Combustion assembly structure of turbojet engine

A technology of turbojet engine and component structure, applied in machine/engine, liquid fuel engine, combustion chamber, etc., can solve the problems of stress relief and recovery performance, complex connection structure, affecting the performance and quality of engine combustion chamber products, etc. The effect of improving printing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

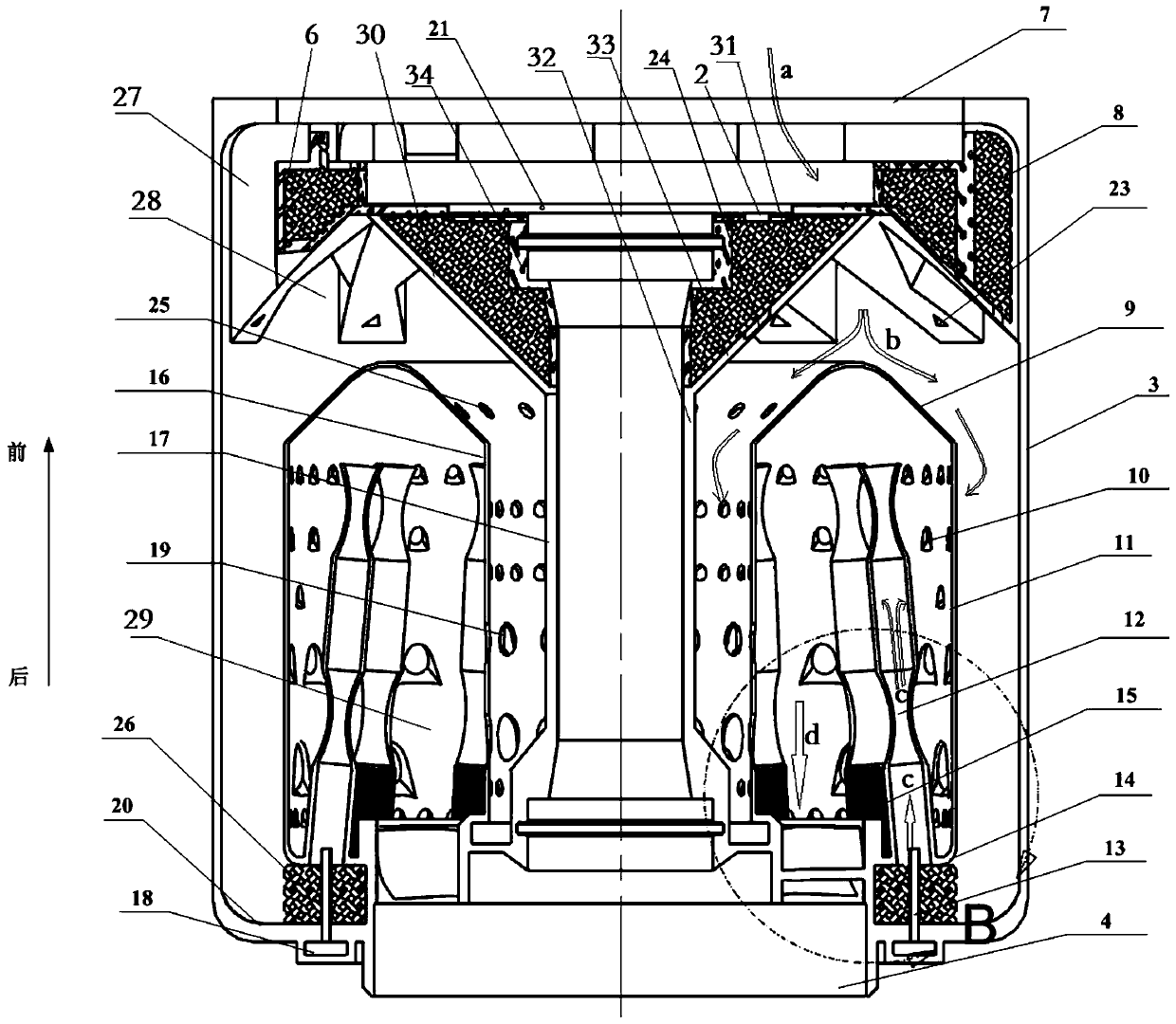

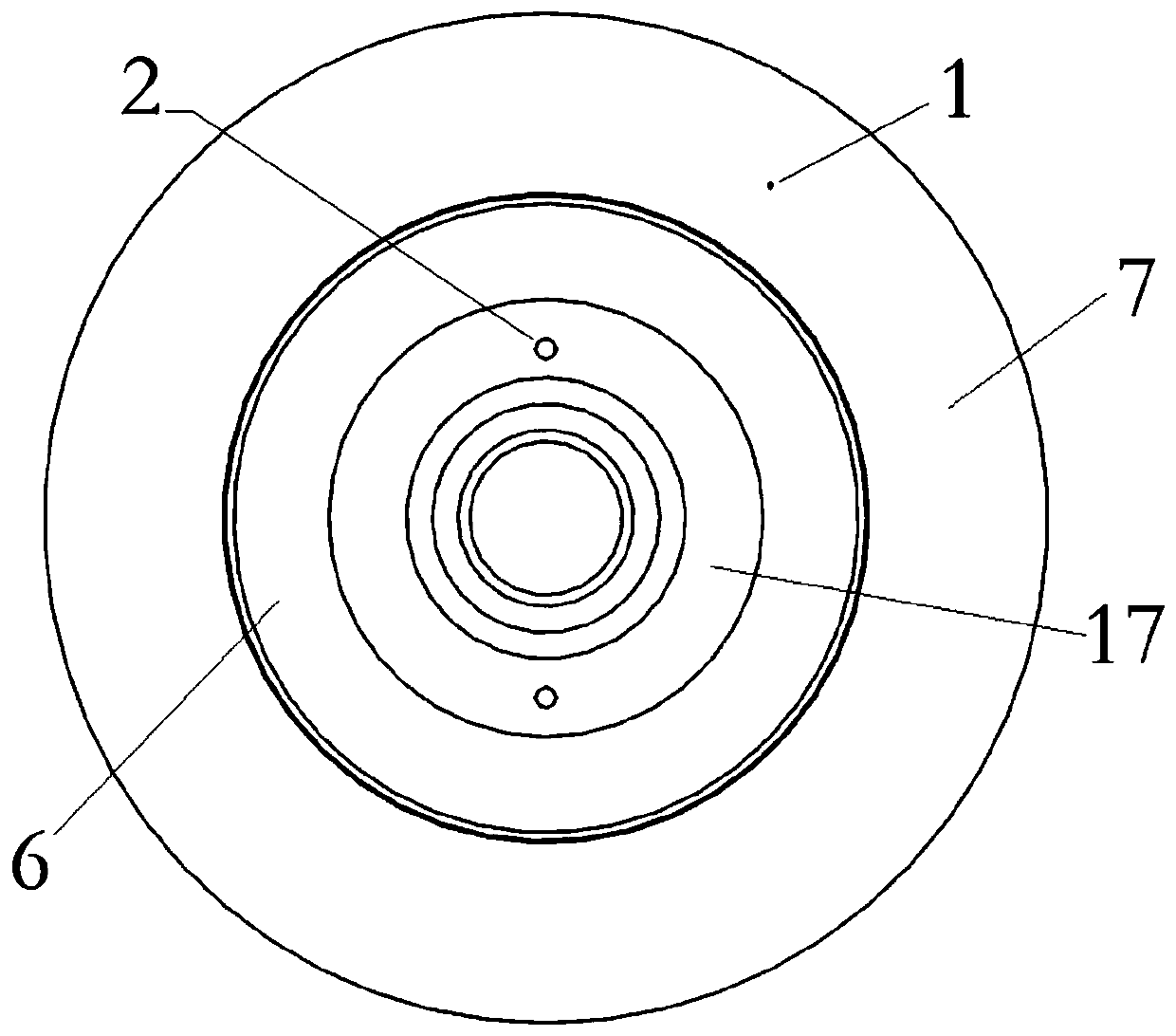

[0035] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0036] see Figure 1 to Figure 3 As shown, a turbojet engine combustion assembly structure of the present invention includes a casing 3 with a cavity structure in the middle, and a guide 4 is arranged at one end of the casing 3, and a shaft coaxial with the casing 3 is fixed on the guide 4. Sleeve 17, one end of the shaft sleeve 17 is fixed on the guider 4, and the outer ring of the other end of the shaft sleeve 17 is fixed with a diffuser 6; A diffuser air duct 28 is formed between the two guide vanes 27, a front cover 7 is provided at the end of the diffuser 6, and a circular opening is arranged in the middle of the front cover 7; The section of the 17 axis is V-shaped; the outer ring of the shaft sleeve 17 is provided with a double-layer annular combustion chamber 29 coaxially arranged with the shaft sleeve 17, and the bulkhead wall of the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com