Reed type self-adaptive flow-constant device

A constant flow and self-adaptive technology, applied to safety valves, engine components, balance valves, etc., can solve the problems of untimely manual valve adjustment, inaccurate flow, etc. reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

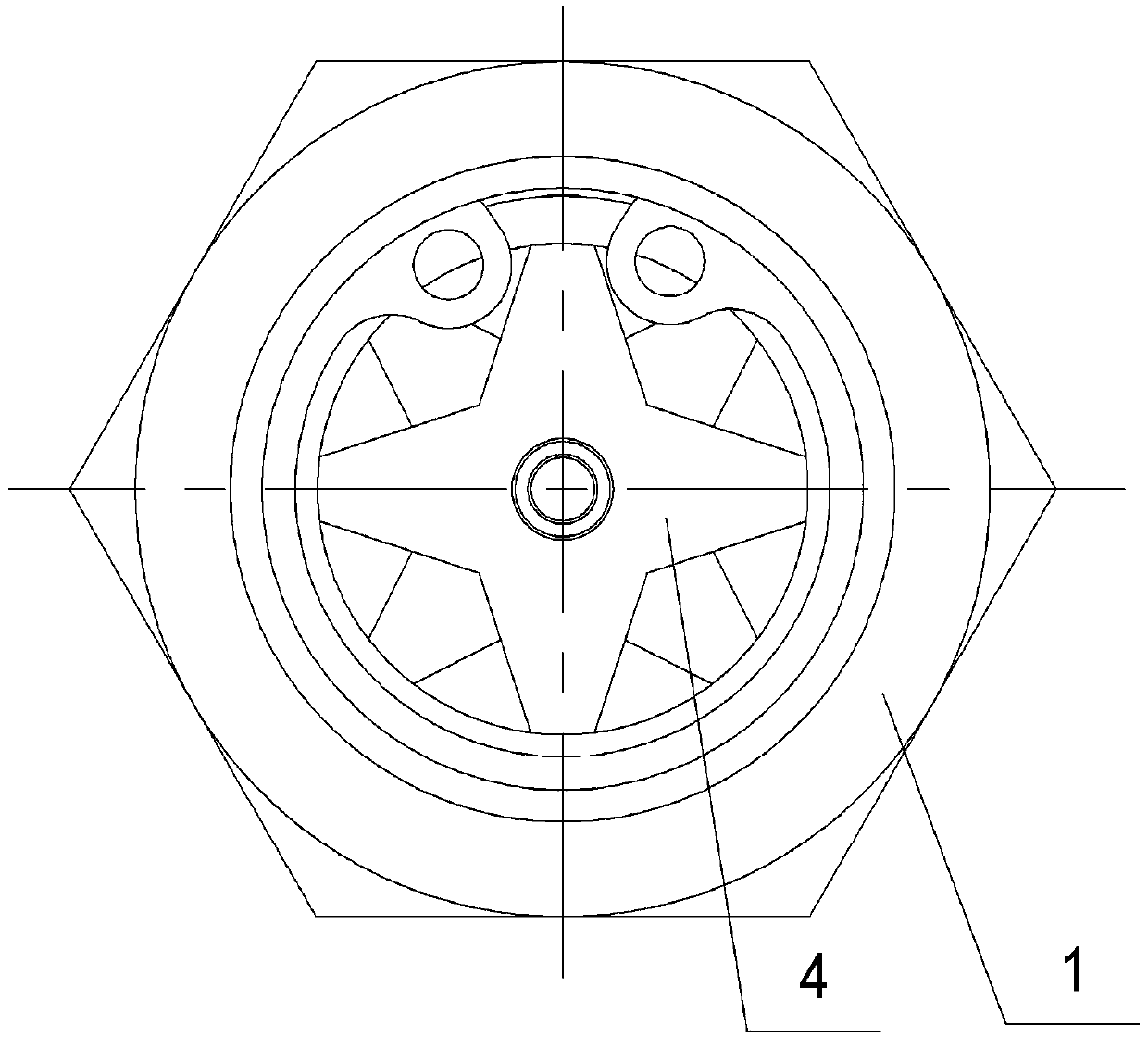

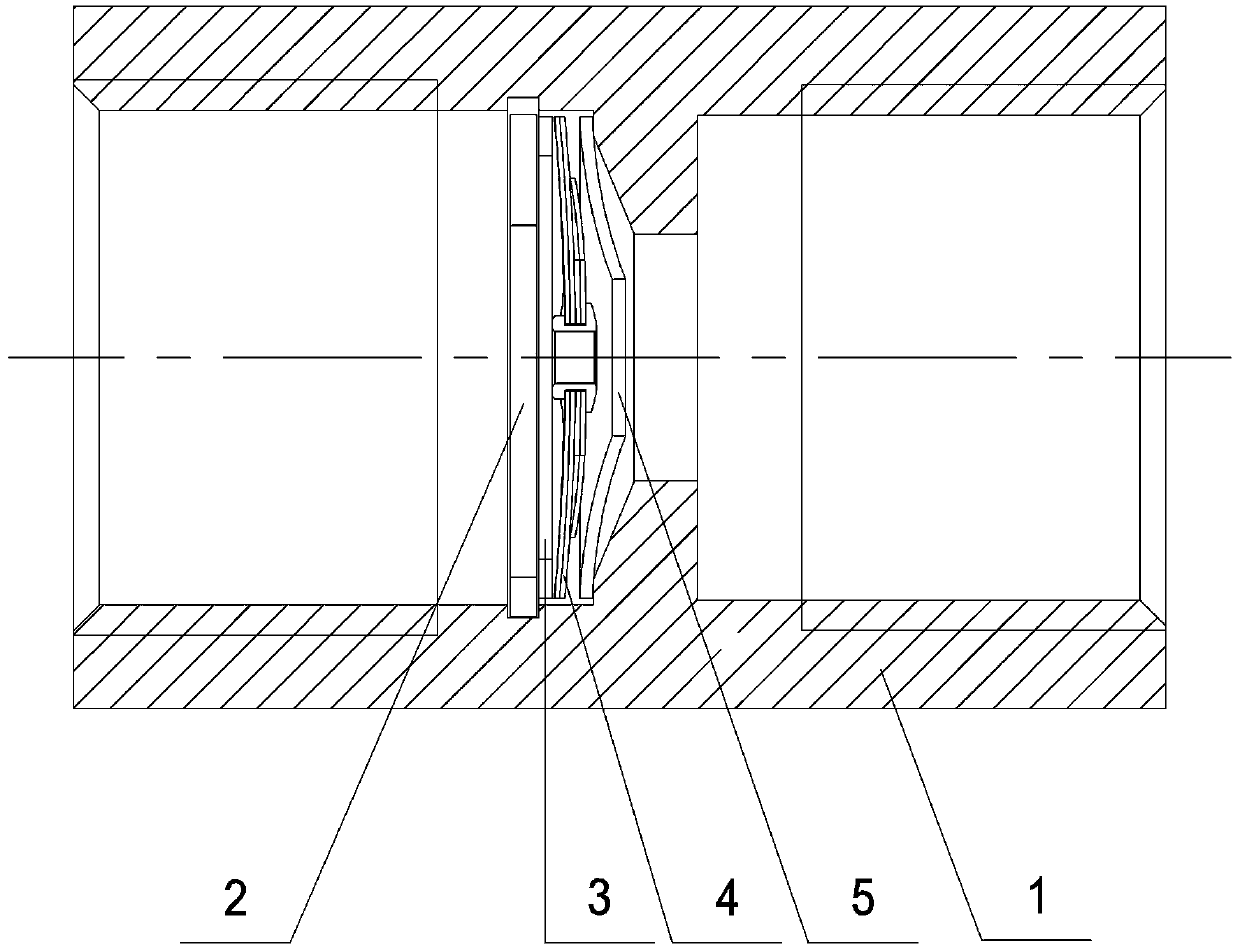

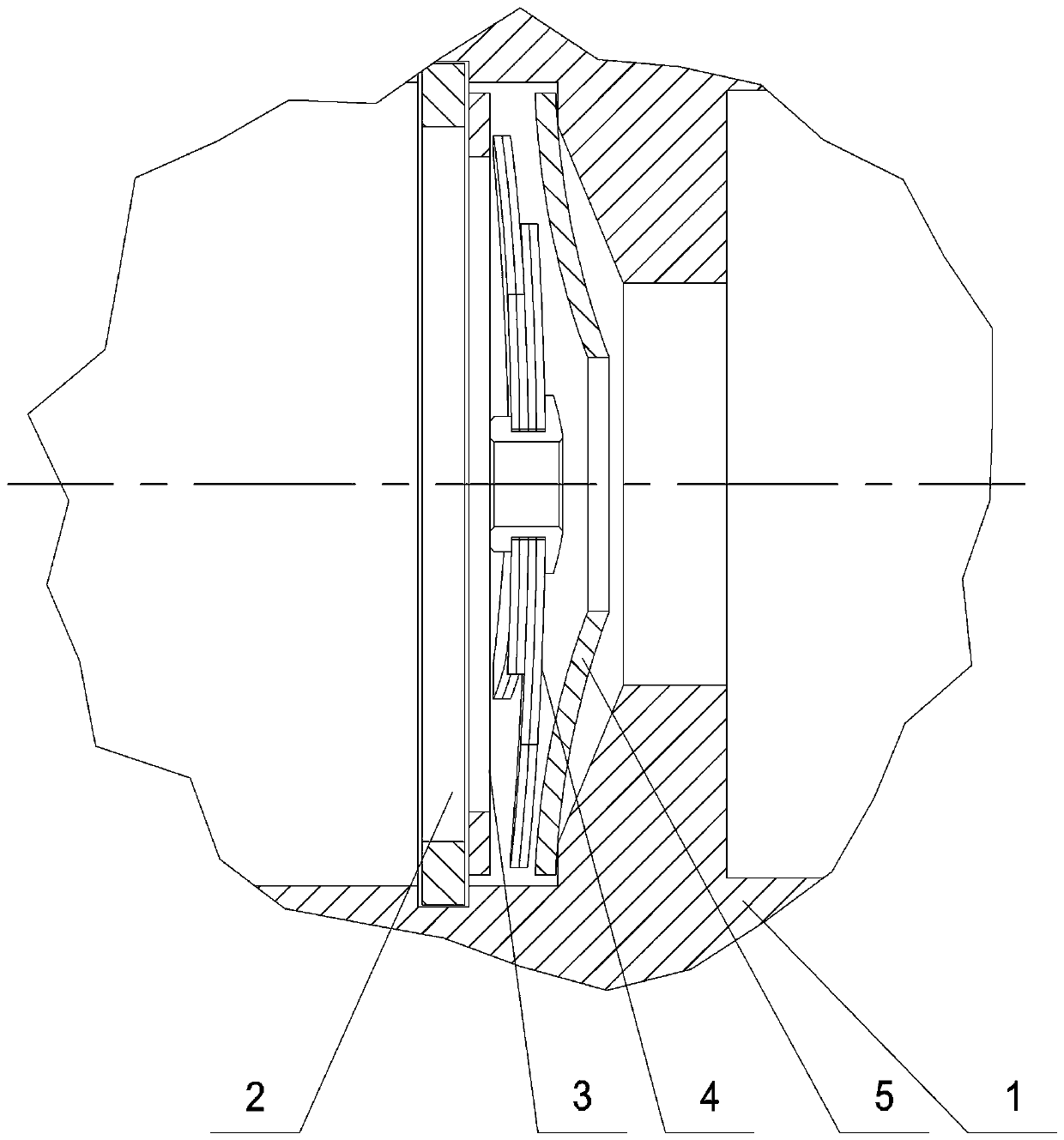

[0017] According to attached Figure 1~5 , the present invention is a reed-type self-adaptive flow constant, comprising a housing 1 provided with a diameter-reducing section of the inner chamber, a circlip 2 sequentially arranged at the diameter-reducing section of the inner chamber in the middle section of the housing 1, and an adjusting ring 3. Combined reed assembly 4 and arc-shaped conical flow plate 5 . The inner cavity reducing section is a tapered hole arranged in the middle section of the housing 1 and the diameter of its large end matches the size of the combined reed assembly 4 and the arc-shaped conical flow plate 5. The arc The tapered direction of the tapered baffle 5 is consistent with the direction of the tapered hole of the diameter reducing section of the inner cavity. The combined reed assembly 4 passes through the adjustment ring 3 and is set at the position of the large end of the inner cavity diameter reducing section of the housing 1 through the elastic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Taper | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com