Patents

Literature

150results about How to "Shorten the axial distance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

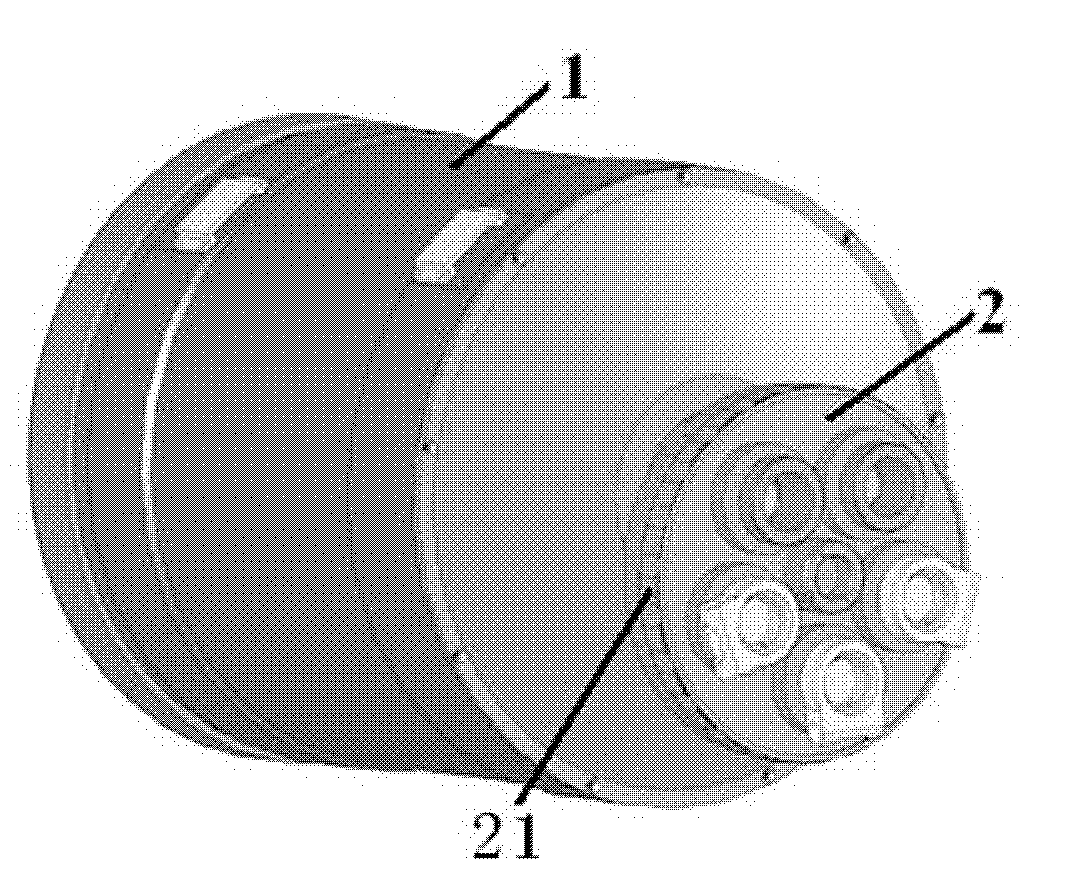

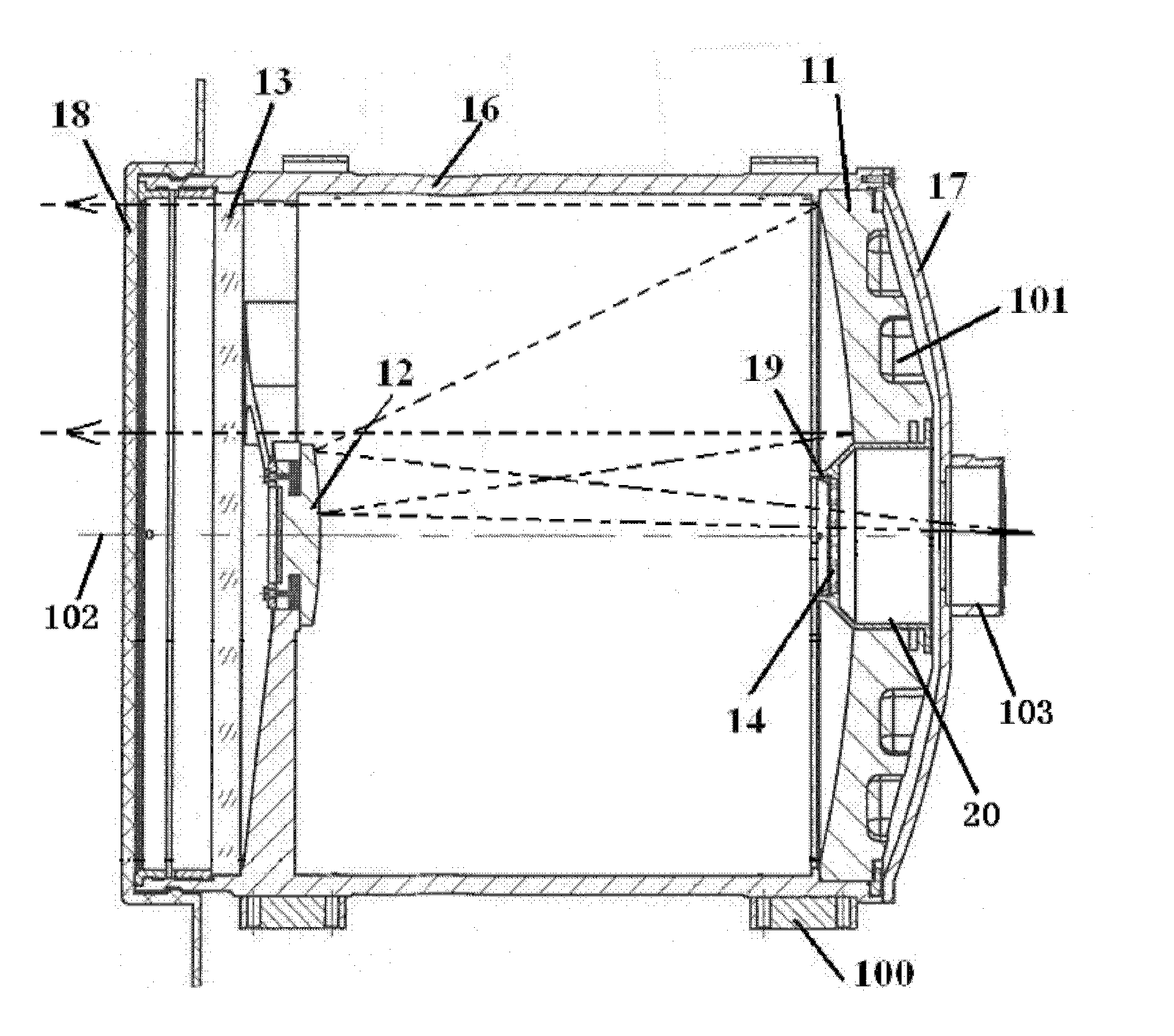

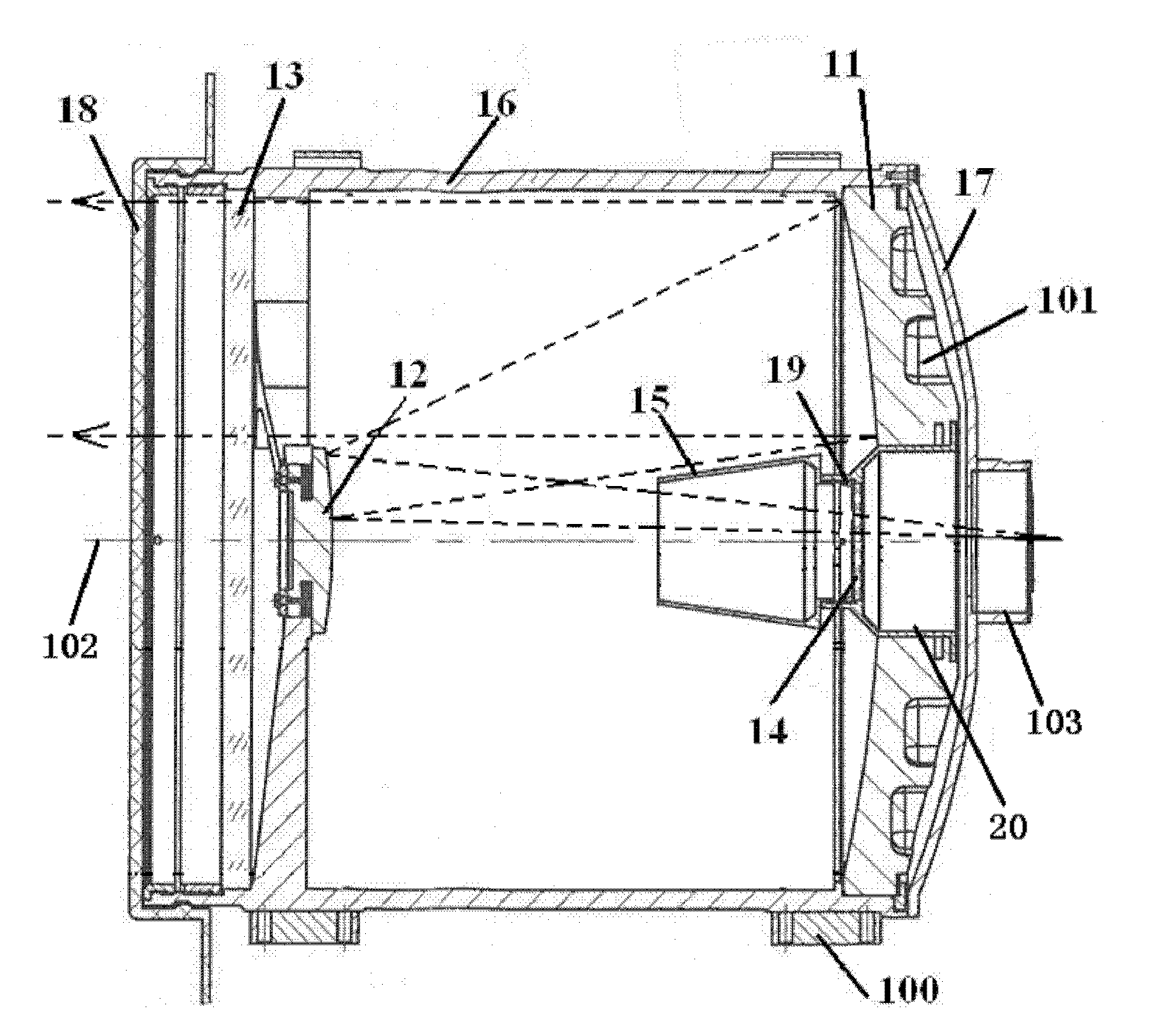

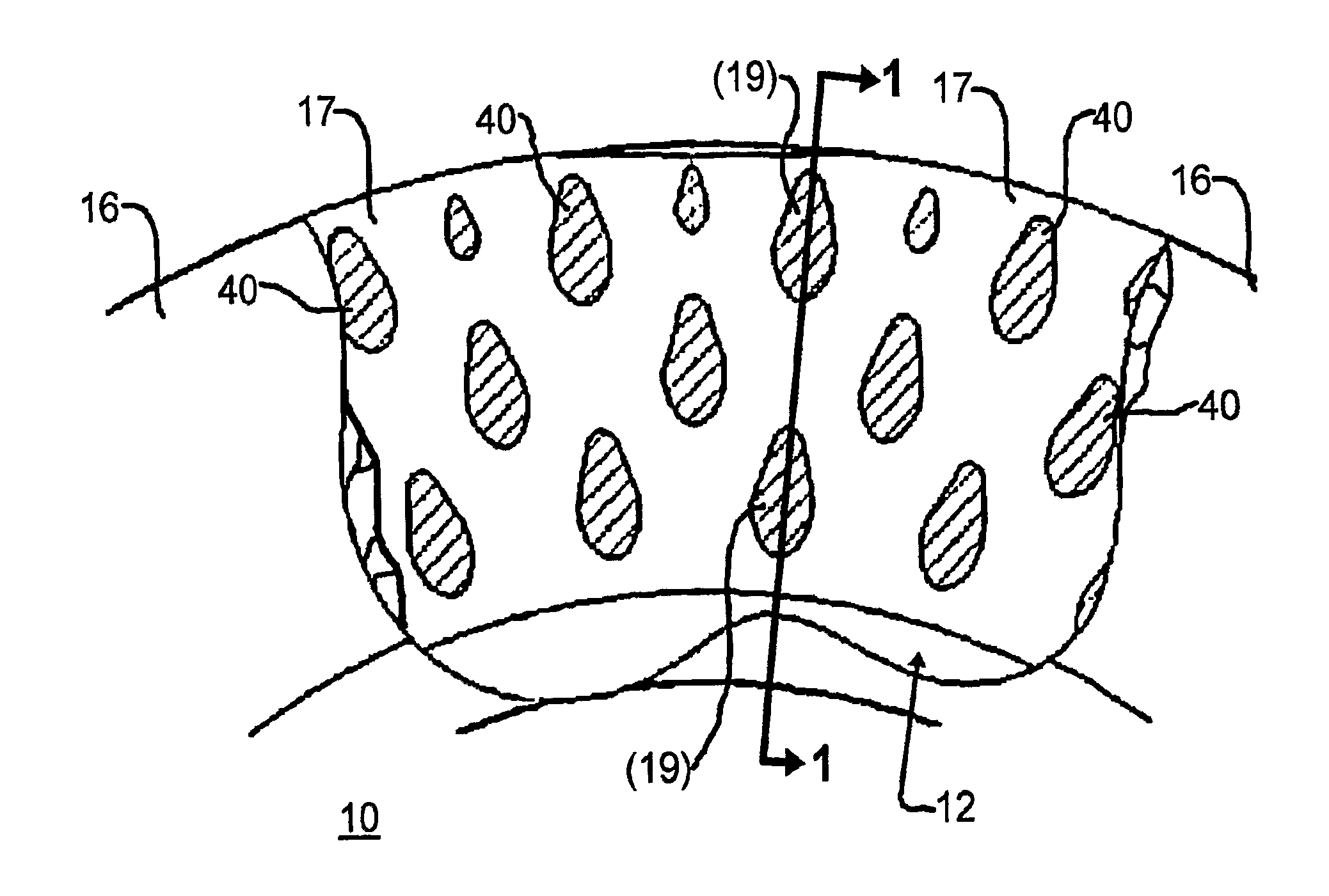

Small Field Intensity Modulated Radiation Therapy Machine

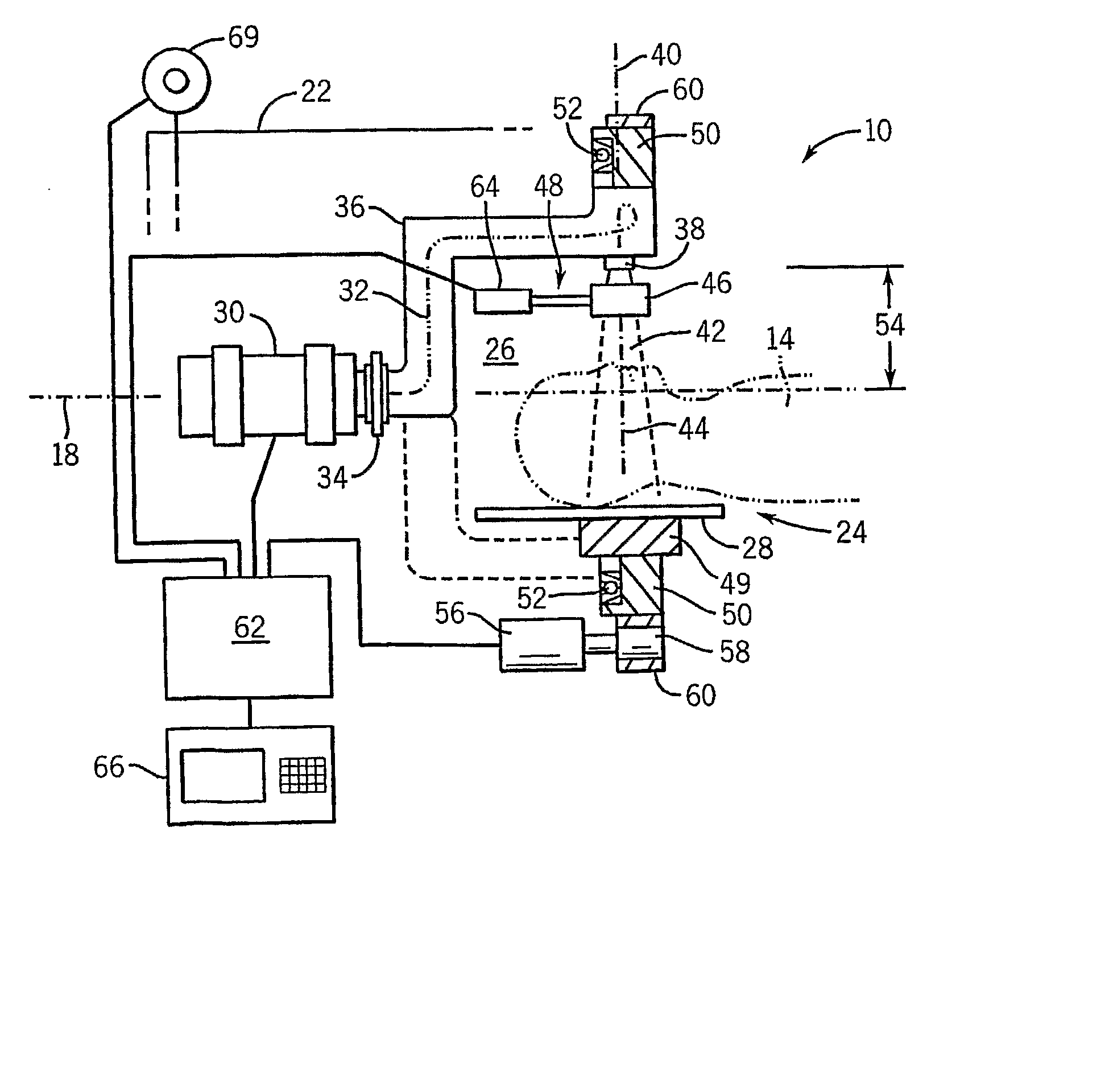

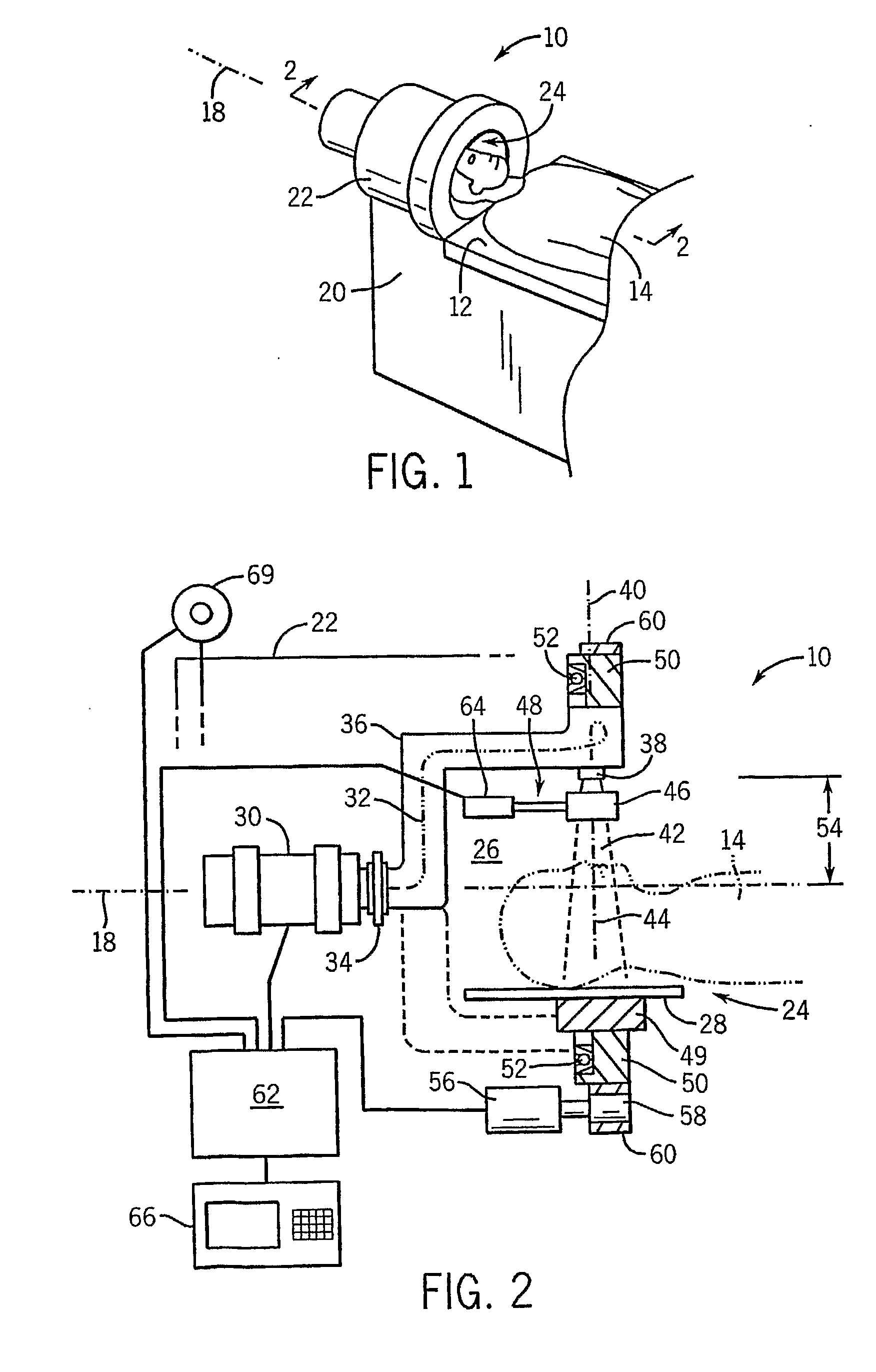

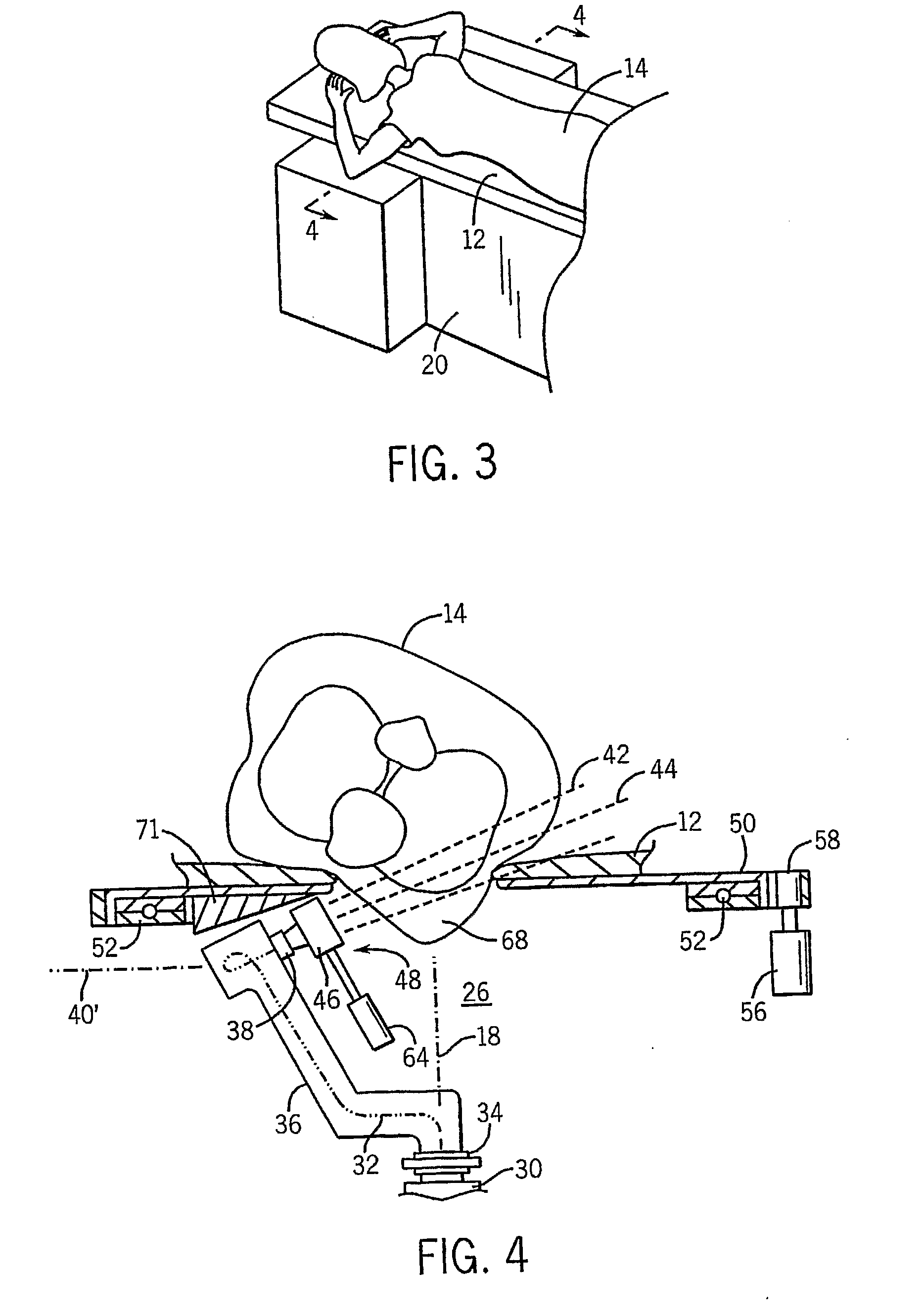

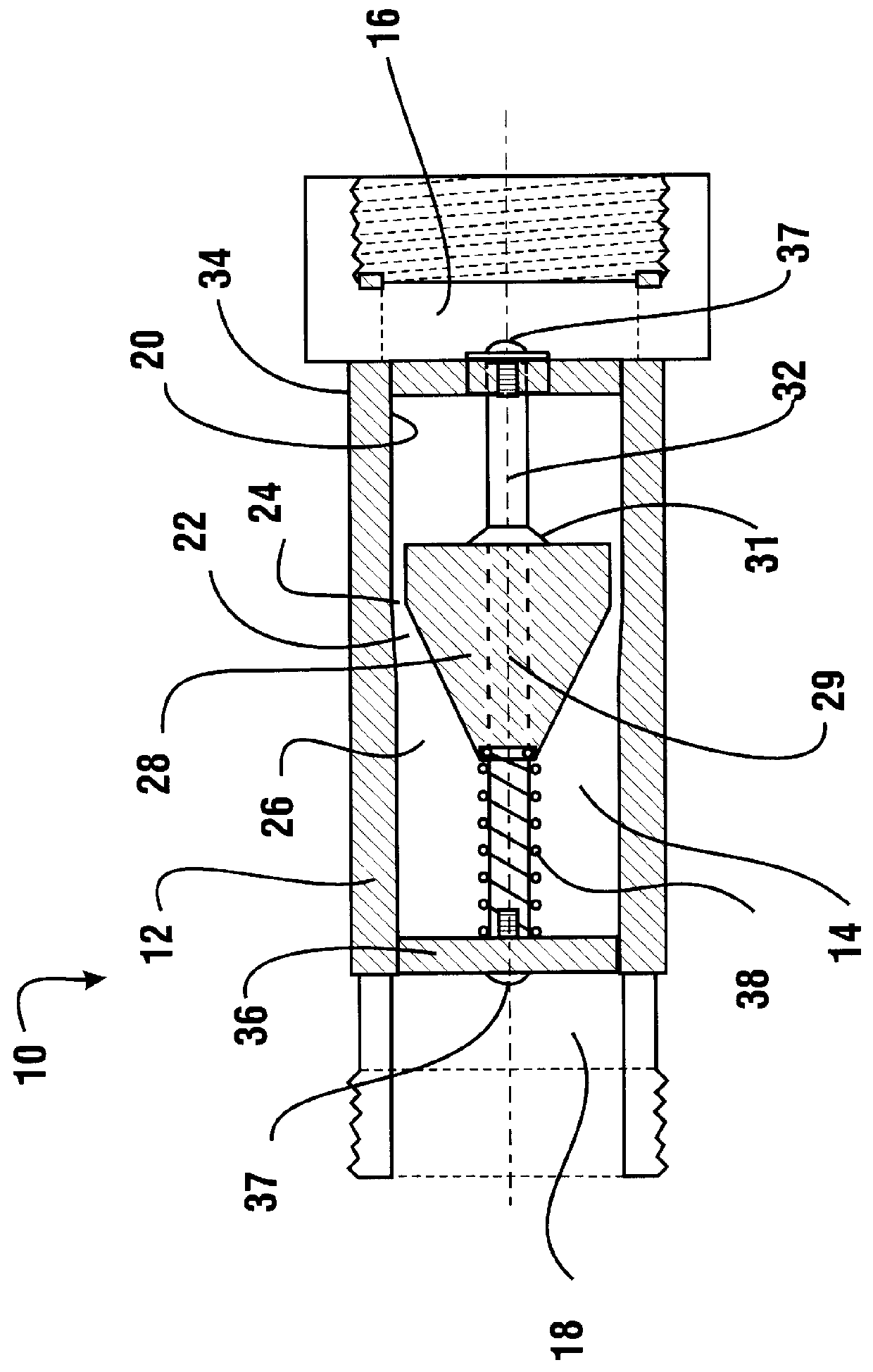

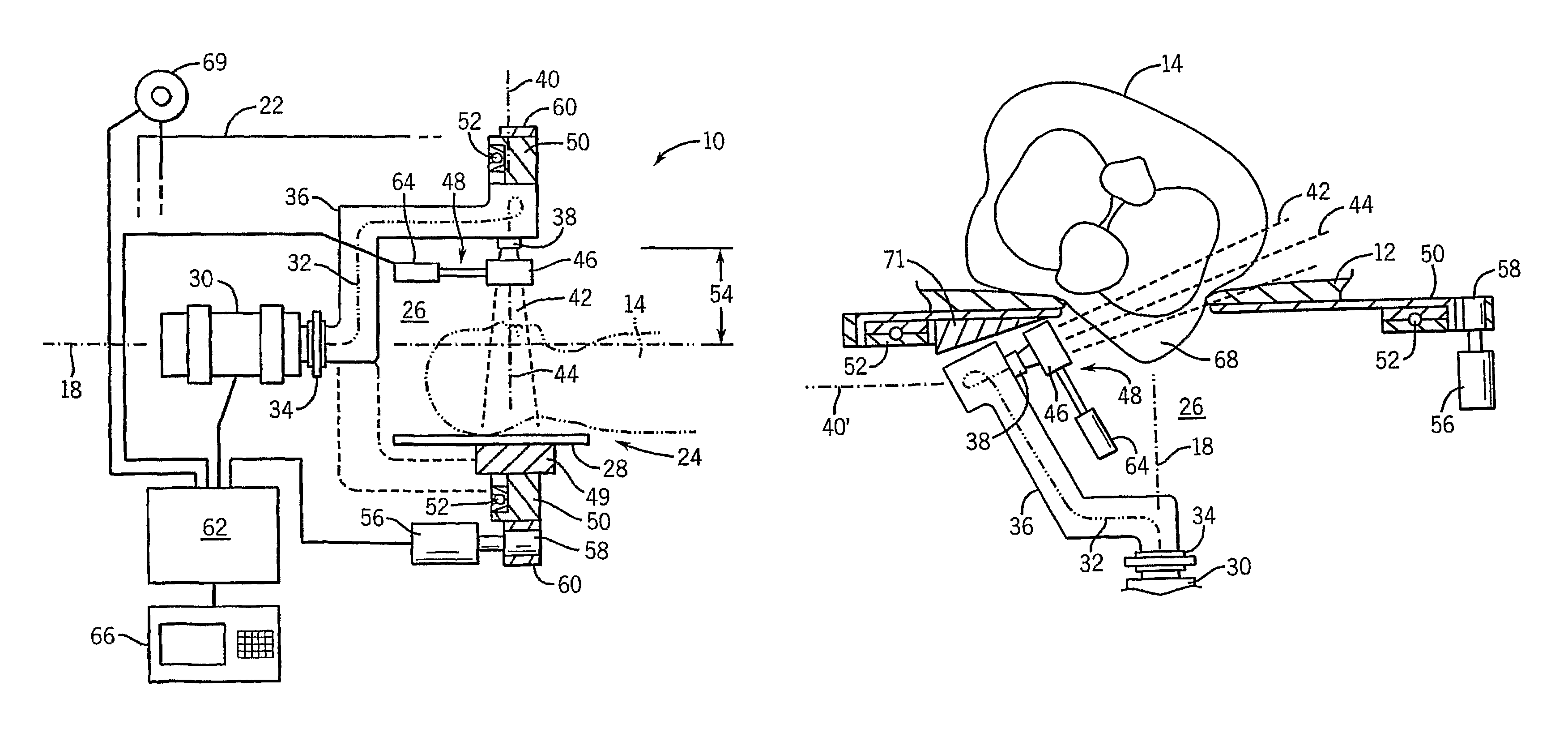

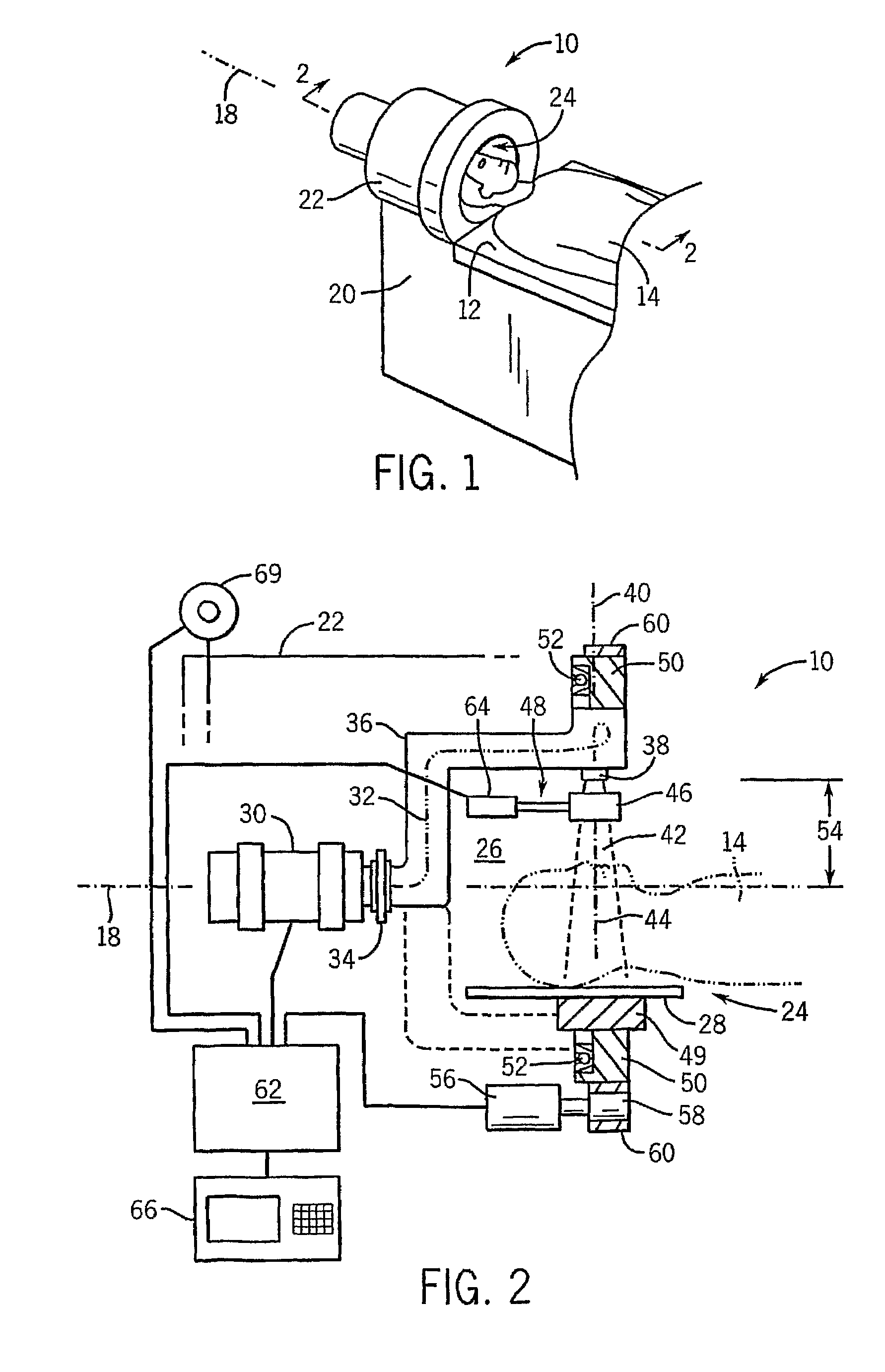

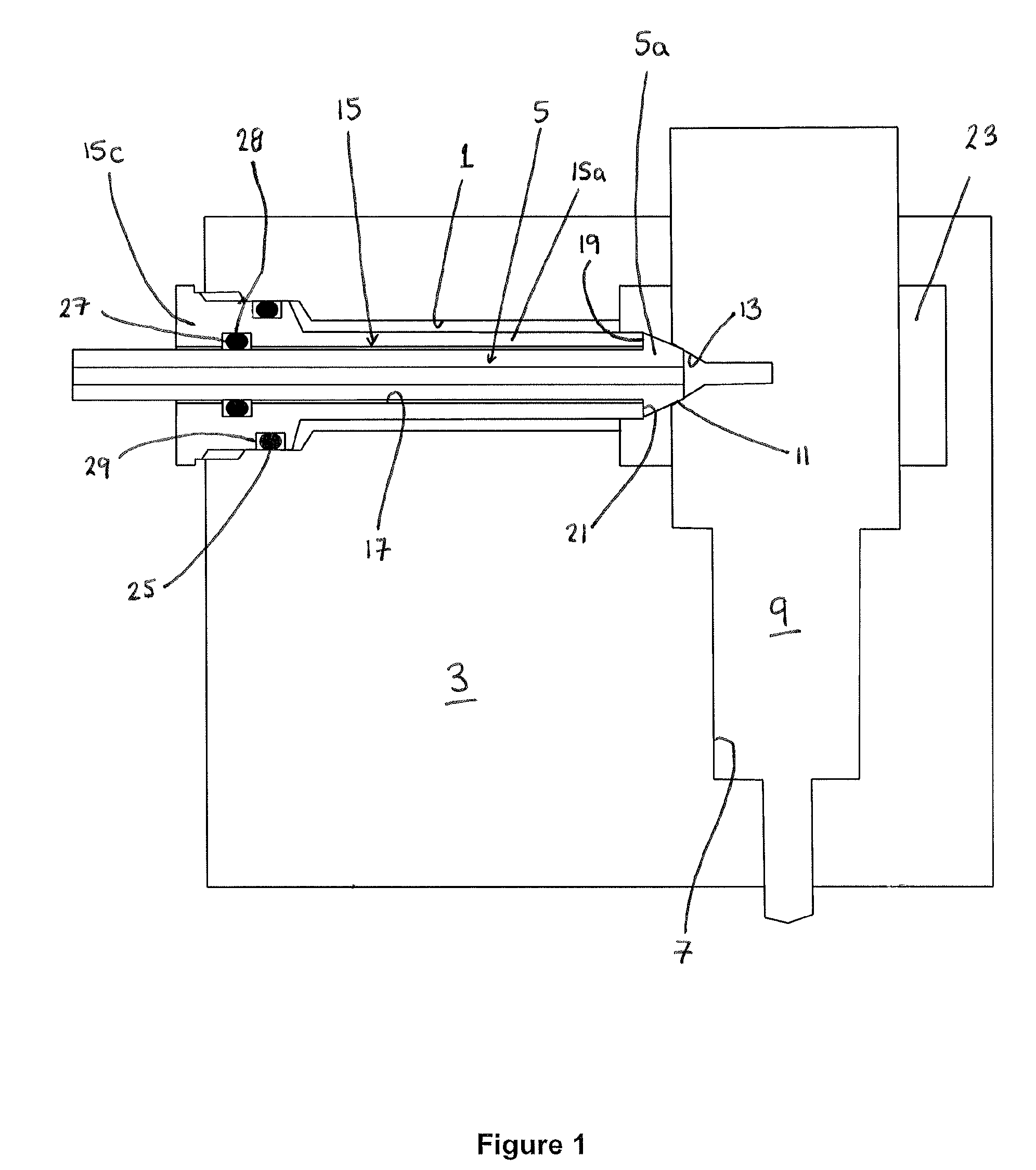

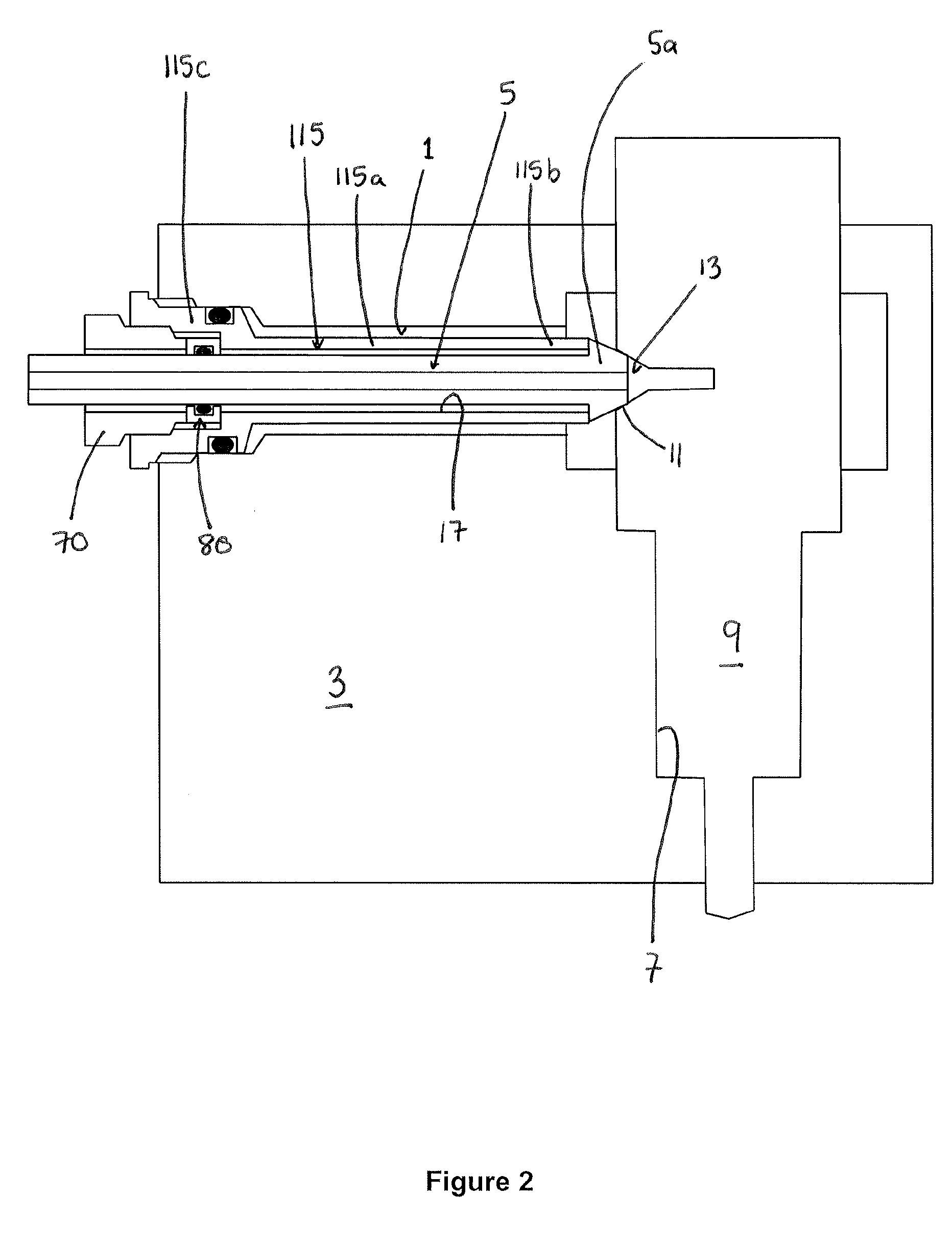

ActiveUS20070242801A1Easy to controlShorten the axial distancePatient positioning for diagnosticsX-ray/gamma-ray/particle-irradiation therapyHuman bodyRadiation therapy

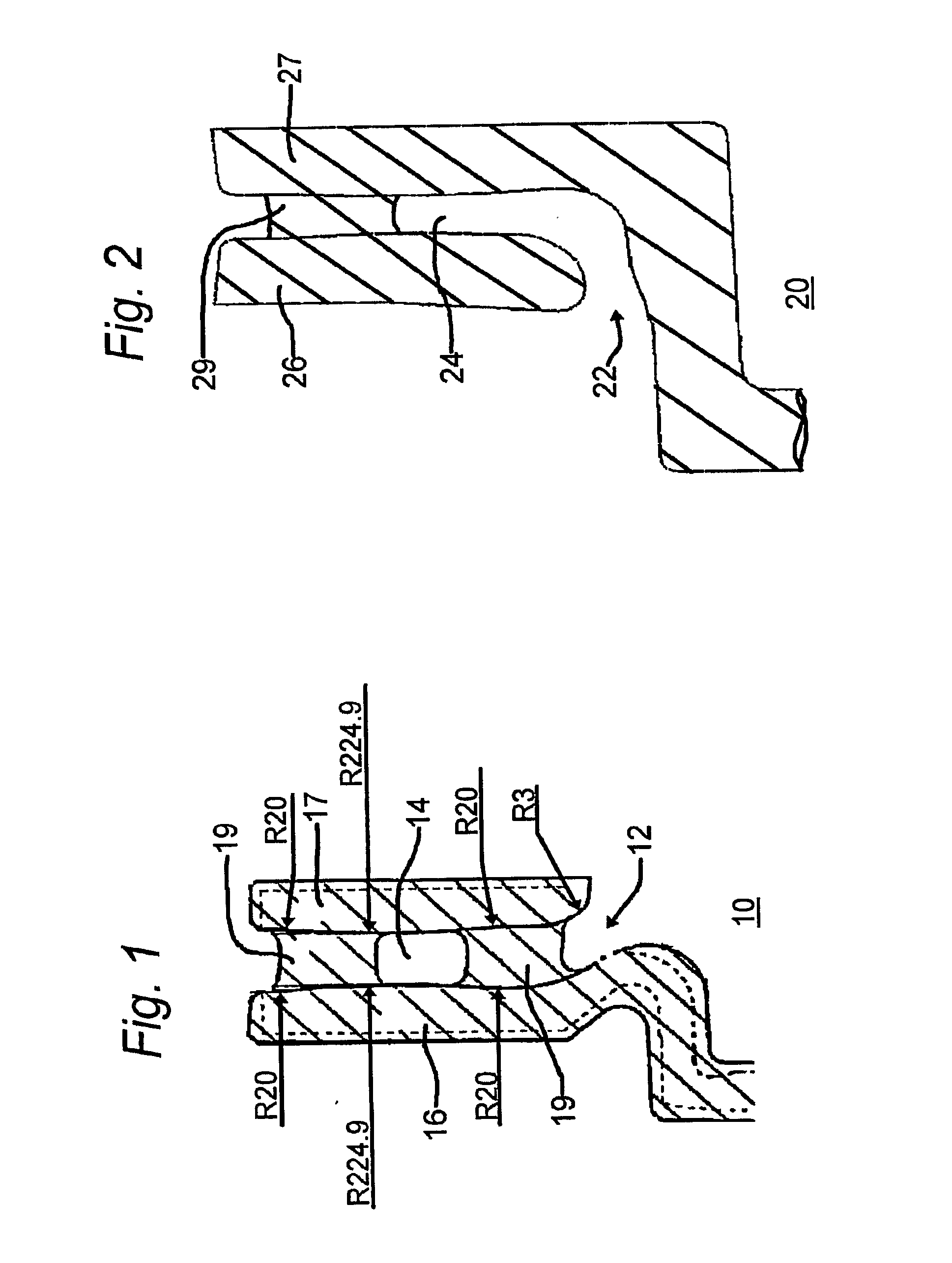

A small field radiation therapy machine having an aperture diameter of 30 cm or less provides improved ray definition for specialized treatment of portions of the human body such as head a breast.

Owner:WISCONSIN ALUMNI RES FOUND

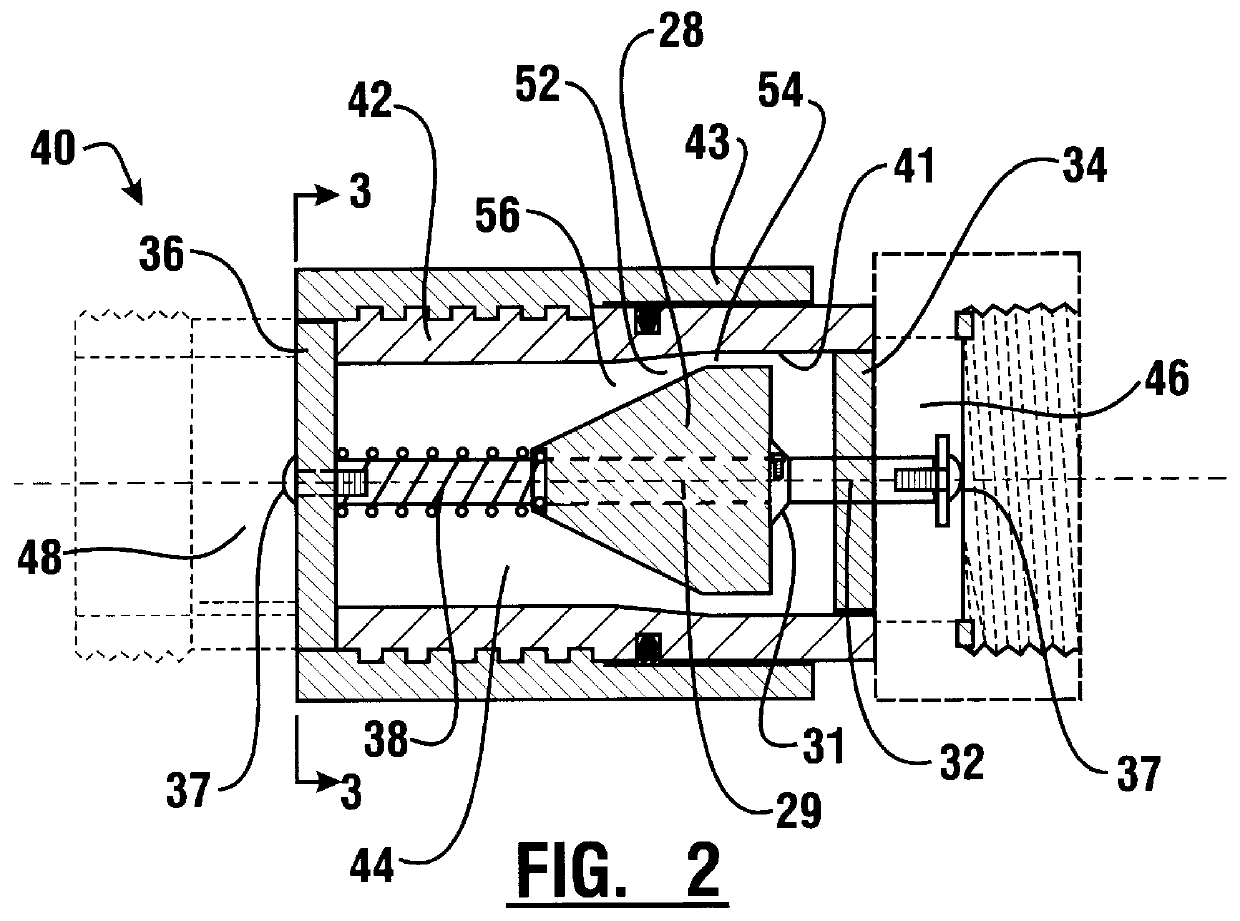

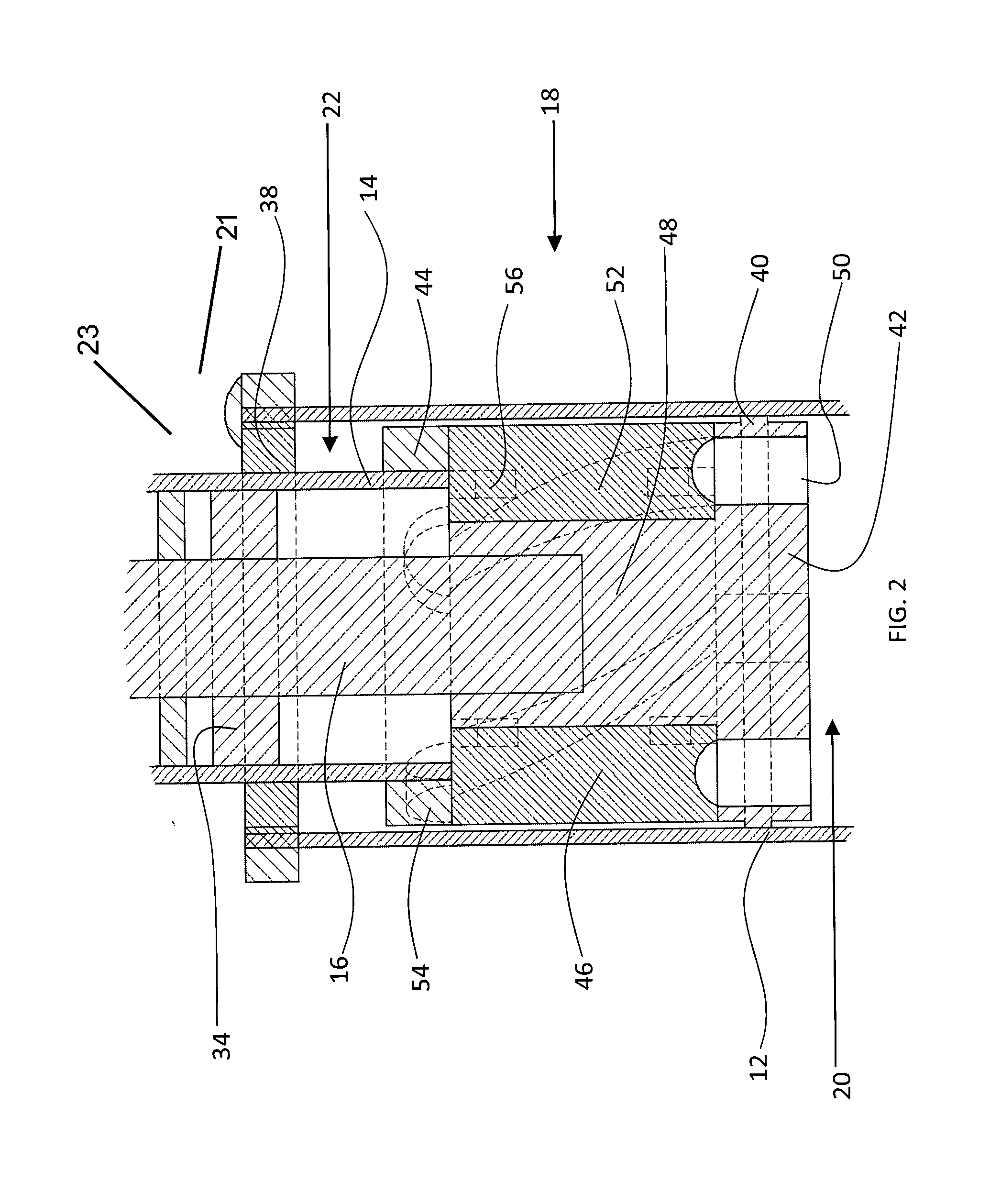

Hose nozzle apparatus and method

InactiveUS6089474AShorten the axial distanceMore aerodynamicOperating means/releasing devices for valvesCheck valvesSpray nozzleEngineering

An apparatus (100) for selectively discharging a stream of liquid has a body (102) adapted for connection to a source of liquid under pressure, a throttle valve assembly (120) for maintaining a constant output flow throughout changes in supply pressure, a smooth bore barrel (140) for providing a deluge stream, a fog tip (160) for providing an aspirated fog spray and a shut off valve (180). The fog spray pattern is variable from a straight stream parallel to the axis of the apparatus to a wide spray at an angle to the axis of the apparatus. The deluge stream and the fog spray are selectable separately or in combination.

Owner:WS ACQUISITION LLC

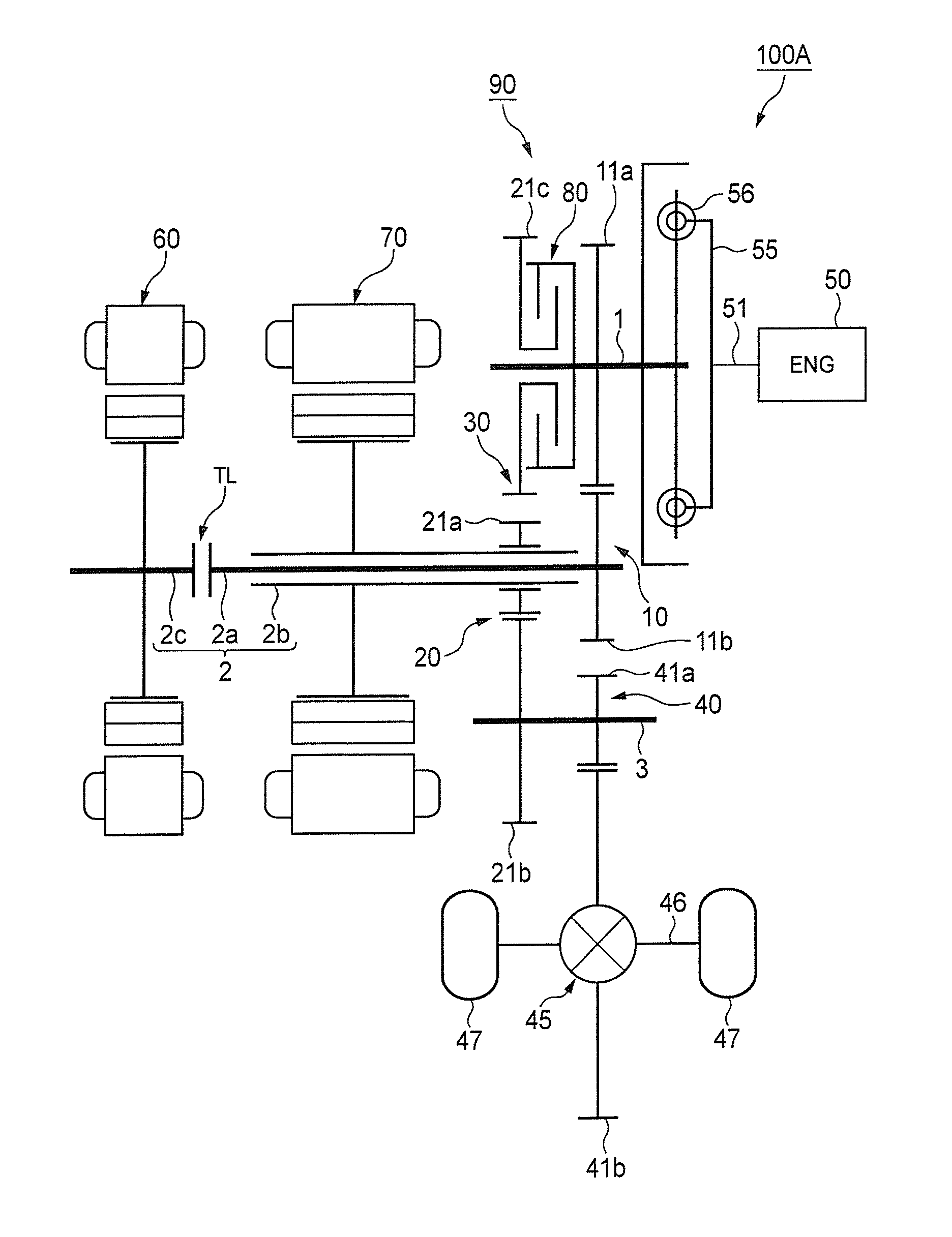

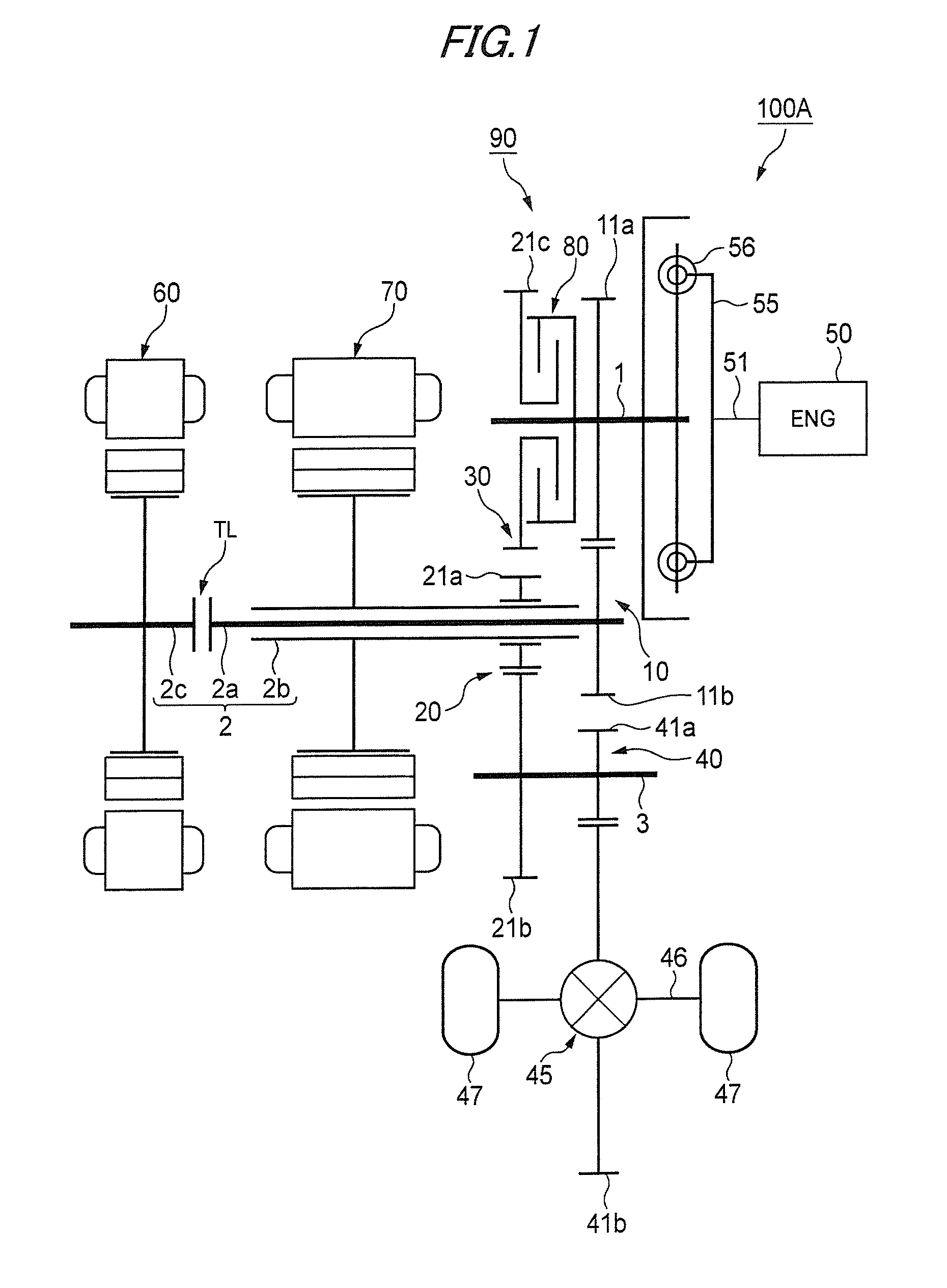

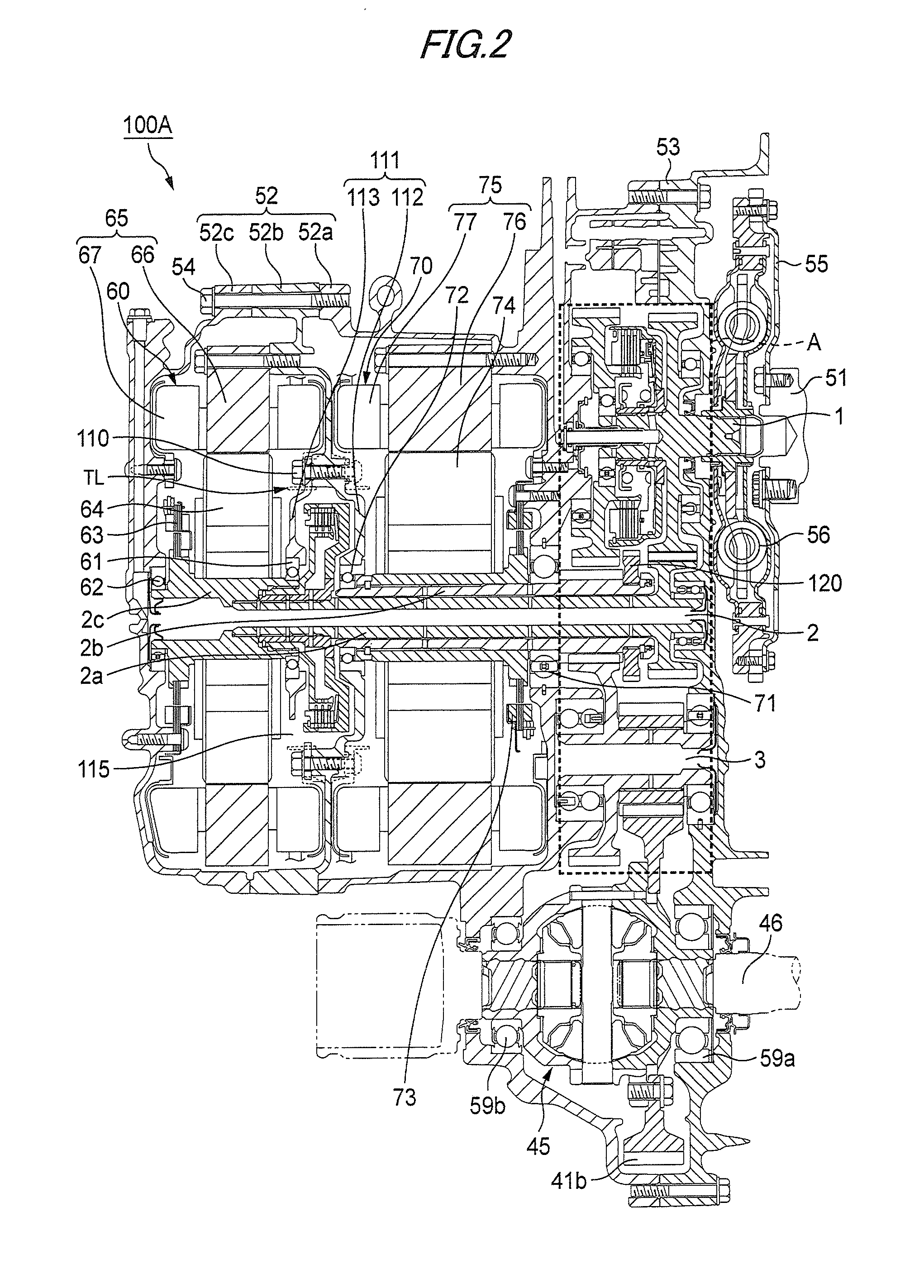

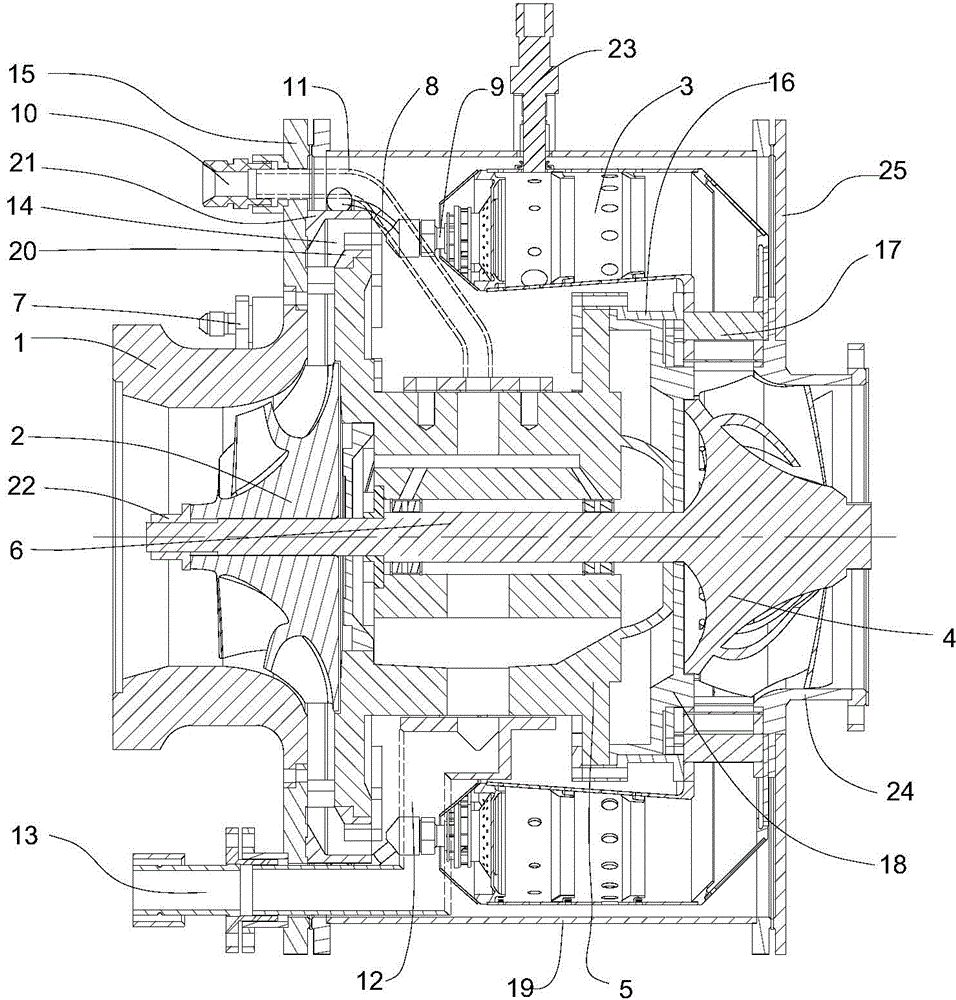

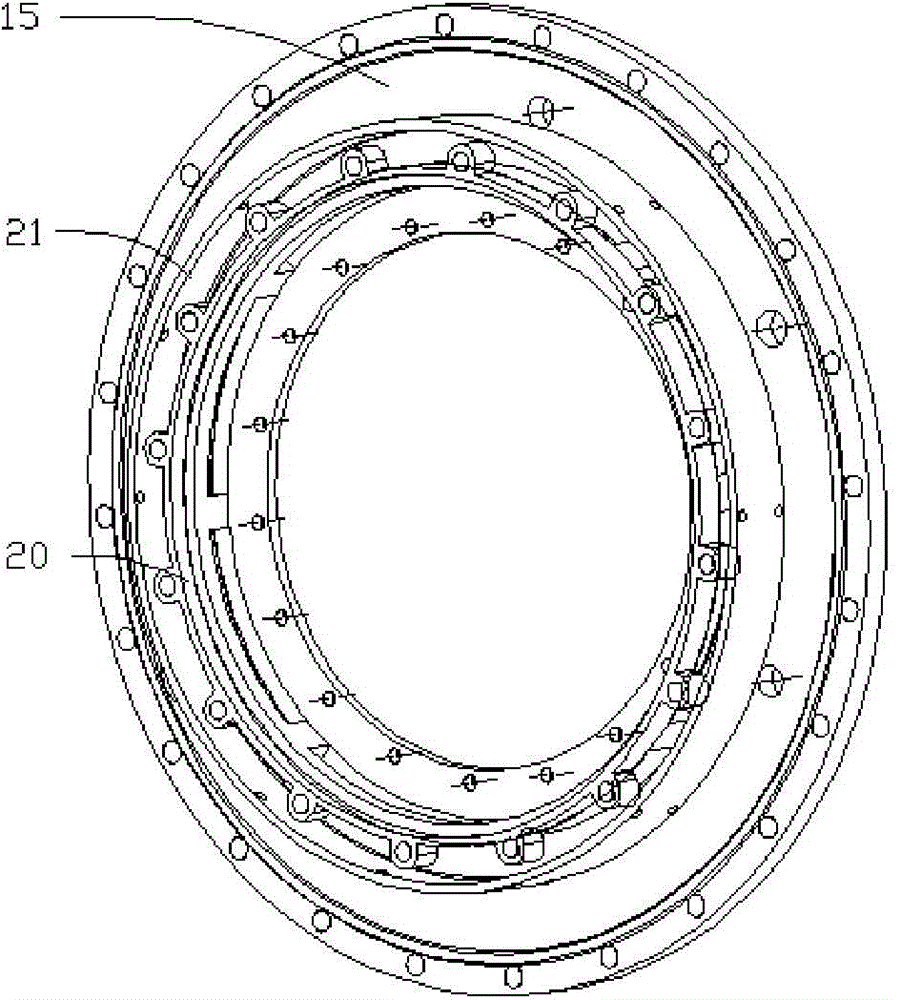

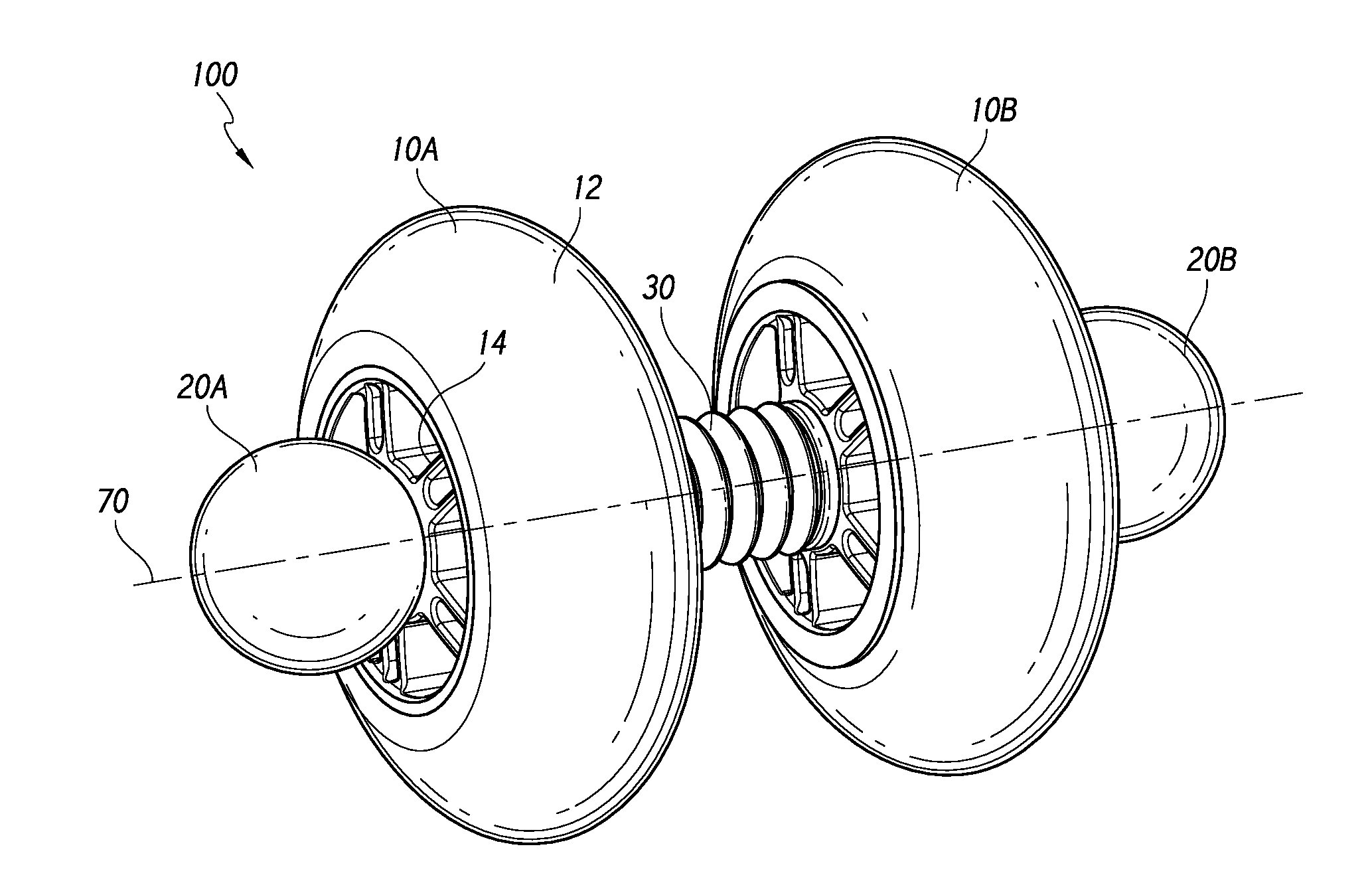

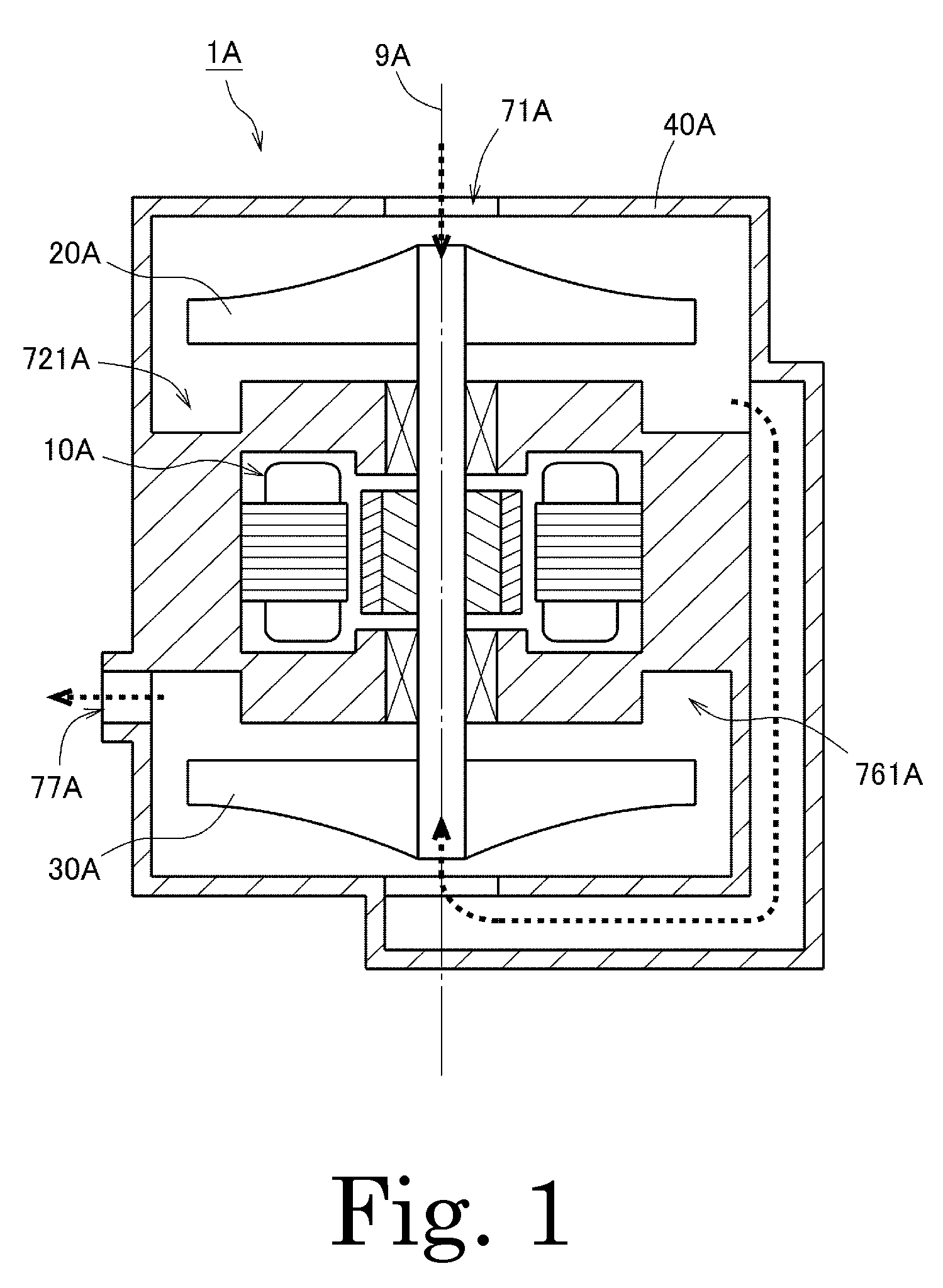

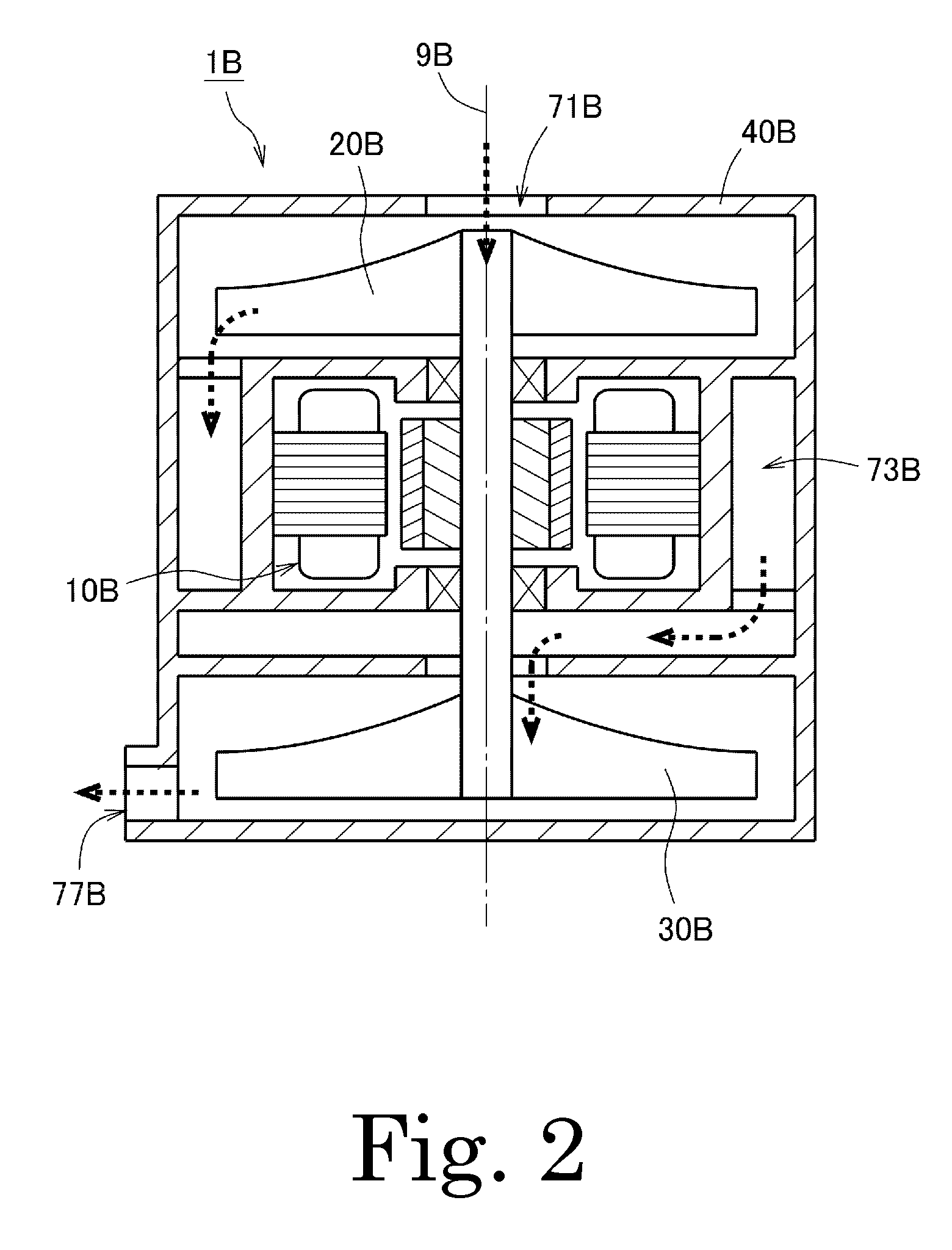

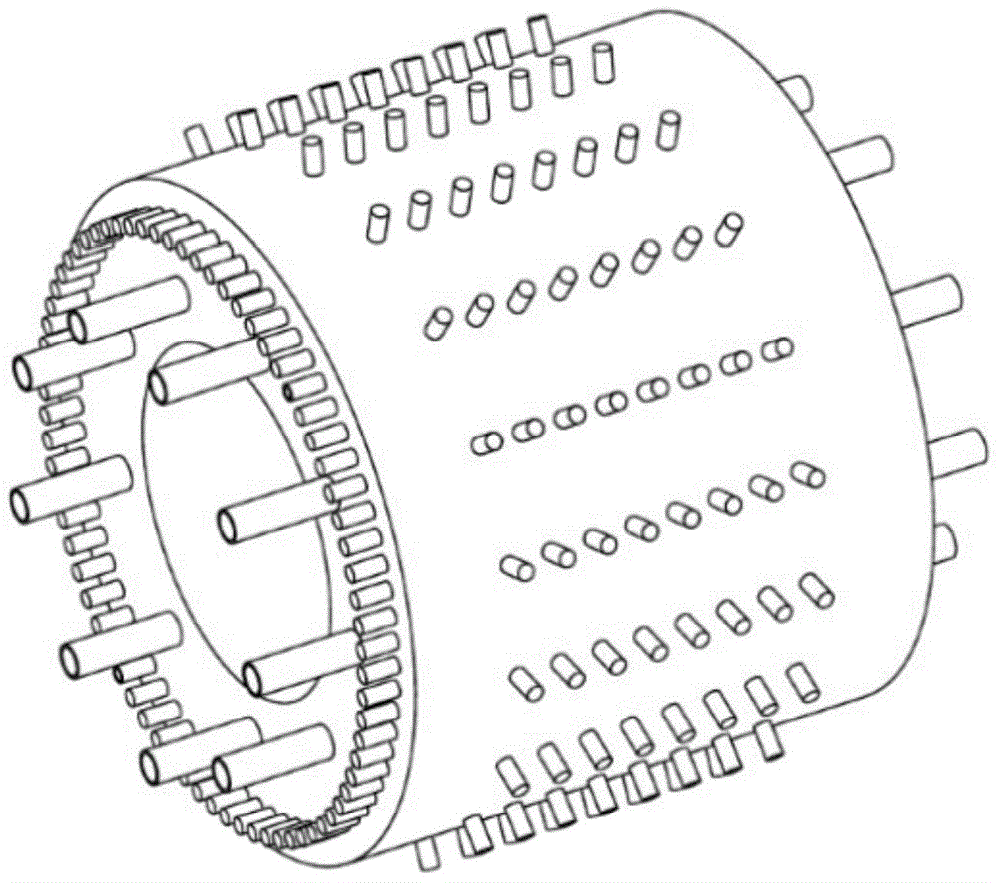

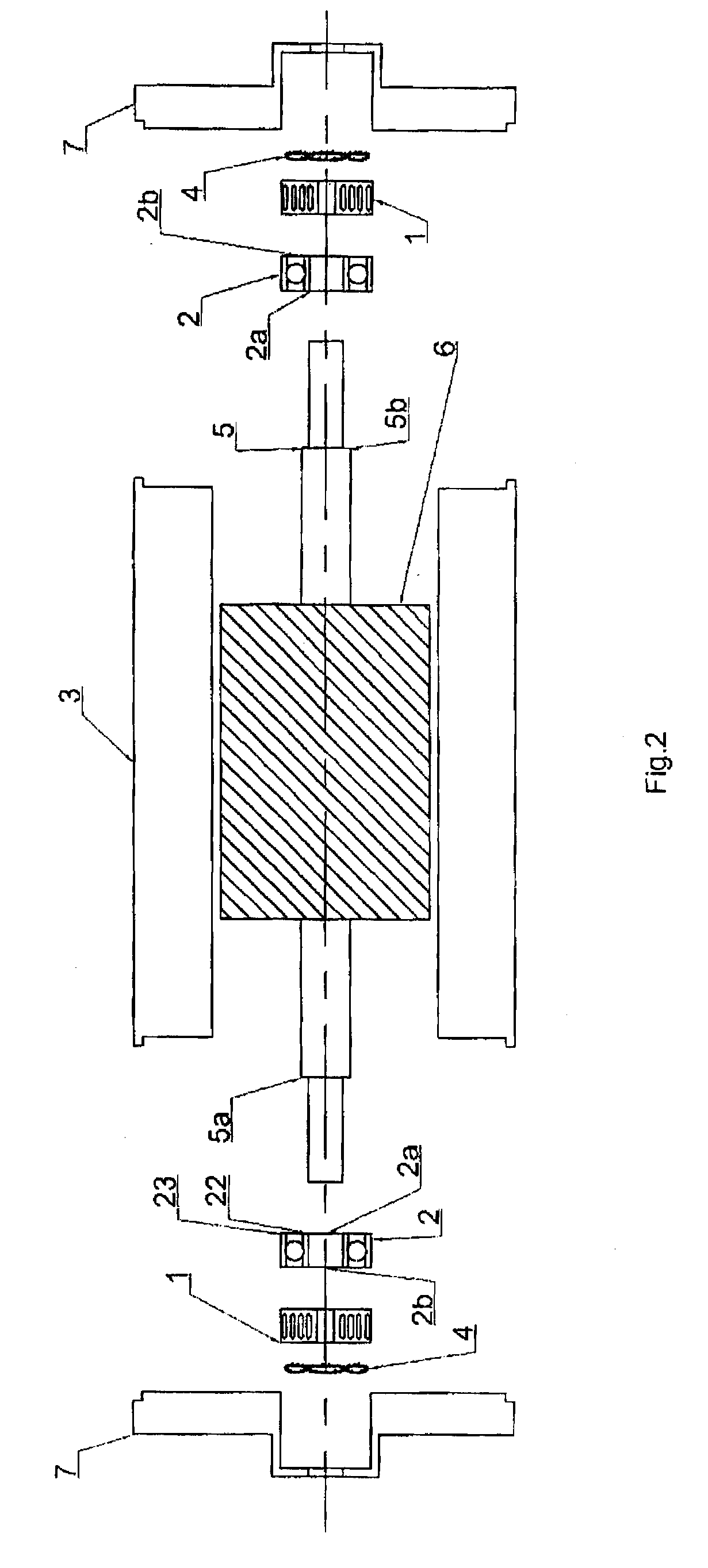

Drive apparatus for hybrid vehicle

Provided is a drive apparatus of a hybrid vehicle, configured in such a manner that the occurrence of a resonance phenomenon is minimized and that the efficiency of utilization of the space occupied by a torque limiter mechanism is improved. A drive apparatus 100A for a hybrid vehicle is configured in such a manner that a torque limiter TL is provided in the path of power transmission between an inner shaft 2a and a generator 60 at a position between the generator 60 and a motor 70. The torque limiter TL axially overlaps with at least a part of the stator 65 of the generator 60 and / or at least a part of the stator 75 of the motor 70.

Owner:HONDA MOTOR CO LTD

Small field intensity modulated radiation therapy machine

ActiveUS7519149B2Easy to controlShorten the axial distancePatient positioning for diagnosticsX-ray/gamma-ray/particle-irradiation therapyHuman bodyIntensity-modulated radiation therapy

A small field radiation therapy machine having an aperture diameter of 30 cm or less provides improved ray definition for specialized treatment of portions of the human body such as head a breast.

Owner:WISCONSIN ALUMNI RES FOUND

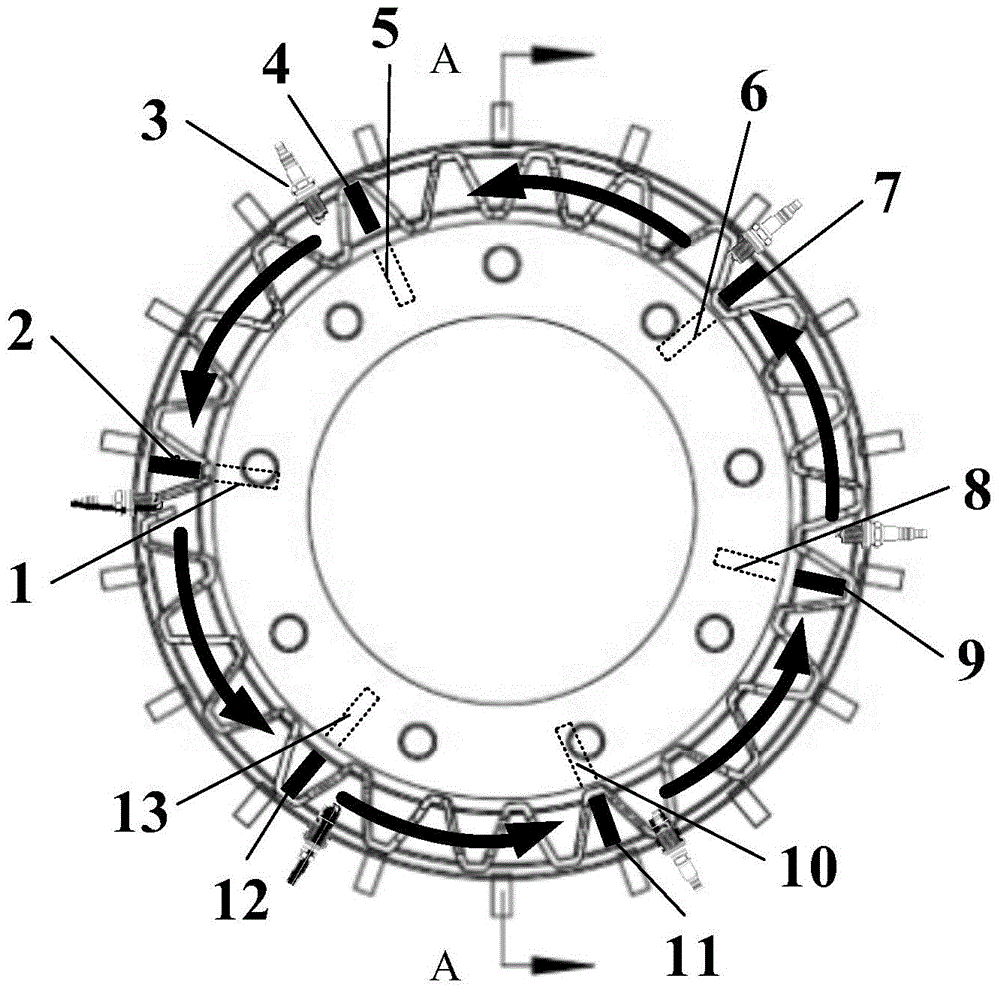

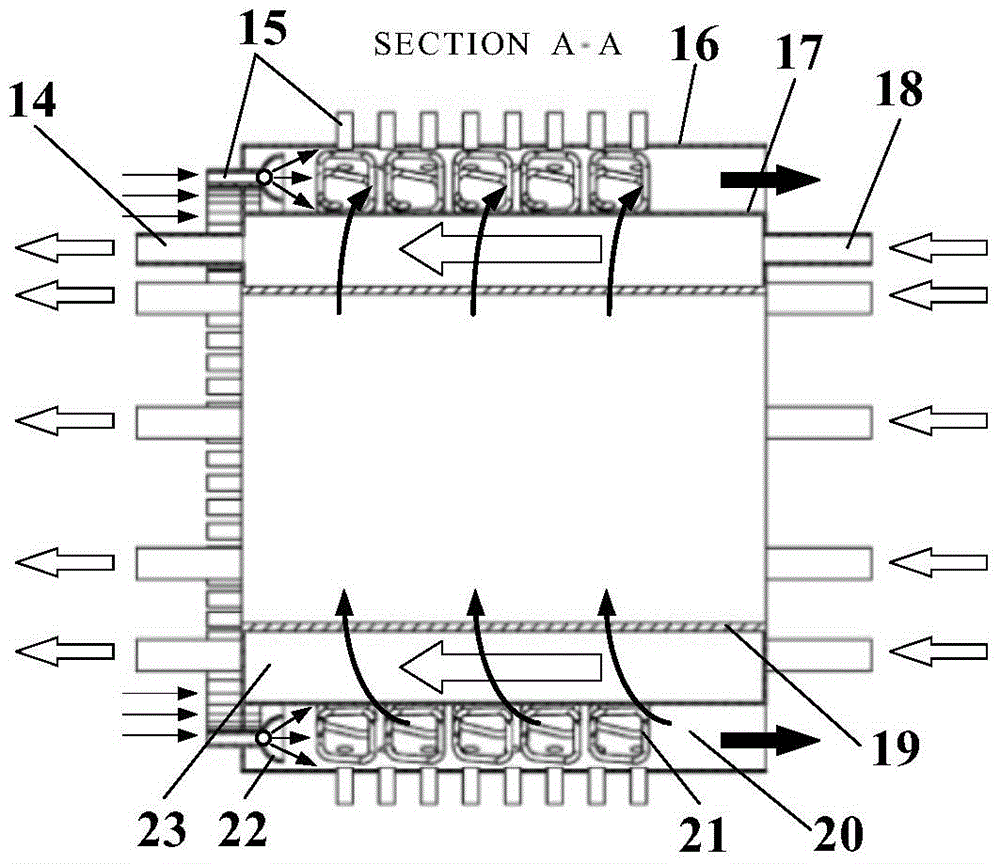

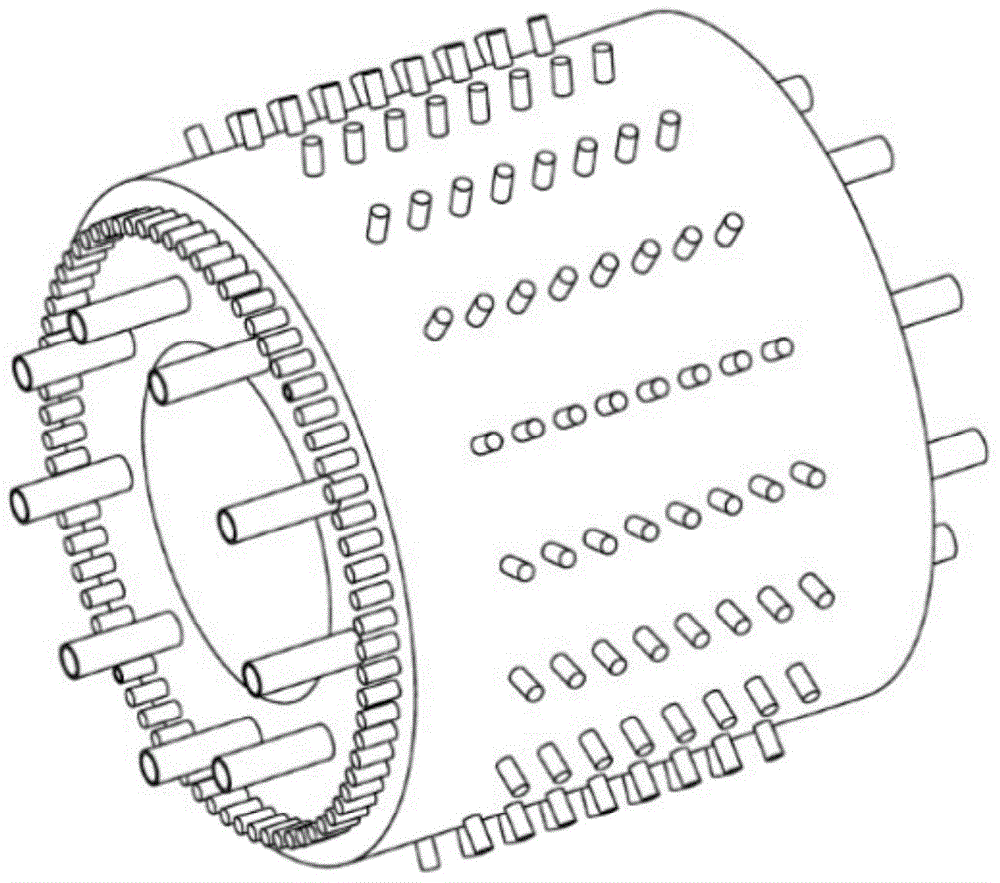

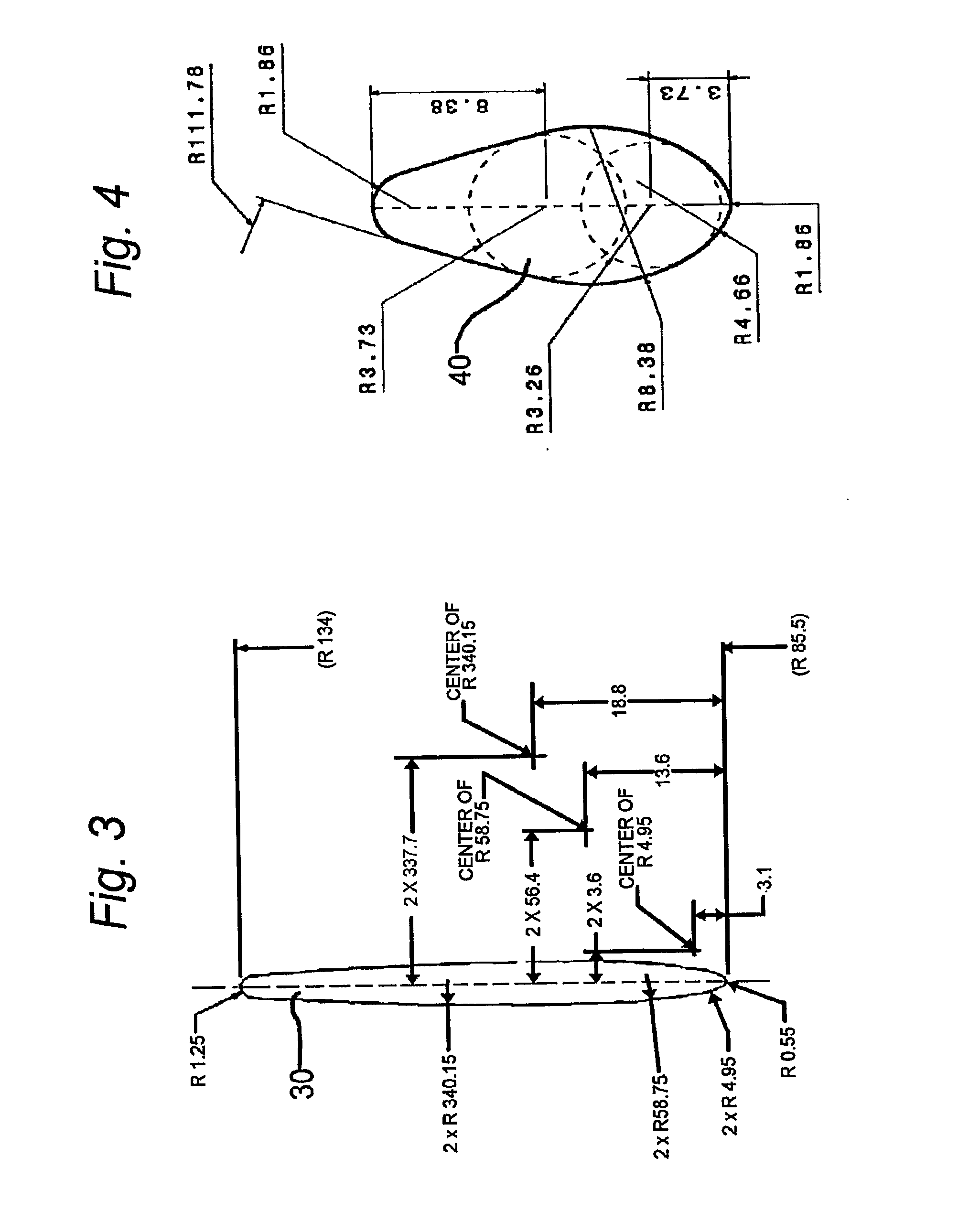

Rotating detonation combustion chamber

InactiveCN104154567AImprove self-pressurization abilityImprove stabilityContinuous combustion chamberDetonationAxial distance

The invention provides a rotating detonation combustion chamber. According to the rotating detonation combustion chamber, besides a plurality of fuel spray nozzles which are distributed on the head portion of the combustion chamber in an annular mode at equal intervals, a plurality of fuel spray nozzles are further evenly arranged in the axial direction and the circumferential direction of an outer shell of the combustion chamber, so that the annular detonation combustion chamber is divided into a plurality of small spaces; each spray nozzle is responsible for supplying fuel to the corresponding small space, and therefore filling efficiency of fuel can be improved, the filling space of fuel of the combustion chamber can be enlarged, and the combustion thermal intensity of the combustion chamber can be improved. The axial distance of rotating detonation combustion waves can be lengthened due to the fact that the filling space of fuel of the combustion chamber is enlarged, so that the rotating detonation waves penetrate through the whole combustion chamber, and meanwhile the rotating detonation waves can be prevented from degeneration and disappear which are caused by fuel shortage in the spreading process. A spiral obstacle is arranged in an annular cavity of the rotating detonation combustion chamber in the circumferential direction, and therefore the distance by which slow combustion is converted into detonation combustion in the starting process of the combustion chamber can be shortened, the intensity of the rotating detonation waves is enhanced, the overall self-pressurization capacity is improved in the combustion process of the combustion chamber, and meanwhile stability of the rotating detonation waves can be enhanced in the spreading process.

Owner:XIAN THERMAL POWER RES INST CO LTD

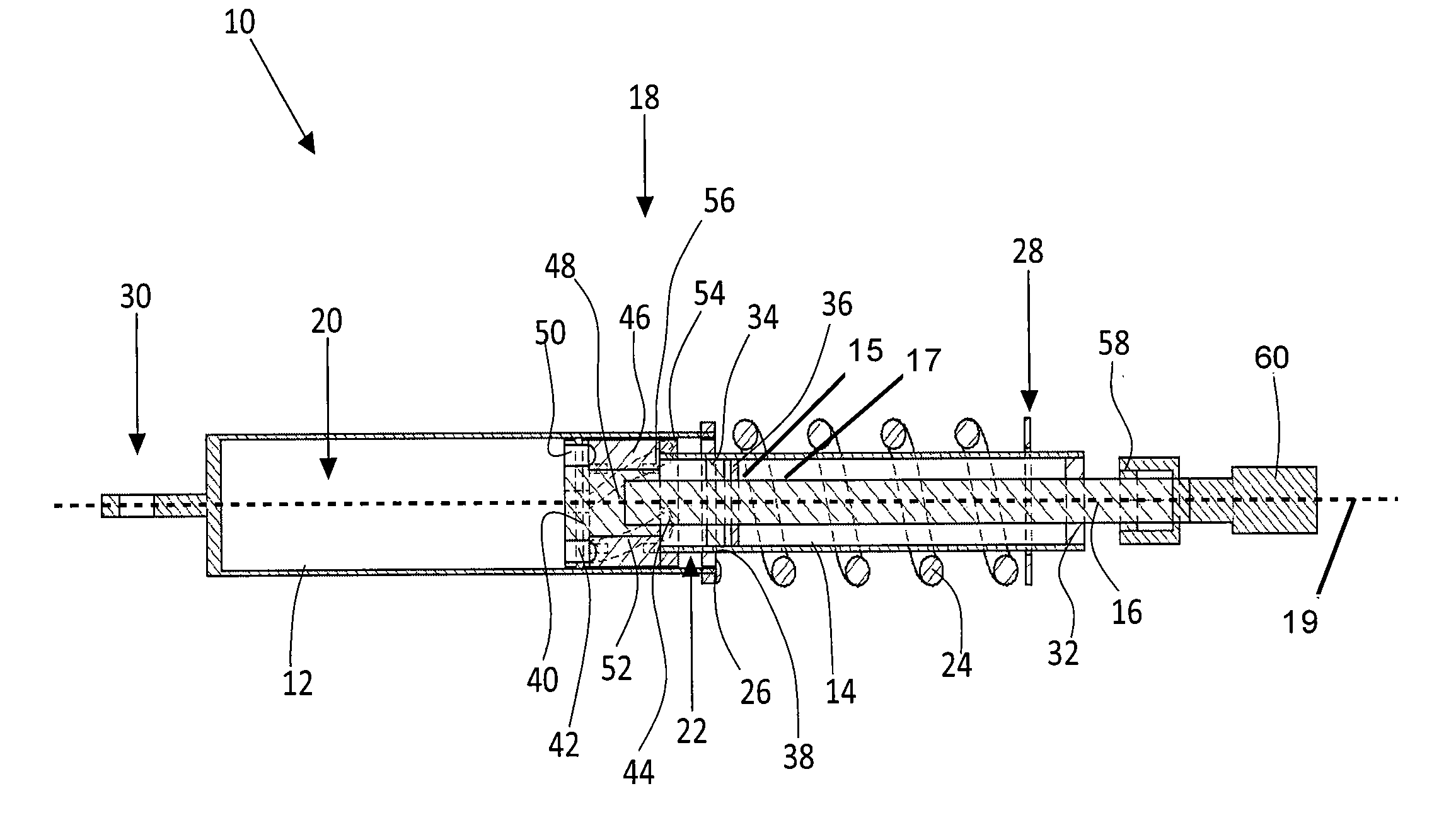

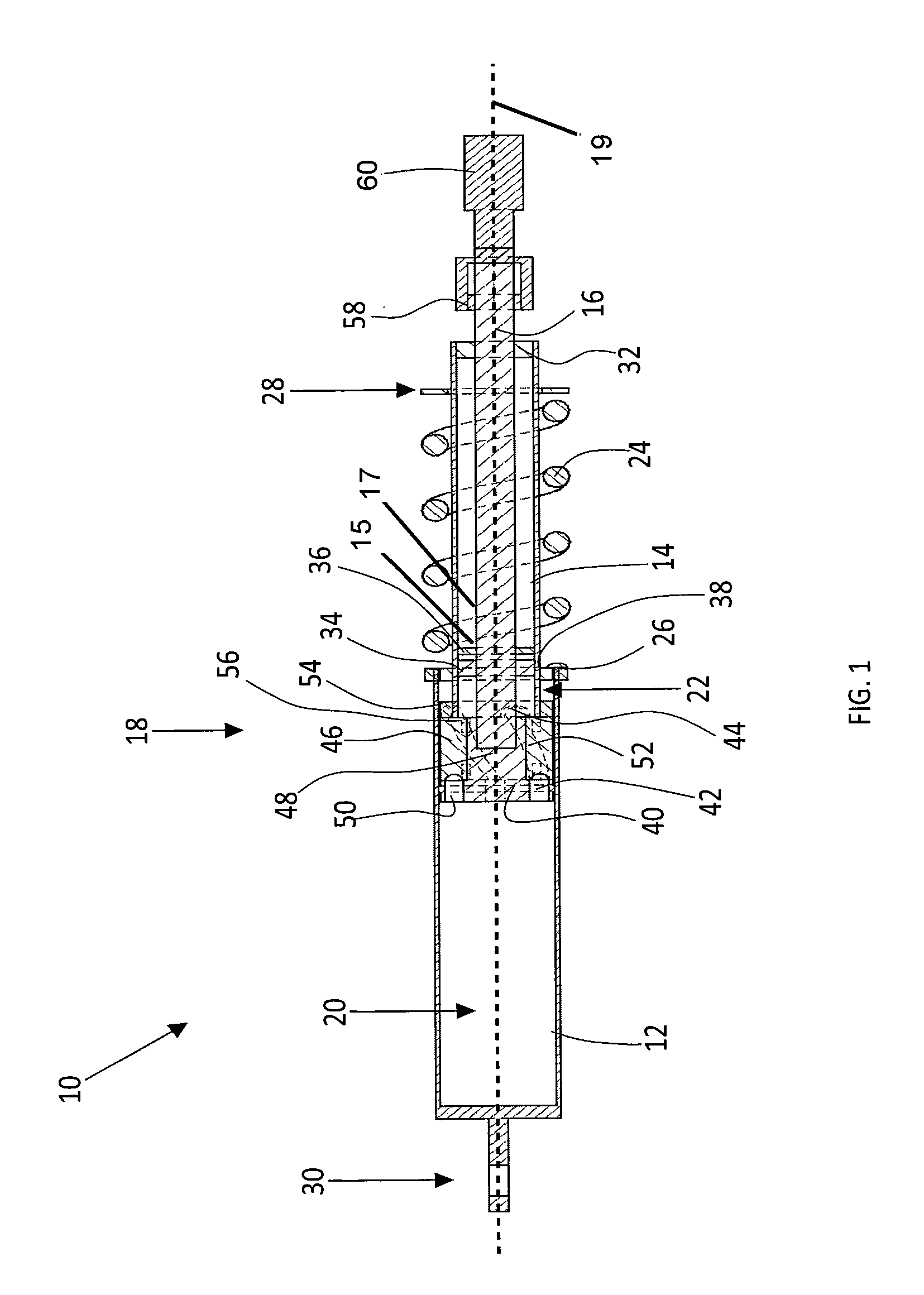

Fuel pipe assembly and clamping means

ActiveUS20110174272A1Easy clamping actionReduce radial clearanceFuel injection apparatusMachines/enginesCylinder headEngineering

A fuel pipe assembly for supplying fuel to a fuel injector located within a bore of an engine cylinder head comprises a tube nut for connecting the fuel pipe to the fuel injector and a securing arrangement comprising a locking nut and a deformable clamp member for securing the fuel pipe within the tube nut. The tube nut comprises a tubular member defining an axial bore to receive the fuel pipe, a distal end shaped for cooperation with the head of the fuel pipe, and a proximal end having an attachment mechanism for engaging a compatible attachment mechanism of the locking nut. The locking nut has an axial bore to receive the fuel pipe, and an attachment mechanism for engaging a compatible attachment mechanism of the tube nut. The clamp member defines a bore to receive the fuel pipe and is deformable under compression. In a first state of engagement, the locking nut and tube nut define a volume therebetween that accommodates the clamp member in an unstrained configuration and the fuel pipe is able to move laterally. In a second state of engagement, the clamp member is compressed between the locking nut and tube nut into a strained configuration such that lateral movement of the fuel pipe is constrained.

Owner:DELPHI TECH IP LTD

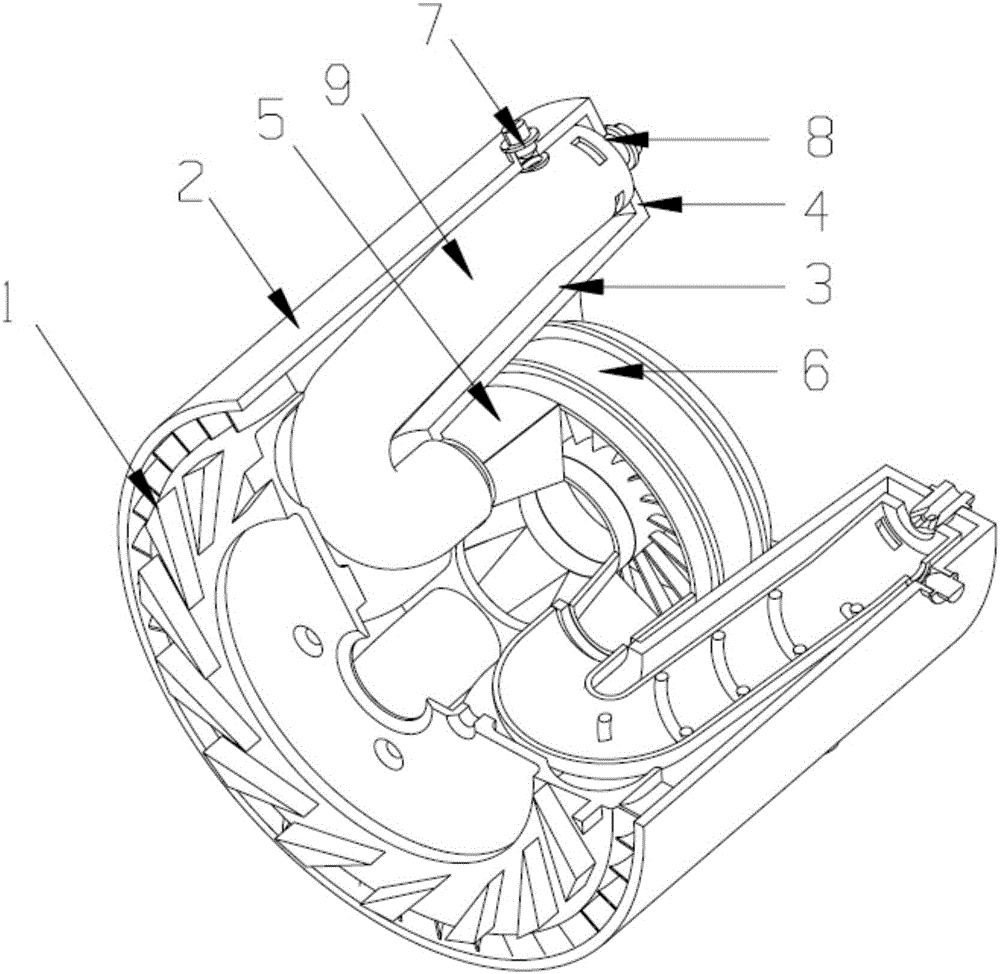

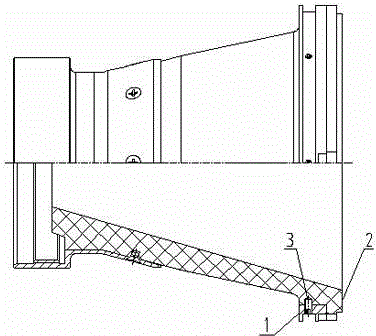

Compact micro gas turbine

ActiveCN104088702AEasy to processReduce volumeBlade accessoriesGas turbine plantsSingle stageCombustion chamber

The invention discloses a compact micro gas turbine, which mainly comprises an air inlet channel, an air compressor, a combustion chamber, a turbine, a shaft system installing body, a shaft and a shell, wherein the air compressor is a single-stage centrifugal air compressor; the combustion chamber is a full ring combustion chamber; the turbine is a single-stage concentric turbine; the air inlet channel is connected with a front flange through a screw; an inner ring of a diffuser and an outer ring of the diffuser are welded on the front flange; the direction of air flow is changed from radial to axial after passing through the diffuser; the shaft system installing body is fixed in the inner ring of the diffuser; the turbine and the shaft are integrally machined; after the turbine shaft penetrates through the shaft system installing body, the air compressor is arranged at the front end of the turbine shaft and is locked through an air compressor wheel locking nut; the rear end of the shaft system installing body is connected with the installing plate of the turbine through screws; the rear end of installing plate of the turbine is fixed with the front end of a guider of the turbine; the combustion chamber is arranged outside the shaft system installing body and axially covers the front half part of the turbine; the direction of the air flow is changed from axial to radical after passing through the combustion chamber; the air flow impacts the turbine through the guider of the turbine; the guider of the turbine, the rear end of the combustion chamber and the shell of the turbine are collectively fixed with a rear flange.

Owner:BEIHANG UNIV

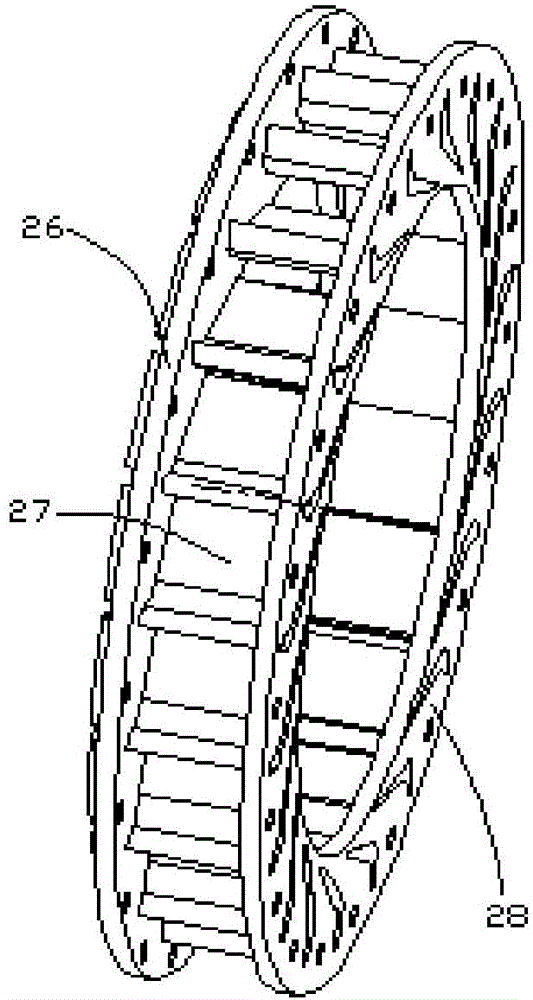

Portable type external field equipment for multi-sensor optical axis calibration

ActiveCN102589605AOvercome the disadvantage of limited coverage band rangeShorten the axial distanceMountingsButt jointOptical axis

The invention discloses potable type external field equipment for multi-sensor optical axis calibration, comprising an adjusting optical axis mechanism, an optical collimation assembly and a rotary target wheel assembly, wherein the adjusting optical axis mechanism is located on sensors with different wave sections; the optical collimation assembly is provided with a front window and a back window; light which is input from any one window of the optical collimation assembly is reflected twice and then is output from the other window; the sensors at the different wave sections are located outside the front window of the optical collimation assembly and parallel light is received or sent by the optical collimation assembly; the optical collimation assembly is in butt joint with the rotary target wheel assembly through a connecting component at the back window side of the optical collimation assembly; and the light is input to the back window of the optical collimation assembly through rotating to select different target positions on the rotary target wheel assembly. The potable type external field equipment disclosed by the invention can work in a wide spectral region and the requirements of carrying out optical axis debugging and calibration on the sensors with the different wave sections in an external field environment are met.

Owner:11TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

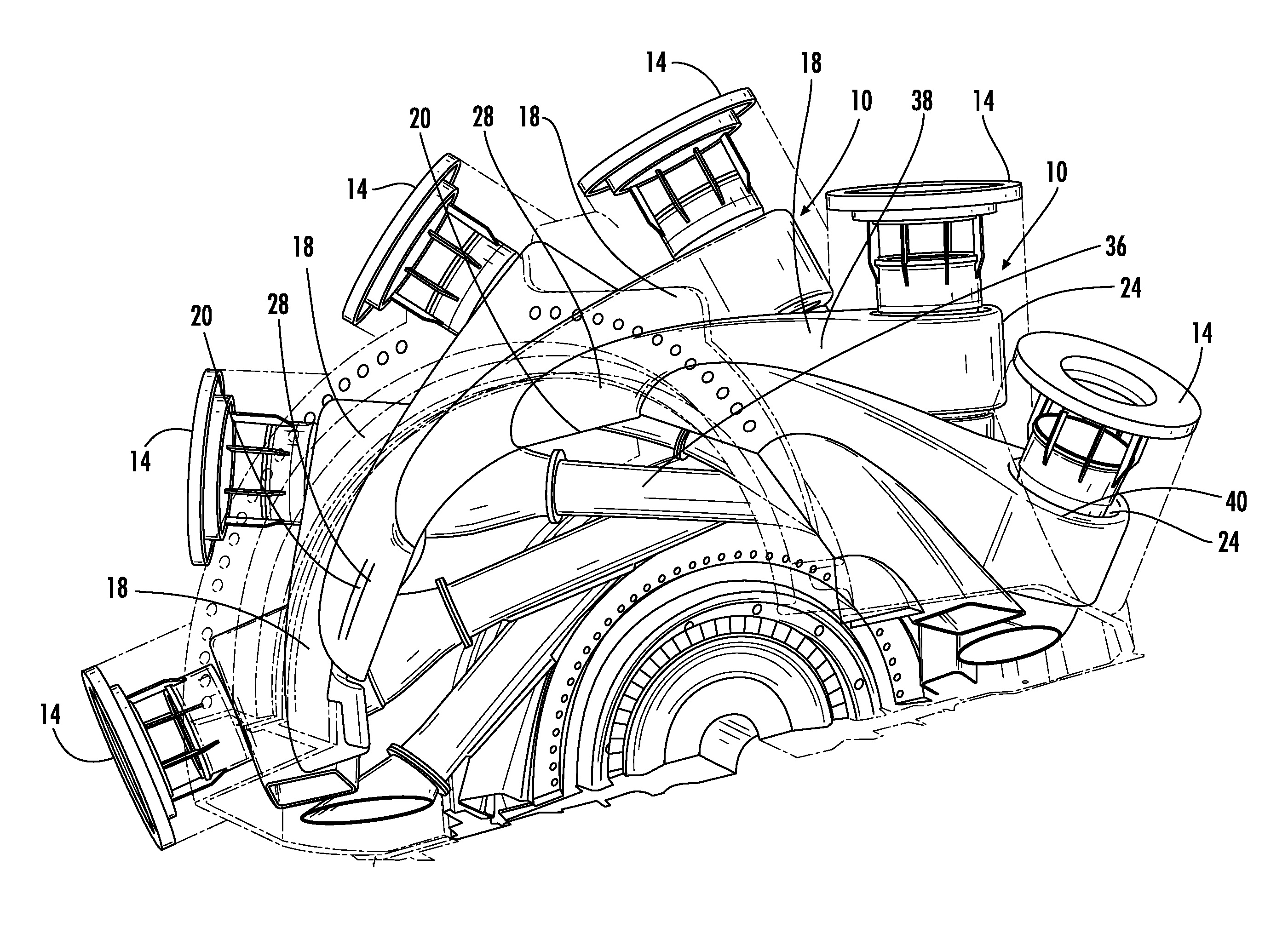

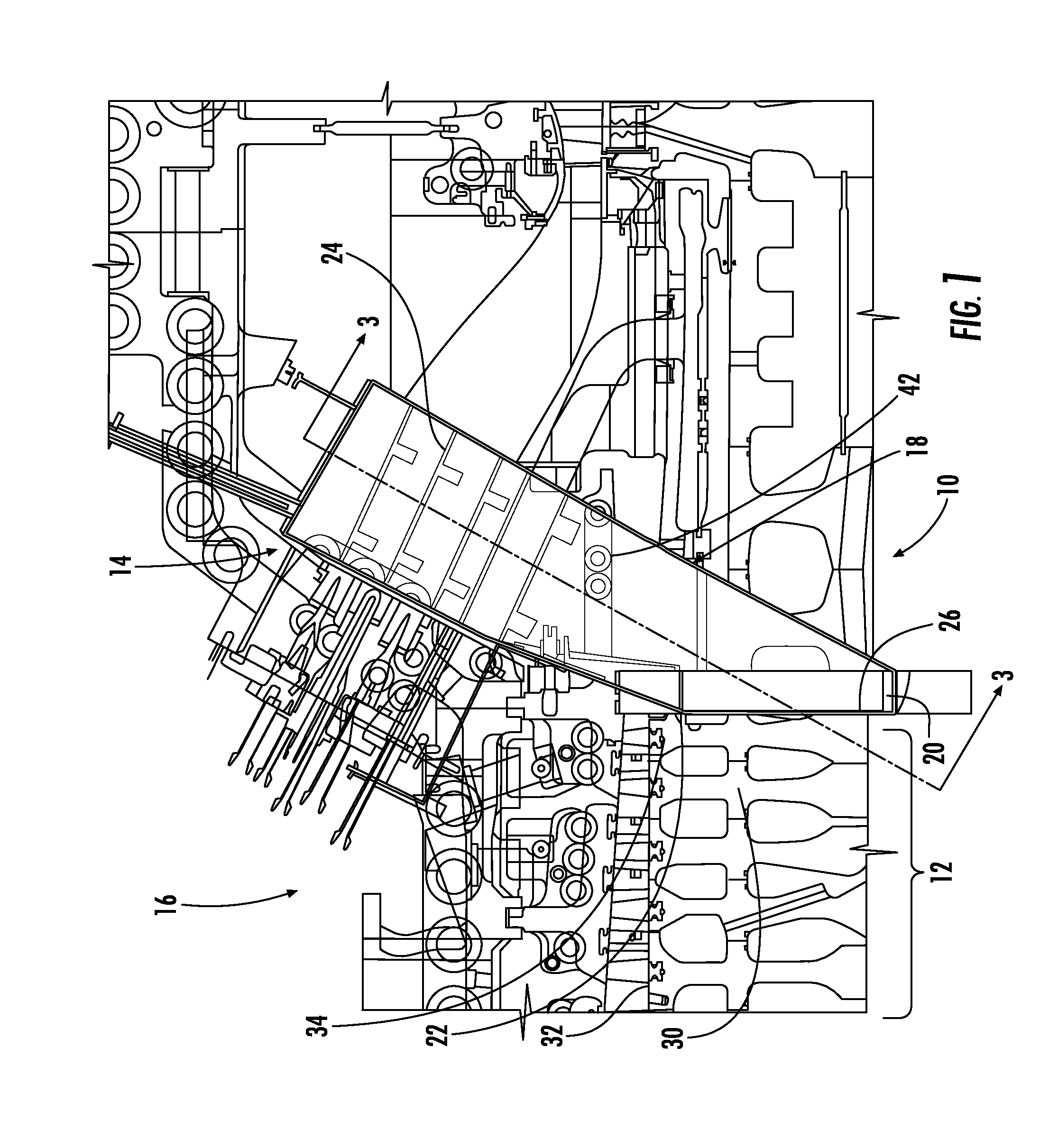

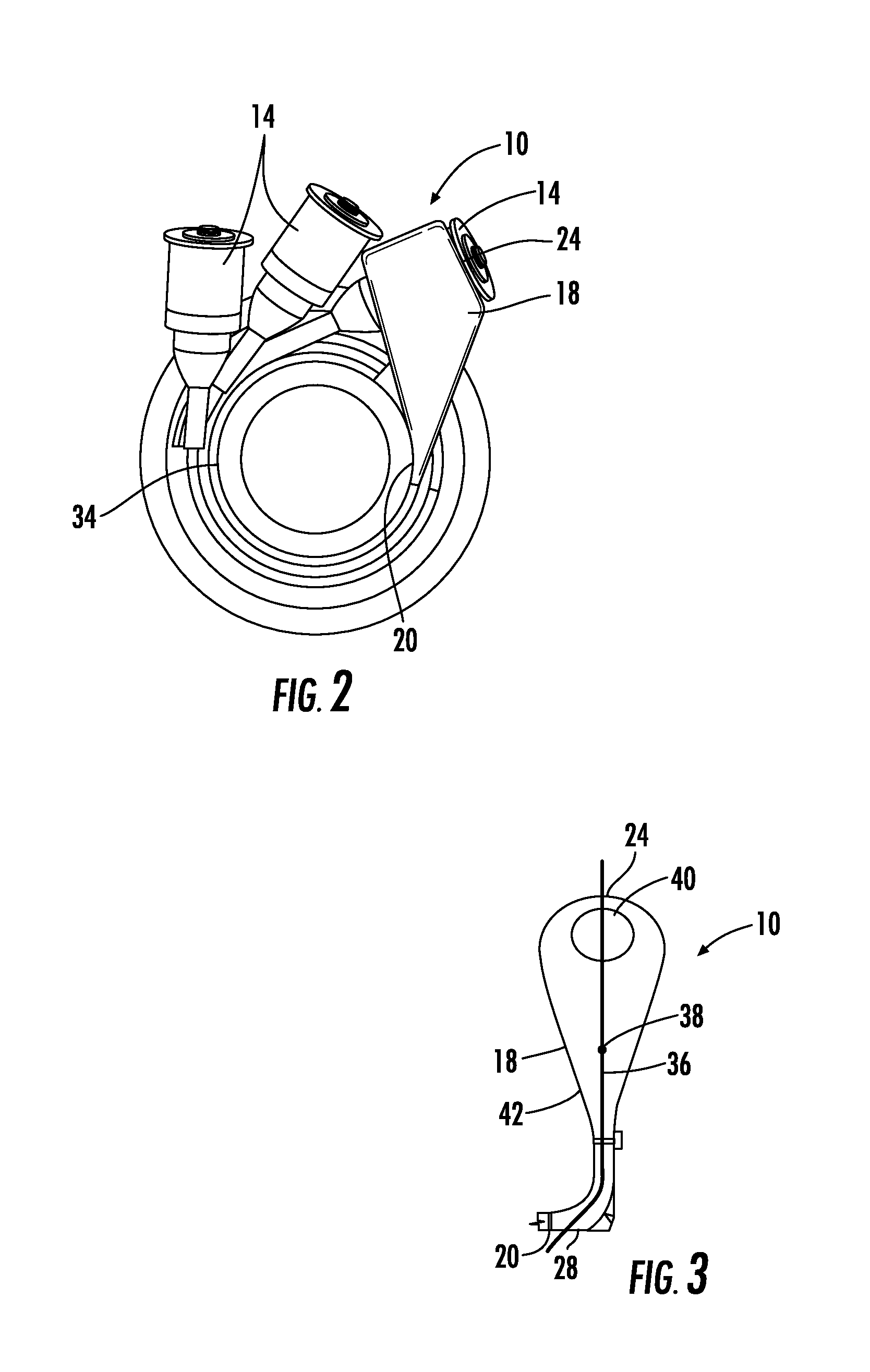

Compressed air plenum for a gas turbine engine

InactiveUS20120031068A1Reduce damageReduce harmEngine fuctionsGas turbine plantsAutomotive engineeringGas turbines

A compressed air supply system for routing compressed air from a compressor to at least one combustor of a gas turbine engine is disclosed. The compressed air supply system may be formed from one or more plenums having an upstream end in fluid communication with an inner chamber of the compressor in which air is compressed and having a downstream end in fluid communication with the at least one combustor. Channeling compressed air through the plenum reduces damage to other components by confining the compressed air within the plenum. An upstream end of the plenum may be sealed to at least a portion of the compressor, and a downstream end of the plenum may be sealed to at least a portion of one or more combustors.

Owner:SIEMENS ENERGY INC

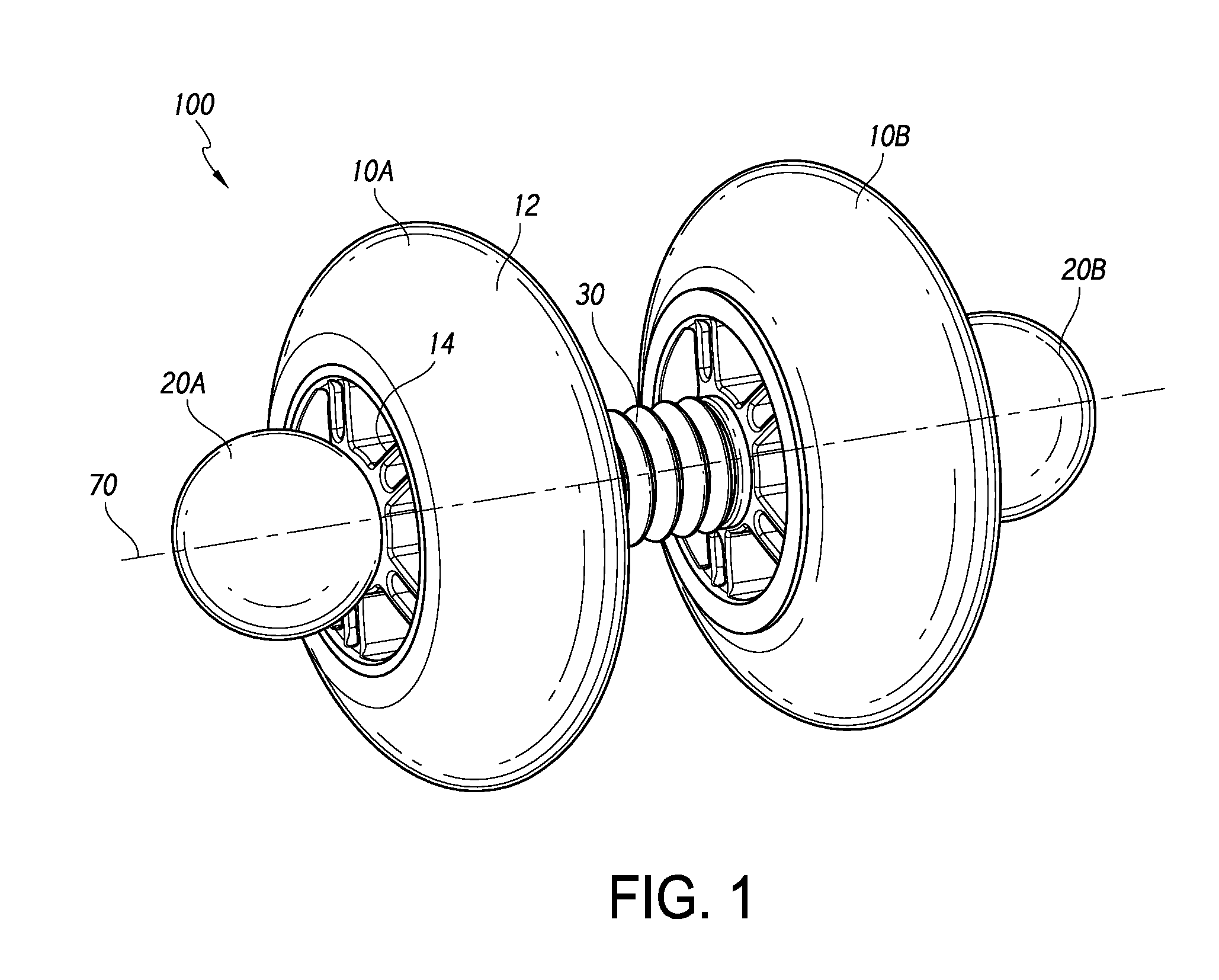

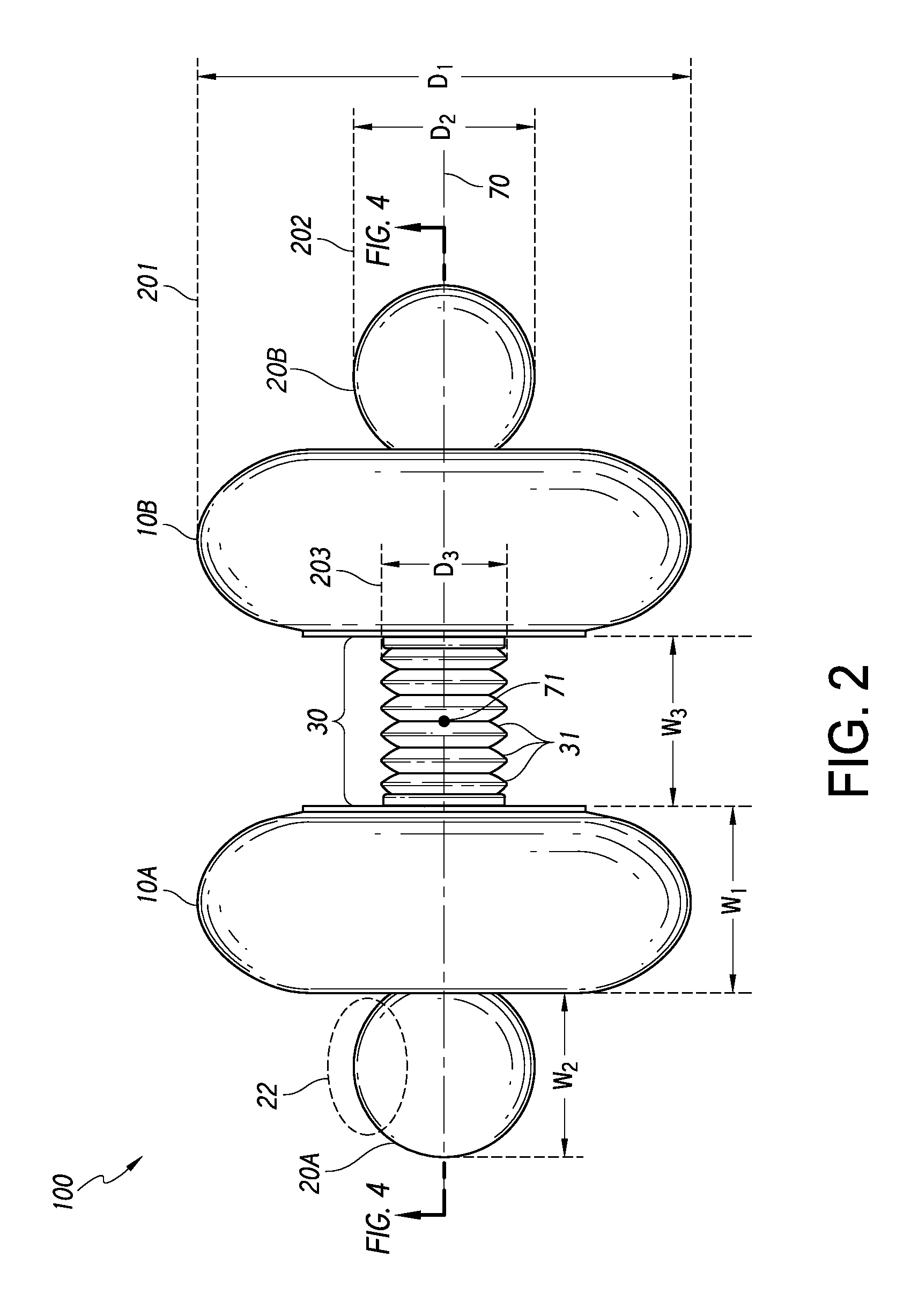

Physical therapy device

A physical therapy device includes an axle member having first and second distal ends, a first wheel of a first diameter disposed about the axle member, a second wheel of the first diameter disposed about the axle member, a first rounded end cap massager disposed at least partially over the first distal end of the axle member, the first rounded end cap massager having a second diameter that is less than the first diameter, and a second rounded end cap massager disposed at least partially over the second distal end of the axle member.

Owner:BURSON SCOTT KENNETH

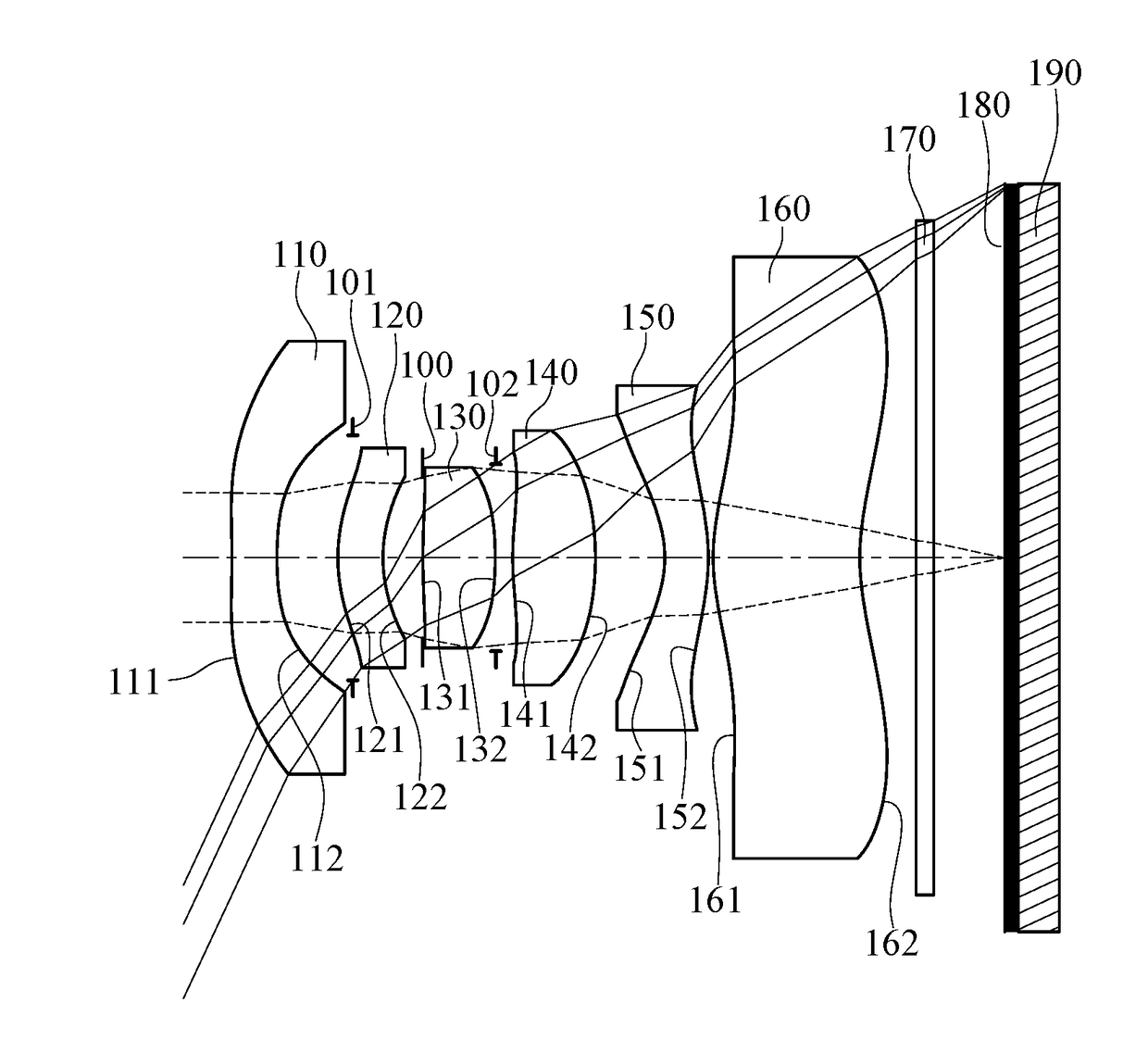

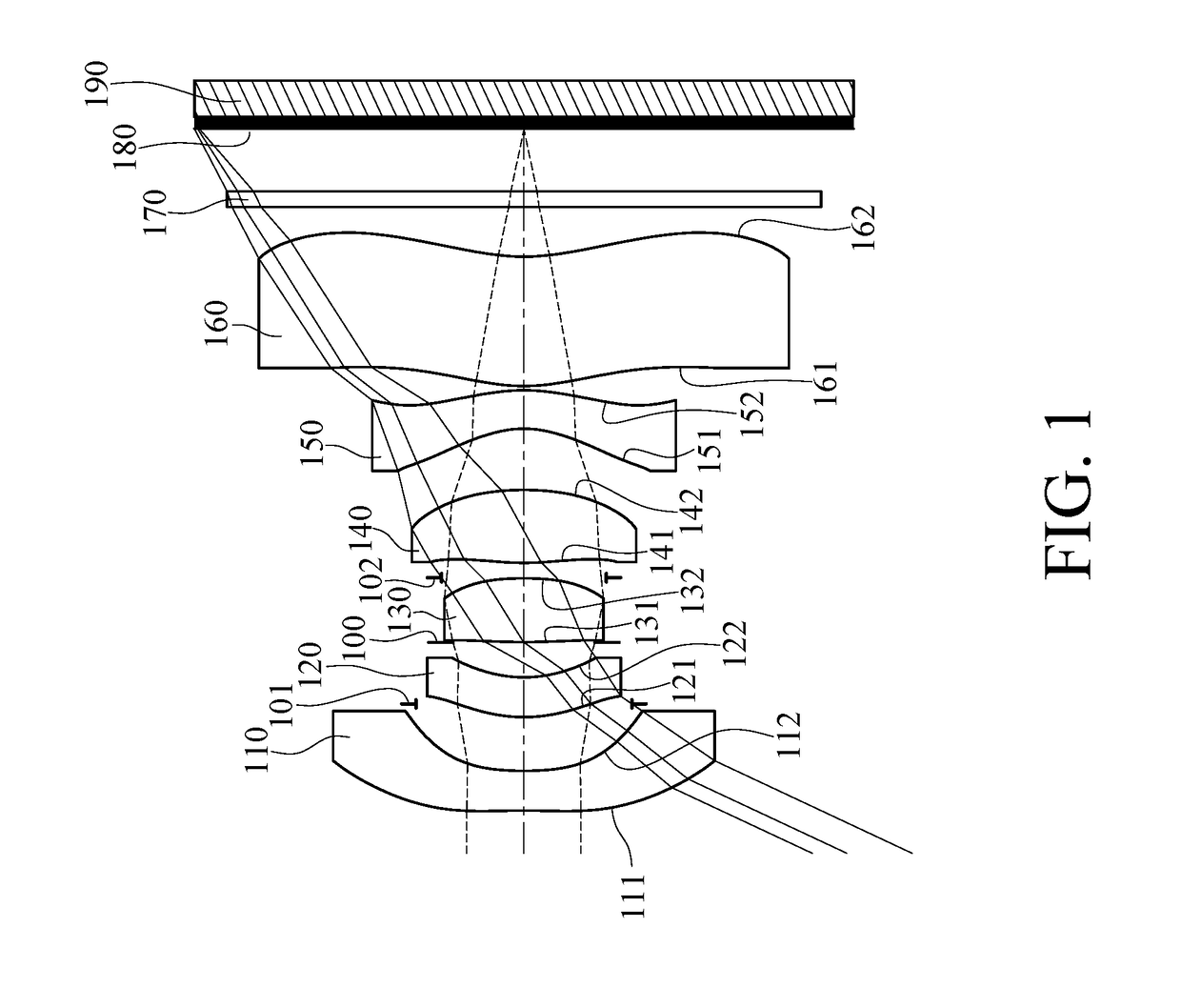

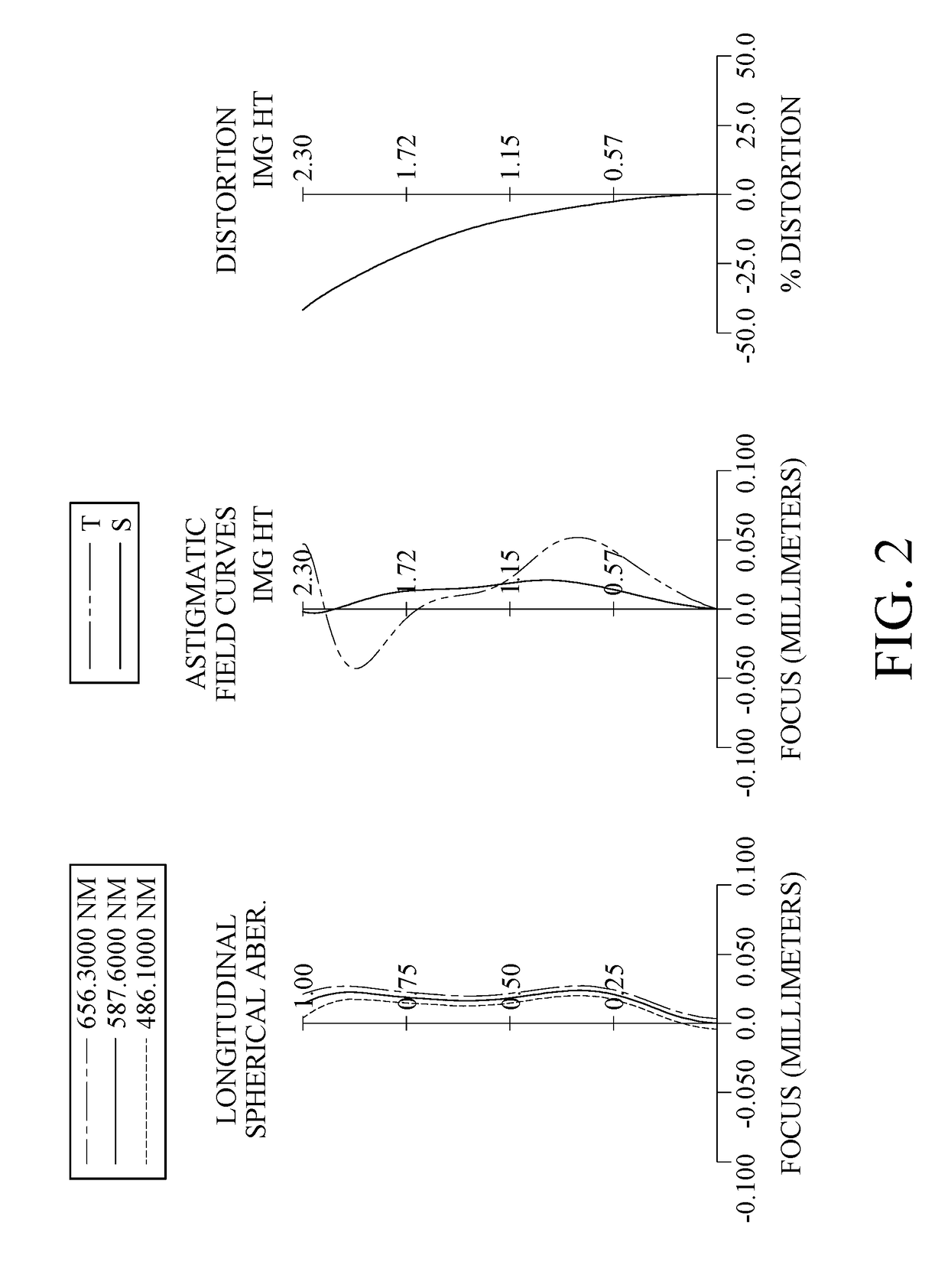

Photographing lens assembly, image capturing unit and electronic device

A photographing lens assembly includes, in order from an object side to an image side: a first, a second, a third, a fourth, a fifth and a sixth lens elements. The first lens element with negative refractive power has an object-side surface being concave in a paraxial region thereof, wherein the object-side surface has at least one convex critical point in an off-axis region thereof. The third lens element has an image-side surface being convex in a paraxial region thereof. The fourth lens element has positive refractive power. The fifth lens element with negative refractive power has an object-side surface being concave in a paraxial region thereof, and an image-side surface being convex in a paraxial region thereof. The sixth lens element has an image-side surface being concave in a paraxial region thereof, wherein the image-side surface has at least one convex critical point in an off-axis region thereof.

Owner:LARGAN PRECISION

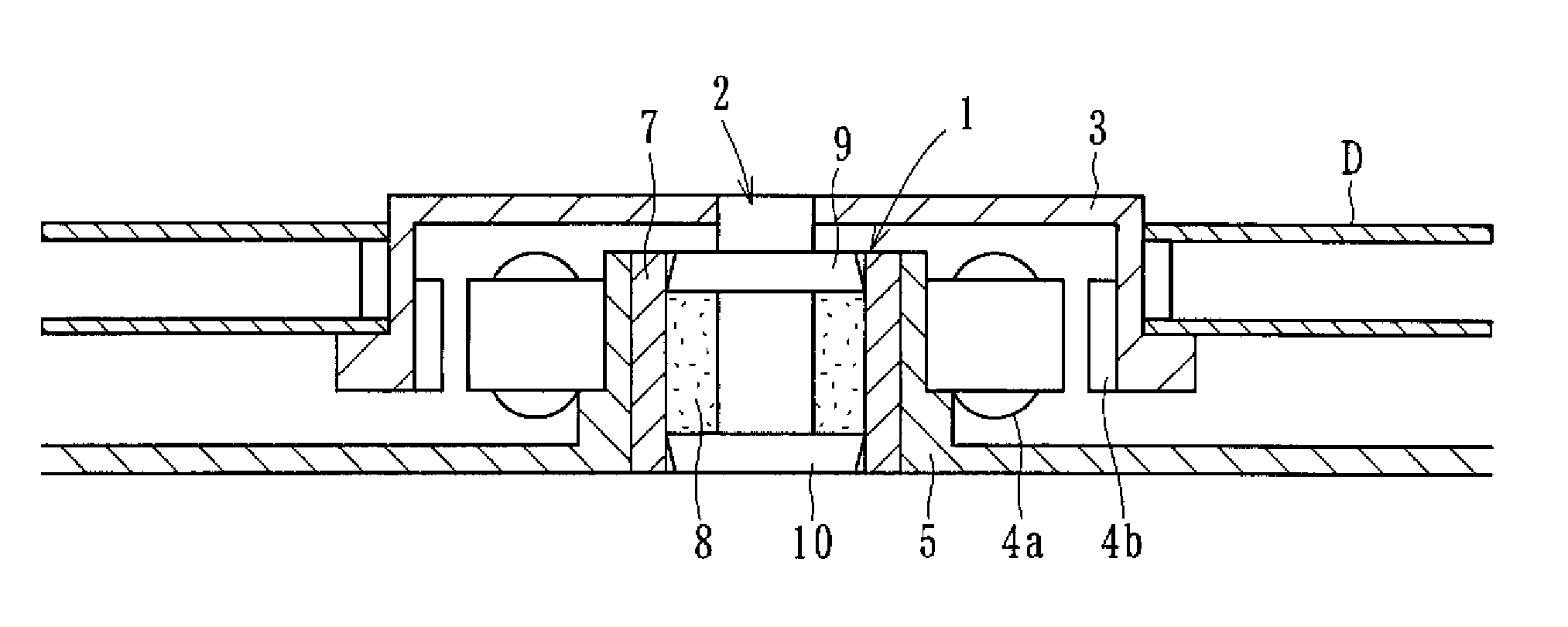

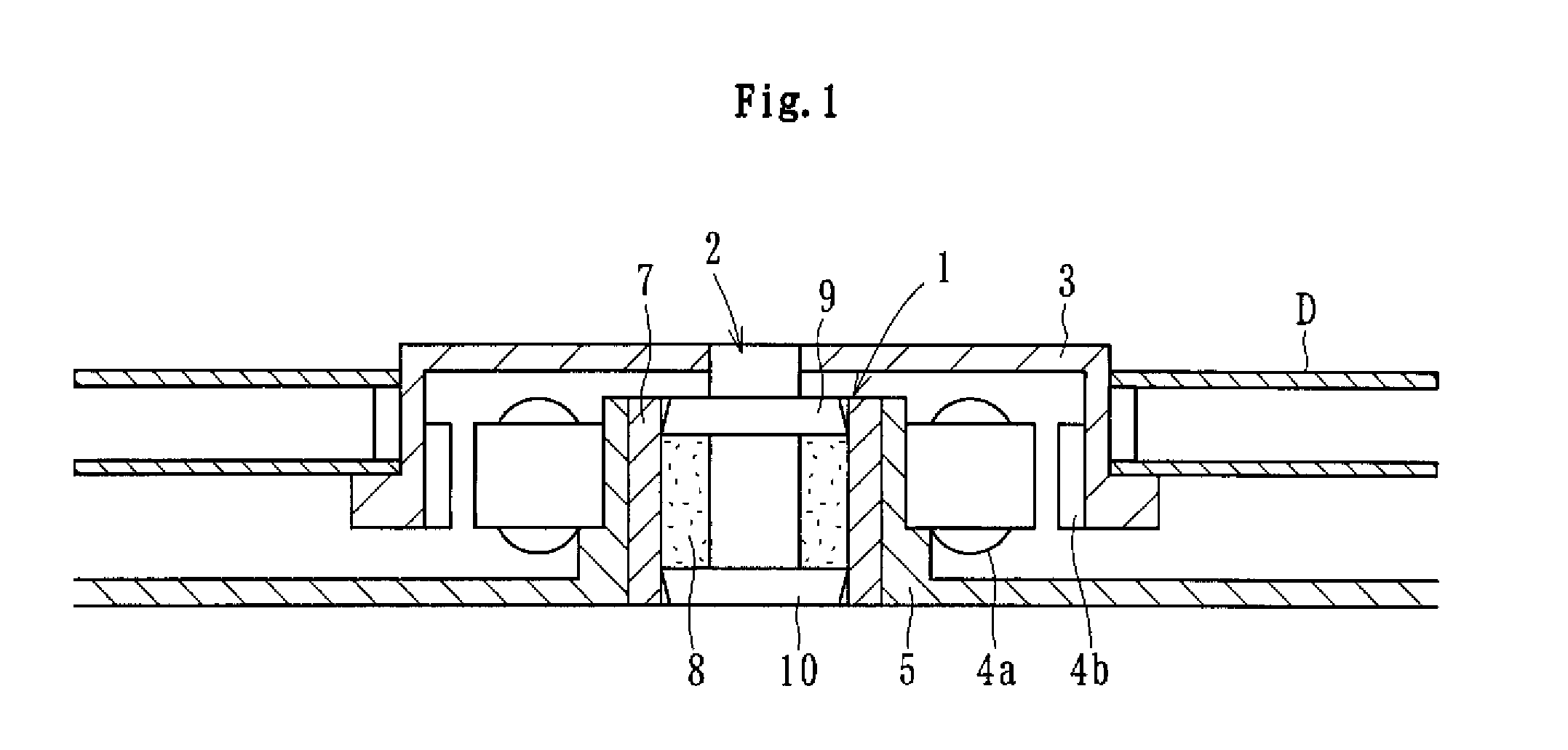

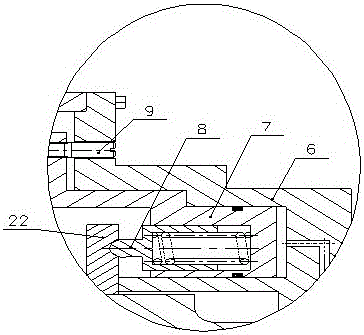

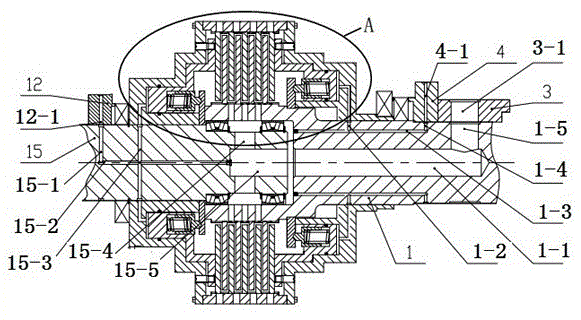

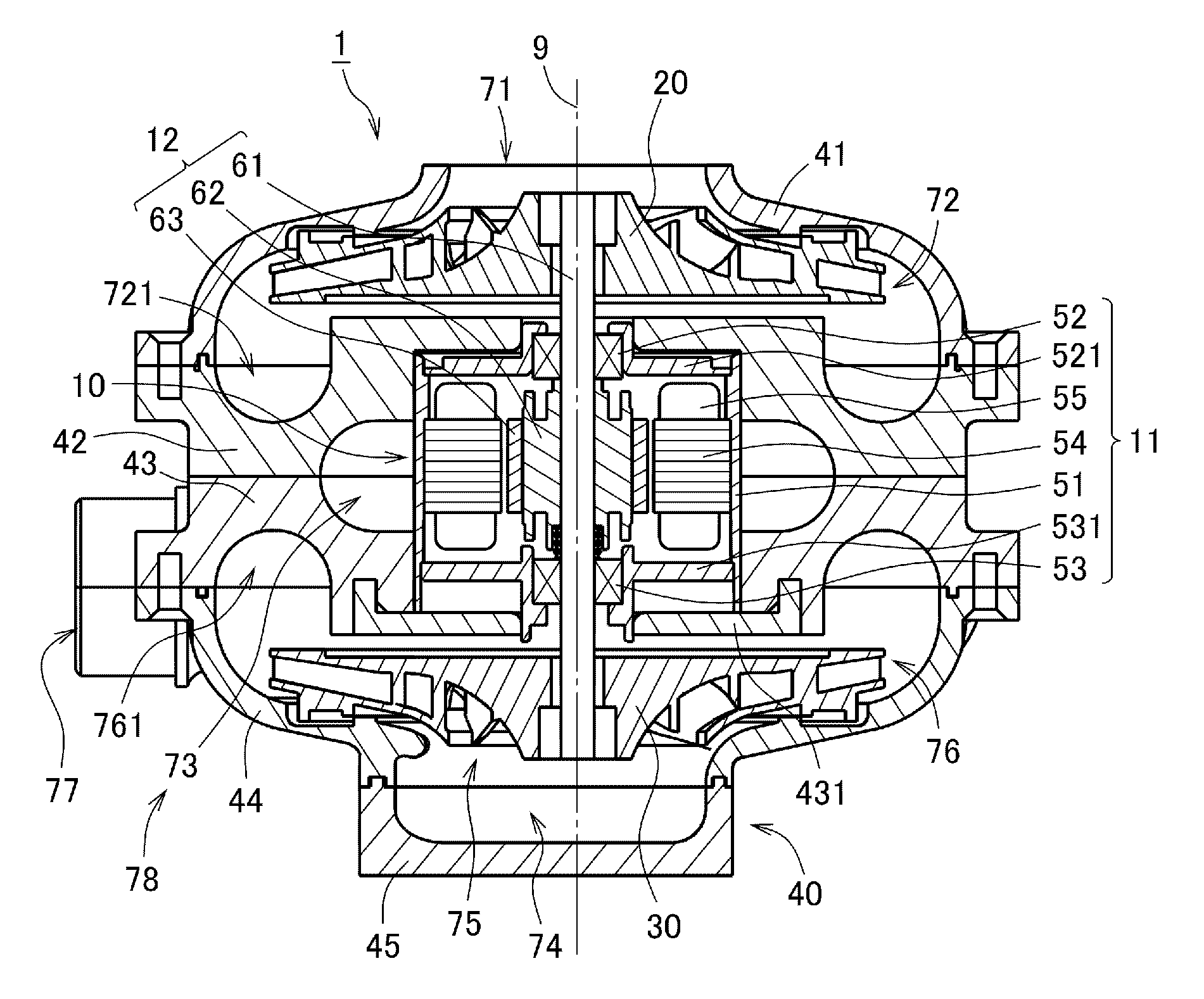

Fluid dynamic bearing apparatus

InactiveUS20090279817A1Improve sealingReduce axial sizeBearing componentsSliding contact bearingsFriction effectThrust bearing

A fluid dynamic bearing apparatus having an increased a value of tolerance for a moment load is provided.A cylindrical sleeve portion 8 is fixed to the inner periphery of the housing 7 whose both ends are open, and a shaft member 2 is further inserted at the inner periphery of the sleeve portion 8. Sealing portions 9, 10 are fixed to the shaft member 2 in the manner of nipping the sleeve portion 8 from both sides in the axial direction, and sealing spaces S1, S2 having the oil level of a lubricating oil are formed between the outer circumferential surfaces 9a, 10a of the sealing portions 9, 10 and the inner circumferential surface 7a of the housing 7. The radial bearing gap between the inner circumferential surface 8a of the sleeve portion 8 and the outer circumferential surface 2a of the shaft member 2 is formed and thrust bearing gaps are formed between the end faces 9b, 10b of the sealing portions 9, 10 and the end faces 8b, 8c of the sleeve portion 8 opposing these to support the shaft member 2 in a non-contact manner in the radial direction and in the thrust direction by the hydrodynamic effect of the lubricating oil produced in each bearing gap.

Owner:NTN CORP

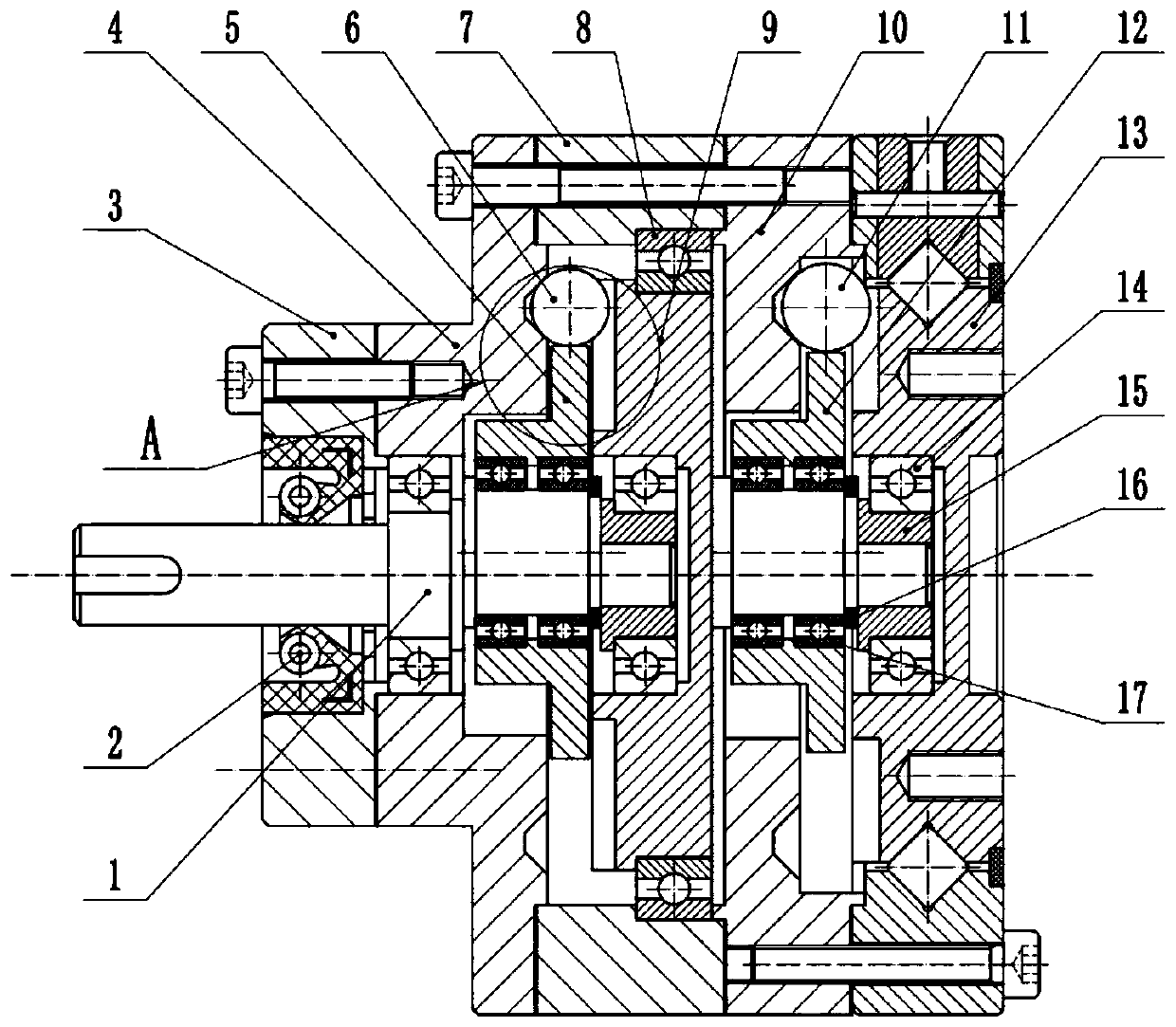

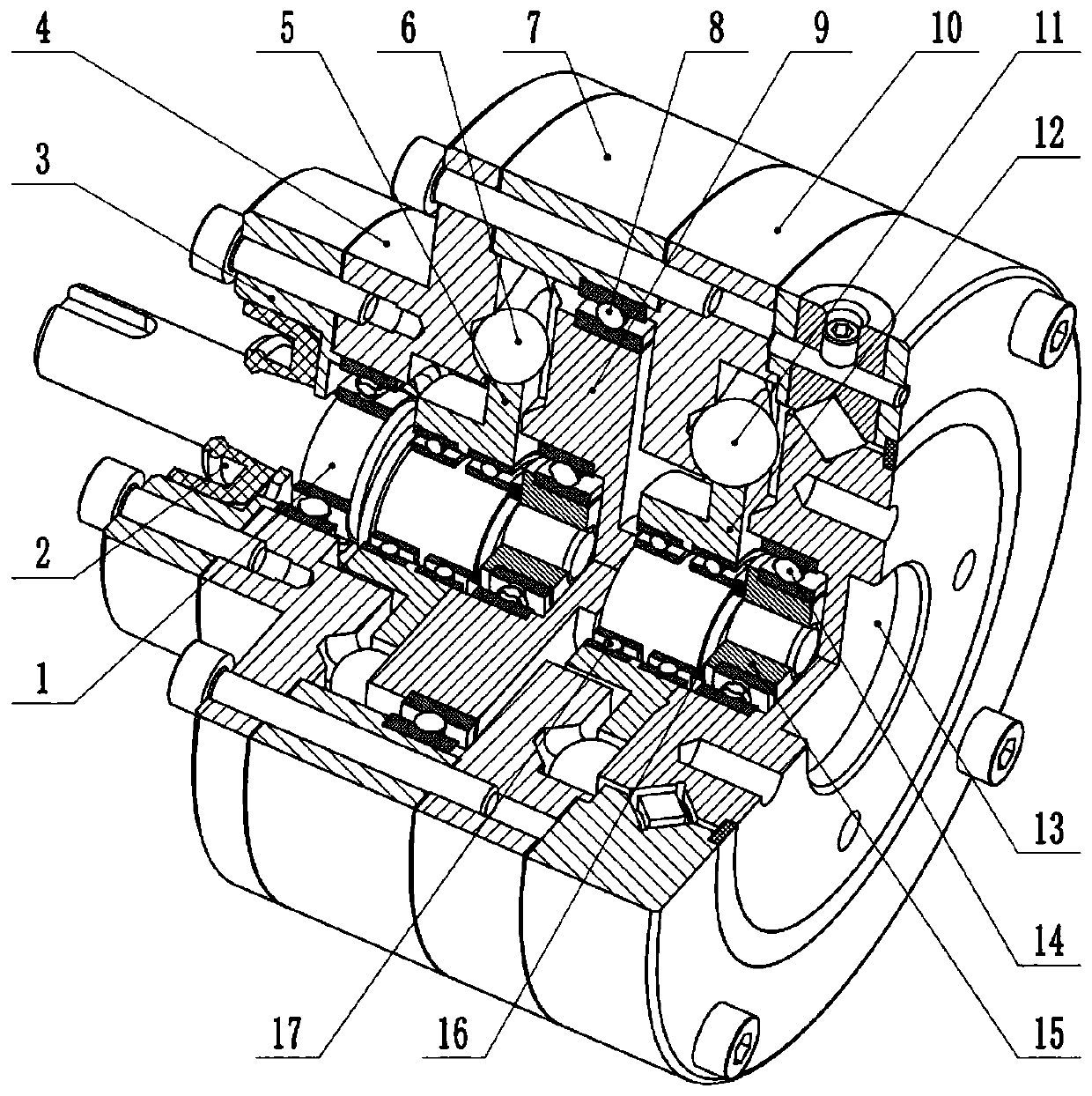

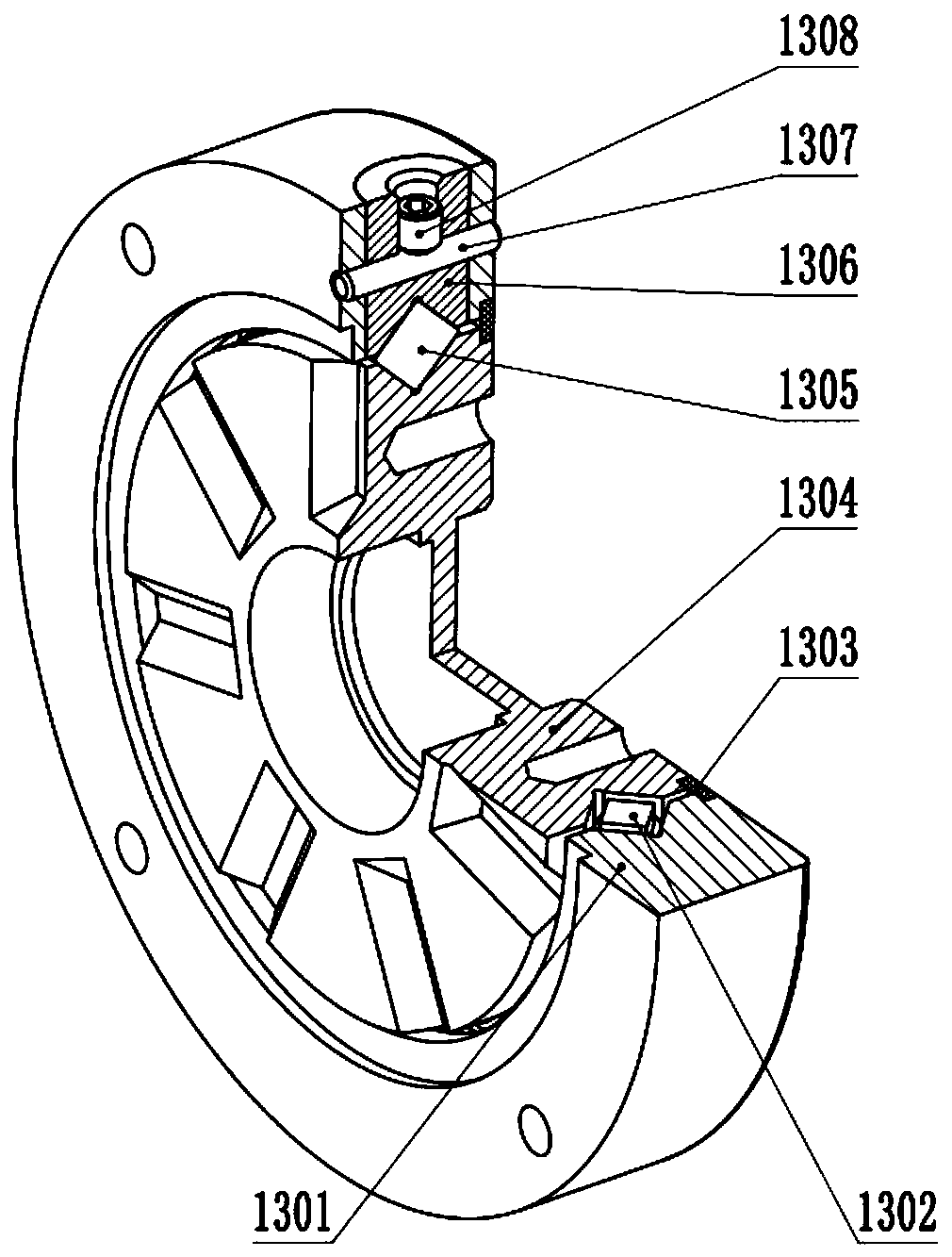

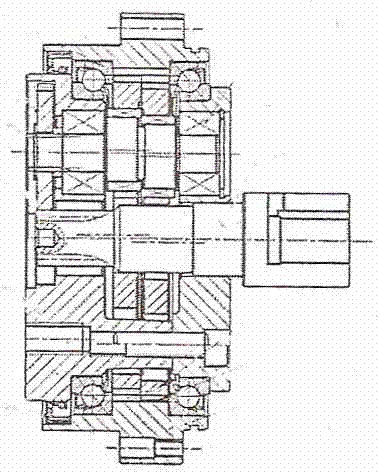

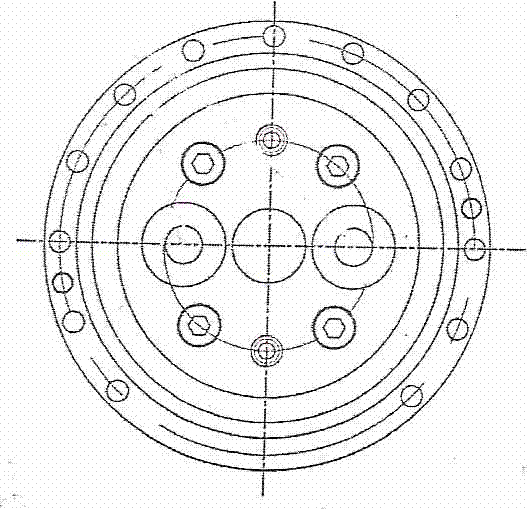

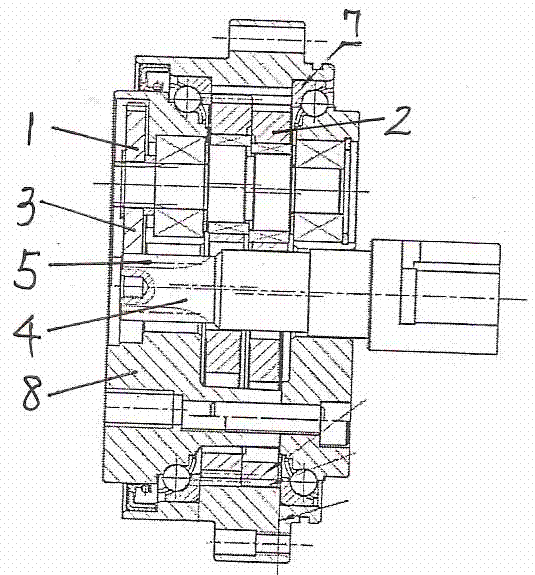

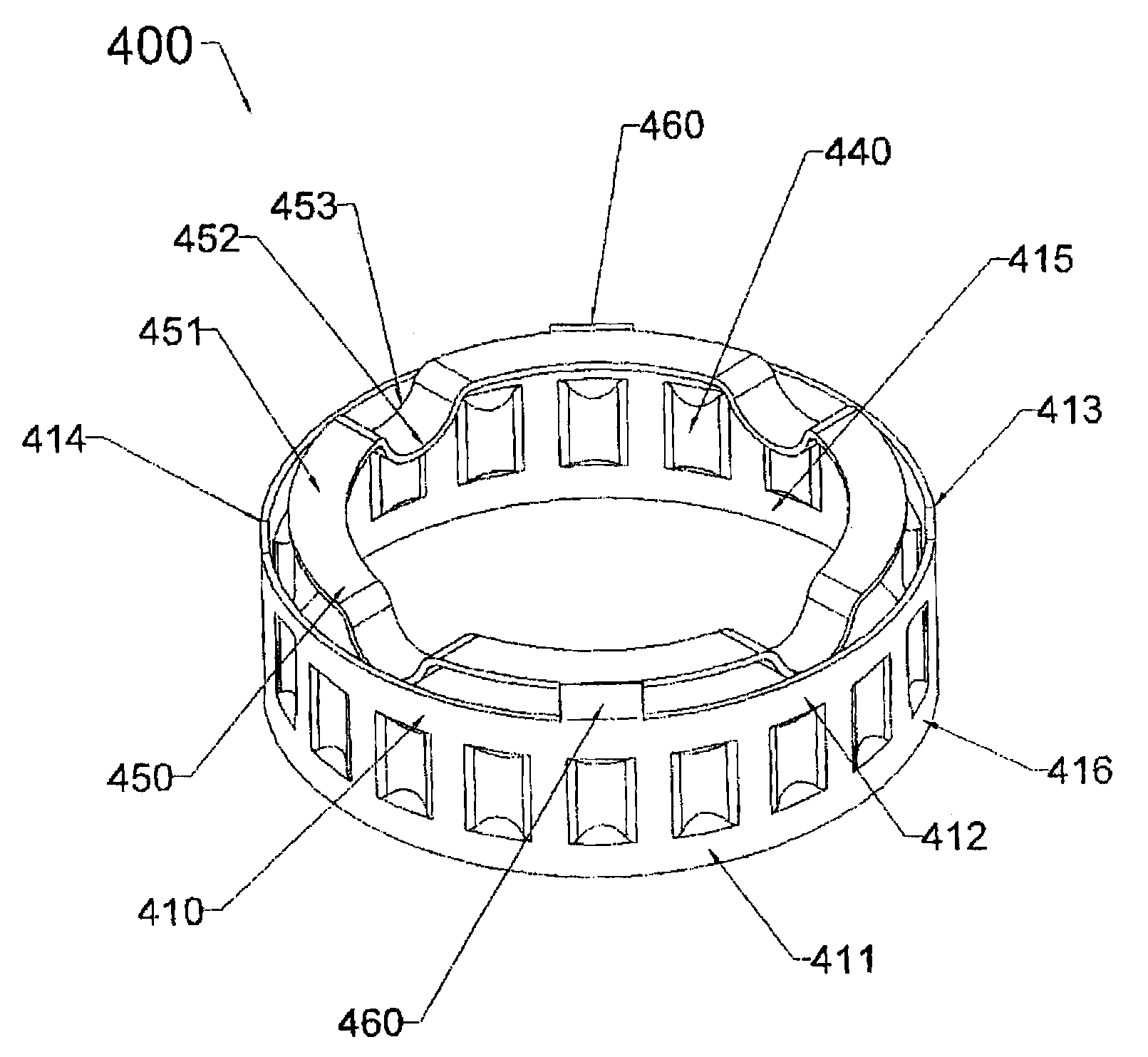

Cam shock wave type two-stage planar steel ball reducer

The invention provides a cam shock wave type double-stage planar steel ball reducer. The cam shock wave type double-stage planar steel ball reducer comprises an input shaft, a lip type sealing ring, aleft end cover, a first-stage center wheel, a first-stage shock wave cam, a first-stage steel ball, a shell, a first thin-wall bearing, a first-stage guide frame, a second-stage center wheel, a second-stage steel ball, a second-stage shock wave cam, a cross roller bearing, a deep groove ball bearing, a sleeve cup, a check ring and a second thin-wall bearing. The first-stage shock wave cam and thesecond-stage shock wave cam are hinged to the corresponding shaft section through the second thin-wall bearing, the right side of the second thin-wall bearing is limited through the check ring, the left end cover is connected to the left end of the first-stage center wheel through screws, the right end of the first-stage center wheel and the shell are fixedly arranged at the left end of the second-stage center wheel through screws, and the cross roller bearing and the right end of the second-stage center wheel are fixedly connected. The cam shock wave type double-stage planar steel ball reducer has the advantages of being simple and compact in structure, high in transmission efficiency, wide in transmission ratio range, large in bearing capacity and the like, can be subjected to parameterization and serialized design and is suitable for wide application.

Owner:YANSHAN UNIV

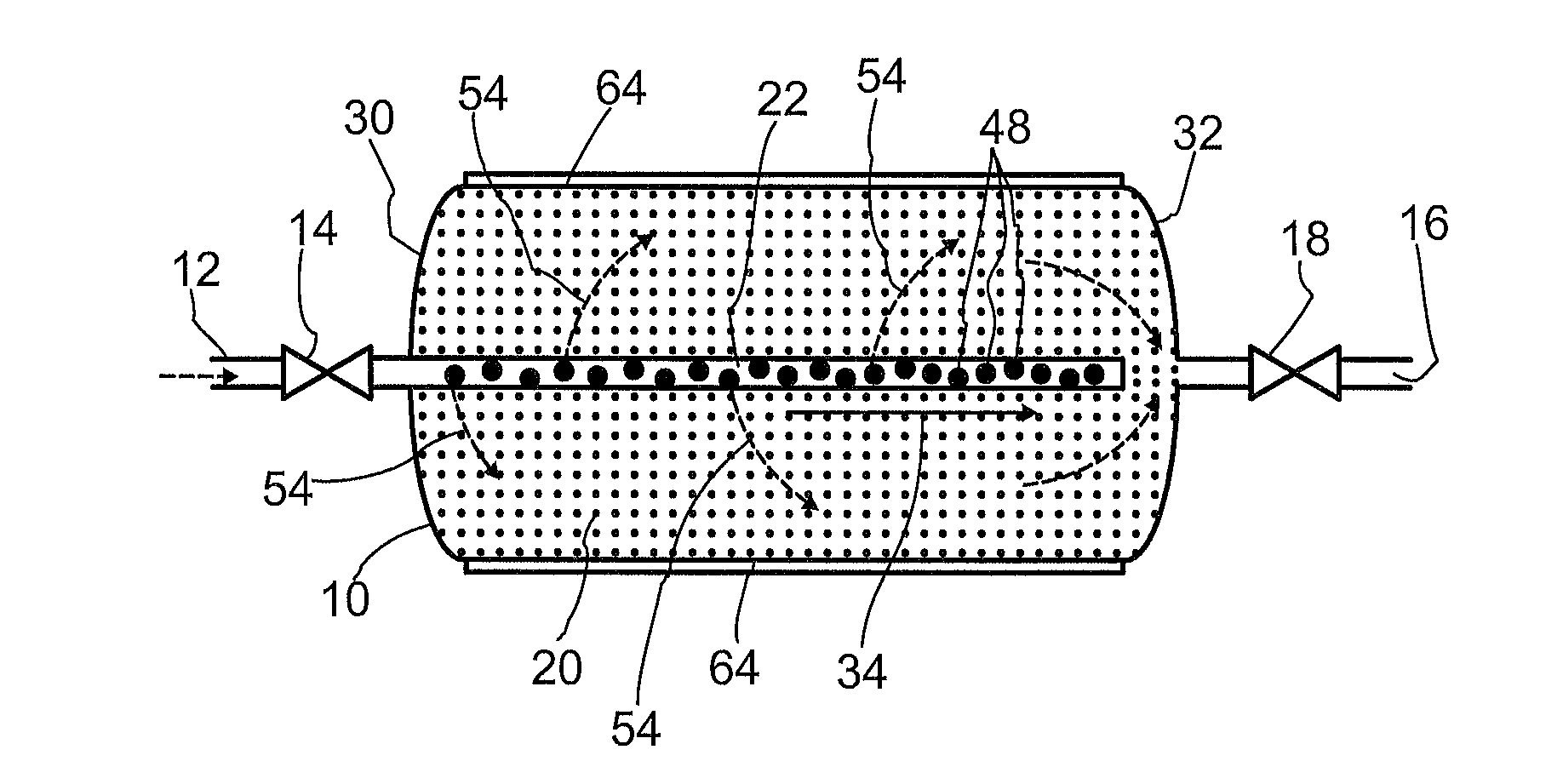

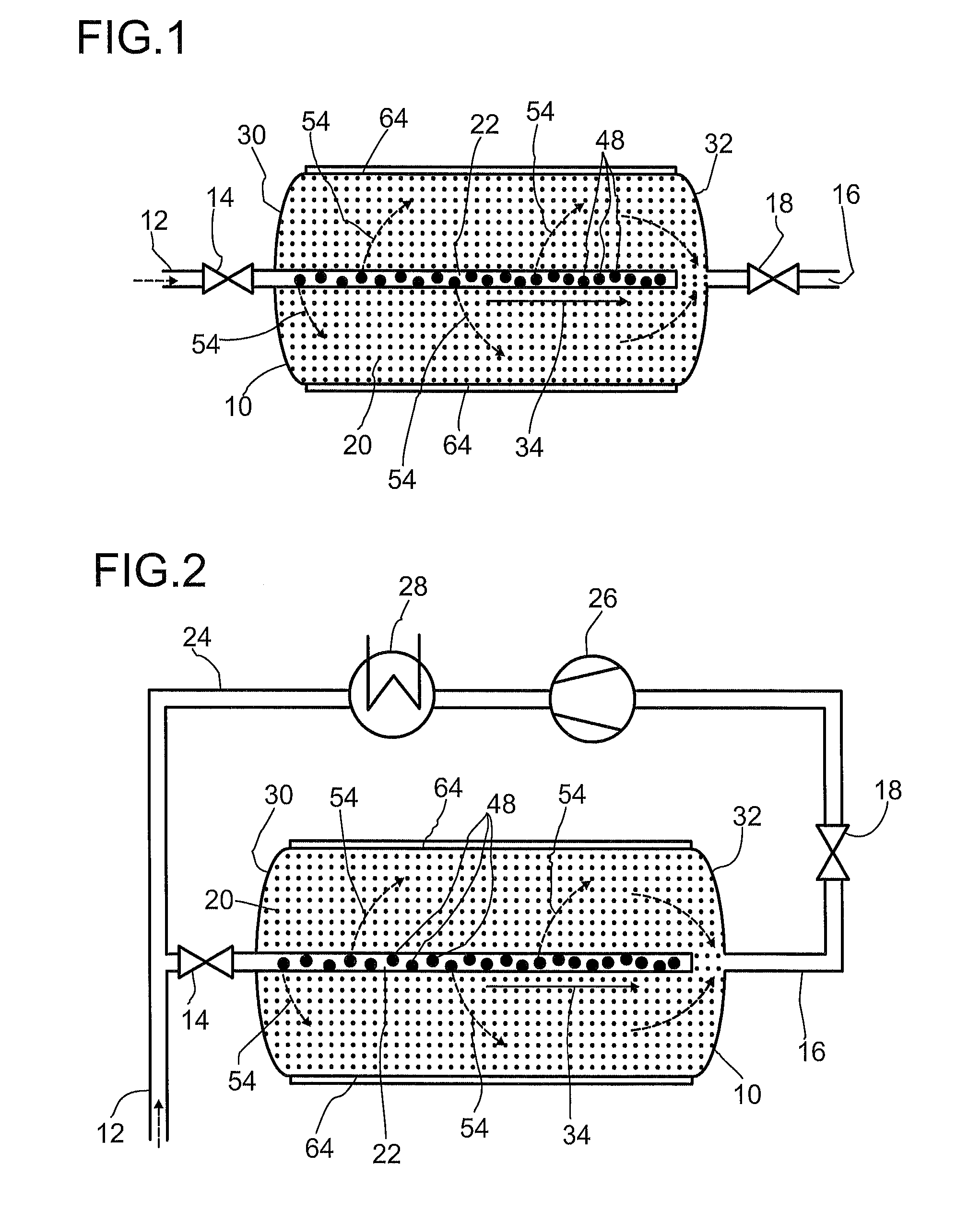

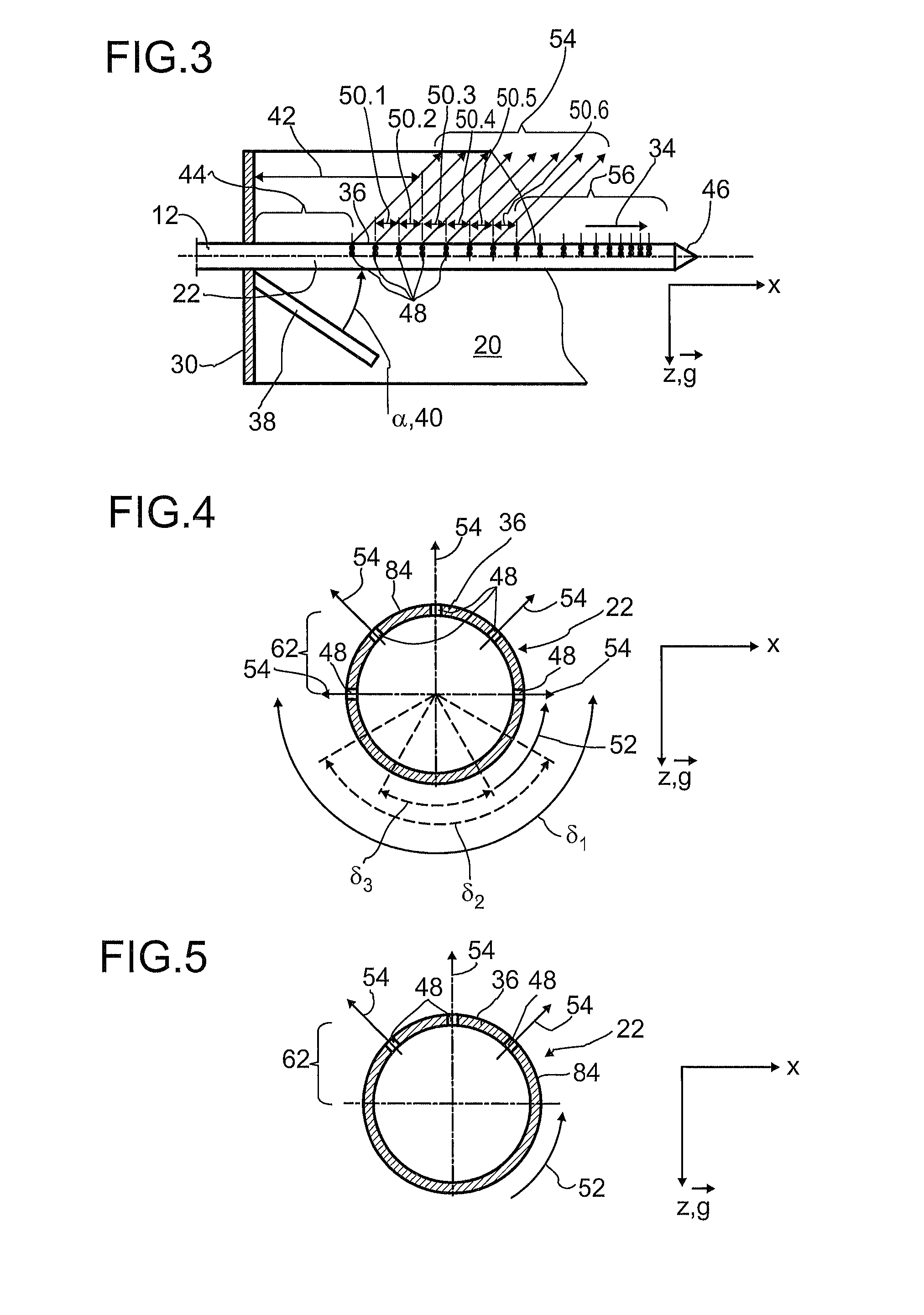

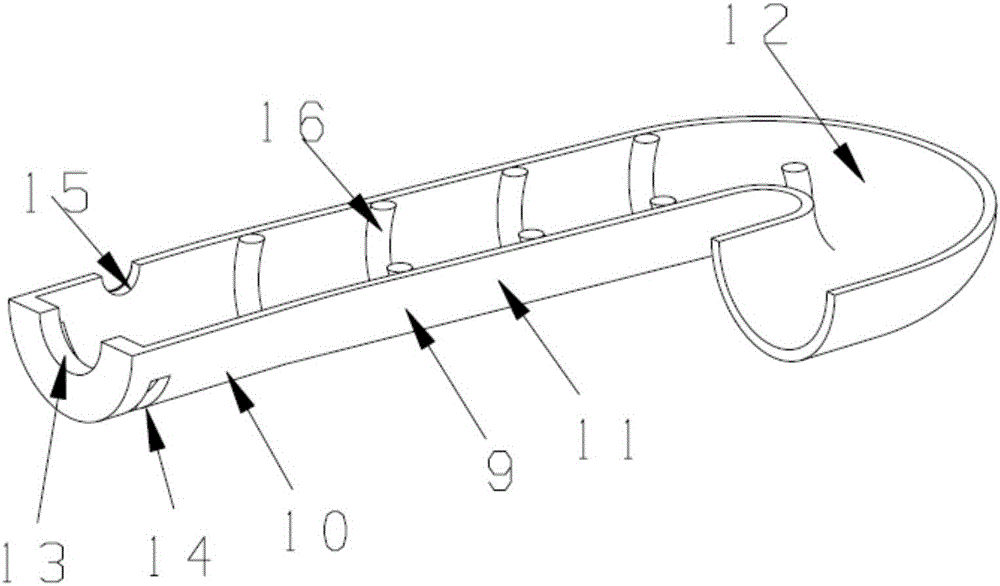

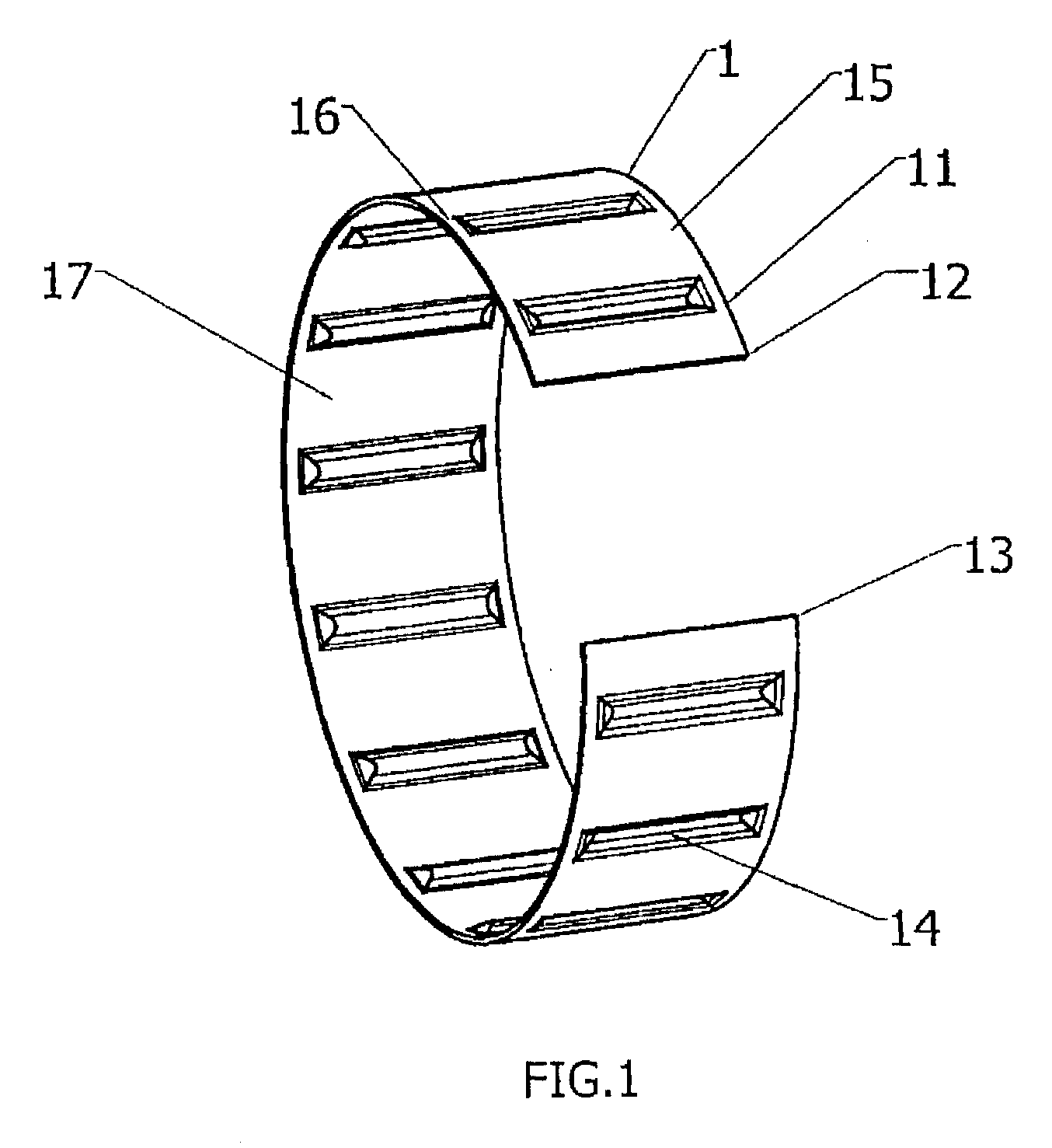

Filling device for a sorption store and sorption store

InactiveUS20160201853A1Duration and storage capacity be enhanceDecrease axial distanceGas handling applicationsFluid handledSorptionBiomedical engineering

Filling device (22) for an ANG-sorption store (10) containing at least one adsorption medium (20), said filling device (22) being of tubular shape, having a mantle (36) defining a hollow interior, orifices (48) in said mantle (36), said ANG-sorption store (10) substantially mounted horizontally, wherein said orifices (48) are arranged on an upper part (62) of said mantle (36) of the filling device (22) extending in axial direction (34) through said ANG-sorption store (10).

Owner:BASF SE

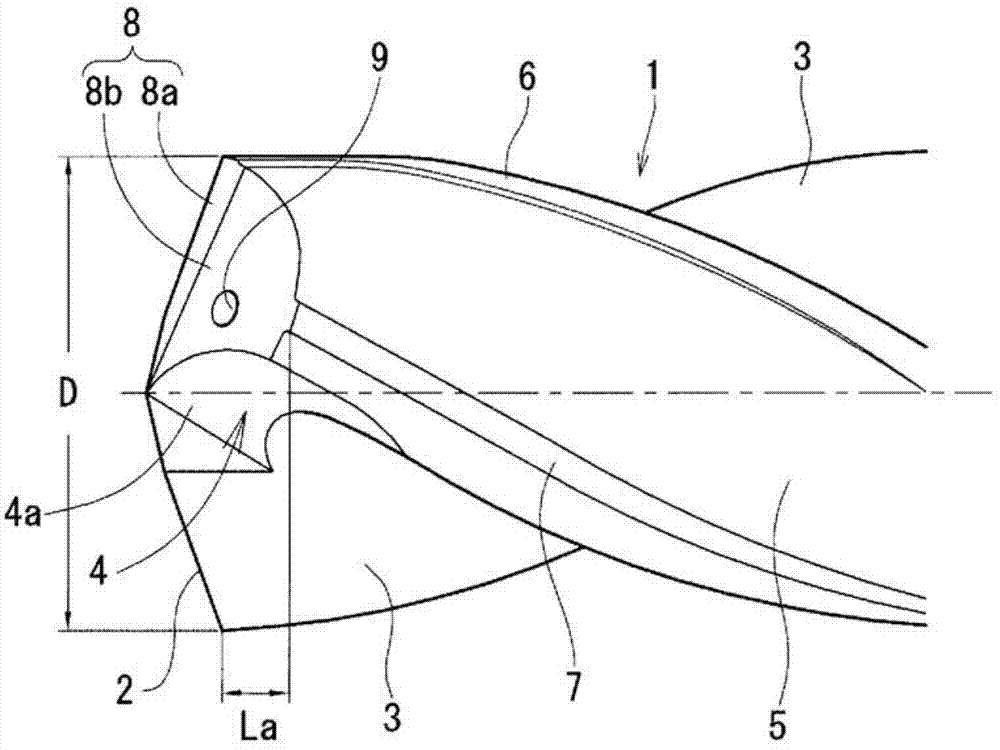

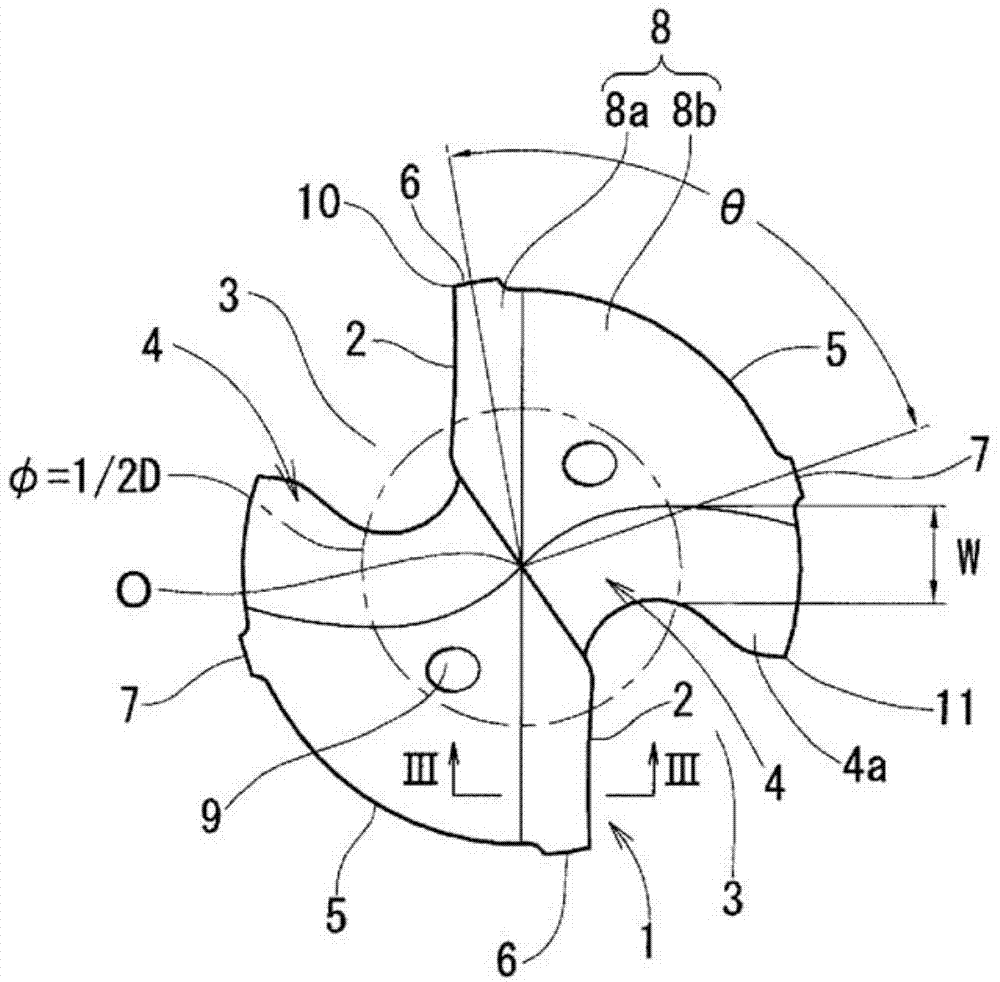

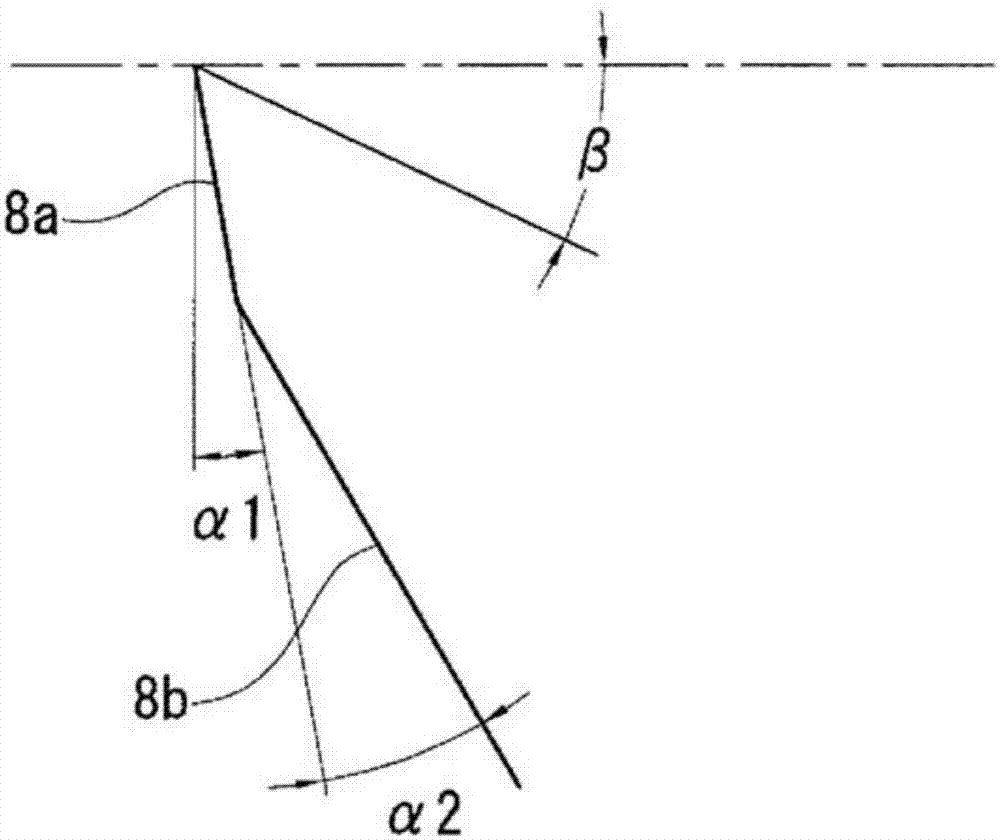

Two-edge double margin drill

ActiveCN104755211APrevent extensionEasy to processTransportation and packagingTwist drillsEngineeringDrill bit

The present invention addresses the problem of making it possible to shorten as much as possible the distance in the axial direction from the primary margin to the secondary margin of a two-edge double margin drill and to keep the interval between the primary margin and the secondary margin within an ideal range. The interval (θ) between the primary margin (6) and the secondary margin (7) provided on the outer circumference of land sections (5) is set to be 80° - 100°. The flanks (8) are configured from a second flank (8a) and a third flank (8b) that are coplanar. Moreover, at the central part of the tip, thinning sections (4) having thinning surfaces (4a) that form convex arcs in the direction of drill rotation in front view of the drill are formed, and the outer edges of the thinning surfaces (4a) in the radial direction are disposed behind the leading end of the secondary margin (7) in the direction of drill rotation and are extended to the circumference of the land sections (5).

Owner:SUMITOMO ELECTRIC HARDMETAL CORP

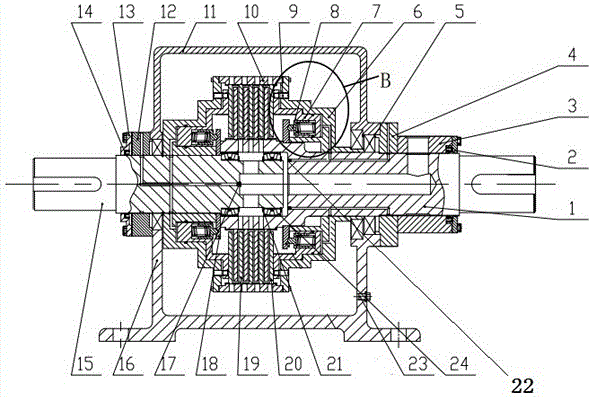

Two-way-controlled liquid viscosity speed regulation clutch

InactiveCN105937565AImprove transmission efficiencyShorten the axial distanceFluid clutchesLiquid viscosityDrive shaft

The invention discloses a two-way-controlled liquid viscosity speed regulation clutch comprising a transmission mechanism, a control mechanism and a box body. Control oil ways are arranged in a driving shaft and a driven shaft and do not communicate with an axial lubricating oil pipe of the driving shaft; a first radial oil way in a driving shaft transparent cover communicates with the first axial oil way of the driving shaft; a second radial oil way in the driving shaft transparent cover communicates with the second axial oil way of the driving shaft and a third radial oil way in a first piston cylinder; and a first radial oil way in a driven shaft transparent cover communicates with the first axial oil way of the driven shaft and a second radial oil way in a third piston body cylinder. According to the two-way-controlled liquid viscosity speed regulation clutch, the control oil ways are arranged in the driving shaft and the driven shaft, pipelining is omitted, the structure is compact, the part volume is reduced, and the integration degree is high. Besides, a ball head plunger reset mechanism is adopted, abrasion is reduced, and the service life of a workpiece is prolonged.

Owner:JIANGSU UNIV

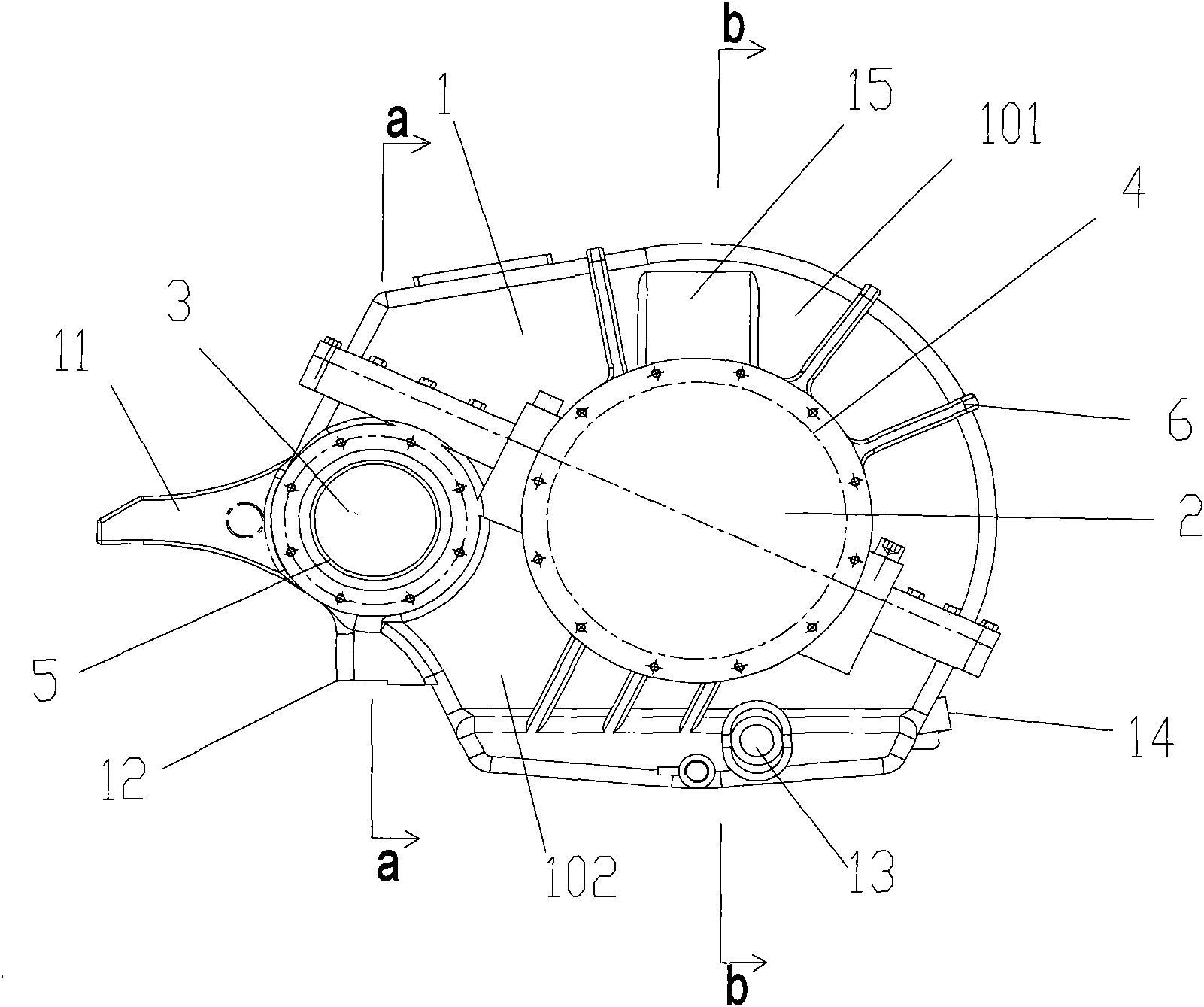

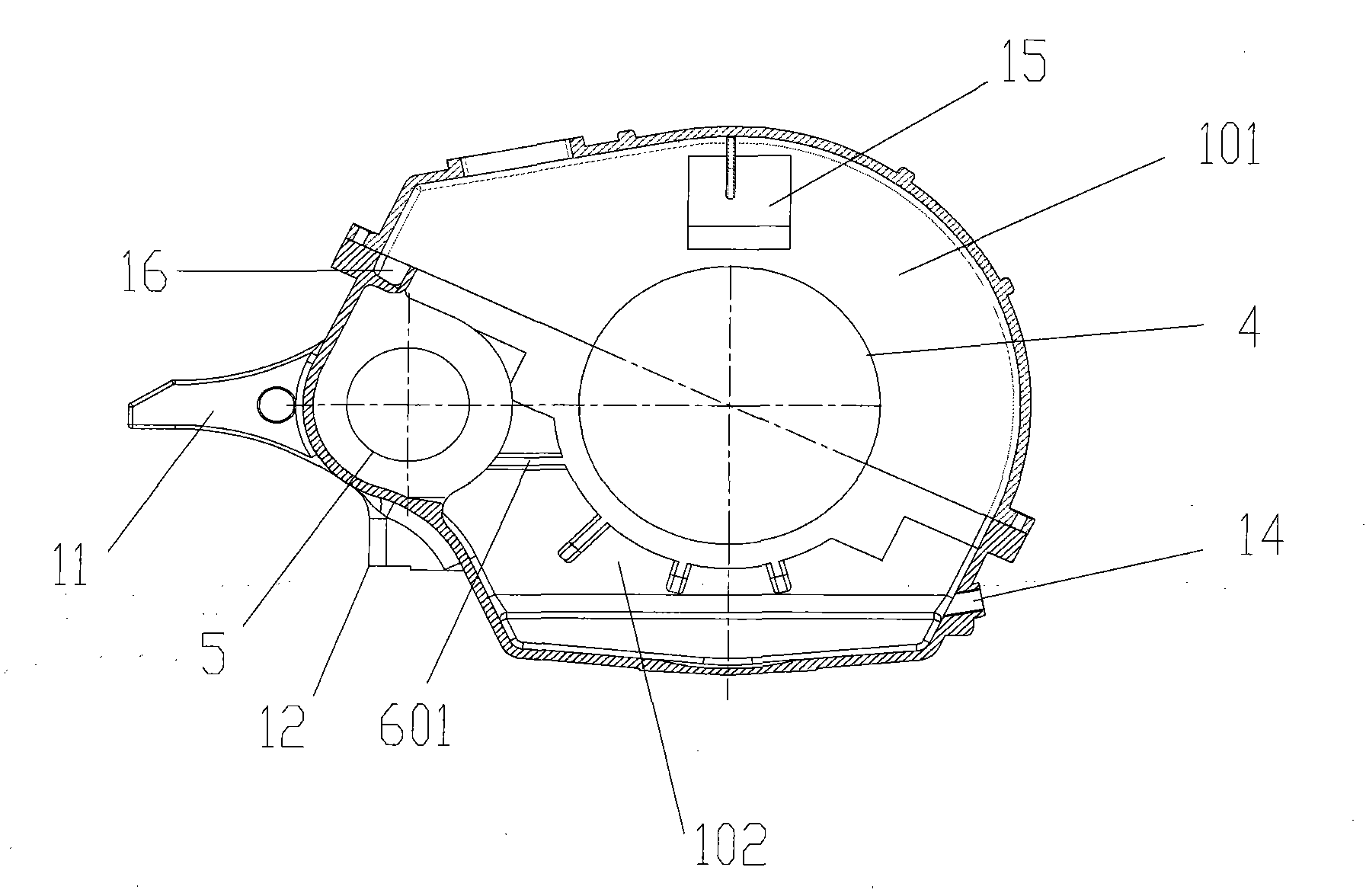

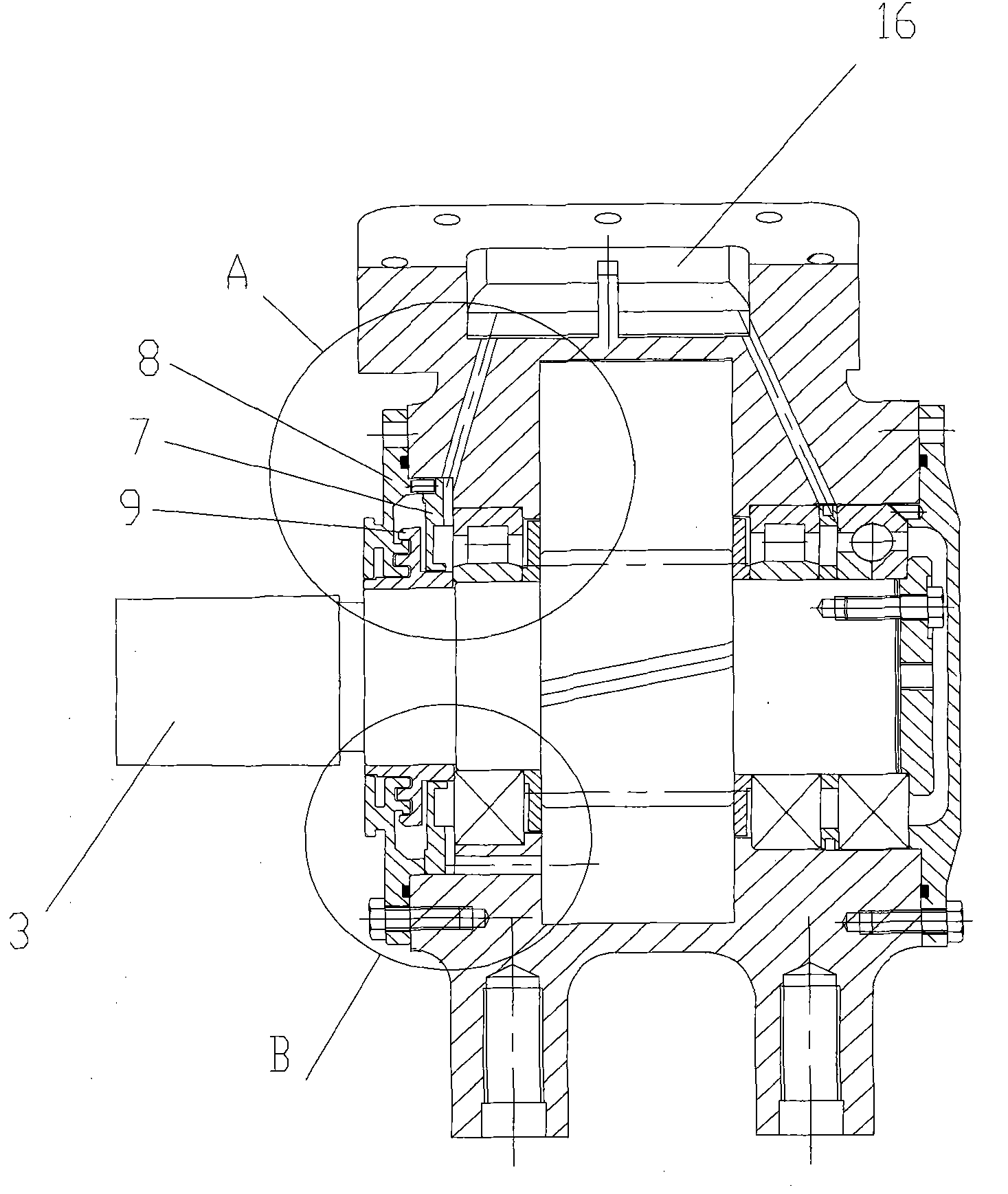

Gear case used for rail traffic vehicle

ActiveCN101806350AReduce displacement differenceGuaranteed normal operationGearboxesGearing detailsGear wheelEngineering

The invention relates to a gear case used for a rail traffic vehicle, which comprises a case body, an output shaft and an input shaft, wherein the case body is respectively provided with an axle bearing pedestal and an input shaft bearing pedestal from front to back; the output shaft and the input shaft are connected by a gear; the joint portion of the shaft and the case body is provided with a labyrinth oil seal. The case body comprises an upper case body and a lower case body; a joint surface between the upper case body and the lower case body passes through the axial lead of the axle bearing pedestal; the joint surface is obliquely arranged; the end surface of the lower case body is provided with a safety nose; and the bottom end of the end surface of the lower case body is provided with a torsion bar connecting point. The original horizontal arrangement of the joint surface is changed into oblique arrangement, and thus, enough space can be reserved for the arrangement of a torsion bar. Meanwhile, the end surface of the lower case is provided with the safety nose. When the torsion bar on the gear case is broken, the normal operation of the gear case can be ensured by preventing the rotation of the gear case. Moreover, the bottom end of the end surface of the lower case body is provided with the torsion bar connecting point. The arrangement of the torsion bar can reduce the displacement errors of the centers of the input shaft and motor shaft of the gear case in operation.

Owner:南京高精轨道交通设备有限公司

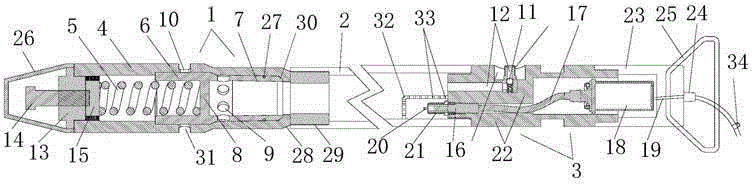

Carbon dioxide exploder

The invention discloses a carbon dioxide exploder, and belongs to the technical field of exploding devices. The carbon dioxide exploder comprises an energy relief valve, a main body pipe and a start mechanism. The energy relief valve and the start mechanism are fixed to the two ends of the main body pipe respectively. The energy relief valve comprises an energy relief valve sleeve, an energy relief valve element and a spring. The energy relief valve element is in a ladder cylinder shape with the two ends being open. The exploder comprises a compression cylinder with the large outer diameter and an energy relief cylinder with the small outer diameter. A partition plate is arranged between the compression cylinder and the energy relief cylinder. Correspondingly an inner cavity of the energy relief valve sleeve is a ladder-shaped inner cavity. One end of the energy relief valve sleeve is connected with the main body pipe in a sealed mode. The spring is arranged in the energy relief valve sleeve. One end of the spring enters the compression cylinder. Energy relief inner holes are formed in the energy relief cylinder in the peripheral direction. Energy relief outer holes are formed in the middle of the energy relief valve sleeve in the peripheral direction. By the adoption of the high-tension ignition exploder and the energy relief valve capable of achieving automatic reset, relighting and repeat energy relief can be achieved conveniently and fast.

Owner:湖南烈岩科技有限公司

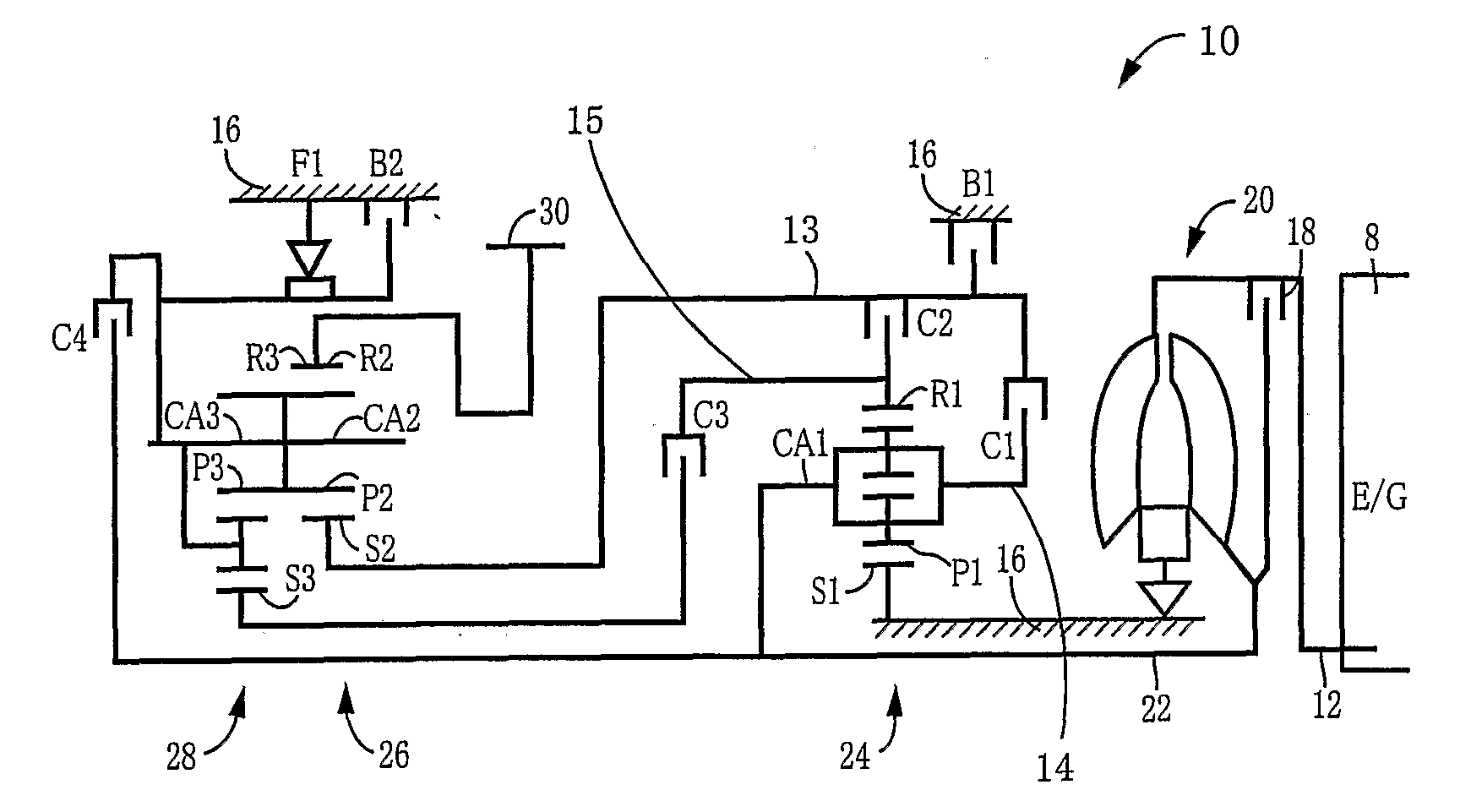

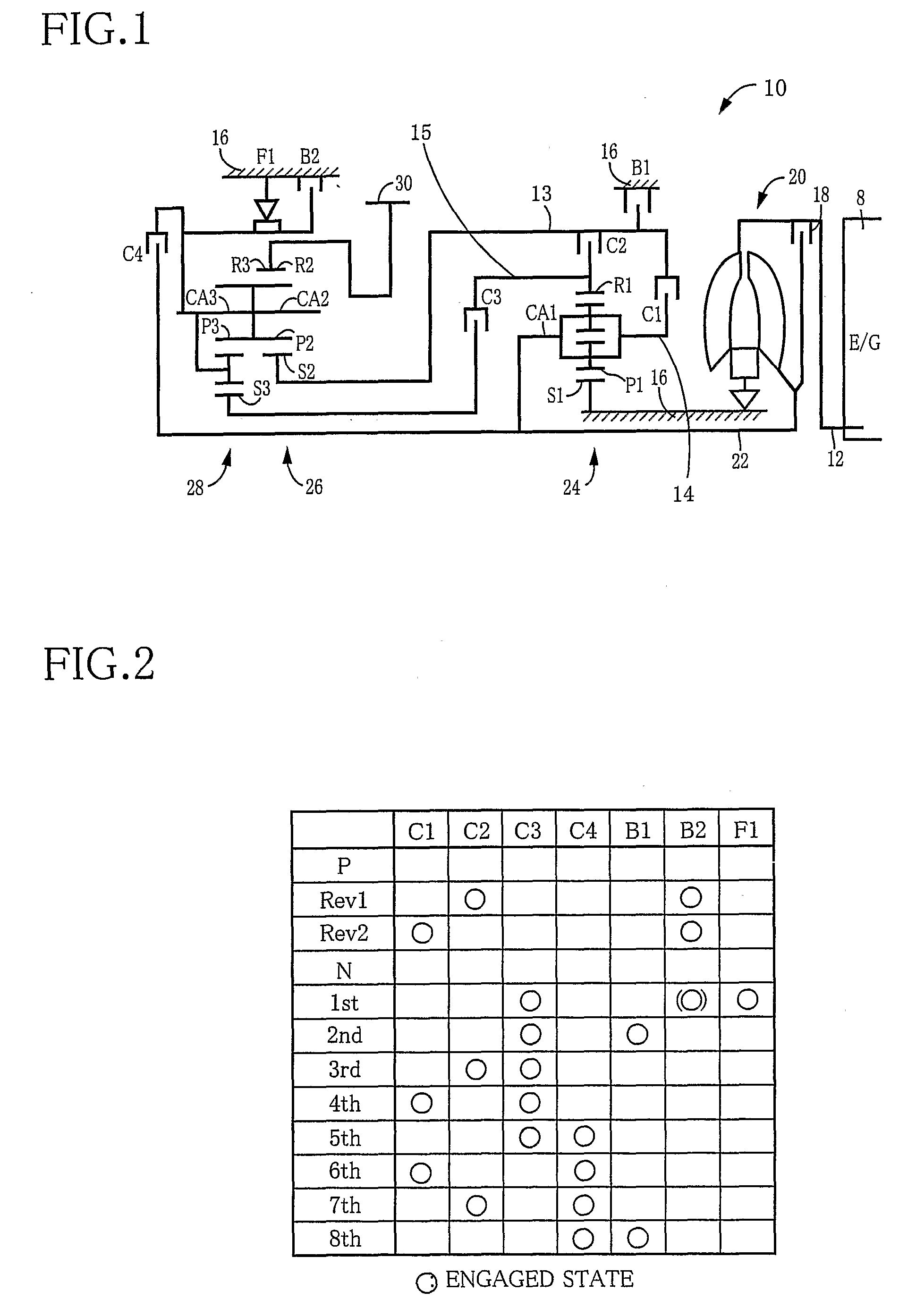

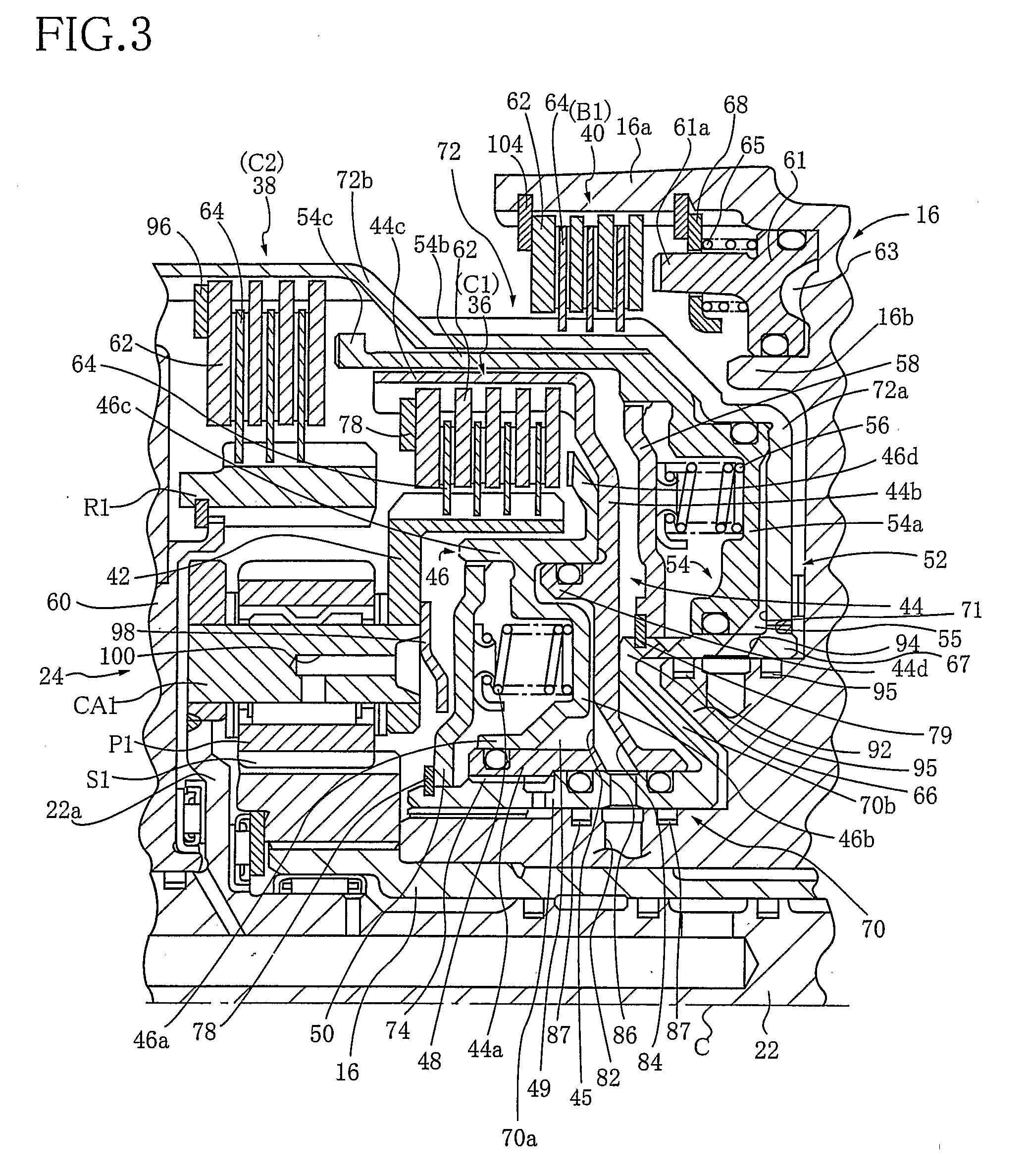

Automatic transmission including clutch devices

InactiveUS20090020386A1Low costPrevent rotationFluid couplingsGearboxesAutomatic transmissionEngineering

An automatic transmission including a first clutch selectively connecting a first rotary member and a second rotary member disposed coaxially with the first rotary member, a second clutch selectively connecting the first rotary member and a third rotary member disposed coaxially with the first rotary member, a first drum in which a first piston of the first clutch is axially slidably received, a second drum disposed coaxially with the first drum, to accommodate the first drum, and in which a second piston of the second clutch is axially slidably received, an abutting portion abutting contact of the first and second drums with each other in an axial direction of the first and second drums, and a fitting portion at which the first drum is fitted in the second drum and that inhibits relative rotation of the first and second drums about a common axis of the first and second drums.

Owner:TOYOTA JIDOSHA KK

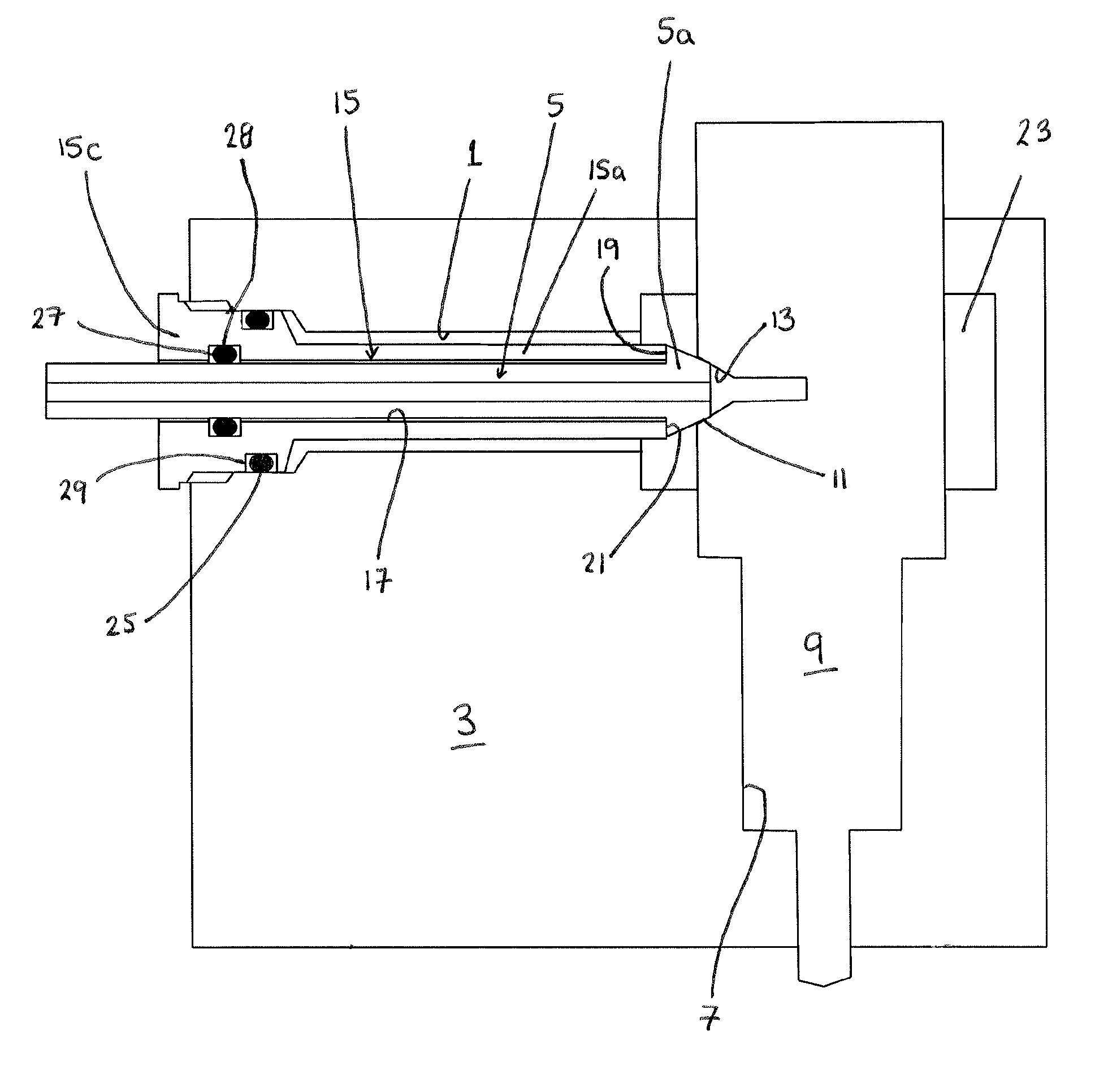

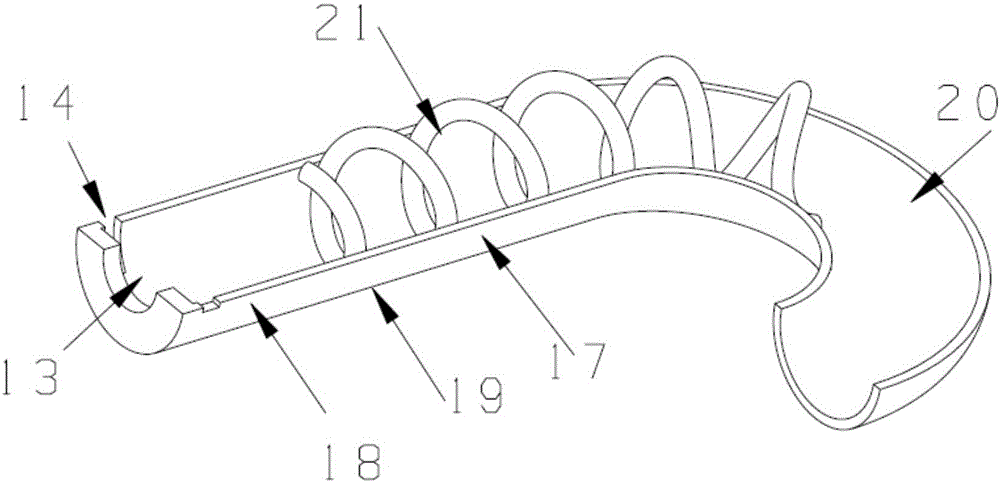

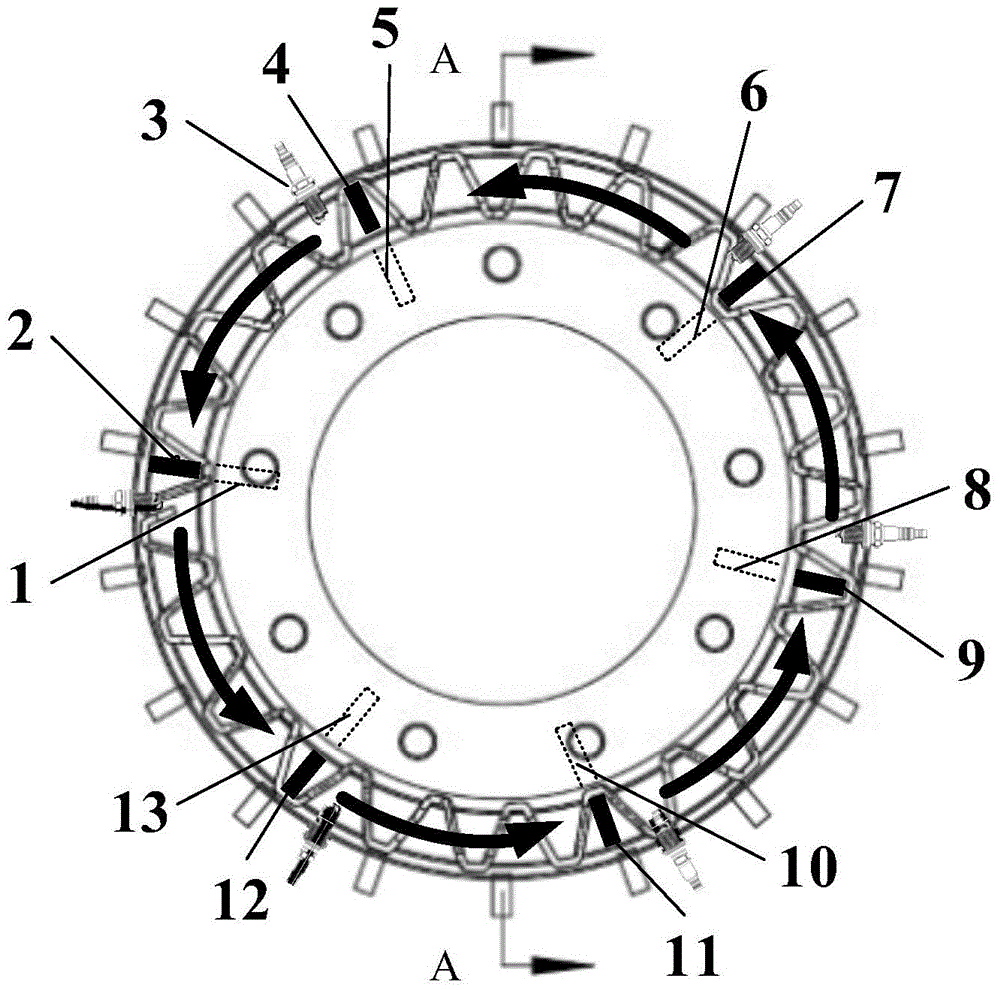

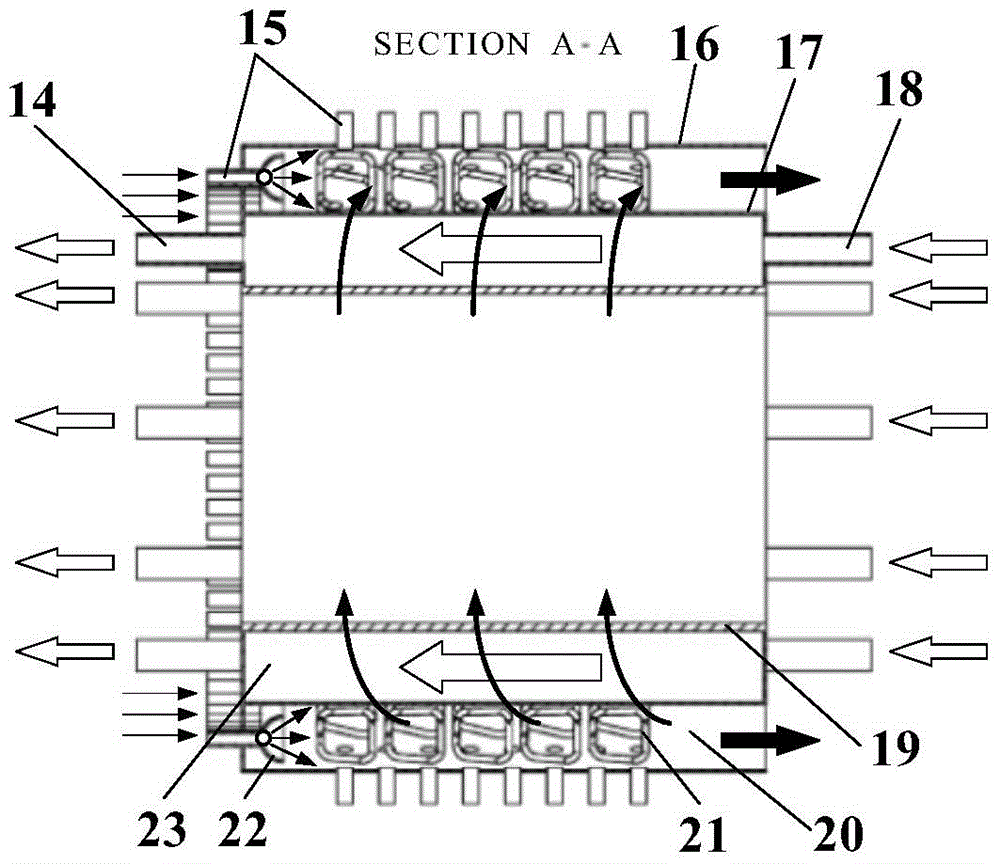

Reverse-flow type pulse detonation combustor

ActiveCN105972638AShorten the axial distanceExtended use timeContinuous combustion chamberCombustion chamberFuel gas

The invention provides a reverse-flow type pulse detonation combustor. The reverse-flow type pulse detonation combustor comprises a diffusion case, an outer combustor case, an inner combustor case, a combustor head case, a vortex guide unit, an oil nozzle, an electric spark, a fuel gas shaping chamber, a J-type reverse-flow detonation tube and a Shchelkin threaded strengthening device. An axial main air intake hole and a radial auxiliary air intake hole are formed in the air intake mixing section of the head portion of the J-type reverse-flow detonation tube, and the air intake mixing section is connected with the outer combustor case through an ignition base. The bent air exhaust section on the tail of the J-type reverse-flow detonation tube is fixed in a mounting hole in the inner combustor case and connected with the fuel gas shaping chamber. The vortex guide unit is installed behind the fuel gas shaping chamber. The axial distance of the detonation combustor can be decreased through the bent air exhaust section, the influence of detonation feedback is reduced through the volume between an inner sleeve and an outer sleeve of the combustor, air is preheated through the bent exhaust section so that combustible materials are mixed more sufficiently, and detonation combustion is made to be organized more easily.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

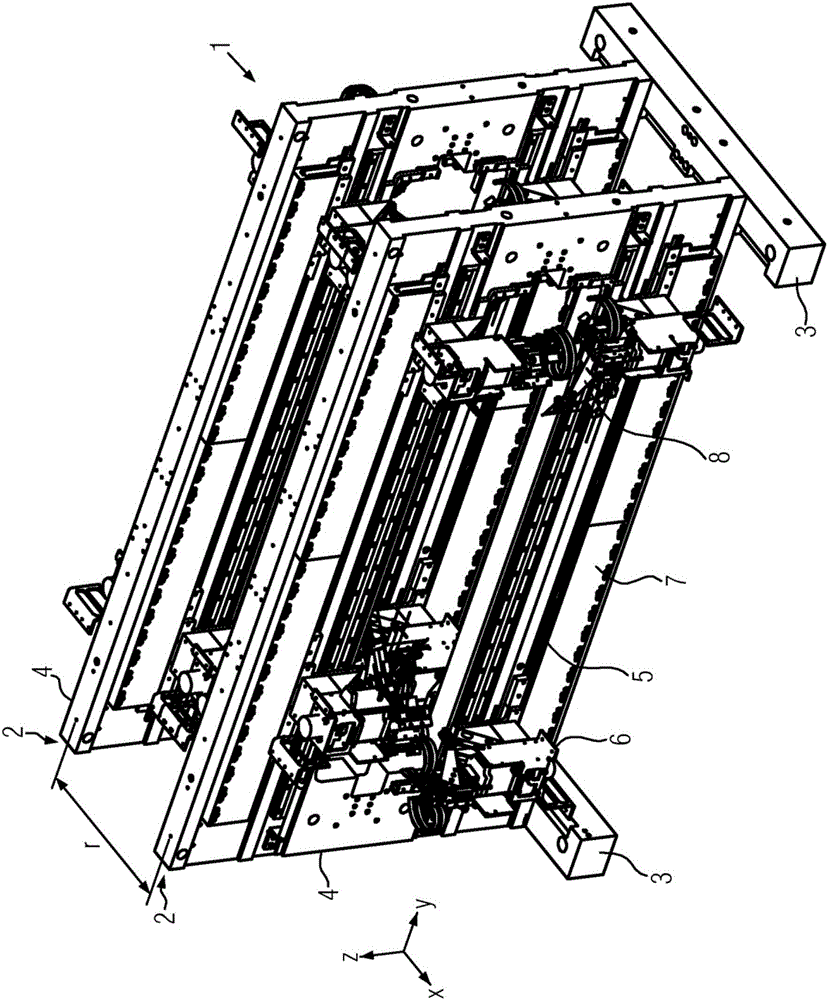

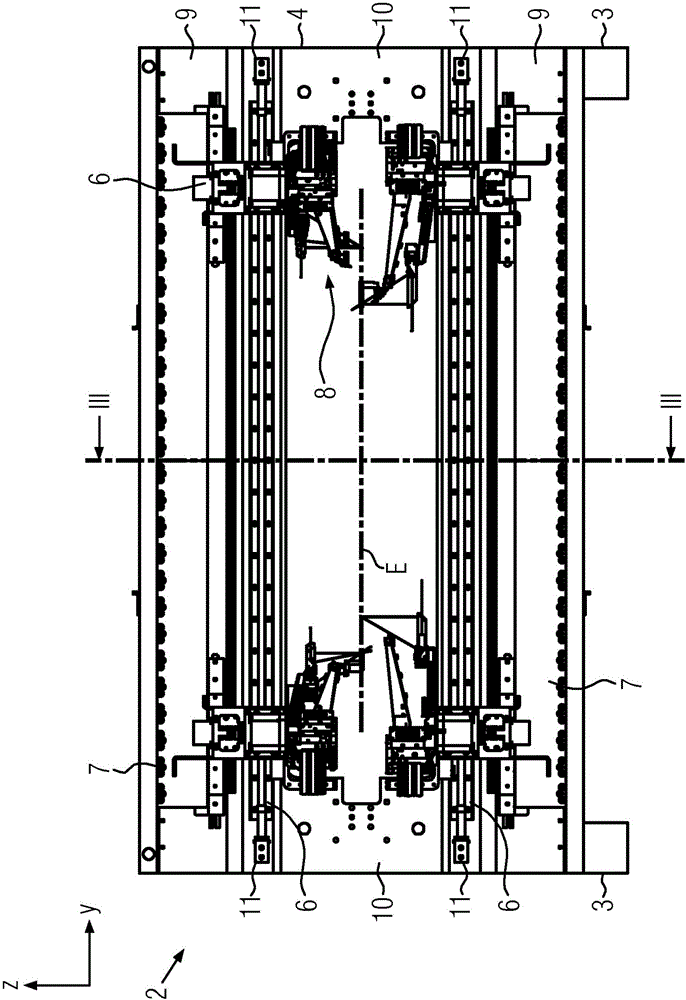

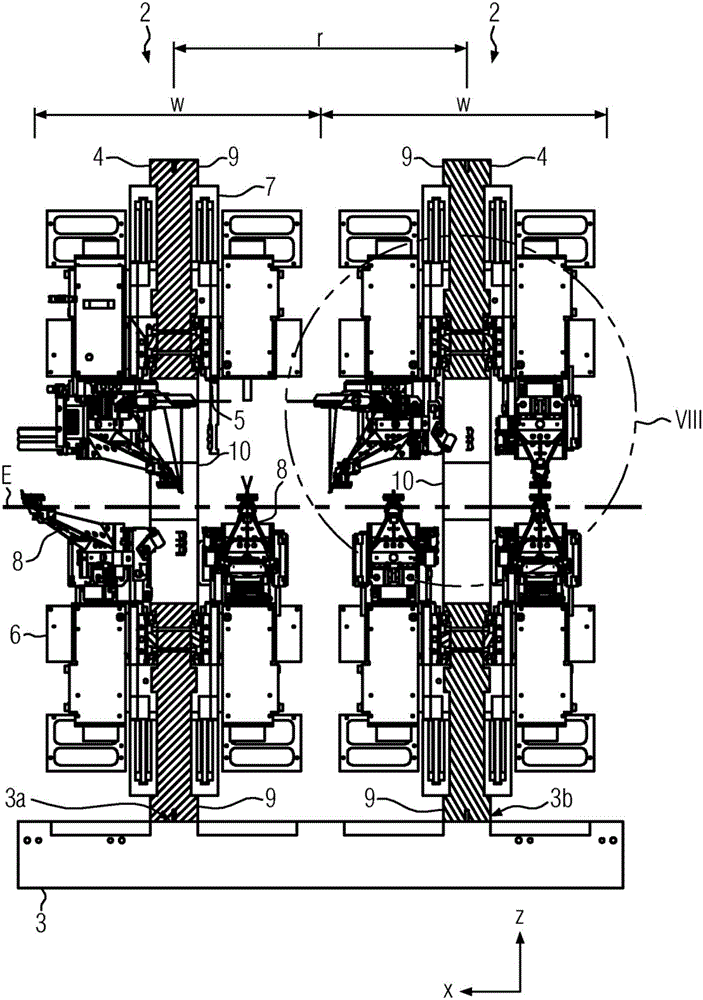

Crossmember unit for a test apparatus for printed circuit boards, and test apparatus having said crossmember unit

ActiveCN105074476AIncrease productionHigh speedElectrical measurement instrument detailsPrinted circuit testingEngineeringTest fixture

The invention relates to a crossmember unit (2) for a test apparatus (1) for printed circuit boards, wherein the crossmember unit (2) has at least one crossmember (9), which spans a test area in which a printed circuit board to be tested can be arranged, and is designed to receive positioning units (6) for test fingers (8) in a linearly movable manner in such a way that the test fingers (8) can scan at least a portion of the test area. According to the invention, the crossmember unit (2) is designed to receive at least two linear guides (5), which are independent of one another, for guiding in each case at least one of the positioning units (6). The invention is also directed to a test apparatus (1) having at least one crossmember unit (2) of this kind.

Owner:ATG路德迈股份有限公司

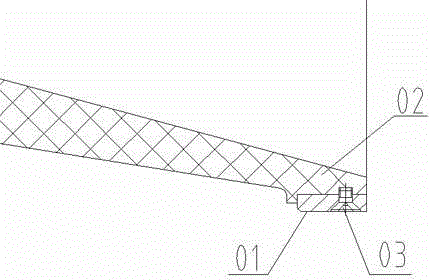

Sealing structure of exhaust nozzle outlet of solid rocket engine

ActiveCN104696109AIncreasing the thicknessHigh working reliabilityRocket engine plantsInsulation layerEngineering

The invention discloses a sealing structure of an exhaust nozzle outlet of a solid rocket engine. The sealing structure comprises a tail ring and a diffuser insulation layer, wherein the diffuser insulation layer is located on the external surface of an exhaust nozzle; the diffuser insulation layer and the tail ring are fixed via screws; a bottom groove is formed in a radial direction of the tail ring; and the bottom groove is used for placing a sealing ring for realizing sealing between a diffuser and a steering engine room, so that a cabin is sealed. The sealing structure of the exhaust nozzle outlet of the solid rocket engine fully uses the overall given external structure dimension, so that the thickness of the insulation layer at the outlet is increased, and the working reliability of the exhaust nozzle is improved; and sealing is effectively performed, flame at the exhaust nozzle outlet and the steering engine room are isolated and equipment in the steering engine room is protected for the overall proposed consumable jet vane design.

Owner:SHANGHAI XINLI POWER EQUIP RES INST

Centrifugal fan

InactiveUS9074604B2Reduced size and axial dimensionIncrease static pressurePump componentsStatorsImpellerCentrifugal fan

Owner:NIDEC CORP

Variable-Elastomer Semi-Active Damping Apparatus

InactiveUS20120261869A1Shorten the axial distanceReduce the cross-sectional areaSpringsResilient suspensionsSemi activeElastomer

A variable semi-active damping assembly comprising a shock body defining a fluid-filled chamber; a piston tube having a first end slidably disposed within the shock body; an inner rod slidably disposed within the piston tube and the shock body, the inner rod having a first end connected to a lower piston mount and a second end extending outward from the piston tube and engaging an adjustment mechanism that is configured to move the inner rod with respect to the shock body; an upper piston mount slidably disposed within the shock body and connected to the piston tube; and a deformable member disposed between the lower piston mount and the upper piston mount, the deformable member being configured to transition between a compressed state and a non-compressed state in response to movement by the lower piston mount.

Owner:RODENBECK PHILLIP D

Novel hydro-viscous transmission device

InactiveCN103075449AIngenious ideaSimplify the assembly processLiquid resistance brakesCoupling-brake combinationStatic frictionPiston

The invention discloses a hydro-viscous transmission device, which comprises a box body, a speed regulating mechanism and a braking mechanism, wherein the speed regulating mechanism comprises a speed regulating shaft, a speed regulating shaft transparent cover, a driving friction plate, a driven friction plate, a driven drum, a driven disc, a first piston cylinder, a third piston cylinder and a first control oil pipe, and the braking mechanism comprises a braking shaft, a braking shaft transparent cover, a movable friction plate, a static friction plate, a braking drum, a braking disc, a second piston cylinder, a fourth piston cylinder, a second control oil pipe and a third control oil pipe. The hydro-viscous transmission device has the advantages that the ingenious structure is adopted, the design is simple and reasonable, a stepless speed regulation function of a hydro-viscous speed regulating clutch and a braking speed reduction function of a hydro-viscous brake can be simultaneously realized on a set of device, in addition, the work speed regulating performance and the service life of the device can be obviously improved and prolonged, and the hydro-viscous transmission device is particularly suitable for occasions that a high-power work machine simultaneously needs two kinds of work conditions of speed regulation and braking.

Owner:ZHEJIANG UNIV

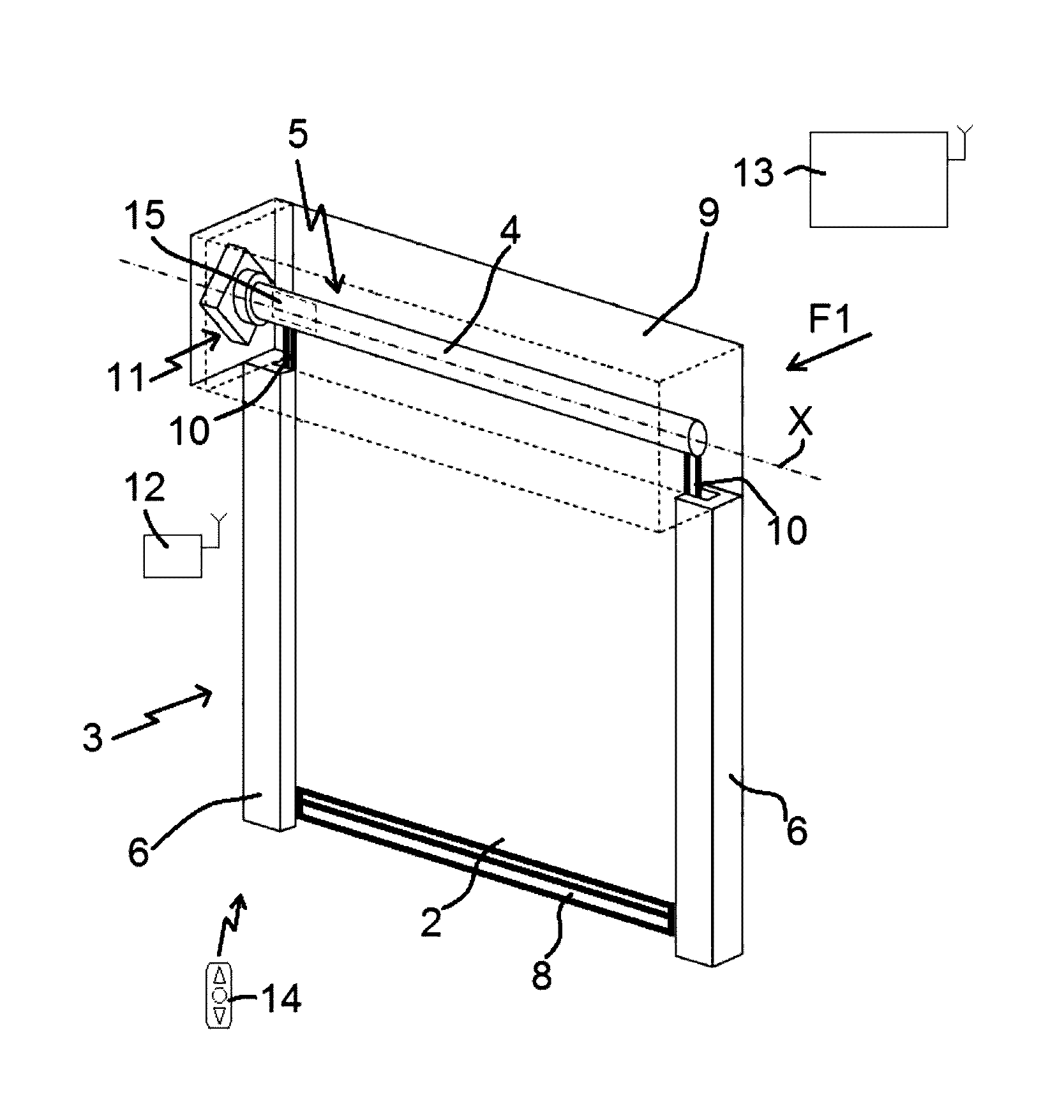

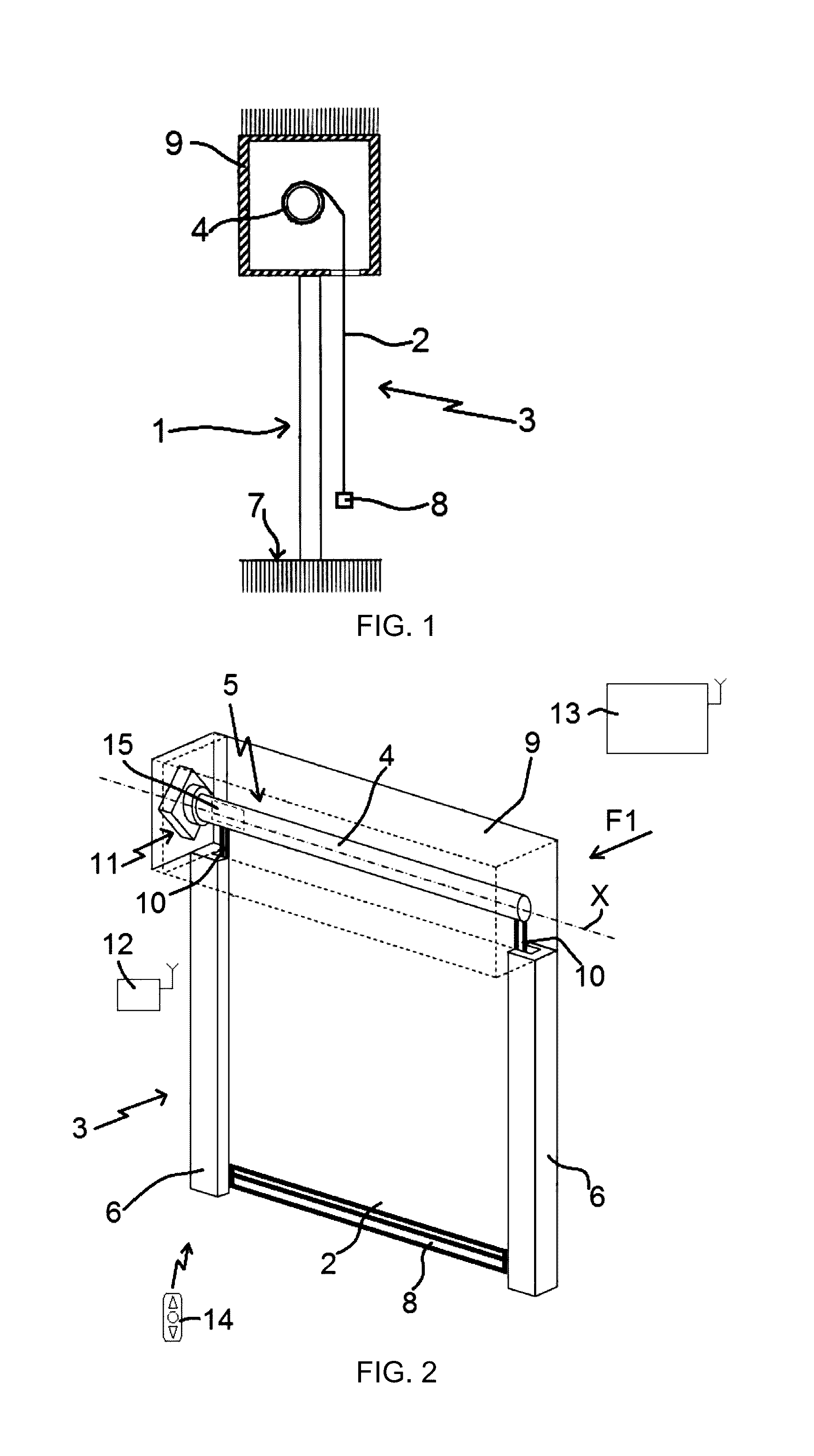

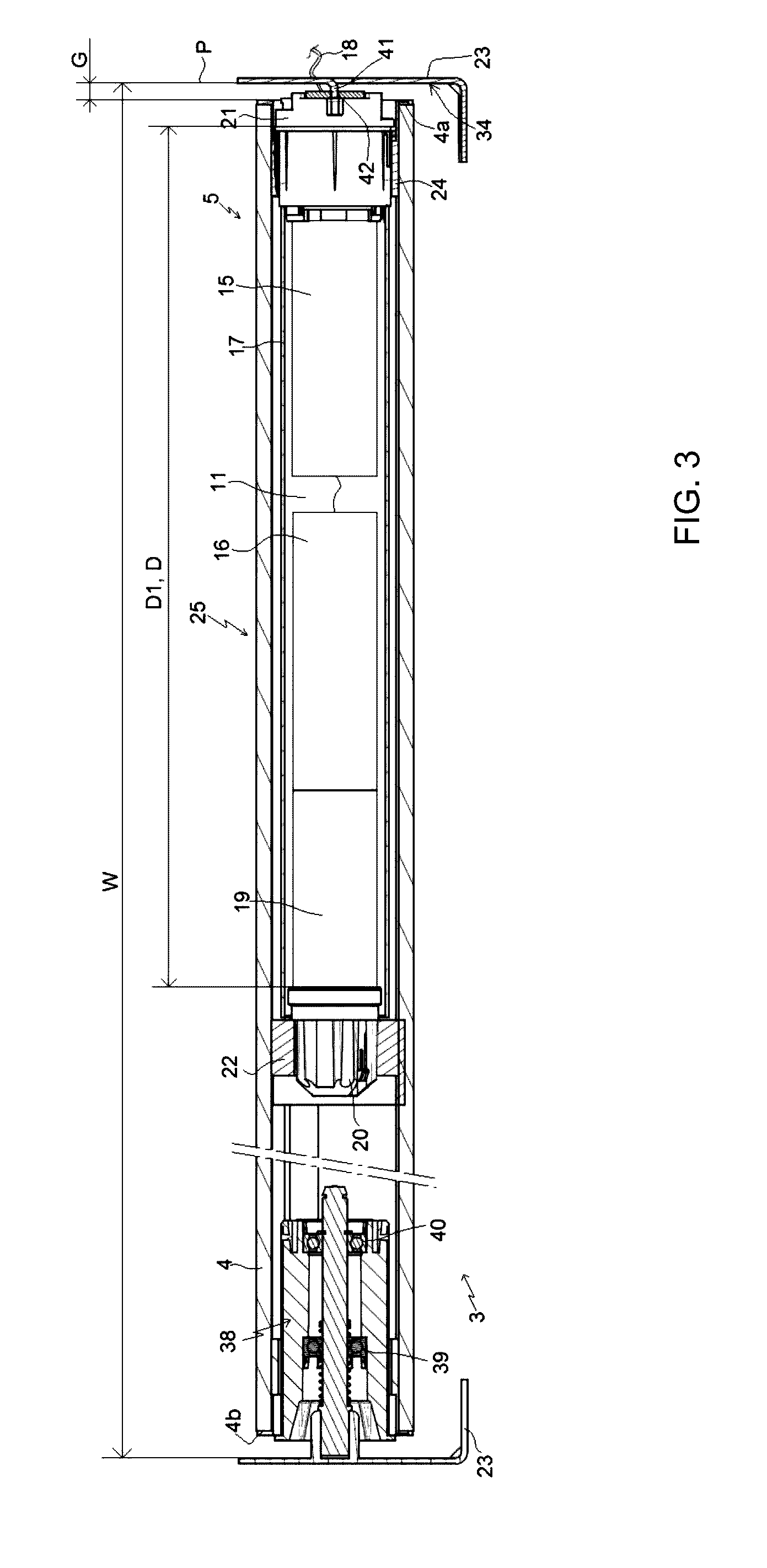

Winding device for a windable screen and closure or sun-protection home-automation installation including such a device

ActiveUS20160376842A1Reduce distanceSpace minimizationLight protection screensPower-operated mechanismSun protectionEngineering

A winding device for a windable screen of a closure or sun-protection home-automation installation, includes: a winding tube movable around a rotation axis; a hollow sleeve positioned at one of the two ends and inside the winding tube; a tubular electromechanical actuator inserted inside the hollow sleeve; and two supports, each support being positioned across from one of two ends of the winding tube. The tubular electromechanical actuator includes: a case, and a closing off element positioned at one end of the case. The closing off element has a front face positioned in a plane parallel to a wall of one of the two supports, and includes first fastening elements cooperating with second fastening elements of the support. The hollow sleeve includes a first stop cooperating with a stop of the closing off element, and a second stop cooperating with the end of the winding where the sleeve is inserted.

Owner:SOMFY ACTIVITES SA

High-performance structure RV reduction machine

InactiveCN104712710AReasonable structureExtended service lifeToothed gearingsTransmission elementsEngineeringCycloid

The invention discloses a high-performance structure RV reduction machine. The high-performance structure RV reduction machine comprises a one-level planet speed reducing mechanism, a two-level cycloid speed reducing mechanism and an angular contact bearing. A planet gear of the one-level planet speed reducing mechanism is meshed with a center gear at one end of an input shaft. The one-level planet speed reducing mechanism and the two-level cycloid speed reducing mechanism are connected through three eccentric shafts, and the three eccentric shafts are evenly distributed on a circumference at 120-degree intervals. The angular contact bearing is in a connection shape, that is, an outer ring is independent, and an inner ring and an output disk rack are of an integrated structure. The high-performance structure RV reduction machine is reasonable in structure and long in service life.

Owner:NANTONG ZHENKANG WELDING ELECTROMACHINERY

Venturi Nozzle Aerodynamic Vent Design

InactiveUS20090272609A1Shorten the axial distanceIncrease ratingsFluid actuated brakesBraking discsCOMPONENT IIEngineering

A rotor arrangement for the brake system of a vehicle has first and second annular rotor plates substantially in parallel, with a ventilated region therebetween for cooling the rotor plates. A plurality of airfoil-shaped structures is arranged in the ventilated region, each being coupled at one portion thereof to the first rotor plate, and at a second portion thereof to the second rotor plate, to maintain the first and second rotor plates in fixed spatial relation. The first and second rotor plates and the airfoil-shaped pillar structures are integrally formed, the interior surfaces of the rotor plates being configured as an annular venturi that increases the air flow therebetween. The airfoil-shaped structures are configured as airfoil-shaped pillars and fins to form a corresponding plurality of effective venturi nozzles whereby the flow of air between the rotor plates is laminar and increased to enhance the cooling of the annular rotor plates.

Owner:RASSINI FRENOS S A DE

A rotary detonation combustor

InactiveCN104154567BImprove self-pressurization abilityImprove stabilityContinuous combustion chamberDetonationSpray nozzle

The invention provides a rotating detonation combustion chamber. According to the rotating detonation combustion chamber, besides a plurality of fuel spray nozzles which are distributed on the head portion of the combustion chamber in an annular mode at equal intervals, a plurality of fuel spray nozzles are further evenly arranged in the axial direction and the circumferential direction of an outer shell of the combustion chamber, so that the annular detonation combustion chamber is divided into a plurality of small spaces; each spray nozzle is responsible for supplying fuel to the corresponding small space, and therefore filling efficiency of fuel can be improved, the filling space of fuel of the combustion chamber can be enlarged, and the combustion thermal intensity of the combustion chamber can be improved. The axial distance of rotating detonation combustion waves can be lengthened due to the fact that the filling space of fuel of the combustion chamber is enlarged, so that the rotating detonation waves penetrate through the whole combustion chamber, and meanwhile the rotating detonation waves can be prevented from degeneration and disappear which are caused by fuel shortage in the spreading process. A spiral obstacle is arranged in an annular cavity of the rotating detonation combustion chamber in the circumferential direction, and therefore the distance by which slow combustion is converted into detonation combustion in the starting process of the combustion chamber can be shortened, the intensity of the rotating detonation waves is enhanced, the overall self-pressurization capacity is improved in the combustion process of the combustion chamber, and meanwhile stability of the rotating detonation waves can be enhanced in the spreading process.

Owner:XIAN THERMAL POWER RES INST CO LTD

Combination mounting ring

ActiveUS20080060905A1Shorten the axial distanceReduce component countClutchesWashersEngineeringMechanical engineering

Owner:SAINT GOBAIN PERFORMANCE PLASTICS RENCOL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com