Production method of polyamide-6 fiber

A production method and technology of nylon, which is applied in the production field of nylon 6 fiber, can solve the problems such as the air blowing is easy to be distorted and the cooling performance is not good, so as to achieve good spinning cooling effect, good market competitiveness, and avoid uneven cooling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

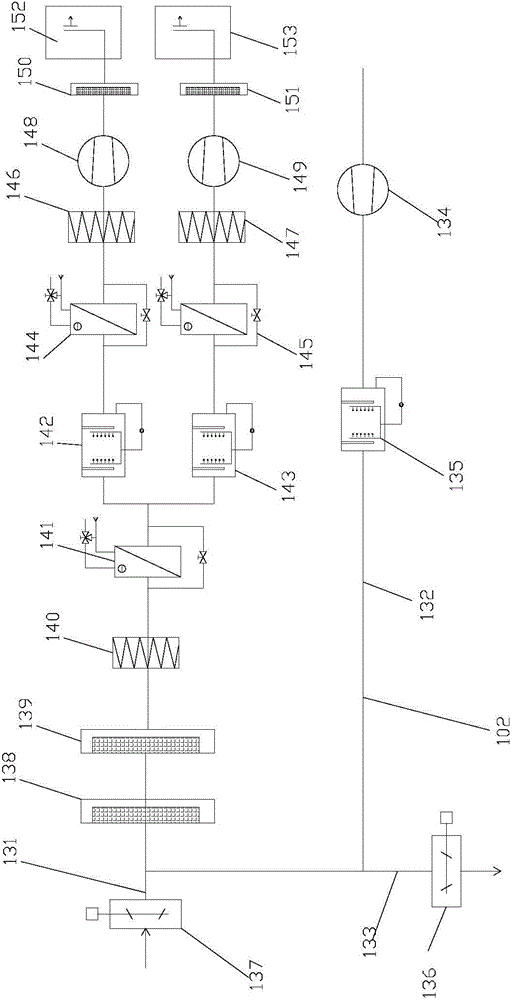

[0028] The production method of the nylon 6 fiber described in the present embodiment may further comprise the steps:

[0029] a. Add nylon 6 chips into the screw extruder for melt extrusion;

[0030] b. Transport the molten mixed melt to the spinning box, and extrude the melt into the spinning assembly through the metering pump for spinning;

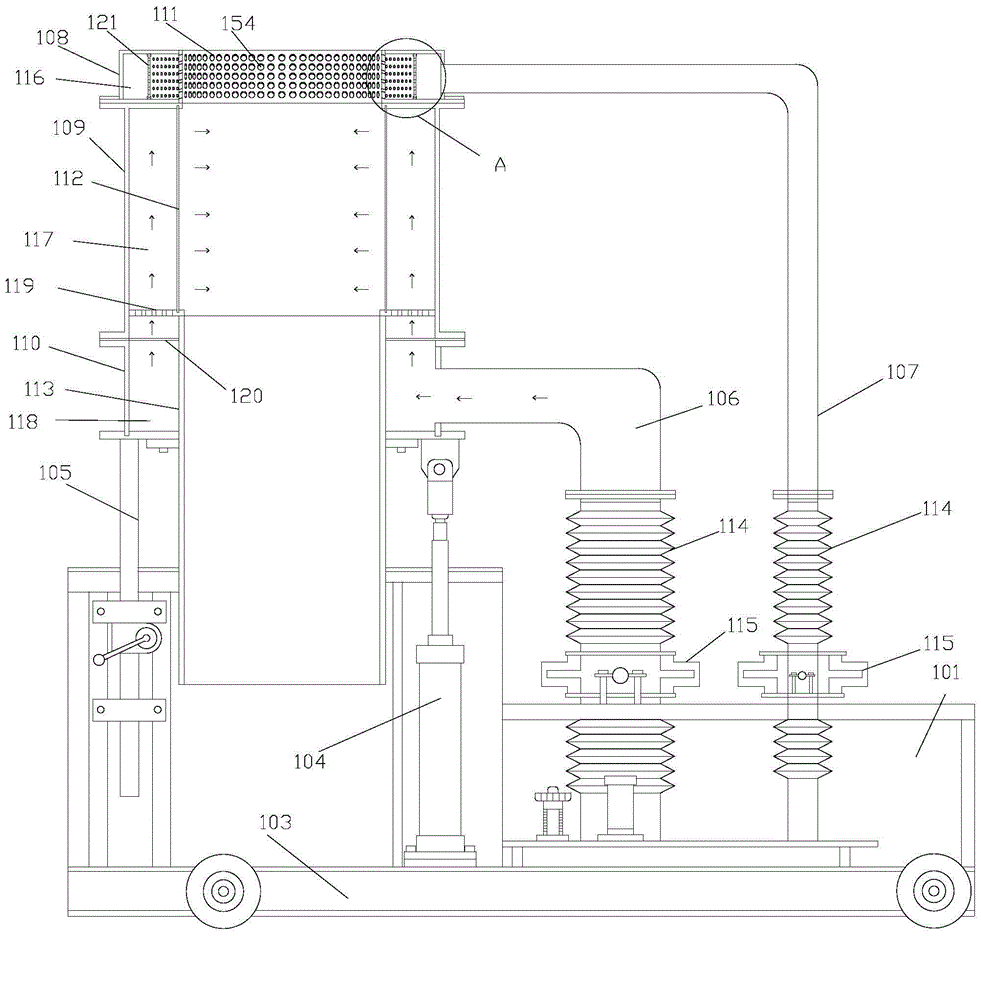

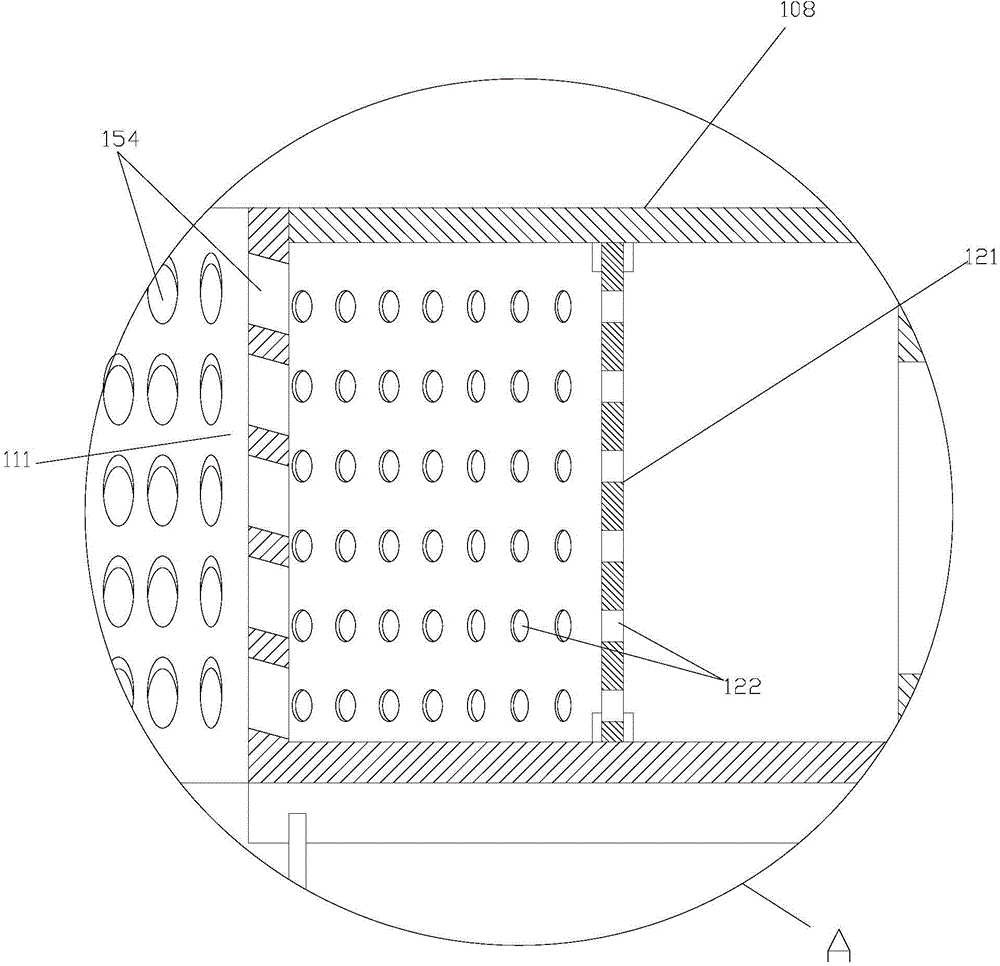

[0031] c. Use the ring blowing spinning cooling device to cool and shape the tow with ring blowing, and then oil the cooled tow. In the ring blowing cooling device, the ring blowing of the tow is divided into upper and lower Two layers and independent of each other, the upper ring air blows out obliquely upwards, the lower ring air is the main body, blows out horizontally from the ring blower, and the temperature and temperature of the upper ring air are lower than the lower ring air;

[0032]d. Pre-network the oiled tow through the tunnel and the wire gate, then draft the tow with cold rollers and hot rollers, add the drawn tow to the...

Embodiment 2

[0038] The production method of nylon 6 fiber described in this embodiment is different from Example 1 in that the control parameters are different: in the step a, the heating zones of the screw extruder are six, and the temperature is 262° C. in the first zone, and 262° C. in the second zone. zone 268°C, zone three 268°C, zone four 268°C, zone five 268°C, zone six 268°C, the melt pressure is 12.5Mpa; the temperature of the spinning box in the step b is 270°C; the step c The air blowing temperature of the middle and upper rings is 19.5°C, the speed is 0.5m / s, and the humidity is 78%. The temperature of the lower ring blowing is 20°C, the speed is 0.5m / s, and the humidity is 80%. In the step d, two cold rolls are used for drafting first, and then two hot rolls are used for drafting. The temperature of the hot rolls is 170° C., the drafting speed is 1.1, and the winding speed is 4200 m / min.

Embodiment 3

[0040] The production method of nylon 6 fiber described in this embodiment is different from Example 2 in that the control parameters are different: in the step a, there are six heating zones of the screw extruder, and the temperature is 261° C. in the first zone and 261° C. in the second zone. zone 267°C, zone three 267°C, zone four 267°C, zone five 267°C, zone six 267°C, the melt pressure is 12Mpa; the temperature of the spinning box in the step b is 267°C; the step c The air blowing temperature of the middle and upper rings is 18°C, the speed is 0.4m / s, and the humidity is 70%. The temperature of the lower ring blowing is 18.5°C, the speed is 0.4m / s, and the humidity is 75%. In the step d, two cold rolls are used for drafting first, and then two hot rolls are used for drafting. The temperature of the hot rolls is 160° C., the drafting speed is 1.1, and the winding speed is 4100 m / min.

[0041] The nylon 6 fiber performance parameter that makes in above-mentioned three embod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| coefficient of variation of linear density | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com