Patents

Literature

49results about How to "Wide working pressure range" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

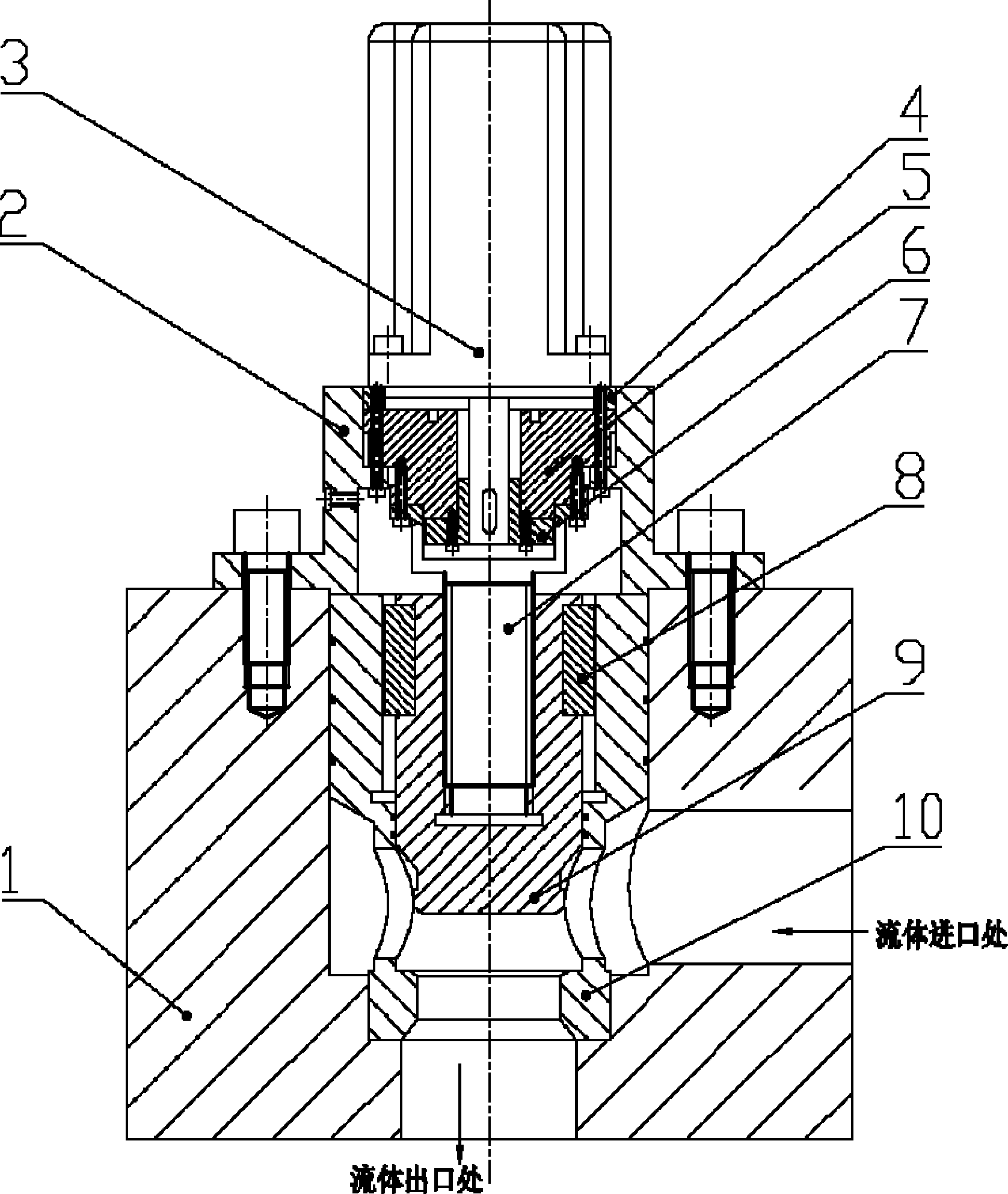

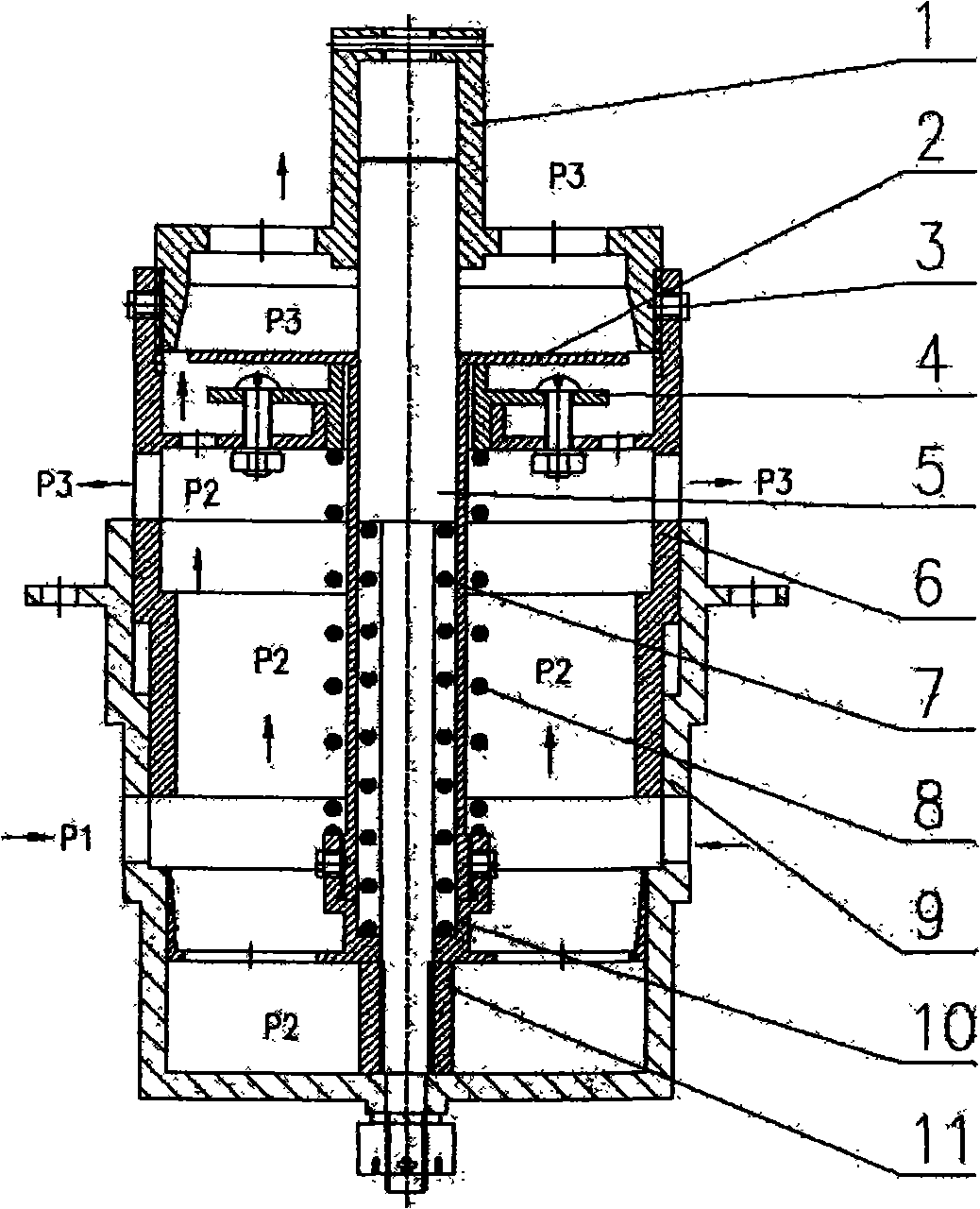

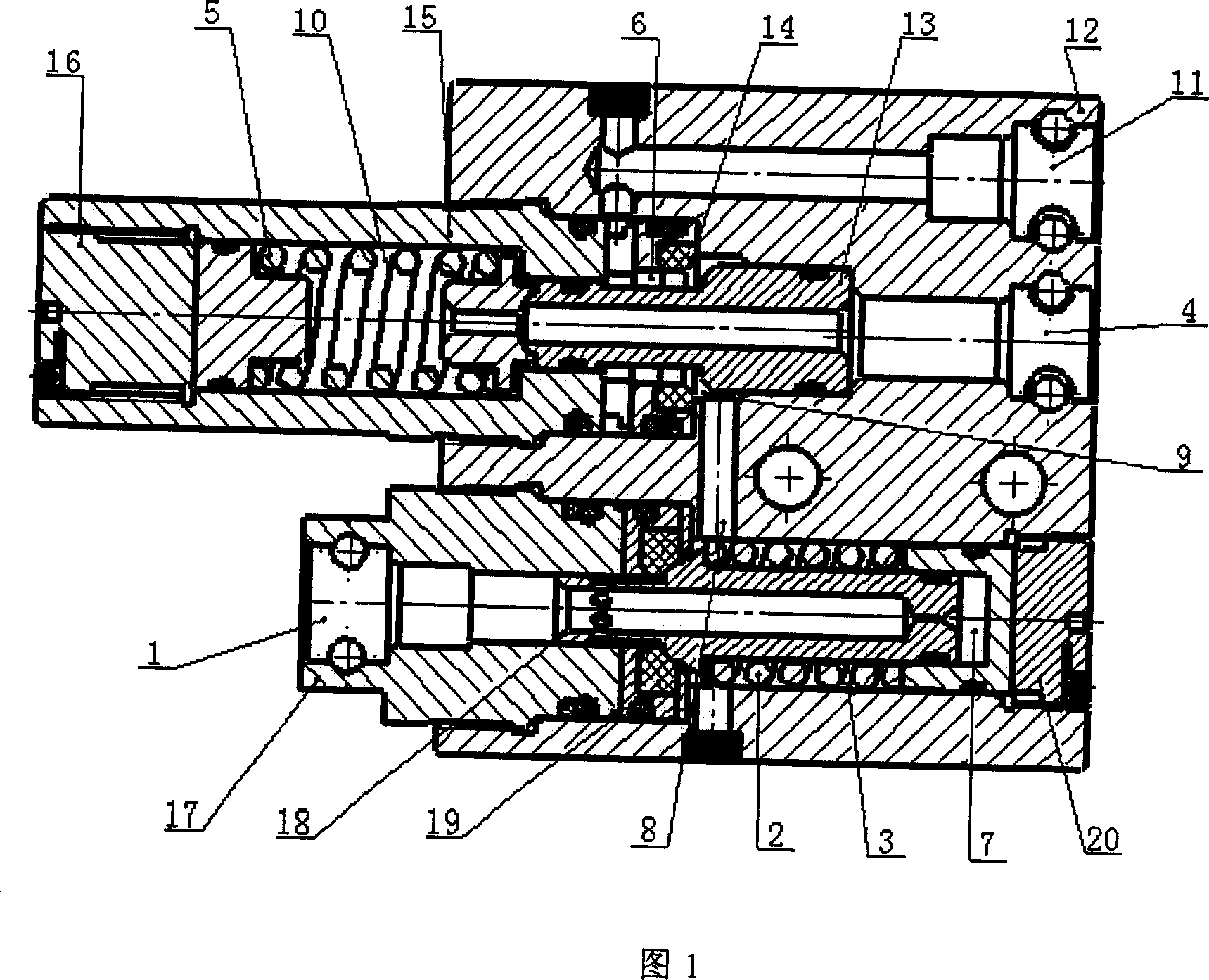

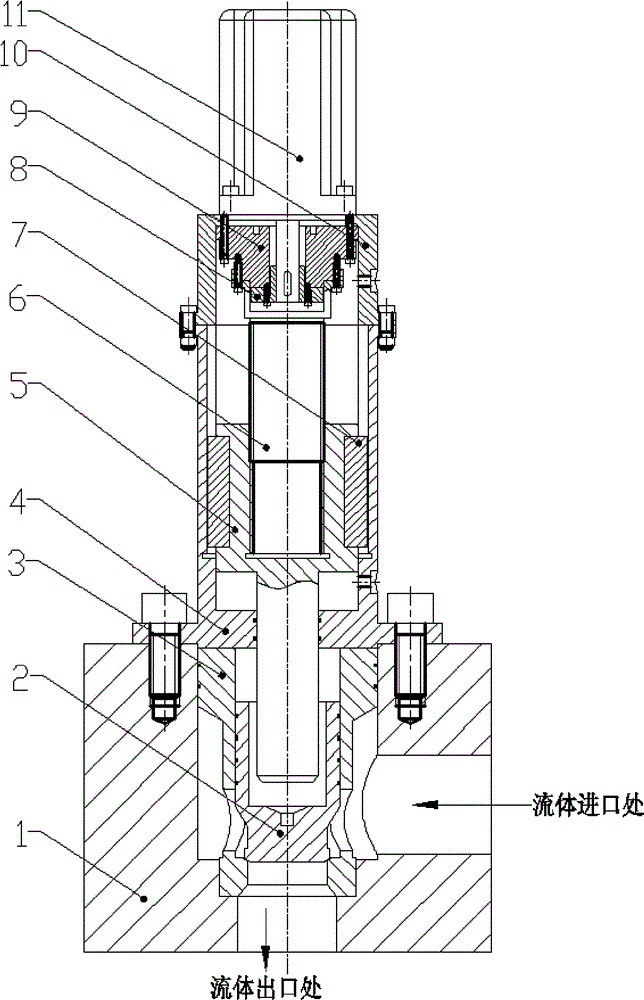

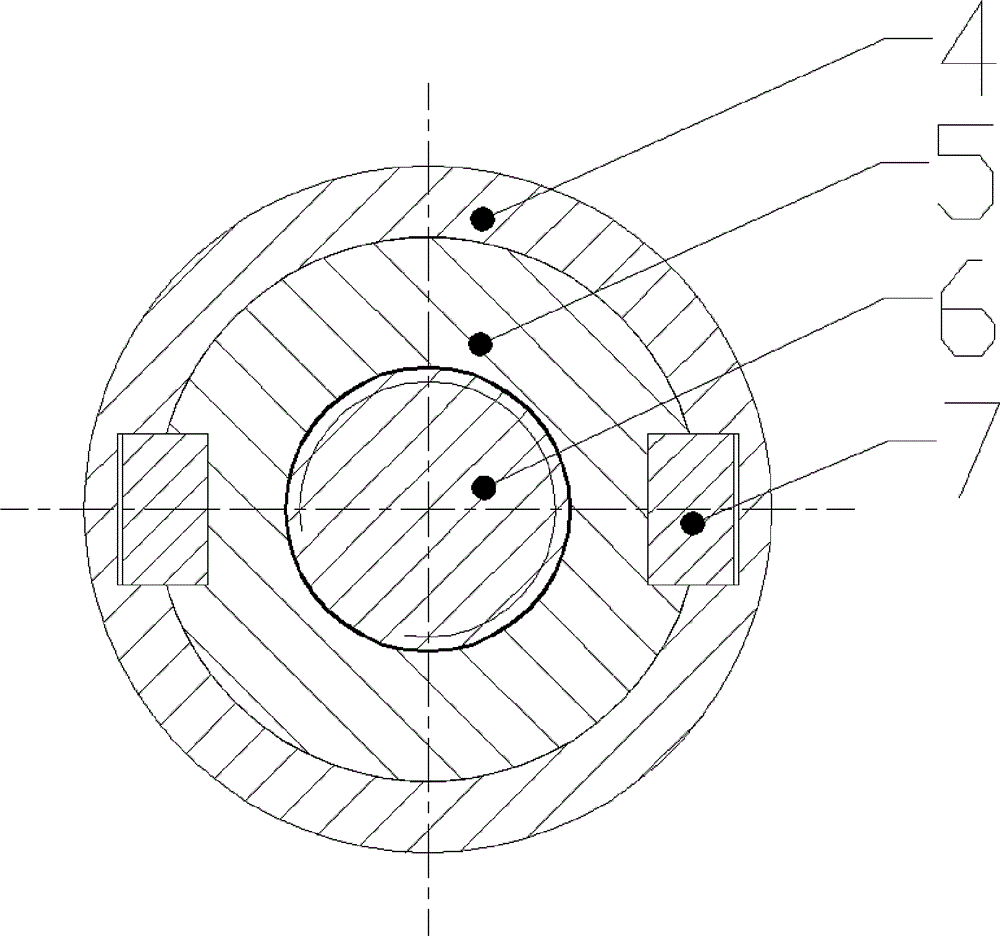

High-pressure high-flow alternating-current servo direct-driven threaded flow valve

InactiveCN102635582AOvercoming contamination sensitivityReduce manufacturing costsServomotor componentsElectricityWorking pressure

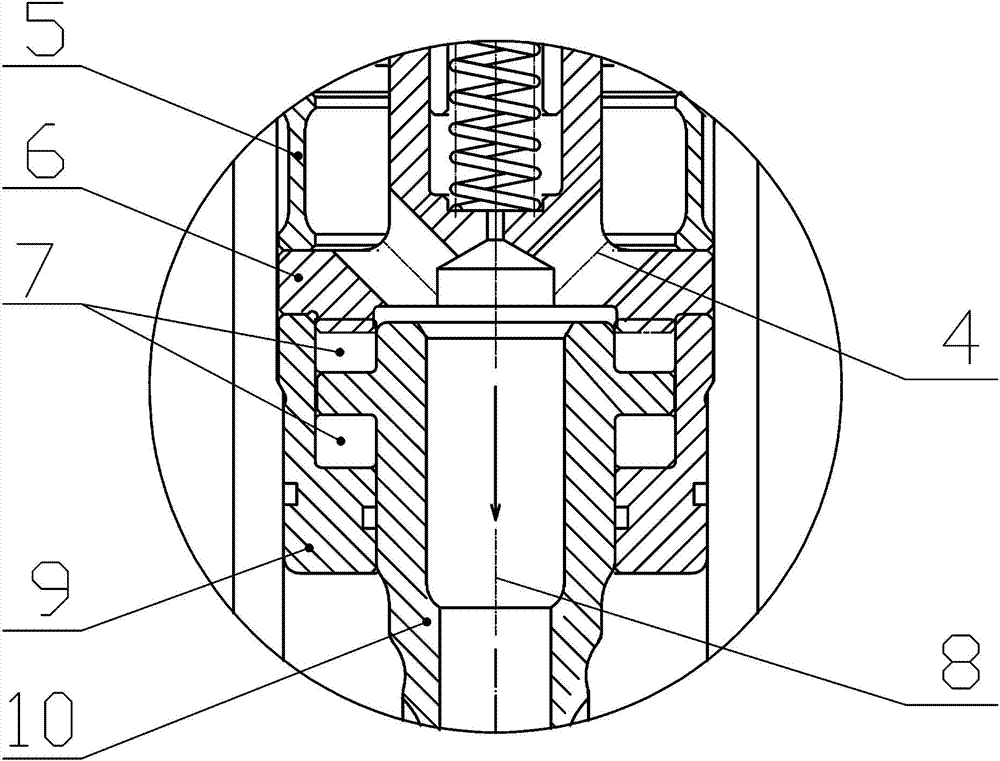

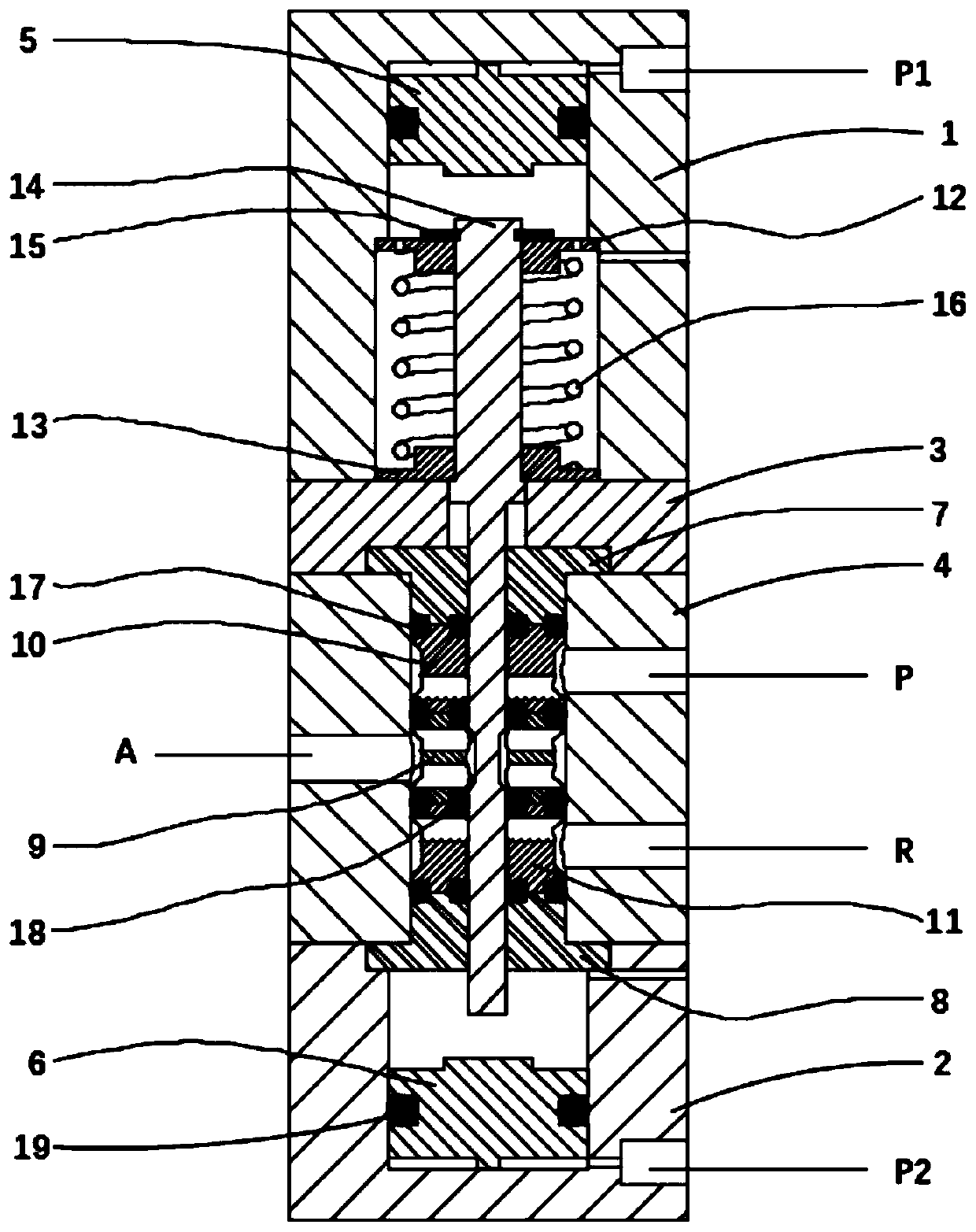

Disclosed is a high-pressure high-flow alternating-current servo direct-driven threaded flow valve. An alternating-current servo motor directly drives a valve spool to open and close by the aid of transmission of threads, and the threads only need to transmit driving force on a single side during integral operation of the valve due to hydraulic force, and are selectively one-way transmission saw-toothed threads. The valve is simple in structure, accurate in control and convenient in use, can be directly digitally controlled by a computer and has excellent buffering and positioning performances, the requirement on positioning at an optional point can be met, a closed-loop system with an electrical feedback function can be realized, particularly, the problem that an original servo valve is sensitive to oil pollution can be effectively solved, and shortcomings that the original servo valve is used difficultly in high-pressure and high-flow environments and the like are also overcome. In addition, the valve is wide in working pressure range and high in flow, and can also work under extremely low oil supply pressure, the dynamic performance of the valve is rarely affected by the oil supply pressure, and the efficiency of a system can be improved due to the fact that intermediate transmission links are few.

Owner:XI AN JIAOTONG UNIV

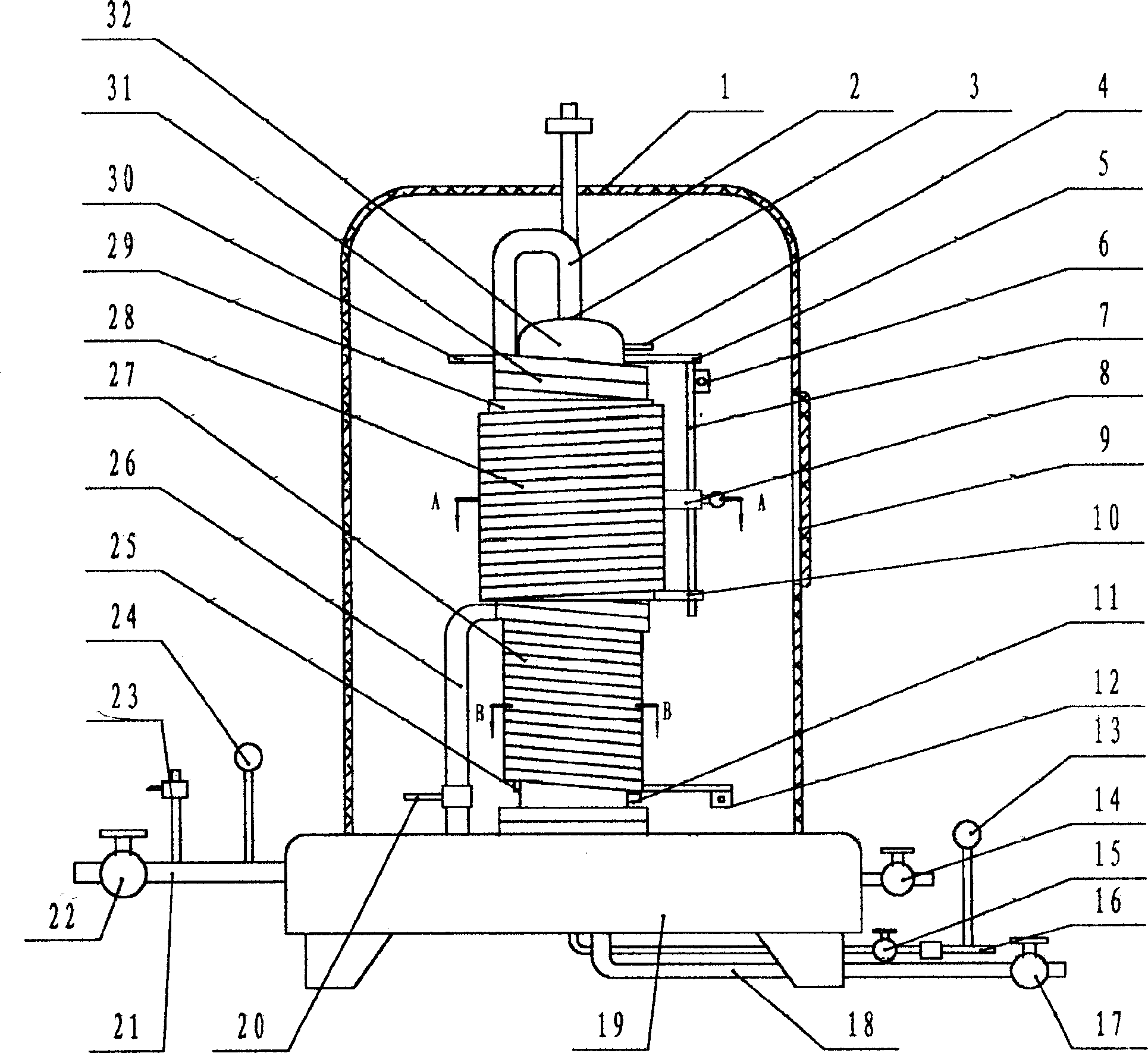

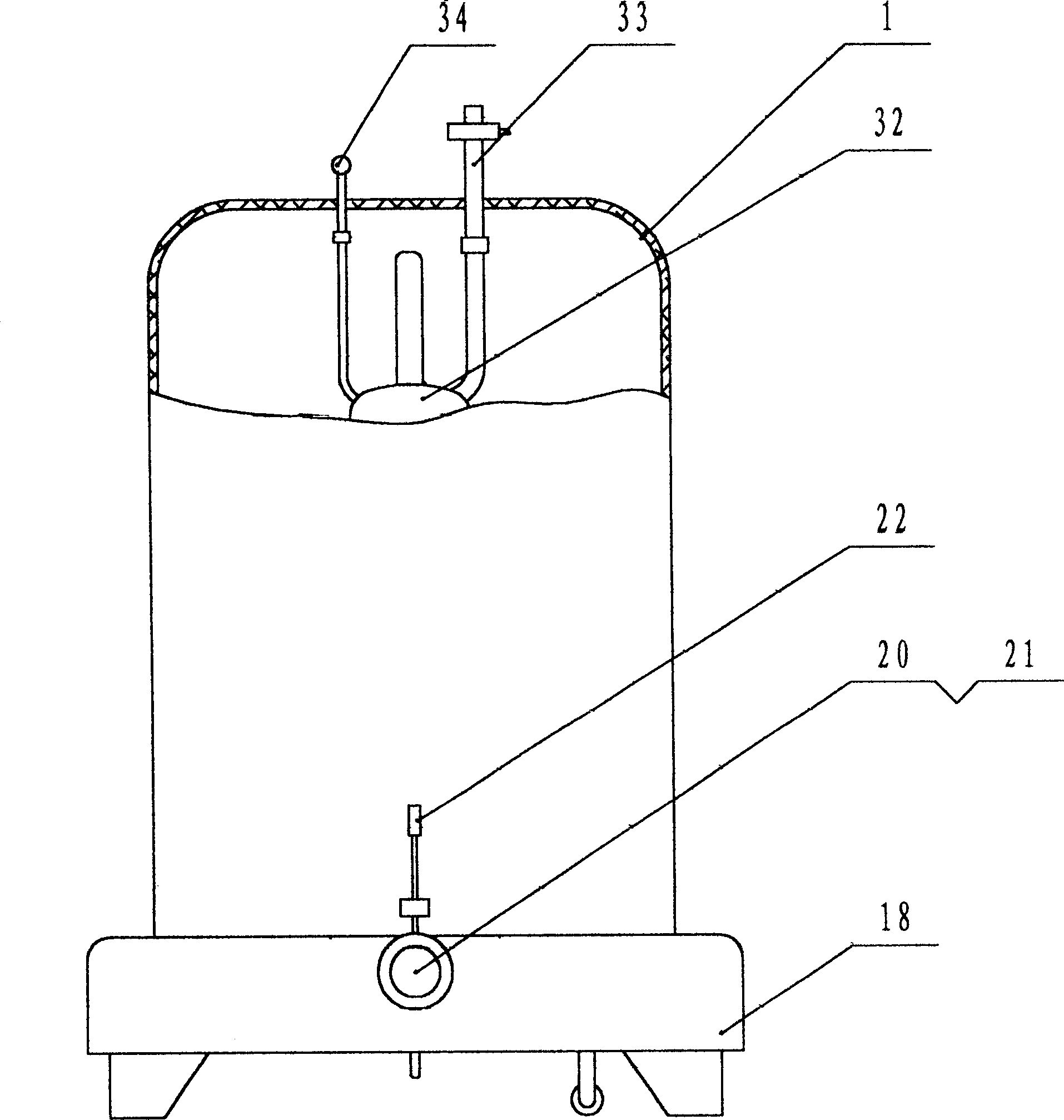

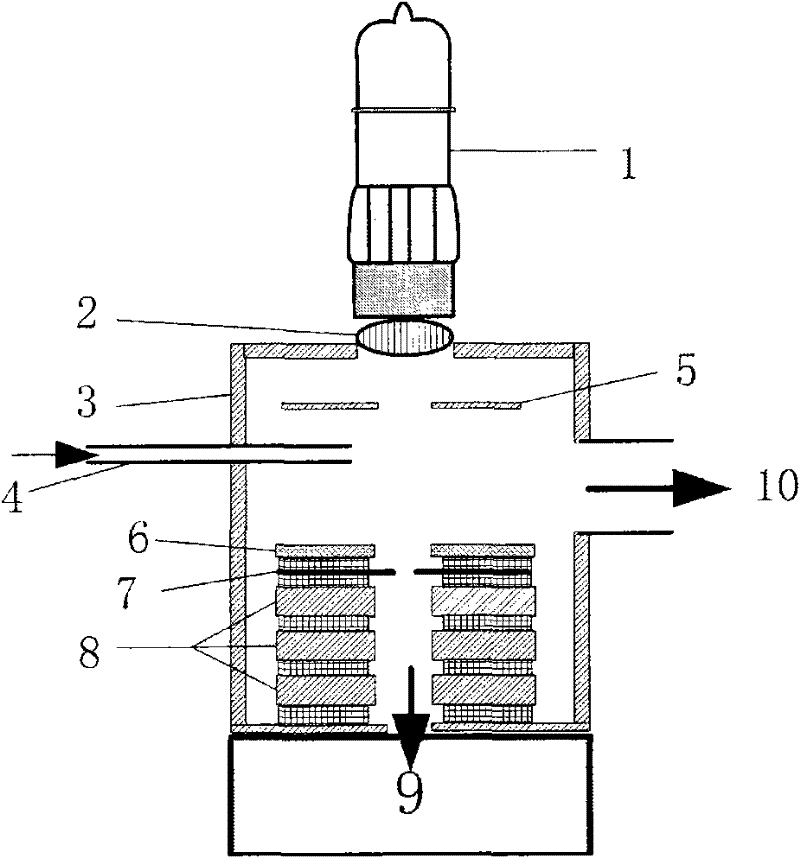

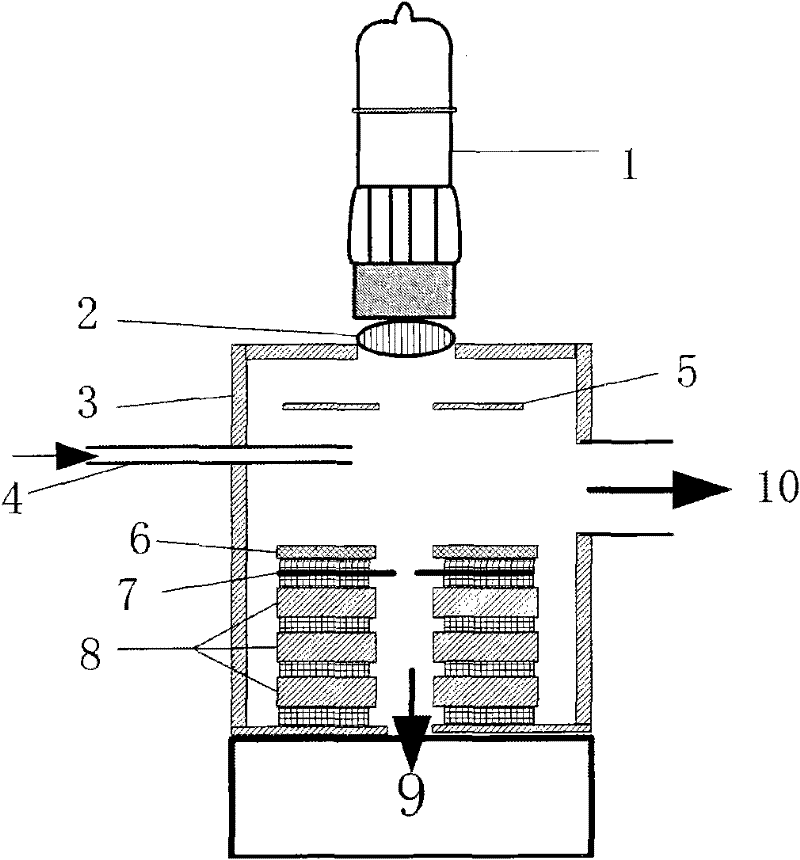

Water vaporization method and device as well as medium frequency induced water vaporization method and device

InactiveCN1431424AReduce lossImprove the heating effectSteam generation heating methodsSteam superheatersMedium frequencyInduction heater

A water evaporation method and its device is to heat a seal container with an atomizing jet to over 140 deg.C to spray water to the internal wall of the container from the jet to steam it then IF induction method is applied to heat the container or the steamed water is input into a solenoidal steam adjuster to be heated by another induction heater wrapped on the steam adjuster. Steaming device has a seal cylindrical shell with a spray tube having an atomizing jet inside to form a steam generator, the cylinder shell is set in the heating device. The solenoidal induction heater wrapped outside the steam generator can be the heating device and solenoidal steam adjuster sleeved tightly by another induced heater can be set outside the generator with connecting inlets and outlet of the steam adjuster with exhausting steam tube.

Owner:北京东方华奇环保科技有限公司

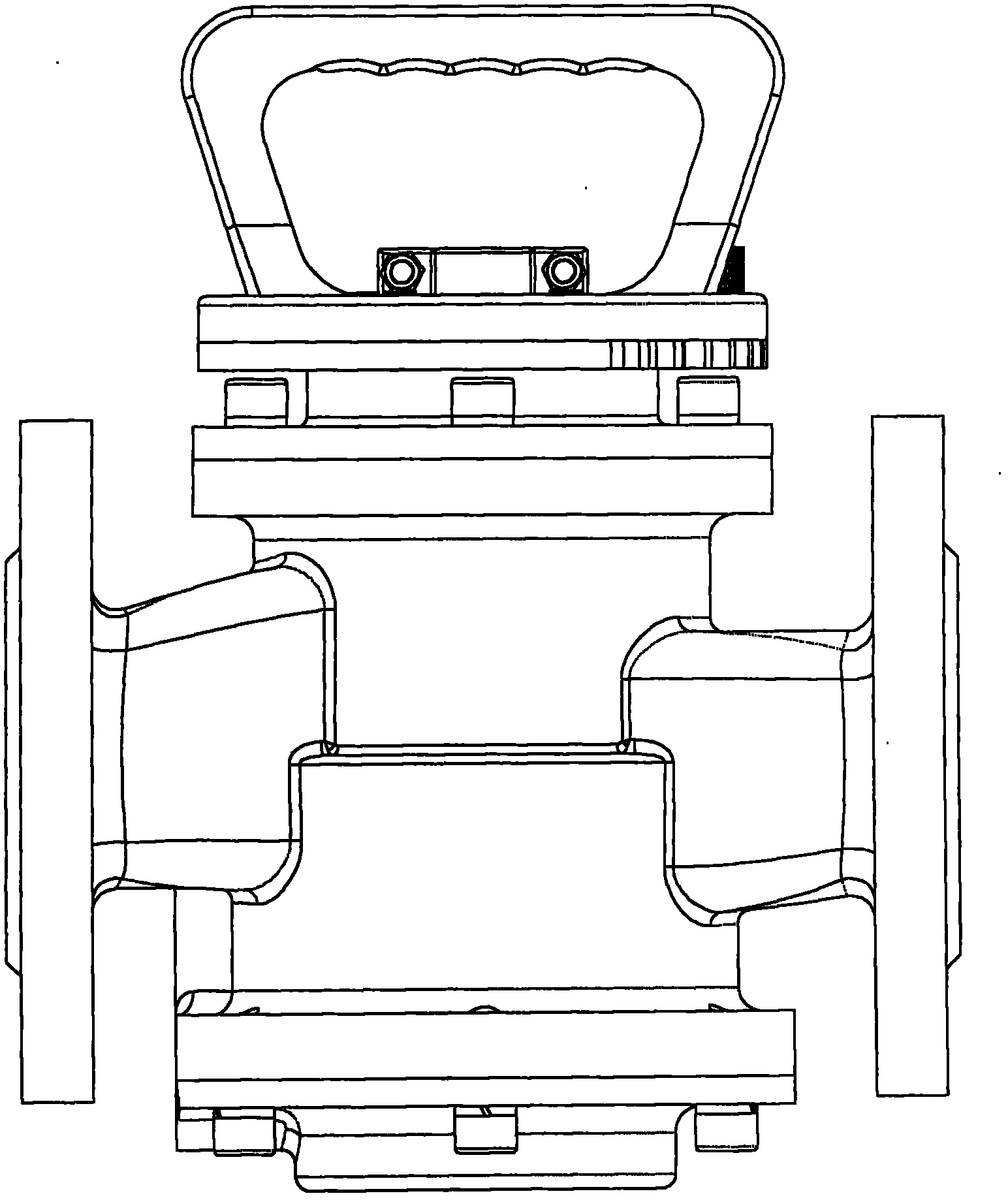

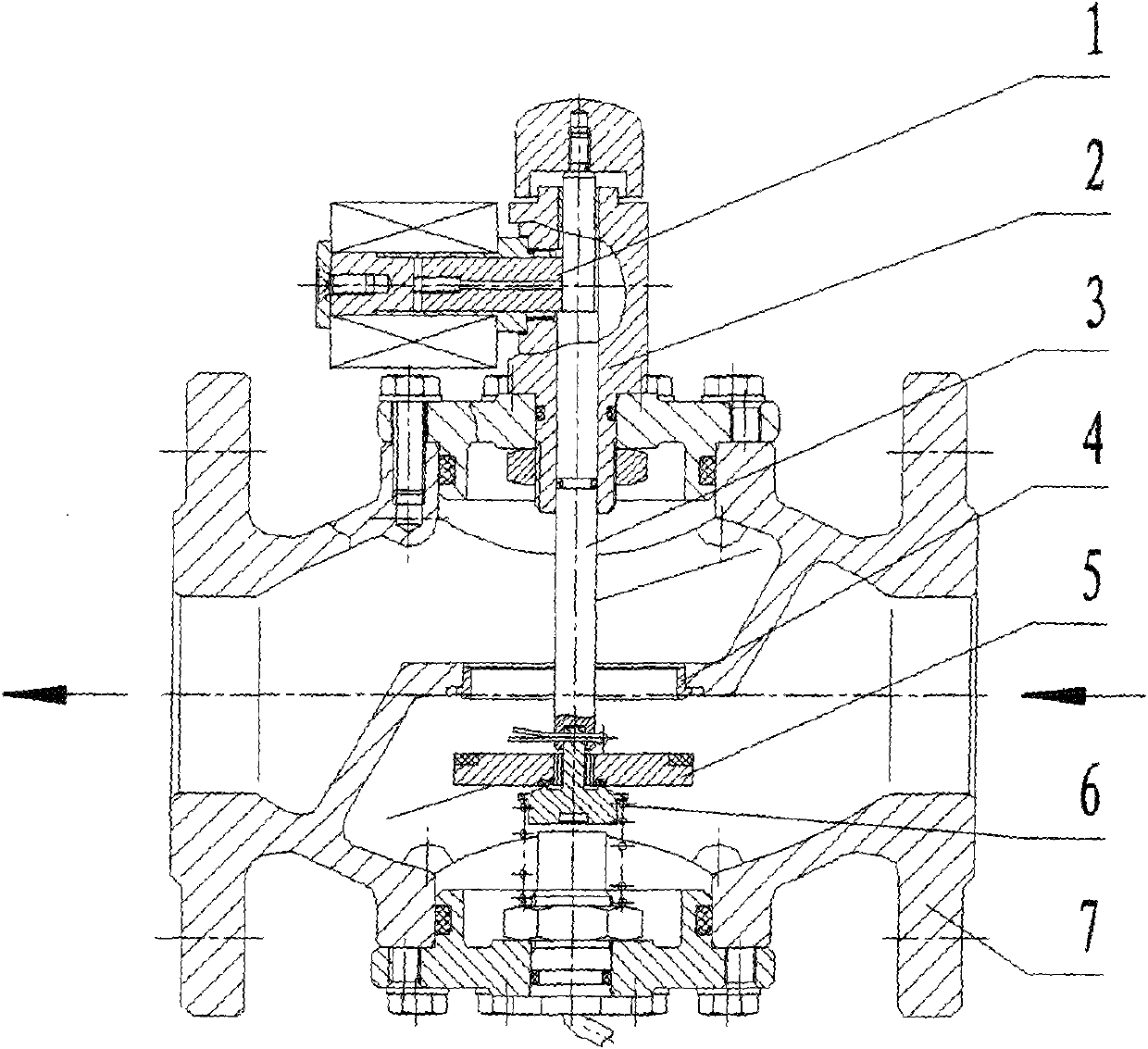

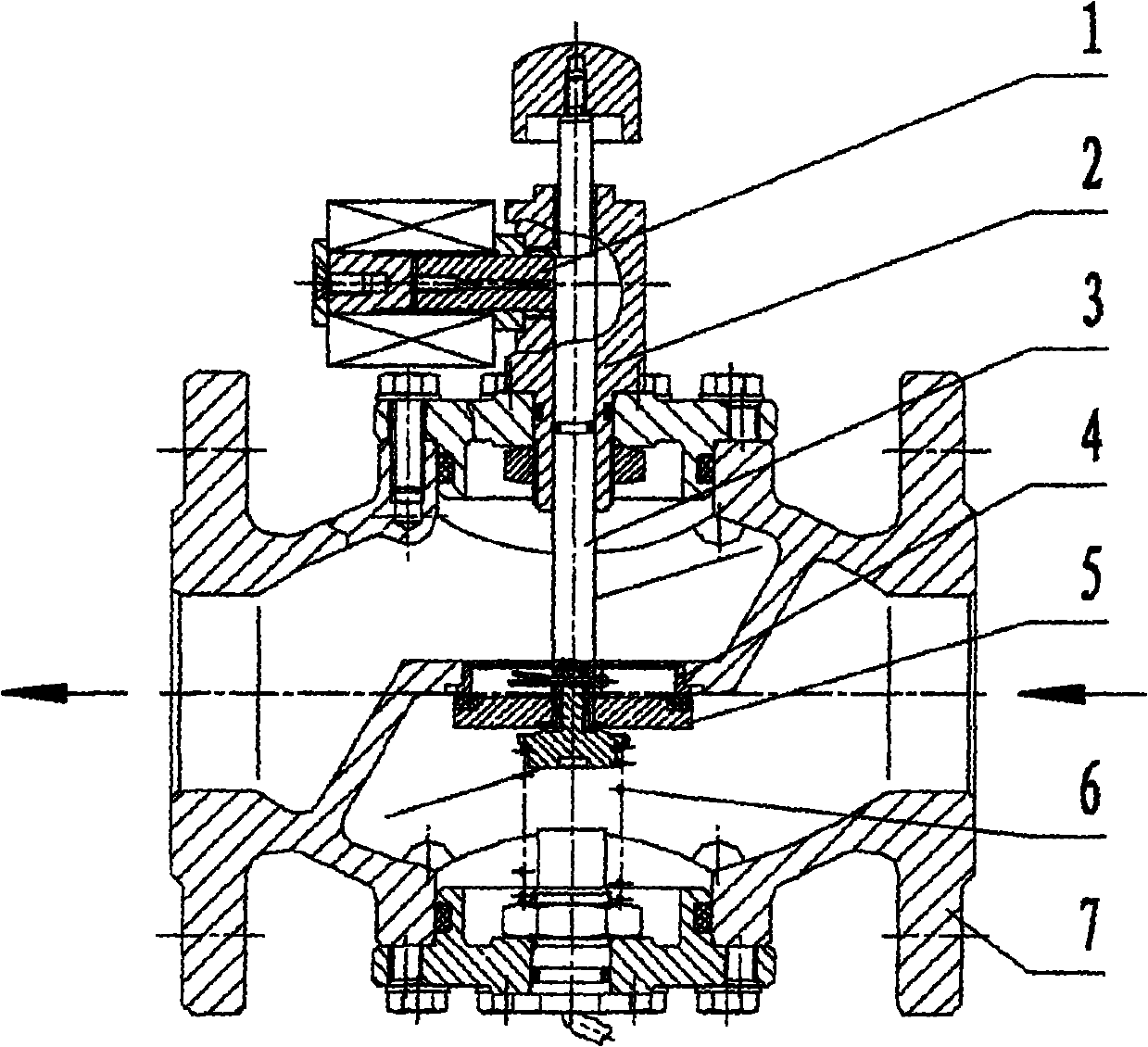

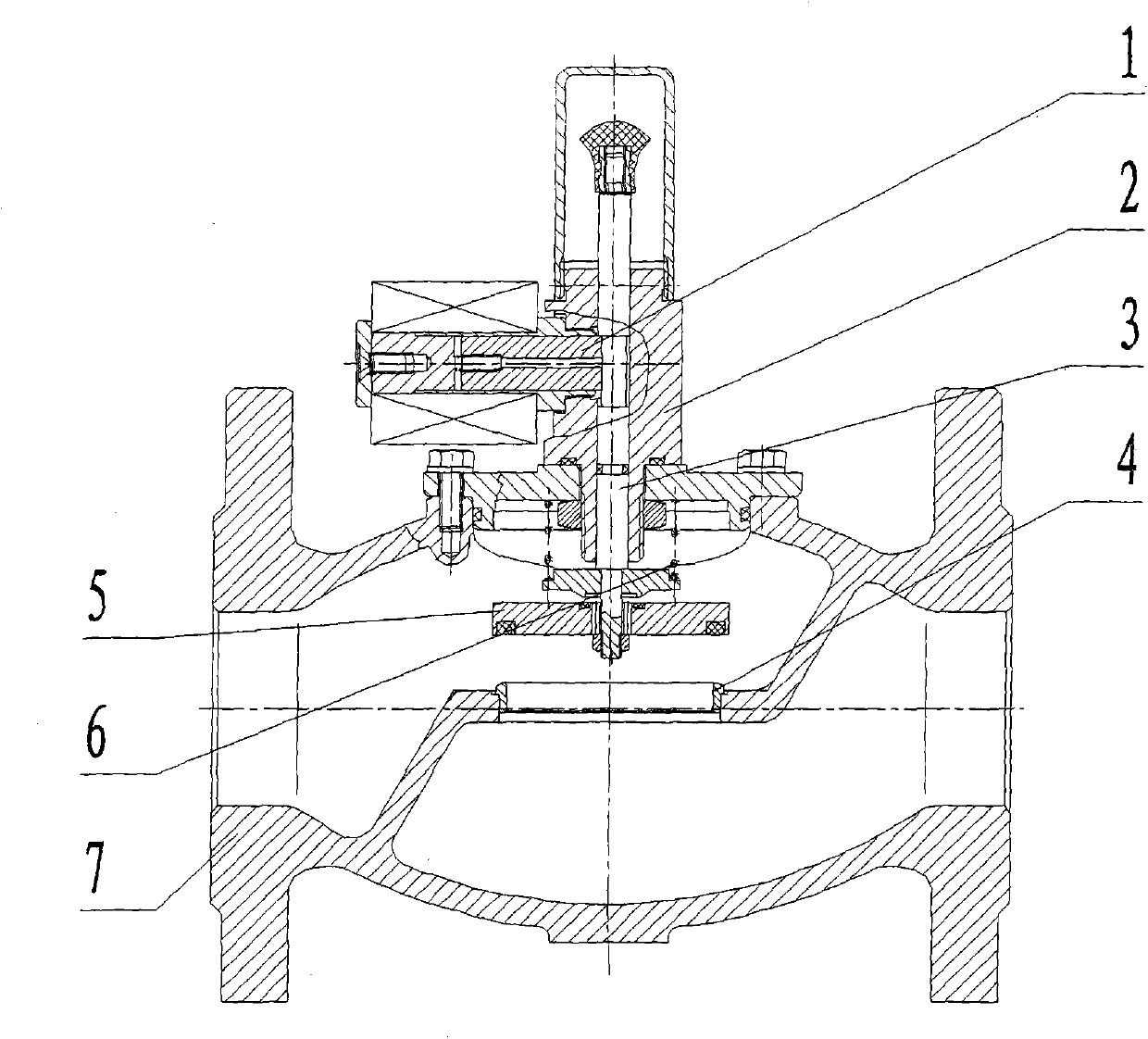

Membrane pressure type dynamic balance manual adjusting valve

InactiveCN102072346ASolve the imbalance of water conservancy flowAddressing DissonanceOperating means/releasing devices for valvesEqualizing valvesChemical industryDynamic balance

The invention provides a membrane pressure type dynamic balance manual adjusting valve. The adjusting valve comprises a handle component and an integrated valve which is positioned below the handle component and is fixedly connected with the handle component, wherein the adjusting valve is uniquely and integrally designed, so the dynamic flow balance of the valve is integrally combined with flow adjustment; the flow adjustment is realized through a low-torque small-angle travel turn-off structure; a valve body and an automatic flow balance component structure are optimally designed, so flow resistance and noise are reduced; the design of the handle component is suitable for the operation environment of a pipeline well; the adjusting valve has the advantages of high flow capacity, accuracy and convenience of operating control, wide working pressure difference range, convenience of assembly and maintenance, long life and low cost; a manual setting state can be controlled in real time through the flow of the valve; the adjusting valve is mainly applied to building heating, ventilating and air conditioning systems, industrial or residential fluid pipe network transmission and distribution systems and industries such as petroleum, chemical industry and the like; thus, the misadjustment phenomenon of water conservancy flow of a client pipe network system can be substantially eliminated and the valve is adjusted in real time to fulfill the aim of guaranteeing dynamic flow balance of a pipe network and energy conservation.

Owner:OVENTROP VALVES & SYST BEIJING

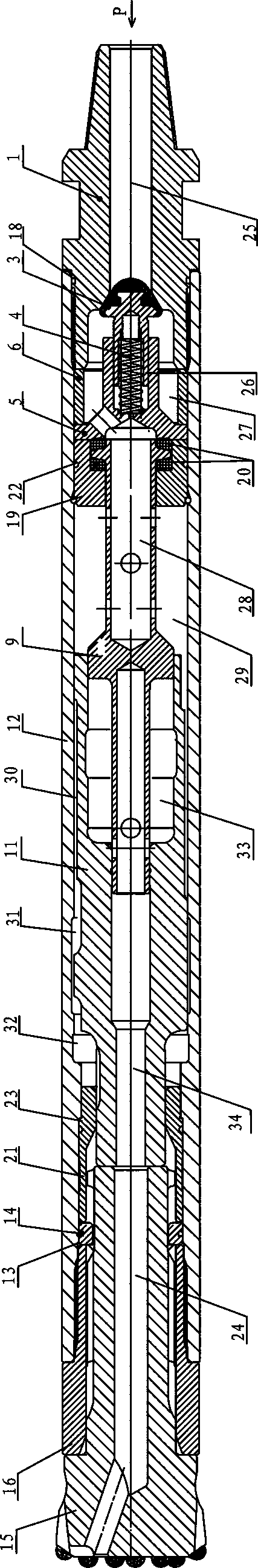

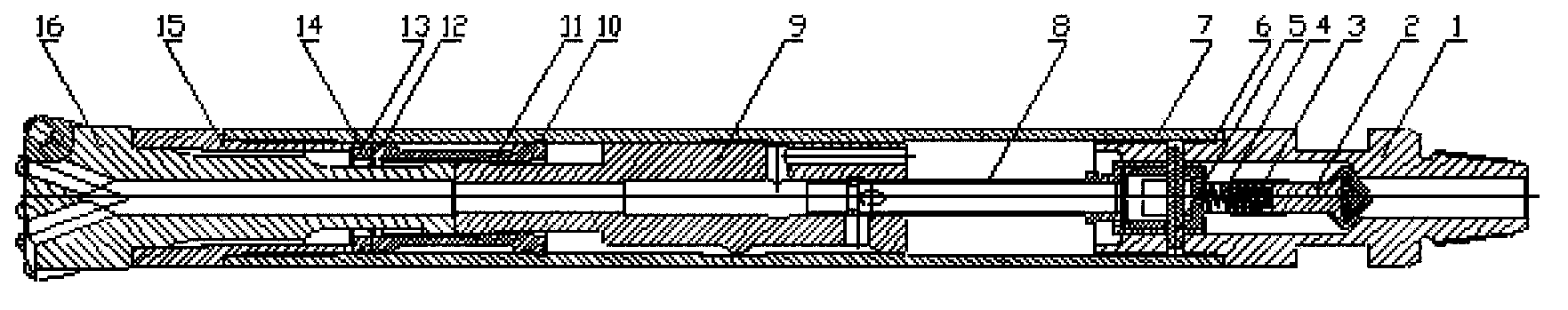

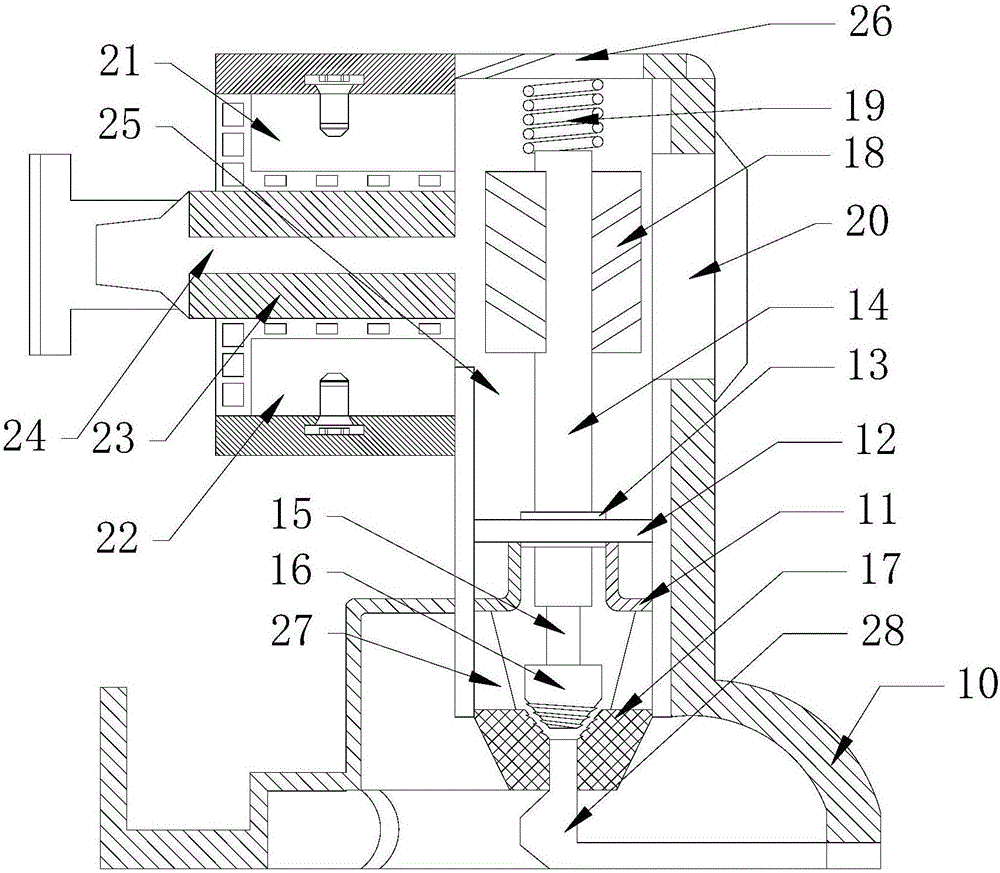

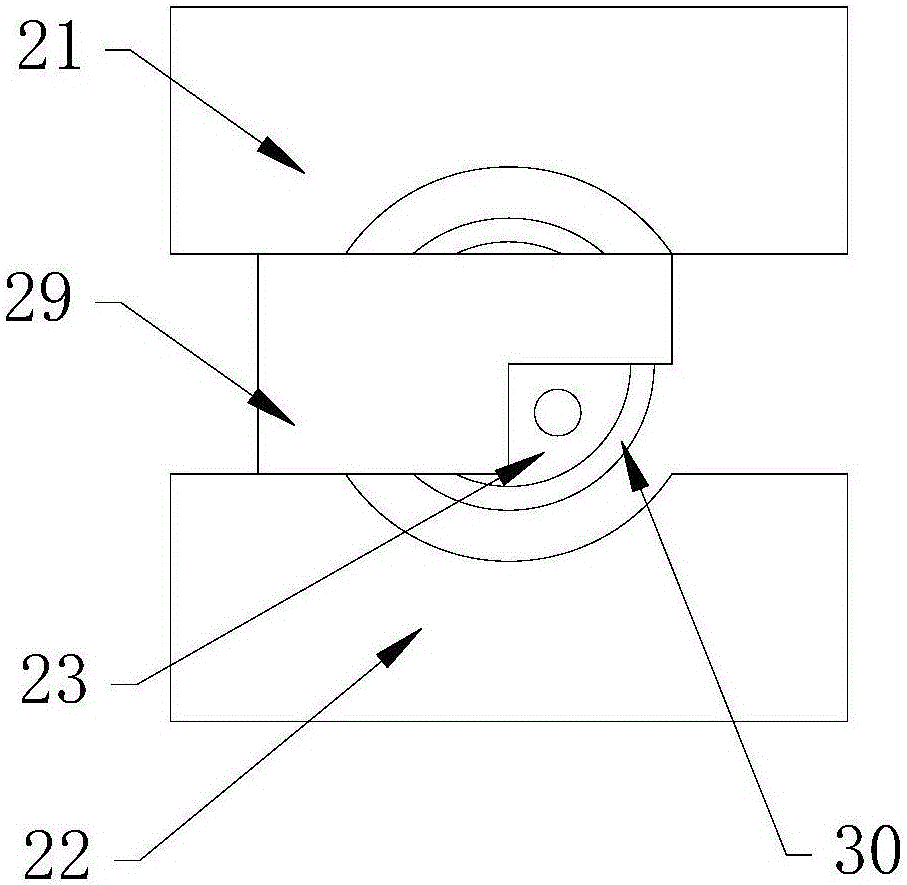

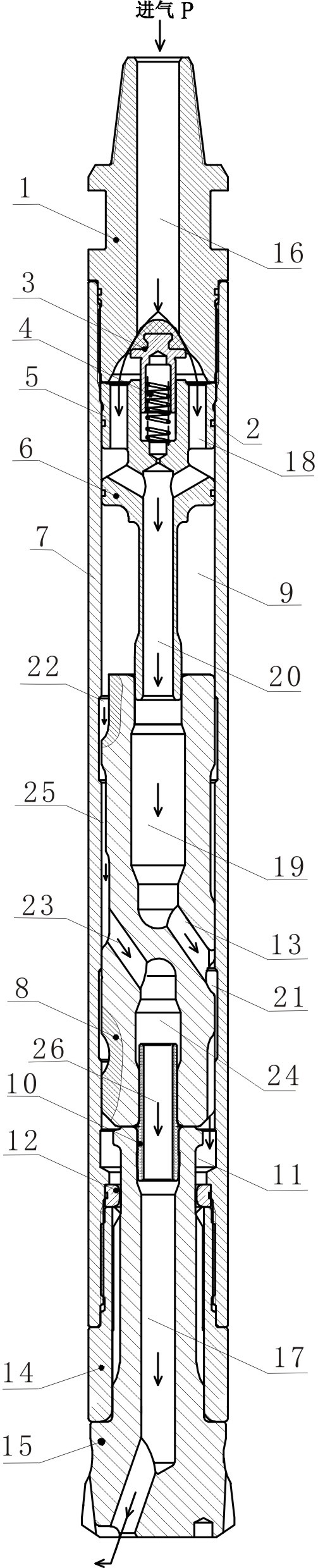

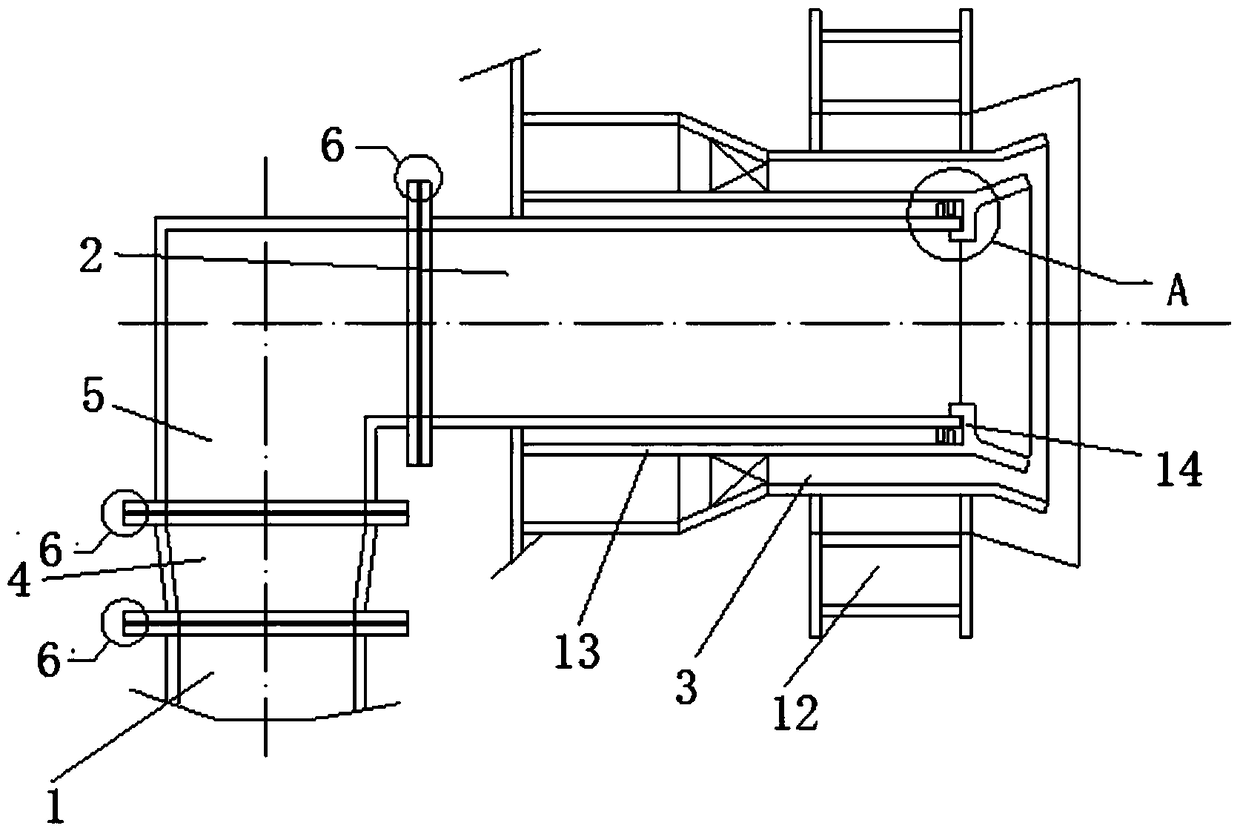

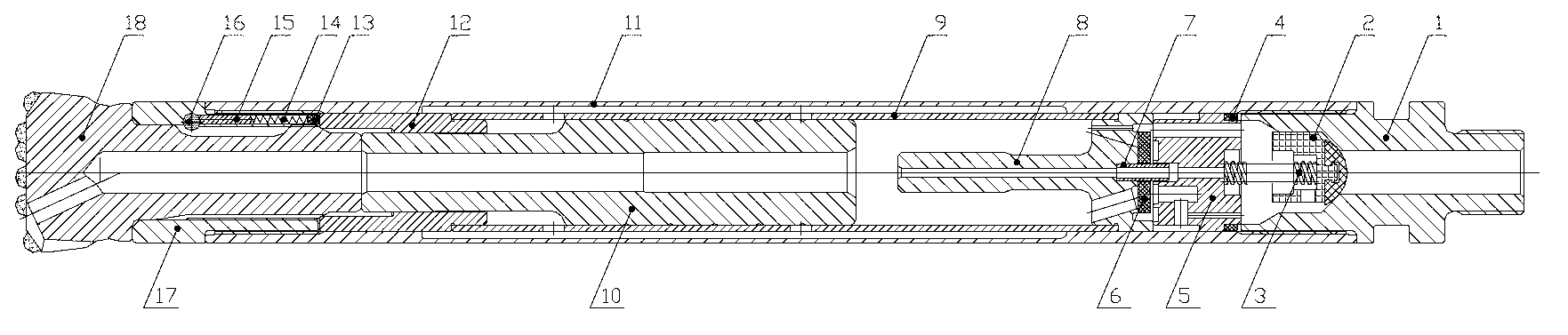

Efficient down-hole hammer

InactiveCN103375131AReliable connectionGuaranteed stability and efficiencyBorehole drivesPistonDrill bit

An efficient down-hole hammer comprises a back joint, a check valve, an air distribution rod, a piston, a cylinder, a clamping ring, a drill head and a front joint. The check valve is a one-way valve and comprises a valve seat, a spring and a steel washer. The slotted piston is provide with a hole, a positioning sleeve is arranged at the back end of a valve end cover, and the air distribution rod, a positive vibration-proof rubber ring and a negative vibration-proof rubber ring are clamped in the positioning sleeve together. The efficient down-hole hammer is not provided with an inner cylinder structure, the air distribution mode is greatly innovated, a vibration-proof fine tuning device arranged between the back joint and the air distribution rod can effectively absorb counterforce of piston motion, the air distribution rod can be subjected to automatic fine tuning so as to keep the assembling verticality, the adaptive drill head is not provided with a tail pipe, and therefore high pressure air leakage is reduced, work efficiency is improved and production cost is reduced. In addition, the piston has a reliable service life.

Owner:YICHANG WUHUAN ROCK DRILLING TOOLS

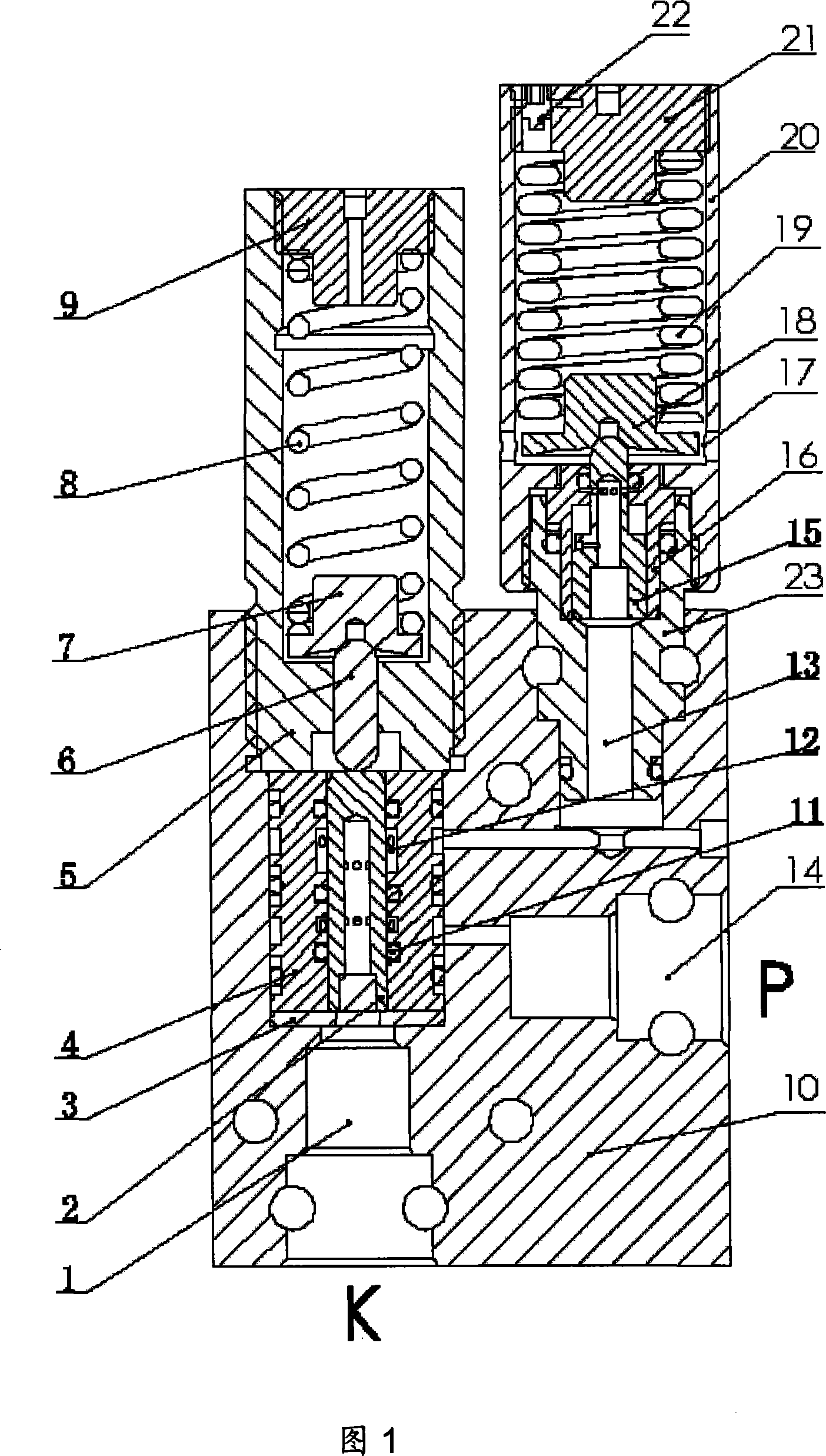

Multilevel control valve

InactiveCN101173609AExtend your lifeEasy to transformMine roof supportsProps/chocksControl valvesSafety valve

The invention discloses a multilevel control valve, comprising a reversing valve component, a safety valve component and a valve body; wherein, the reversing valve component comprises a reversing valve liquid intake cavity communicated to a balance cylinder of a hydraulic support, a reversing valve control cavity communicated to an upright column cylinder of the hydraulic support and reversing valve liquid return cavity communicated to the safety valve component, a valve core and a valve sleeve positioned inside the reversing valve component, an adjusting spring for the reversing valve component which is arranged inside the reversing joint of the reversing valve component and puts the predetermined load on the reversing valve core through the a spring base and an ejection pin, and a reversing joint matched with the reversing ejector pin under the action of the predetermined load of the adjusting spring in the reversing valve component; the safety valve component comprises a liquid intake cavity connected with the reversing valve liquid outlet cavity used to empty the reversing valve liquid return cavity, a valve core of the safety valve, a valve spring of the safety valve and a safety valve guiding piston matched with the valve core of the safety valve under the action of the predetermined load of the valve spring of the safety valve. The invention has the advantages of prolonging the service life of the high hydraulic support balance cylinder, improving the stability of the gesture adjusting of the hydraulic support and guaranteeing the safe operation of the hydraulic support.

Owner:SICHUAN AEROSPACE FENGHUO SERVO CONTROL TECH CO LTD

Ultraviolet lamp ionizing device

InactiveCN102479660AWide range of choicesSolution to short lifeIon sources/gunsVena contracta diameterElectron source

The invention discloses an ultraviolet lamp ionizing device taking photoelectrons as an electron source. The ultraviolet lamp ionizing device comprises an ionizing cavity, an ultraviolet lamp, a repulsion electrode, a focusing ring, an orifice plate, a capillary sample and a lens system. In the invention, the ultraviolet lamp generates photoelectrons on the metal electrode, and then the photoelectrons are accelerated to be collided with molecules of the sample by utilizing an electric field to realize electron ionizing. The ultraviolet lamp ionizing device has the characteristics of wide range of samples to be tested, oxidation resistance, long service life, wide working voltage range and the like so as to have broad application prospect on the aspects of process monitoring and pollutant real-time on-line analysis.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Novel atomizing nozzle based on bubble cutting

PendingCN110449283ASmall diameterImprove atomization qualityLiquid spraying apparatusEngineeringMixing chamber

The invention provides a novel atomizing nozzle based on bubble cutting. The novel atomizing nozzle comprises an internal assembly and an external assembly, wherein closed space formed by the internalassembly and the external assembly constitutes a mixing chamber of the nozzle, the internal assembly comprises an inner core and a bubble divider, the external assembly comprises a casing and a sprayhead, a first air inlet hole is formed in the top of the inner core, an external thread is formed at the upper part of the inner core below the first air inlet hole, multiple second air inlet holes are formed in the inner core below the external thread, and swirling grooves are formed in the inner core located below the second air inlet holes; the casing is a hollow opening round tube, an internal thread at the upper part of the casing is tightly connected with the external thread on the inner core through a sealing structure, a liquid inlet hole is formed in the side surface of the casing, and an external thread is formed at the lower part of the casing; an internal thread is formed at the upper part of the spray head, a spray hole is formed in the central position of the closed end of the spray head, the bubble divider is mounted in a hollow cavity in the lower part of the casing, and the casing and the bubble divider are tightly connected with the spray head through a sealing structure. The novel atomizing nozzle has higher atomizing quality, and the average diameter of particles is smaller and more uniform.

Owner:HEBEI UNIV OF TECH

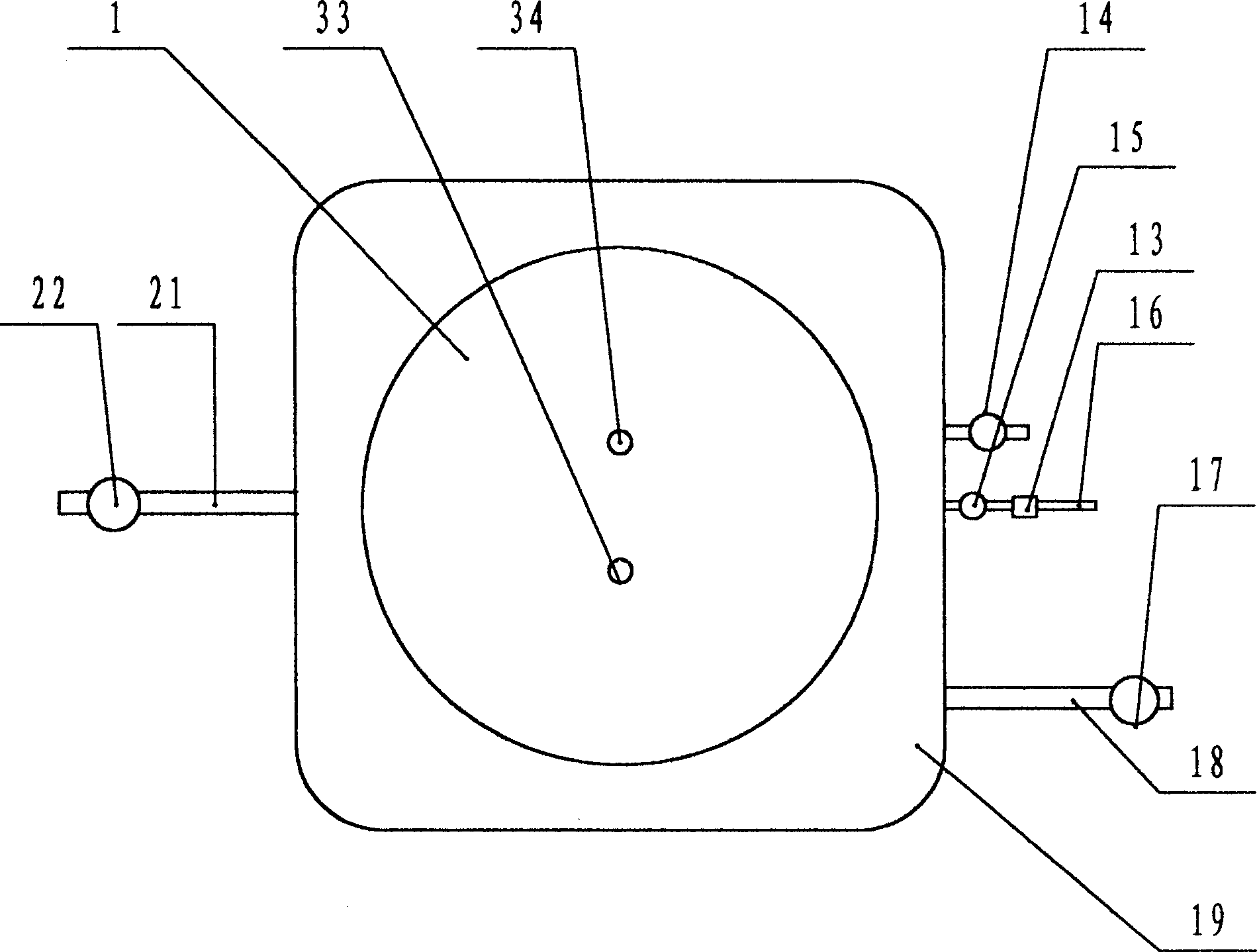

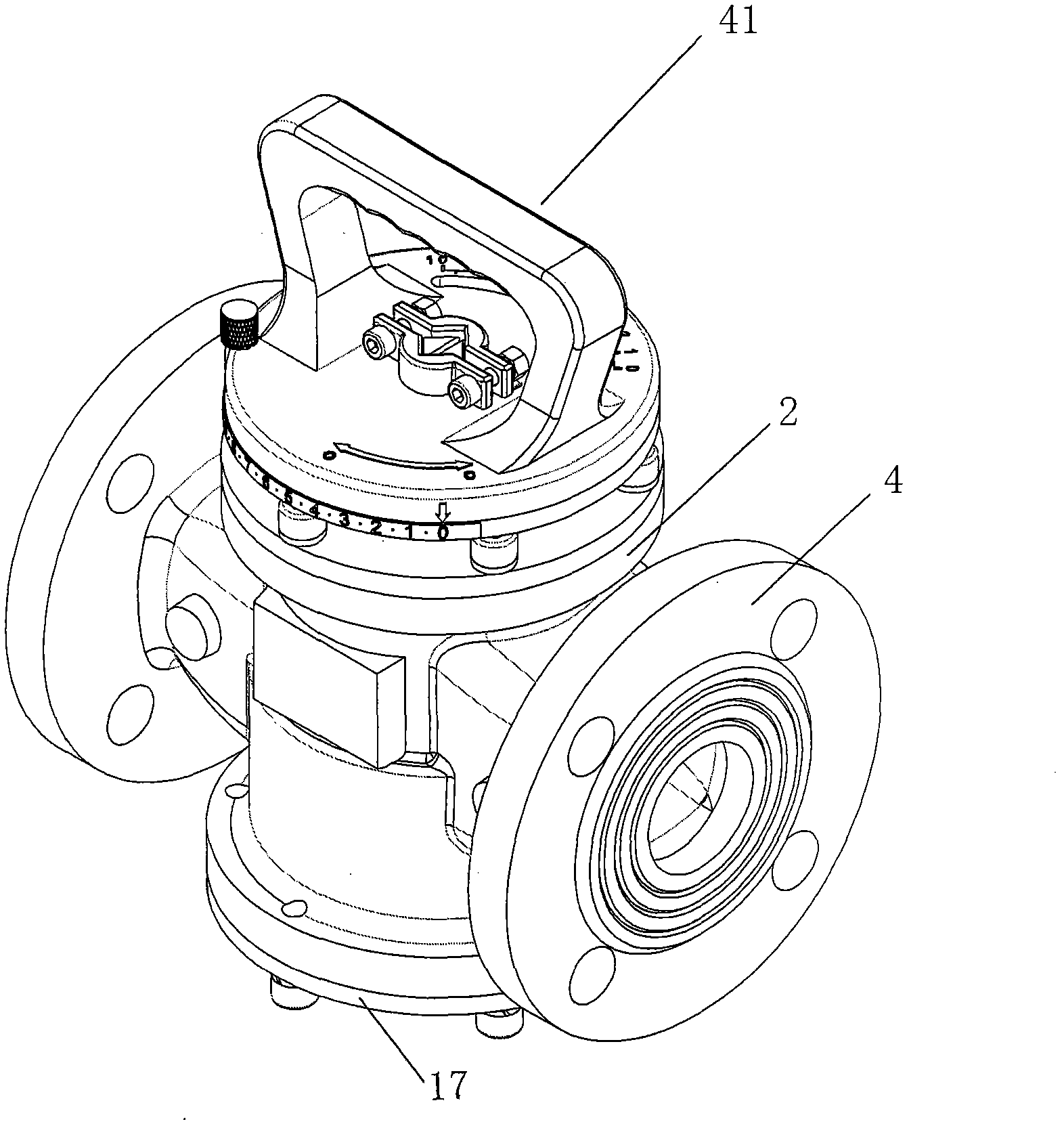

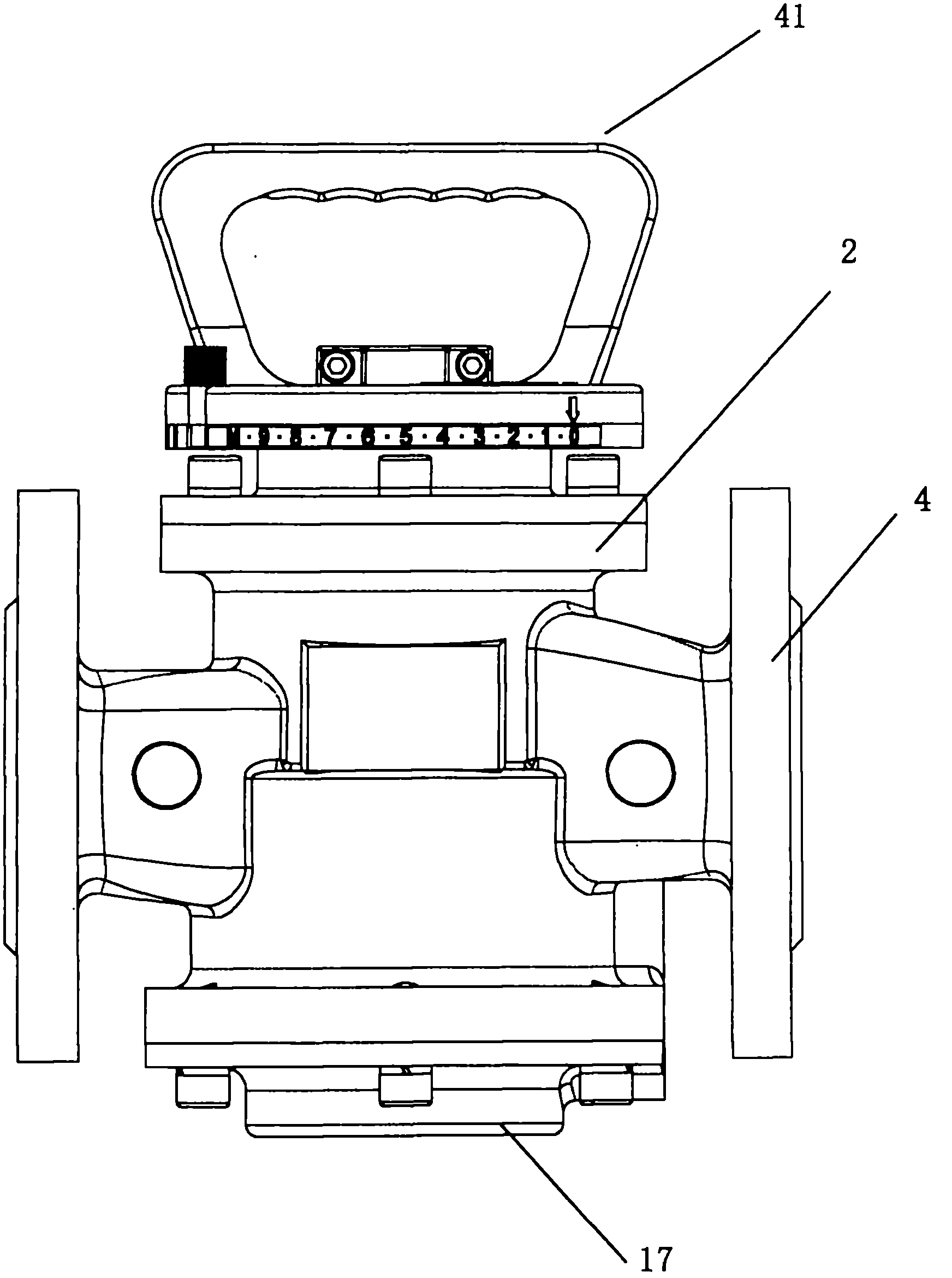

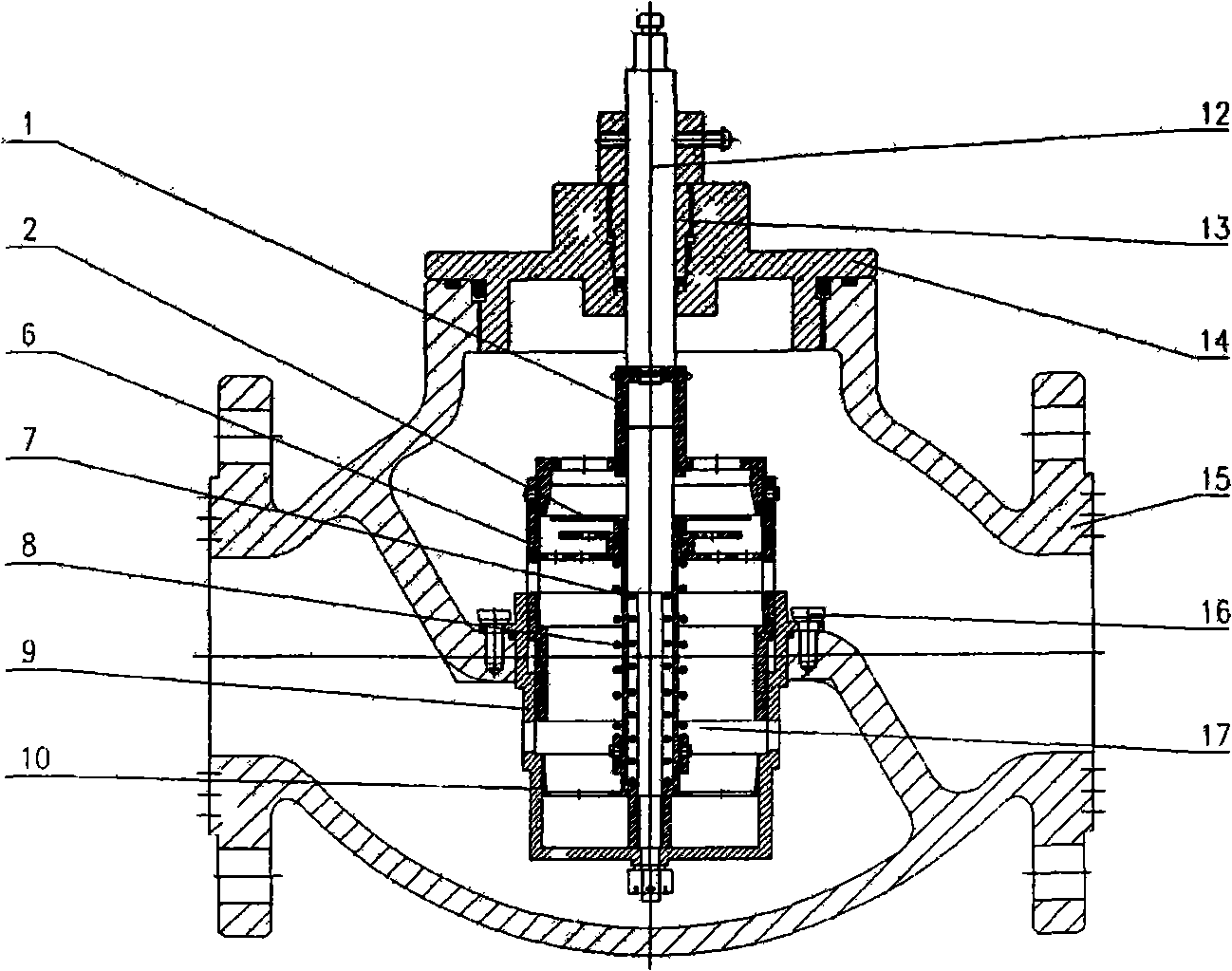

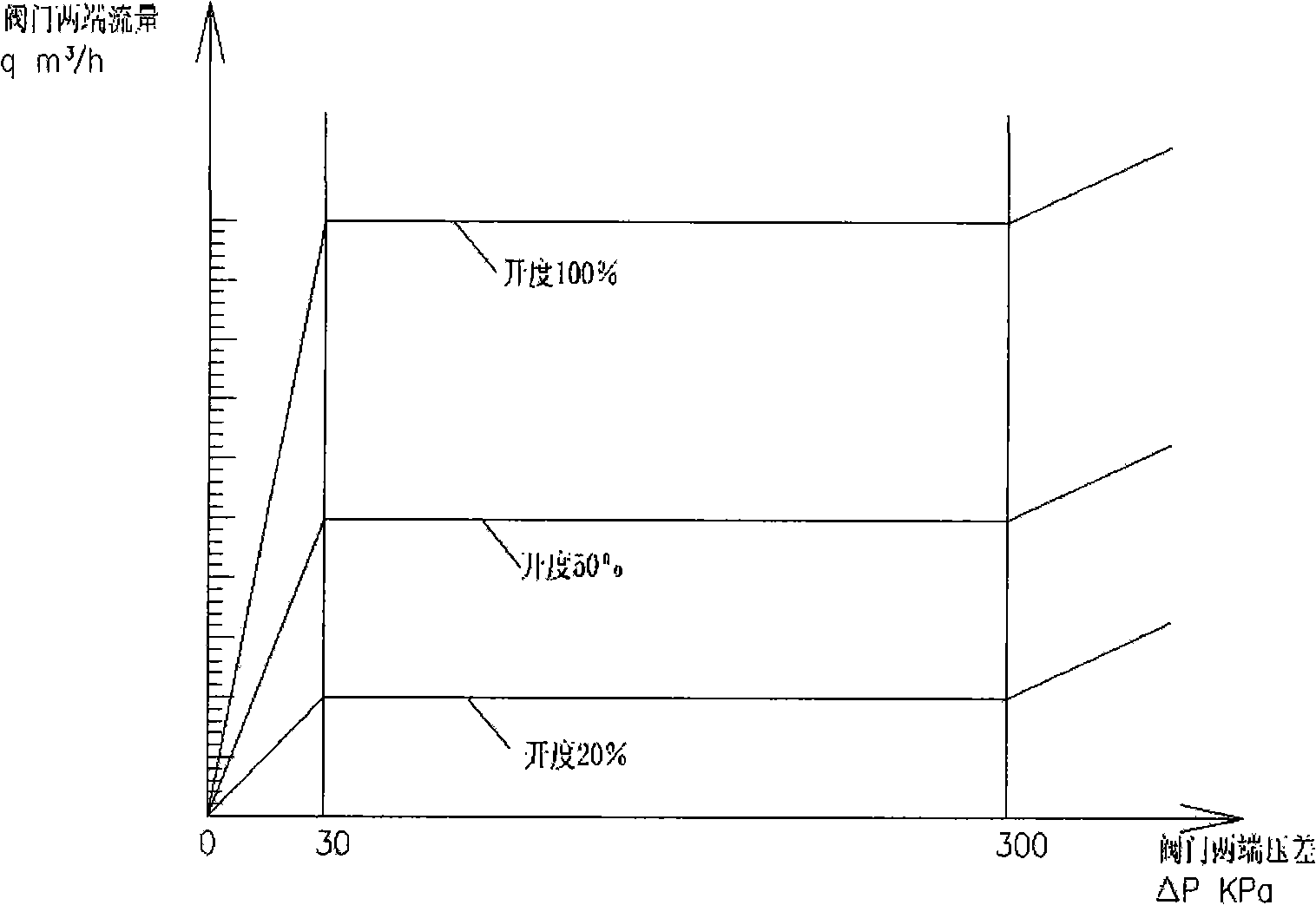

Embedded valve container type adjustable dynamic flow equalizing valve

ActiveCN101270829AHigh flow accuracyWide working pressure rangeEqualizing valvesSafety valvesChemical industryWorking pressure

The invention discloses an adjustable dynamic flow balance valve with an internal lining, which has the function of the dynamic flow balance valve and can adjust the flow capacity passing the valve within certain pressure difference according to the requirement. The invention comprises a valve body, the internal detachable valve lining, a gland cover, a connecting rod and an actuator. The valve lining is fixedly mounted inside the valve body. The connecting rod connected with the valve lining drills through the upper gland cover to be connected with an adjusting handle or the actuator. The opening degree of the valve is controlled for adjusting the flow capacity. The valve lining comprises a pressure sensing board, a pressure regulating slide sleeve, an internal spring, an external spring, the upper end cap with the correction conical surface of the valve lining, a current regulating cylinder body and a lower cylinder body. The invention has the advantages of large current regulating range, large flow capacity, high control precision, broad working pressure difference, convenient assembly, long service life, detachable valve lining and low manufacture cost. The invention can be applied to the central air conditioner, the water system of the heating network, petroleum industry, chemical industry and electric power plant, fundamentally solving the problem of hydraulic disorder and meeting the requirement of flow control.

Owner:JINAN ANGLE TECH DEV CO LTD

Intelligent atomizing device of breathing machine

InactiveCN105457136ANo Interfering Oxygen ConcentrationNo Interference Tidal VolumeRespiratorsMedical devicesTidal volumeEngineering

The invention discloses an intelligent atomizing device of a breathing machine. An atomizer is spirally installed at the upper end of a volume cup. An upper end cover is installed on the top of the atomizer. A one-way valve is arranged on the upper end cover and sleeved with a connecting pipe. A discharge port is formed in the side wall of the volume cup. A rubber plug is arranged in the discharge port. A gas inlet port is formed in the lower end of the volume cup and sleeved with a connecting port. The connecting port is connected with a gas flow controller through a guide pipe. The gas flow controller is connected with the port of the breathing machine through a flow division port. Gas flow power used by the atomizing device comes from the breathing machine, flow speed is stable, flow is more precise compared with the prior art, the oxygen concentration and tidal volume of the breathing machine during treatment are not influenced, the safety of patients is ensured, and it can be ensured that medical work and nursing work are smoothly conducted; in the medicine addition process, by means of the discharge port in the outer side of the volume cup, the upper cover of the atomizer does not need to be opened, and ventilation continuity can be ensured.

Owner:李振翮

Balancing compensation valve

This invention relates to balance compensation valve, which comprises safety valve parts and switch valve parts, wherein, the safety valve parts have safety valve liquid-in chamber, safety valve parts liquid back chamber, safety valve part center, safety adjusting spring, safety valve socket matching with safety part chip under preset load of adjust spring; the switch parts have main valve liquid back chamber, switch valve liquid-in chamber connected and switch valve parts control chamber connected to switch valve chip.

Owner:SICHUAN AEROSPACE FENGHUO SERVO CONTROL TECH CO LTD

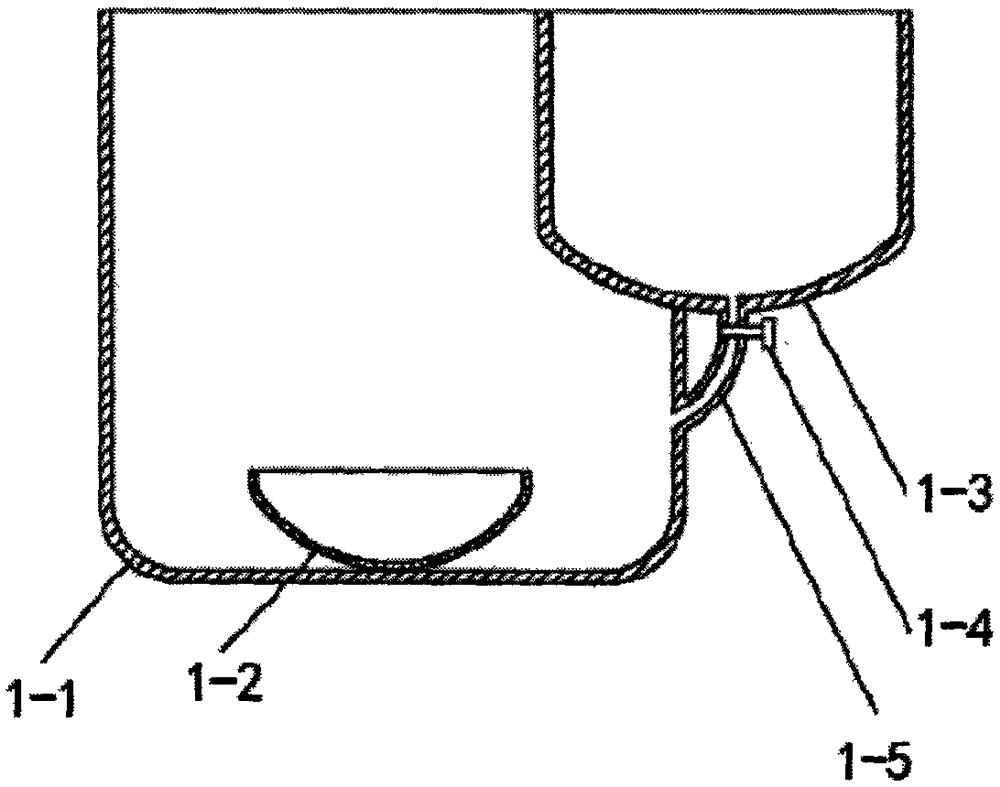

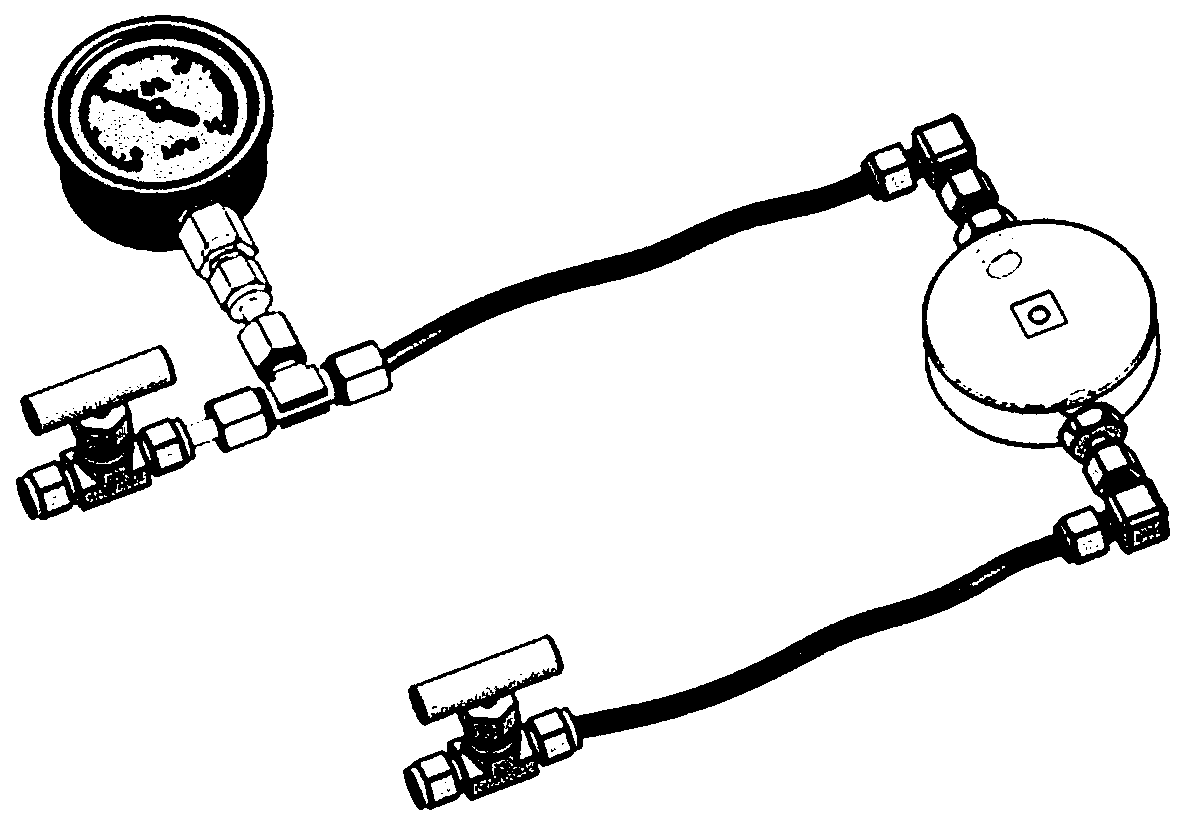

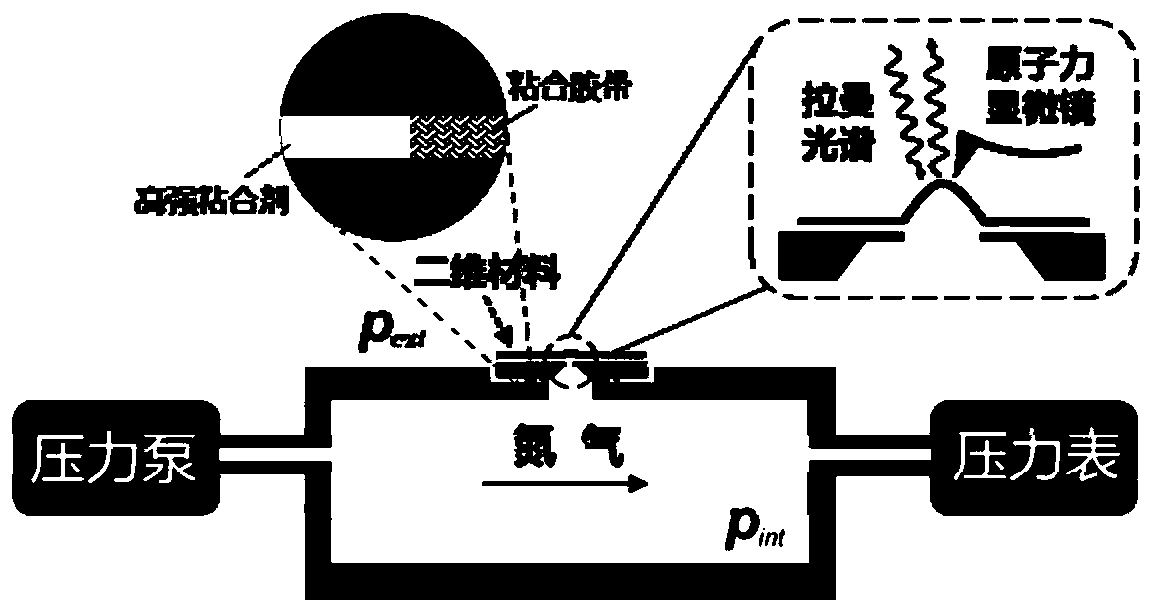

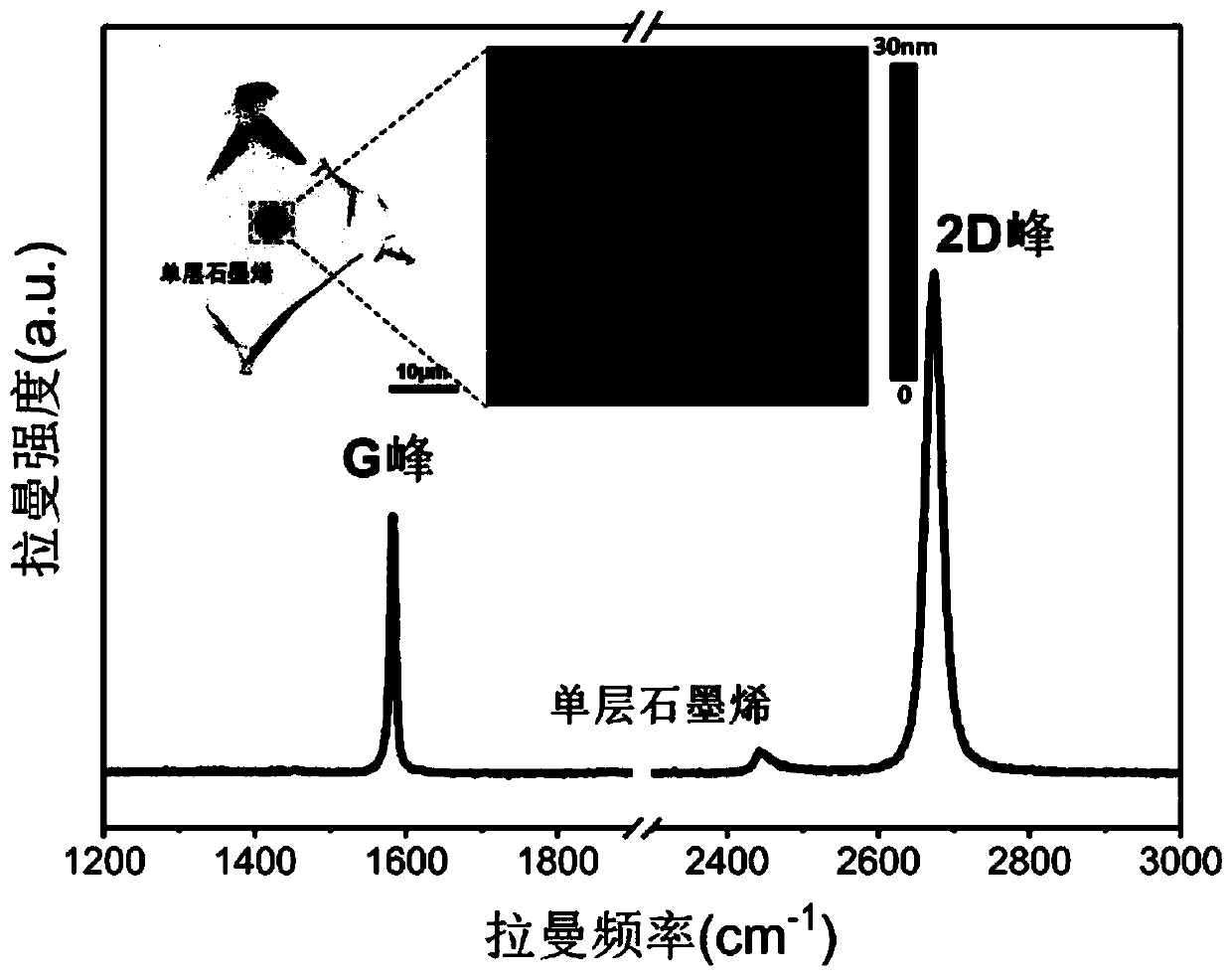

Bubbling device and measuring method for measuring Young modulus of two-dimensional material

ActiveCN110220777AHigh pressure working rangeImprove universalityMaterial strength using tensile/compressive forcesEngineeringAtomic force microscopy

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

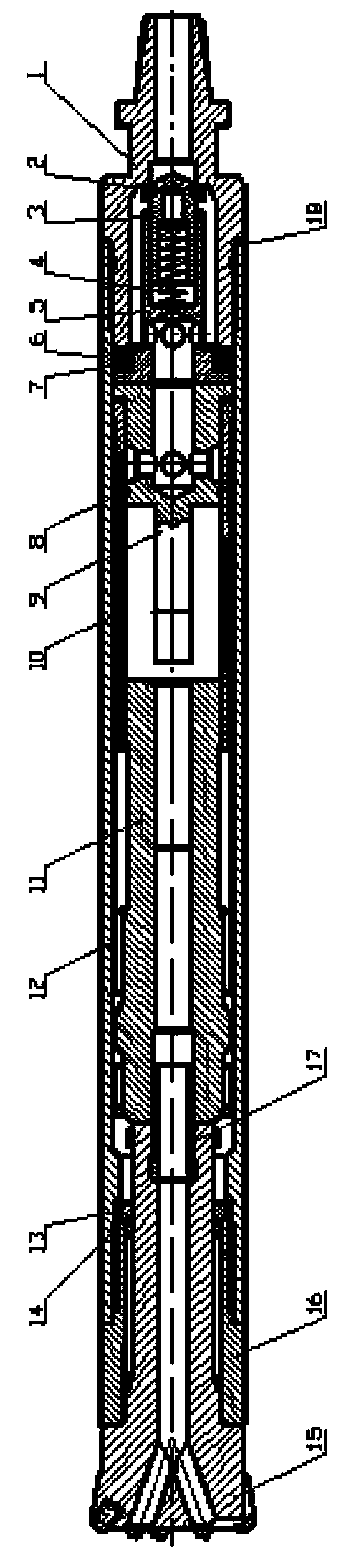

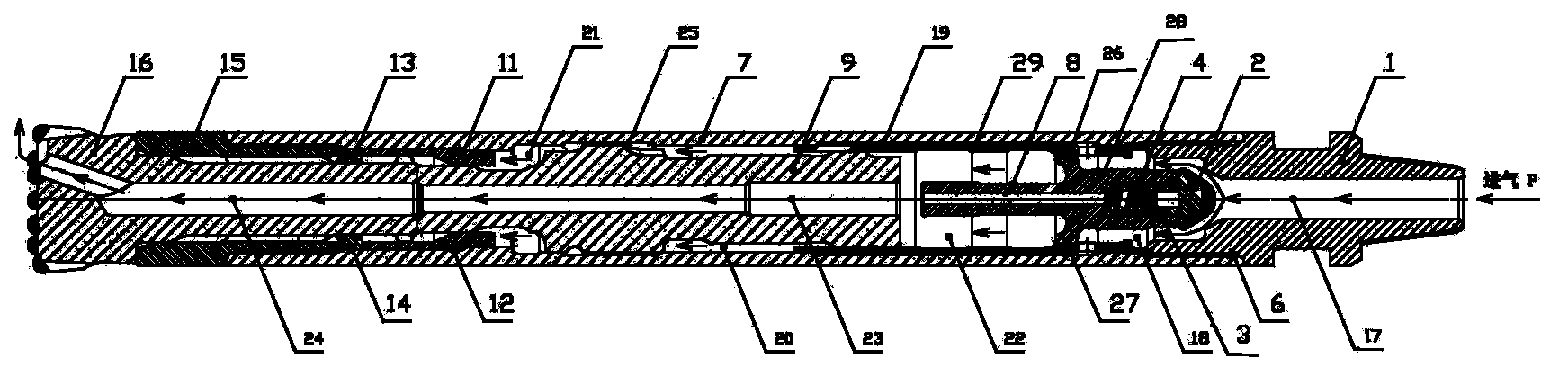

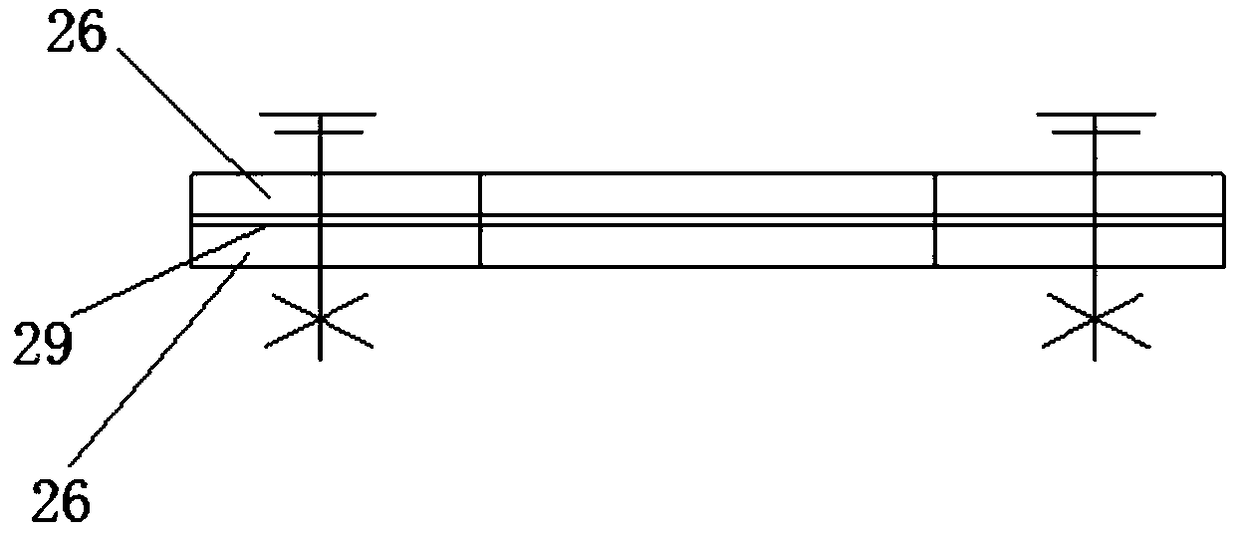

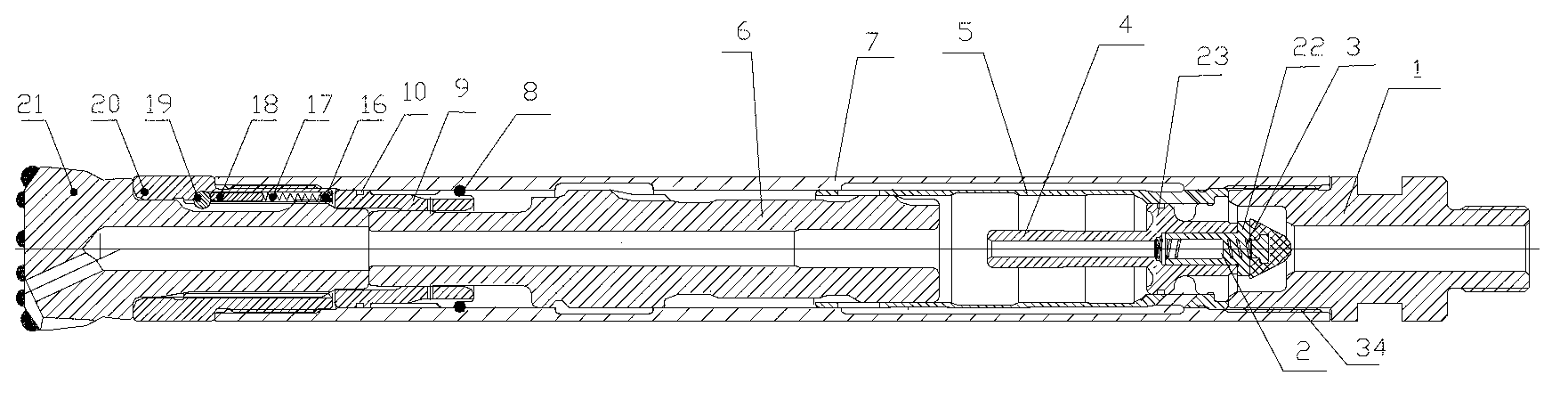

Piston guide sleeve type valveless double-cylinder down-hole hammer

InactiveCN103573182APrevent jumpingReasonable assembly designReciprocating drilling machinesConstructionsPiston GuideEngineering

A piston guide sleeve type valveless double-cylinder down-hole hammer comprises a rear connector, a check valve, an air distributing rod, a piston, a cylinder body, a guide sleeve, a clamping ring, a drill body and a front connector. The check valve is a one-way valve and is provided with a valve seat and a spring. The piston is a long and thin piston with a duct, the air distributing rod and an air inlet base at the rear end of the check valve are of an integrated structure, an inner cylinder is arranged in the cylinder body and on the outer sides of the air distributing rod and the piston, and in a piston moving process, the matching end of the piston and the air distributing rod is arranged in the inner cylinder all the time. The air distributing rod and the check valve seat are integrated, the structure is simple, functions of location, damping and air suction can be achieved, and the hammer is stable and reliable during working. The piston is free of a radial hole structure, compressed air can reach a front air cavity and a rear air cavity through the shortest paths, and hammer efficiency is improved.

Owner:YICHANG WUHUAN ROCK DRILLING TOOLS

Reverse sealing structure of emergency cut-off valve for gas

The invention relates to a reverse sealing structure of an emergency cut-off valve for gas, in particular to an emergency cut-off valve structure for gas and with a large working pressure range. The reverse sealing structure of the emergency cut-off valve for gas is characterized in that the closing direction of a valve is the same with the F1 direction of rod pulling force, and the pressure difference of the inside and the outside of a valve body is utilized to assist to close the valve. The reverse sealing structure of the emergency cut-off valve for gas has the advantages that 1 the structure is simple, and the cost is reduced slightly compared with an existing commonly-used structure; 2 the requirements can be met without the large spring force P, and the design difficulty is reduced; and 3 due to the fact that the dependence of a spring to provided spring force is reduced, the working pressure range of the valve is large.

Owner:北京市燕山工业燃气设备有限公司

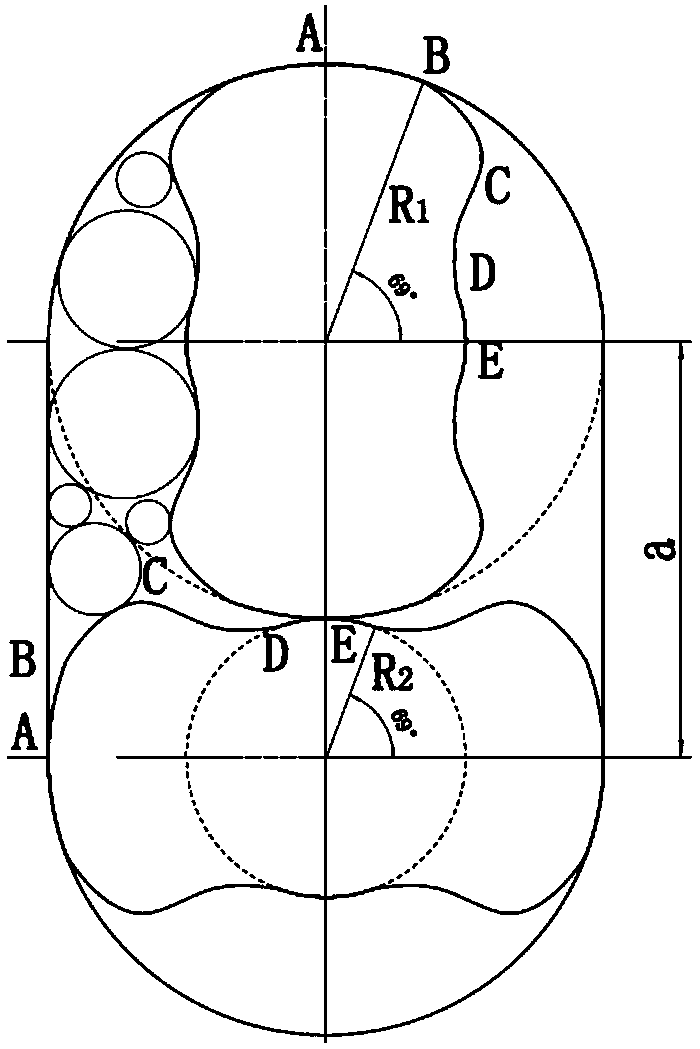

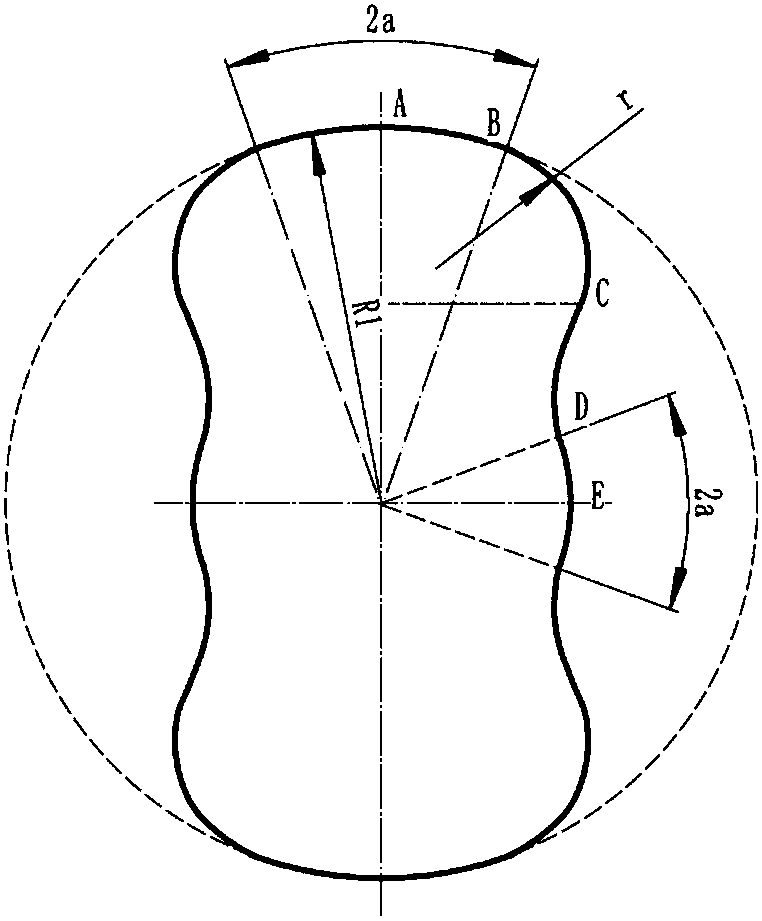

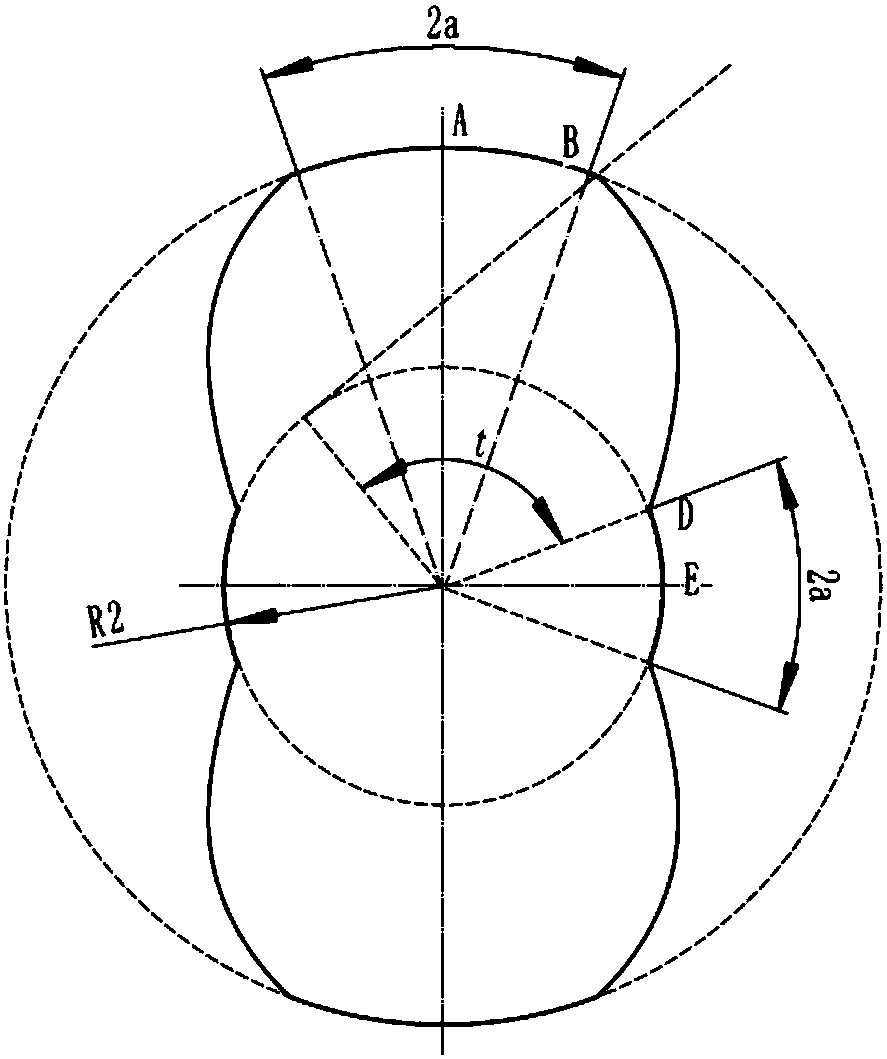

Wide head rotor of high vacuum displacement pump

ActiveCN107061271AWide working pressure rangeIncrease the shaft diameterPump componentsRotary piston pumpsMetal frameworkEngineering

The invention discloses a wide head rotor of a high vacuum displacement pump. In an existing cam pump technology, seal between a pump body and a rotor is linear pump, and therefore, vacuum capacity is easily caused to drop after the rotor and the pump body are worn. The end surface of the wide head rotor of the high vacuum displacement pump is of an axisymmetric structure, and a 1 / 4 molded line of the end surface consists of three parts: a top end wide head circular arc AB, a transition curve BD and an intermediate circular arc DE, and the rotor is formed by wrapping a metal framework and rubber; and the top end wide head circular arc AB and the intermediate circular arc DE of the wide head rotor are two conjugate curves. The wide head rotor effectively increases a working pressure range of the high vacuum displacement pump, ensures lasting stability of conveying pressure, reduces pulsation and improves working efficiency.

Owner:HANGZHOU DIANZI UNIV

High pressure pneumatic valve

ActiveCN106051173AWide working pressure rangeReduce lossesOperating means/releasing devices for valvesLift valveImpellerPneumatic valve

The invention provides a high pressure pneumatic valve. The high pressure pneumatic valve comprises a valve body, a valve cover, an air inlet port, an air inlet core, a valve core, a cone valve core, an air outlet valve sleeve and an air outlet port. The valve body and the valve cover form a sealed sealing air chamber. The air inlet port and the air inlet core are arranged on the upper end side of the sealing air chamber and a sealing baffle is arranged at the position, communicating with the sealing air chamber, of the air inlet core. A valve core shaft is arranged on the axis of the sealing air chamber. At least two impellers are arranged at the positions, corresponding to the air inlet port, of the valve core shaft and impeller magnets are arranged at the positions, corresponding to the impellers, of the valve body. The valve core shaft is fixedly connected with the cone valve core by a connecting shaft. The cone valve core comprises a cone-shaped bottom and the cone-shaped bottom is provided with a spiral boss. An air outlet valve sleeve, which is matched with the cone valve core, is arranged at the bottom of the sealing air chamber. The air outlet valve sleeve conducts the air outlet port to the sealing air chamber through an airflow through hole. The high pressure pneumatic valve has the following advantages of being fast in response speed, simple in structure, low in cost, wide in working pressure range and the like.

Owner:BRAY (TIANJIN) CONTROL SYST MFG CO LTD

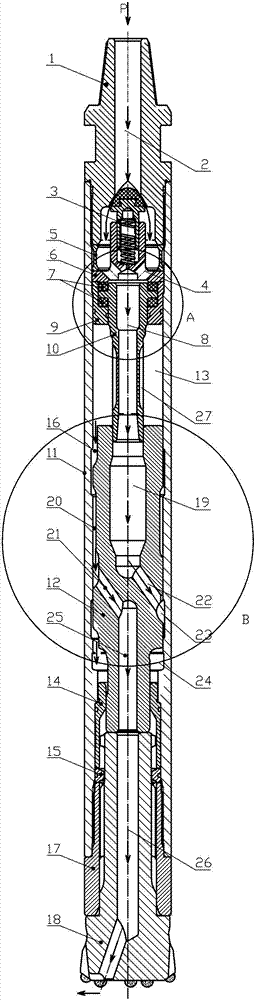

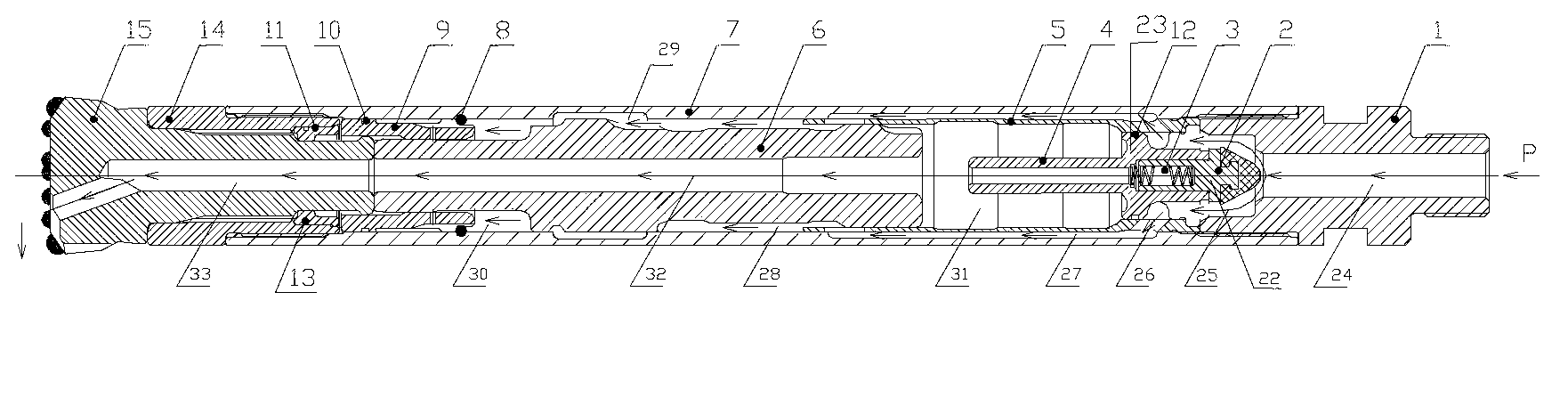

Piston tail pipe type impacter of valveless single-cylinder type downhole

The invention discloses a piston tail pipe type impacter of a valveless single-cylinder type downhole, which comprises a cylinder body, a rear joint, a front joint and a drill bit; an air distributing seat provided with an axial air-distribution seat pore canal is hermetically arranged in a cylinder body; a check valve is arranged on the air distribution seat; an air distribution rod is provided with an air distribution rod big end and an air distribution rod small end; the air distribution rod and a check valve seat are of an integrated structure; the air distribution rod small end is arranged in a piston air-supply chamber on a piston; the inner diameter of a middle part of a piston air-supply chamber is more than the outer diameter of the air distribution rod small end; the piston is provided with a piston big end and a piston small end; a rear air chamber is formed between the air distribution rod and the piston small end; a front annular channel and a rear annular channel are formed between the cylinder body inner wall and the cylinder body outer wall; a piston surface air groove is formed on the outer surface of the piston; and a front air chamber is formed between a drill bit tail pipe and a piston big end. The piston tail pipe type impacter of the valveless single-cylinder type downhole, provided by the invention effectively overcomes the defects of the traditional impacter of the valveless single-cylinder type down hole, and has the advantages of high working efficiency, good reliability and greatly increased pneumatic efficiency.

Owner:YICHANG WUHUAN ROCK DRILLING TOOLS

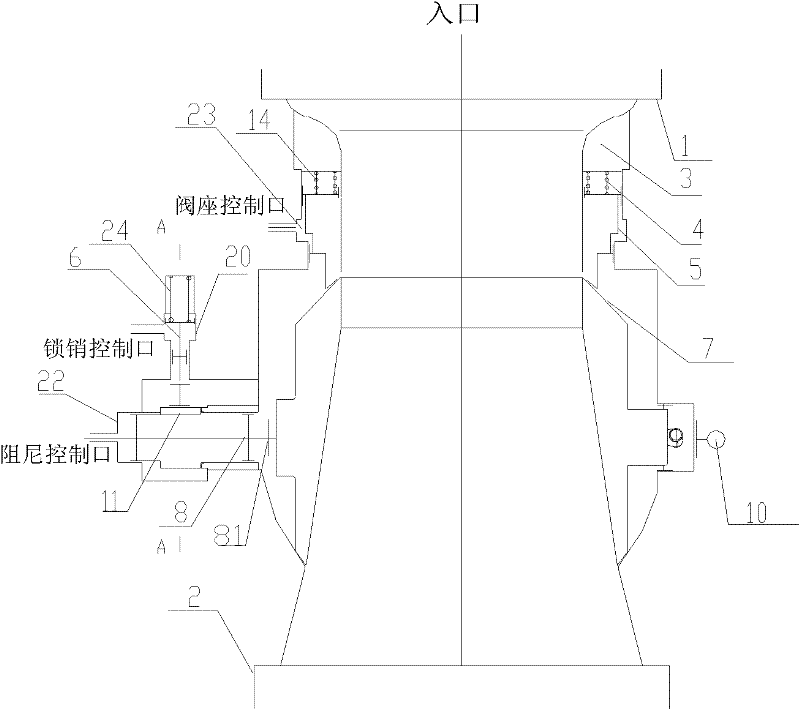

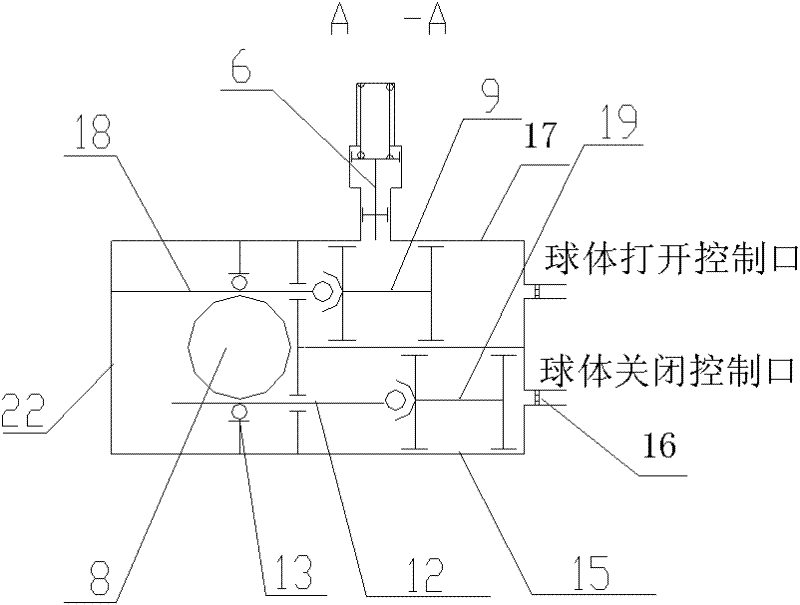

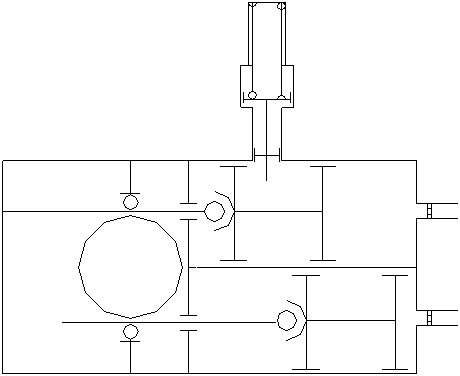

Low flow resistance and high pressure pneumatic damping ball valve with self-locking function

ActiveCN102537402AWide working pressure rangeConvenient distancePlug valvesPreventing unauthorised/accidental actuationExternal energyControl system

The invention relates to a low flow resistance and high pressure pneumatic damping ball valve with a self-locking function, comprising an inlet shell, a flow guiding sleeve, a sphere and an outlet shell. The inlet shell is sleeved outside the flow guiding sleeve and connected with the outlet sleeve. The sphere is arranged between the flow guiding sleeve and the outlet sleeve. The low flow resistance and high pressure pneumatic damping ball valve further comprises a high-pressure air source, a pneumatic rotating-shaft component, a pneumatic lockpin component and a pneumatic valve component. According to the low flow resistance and high pressure pneumatic damping ball valve, the technical problems that the existing pneumatic control ball valve needs to be maintained by external energy after being opened and has requirements on control pressure and use occasion are solved. The pneumatic damping ball valve with small low diameter reduction ratio, low flow resistance and high pressure and with the self-locking function is used for controlling the opening and the closing of a liquid pipe in a liquid pipe control system.

Owner:NO 11 INST OF NO 6 ACADEMY OF CHINA AEROSPACE SCI & TECH

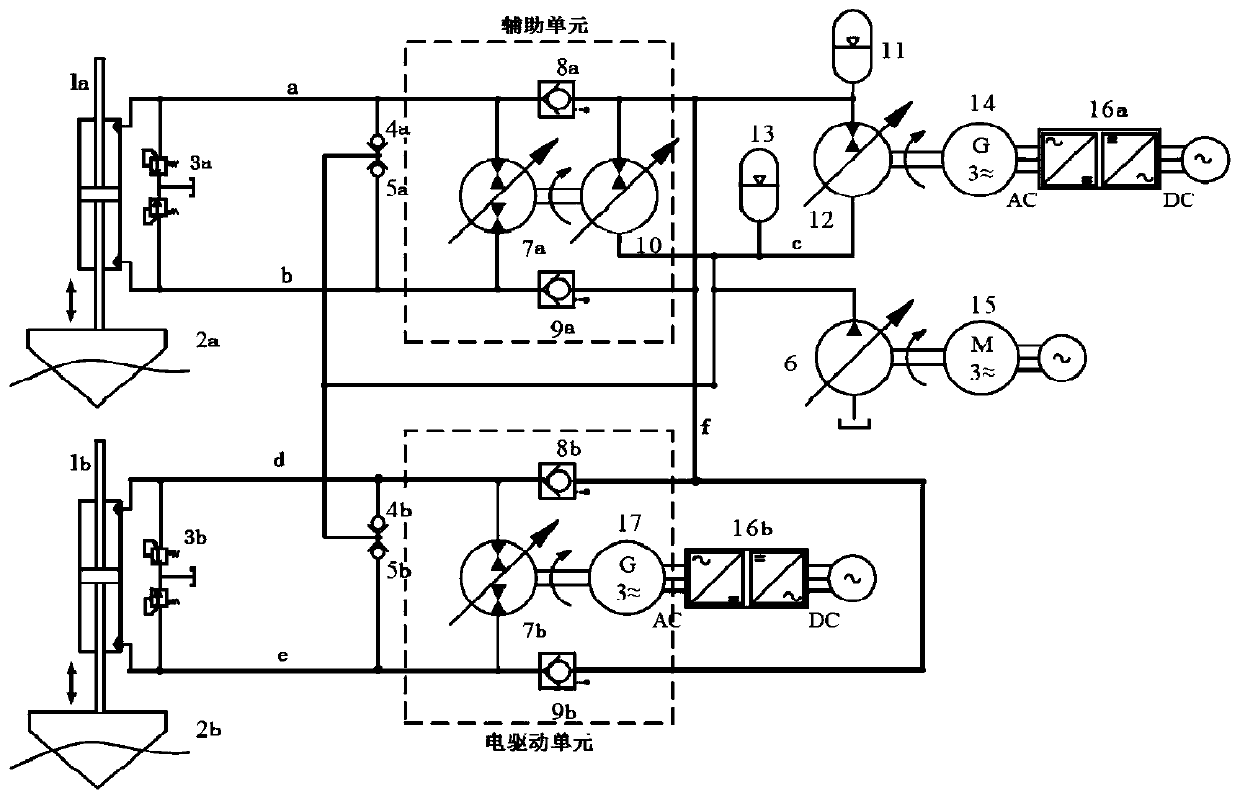

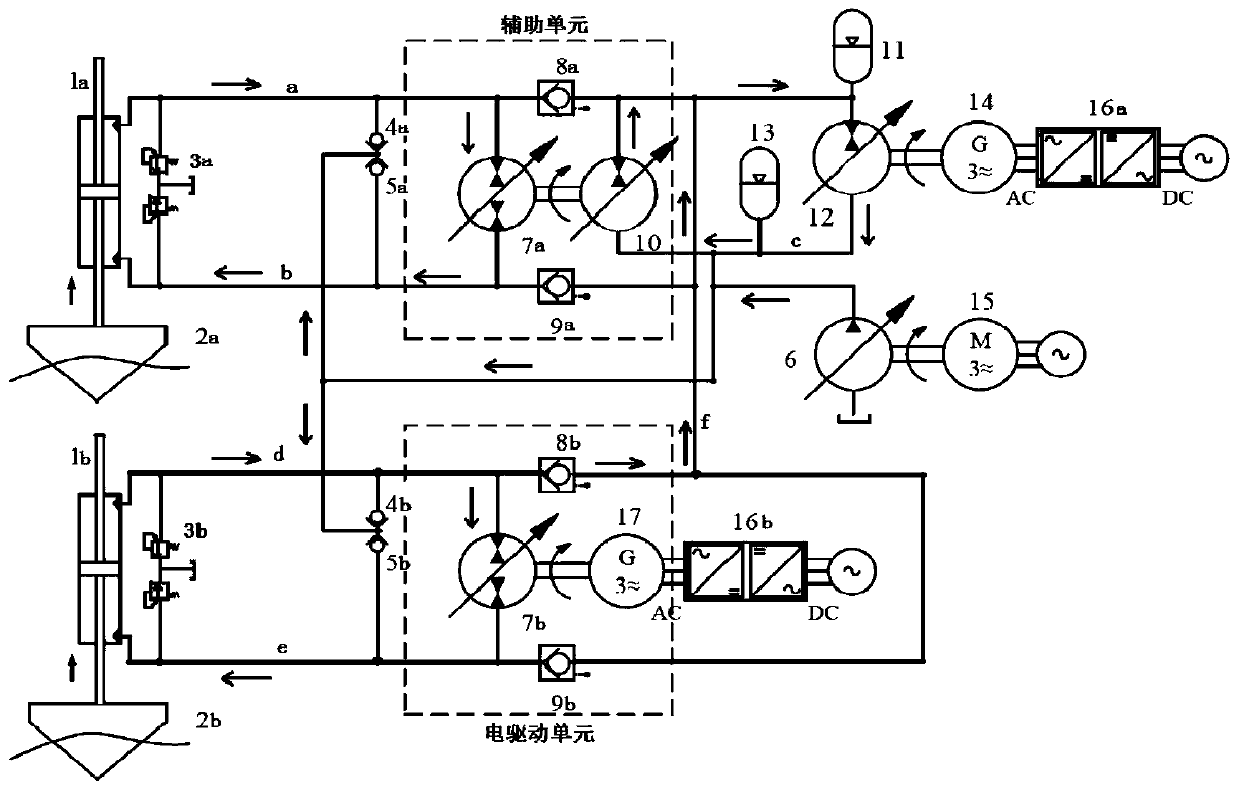

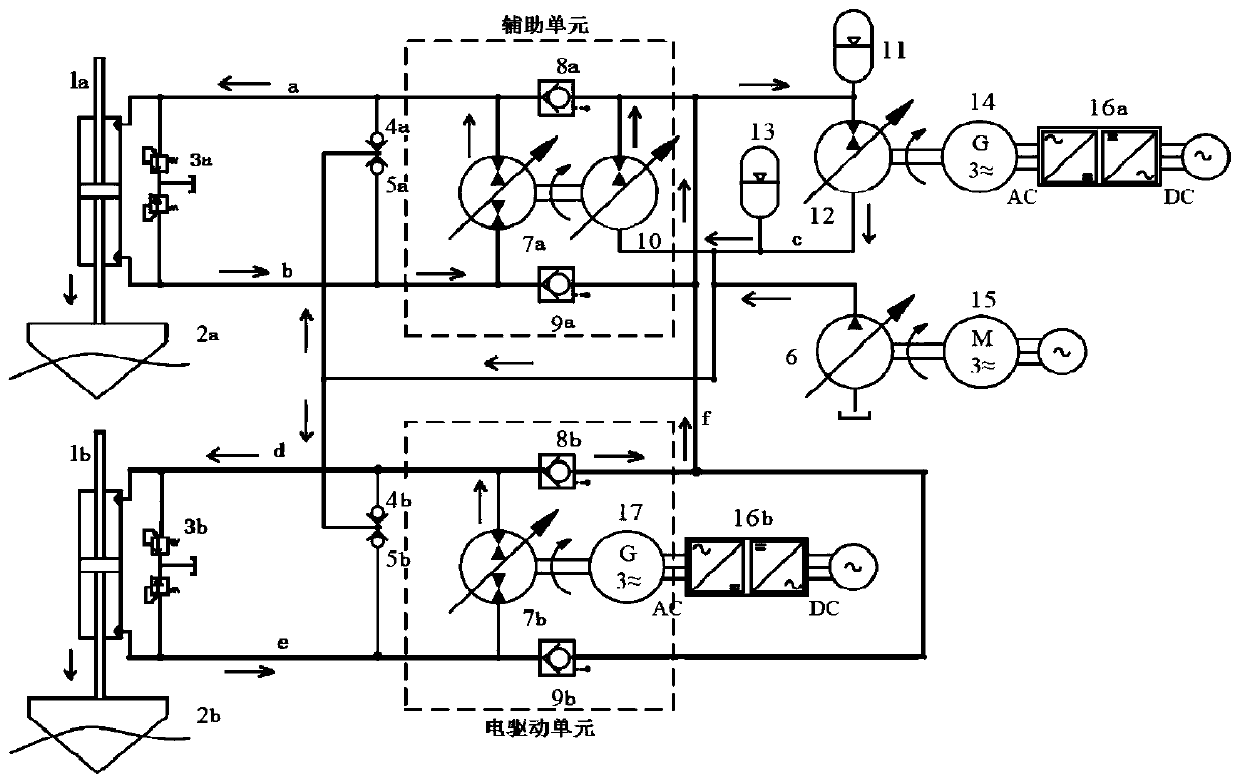

Control system of wave energy converter

ActiveCN111535986AGuaranteed conversion efficiencyGuaranteed pressureMachines/enginesSafety/regulatory devicesConvertersEngineering

The invention provides a control system of a wave energy converter. Wave energy is captured through a main hydraulic cylinder and a float, and electricity is generated through the wave energy converter. An electric drive unit in parallel with an auxiliary unit is arranged, the electric drive unit can not only drive a generator to generate electricity, but also act as a speed control mechanism to control the rotating speed of a second variable displacement pump. An oil replenishment voltage stabilizing unit performs oil supplementary speed increasing on the second variable displacement pump, and the electric drive unit and the oil replenishment voltage stabilizing unit cooperate to control the rotating speed and displacement of the second variable displacement pump. A four-quadrant workingmode of a first four-quadrant pump is used to ensure the second variable displacement pump to drive a motor to continuously generate electricity when the float moves up and down, and a high-pressure accumulator and a low-pressure accumulator are designed into metal bellows type accumulators. The energy conversion efficiency and operation stability of the wave energy converter are improved.

Owner:XIHUA UNIV

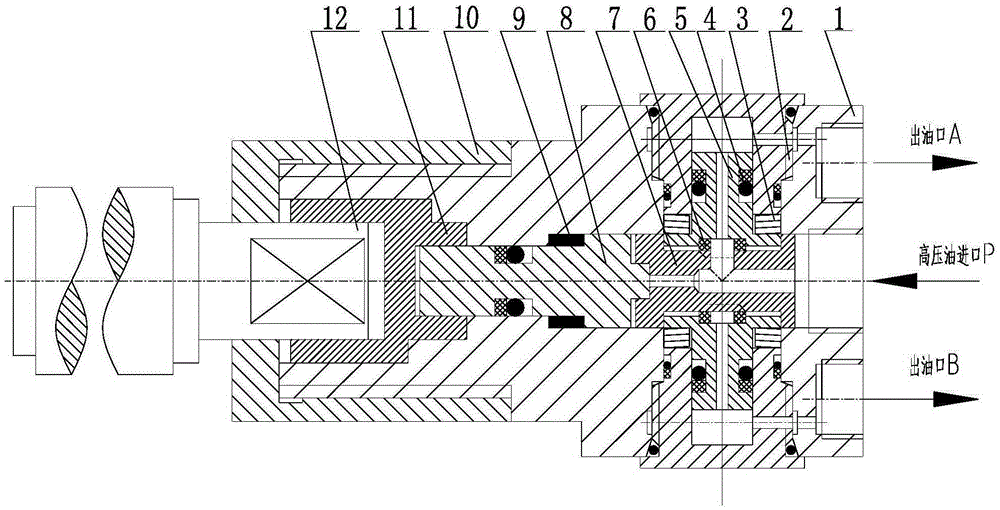

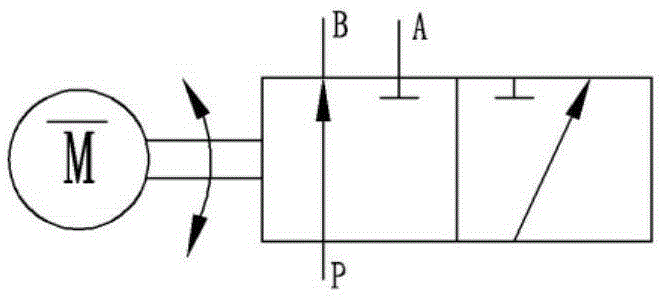

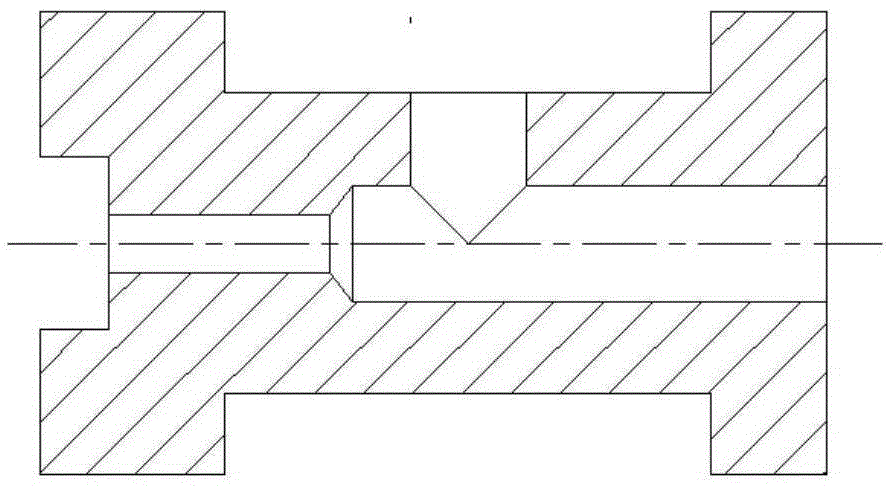

Miniature high-temperature and high-pressure electric rotary valve

InactiveCN105351557ACommutation is reliableReduce volumePlug valvesOperating means/releasing devices for valvesRotary valveEngineering

The invention discloses a miniature high-temperature and high-pressure electric rotary valve. The miniature high-temperature and high-pressure electric rotary valve comprises a cylindrical valve body, a valve core, a valve rod and a limiting connecting shaft, wherein valve seat holes are symmetrically formed in both sides of a valve core hole in the valve body, floating valve seats are arranged in the valve seat holes, the floating valve seats are matched with the valve core through curved surfaces, a port P, a port A and a port B are formed in the right end of the valve body, the three oil ports are all axially formed and are positioned in the same end surface, a part, which is communicated with the port P, of the valve core forms a cavity P, parts, which are respectively communicated with the port A and the port B, of the two floating valve seats form a cavity A and a cavity B, and the valve core is driven to reverse leftwards or rightwards by a motor, so that the port A is communicated with the port A or the port B to form a two-position three-way reversing valve. The miniature high-temperature and high-pressure electric rotary valve has the advantages of small size, compact structure and reliable sealing performance and is compatible with the small installation space of an annular pipeline, the reliable reversing of an oil system can be guaranteed, and the miniature high-temperature and high-pressure electric rotary valve can be applied in high-temperature and high-pressure severe environments such as power plants, petroleum and natural gas exploitation and the like.

Owner:PETROLEUM ENG TECH RES INST OF JIANGHAN OILFIELD BRANCH OF

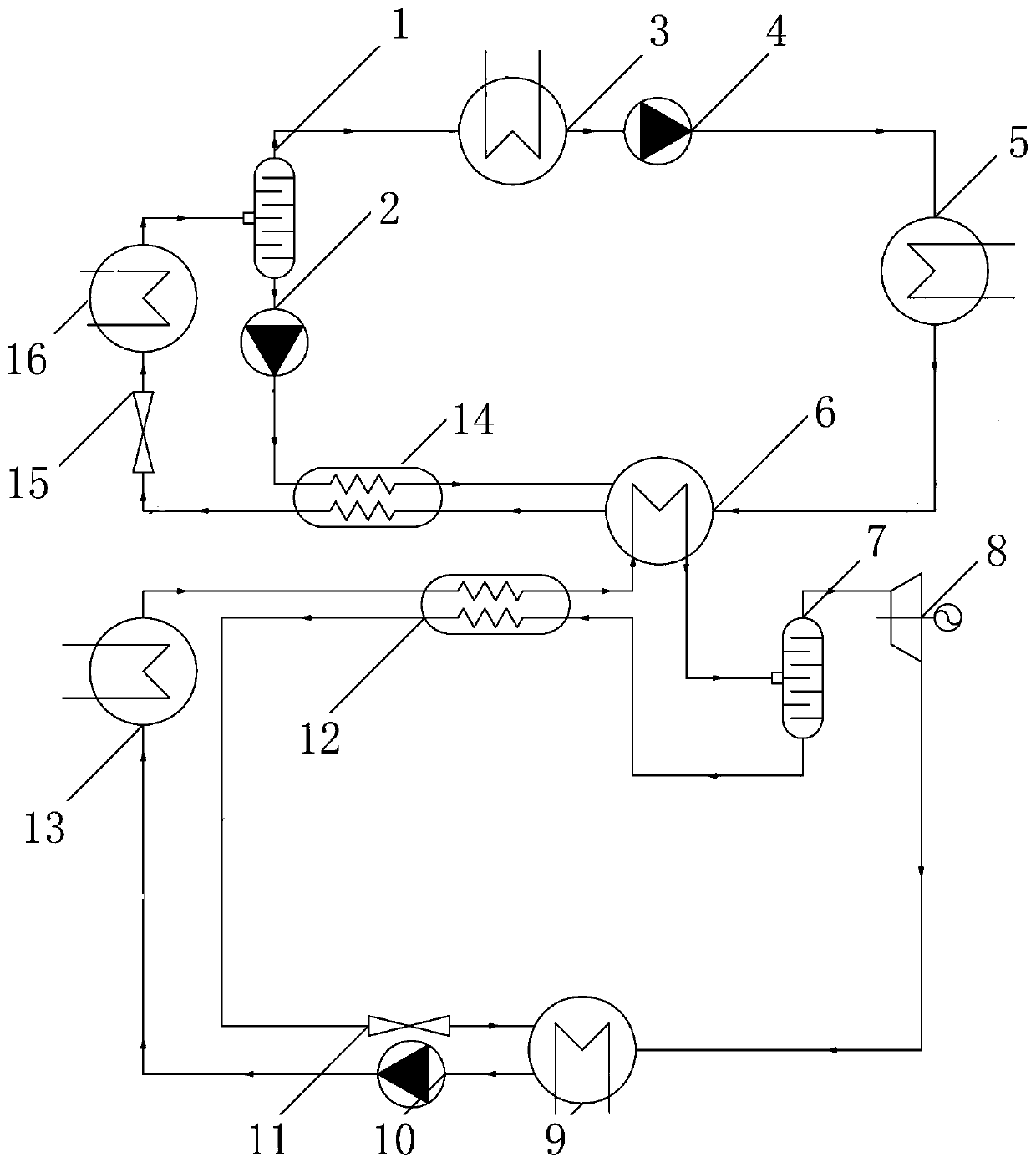

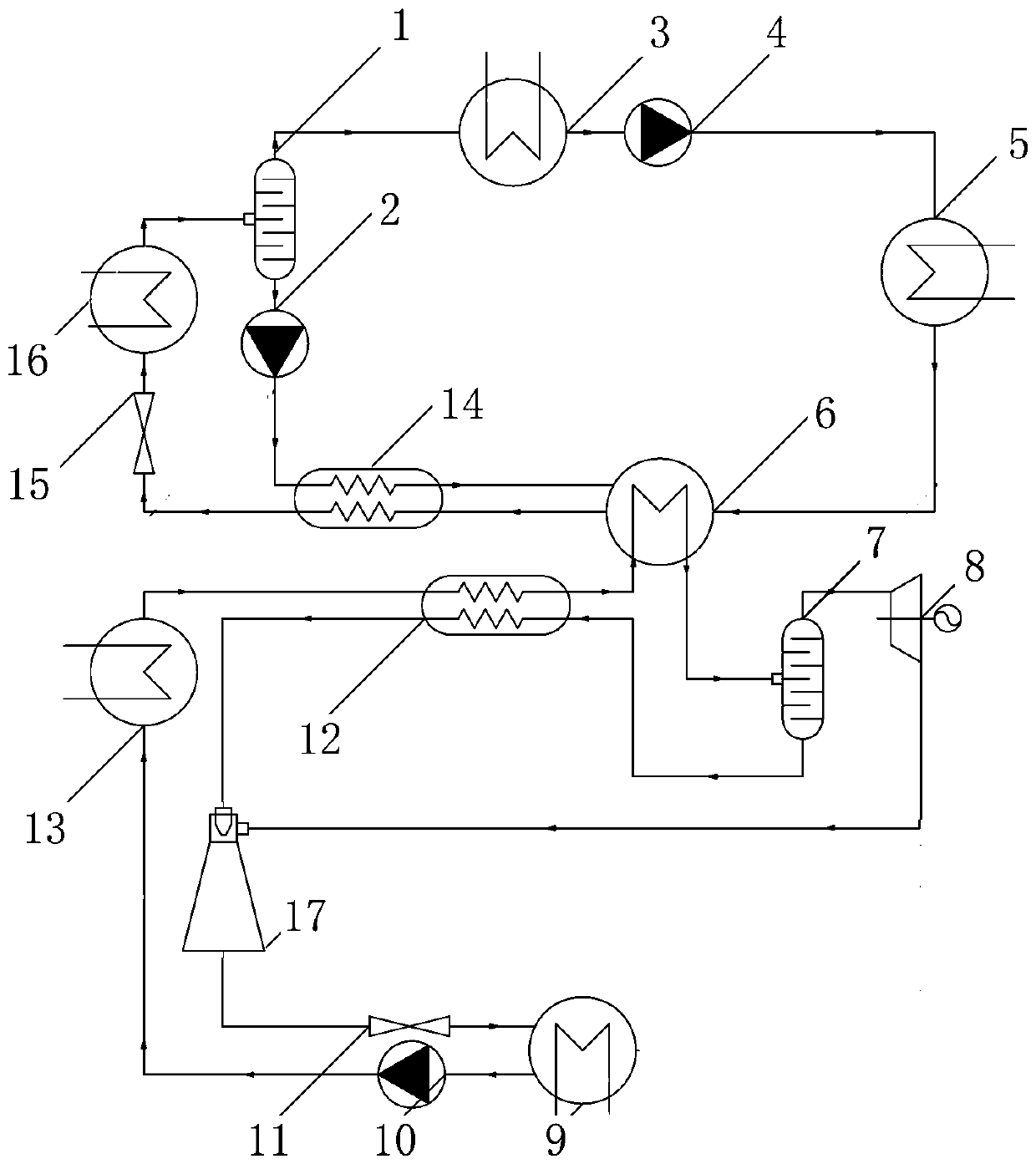

Absorption circulating system based on temperature and pressure raising technique

ActiveCN110986418AImprove working conditionsEfficient use ofClimate change adaptationEnergy efficient heating/coolingInlet pressureTurbine

The invention discloses an absorption circulating system based on a temperature and pressure raising technique and belongs to the field of energy recycling. The absorption circulating system based onthe temperature and pressure raising technique comprises a temperature and pressure raising sub circle and an absorption power sub circle. The temperature and pressure raising sub circle comprises a generator, a first separator, a condenser, a first working medium pump, an evaporator and a temperature and pressure booster, wherein an inlet of the first separator is connected to an outlet of the generator; an inlet of the condenser is connected to a gas outlet of the first separator; an inlet of the first working medium pump is connected to an outlet of the condenser; an inlet of the evaporatoris connected to an outlet of the first working medium pump; and a gas inlet of the temperature and pressure booster is connected to an outlet of the evaporator. An inlet temperature and an inlet pressure of a turbine are enhanced by means of power circular waste heat / conventional waste heat, and the working condition of the turbine is improved, so that energy is utilized thoroughly more effectively. In addition, compared with a conventional circle, a transformation mode is relatively easy to achieved, so that an existing industrial waste heat utilizing level is improved favorably.

Owner:OCEAN UNIV OF CHINA

Structure for preventing pulverized coal leakage of swirl burner

ActiveCN108662579ANot easy to squeeze outPrevent leakagePulverulent fuel combustion burnersCombustorWorking pressure

The invention relates to the technical field of boilers and discloses a structure for preventing pulverized coal leakage of a swirl burner. The structure comprises a pulverized coal pipe, a primary air pipe and a secondary air pipe. The pulverized coal pipe is communicated with the primary air pipe through a connecting pipe. The connecting pipe is connected with the pulverized coal pipe through aflange, and the connecting pipe is connected with the primary air pipe through a flange. A nozzle of the primary air pipe is communicated with the secondary air pipe, an interlayer is arranged betweenthe primary air pipe and the secondary air pipe, and the primary air pipe, the secondary air pipe and the interlayer are coaxially arranged. A baffle blocking the nozzle of the primary air pipe is arranged at the end of the interlayer, and each flange comprises a convex flange and a concave flange which are matched and connected. The connecting faces of the convex flanges are convex faces, and the connecting faces of the concave flanges are concave faces. A flexible gasket is arranged between each convex flange and the corresponding concave flange. Each flange is configured to the concave-convex face, each gasket is not extruded easily, centering is facilitated during assembly, the working pressure range is wider than that of a flat-face flange, the airtightness is better, and pulverizedcoal leakage of the burner can be prevented.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

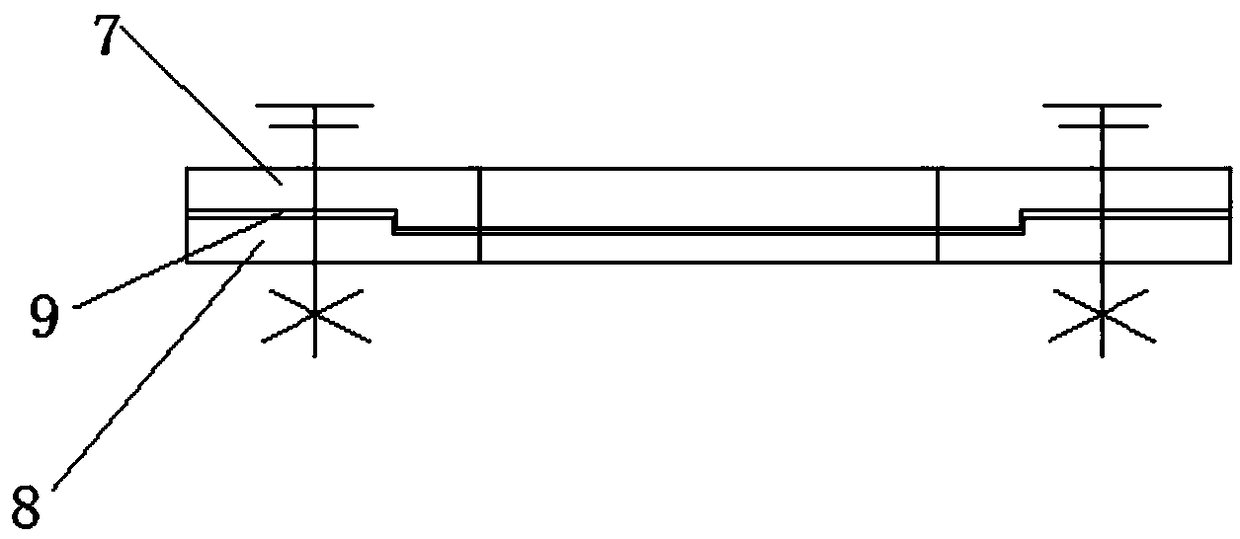

Valveless single cylinder blind hole channel down-hole hammer

A valveless single cylinder blind hole channel down-hole hammer comprises a cylinder block. The upper end of the cylinder block is connected with a rear connector. A one-way air inlet channel of the rear connector is matched with a check valve mounted in a check valve seat. The lower end of the cylinder block is connected with a drill bit through a connector. The check valve seat is provided with an air distributing hole. A positioning sleeve is disposed below the check valve seat. The inner wall of the positioning sleeve is matched with an air distributing rod. A plurality of rubber rings are further disposed between the inner wall of the positioning sleeve and the air distributing rod. The air distributing hole is communicated with a central duct of the air distributing rod. The lower end of the air distributing rod is matched with a piston upper air supply chamber at the upper end of the piston. The piston upper air supply chamber is communicated with a piston upper exhaust hole. A piston lower air supply chamber which is communicated with a piston lower exhaust hole is disposed at the lower end of the piston. A guide sleeve is disposed between the lower end of the piston and the cylinder block. By the valveless single cylinder blind hole channel down-hole hammer, operation stability of the hammer is improved, the service lives of the rubber rings are prolonged, and reliability of an air distributing mechanism is improved.

Owner:YICHANG WUHUAN ROCK DRILLING TOOLS

Pneumatic control three-position and three-way reversing valve

PendingCN111536267AImprove general performanceCompact structureOperating means/releasing devices for valvesMultiple way valvesWorking pressureEngineering

The invention discloses a pneumatic control three-position and three-way reversing valve. The pneumatic control three-position and three-way reversing valve comprises a valve body, an upper sealing bracket, an intermediate sealing bracket and a lower sealing bracket are sequentially arranged in the valve body in the vertical direction from top to bottom, first sealing rings and second sealing rings are correspondingly arranged at the two ends of the upper sealing bracket, the intermediate sealing bracket and the lower sealing bracket, and an air source port communicating with the upper sealingbracket, a testing port communicating with the intermediate sealing bracket, and an exhaust port communicating with the lower sealing bracket are formed in the valve body. The pneumatic control three-position and three-way reversing valve is suitable for the valve body, the gas path switching of pressurization, detection and exhaust of a tested object can be achieved, testing can be conducted bythe negative pressure and the positive pressure, the working pressure range is large, meanwhile the universality of the valve body is high, the structure is compact, the volume is small, and the manufacturing cost of an instrument is effectively lowered.

Owner:深圳天邦美科技有限公司

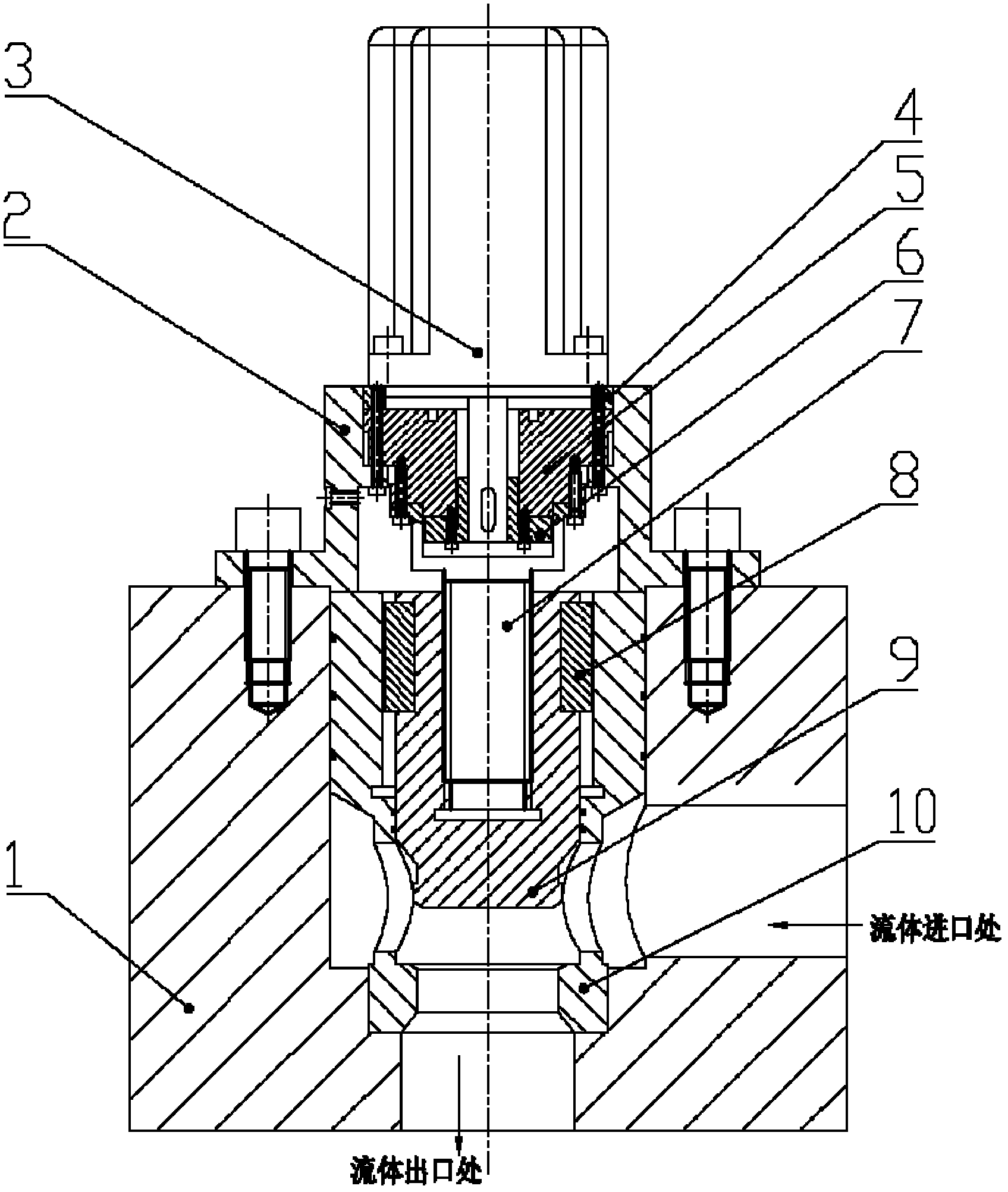

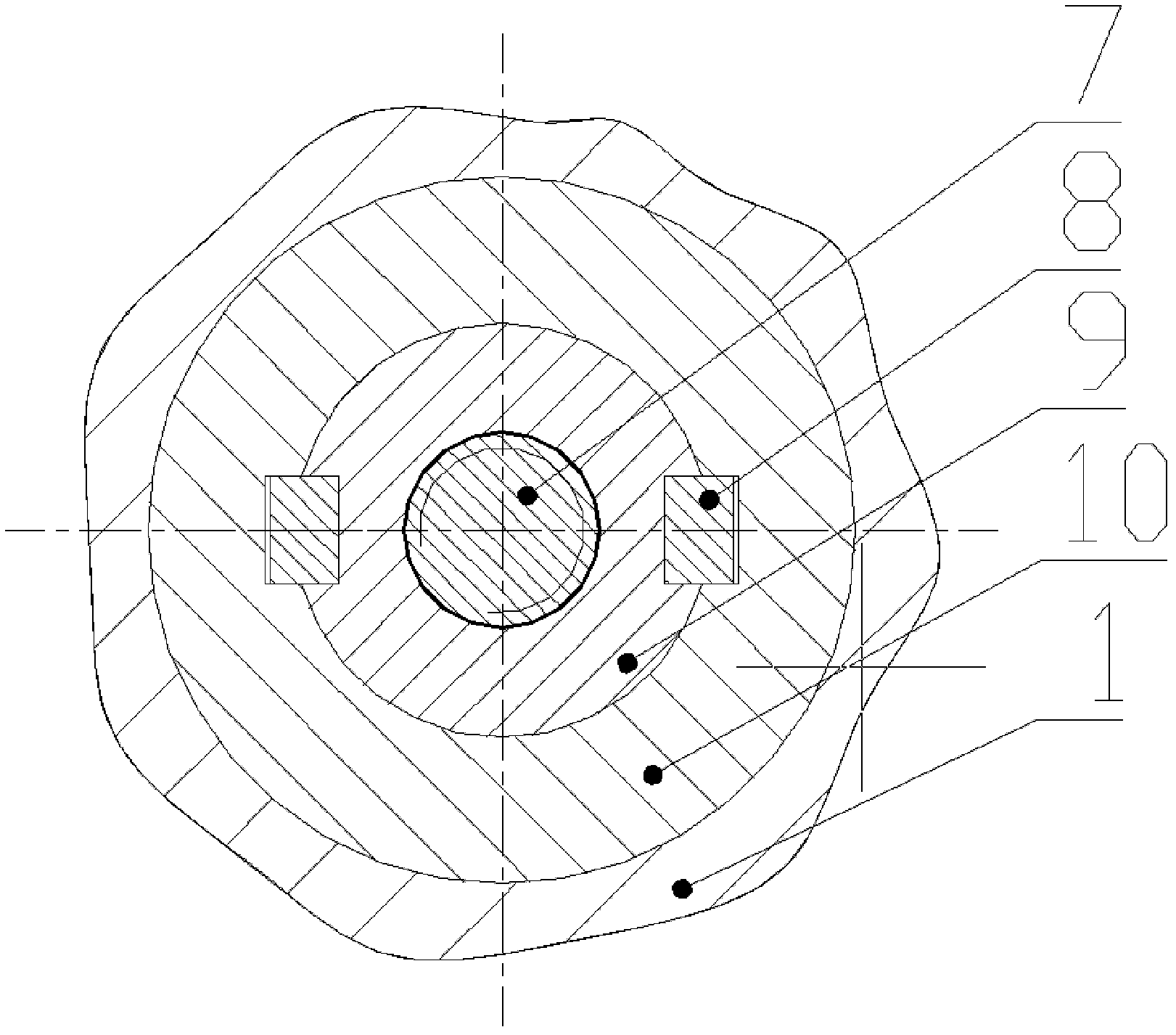

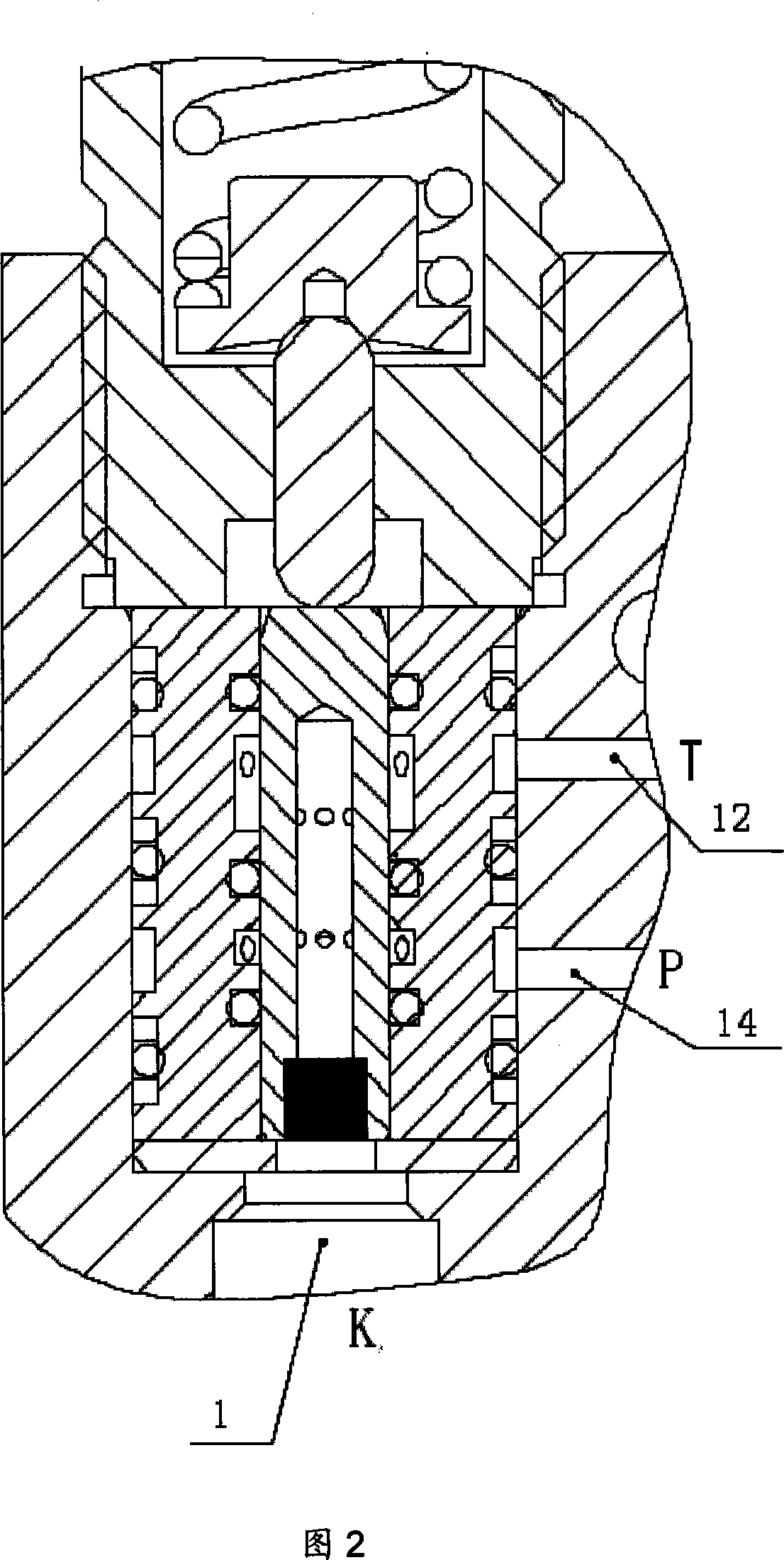

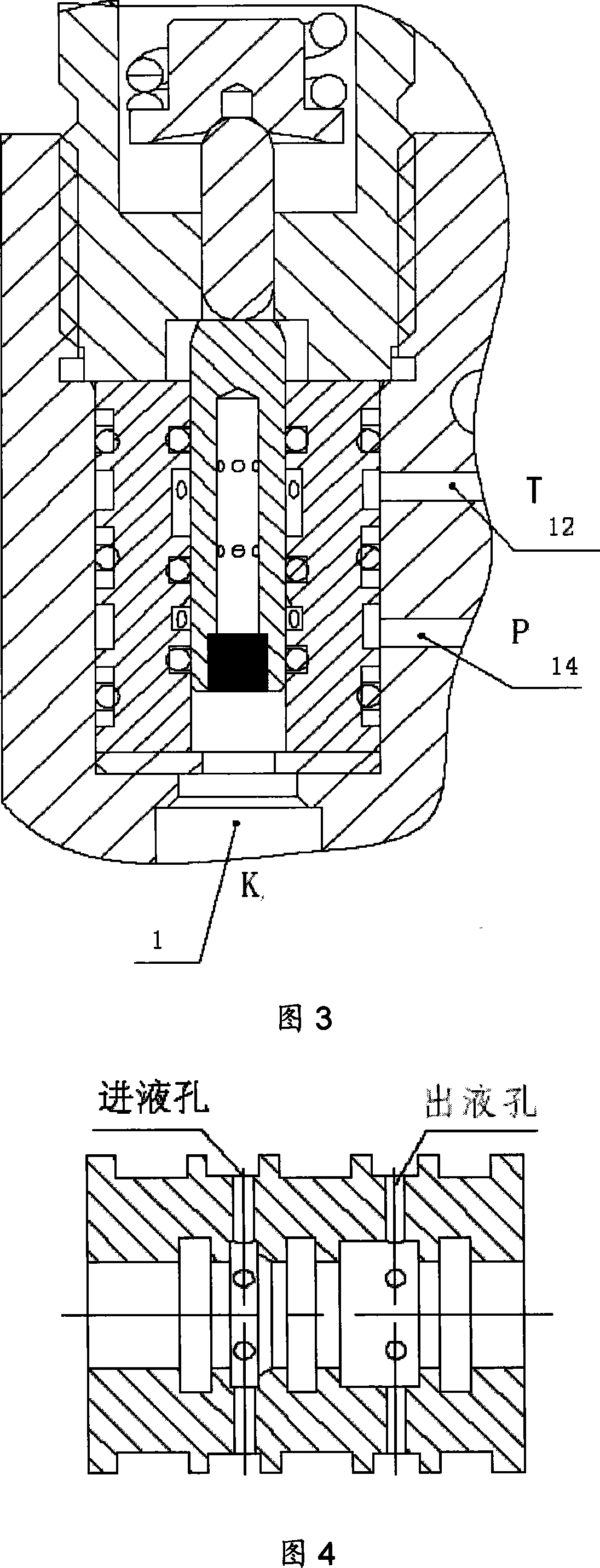

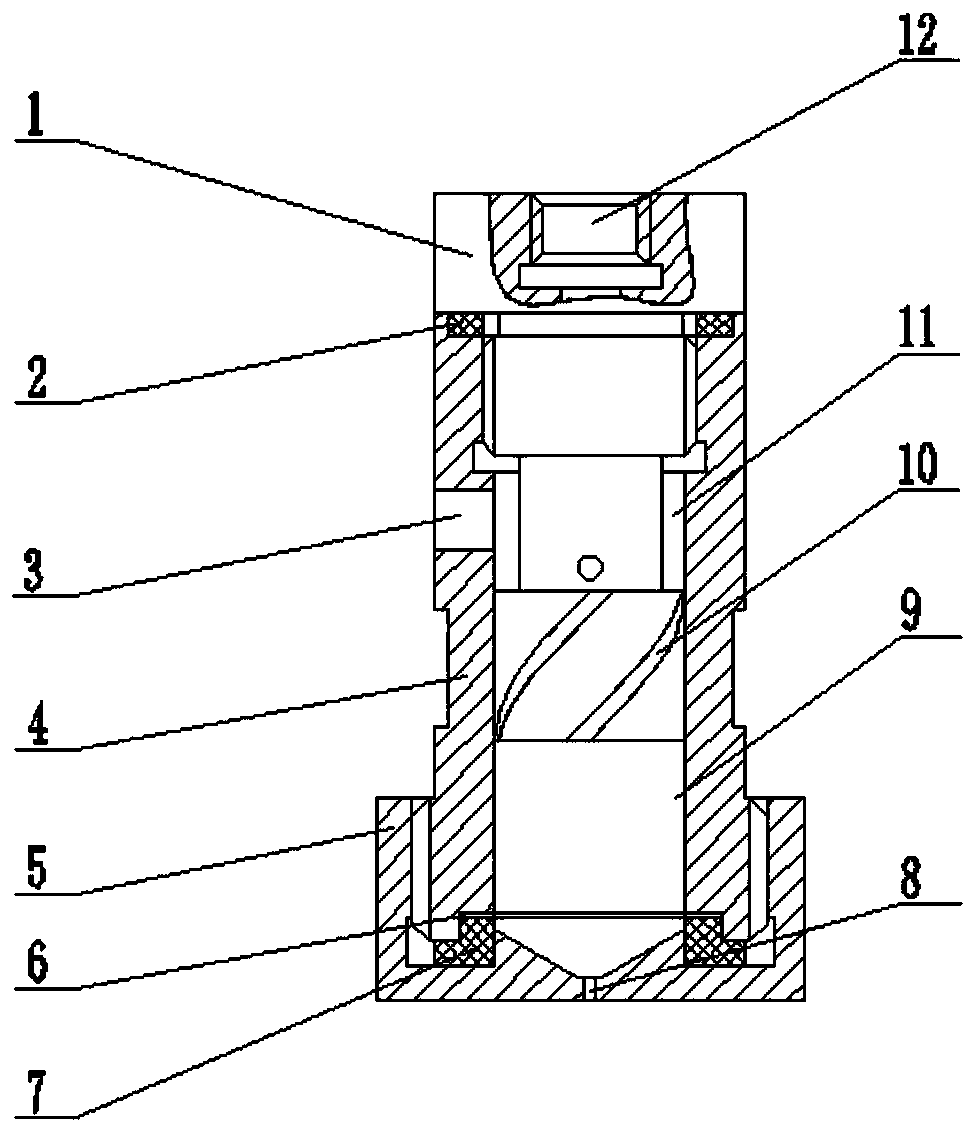

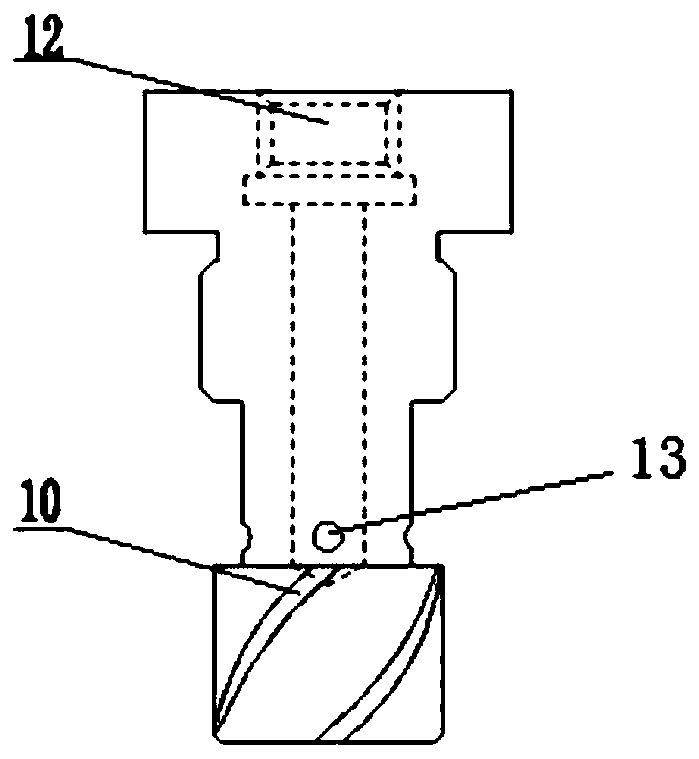

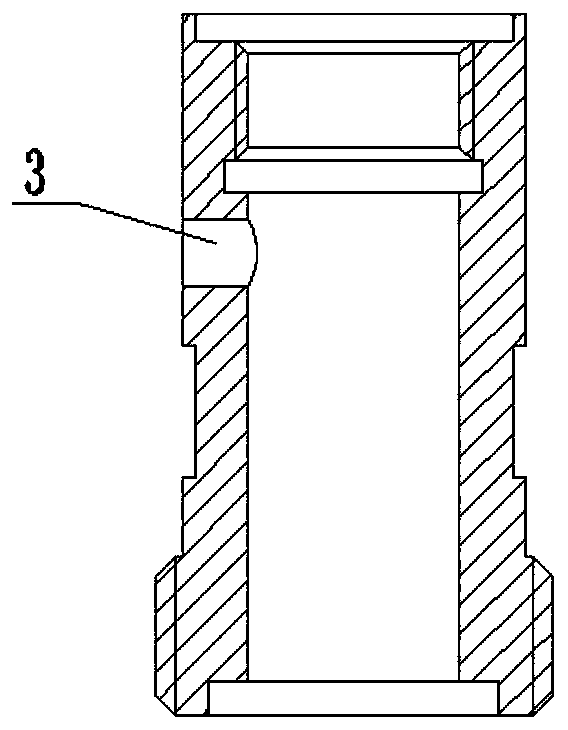

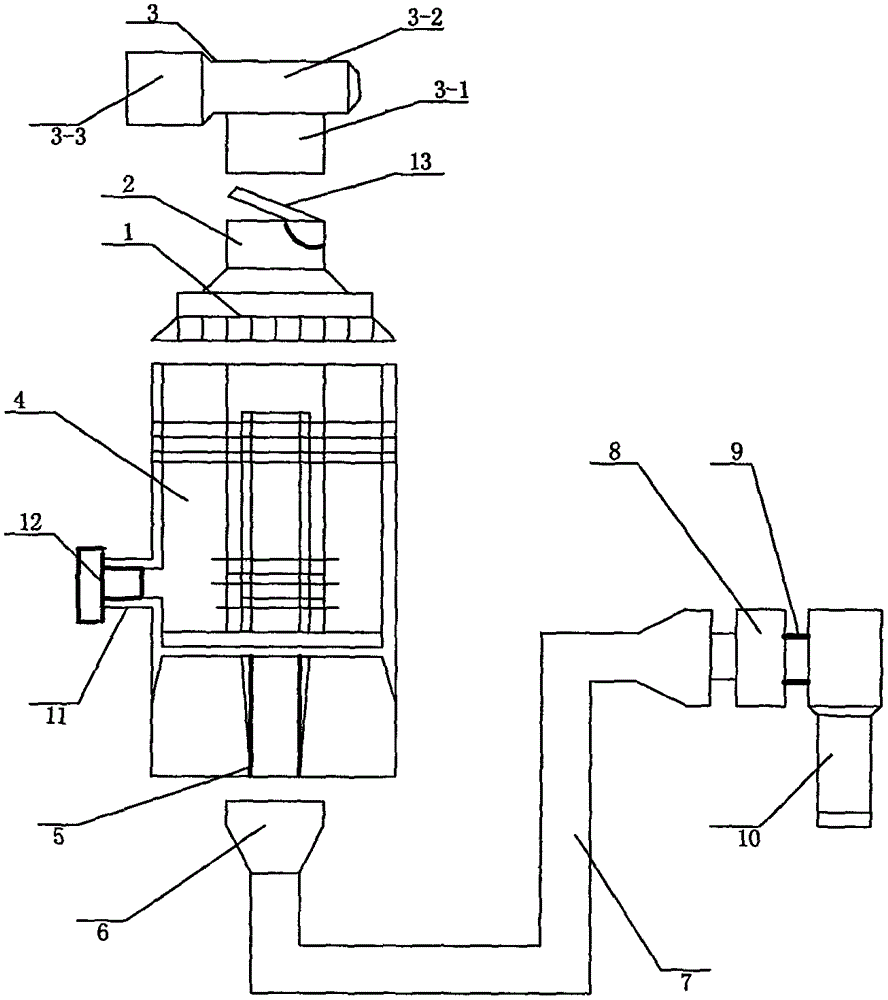

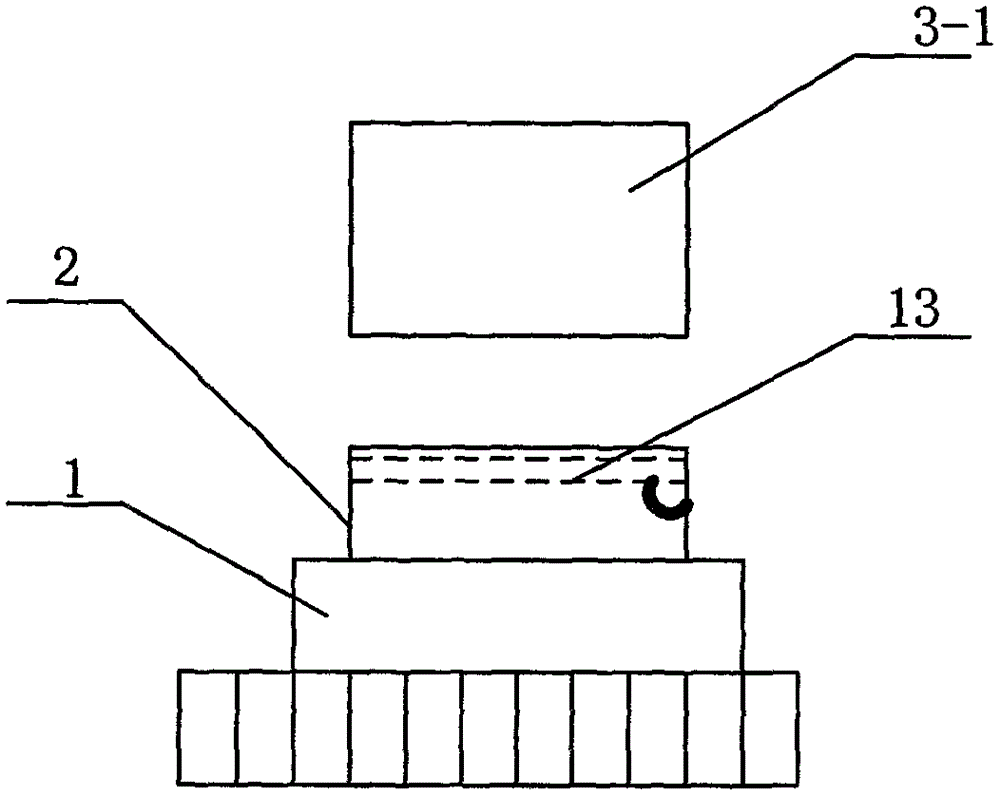

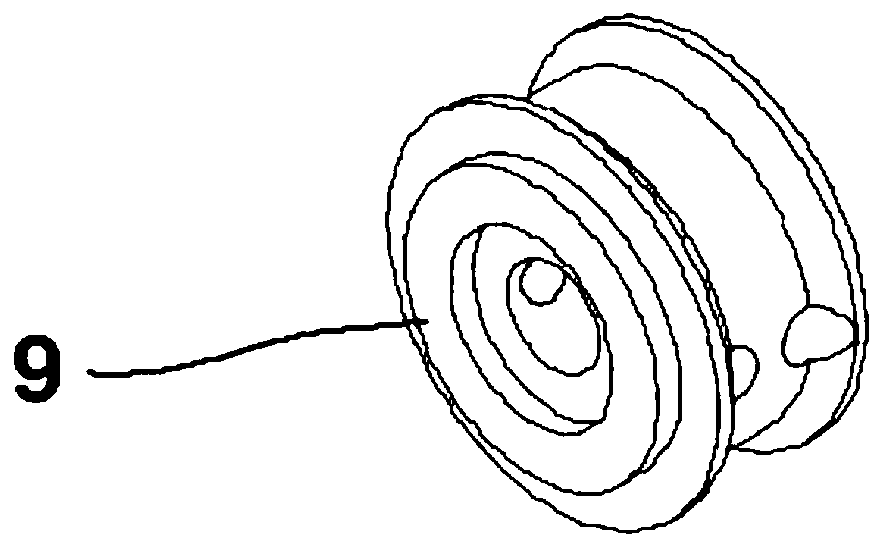

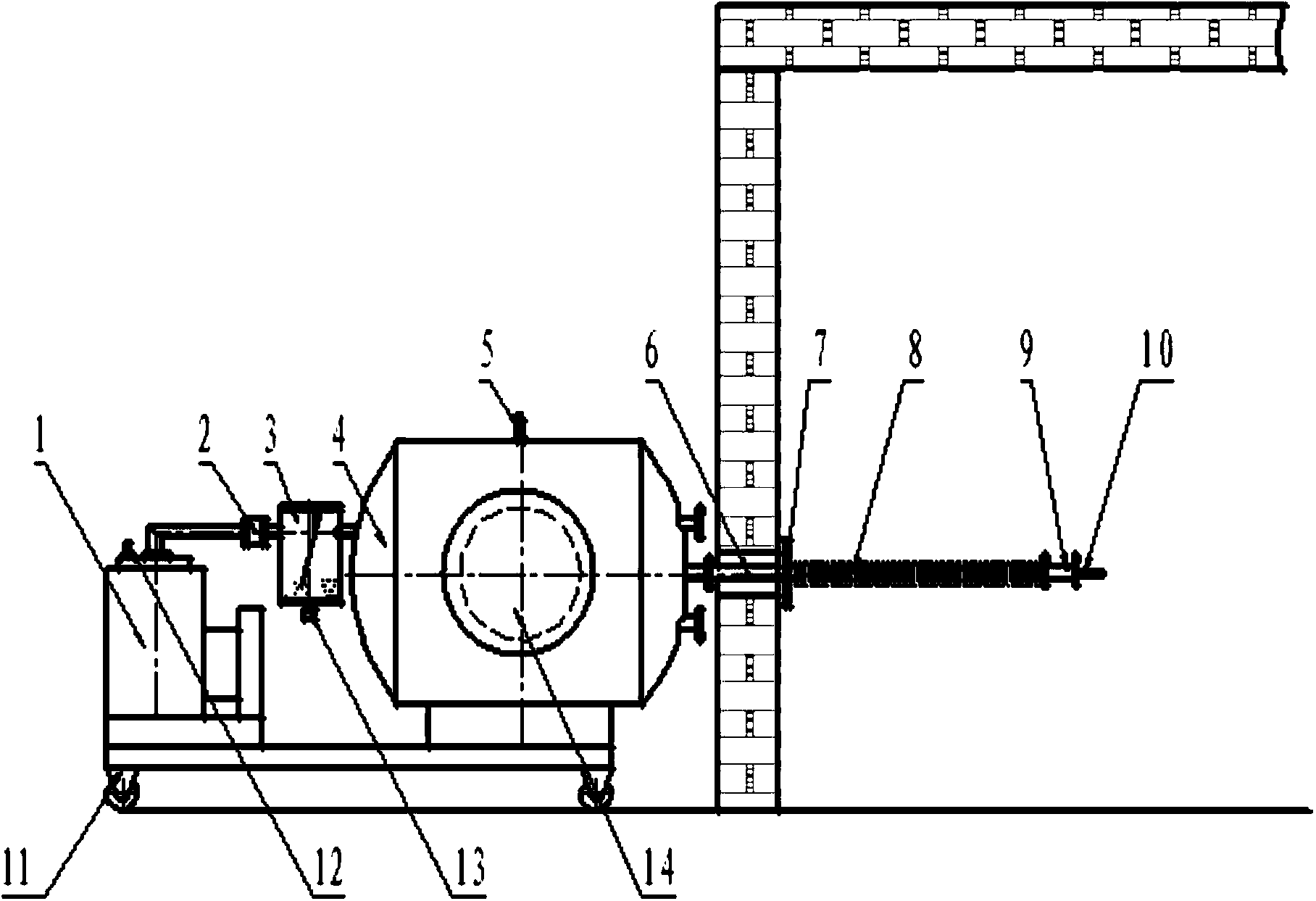

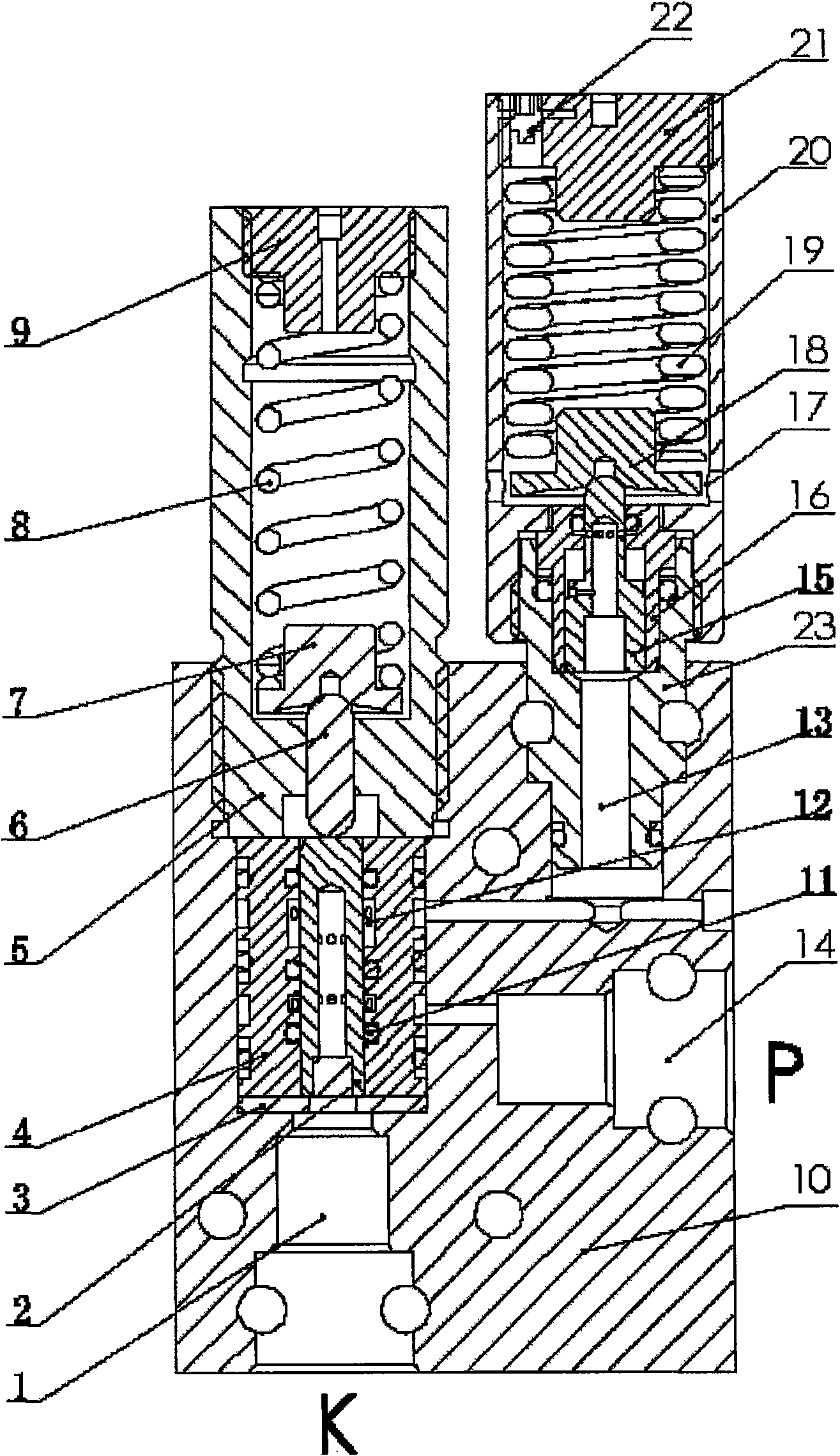

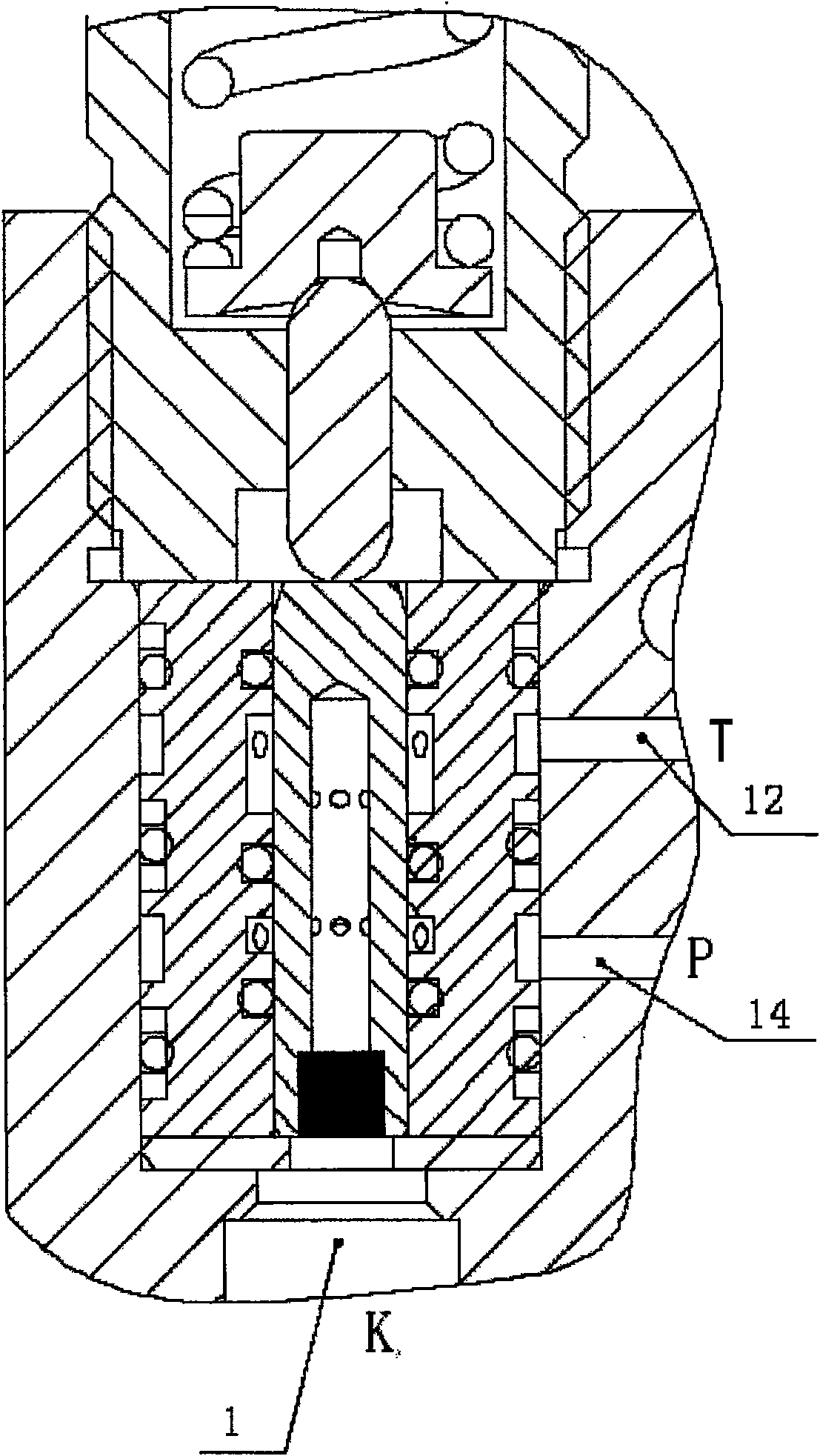

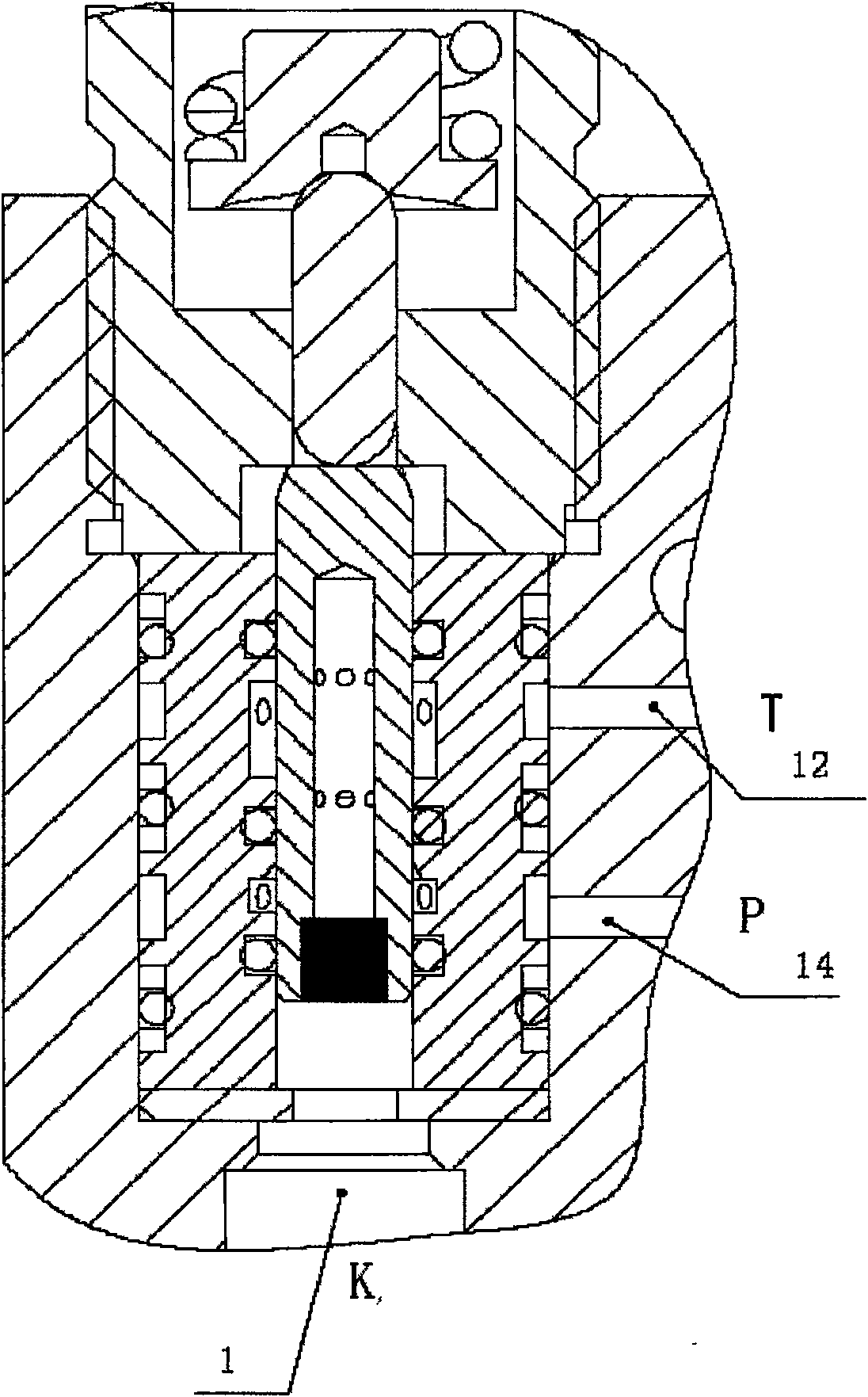

Combined type flow valve for liquid of high-pressure large-flow alternating current servo direct-drive machine

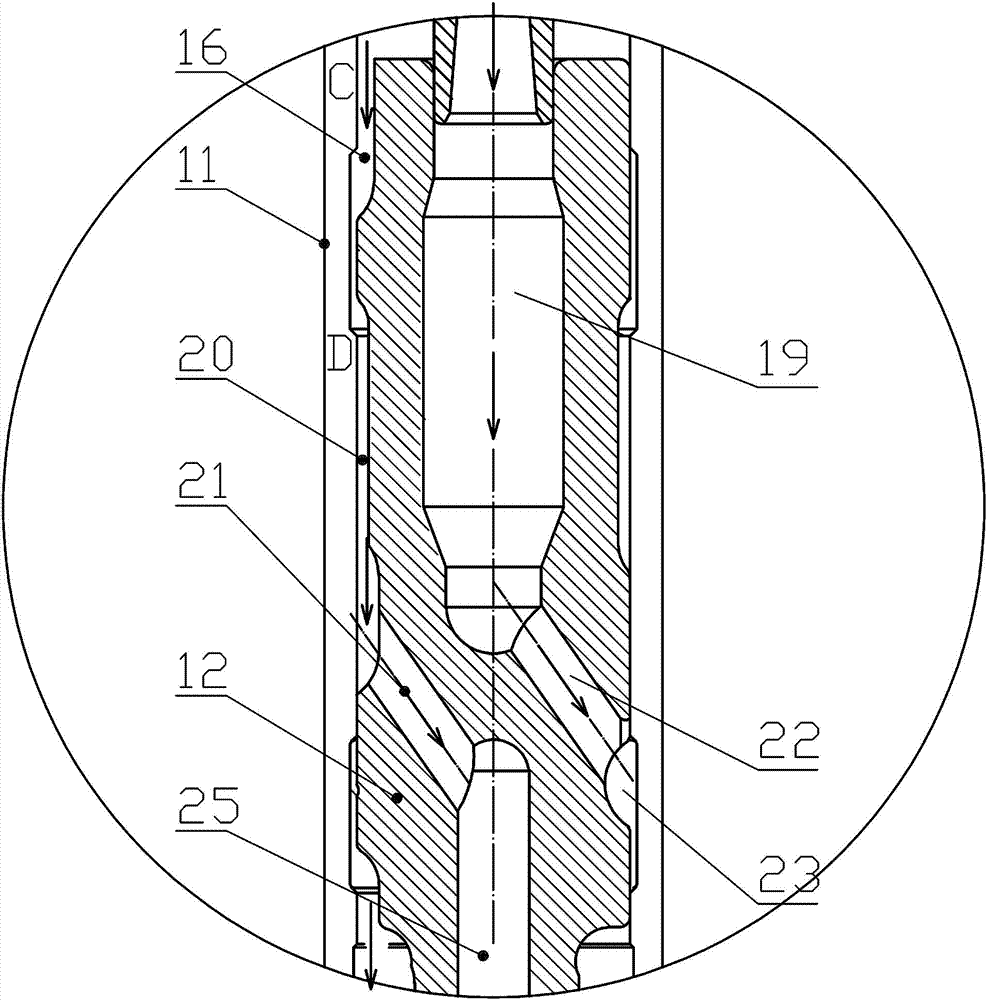

InactiveCN102635583BOvercoming contamination sensitivityReduce manufacturing costsServomotor componentsElectricityMotor drive

The invention provides a combined type flow valve for liquid of a high-pressure large-flow alternating current servo direct-drive machine. An alternating current servo motor drives a push rod through the transmission of a thread and the push rod acts on a hydraulic transmission cavity which is sealed with hydraulic oil; when the push rod moves, the inner volume of the hydraulic transmission cavity is changed and a valve core moves to the same side to compensate the change of the volume, so that the movement of the valve core is controlled through controlling the movement of the push rod. The valve has the advantages of simple structure, accurate control and convenience for use, can directly use a computer to carry out digital control, has good buffering and positioning performances, can meet the requirements of positioning any point, can realize a closed ring system of electric feedback, and especially can be used for better solving the problem that the previous servo valve is sensitive to oil liquid pollution. The valve is wide in working pressure range and large in flow and can work under a very low oil supply pressure, and the dynamic performance is not greatly influenced by the low oil supply pressure; and the valve has fewer middle transmission links so that the efficiency of the system can be improved.

Owner:XI AN JIAOTONG UNIV

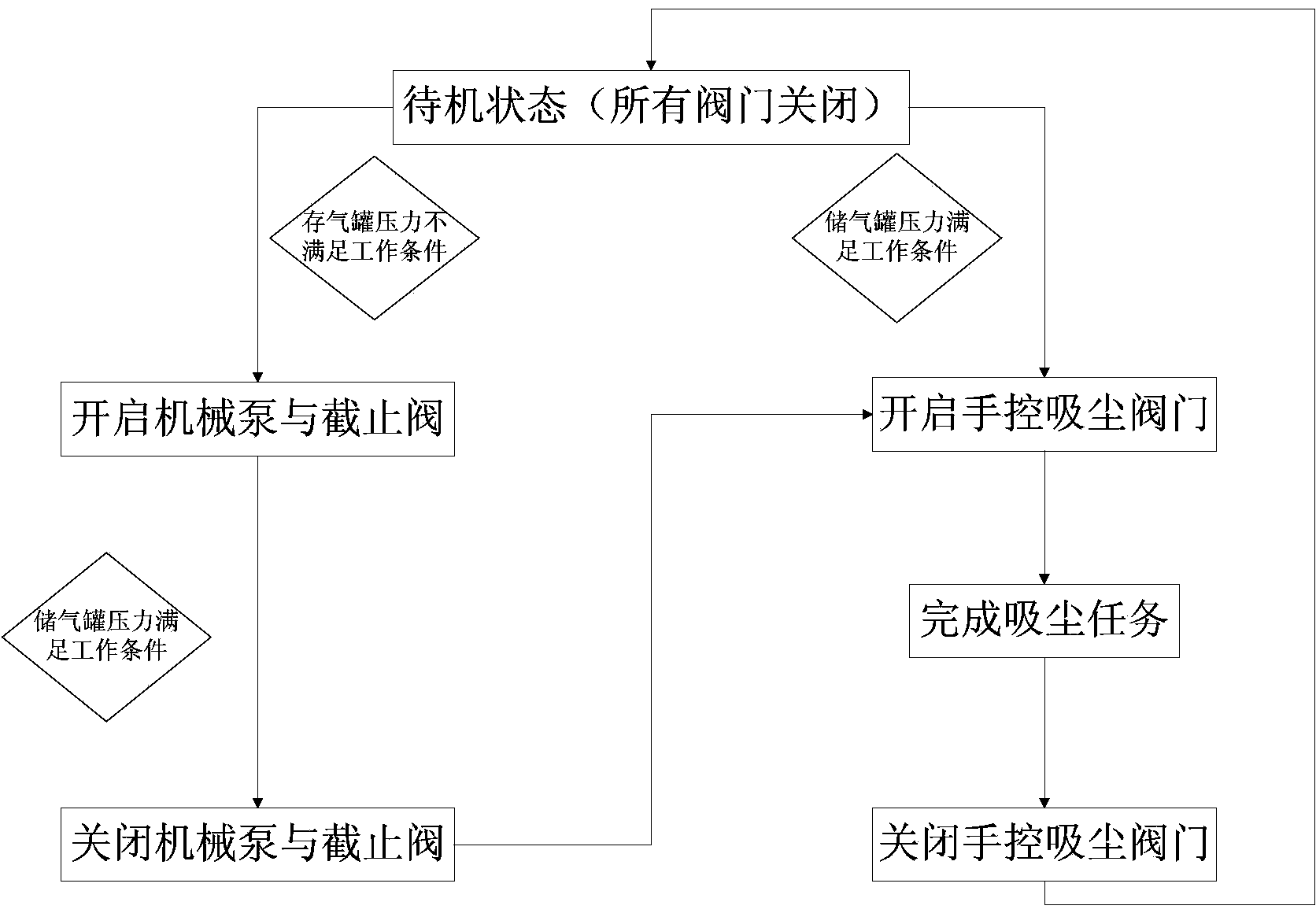

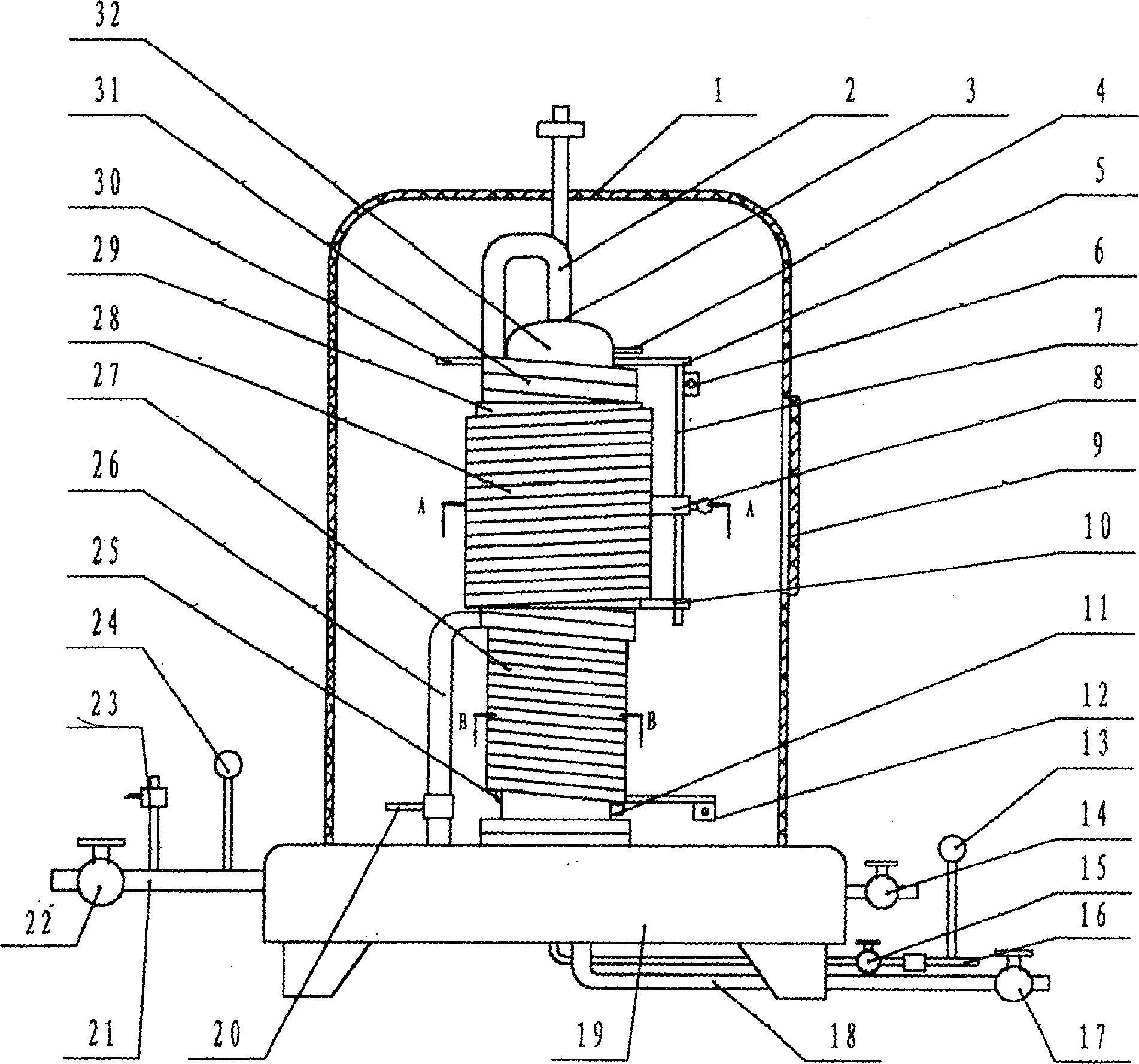

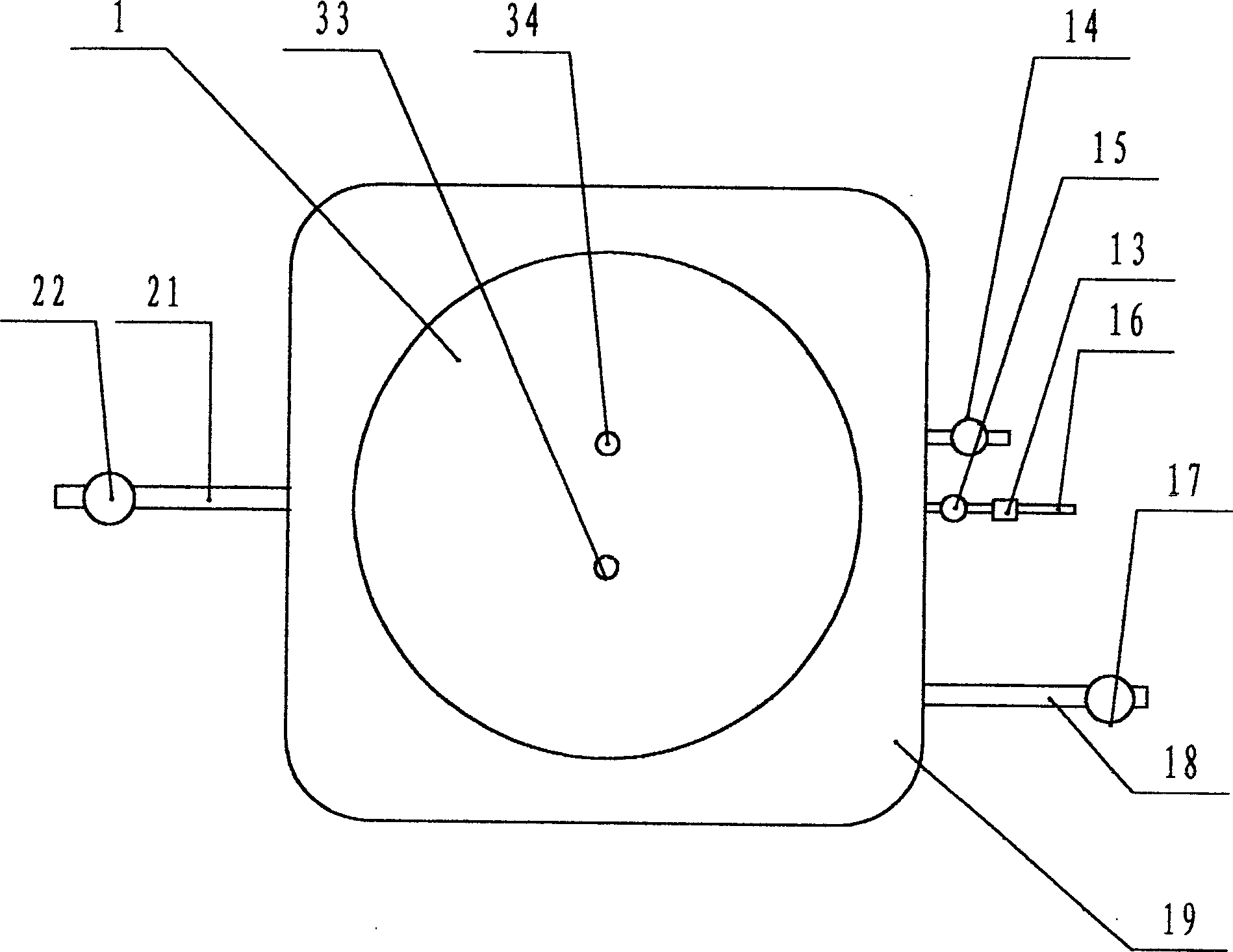

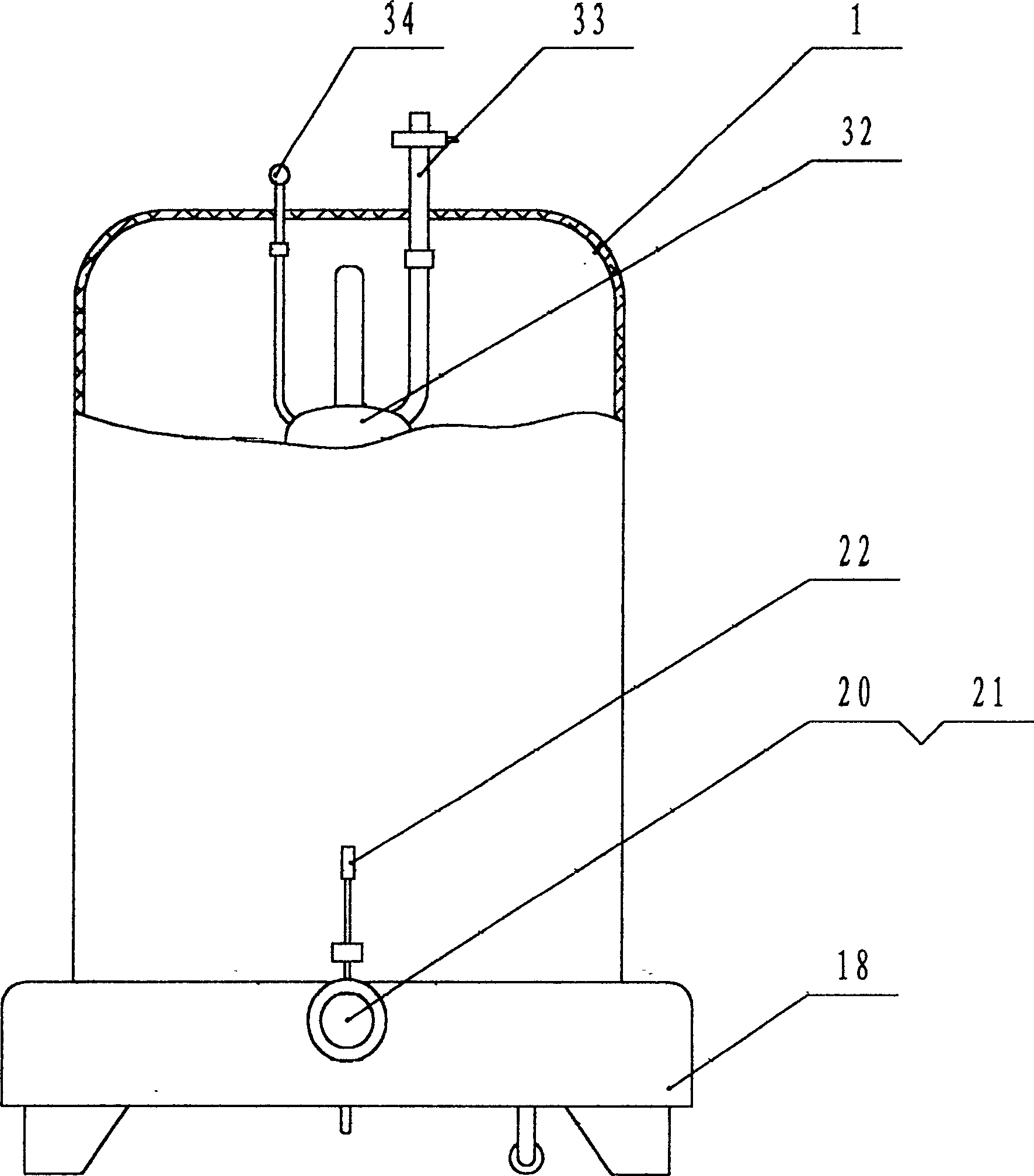

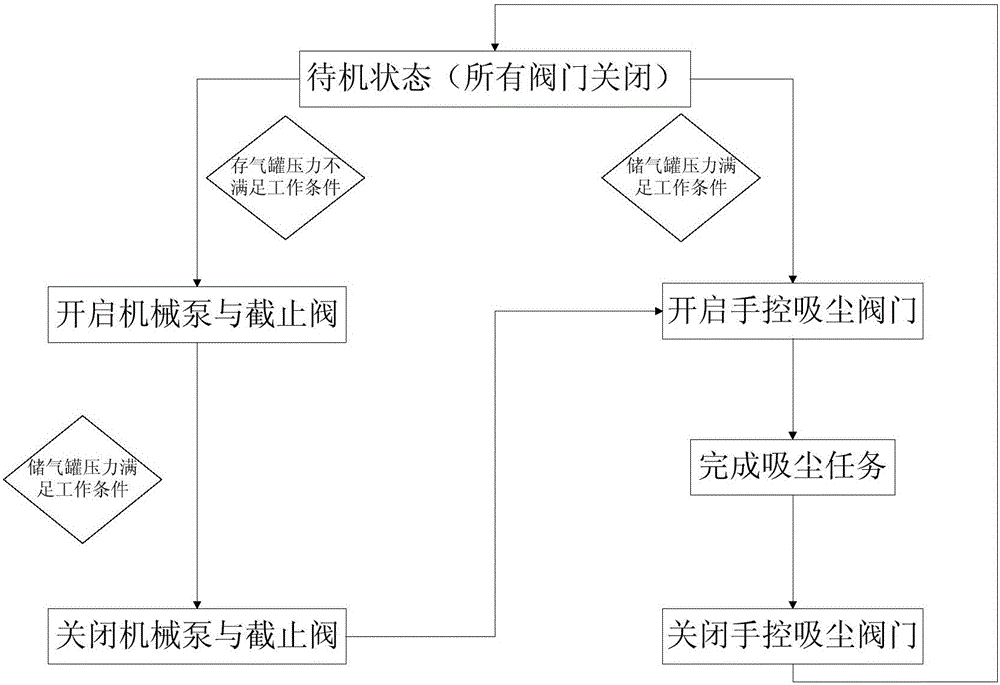

Special dust collector for clean room

The invention relates to a special dust collector for a clean room and belongs to the fields of biological medicine, precision machining and machinery. By arranging a dust collecting system of the special dust collector outside the clean room completely and by using an air storage tank which has certain volume and is pumped to certain vacuum degree through a mechanical pump to provide suction force, various dusts and pollutants in the clean room can be sucked to the outside of the clean room flexibly and efficiently, and no secondary pollution can be caused. By means of joint effect of the mechanical pump and the air storage tank, working pressure of the special dust collector has a wide adjustable range, the suction force can be set and adjusted flexibly, and a suction head and a suction pipeline can be switched freely. Meanwhile, device maintaining is simple and efficient. By means of the special dust collector, various pollutants can be removed efficiently, and local cleaning work in the clean room is greatly facilitated.

Owner:BEIJING TECHNOL SCI

Water vaporization method and device as well as medium frequency induced water vaporization method and device

InactiveCN1240961CReduce pressure requirementsWide working pressure rangeSteam generation heating methodsSteam superheatersMedium frequencyInduction heater

Owner:北京东方华奇环保科技有限公司

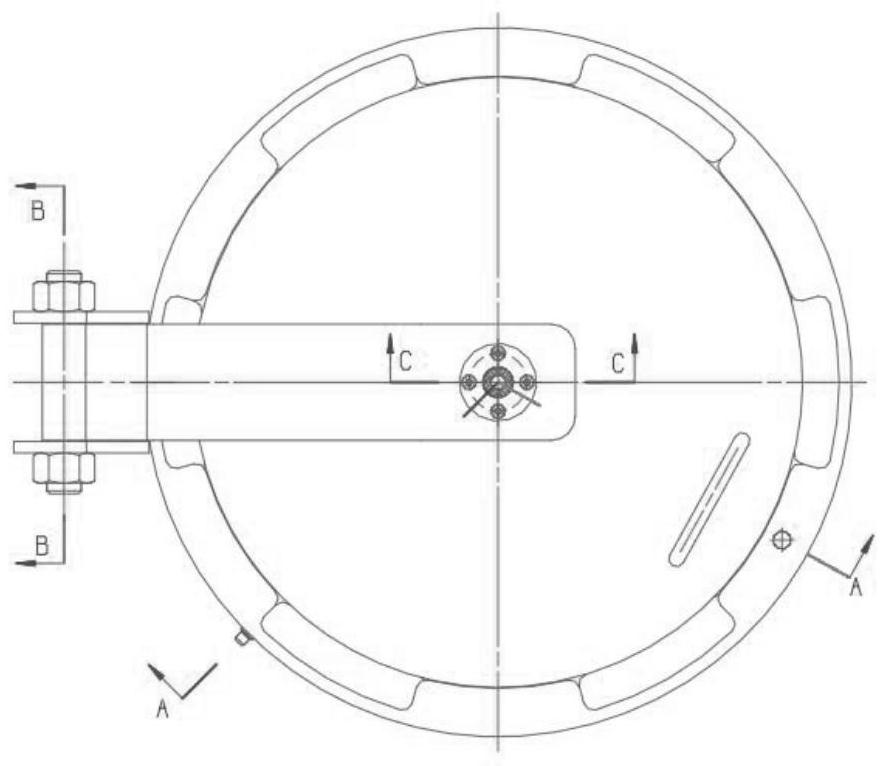

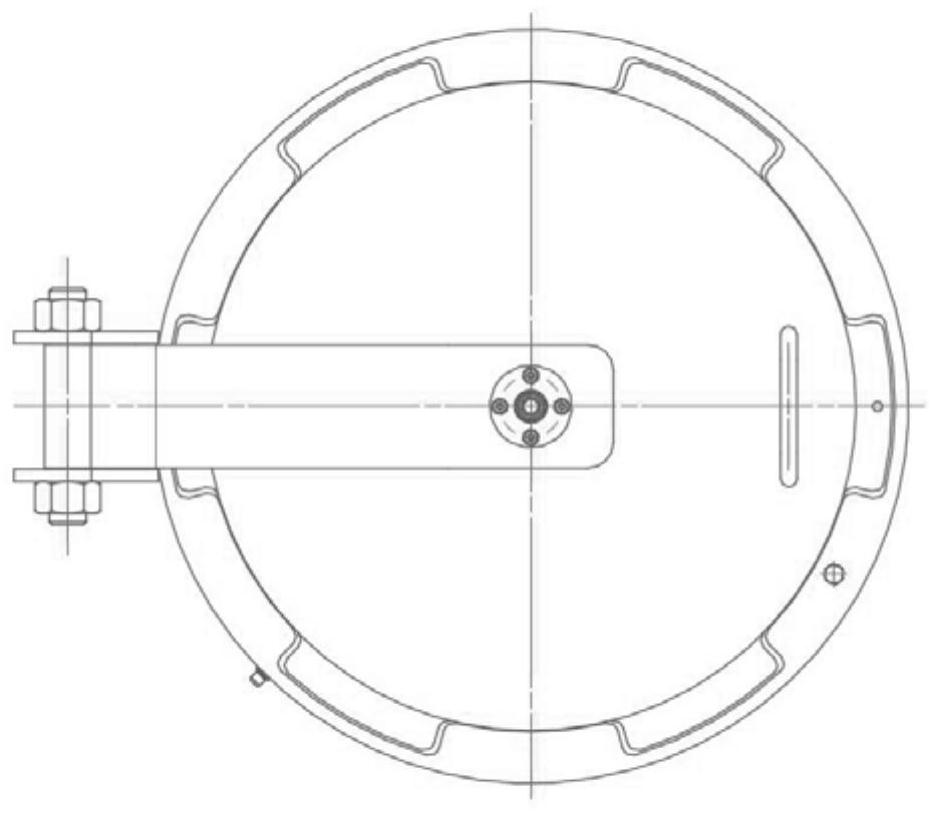

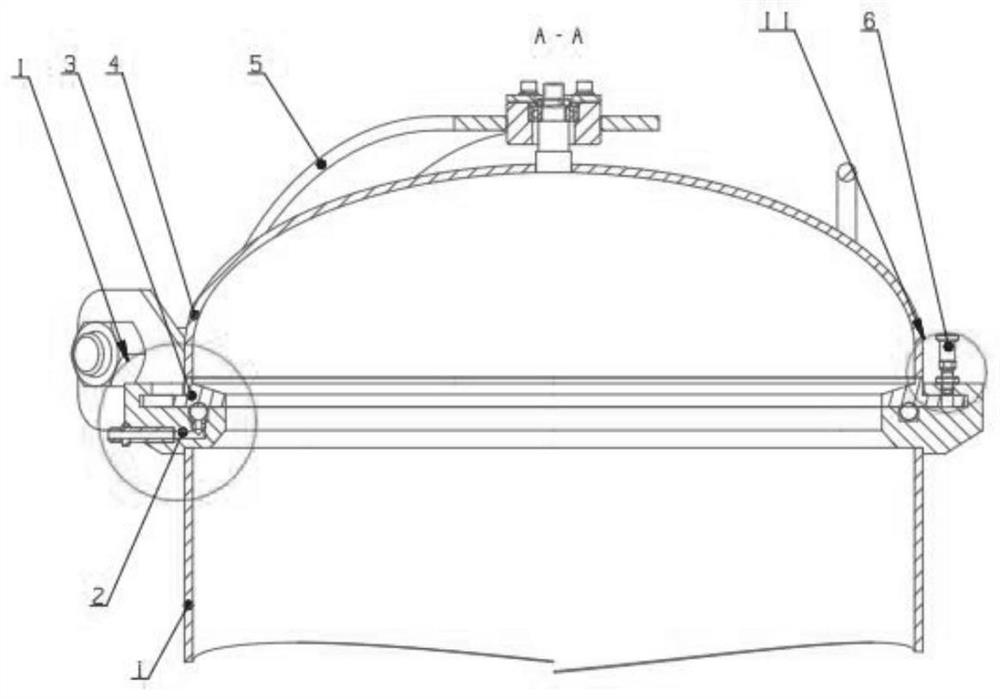

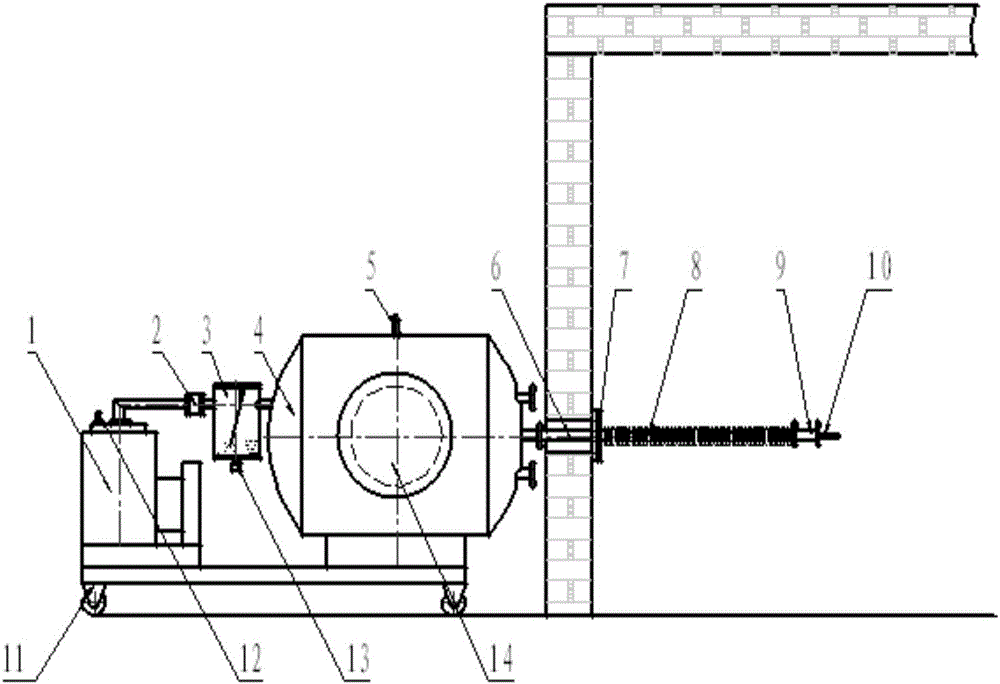

Test chamber tooth-meshing type quick-opening manhole

ActiveCN111810633AQuick opening and closingWide working pressure rangeEngine sealsPressure vesselsClassical mechanicsStructural engineering

The invention discloses a test chamber tooth-meshing type quick-opening manhole, and belongs to the technical field of test bench test chamber devices. The manhole comprises a cylinder, a cylinder flange, lug plates and a rotating shaft. The cylinder, the cylinder flange and the lug plates are welded, the rotating shaft is inserted into the lug plates, and the two ends of the rotating shaft are limited and fixed through nuts. The manhole also comprises a cover flange and a cover, the cover flange is welded to the cover, a fixing shaft is arranged on the cover and provided with a bearing type rotary mechanism, and the bearing type rotary mechanism and the rotating shaft are fixedly connected with a rotary arm. Teeth are uniformly distributed on the circumference of the cylinder flange and on the circumference of the cover flange, and the cover flange is rotated to mesh with or disengage with the teeth of the cylinder flange to close or open the manhole, so that when the manhole is opened, the rotary arm can rotate around the axis where the rotating shaft is located, and when the manhole is closed, the cover flange and the cover can flexibly rotate around the axial direction of the fixing shaft. The manhole is simple and reasonable in structural design, low in cost and capable of being quickly opened and closed, the working intensity for opening and closing the manhole is reduced, and the sealing effect is good.

Owner:湖南汉能科技有限公司

A special vacuum cleaner for a purification workshop

The invention relates to a special dust collector for a clean room and belongs to the fields of biological medicine, precision machining and machinery. By arranging a dust collecting system of the special dust collector outside the clean room completely and by using an air storage tank which has certain volume and is pumped to certain vacuum degree through a mechanical pump to provide suction force, various dusts and pollutants in the clean room can be sucked to the outside of the clean room flexibly and efficiently, and no secondary pollution can be caused. By means of joint effect of the mechanical pump and the air storage tank, working pressure of the special dust collector has a wide adjustable range, the suction force can be set and adjusted flexibly, and a suction head and a suction pipeline can be switched freely. Meanwhile, device maintaining is simple and efficient. By means of the special dust collector, various pollutants can be removed efficiently, and local cleaning work in the clean room is greatly facilitated.

Owner:BEIJING TECHNOL SCI

Multilevel control valve

InactiveCN100559014CExtend your lifeEasy to transformMine roof supportsProps/chocksSpool valveHydraulic cylinder

Owner:SICHUAN AEROSPACE FENGHUO SERVO CONTROL TECH CO LTD

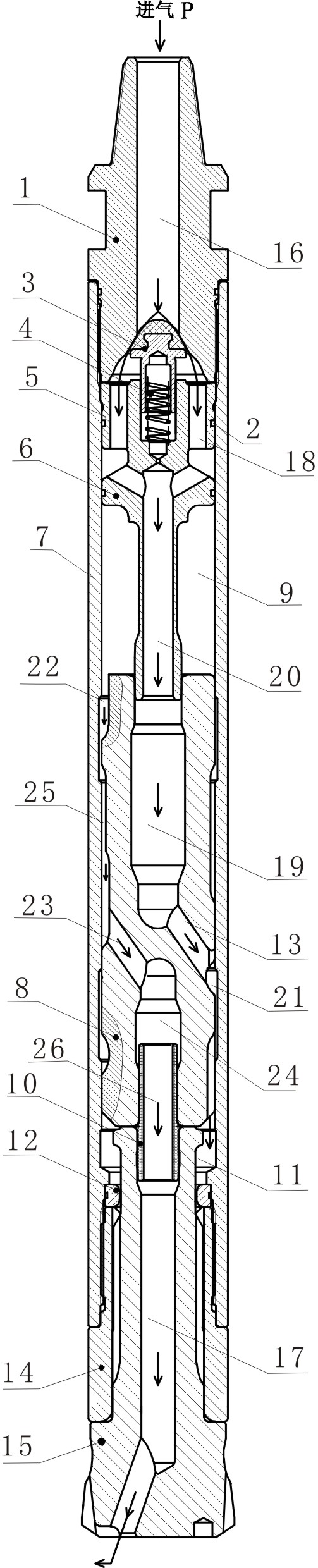

Middle-low air pressure down-hole hammer

Provided is a middle-low air pressure down-hole hammer. The middle-low air pressure down-hole hammer comprises a back joint, a check valve, an air-distribution rod, a piston, an internal cylinder, an outer casing pipe, a clamping ring, a guide sleeve, a plug, a first spring, a rubber stick, a lateral pin, a pin-hanging type drill and a pin-hanging type front joint. The check valve is a one-way valve and provided with a valve seat and a second spring. The piston is a long-and-thin-shaped piston with a hole path. The air-distribution rod and an air inlet seat at the back end of the check valve are of an integrated structure. The internal cylinder is placed outside the air-distribution rod and the piston. In the process of piston motion, the matched end of the piston and the air-distribution rod is in the internal cylinder all the time, a cavity is formed between part of the piston and the outer casing pipe, and other parts of the piston are matched with the internal cylinder. According to the middle-low air pressure down-hole hammer, the air distribution rod and the valve seat of the check valve are integrated, the structure is simple, the functions of locating, vibration damping and air suction can be achieved, and stability and reliability are achieved in the process of work. Contact portions of the piston and the internal cylinder are reduced, and therefore the internal cylinder is wear-resisting, and working pressure ranges of the hammer are wide.

Owner:YICHANG WUHUAN ROCK DRILLING TOOLS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com