Novel atomizing nozzle based on bubble cutting

A technology of atomizing nozzles and air bubbles, applied in the direction of spraying devices, liquid spraying devices, etc., can solve the problems of large particles, poor atomization effect, large average diameter of liquid mist particles, etc., and achieve small diameter of atomized particles and high working pressure Wide range, uniform and stable bubbly flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

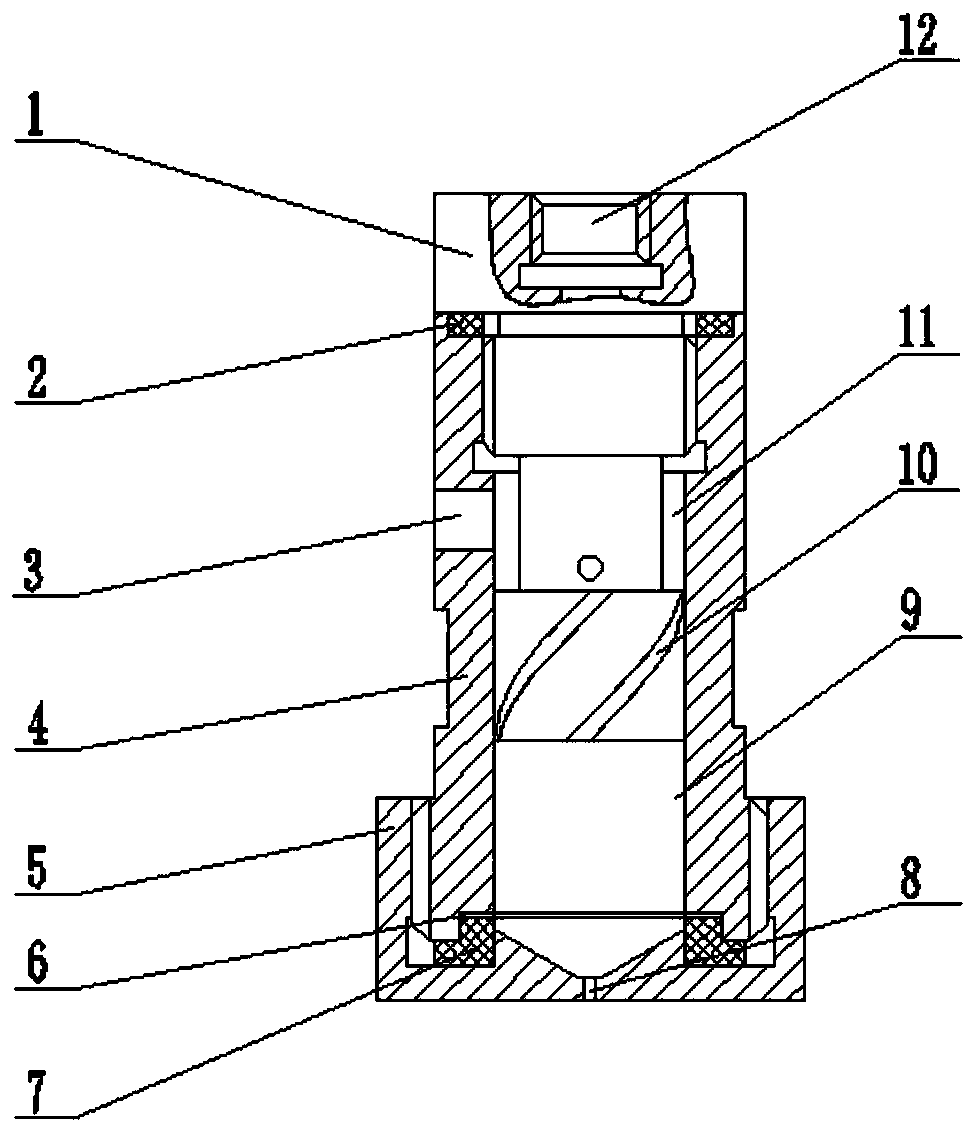

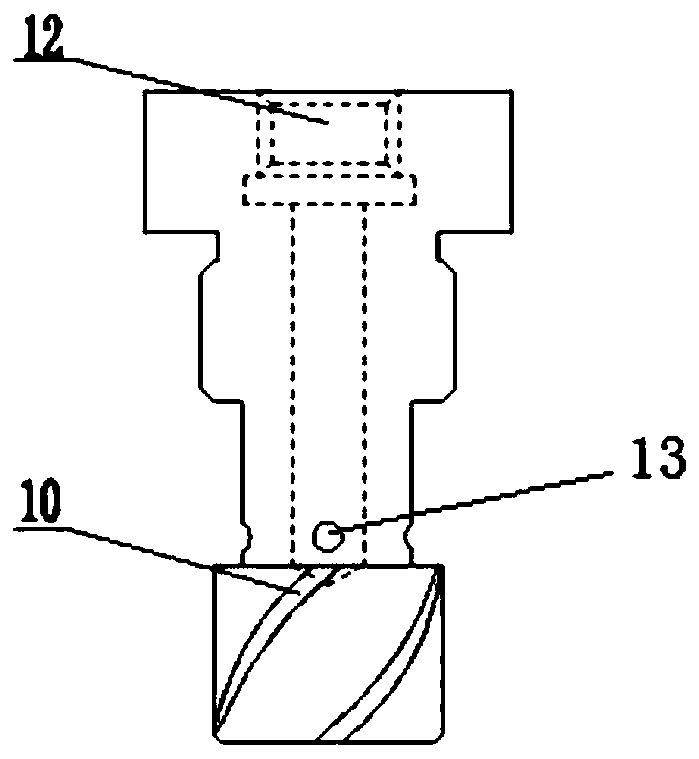

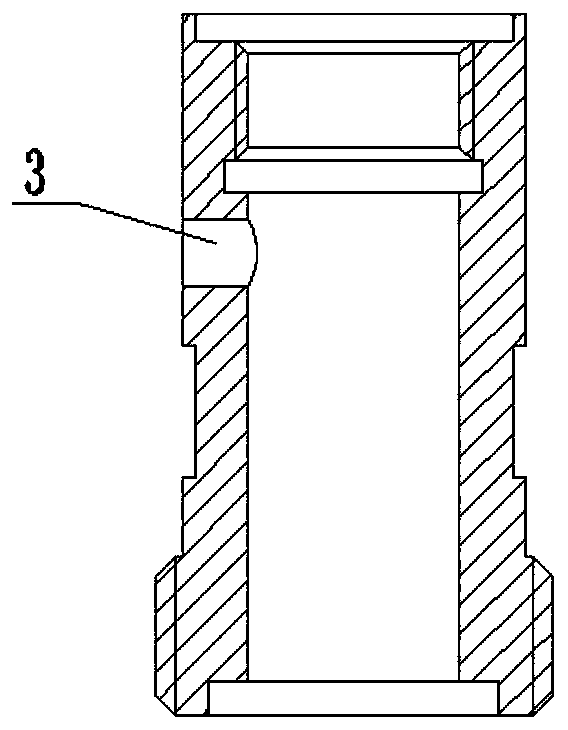

[0040] In this embodiment, the diameter of the liquid inlet hole is 2 mm, the aspect ratio of the secondary mixing chamber is 1.25:1, the bubble cutter is a 200-mesh wire mesh, and the circular hole D=1.0 mm. The nozzle hole 8 is cylindrical, with an aspect ratio of 2:1, a diameter of 1.0 mm, and a length of the nozzle hole of 2 mm.

[0041] Liquid and compressed air enter the primary mixing chamber 11 through the liquid inlet hole 3 and the first air inlet hole 12 respectively, and enter the secondary mixing chamber 9 tangentially through the swirl tank 10 after preliminary mixing; Fully mixed in the stage mixing chamber to form a gas-liquid two-phase bubble flow, which is sprayed through the nozzle hole 8 to form a uniform and stable fog torch. image 3 It is the atomization state diagram of the nozzle when the gas-liquid mass flow ratio is 0.11. It can be seen from the figure that the particles after atomization are uniform and of good quality, and a stable fog torch can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com