Intelligent control system and method of movable work shed

A control system and shed technology, which is applied in industrial buildings, buildings, building structures, etc., can solve problems such as inconvenient movement, difficulty in moving sheds, and poor automation level, so as to achieve accurate and rapid movement, improve control response effect, The effect of convenient construction control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1 of the present disclosure provides an intelligent control system for a mobile shed, which is realized by using four motors to drive four road wheels. The three-phase asynchronous motor drives the four wheels through a reducer to move forward and backward along the guide rail.

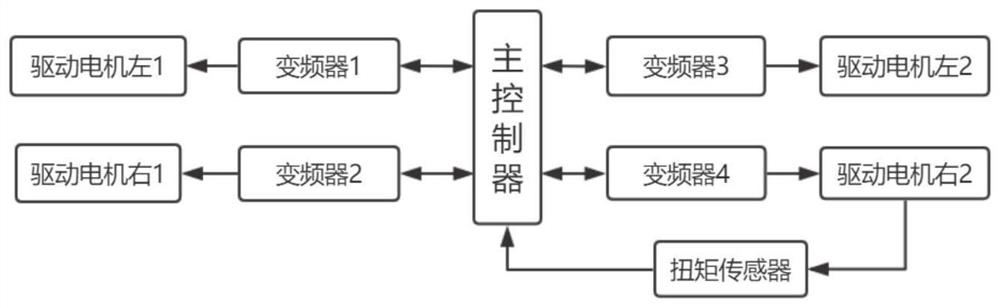

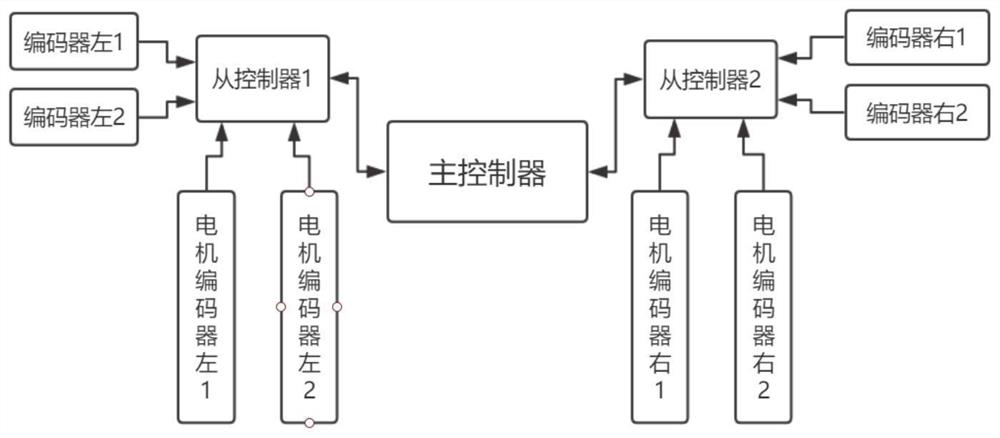

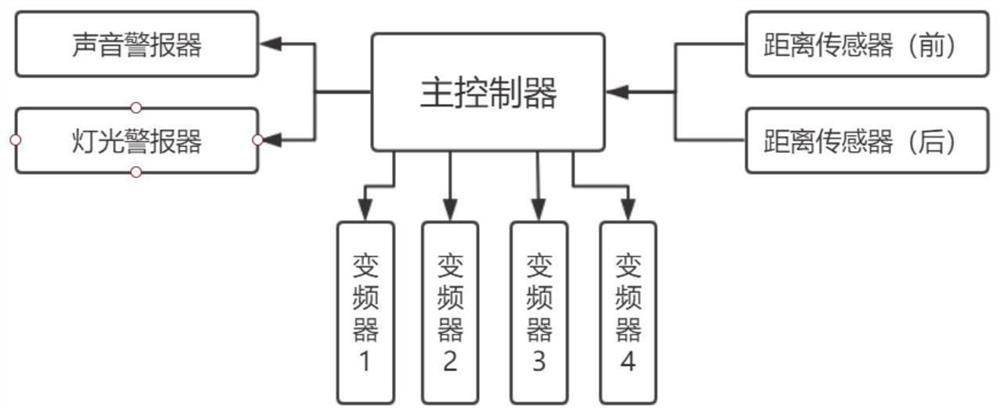

[0035] The speed of the four wheels is controlled by the frequency converter matched with the motor, and the controller sets the same starting acceleration / deceleration curve, walking speed and synchronous start / stop signal for the frequency converter to realize basic walking control, such as figure 1 This is the schematic diagram of the walking control, and the frequency converter is used to set the same working state for each walking, which ensures the stability of the shed when moving, and also reduces the direction deviation caused by the inconsistent speed on both sides.

[0036] Intelligent switching between two-wheel drive and four-wheel drive, installing a load detection senso...

Embodiment 2

[0044] Embodiment 2 of the present disclosure provides an intelligent control method for a mobile shed, using the intelligent control system for a mobile shed described in Embodiment 1, specifically including the following aspects:

[0045] (1) The shed moves automatically

[0046] Four motors are used to drive four road wheels. The three-phase asynchronous motor drives the four wheels through the reducer, and moves forward and backward along the guide rail. The speed of the four wheels is controlled by a frequency converter matched with the motor. The controller sets the same starting acceleration / deceleration curve, walking speed and synchronous start / stop signal for the inverter to realize basic walking control;

[0047] Intelligent switching between two-wheel drive and four-wheel drive, installing a load detection sensor on the driving motor to detect the motor load in real time, when the load is less than the set value, the two-wheel drive is enabled, and when the load i...

Embodiment 3

[0059] Embodiment 3 of the present disclosure provides a mobile work shed, including the intelligent control system for the mobile work shed described in Embodiment 1 of the present disclosure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com