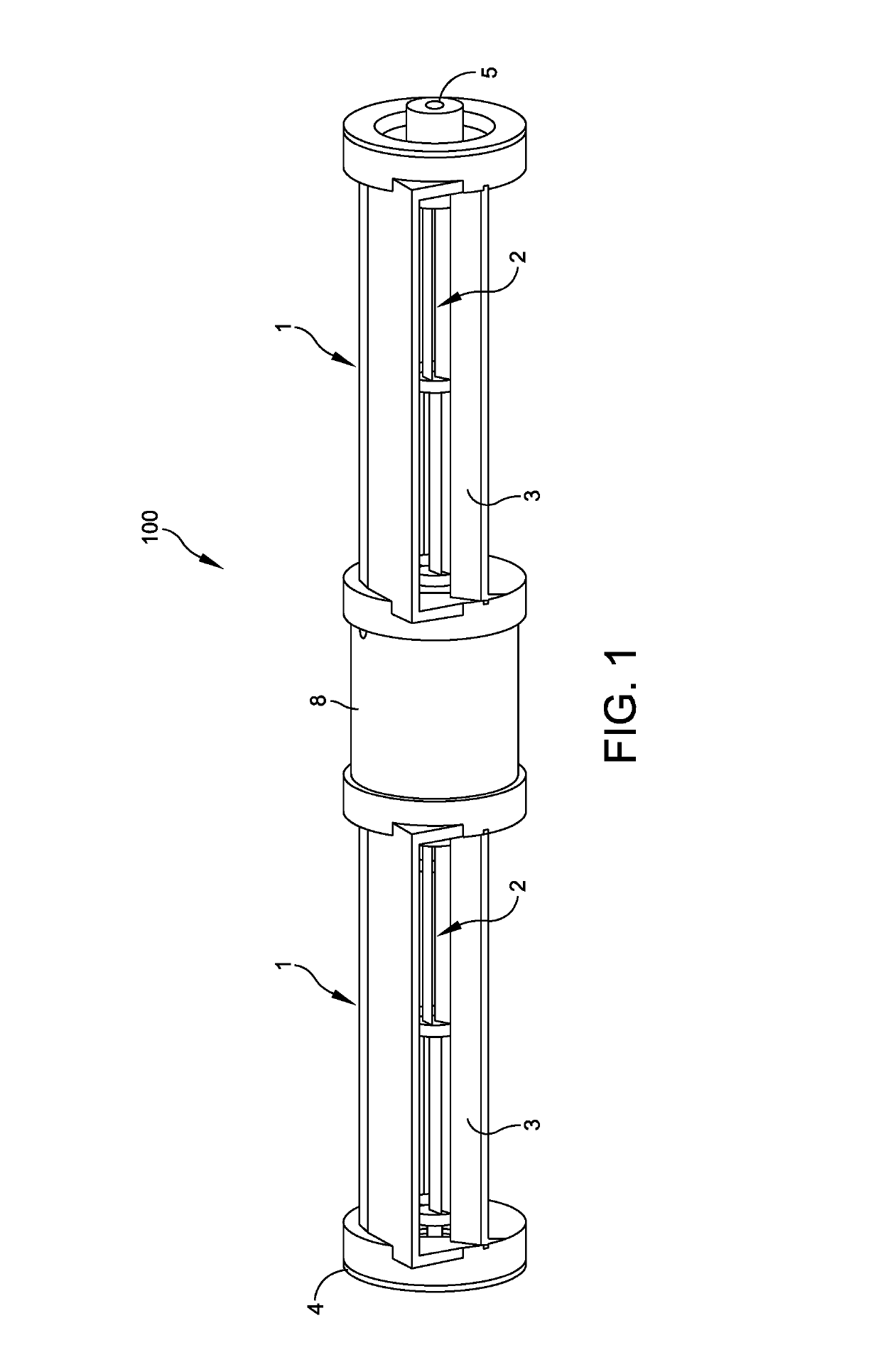

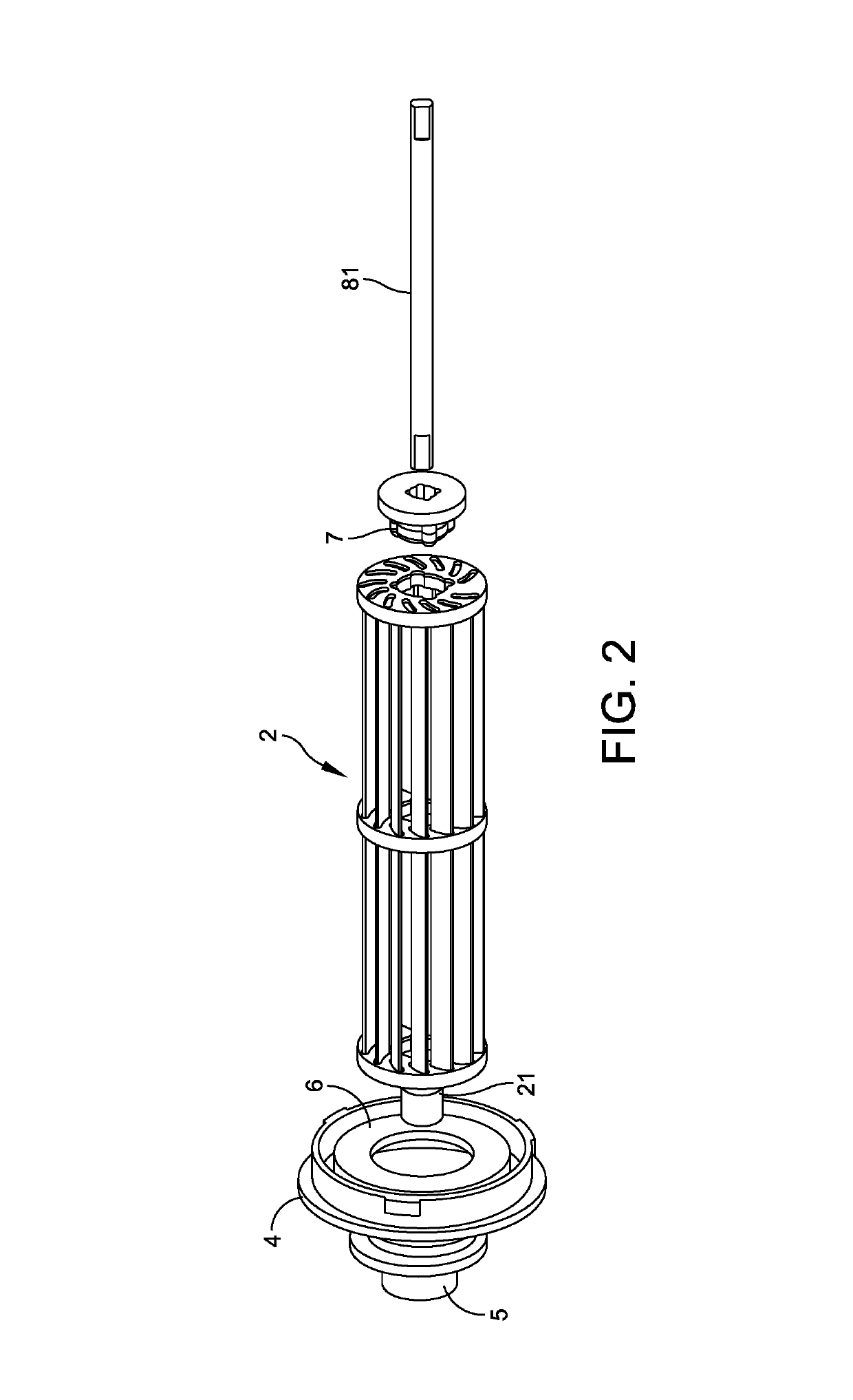

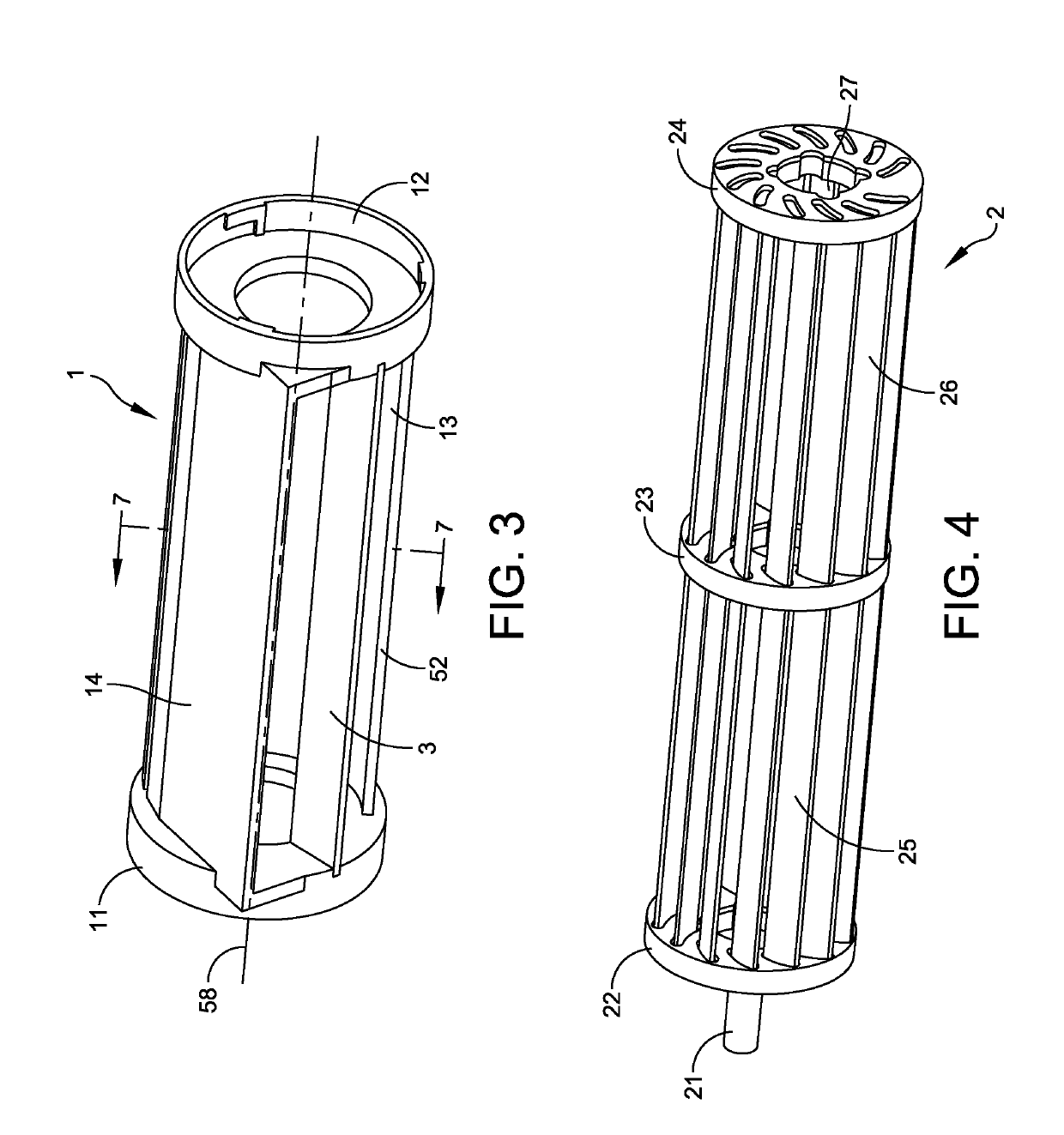

Cross-flow wave making pump

ActiveUS20170248141A1Reduce liquid flowIncrease torquePump componentsWave producing pumpsImpellerEngineering

This invention relates to a cross-flow wave making pump comprising an impeller shell forming a water intake and a water outlet, an impeller assembly pivotally connected to two ends of the impeller shell, and a motor used for driving the impeller assembly; wherein, the impeller assembly comprises an impeller used for driving a liquid flow, a first turntable and a second turntable respectively fixed at two ends of the impeller, wherein the first turntable is provided with a shaft rotatably mounted in the impeller shell, the second turntable is provided with a cavity used for receiving a rotor shaft of the motor. The embodiments of the present invention can provide a sufficient liquid-circulation in a container, and significantly reduce the dead zone where the liquid flows extremely slowly. Other embodiments are disclosed.

Owner:GUANGZHOU MAIGUANG ELECTRONIC TECHNOLOGY CO LTD

Oxidizer and oxidation process for a desulphurization process

ActiveUS7226883B1Small apertureReduce tensionOther chemical processesOrganic-compounds/hydrides/coordination-complexes catalystsOxygenHollow fiber membrane

An improved oxidizer for liquid reduction-oxidation desulphurization processes uses a hollow fiber membrane contactor. A pressurized, oxygen containing gas stream is introduced into the interior of the hollow fiber membrane while a liquid reduction-oxidation catalyst solution contacts the exterior of the membrane. Oxygen diffuses through the membrane into the liquid reduction-oxidation catalyst solution whereby the solution is oxidized and can be recycled for further us in a desulphurization process.

Owner:MERICHEM CHEM & REFINERY SERVICES

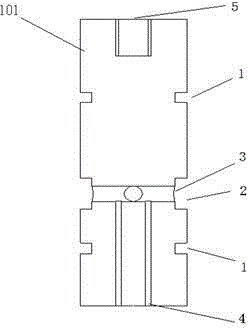

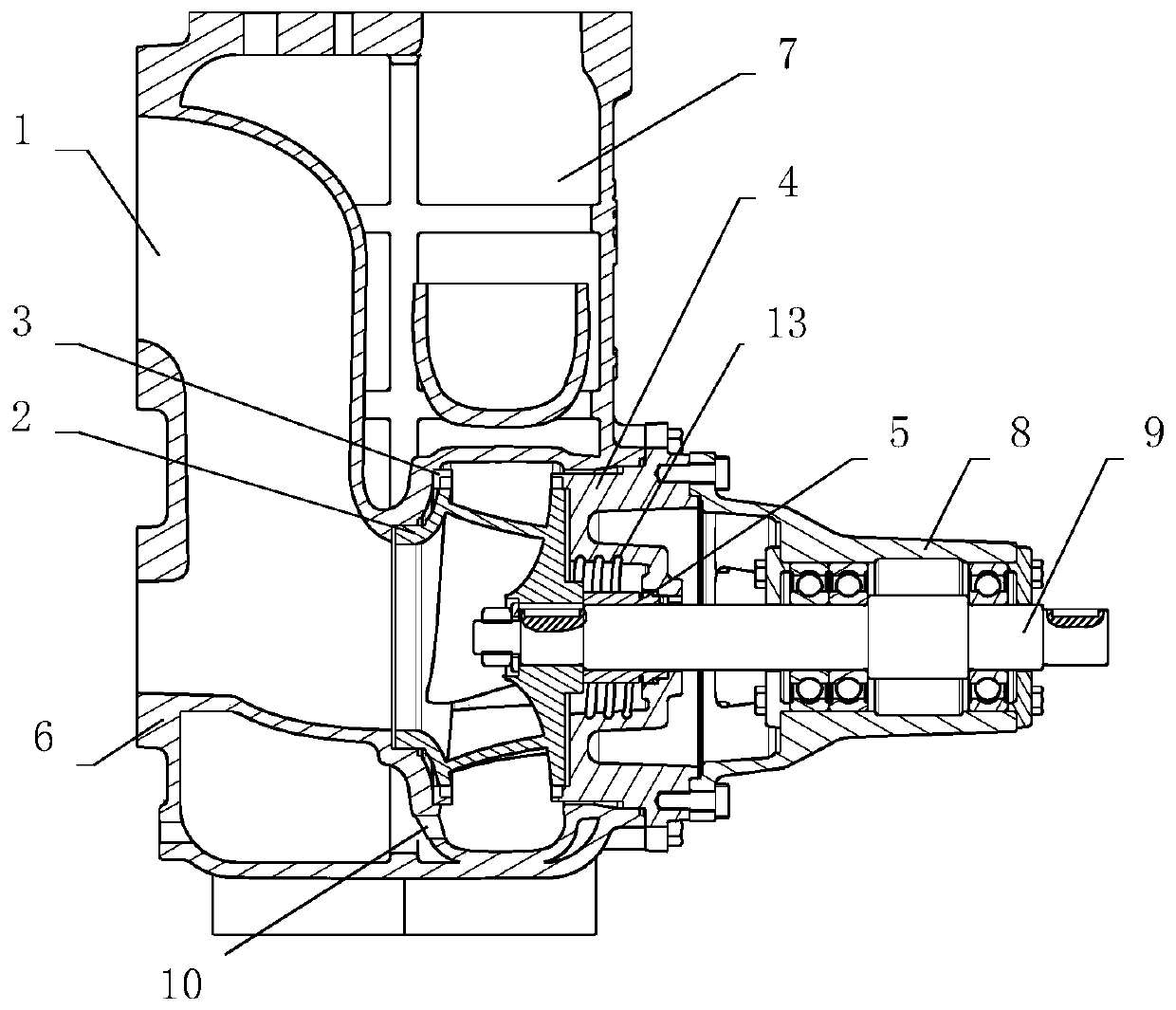

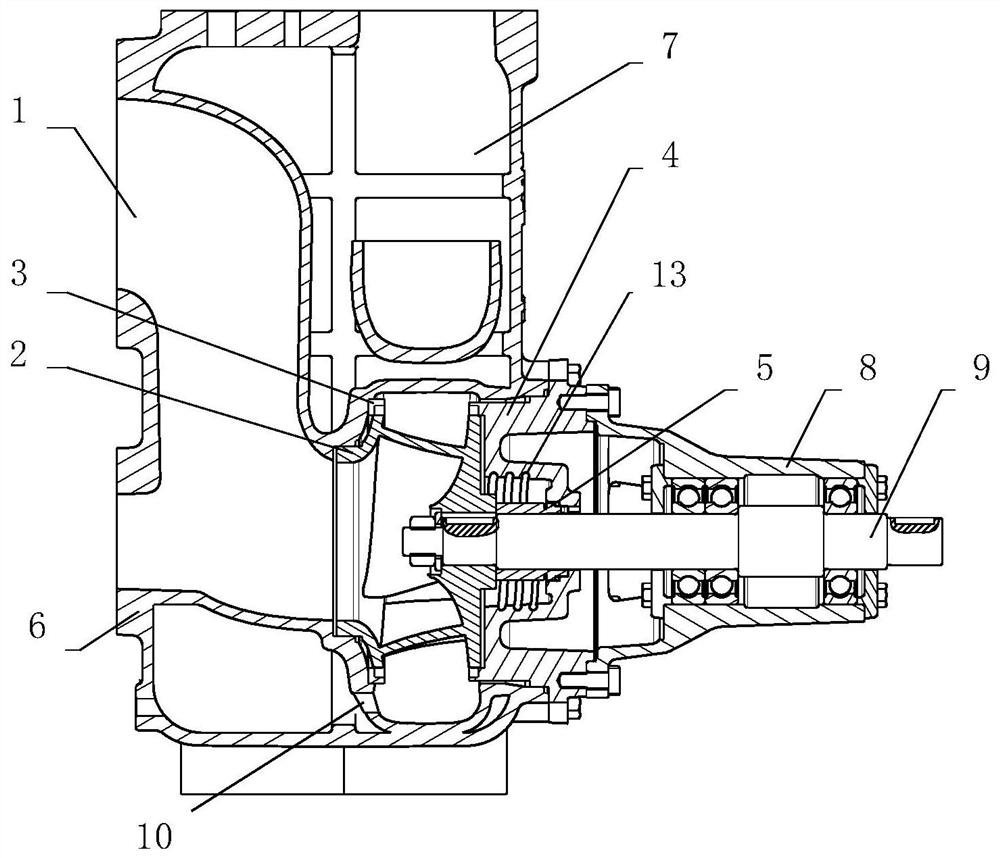

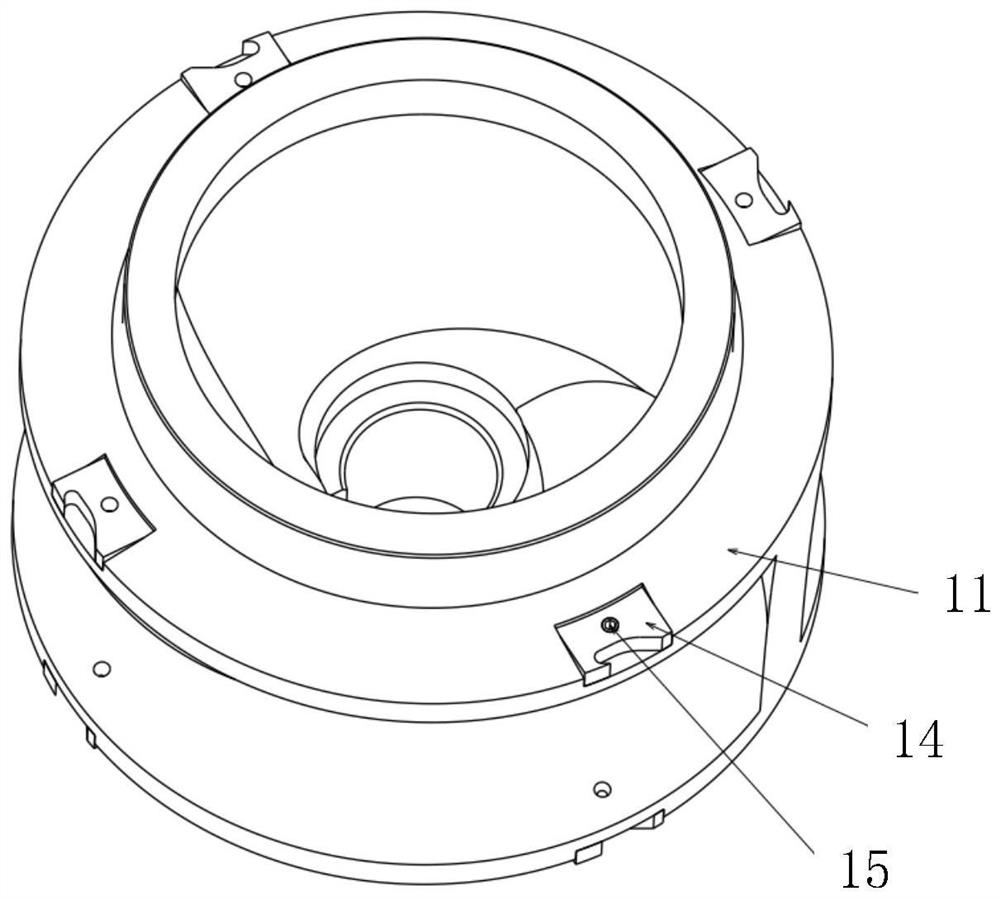

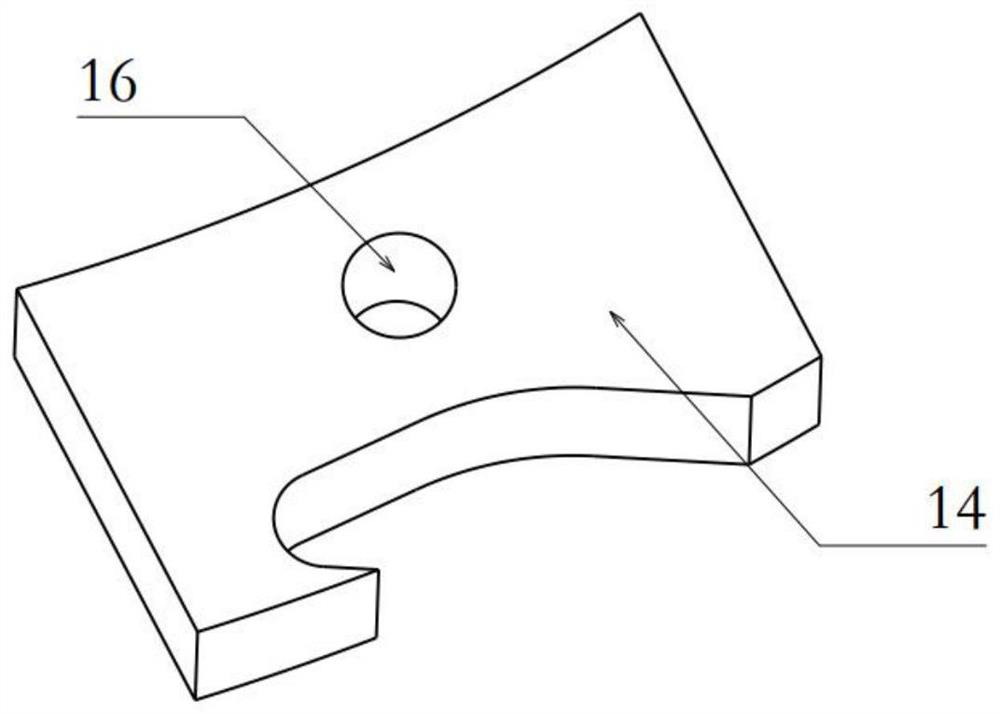

Self-suction sewage pump with double port rings sealing

ActiveCN110541830AEasy to get stuckSolve the problem of easy wear and tear of the mechanical sealSpecific fluid pumpsPump componentsImpellerEdge orientation

The invention discloses a self-suction sewage pump with double port rings sealing. The self-suction sewage pump comprises a water suction chamber, an impeller with cutting blades, a front sealing ringwith cutting grooves, a rear pump cover with cutting grooves, a mechanical seal, a backflow hole, a pump body, a gas-liquid separation chamber, a pump shaft and a bearing body; the impeller with thecutting blades is arranged on the pump shaft, and is connected with the pump body through the rear pump cover with the cutting grooves and the bearing body; the cutting blades are uniformly distributed on the edges of an impeller front cover plate and an impeller rear cover plate in a 360 degrees / n separation mode; n groups of blades are arranged on each cover plate, wherein n is an even number, and the edge orientations of the blades are consistent with the rotation direction of the impeller; and the front sealing ring and the rear pump cover are static parts, and n cutting grooves which areuniformly distributed are formed in the inner side edge of each of the front sealing ring and the rear pump cover. According to the self-suction sewage pump with double port rings sealing, the problems that the port rings of the self-suction sewage pump are easily clamped and the machine seal is prone to abrasion are solved; and meanwhile, the double-port ring sealing type of the impeller greatlyreduces the liquid flow of high-pressure fluid back-flowing from an impeller outlet to an impeller inlet, the energy loss is reduced, and the pump efficiency is improved.

Owner:CHINA JILIANG UNIV

Bubble atomizing nozzle and adjustment method of bubble atomizing nozzle

InactiveCN104624423BStable sprayingImprove atomization efficiencyLiquid spraying apparatusRubber ringPhase mixing

The invention relates to a bubble atomizing nozzle and an adjusting method of the bubble atomizing nozzle. The bubble atomizing nozzle comprises a multi-channel air intake structure consisting of two or more layers of sealing rings, or an external part of an air intake structure of a swirl groove, and an external part having a diffusion conical spray hole, a jackscrew hole and an air-liquid inlet quick mounting joint, wherein the internal part is directly inserted in the external part to assemble the nozzle; the internal part and the external part are sealed by an O-shaped rubber ring and fixed by a jackscrew; and a space between the internal part and the external part is a mixing chamber. The flowing resistance of the internal part is lower, so that the pressure of the mixing chamber can be kept in a higher range, and the atomizing efficiency of the nozzle is higher; a bubble flow formed in the air-liquid two-phase mixing process in the mixing chamber is uniform and stable, so that the stable atomizing effect is realized under the low-air-liquid mass flow ratio (between 0.07-0.1); and the working pressure is low, and the liquid flow is low, so that the stable atomization can be kept under the liquid flow of 3.5-6.0 kg / h and the absolute air-liquid inlet pressure of 0.36-0.40 MPa. The bubble atomizing nozzle is applied to such fields as chemical engineering, motive power and heating and ventilation.

Owner:HEBEI UNIV OF TECH +1

Machine for preparing a drink and method for preparing a drink using such a machine

InactiveUS20180125285A1Guaranteed continuous supplyShorten speedBeverage vesselsCoffee extractionMechanical engineeringPiston

An infusion chamber (2) for housing a dose of product and means for supplying a liquid under pressure to said infusion chamber, said supply means comprising a hydraulic accumulator device (4a, 4b) susceptible of storing under pressure a liquid from liquid injection means (8, 8a, 8b, 9, 25) of said machine (1, 1′), characterised in that said liquid injection means (8, 8a, 8b, 9, 25) and said hydraulic accumulator device (4a, 4b) are configured and disposed interconnected to the infusion chamber (2), so that a first fraction of injected liquid is susceptible of being stored under pressure in a cavity (5) of said accumulator device (4a, 4b), while a second fraction of the injected liquid is simultaneously distributed or supplied to the exterior through the infusion chamber (2) of the machine (1, 1′), allowing said accumulator device (4a, 4b) to store a fraction of liquid configured to ensure the continuous supply of a certain flow (Qc) during a predetermined beverage preparation time or distribution time (te). The process comprises the steps of retracting the distribution cylinder (4a) piston (4b) or an element of said accumulator device to its active position through the injection of a liquid from an independent storage reservoir (9), and simultaneously supplying the liquid injected under pressure.

Owner:MINIMMA ESPRESSO

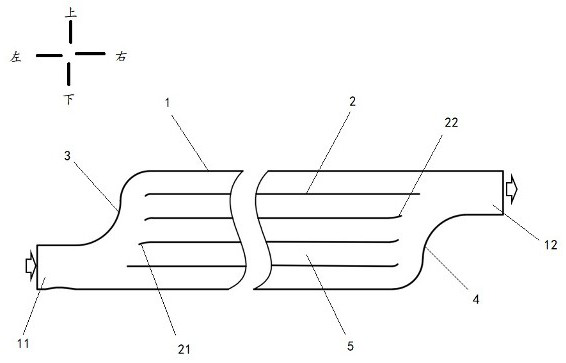

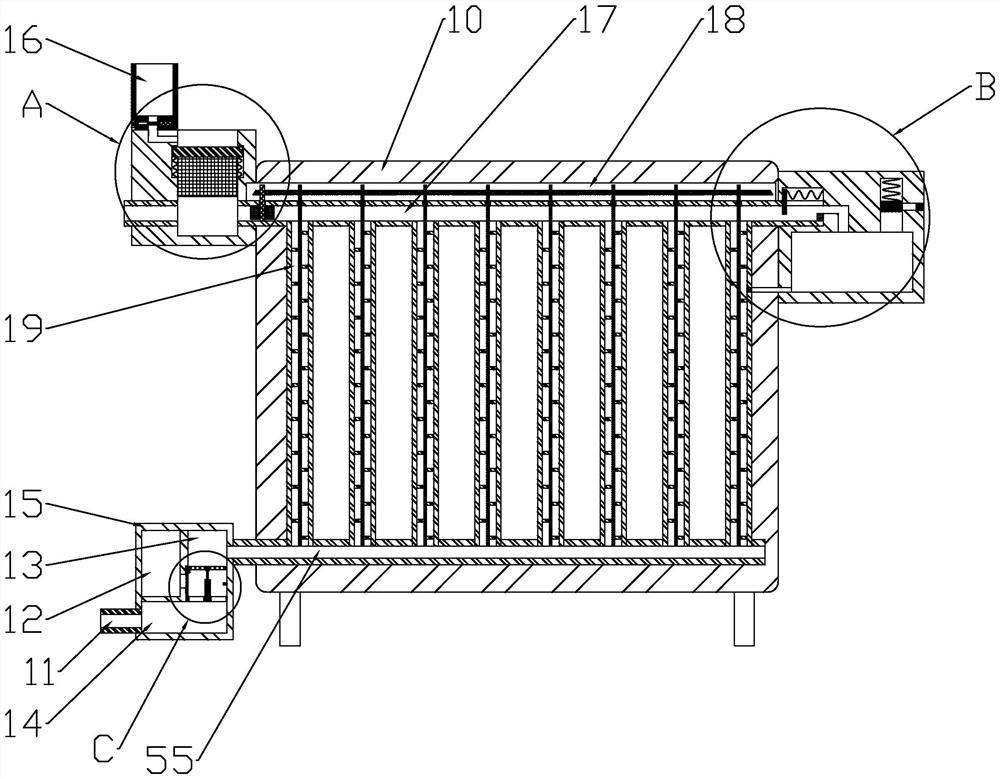

Thermoelectric conversion device and system

ActiveCN114189174AAvoid shockReduce the formation of swirl zonesThermal electric motorPhysicsHeat sink

The invention provides a thermoelectric conversion device and system, and belongs to the technical field of thermoelectric conversion. Comprising a heat exchange heat sink shell, a liquid inlet and a liquid outlet are formed in the two ends of the heat exchange heat sink shell in the length direction respectively, and a plurality of rib walls are arranged in the heat exchange heat sink shell; the end where the liquid inlet is located is provided with a first arc-shaped area, and the end where the liquid outlet is located is provided with a second arc-shaped area. The first end, close to the liquid inlet, of each rib wall is bent towards the liquid inlet, and the second end, close to the liquid outlet, of each rib wall is bent towards the liquid outlet. In the plurality of first end parts, the bending radian of the first end part far away from the liquid inlet is greater than that of the first end part close to the liquid inlet; the distance from the first end part far away from the liquid inlet to the first arc-shaped area is smaller than the distance from the first end part close to the liquid inlet to the first arc-shaped area. By using the thermoelectric conversion device and system provided by the invention, the flow resistance of the liquid can be reduced while the heat exchange uniformity and the thermoelectric conversion efficiency are improved.

Owner:SICHUAN UNIV

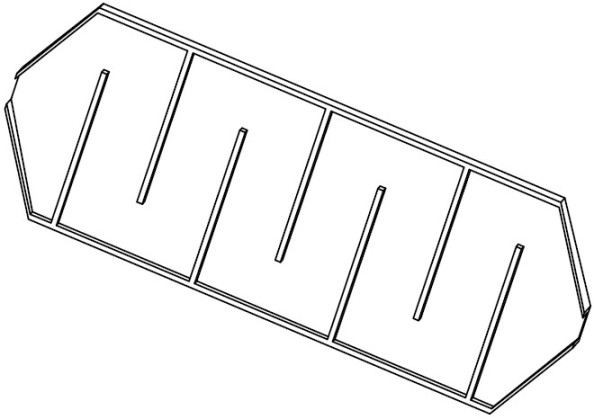

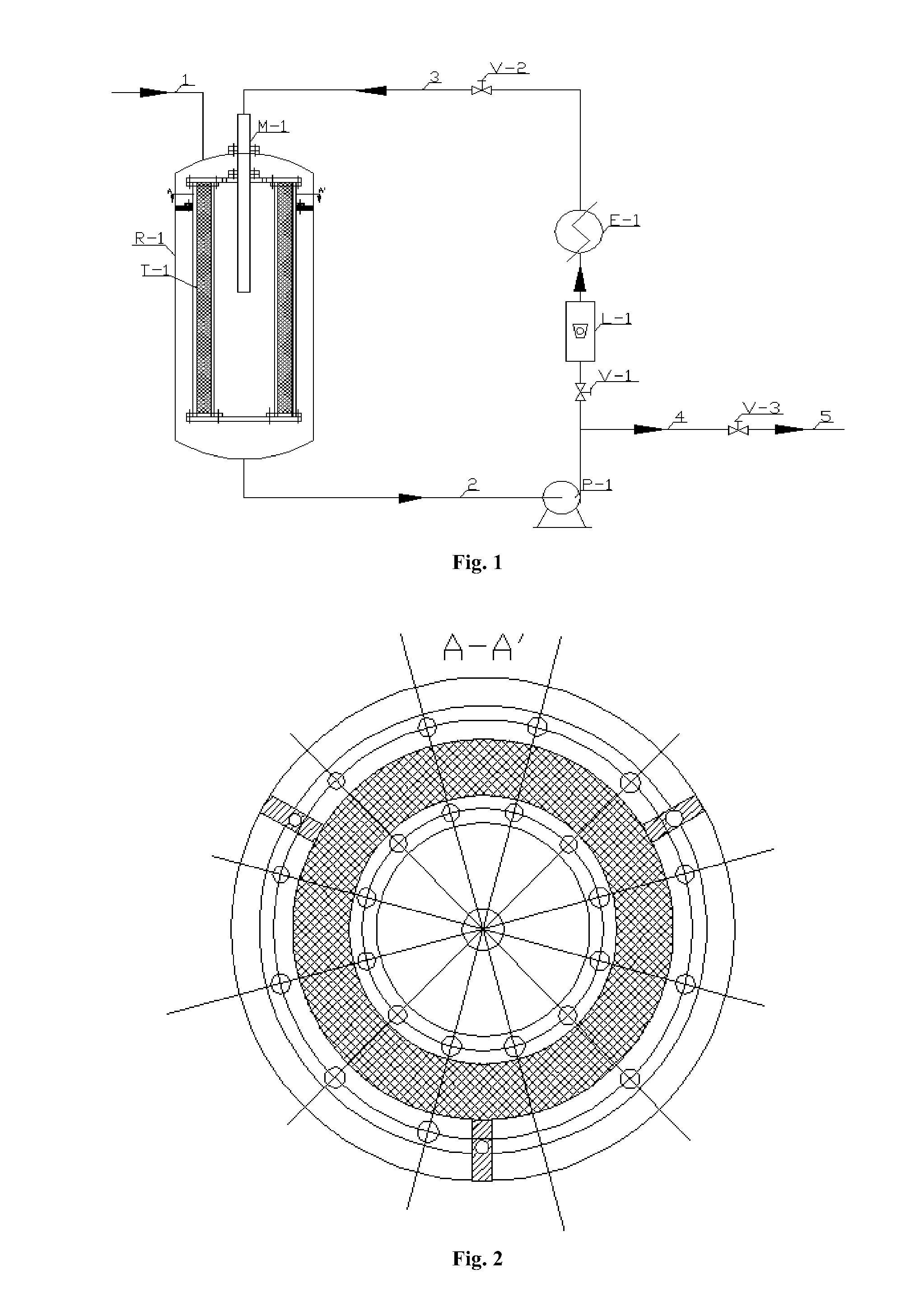

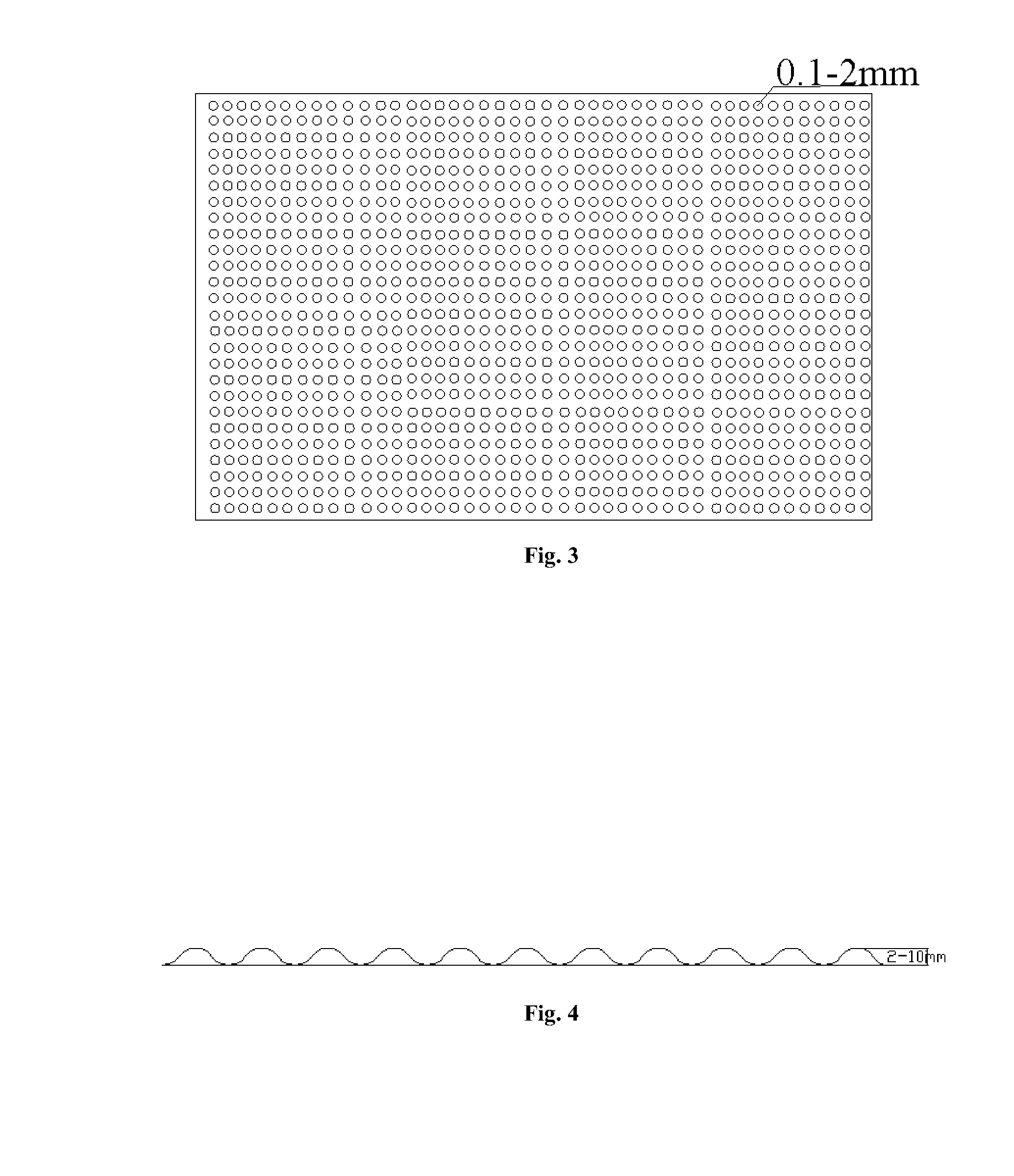

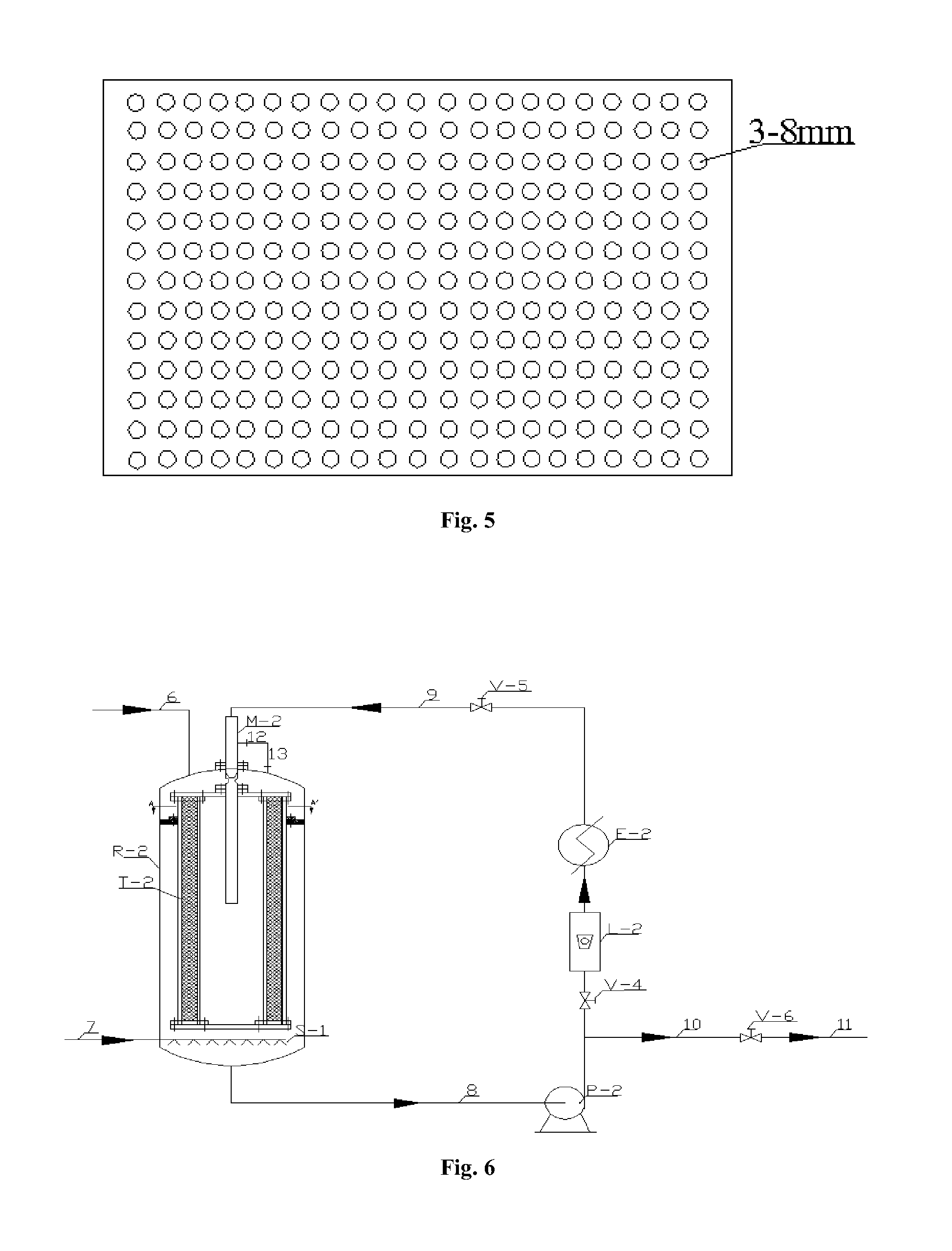

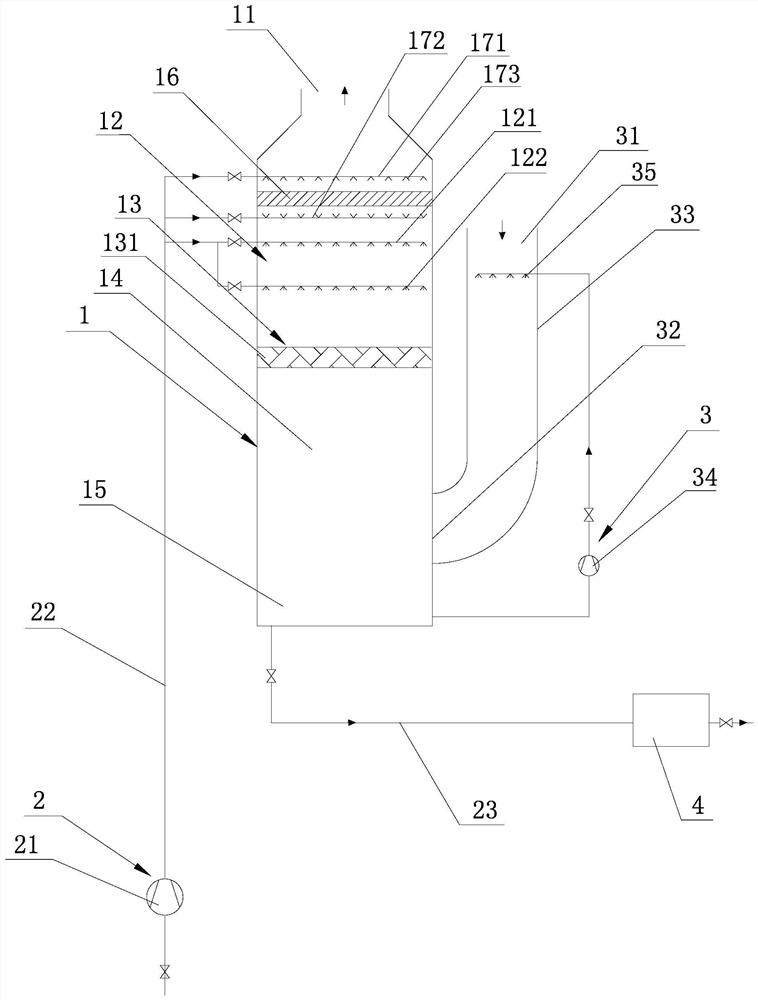

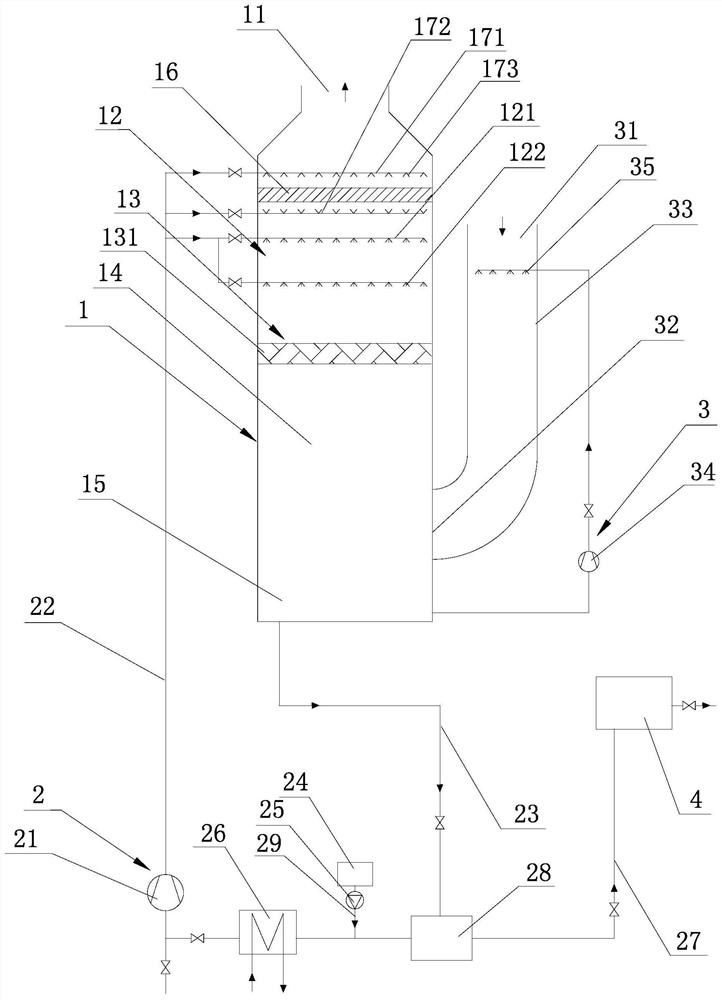

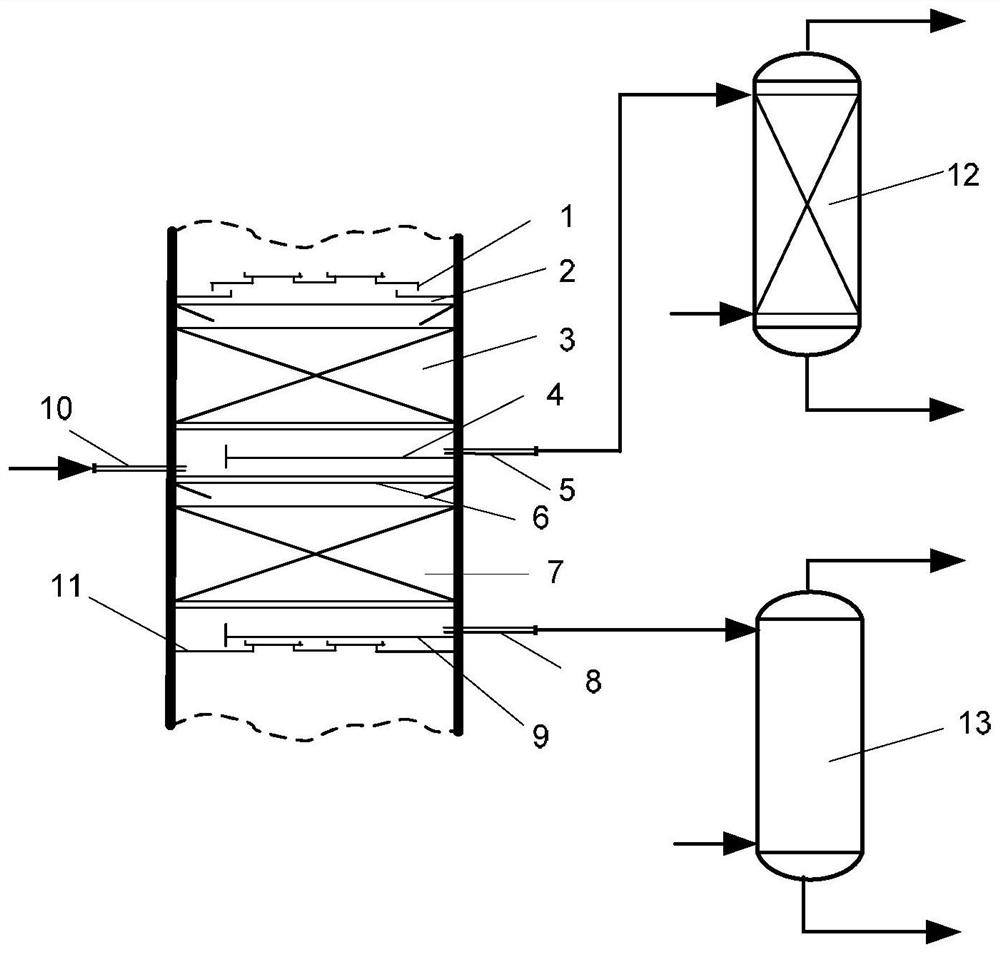

Immersion fixed bed reactor intensified by liquid flow

ActiveUS20140369892A1Increase surface areaReduce liquid flowSamplingLavatory sanitorySteel platesEngineering

An immersion fixed bed reactor intensified by liquid flow contains a cylindrical tank internally installed with an annular cylindrical catalyst bed (ACCB) packed with solid catalysts is provided. The inner and outer walls of the ACCB are composed of two layers of stainless steel sheets with holes. The outer layer of stainless steel perforated with holes. The inner layer of catalyst contacting stainless steel is covered with stainless steel waved mesh in circumferential direction. The bottom of AACB is sealed with a steel plate by welding or a blind plate and the top of ACCB is fixed to cylindrical tank with a flange. The solid catalysts are packed in the ACCB.

Owner:NANJING UNIV

A kind of preparation technology of curved colored glass

ActiveCN106183329BUneven color distributionReduce liquid flowLayered product treatmentLaminationFlat glassNatural ventilation

The invention provides a technology for preparing curved-surface colored glass. The technology includes the following operation steps that 1, an arc mold is manufactured according to the size, the shape and the curvature of the to-be-processed glass; 2, sheet glass is laid on the arc mold; 3, the arc mold in which the sheet glass is clamped is placed into an electric furnace for hot bending; 4, the arc mold obtained after the processing in the third step is taken out and cooled in a natural-ventilation mode; 5, a colored film is placed on the upper surface of the curved-surface glass blank processed in the fourth step, and covered with a curved-surface glass blank with the radian the same as the bottom radian, mold setting is carried out, and the product is fed into the electric furnace and subjected to compounding curing; 6, the curved-surface glass blank obtained in the fifth step is subjected to edge elimination, grinding and polishing. By means of the technology, the curved-surface colored glass is effectively prepared and produced, the structural strength of the curved-surface glass is not influenced, the color contrast formed on a curved surface can be reduced, and further application and popularization can be carried out.

Owner:安徽晶晶玻璃制品有限公司

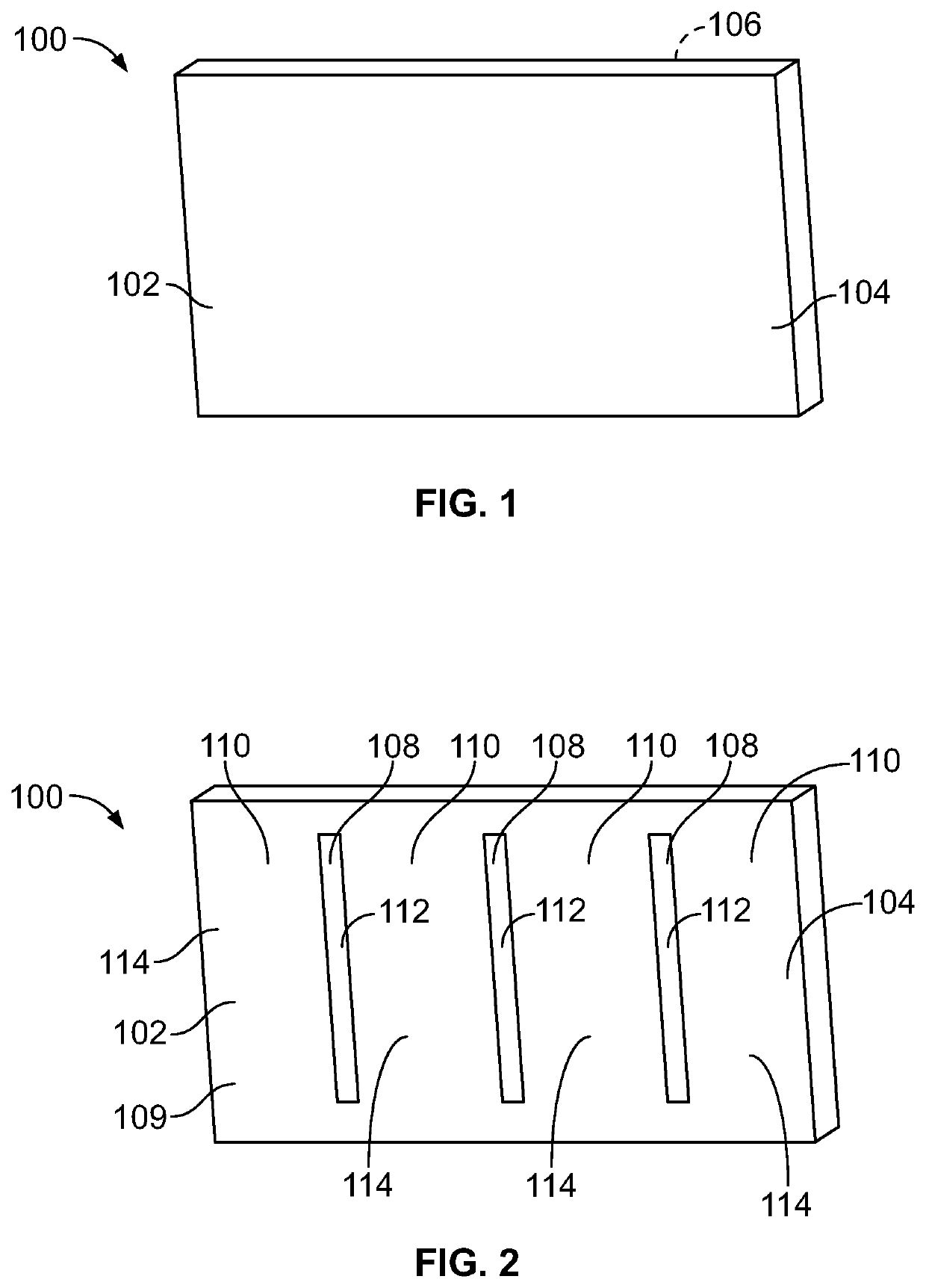

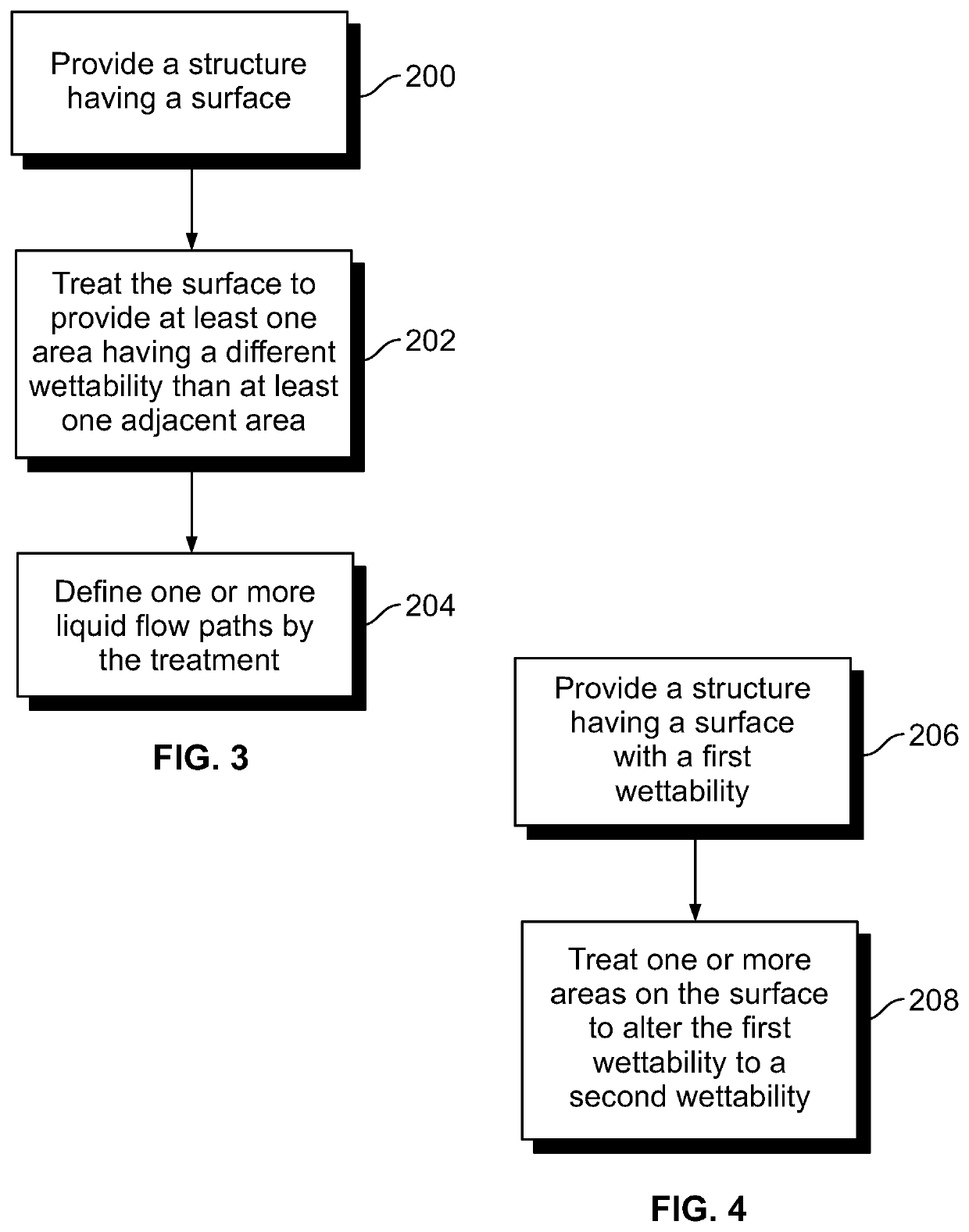

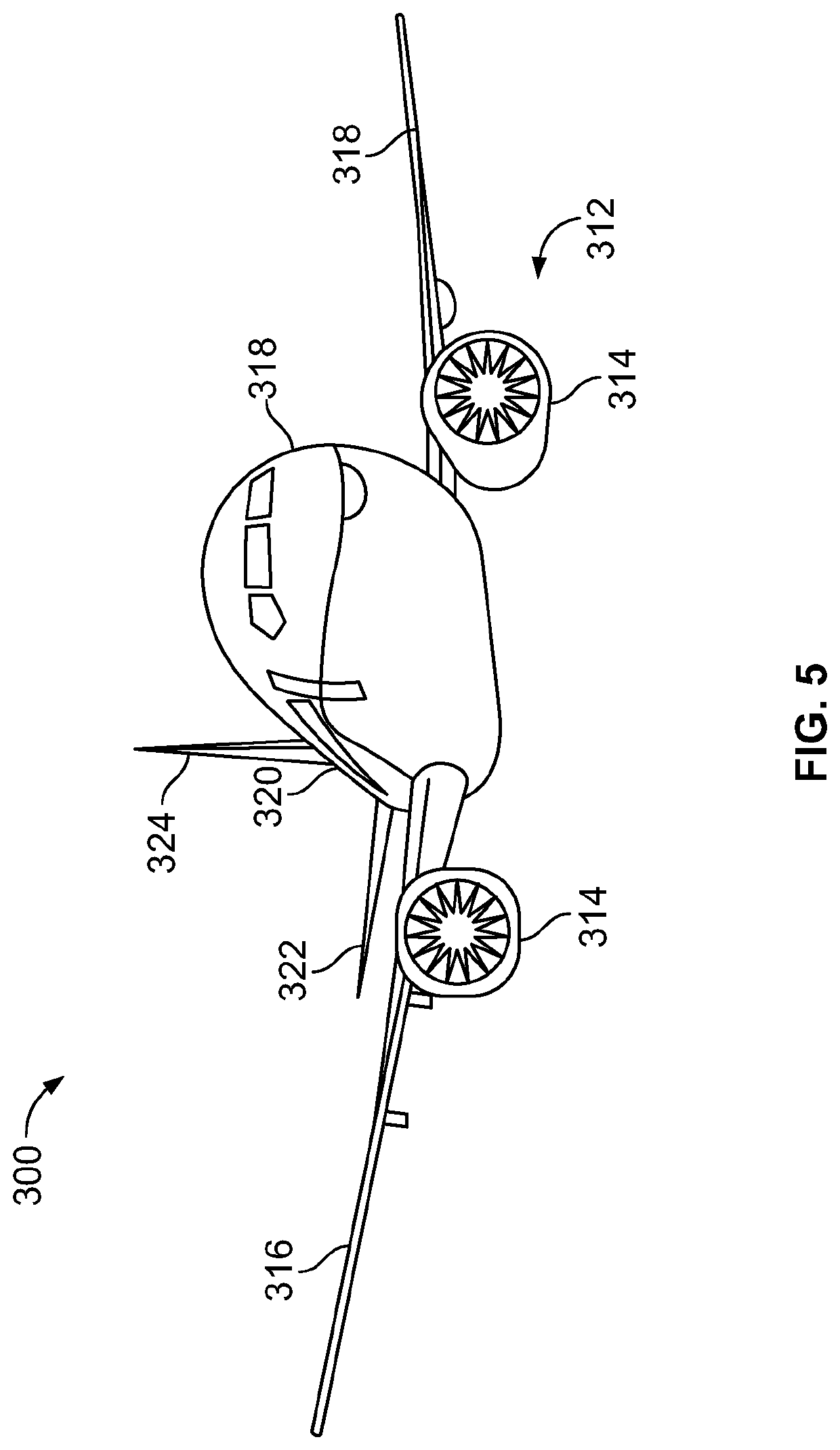

Methods for forming liquid flow paths on a surface of a structure

PendingUS20210245858A1Accelerate liquid flowReduce liquid flowFuselage framesLayered productsEngineeringMechanical engineering

Owner:THE BOEING CO

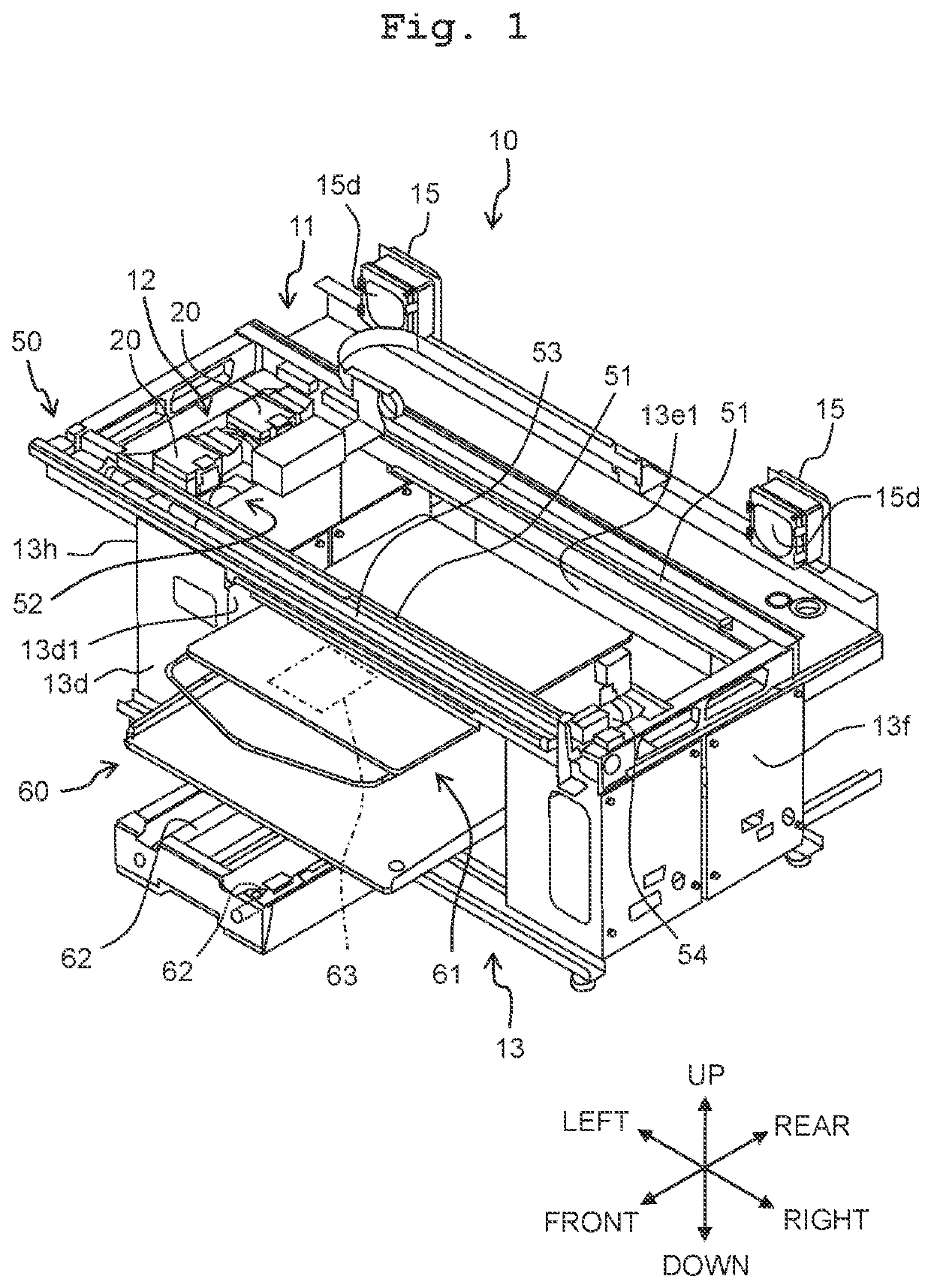

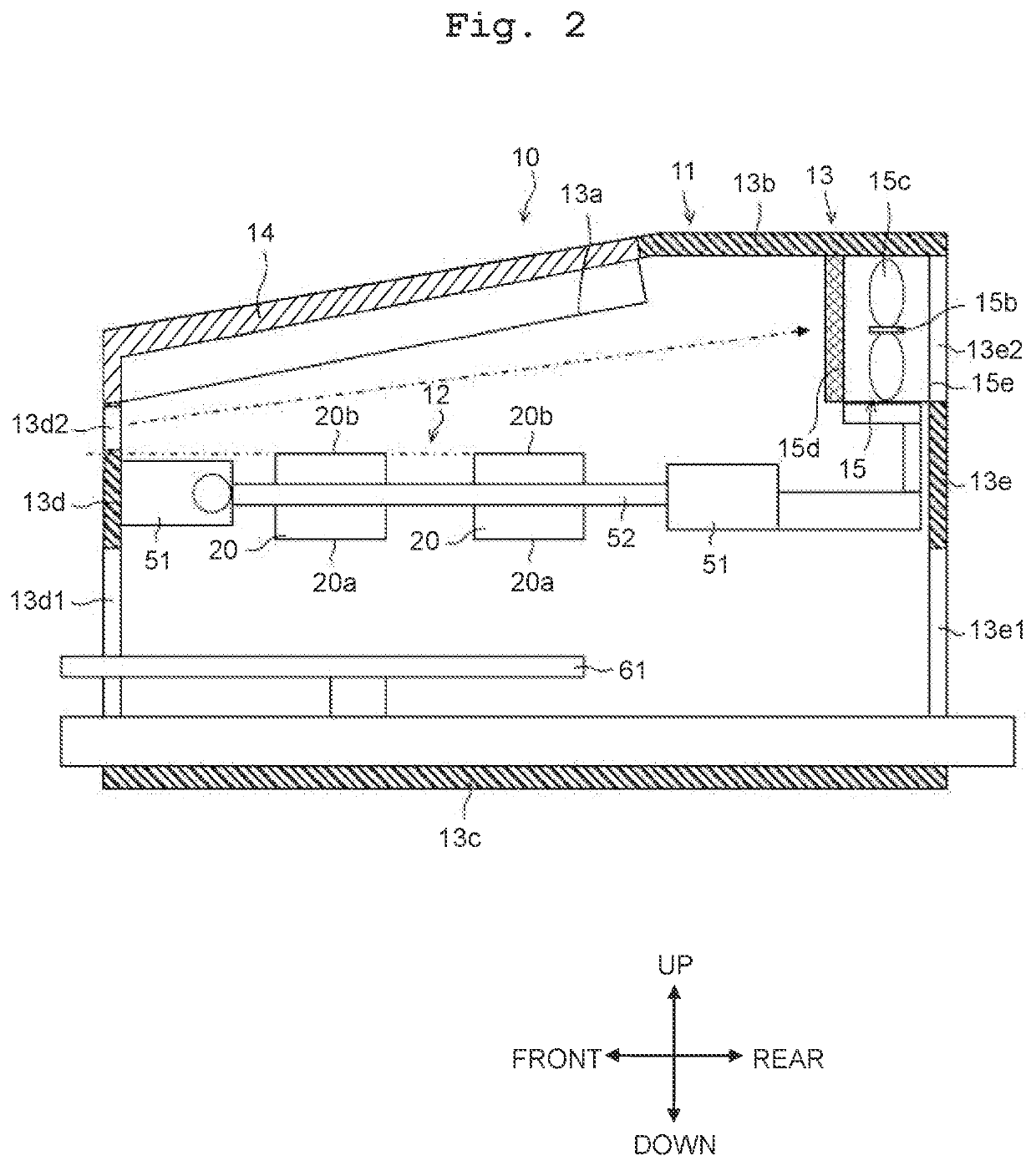

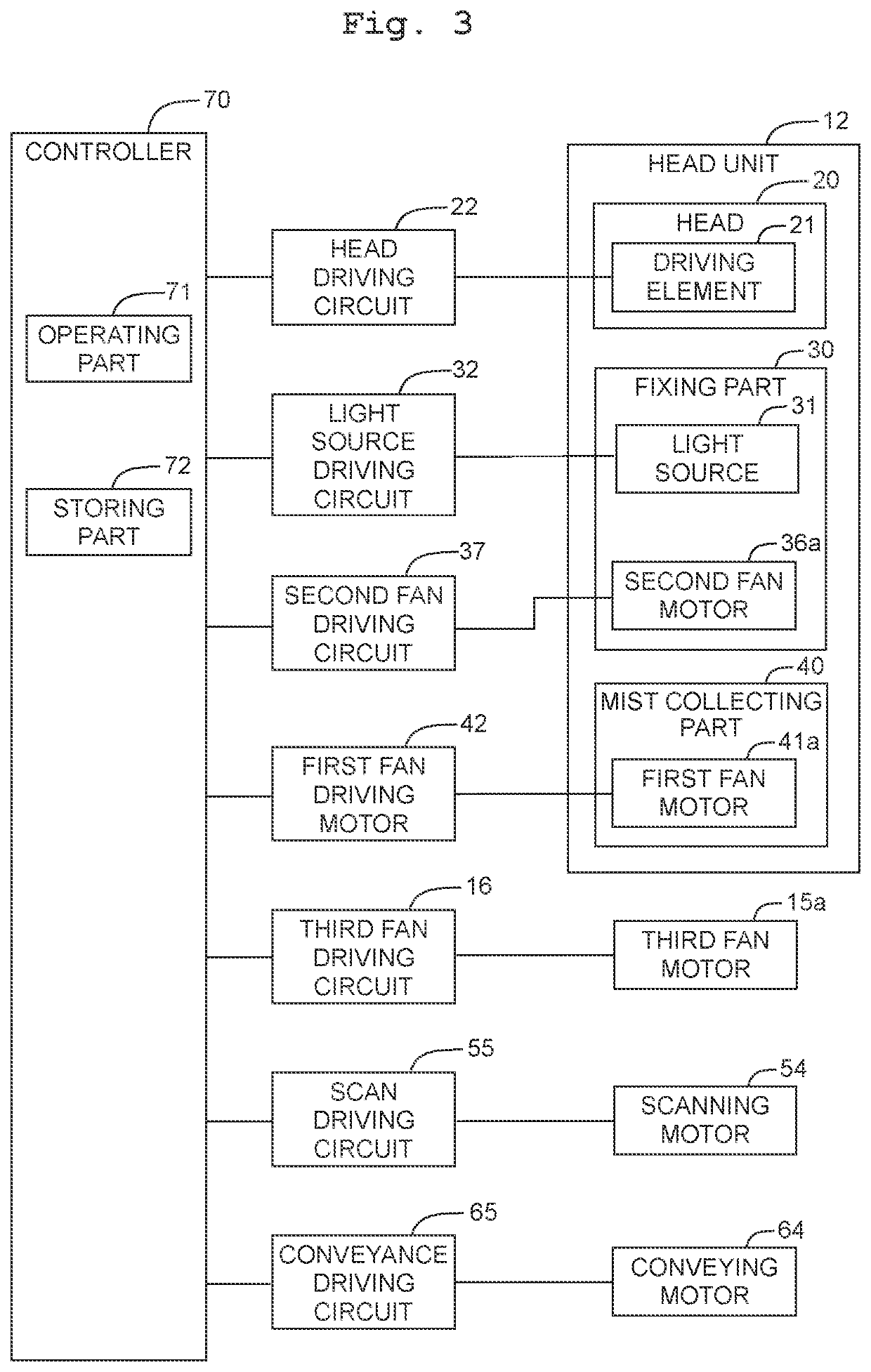

Liquid Discharge Apparatus, Head Unit and Mist Collector

There is provided a liquid discharge apparatus including: a head, a fixing device and a mist collector configured to collect a mist of a liquid. The mist collector and the fixing device are arranged side by side in this order in a first direction. The mist collector is provided with an air channel having a suction port and an exhaust port. The air channel has: a first part and a second part connected to an other end of the first part. The exhaust port is opened, in the second part, toward any one of directions which are: a direction including a direction opposite to the first direction as a directional component thereof, a third direction orthogonal to the first direction and a second direction, and a direction opposite to the third direction.

Owner:BROTHER KOGYO KK

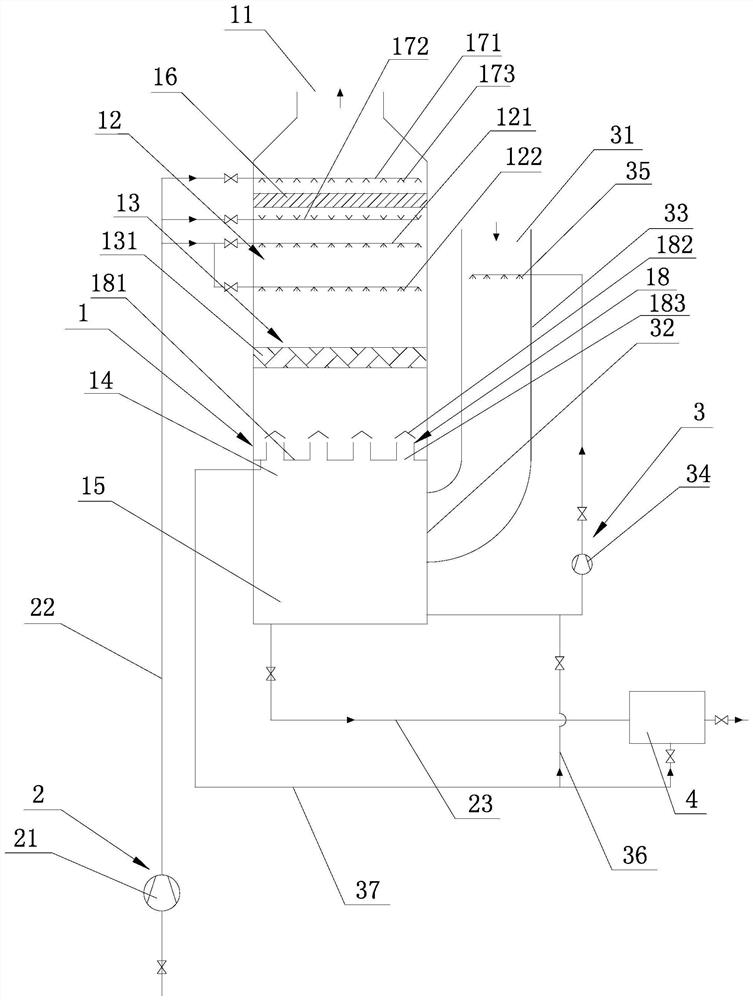

Ship waste gas washing device

PendingCN112675704AImprove spray coverageEvenly distributedDispersed particle separationExhaust fumesWastewater

The invention discloses a ship waste gas washing device which is composed of a washing tower, a washing liquid supply and discharge system and a ship waste gas cooling system, a ship waste gas outlet is formed in the top of the washing tower, and a spraying layer washing area, a packing layer washing area and a ship waste gas cooling area are sequentially arranged in the washing tower from top to bottom. A supply part of the washing liquid supply and discharge system provides washing liquid for the spraying layer washing area, a discharge part of the washing liquid supply and discharge system discharges washing wastewater, and the ship waste gas cooling system is provided with a ship waste gas inlet; ship waste gas introduced from the ship waste gas inlet is cooled by cooling liquid provided by the ship waste gas cooling system, enters the ship waste gas cooling area and then flows back from bottom to top; meanwhile, washing liquid provided by the supply part of the washing liquid supply and discharge system uniformly passes through the spraying layer washing area and the packing layer washing area in sequence to be in contact with ship waste gas flowing reversely from bottom to top to wash the ship waste gas, and the washed ship waste gas is discharged through a ship waste gas outlet; the invention has the advantage that low-resistance, low-consumption and high-efficiency washing can be realized.

Owner:NINGBO UNIV

Method for increasing yield of aviation kerosene fraction by adjusting catalytic cracking main fractionating tower

ActiveCN112500882AReduce the amount of modification worksLess investmentHydrocarbon distillationKeroseneDiesel fuel

The invention relates to a method for increasing the yield of aviation kerosene fraction by modifying a catalytic cracking main fractionating tower. The method comprises the following steps that: S1,a plurality of tower plates above a light diesel oil extraction hopper and below a top cycle extraction hopper are removed, and a filler A and an oil collecting tank A are arranged from top to bottom,wherein an aviation kerosene fraction can be extracted from the oil collecting tank A and sent to an aviation kerosene refining device; S2, a plurality of tower plates below a rich absorption oil inlet are removed, and a liquid distributor B, a filler B and an oil collecting tank B are arranged from top to bottom, wherein a light diesel fraction can be extracted from the oil collecting tank B; and S3, an aviation kerosene fraction stripping tower utilizes an original heavy diesel oil stripping tower, the aviation kerosene fraction enters the aviation kerosene fraction stripping tower to be stripped, the aviation kerosene fraction is cooled and sent to the aviation kerosene refining device, and the 95% distillation point of the aviation kerosene fraction is controlled according to the extraction amount of the aviation kerosene fraction. The aviation kerosene extraction line of the qualified aviation kerosene distillation range is added to the catalytic device fractionating system by modifying part of tower trays of the catalytic cracking device fractionating tower and other measures, existing conditions of an old original device are fully utilized, the modification work amount is reduced, investment is saved, and important guiding significance is achieved for aviation kerosene production increase of refinery enterprises.

Owner:PETROCHINA CO LTD +1

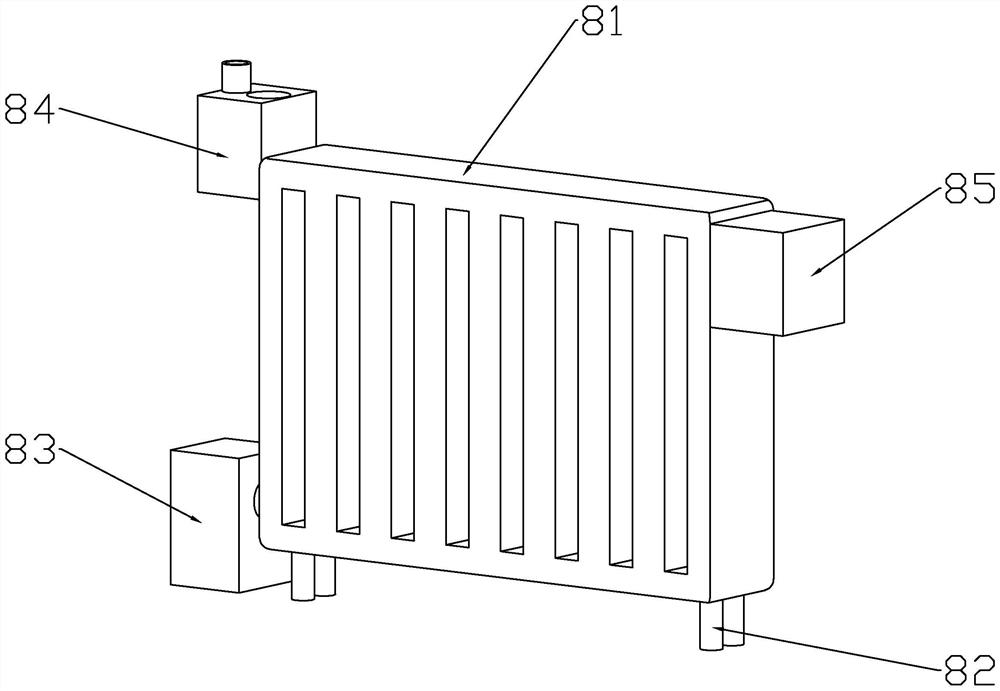

Humidification type heating radiator for greenhouse

ActiveCN113994834AIncrease humidity regulationReduce liquid flowClimate change adaptationGreenhouse cultivationThermodynamicsGreenhouse

The invention belongs to the field of heating equipment, and relates to a humidification type heating radiator for a greenhouse. The humidification type heating radiator for the greenhouse comprises a cuboid-shaped heating radiator. Supporting legs are fixedly mounted at the bottom of the heating radiator; a water inlet module is fixedly installed on the narrow side, away from the direction of the supporting legs, of the heating radiator. A water outlet module is fixedly mounted on one side, close to the supporting legs and in the same direction as the water inlet module, of the heating radiator; the side, opposite to the water inlet module, of the water inlet module is fixedly provided with an air leakage module. The liquid flow in the heating pipeline is reduced through the water inlet module when the indoor temperature is high, so that temperature adjustment is controlled, and meanwhile indoor humidity adjustment is improved. According to the invention, when the heating effect of the heating radiator is poor, air in the heating radiator is automatically exhausted through the air leakage module, and the heating effect of the heating radiator is improved. The cleaning structure for the water scale in the heating radiator is designed, and meanwhile the cleaned water scale is separated through the water outlet module and is recycled and cleaned in a unified mode.

Owner:北京四良科技有限公司

Cross-flow wave making pump

ActiveUS10267333B2Reduce the dead zoneIncrease torquePump componentsWave producing pumpsImpellerEngineering

This invention relates to a cross-flow wave making pump comprising an impeller shell forming a water intake and a water outlet, an impeller assembly pivotally connected to two ends of the impeller shell, and a motor used for driving the impeller assembly; wherein, the impeller assembly comprises an impeller used for driving a liquid flow, a first turntable and a second turntable respectively fixed at two ends of the impeller, wherein the first turntable is provided with a shaft rotatably mounted in the impeller shell, the second turntable is provided with a cavity used for receiving a rotor shaft of the motor. The embodiments of the present invention can provide a sufficient liquid-circulation in a container, and significantly reduce the dead zone where the liquid flows extremely slowly. Other embodiments are disclosed.

Owner:GUANGZHOU MAIGUANG ELECTRONIC TECHNOLOGY CO LTD

A self-priming sewage pump with double-port ring seal

ActiveCN110541830BAchieve reductionEasy to get stuckSpecific fluid pumpsPump componentsImpellerEngineering

The invention discloses a self-suction sewage pump with double port rings sealing. The self-suction sewage pump comprises a water suction chamber, an impeller with cutting blades, a front sealing ringwith cutting grooves, a rear pump cover with cutting grooves, a mechanical seal, a backflow hole, a pump body, a gas-liquid separation chamber, a pump shaft and a bearing body; the impeller with thecutting blades is arranged on the pump shaft, and is connected with the pump body through the rear pump cover with the cutting grooves and the bearing body; the cutting blades are uniformly distributed on the edges of an impeller front cover plate and an impeller rear cover plate in a 360 degrees / n separation mode; n groups of blades are arranged on each cover plate, wherein n is an even number, and the edge orientations of the blades are consistent with the rotation direction of the impeller; and the front sealing ring and the rear pump cover are static parts, and n cutting grooves which areuniformly distributed are formed in the inner side edge of each of the front sealing ring and the rear pump cover. According to the self-suction sewage pump with double port rings sealing, the problems that the port rings of the self-suction sewage pump are easily clamped and the machine seal is prone to abrasion are solved; and meanwhile, the double-port ring sealing type of the impeller greatlyreduces the liquid flow of high-pressure fluid back-flowing from an impeller outlet to an impeller inlet, the energy loss is reduced, and the pump efficiency is improved.

Owner:CHINA JILIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com