Patents

Literature

424results about How to "Assembly accuracy is low" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

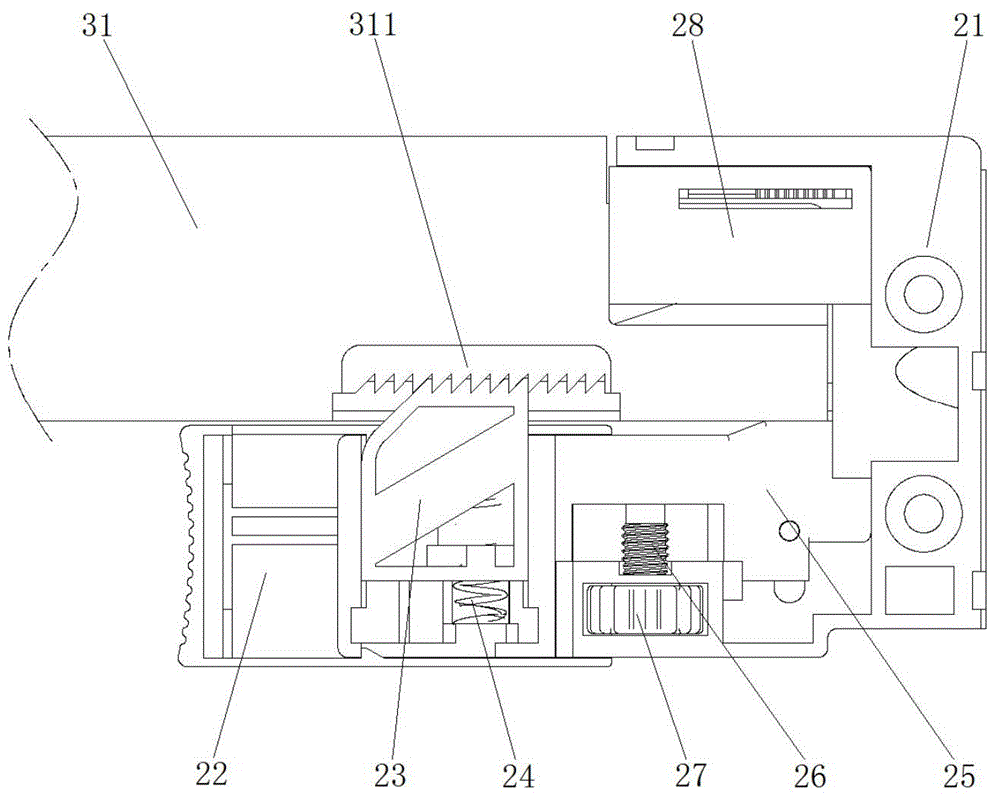

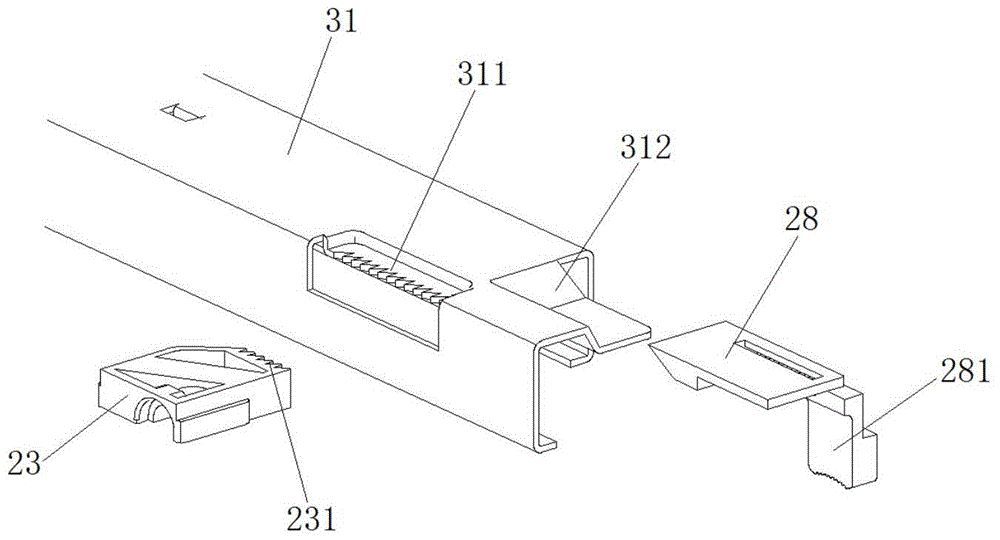

Electric pressure cooker

PendingCN108245000AManufacturing precision requirements are lowAssembly accuracy is lowPressure-cookersCooked foodExhaust pipe

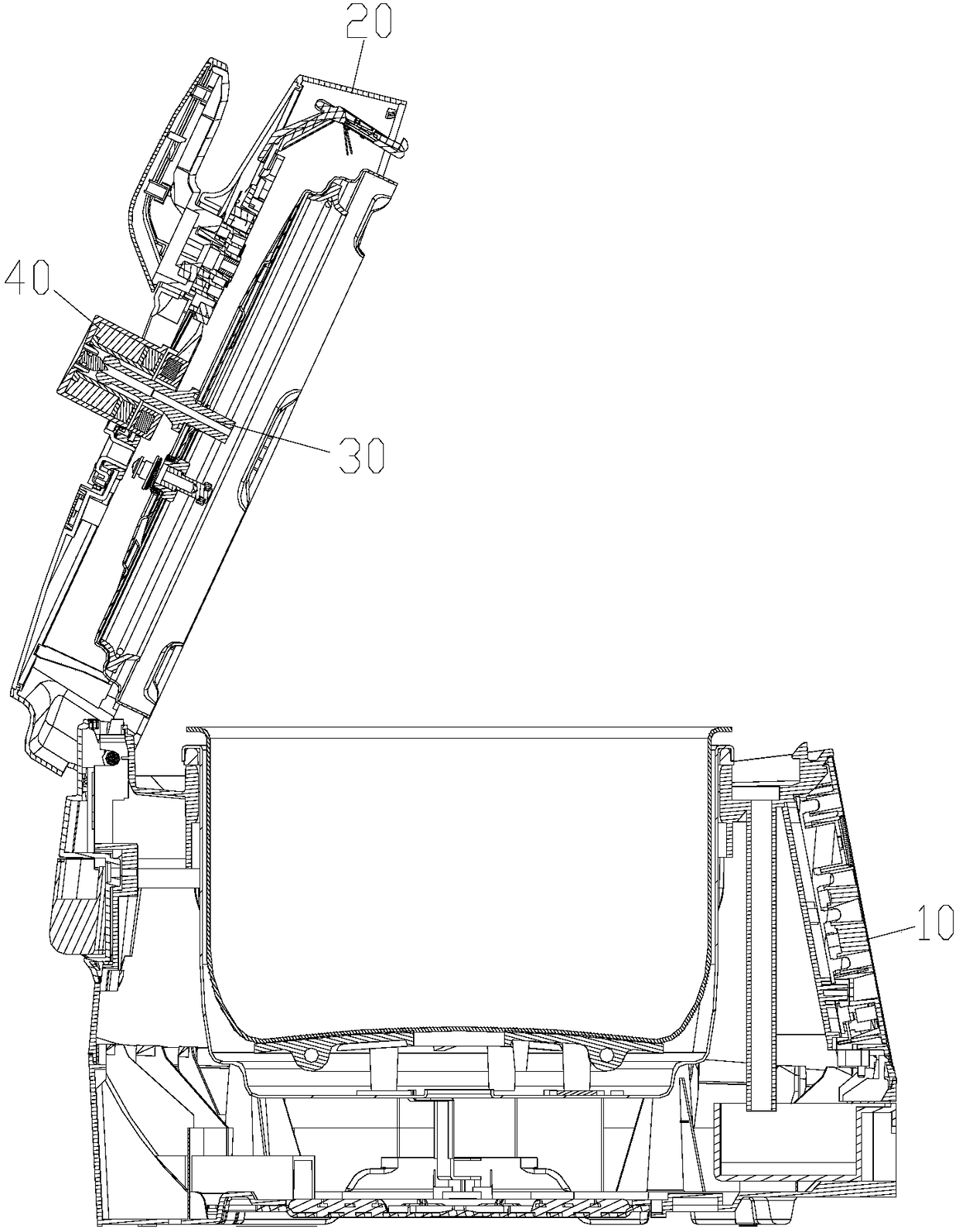

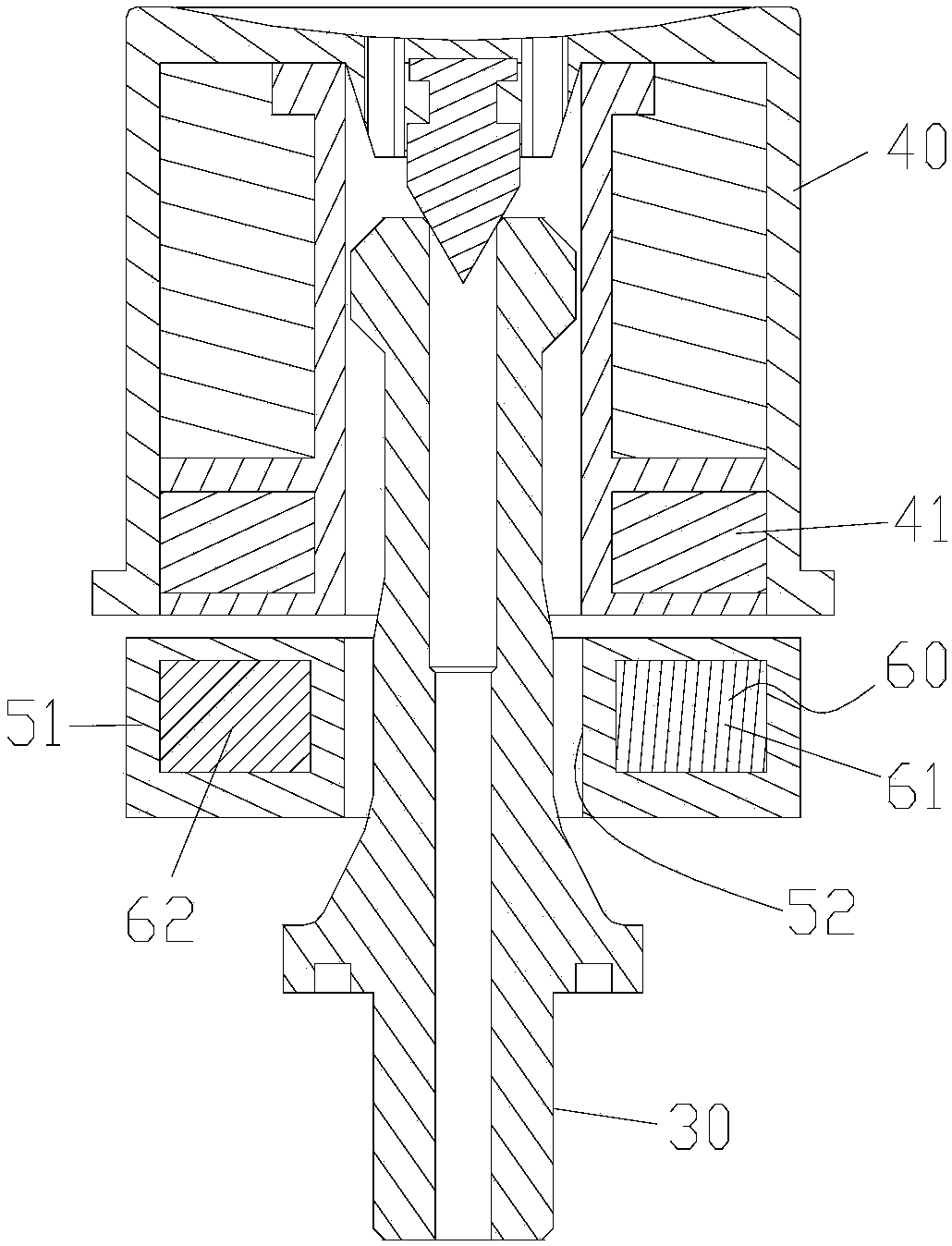

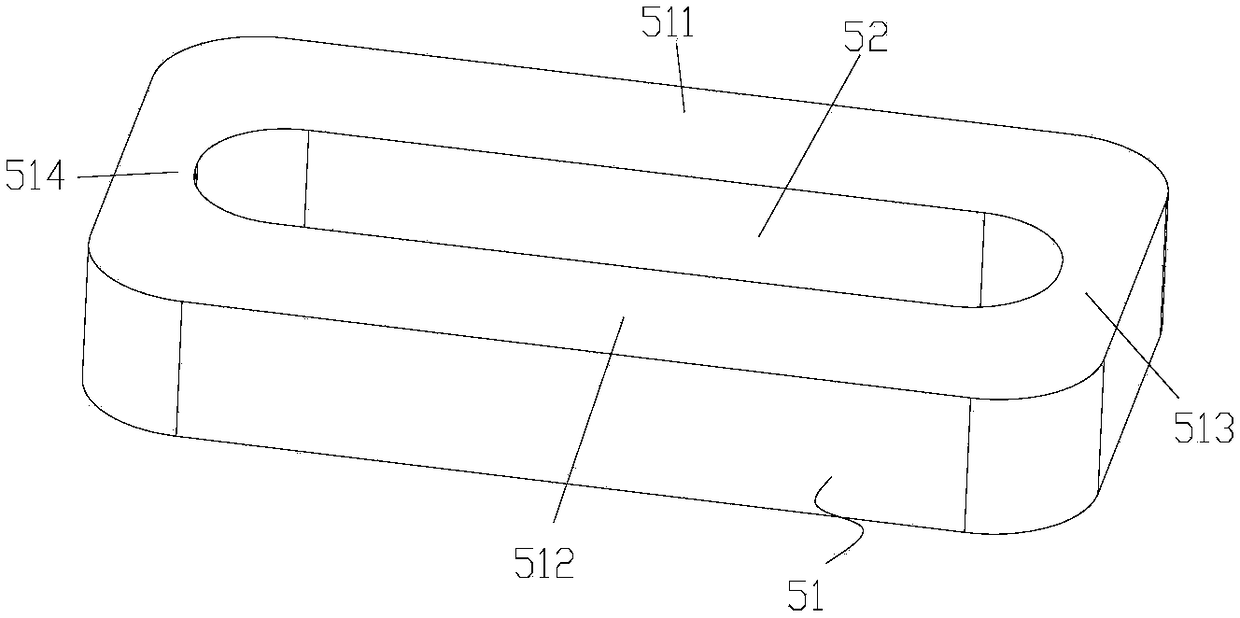

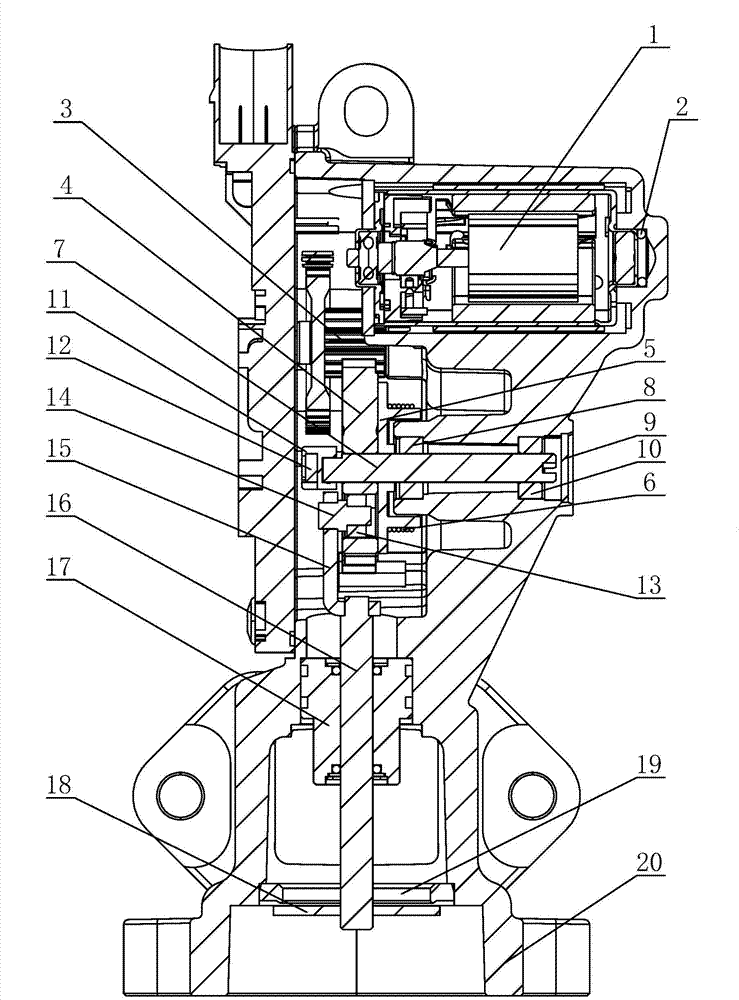

The invention provides an electric pressure cooker. The electric pressure cooker comprises a cooker body, a cooker lid, an exhaust pipe, a relief valve and a switching device; the cooker body is usedfor containing cooked food, the cooker lid is arranged on the cooker body, the exhaust pipe is arranged on the cooker lid and communicated with the cooker body, the relief valve is arranged on the exhaust pipe, and a first magnetic part is arranged on the relief valve; the switching device is arranged in the cooker lid and movably arranged relative to the relief valve, multiple second magnetic parts different in magnetism are arranged on the switching mechanism, the second magnetic parts and the first magnetic part cooperate with each other and apply magnetic force to the relief valve, the switching device has multiple switching positions, and when the switching device moves between the different switching positions, the magnetic force applied to the relief valve is changed. According to the technical scheme, the problem that in the prior art, a magnetic drive structure of the relief valve of the electric pressure cooker needs high manufacturing precision and installation precision issolved.

Owner:ZHEJIANG SHAOXING SUPOR DOMESTIC ELECTRICAL APPLIANCE CO LTD

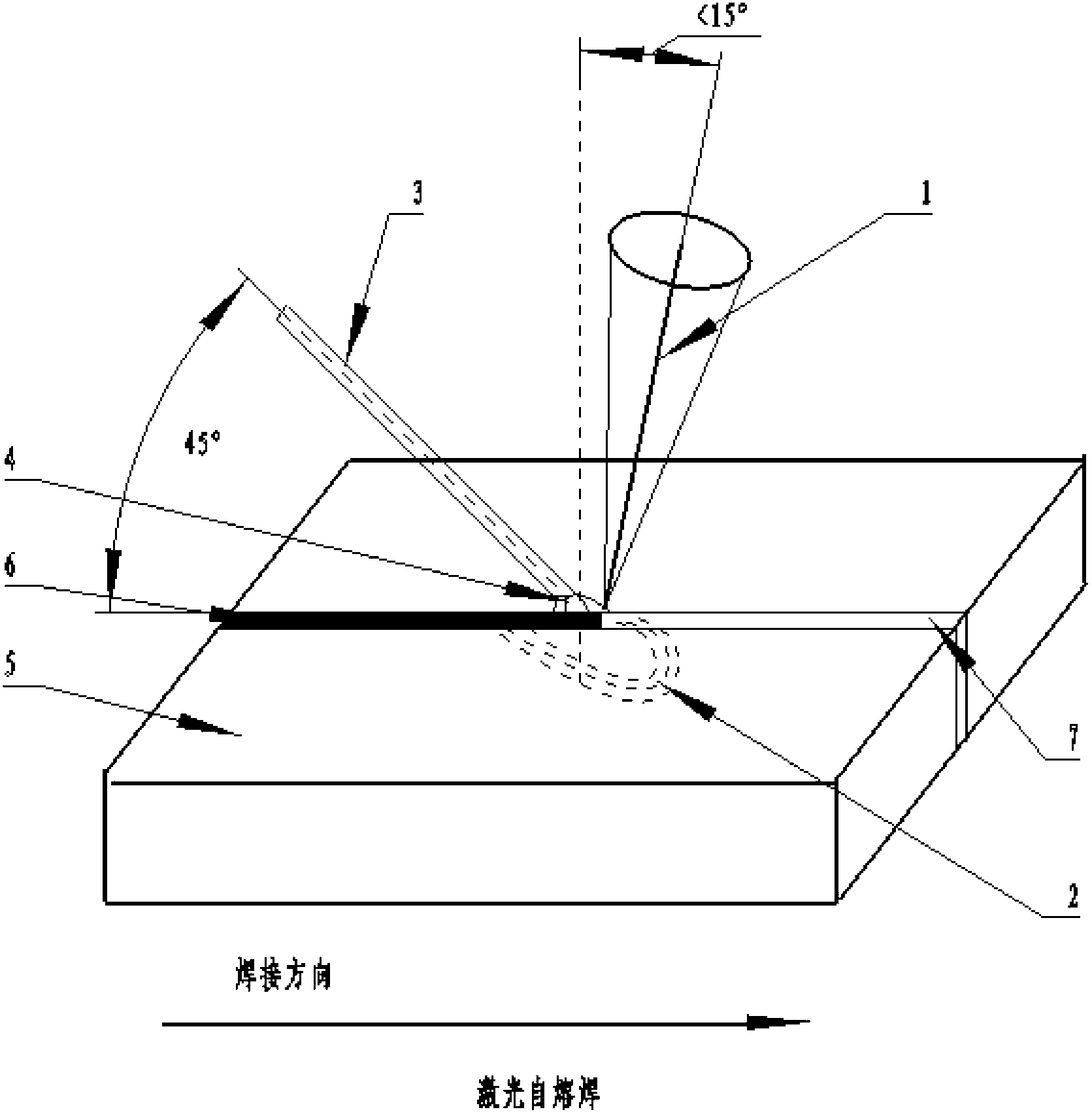

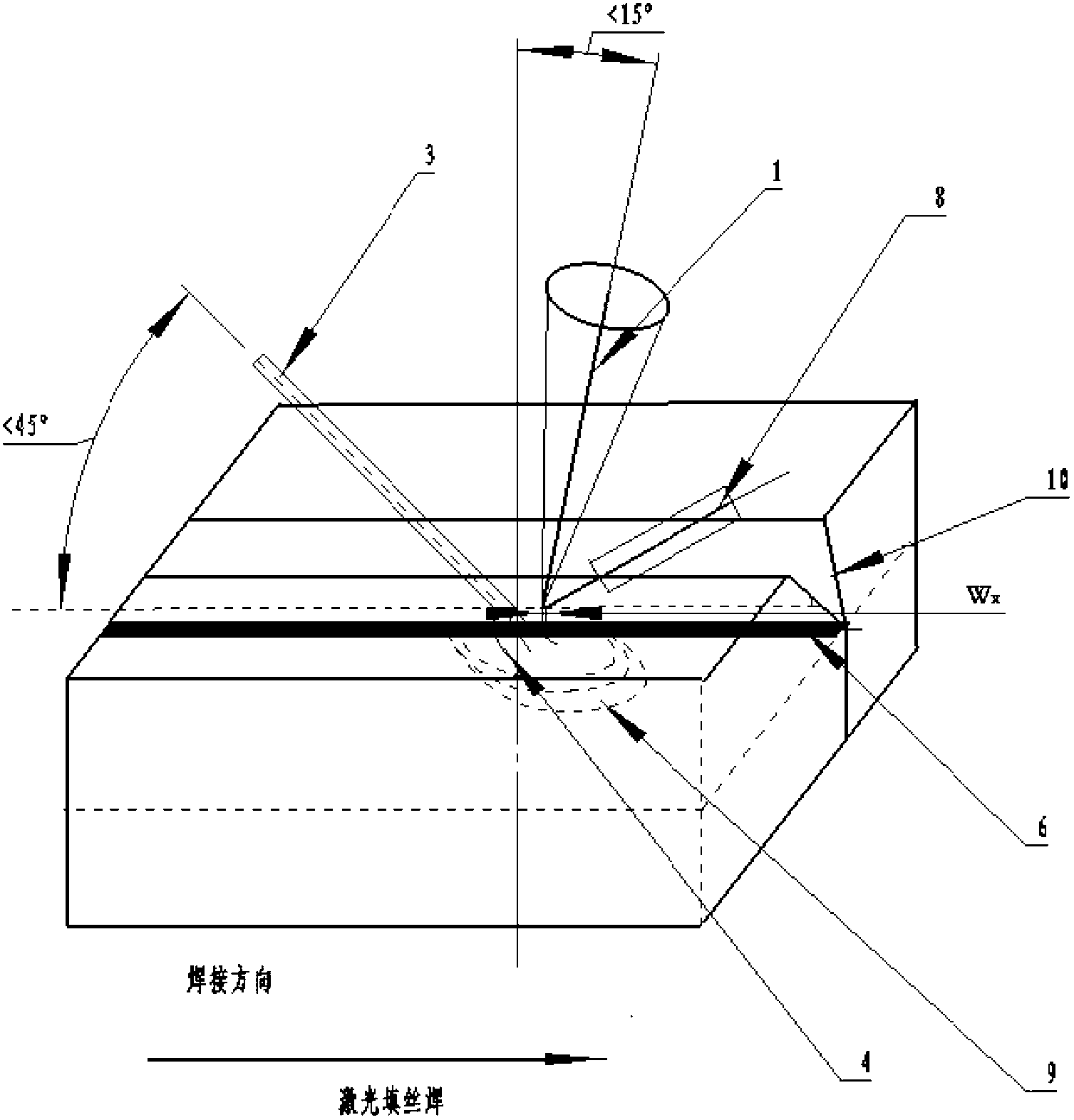

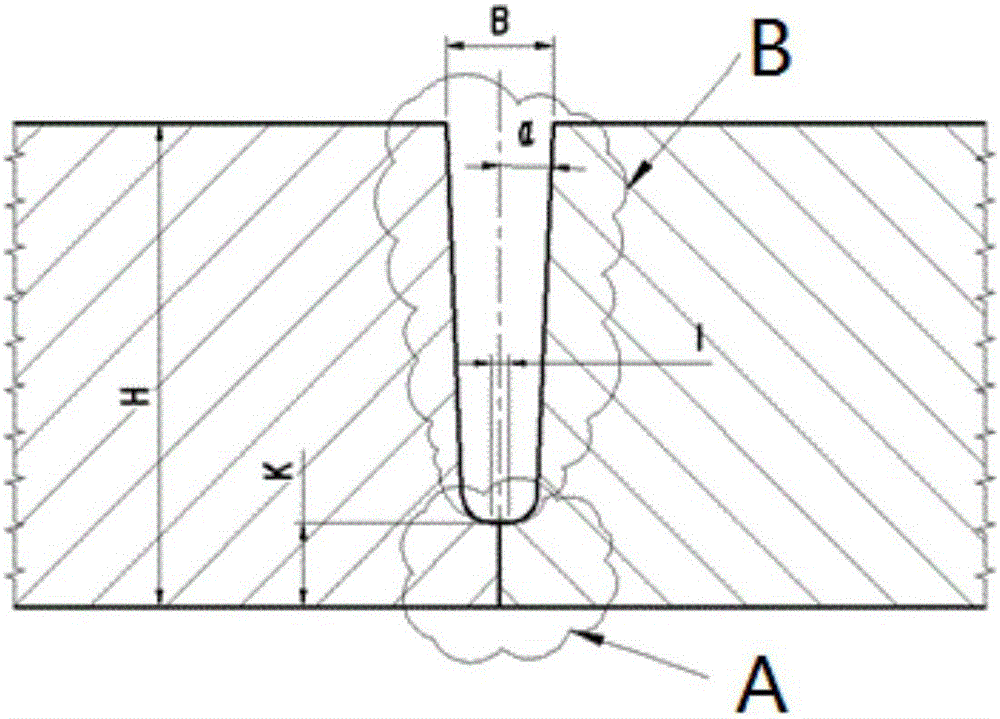

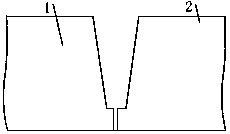

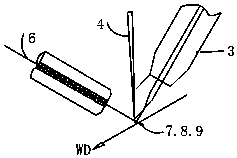

Narrow gap multi-pass laser welding method for thick plate

InactiveCN103008895AReduce consumptionImprove welding productivityLaser beam welding apparatusWorkpiece edge portionsThick plateGas metal arc welding

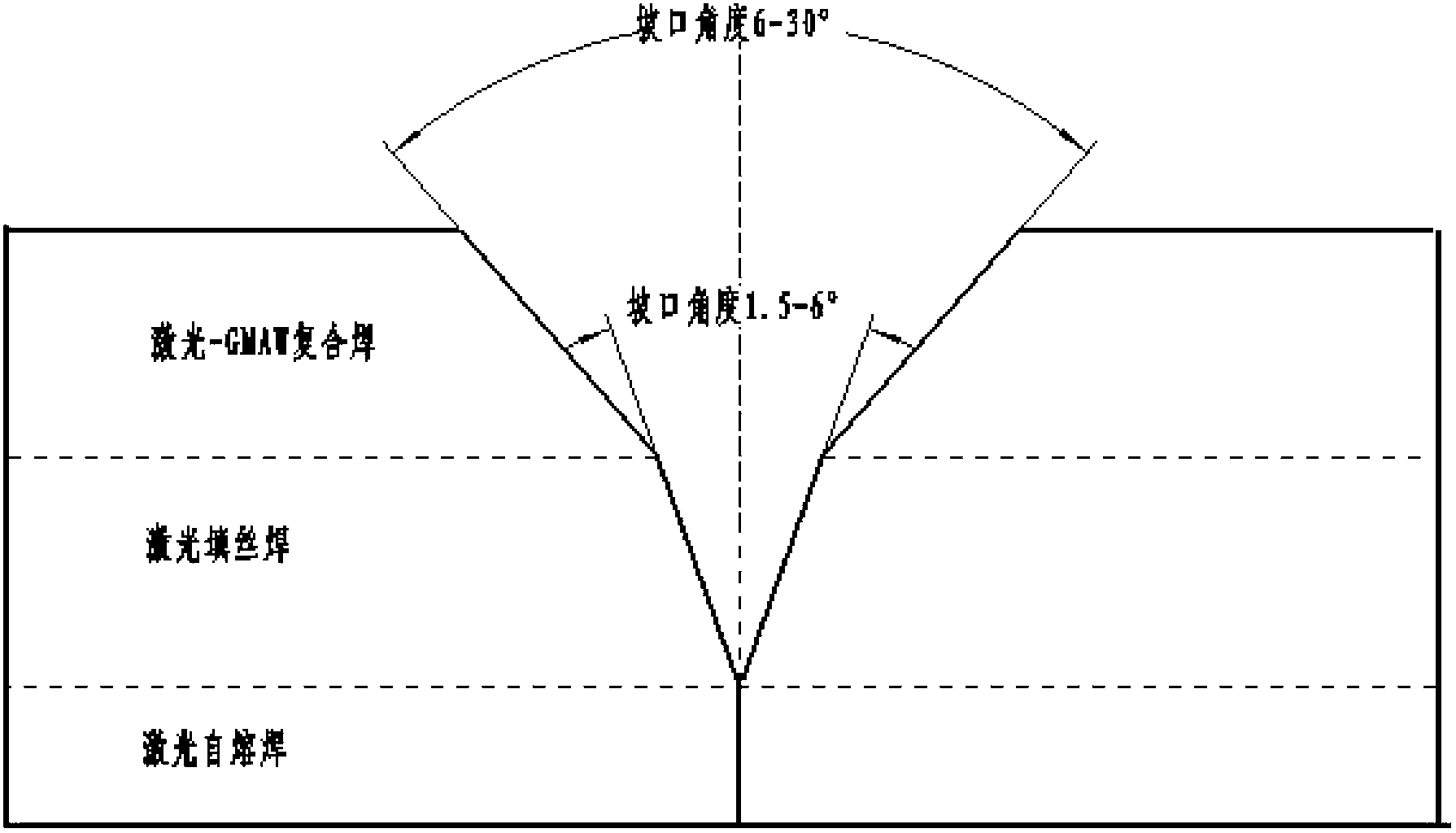

The invention discloses a laser welding method for a thick plate. A gap is reserved on the thick plate or a divided edge with a blunted edge is performed, a laser autogenous welding is adopted at the welding bead part for welding a pass for bottoming, then, the laser wire filling welding is carried out, a welding wire and a laser beam maintain an included angle being 15 degrees to 75 degrees, the welding wire extends into the divided edge gap from the front of the laser beam, when the filling wire welding cannot fully fill the divided edge gap, the laser-GMAW (gas metal arc welding) composite welding is finally carried out, and the welding of the thick plate is completed. The preserved gap value is respectively smaller than or equal to 0.5mm, the width of the performed welding bead used for the wire filling welding is smaller than or equal to 2.5mm, and the width of the performed welding bead used for the composite welding is smaller than or equal to 10mm. The laser welding method has the advantages that the problem of high-efficiency and high-quality welding of the thick plate is solved, so high-quality and efficient thick plate welding joints with small welding deformation and high gap bridging capability are obtained.

Owner:HUAZHONG UNIV OF SCI & TECH

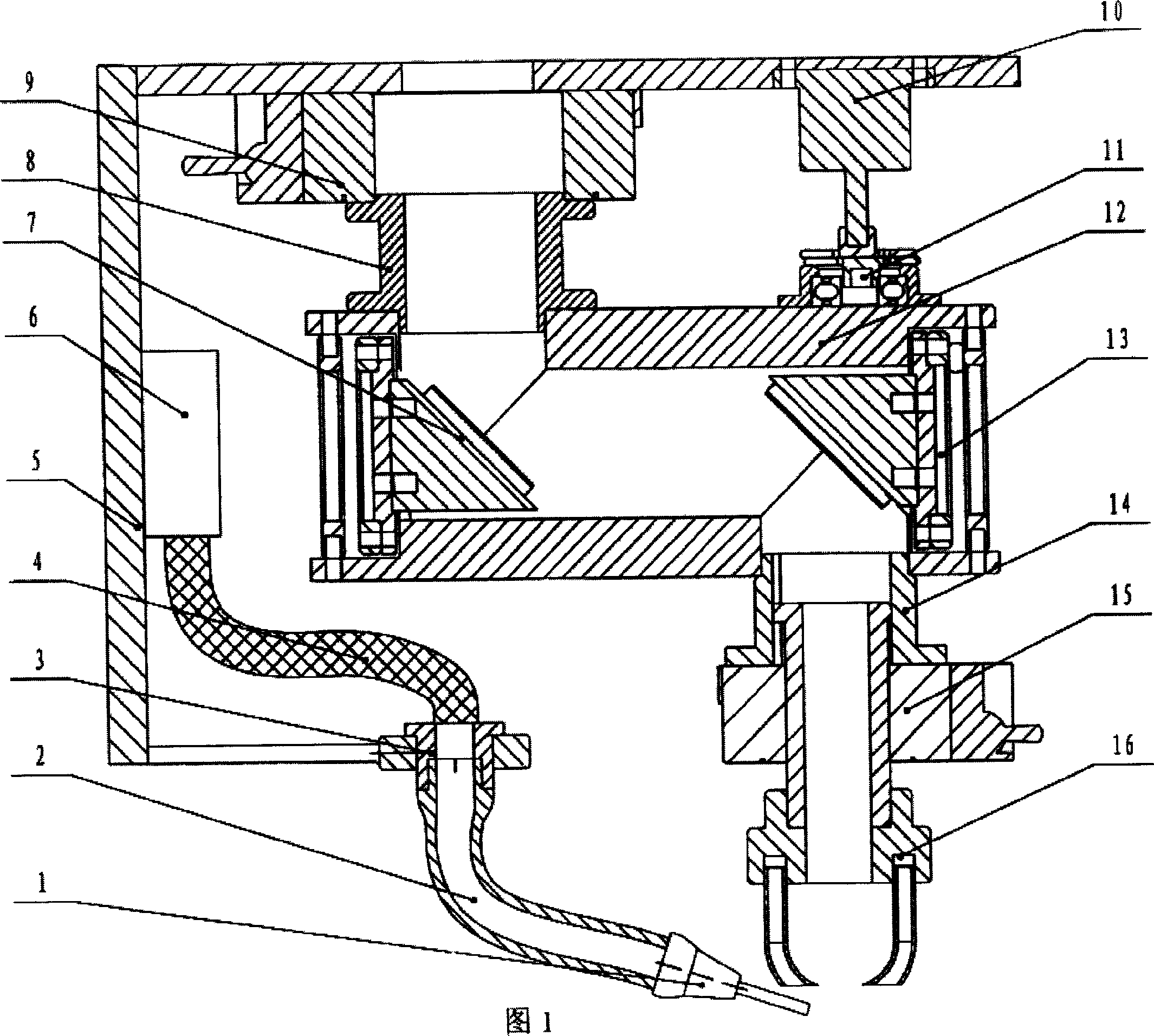

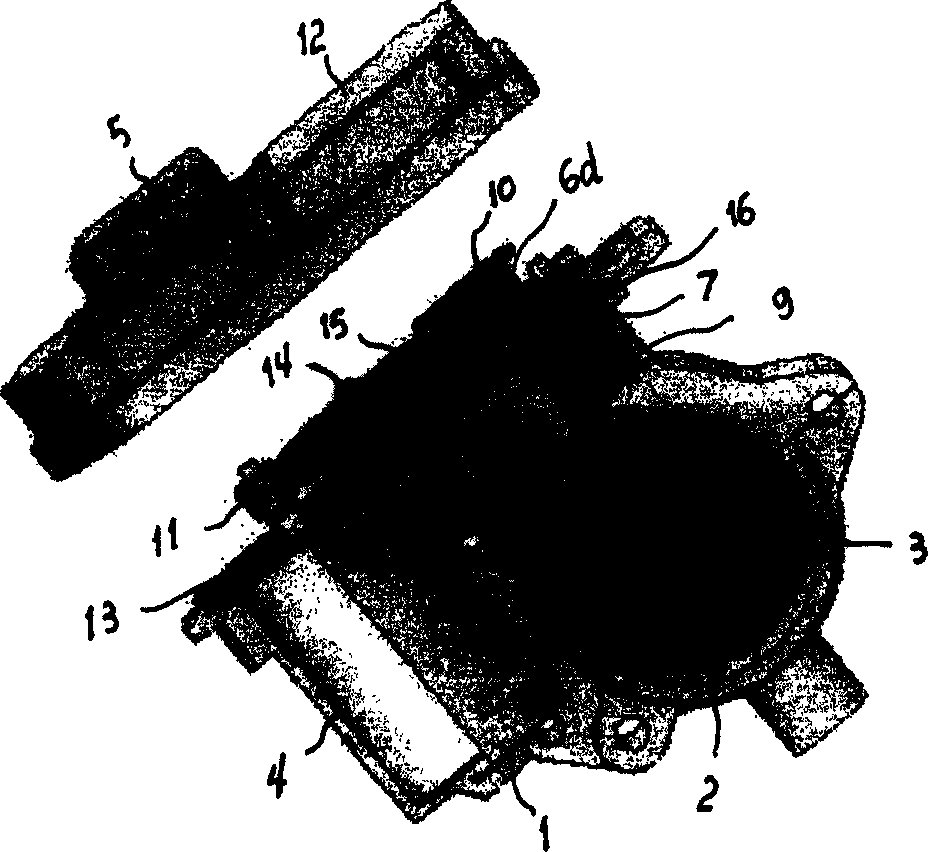

Rotary double focus laser-MIG electric arc composite welding head

InactiveCN1586788APromote absorptionImproving Laser Welding Process PerformanceArc welding apparatusLaser beam welding apparatusWide areaLaser

The composite rotary double focus laser-MIG electric arc welding head includes mainly two parts, the rotary double focus laser welding head and the MIG electric arc welding wire feeding welding gun, connected via a connecting plate. It has welding wire feeder fixed on the connecting plate, welding wire feeding hose connected to the feeder, conducting nozzle and goose neck for welding wire to pass through; protecting nozzle in the end of the goose neck; and rotating table with reflecting cavity, regulating frame, reflector, connecting barrel and welding laser head. The present invention combines the rotary double focus laser welding and the MIG electric arc welding, and has greatly raised welding performance and lowered assembling precision requirement for even wide application.

Owner:BEIHANG UNIV +1

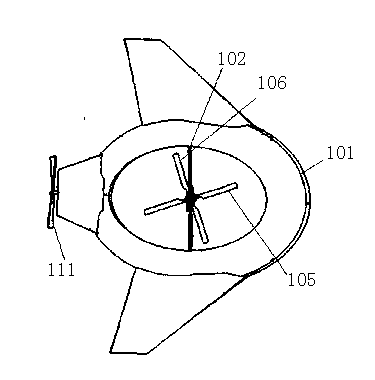

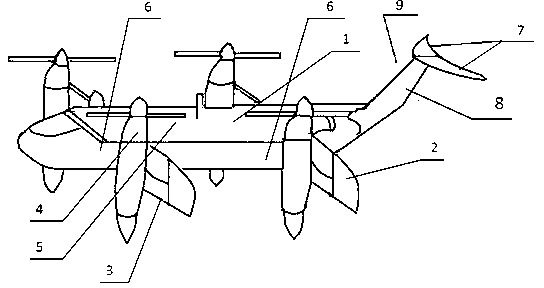

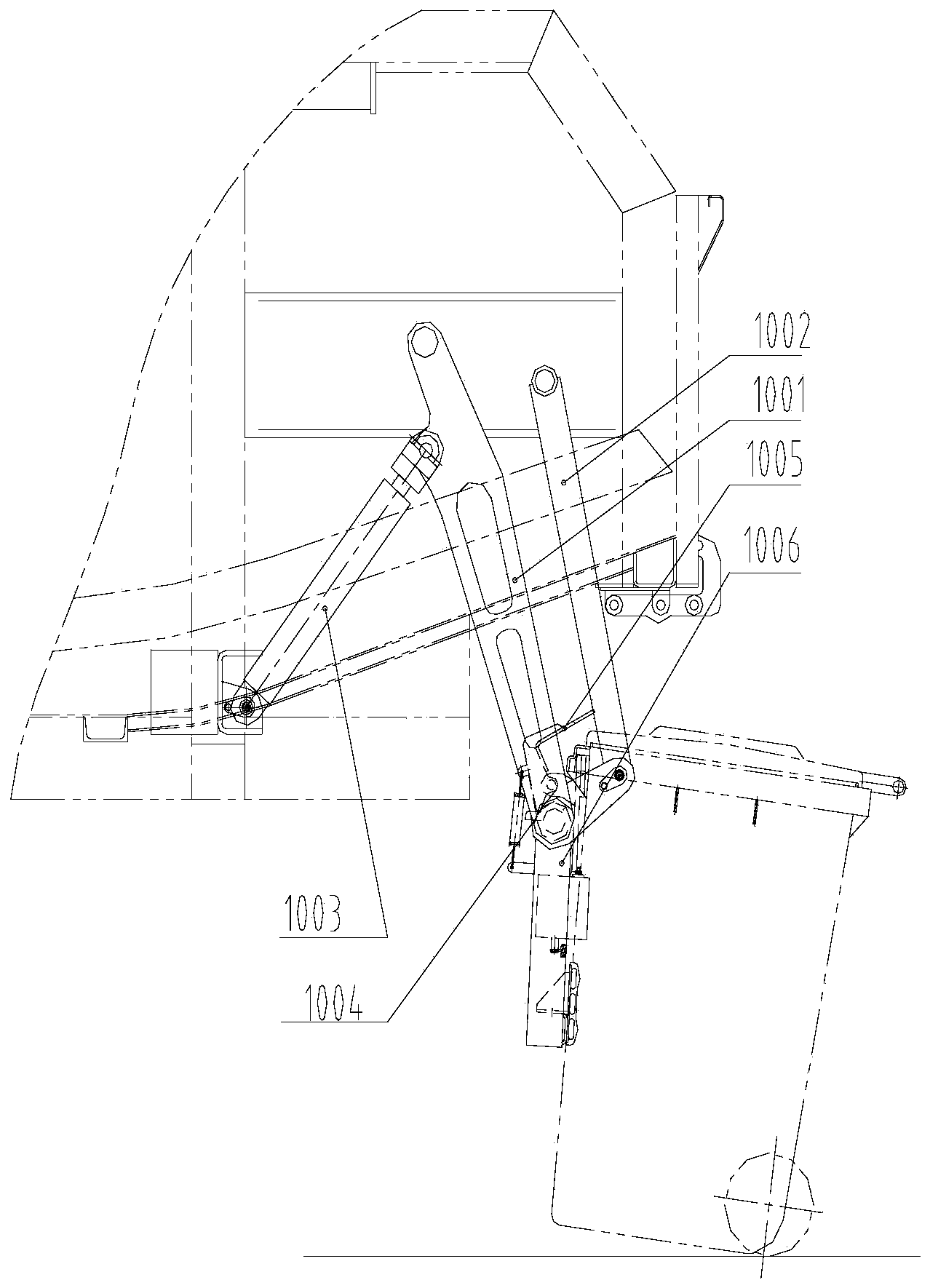

Inclined fixed wing unmanned plane

InactiveCN103129737AImprove power utilization efficiencyImprove aerodynamic efficiencyRotocraftCruise speedVertical take off and landing

The invention discloses an inclined fixed wing unmanned plane. The inclined fixed wing unmanned plane comprises a plane body and a wing inclined mechanism which can incline the wings, wherein the two sides of the plane body are provided with at least one pair of wings, and the tail of the plane body is also provided with a tail wing; and each wing is fixedly provided with a power device, each power device is connected with a screw propeller, the wings and the power devices are fixedly arranged together and can simultaneously move, and the rotation surfaces of the screw propellers are perpendicular to the horizontal planes of the wings all the time. The inclined fixed wing unmanned plane adopting the technical scheme can vertically take off and land and can realize high the cruising speed and power utilization efficiency and reasonable structure of a fixed wing plane; as the preferred technical scheme, the wings are both provided with subsidiary wings which are controlled by the wing inclined mechanism, and the power devices are all fixedly arranged on the middle parts of the wings; and the wings have enough rigidity and intensity, the wings are prevented from deforming because the power devices are fixedly arranged, and the localization of the wings is exact in revolution and fixation.

Owner:南京傲翼飞控智能科技有限公司

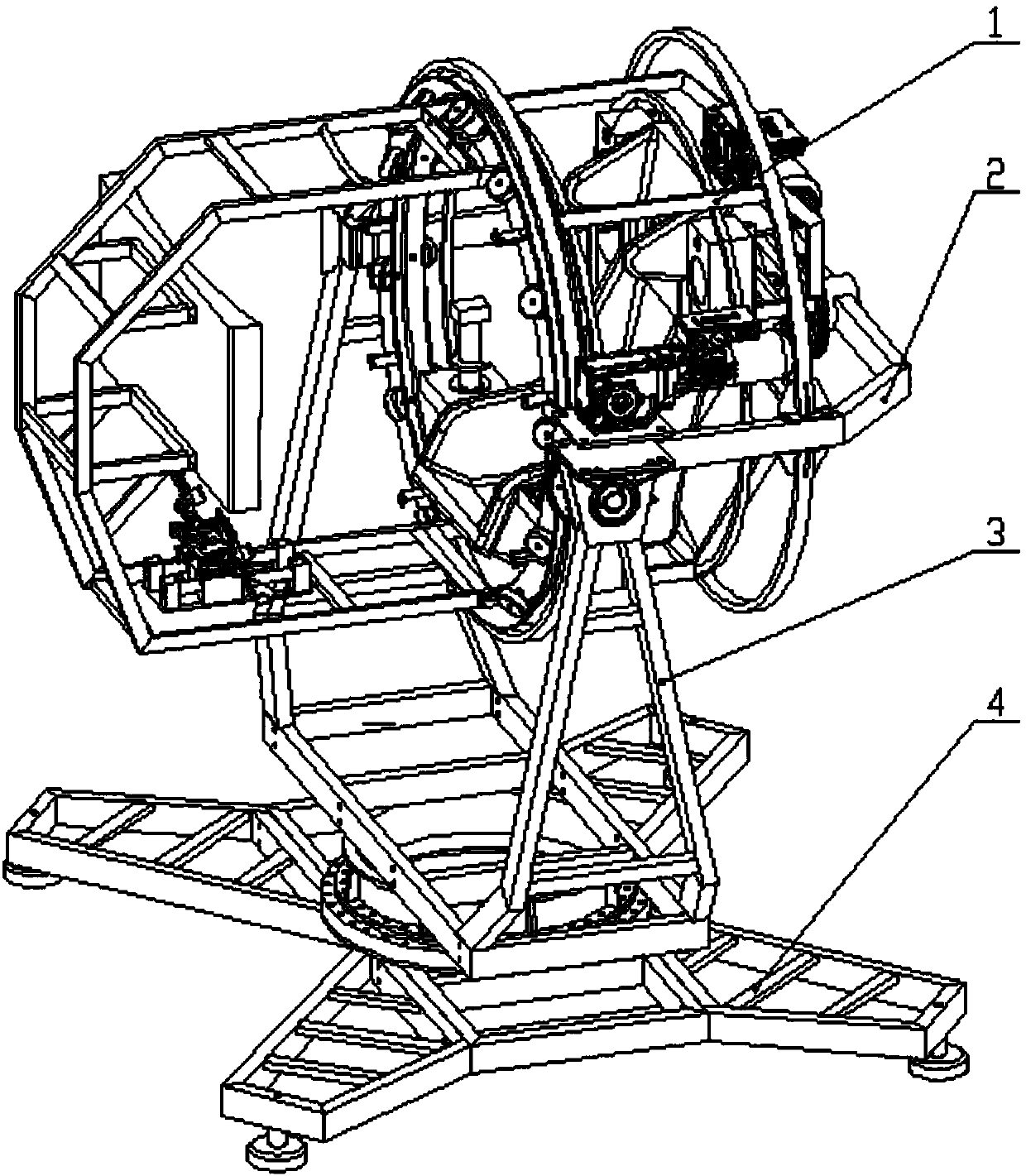

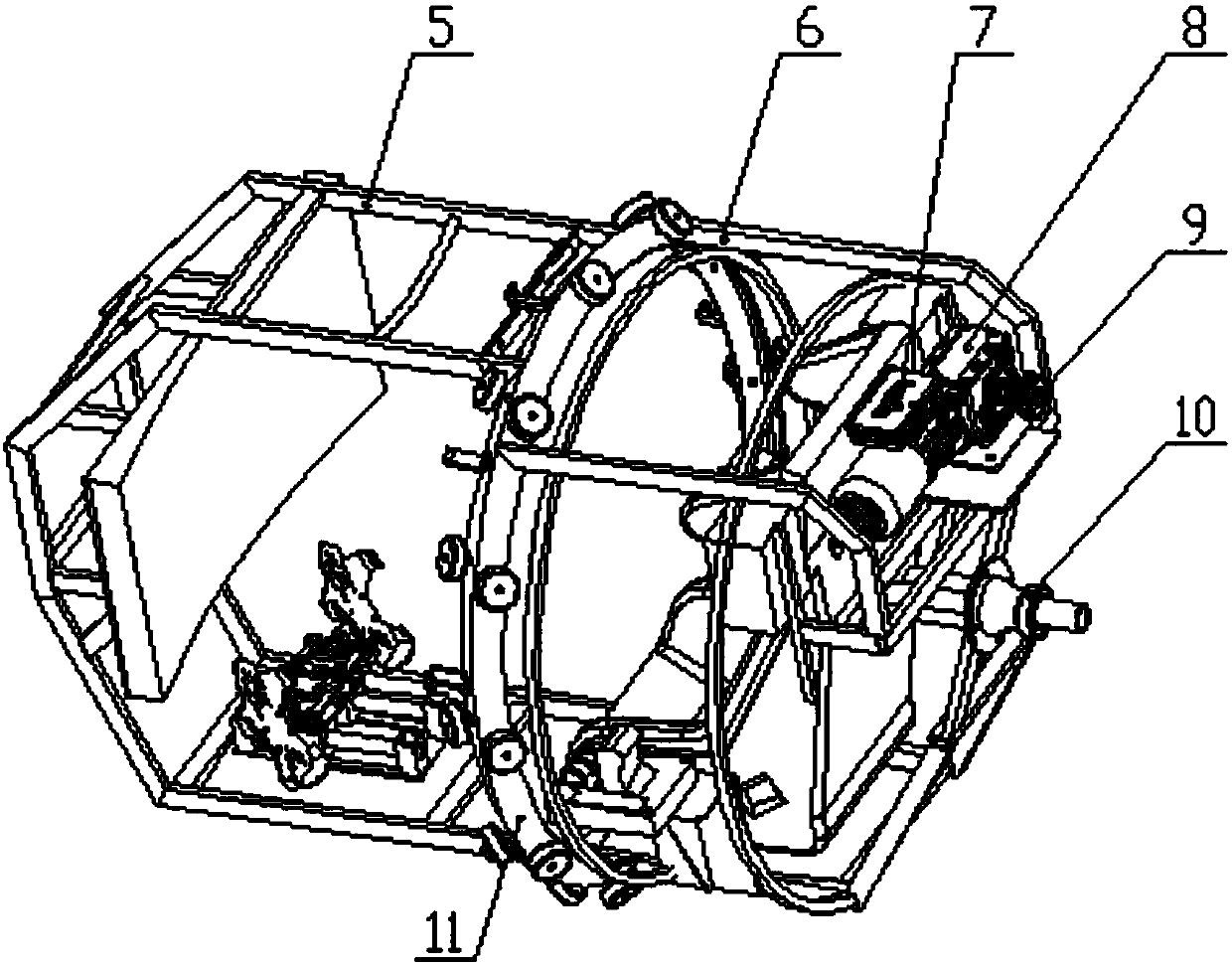

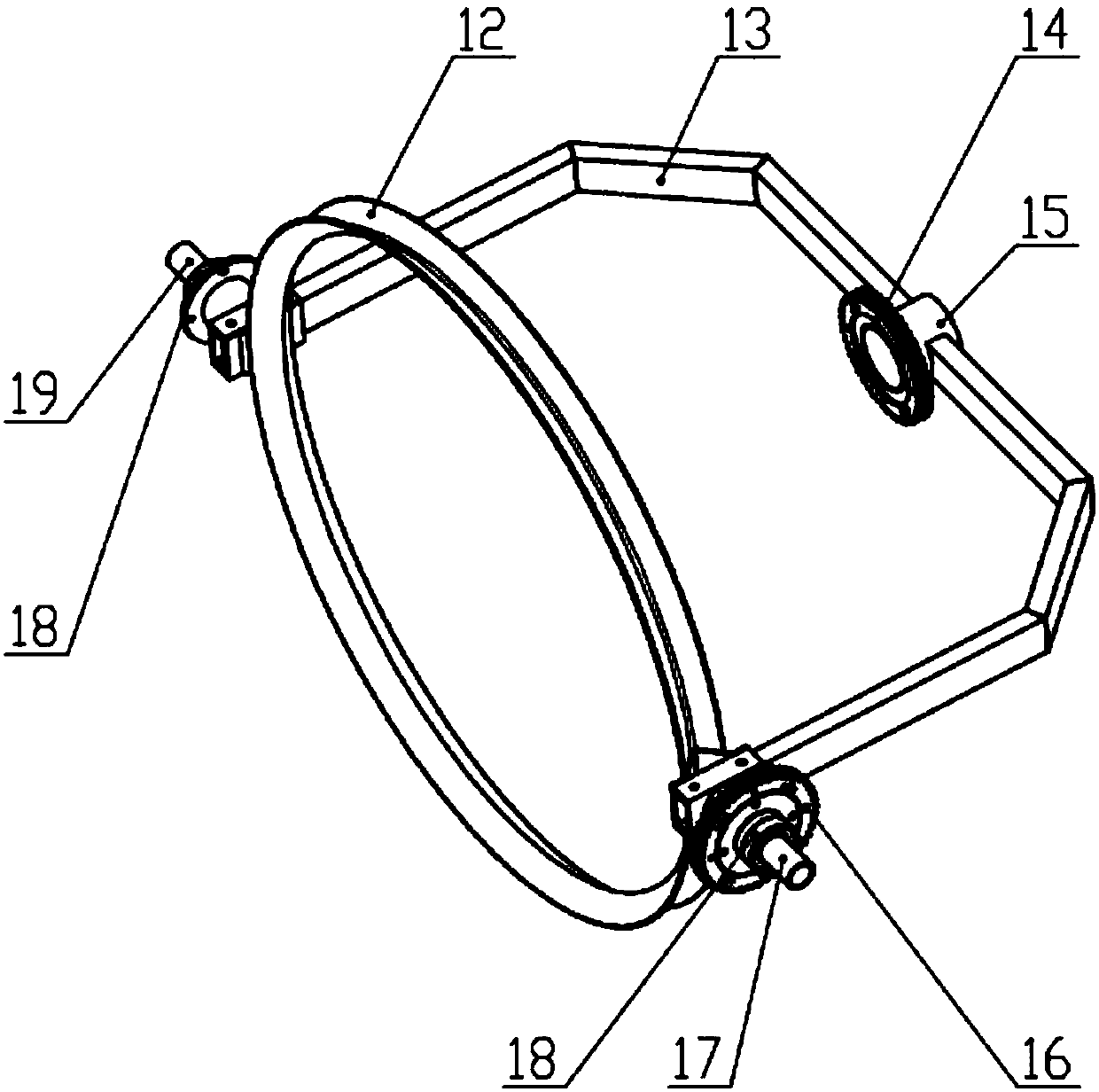

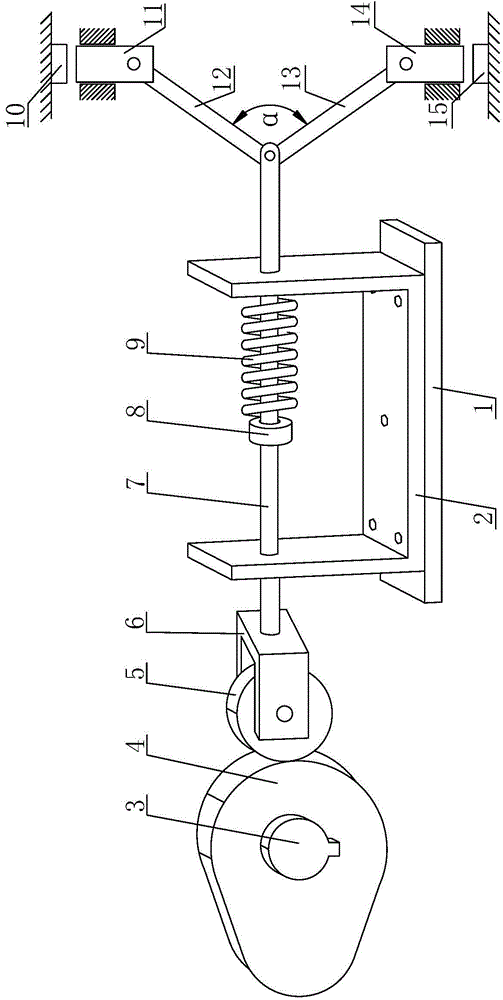

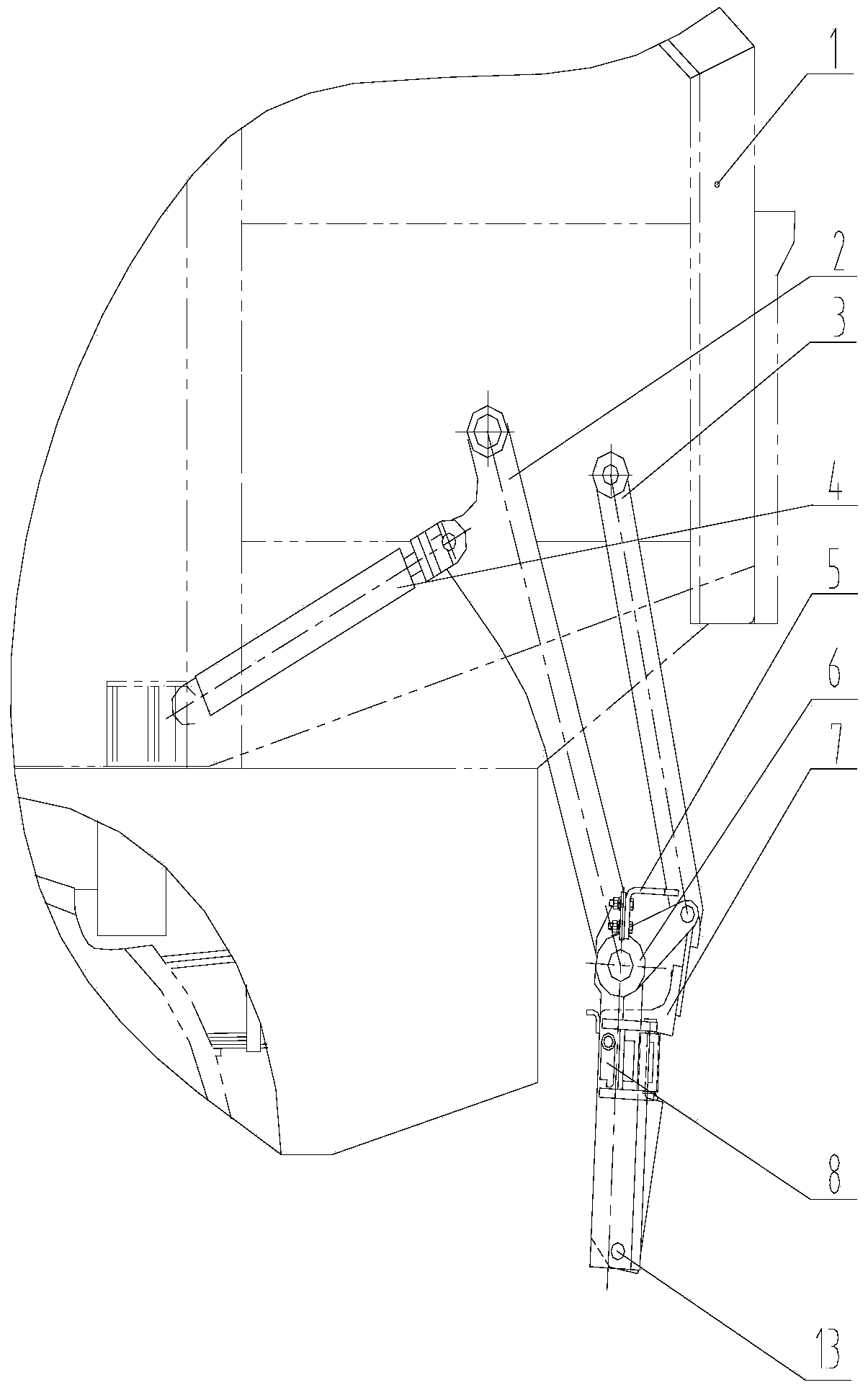

Three-axis simulation flight simulator executing mechanism

PendingCN108022473AImprove qualityImprove efficiencyCosmonautic condition simulationsSimulatorsReduction driveThree degrees of freedom

The invention discloses a three-axis simulation flight simulator executing mechanism. The mechanism includes a roll platform, a pitch platform, a yaw platform, and a base platform. The roll platform includes a front cabin, a rear cabin, a roll motor, a roll reducer, a roll sprocket pair minor sprocket, a roll cylindrical bore self-aligning roller bearing, and a large-diameter rubber roller pivotalbearing inner ring. The pitch platform includes a pivotal bearing outer ring, a U-shaped frame, a roll sprocket pair large sprocket, a roll bearing seat, a pitch sprocket pair large sprocket, a pitchright shaft, a pitch cylindrical bore self-aligning roller bearing, and a pitch left shaft. The yaw platform includes a U-shaped bracket, a pitch bearing seat, a pitch motor, a pitch reducer, a pitchsprocket pair minor sprocket and a yaw bearing seat. The base platform includes a base, a base bracket, a large-diameter pivotal bearing, a yaw motor, a yaw reducer, an open internal gear meshing pair small gear, and support feet. The mechanism of the invention can simulate that a single person operates an aircraft to perform three degrees of freedom of roll, pitch and yaw movements to realize asimulated flight function.

Owner:AVIC SHANGHAI AERONAUTICAL MEASUREMENT CONTROLLING RES INST

Electronic throttle body

InactiveCN1710267APrecise control of air intakeReduce wearEngine controllersMachines/enginesLow speedElectric machine

This is about a kind of electronic door of saving gas, which belongs to the system of saving air in the engine in the car. It includes the saving gas body, valve chip of saving air, the axis of saving air, DC engine, gear structure for decreasing speed, location sensor and spring, one of whose side is fixed on the body of saving gas, the other side is fixed on the axis of saving gas door. there is also the structure of changing speed. The outside bolt is fixed on the body of saving gas and the inside one on the inside of changing bolt. The spring is fixed between them. In the invention the position is capable to change. The amount of inside gas can be controlled accurately in the low speed, and at the same time it cuts the precision of the production.

Owner:SICHUAN HONGGUANG AUTO MACHINERY ELECTRONICS

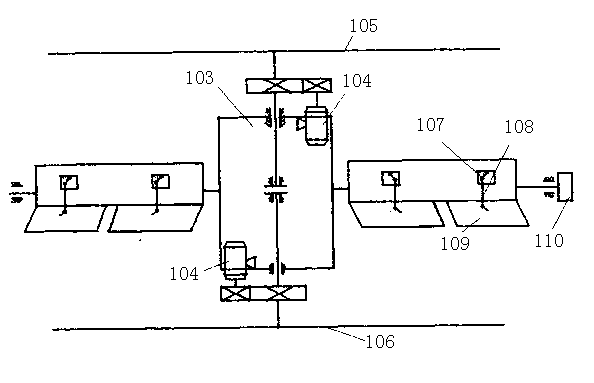

In-position gas analyzing system with in-position calibrating function

ActiveCN1740775AAssembly accuracy is lowSimple installation and debuggingColor/spectral properties measurementsGas pipelineEngineering

The gas analysis system includes light-emitting device, light-receiving device, signal analysis device, mechanical connection structure and measuring pipe. The light-emitting device and light-receiving device are mounted on the tested gas pipeline by means of mechanical connection structure. Said system also includes an additional pipe, a control device and a gas replacement device. Said additional pipe and measuring pipe are formed into a basically-closed pipeline which is isolated from tested gas. Said invention also provides the concrete structure of the gas replacement device.

Owner:FOCUSED PHOTONICS

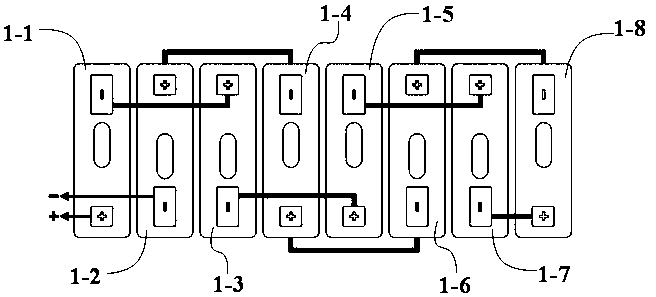

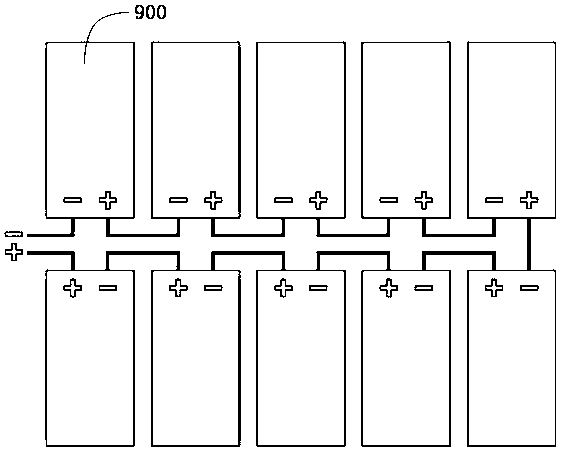

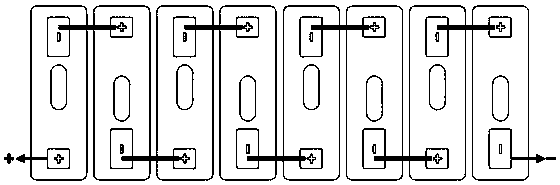

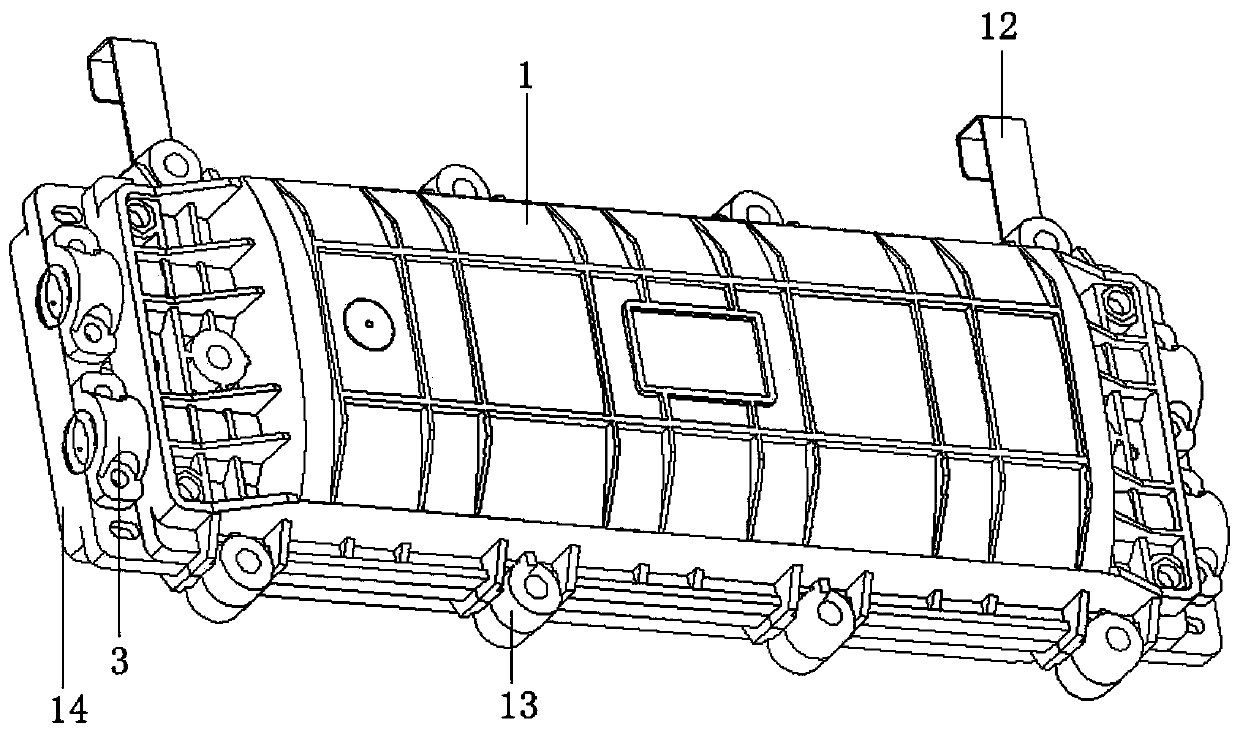

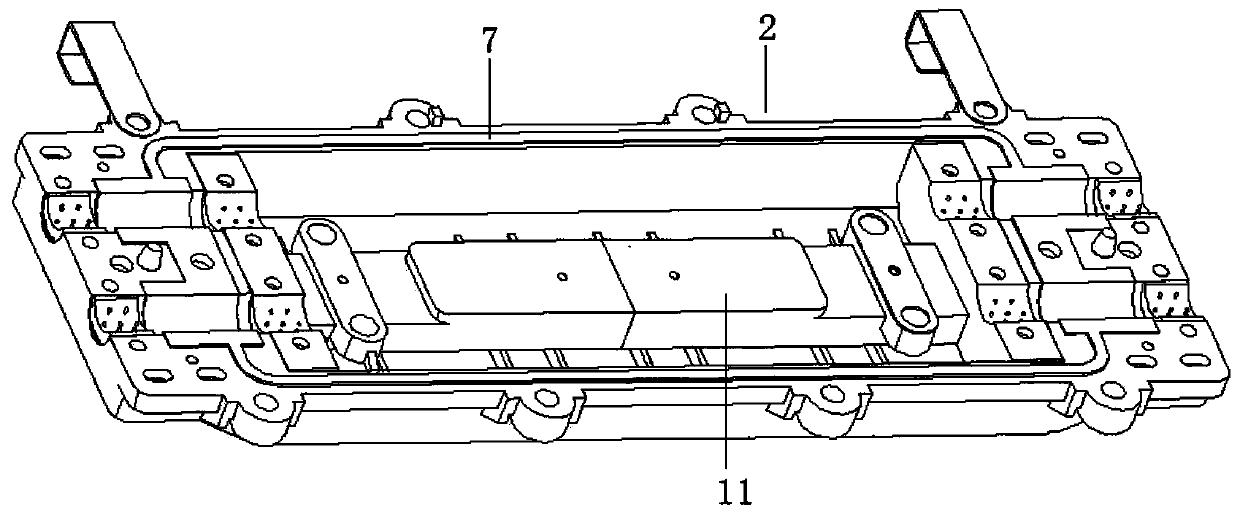

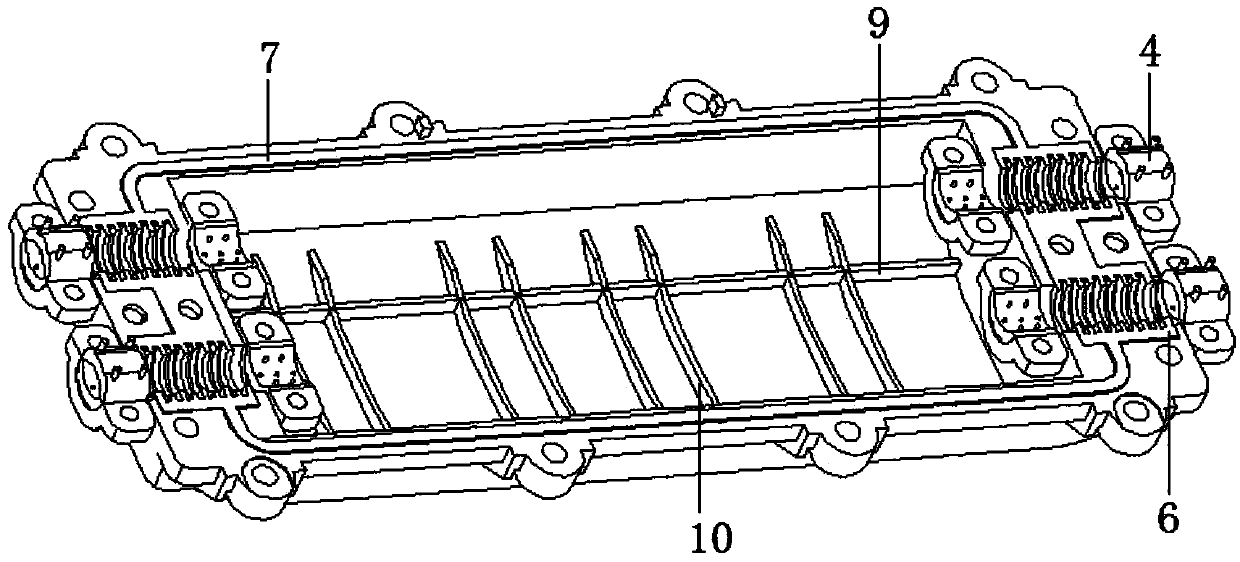

Battery module with same-side electrode output

PendingCN110931694AReduce complexityImprove physical performanceCurrent conducting connectionsCells structural combinationElectrical batteryHemt circuits

The invention discloses a battery module with same-side electrode output, which comprises a plurality of square batteries arranged in sequence, and the positive electrodes and the negative electrodesof the batteries are positioned at the top and are respectively arranged at two sides of the central axis of the arrangement direction of the batteries. Along the arrangement direction of the batteries, the positive and negative electrodes of the first battery and the second battery are arranged on different sides, and then the positions of the positive and negative electrodes of every two batteries are changed. The positive electrode of the first battery is connected with the positive output electrode of the battery module, and the negative electrode of the second battery is connected with the negative output electrode of the battery module; the negative electrode of the first battery is connected to the positive electrode of the third battery, and the positive electrode of the second battery is connected to the negative electrode of the fourth battery, and so on. The bus connection mode of the series batteries in the battery module can reserve enough space for the monitoring circuitboard, and when the module package is formed, the low-voltage line connected with the monitoring circuit can be separated from the bus high-voltage wiring harness connected with the positive electrodeand the negative electrode of the battery module, so that the electromagnetic interference of the bus to the low-voltage line is greatly reduced.

Owner:JIANGSU ZENIO NEW ENERGY BATTERY TECH CO LTD

Optical cable splice box

ActiveCN103995327AStructural continuityImprove stress resistanceFibre mechanical structuresEngineeringUltimate tensile strength

The invention discloses an optical cable splice box, and aims at providing a splice box which is good in matching and low in accuracy requirement and can ensure a sealing effect during bearing and heating. The optical cable splice box comprises an upper half box and a lower half box, wherein the upper half box and the lower half box are connected to forma box body; at least two optical fiber hole frames are arranged at the two ends of the box body respectively; each optical fiber hole frame comprises an outer section and an inner section; optical fiber inlet sleeves are arranged in the outer sections; the inner sections consist of half slots in the lower half box and half slots in the upper half box; corresponding elastic clamp sleeves are arranged in the half slots; sealing grooves are formed in the upper half box and the lower half box; sealing strips are arranged in the sealing grooves; the sealing strips and the elastic clamp sleeves are connected to form sealing rings; each sealing strip is 0.5-1mm higher than an opening of each sealing groove; and cross sections of the sealing strips are trapezoids with outward large bottom edges. The optical cable splice box has the benefits that an assembling accuracy requirement is low; the cost is saved; displacement is not easy to generateat butting parts of the sealing rings; the sealability is good; and a reinforcing structure is arranged in the box body, so that the compressive capacity and the overall strength are high.

Owner:杭州华宏通信设备有限公司

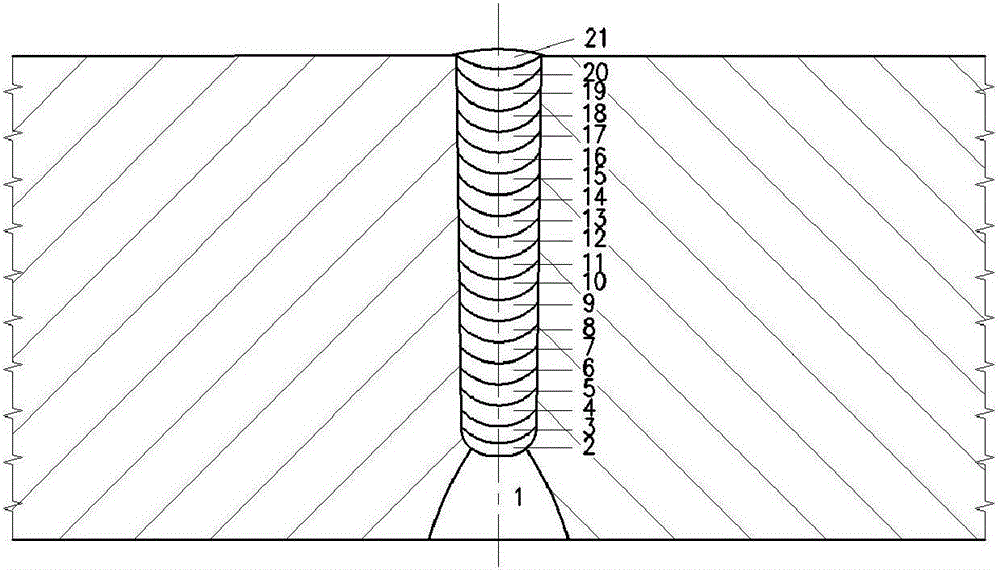

Efficient combined automatic TIG welding technology of butt joint of thick plates

InactiveCN106378516ARealize single-sided welding and double-sided formingImprove welding efficiencyArc welding apparatusWelding/soldering/cutting articlesThick plateButt joint

The invention discloses an efficient combined automatic TIG welding technology of butt joint of thick plates. The efficient combined automatic TIG welding technology comprises the steps of S1, processing connection parts of to-be-welded workpieces into single-surface grooves with blunt edges; S2, carrying out autogenous welding of the blunt edges at the outer parts of the grooves through adopting automatic deep hole type TIG root sealing welding, so as to achieve double-side molding through single-side welding; and S3, filling the grooves through adopting automatic narrow gap TIG filling welding. According to the efficient combined automatic TIG welding technology of butt joint of the thick plates, the advantages of two automatic TIG welding methods of automatic deep hole type TIG root sealing welding and automatic narrow gap TIG filling welding are combined, the welding quality is stable, the welding efficiency is high, the practicability is high, and the comprehensive cost is low.

Owner:CFHI DALIAN HYDROGENANT REACTOR +1

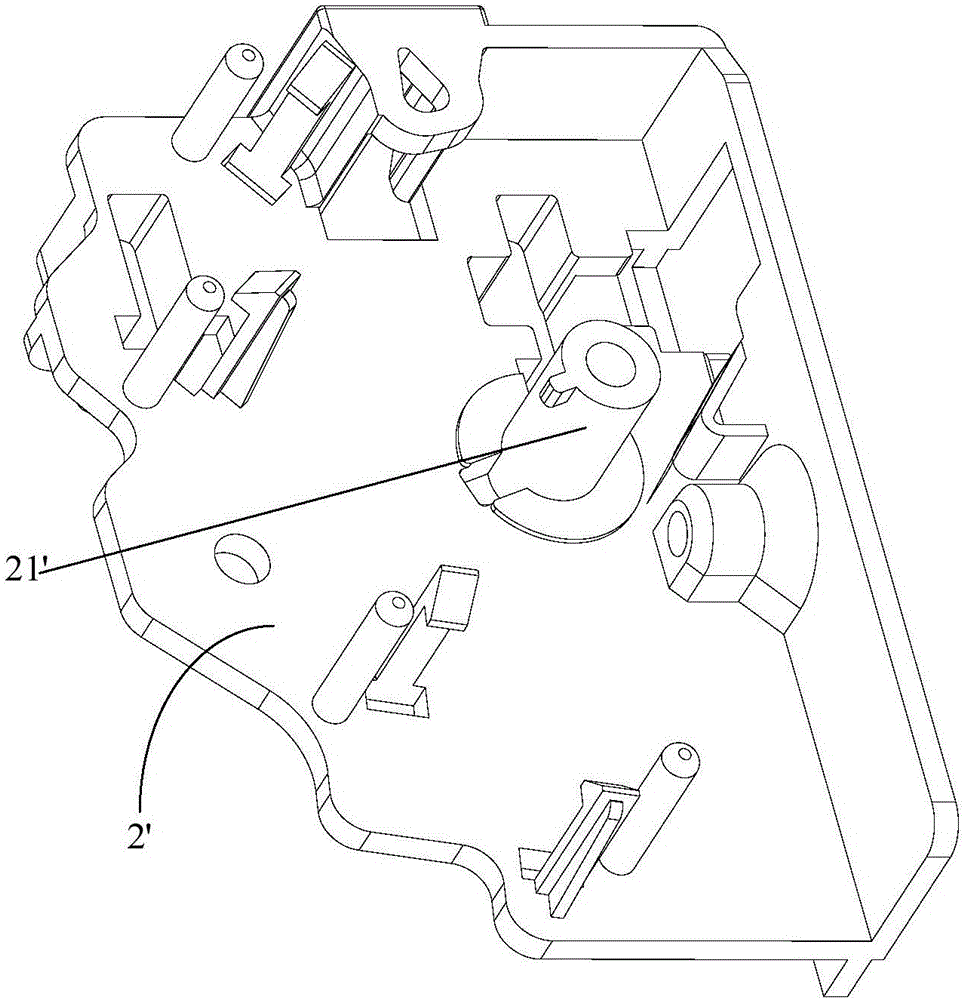

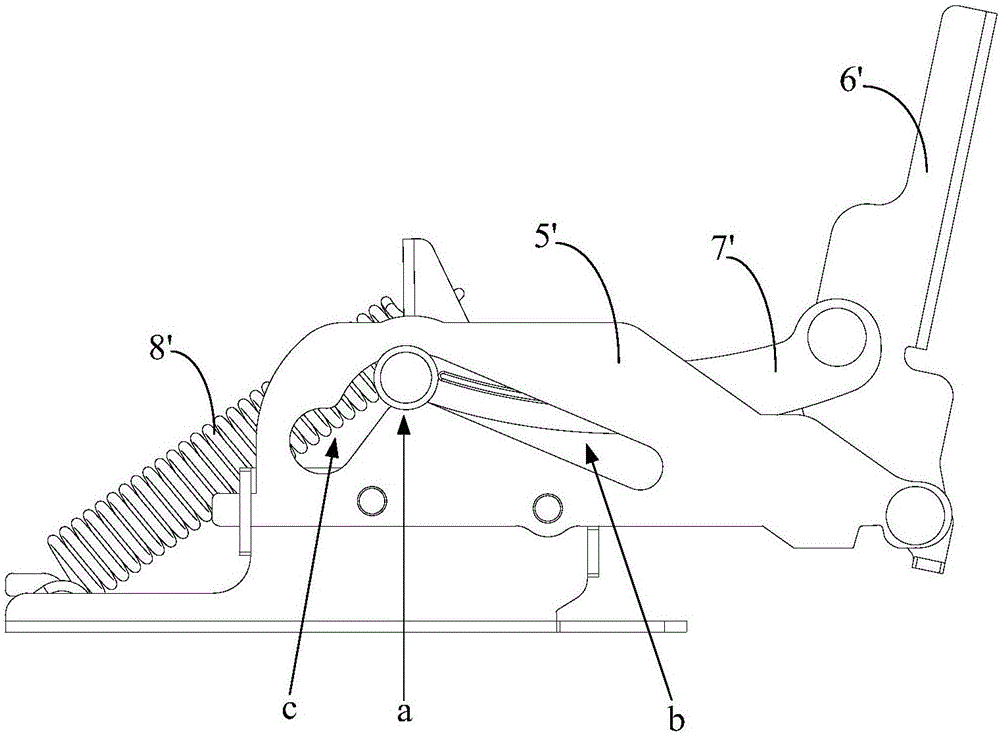

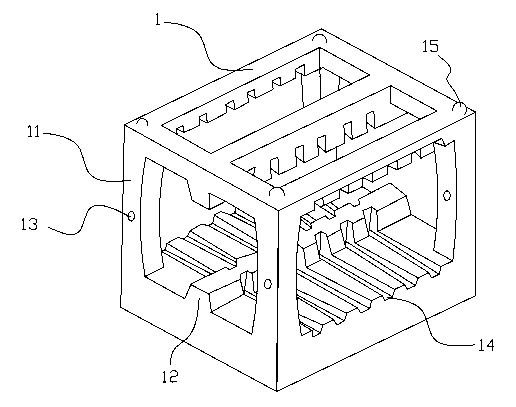

Interlocking assembly and cooking utensil

ActiveCN106812393AReduce momentumReduce shockBuilding locksRoasters/grillsEngineeringMechanical engineering

The invention provides an interlocking assembly and a cooking utensil. The interlocking assembly comprises a door hook, an interlocking support, an interlocking rotary block, a positioning torsional spring and a buffer device. According to the scheme, the buffer device is additionally arranged on the basis of an existing interlocking assembly, a door body is in an open state, the interlocking rotary block is in an unlocking position, and the door hook and the interlocking rotary block are separated; and in the door closing process, the door hook abuts against the interlocking rotary block and then pushes the interlocking rotary block to rotate, the buffer device applies resistance to the interlocking rotary block in the process that the interlocking rotary block rotates to a locking position from the unlocking position, momentum of the door body is reduced so that impact to a box body front plate can be reduced when the door body is closed, and thus the problem that paint of the box body front plate or the door body is peeled off due to the fact that door closing force of a user or a tension hinge is too large is solved.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

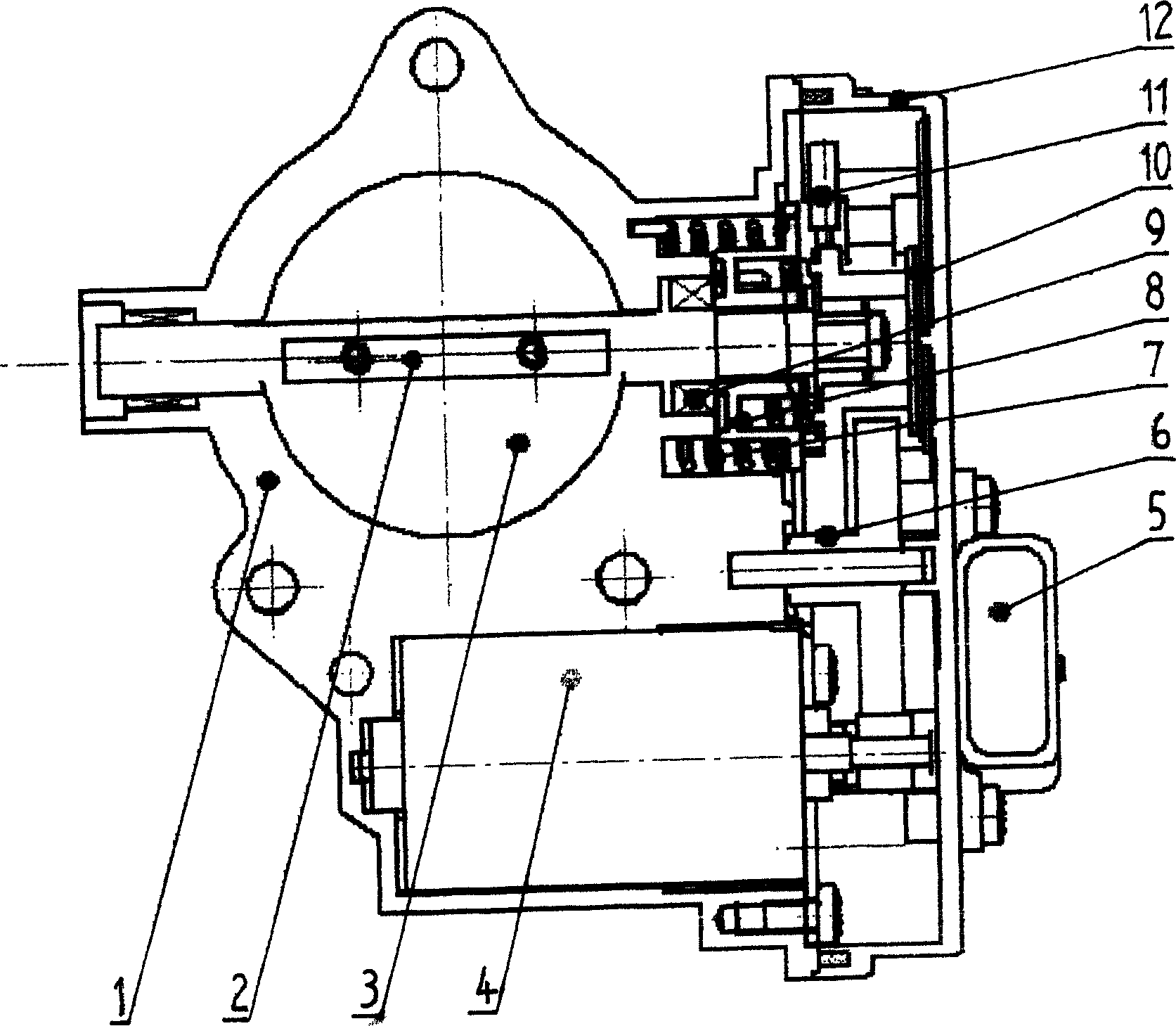

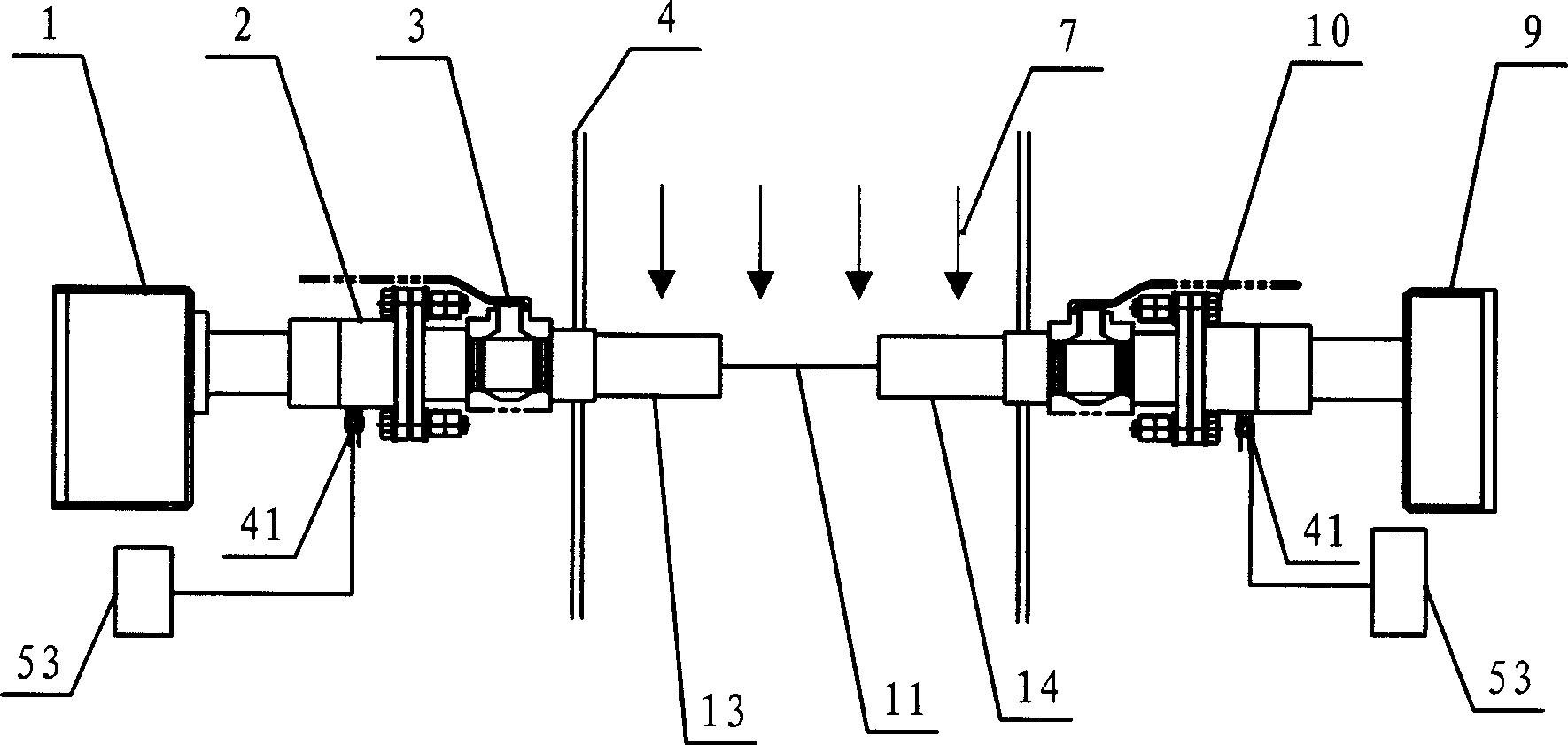

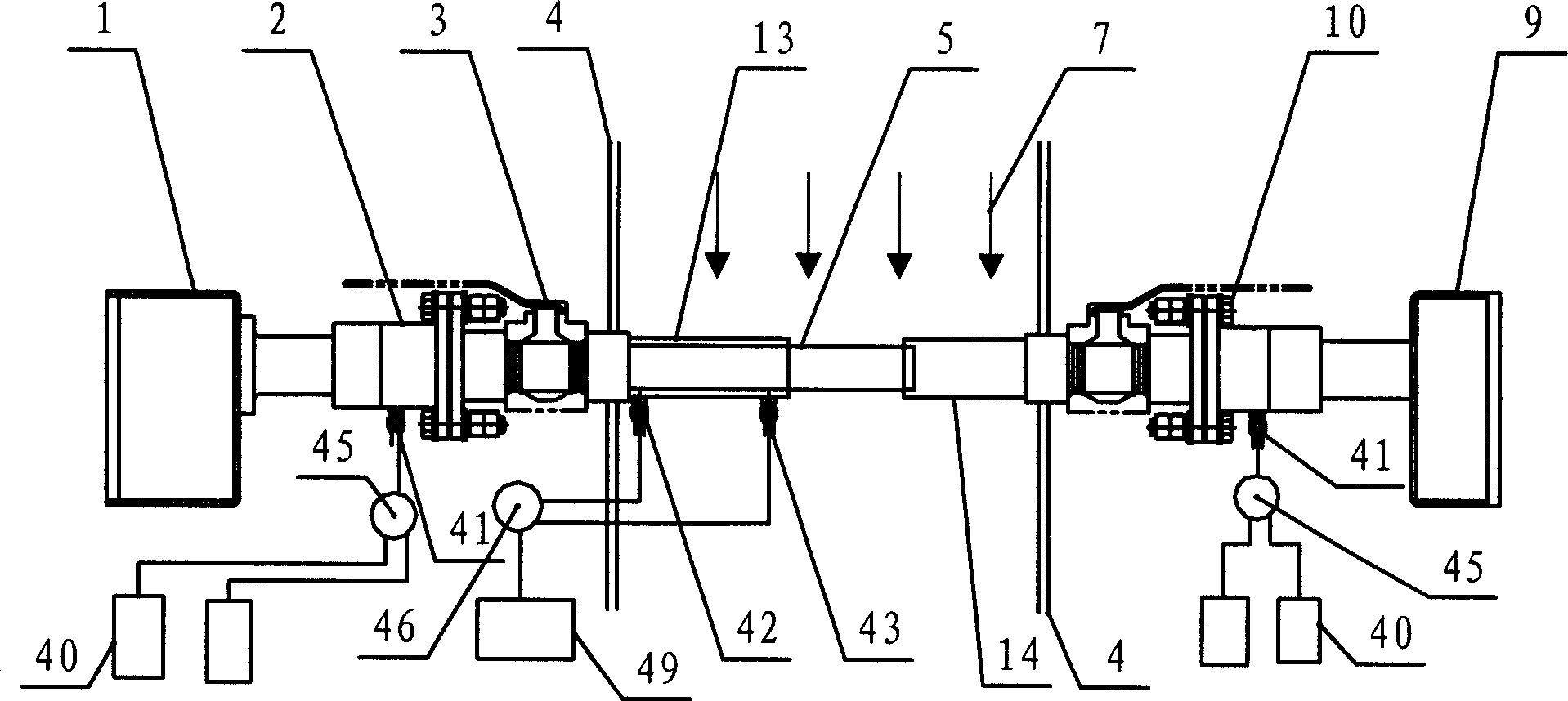

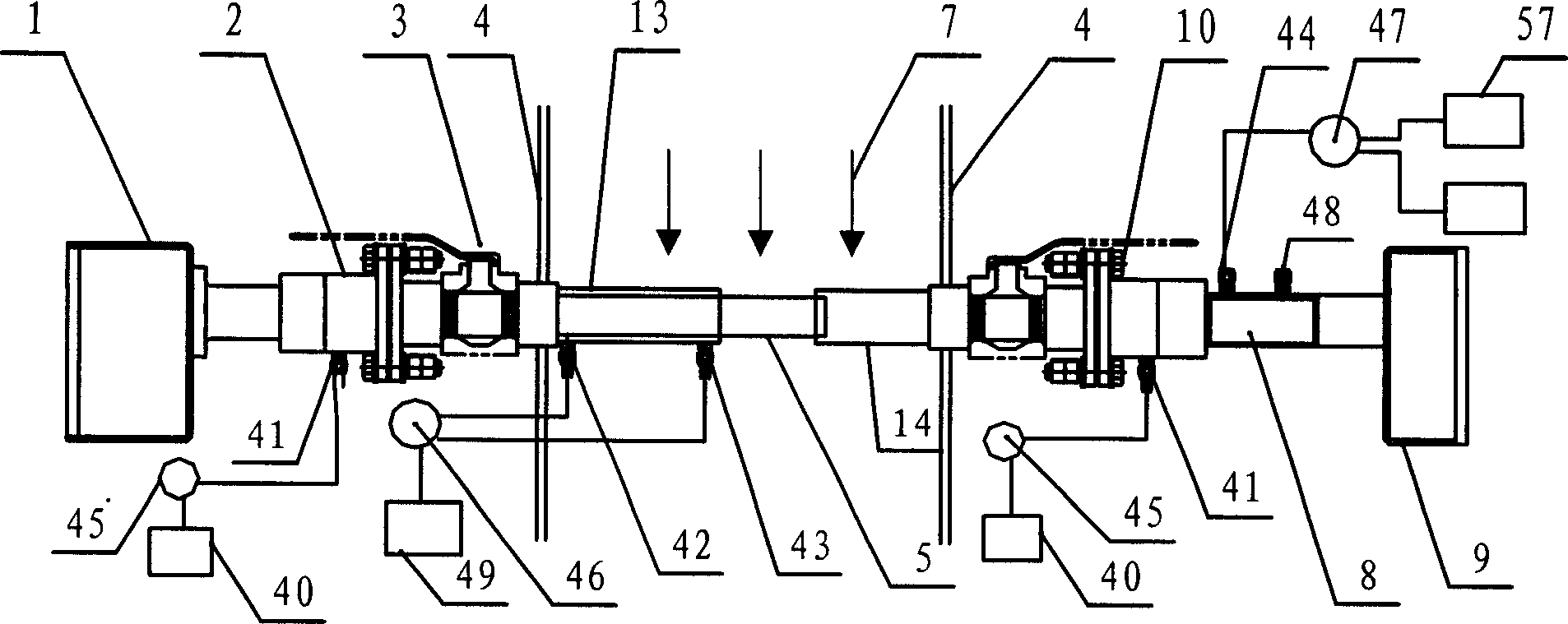

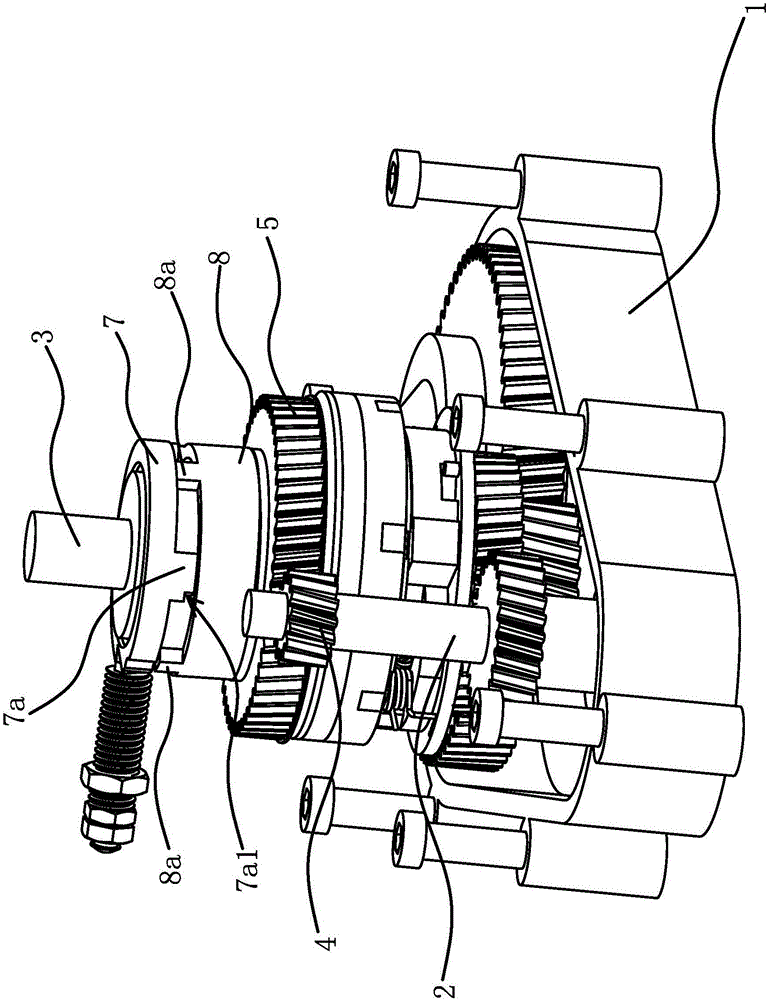

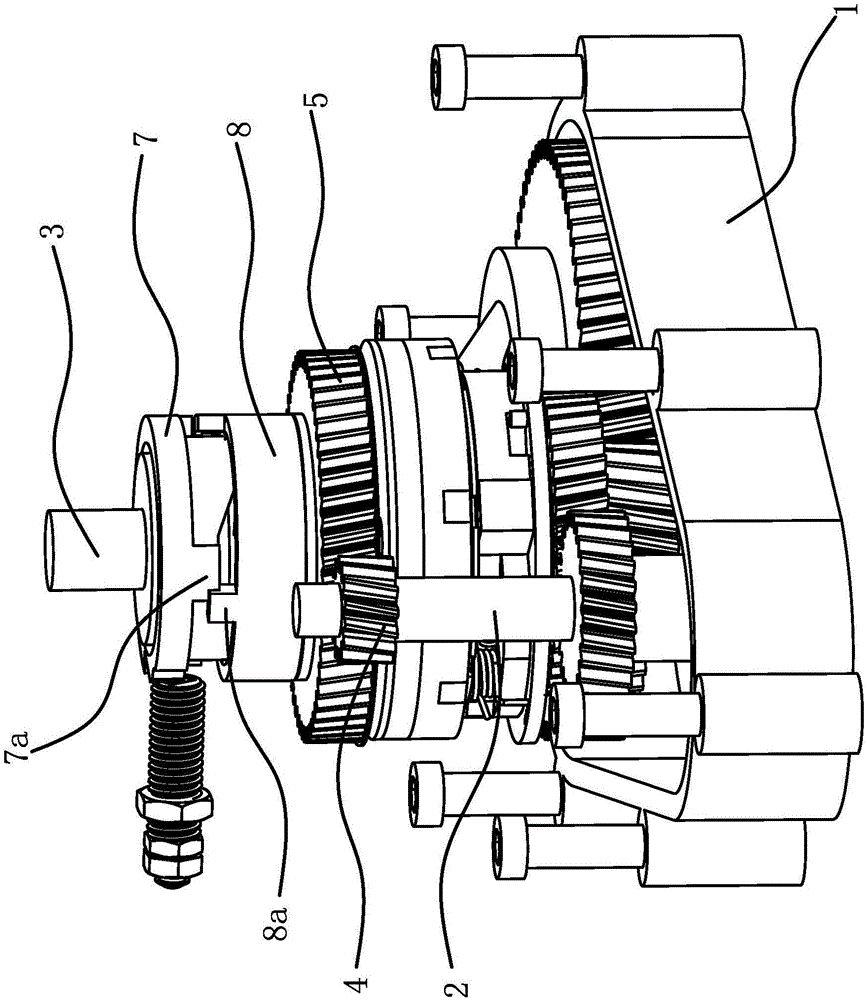

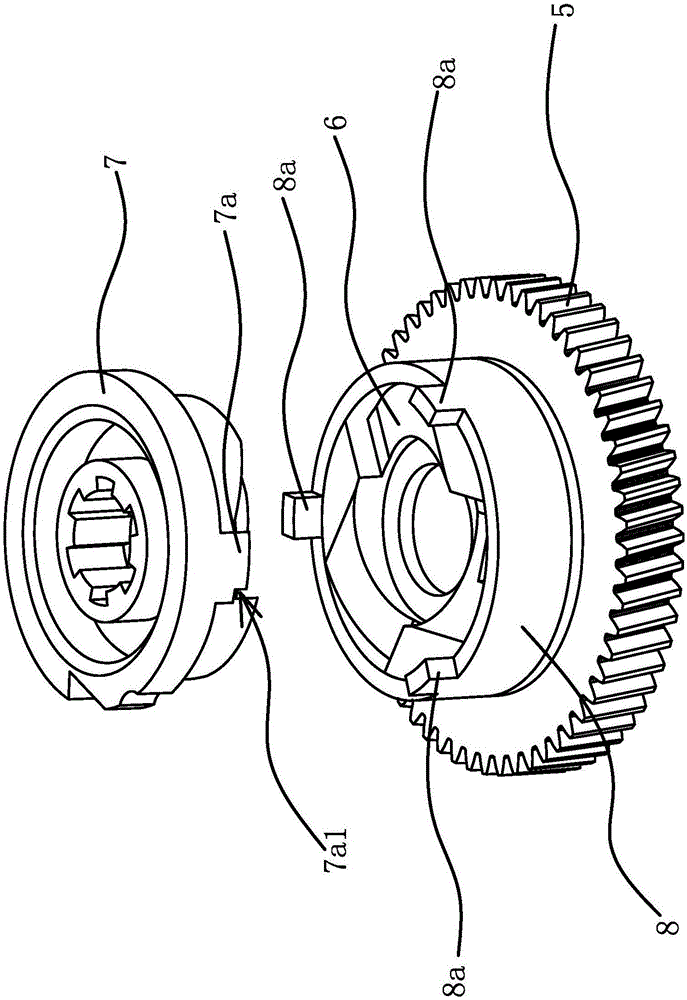

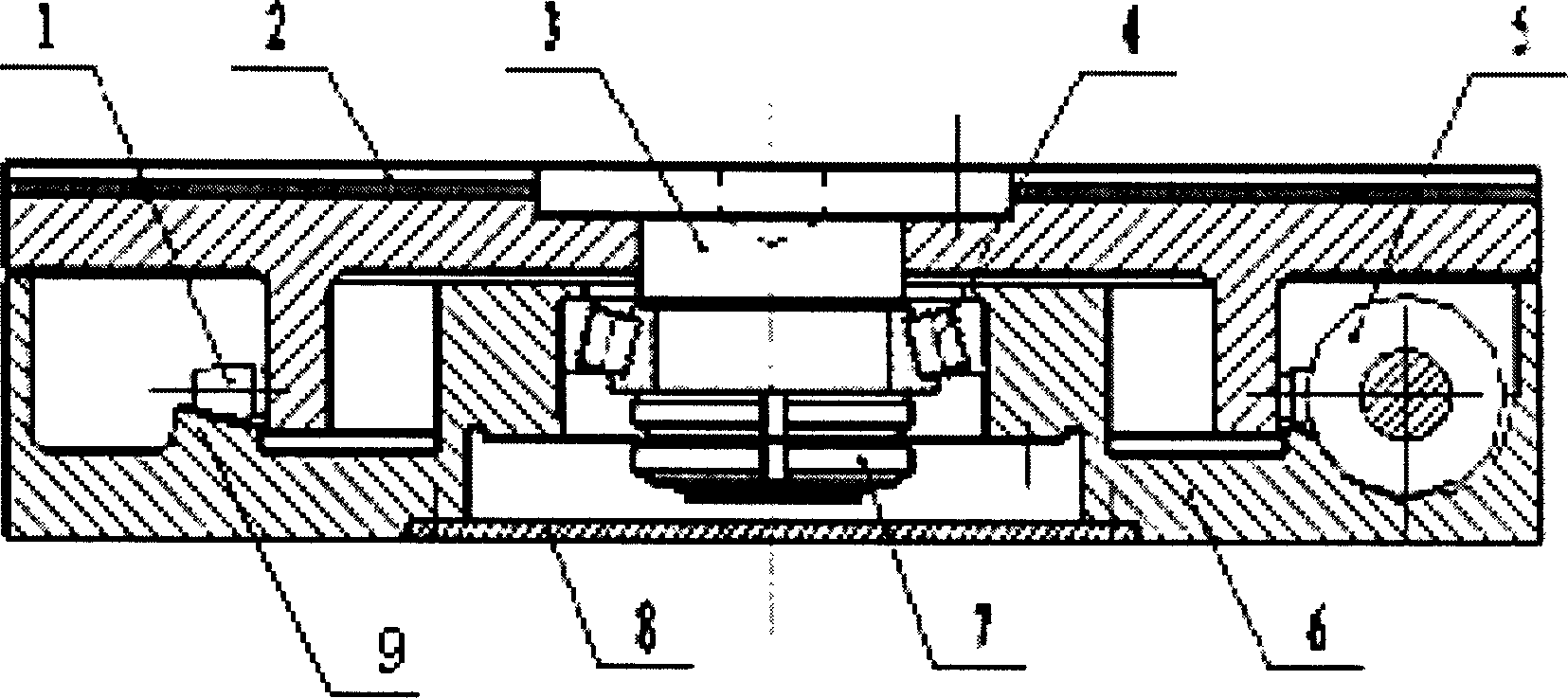

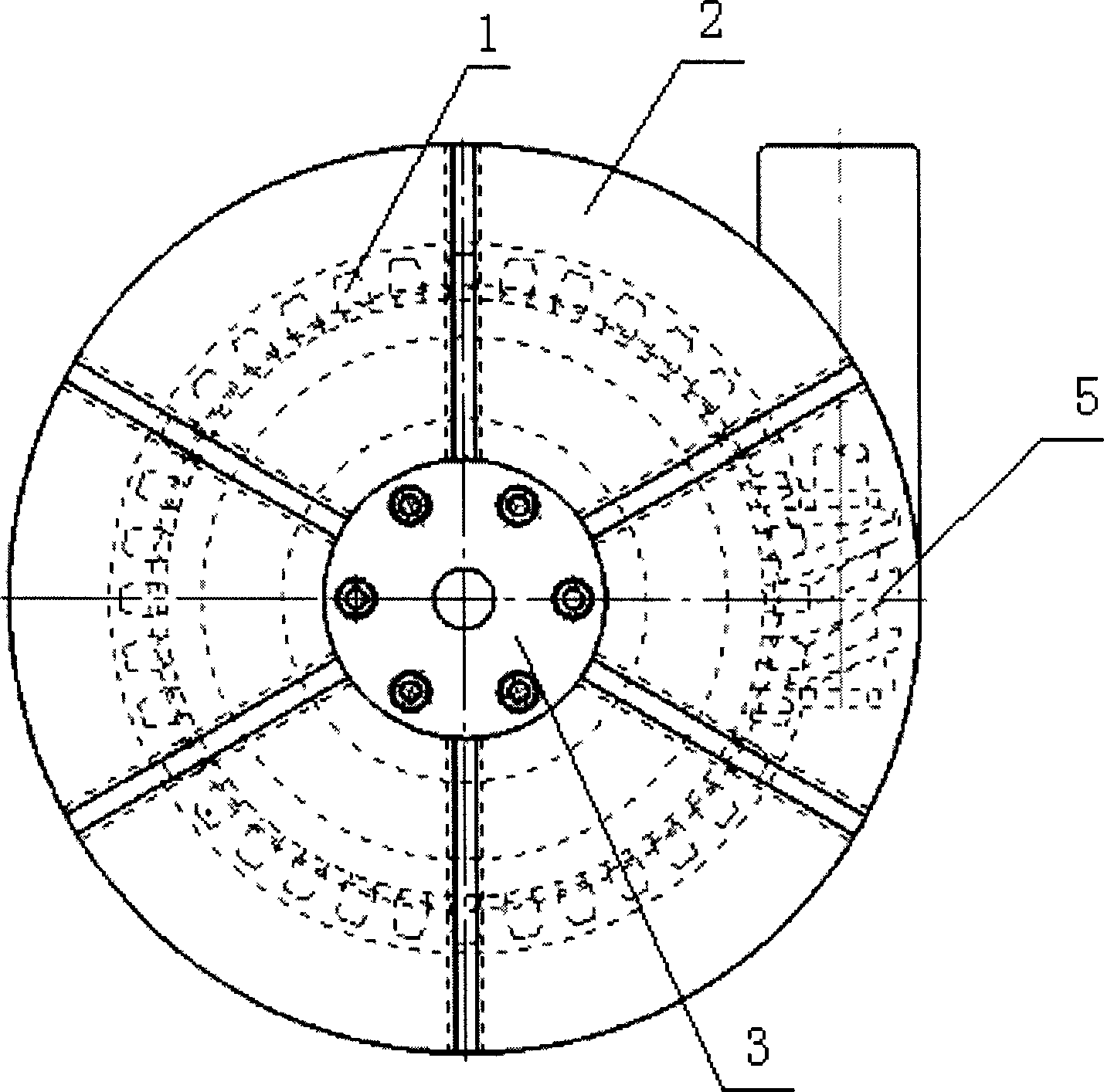

Bidirectional automatic variable-speed motor transmission device

ActiveCN106090144ALow machining accuracy requirementsEasy to processToothed gearingsFreewheel clutchesDrive shaftEngineering

The invention provides a bidirectional automatic variable-speed motor transmission device, belonging to the technical field of machines. According to the bidirectional automatic variable-speed motor transmission device, the problem that an existing bidirectional automatic variable-speed motor transmission device has a high assembling precision requirement is solved. The bidirectional automatic variable-speed motor transmission device comprises a shell, an input shaft and a transmission shaft, wherein the input shaft and the transmission shaft are arranged in the shell, a driving gear is fixed on the input shaft, the transmission shaft is sleeved with a transmission gear, a connecting sleeve is fixed on the transmission gear, the transmission shaft is connected with a transmission sleeve through a spline, and the transmission sleeve is located above the connecting sleeve; a combining mechanism and a separating mechanism are arranged between the transmission sleeve and the connecting sleeve, a bidirectional ring is arranged outside the connecting sleeve, a bidirectional mechanism is arranged between the connecting sleeve and the bidirectional ring, and a blocking part which protrudes upwards is arranged on the bidirectional ring; and a propping part which protrudes downwards is arranged on the edge of the lower end of the transmission sleeve and can prop against the blocking part to separate the transmission sleeve from the transmission shaft, and a blocking structure is arranged between the propping part and the blocking part. The bidirectional automatic variable-speed motor transmission device has the advantages of low assembling precision requirement, high use safety and the like.

Owner:屠申富 +1

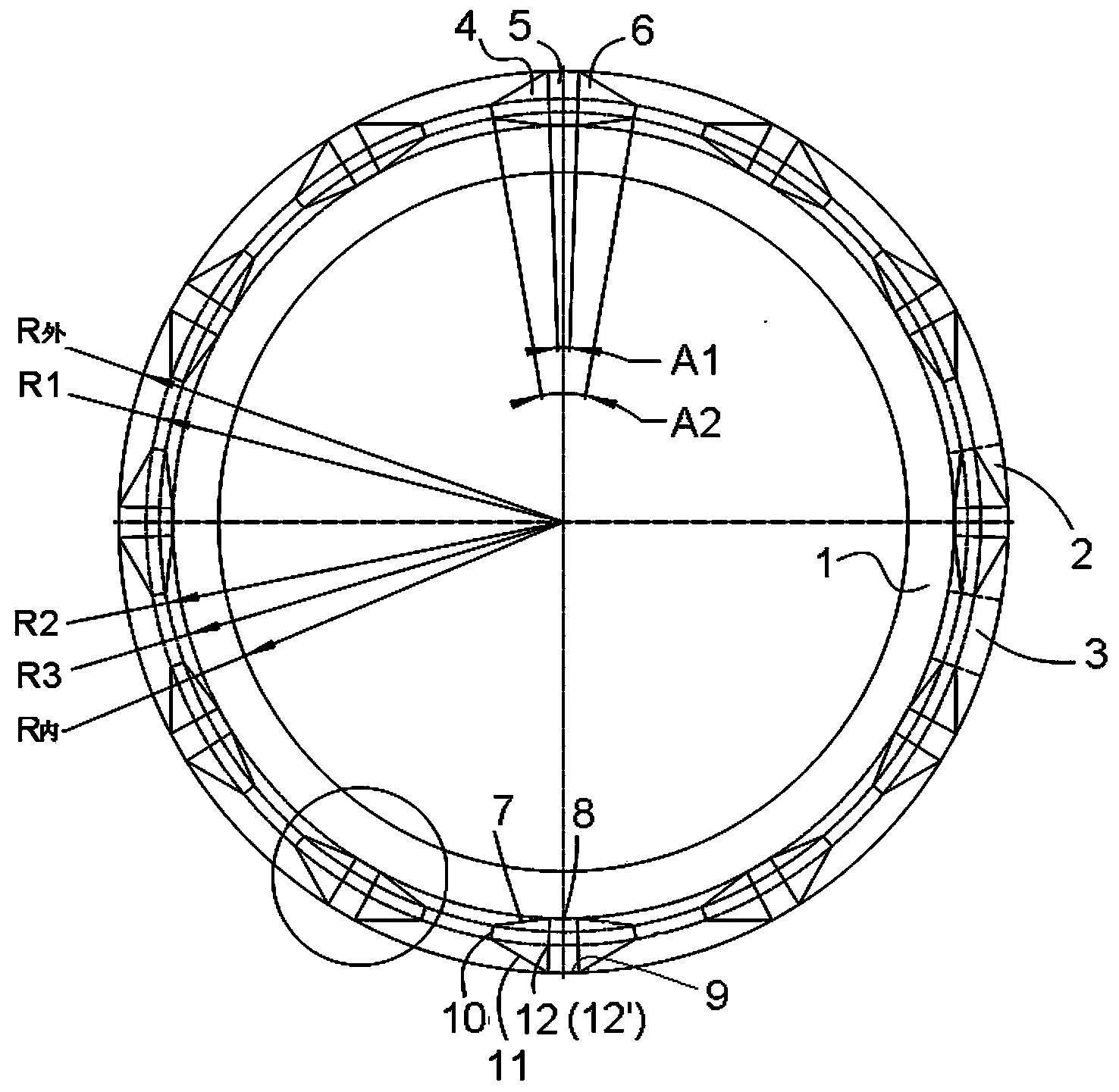

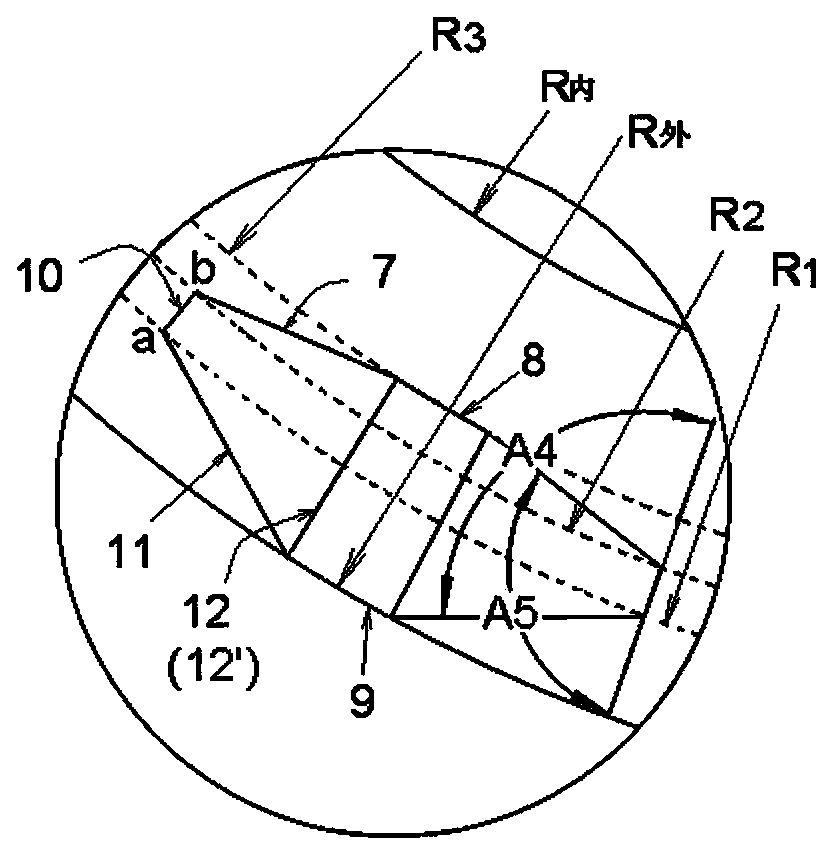

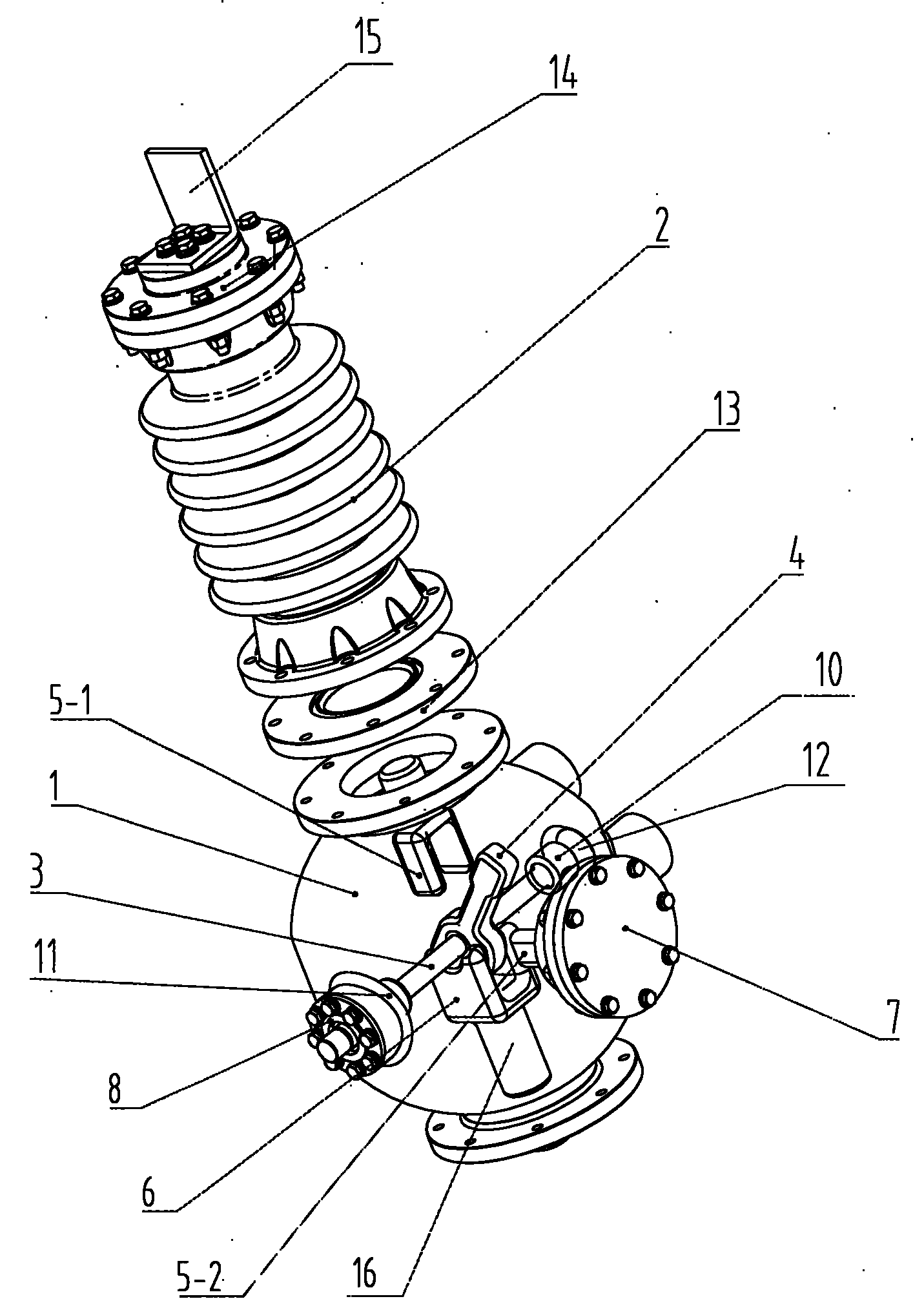

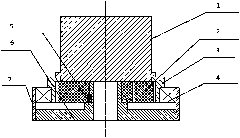

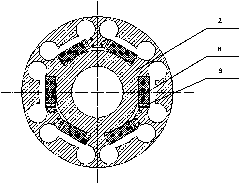

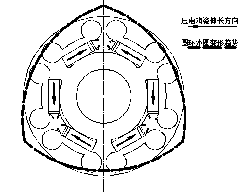

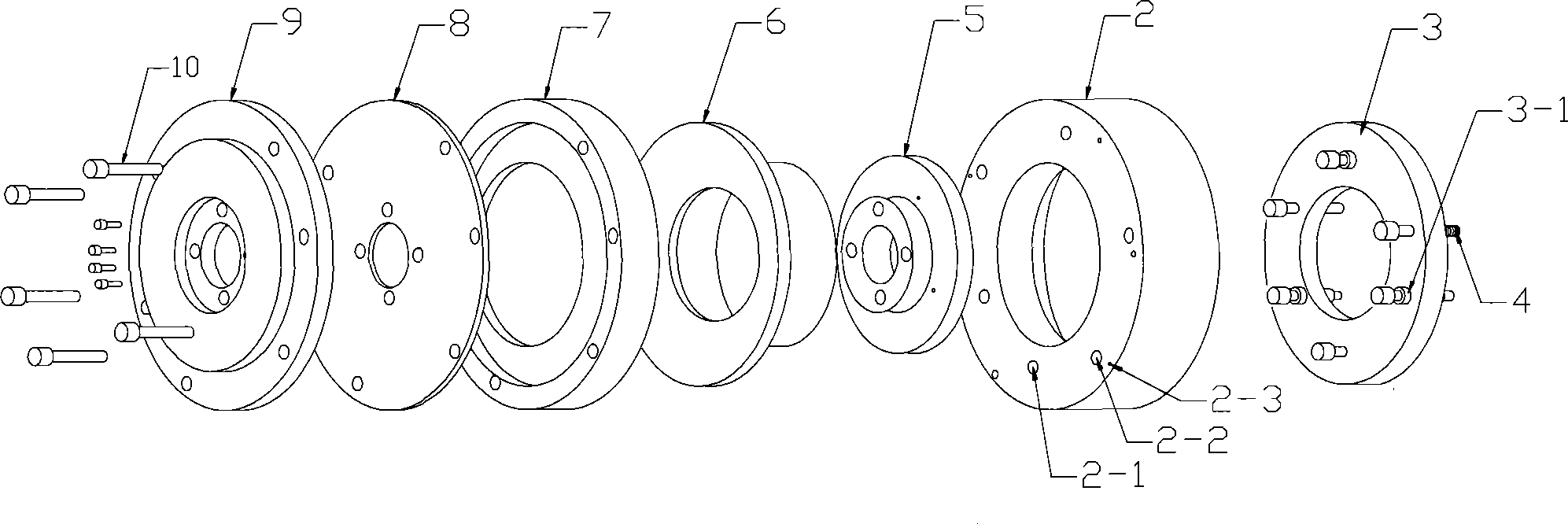

Non-contact mechanical seal ring with dual-rotating-direction hydrodynamic grooves

ActiveCN103453147AImprove opening forceImprove job stabilityEngine sealsEngineeringMechanical engineering

The invention provides a non-contact mechanical seal ring with dual-rotating-direction hydrodynamic grooves. Hydrodynamic groove structure units in same forms are arranged on the outer side of a seal end face circumferentially at equal intervals; the hydrodynamic groove structure unit is in a wing-shaped structure formed by a central groove and same wing grooves which are connected to two sides of the central groove respectively and which extend symmetrically in a converged manner; the central groove and two wall edges thereof are two radial extending segments of the seal end face respectively, the wall edge on the inner side is an arc concentric with the seal end face, and the central groove is formed in the circumferential wall of a seal ring body, long side edges of two sides of the wing grooves and short grooves at the converged-extending ends are two radial extending segments of the seal end face; the long side edges of two sides of the wing grooves fit and are connected with the side wall of the central groove where the same located. By the aid of the hydrodynamic groove structure, seal hydrodynamic effect can be improved, seal end face opening force is increased, thickness and strength of the fluid film between the seal end faces are increased, seal leakage is reduced, groove processing difficulty is reduced, and process requirements on seal parts processing and assembling are lowered.

Owner:SICHUAN SUNNY SEAL

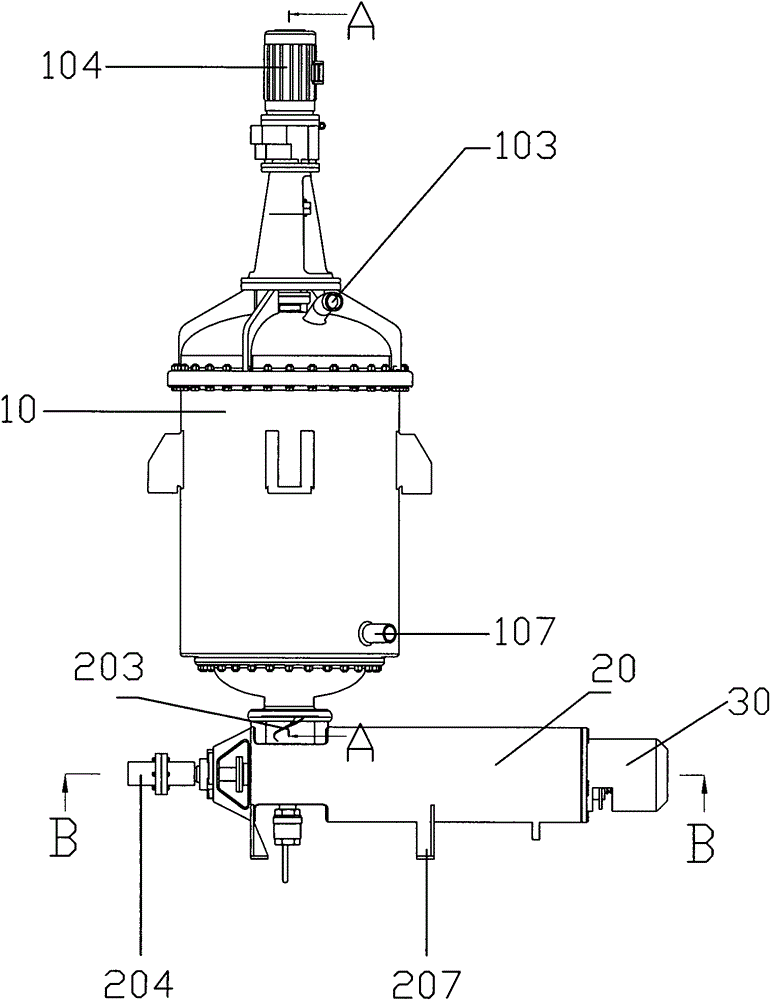

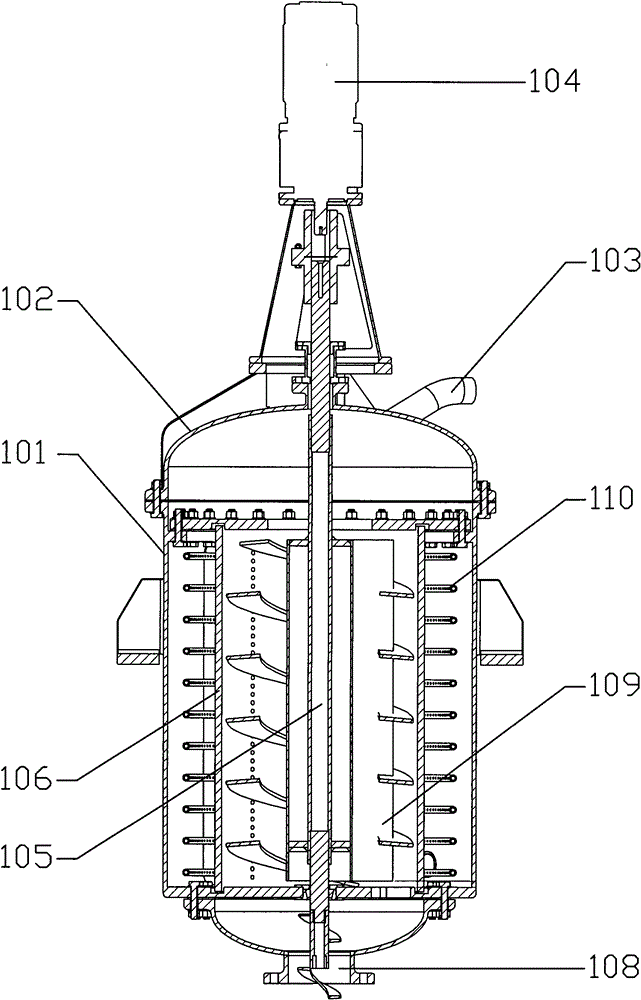

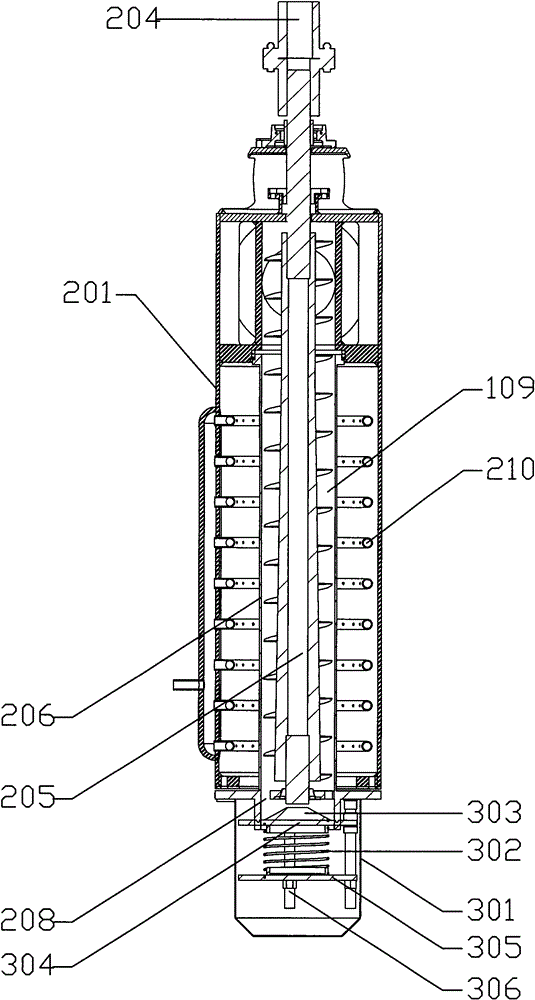

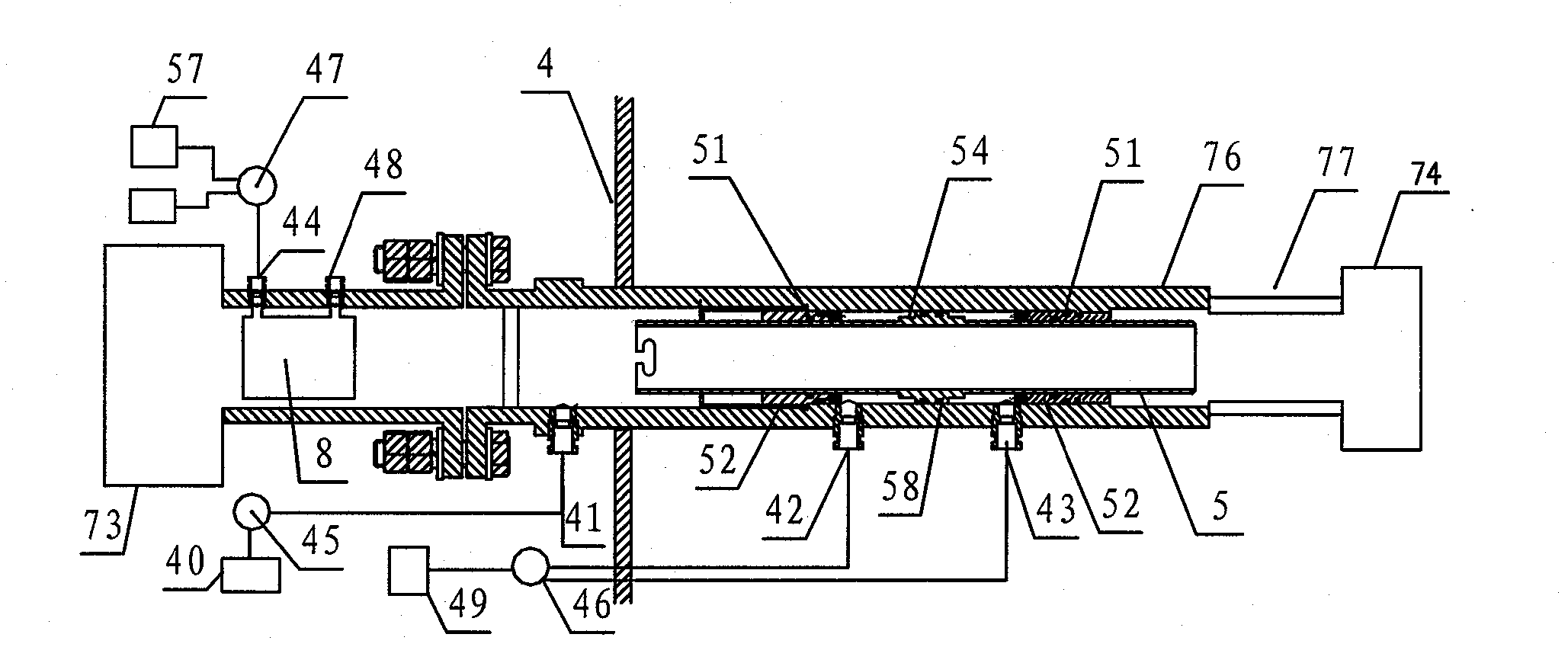

Full-automatic continuous filtering and filter pressing slag unloading machine

The invention relates to a full-automatic continuous filtering and filter pressing slag unloading machine comprising a filtering device, wherein the filtering device comprises a filter cartridge, a filtering stirring shaft and a first filtering medium; a liquid inlet is arranged on the top end of the filter cartridge; the filtering stirring shaft is installed in the filter cartridge through a sealing bearing, and a helical blade is arranged on the filtering stirring shaft; the first filtering medium is arranged between the inner wall of the filter cartridge and the filtering stirring shaft; a liquid outlet is arranged on the bottom end of the filter cartridge; and a press filtering device, the press filtering device comprises a press filter cartridge, a press filtering stirring shaft and a second filtering medium; a slag inlet is arranged on the top end of the press filter cartridge, and the slag inlet is communicated with the liquid outlet; the press filtering stirring shaft is installed in the press filter cartridge through a sealing bearing, and a helical blade is arranged on the press filtering stirring shaft; the second filtering medium is arranged between the inner wall of the press filter cartridge and the press filtering stirring shaft; and a slag outlet is arranged on the bottom end of the press filter cartridge, and an automatic resetting switch is arranged at the slag outlet. The full-automatic continuous filtering and filter pressing slag unloading machine provided by the invention can be conducted with continuous pressure filtration, can automatically feed and automatically discharge and unload slag and is consistently located at a thin layer filtering environment, so that the filtering speed is high, and the machine is operated under a complete sealed state, and the operation environment is excellent.

Owner:王启

Three-station isolating/grounding switch adopting floating structure and self-adaptive conductive contact

InactiveCN101882527AAchieving electrical performanceNo misuseSwitchgear arrangementsHigh-tension/heavy-dress switchesElectricityElectrical conductor

The invention discloses a three-station isolating / grounding switch which adopts a floating structure and self-adaptive conductive contact and is mounted in a closed metal grounding shell filled with an insulating medium. The three-station isolating / grounding switch comprises an upper static contact, a lower static contact and a movable contact, wherein the contact seat of the movable contact is mounted on a transmission insulated shaft, a U-shaped conductor is arranged below the transmission insulated shaft, conductively connected with a main loop conductor arranged outside the switch, and directly fixed on the main loop conductor or fixed at the bottom of the shell through a pan-type insulator, and the outline of the contact seat of the movable contact is longitudinally arranged in a groove of the U-shaped conductor and keeps electric contact with the groove through sensing fingers. The three-station isolating / grounding switch can be driven by an operation mechanism without misoperation between separation and grounding and can save electric operation linkage between the separation and the grounding. Moreover, due to the adoption of a floating-type self-adaptive conductive contact structure, the switch is easy to process and assemble and can also greatly lower the size accuracy requirement in assembly.

Owner:广西中电新源电气有限公司

Cam-driven-type dual-station stamping device

The invention discloses a cam-driven-type dual-station stamping device which comprises a U-shaped support for supporting a pushing rod. The pushing rod is installed on the U-shaped support in a sliding mode. An elastic stop block is fixedly arranged in the middle of the pushing rod. A reset spring is arranged between the elastic stop block and the U-shaped support. A roller is installed at one end of the pushing rod in a rotating mode through a roller carrier. A disc cam is installed at the end of a power shaft. The other end of the pushing rod is hinged to one end of a first transmission rod and one end of a second transmission rod. The other end of the first transmission rod is hinged to a first stamping head. The other end of the second transmission rod is hinged to a second stamping head. The cam-driven-type dual-station stamping device has the advantages of being reasonable in design, convenient to operate, high in automation degree, high in production efficiency, long in service life, wide in application range, low in production cost and convenient to use and popularize and saving time and labor.

Owner:XIAN ZHIYUE ELECTROMECHANICAL TECH

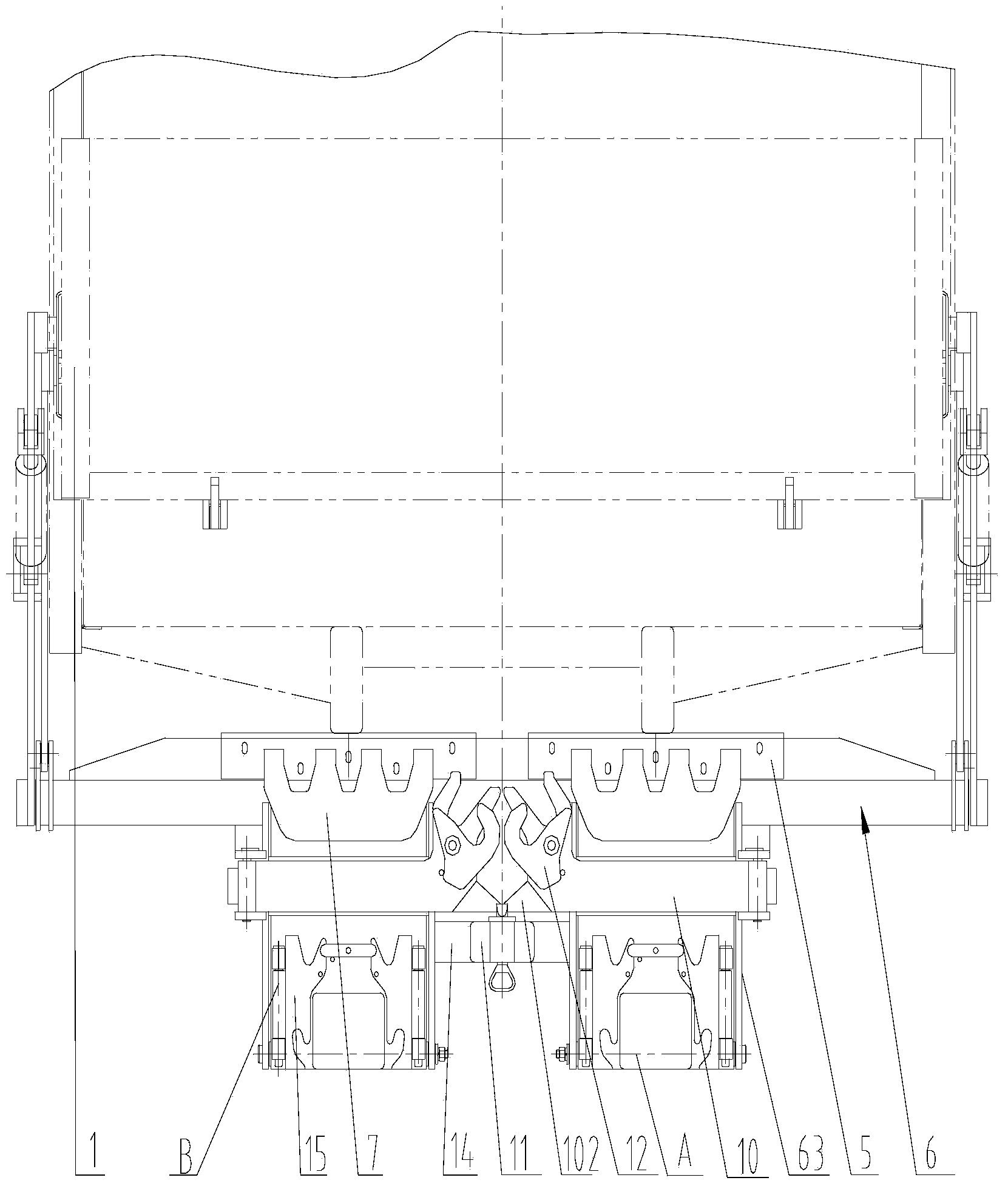

Garbage truck loading mechanism and garbage truck

The invention discloses a garbage truck loading mechanism and a garbage truck. The garbage truck loading mechanism comprises a barrel overturning frame (6) used for overturning garbage barrels (9), the barrel overturning frame (6) comprises a rotating shaft (61) and a plurality of vertical plates (63) fixedly connected to the rotating shaft (61), the garbage truck loading mechanism comprises a first loading component which comprises at least one barrel hanging plate (7) used for hanging the garbage barrels (9), each barrel hanging plate (7) comprises a barrel hanging plate body mounted on the corresponding vertical plate (63), and each barrel hanging plate body is hinged to the corresponding vertical plate (63) to enable the barrel hanging plate (7) to rotate relative to the corresponding vertical plate (63); a first limiting bar (72) and a second limiting bar (75) are arranged on each barrel hanging plate body, and rotation of each barrel hanging plate (7) relative to the corresponding vertical plate (63) in two opposite directions is limited by the first limiting bar and the second limiting bar respectively. The garbage truck loading mechanism can firmly fix the garbage barrels, and the garbage barrels can not fall off.

Owner:ZOOMLION ENVIRONMENTAL IND CO LTD

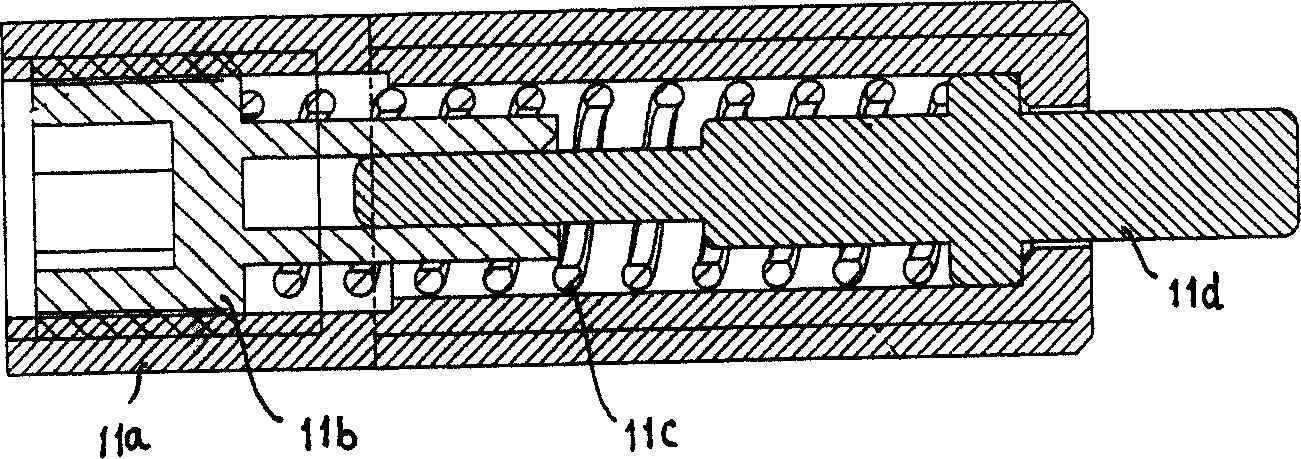

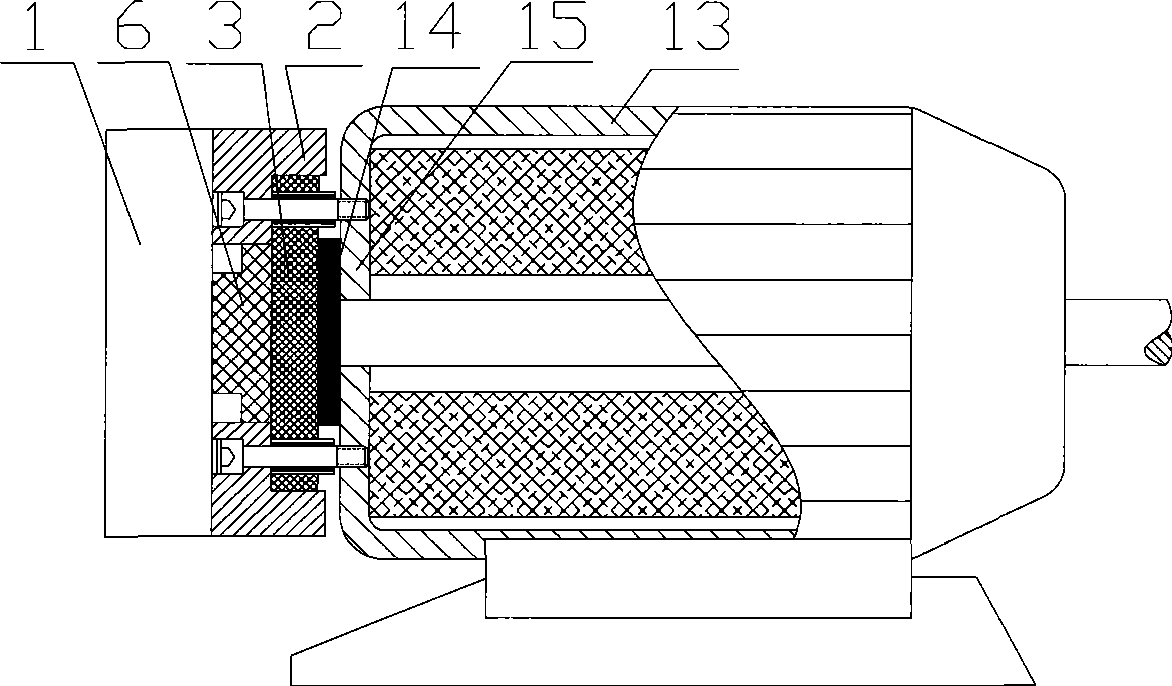

Laminating type piezoelectric brake adopting flexible amplifying structure and working method thereof

InactiveCN103994159AEasy to install precisionLarge displacement and forceDrum brakesBrake actuating mechanismsElectromagnetic interferenceCeramic

The invention discloses a laminating type piezoelectric brake adopting a flexible amplifying structure and a working method thereof. The piezoelectric brake comprises a non-rotation part, a brake support, a circular ring, a key, a brake disk and a rotating part, wherein the brake support, the circular ring, the key, the brake disk and the rotating part are installed in the non-rotation part. The circular ring is located in the non-rotation part, the inner circle of the circular ring and the brake support are connected through the key and located, and the inner circle of the brake disk and the outer circle of the circular ring are in clearance fit. The rotating part is installed on the circular ring and fixedly connected with the brake disk. The laminating type piezoelectric brake adopting the flexible amplifying structure further comprises laminating piezoelectric ceramic embedded in the circular ring, a wedge arranged on one side of the laminating piezoelectric ceramic and used for providing the pretightening force, and an isosceles triangle displacement amplifying structure used for amplifying and controlling extension displacement of the laminating piezoelectric ceramic. The laminating type piezoelectric brake adopting the flexible amplifying structure has the advantages of being small in size, easy to process, assemble and use, fast in response, easy to control and the like, and electromagnetic interference is avoided.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

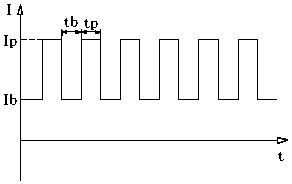

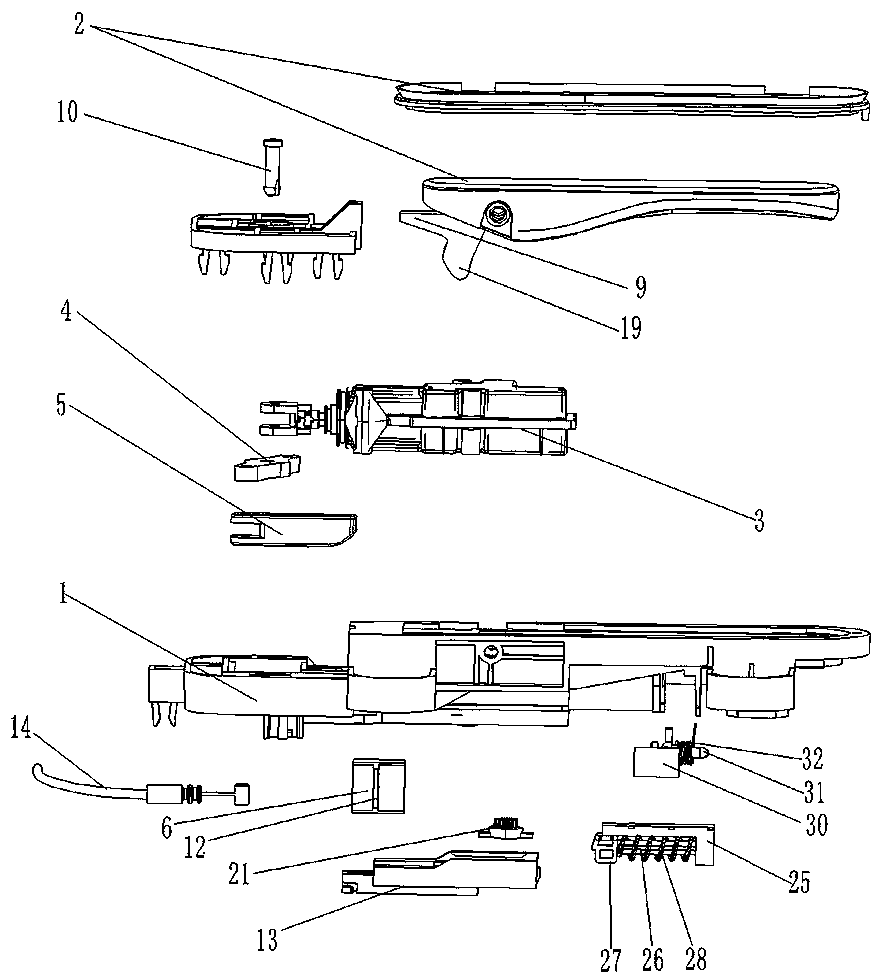

Scanning galvanometer laser-high frequency pulse TIG composite welding method

PendingCN110814552AExtended cooldownIncrease the area of actionLaser beam welding apparatusWelding accessoriesGalvanometerWeld seam

The invention provides a scanning galvanometer laser-high frequency pulse TIG composite welding method. A steel plate to be welded is made into a welding groove, and assembling and cleaning are carried out. A first workpiece to be welded is in butt joint with a second workpiece to be welded. The first workpiece to be welded and the second workpiece to be welded are thick steel plates. A welding seam to be welded with the selected width and length is formed between the two workpieces to be welded. A welding wire is used, laser beams generated by a scanning galvanometer laser-high frequency pulse TIG composite welding gun and a TIG welding gun are used for travelling welding for the welding seam in the direction from one end to the other end, and a mode of a straight-line swing, a circular swing or a "8-shaped" swing is adopted in the welding process. According to the scanning galvanometer laser-high frequency pulse TIG composite welding method, scanning galvanometer laser-high frequencypulse TIG composite welding is adopted, the probability of pore generation can be reduced, the welding seam property is improved, the welding seam heat input is reduced, and the welding deformation is reduced. The scanning galvanometer laser-high frequency pulse TIG composite welding method is suitable to be used as a method of swing laser-high frequency pulse TIG composite welding for members ofthick wall high-strength steel, stainless steel and the like.

Owner:中国船舶集团渤海造船有限公司

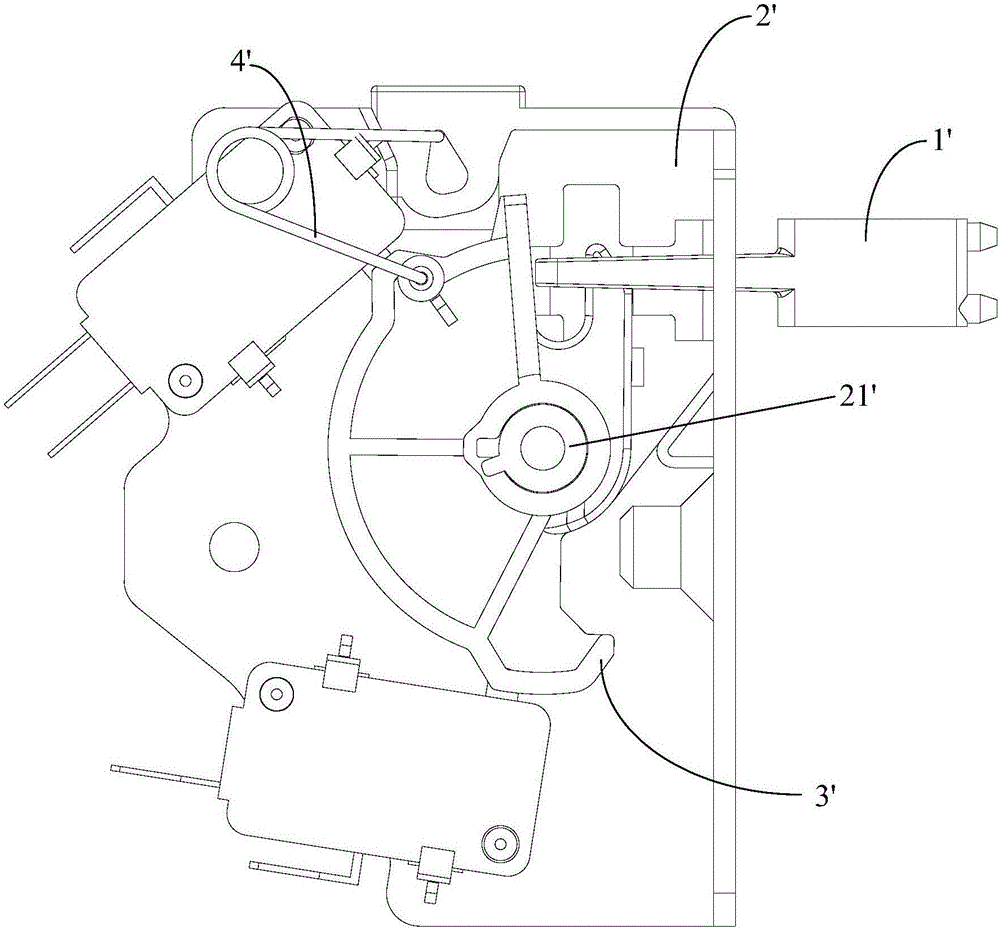

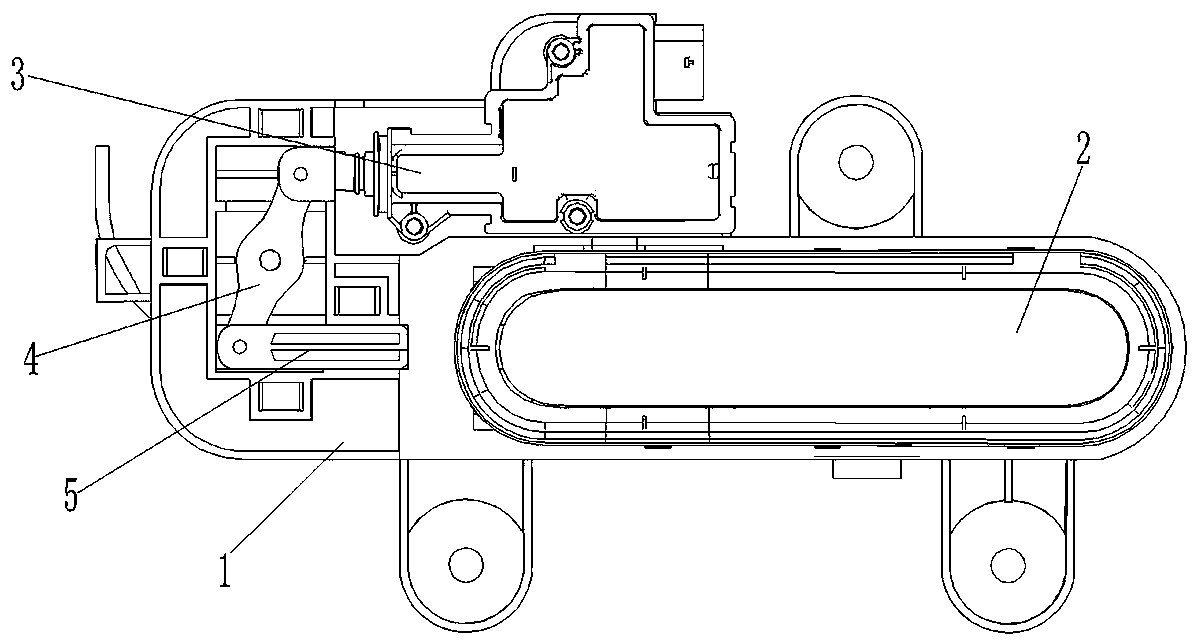

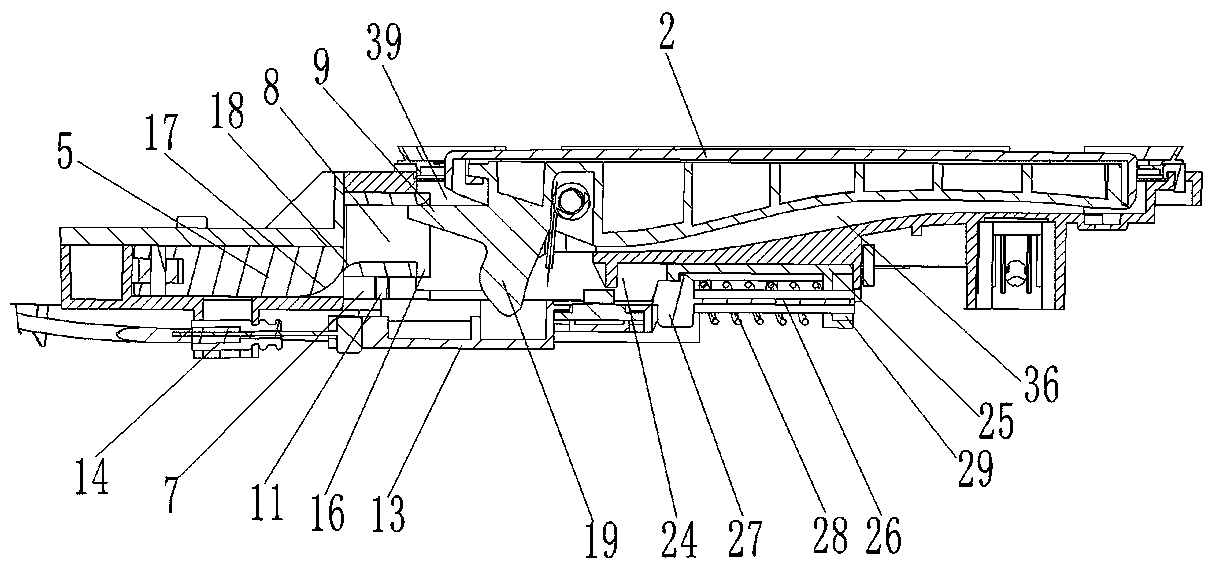

Automatic backswing outer handle structure for car

PendingCN110344680AImplement electric push functionSimple structureVehicle locksElectricityEngineering

The invention provides an automatic backswing outer handle structure for a car. The automatic backswing outer handle structure for the car comprises a handle base, a handle main body and an electric push-out mechanism, wherein the handle base is fie to a car body; the handle main body is hidden in the handle base and is flush with the car body; the handle main body is rotatably connected with thehandle base and can move between the initial hidden state and a pre-unfolding state; under the power shortage condition of the car, the front end of the handle main body is pressed to enable the handle main body to move from the initial hidden state to the pre-unfolding state; the handle main body at least has an complete unfolding state; when the handle main body is in the pre-unfolding state, auser continues to pull the handle main body to enable the handle main body to move from the pre-unfolding state to the complete unfolding state; and the electric push-out mechanism can drive the handle main body to move from the initial hidden state to the pre-unfolding state. According to the automatic backswing outer handle structure for the car, the electric push-out mechanism is adopted; whenan actuator receives a signal to be started, the handle main body can be driven through a rotary arm, a push rod and a sliding block to move from the initial hidden state to the pre-unfolding state.

Owner:NINGBO HUADE AUTOMOBILE PARTS

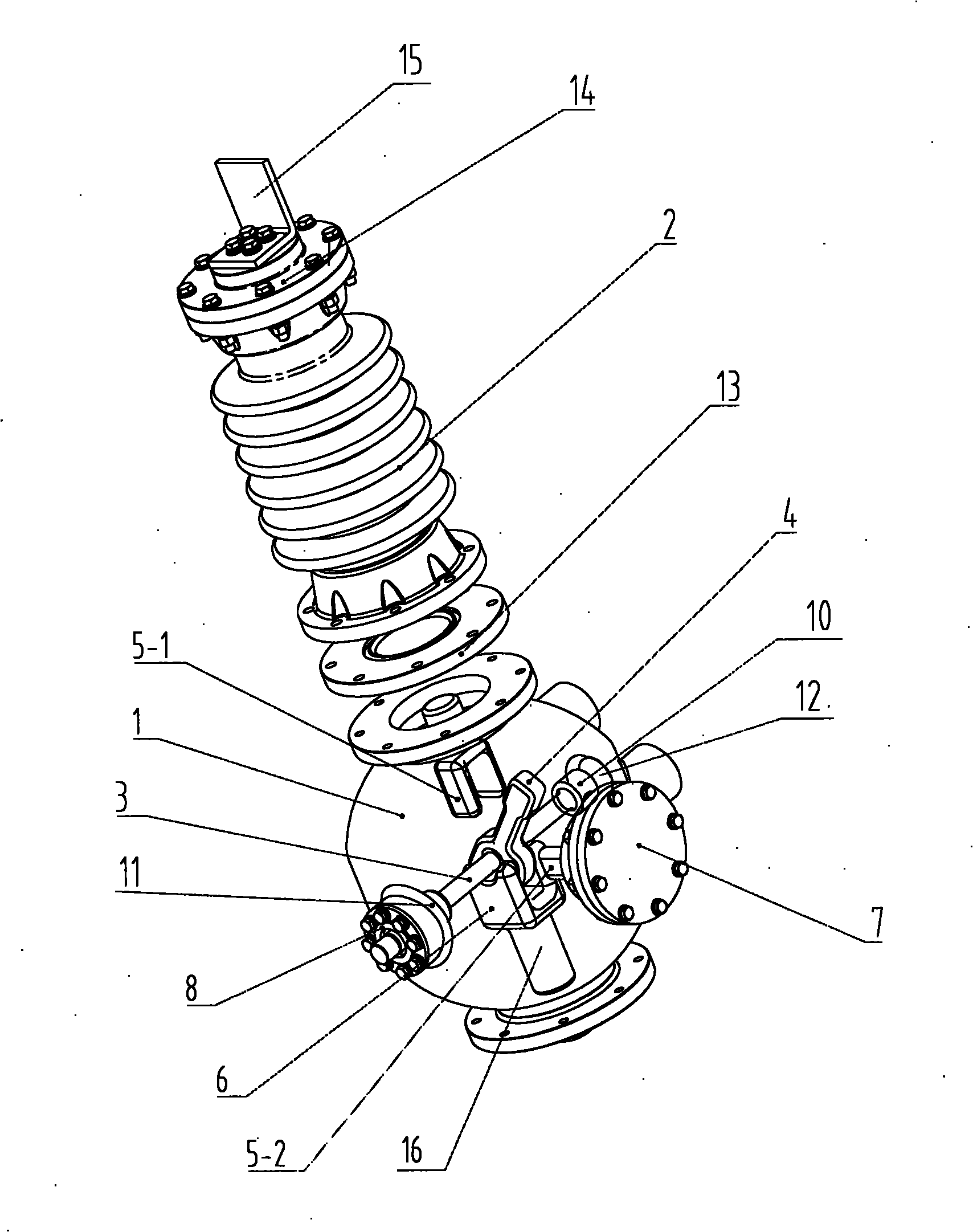

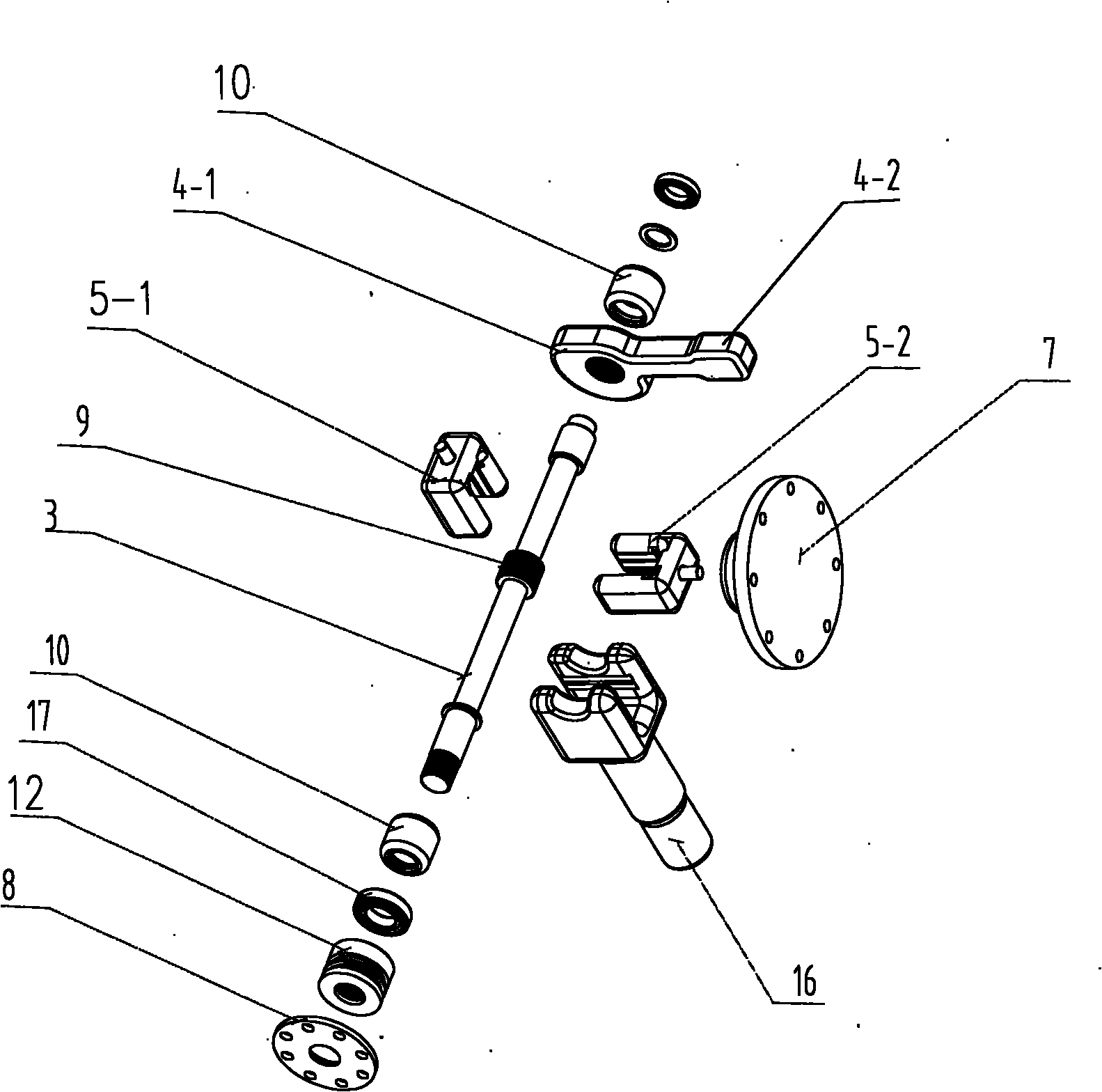

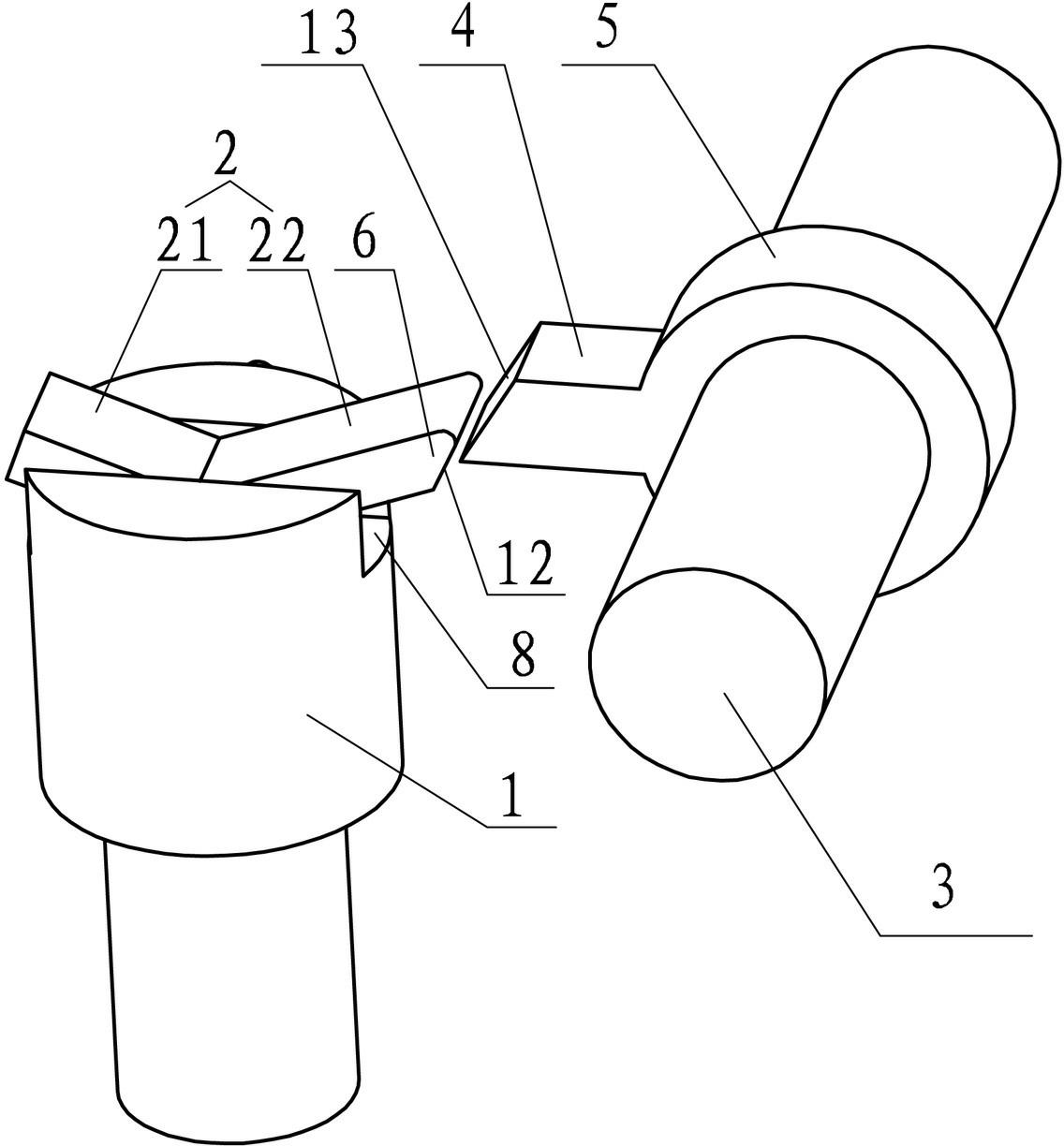

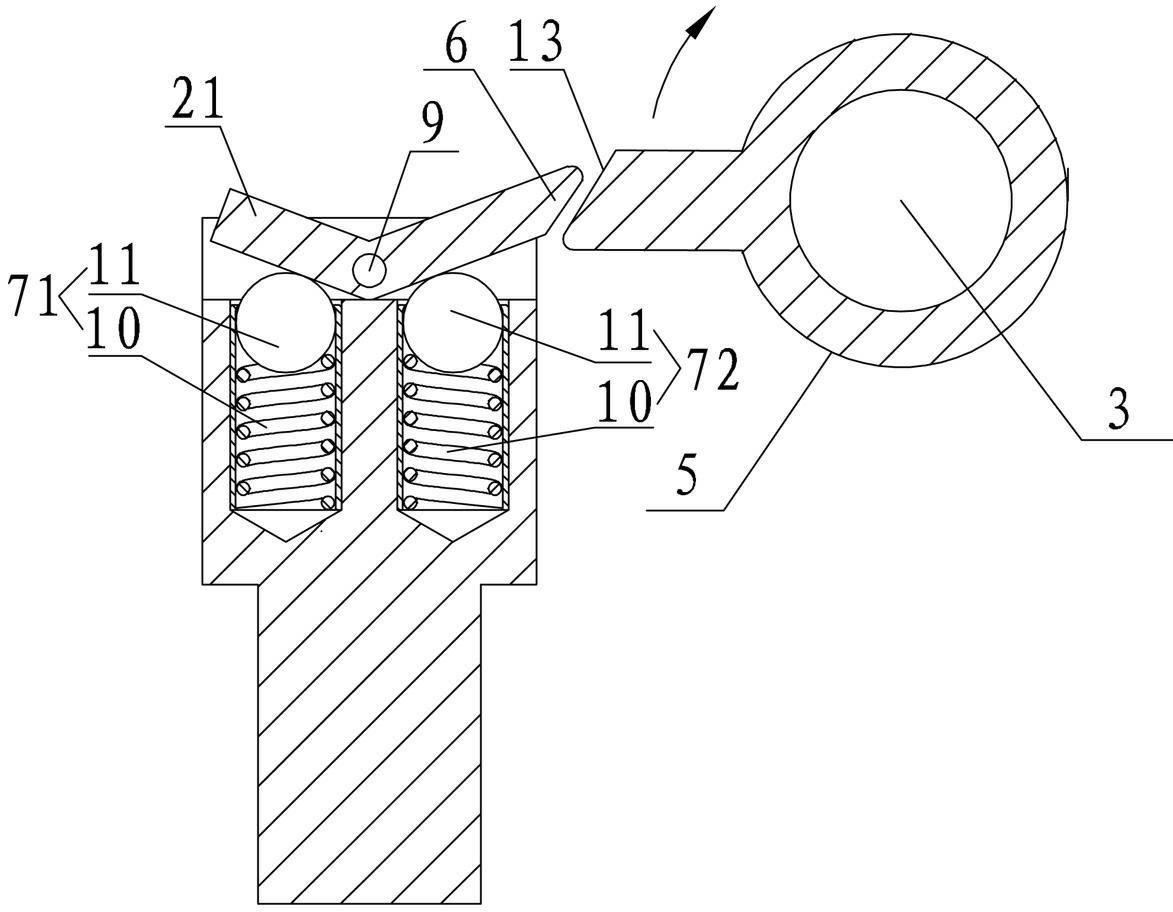

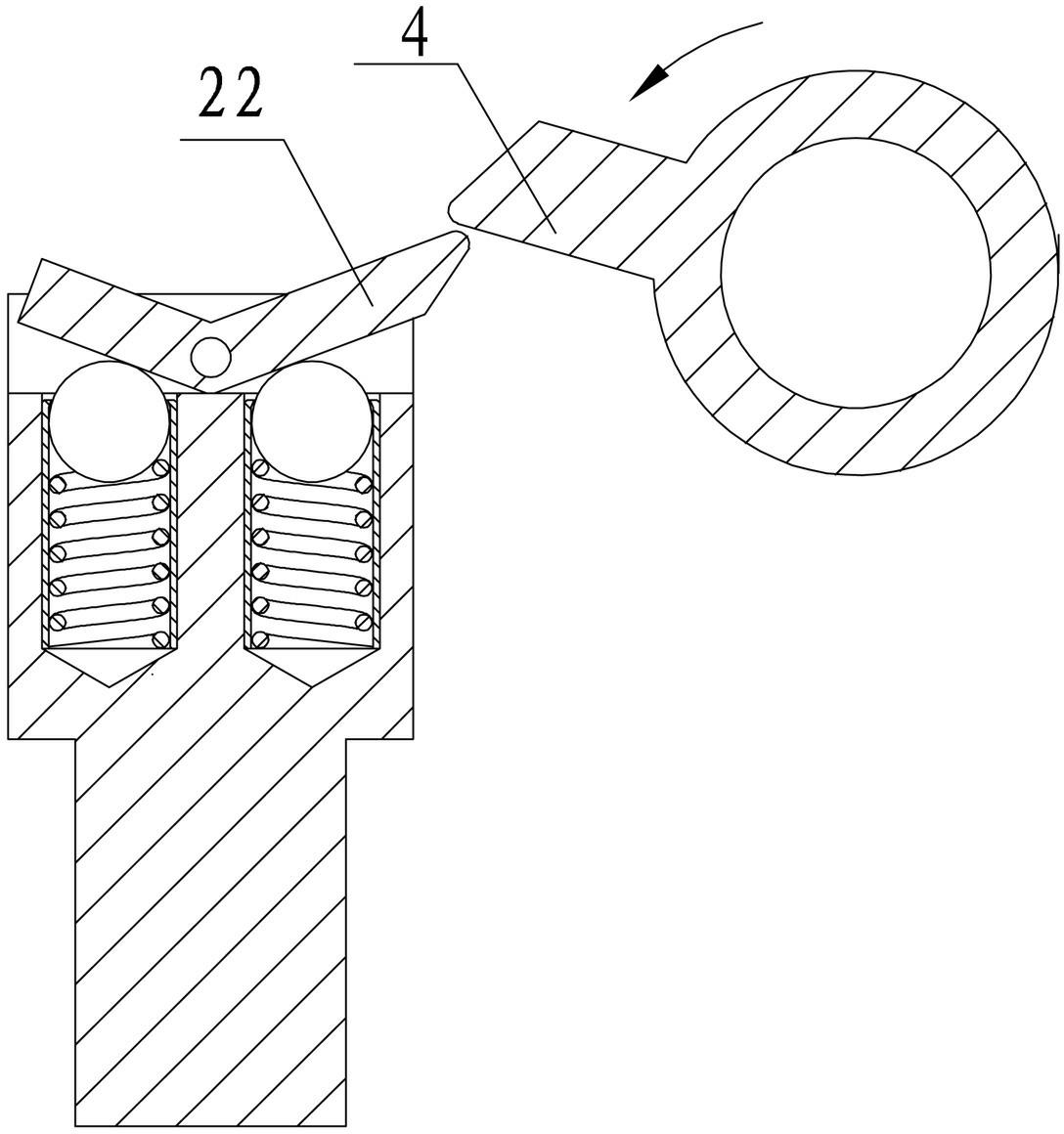

Gear reversing locking device of automobile transmission

InactiveCN102678910AEasy to locate and installAvoid shakingGearing controlEngineeringMechanical engineering

The invention relates to a gear reversing locking device of an automobile transmission. The gear reversing locking device comprises a fixed block (1) fixed relative to a transmission casing, a gear reversing locking block (2) rotatably arranged on the fixed block (1), a resetting device and an interlocking shifting block (5) with a shifting head (4). The gear reversing locking block (2) is provided with a combination portion (6) located in a rotating area of the shifting head (4) formed with rotating of a gear shifting shaft (3). The gear reversing locking block (2) is in the shape of V formed by fixedly connecting a first locking arm (21) and a second locking arm (22), and the combination portion (6) is arranged on the first locking arm (21) or the second locking arm (22). The resetting device includes a first elastic device (71) and a second elastic device (72) for pushing the first locking arm (21) and the second locking arm (22) in elastic abutting mode. By means of the structure, the gear reversing locking device reduces requirements of the resetting device for manufacture and assembly accuracy, achieves identity of reciprocating gear selection force and effectively improves gear shifting quality.

Owner:GREAT WALL MOTOR CO LTD

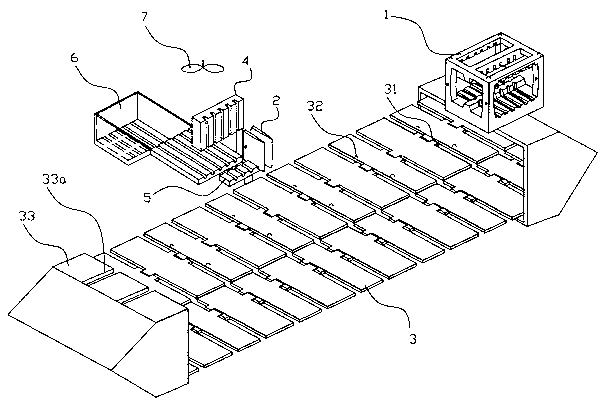

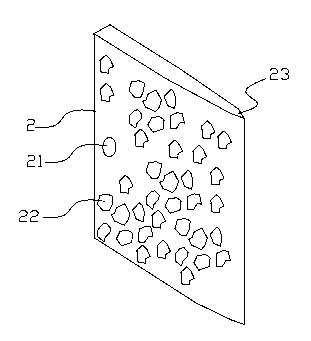

Modularized algae multiplication method

InactiveCN103270989AQuickly reach the purpose of assemblyTo achieve the purpose of assemblyClimate change adaptationPisciculture and aquariaEngineeringAssembly line

The invention discloses a modularized algae multiplication method including the steps such as egg attaching, transplanting and species alternating. A dragging protruded ball is arranged on a conveyor belt integrated with a specified assembly line. Tail end covers are arranged at two ends of the chained conveyor belt. Reserved grooves are formed in the tail end covers to accommodate the dragging protruded ball. A lifting table is arranged near a lateral face of the chained conveyor belt. A reciprocating pushing plate is arranged near the top of the lifting table. Parallel sliding grooves are reserved on the upper surface of the lifting table. A soaking sliding-groove container is arranged near the lifting table and on one side of the lower portion of the reciprocating pushing plate. The soaking sliding-groove container is provided with a water tank capable of containing liquid; and one side edge opening of the water tank extends outside near the lifting table. Thereby, the modularized algae multiplication method has the advantages that splicing and assembling are quick, egg attachment can be controlled, requirements on splicing accuracy are low, mass fishing reef arrangement application is suitable, operation is facilitated extremely, and labor is saved.

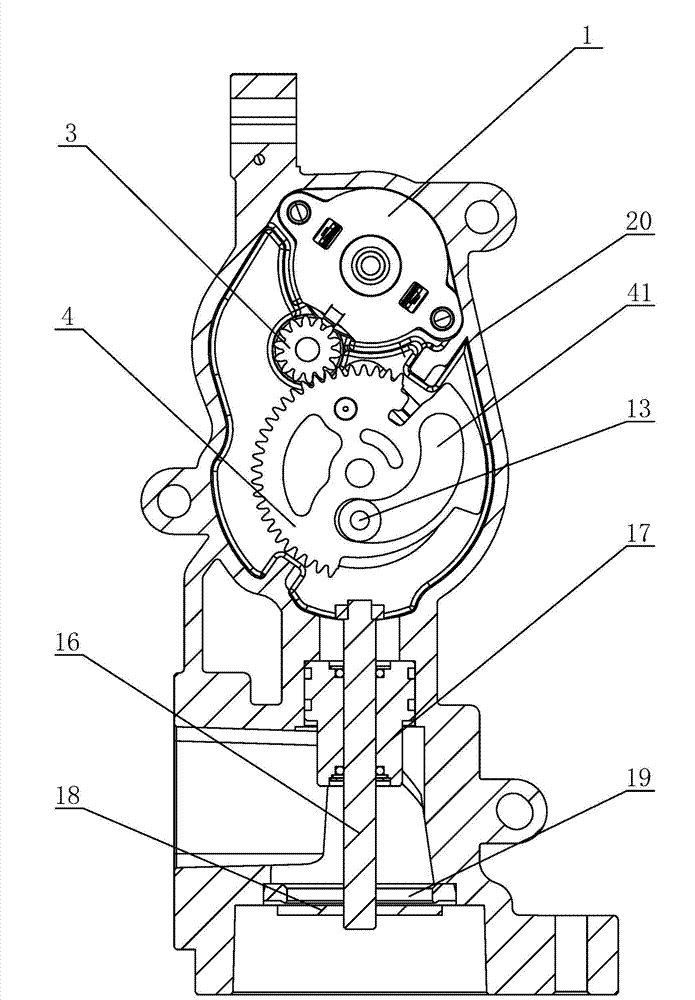

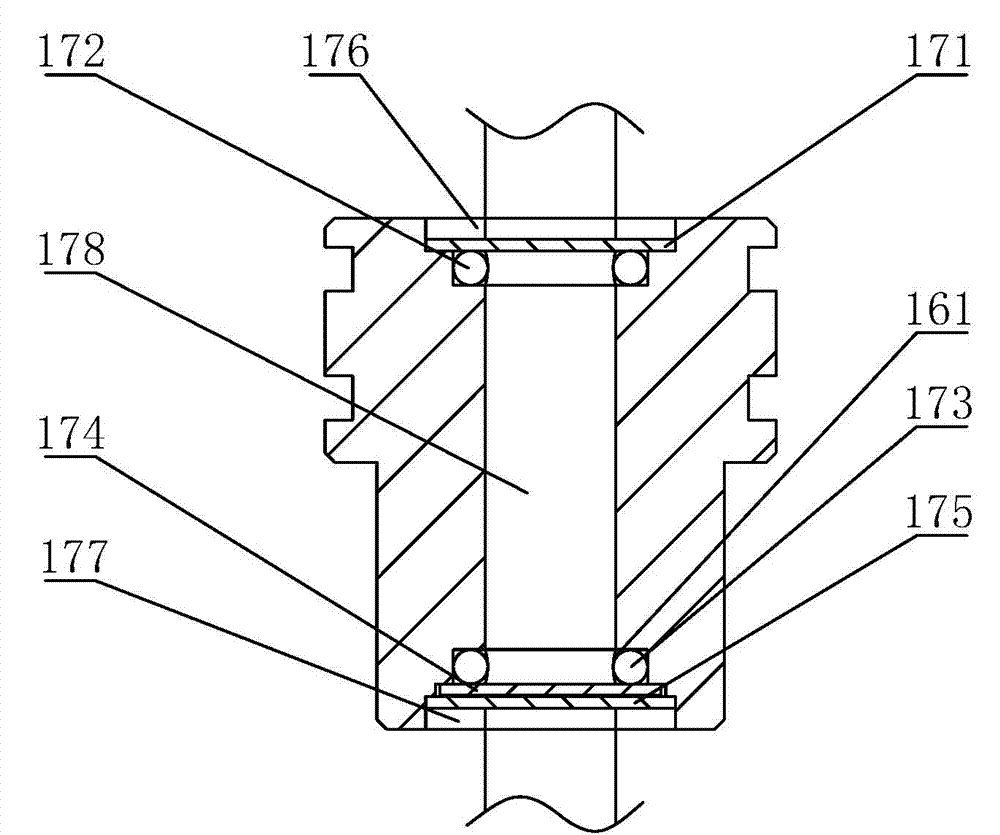

Electric EGR valve

ActiveCN104727989AAccurate opening controlTroubleshoot Signal Transmission DistortionNon-fuel substance addition to fuelInternal combustion piston enginesFailure rateDrive shaft

The invention discloses an electric EGR valve which comprises a shell, a driving motor, a valve rod and a valve block. The driving motor is arranged in the shell, and connected with an intermediate gear, the intermediate gear is meshed with a sector gear, the sector gear is integrally connected with a torsional spring seat, the torsional spring seat is connected with a return torsional spring, the other end of the return torsional spring is fixed to the shell, the sector gear is fixed to a driving shaft, the driving shaft is rotatably arranged in the shell through a rolling bearing and a sliding bearing, an induction magnet is arranged on the driving shaft, and electrically connected with a Hall sensor, a cam groove is formed in the sector gear, a cam bearing is arranged in the cam groove, the cam bearing is connected with a cam bearing shaft and a cam bearing support, the upper end of the valve rod is connected with the cam bearing support, and the lower end of the valve rod is connected with the valve block. The EGR valve is accurate in control, convenient to assemble and low in failure rate.

Owner:KAILONG HIGH TECH

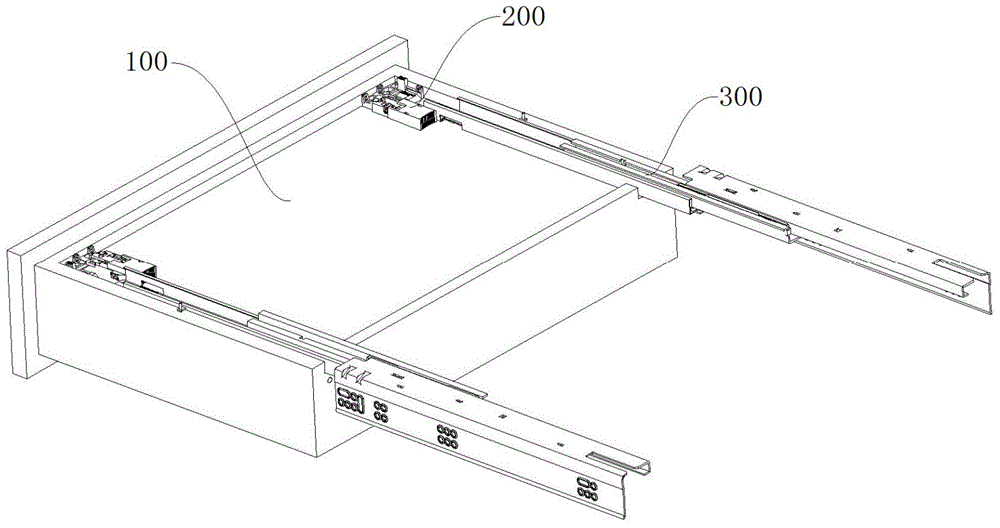

Detachable and adjustable drawer front panel locking device

The invention discloses a detachable and adjustable drawer front panel locking device and belongs to the field of drawer sliding rails. The device comprises a left-right adjusting mechanism, a height adjusting mechanism and a disassembling and assembling mechanism. The left-right adjusting mechanism drives a left-right adjusting block to move left and right through cooperation between an adjusting rotary knob and an adjusting screw rod, and then left-right adjustment of a drawer front panel is achieved. The disassembling and assembling mechanism controls a movable clamping and locking block to move through a guide sliding column on a disassembling button and an inclined sliding groove in the movable clamping and locking block, so that movable clamping teeth on the movable clamping and locking block to be engaged with or disengaged from locking teeth on a movable rail, and drawer assembling and disassembling are achieved. According to the detachable and adjustable drawer front panel locking device, the left-right adjusting mechanism, the height adjusting mechanism and the disassembling and assembling mechanism are originally combined, all functions harmoniously act, drawer assembling and disassembling are convenient and fast, position adjustment is convenient, drawer installation is stable and reliable, meanwhile, the structure is compact, manufacturing is convenient and the cost is low.

Owner:HEFEI REGGAR HARDWARE MFG CO LTD

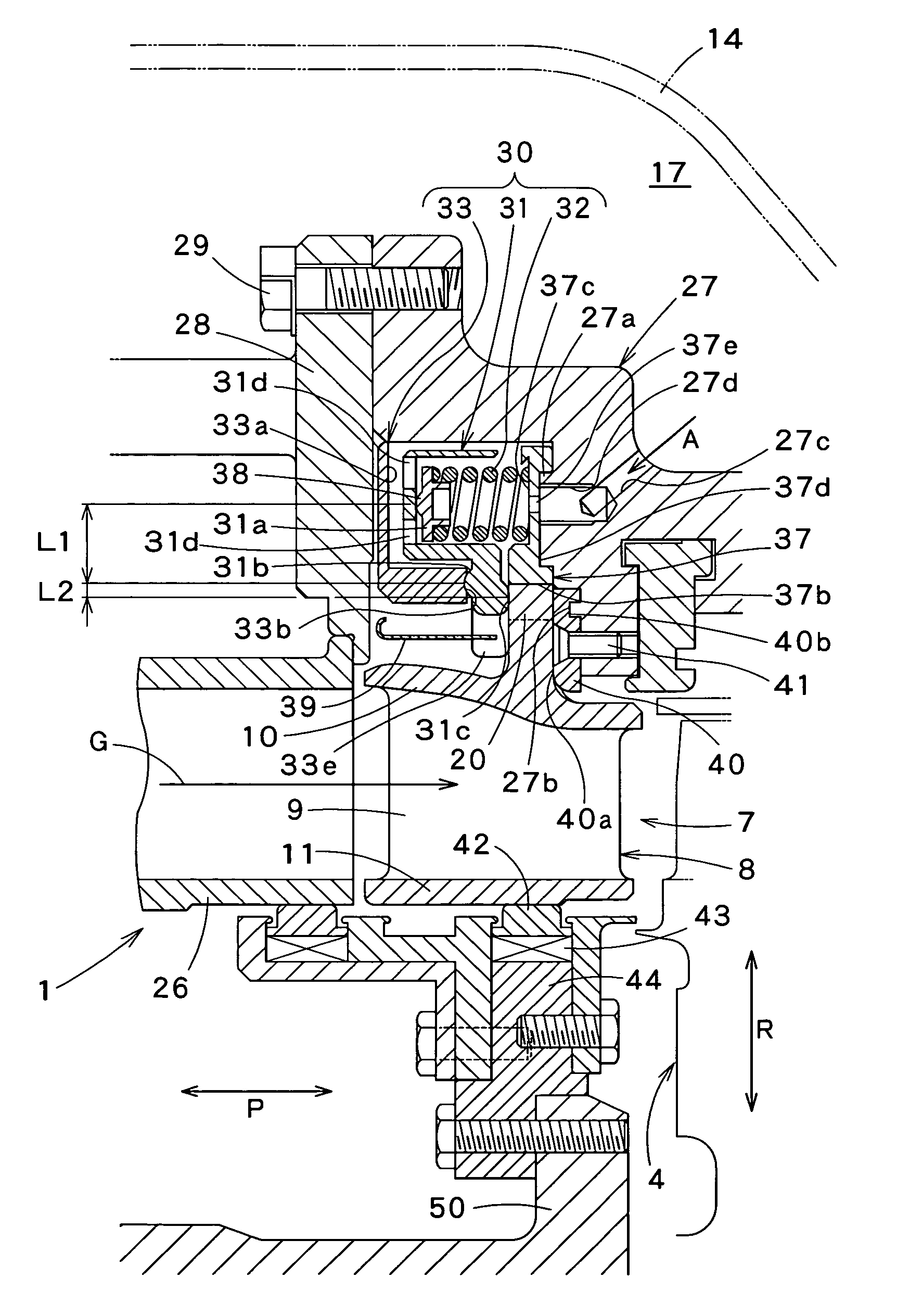

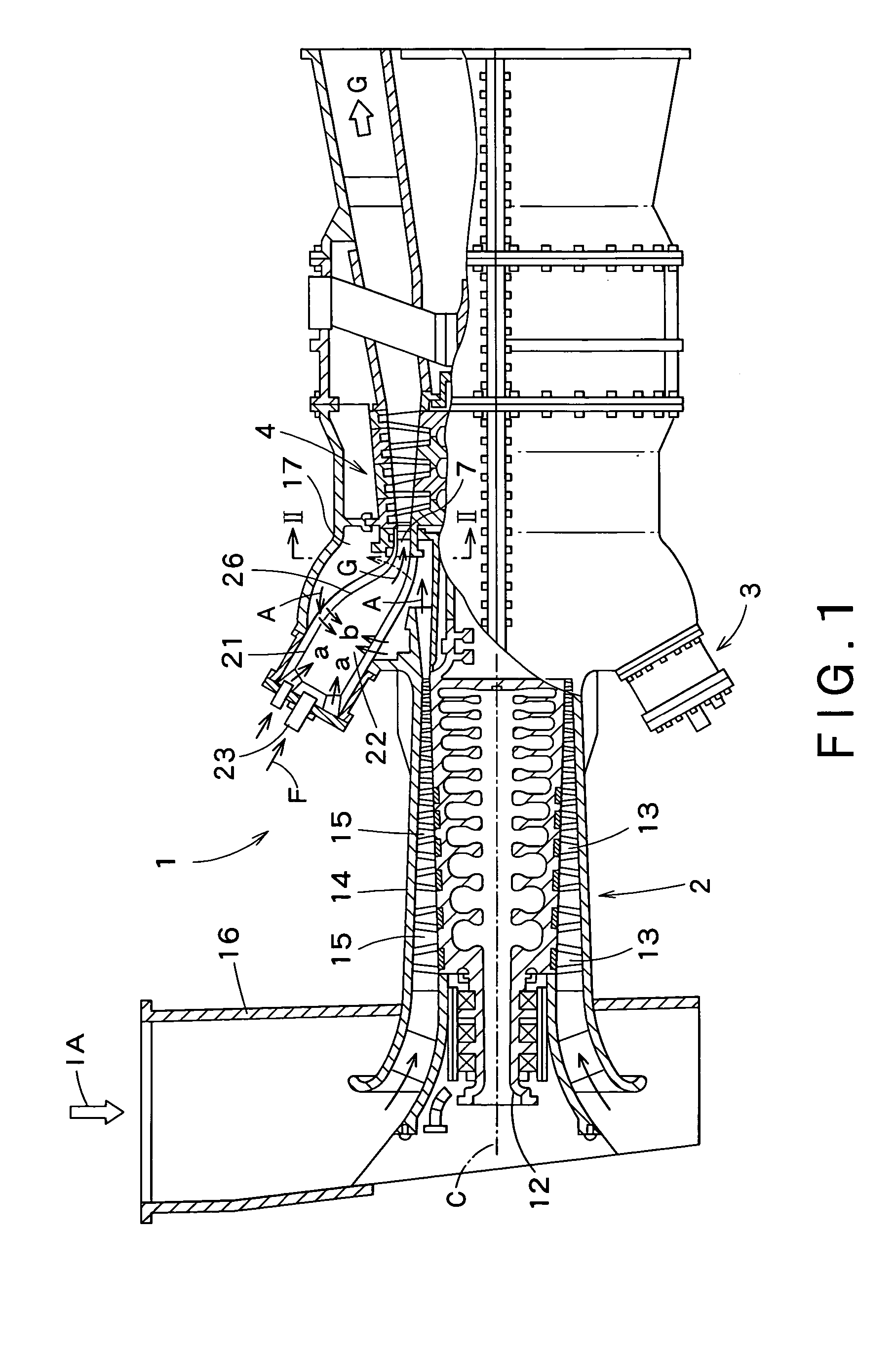

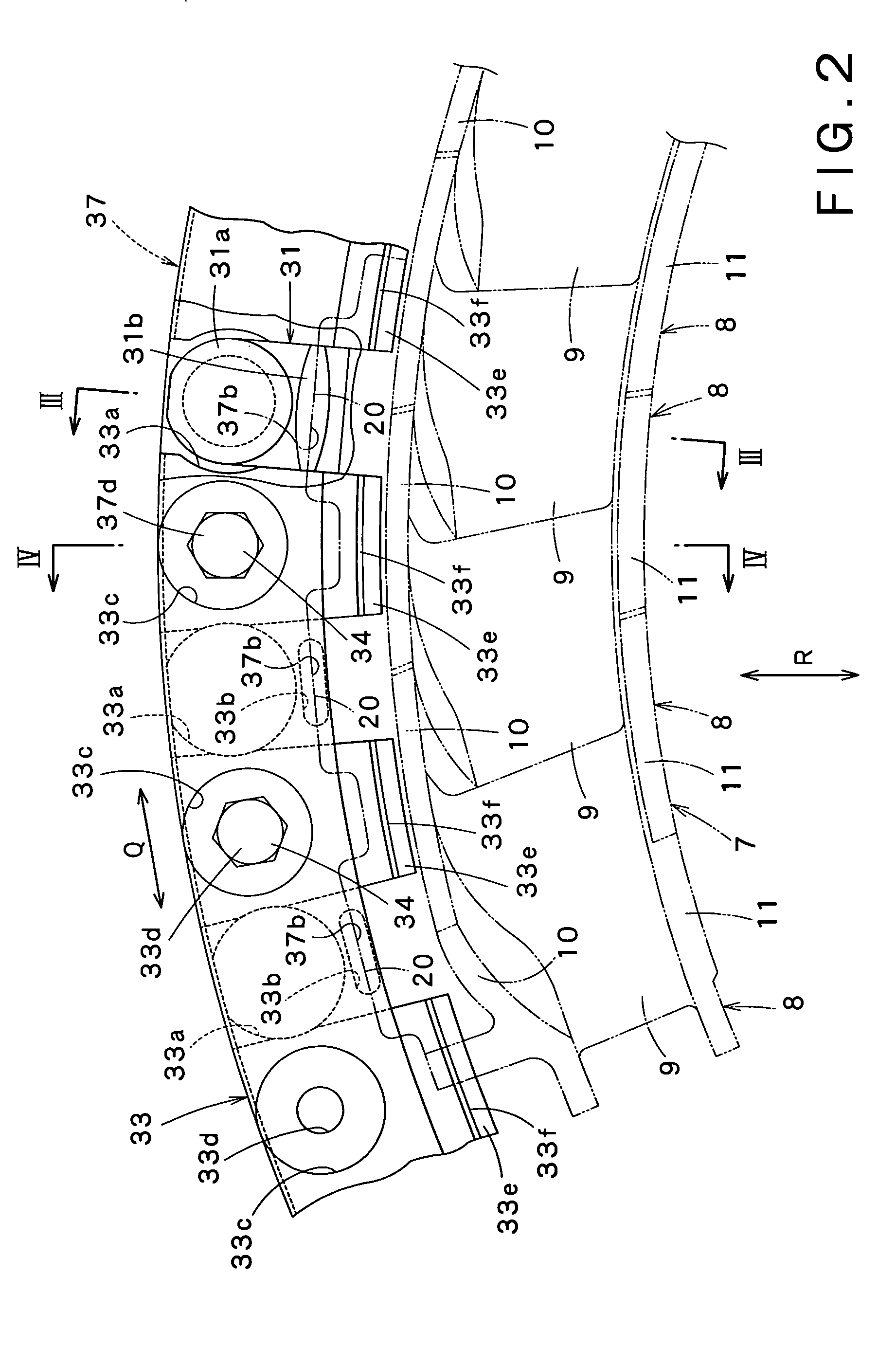

Turbine nozzle support structure

ActiveUS7112042B2Improve heat resistanceProlong lifePump componentsReaction enginesEngineeringTurbine

Owner:KAWASAKI HEAVY IND LTD

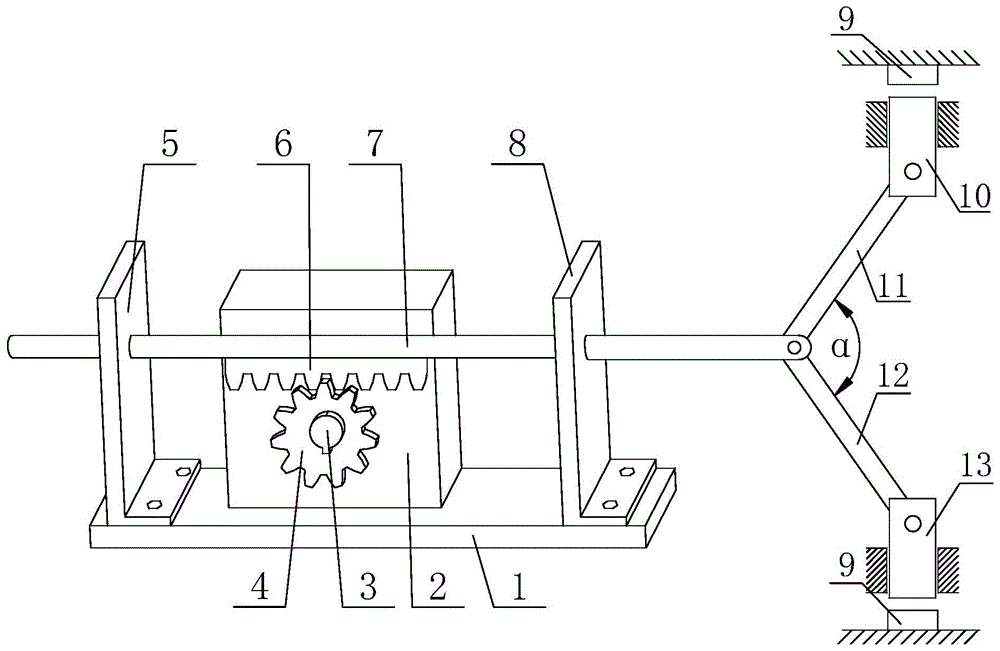

Gear rack driving type decompressor

The invention discloses a gear rack driving type decompressor. The gear rack driving type decompressor comprises a rectangular bottom plate, a power box and a push rod. The gear rack driving type decompressor further comprises a first punching head and a second punching head which are used for punching a work piece; a gear is fixedly installed on a power output shaft of the power box, and the gear is meshed with a rack to form a gear rack transmission pair; the rack is fixedly installed at the downside of the push rod, and the push rod is glidingly installed on a first supporting plate and a second supporting plate; the first supporting plate and the second supporting plate are fixedly installed at upside of the rectangular bottom plate through a screw; the front end of the push rod is respectively and rotationally connected with one end of a first linking rod and a second linking rod, and the other end of the first linking rod is rotationally connected with the first punching head, and the other end of the second linking rod is rotationally connected with the second punching head. The gear rack driving type decompressor has the following characteristics of being reasonable in design, convenient to operate, high in degree of automation, high in production efficiency, time-saving and labor-saving, long in service life, wide in application scale, low in production cost, and convenient to popularize and use.

Owner:XIAN ZHONGZHI HUIZE PHOTOELECTRIC TECH

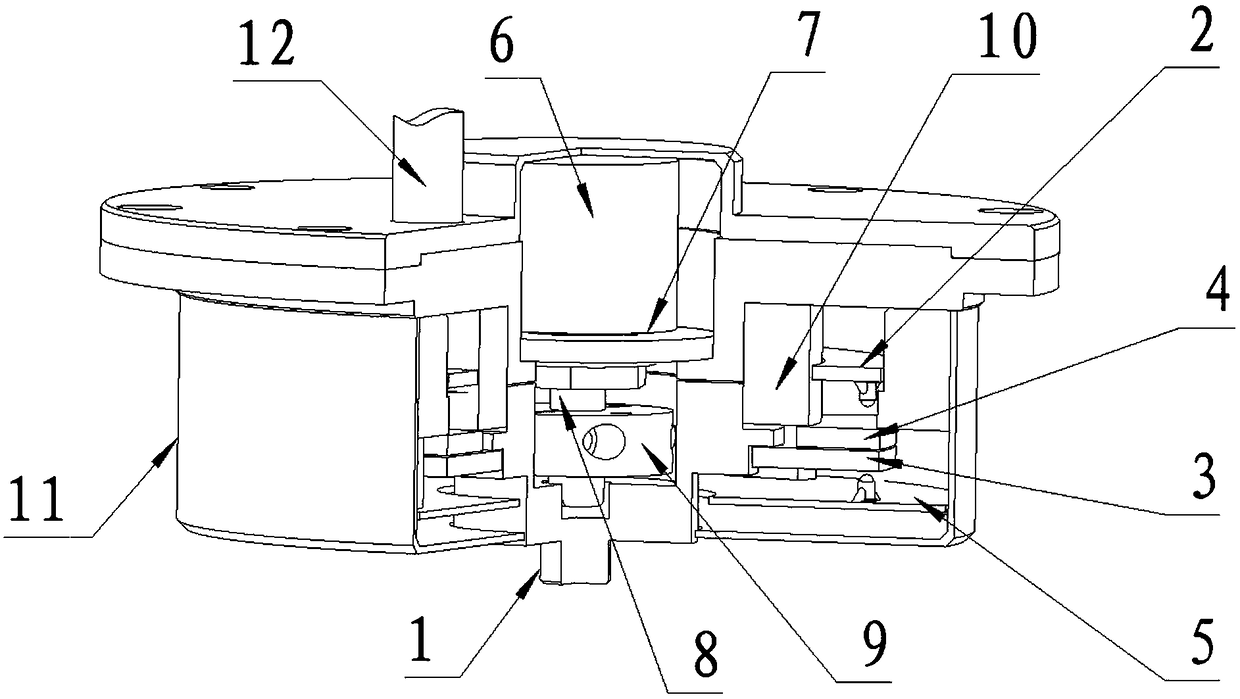

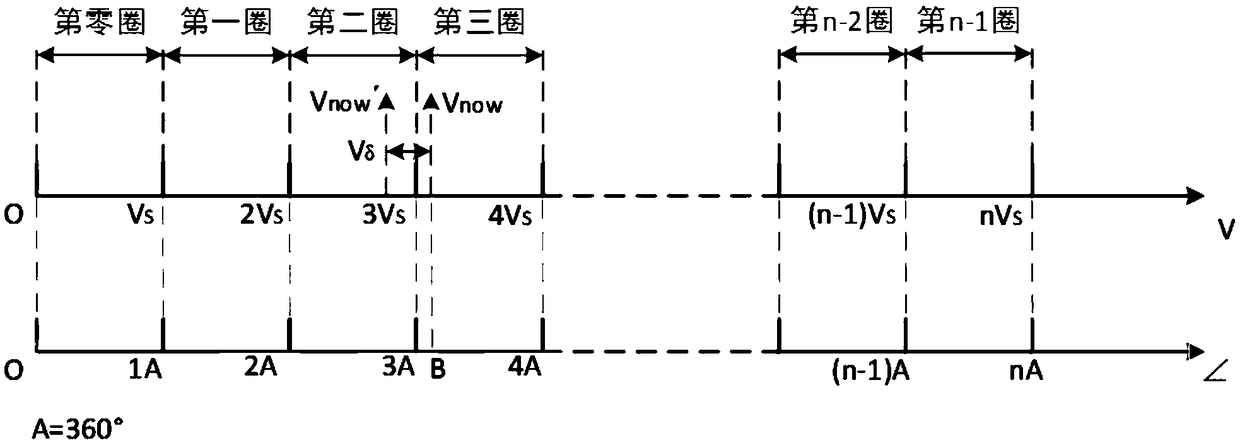

Composite angle sensor with function for measuring multi-turn angle

ActiveCN109238177AImprove angle measurement accuracyAccurate measurementUsing optical meansGratingAngular degrees

The invention relates to the technical field of the sensor, and provides a composite angle sensor with a function for measuring multi-turn angle. The composite angle sensor comprises a shell, and an absolute photoelectric angle encoder, a potentiometer and a circuit board which are arranged in the shell; the absolute photoelectric angle encoder comprises an input shaft, a light source, a movable grating and a stationary grating, wherein the input shaft is arranged at an axes of the shell and the movable grating is fixed on the same; the light source is arranged above the movable grating and the fixed grating; the movable grating and the fixed grating are engraved with the absolute codes; the potentiometer comprises a stator and a rotor; the rotor is connected with the input shaft of an elastic coupling; the input shaft can drive the movable grating and the rotor to rotate; the circuit board comprises a sampling module and a micro control unit; the sampling module is electrically connected with each of the micro control unit, the absolute photoelectric angle encoder and the potentiometer. The accurate measurement of the full-scale number of turns can be realized, and the measurementprecision of the multi-turn angle is improved.

Owner:大连探索者科技有限公司

On-position type gas analysis system with on-position calibration function

ActiveCN101281129BAssembly accuracy is lowSimple installation and debuggingScattering properties measurementsColor/spectral properties measurementsGas analysisIn situ calibration

The invention discloses an in situ gas analysis system with an in situ calibration function, which includes a light emitting device, a light receiving device, a signal analysis device, a mechanical connection structure and a measuring probe, wherein, the light emitting device and the light receiving device is combined with a measured gas pipeline through the mechanical connection structure, and also includes an attached tube, a control device and a gas replacement device; the attached tube moveablely sleeves on the measuring probe, the extension end of the attached tube and the measuring probe are matched with each other in a measured gas pipeline and on a measured optical path to form a closed pipeline which is isolated from the measured gas, the gas analysis system can be in calibrationor measurement situation caused by the extension or the retraction of the attached tube, the control device is used to control the attached tube and the measuring probe to form the closed pipeline which is isolated from the measured gas, the gas replacement device comprising a gas source with a known concentration, a valve and a ventilation joint communicates with the closed pipeline.

Owner:FOCUSED PHOTONICS

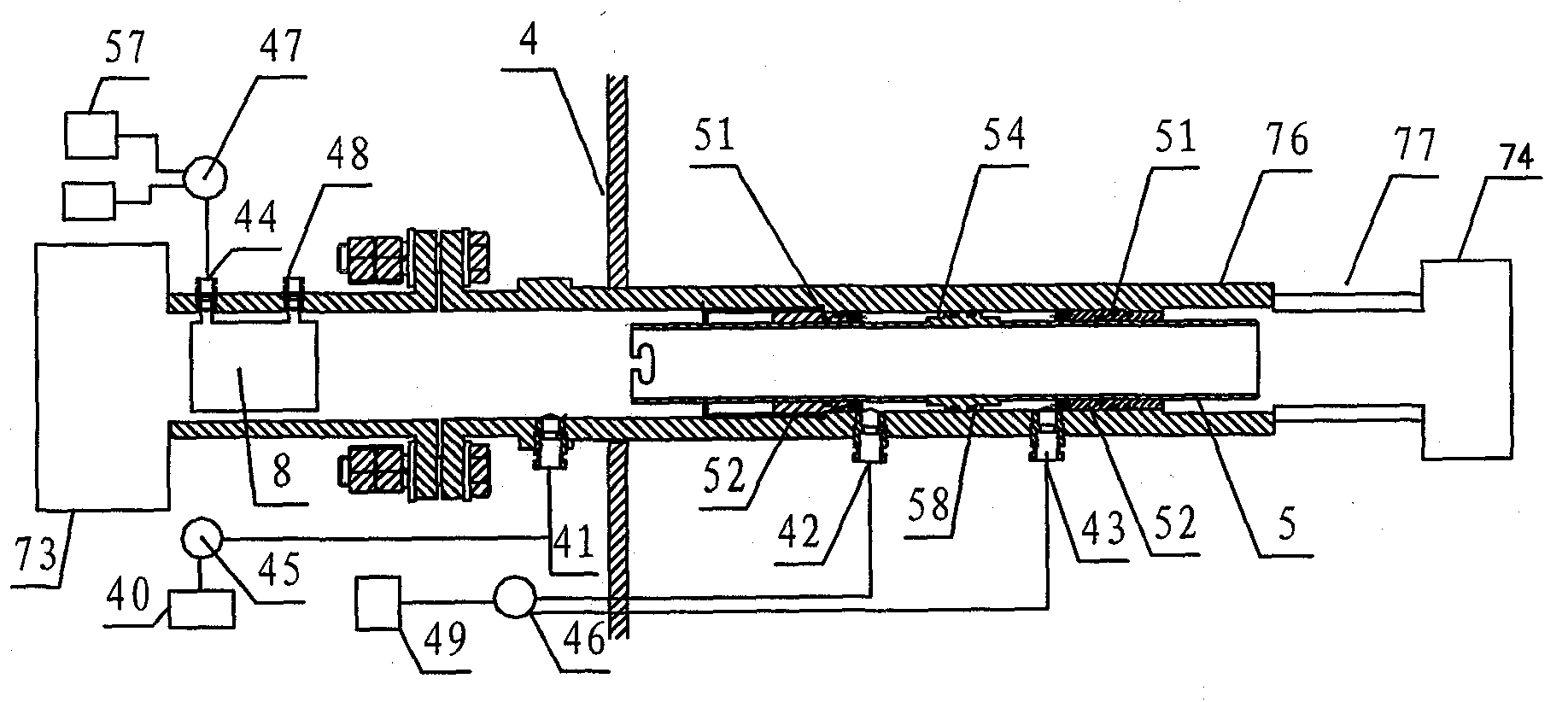

Pneumatic brake motor and pneumatic brake method

ActiveCN101447714ASimple structureReliable brakingBraking elementsMechanical energy handlingElectricityEngineering

The invention relates to a pneumatic brake motor and a pneumatic brake method of a pneumatic brake motor friction plate. When compressed air is filled into a brake cylinder through an air inlet hole in the brake cylinder, a piston in the brake cylinder pushes a brake plate to press the friction plate in the motor and completes the brake action; when the compressed air is released, the piston in the brake cylinder is reset, and the brake plate is reset under the action of a return spring, thereby completing one brake action. The invention has the advantages that: firstly, the invention does not use electricity and generates no heating; secondly, the structure is simple, the brake is reliable and the braking force is adjustable; thirdly, the manufacturing cost is low, the assembly precision requirement is low and the invention has no faults basically.

Owner:HANGZHOU XIANGSHENG ABRASIVE MACHINE MFG

Horizontal thin type numeral control panoramic table for point gearing cambered surface cam mechanism

The invention relates to a digit-control rotation cam of horizontal thin point mesh arc cam, wherein it comprises a base 6, and a rotation axle with bearing; the rotation axle via the bearing is arranged on the base; the base also has a rotation disc connected to the rotation axle; the outer side of rotation disc has a taper roller meshed with the arc cam inside the base. The invention uses controllable mesh contact; when the profile of taper roller and the profile of arc cam rotate, the adaptive ability of device on the position error and shape error can be improved; the invention has long service life, high positioning accuracy and simple process.

Owner:SHAANXI UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com