Patents

Literature

56results about How to "Achieving autonomous mobility" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

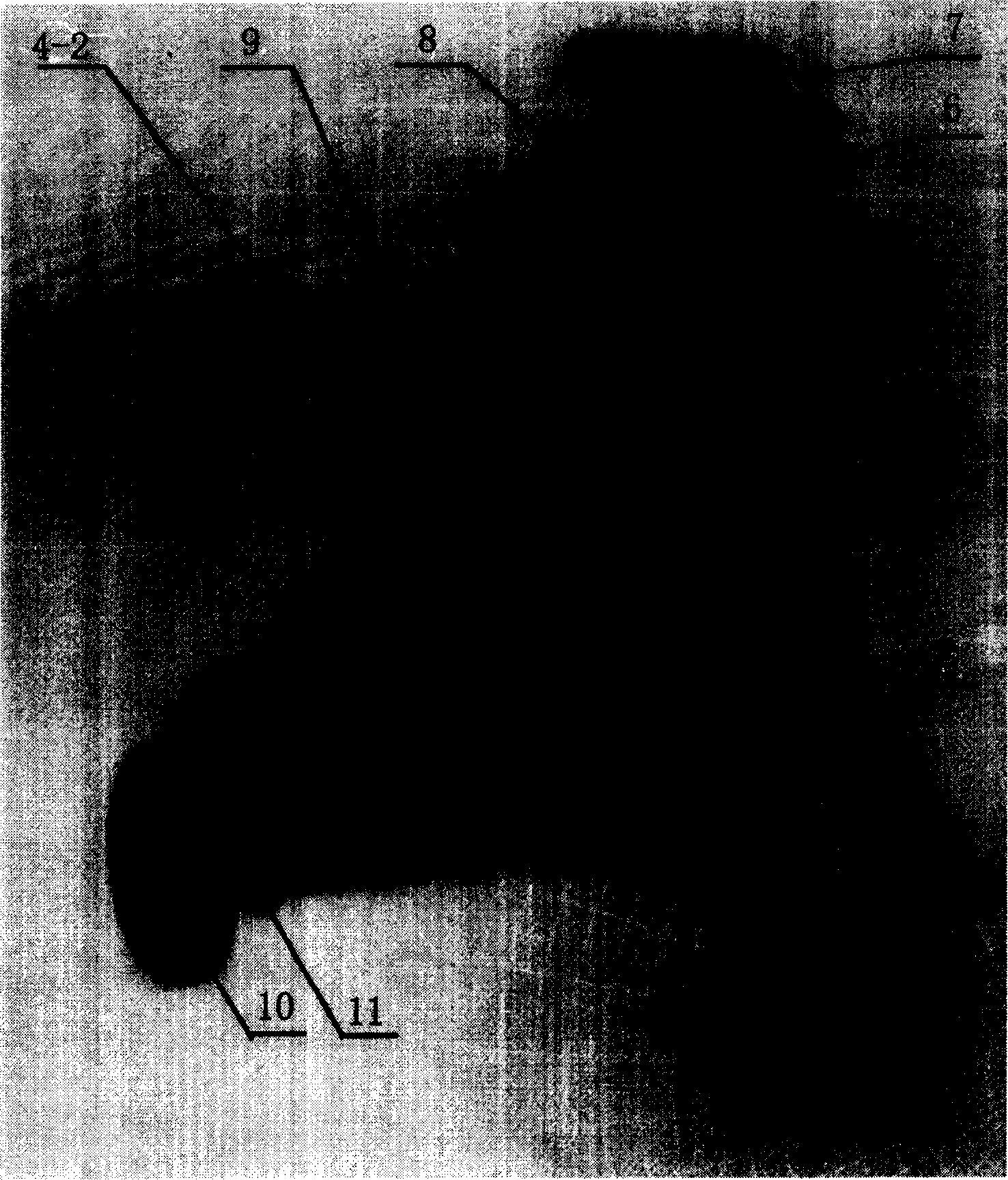

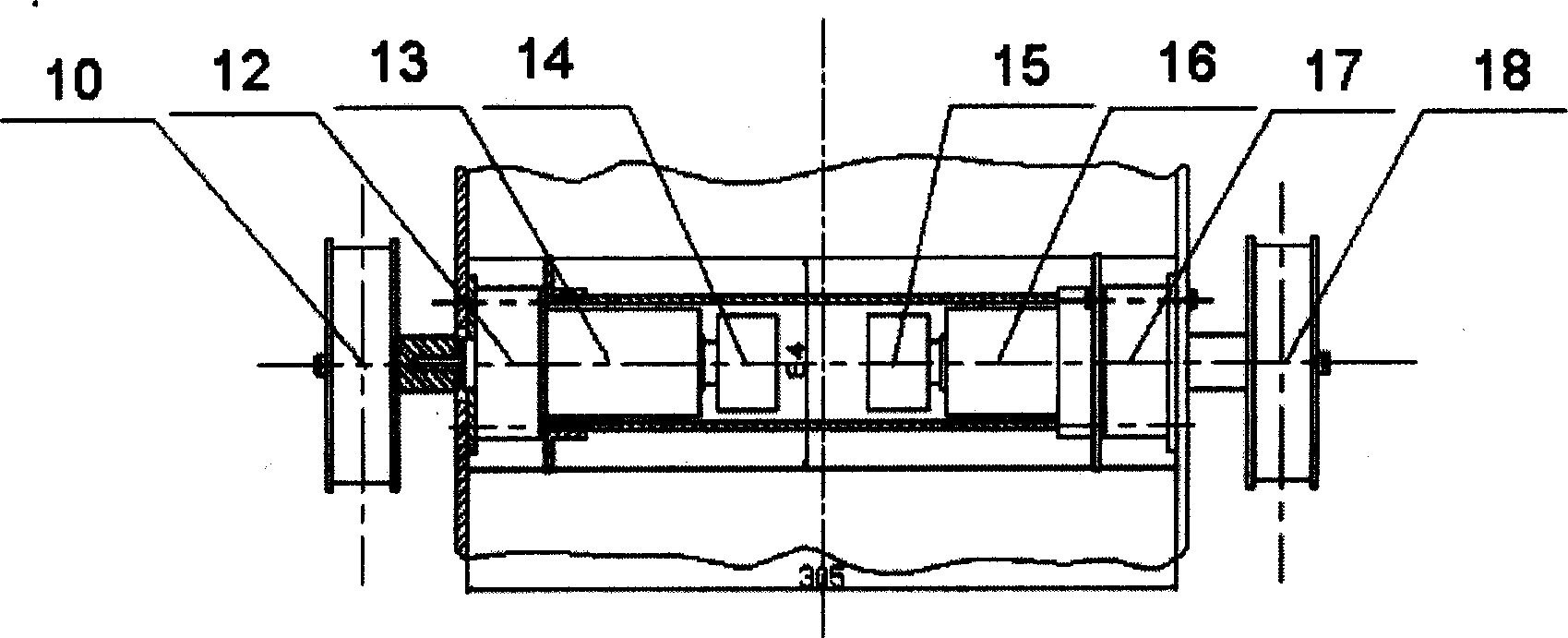

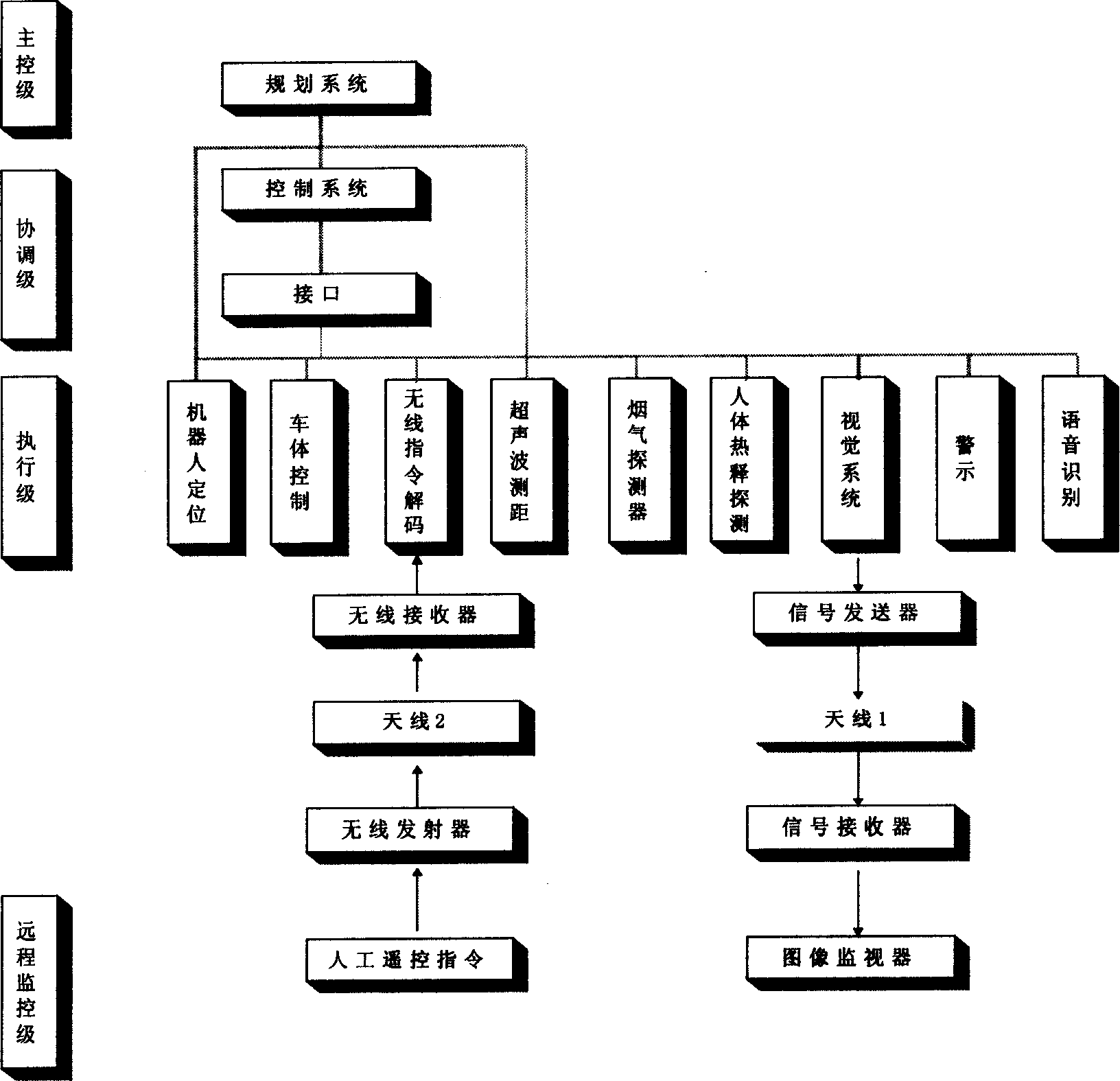

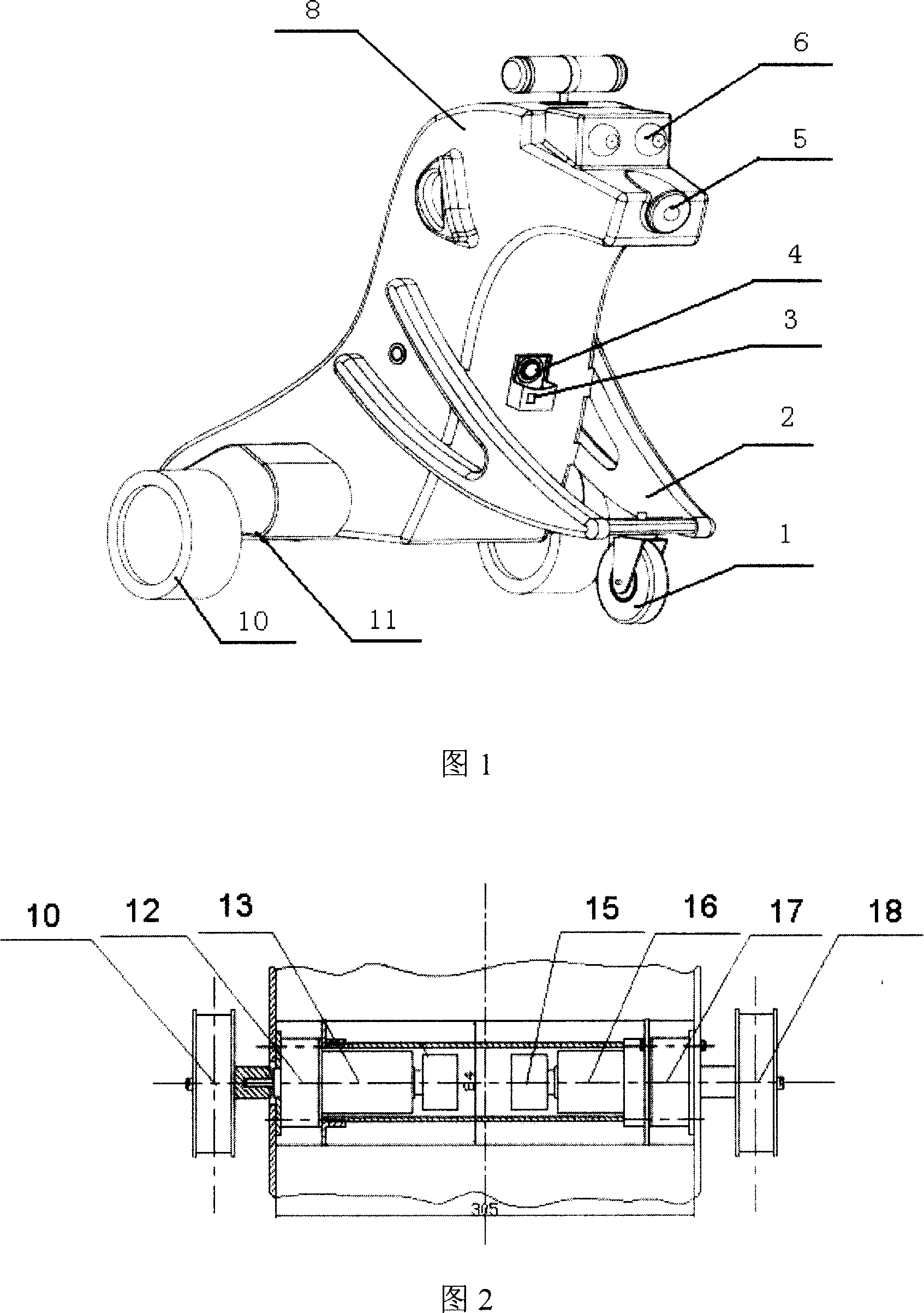

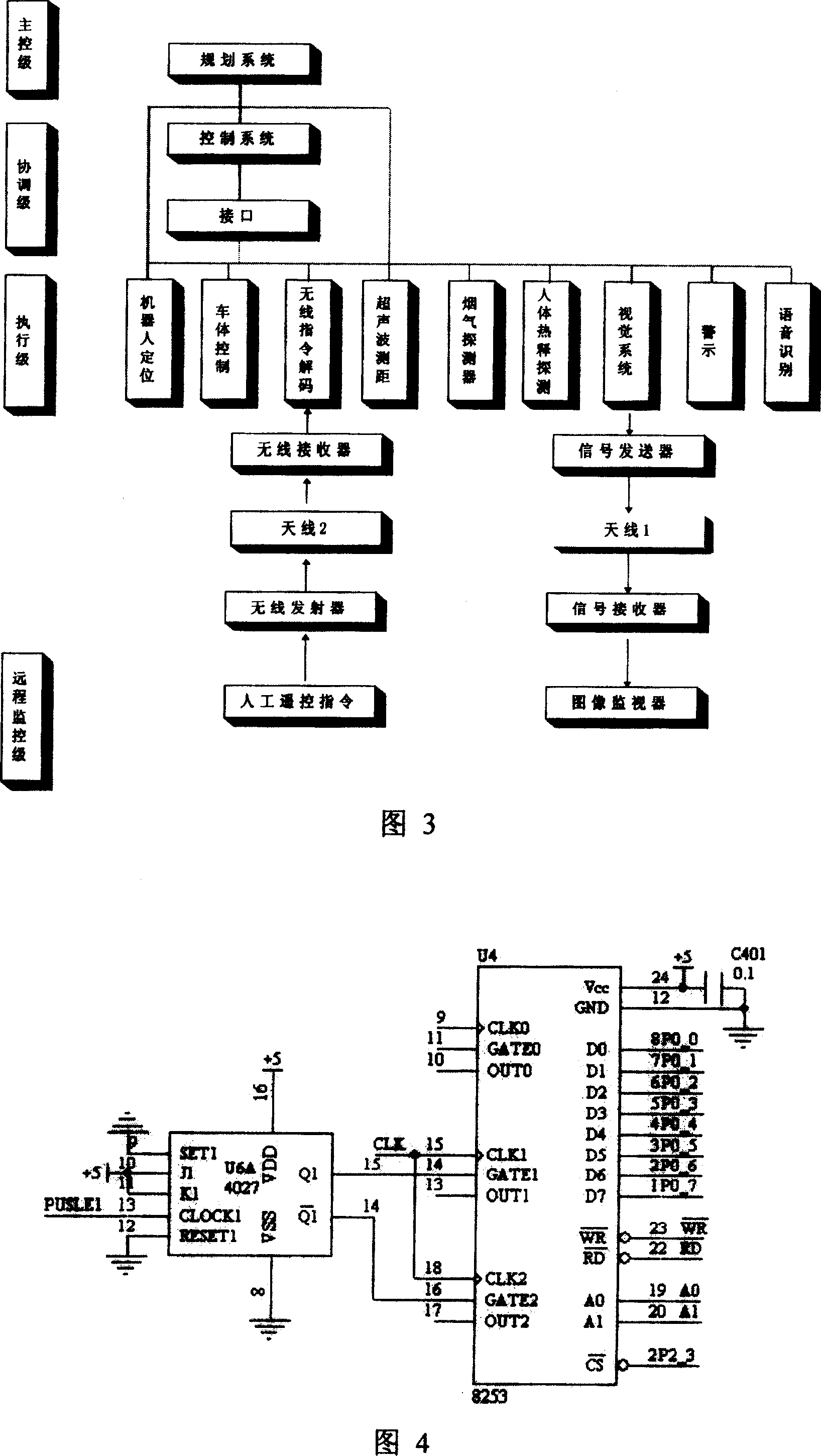

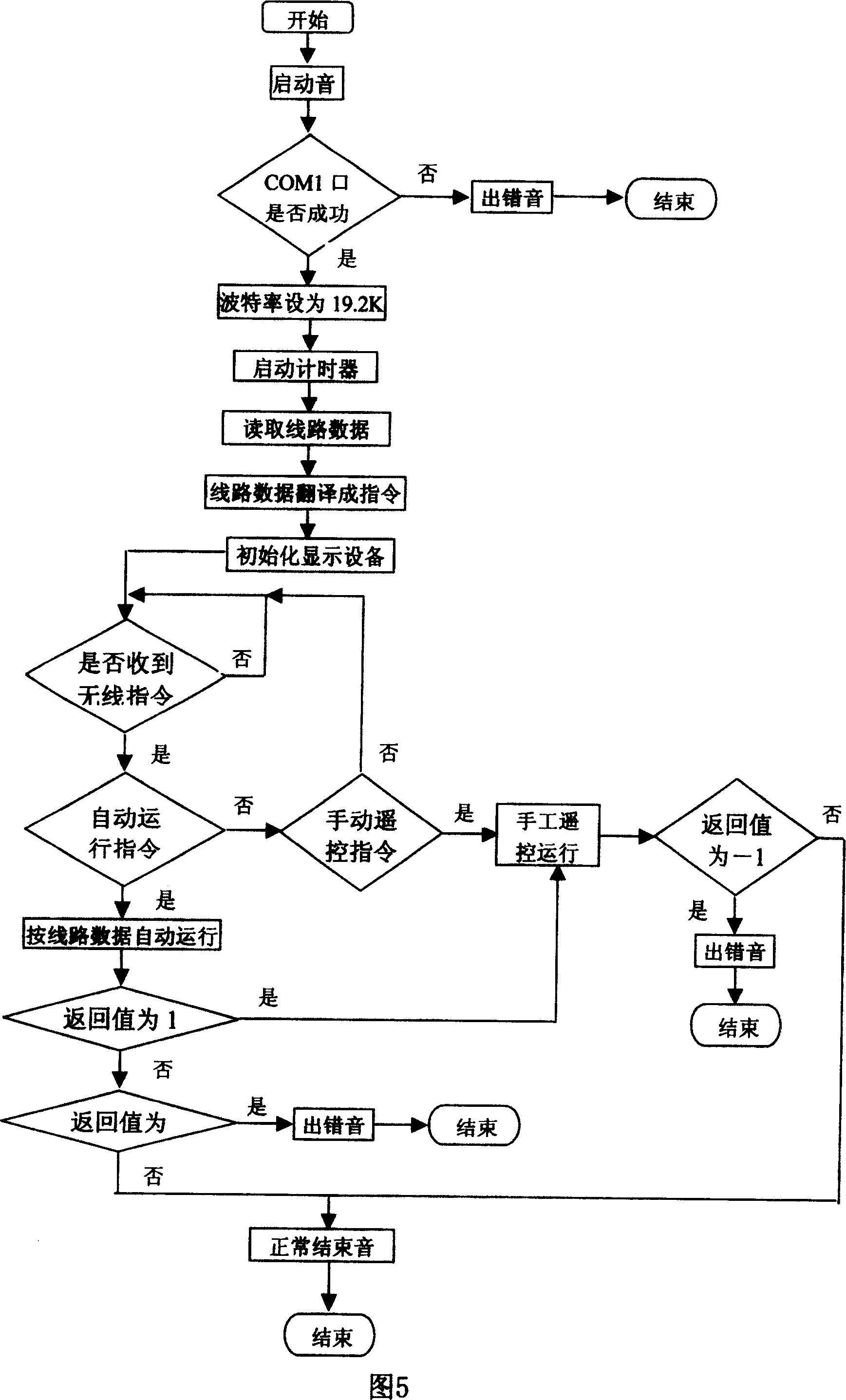

Security ensuring and patrolling robot

InactiveCN1593859AReliable completionStabilize security patrol tasksManipulatorControl systemPatrolBot

The invention relates to a kind of patrolling robot. It consists of robot body, the movable controlling unit and the bearing rack of which is fixed firmly to the outer shell; anti- stakeout system, which consists of infrared temperature sensor, smoking sensor, hot releasing infrared sensor, mini CCD camera eye, signal lamp, buffer, and graphic message wireless conveying module; the controlling system that sends message to control the robot to patrol, move to control and give an alarm automatically within the circumstance; multi-sensor system. The robot can patrol along the scheduled path, and judge the location is at according to the messages from the sensors to avoid the impediment and change the moving path. The invention is more suitable to increasing onerous security task, and improves the atomicity of security work.

Owner:SOUTH CHINA UNIV OF TECH

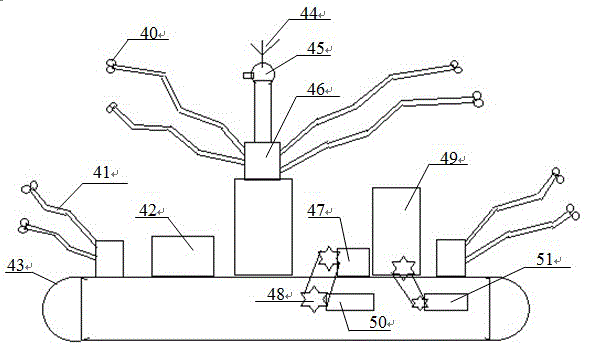

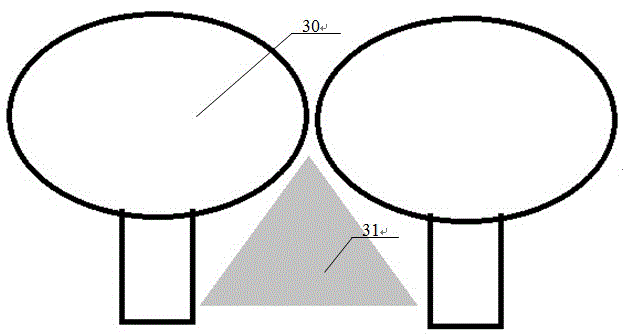

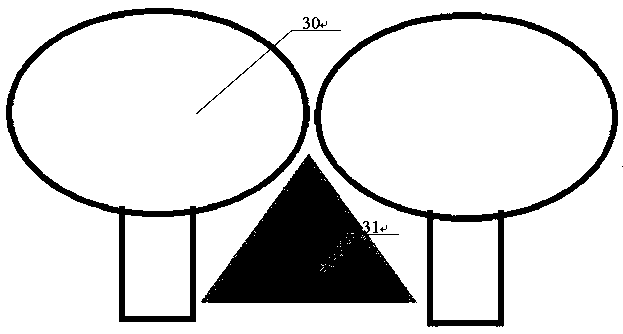

Intelligent independent spraying robot for orchard

InactiveCN104476545AImprove work efficiencyIncrease profitManipulatorInsect catchers and killersChemical usedFruit tree

The invention discloses an intelligent independent spraying robot for an orchard. The intelligent independent spraying robot comprises a central control module, a spraying module, a dispensing module, a wireless communication module, a locating module, a man-machine interaction module, an image processing module, a detection module, a driving module, a power supply module, an alarm module and a storage module. The intelligent independent spraying robot for the orchard conforms to the current orchard building standard, does not need artificial control, simultaneously sprays the fronts and backs of the leaves at the tops and bottoms of four fruit trees, is capable of locating and moving independently to finish the whole spraying process for the orchard, enables the working efficiency to be improved, enables the chemical use ratio to be improved, enables the labor force to be reduced and protects people from chemical harm.

Owner:UNIV OF JINAN

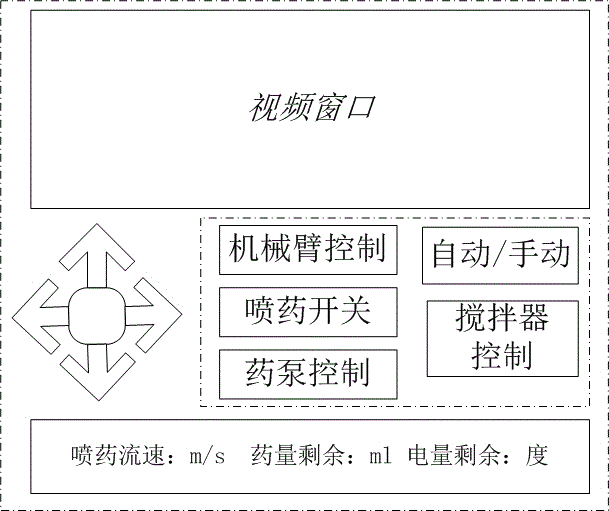

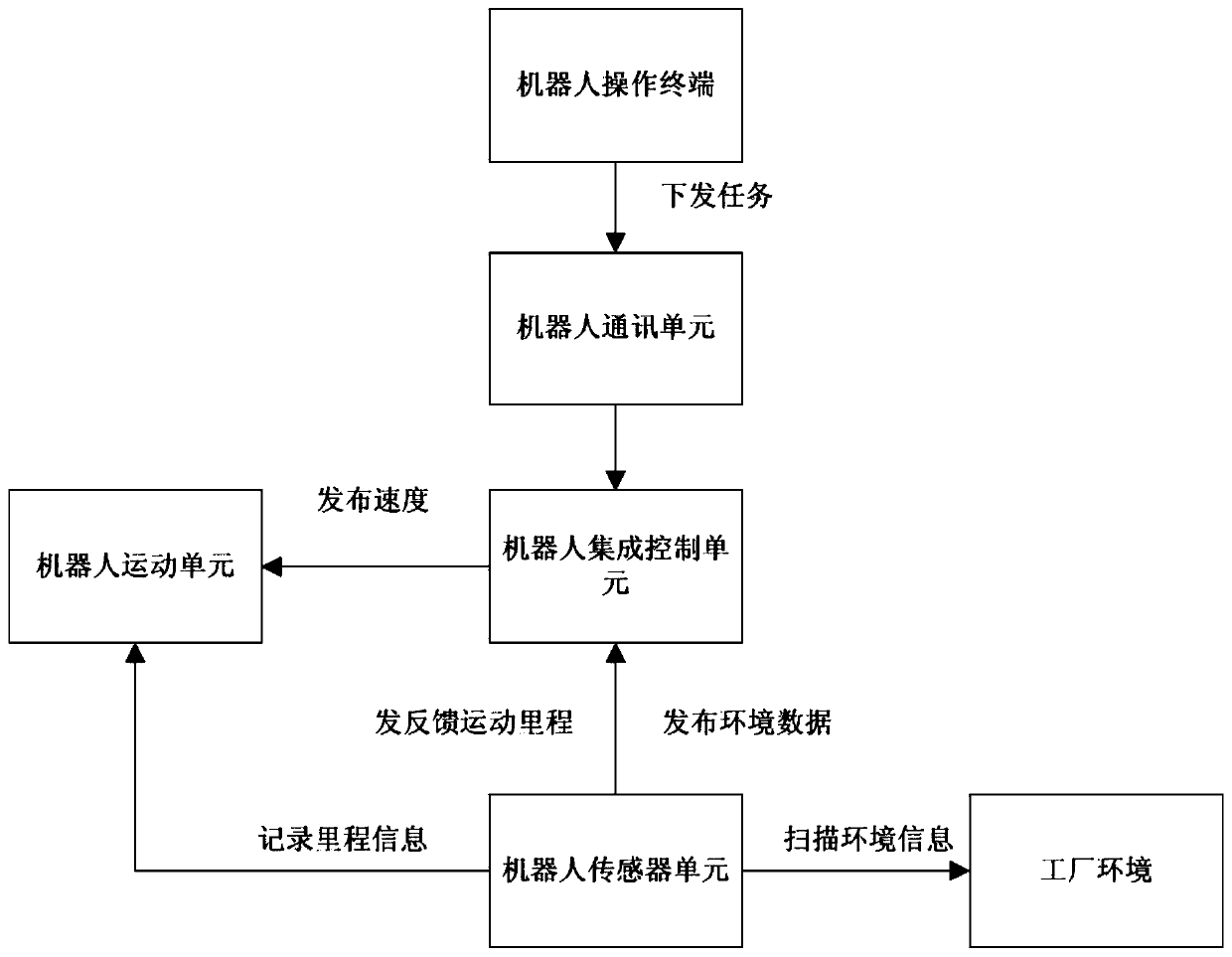

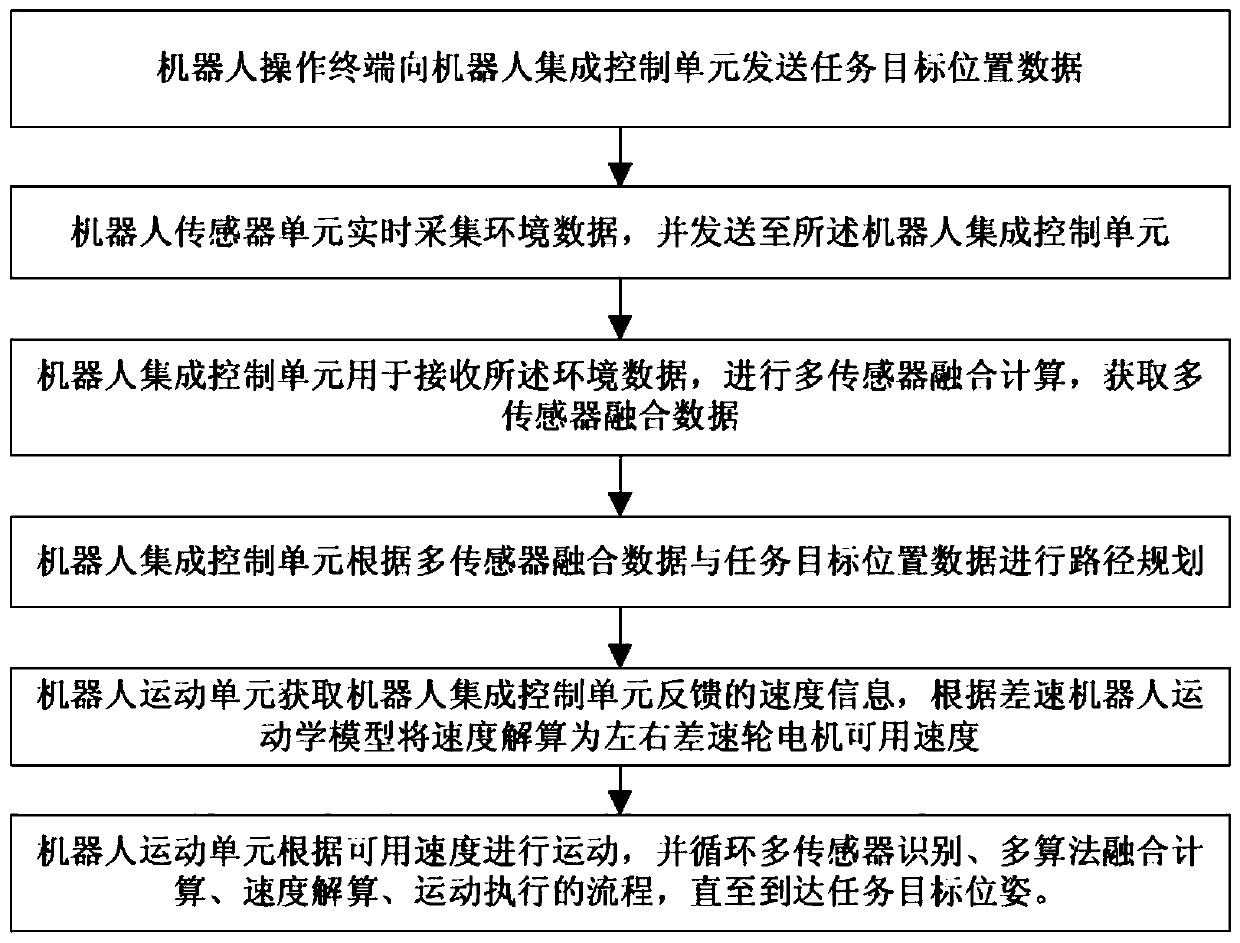

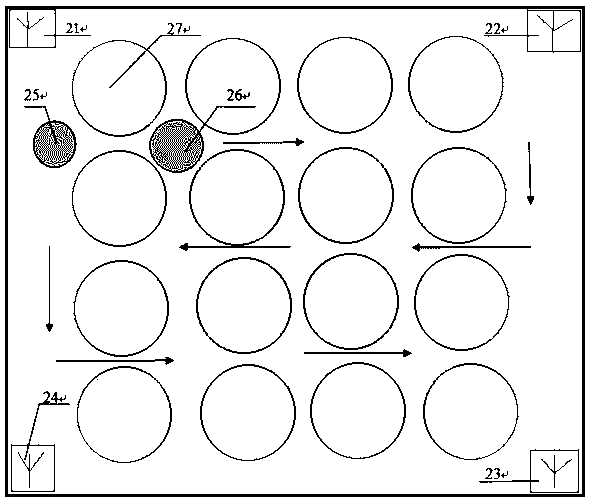

Mobile robot navigation system and method

InactiveCN111123925AAchieving autonomous mobilityMake up for the error defectPosition/course control in two dimensionsVehiclesMultiple sensorControl cell

The invention discloses a navigation system for a mobile robot. The system comprises a robot operation terminal for transmitting task target pose data to a robot integrated control unit, a robot sensor unit for acquiring environmental data in real time, and the robot integrated control unit for receiving the environment data, carrying out multi-sensor fusion calculation, obtaining multi-sensor fusion data, and carrying out path planning according to the multi-sensor fusion data and task target pose data. The invention further provides a navigation method of the mobile robot by corresponding tothe system. According to the invention, technologies such as an artificial intelligence algorithm, intelligent perception, operation execution and the like are combined to realize autonomous movement, accurate positioning and safety cooperation of the robot; trackless operation is achieved; the basic environment does not need to be modified, the error defect of a single sensor and a single algorithm is overcome; the positioning precision and safety of the motion robot can be greatly improved; and the production and transportation efficiency and safety of complex factories are ensured.

Owner:TIANJIN LIANHUI OIL GAS TECH CO LTD

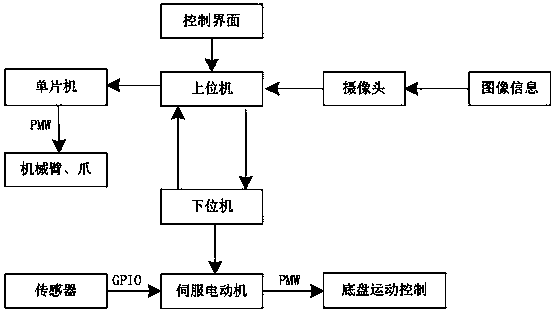

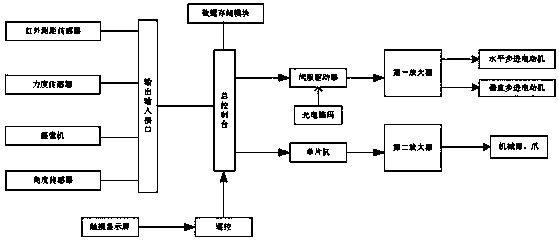

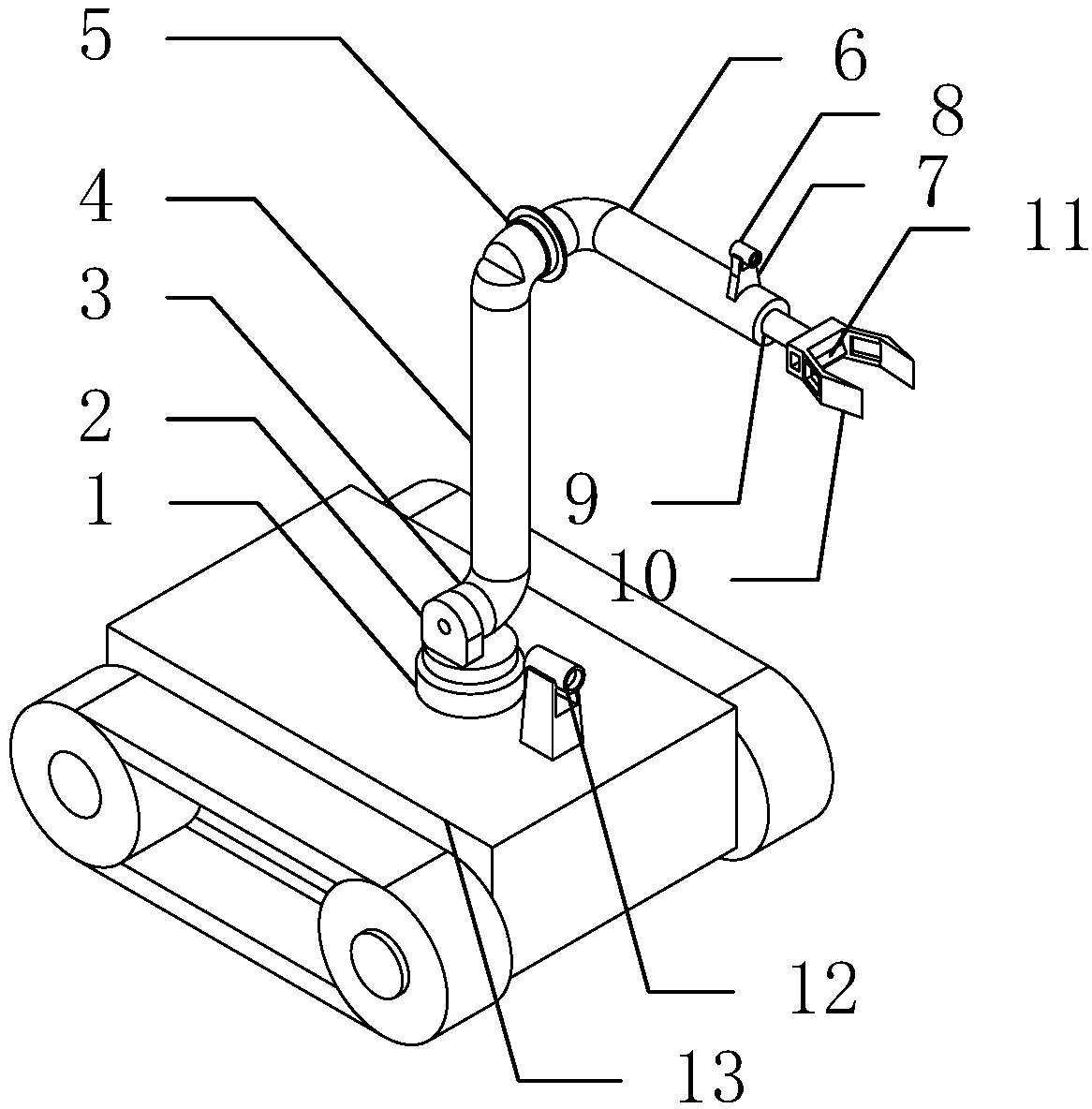

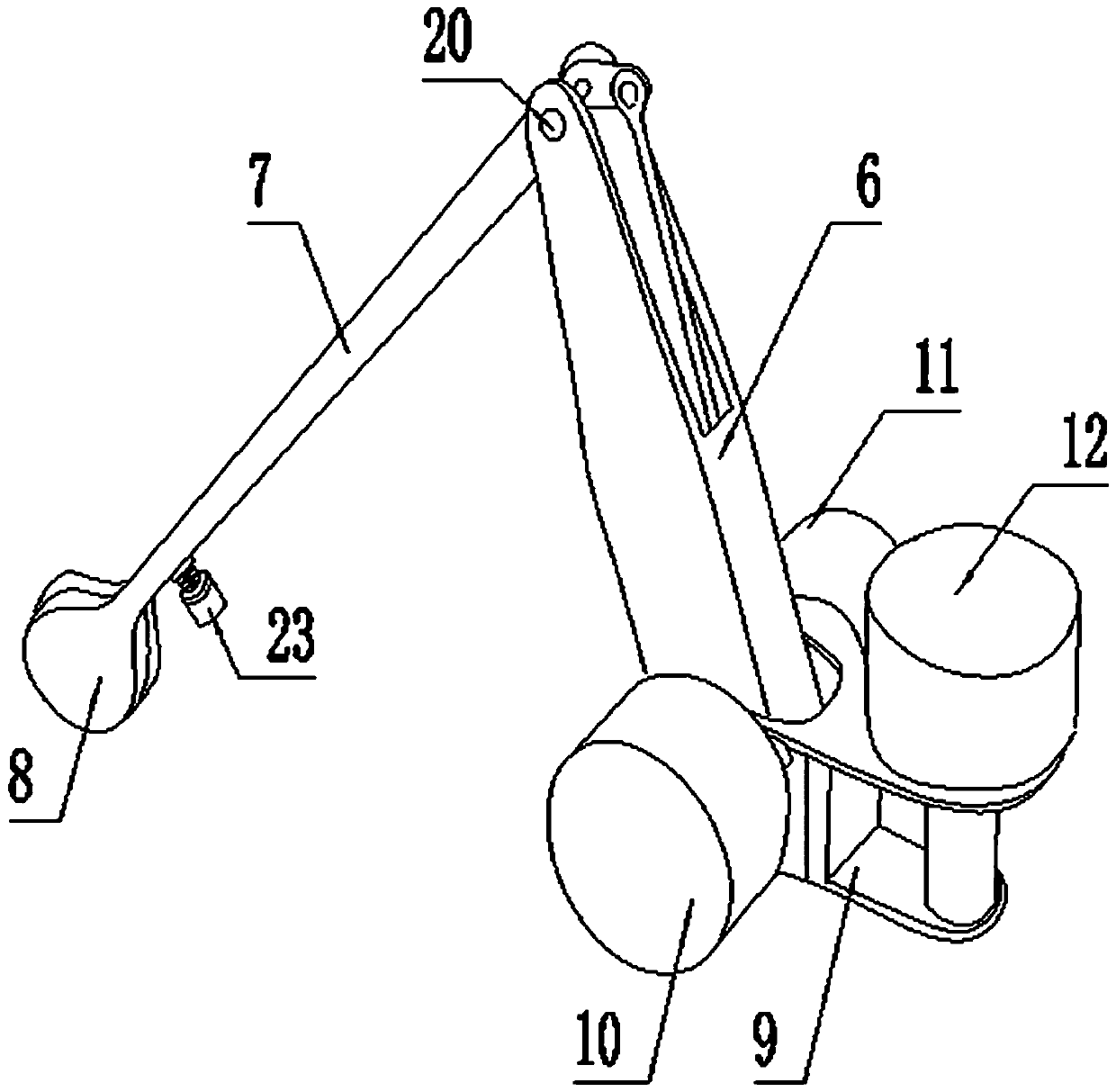

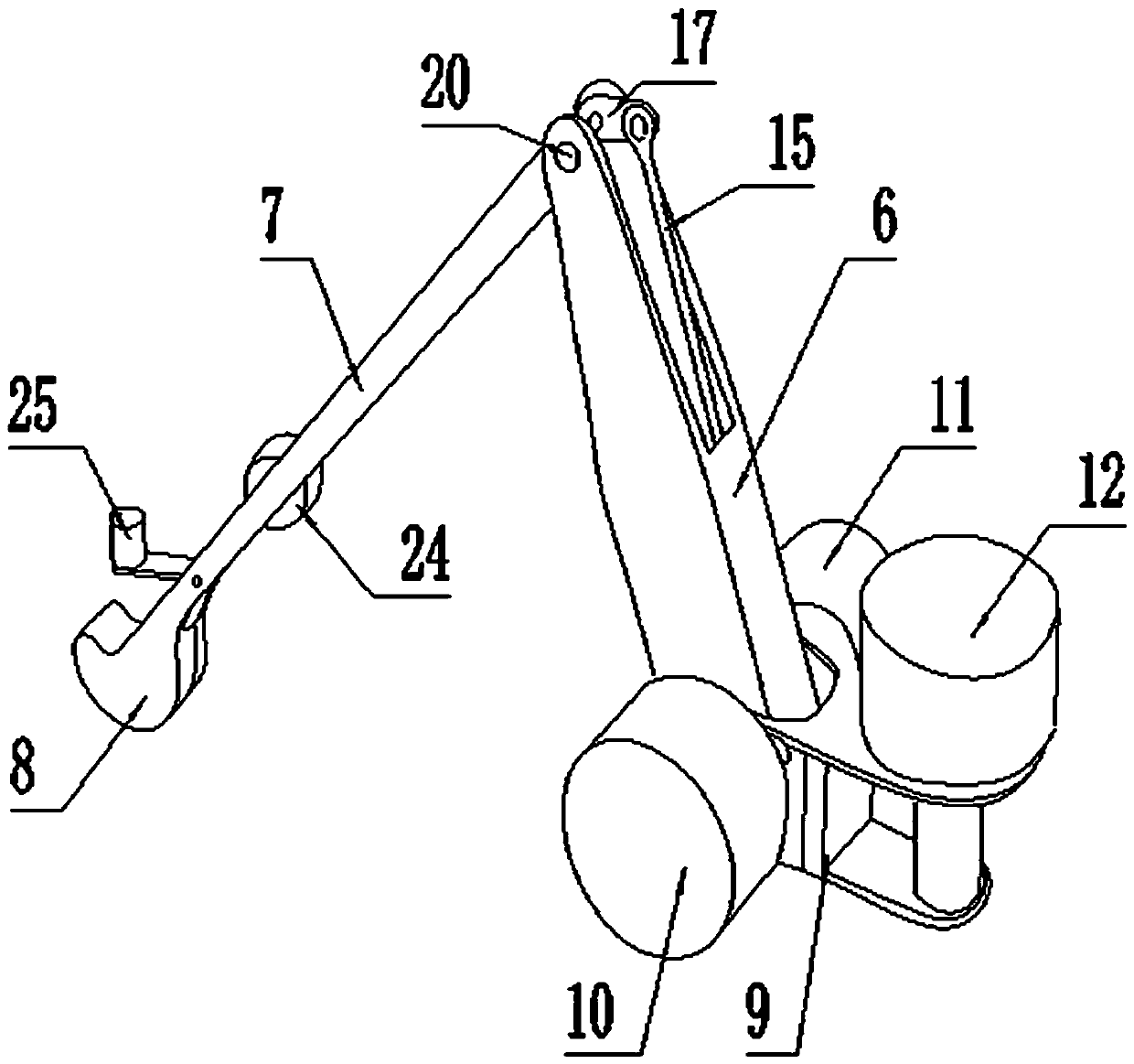

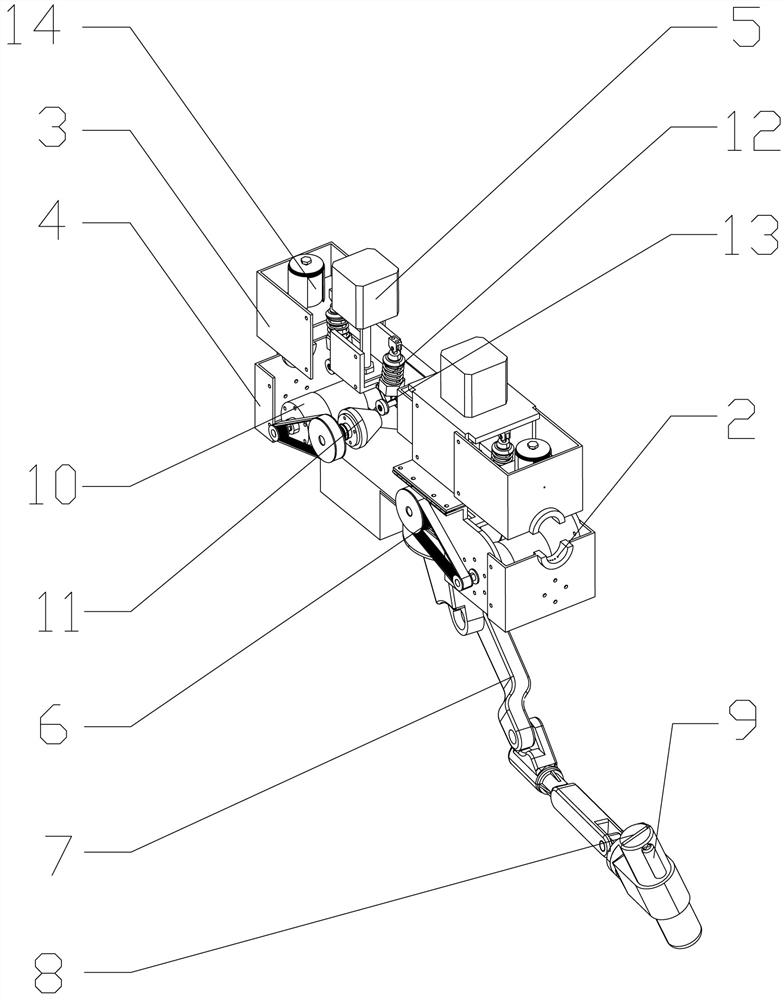

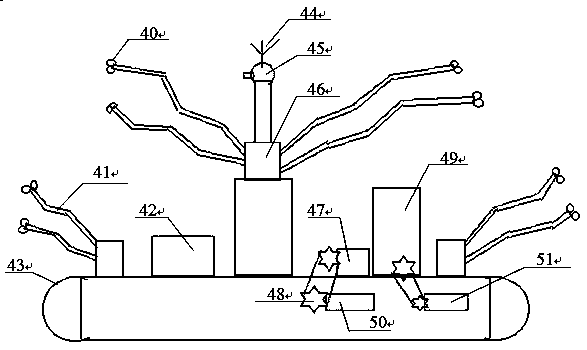

Express package sorting robot and control system

InactiveCN108908374AAchieving autonomous mobilityProgramme-controlled manipulatorControl systemComputer module

The invention discloses an express package sorting robot and a control system. The robot comprises a mechanical big arm. One end of the mechanical big arm is connected with a rotary pan-tilt through amechanical arm support. The other end of the mechanical big arm is connected with one end of a mechanical forearm. The other end of the mechanical forearm is connected with a mechanical gripper. A camera is arranged at the end of the mechanical forearm. A sensor mechanism is mounted on the mechanical gripper. A first motor, a second motor and a third motor providing steering power are arranged between the mechanical big arm and the mechanical arm support, between the mechanical big arm and the mechanical forearm, and between the mechanical forearm and the mechanical gripper correspondingly. Acamera is mounted at the bottom of the robot, and a chassis is a crawler-type travelling mechanism driven by a servo motor. The camera transmits received information to a controller, the controller controls the rotary pan-tilt and the motors to operate after performing data comparison with a data storage module, and the robot is controlled to operate. The express package sorting robot and the control system have the characteristics that the flexibility of a mechanical arm mechanism is high, the coverage area is wide, and sorting is accurate and rapid.

Owner:ANHUI UNIV OF SCI & TECH

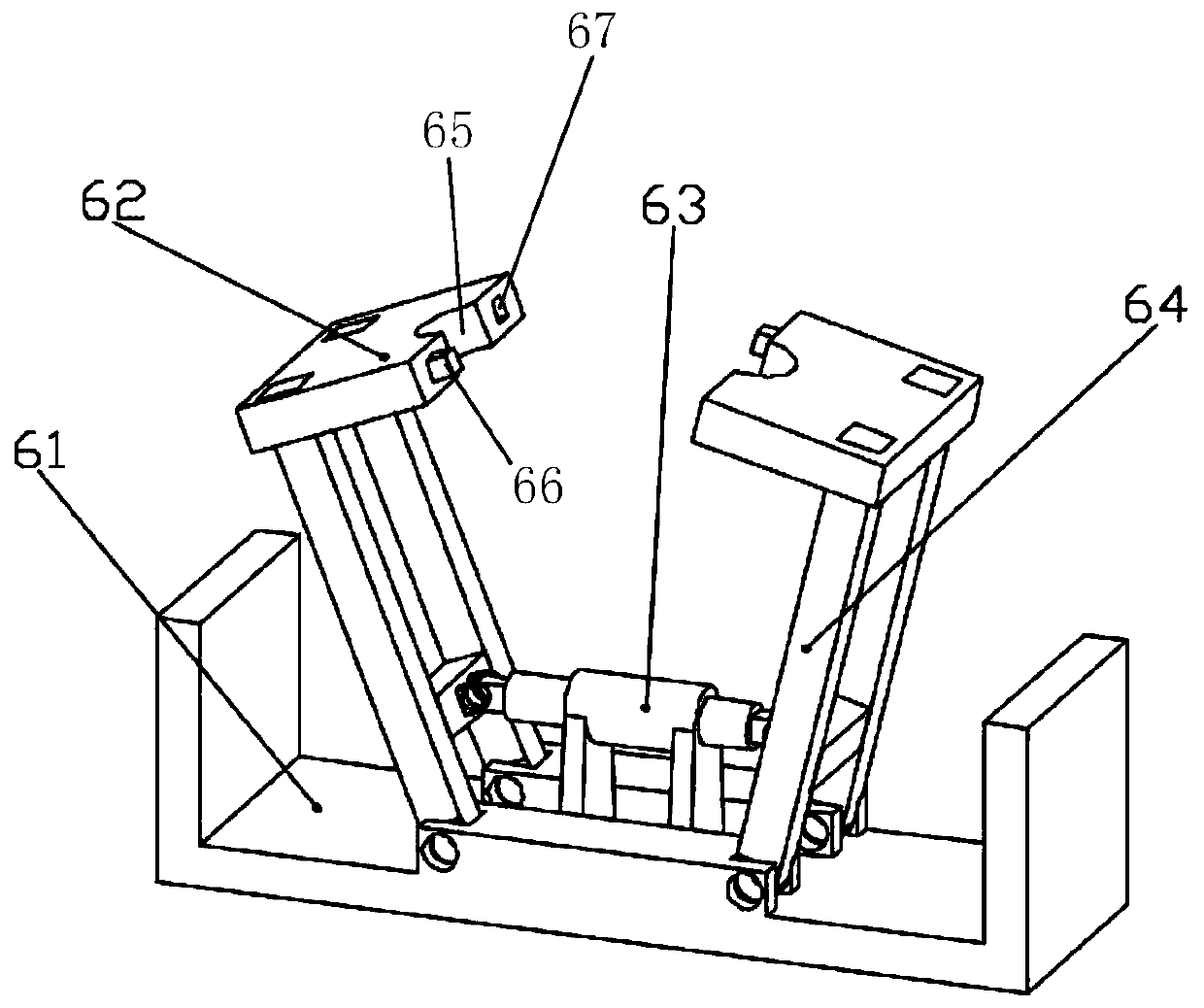

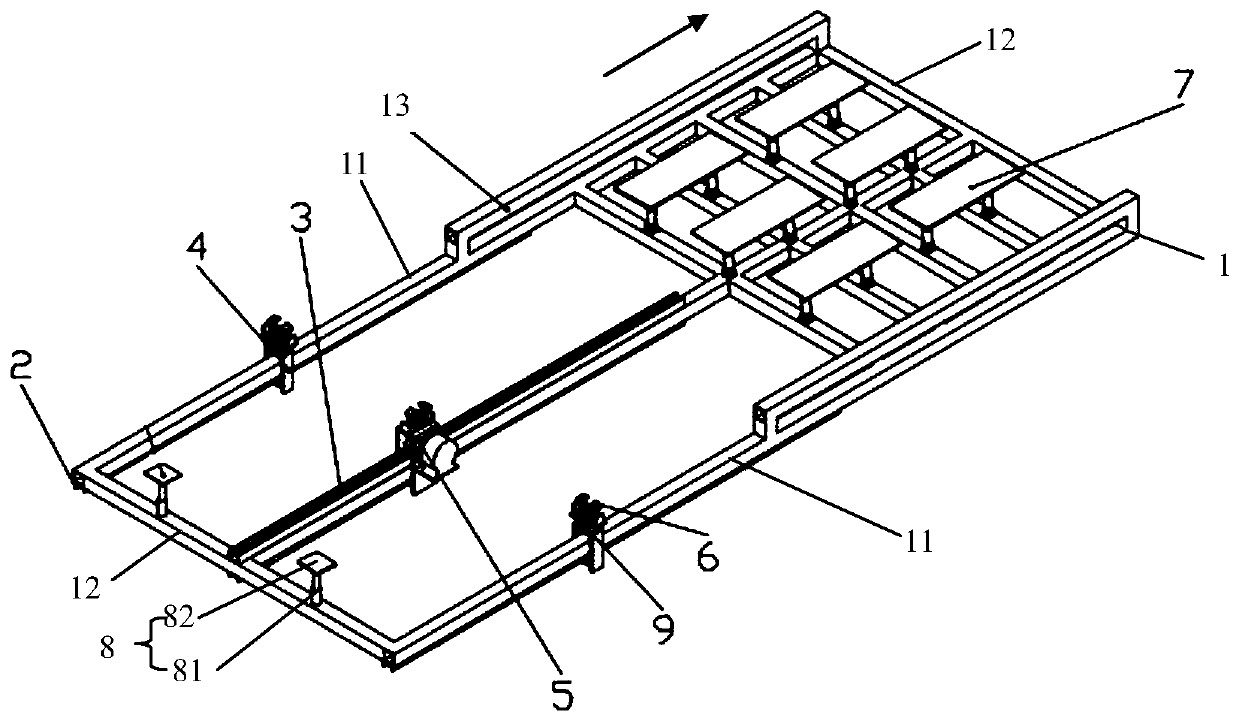

Driving face temporary support equipment and working method thereof

ActiveCN110145347AAvoid working with empty topsImprove productivityUnderground chambersTunnel liningSteel beltSteel tube

The invention discloses driving face temporary support equipment and a working method thereof, and belongs to the field of roadway support. The equipment comprises a front beam frame; the front beam frame comprises three square steel pipes, and connecting rods for connecting the three square steel pipes; at least four sets of connecting rods are arranged at the front end of the front beam frame, and a set of connecting rods is arranged at the back end; a driving mechanism is arranged on the square steel pipe in middle; guide mechanisms are arranged on the square steel pipes on two sides; a clamping device is fixedly arranged at the upper part of the driving mechanism; clamping mechanisms are mounted at the upper parts of the guide mechanisms through undercarriages; multiple sets of liftingplatforms are uniformly arranged on the four sets of connecting rods at the front end of the front beam frame; projection brackets are arranged at the front ends of the square steel pipes on two sides; and a tail leveling device is arranged at the back end of the front beam frame. The anchor net and steel strip pavement and the temporary support work are once realized to effectively prevent the operation of workers under empty tops; and the autonomous movement of the temporary support equipment is realized to achieve important significance on improvement of the support efficiency and reduction of the manpower and the labor intensity.

Owner:SHANDONG UNIV OF SCI & TECH

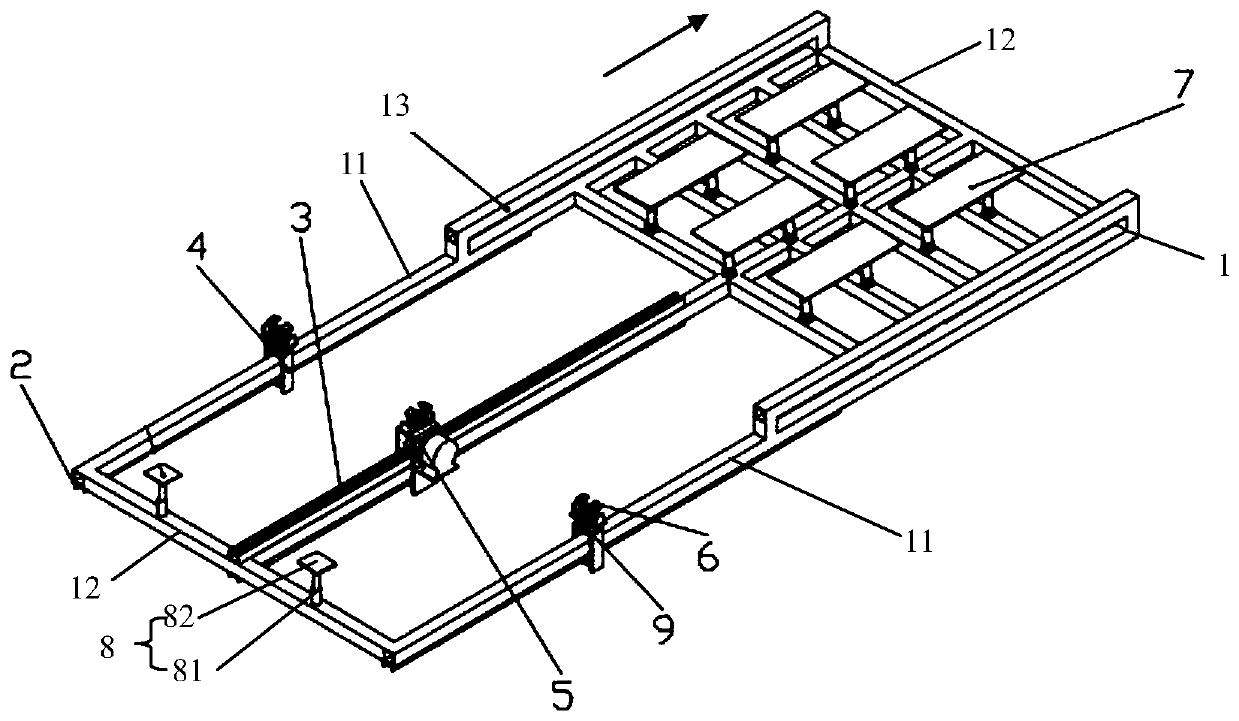

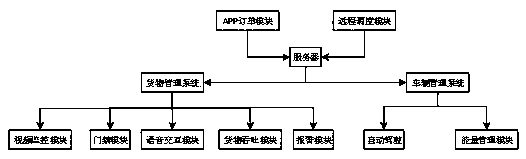

Unmanned selling vehicle system and using method

InactiveCN110096058AMeet the needs of intelligent developmentImprove freight efficiencyRoad vehicles traffic controlCoin-freed apparatus detailsRadarEngineering

The invention discloses an unmanned selling vehicle system and a using method. The unmanned selling vehicle system comprises an order module and a remote dispatching module, wherein the order module and the remote dispatching module are both in communication connection with a vehicle-mounted end by means of a server, the vehicle-mounted end comprises a vehicle management system arranged on a chassis and a cargo management system arranged on a vehicle body, and the chassis is detachably connected with the vehicle body; the vehicle management system comprises an automatic driving module; the cargo management system comprises a cargo throughput module and an access control module; and the automatic driving module comprises an industrial control computer, a laser radar and a GPS module. The unmanned selling vehicle system and the using method have the advantages of saving manpower, improving freight efficiency, having good expansibility and saving resources.

Owner:HANKAISI INTELLIGENT TECH CO LTD GUIZHOU

Security ensuring and patrolling robot

InactiveCN1331641CReliable completionStabilize security patrol tasksManipulatorControl systemEngineering

The invention relates to a kind of patrolling robot. It consists of robot body, the movable controlling unit and the bearing rack of which is fixed firmly to the outer shell; anti- stakeout system, which consists of infrared temperature sensor, smoking sensor, hot releasing infrared sensor, mini CCD camera eye, signal lamp, buffer, and graphic message wireless conveying module; the controlling system that sends message to control the robot to patrol, move to control and give an alarm automatically within the circumstance; multi-sensor system. The robot can patrol along the scheduled path, and judge the location is at according to the messages from the sensors to avoid the impediment and change the moving path. The invention is more suitable to increasing onerous security task, and improves the atomicity of security work.

Owner:SOUTH CHINA UNIV OF TECH

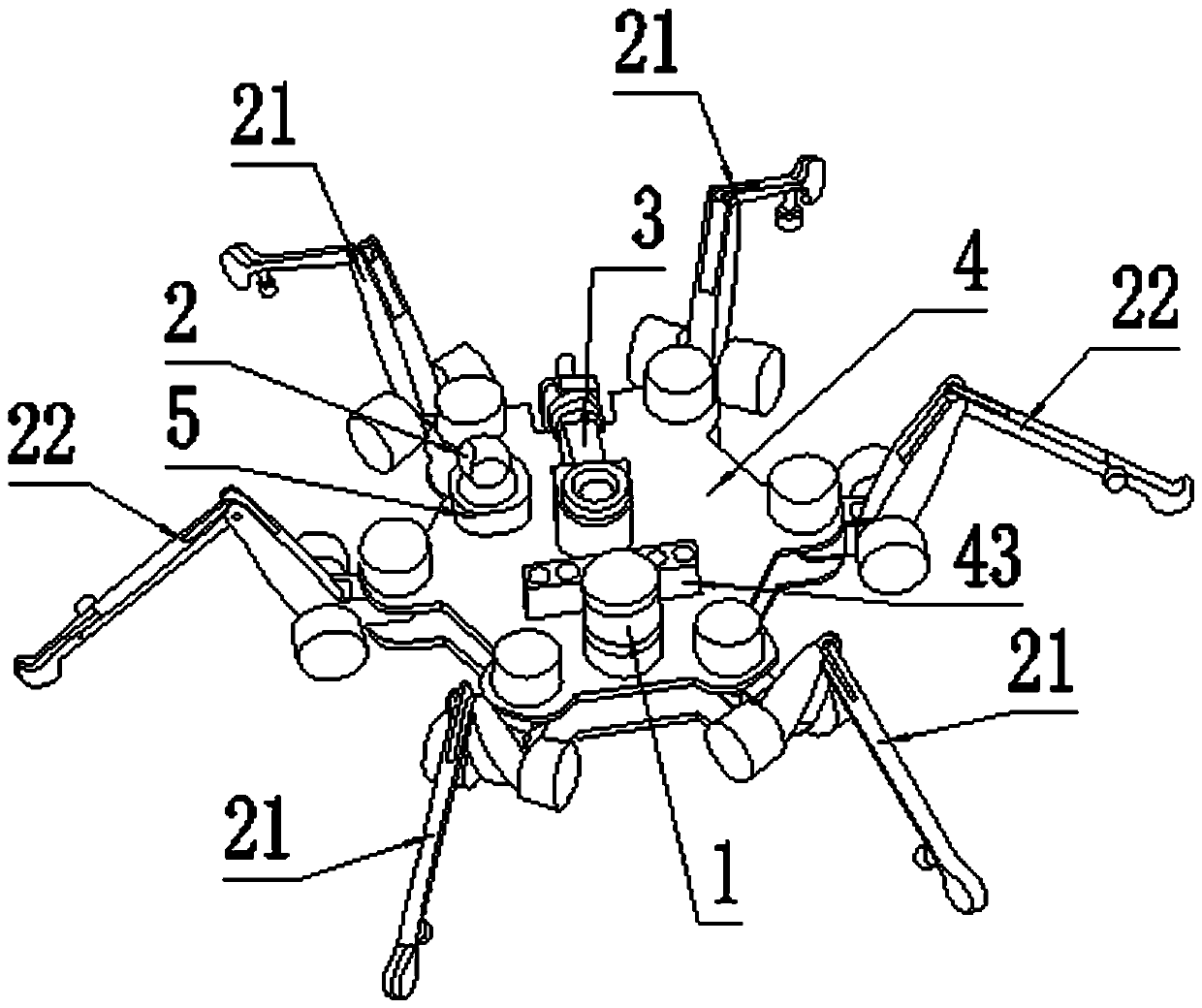

Hexapod robot for maintenance of heavy vehicle chassis

ActiveCN111361532AImplementation locationRealize regulationVehicle servicing/repairingMetal working apparatusHexapodControl engineering

The invention discloses a hexapod robot for maintenance of a heavy vehicle chassis, and relates to the technical field of vehicle maintenance equipment. The hexapod robot comprises a controller and amobile platform for bearing a laser radar, a camera and an operating arm, the edge of the mobile platform is provided with a hexapod walking device, and the controller is in wireless connection with the laser radar, the camera and the operating arm. The laser radar scans a vehicle and automatically plans a path, the environment below the vehicle chassis is observed by means of the camera to facilitate maintenance operation, the hexapod walking device on the edge of the mobile platform is remotely controlled by the controller to conduct coordination and posture adjustment movement to achieve autonomous movement and multi-leg-foot coordination work, all-around position and posture adjustment of the maintenance robot below the vehicle chassis can be achieved, and maintenance operation is conducted by controlling the action of the operation arm. Bolt loading, unloading, oil changing or cleaning maintenance work can be carried out on the chassis system, and the chassis system is particularly suitable for maintenance of narrow space places below the vehicle chassis.

Owner:中国人民解放军32181部队

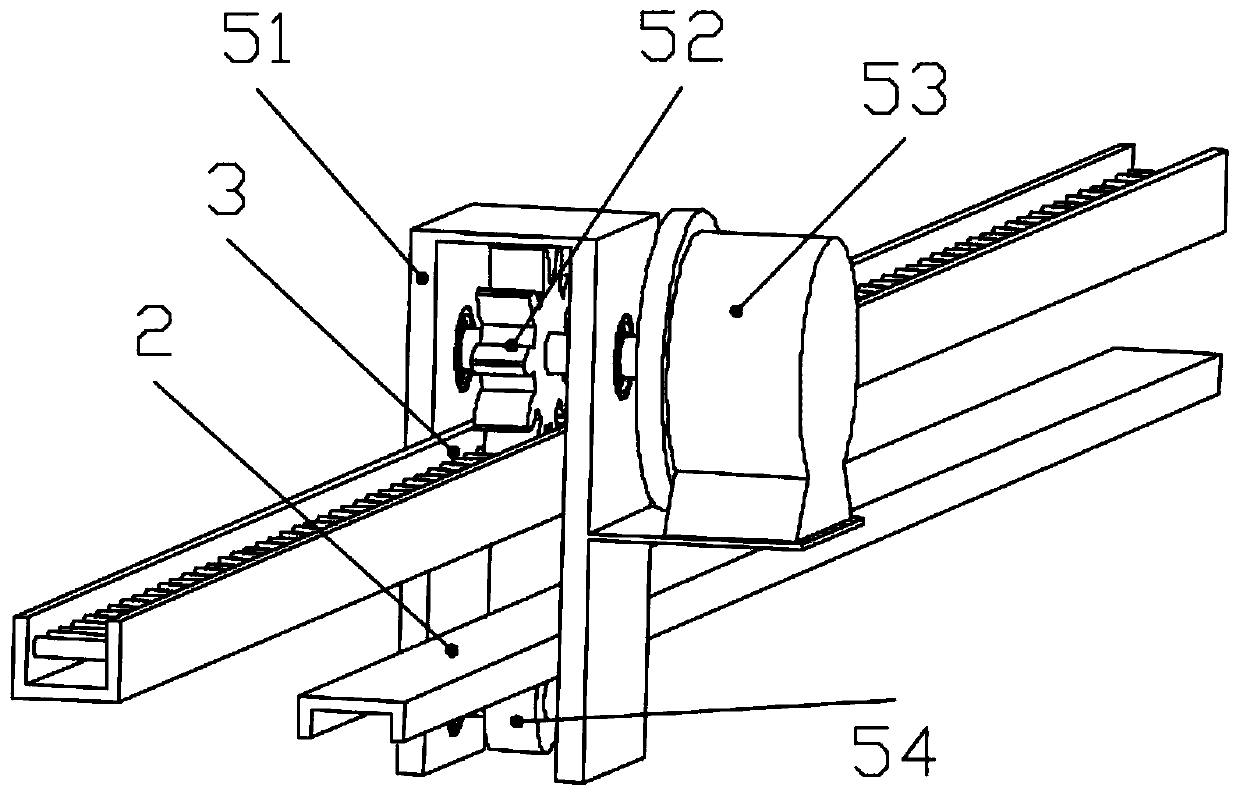

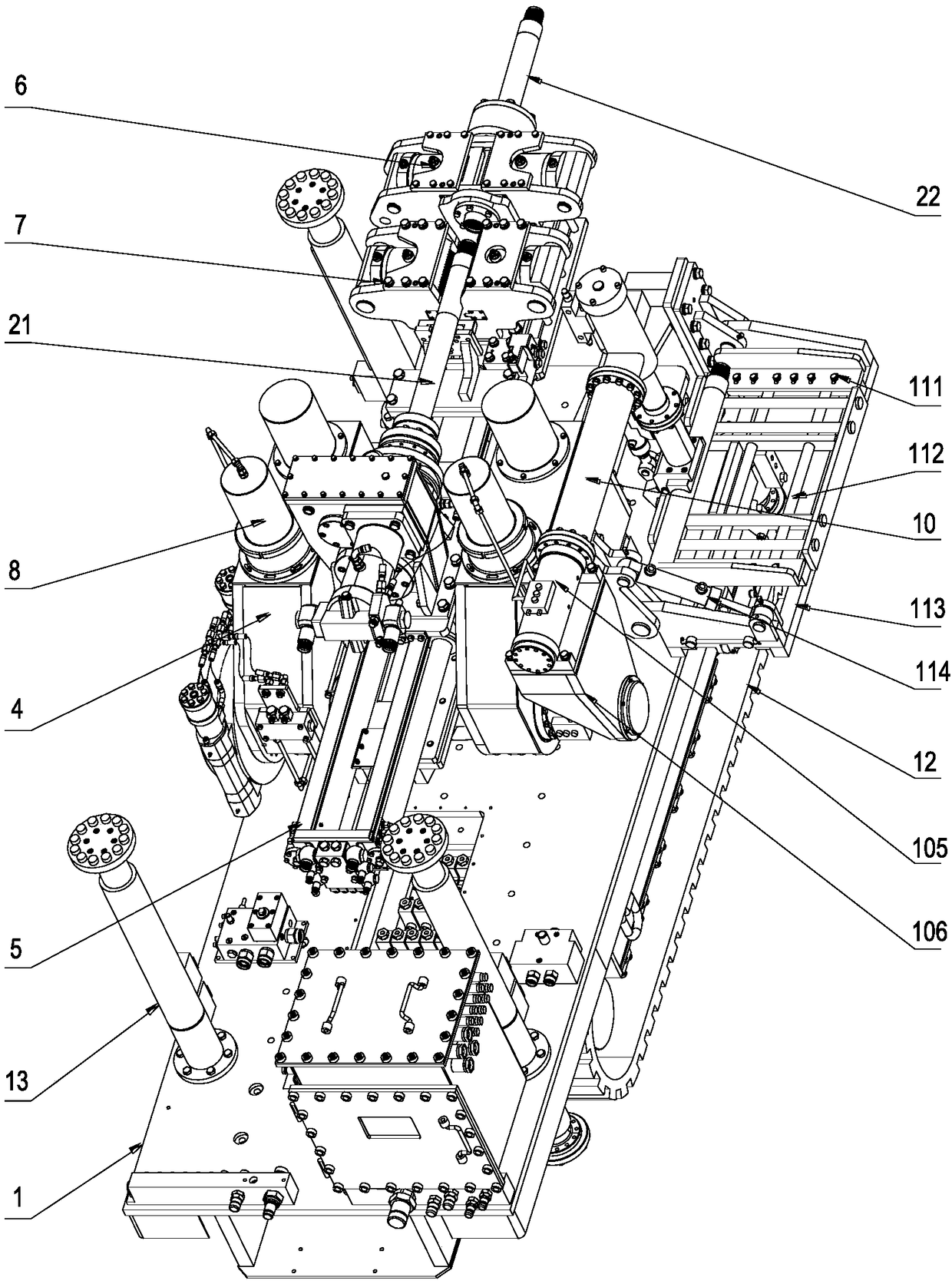

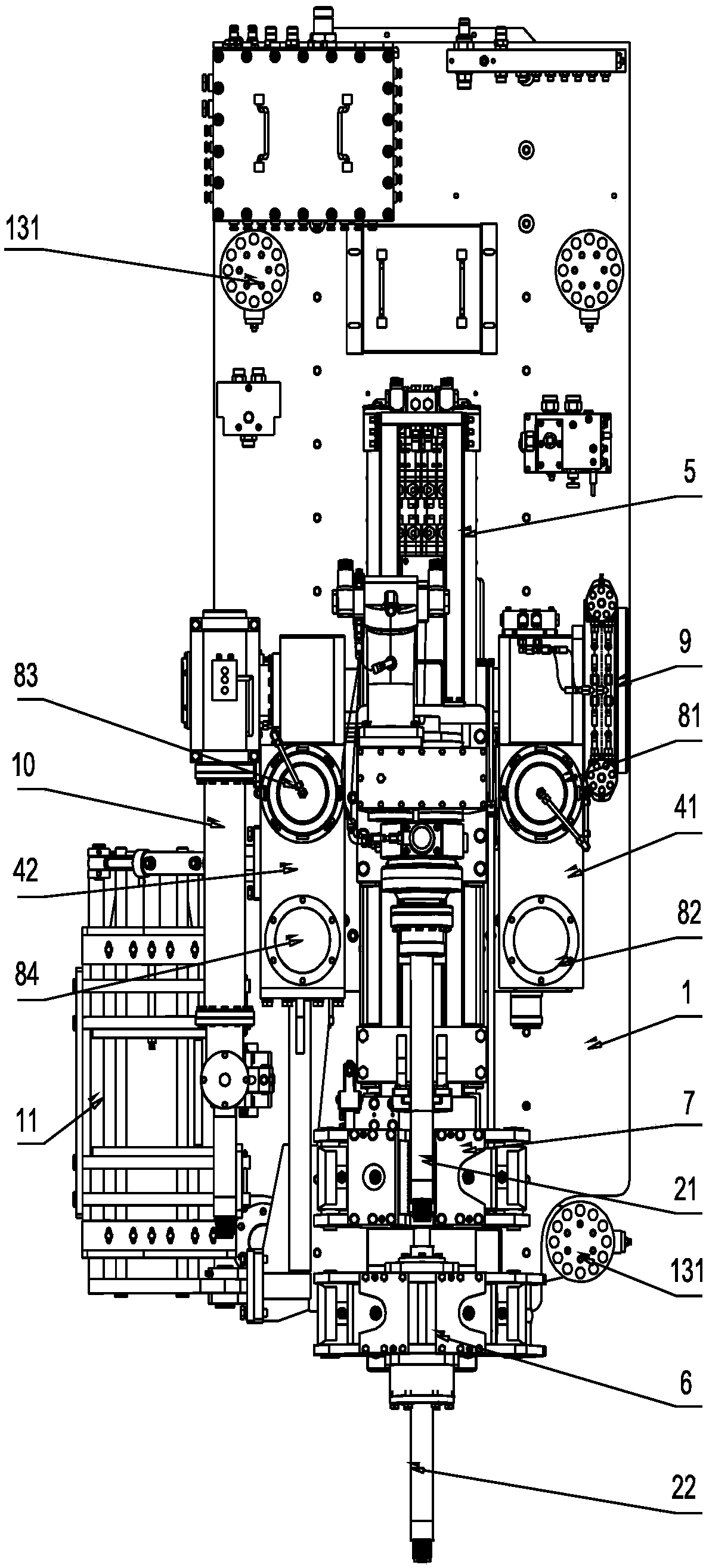

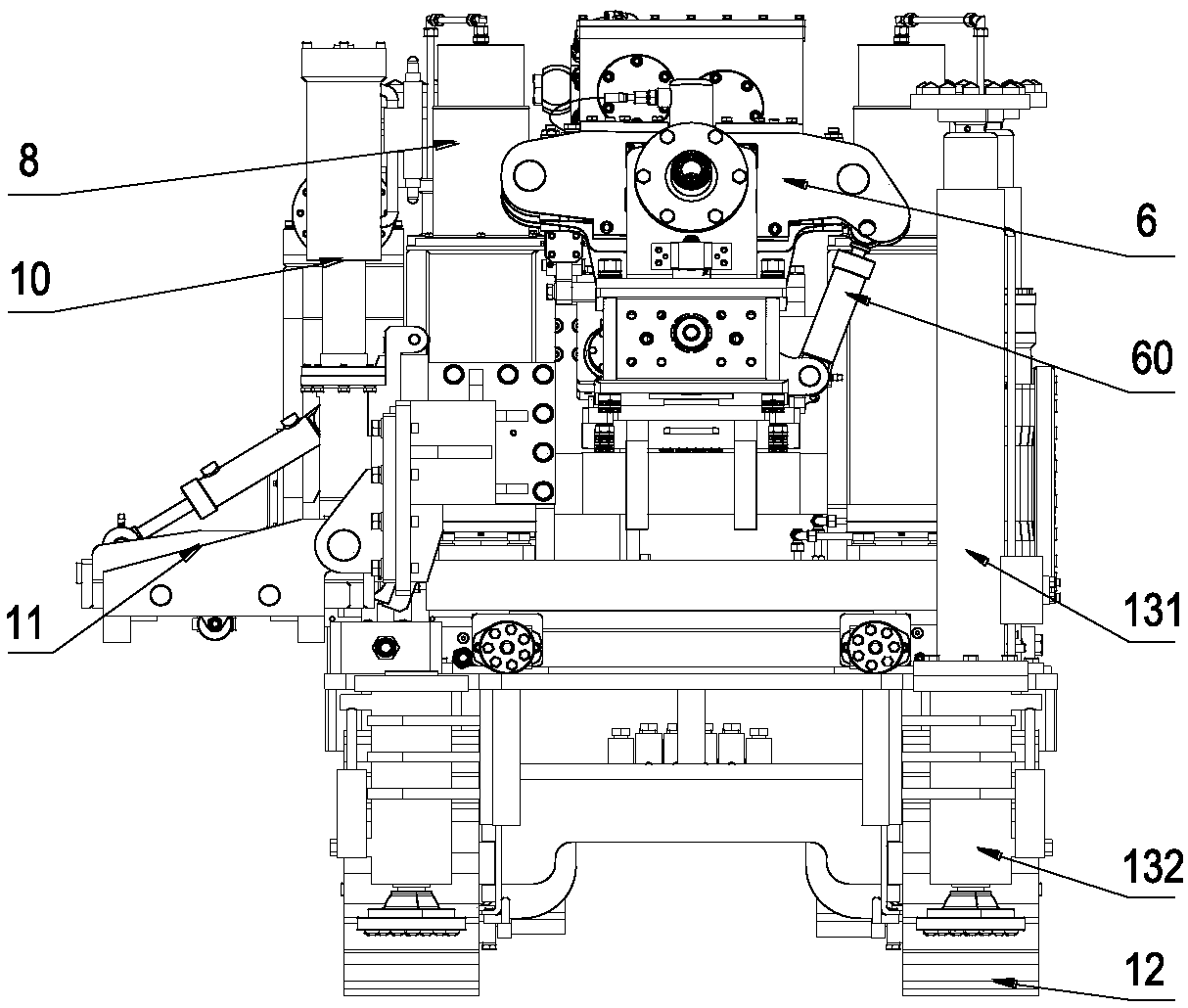

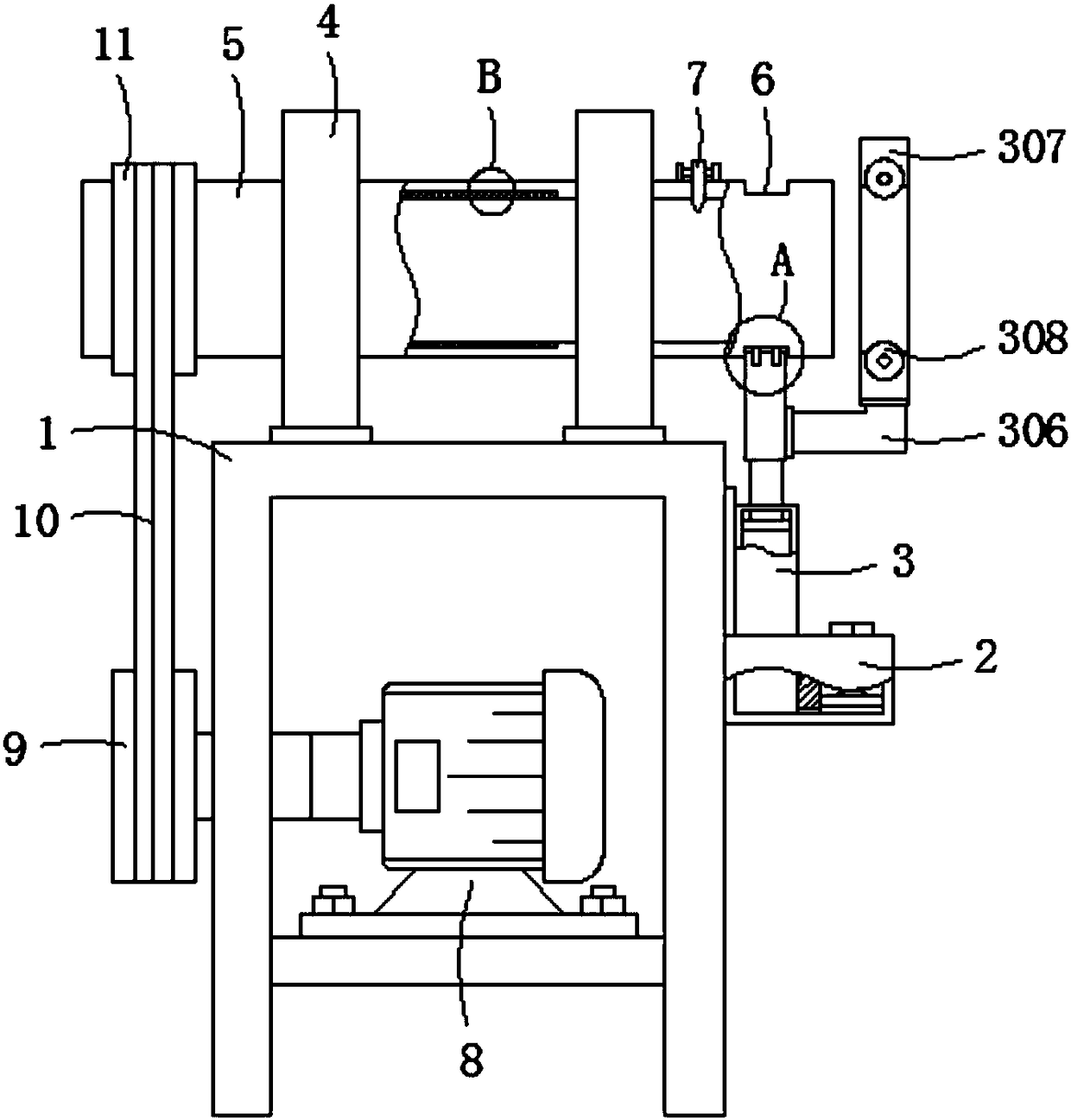

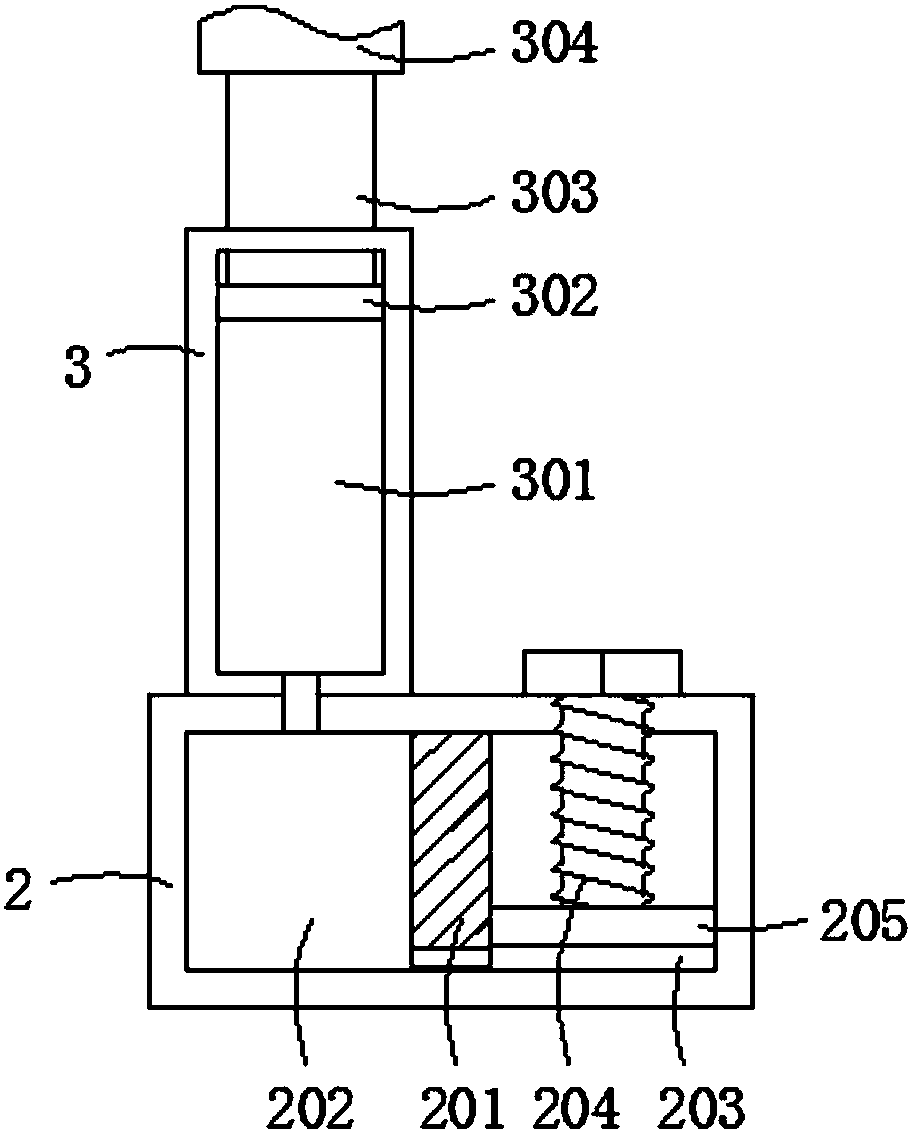

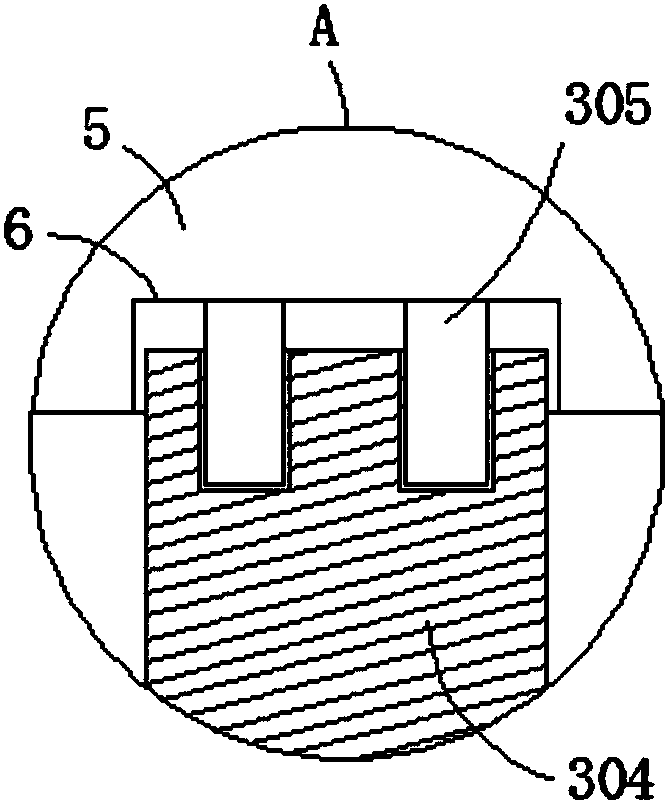

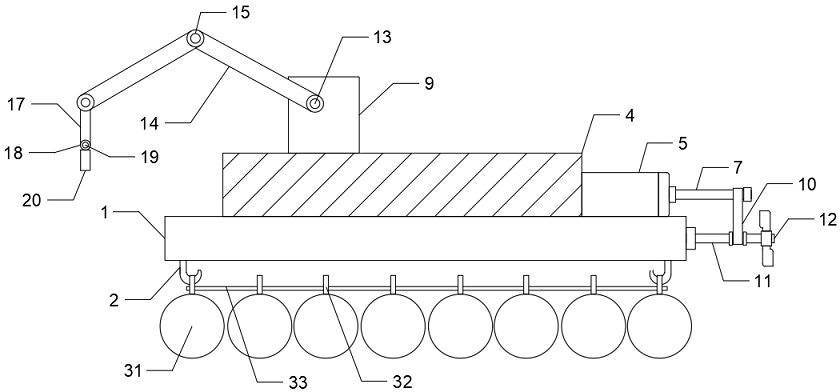

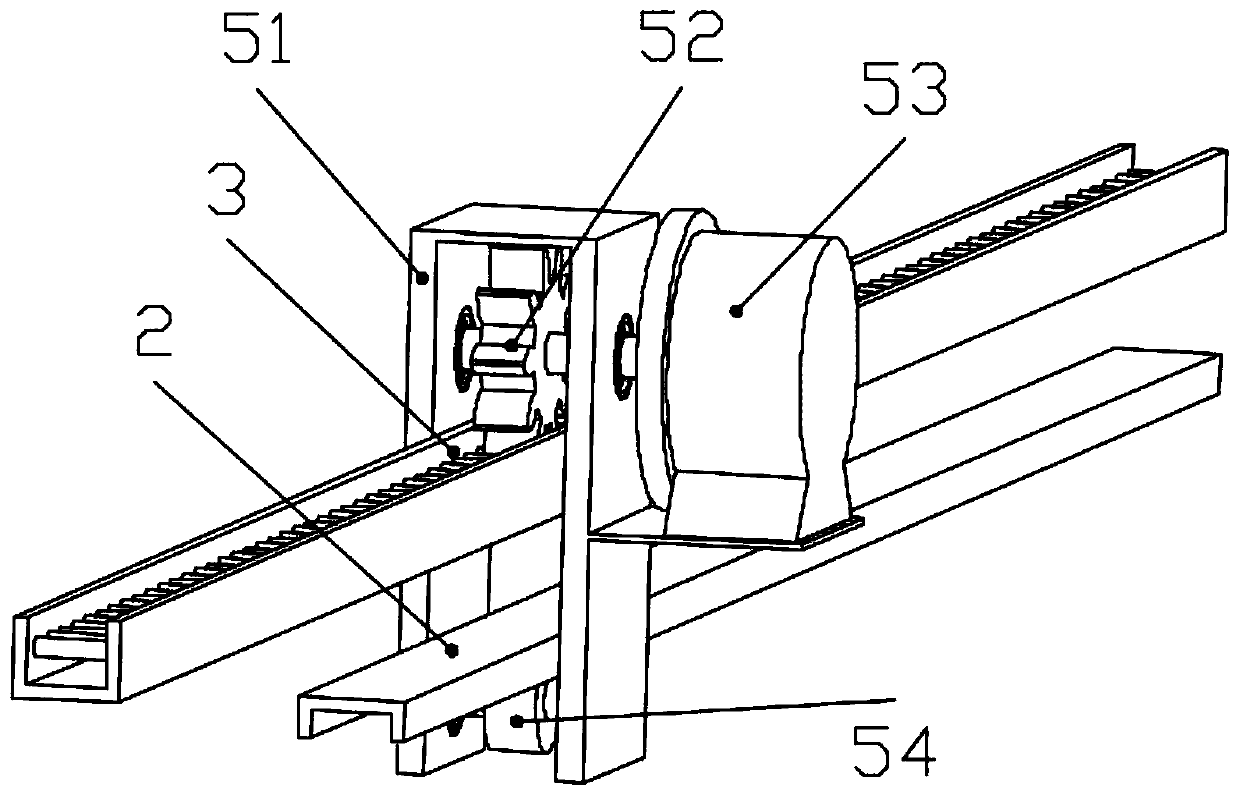

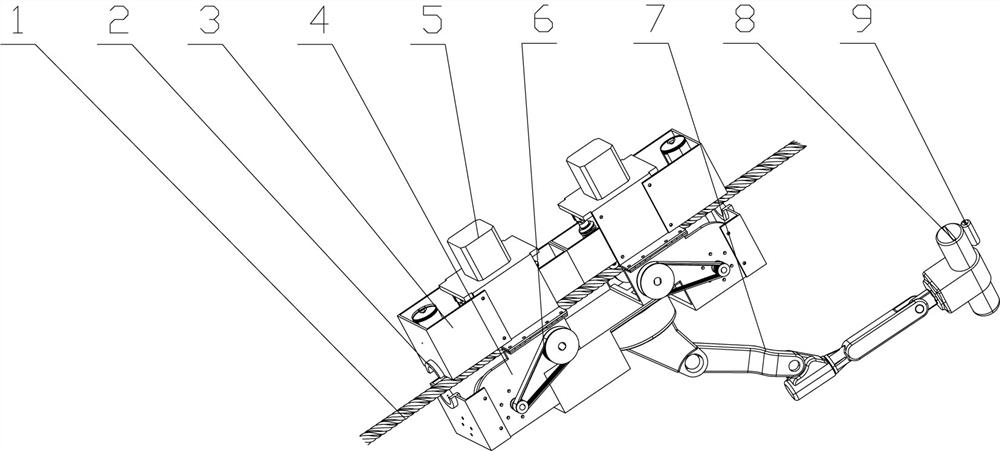

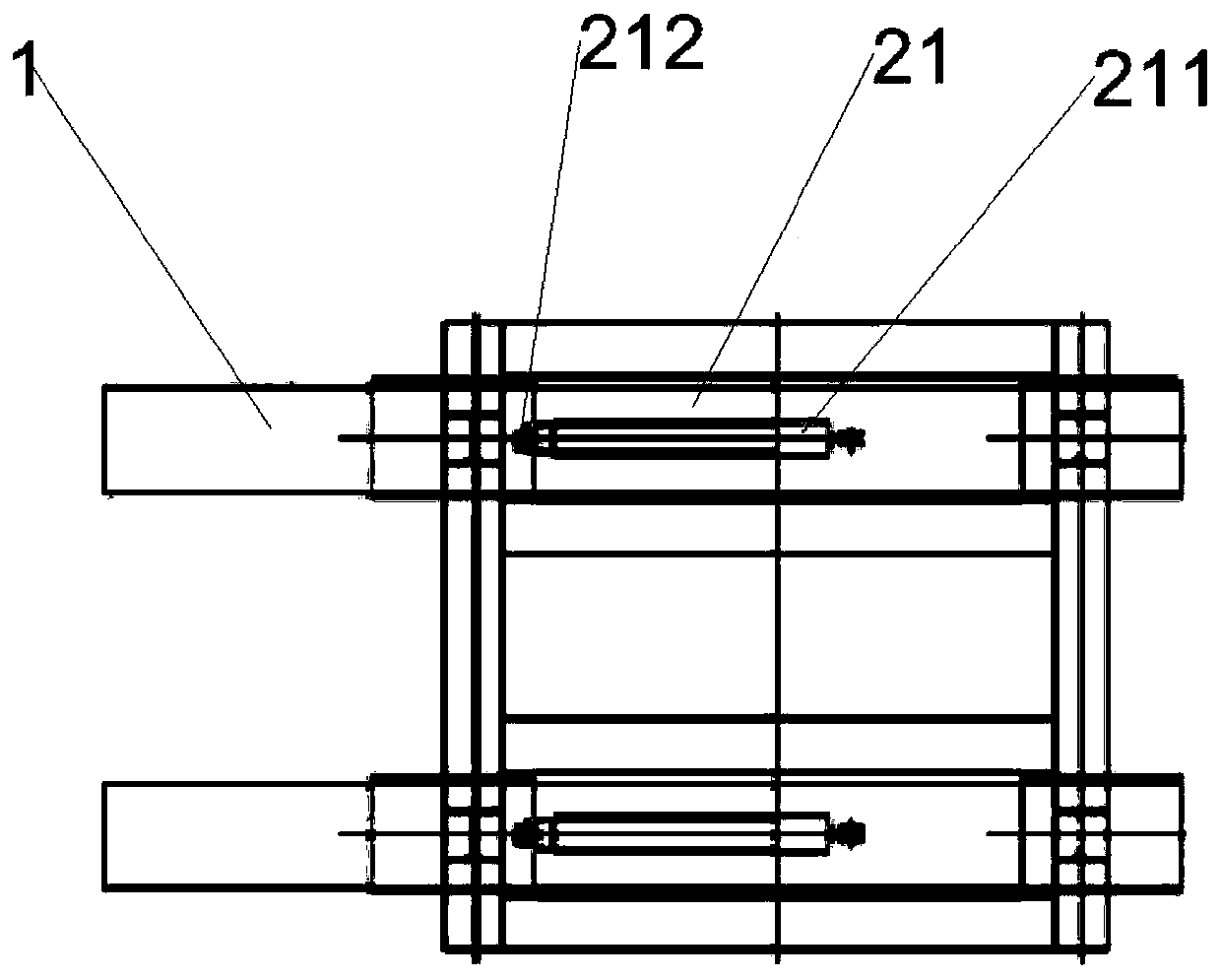

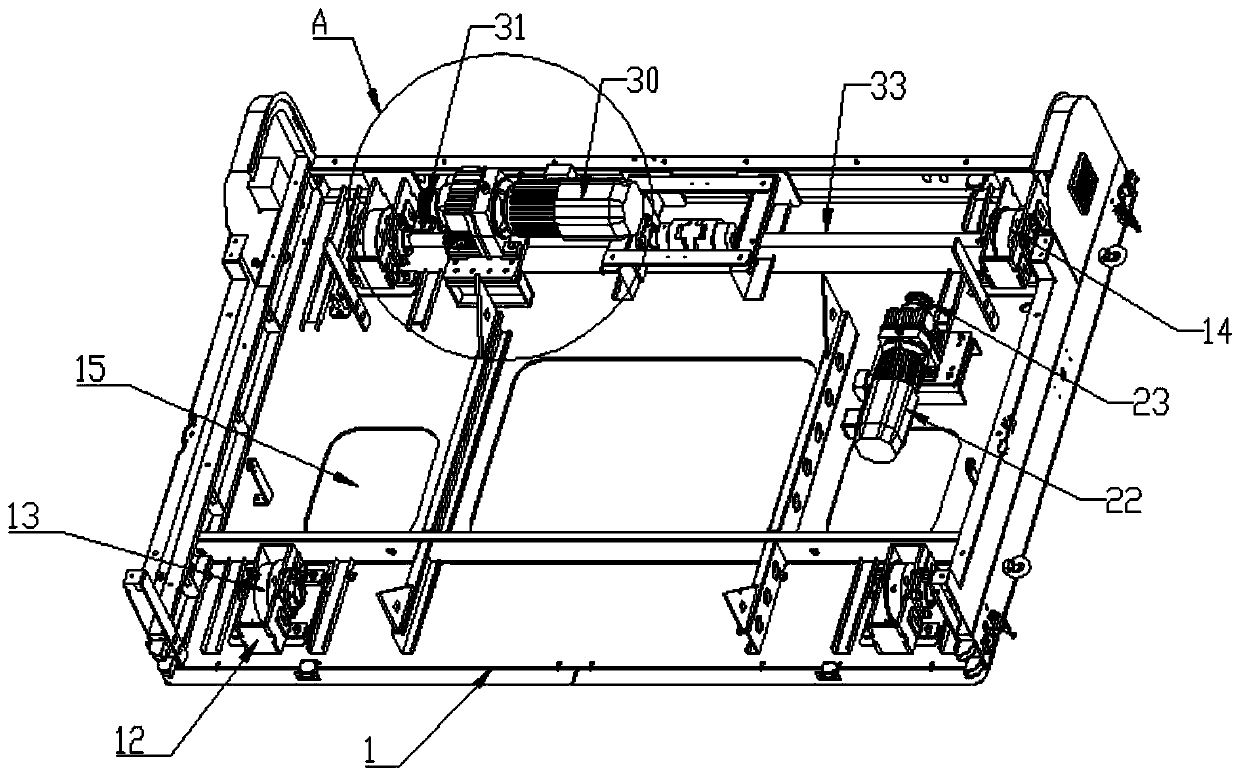

Full-automatic underground drill rig

PendingCN108071339AFully automatedAchieving autonomous mobilityDrilling rodsDerricks/mastsEngineeringDrill

The invention discloses a full-automatic underground drill rig including a workbench, a drill rod, a supporting base and a drill rod main driving device, and further including a guide device connectedto the bottom of the drill rod main driving device and mounted on the supporting base, a front clamp fixed to the end of the guide device, a rear clamp located between the drill rod main driving device and the front clamp and fixed to the end of the guide device, a mechanical arm mounted on the outer side of the supporting base, a drill rod adjusting box arranged at the end of the supporting baseclose to one side of the mechanical arm, and a walking device mounted at the bottom of the workbench, wherein the periphery of the front clamp is provided with a rotating driving device connected with the guide device. By application of the drill rig, various parts can cooperate with each other to achieve actions such as automatic positioning, automatic drill rig installation, automatic drillingand automatic pulling out of a hole, so the full-automatic underground drill rig can implement automatic operation.

Owner:CHONGQING PINGSHAN MINING ELECTROMECHANICAL EQUIP

MPP power cable protection pipe thread machining device

The invention discloses an MPP power cable protection pipe thread machining device. The MPP power cable protection pipe thread machining device comprises a machine frame. A fine adjustment base is welded to the outer wall of one side of the machine frame, and a gas rod is welded to the top end of the fine adjustment base. A separating plate is welded inside the fine adjustment base, a first separated cavity and a second separated cavity are formed in the two sides of the separating plate, and gas holes are connected between the first separated cavity and the second separated cavity and betweenthe second separated cavity and the gas rod. A fixed bearing pedestal is welded at the top end of the machine frame, and a sleeve penetrates through the interior of the fixed bearing pedestal. According to the MPP power cable protection pipe thread machining device, the fine adjustment base, the gas rod and a sliding groove are arranged, adjustment of an overall positioning device is achieved through mutual cooperation of the fine adjustment base and the gas rod, a fine adjustment bolt on the fine adjustment base is rotated in the adjustment process and pushes a first piston to move, and therefore the distribution state of gas located inside the first separated cavity and the second separated cavity is changed, the gas can enter the gas rod along the first separated cavity and push a second piston so as to change the position of a positioning rod.

Owner:浙江荣正管业有限公司

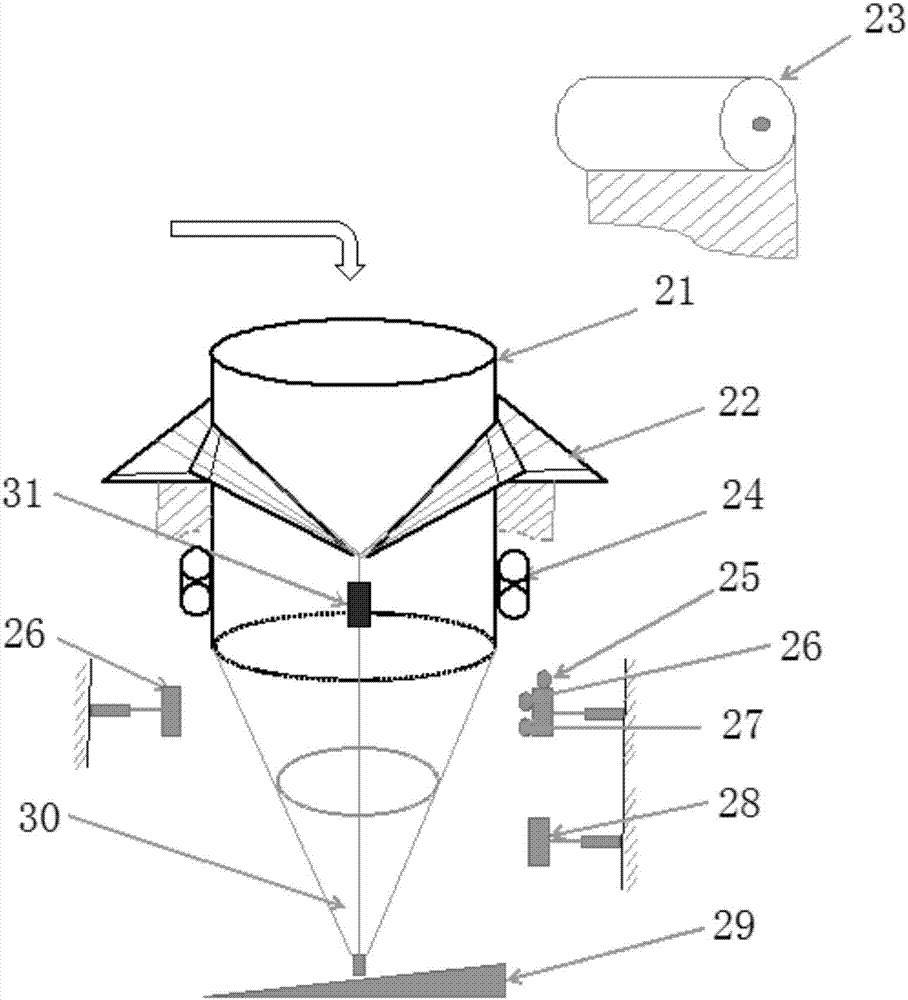

Power transmission line multi-angle intelligent spraying robot

ActiveCN111555179AAchieving autonomous mobilityAchieve compactionOverhead installationApparatus for overhead lines/cablesRemote controlControl engineering

The invention discloses a power transmission line multi-angle intelligent spraying robot. The robot is characterized in that a driving device is used for driving a driving roller to rotate, so that the autonomous movement of the spraying robot in the front-back direction along a power transmission cable is realized; meanwhile, two groups of pressing wheel mechanisms are adopted to press the powertransmission cable, so that slipping in the walking process is avoided; the walking speed can be adjusted through a speed feedback signal of a speed measuring device, both a front brush device and a rear brush device adopt the steel wire brush discs, the surface of the power transmission line and aluminum wire gaps are swept, brushed and cleaned from the upper, lower, left and right directions along the aluminum wire twisting direction, so that a clean environment is provided for the subsequent spraying work; in addition, a distance measuring instrument and a laser radar are used for sensingthe distance between obstacles, such as line towers, insulators, etc., so that the collision can be effectively avoided, and a collision buffering function is achieved even if collision occurs. The robot is high in intelligent degree, small in energy consumption, large in operation area and is capable of conducting remote control operation.

Owner:武汉露能科技有限公司

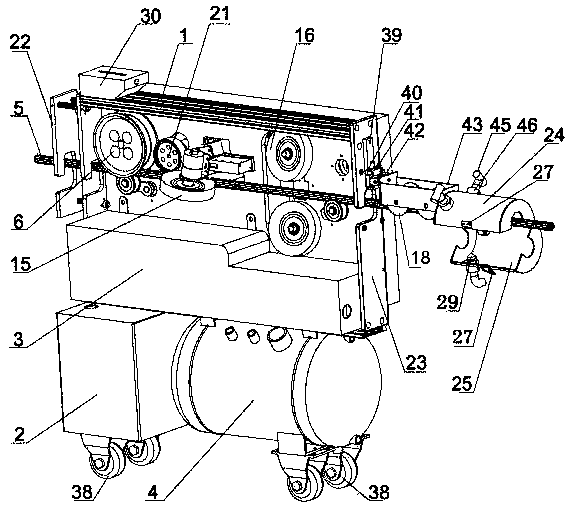

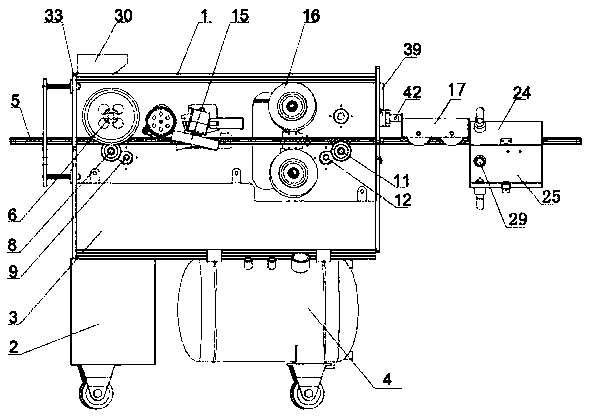

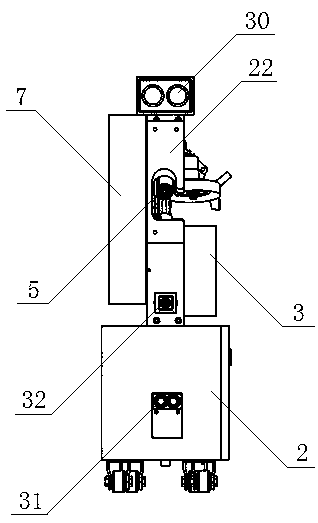

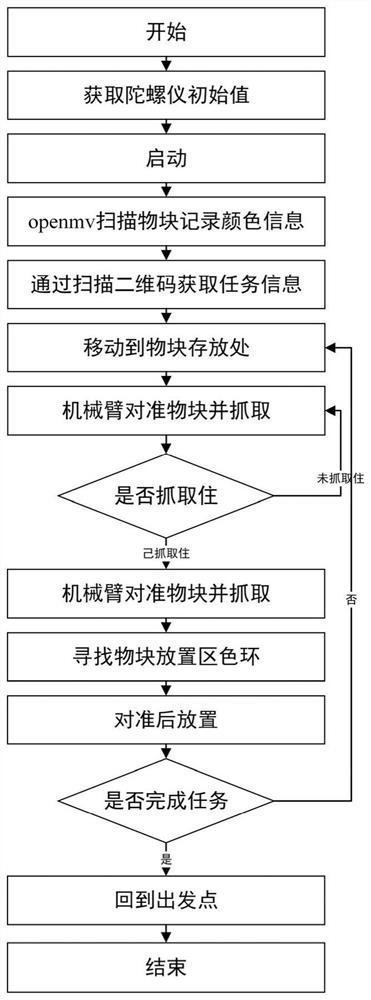

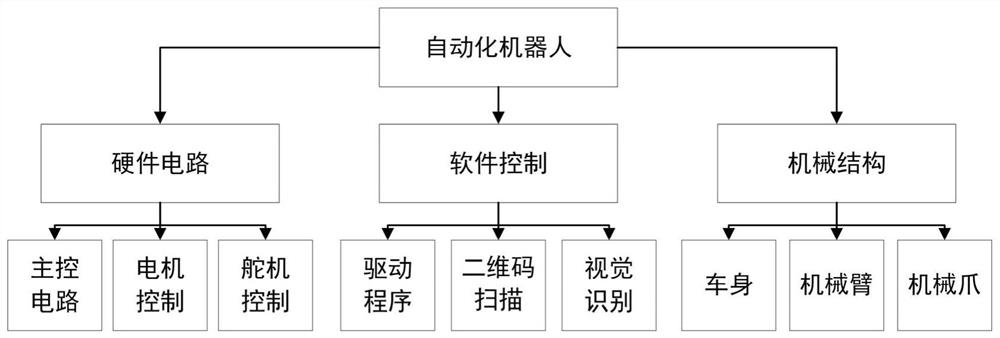

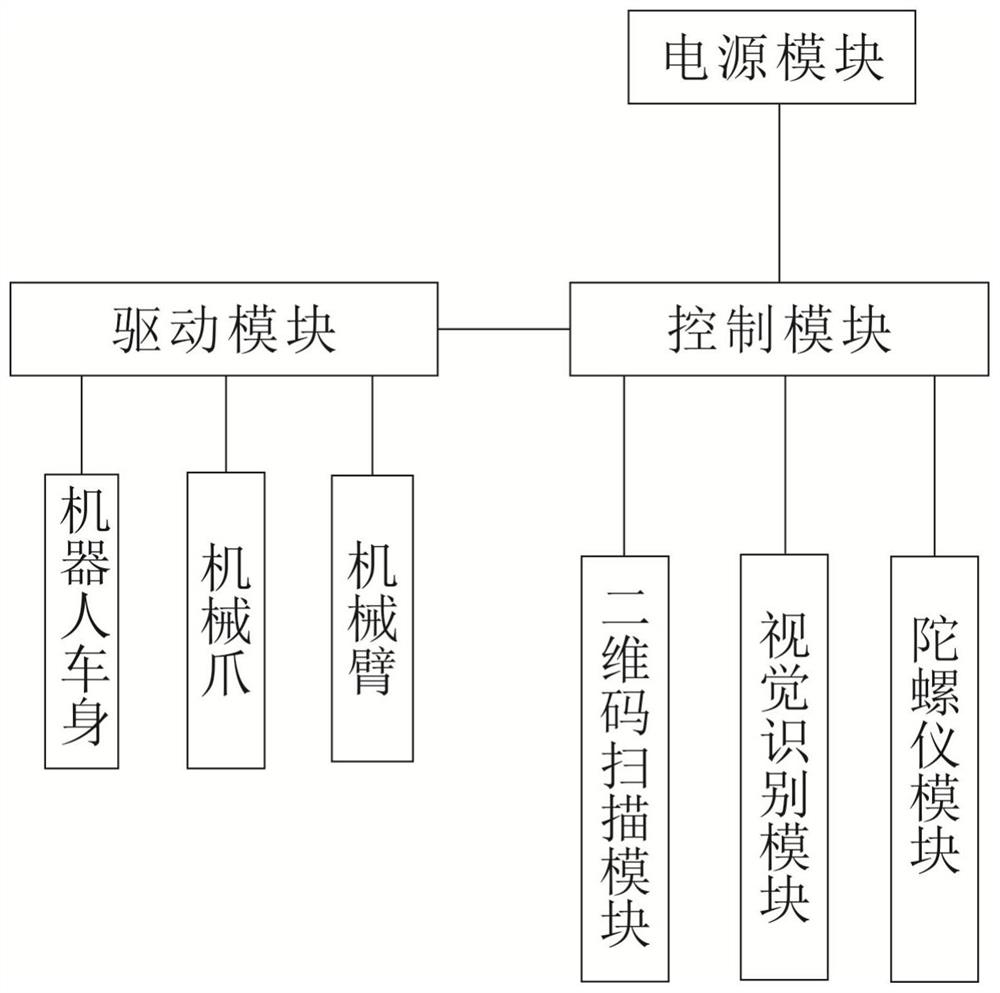

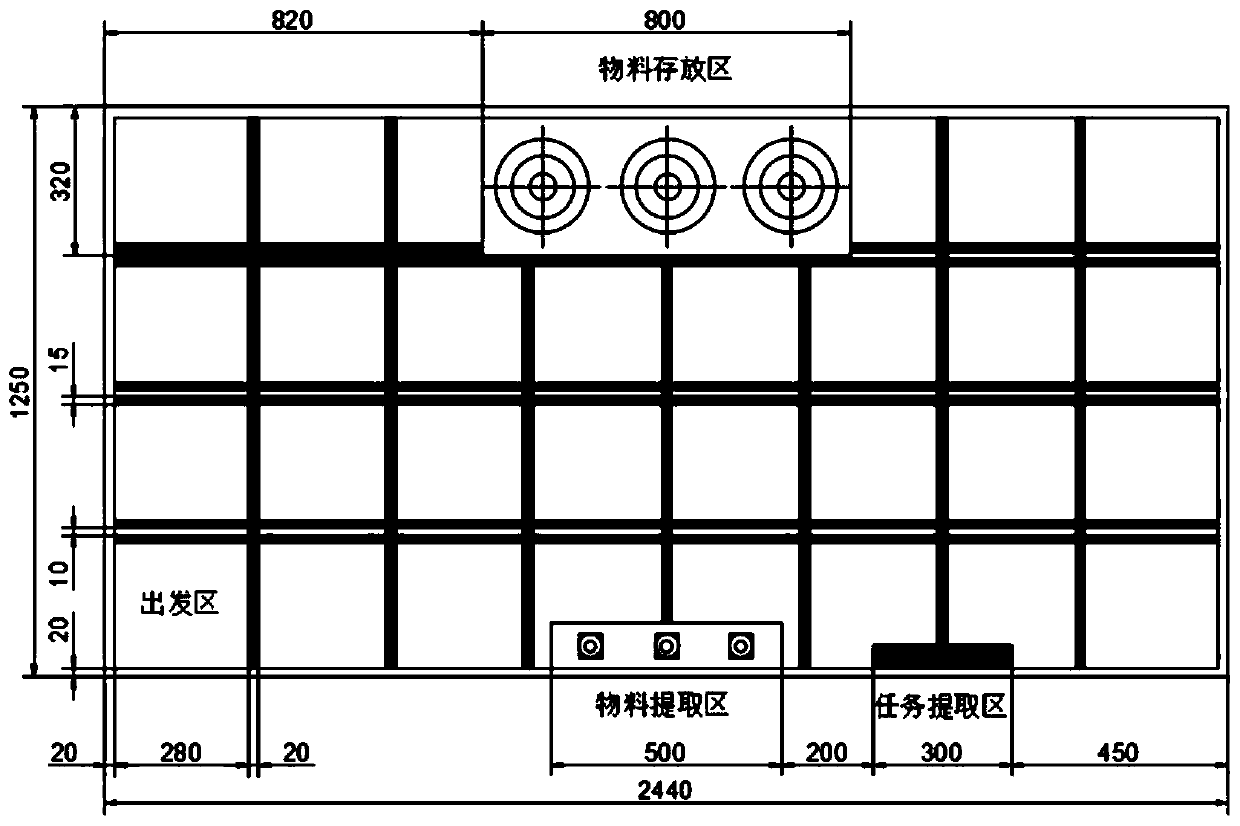

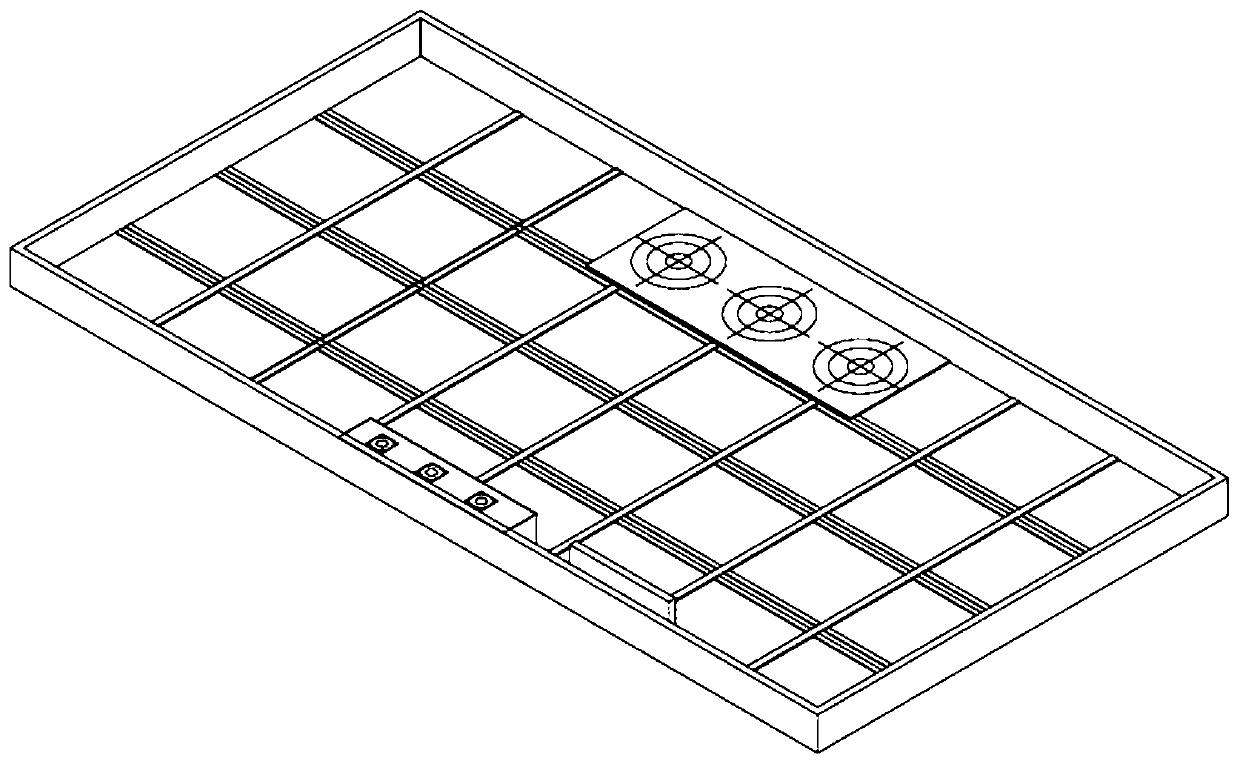

Automatic material transfer robot system and control method thereof

PendingCN112873163AAchieve crawlingRealize handlingProgramme-controlled manipulatorGyroscopeRectangular coordinates

The invention discloses an automatic material transfer robot system and a control method thereof. The system comprises a gyroscope module, wherein the gyroscope module is used for obtaining the initial angle of a transfer robot, constructing a site rectangular coordinate system, and setting the initial position of the transfer robot as a coordinate origin; a two-dimensional code scanning module, wherein the two-dimensional code scanning module is used for scanning a two-dimensional code to read target material task information and uploading the target material task information to a control module; a visual identification module, wherein the visual identification module is used for identifying a target material according to the color and the shape and uploading the identified target material information to the control module; the control module, wherein the control module is used for sending a control instruction to a driving module according to the received target material task information and the identified target material information and completing material grabbing operation; and the driving module, wherein the driving module is used for receiving an action instruction of the control module, moving the transfer robot to the target material and driving a mechanical claw and a mechanical arm to cooperatively grab and place the target material.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

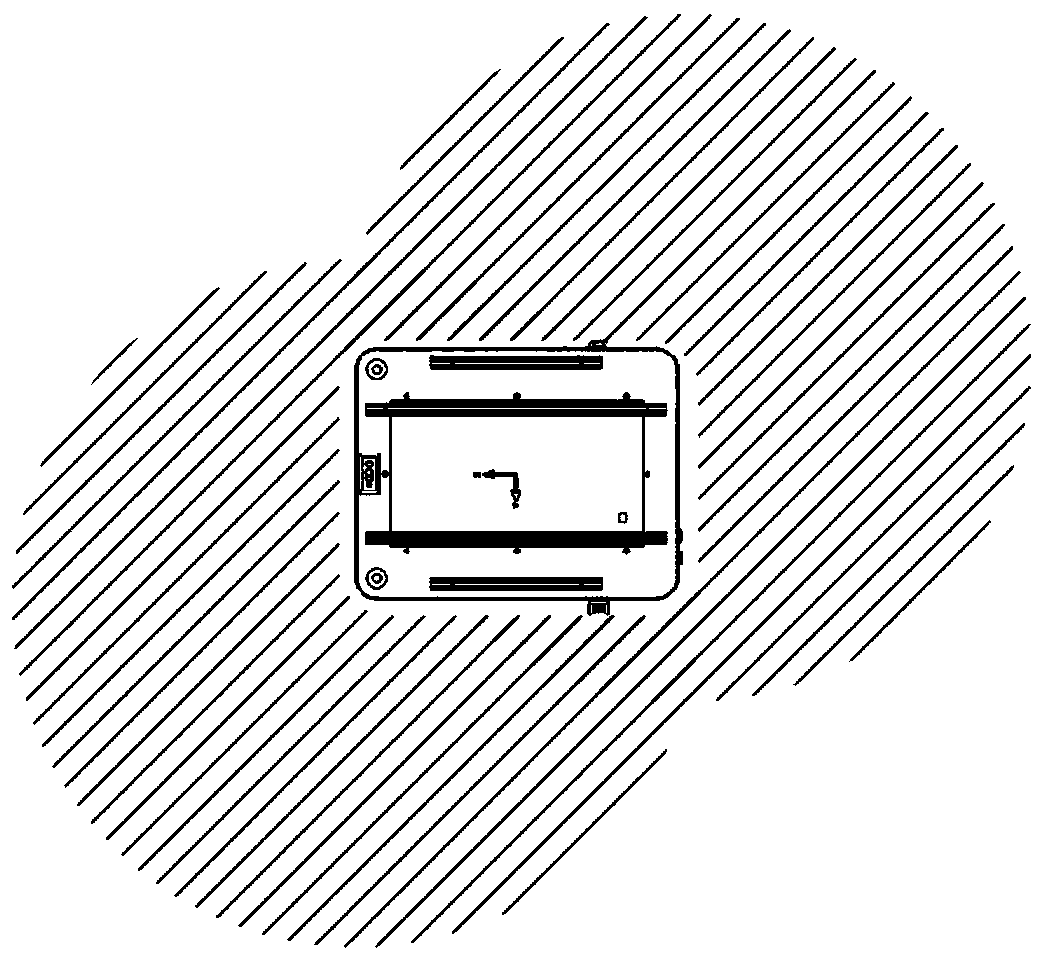

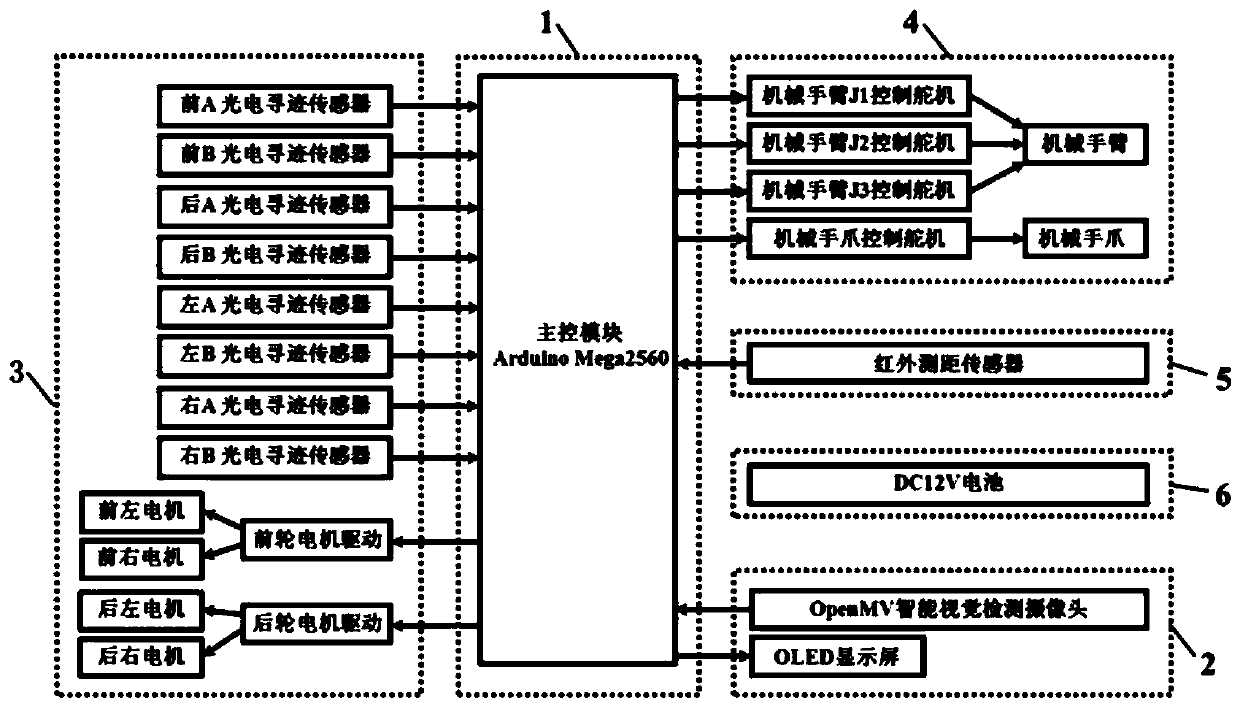

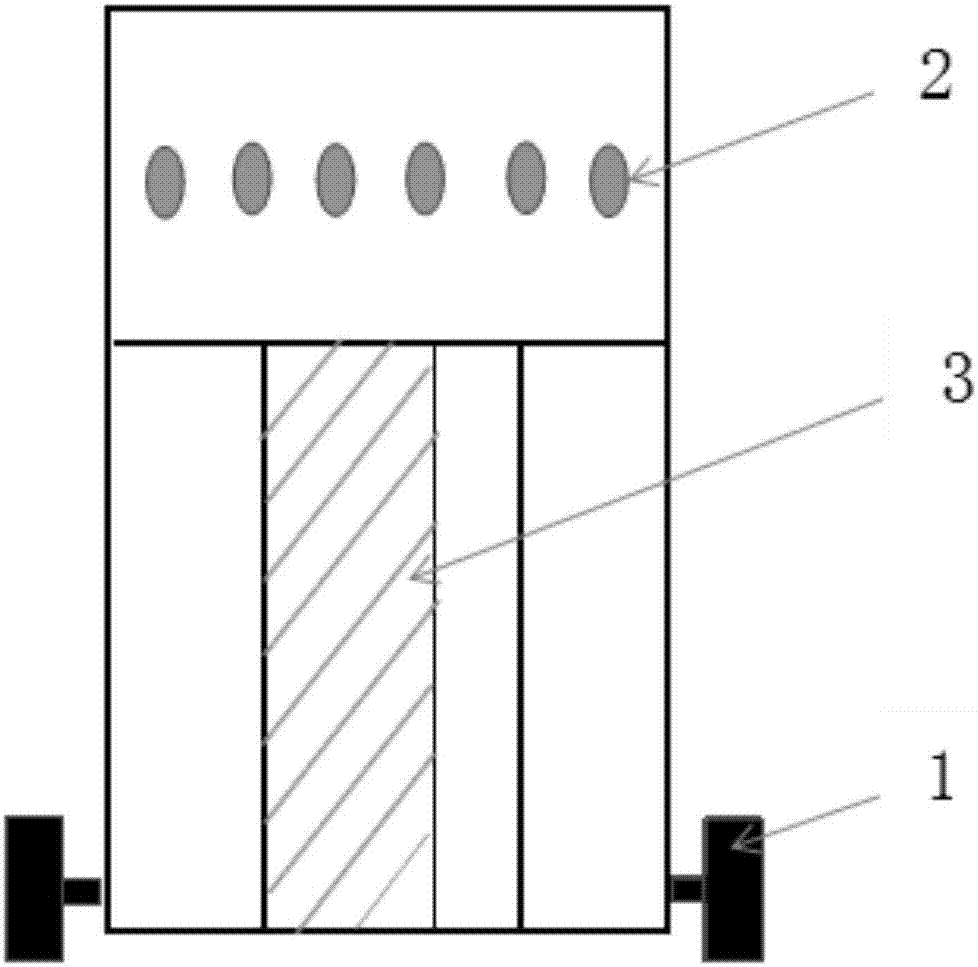

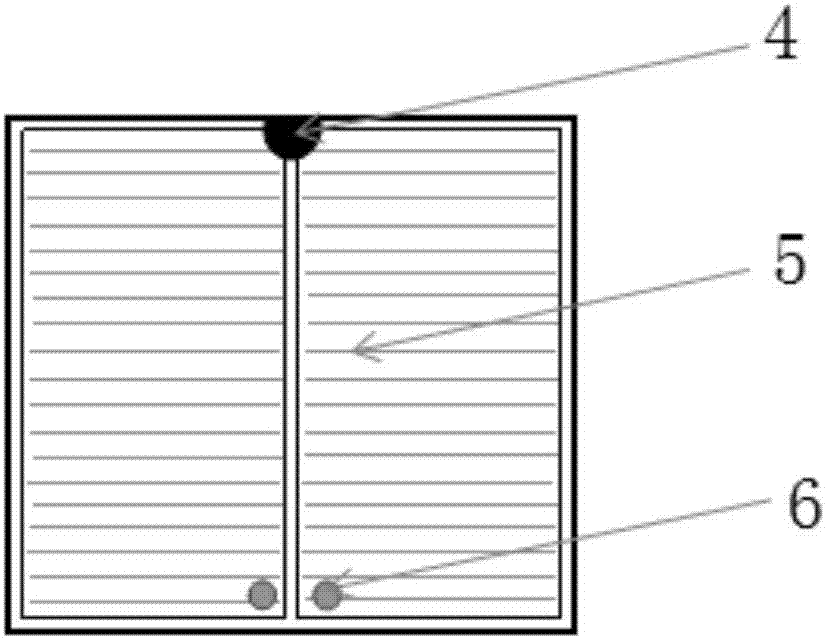

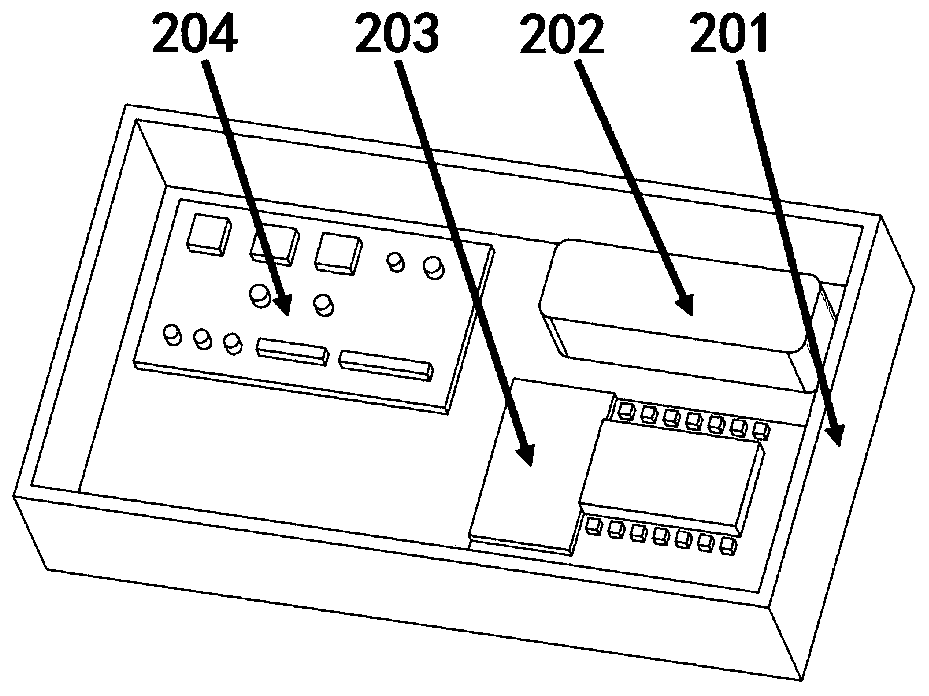

Control system of intelligent logistics transfer robot for teaching competition

PendingCN110919647ARealize target location recognitionAchieving autonomous mobilityProgramme-controlled manipulatorLogistics managementControl system

The invention discloses a control system of an intelligent logistics transfer robot for teaching competition, and the control system comprises a main control module which is connected with a visual detection module, a walking control module, a transfer control module, a start control module and a power supply control module. By means of the robot, in a set competition field, according to competition rules, the functions of target position recognition, autonomous path planning, autonomous movement, two-dimensional code reading, carrying task display, material color recognition, material shape recognition, material grabbing and carrying control of the robot can be achieved.

Owner:TIANJIN SINO GERMAN VOCATIONAL TECHNICAL COLLEGE

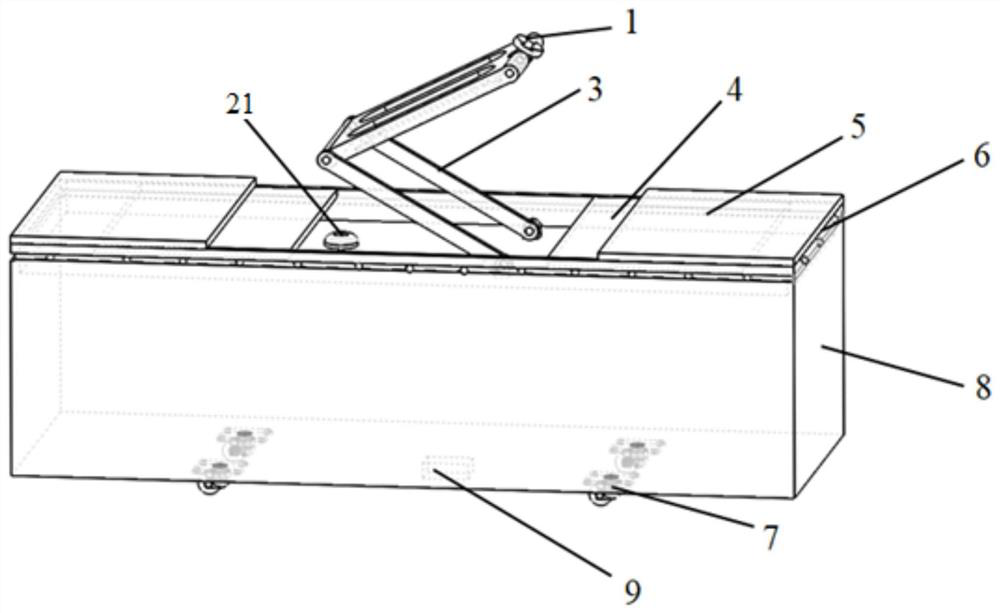

Full-automatic intelligent garbage can

InactiveCN107973029AAvoid spreadingPrevent overflowRefuse receptaclesOperational systemControl system

The invention relates to a full-automatic intelligent garbage can. Hardware facilities of the intelligent garbage can comprise a garbage can driving chassis, an air pressure driving system, a garbagebag automatic packaging system, a sensor module, a GPS / Beidou navigation system and a network communication module, and a software control system of the intelligent garbage can comprises an ARM microprocessor, an operating system and a mobile terminal. The driving chassis, the air pressure driving system, the garbage bag automatic packaging system, the sensor module, the GPS / Beidou navigationsystem and the network communication module are integrated into one garbage can. The driving chassis enables the garbage can to be capable of receiving garbage in hands of people in the moving process, the garbage can placing number is decreased, meanwhile the environment is further beautified, a bag forming-sealing system enables a garbage bag to be automatically sealed, secondary contact of thegarbage and people is avoided, and spreading of the disease is prevented. Automatic navigation of the garbage can is achieved under the help of a sensor and the navigation system, the well sealed garbage is conveyed to a fixed garbage station, the cleaning efficiency is improved, and the burdens of people are relieved.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

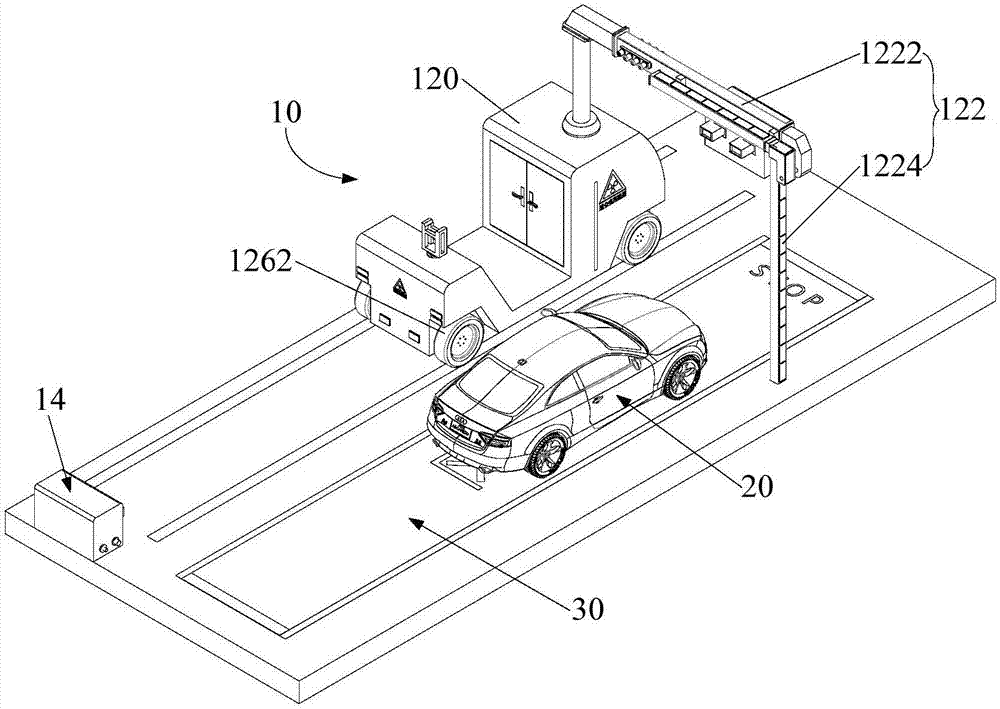

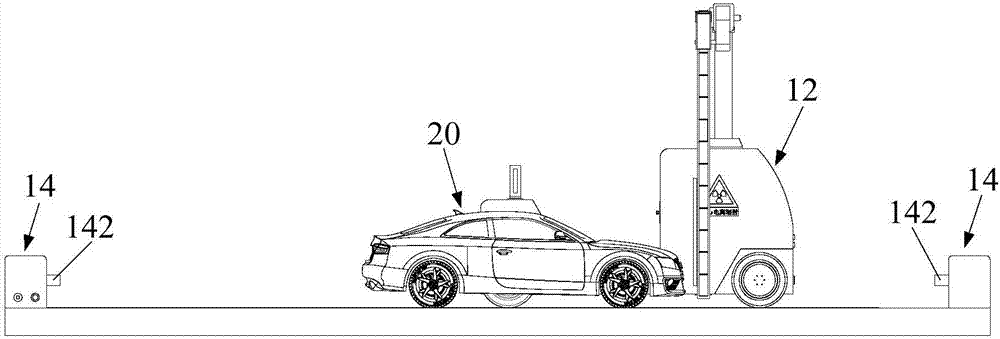

AGV type vehicle inspection system

PendingCN106908852AAchieving autonomous mobilityIncrease flexibilityNuclear radiation detectionVehicle inspectionEngineering

The invention provides an AGV type vehicle inspection system comprising a self-walking inspection vehicle which comprises a vehicle body and a boom which is installed on the vehicle body. The vehicle body is provided with a self-driven system and a walking straight control system so that the self-walking inspection vehicle is enabled to move according to a preset guiding path. A passage for passing of a vehicle for inspection is formed between the boom and the vehicle body. A ray inspection device is arranged on the boom and used for performing safety inspection on the vehicle for inspection when the self-walking inspection vehicle moves the position corresponding to the vehicle for inspection. According to the technical scheme, the self-walking inspection vehicle comprises the self-driven system and the walking straight control system which are installed on the vehicle body so that the self-walking inspection vehicle is enabled to move according to the preset guiding path without limitation of track, the accuracy of the movement direction of the self-walking inspection vehicle can be effectively guaranteed, the self-walking inspection vehicle is enabled to have no site limitation for safety inspection of the vehicle, conversion of the inspection site is facilitated and the inspection flexibility can be effectively enhanced.

Owner:BEIJING HUALIXING SCI TECH DEV

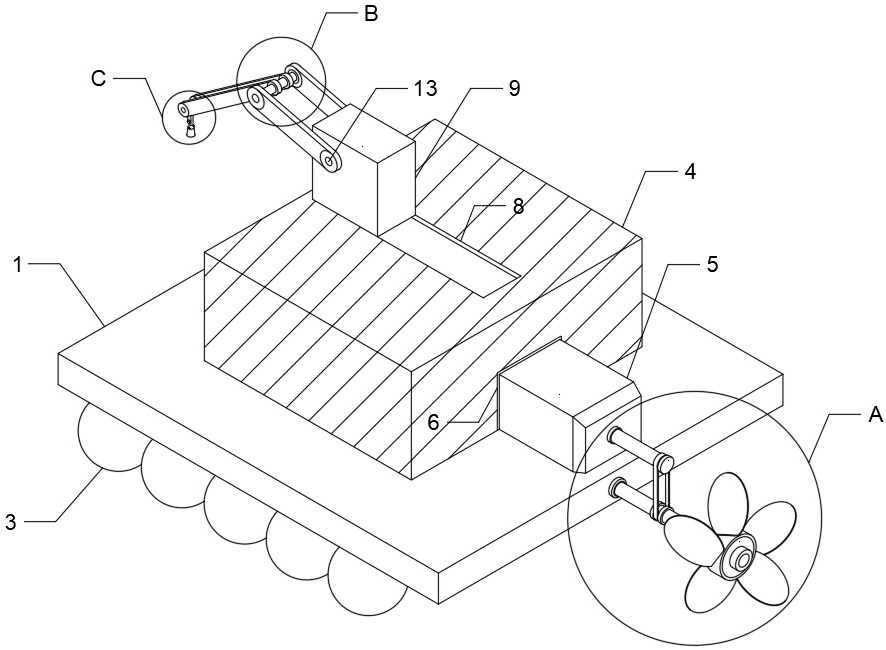

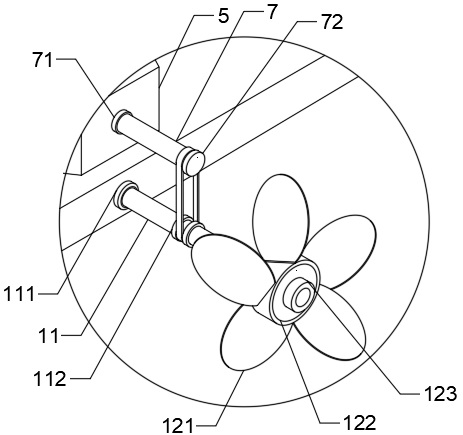

Non-contact monitoring data acquisition device in water conservancy project construction period

InactiveCN112078735AEasy to sampleAchieving autonomous mobilityRotary propellersWithdrawing sample devicesEnvironmental resource managementDrive shaft

The invention belongs to the field of data acquisition devices, and particularly relates to a non-contact monitoring data acquisition device in a water conservancy project construction period. The device comprises a separation bottom plate, a hook is fixedly connected to the bottom end of the separation bottom plate, a floating ball group is fixedly connected to the lower end of the separation bottom plate, and a control box is fixedly connected to the upper end of the separation bottom plate. A motor is fixedly connected to the surface of the right side of the separation bottom plate, a motorthrough hole is connected with the control box, a groove hole is formed in the corresponding position of the control box, a transmission shaft is rotatably connected to the right end of the motor, asliding groove is formed in the upper end of the control box, and a sliding block is slidably connected to the sliding groove. By arranging a movable part, after a sampling device reaches a designatedposition under the action of a propeller, a sampling bottle is immersed into water through the movable part, a proper water sample is taken, then the movable part is collected and returned to the shore, the whole process is remotely controlled manually, and convenience and rapidness are achieved.

Owner:乔爽

A kind of support equipment and its working method in the face of excavation work

ActiveCN110145347BAvoid working with empty topsImprove productivityUnderground chambersTunnel liningSteel beltIndustrial engineering

The invention discloses driving face temporary support equipment and a working method thereof, and belongs to the field of roadway support. The equipment comprises a front beam frame; the front beam frame comprises three square steel pipes, and connecting rods for connecting the three square steel pipes; at least four sets of connecting rods are arranged at the front end of the front beam frame, and a set of connecting rods is arranged at the back end; a driving mechanism is arranged on the square steel pipe in middle; guide mechanisms are arranged on the square steel pipes on two sides; a clamping device is fixedly arranged at the upper part of the driving mechanism; clamping mechanisms are mounted at the upper parts of the guide mechanisms through undercarriages; multiple sets of liftingplatforms are uniformly arranged on the four sets of connecting rods at the front end of the front beam frame; projection brackets are arranged at the front ends of the square steel pipes on two sides; and a tail leveling device is arranged at the back end of the front beam frame. The anchor net and steel strip pavement and the temporary support work are once realized to effectively prevent the operation of workers under empty tops; and the autonomous movement of the temporary support equipment is realized to achieve important significance on improvement of the support efficiency and reduction of the manpower and the labor intensity.

Owner:SHANDONG UNIV OF SCI & TECH

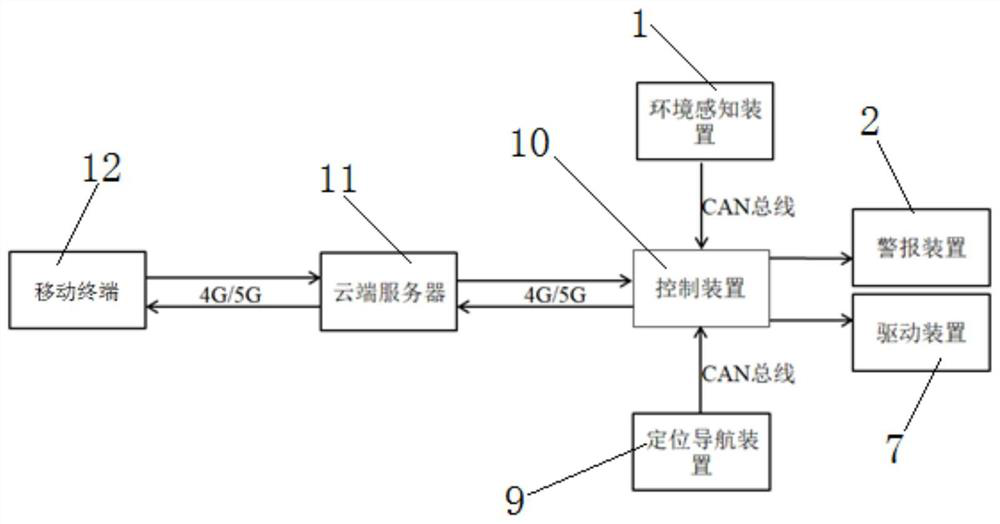

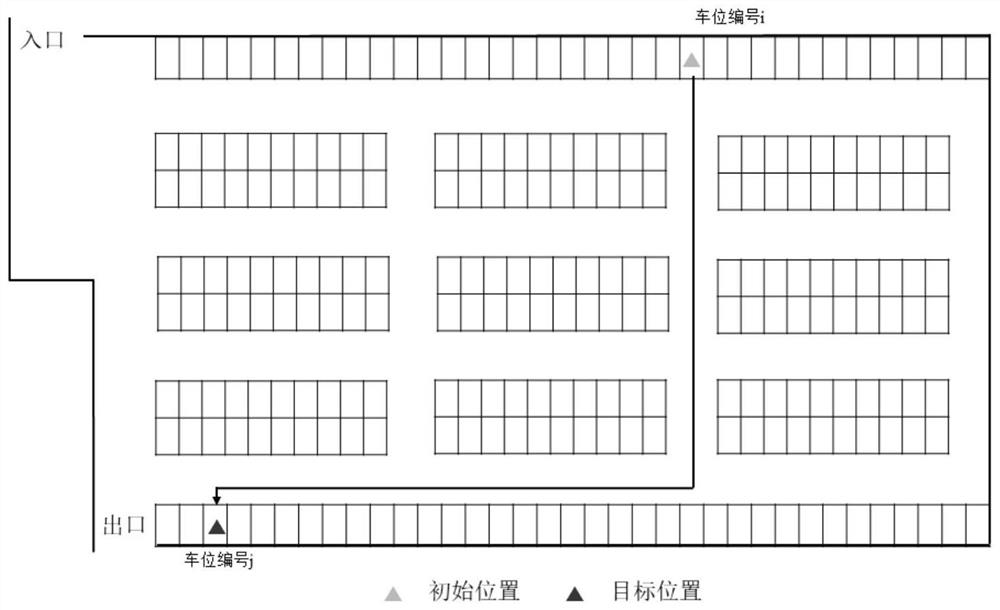

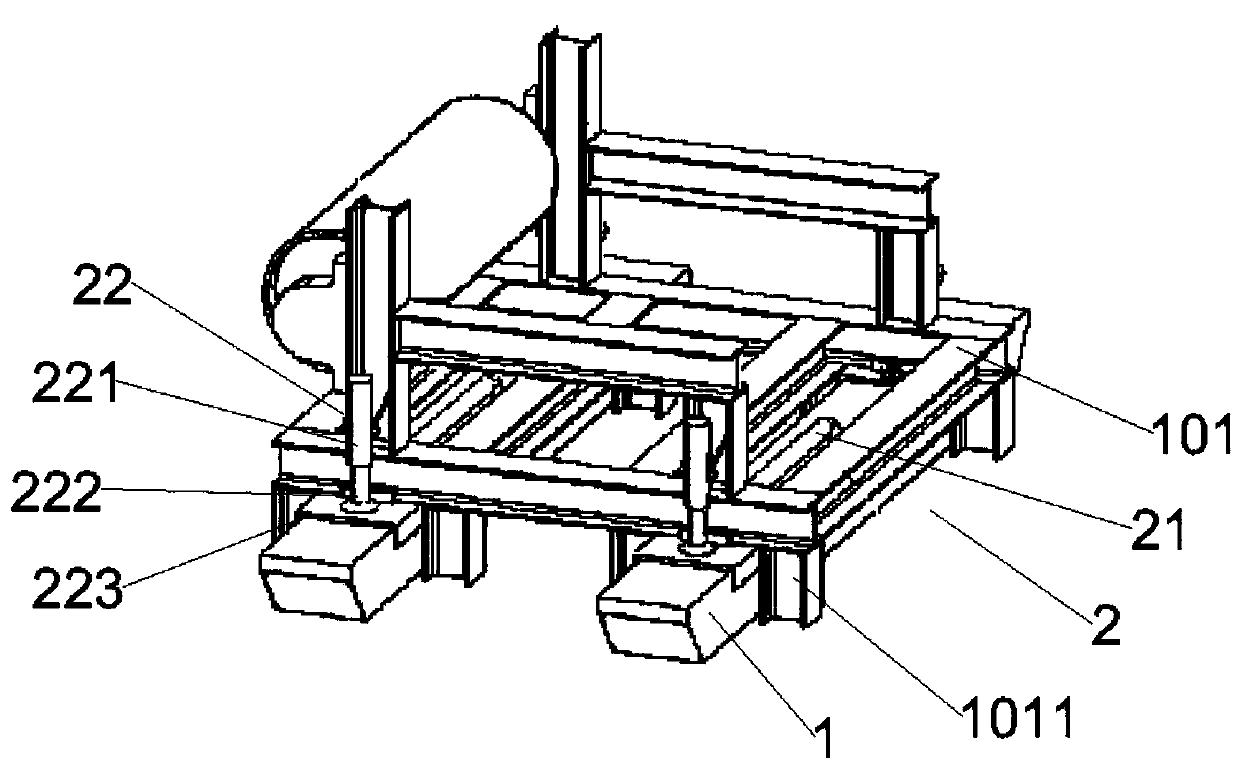

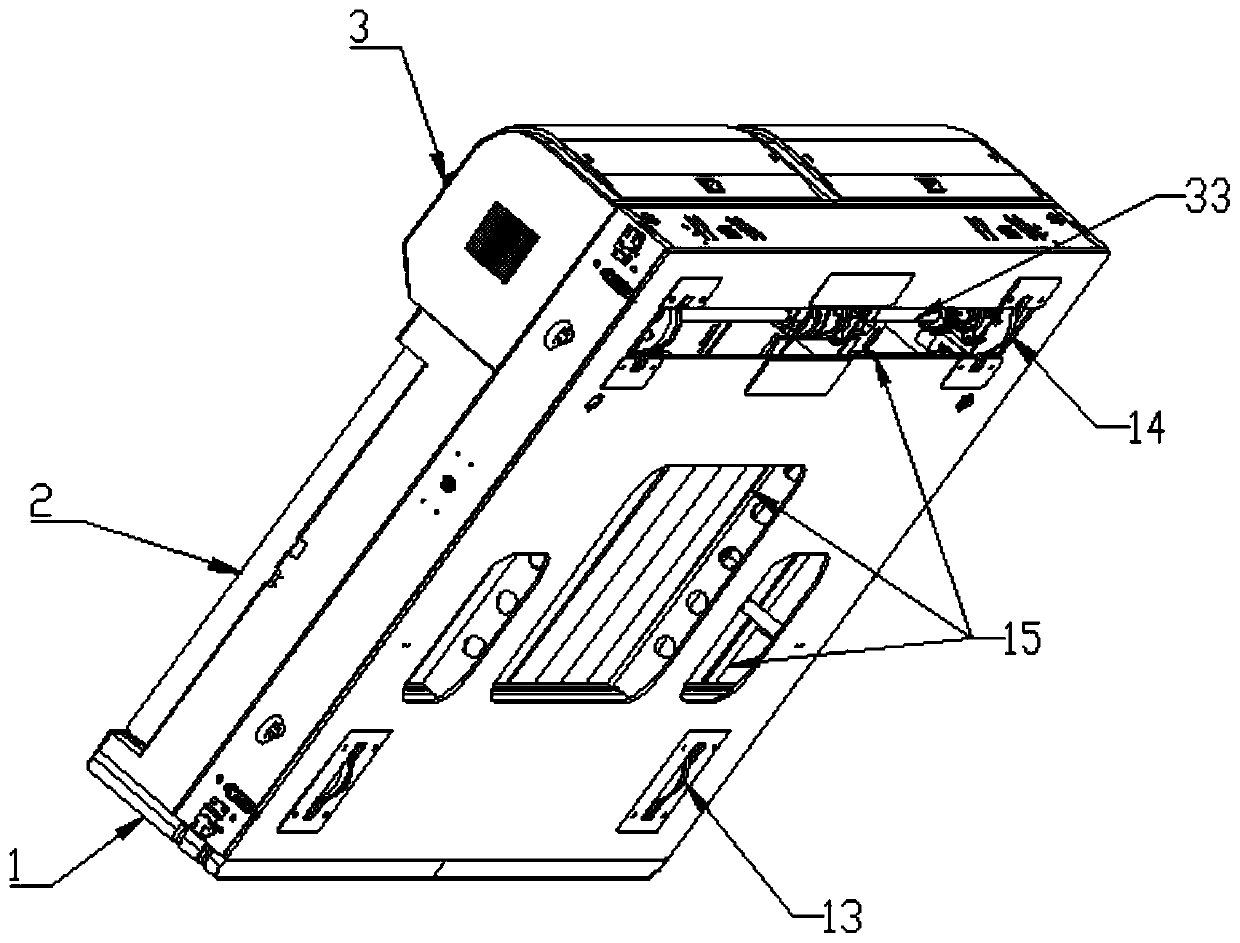

Autonomously movable electric vehicle battery pack and battery system, and control method of battery system

ActiveCN112477679AAchieving autonomous mobilityAutomate processingCharging stationsElectric vehicle charging technologyElectric-vehicle batteryElectrical battery

The invention discloses an autonomously movable electric vehicle battery pack and battery system, and a control method of the battery system. The battery pack comprises a battery module, and further comprises a control device, an environment sensing device, a positioning navigation device, a driving device and a communication module which are arranged on the battery module; the environment sensingdevice is used for collecting surrounding obstacle information; the positioning navigation device is used for determining the position information of the electric vehicle battery pack; the communication module is used for mutual communication between the control device and the cloud server; the control device is used for receiving the driving path planned by the cloud server, the obstacle information sent by the environment sensing device and the position information sent by the positioning navigation device which are transmitted by the communication module, and sending a control signal to the driving device according to the received information; and the driving device is used for receiving the control signal and driving the electric automobile battery pack to move. Automatic movement ofthe electric vehicle battery pack is achieved, manual participation is not needed, the labor cost is saved, and the use convenience is enhanced.

Owner:HUNAN UNIV

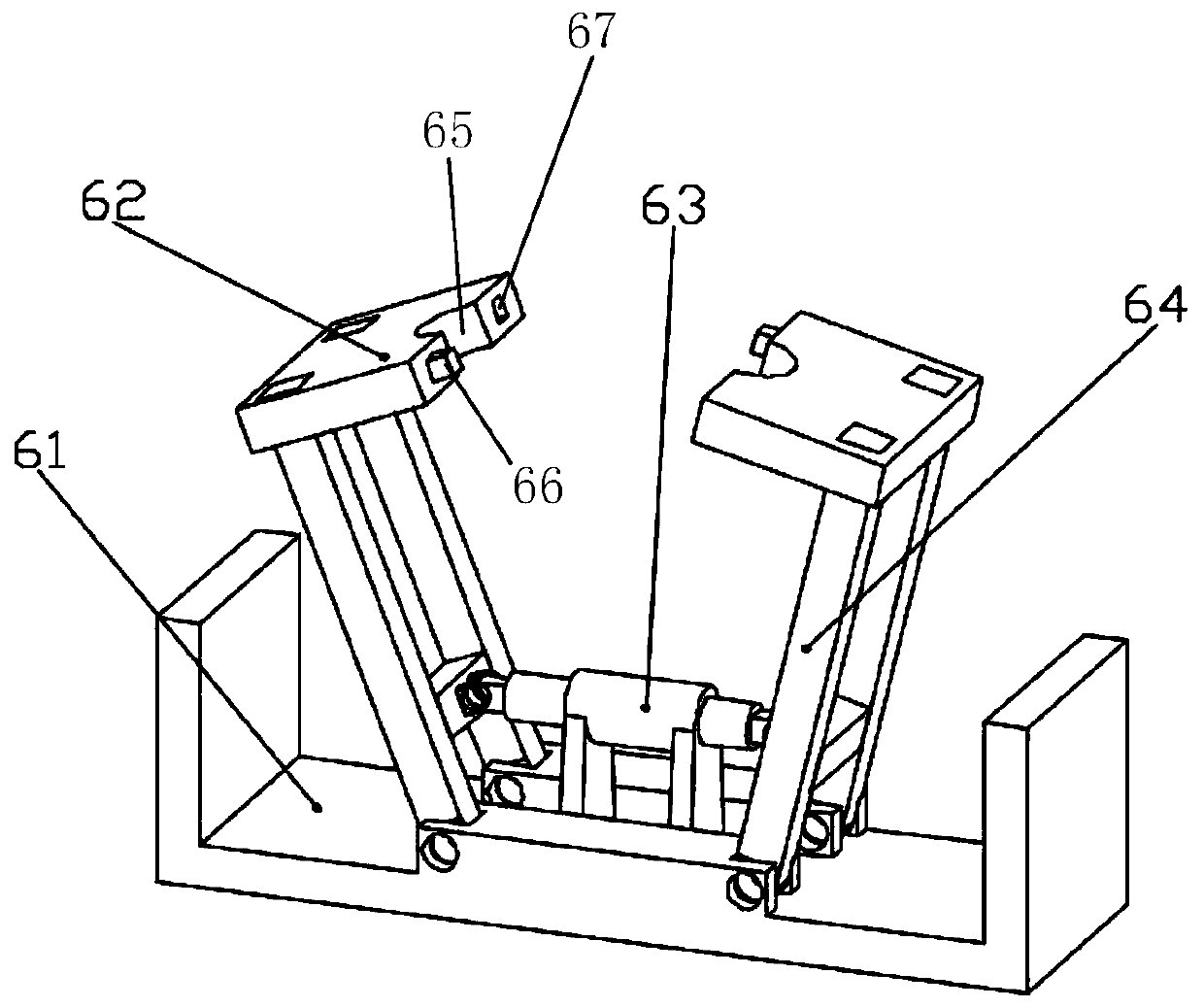

Power transmission tower stay wire rust removal robot

InactiveCN111745300AAchieving autonomous mobilityAvoid insufficient frictionManipulatorLaser beam welding apparatusControl engineeringElectric machinery

The invention relates to a power transmission tower stay wire rust removal robot comprising an upper shell and a lower shell which are connected in a separable mode. A plurality of clamping mechanismsare installed in the upper shell, and a plurality of driving devices and a rust removal device are installed in the lower shell; the clamping mechanisms comprise electric cylinders arranged on the upper shell, a piston tower of each electric cylinder is fixedly connected with a weighing sensor arranged in the upper shell, the two ends of the weighing sensor are respectively hinged with a first grooved pulley through top plates, and each top plate is hinged with the upper shell through a shock absorber; the driving devices comprise speed reducing motors arranged in the lower shell and second grooved pulleys arranged in the lower shell, and the speed reducing motors are in transmission connection with the second grooved pulleys through a synchronous belt transmission mechanism; and the rustremoval device comprises a mechanical arm and a laser rust removing machine, the mechanical arm is arranged on the lower shell, and the laser rust removing machine is arranged at one end of the mechanical arm. The power transmission tower stay wire rust removal robot solves the technical problems of low rust removal efficiency, manpower and material waste and incapability of comprehensively removing rust and painting in the existing power transmission tower stay wire rust removal technology.

Owner:CHINA THREE GORGES UNIV

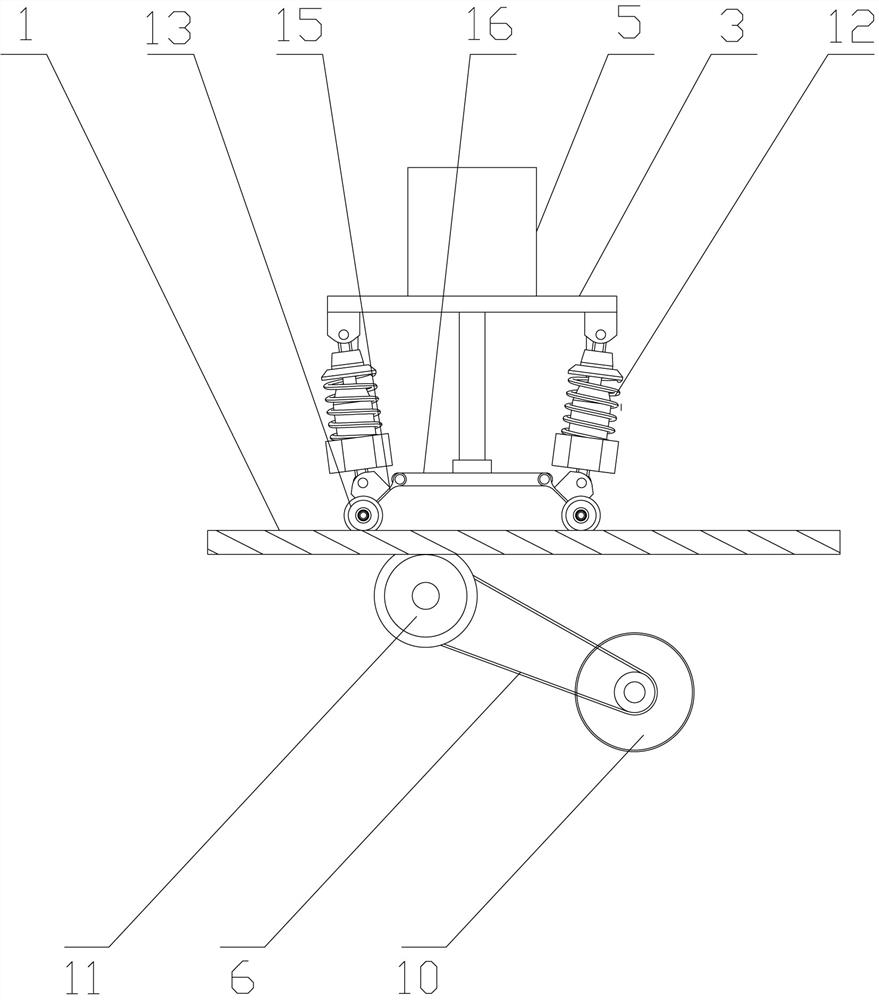

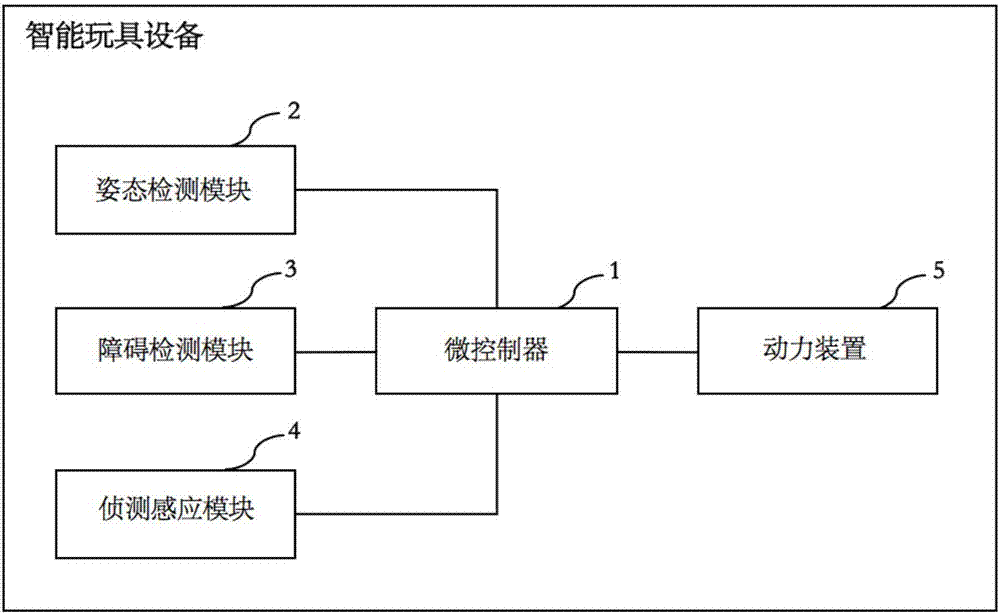

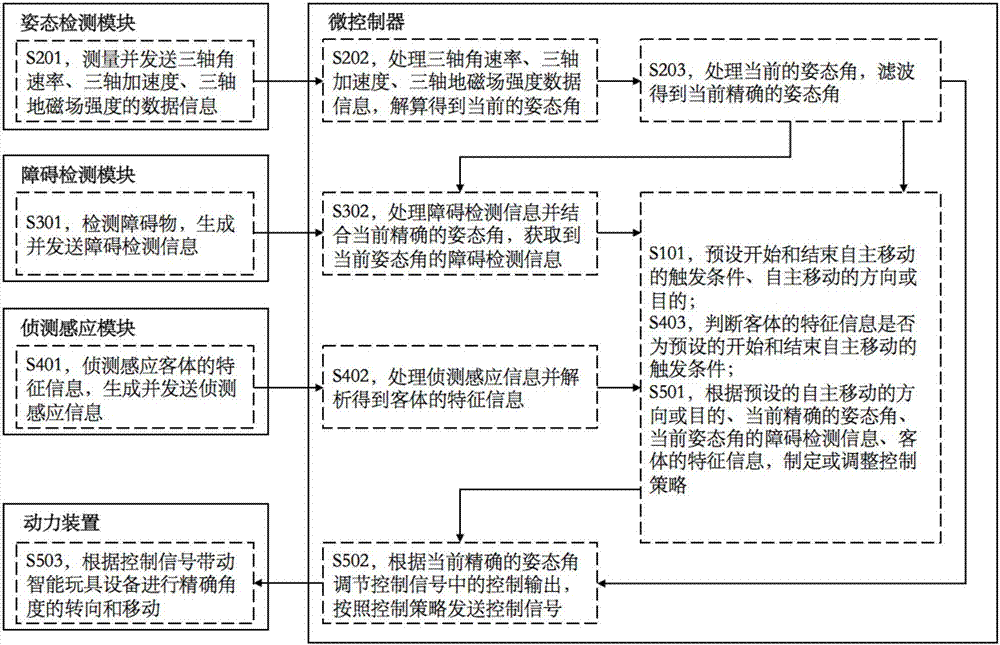

Automatic moving system and control method thereof

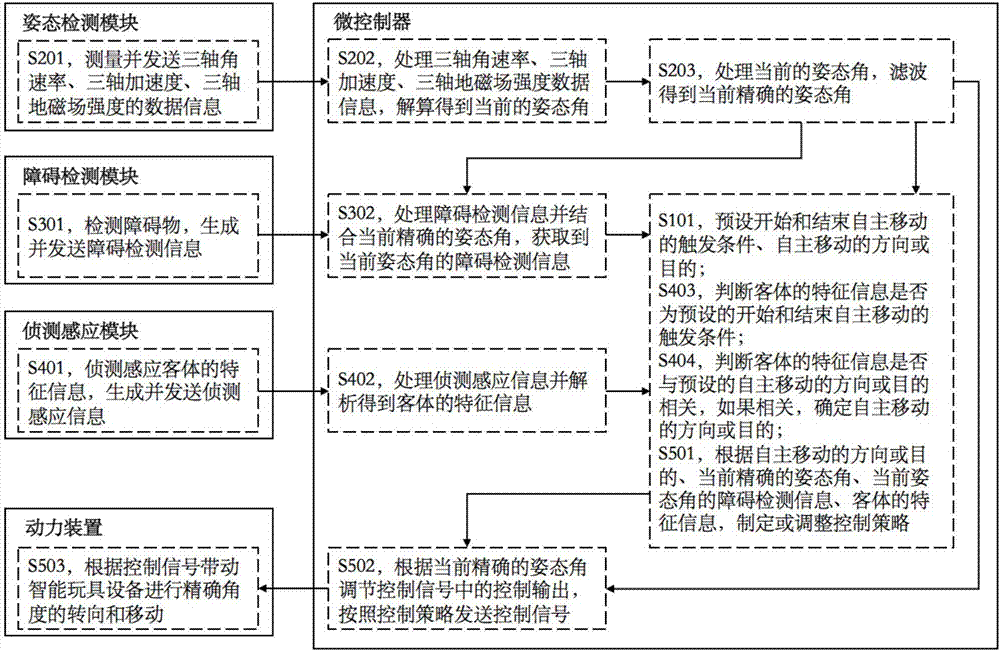

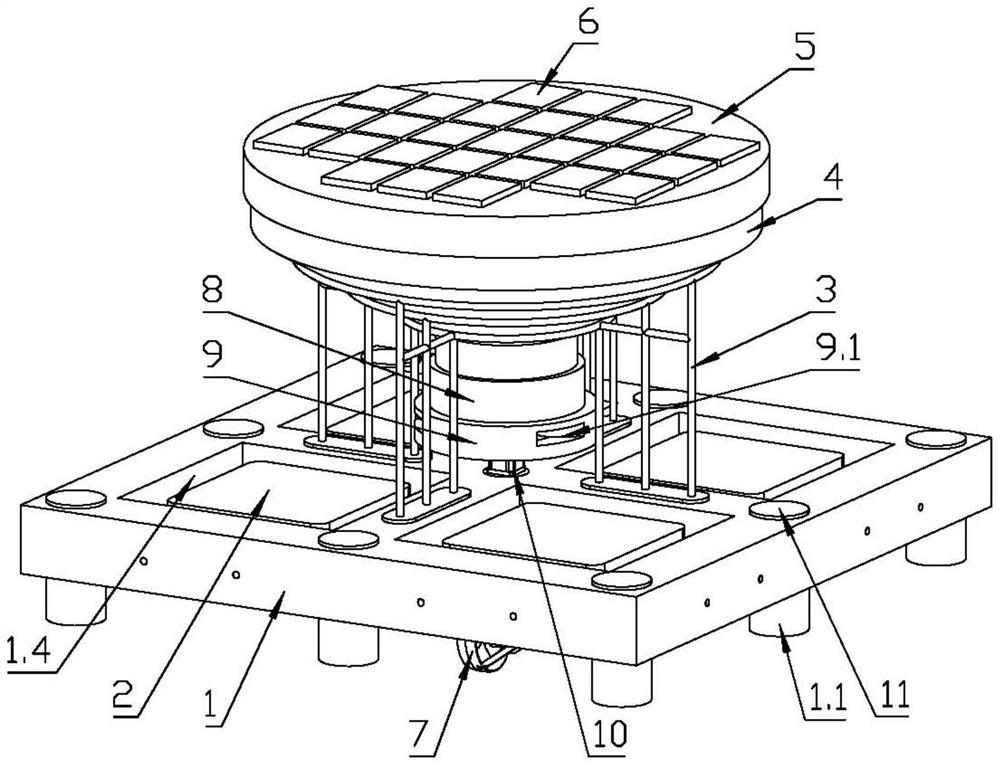

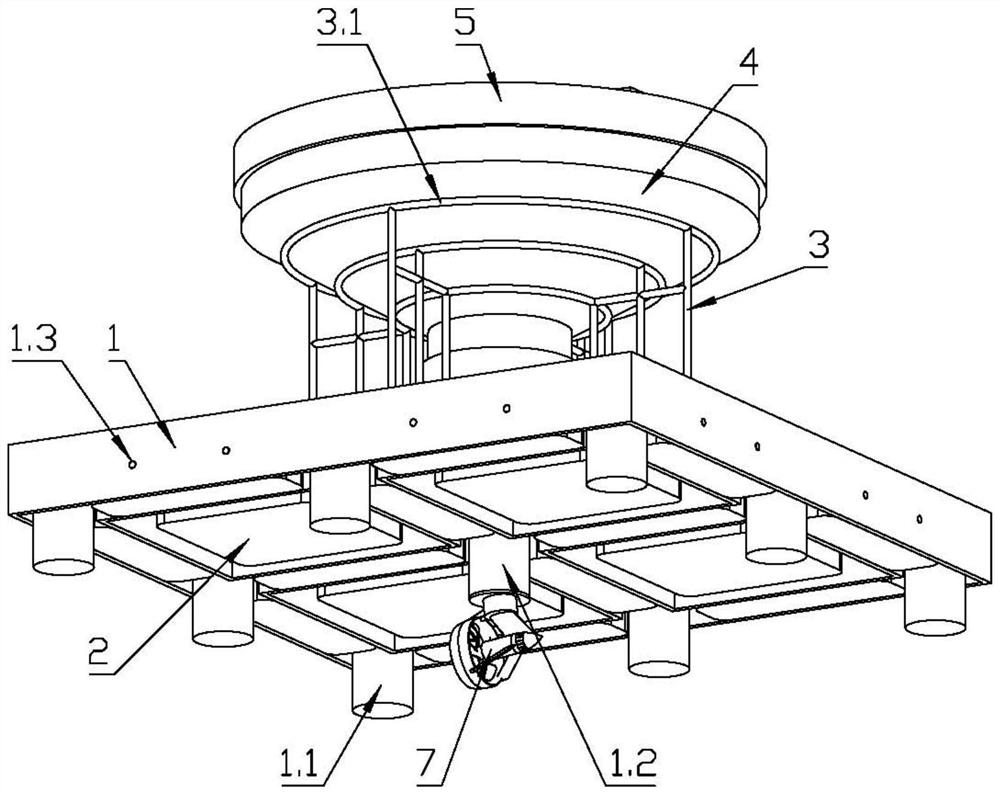

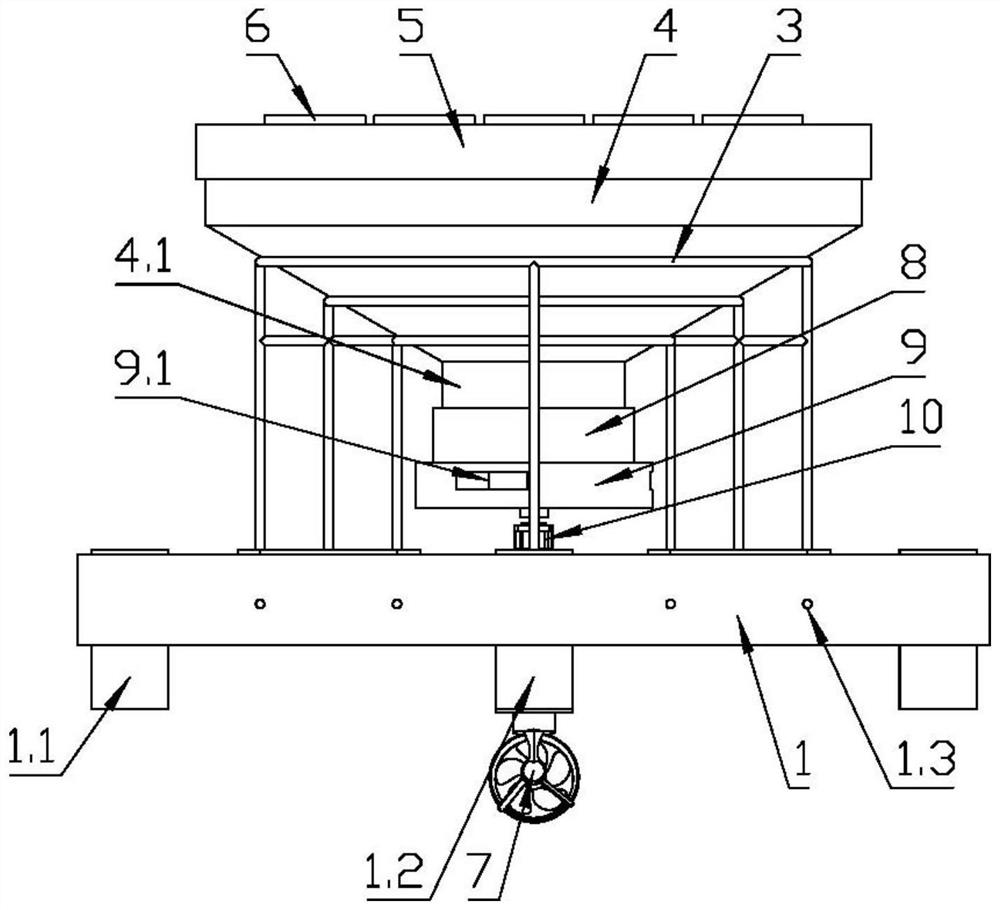

InactiveCN107115679AAchieving autonomous mobilityObtain attitude angle in real timeRemote-control toysPower apparatusComputer module

The invention aims at solving the technical problem of providing an automatic moving system and a control method thereof. The automatic moving system comprises a microcontroller, a posture detection module, an obstacle detection module, a detection sensing module and a power device. By applying the system, intelligent toy equipment can acquire a current posture angle in real time, detect surrounding obstacles, detect characteristic information of an object in the surrounding environment in real time, and is triggered to start or finish movement, can make a control strategy according to a preset direction or target, can steer and move at an exact angle to avoid obstacles, and can automatically move according to the preset direction or target.

Owner:SHENZHEN CHEERBLE TECH CO LTD

Autonomous feeding device

InactiveCN111642442AIncrease flexibilityAchieving autonomous mobilityWaterborne vesselsClimate change adaptationMarine engineeringMechanical engineering

The invention discloses an autonomous feeding device. A floating seat is provided with a plurality of hollowed-out structures uniformly distributed on the horizontal plane, and buoyancy blocks are mounted in the hollowed-out structures of the floating seat; a mounting rack is mounted on the top surface of the floating seat; an outlet is formed in the bottom of a barrel, and an opening is formed inthe top; a bottom cover is mounted at the outlet of the barrel and is provided with a discharging port; a spreading plate is rotationally arranged at the bottom of the bottom cover, a spreading channel extending to the outer circular surface of the spreading plate is formed in the spreading plate, and a material falling port communicating with the spreading channel is formed in the top surface ofthe spreading plate; a rotating device is mounted on the floating seat; a turning device is vertically mounted in the center of the bottom of the floating seat; and a propelling device is mounted onthe floating seat and driven by the turning device to turn. Autonomous movement on a water surface can be realized, the movement range is enlarged, the feed adding flexibility is improved, and meanwhile, hypoxia caused by gathering of fish schools is avoided by cooperation with a large-range feeding manner of the spreading plate.

Owner:CHANGZHOU INST OF MECHATRONIC TECH

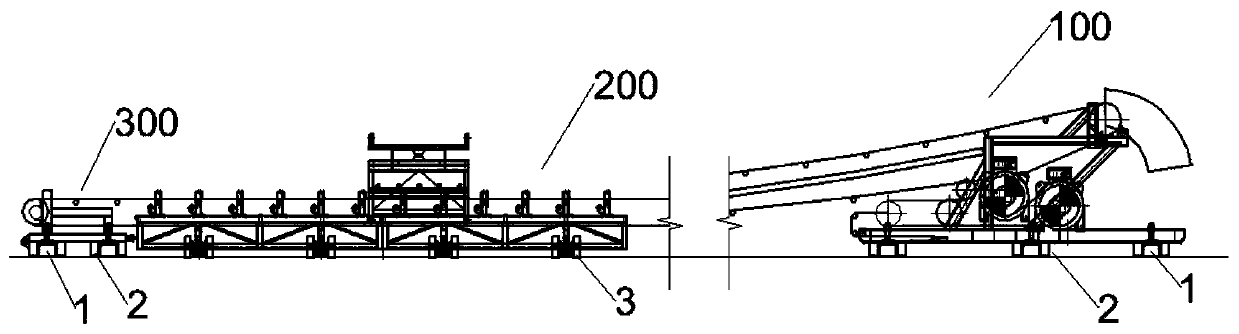

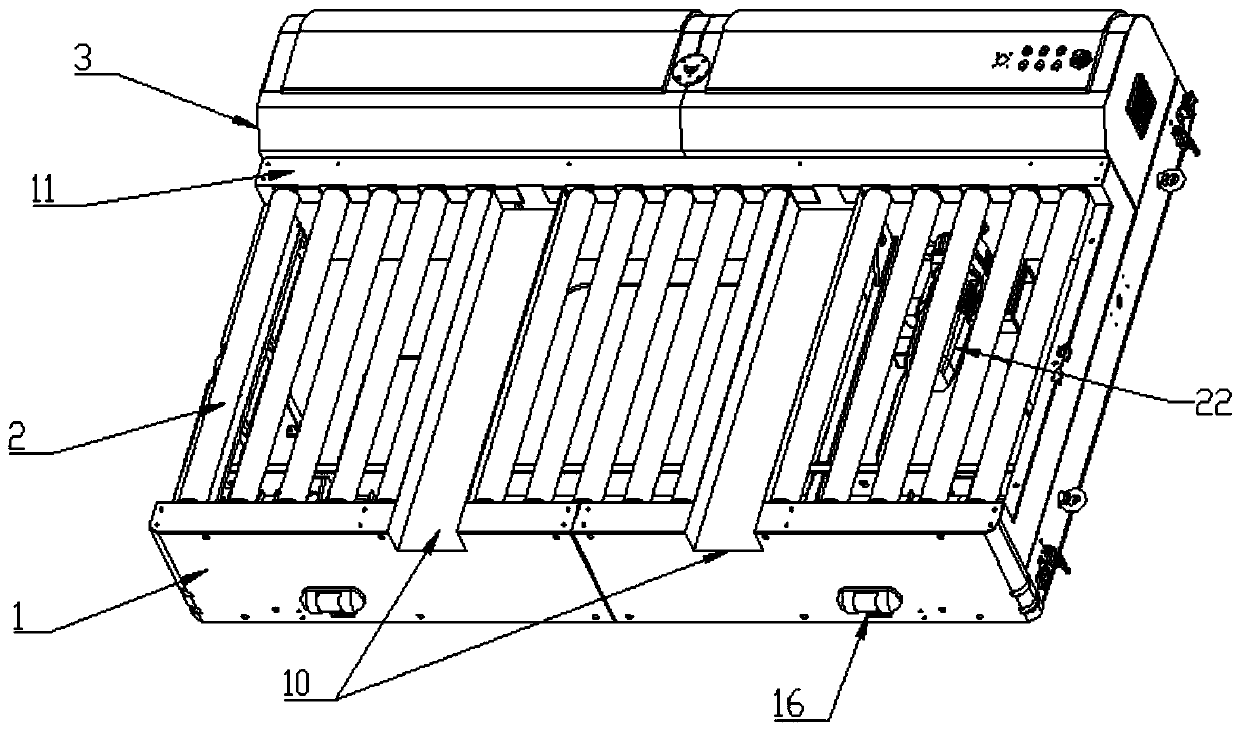

Automatic moving belt conveyor

PendingCN109879002AImprove stabilityAchieving autonomous mobilitySupporting framesBelt conveyorEngineering

The invention discloses an automatic moving belt conveyor. The conveyor comprises a machine head part (100), a middle part (200) and a machine tail part (300), wherein the machine head part (100) andthe machine tail part (300) are both provided with first sliding shoes (1), the middle part (200) is provided with second sliding shoes (4), the machine head part (100) and the machine tail part (300)both comprise first automatic moving mechanisms (2) which are arranged on the first sliding shoes (1), the first automatic moving mechanisms (2) are used for pushing the machine head part (100) and the machine tail part (300) to move in the direction of the first sliding shoes (1), the middle part (200) comprises second automatic moving mechanisms (3) which are arranged on the second sliding shoes (4), and the second automatic moving mechanisms (3) are used for pushing the middle part (200) to move in the direction of the second sliding shoes (4). The automatic moving belt conveyor realizes autonomous movement of the conveyor and autonomous leveling after movement, and is good in stability, ingenious and simple in structure, low in economic cost and wide in adaptability.

Owner:新疆金能矿业有限公司

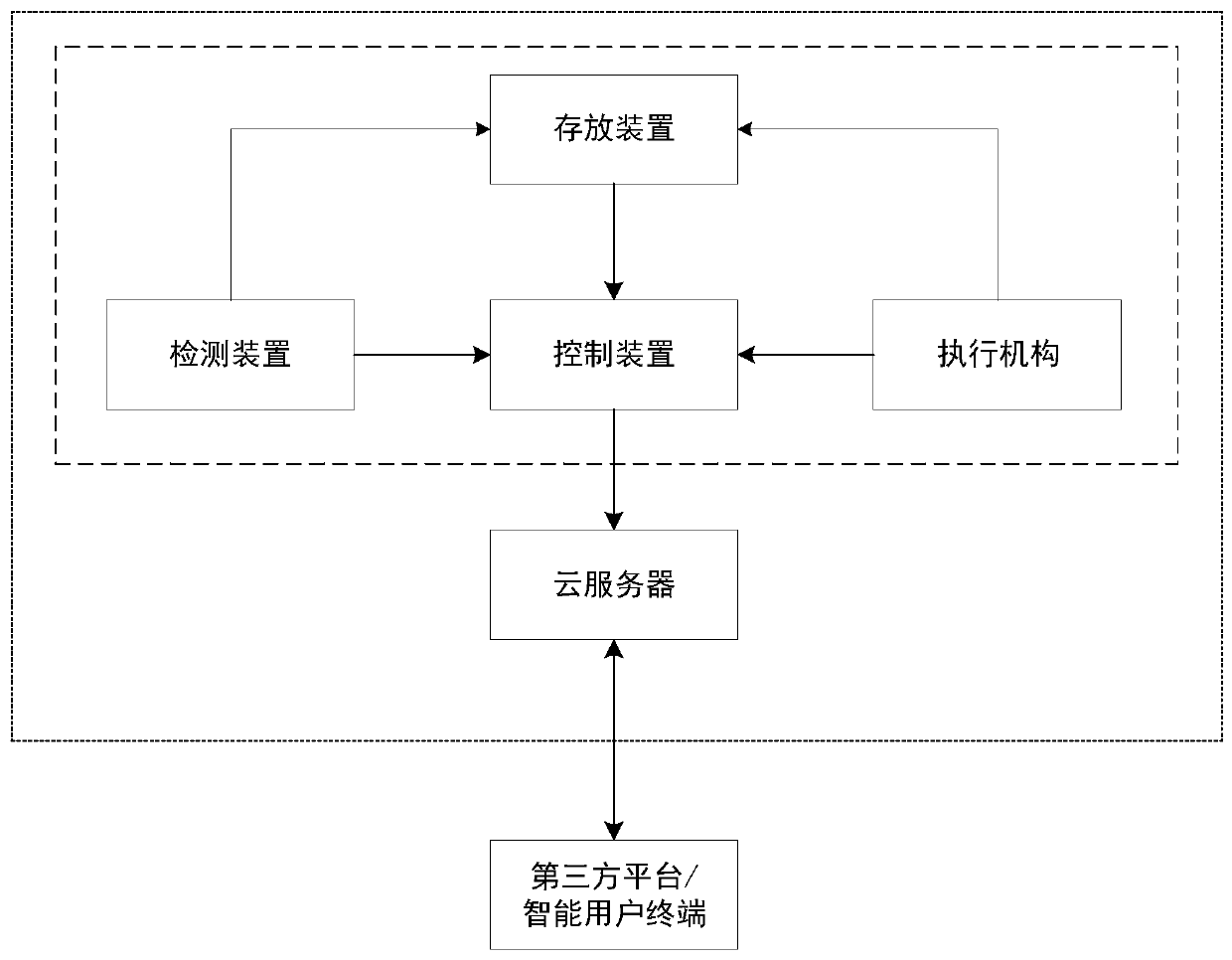

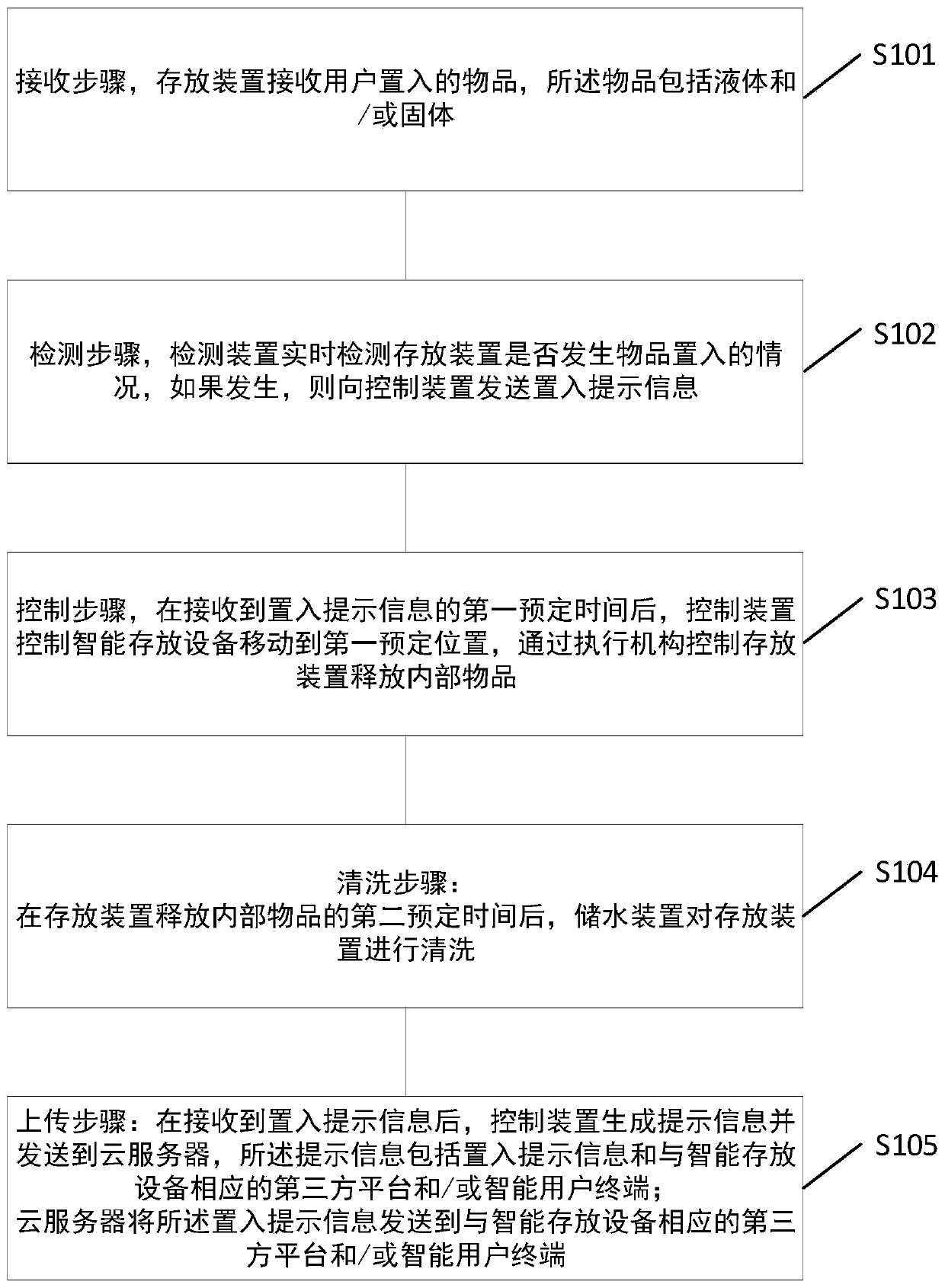

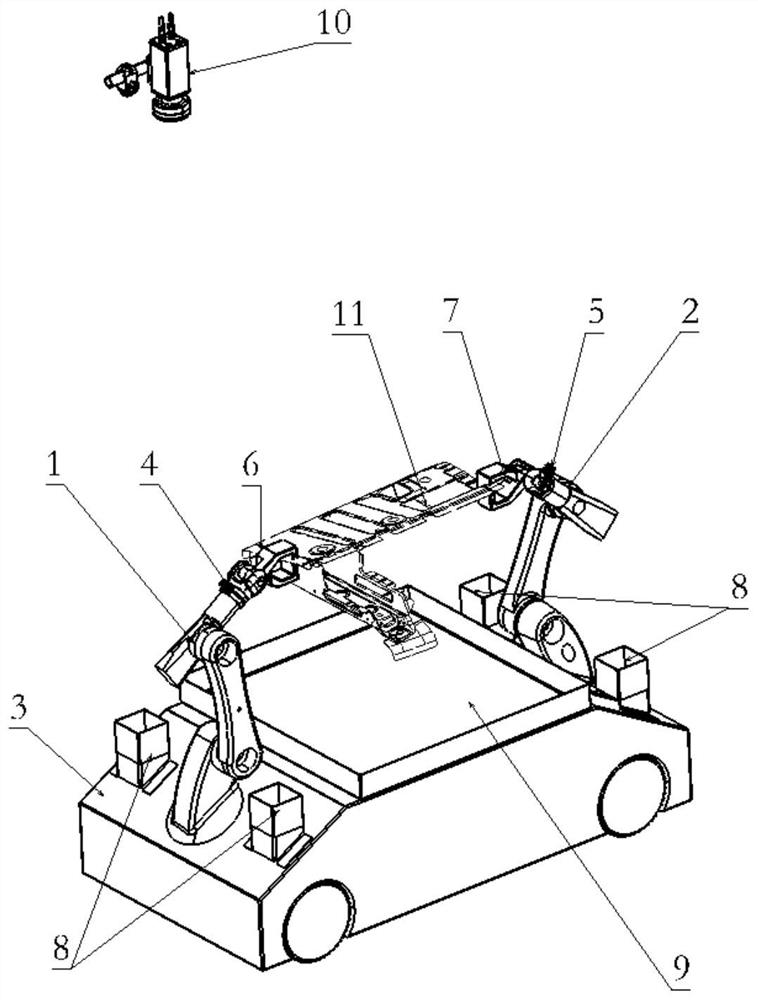

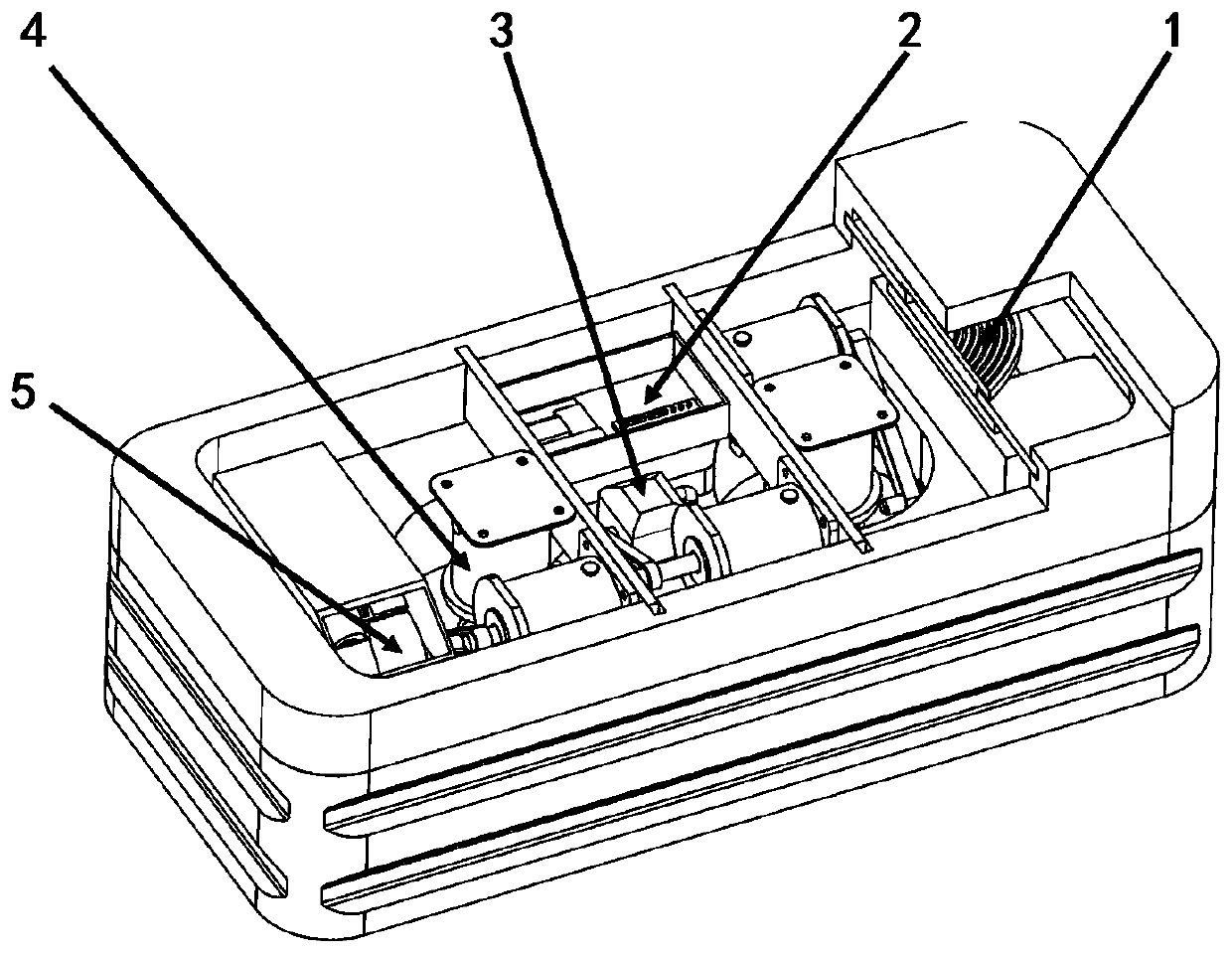

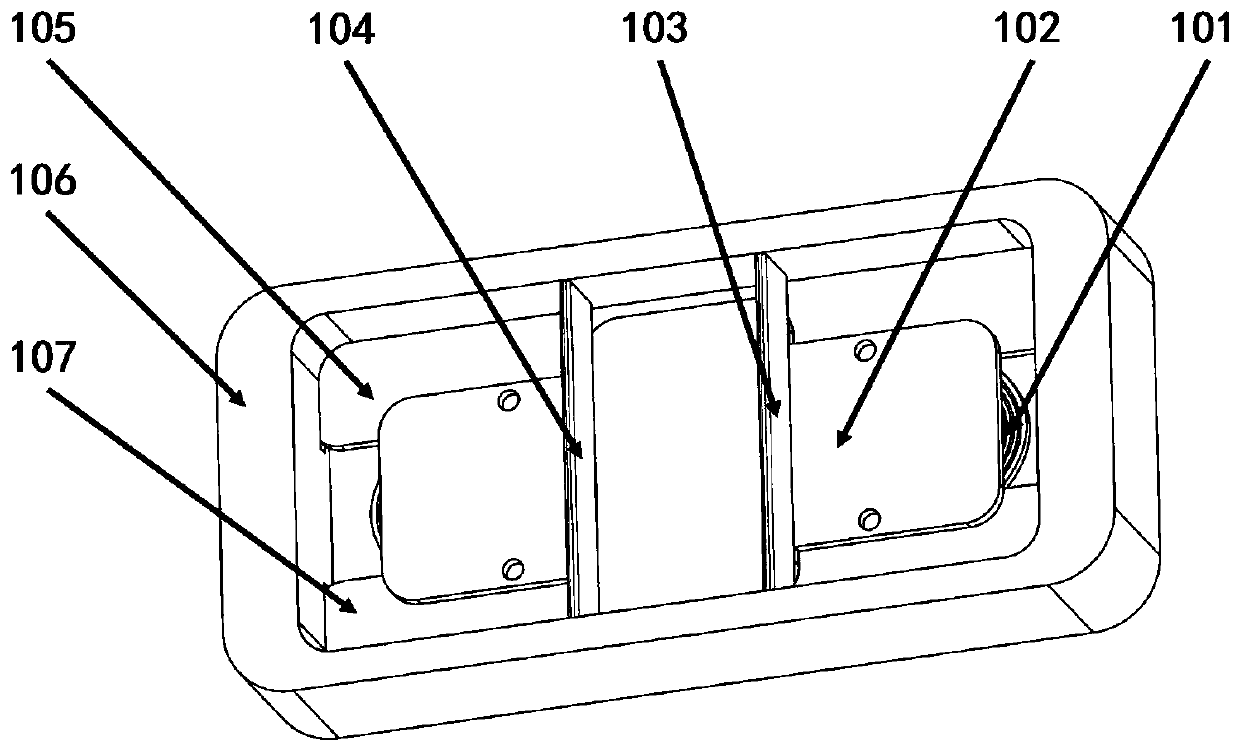

Intelligent storage system and application method thereof

InactiveCN109951552AShorten the timeImprove experienceTransmissionProgramme control in sequence/logic controllersReduced mobilityIntelligent agent

The invention discloses an intelligent storage system and an application method thereof. The method comprises: a storage device receives an article placed by a user, a detection device detects whetherthe article is placed in the storage device in real time, and if yes, placement prompt information is sent to a control device; and after first preset time of the imbedding prompt information is received, the control device controls the intelligent storage equipment to move to a first preset position, and the execution mechanism controls the storage device to release internal articles. Therefore,after the storage device is placed into an object. The automatic moving and garbage releasing of the storage device are realized, and if the storage device is used as a urinal, the situation of peculiar smell diffusion caused by long-time retention of urine in the urinal is prevented, so that a function of conveniently collecting the urine and excrement is provided for the old, people who are inconvenient to move and people in a cold environment in winter. Preferably, the invention also provides an automatic cleaning function, an article placement amount detection function, a data uploading function and a data service function.

Owner:广东比铉智能科技有限公司

Automatic guiding intelligent double-arm carrying robot

InactiveCN111673738AAchieving autonomous mobilityProgramme-controlled manipulatorGripping headsControl systemControl engineering

The invention belongs to the technical field of automobiles, and particularly relates to an automatic guiding intelligent double-arm carrying robot. The robot comprises a first mechanical arm, a second mechanical arm, an automatic guiding platform, a first quick-change device, a second quick-change device, a first tool hand, a second tool hand, tool hand storage warehouses, a hopper and a machinevision system; the automatic guiding platform is placed on a horizontal ground; one end of the first mechanical arm and one end of the second mechanical arm are symmetrically fixed at the two ends ofthe automatic guiding platform; the other end of the first mechanical arm is connected with the first tool hand through the first quick-change device; the other end of the second mechanical arm is connected with the second tool hand through the second quick-change device; the tool hand storage warehouses are arranged at the two ends of the automatic guiding platform; the hopper is arranged in themiddle of the automatic guiding platform; the automatic guiding platform is connected with a central control system; and the central control system is connected with a machine vision system. Autonomous movement of the robot in the working area can be realized, and flexible carrying requirements of workpieces of various shapes and sizes are met.

Owner:CHINA FIRST AUTOMOBILE +1

Forest region-crossing transmission line patrol robot system

InactiveCN104701781AAchieving autonomous mobilityImprove securityApparatus for overhead lines/cablesSimulationSolar power

The invention relates to power system checking equipment, and particularly relates to a forest region-crossing transmission line patrol robot system, which comprises a robot moving on the line, a ground mobile base station, and a backstage patrol management system, wherein the robot is hung upside down on the line via a pressing wheel; the ground mobile base station is used for receiving state information of the robot, sending a ground remote control command and receiving and keeping patrol data and images; and the backstage patrol management system is used for carrying out offline analysis, processing and diagnosis on visible light images and videos acquired by the robot, and carrying out computer management on line design parameters, analysis and diagnosis results, patrol work and the like. The robot is provided with a visible light camera. The robot adopts a dual-power supply system, that is, a rechargeable high-capacity high-energy lithium ion battery and a solar power supply. The robot is used for line patrol, the patrol fee is low, the patrol precision is high, and the operation is safe and reliable.

Owner:STATE GRID CORP OF CHINA +1

Full-automatic dust removal blackboard eraser based on stm 32F10x main control chip

PendingCN111137051AImplement automatic erasureAchieve purificationBoard cleaning devicesControl systemDust control

The invention relates to a full-automatic dust removal blackboard eraser based on a stm 32F10x main control chip. The full-automatic dust removal blackboard eraser comprises an electromagnetic adsorption device, a control system, a dust removal purification device, a multi-mode erasing device and a moving device, the full-automatic dust removal blackboard eraser is characterized in that the dust removal purification device is embedded in the upper part of the lower cover of the shell of the multi-mode erasing device, the lower cover of the shell of the multi-mode erasing device is connected with the upper cover of the shell of the electromagnetic adsorption device, the control system is fixed on the upper surface of the dust storage box of the dust removal purification device, and the moving device is installed in the dust storage box of the dust removal purification device. According to the invention, through the design of the control system and the moving device, automatic erasing ofthe blackboard eraser is realized, manpower is saved, and efficiency is improved; through the design of the dust removal purification device, dust collection is realized, and the health of teachers and students is protected; through the design of the multi-mode erasing device, the combination of rotary erasing and translational erasing is realized, the erasing degree is improved, and the erasingeffect is ensured.

Owner:ANHUI UNIV OF SCI & TECH

Automatic moving conveyor

PendingCN110606324AEasy to pick and placeAchieving autonomous mobilitySupporting framesRoller-waysMotor driveSurface plate

The invention discloses an automatic moving conveyor. The conveyer comprises a conveyor base, wherein the top surface of the conveyor base is rotationally fixed with a row of conveying rollers, a roller motor is arranged right below the conveying rollers, the roller motor drives the conveying rollers to roll on the surface of the conveyor base through a roller driving mechanism, a plurality of fork position grooves for insertion of fork plates are arranged on the conveying rollers at intervals, a plurality of wheels used for driving the conveyor base to move in the direction perpendicular to the conveying direction of the conveying rollers are arranged at the four corners of the bottom of the conveyor base, a stroke motor box is arranged on one side of a rear panel of the conveyor base, and a stroke driving mechanism for driving the wheels to rotate is arranged in the stroke motor box. According to the conveyer, the whole conveyor base can be used as an object moving and carrying device to carry materials, the installation and the movement of the base are facilitated, and the cross conveying function can be realized by combining and matching with other conveying belts.

Owner:广东友力智能科技有限公司

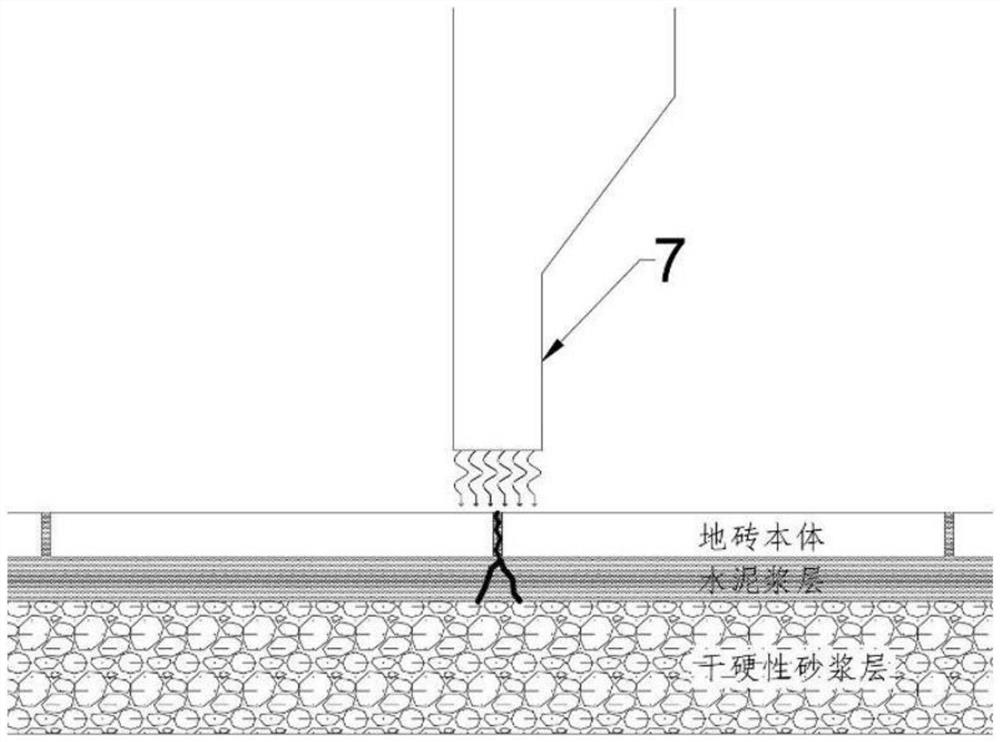

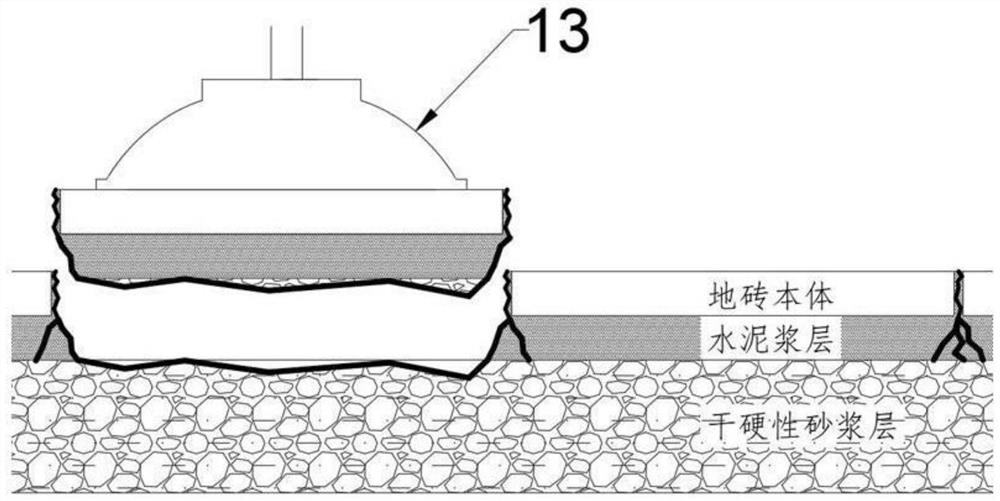

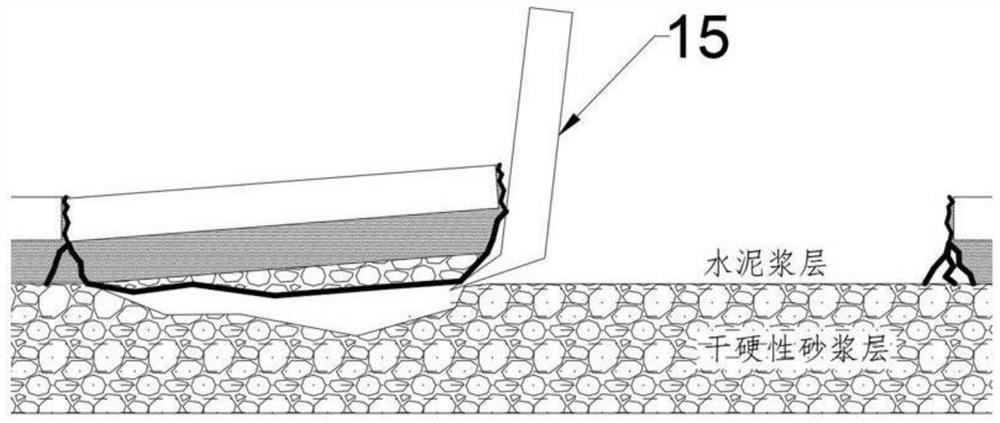

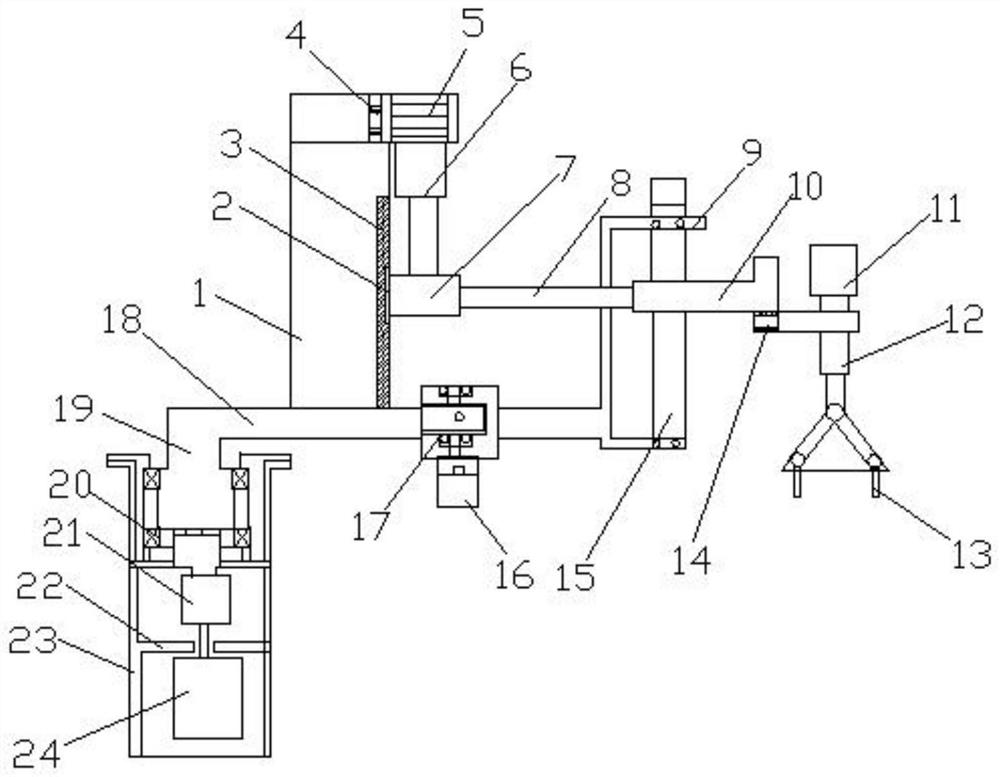

A kind of floor tile removal method and removal device based on microwave cracking cement stone technology

ActiveCN113668891BQuiet and Controlled DemolitionEfficient demolitionBuilding repairsScreedPhysical chemistry

The invention belongs to the technical field of floor tile removal, and in particular relates to a floor tile removal method and a removal device based on microwave cracking cement stone technology. Select appropriate irradiation conditions to irradiate the cement slurry joint with mobile microwave until the cement slurry joint is heated to generate penetrating cracks along the depth direction, and then use manual or vacuum suction cups and jacks or remove the components to remove the loose floor tiles and the lower part of the dry hard. The cement mortar layer is detached; the dismantling device includes a microwave power source, a microwave system, a shielding box, a mobile device, a sensor system, a microwave focusing antenna, a vacuum suction cup, a jack and a shoveling assembly. The dismantling method and the dismantling device of the present invention utilize the feature of selectively heating the cement stone by microwaves, so as to promote the cracking of the cement slurry joints between the floor tiles, and realize the quiet demolition and complete recovery of the floor tiles.

Owner:SOUTHEAST UNIV

Industrial autonomous moving robot with novel power assisting device

PendingCN112975923AAchieving autonomous mobilityReduce difficultyProgramme-controlled manipulatorGripping headsElectric machineryEngineering

The invention discloses an industrial autonomous moving robot with a novel power assisting device. The industrial autonomous moving robot comprises a power assisting table and a machine arm, wherein a connecting buckle is arranged at the upper end of the right side of the power assisting table, an electric cylinder is arranged on the right side of the connecting buckle, an electric lifting rod is arranged at the lower end of the electric cylinder, a sleeve is arranged at the lower end of the electric lifting rod, a sliding block is arranged on the left side of the sleeve, a sliding groove is formed in the left side of the sliding block, a connecting rod is arranged on the right side of the sleeve, a connector is arranged on the right side of the connecting rod, a rotating shaft is arranged at the lower end of the connector, a vertical rod is arranged on the right side of the rotating shaft, a first motor is arranged at the upper end of the vertical rod, a paw is arranged at the lower end of the vertical rod, a support is arranged on the outer side of the connector, a fixing rod is arranged on the inner side of the support, and a machine arm is arranged at the lower end of the power assisting table. According to the industrial autonomous moving robot, autonomous movement of the robot is achieved through the power assisting device, the material taking difficulty is reduced, meanwhile, the working efficiency is improved, and rotation is more convenient and faster.

Owner:KUNMING UNIV OF SCI & TECH

An orchard autonomous spraying intelligent robot

InactiveCN104476545BAchieving autonomous mobilityIncrease profitManipulatorInsect catchers and killersFruit treeImaging processing

The invention discloses an intelligent independent spraying robot for an orchard. The intelligent independent spraying robot comprises a central control module, a spraying module, a dispensing module, a wireless communication module, a locating module, a man-machine interaction module, an image processing module, a detection module, a driving module, a power supply module, an alarm module and a storage module. The intelligent independent spraying robot for the orchard conforms to the current orchard building standard, does not need artificial control, simultaneously sprays the fronts and backs of the leaves at the tops and bottoms of four fruit trees, is capable of locating and moving independently to finish the whole spraying process for the orchard, enables the working efficiency to be improved, enables the chemical use ratio to be improved, enables the labor force to be reduced and protects people from chemical harm.

Owner:UNIV OF JINAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com