Automatic moving conveyor

A conveyor, self-moving technology, applied in the direction of conveyor objects, transportation and packaging, support frame, etc., can solve the problems of difficult and fast sorting things, inconvenience, complexity, etc., to improve the overall conveying efficiency, reduce manual handling or mechanical The effect of grasping, easy installation and movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

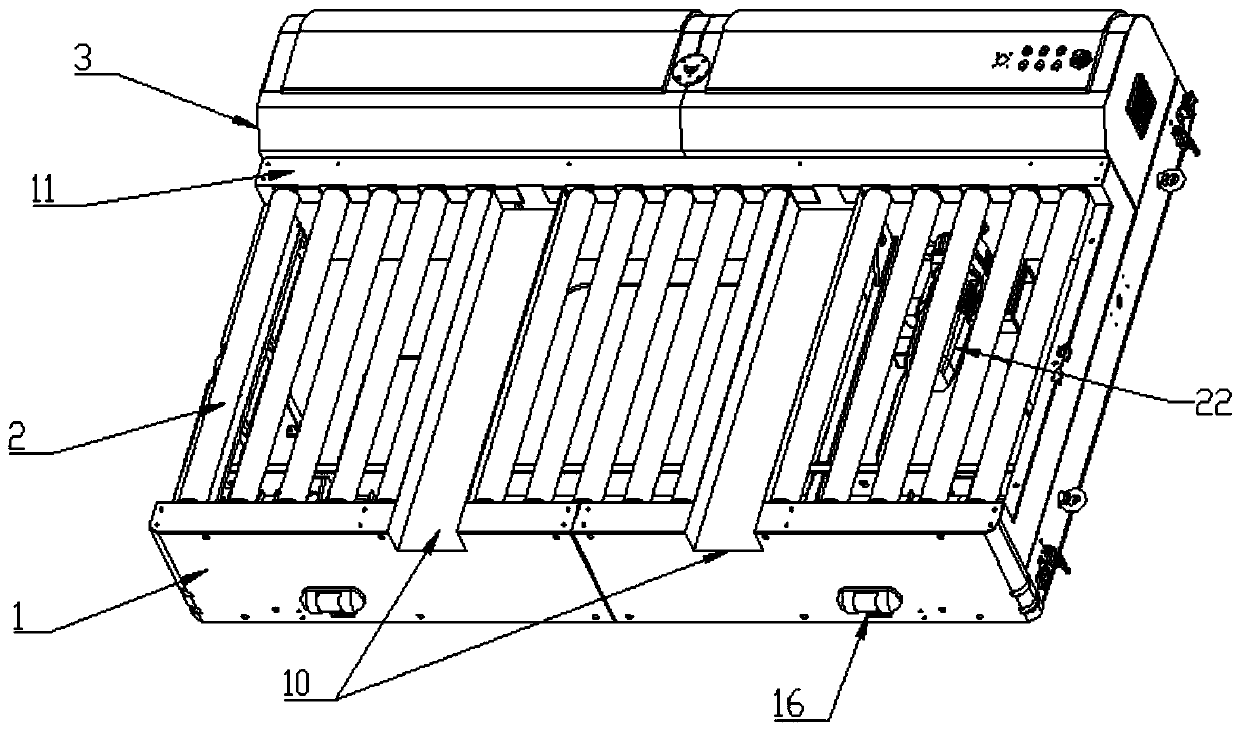

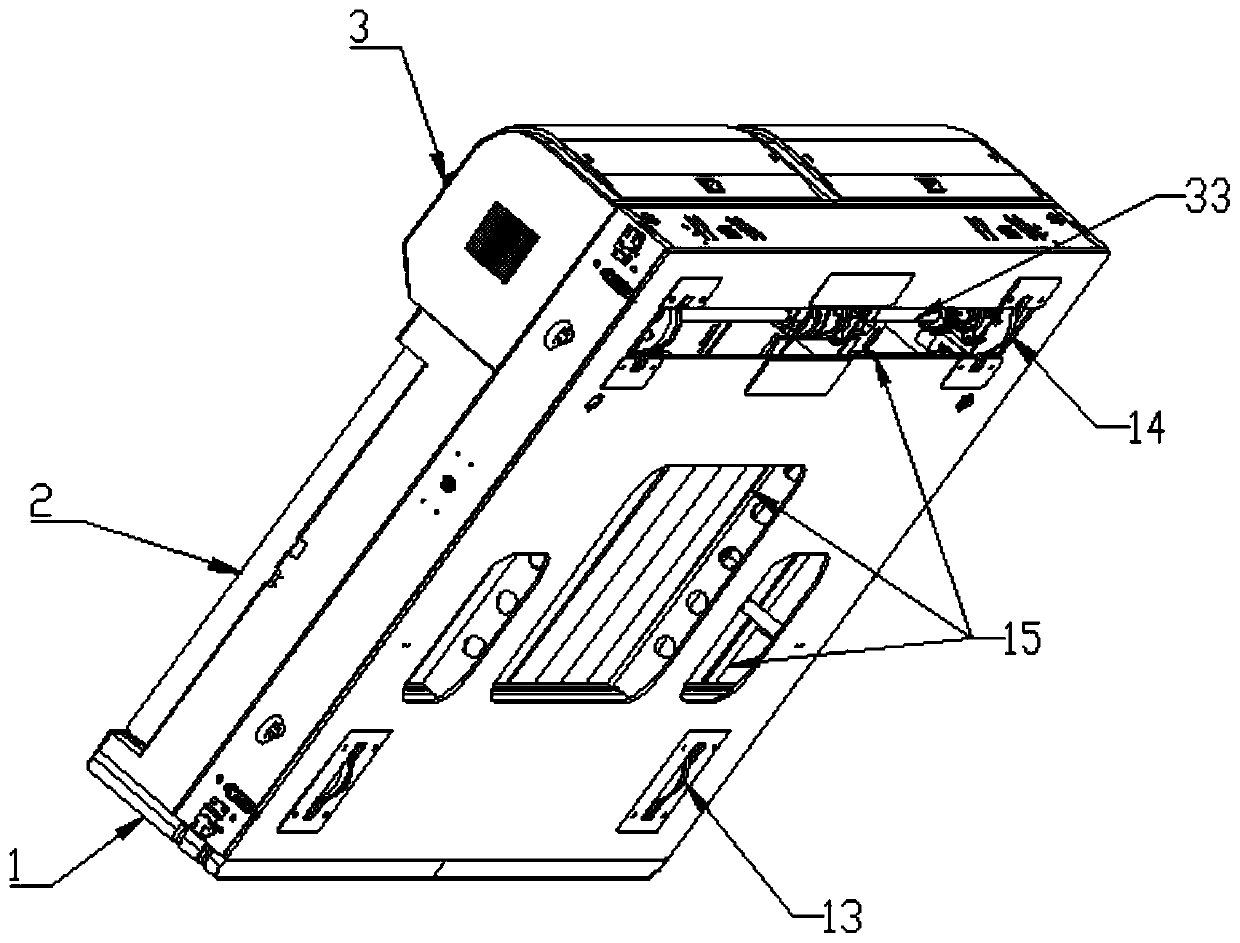

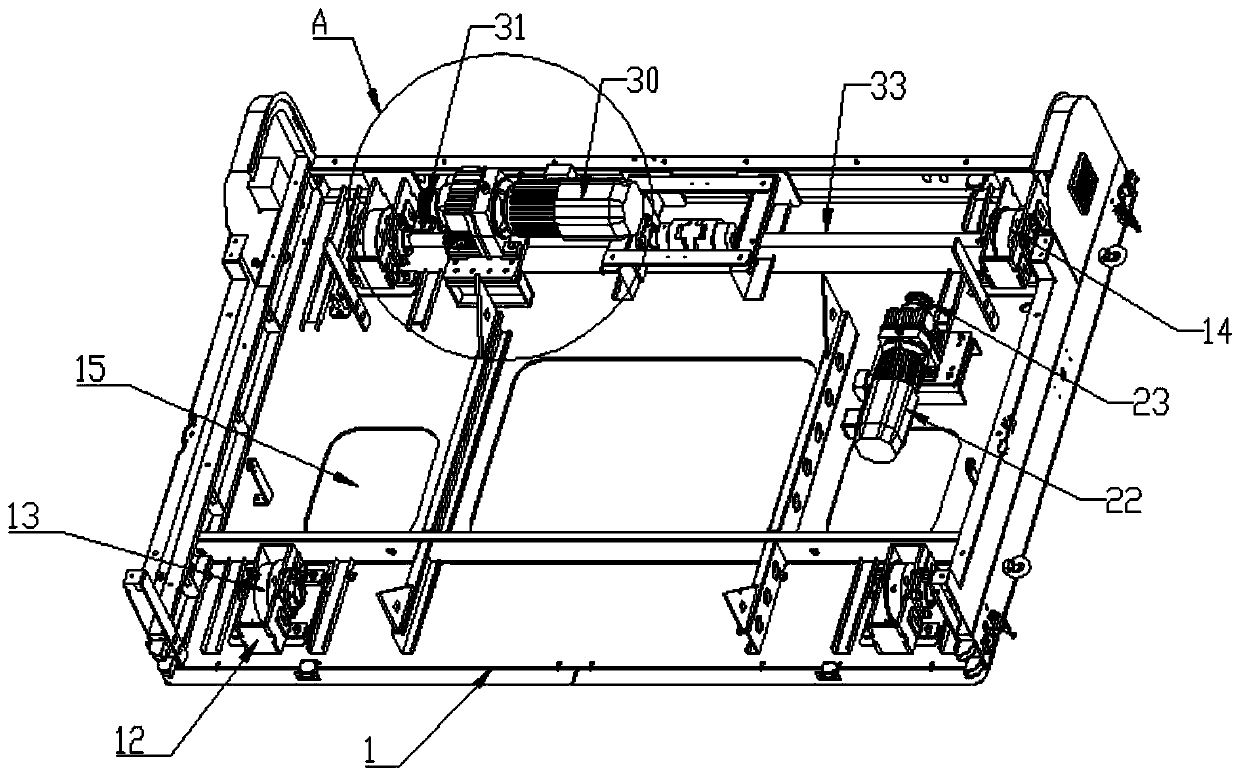

[0025] see Figure 1~4 , in an embodiment of the present invention, a self-moving conveyor includes a conveyor base 1, a row of conveying rollers 2 is fixed on the top surface of the conveyor base 1, and a roller motor is provided directly below the conveying rollers 2 22. The roller motor 22 drives the conveying roller 2 to roll on the surface of the conveyor base 1 through the roller driving mechanism. The conveying roller 2 is provided with a plurality of fork slots 10 for inserting fork plates at intervals. The conveyor base 1 The four corners of the bottom are provided with a plurality of wheels for driving the conveyor base 1 to move perpendicularly to the conveying direction of the conveying roller 2. The rear panel side of the conveyor base 1 is provided with a stroke motor box 3, and the stroke motor box 3 is equipped with There is a stroke drive mechanism that drives the wheels to rotate.

[0026] The roller driving mechanism includes a chain chamber 11 arranged at ...

Embodiment 2

[0031] The difference between this embodiment and embodiment 1 is:

[0032] The stroke drive mechanism and the roller drive mechanism are provided with a reduction device, and the reduction device includes a reduction gear box 34 .

[0033] The bottom surface of the conveyor base 1 is provided with an inspection opening 15 for maintenance, and the side wall of the conveyor base 1 is provided with a working indicator light 16 .

[0034] Working principle of the present invention: the reduction gear box 34 provided is used to reduce the speed of the stroke drive mechanism and the roller drive mechanism to increase the torque, the provided inspection port 15 is convenient for maintenance of the internal components of the conveyor base 1, and the provided working indicator light 16 It is mainly used to remind and warn the operator during the longitudinal movement of the conveyor base 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com