Thermoelectric conversion device and system

A technology of thermoelectric conversion devices and heat sinks, which is applied to motors, electrical components, generators/motors, etc. that apply thermal effects, and can solve problems such as increased power consumption of thermoelectric conversion devices, increased liquid flow resistance, and obstruction, so as to reduce swirl The formation of the zone, the reduction of flow resistance, and the effect of avoiding impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

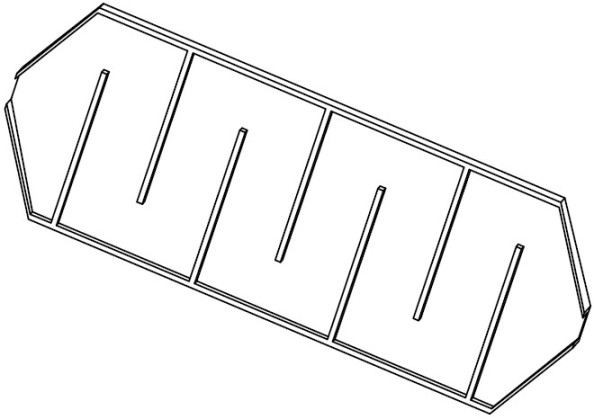

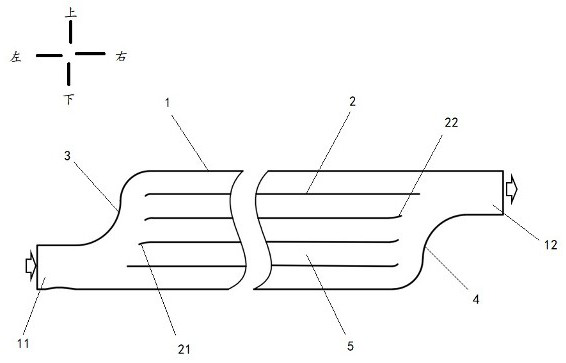

[0044] This application provides a thermoelectric conversion device, please refer to image 3 As shown, the device includes: a heat exchange heat sink shell 1, the two ends of the heat exchange heat sink shell 1 in the length direction are respectively provided with a liquid inlet 11 and a liquid outlet 12, and the heat exchange heat sink shell 1 is provided with a A plurality of rib walls 2 extending in length, and the plurality of rib walls 2 are arranged at intervals along the width direction of the heat exchange heat sink shell 1 , and a plurality of channels 5 are formed between the plurality of rib walls 2 .

[0045] In the present invention, the liquid inlet 11 and the liquid outlet 12 are located at both ends of the heat exchange heat sink shell 1 in the length direction, and the connection line between the liquid inlet 11 and the liquid outlet 12 is inclined, so that the liquid inlet The ports 11 and liquid outlets 12 are staggered, that is, the position of the liquid...

Embodiment 2

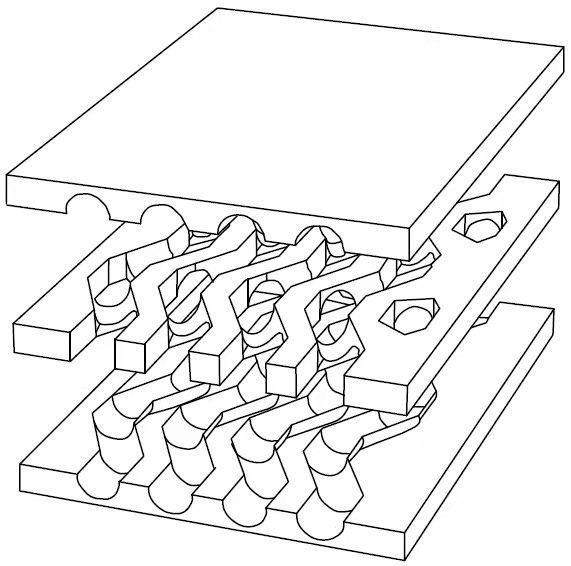

[0094] Based on the same inventive concept, another embodiment of the present application provides a thermoelectric conversion system, including: a plurality of thermoelectric conversion devices as provided in Embodiment 1 of the present invention; A thermoelectric module 6 is arranged between the conversion devices; the liquid inlets 11 of each adjacent two thermoelectric conversion devices are located on different sides, and the liquid inlet 11 of one thermoelectric conversion device in each adjacent two thermoelectric conversion devices is connected to the other thermoelectric The liquid outlets 12 of the conversion device are staggered.

[0095] In this invention, see Figure 6 As shown, the thermoelectric conversion device is stacked with the thermoelectric module 6 , and the heat dissipated by the thermoelectric conversion module is received by the thermoelectric module 6 and then converted into electrical energy.

[0096] Specifically, the thermoelectric module 6 may b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com