Scanning galvanometer laser-high frequency pulse TIG composite welding method

A high-frequency pulse and scanning galvanometer technology, which is applied in laser welding equipment, welding equipment, welding accessories, etc., can solve problems such as poor fusion of side walls and interlayers, poor formation of bottom welding, and large welding heat input, etc., to achieve Improve the quality of interlayer fusion, avoid the collapse of molten pool, and reduce the effect of heat input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Taking the SA-738 Gr.B steel butt horizontal welding with a plate thickness of 50mm and a blunt edge of 6mm as an example, the welding implementation steps and process are explained in detail.

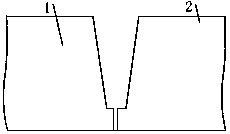

[0019] Groove making: machine the workpiece 1 to be welded and the workpiece 2 to be welded to make a welding groove;

[0020] Assembly: Assemble the workpiece to be welded and the workpiece to be welded;

[0021] Removal of dirt: remove scale, oil, rust, water and other dirt from the groove and its surroundings before welding;

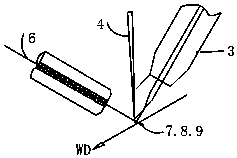

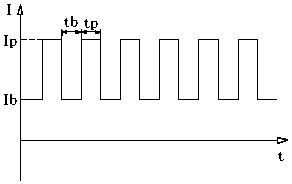

[0022] Bottom welding: scanning galvanometer laser-high-frequency pulse TIG composite welding torch 3 is used for bottom welding through laser beam 4, welding wire 6 has a diameter of φ1.2mm, laser power is 3.5kW, and the scanning shape is linear 7, and the scanning width is 2mm. Speed 250mm / s, peak current 350A, base current 105A, duty cycle 50%, pulse frequency 300HZ, welding speed 300mm / min, argon flow 20L / min;

[0023] Filling welding: scanning ...

Embodiment 2

[0025] Taking the horizontal butt welding of A514 Gr.Q steel with a plate thickness of 60mm and a blunt edge of 8mm as an example, the welding implementation steps and process are explained in detail.

[0026] Groove making: machine the workpiece to be welded and the workpiece to be welded to make a welding groove;

[0027] Assembly: Assemble the workpiece to be welded and the workpiece to be welded;

[0028] Removal of dirt: remove scale, oil, rust, water and other dirt from the groove and its surroundings before welding;

[0029] Bottom welding: scanning galvanometer laser-high frequency pulse TIG composite welding torch is used for bottom welding with laser beam, welding wire diameter φ1.0mm, laser power 4.5kW, scanning shape is circular 8, scanning width 1.5mm, swing speed 500mm / s, peak current 400A, base current 160A of peak current, duty cycle 50%, pulse frequency 500HZ, welding speed 350mm / min, argon gas flow rate 15L / min;

[0030] Filling welding: scanning galvanome...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com