Gear case used for rail traffic vehicle

A technology for rail transit vehicles and gearboxes, which is applied in the field of gearboxes for rail transit vehicles. It can solve the problems of small space occupied by oil seals, insufficient compensation for motor shafts and gearbox input shafts, etc., and achieves convenient disassembly and maintenance, and easy observation Oil level, effect of reducing axial distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

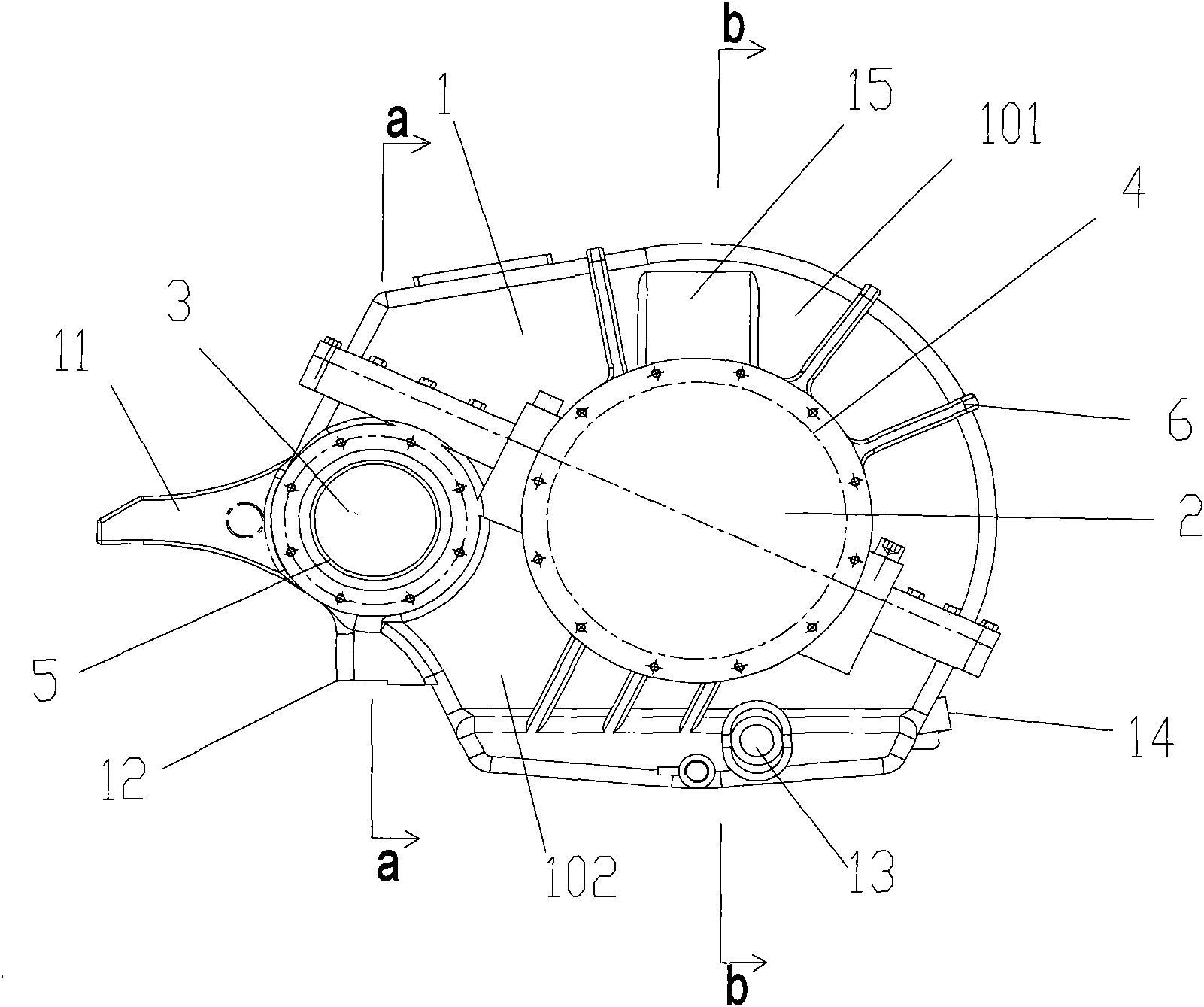

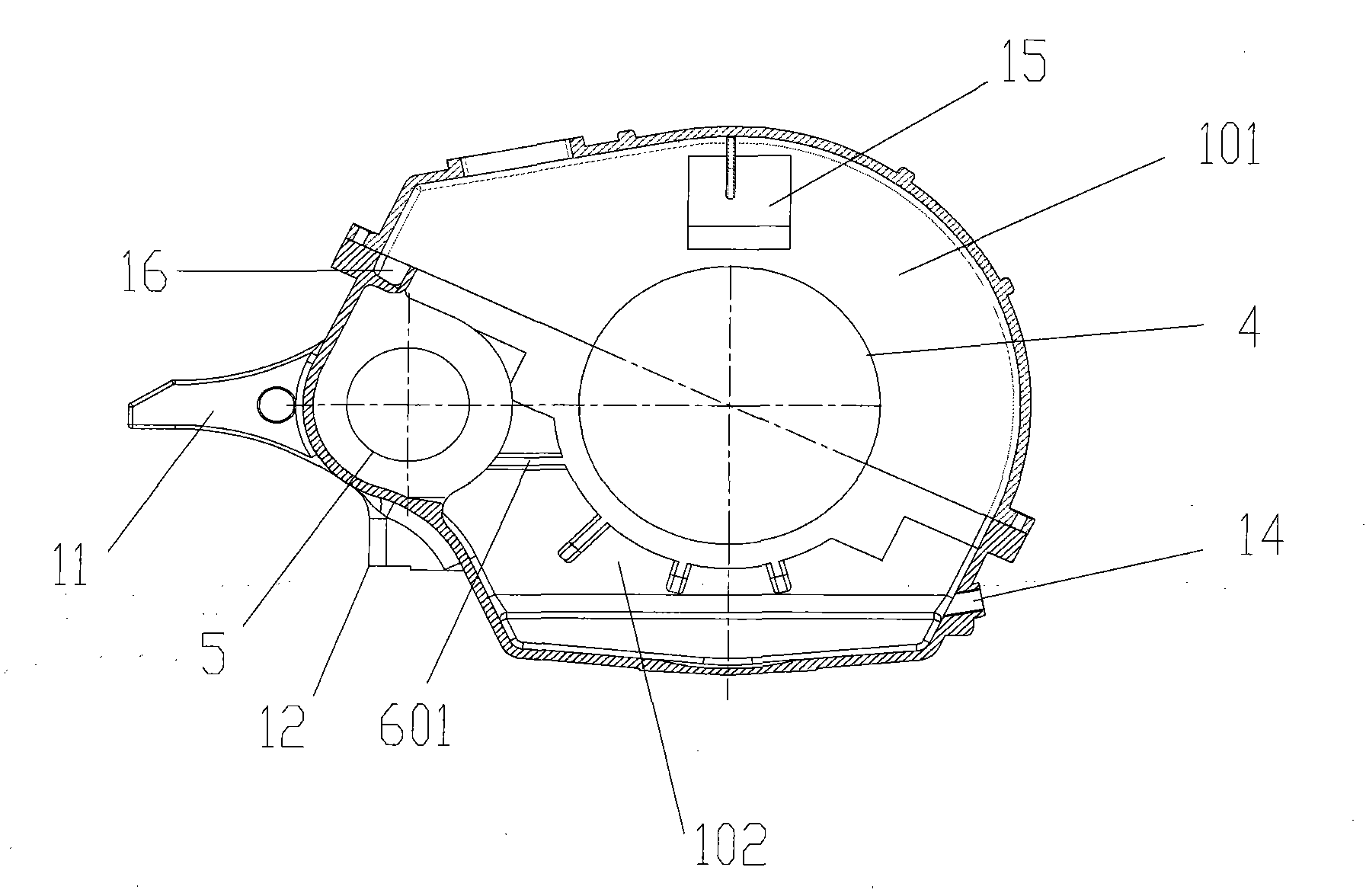

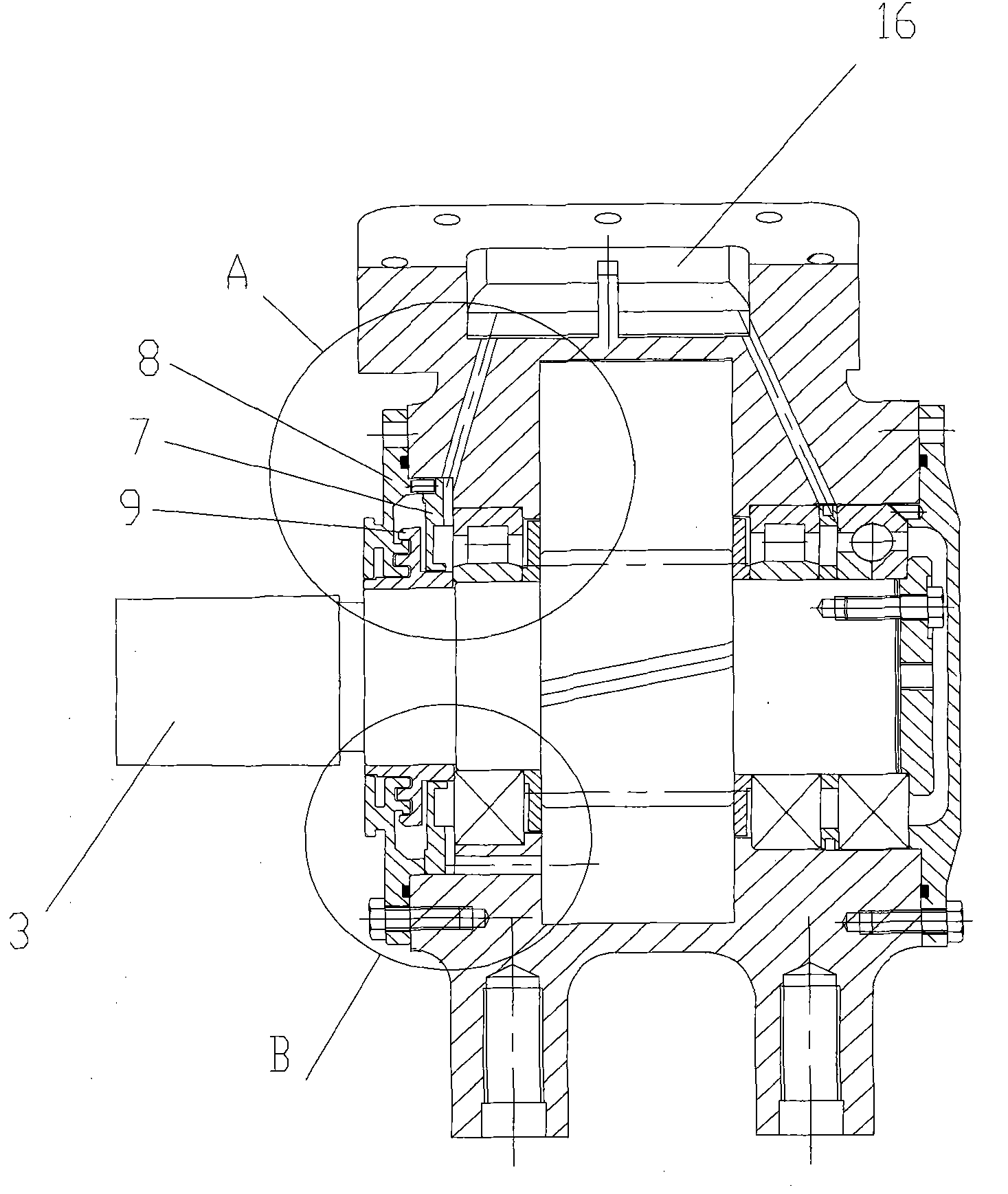

[0027] like figure 1 , figure 2 , image 3 and Figure 8 As shown, a gear box for a rail transit vehicle of the present invention includes a box body 1 , an output shaft 2 and an input shaft 3 . The box body 1 is respectively arranged with an axle bearing seat 4 and an input shaft bearing seat 5 from front to back, and the centerlines of the shaft holes of the bearing seats are parallel to each other. The box body 1 includes an upper box body 101 and a lower box body 102, both of which are made of castings, and the two are fixedly connected, and reinforcing ribs 6 are distributed on the outer surface. The reinforcing rib 6 extends from the bearing seat to the outer edge. The input shaft 3 passes through the input shaft bearing seat 5, the output shaft 2 passes through the axle bearing seat 4, the output shaft 2 and the input shaft 3 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com