Gas dilutor

A diluter, gas technology, applied in the fields of gas and gas/vapor mixing, chemical instruments and methods, dissolution, etc., can solve the problems of inability to provide on-site gas distribution, inability to dilute gas, and reduce gas accuracy, and achieve light weight and dilution. Wide concentration range, compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

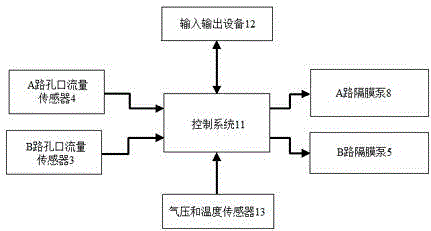

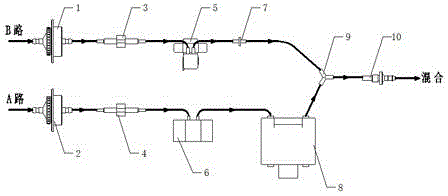

[0013] Such as figure 1 , 2 A gas diluter shown in the figure includes: A-way gas inlet 2, A-way orifice flow sensor 4, A-way gas capacity 6, A-way diaphragm pump 8, and B-way gas inlets 1, B Road orifice flow sensor 3, B-way diaphragm pump 5, B-way check valve 7, tee 9 connected to A-way diaphragm pump 8, B-way check valve 7, mixed gas outlet connected to the outlet of tee 9 10, and control system 11, input and output equipment 12, air pressure and temperature sensor 13; Described control system 11 connects A road orifice flow sensor 4, B road orifice flow sensor 3, A road diaphragm pump 8, B road diaphragm pump 5. Input and output devices 12, air pressure and temperature sensors 13.

[0014] Further, a filter membrane is installed inside the B-path gas inlet 1 .

[0015] Further, the A-way orifice flow sensor 4 and the B-way orifice flow sensor 3 are all electronic orifice flow sensors.

[0016] The control system 11 is mainly used to receive the flow signals of the A-wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com