Patents

Literature

99results about How to "Avoid uneven cooling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

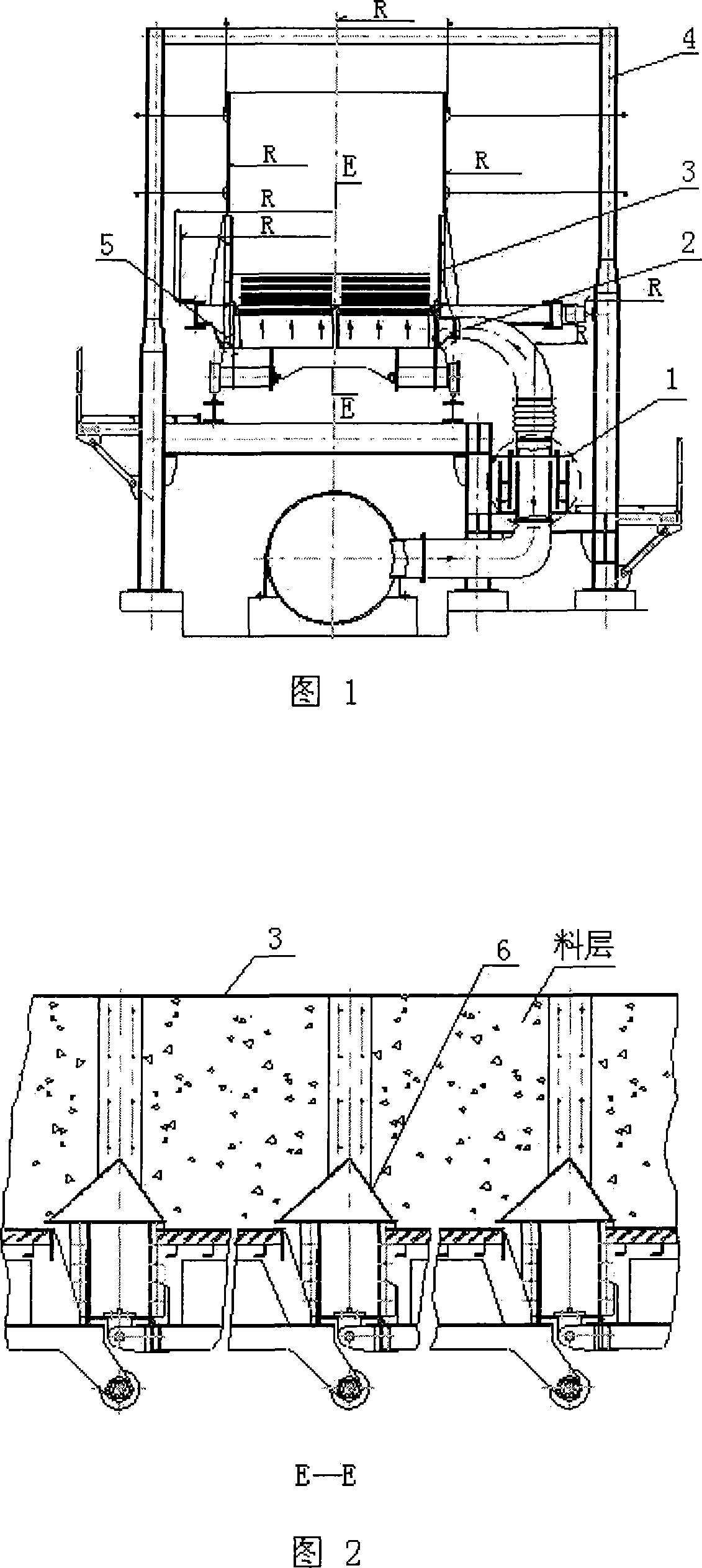

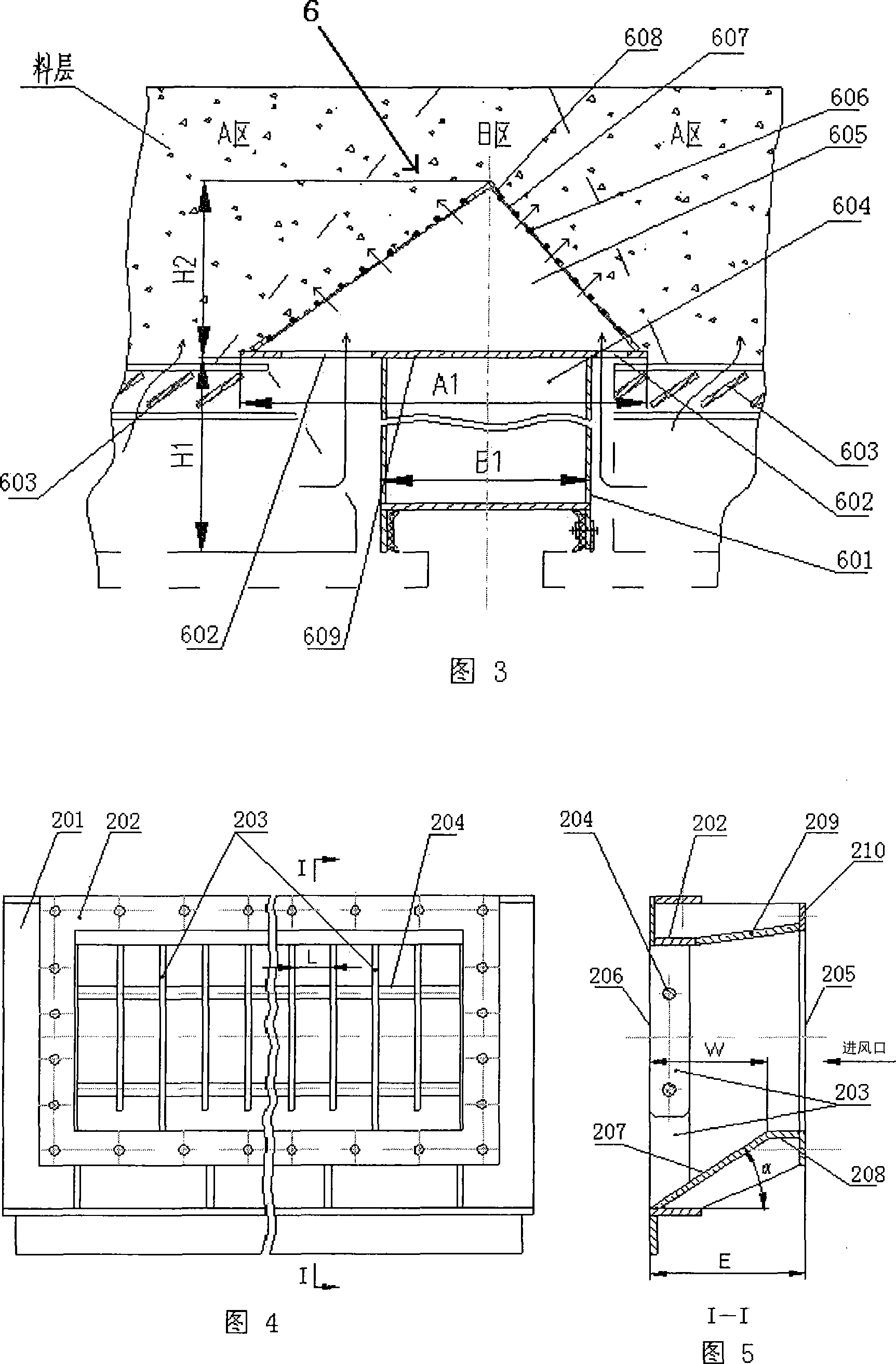

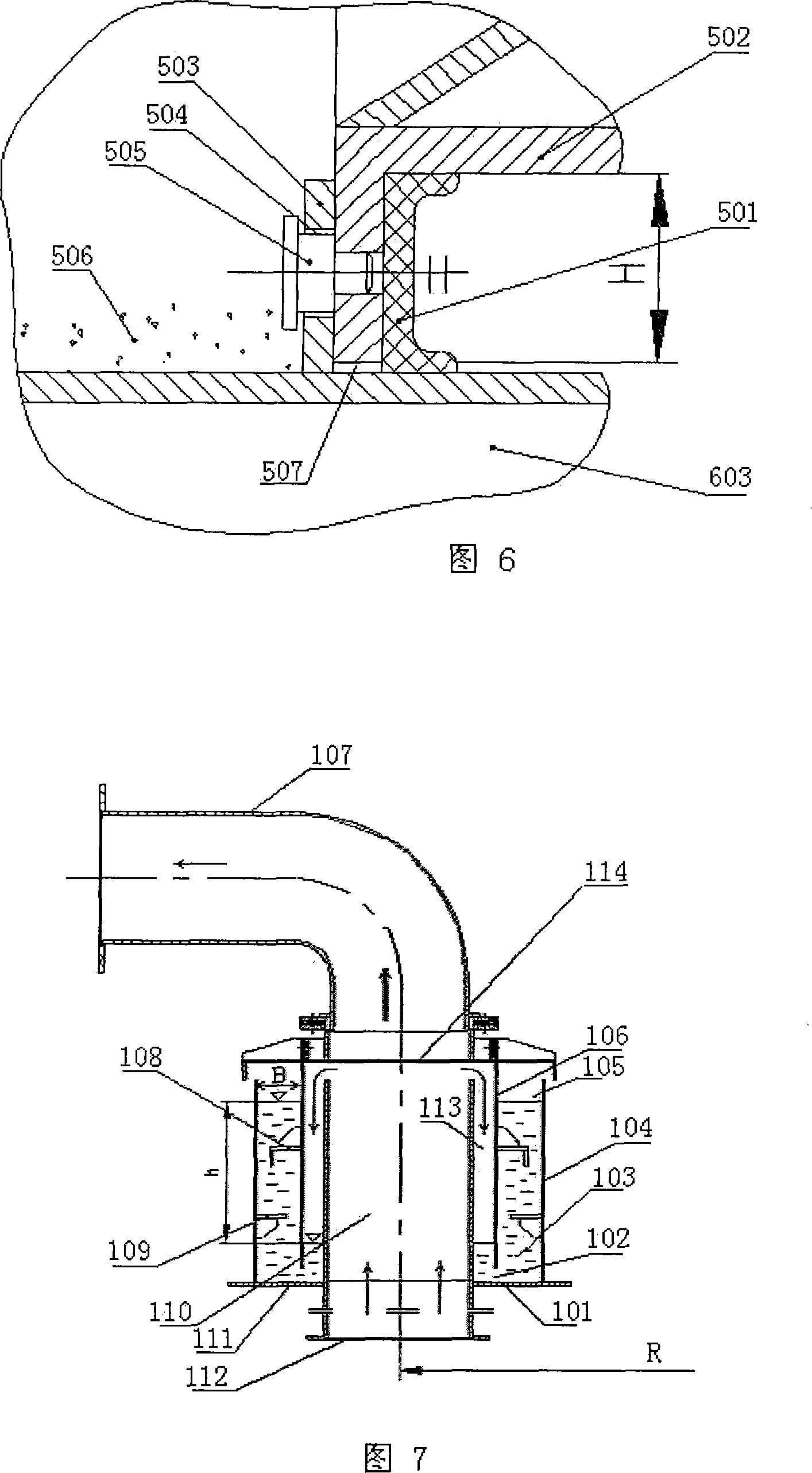

Improved blast circular cooling machine

ActiveCN101118118AImprove cooling effectImprove sealingCharge manipulationFurnace typesForced-airEngineering

The present invention discloses an improved rotary forced-air cooler, which comprises a double layer trolley, a supporting beam structure, a material blocking proof air duct sealing plate arranged at the connecting part of the double layer trolley and an air supplying system, a double layer trolley unit static seal device and an air duct device. The supplying system structure is based on a rectangular beam, a triangle beam is arranged on the rectangular beam, and a plurality of ventilation channels are arranged on the bevel edge steel plates at the both waists; an air duct pipe is arranged on the air vent of the material blocking proof air duct sealing plate, an inclined plate inclining upwards from the air vent at the bottom part of the air duct pipe has a transition to a horizontal plate, a stopping ventilation fence is added to the air duct pipe at the side of the trolley; two rubber sealing parts with extended bottom edges are arranged at the outer sides of the lower parts of inner and outer sealing plates of the double layer trolley unit static seal device, an ash baffle plate which can move up and down is hung at the inner side; an air water sealing wave subduing device adopting a damping plate is arranged on the air duct device. The present invention further improves the sealing performance of the equipment, and reduces energy consumption and pollution.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

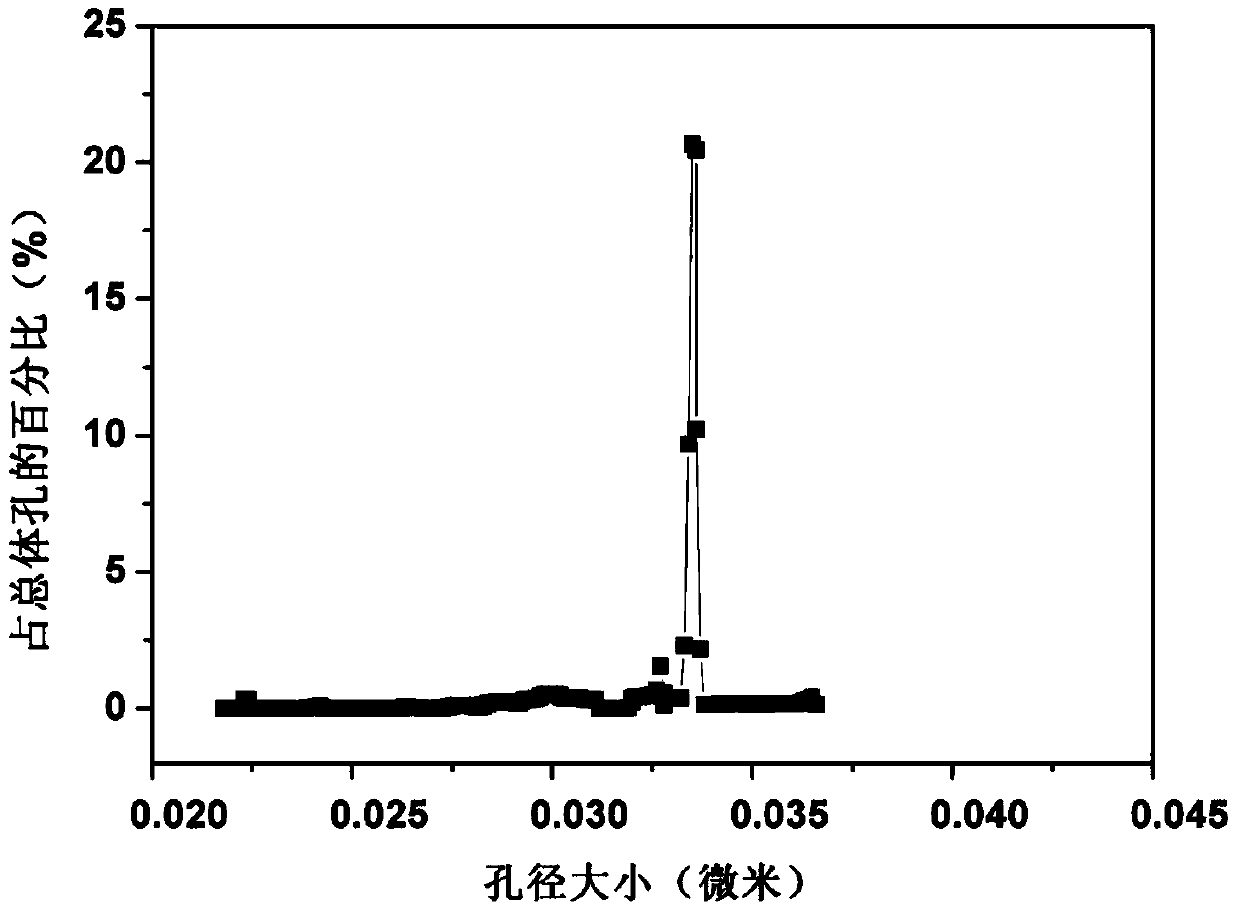

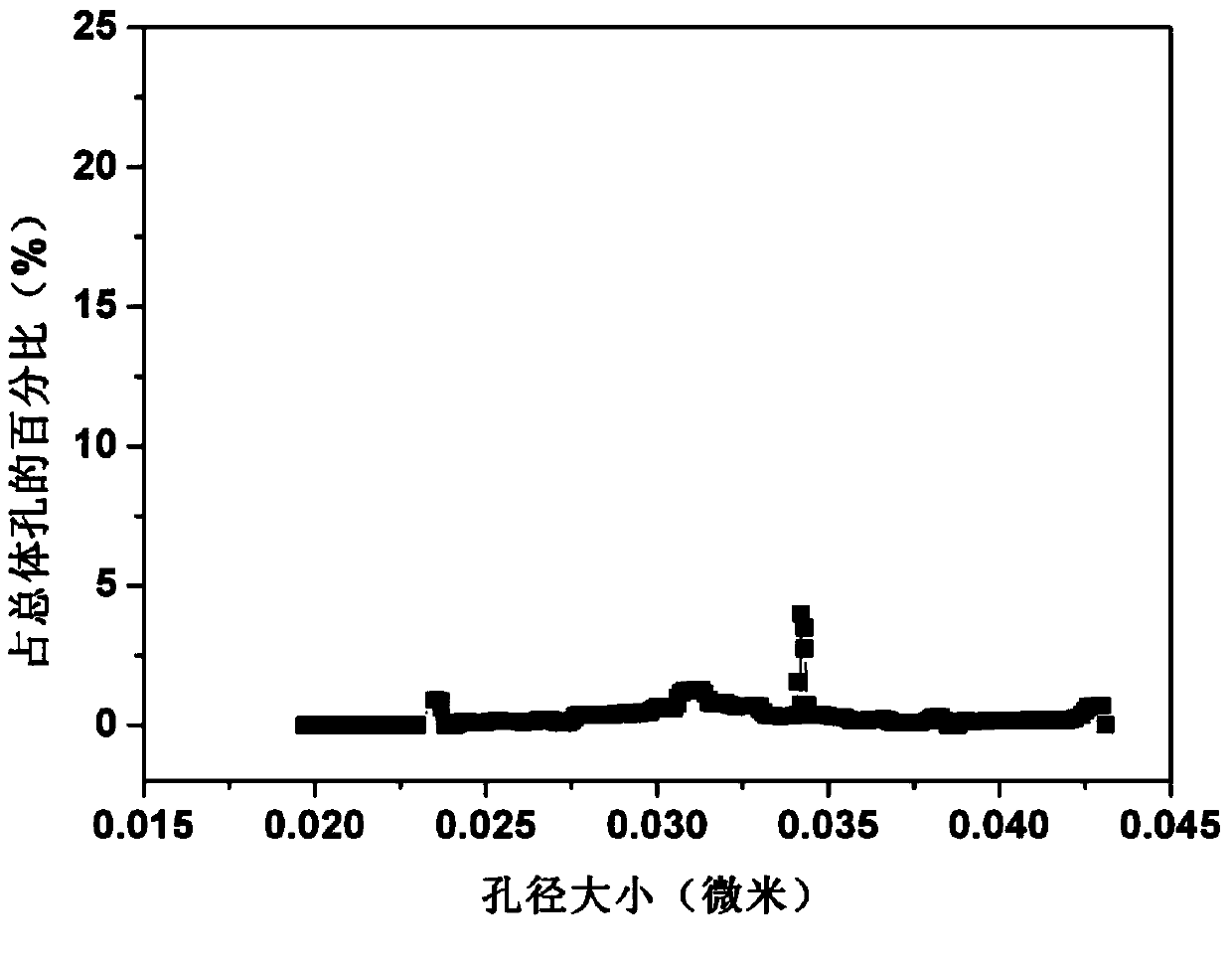

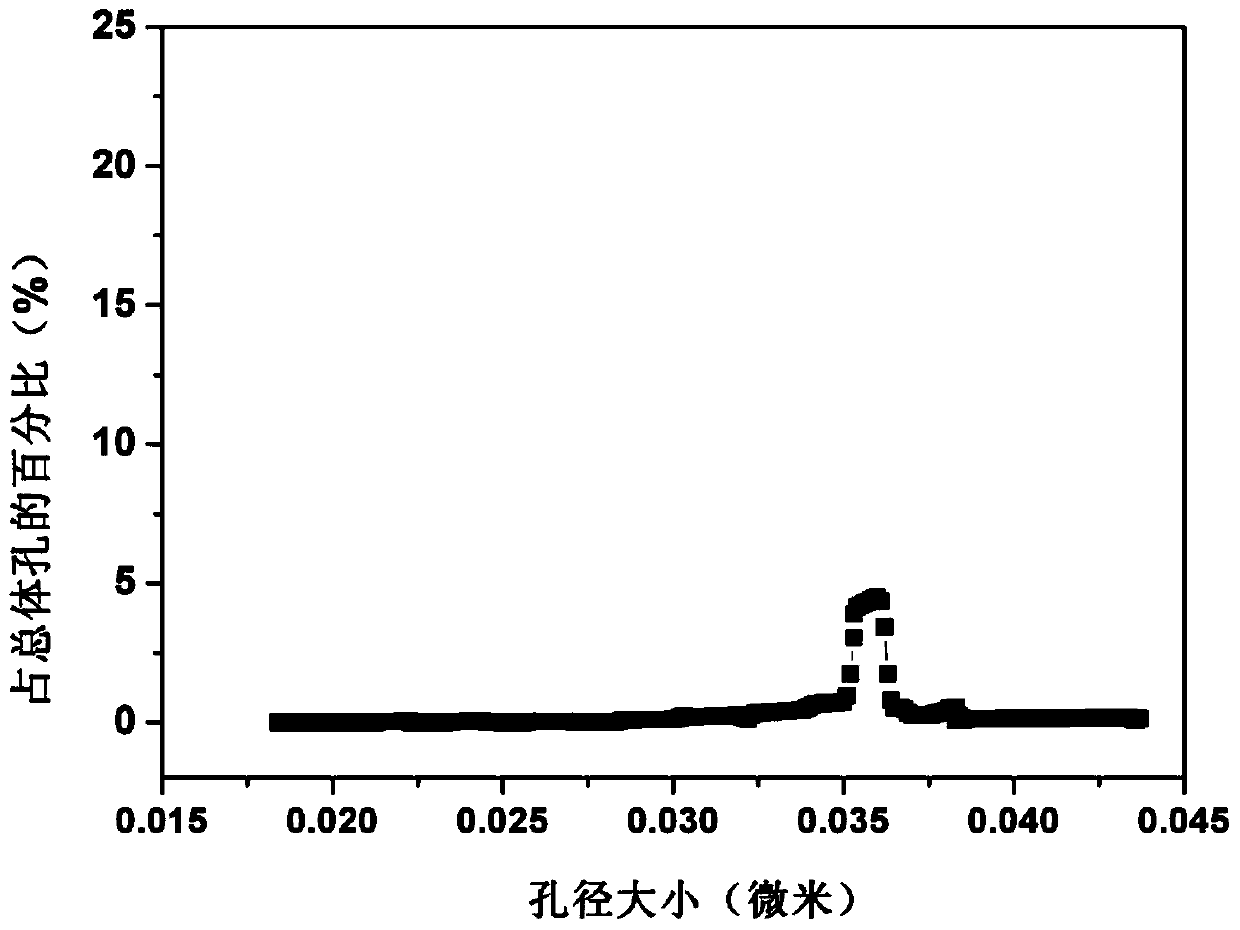

Polyolefin microporous membrane as well as preparation method and application thereof

The invention discloses a preparation method of a polyolefin microporous membrane, the polyolefin microporous membrane prepared by using the preparation method and an application of the polyolefin microporous membrane. According to the preparation method, a polyolefin melt can be rapidly subjected to draft cooling to form a base membrane at a speed of 10-200m / min by adopting a matte chilling roller which has the surface roughness (Ra value) of 0.04-2mu m, the diameter of 200-2000mm and the temperature of 10-100 DEG C, wherein the distance between the melt and the roller surface is 2-200mm. The melt cooling and freezing speed is accelerated by using the matte chilling roller, the influence of air in the casting and cooling process is effectively reduced and wavy patterns are reduced. The polyolefin microporous membrane prepared by adopting the preparation method has better uniformity and can be widely applied to the fields of battery diaphragms, filtering membranes, medicinal membranes or the like.

Owner:SHENZHEN ZHONGXING NEW MATERIAL TECH CO LTD

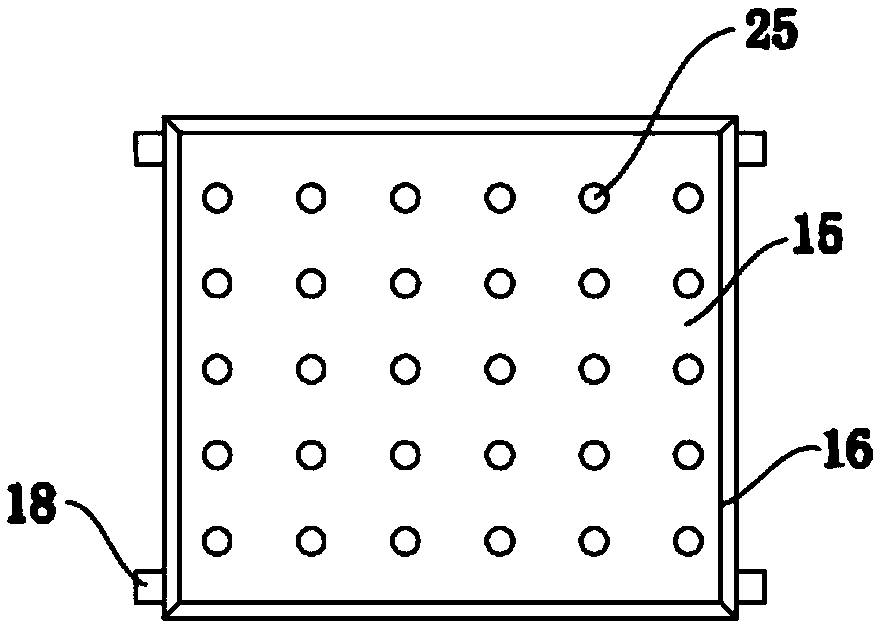

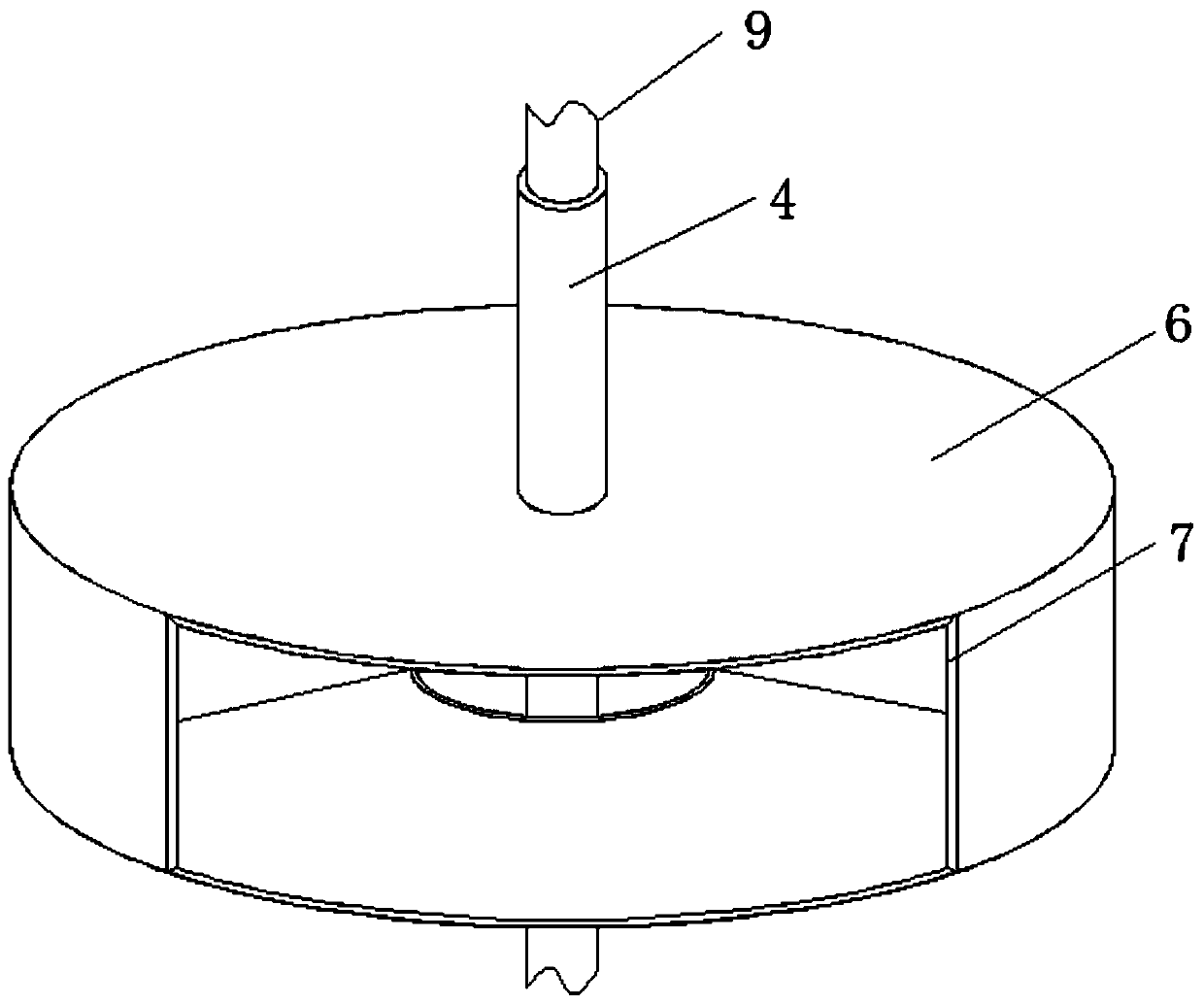

Thin vermicelli and/or vermicelli vertical cooler

ActiveCN102726784AImprove flexibilityHigh strengthFood shapingFood preparationCold airEconomic benefits

The invention discloses a thin vermicelli and / or vermicelli vertical cooler, which is provided with a cold air blower, a cooling tank, a cooler and a heat exchanger, wherein the cooler is provided with an air distributor, a bean vermicelli inlet, a bean vermicelli outlet, a cooling air inlet and a cooling air outlet, wherein the air distributor is arranged at the lower end of the cooler, and is adisk circular tube provided with even air distribution holes, or an air distribution card provided with even air outlet holes; the upper and lower ends of the air distribution card are welded with the cooler; the cooling air outlet is arranged at the upper end of the cooler; the top part of the cold air blower is provided with an exhaust opening, a liquid feeding opening, a vacuum meter and a thermometer; an air pipe and a cooling liquid are arranged at the lower end of the cooling tank; and the cooler, the cold air blower, the cooling tank and the heat exchanger are circularly connected in turn. With the adoption of the vertical cooler, the bean vermicelli is cooled in time, the flexibility and strength of the bean vermicelli are enhanced due to vertical stretching; a frequency modulation variable speed motor is automatically controlled by a computer, so that the operation is easy, the safety is high, the apparatus failure rate is low, the production efficiency and the product quality thin vermicelli and / or vermicelli are enhanced, and the thin vermicelli and / or vermicelli vertical cooler is suitable for industrial production, and has high economic benefit.

Owner:广西崇左天赐生物科技有限公司

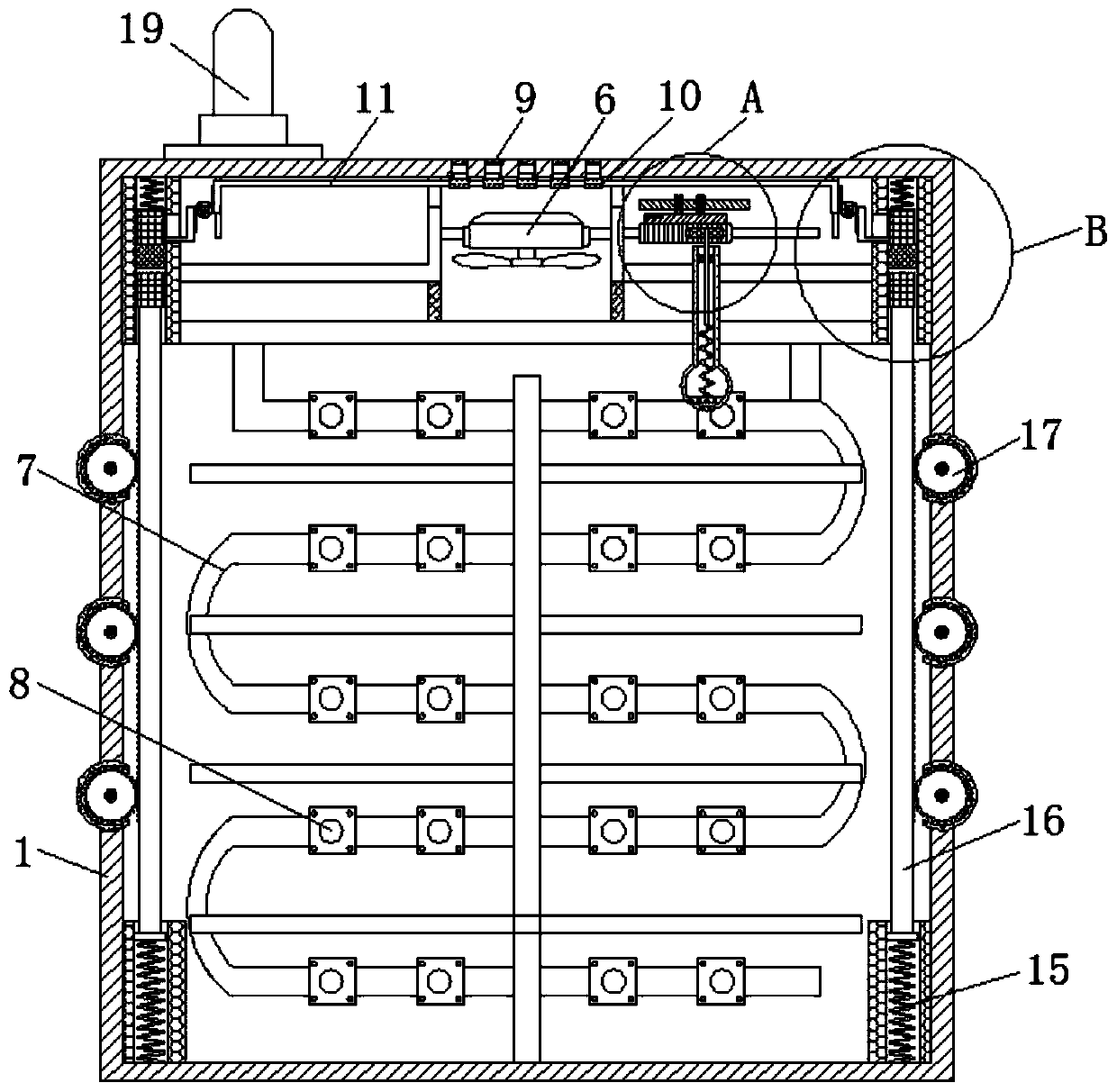

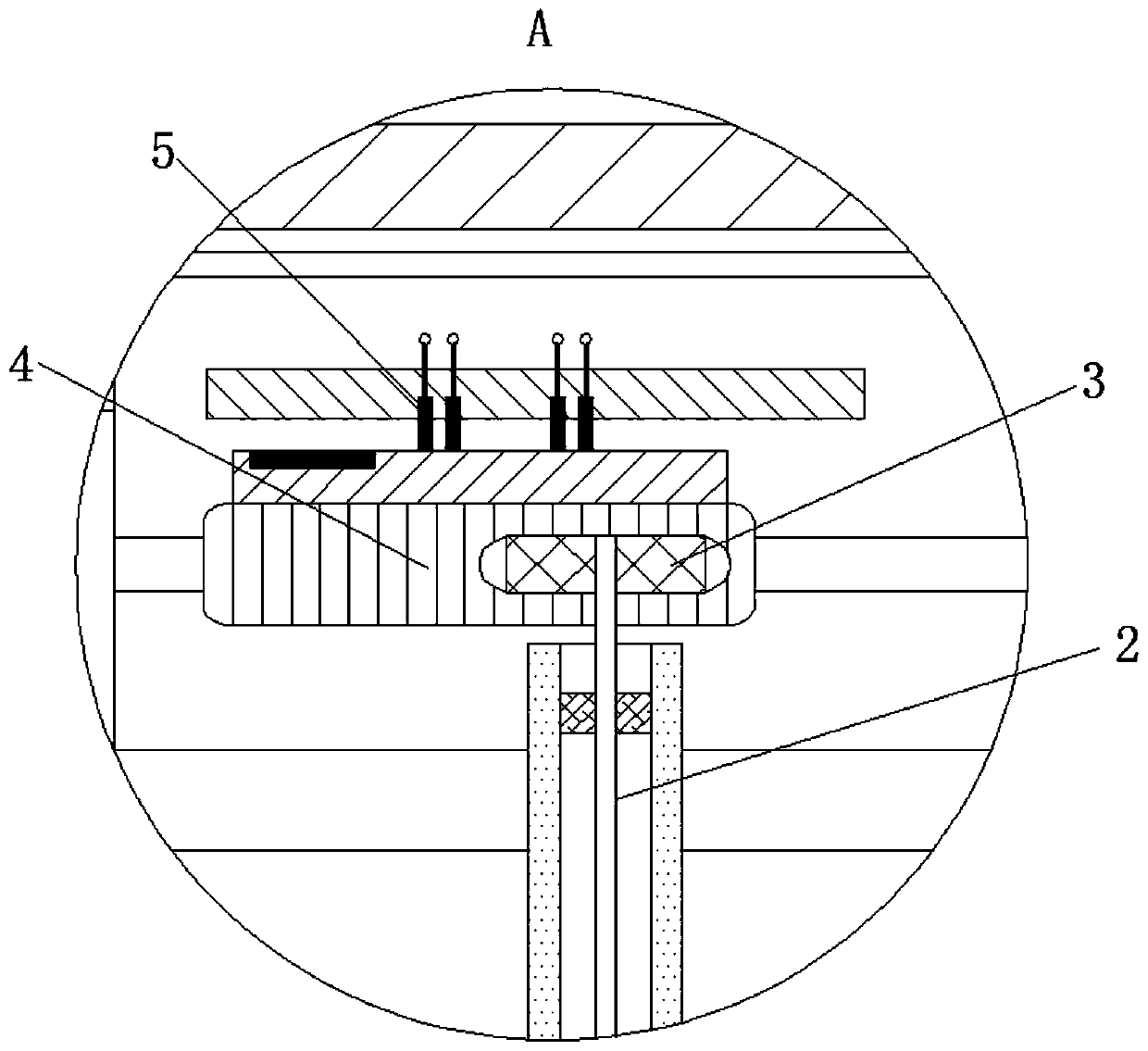

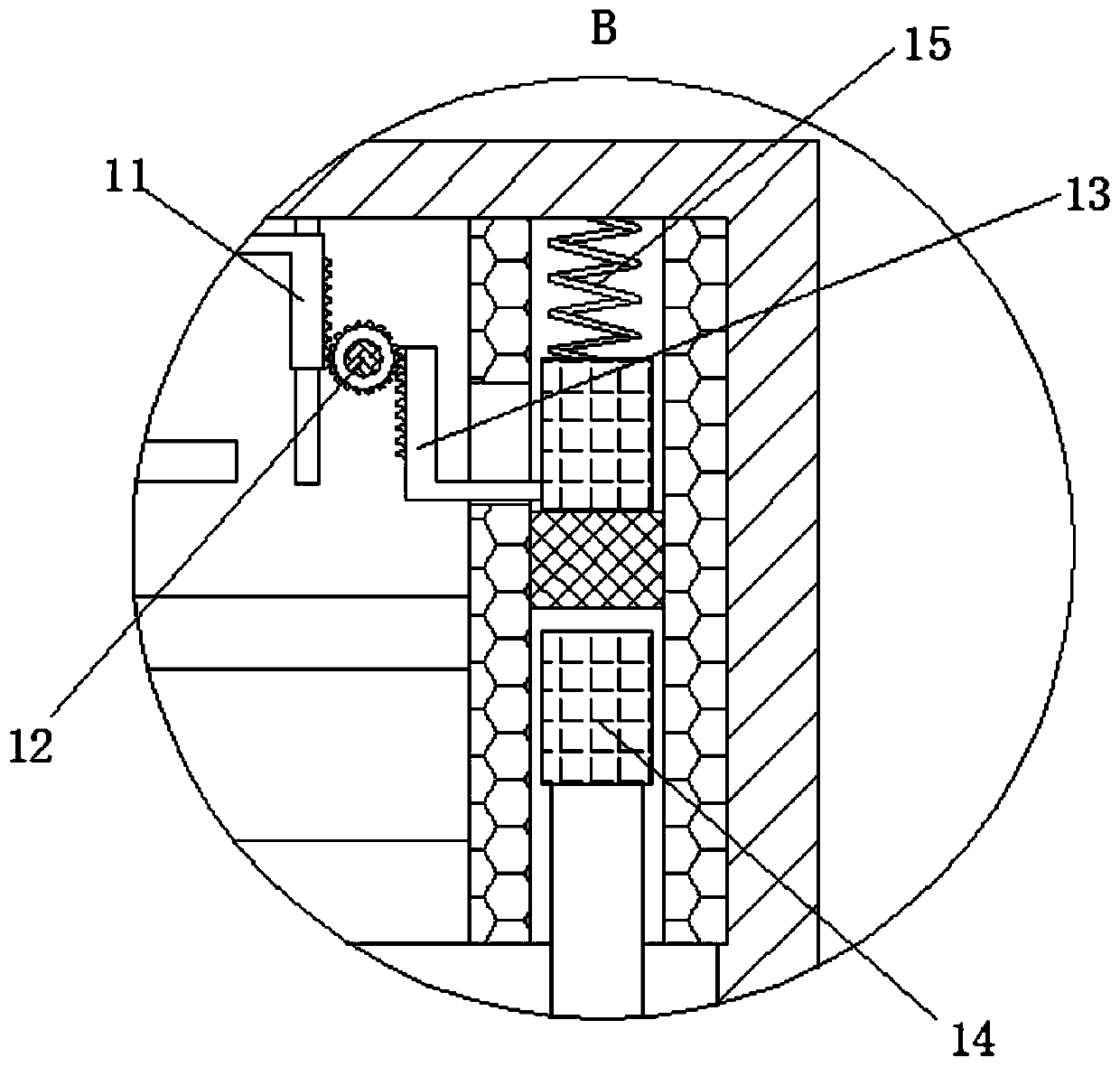

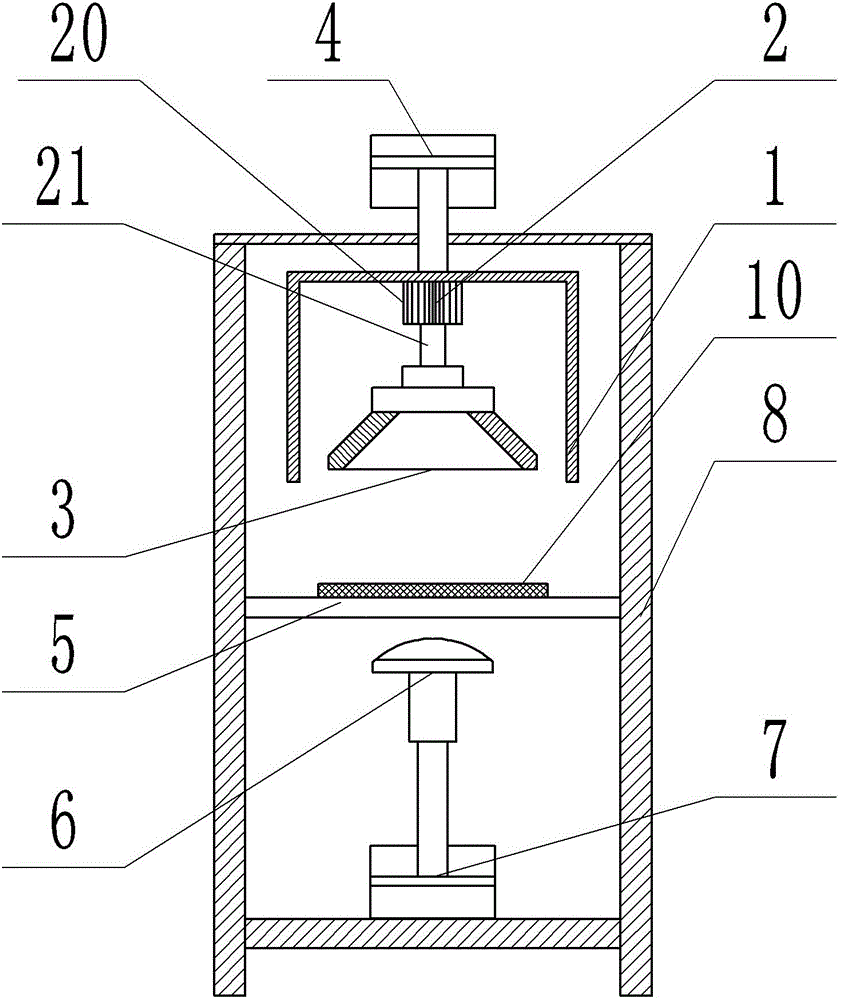

Memory mounting cabinet heat dissipation device based on bimetallic strip principle

InactiveCN111587050AGuaranteed uptimeTo achieve the effect of automatic control of heat dissipationHermetically-sealed casingsCooling/ventilation/heating modificationsAutomatic controlEngineering

The invention relates to the technical field of large-scale storage. The invention further discloses a memory mounting cabinet heat dissipation device based on the bimetallic strip principle. The device comprises a cabinet body, the interior of the cabinet body is fixedly connected with a temperature sensing rod, the top of the temperature sensing rod is fixedly connected with an adjusting gear; acontrol block is connected to the outer part of the adjusting gear in a meshing manner; a connecting contact block is movably connected to the outer part of the control block; a negative pressure fanis fixedly connected to the interior of the cabinet body; a flow guide pipe is movably connected to the outer part of the negative pressure fan; the temperature sensing rod, the adjusting gear, the control block, the connecting contact block, the negative pressure fan, the flow guide pipe, the air outlet and the air inlet hole are matched for use; therefore, the effect of automatically controlling heat dissipation is achieved, the energy is effectively saved, the heat dissipation effect can be fully guaranteed, wind power is evenly introduced into the cabinet body through the flow guide pipe,the uniformity of air flowing in the cabinet body is guaranteed, the sufficient heat dissipation effect is guaranteed, uneven heat dissipation is avoided, and the normal operation of equipment in thecabinet body is effectively guaranteed.

Owner:杭州成昌网络科技有限公司

Production method of polyamide-6 fiber

ActiveCN104805513AImprove performanceAvoid uneven coolingArtificial thread manufacturing machinesMelt spinning methodsFiberPolyamide

The invention discloses a production method of polyamide-6 fiber. The production method comprises the following steps: a, adding polyamide-6 chips to a screw extruder, and carrying out melted extrusion; b, spinning; c, carrying out cooling forming on silk bundles by using cross air blow by using a cross air blow spinning cooling device and oiling the cooled silk bundles, wherein the cross air blow to the silk bundles in the cross air blow spinning cooling device is divided into an upper layer and a lower layer which are independent of each other, wherein the upper layer of cross air blow is obliquely blown out upwards, and the lower layer of cross air blow is taken as a main body and horizontally blown out from a cross air blow cylinder; d, carrying out pre-interlacing, drafting, interlacing and winding; e, carrying out inspection package. According to the production method disclosed by the invention, the cross air blow is adopted to substitute for side air blow, so that a melt is uniformly cooled in each direction; the phenomenon that the inner layers and the outer layers of the silk bundles cannot be uniformly cooled is effectively avoided, and the unevenness rate of the silk bundles is reduced, so that the molding quality of the silk bundles is greatly improved; the polyamide-6 fiber prepared by the production method disclosed by the invention is excellent in various performances and has favorable market competitiveness.

Owner:光山县群力化纤有限公司

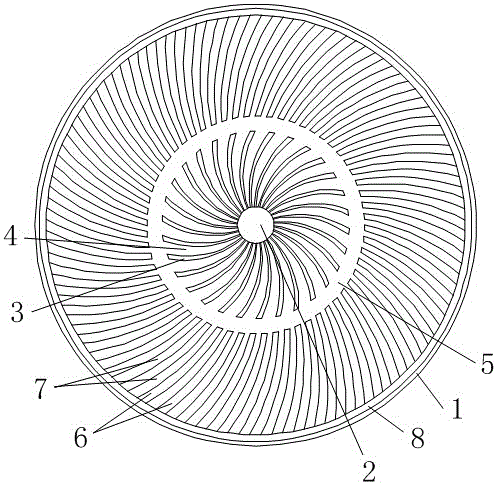

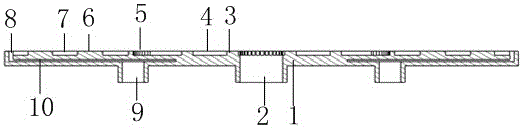

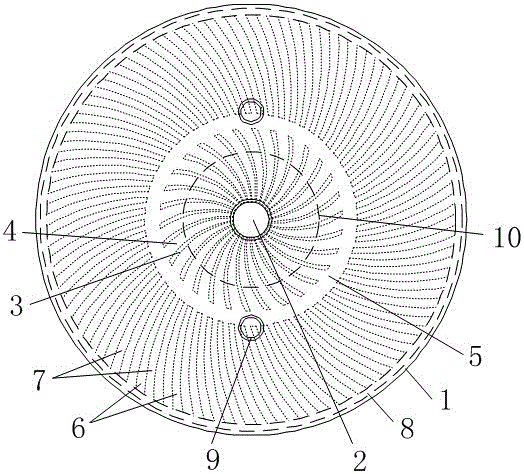

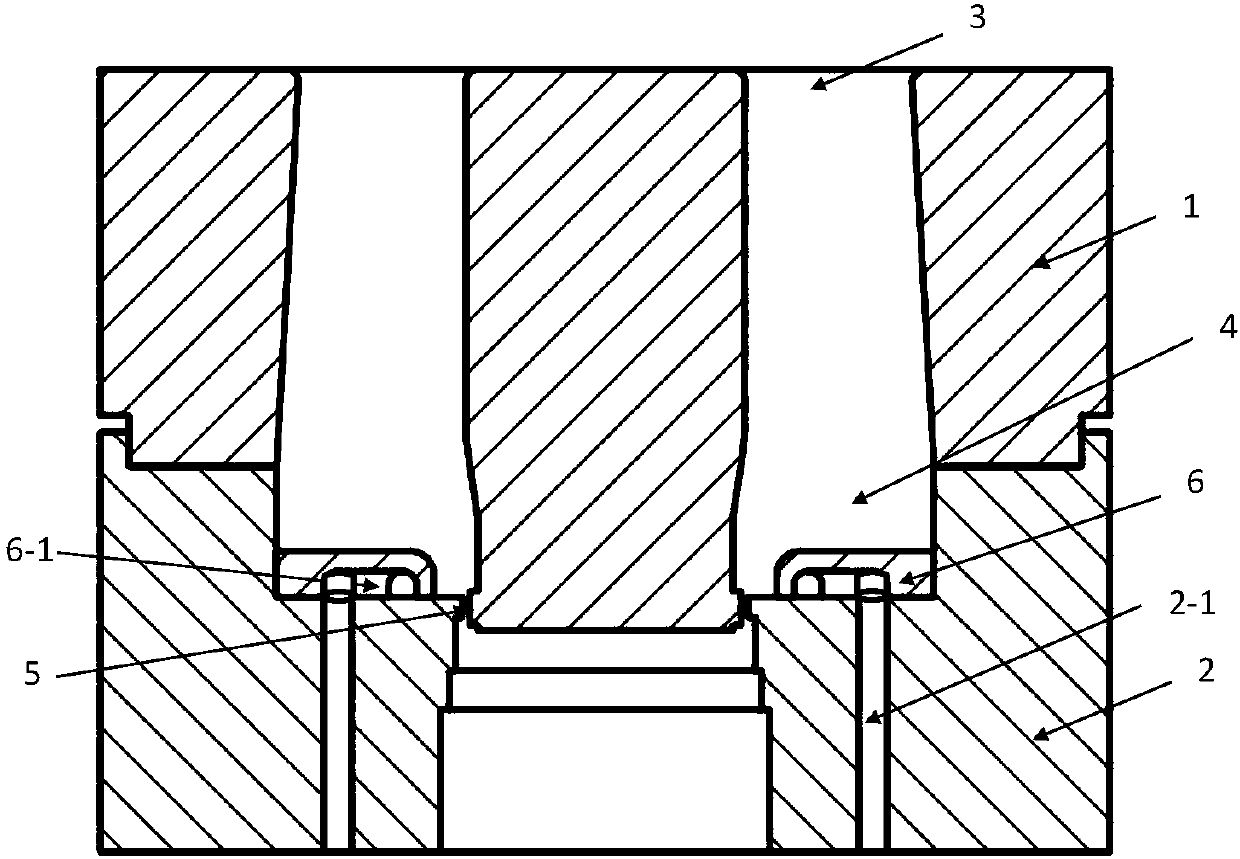

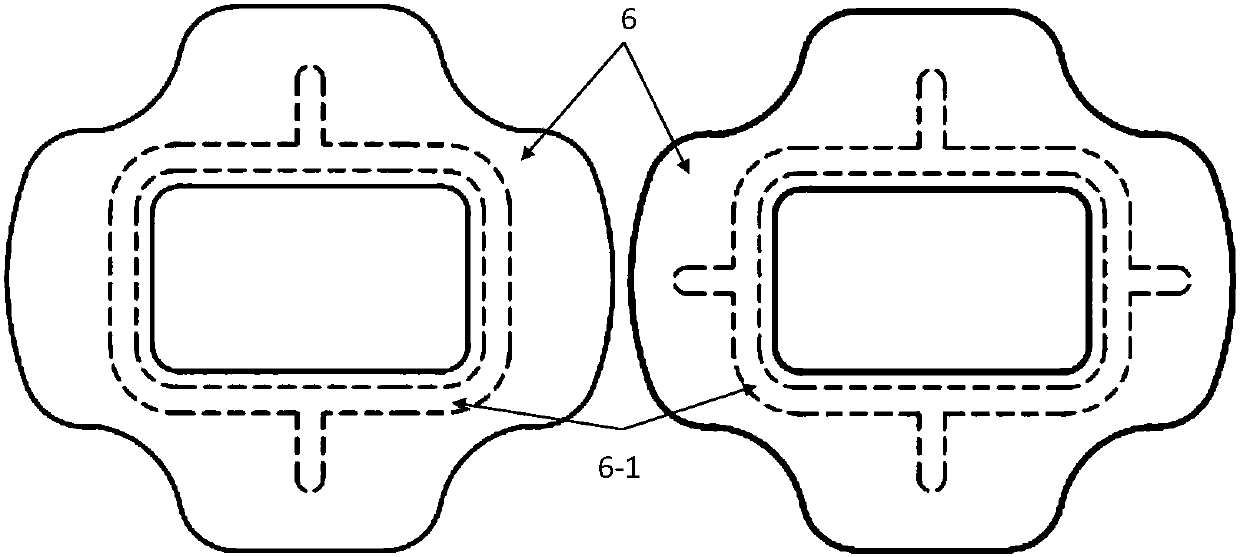

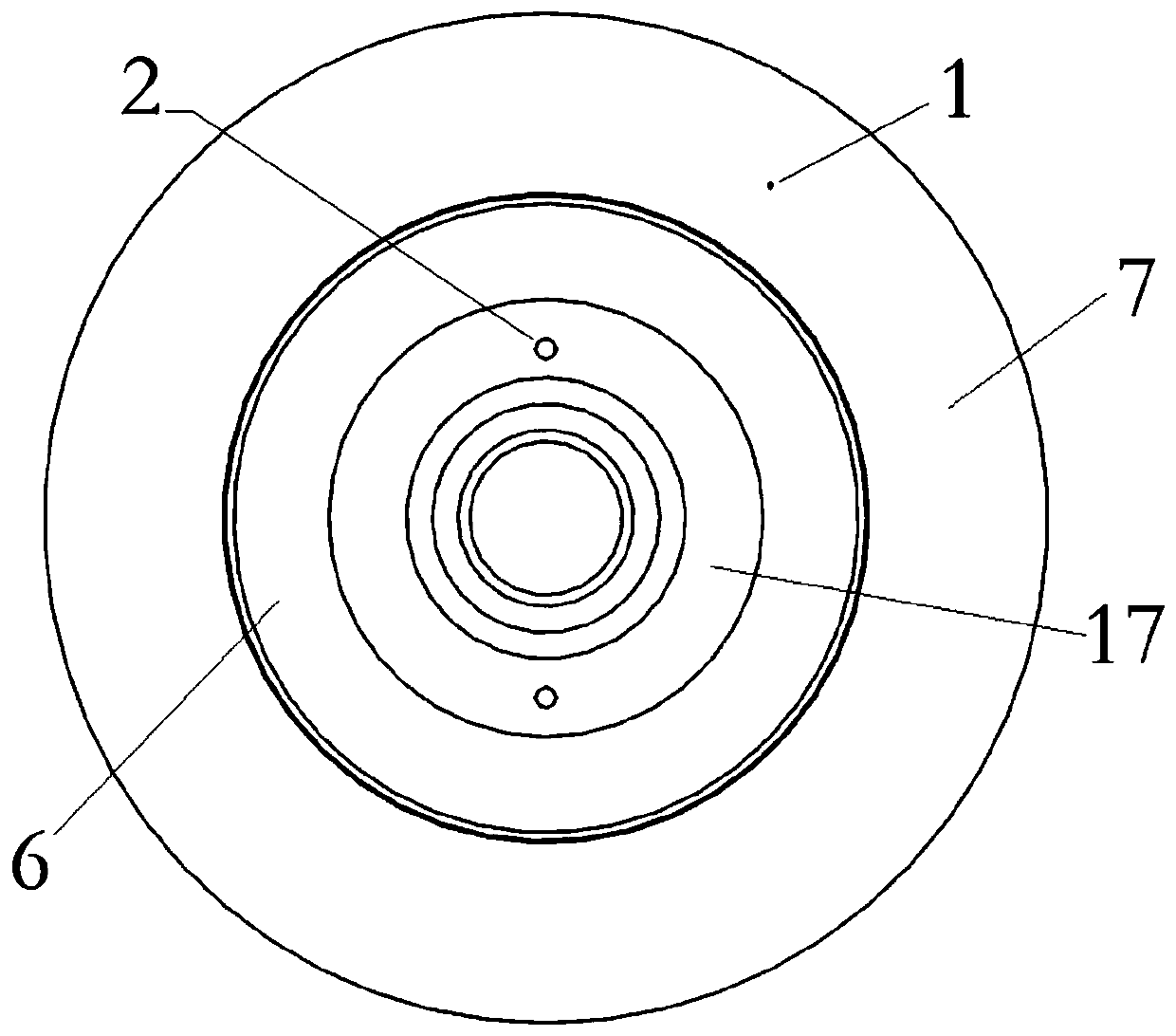

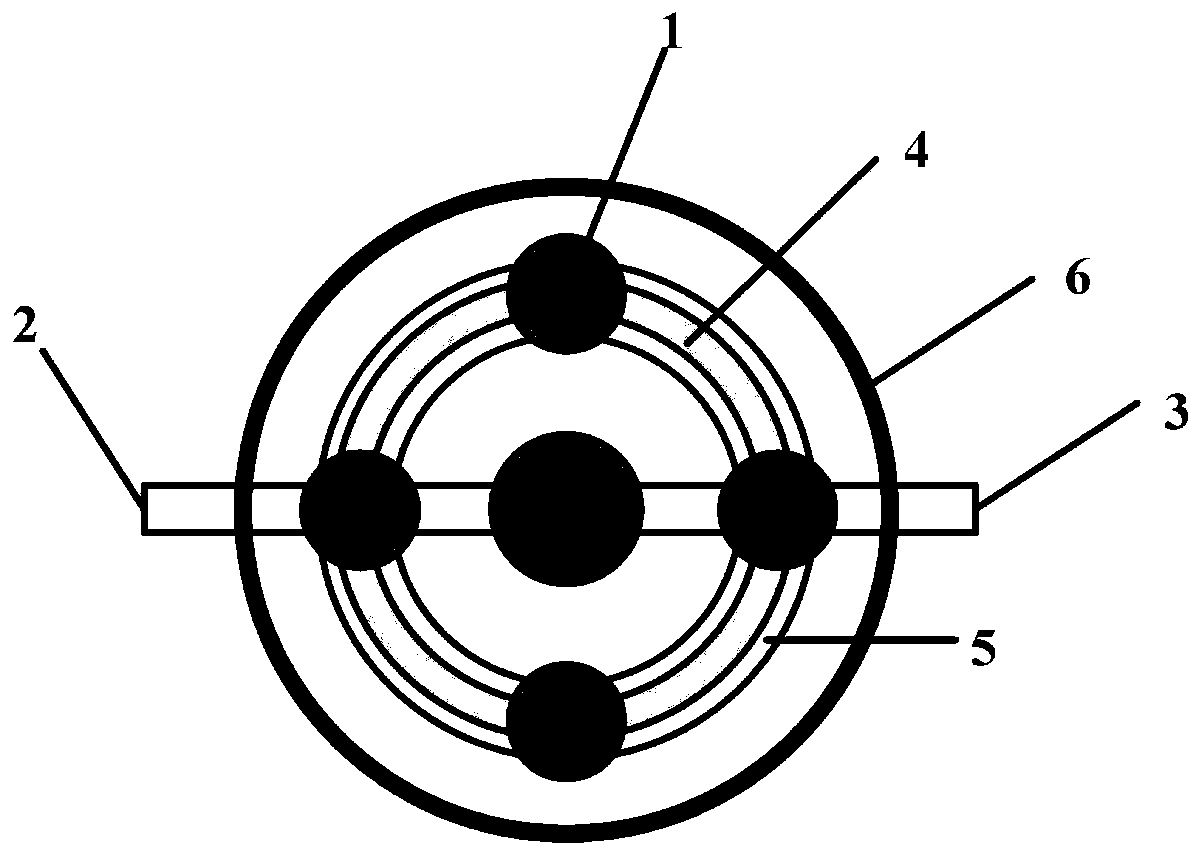

Centrosymmetric radial bipolar plate flow field structure for solid polymer electrolyte (SPE) electrolysis

ActiveCN105839136AUniform pressure distributionReduce mass transfer resistanceElectrode shape/formsPolymer electrolytesElectrolysis

The invention discloses a centrosymmetric radial bipolar plate flow field structure for solid polymer electrolyte (SPE) electrolysis. The centrosymmetric radial bipolar plate flow field structure for SPE electrolysis comprises a bipolar plate body, an internal radial flow channel, an external radial flow channel, a pressure equalizing transition belt, an outlet notch and a communication region, wherein the bipolar plate body is provided with a water inlet and an outlet; the internal radial flow channel is composed of a plurality of internal ring ridges which extend in the radial direction of the bipolar plate body and are centrally symmetrical, and the external radial flow channel is composed of a plurality of external ring ridges; the pressure equalizing transition belt is arranged between the internal radial flow channel and the external radial flow channel; the outlet notch communicates with the tail end of the external radial flow channel; the communication region communicates with the outlet notch and the outlet; and the water inlet is located in the center of the bipolar plate body and communicates with the internal radial flow channel. According to the centrosymmetric radial bipolar plate flow field structure for SPE electrolysis, the centrally-symmetrical radial ridges form the flow channels, so that the distances of the flow channels are shortened; and the pressure in all flow channel units is evenly distributed through the pressure equalizing transition belt, and the distribution uniformity of the pressure and water in a flow field is kept under the condition that the number of water inlets is not increased, so that the hydrogen yield of an SPE electrolytic tank manufactured based on the centrosymmetric radial bipolar plate flow field structure can be increased by increasing the catalyst loading areas or / and the overlapping number of membrane electrode assemblies (MEAs), the electrolytic efficiency is improved, and the service life is prolonged.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

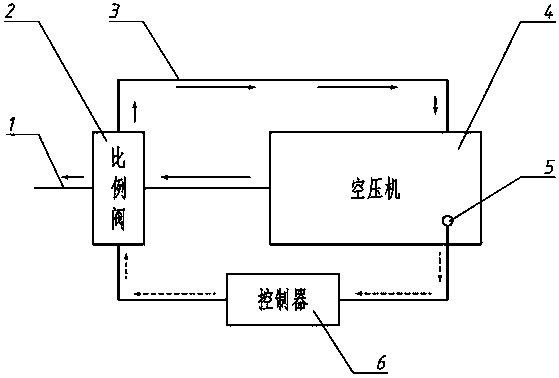

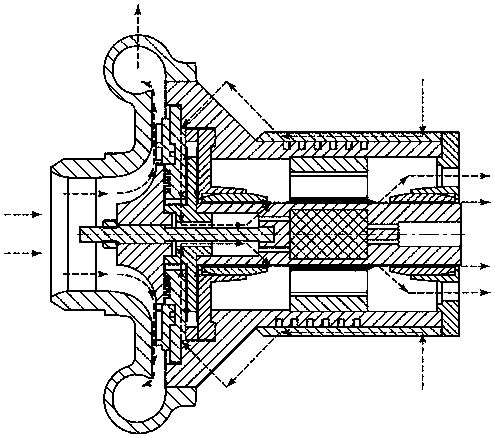

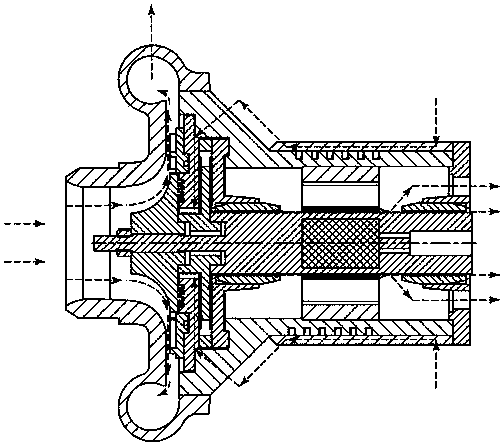

Self-cooling system of air compressor rotor borne by air foil bearing

InactiveCN108252956AImprove stabilityExtend effective lifePump componentsPump controlLoop controlClosed loop

The invention relates to the technical field of air compressors, and discloses a self-cooling system of an air compressor rotor borne by an air foil bearing. The system mainly comprises an air compressor outer cooling runner, a self-cooling control method and an air compressor inner cooling runner; the air compressor outer cooling runner achieves re-injection of part of high-pressure gas, the aircompressor inner cooling runner achieves flowing of high-pressure cooling gas from the front end of an air compressor to the back end of the air compressor along the air compressor rotor surface, andcooling of the air compressor rotor is achieved; the self-cooling control method finishes re-injection gas flow and air compressor rotor real-time temperature adaption closed-loop control. According to the self-cooling system of the air compressor rotor borne by the air foil bearing, the temperature of the air compressor rotor system can be effectively controlled, intelligent cooling is achieved,energy is saved, the air compressor rotor system is comprehensively cooled, the stability of the air compressor is improved, and the effective service life of the air compressor is prolonged.

Owner:HUNAN UNIV

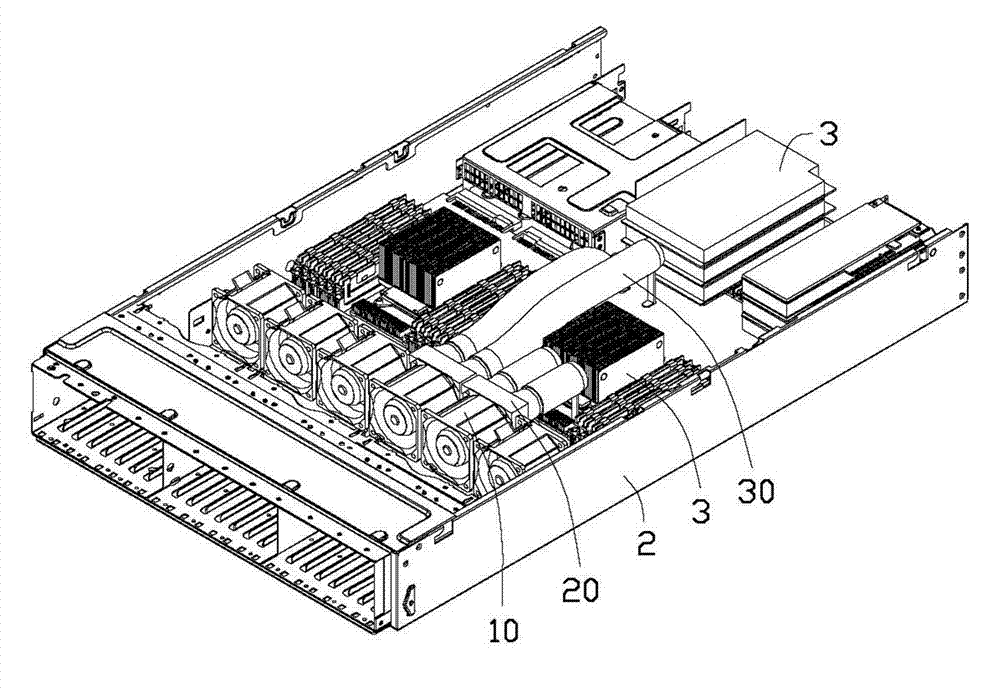

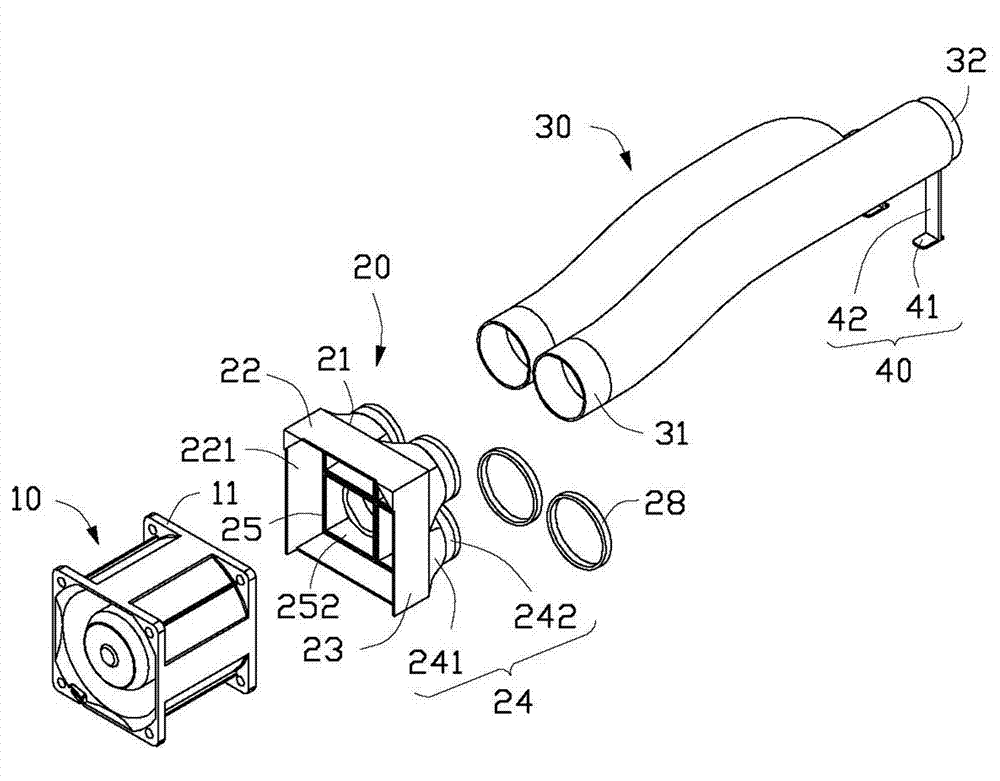

Electronic device

An electronic device comprises a case, a plurality of electronic elements arranged in the case, a plurality of fans arranged in the case and a plurality of adapters. Each adapter is detachably mounted at the air outlet of each fan, first ends of a plurality of air guide pipes are detachably connected with the adapters while second ends of the air guide pipes rightly face to the electronic elements. By the arrangement, cold air is directly delivered to the electronic elements for heat dissipation through the air guide pipes, and uneven heat dissipation of the electronic elements is avoided.

Owner:WARECONN TECH SERVICE (TIANJIN) CO LTD

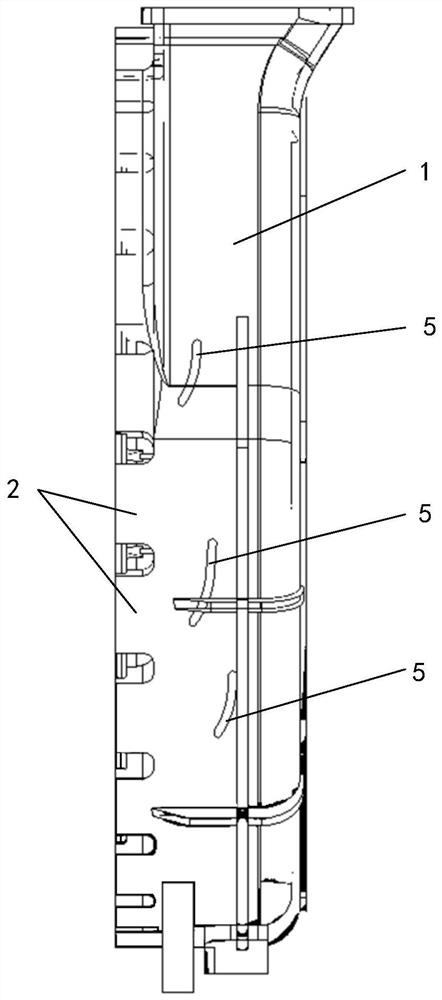

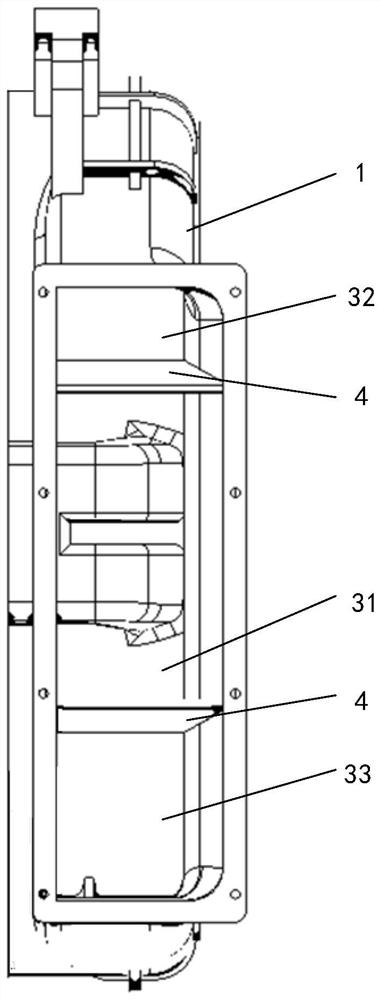

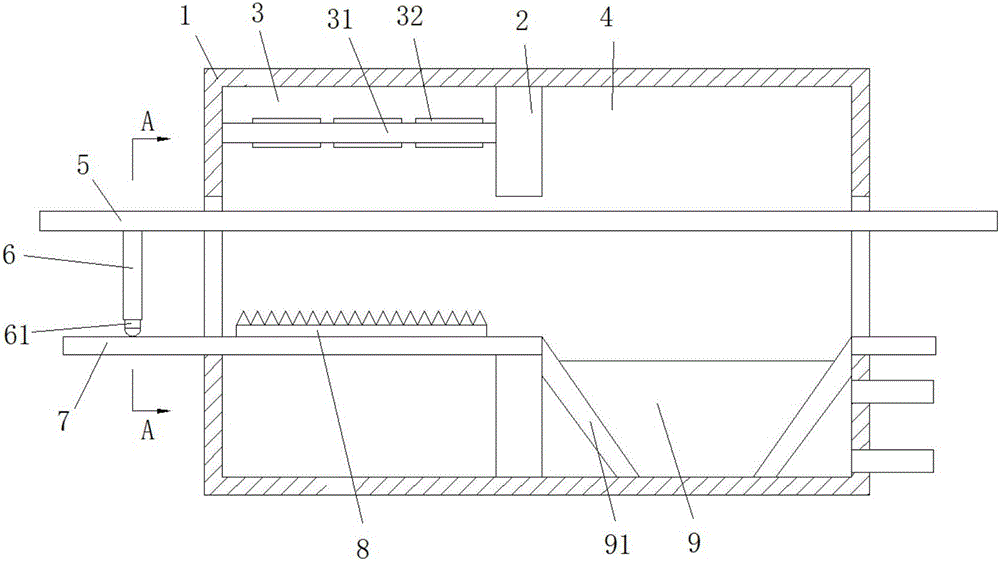

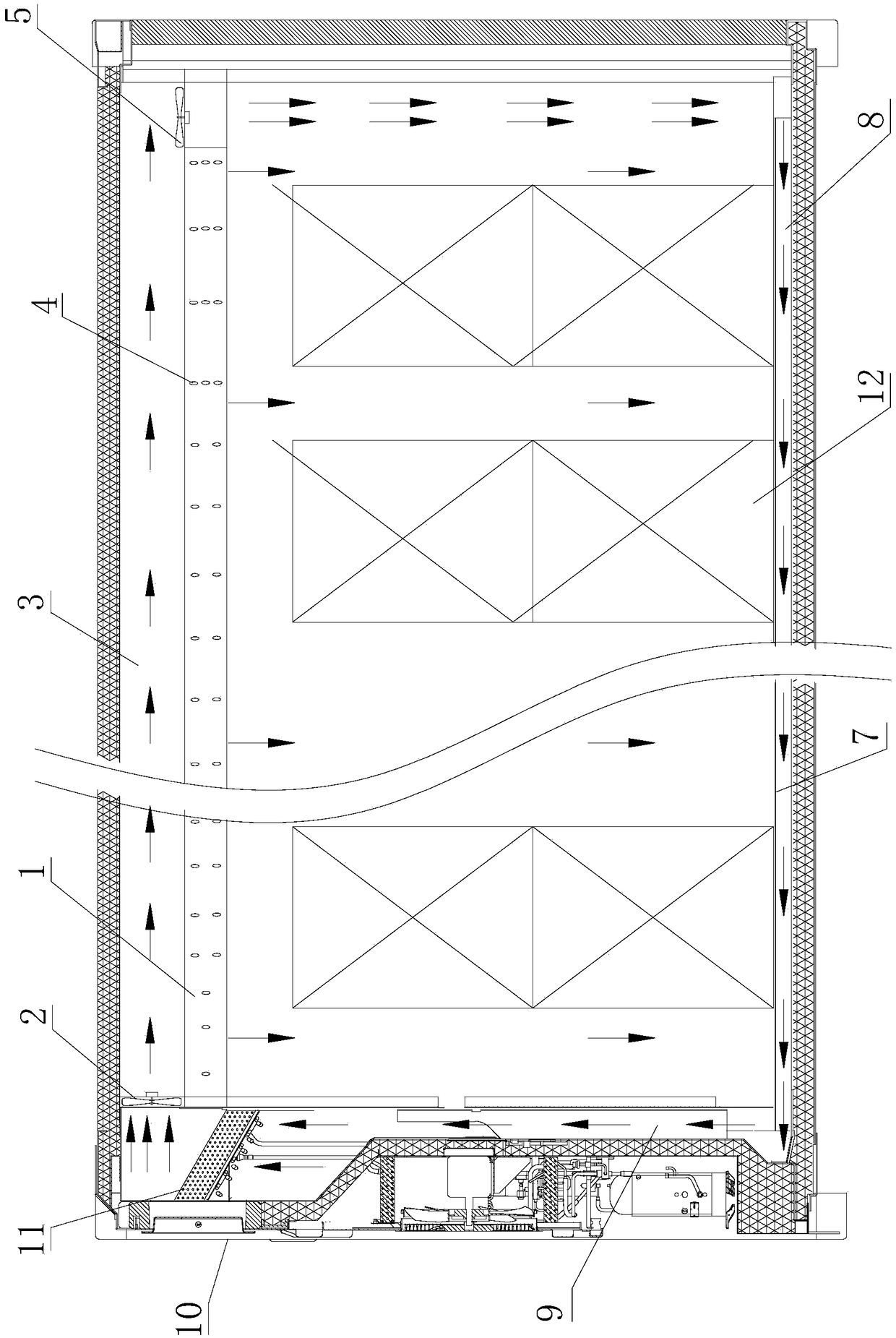

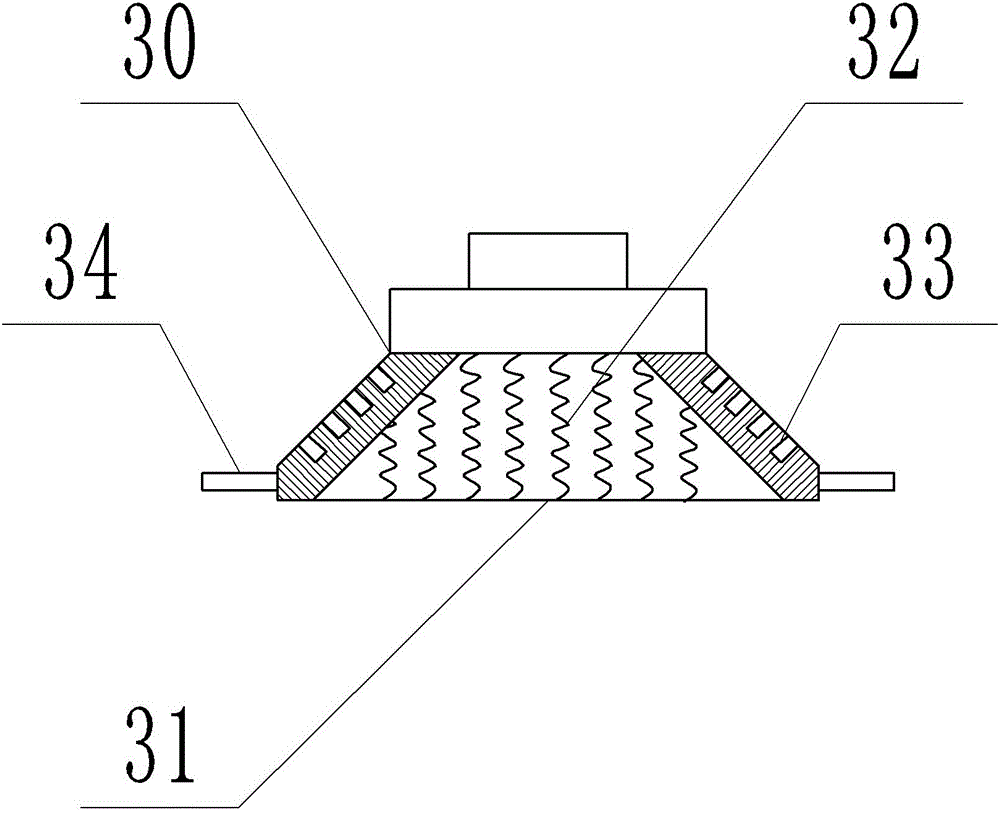

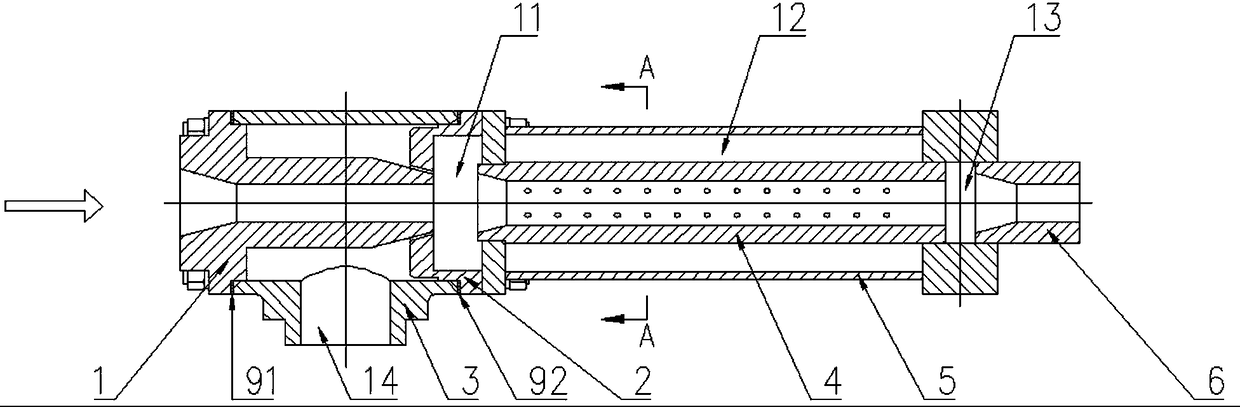

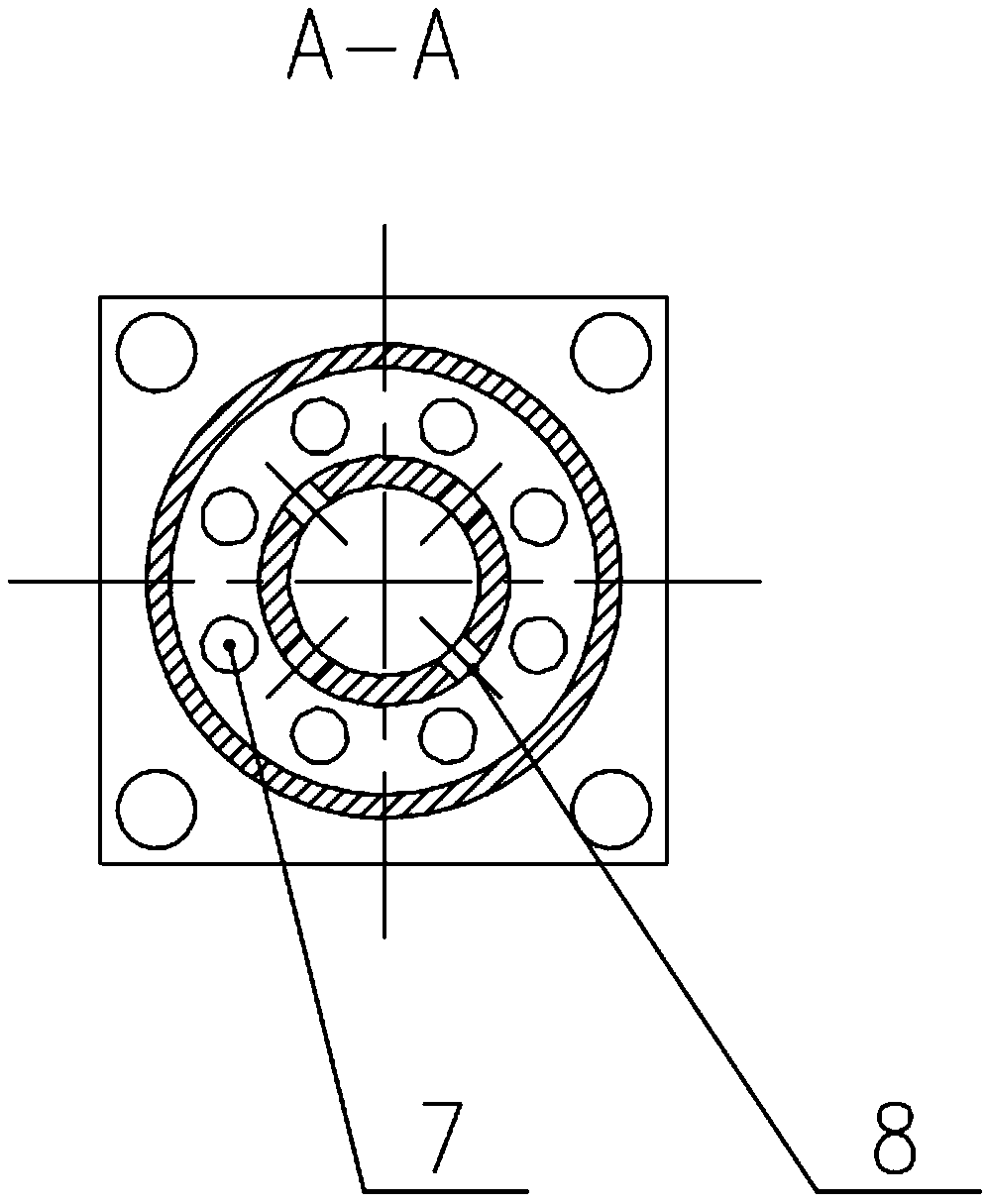

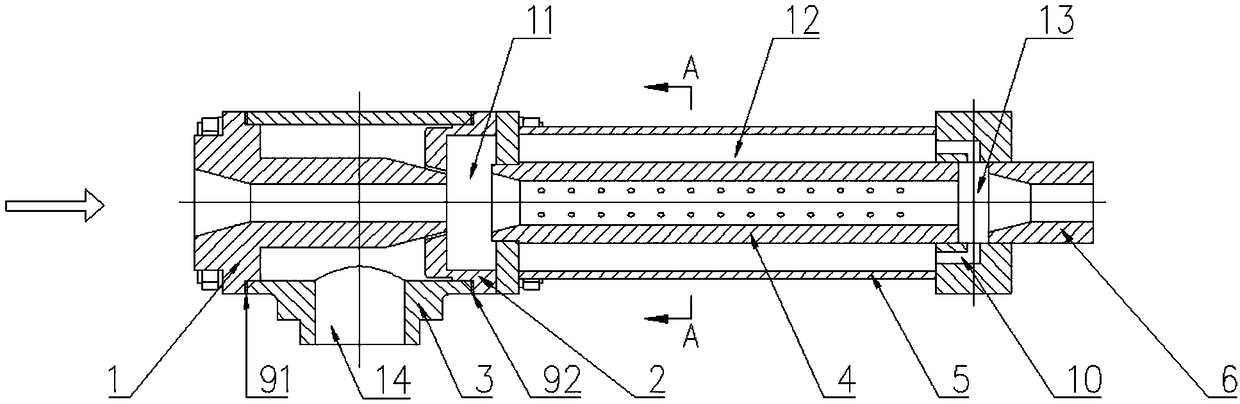

Circular blowing polyester spinning cooling device and method

The invention discloses a circular blowing polyester spinning cooling device. The device is composed of two parts, namely a blowing device and air-conditioning systems; the blowing device comprises a frame, a lifting cylinder, a lifting rod, a first air inlet pipe, a second air inlet pipe, a first air duct, a second air duct and a guide duct; a first annular cavity is arranged outside the first air duct, while a second annular cavity is arranged outside the second air duct and a third annular cavity is arranged outside the third guide duct; a first annular air equalizing cover is arranged outside the first annular cavity, while a second annular air equalizing cover is arranged outside the third annular cavity; the inlet pipeline of the first annular air equalizing cover is communicated with the first air inlet pipe; the inlet pipeline of the second annular air equalizing cover is communicated with the second air inlet pipe; the first air-conditioning system provides the first air inlet pipe with cooling air, while the second air-conditioning system provides the second air inlet pipe with cooling air. According to the circular blowing polyester spinning cooling device, a circular blowing cooling manner is adopted, air can be fed in each direction so that nascent fibers can be evenly cooled in each direction, and meanwhile, the upper and lower layers of circular blowing are evener, and the fiber cooling effect is good.

Owner:扬州天富龙集团股份有限公司

Chinlon high-speed spinning technology

ActiveCN103422181AAvoid uneven coolingReduce unevennessMelt spinning methodsComing outProduction line

The invention relates to a chinlon high-speed spinning technology which comprises the following steps of using chinlon slicing as raw materials, and carrying out fusion, spinning, circular air blowing, drafting, heat shaping, oiling, mesh forming and winding in sequence. The chinlon high-speed spinning technology differs from the prior art, and has the advantages that the circular air blowing is adopted to replace side air blowing to enable fusion bodies to be cooled evenly in all directions, the phenomenon that the inner layer and the outer layer of a yarn bundle are uneven in cooling is avoided effectively, yarn unevenness of the yarn bundle is reduced, the shaping quality of the yarn bundle is improved greatly, cooling time is shortened at the same time, and energy consumption needed by cooling is reduced; the oiling is changed to be carried out after the heat shaping, due to the fact that the moisture contained in the yarn bundle will be evaporated under heating when the heat shaping is carried out, the oiling can be carried out on the yarn bundle directly after the yarn bundle comes out of the heat shaping procedure, drying equipment, drying time and energy consumption needed by drying are eliminated, a production line is simplified greatly, production efficiency is improved, production energy consumption is reduced, and meanwhile the whole production process is made to be smoother.

Owner:FUJIAN JINGFENG TECH

Aluminum profile extrusion die for cooling in die

An aluminum profile extrusion die for cooling in a die includes an upper die, a lower die, a tap hole, a welding room, a working tape and a profile outlet; the upper die and the lower die are installed in a matching mode, the upper end surface of the upper die is provided with the tap hole, the welding room is arranged below the tap hole, the working tape is arranged below the welding room to enable every material-flows to enter the working tape after being joined in the welding room and be subjected to extrusion forming, and the profile outlet which communicates with the working tape is manufactured at the bottom surface of the lower die; and the aluminum profile extrusion die for cooling in the die also includes a cooling pad which is used for the working tape. The cooling pad can directly and efficiently guide cooling medium to a high temperature position, nearby the working tape of the die, of the most violent metal deformation, cooling method of direct cooling superheat region ismore efficiently, and other cooling methods such as indirect cooling from outside of the die is prone to generating internal stress and crack due to cooling unevenness of the die.

Owner:YANTAI UNIV

Injection molding device capable of conducting even cooling

The invention belongs to the field of injection molding equipment and discloses an injection molding device capable of conducting even cooling. The injection molding device comprises a die. A cooling cavity, a containing cavity and a power cavity which are concentric and are in a ring shape are sequentially formed in the side wall of the die from interior to exterior. A storage barrel is arranged above an inner cavity of the die. A discharging valve is arranged at the bottom end of the storage barrel. A first piston is arranged in the storage barrel, and a first piston rod is arranged at the upper end of the first piston. The upper end of the containing cavity is provided with a ring-shaped liquid storage box, and multiple pressure valves are arranged between the liquid storage cavity and the containing cavity. Multiple capillary holes are evenly distributed in the side wall between the containing cavity and the cooling cavity. A ring-shaped second piston is arranged in the power cavity, and multiple piston rods are arranged at the upper end of the second piston. A lever is arranged between each second piston rod and the first piston rod. A through groove is formed in the lower portion of the side wall between the containing cavity and the power cavity. The injection molding device solves the problems that when an existing injection molding device is used for cooling forming, cooling is not even, and consequently the quality of formed products is poor.

Owner:莒南县锦润建材厂

Rubber sealing ring processing cooling device

InactiveCN109080047AImprove practicalityFreely adjust the distanceDomestic articlesBiochemical engineeringCooling efficiency

The invention discloses a rubber sealing ring processing cooling device which comprises a base and a sealing ring holding frame, wherein a tank body is arranged on the right side of the top of the base; a slideway is arranged inside the bottom of the tank body; an electric cylinder is fixedly mounted on the outer side above the tank body; a baffle plate is fixedly connected with the output end ofthe electric cylinder; a bottom disc is arranged on the slideway; wheels are mounted on the bottom disc; the wheels and the slideway are in sliding connection; a baffle plate is fixedly connected withthe output end of the electric cylinder; the baffle plate is positioned inside the tank body; a heating plate is fixedly mounted on one side of the inner side wall of the tank body, and convenience in heating can be achieved; an air cooling device is fixedly mounted on the other side of the inner side wall of the tank body, and convenience in cooling is achieved. The rubber sealing ring processing cooling device is simple in structure, sectional cooling is facilitated, high cooling efficiency can be achieved, very good practicability can be achieved, the use functionality of the rubber sealing ring processing cooling device can be greatly improved, use effects and use benefits can be ensured, and the device is applicable to wide popularization.

Owner:邹梨花

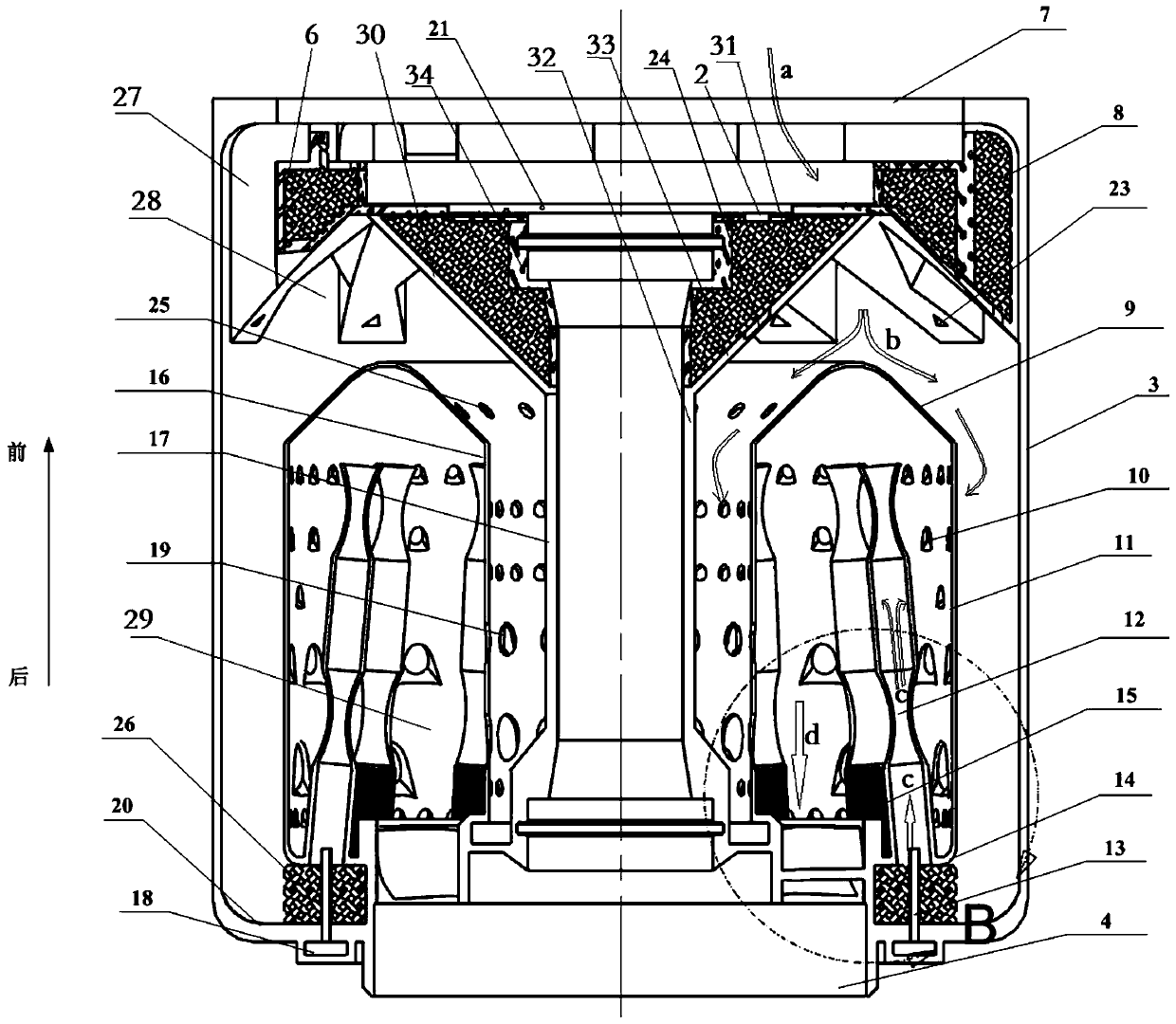

Motor and shell thereof

InactiveCN112134396AEasy to operateAvoid uneven coolingSupports/enclosures/casingsCold airThermodynamics

The invention discloses a motor and a shell thereof. The shell comprises a shell body, wherein the shell body is provided with a plurality of cooling air channels, the shell body is provided with a radial air inlet, and the radial air inlet is communicated with all the cooling air channels, so that cold air flows into the cooling air channels from the radial air inlet. an air inlet guide plate isarranged at the radial air inlet and guides cold air to evenly flow, and conditions are provided for the cold air to evenly flow into the cooling air channels. Furthermore, a plurality of air channelflow guide plates are fixedly arranged on the periphery of the shell body, the air channel flow guide plates divide the cold air entering from the radial air inlet, the cold air evenly flows into allthe cooling air channels, uneven heat dissipation in the cooling air channels is avoided, stable heat dissipation of the stator is achieved, and stable operation of the motor is guaranteed.

Owner:CSR ZHUZHOU ELECTRIC CO LTD

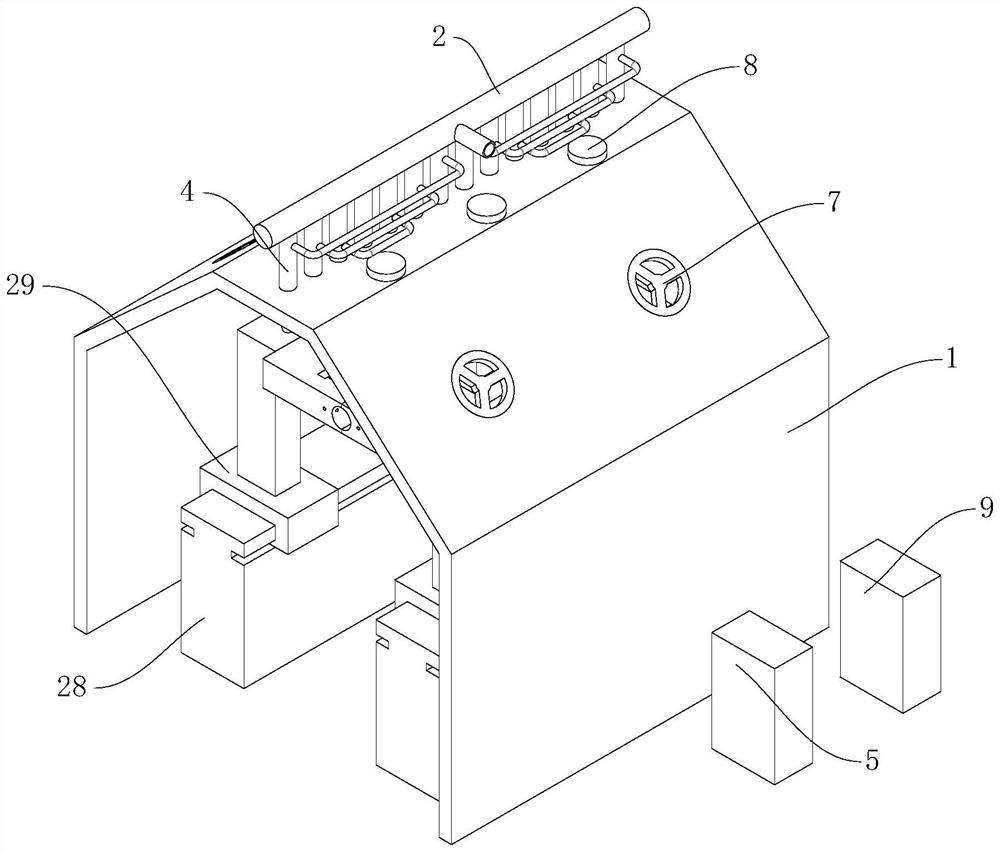

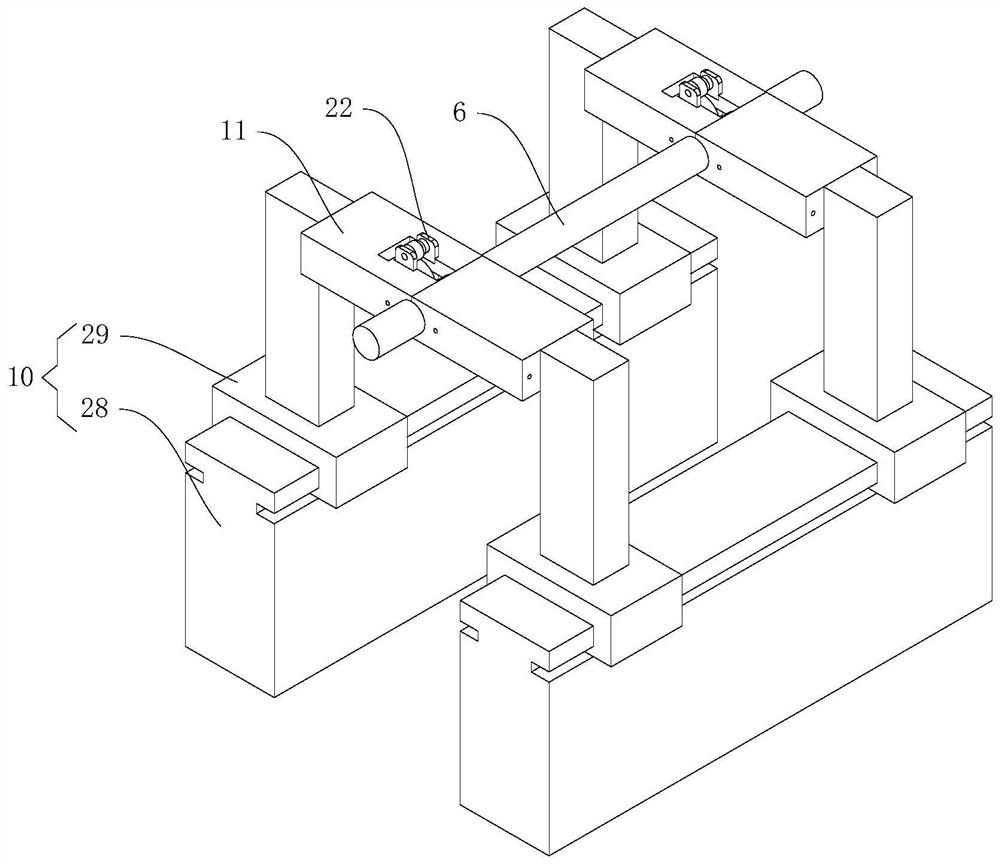

Casting device for cylinder sleeve formation

The invention relates to the technical field of cylinder sleeve formation equipment, and particularly discloses a casting device for cylinder sleeve formation. The casting device comprises a machine frame. The machine frame is connected with a vertical rotating shaft in a rotating mode. The rotating shaft is coaxially and fixedly connected with a circular-truncated-cone-shaped driving wheel. The small-diameter end of the driving wheel faces upwards. The machine frame is transversely connected with a supporting frame in a sliding mode, and the supporting frame is provided with two casting units. The casting units comprise revolving drums, forming dies, upper limiting mechanisms and lower limiting mechanisms. The lower ends of the revolving drums are fixedly provided with friction rings protruding in the radial direction. The friction rings are in friction fit with the side wall of the driving wheel. The forming dies are located in cavities of the corresponding revolving drums and further comprise first die sheets and second die sheets. The upper limiting mechanisms are located at the upper ends of the corresponding revolving drums, and the lower limiting mechanisms are located at the lower ends of the corresponding revolving drums. The machine frame is provided with a motor used for driving the rotating shaft to rotate. The problem that due to the fact that the rotating speed ofeach die is constant in the cylinder sleeve casting process in the prior art, the forming quality can be made poor easily is solved.

Owner:宁波江北珂达汽车技术有限公司

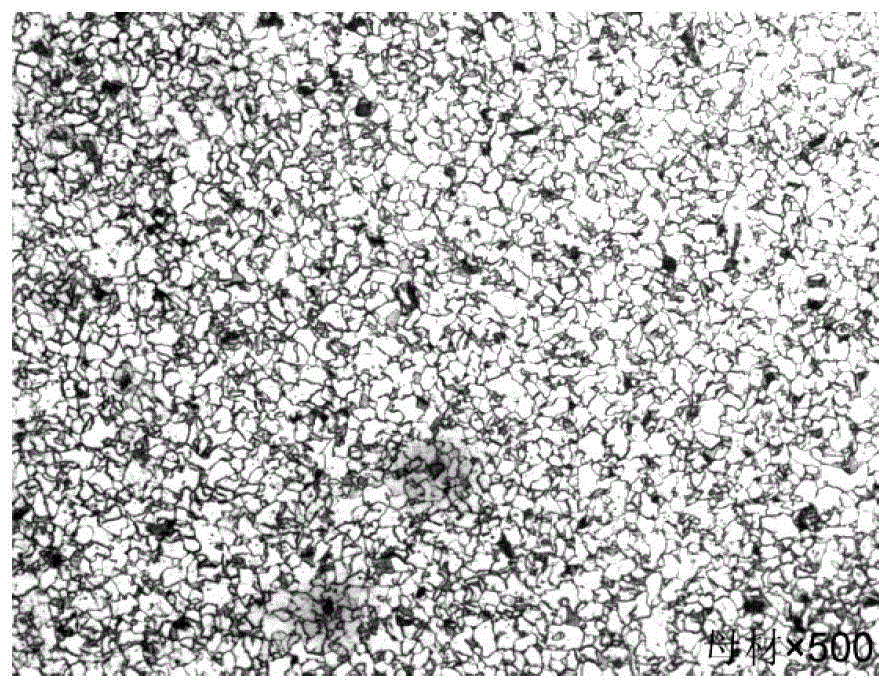

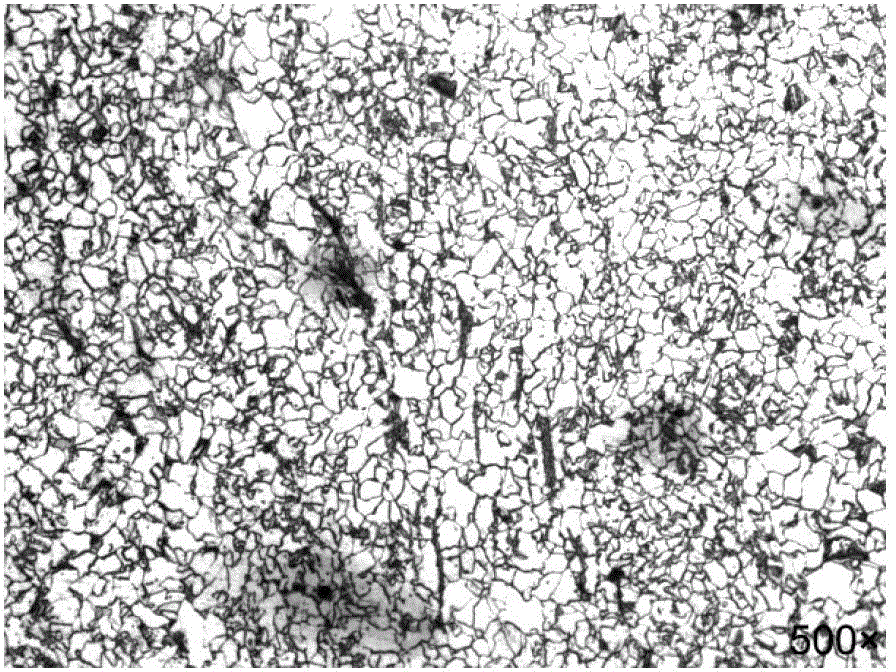

Process for improving comprehensive mechanical performances of weld of high-frequency straight welded tube

InactiveCN103276187BControl growthShorten heating timeFurnace typesIncreasing energy efficiencyIntermediate frequencyHigh surface

The invention discloses a process for improving the comprehensive mechanical performances of the weld of a high-frequency straight welded tube. The process comprises the following steps: 1, carrying out intermediate frequency heating; 2, water mist cooling: allowing the tube to run along a roller way for 1-3m after the intermediate frequency heating insulation of the weld, and carrying out water mist cooling, wherein the water mist cooling water pressure is 0.4-0.6Mpa, the weld cooling speed is 80-100DEG C / s, and the final cooling temperature is 400-600DEG C; 3, air blowing: blowing by compressed air after the water mist cooling, wherein the pressure of the compressed air is 0.1-0.3MPa; and 4, natural cooling and water cooling treatment: naturally cooling through allowing the welded tube to move forward with the roller way after the compressed air blowing, and carrying out the water cooling treatment of the whole welded tube after the body temperature of the welded tube decreases to 350DEG C or less to complete the heat treatment of the weld. The weld processed through the process has the advantages of good mechanical performances, high surface qualify, convenient processing and low cost.

Owner:武钢集团有限公司

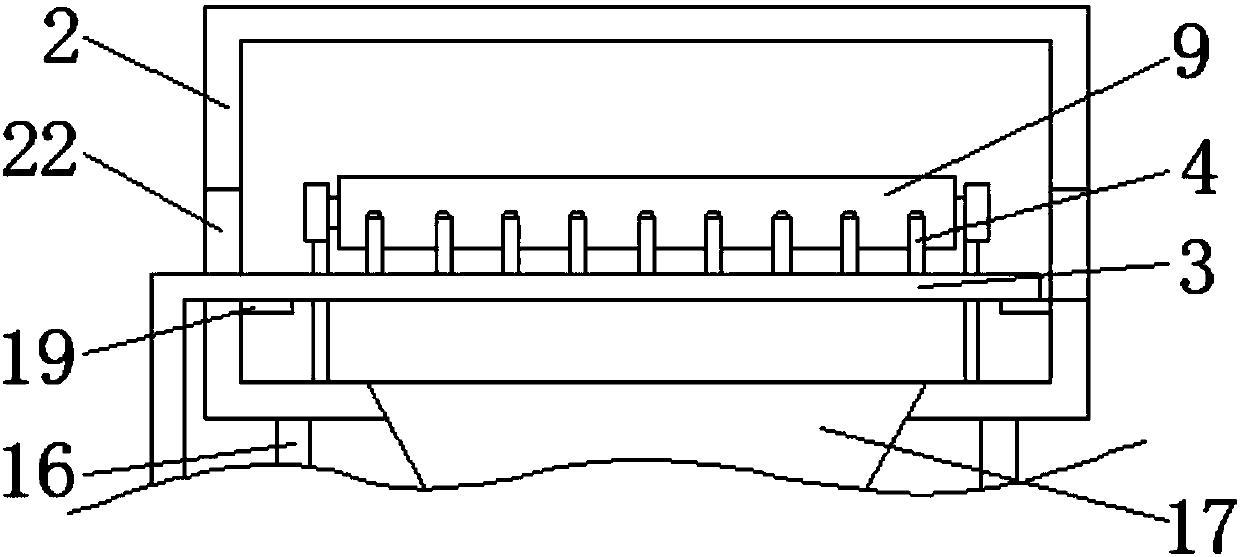

Uniform cooling device for cooling of round steel

ActiveCN113275396ACool evenlyAvoid uneven coolingTemperature control deviceWork treatment devicesThermodynamicsEngineering

The invention relates to the technical field of steel production equipment, and provides a uniform cooling device for cooling of round steel. The device comprises an outer cover, a spraying assembly, a spraying head, a clamping assembly, a fan, an infrared imaging thermodetector and a controller, the spraying assembly comprises a water conveying pipe, a plurality of pressure stabilizing pipes and a plurality of water distribution pipes, ones of the plurality of water distribution pipes communicate with the water conveying pipe, the other ends of the plurality of water distribution pipes penetrate into an accommodating space of the outer cover, the water conveying pipe is used for being connected with a water supply system, the plurality of water distribution pipes are respectively arranged at two sides of a water-outlet point of the water conveying pipe, the water distribution pipe farthest from the water conveying pipe communicate with the water distribution pipe closest to the water conveying pipe through the pressure stabilizing pipe, the water distribution pipe far away from the water conveying pipe communicate with the water distribution pipe near the water conveying pipe through the pressure stabilizing pipe, and the pressure stabilizing pipes are used for keeping water pressures in all positions in the spraying assembly equal. By means of the technical scheme, the problem that in the prior art, the production efficiency is low due to the fact that round steel is not uniformly cooled in the water cooling process is solved.

Owner:唐山盛通锻造有限公司

Combustion assembly structure of turbojet engine

ActiveCN111520745AMiniaturizationReduce weightContinuous combustion chamberPump componentsCombustion chamberAxial distance

The invention discloses a combustion assembly structure of a turbojet engine. The combustion assembly structure is characterized in that a guider and a front cover are arranged at the two ends of a case with a cavity structure in the middle respectively, a shaft sleeve coaxial with the case is fixed to the guider, a diffuser is fixed to the outer ring of the other end of the shaft sleeve, the sections, along the axis of the shaft sleeve, of the connecting faces between guide vanes and the shaft sleeve are in a V shape, the outer ring of the shaft sleeve is provided with a double-layer annularcombustion tank coaxial with the shaft sleeve, the section, along the axis of the shaft sleeve, of the end face of one end of the double-layer annular combustion tank is V-shaped, the two V-shaped structures enable gas entering from the diffuser to be attached to the wall face of the V-shaped structure of the double-layer annular combustion tank better, meanwhile, the gas entering from the diffuser is prevented from flowing back at a gas inlet, the velocity field is more uniform, the high-speed flow field is optimized, a local high-speed area is avoided, a main combustion area of a combustionchamber can be advanced, and the outlet temperature of the combustion chamber is further reduced; and the axial distance between the diffuser and the double-layer annular combustion tank is reduced, so that the total length of the engine is reduced, the weight of the engine is reduced, and miniaturization of the combustion assembly of the turbojet engine is facilitated.

Owner:NAT INST CORP OF ADDITIVE MFG XIAN

High-efficiency cooling device for laser cladding remanufacturing

PendingCN113151819AAvoid uneven coolingGuaranteed uniformityLighting and heating apparatusMetallic material coating processesWater storage tankEngineering

The invention discloses a high-efficiency cooling device for laser cladding remanufacturing. The high-efficiency cooling device for laser cladding remanufacturing comprises a first annular shell body and a laser spray head, the first annular shell body is installed on the outer side of the laser spray head in a sleeving mode, two opposite limiting shell bodies are fixedly installed on the inner top wall of the first annular shell body, and the same second annular shell body is fixedly mounted on the lower surfaces of the two limiting shell bodies. the laser spray head and the first annular shell body are arranged, the first annular shell body can be attached to the laser spray head by utilizing connection between the laser spray head and the first annular shell body, then an annular water outlet formed in the second annular shell body is utilized, cooling liquid can flow out around the inner wall of the first annular shell body at the same time, an arranged water outlet pipe is utilized, then cooling can be carried out on cooling liquid through a water storage tank, an arranged water pump is utilized, and therefore it can be guaranteed that the circular inputting of the cooling liquid is carried out on the device, the cooling uniformity of the device on the laser spray head is guaranteed, and the laser cladding precision is improved.

Owner:徐玲萍

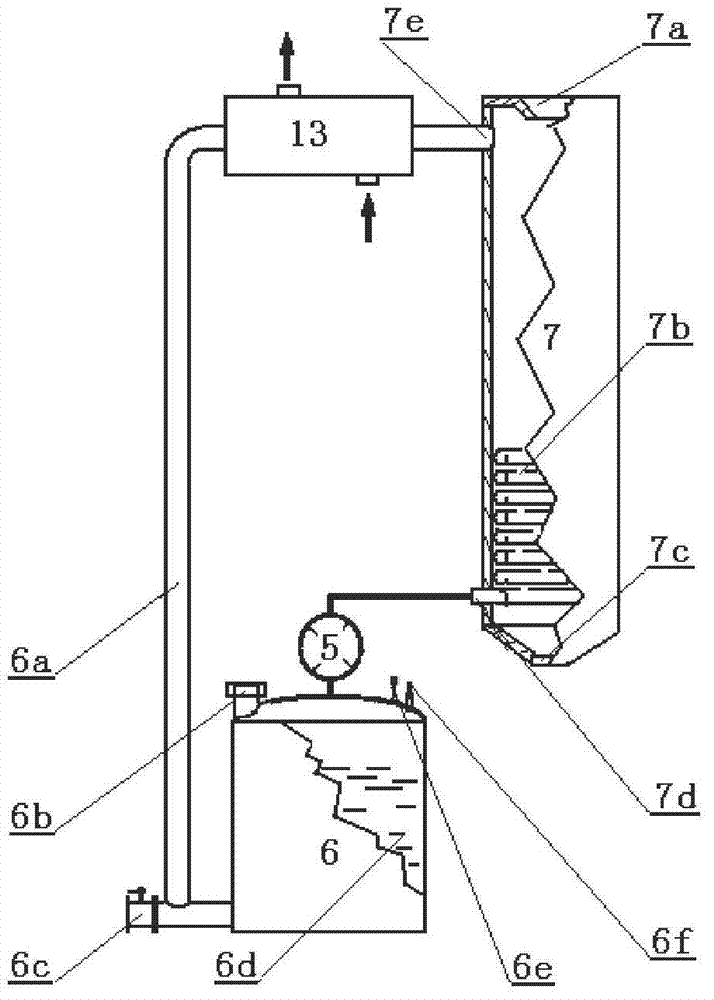

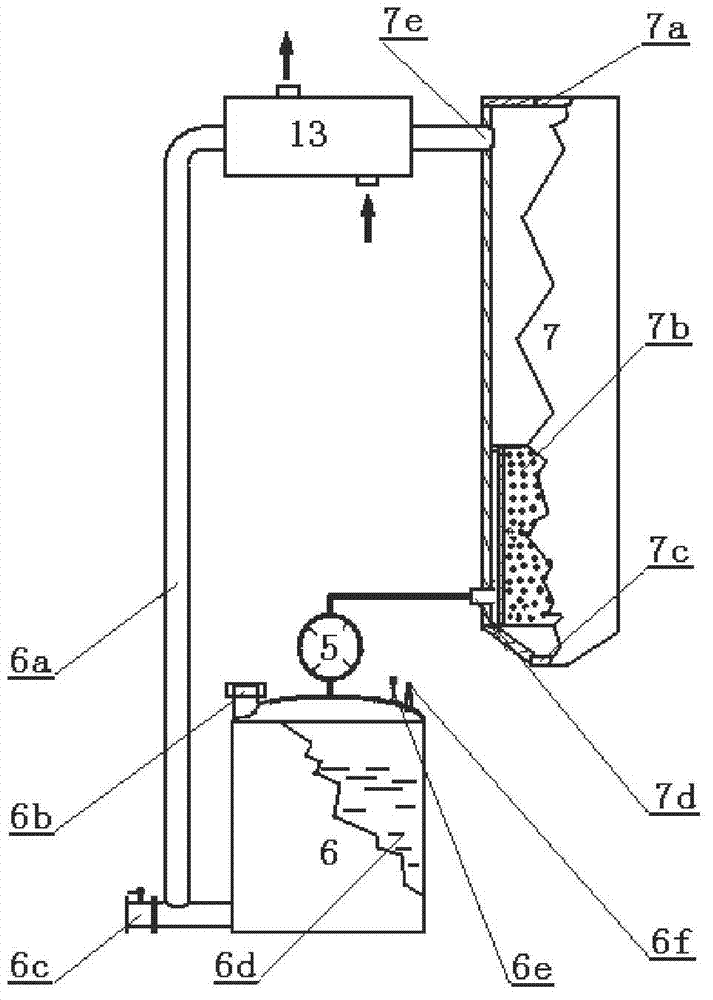

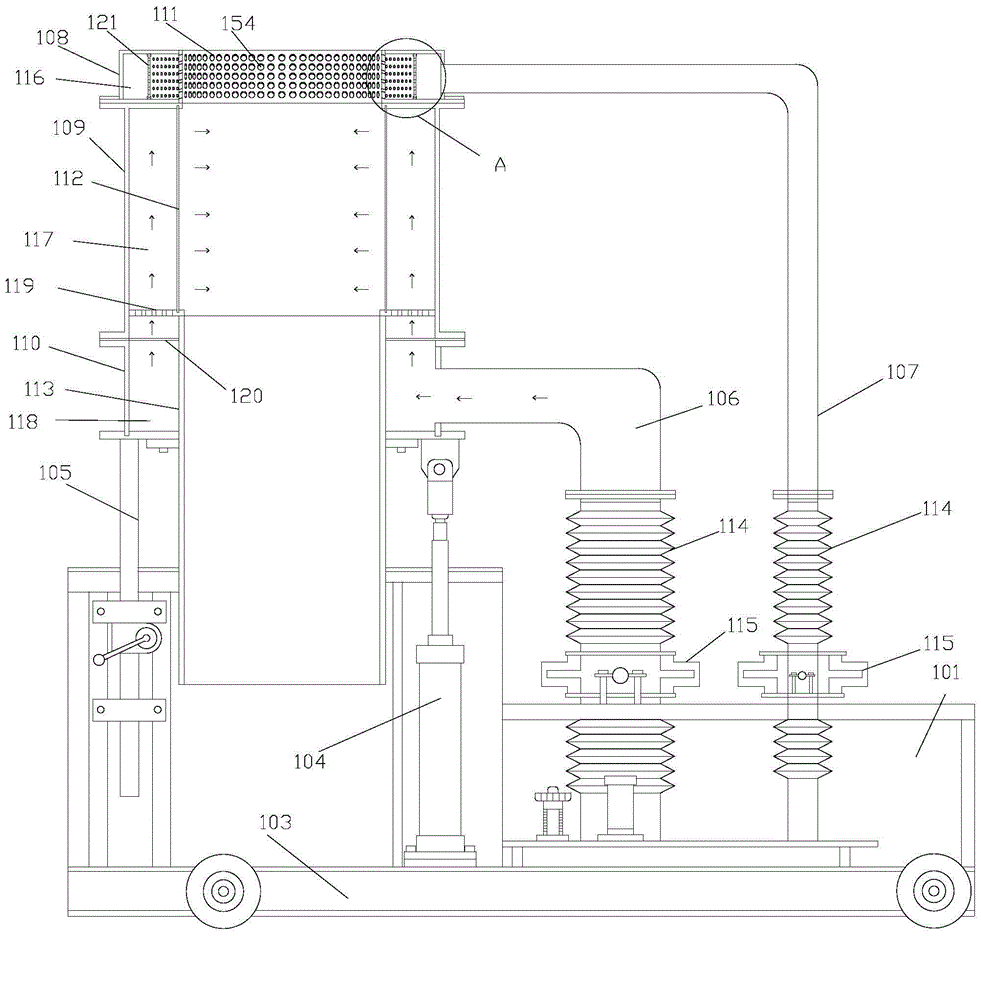

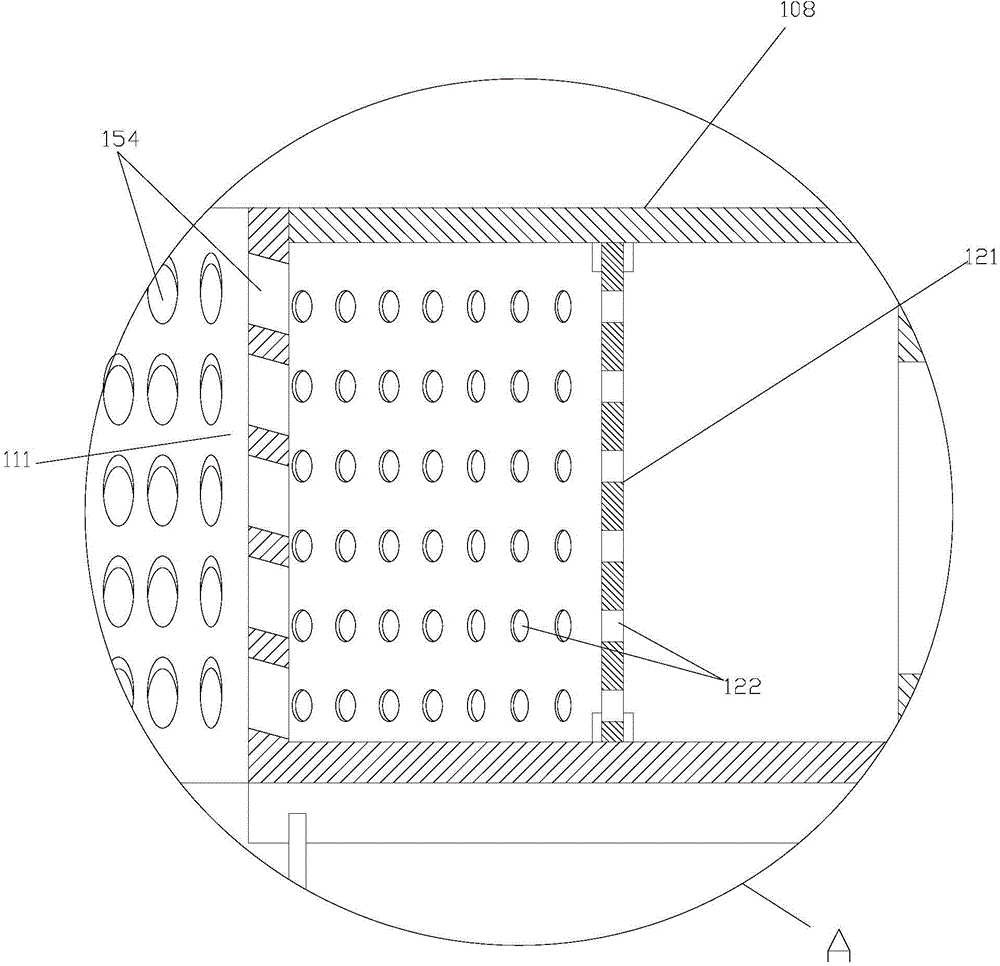

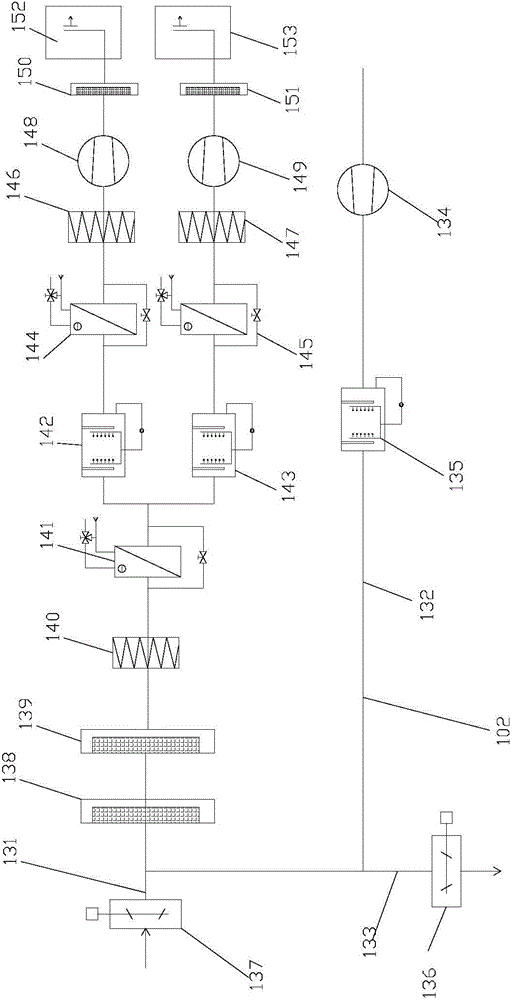

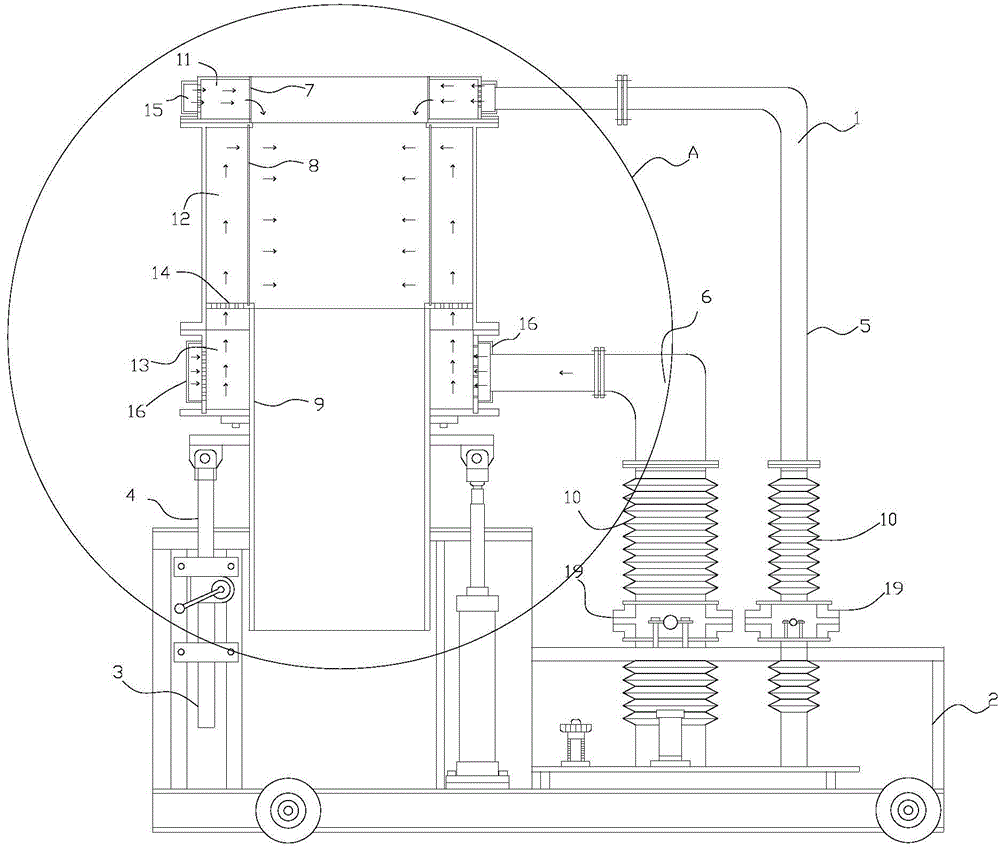

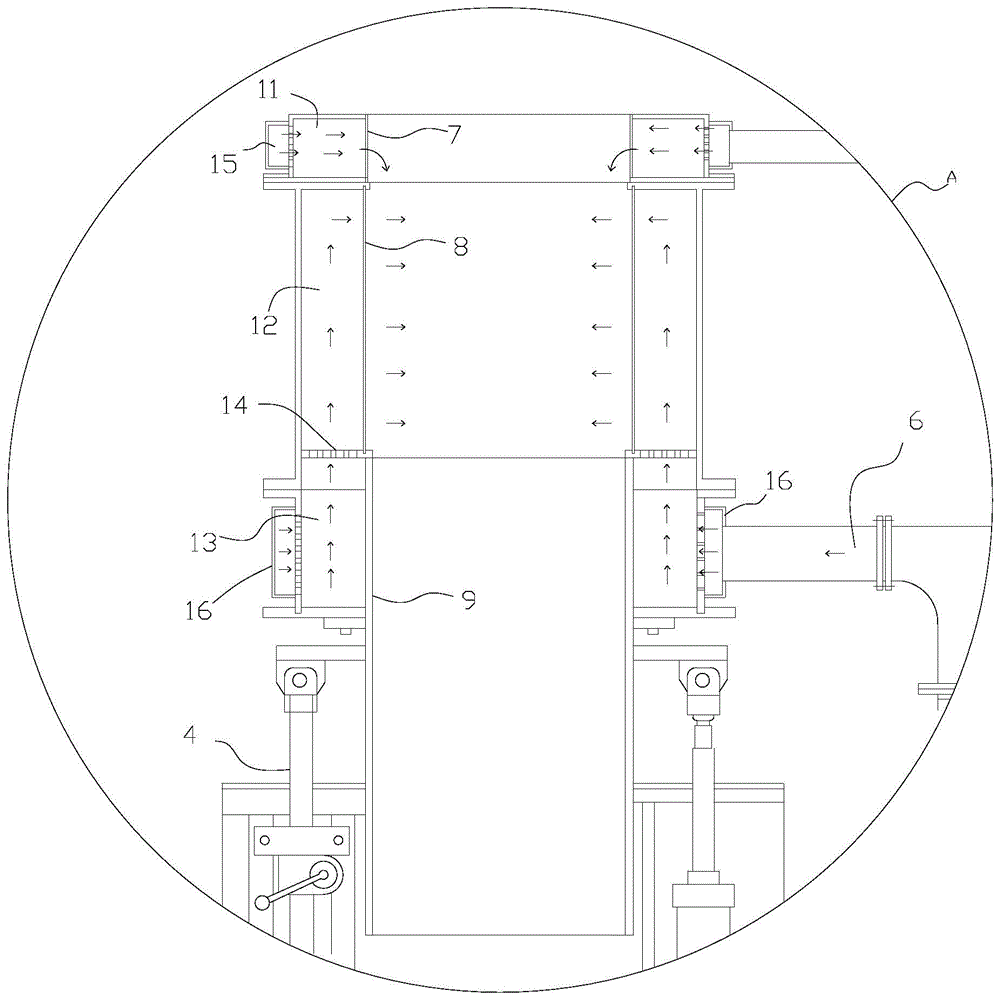

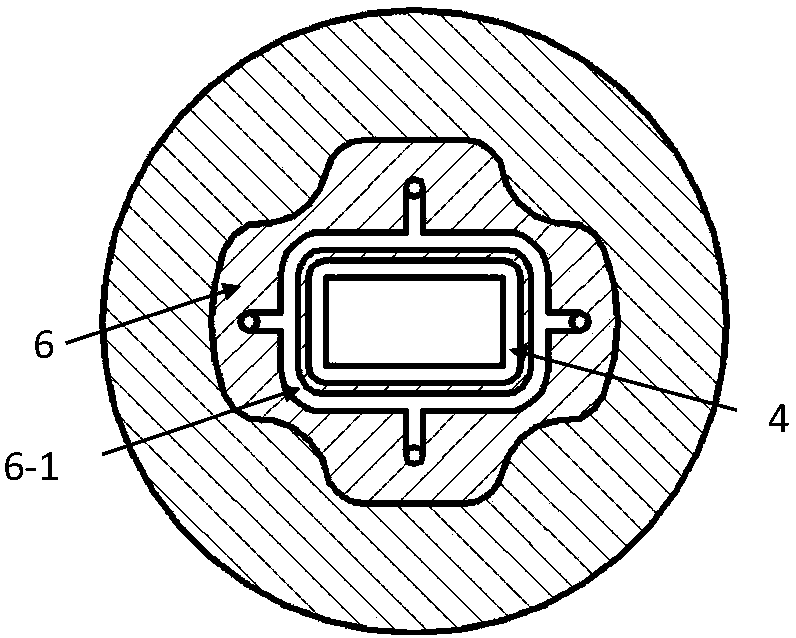

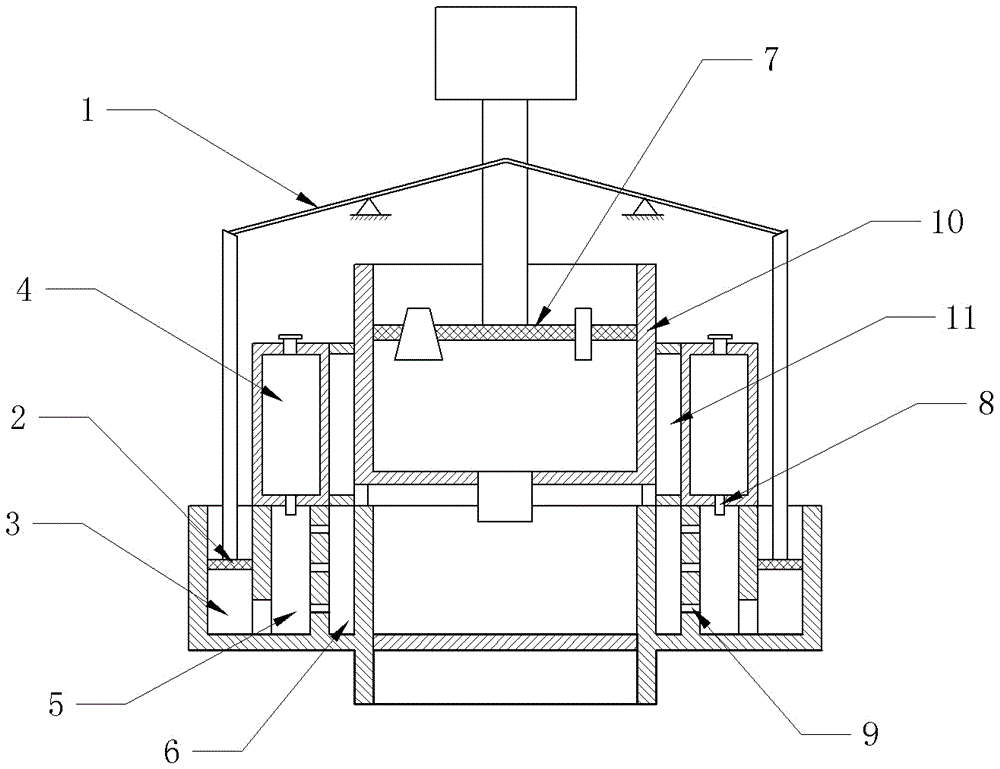

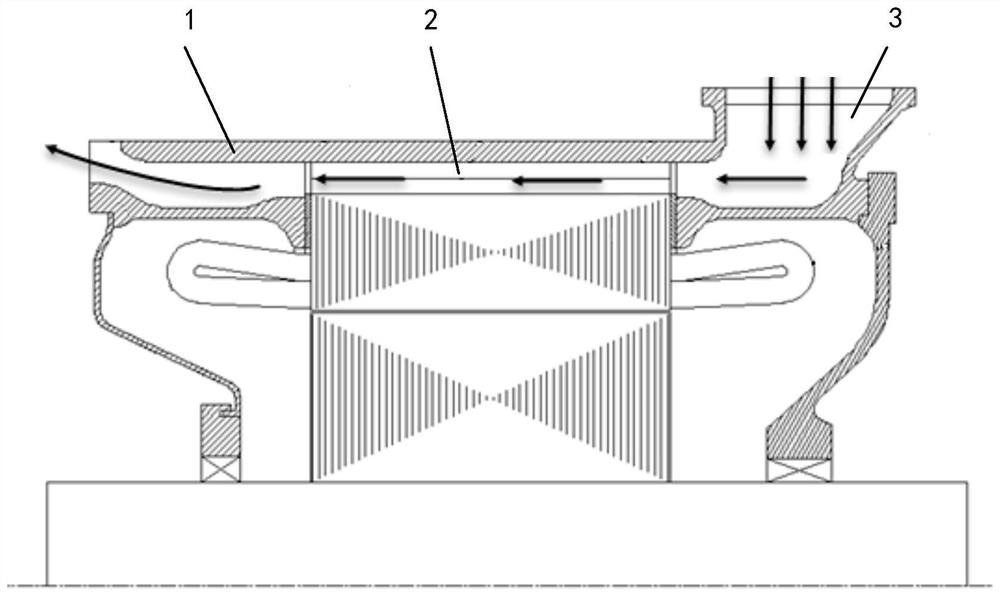

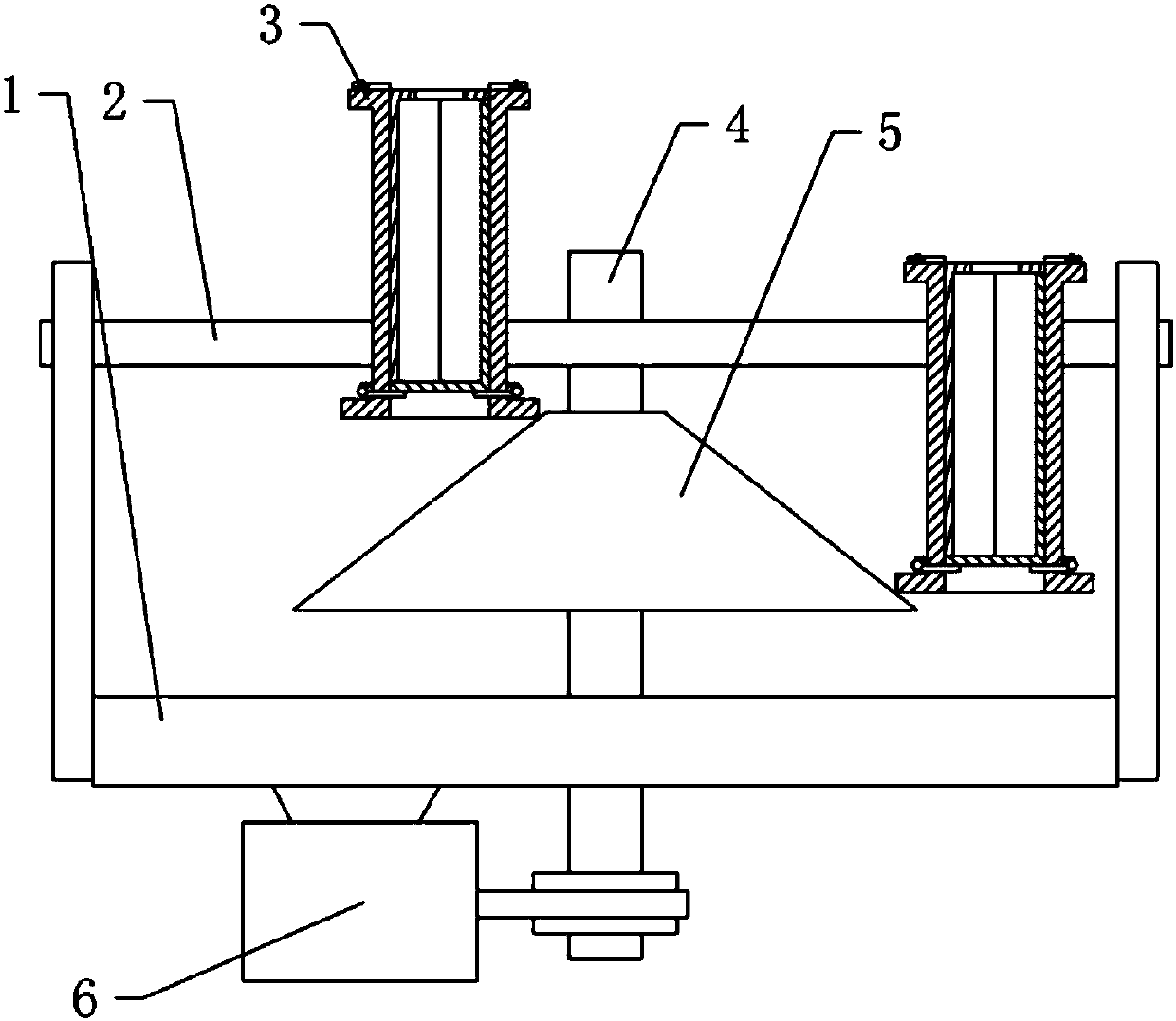

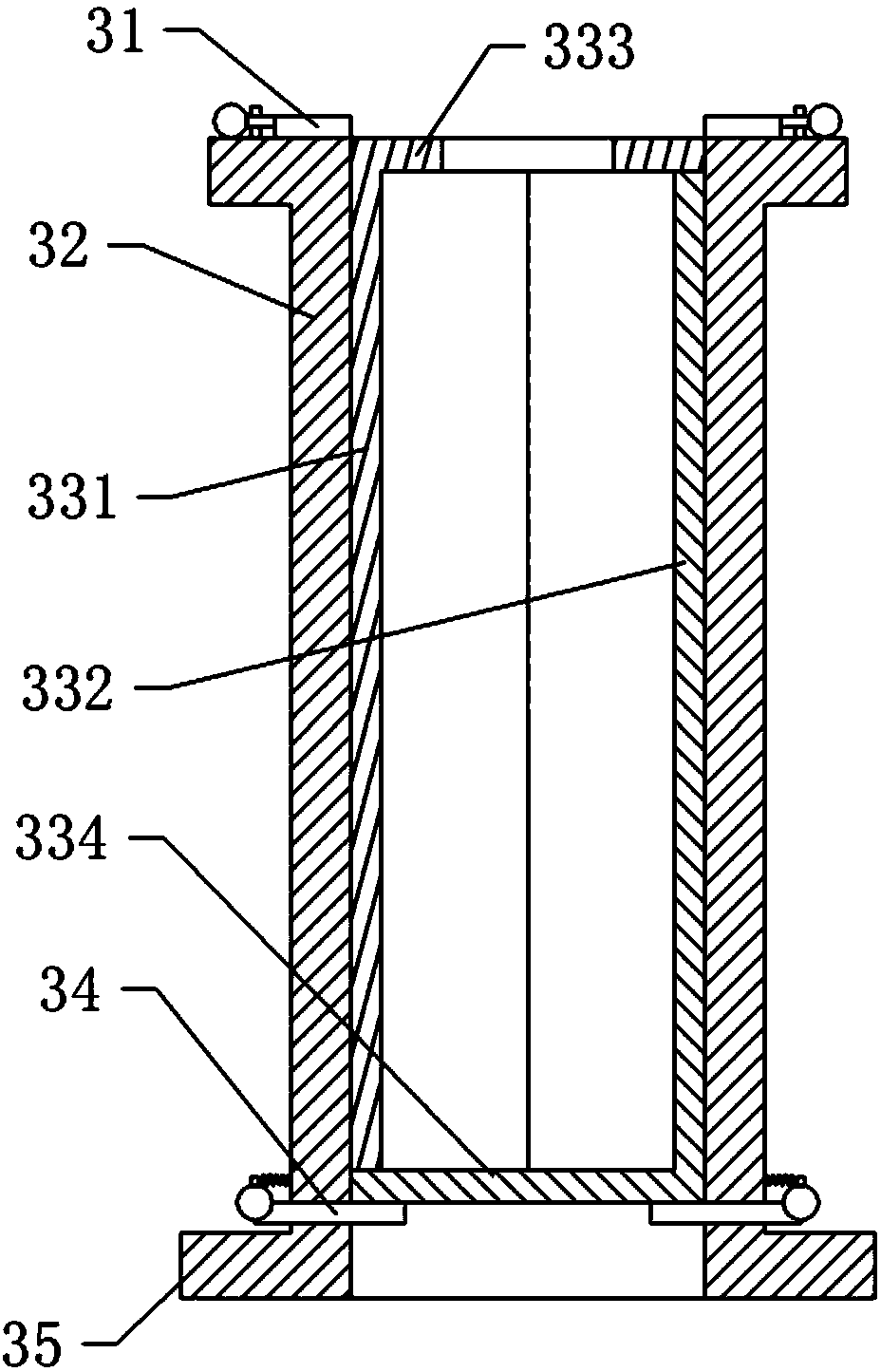

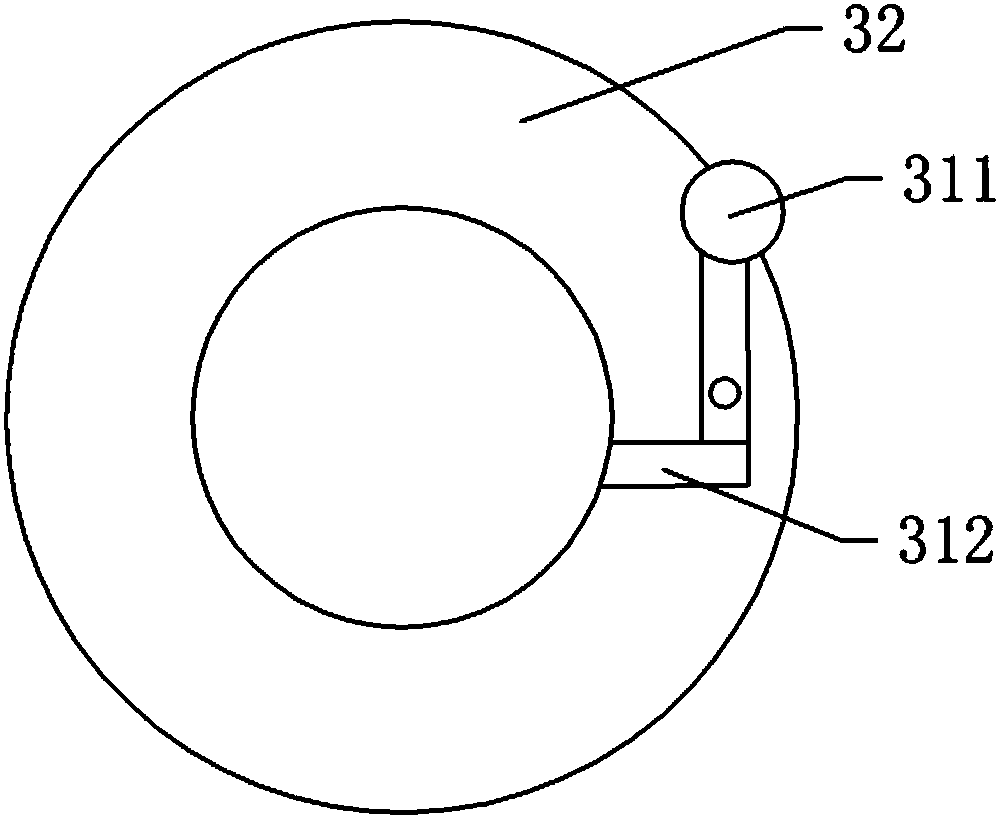

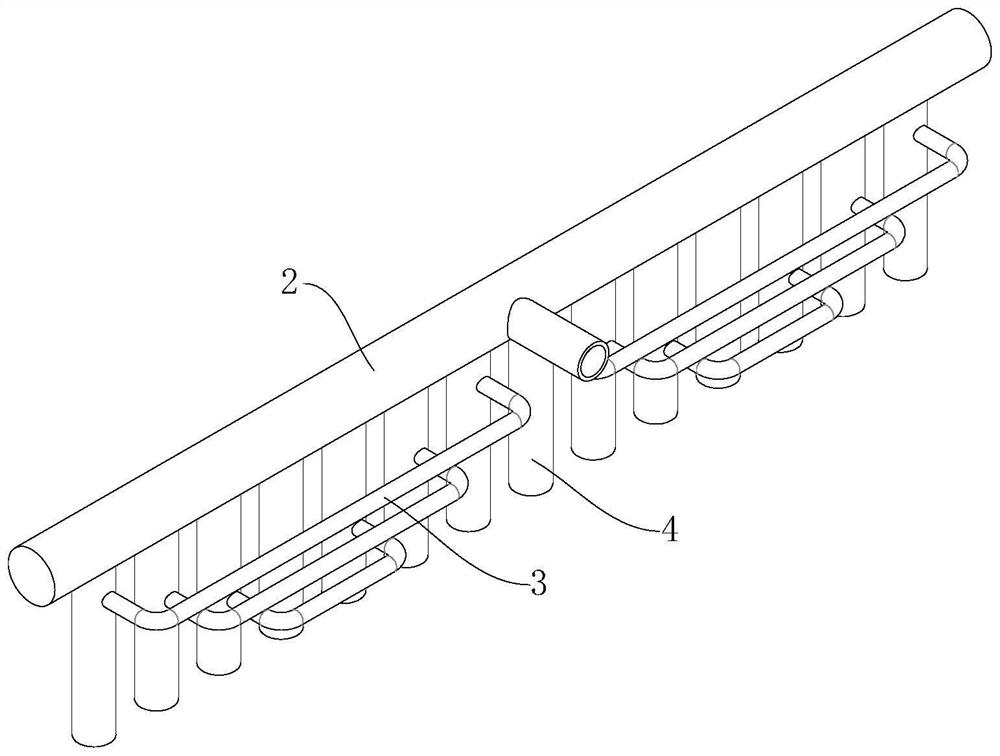

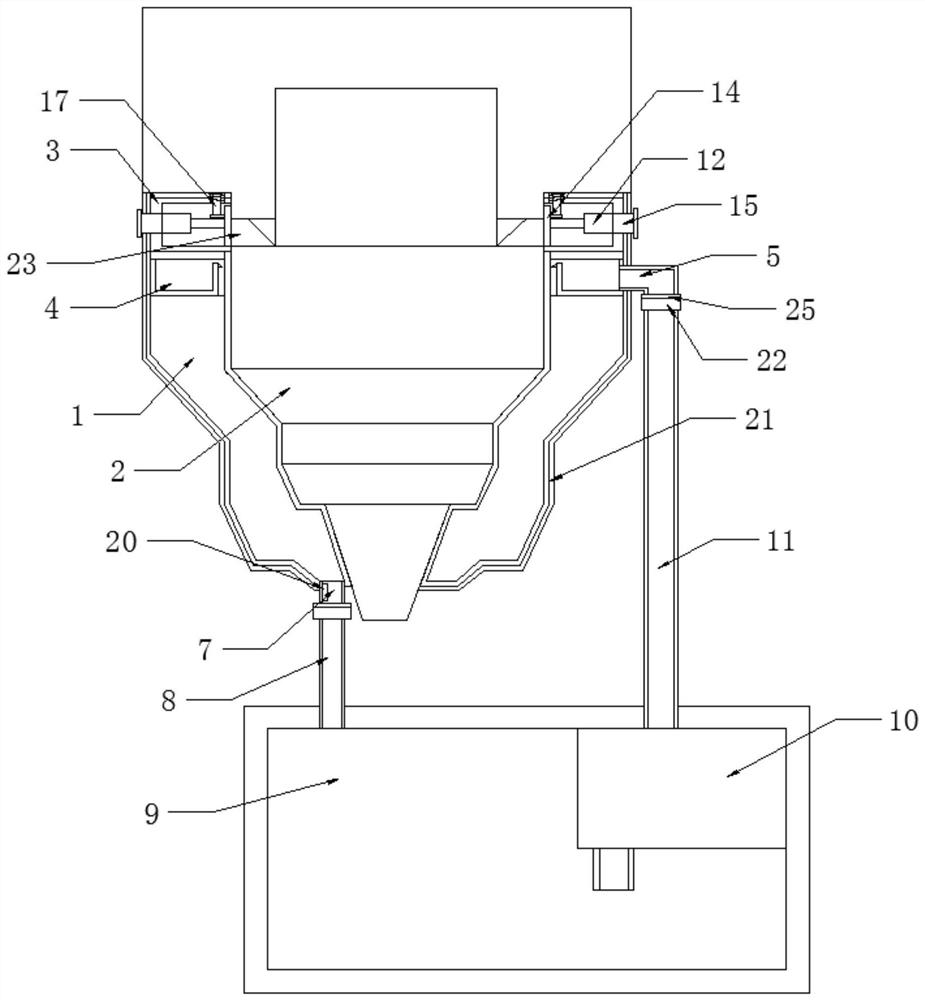

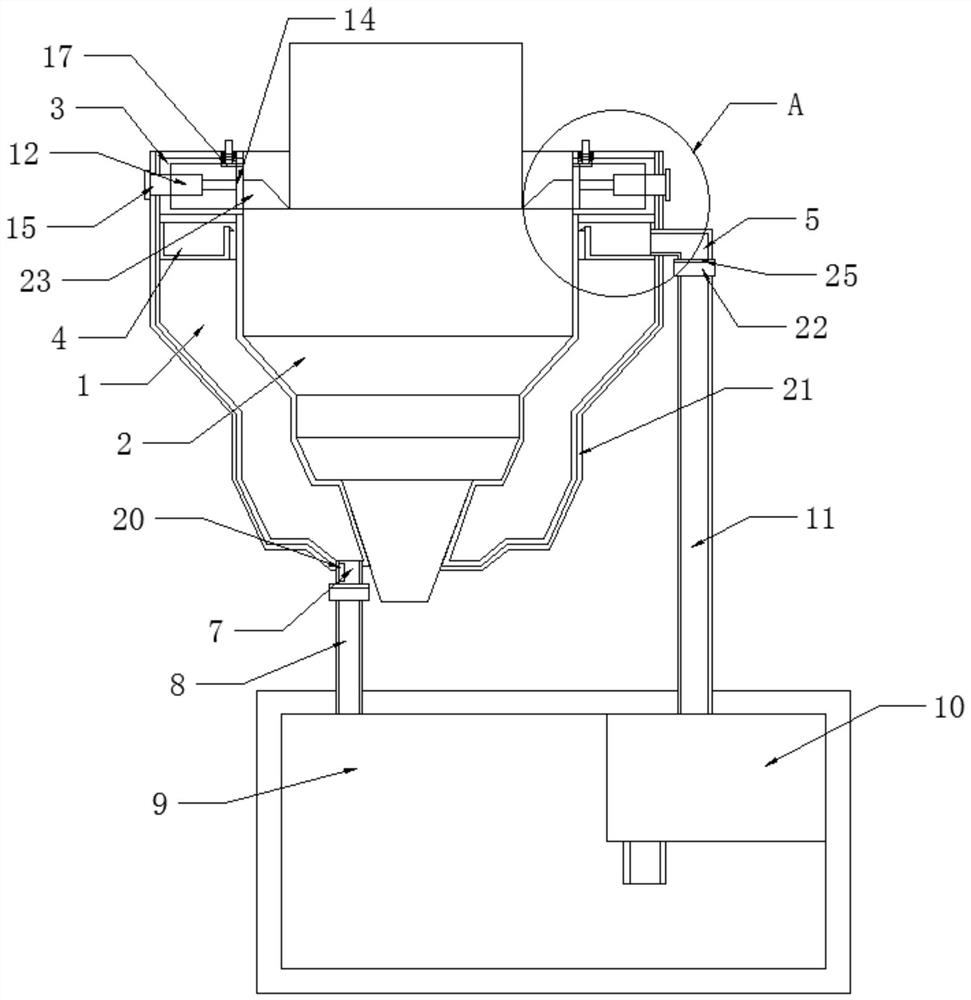

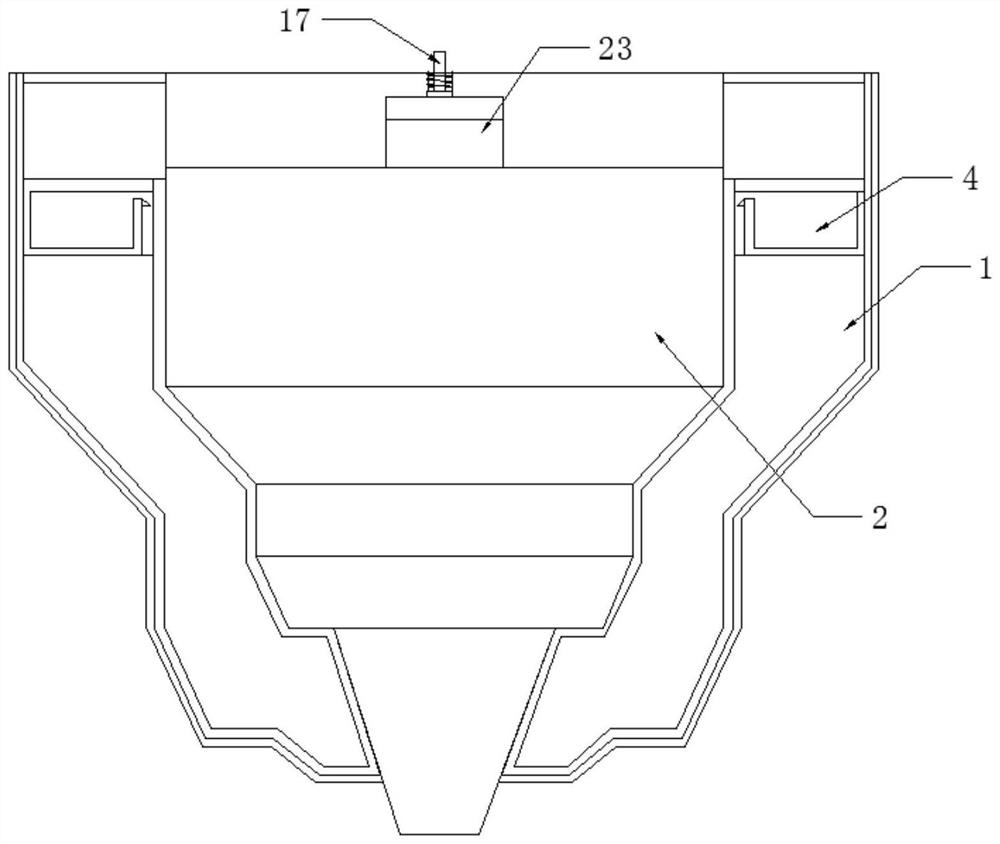

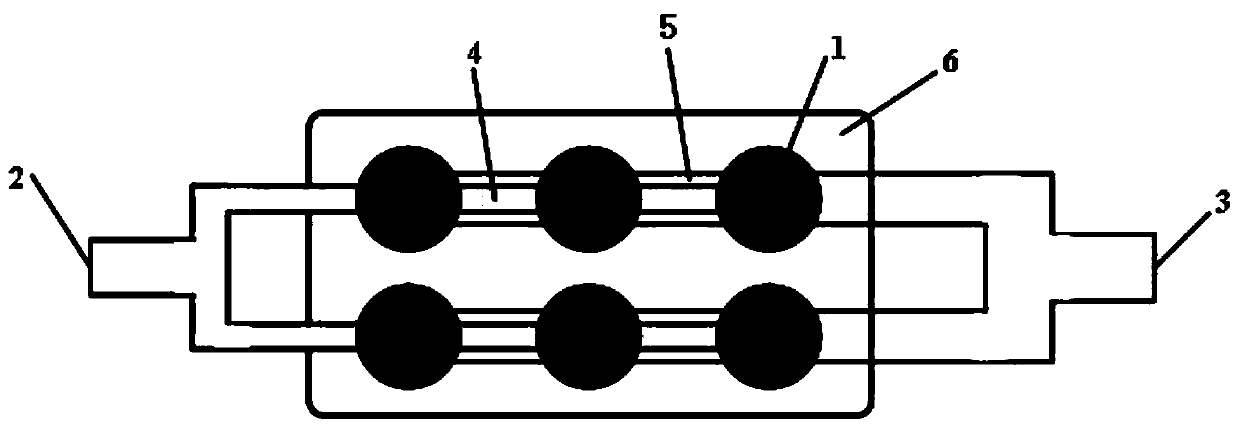

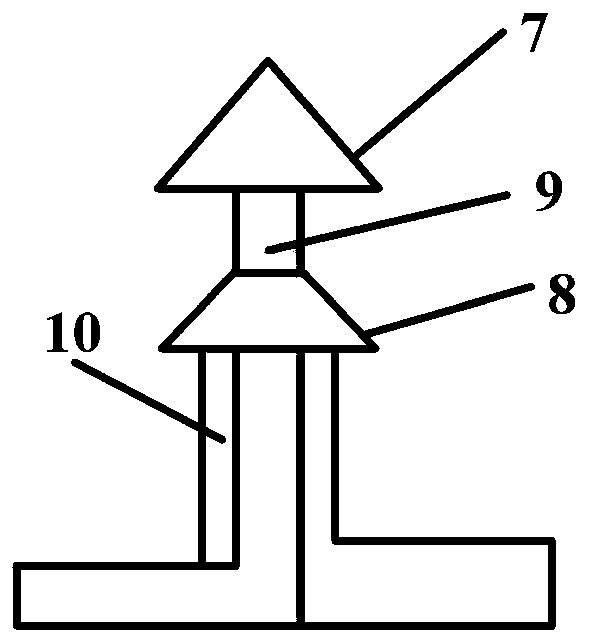

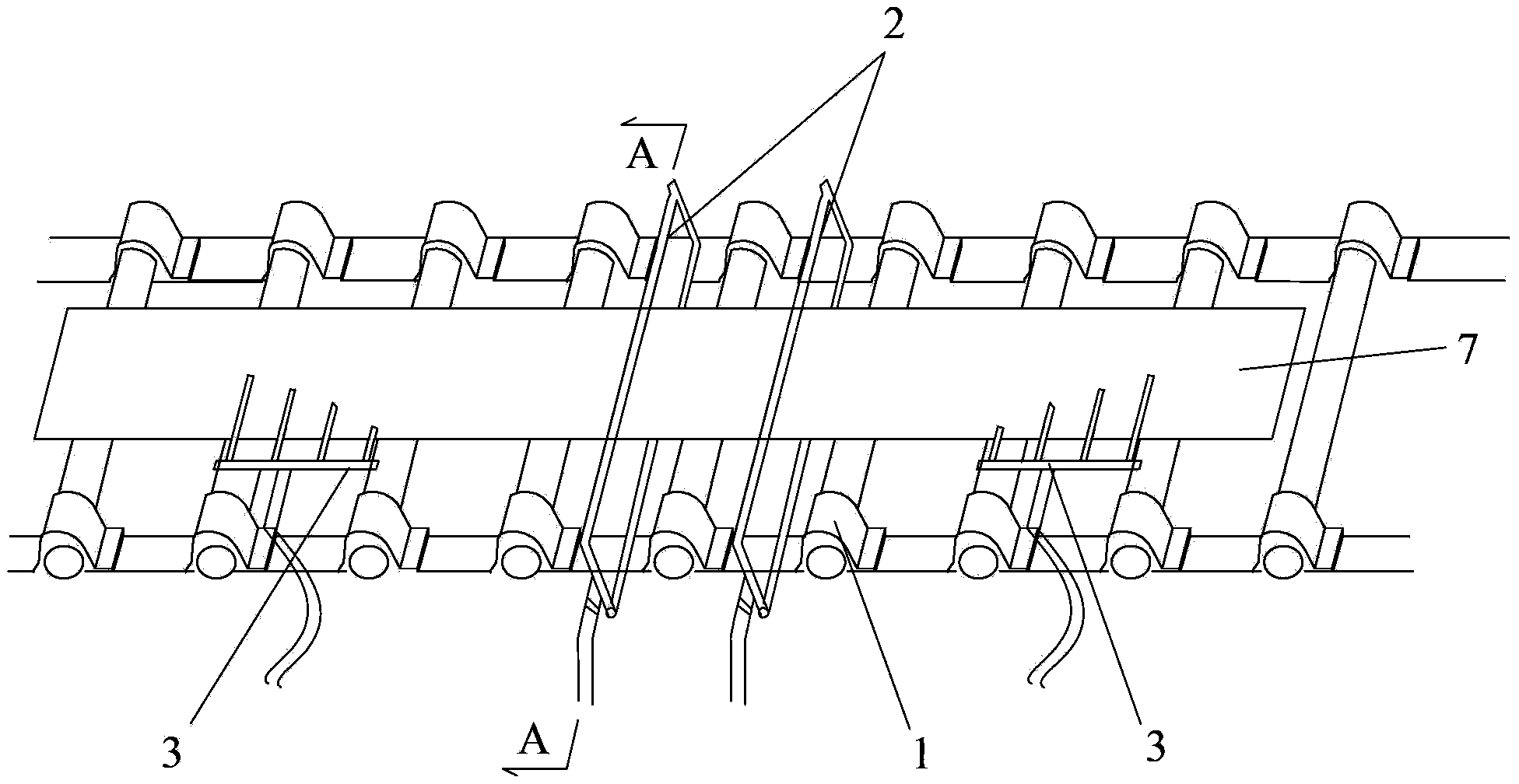

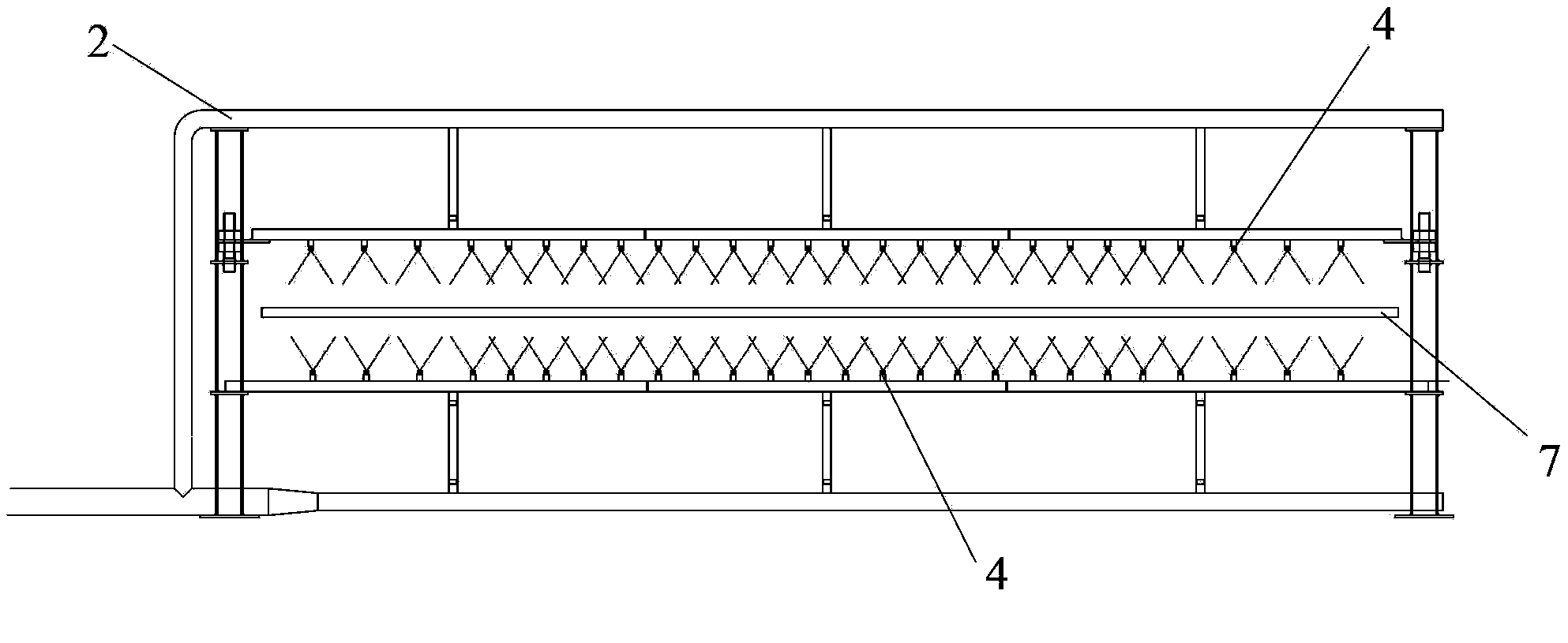

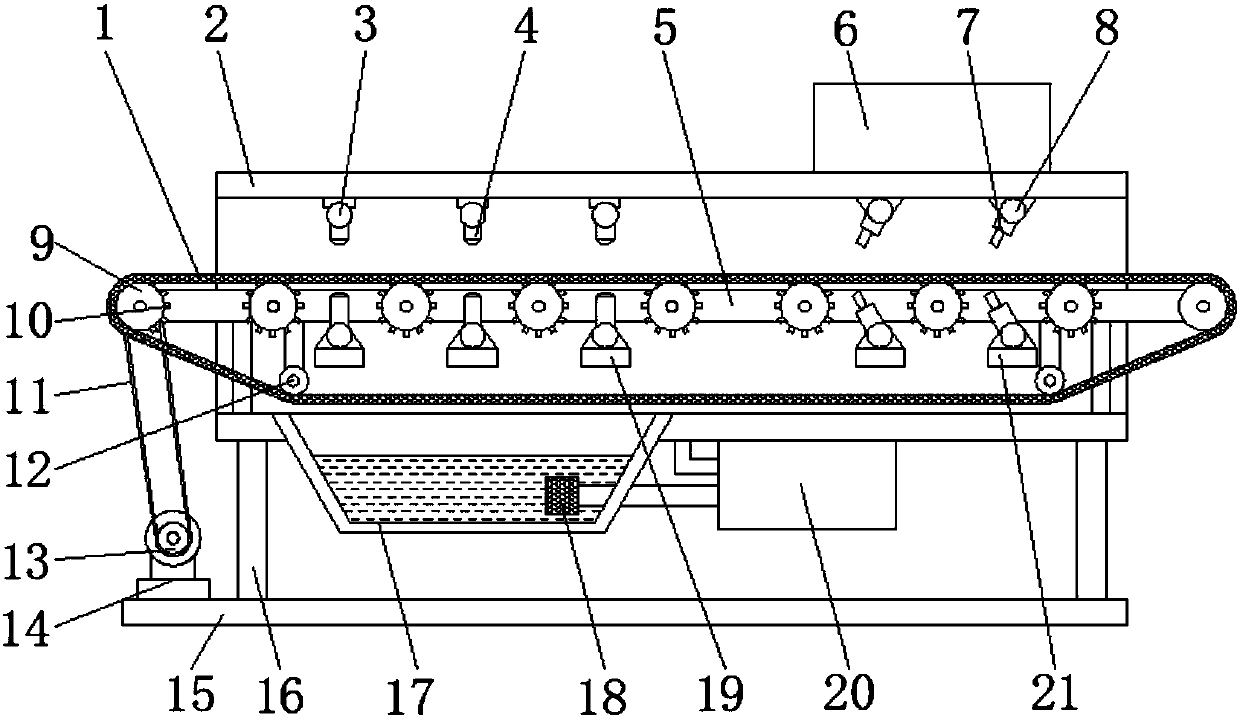

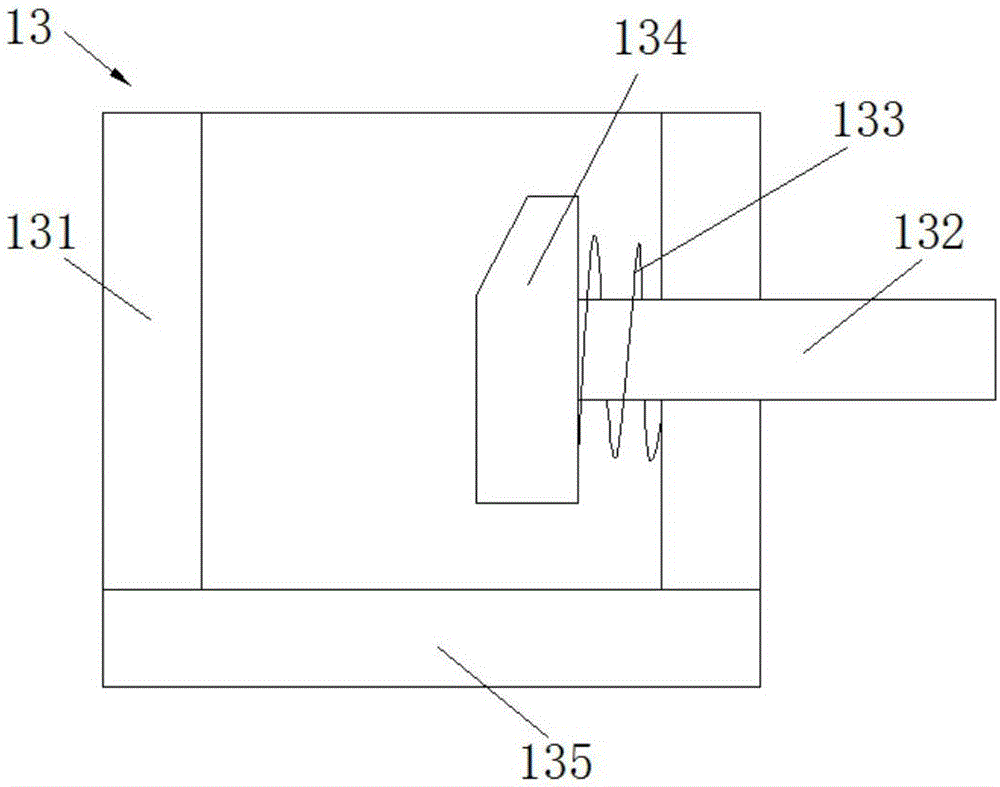

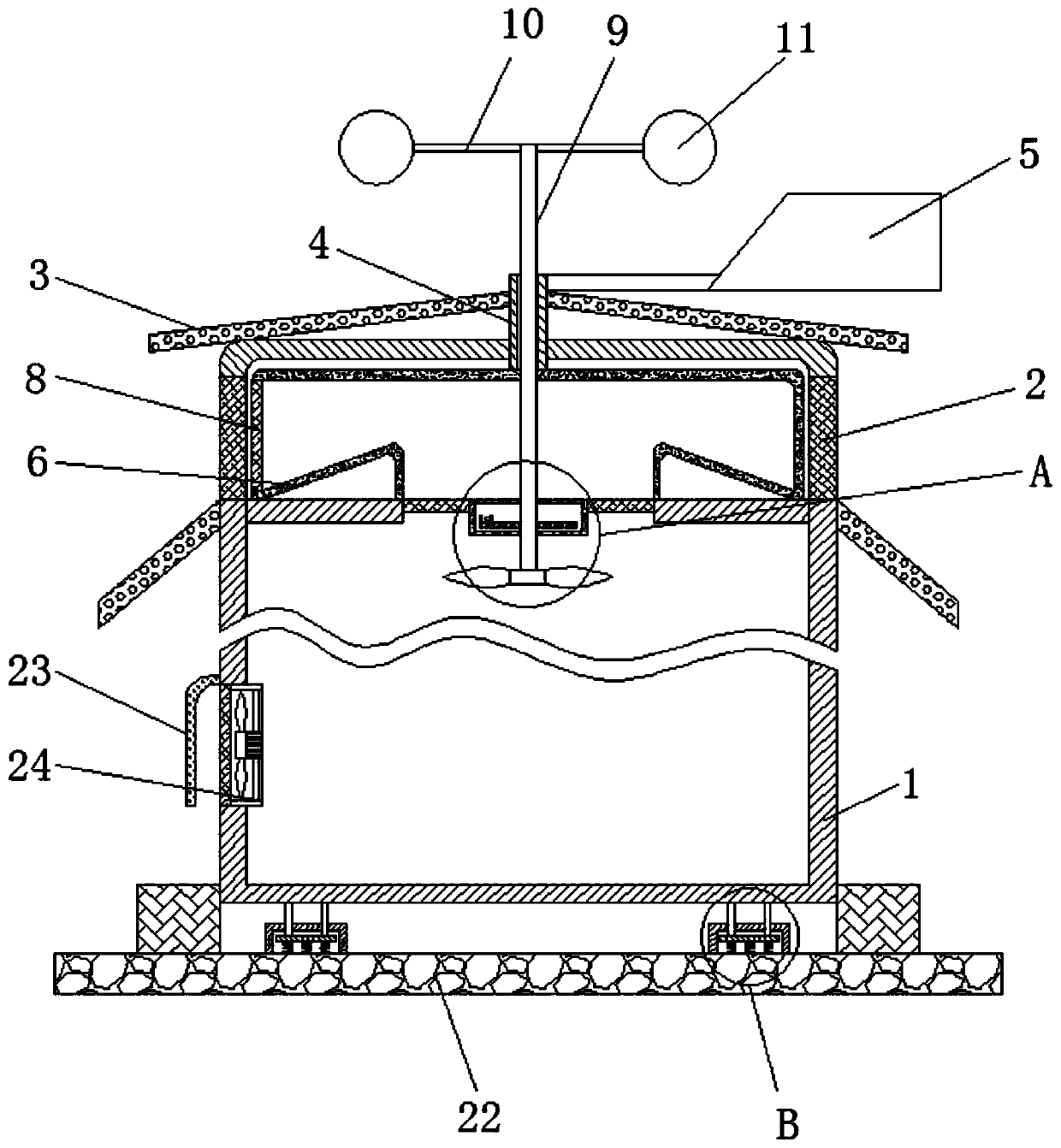

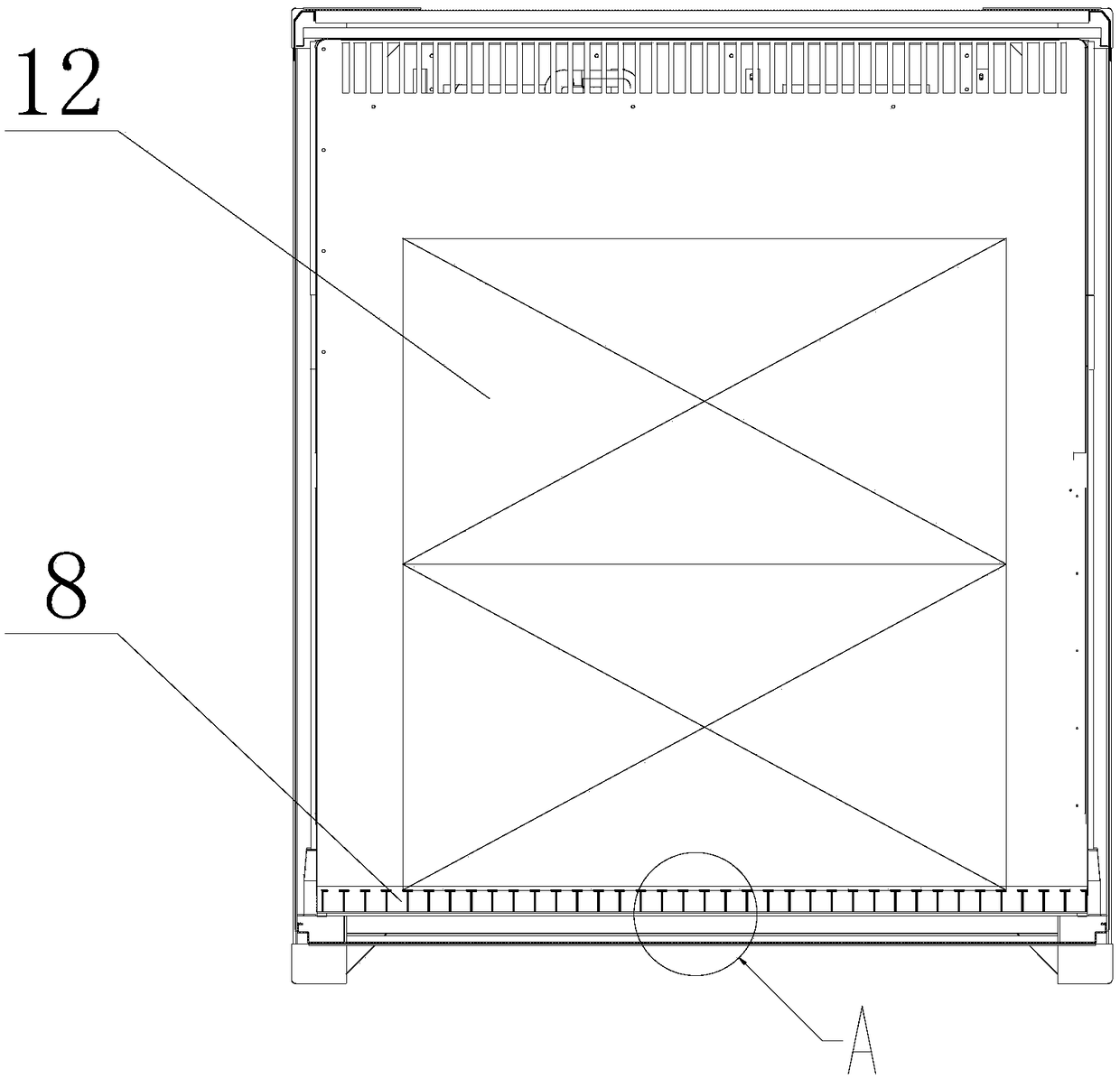

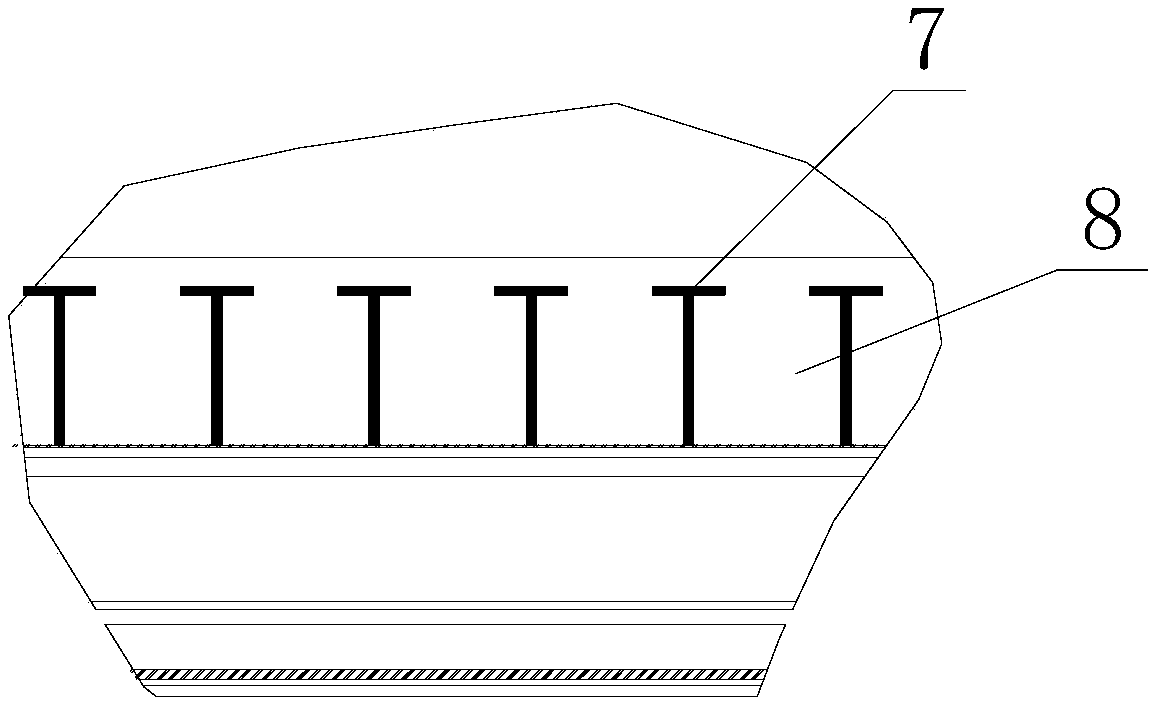

Air distributor system used in gas-solid heat exchange process and gas-solid heat exchange method

ActiveCN110360845ASpread evenlyGuaranteed cooling uniformityHandling discharged materialDirect contact heat exchangersGas solidDistribution system

The invention relates to an air distributor system used in the gas-solid heat exchange process and a gas-solid heat exchange method, and belongs to the field of industry waste heat utilization. The problems that an existing air distribution system is uneven in air distribution, heat exchange between wind and high-temperature materials is uneven, the heat recycling efficiency is low, and the temperature generated after heat exchange is low are solved. The air distributor system comprises hoods, a circulation hot air pipe, an air duct and a gas-solid heat exchange device. High-temperature solidmaterials enter the gas-solid heat exchange device, circulation hot air and air are led into a circulation hot air inlet and an air inlet correspondingly, the hoods are evenly arranged at the lower portion of the gas-solid heat exchange device, the two-layer air outlet design is adopted in the hoods, the high-temperature solid materials sequentially exchange heat with upper-layer circulation hot air and lower-layer air, and stepped cooling is finished. By means of the air distributor system used in the gas-solid heat exchange process and the gas-solid heat exchange method, gas-solid uniform heat exchange can be achieved, stepped heat exchange recycling of high-temperature solid sensible heat through two paths of gas can be achieved, heat exchanging can be uniform, high-quality hot air canbe obtained, and the waste heat utilization efficiency can be better improved.

Owner:CENT IRON & STEEL RES INST +1

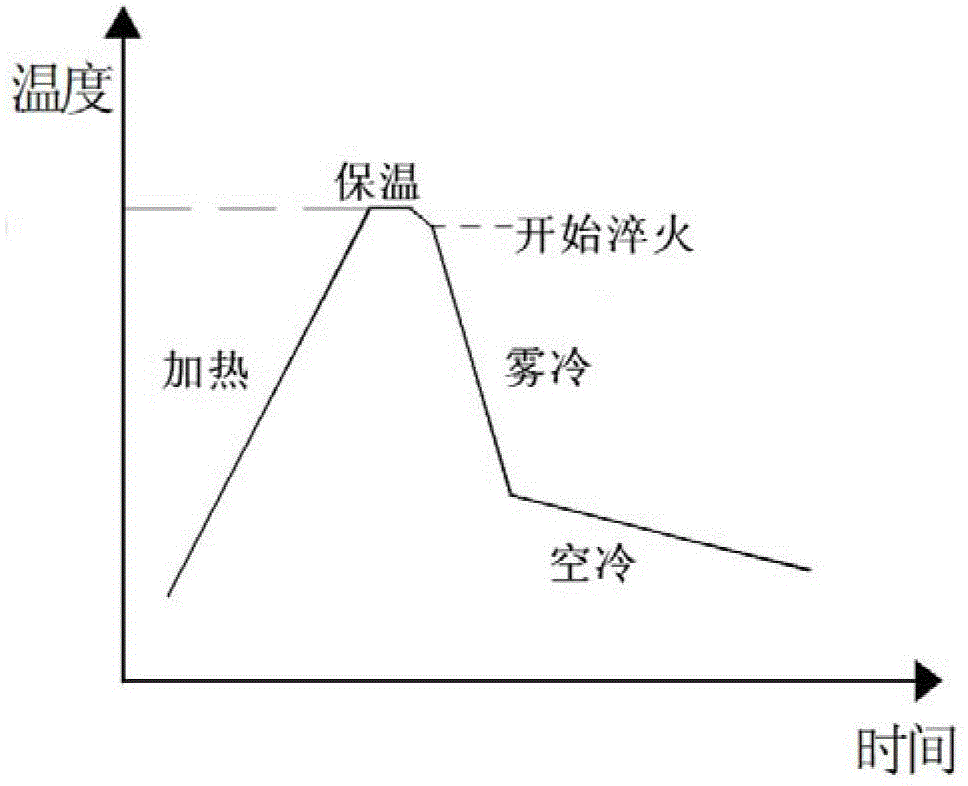

Method and cooling system for improving comprehensive mechanical property of normalized steel plate

ActiveCN102912091BImprove utilization efficiencyReduce CooldownFurnace typesHeat treatment process controlAustenite grainThermal insulation

The invention discloses a method for improving the comprehensive mechanical property of a normalized steel plate. The running time of the steel plate in a heating region in a normalizing furnace is reasonably prolonged and the running time of the steel plate in a thermal insulation region in the normalizing furnace is reasonably shortened, so that the austenite grain growth is avoided to provide favorable conditions for subsequent accelerated cooling. The steel plate is quickly cooled to be 600-700 DEG C from the normalizing temperature in a way of normalizing, atomizing and cooling, so that the mist cooling with higher heat exchange efficiency increases the supercooling degree of the structural transformation of the steel plate and effectively prevents the austenite grain growth; and grains are refined, so that the effect of improving the strength by structure refinement in the heat treatment process of the steel plate is given full play. The invention further provides a cooling system for improving the comprehensive mechanical property of the normalized steel plate. Therefore, the equipment is simple, the investment is low, the surface quality of the steel plate can be improved, and the practicality is better.

Owner:WUHAN IRON & STEEL GRP ECHENG IRON & STEEL CO LTD

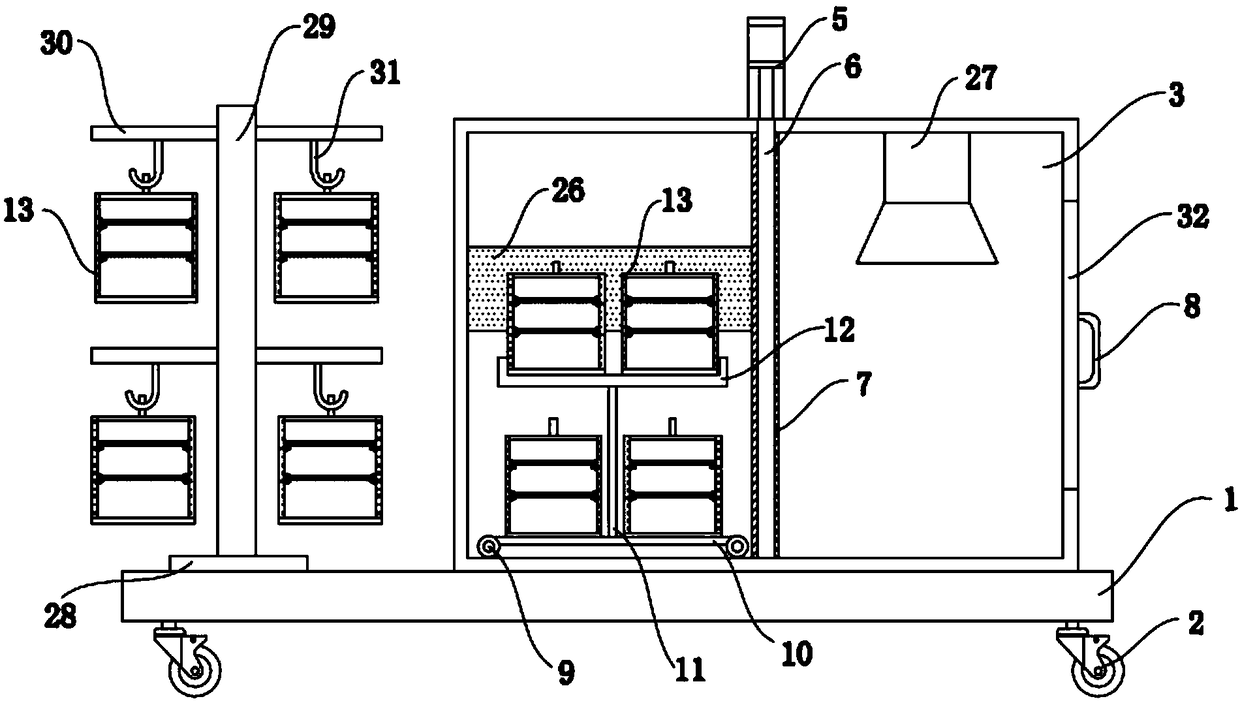

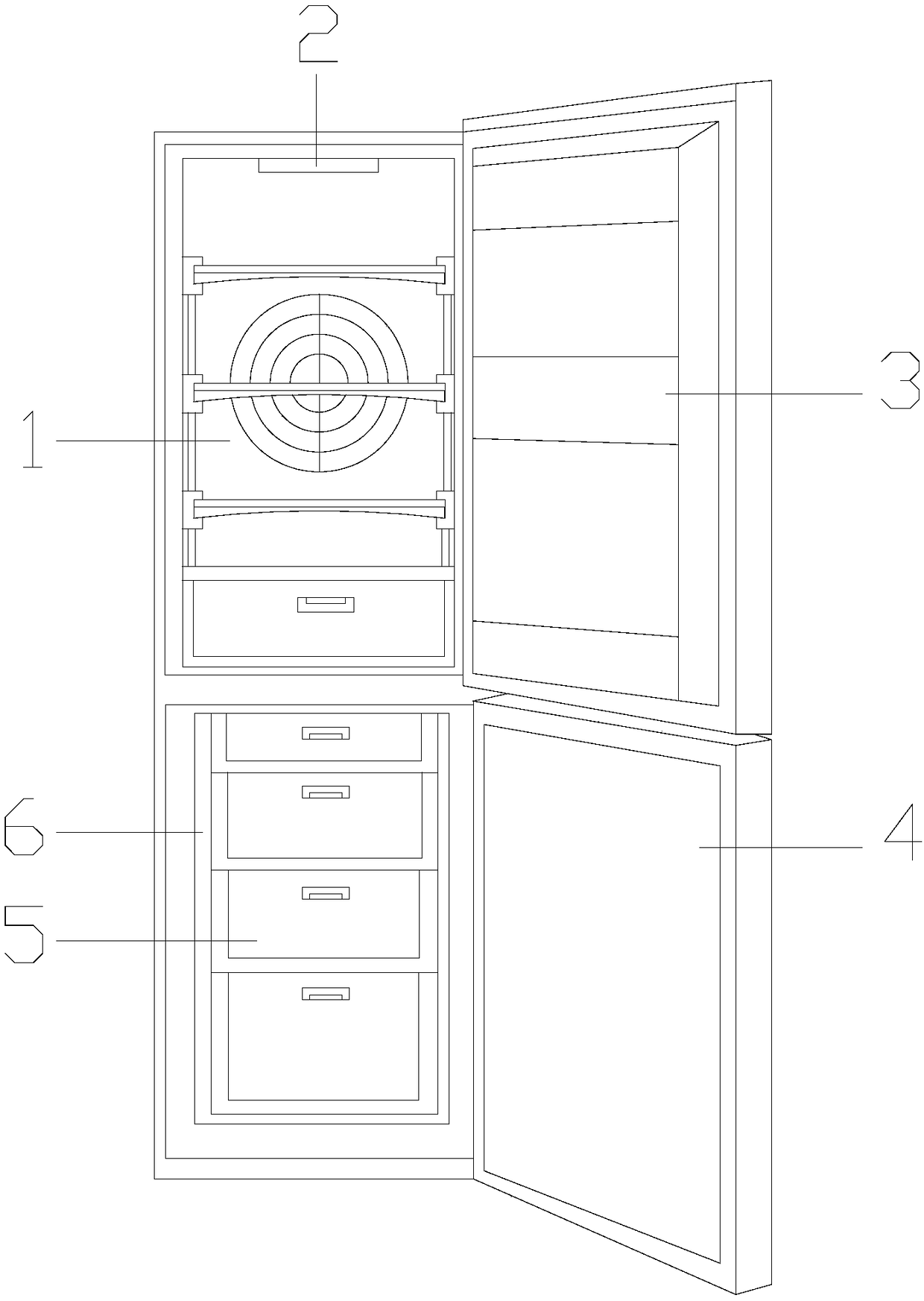

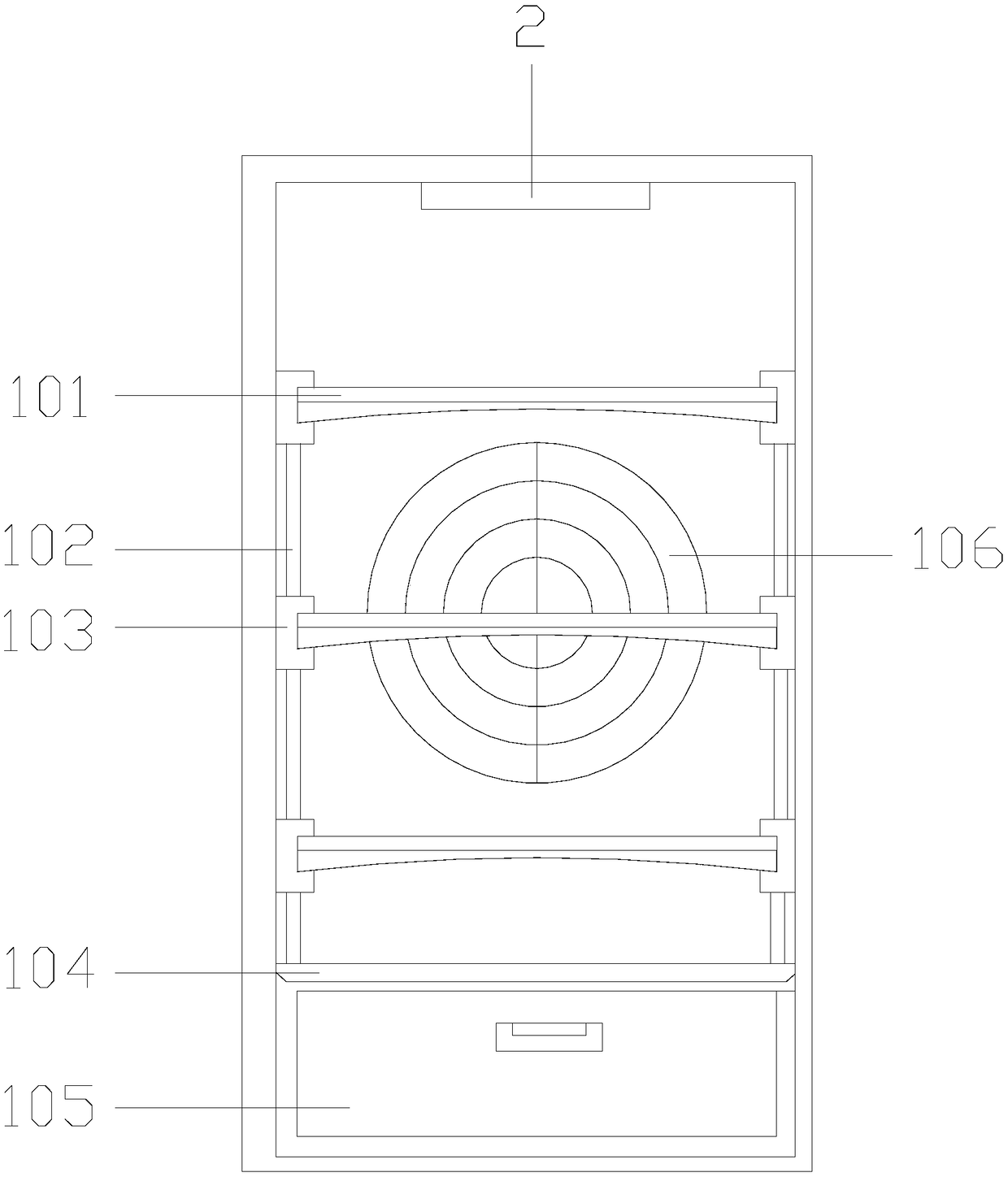

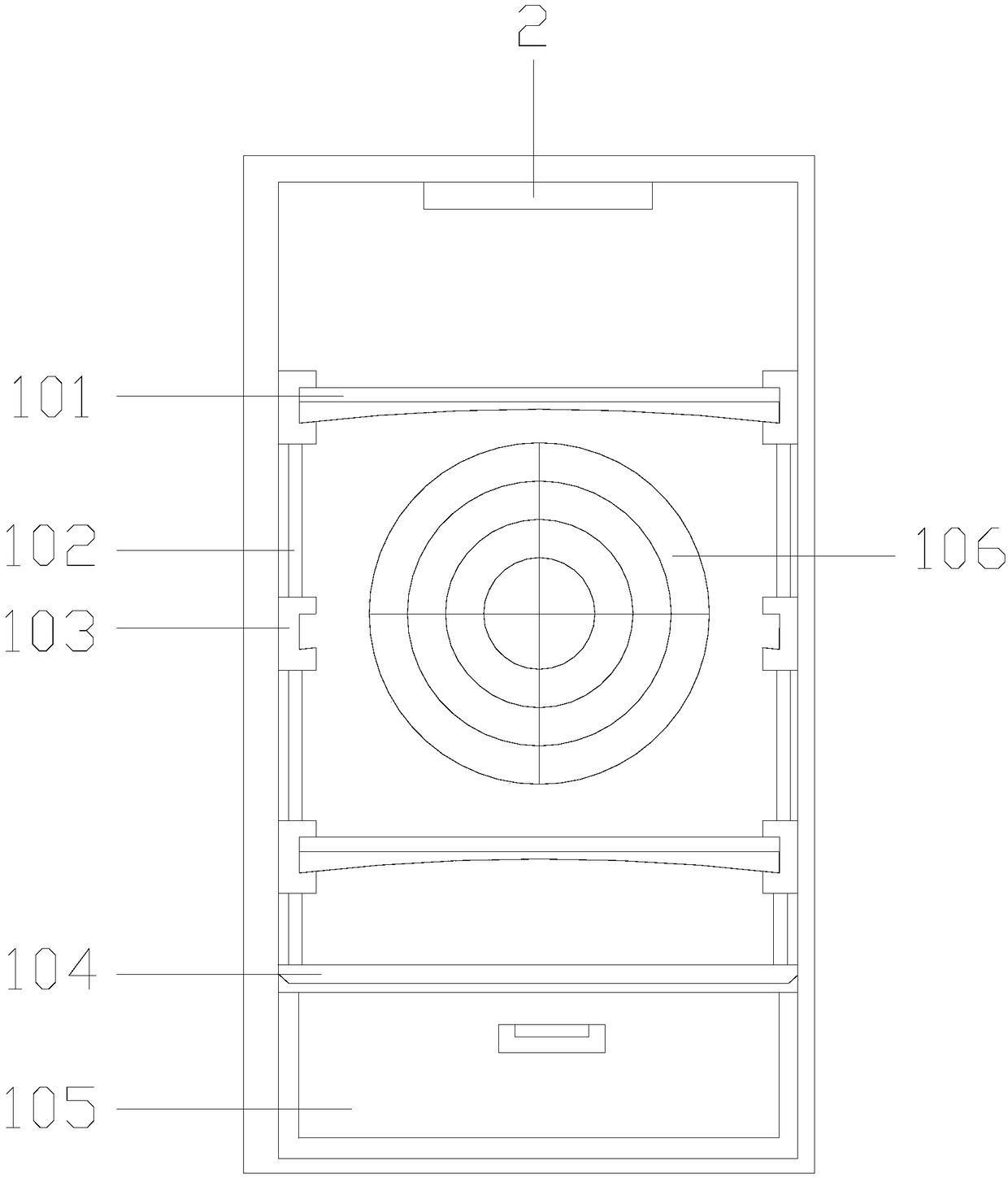

Refrigerator capable of dispersing energy to homogenize cold of refrigerating chamber and separating and unfreezing meat and water

InactiveCN109297232AImprove cold air circulationImprove the preservation effectLighting and heating apparatusDomestic refrigeratorsCold airEngineering

The invention discloses a refrigerator capable of dispersing energy to homogenize cold of a refrigerating chamber and separating and unfreezing meat and water. The refrigerator structurally comprisesa refrigerating chamber, a lamp, a refrigerating chamber door, a freezing chamber door, a freezing chamber drawer and a freezing chamber, wherein the refrigerating chamber comprises a flow guide waterdraining plate, a water draining pipe, a supporting frame, a water collecting tank, a storing drawer and an unfreezing inclining device. The refrigerator has the beneficial effects that cold air produced at the inner rear side of the refrigerating chamber of the refrigerator can be up and down dispersed under the effects of the unfreezing inclining device and an air guide separating plate, and thus the rear side is prevented from being frozen, and the cold air is prevented from directly blowing to vegetable and fruit, and as a result, the vegetable and fruit refreshing effect can be improved;in addition, cold circulation in the refrigerating chamber can be improved, and the problem of non-uniform cooling inside can be avoided; meat and water produced by unfreezing can be effectively separated under the effect of the flow guide water draining plate, so that bacteria can be avoided; and meanwhile, the water produced by unfreezing can be guided to flow and downwards drained, so that water accumulation is avoided; the produced water is collected at the lower part, and thus the cleaning is conveniently carried out.

Owner:黄钦云

Cooling device for metallurgy

InactiveCN107560443ACool evenlyAvoid uneven coolingHandling discharged materialArchitectural engineering

The invention relates to the technical field of metallurgy, in particular to a cooling device for metallurgy. The cooling device comprises a bottom plate. A machine body is arranged above the bottom plate through supporting rods. The machine body is internally provided with a support. A plurality of rolling shafts are equidistantly arranged above the support. One end of each rolling shaft is provided with a transmission device. A steel wire net belt is arranged on the rolling shafts. Limiting rolling shafts are symmetrically arranged below the support through connecting rods and are located inthe steel wire net belt. The two sides of the machine body are symmetrically provided with a plurality of openings. A water pipe on first mounting blocks is located in the steel wire net belt. A plurality of water nozzles are equidistantly arranged on the water pipe. The water nozzles located below the steel wire net belt are located between the rolling shafts. A water collection mechanism is located below the water nozzles. The bottom of the machine body is provided with a water pump. A water inlet of the water pump communicates with the water pipe. The cooling device has the uniform coolingeffect. The situation that the quality of blanks is affected and the blanks are scrapped due to non-uniform cooling of the blanks is avoided.

Owner:黄石市火炬科技实业有限责任公司

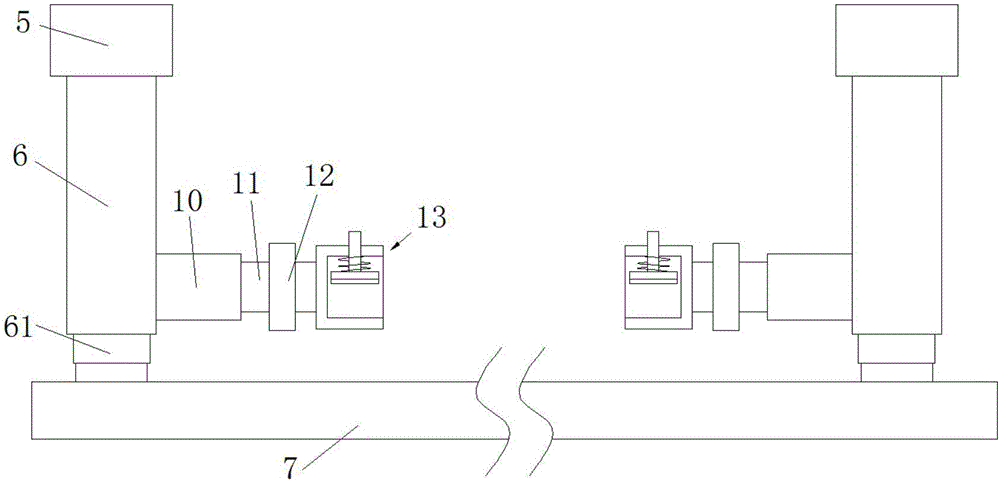

Vehicle part cooling device

ActiveCN106735113AAvoid uneven coolingFurnace typesHeat treatment furnacesMotor vehicle partCooling chamber

The invention relates to the technical field of vehicle manufacturing, in particular to a vehicle part cooling device. The vehicle part cooling device comprises a shell, two conveying chains inserted in the shell in parallel, and a carrier positioned below the conveying chains outside the shell; a separation plate is arranged in the shell for dividing the internal of the shell into an air cooling chamber and a water cooling chamber; the separation plate extends into the air cooling chamber; multiple sets of extension rods are arranged at the bottoms of the two conveying chains at equal intervals; two extension rods are in each set; pulleys are arranged at the bottoms of the extension rods, and are contacted with the carrier; sleeves are respectively mounted at the bottoms of the opposite inner sides of each set of extension rods; rotating shafts are mounted at one ends, far from the extension rods, of the sleeves through bearings; gears are sleeved on the rotating shafts; and clamping devices are mounted at the tail ends of the rotating shafts. The vehicle part cooling device is simple in structure and convenient to operate, and combines air cooling with water cooling to cool parts.

Owner:SHAOXING HUARUI AUTO PARTS CO LTD

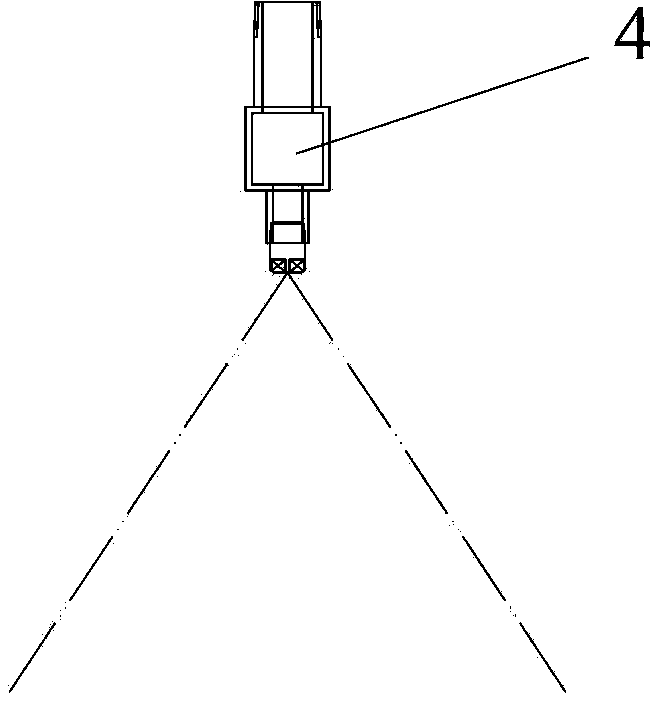

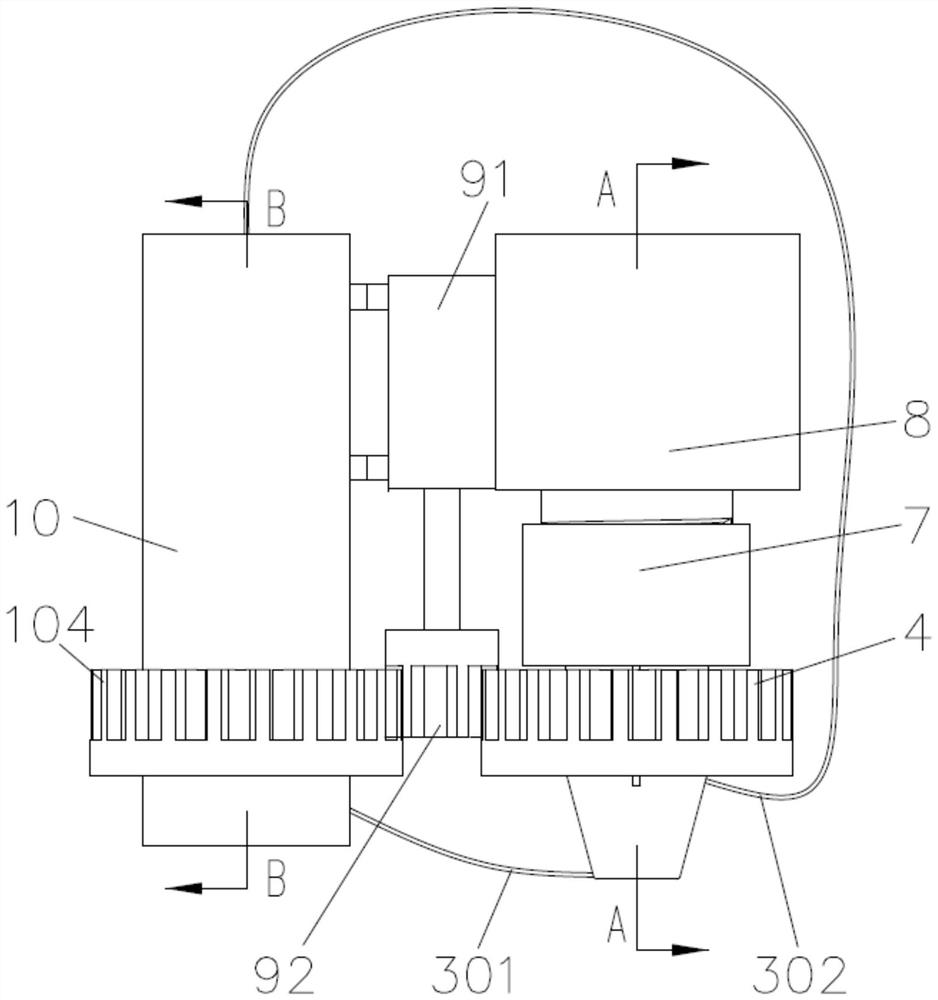

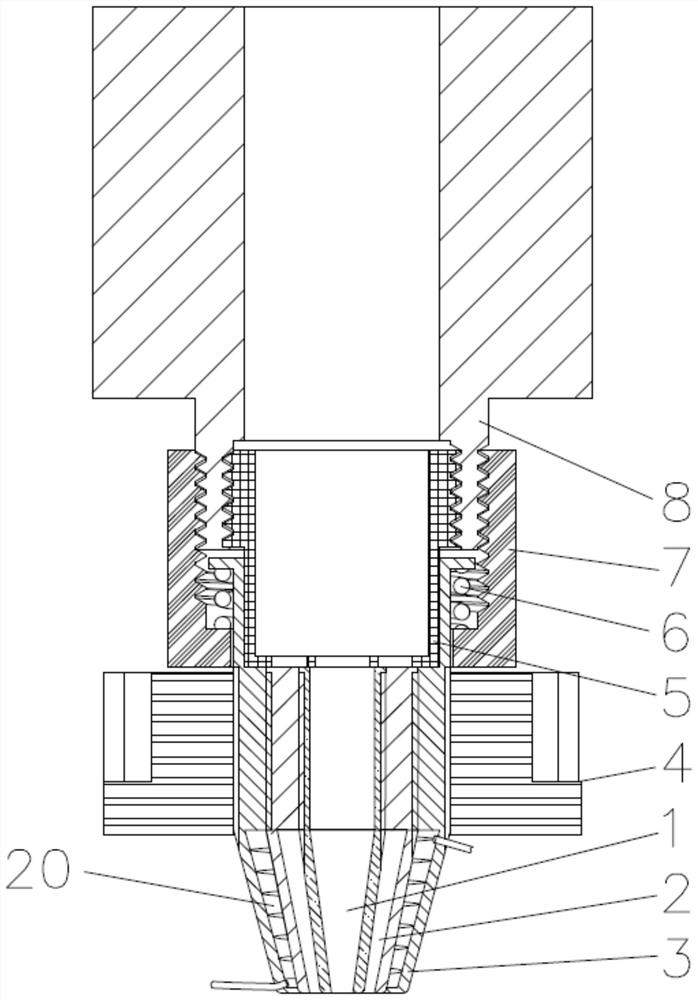

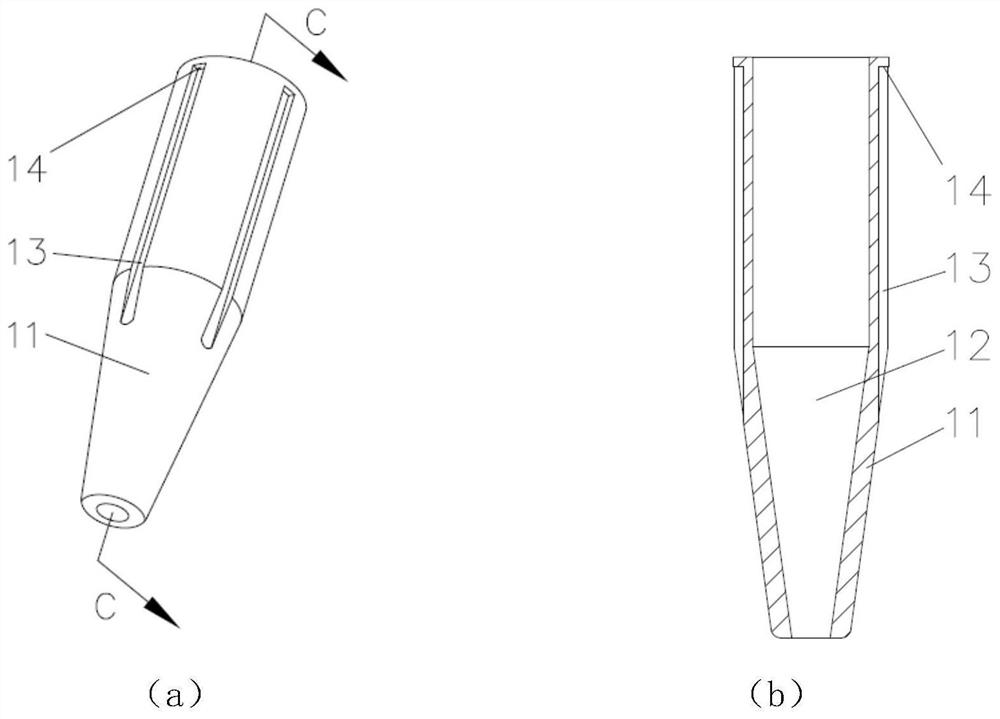

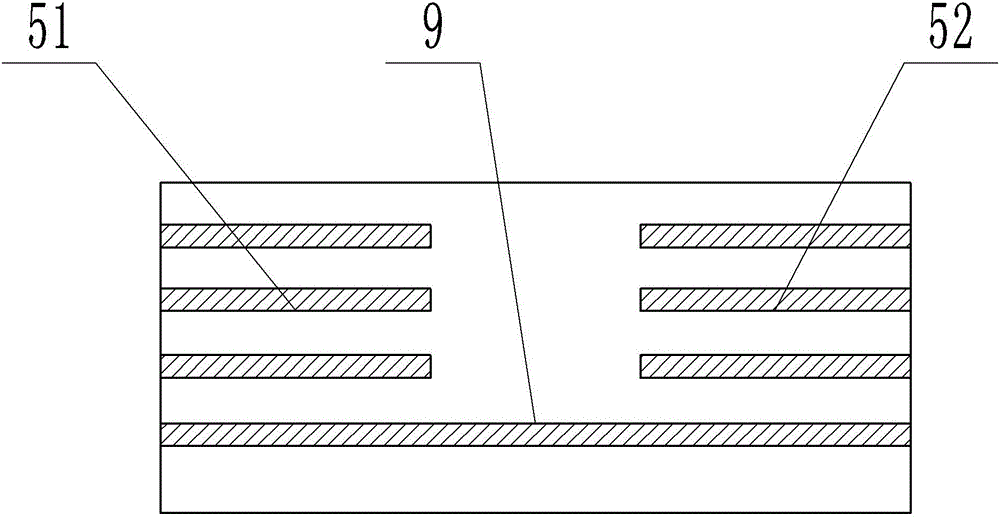

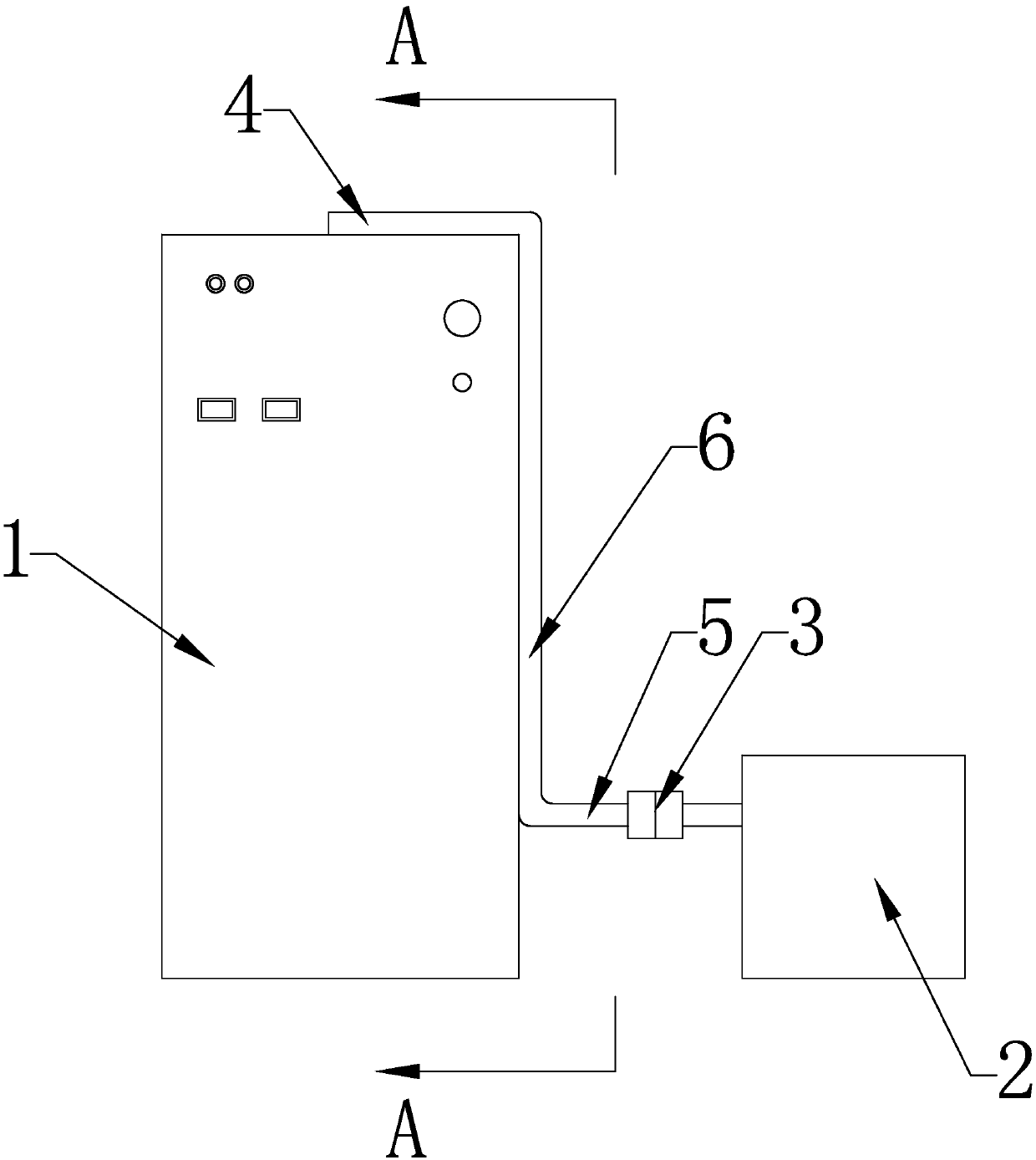

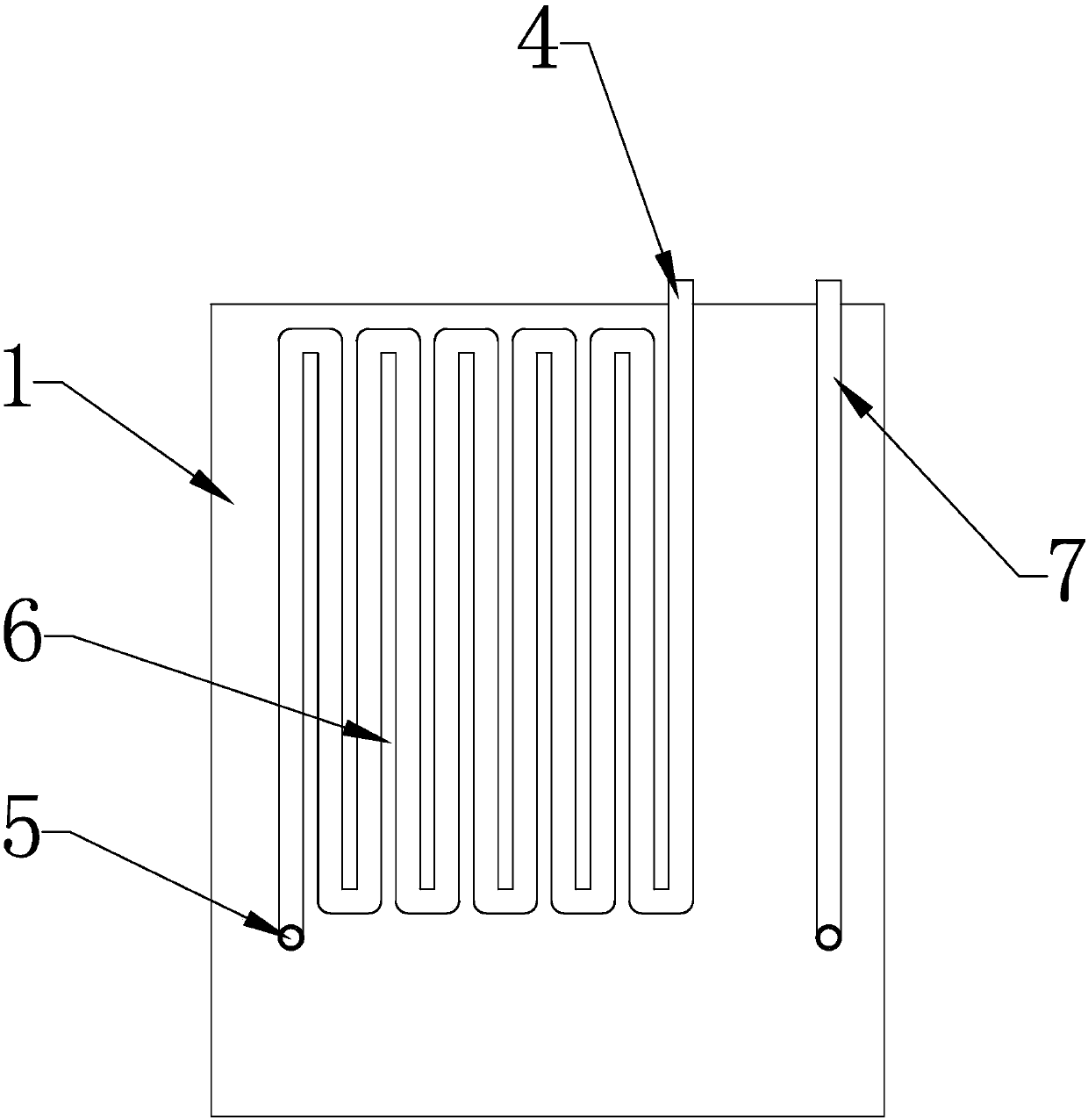

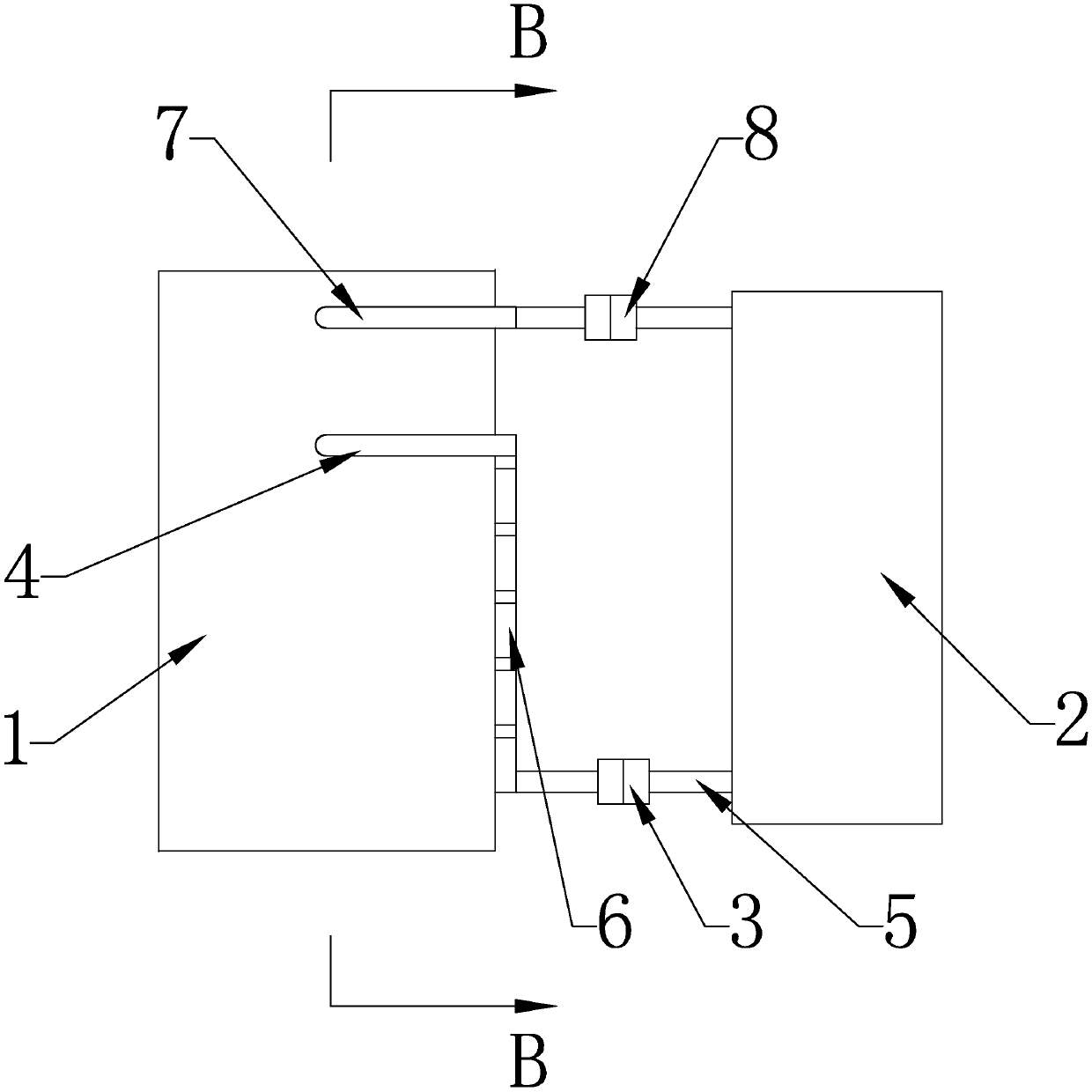

Adjustable 3D printing nozzle

InactiveCN112373031APrevent messing upIncrease or decrease in areaApplying layer meansEngineeringPhysics

The invention provides an adjustable 3D printing nozzle. The adjustable 3D printing nozzle comprises a nozzle assembly, wherein he nozzle assembly comprises a first nozzle body (1), a second nozzle body (2), a third nozzle body (3), a driven gear (4), a blocking piece (5), a spring (6), a fixing piece (7), a feeding piece (8) and a driving assembly (9); the blocking piece (5) is an integrally-formed piece and comprises a blocking piece body (51), a stop block channel (52), a blocking plate (53) and a first fastening thread (54); and the feeding piece (8) comprises a feeding piece body (81), afeeding through hole (82) and an installation face (83). According to the adjustable 3D printing nozzle, the spraying area of the whole nozzle can be adjusted according to needs by adjusting the number of channels for materials to be input into the nozzle and the area of each channel, and therefore different requirements for the material extrusion rate during printing of different structures can be met, the same printing nozzle can be suitable for printing of different structures and transverse streets, the application range is wide, and the printing efficiency is high.

Owner:重庆圣盈达科技开发有限公司

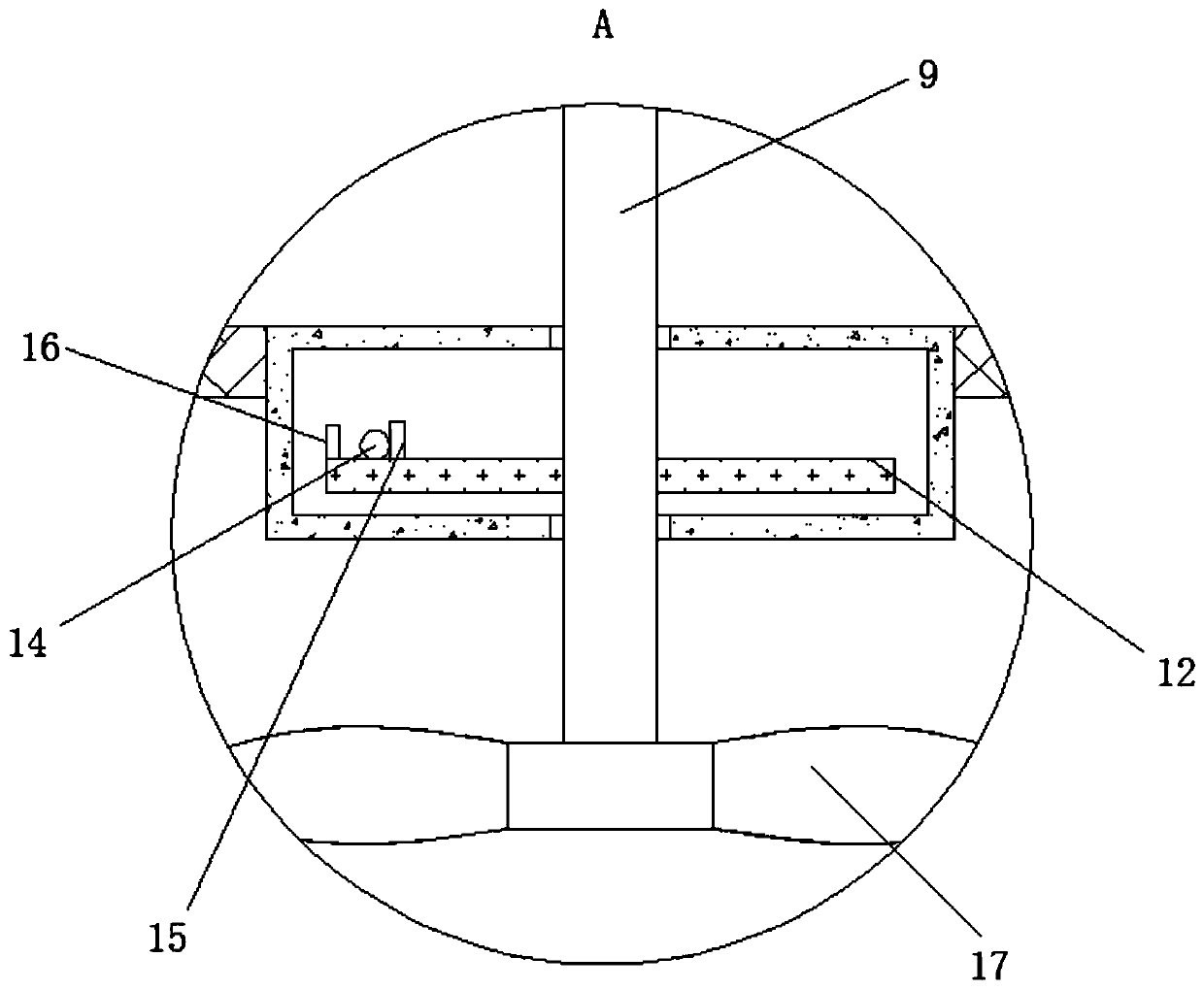

Hybrid power heat dissipation device for outdoor power distribution cabinet based on centrifugal force principle

ActiveCN111293613AImprove cooling effectAvoid uneven coolingSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsEngineeringCentrifugal force

The invention relates to the technical field of power, and discloses a hybrid power heat dissipation device for an outdoor power distribution cabinet based on the centrifugal force principle. The hybrid power heat dissipation device comprises a cabinet body. A separation net is fixedly connected to the interior of the cabinet body; a flashing board is fixedly connected to the exterior of the cabinet body; the interior of the flashing board is movably connected with a sleeve rod; a wind direction plate is fixedly connected to the outer part of the sleeve rod; the bottom of the sleeve rod is fixedly connected with an air inlet cover; an air inlet is formed in the side part of the air inlet cover; a filter screen is fixedly connected to the interior of the air inlet; a vertical rod is rotatably connected to the interior of the sleeve rod; the top of the vertical rod is fixedly connected with a cross rod; the outer portion of the cross rod is fixedly connected with a wind receiving plate;through cooperative use of the wind direction plate, the wind inlet cover and the wind inlet, the wind inlet faces the wind inlet direction all the time, so that it is effectively guaranteed that natural wind fully enters the cabinet body, and the heat dissipation effect is improved.

Owner:南京博普电气成套有限公司

Container temperature adjusting system and container

PendingCN109353707AEven airflowAvoid uneven coolingLarge containersTank wagonsFlueThermoregulatory system

The invention provides a container temperature adjusting system and a container. According to the container temperature adjusting system, an air guide plate and an air outlet fan are included, the airguide plate is arranged on the upper portion of the container, an upper air flue is formed between the air guide plate and the top wall of a container, the air outlet fan is arranged corresponding to the upper air flue, and the container temperature adjusting system enables the cold amount in the container to be uniform.

Owner:GREE ELECTRIC APPLIANCES INC

Glass forming device

ActiveCN106517741AAvoid uneven coolingGuaranteed flatnessGlass pressing apparatusInsulation layerMechanical engineering

The invention discloses a glass forming device. The glass forming device comprises an upper compression part and a bearing frame, the upper compression part comprises an inverted U-shaped shelf, a motor and an upper compression head, the motor comprises a motor shell and an output shaft, the upper compression head comprises a pressing disk and a pressing surface, the motor shell is fixedly connected with one end of the inverted U-shaped shelf, the output shaft is fixedly connected with the pressing disk, a first heating device is arranged inside the pressing disk, a heat-insulation layer is arranged on the pressing surface, multiple grooves are formed in the side face of the pressing disk, the multiple grooves are arranged ringwise relative to the center of the pressing surface, the other end of the inverted U-shaped shelf is connected to a first cylinder, a first conveying roller is arranged below the upper compression head, the first conveying roller comprises a left conveying roller and a right conveying roller, the left conveying roller and the right conveying roller do not abut against with each other and form an empty position in the axial direction, a lower compression mould is arranged below the first conveying roller, one end of the lower compression mould is connected to a second cylinder, and the second cylinder is fixedly connected to the bearing frame. According to the technical scheme, not only the probability that the pressing surface and glass are attached to each other is lowered, but also efficiency of forming of the glass is increased.

Owner:CHONGQING XINGBAOXING GLASS PROD CO LTD

CPU radiator of mini host computer

PendingCN111045496AMultiple design spacesEasy maintenanceDigital data processing detailsEngineeringVALVE PORT

The invention discloses a mini-host computer CPU radiator. The mini-host computer CPU radiator comprises a mini-computer host case and a compressor. A water-cooling heat dissipation device is arrangedat the CPU, and a water inlet pipe and a first water outlet pipe are connected to the water-cooling heat dissipation device; the water inlet pipe penetrates through the mini computer host case to beconnected with the compressor, and an expansion valve is arranged on the water inlet pipe; a heat dissipation coil is arranged on the outer side of the mini computer host case, one end of the heat dissipation coil is connected with the first water outlet pipe, and the other end of the heat dissipation coil is connected with the compressor through a second water outlet pipe; a first separable valvegroup and a second separable valve group are respectively arranged on the second water outlet pipe and the water inlet pipe; the separable valve set comprises a first valve and a second valve, a first flange is arranged on the right side of the first valve, a second flange is arranged on the left side of the second valve, and the first valve and the second valve are hermetically connected throughflanges; cooling media are arranged in the compressor and the water pipes. The LED lamp has the advantages of being small in size and good in heat dissipation performance.

Owner:王旭宁

Cooling pipe

PendingCN109261730AAvoid uneven coolingLow flow rateWork cooling devicesMetal rolling arrangementsSpray nozzleWater pressure

Owner:安徽中钢诺泰工程技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com