Embedded valve container type adjustable dynamic flow equalizing valve

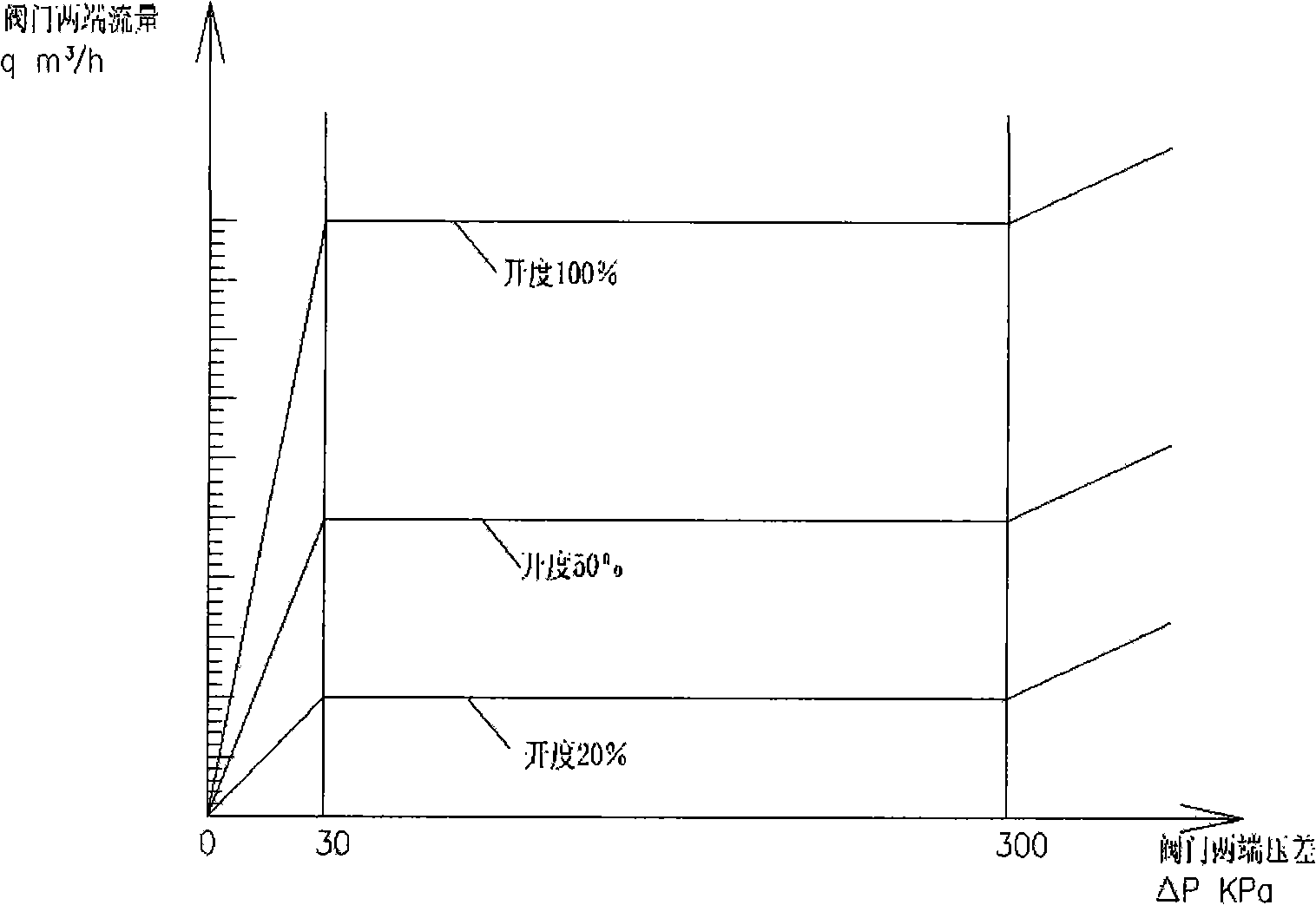

A flow balancing valve and valve cartridge technology, applied in balancing valves, safety valves, valve devices, etc., can solve problems such as short service life, inaccurate hydraulic balance calculation, and increase pump power, and achieve a wide and large working pressure difference. The effect of promoting the prospect of use and meeting the needs of the project

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

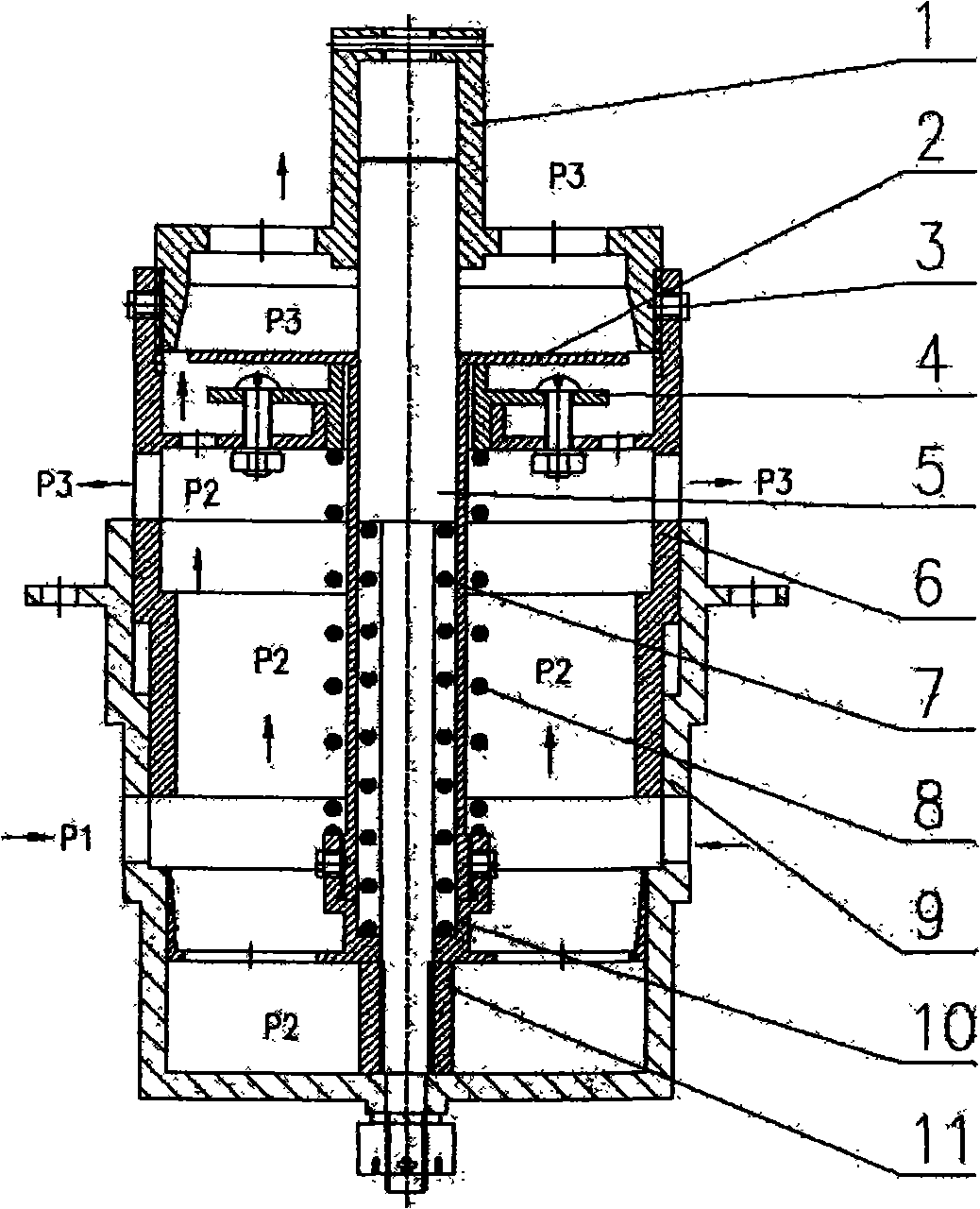

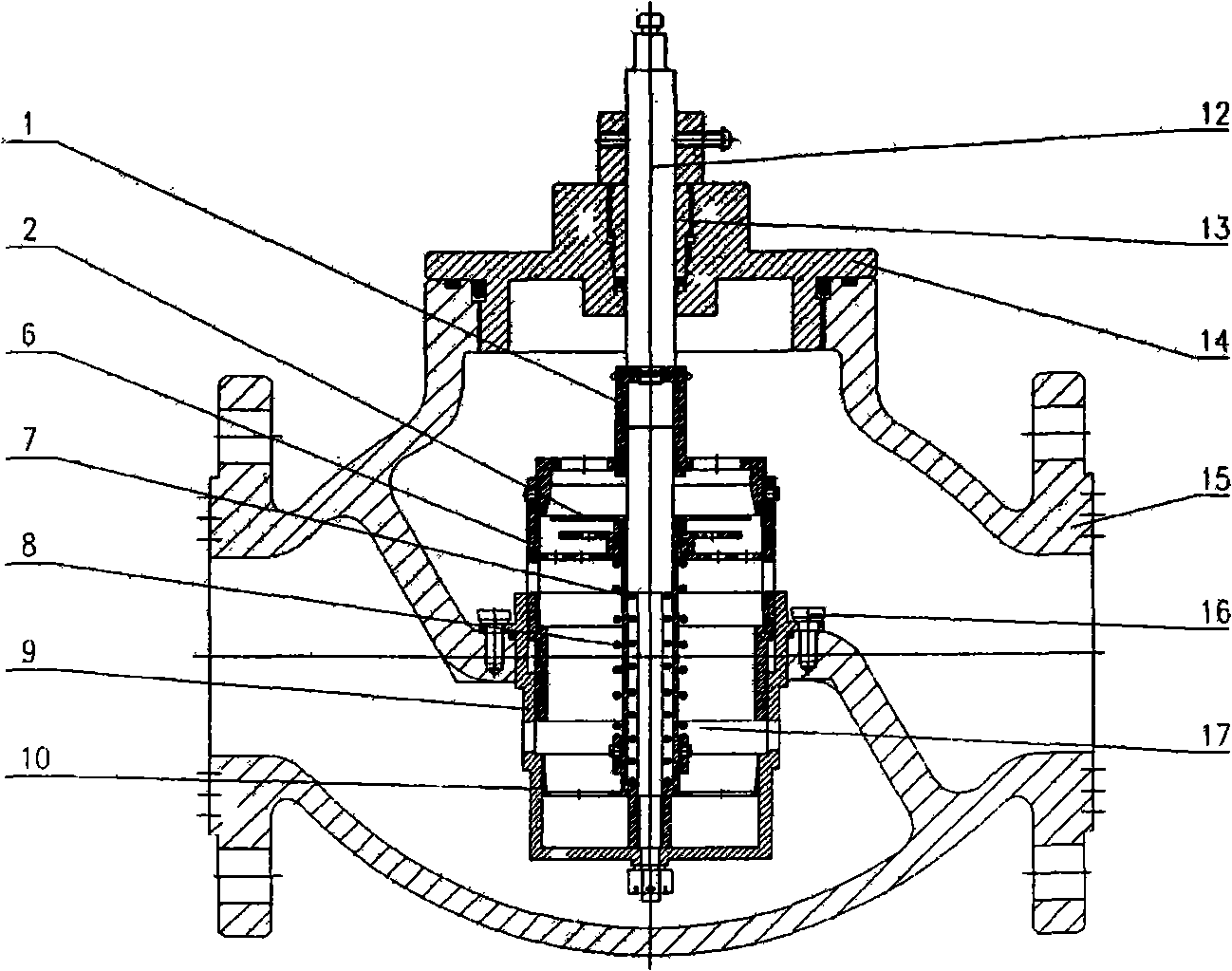

[0022] figure 1 Among them, the dynamic flow balance valve with a built-in spool type includes a valve body 15, a spool 17, an upper sealing cover 14, a sealing gland 13, a connecting rod 12, and fastening screws 16. The valve bladder 17 is fixed inside the valve body 15 by fastening screws 16, and can be disassembled separately. The upper sealing cover 14 and the sealing gland 13 are extended through the connecting rod 12, and the opening of the valve bladder 17 can be adjusted by adjusting the connecting rod 12. . The spool 17 of this valve is fixed in the inner cavity of the valve body 15 with fastening screws 16, and the extension connecting rod 12 is used to adjust the opening of the valve. There is an upper sealing cover 14 on it that is tightly sealed with the valve body 15 by threads. Utilize the sealing gland 13 and the V-shaped rubber ring t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com