Automatic moving belt conveyor

A belt conveyor and self-moving technology, which is applied in the field of conveyors, can solve the problems of being easily affected by terrain, increasing economic costs, and prone to tilting, etc., and achieves the effects of good stability, reasonable structure, and small terrain restrictions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solution of the present invention will be described in further non-limiting detail below in combination with preferred embodiments and accompanying drawings.

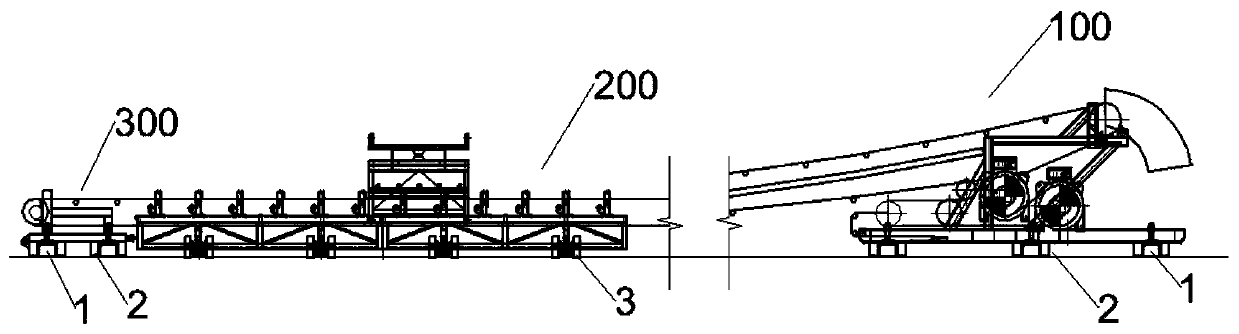

[0025] Such as figure 1 As shown, the present embodiment provides a self-moving belt conveyor, which includes a nose portion 100, a middle portion 200 and a tail portion 300, and the bottom of the nose portion 100 and the tail portion 300 are all provided with a belt for pushing the nose portion 100. The first self-moving mechanism 2 that moves with the tail part 300; the second self-moving mechanism 3 that is used to promote its movement is provided below the middle part 200.

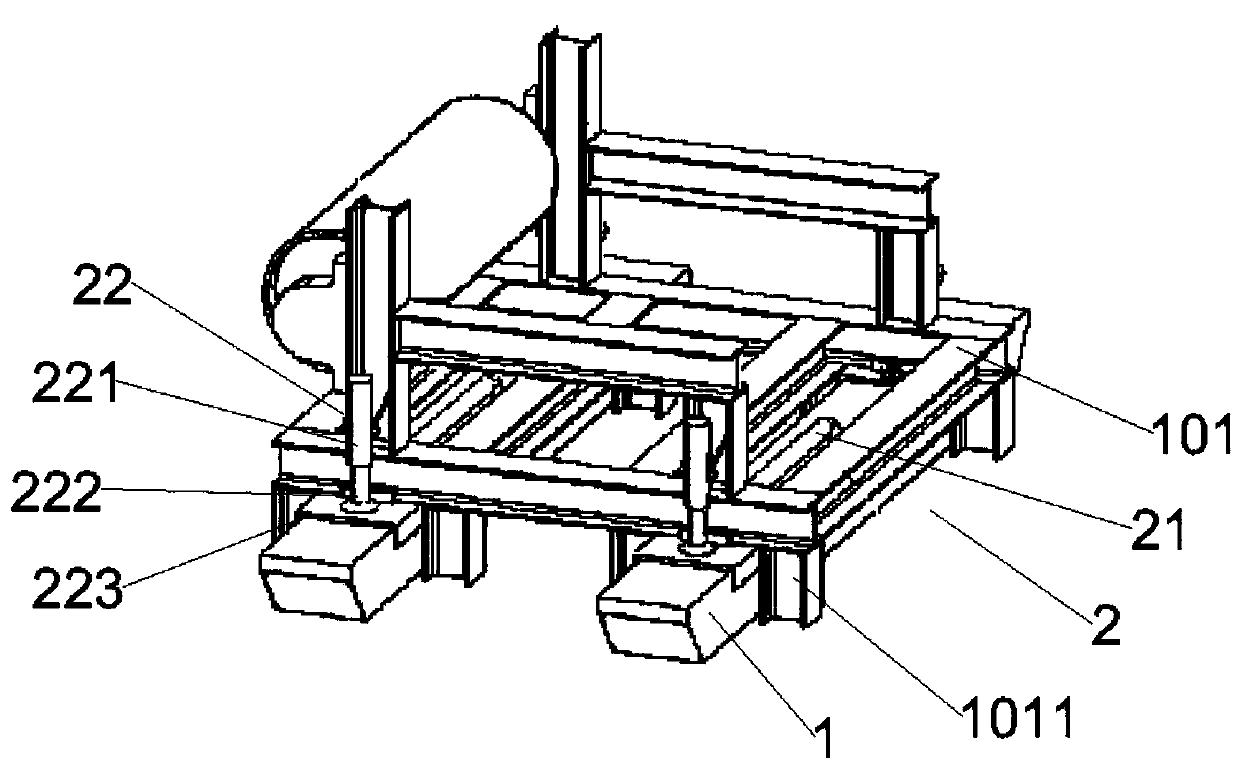

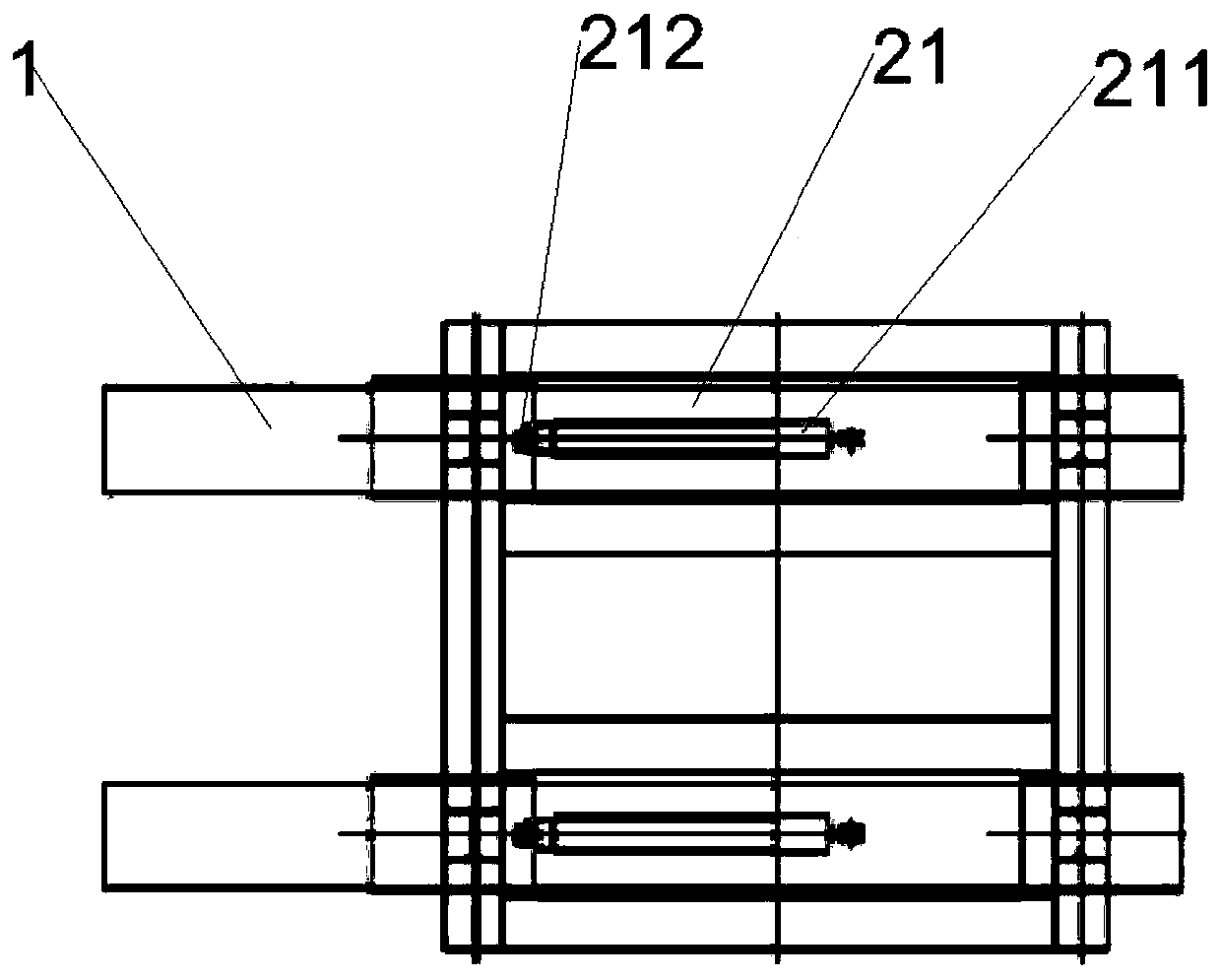

[0026] further reference figure 2 and image 3 , the nose portion 100 and the tail portion 300 both include a frame 101 and a first shoe 1 disposed below the frame 101 . The frame 101 includes several pairs of feet 1011 for supporting the ground. The first sliding shoe 1 is located between the feet 1011 and 1011. The fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com