Patents

Literature

54results about How to "Make sure to move in sync" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

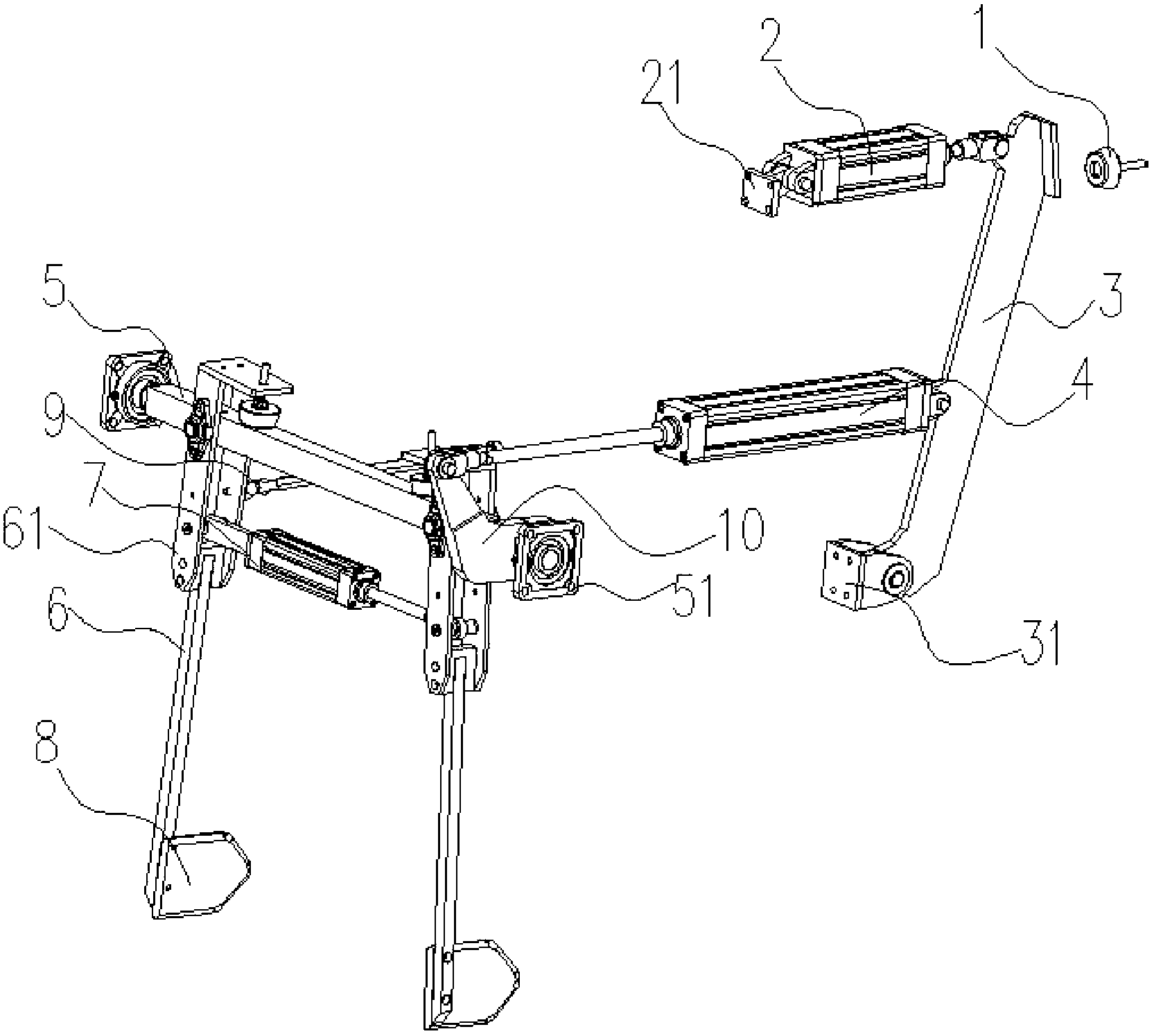

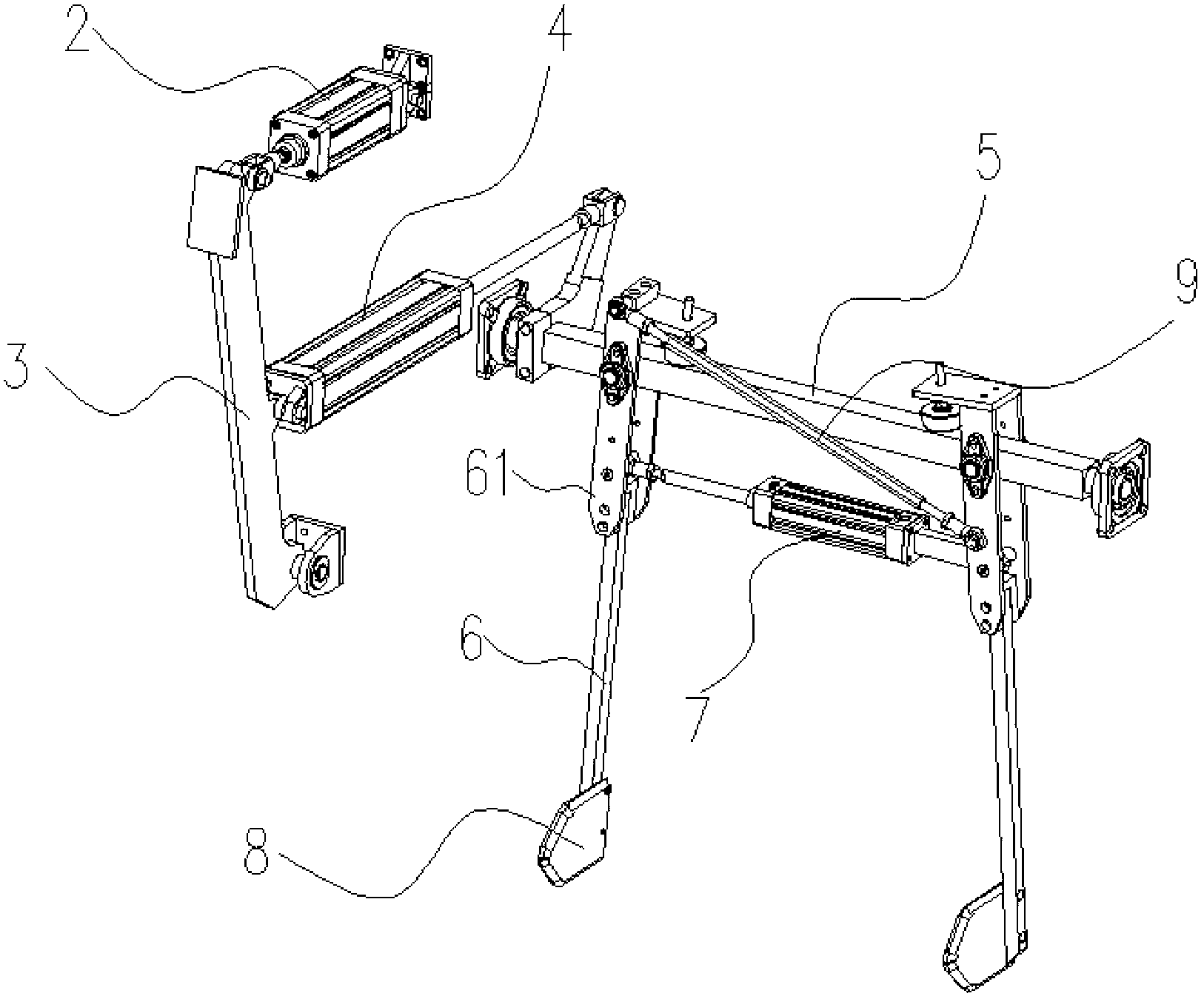

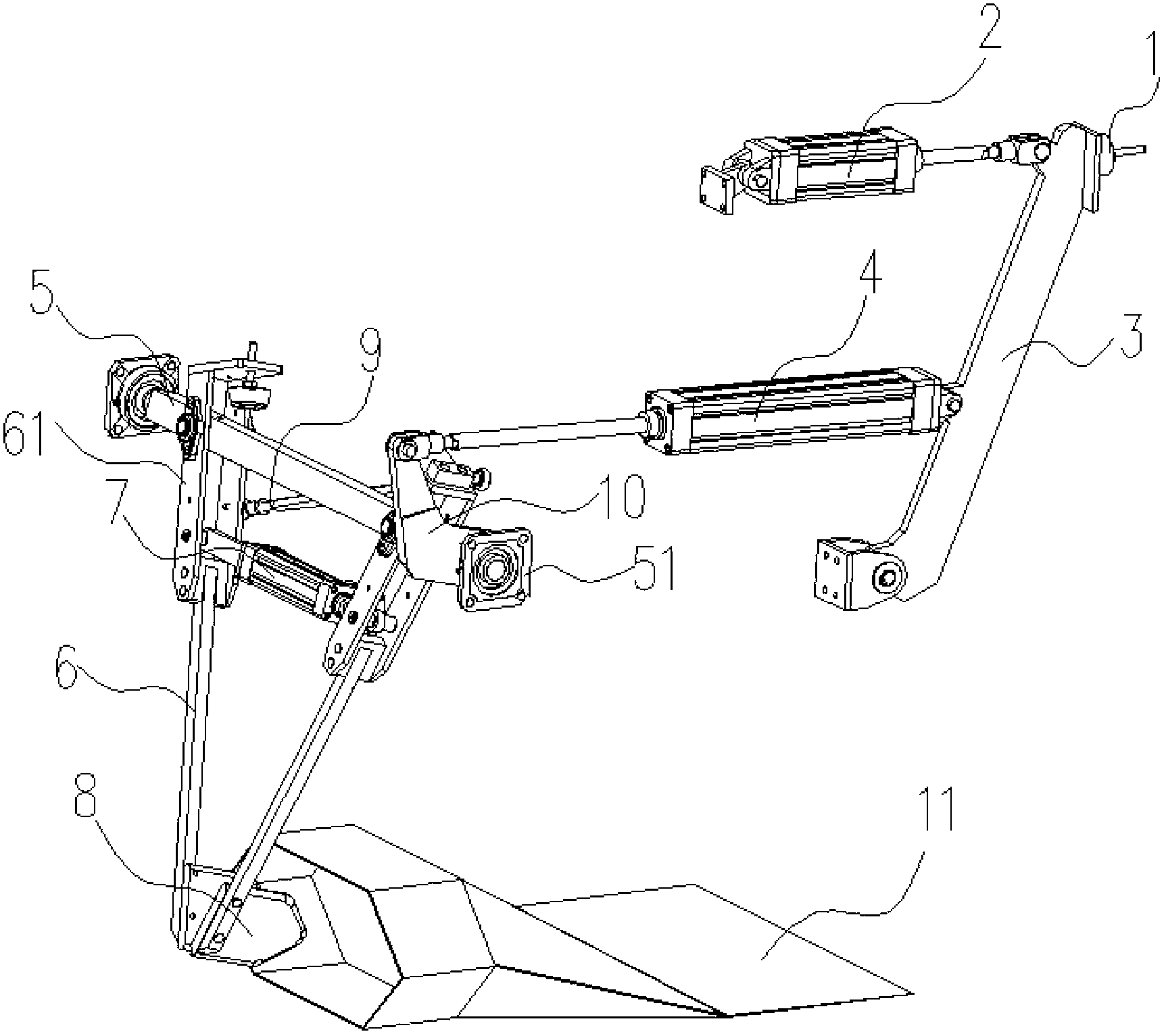

Bag sleeving device

The invention discloses a bag sleeving device which comprises a rotary shaft, swing arms and a power system, wherein the two swing arms are correspondingly mounted on the rotary shaft; supporting plates are arranged at the lower ends of swing arms; the two swing arms are fixedly connected with the rotary shaft; and the power system drives the rotary shaft to rotate, drives the swing arms to swing, and can swing axially along the rotary shaft. The operation process of the bag sleeving device comprises the following steps: preparing bag taking: the mouth of a bag is opened, a main air cylinder and an auxiliary air cylinder expand, a bag sleeving air cylinder contracts, and the two supporting plates are closed; taking the bag: the auxiliary air cylinder contracts, the two supporting plates are sent into the mouth of the bag; sleeving the bag: the bag sleeving air cylinder expands, and the two supporting plates take the bag from a bag opening device; sleeving the bag: the main air cylinder contracts, the opened bag is sent to a bag dragging device by the swing arms; returning the supporting plates: the main air cylinder expands, and the supporting plates are sent back by the swing arms; and waiting for bag taking: the bag sleeving air cylinder contracts, the two supporting plates are closed, and a bag sleeving device is in the state of preparing bag taking.

Owner:无锡市开维物流装备有限责任公司

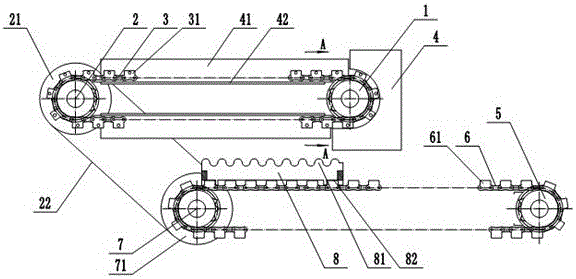

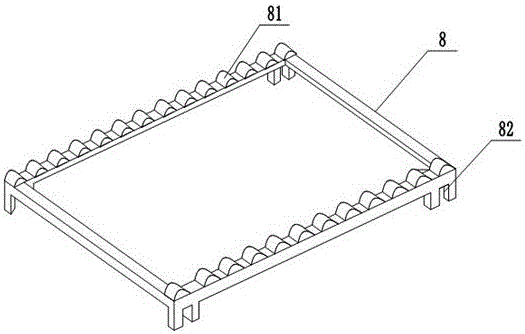

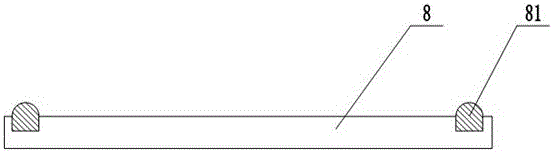

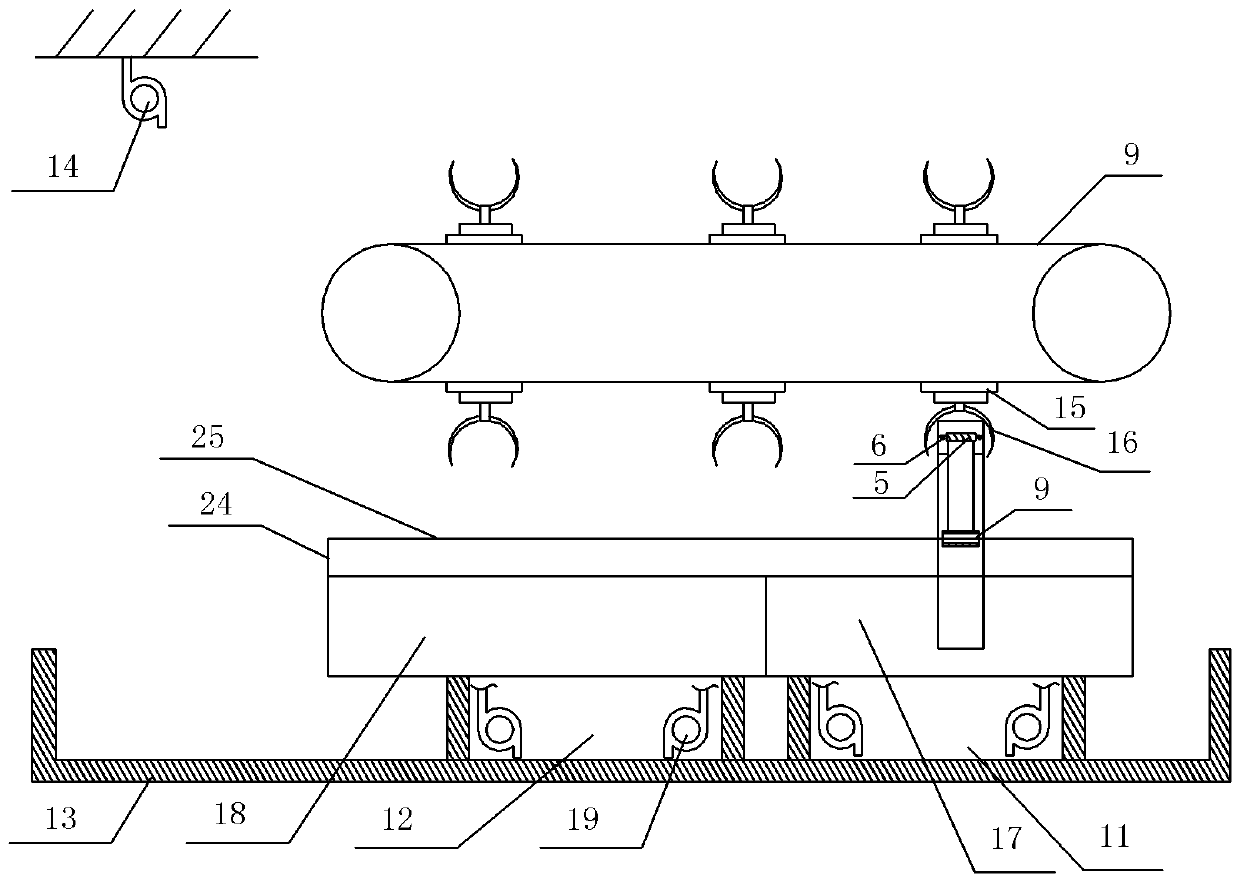

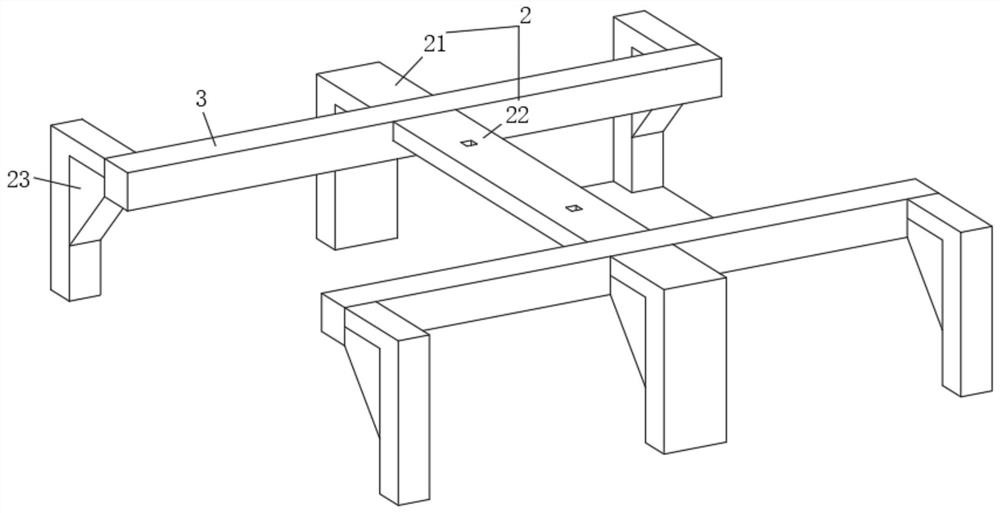

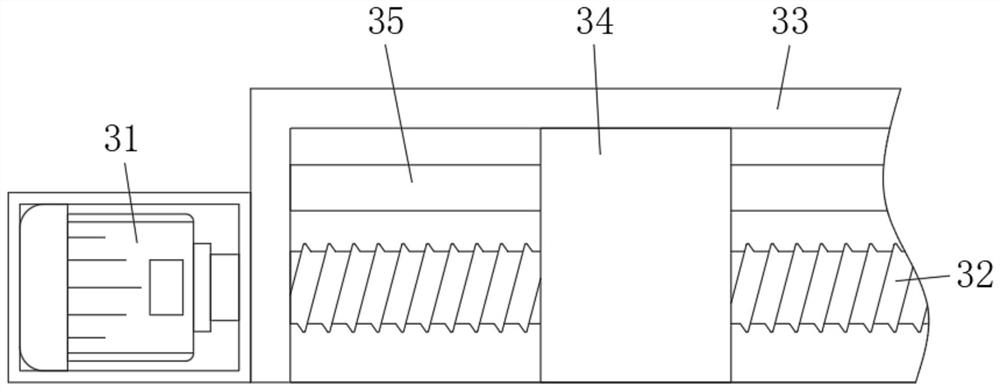

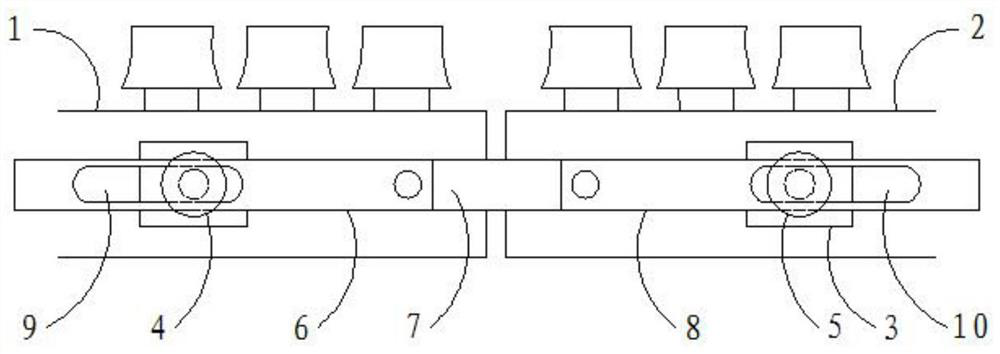

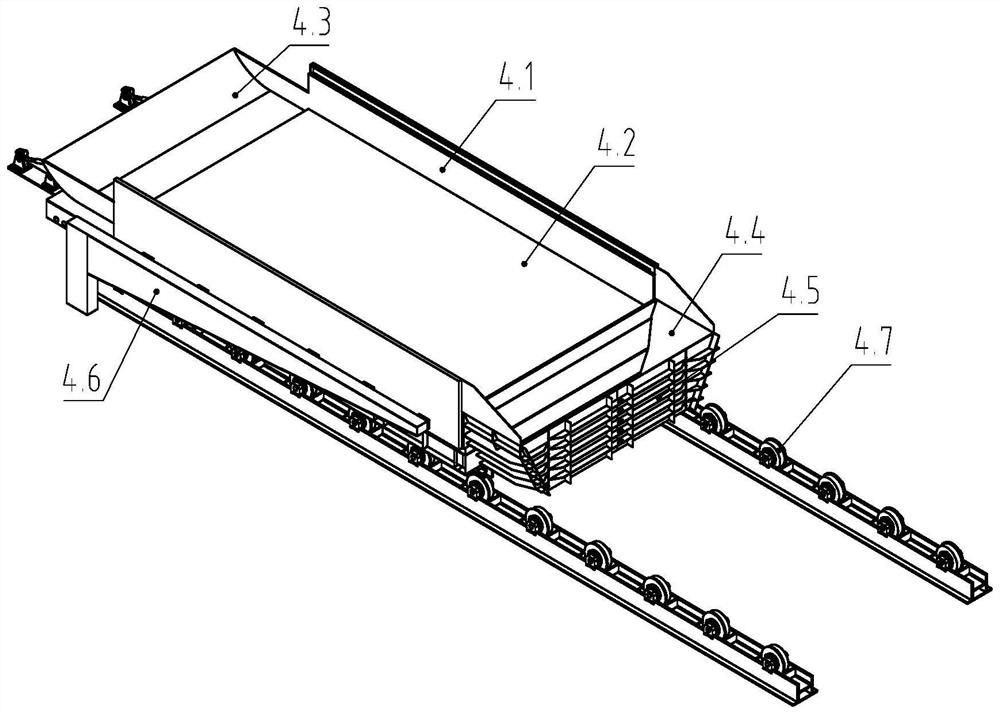

Soybean gluten stick conveying mechanism

The invention relates to the field of food processing and discloses a soybean gluten stick conveying mechanism.The mechanism comprises upper chain wheels, upper chains and upper rotating shafts, the two upper rotating shafts are arranged oppositely, the two ends of each upper rotating shaft are each connected with the corresponding upper chain wheel, the two upper chain wheels located at each same end of the two upper rotating shafts are matched with the corresponding upper chain, upper check blocks are arranged on chain bodies which are located on the upper chains at intervals, and a gap used for allowing for placing a soybean gluten stick therein is reserved between every two adjacent upper check blocks; the mechanism further comprises lower chain wheels, lower chains, lower rotating shafts and a tray, the two lower rotating shafts are arranged oppositely, the two ends of each lower rotating shaft are each connected with the corresponding lower chain wheel, the two lower chain wheels located at each same end of the two lower rotating shafts are matched with the corresponding lower chain, and the tray is detachably connected to the lower chains and provided with limiting teeth which are arranged uniformly.By means of the conveying mechanism, efficiency is improved, and meanwhile errors of manual operation is reduced; the tray is provided with the limiting teeth, so that the soybean gluten sticks are separated uniformly and automatically and arranged in order, it is convenient to air the soybean gluten sticks, and meanwhile time and labor are saved.

Owner:LIANGPING XINGYU BEAN PROD CO LTD

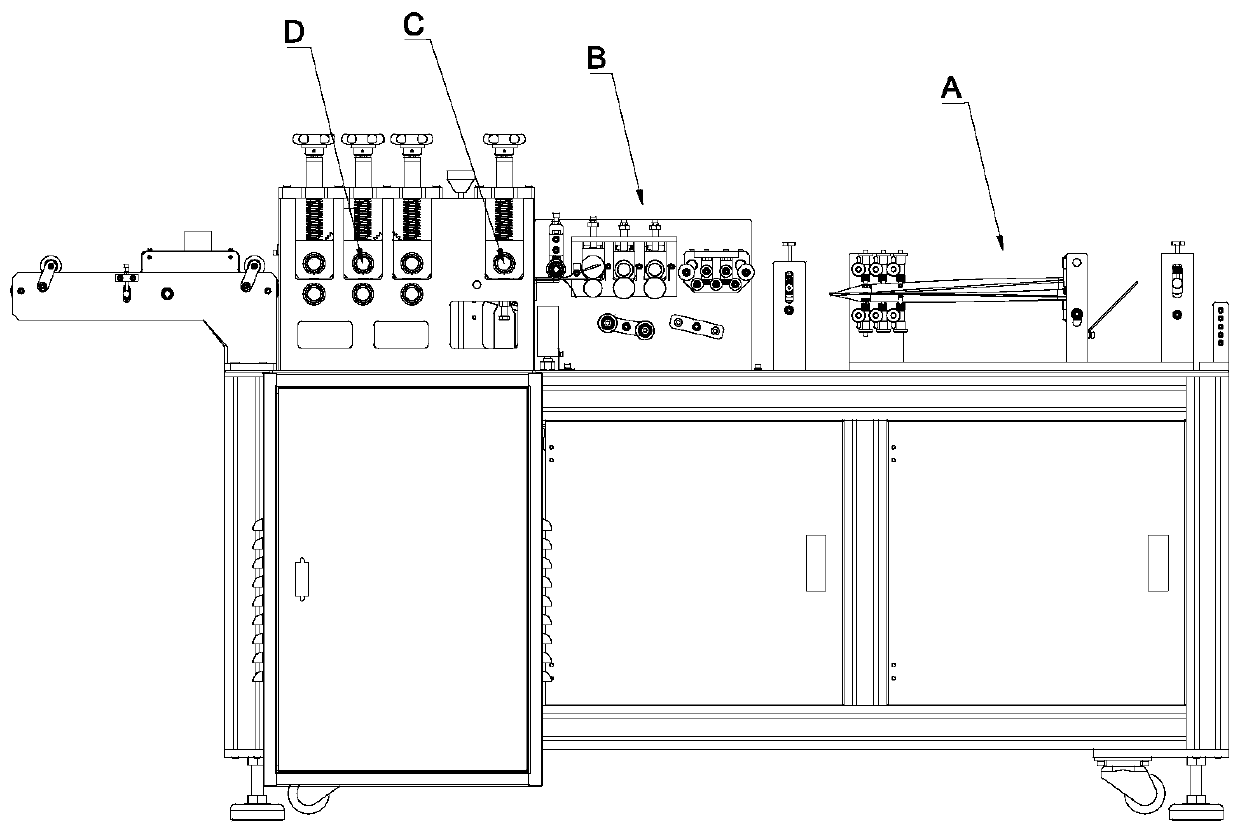

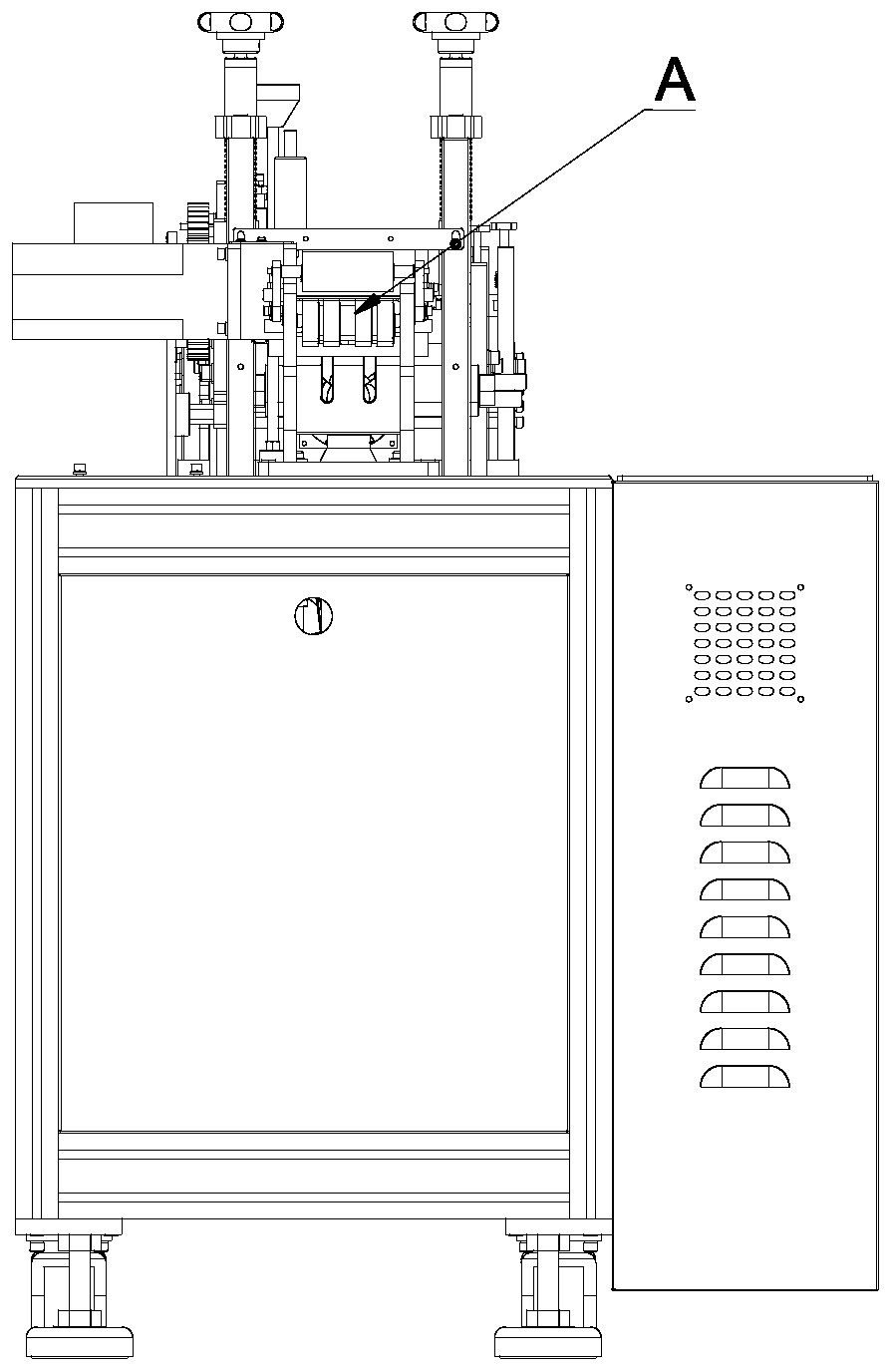

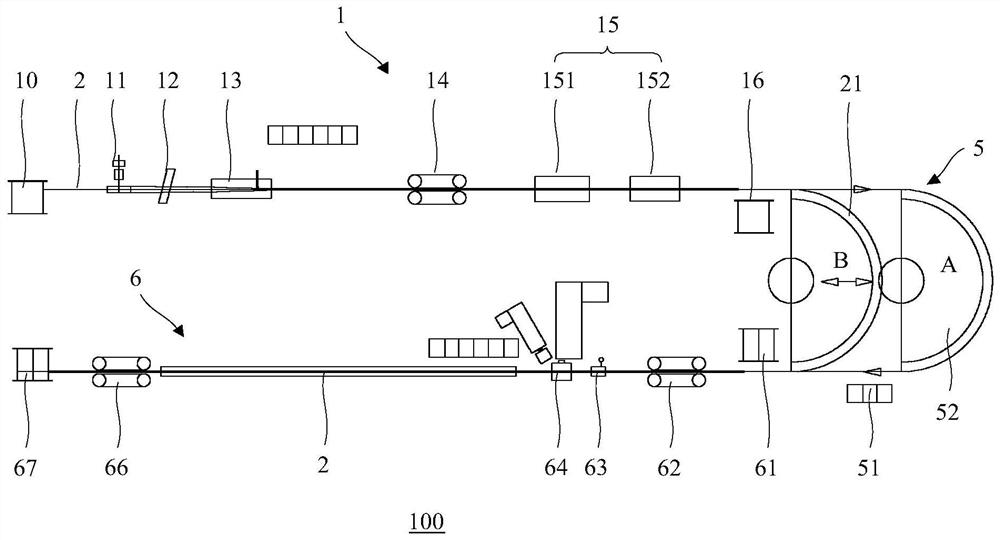

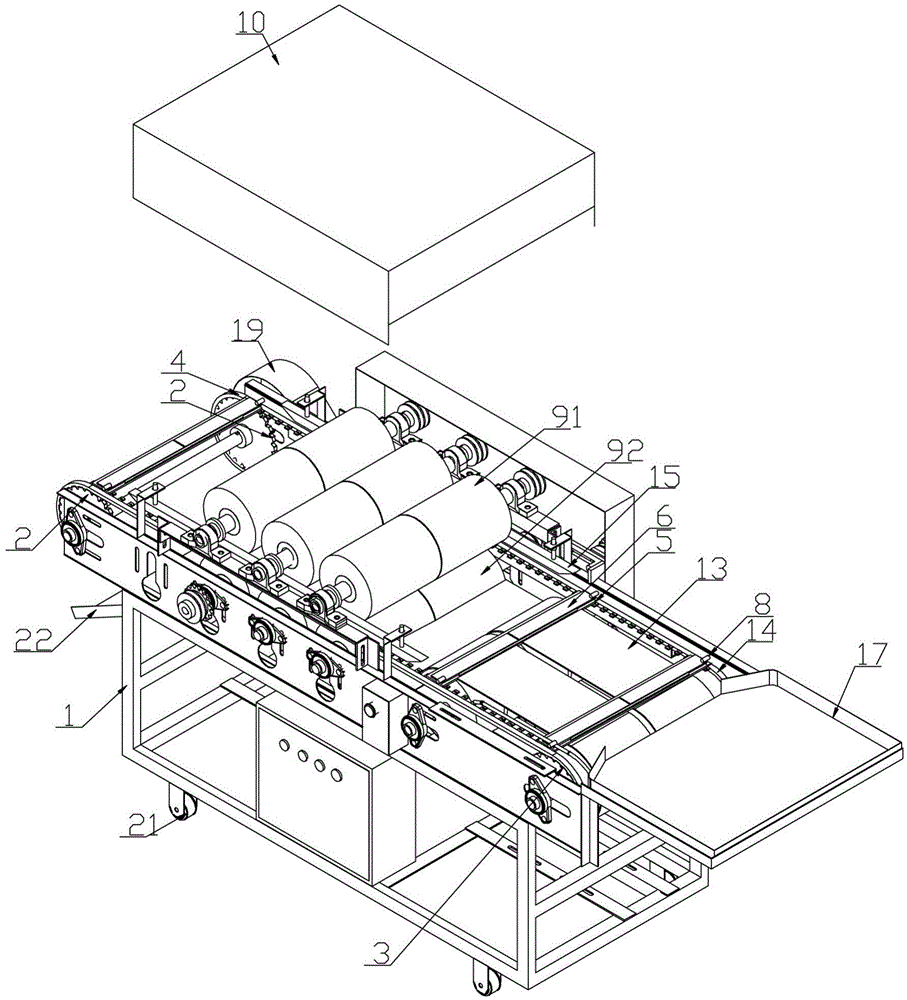

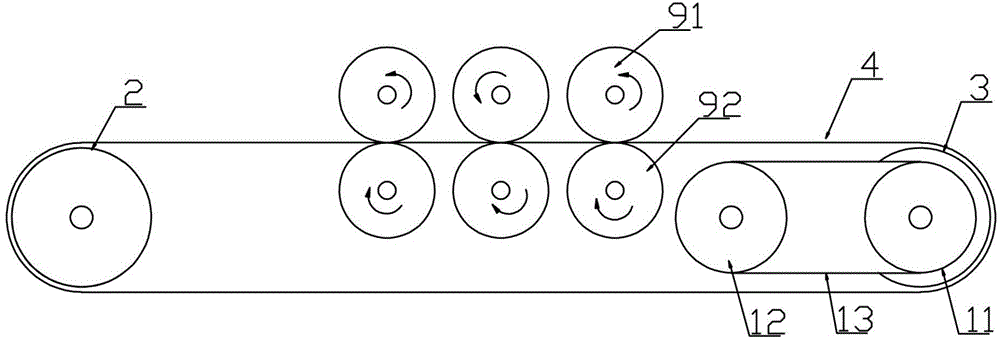

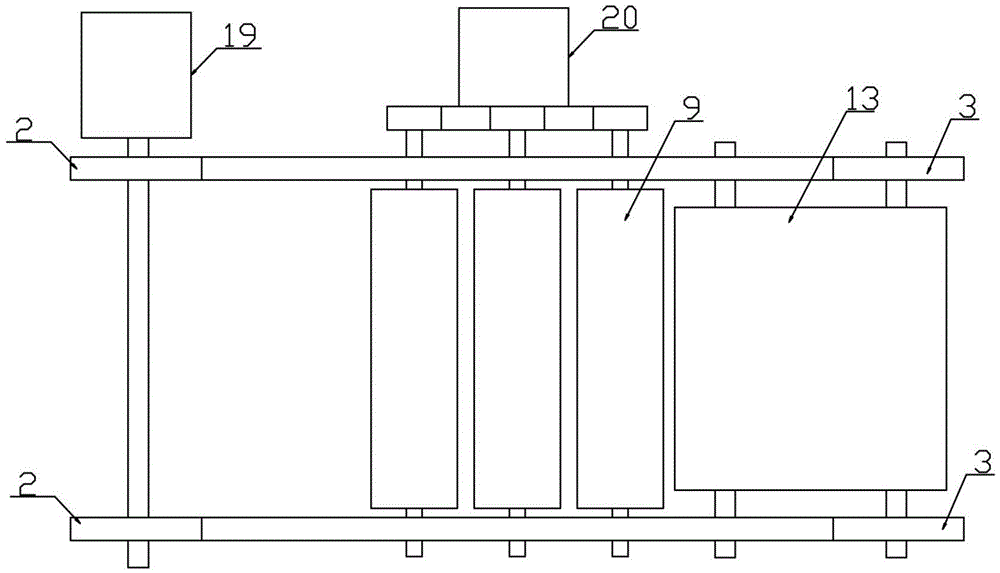

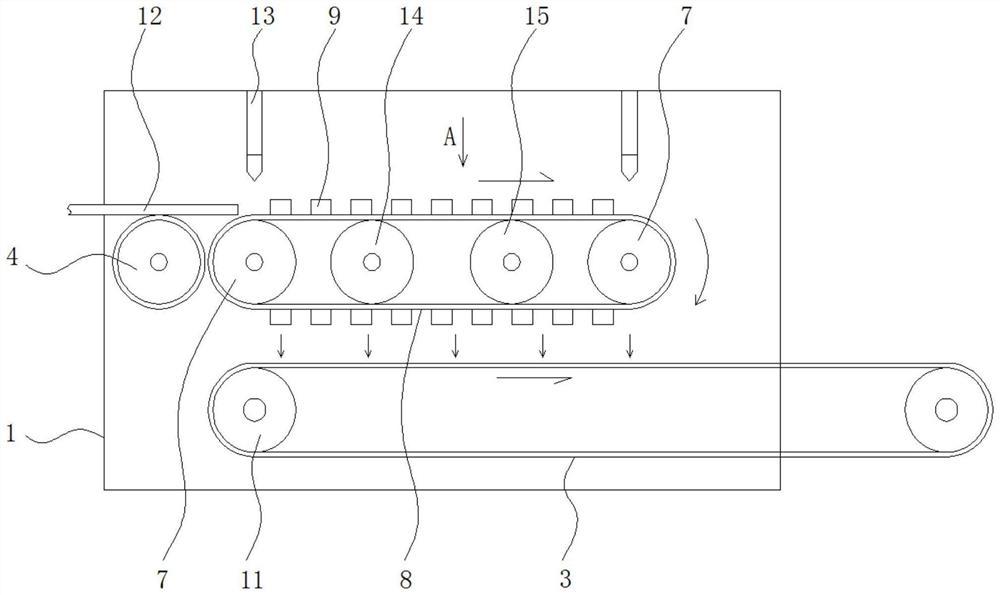

Planar mask production line

PendingCN111513399ARealize automated productionImprove processing qualityProtective garmentClothes making applicancesEngineeringNose bridge

The invention discloses a planar mask production line which comprises a cloth roll feeding module, a wrinkle forming module, a nose line feeding module, a welding module, a slicing module and a powersource. The cloth roll feeding module comprises a plurality of cloth rolls, and the cloth rolls are rotationally connected to a rack; the wrinkle forming module comprises a mounting frame and a plurality of groups of wrinkle assemblies arranged on the mounting frame; the welding module comprises a welding roller, a welding table and ultrasonic equipment; the slicing module comprises a slicing roller and a feeding roller, a slicing knife extending in the axial direction is arranged on the slicing roller, and a cutting edge of the slicing knife is tangent to the circumferential surface of the feeding roller; the welding roller and the slicing roller are connected with the power source through a first transmission mechanism. Full-automatic production of the planar masks is achieved, the feeding precision of the nose bridge line is high, and the machining quality of the planar masks can be improved.

Owner:FOSHAN NANHAI ZHONGNAN MACHINERY +1

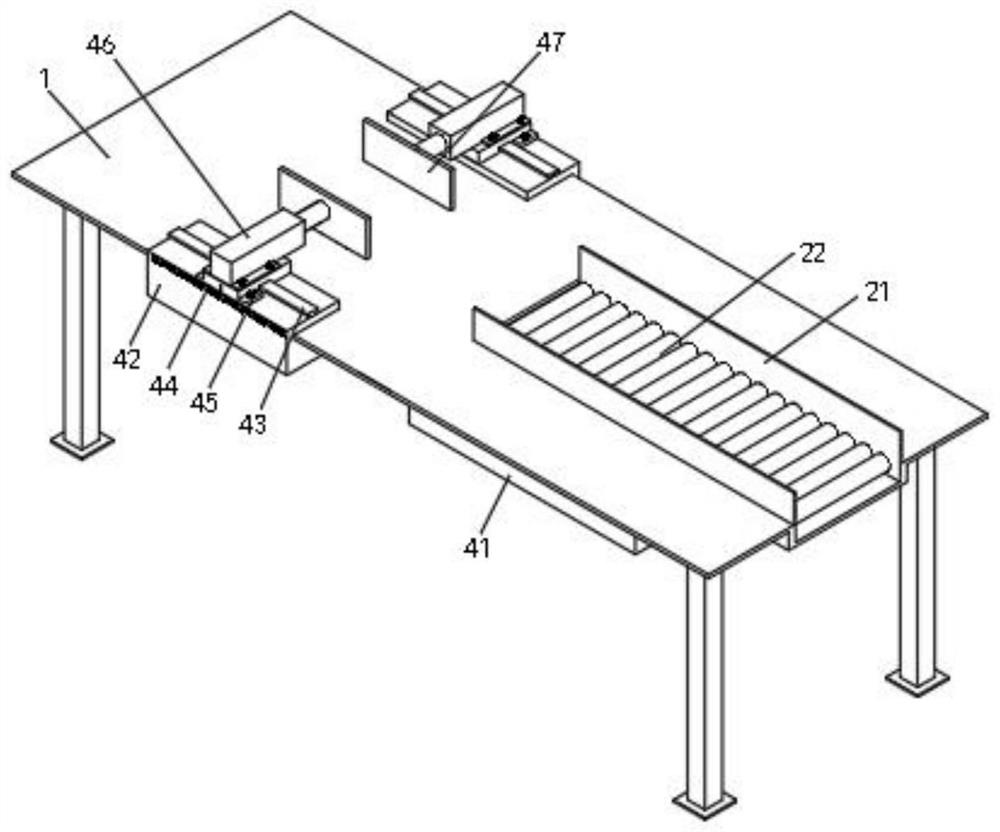

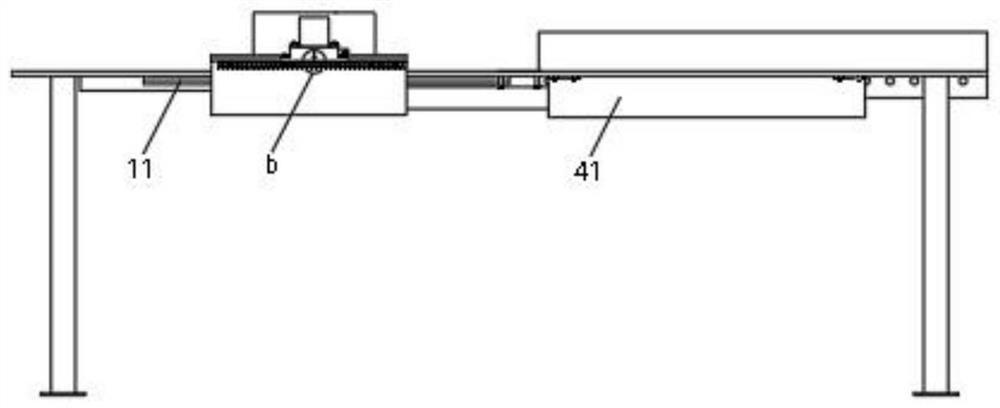

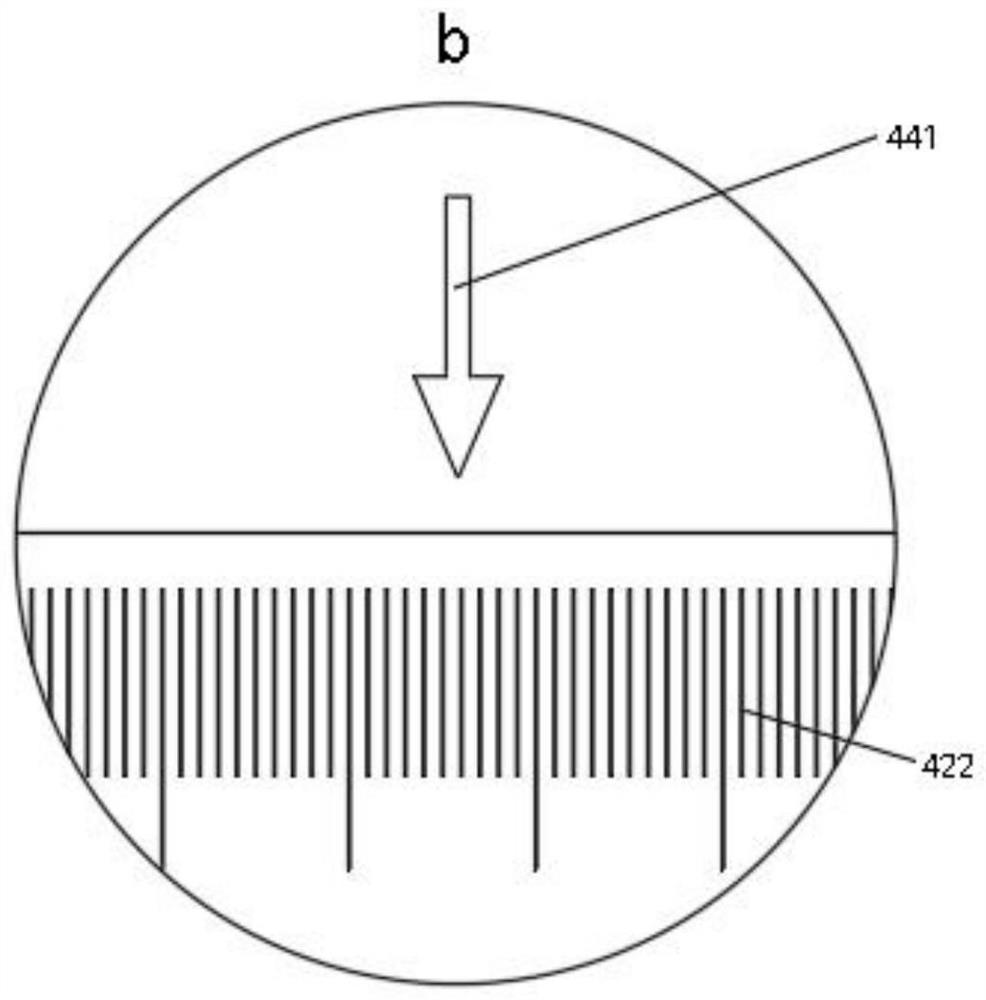

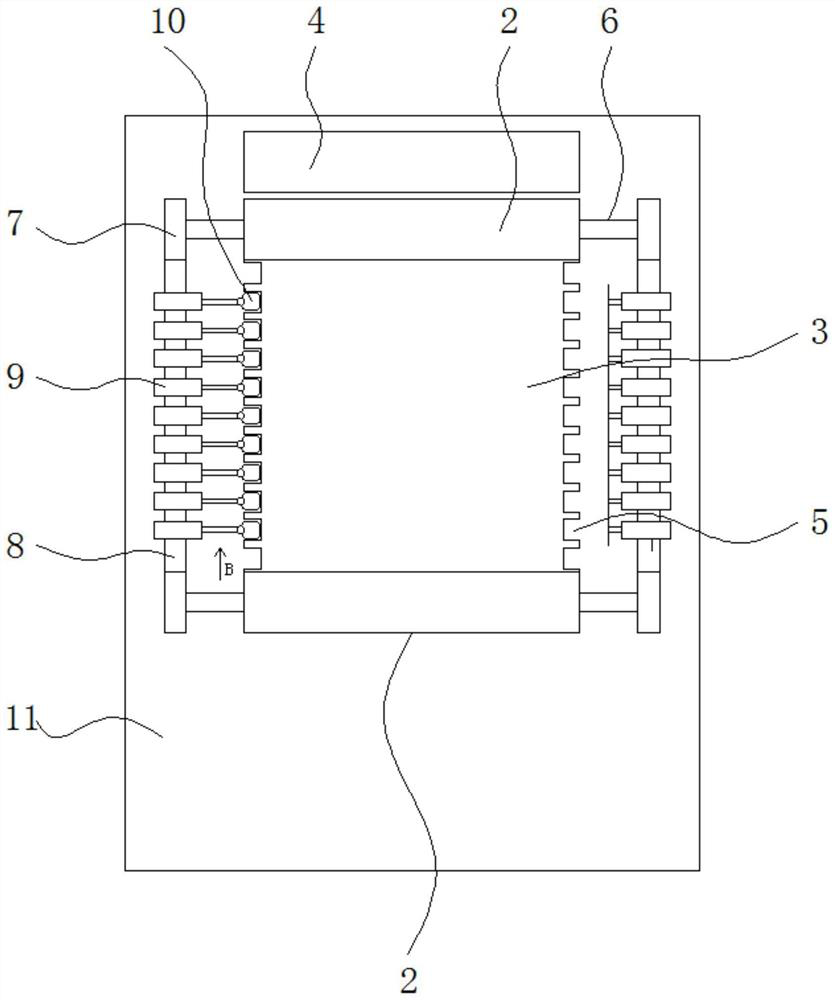

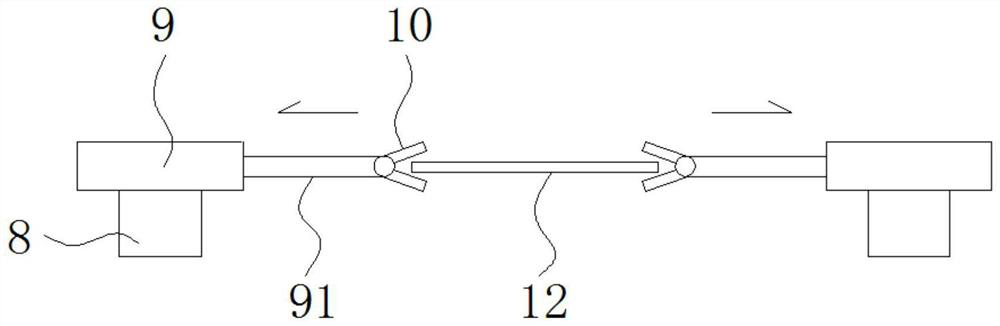

Clamping device for aluminum profile machining

InactiveCN114406766AHigh dimensional accuracyIncrease productivityWork clamping meansPositioning apparatusPhysicsEngineering

The invention discloses a clamping device for aluminum profile machining, and relates to the technical field of aluminum profile machining. The device comprises a conveying table, the conveying table is provided with a roll shaft conveying part, and the conveying table is further provided with a clamping part arranged in the aluminum profile conveying direction; the clamping part comprises a first sliding rail arranged on the lower end face of the conveying table and a second air cylinder installed on the lower end face of the conveying table, a sliding seat is slidably connected to the first sliding rail, the output end of the second air cylinder is fixedly connected with the sliding seat, a second sliding rail is arranged on the sliding seat, a sliding block is installed on the second sliding rail, and a fixing lug is arranged at the bottom of the sliding block. A screw is in threaded connection with the fixing lug and abuts against the sliding base so that the sliding block can be fixed to the sliding base, a third air cylinder is installed at the upper end of the sliding block, and a second baffle is fixed to the output end of the third air cylinder. According to the clamping device, the aluminum profile is clamped and moved in a clamping mode, it is guaranteed that the transferring distance of the aluminum profile is kept stable, the machining precision of the aluminum profile is improved, the production efficiency is improved, and the production cost is reduced.

Owner:江苏高卡轻合金有限公司

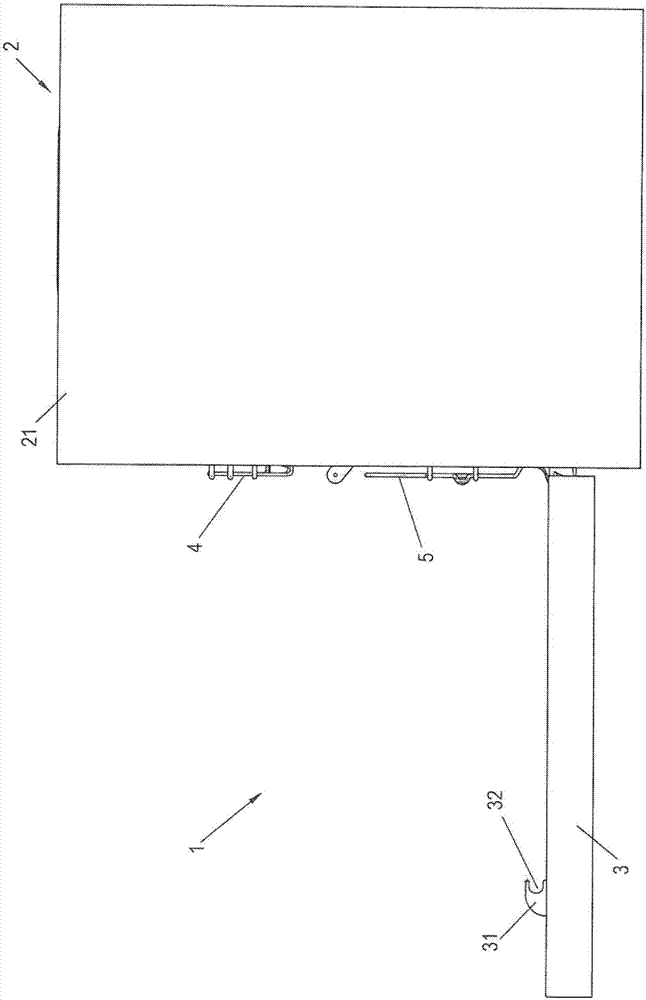

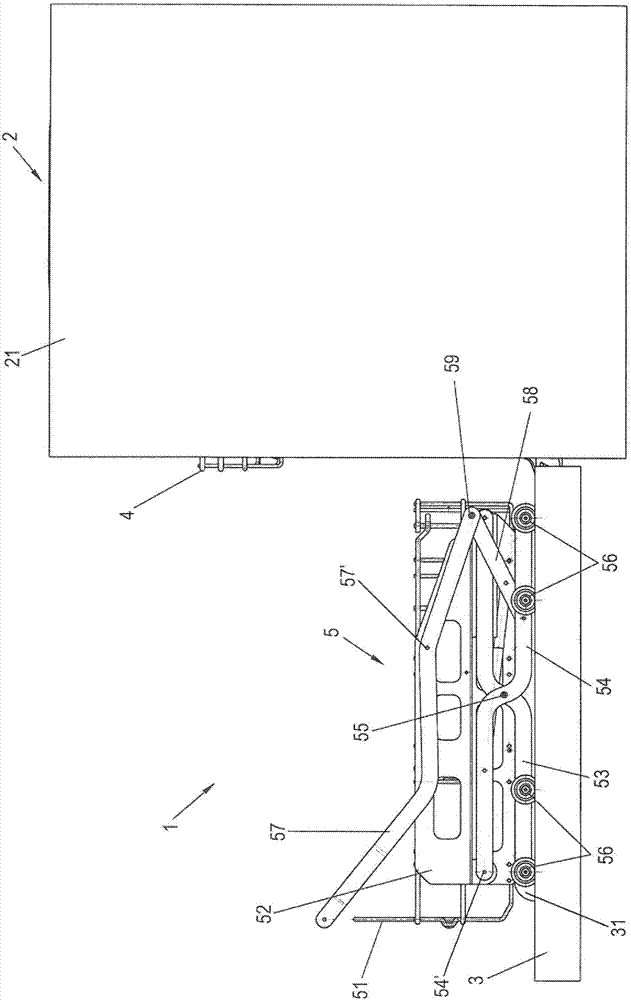

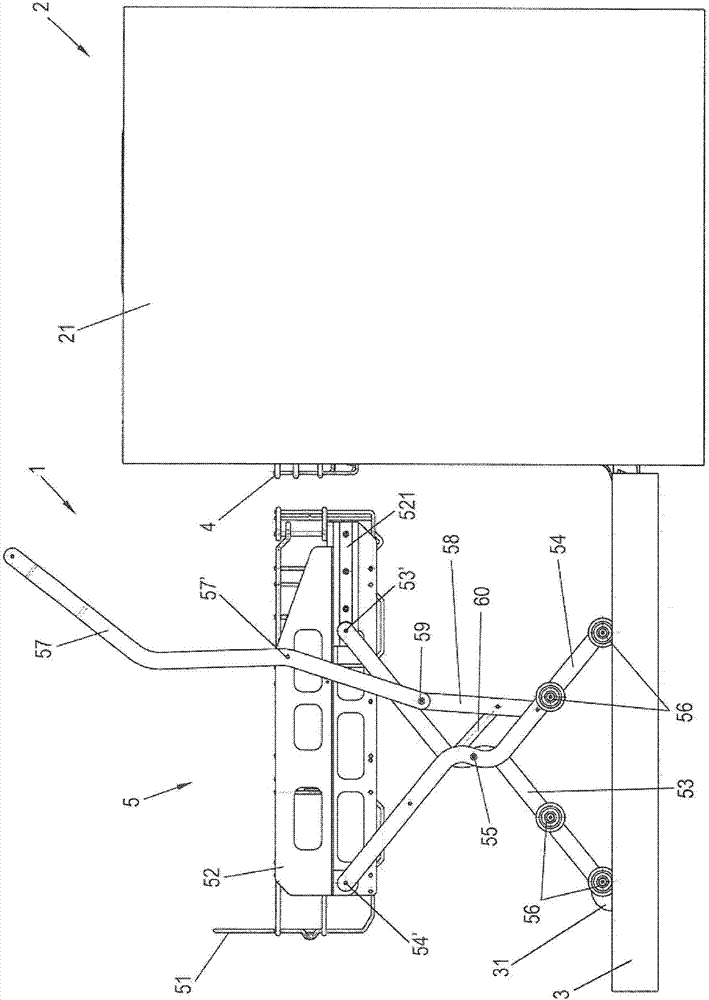

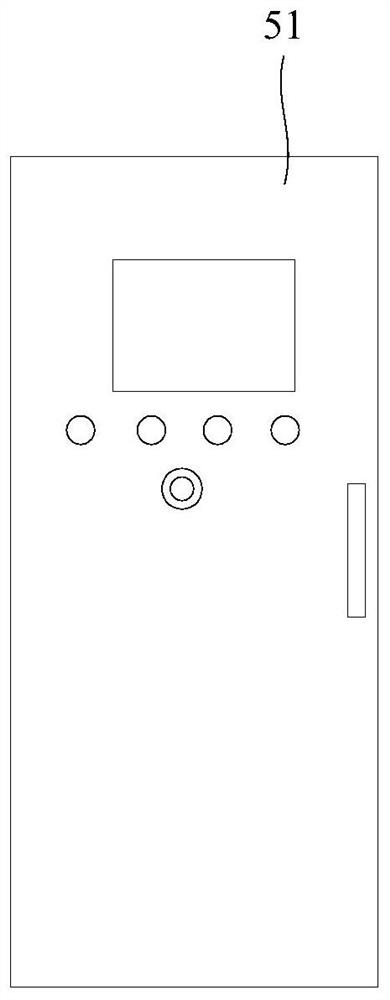

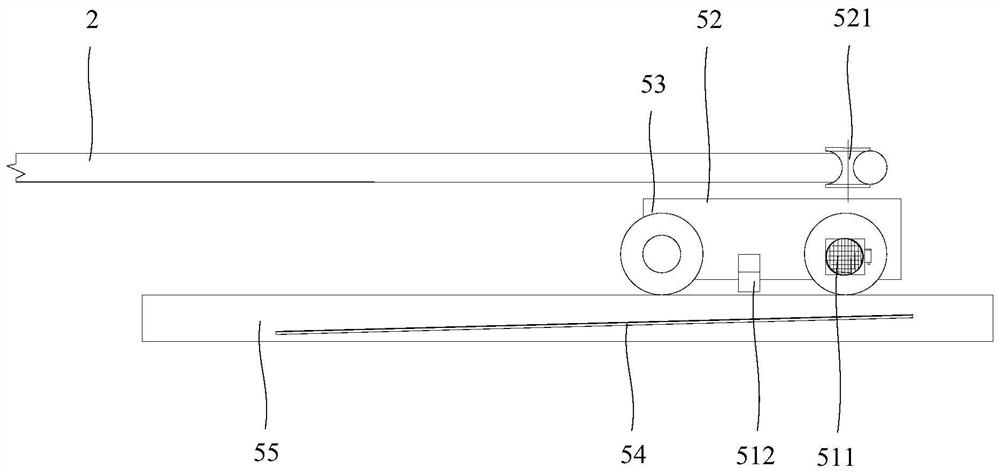

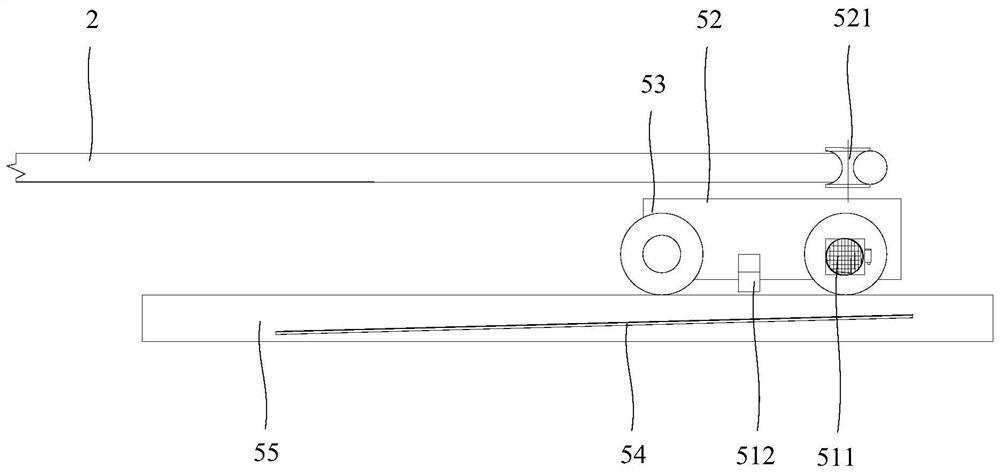

Sliding and lifting mechanism of a shelf of an item of furniture or household device, item of furniture and household device

ActiveCN107205547ARealize sliding movementRealize lifting motionTableware washing/rinsing machine detailsDrawersMechanical engineeringEngineering

The invention relates to a sliding and lifting mechanism of a shelf (5) of an item of furniture or household device (1) having a scissor-type mechanism (53-55) for pulling the shelf (5) out of a body (2) of the item of furniture or household device (1) and for lifting the shelf (5), characterised in that the sliding and lifting mechanism has a knee joint (59) that is coupled to the scissor-type mechanism (53-55) and locks the shelf (5) in a lifted position. The invention also relates to an item of furniture or a household device (1) having a sliding and lifting mechanism of this type.

Owner:PAUL HETTICH

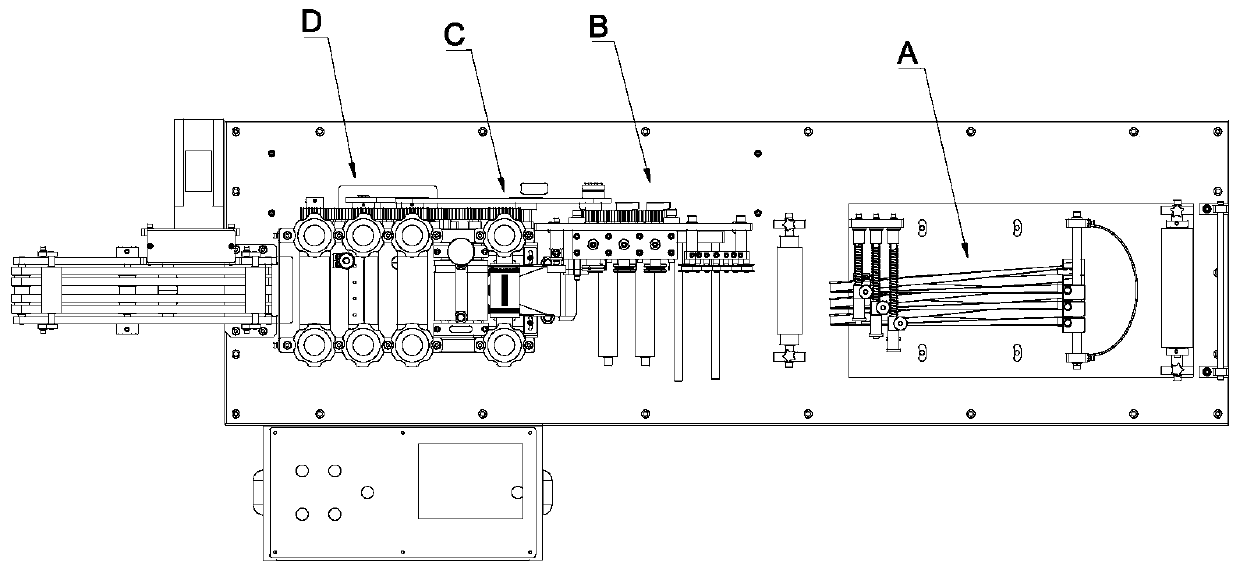

Cable sheath production line

ActiveCN112233861AEasy to operateCompact structureCable/conductor manufactureEngineeringElectric cables

The invention provides a cable sheath production line. The cable sheath production line comprises a metal sheath installation assembly, a non-metal sheath installation assembly and a circulation wirestorage unit, wherein the metal sheath installation assembly, the circulation wire storage unit and the non-metal sheath installation assembly are sequentially arranged in the feeding direction of a semi-finished cable product; the circulation wire storage unit is arranged at the outer sides of the same ends of the metal sheath installation assembly and the non-metal sheath installation assembly,and a distance is between the metal sheath installation assembly and the non-metal sheath installation assembly, so that a part, between the metal sheath installation assembly and non-metal sheath installation assembly, of the semi-finished cable product forms a bent arc-shaped cable storage part; the circulation wire storage unit can move relative to the metal sheath installation assembly and thenon-metal sheath installation assembly so as to change the length of the wire storage part; and the semi-finished cable product synchronously moves in the metal sheath installation assembly and the non-metal sheath installation assembly. The device is compact in structure, small in occupied area and high in production efficiency.

Owner:ZHONGTIAN TECH SUBMARINE CABLE CO LTD

Fish scale removing device

ActiveCN104542883AImprove processing productivityReduce labor intensityFish washing/descalingEngineeringAssembly line

The invention discloses a fish scale removing device and belongs to the technical field of fish product processing. The device comprises a rack, a chain conveyer, an input conveyer, a scale removing assembly and a power mechanism, wherein the chain conveyer comprises a driving chain wheel, a driven chain wheel, an annular chain and clamping mechanisms, each clamping mechanism comprises a fish clamping bottom board and a cutting board which are movably connected, short rods are arranged on the fish clamping bottom boards, the scale removing assembly comprises at least one pair of scale removing roller brushes and a shield, the input conveyer comprises a driving roller, a driven roller and an input conveying belt, inlet and outlet guide rods are arranged at an inlet and an outlet of the rack respectively, the short rods correspondingly extend out of upper parts of the inlet guide rods and extend into lower parts of the outlet guide rods, and pressing boards are also arranged on the rack. The device can remove scales continuously, realizes assembly line processing, is particularly applicable to types of fishes with flat fish bodies, and is high in scale removing efficiency and good in scale removing effect.

Owner:PENGLAI JINGLU FISHERY

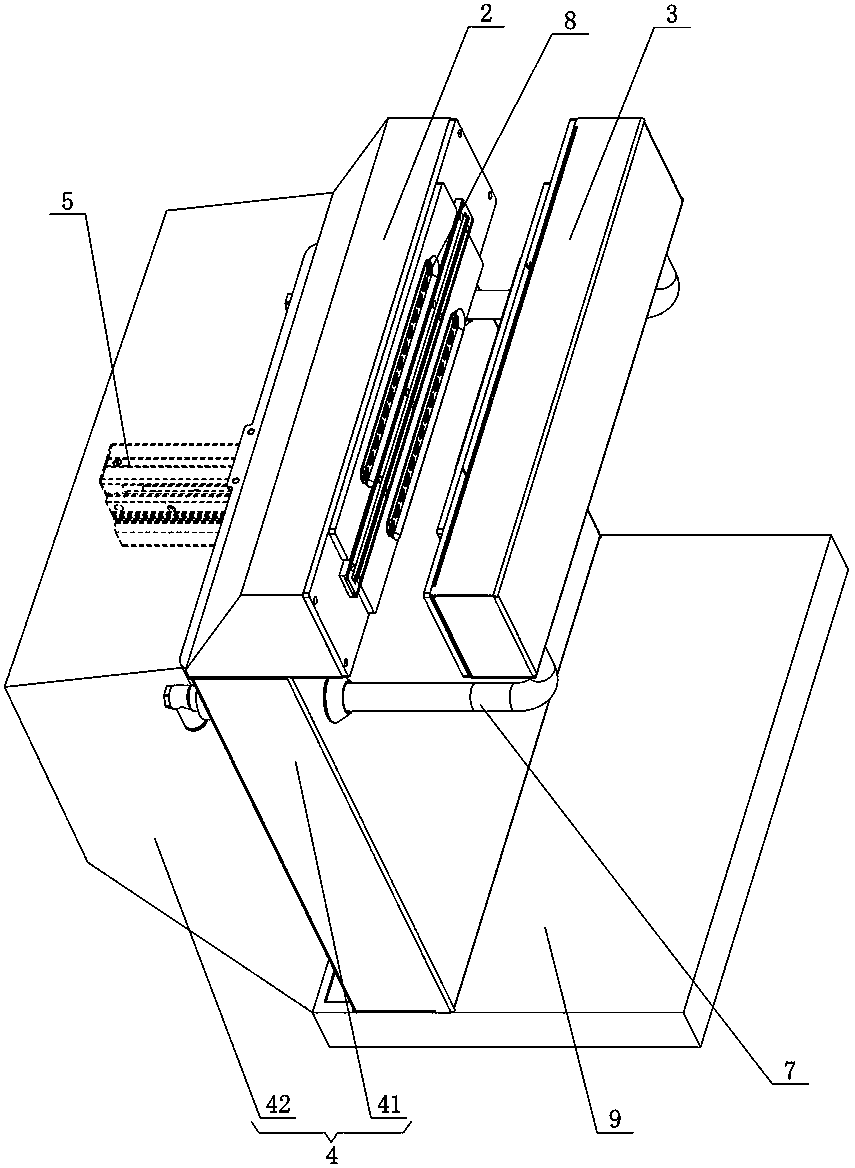

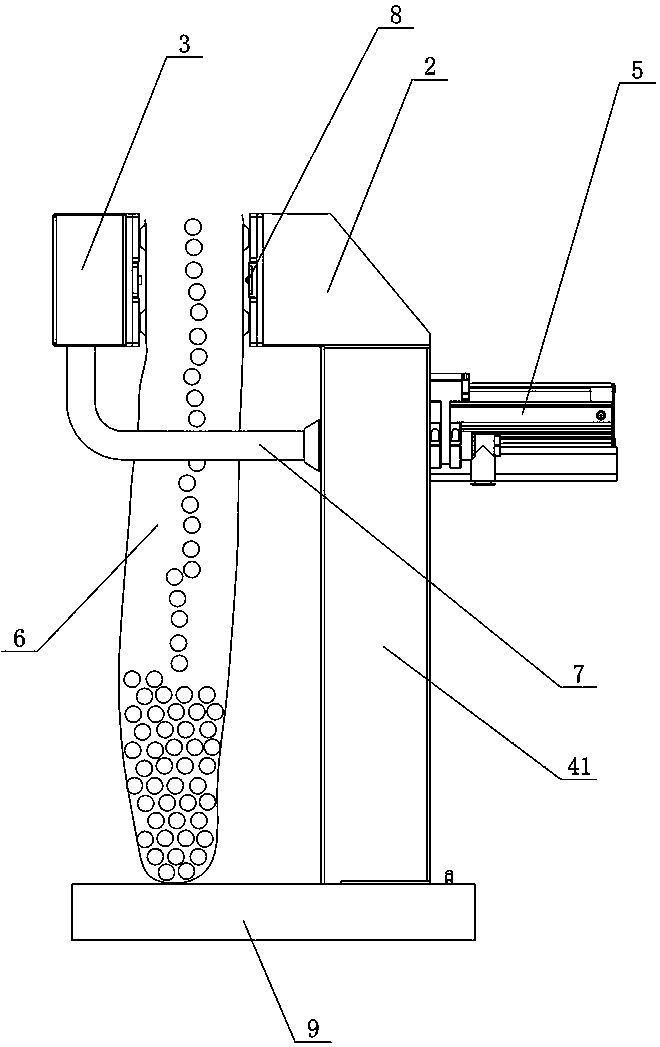

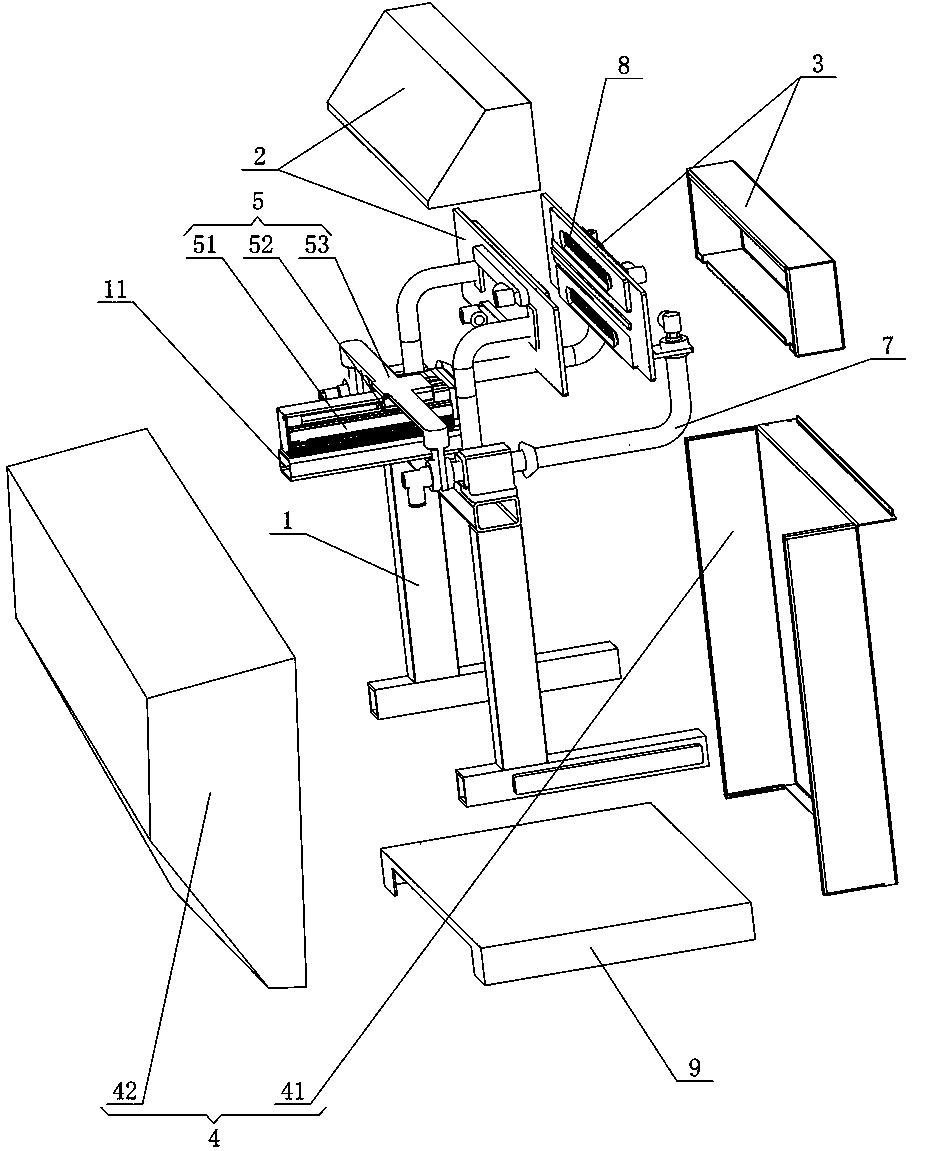

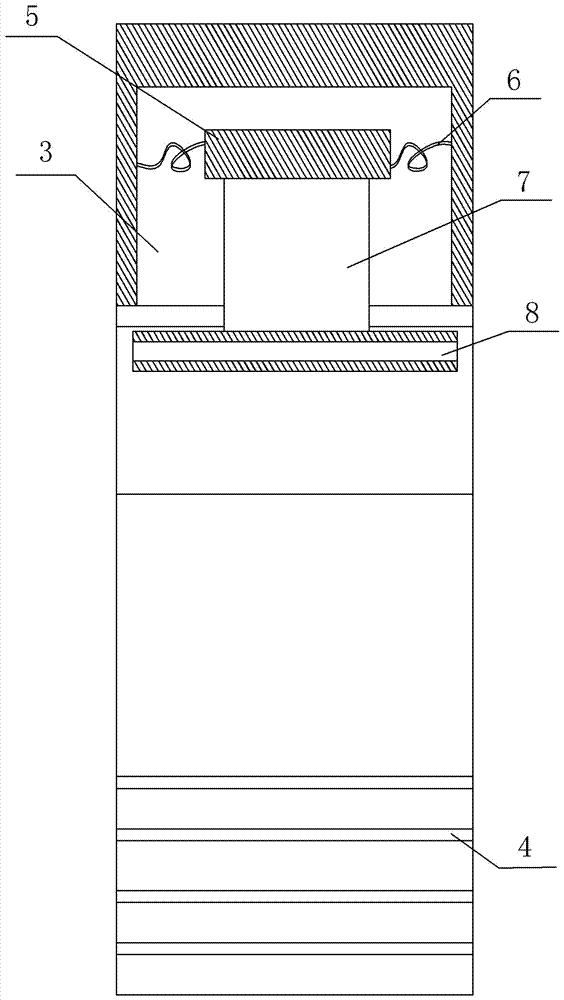

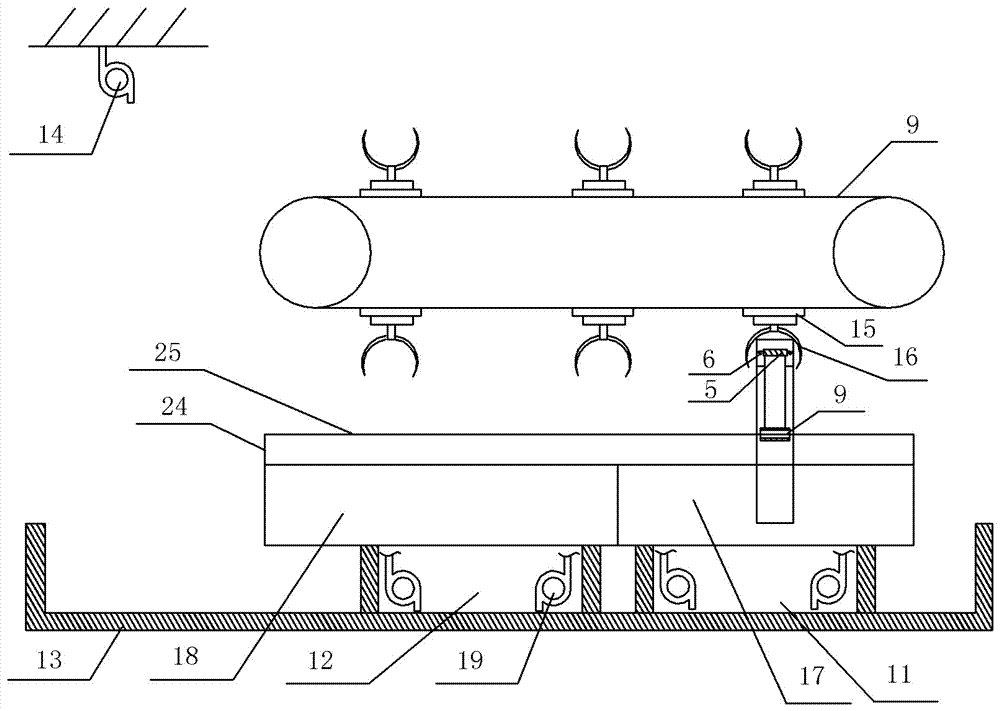

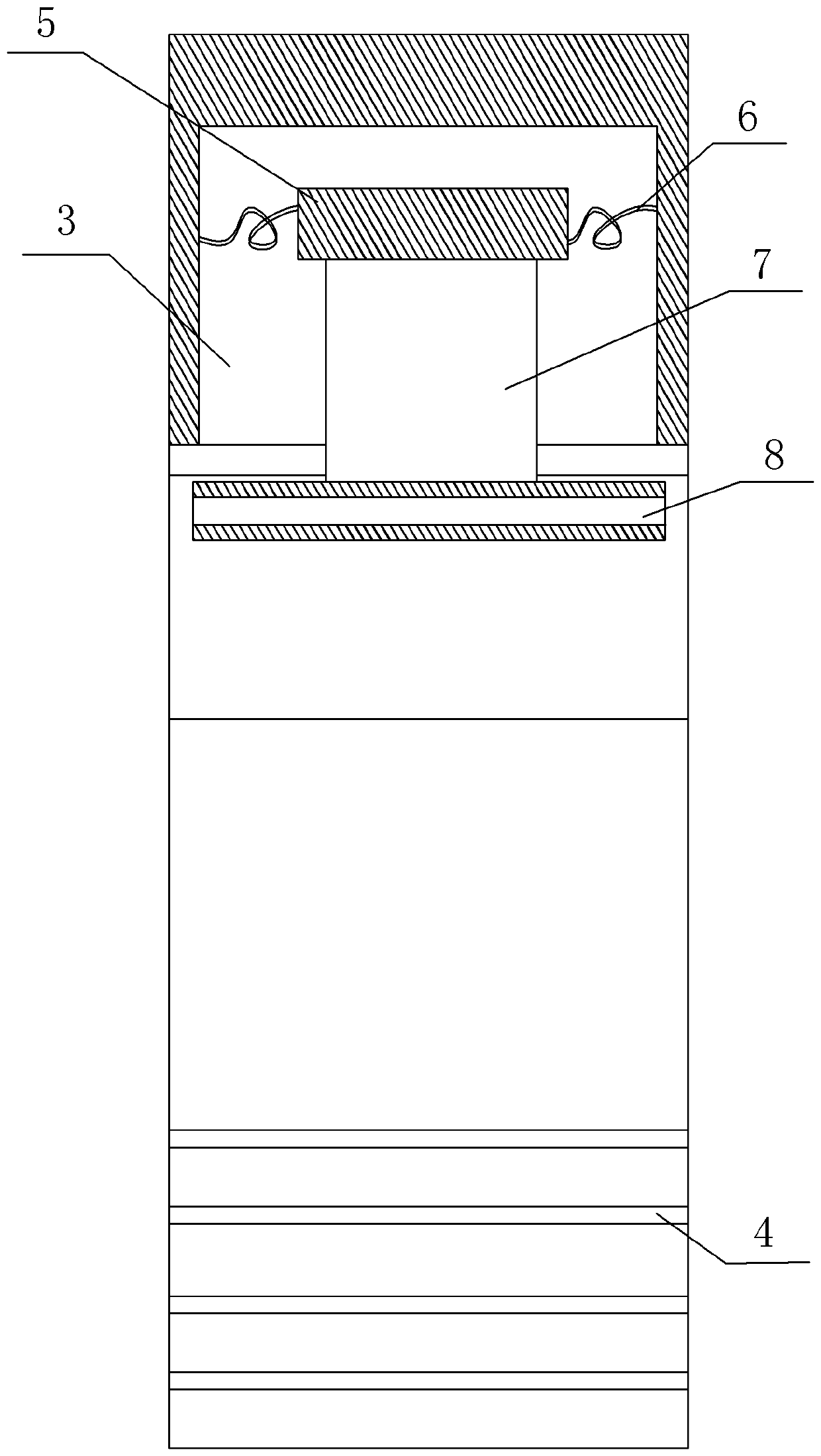

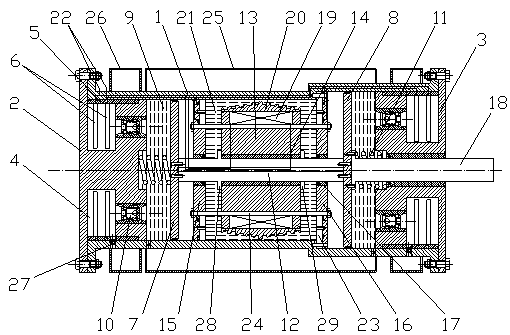

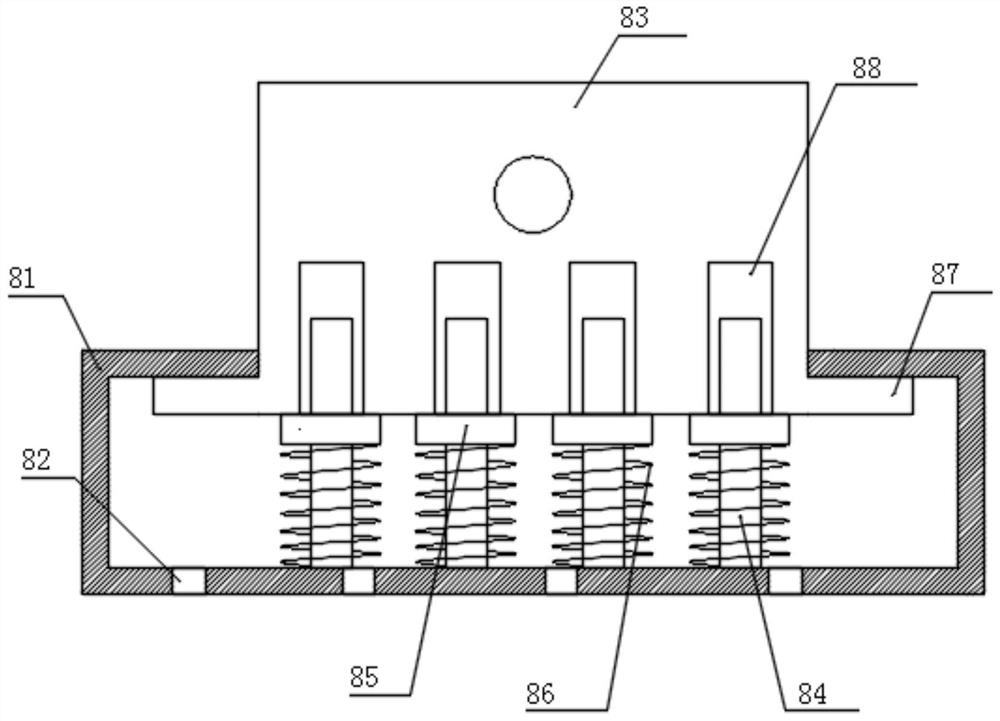

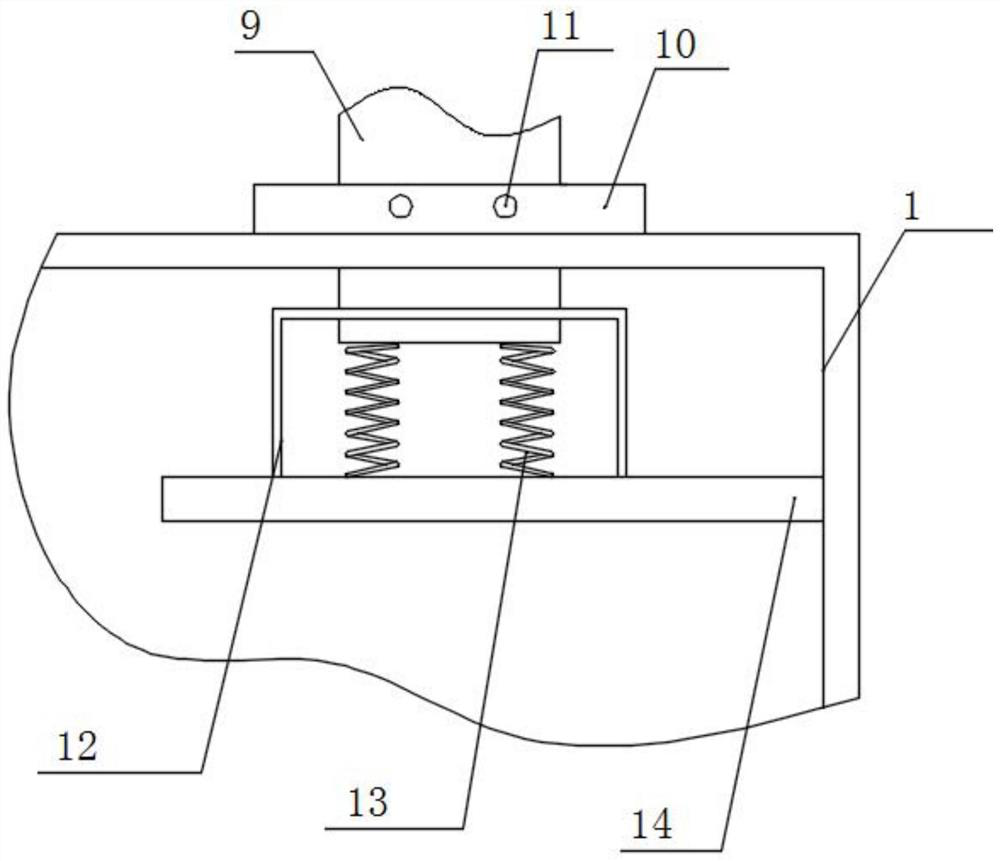

Packing bag heat seal mechanism and rubber plug/aluminum cover discharge device based on same

ActiveCN104260937AMake sure to move in syncOptimize layoutWrapper twisting/gatheringSolid materialEngineeringRelative motion

The invention discloses a packing bag heat seal mechanism and a rubber plug / aluminum cover discharge device based on the same. The packing bag heat seal mechanism comprises a support, a first heat seal plate and a second heat seal plate. The first heat seal plate is arranged on the support, a support cover is arranged on the periphery of the support, and a drive assembly installed on the support is arranged in the support cover. The drive assembly is connected with at least one guide rod which penetrates through the wall of the support cover, is connected with the second heat seal plate and drives the second heat seal plate to do relative motion towards the first heat seal plate. The rubber plug / aluminum cover discharge device comprises a discharge port, and the packing bag heat seal mechanism is arranged below the discharge port. The packing bag heat seal mechanism has the advantages of being tidy and attractive in appearance and capable of effectively improving the heat seal stability.

Owner:TRUKING TECH LTD

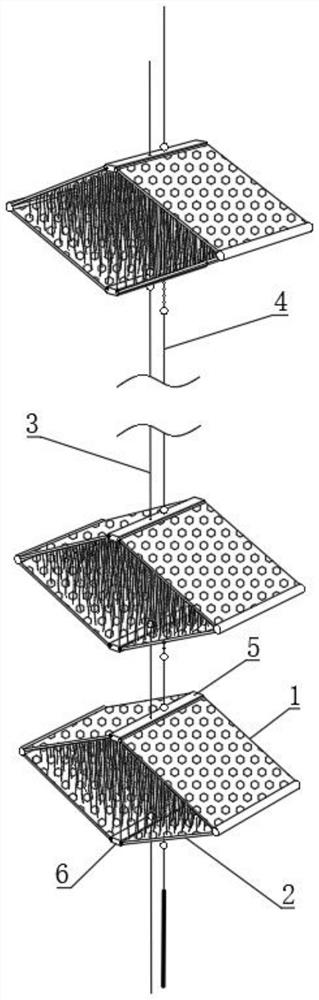

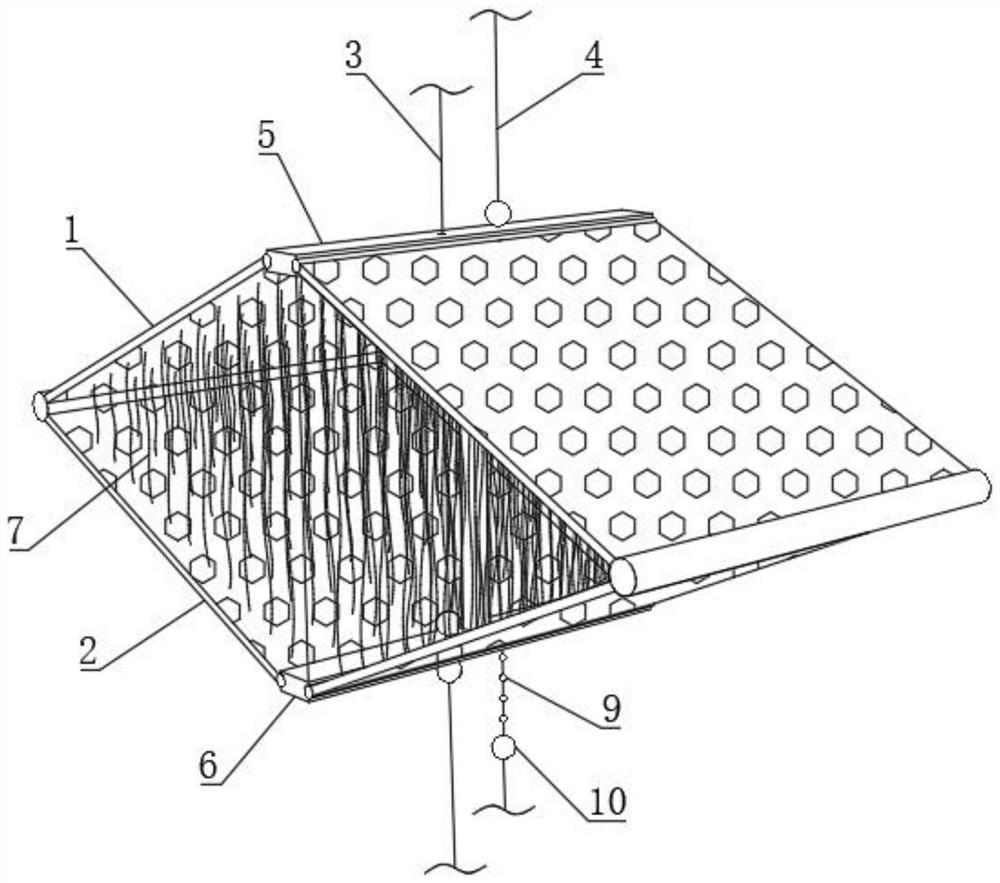

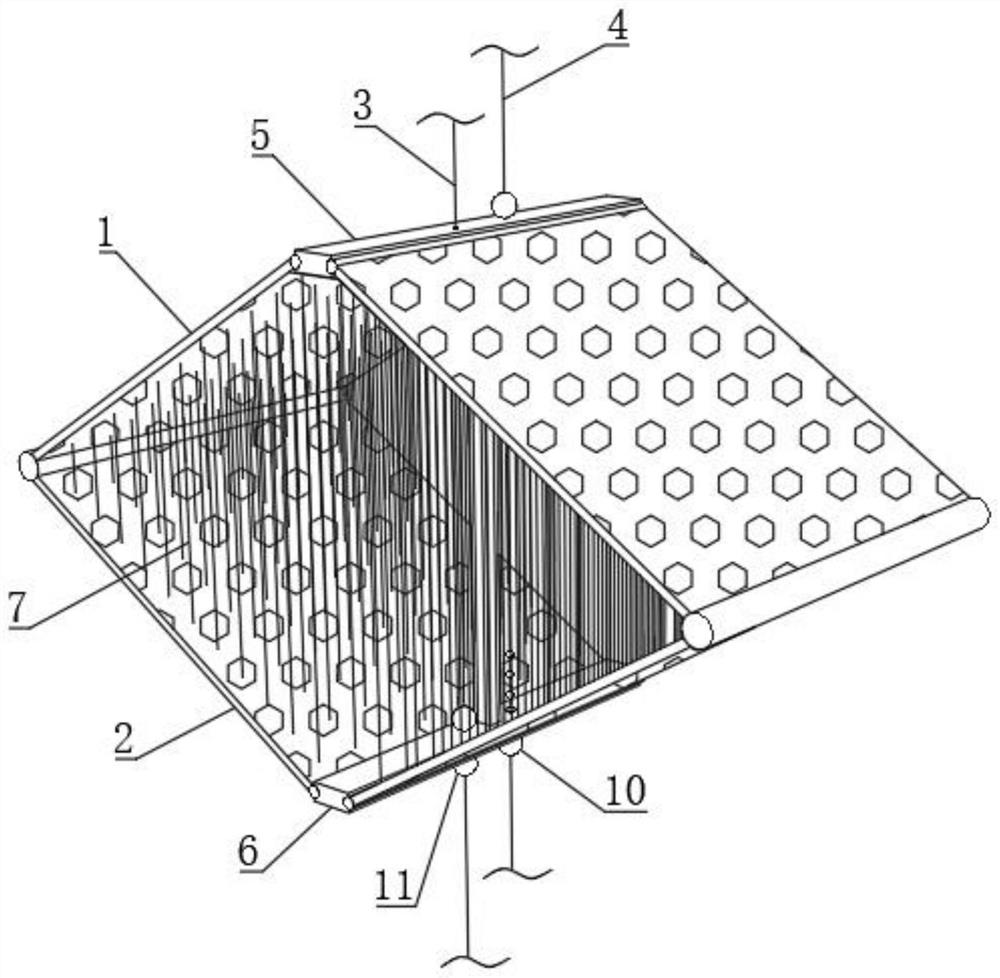

Wire-drawing gathering-scattering type combined filler for sewage treatment

InactiveCN113072194AChange densityIncrease internal porosityBiological treatment apparatusChemistryComposite material

The invention discloses a wire-drawing gathering-scattering type combined filler for sewage treatment, and belongs to the field of combined fillers. The wire-drawing gathering-scattering type combined filler for sewage treatment comprises a fixed rope, a semi-elastic movable rope and a plurality of uniformly distributed rhombic filler bodies, wherein the fixed rope and the semi-elastic movable rope sequentially penetrate through the rhombic filler bodies and are connected with the rhombic filler bodies, and the rhombic filler body comprises a pair of upper net plates and a pair of lower net plates. According to the invention, the shape change of the rhombic filler body is controlled, so that the loose state and the dense degree of the biofilm hanging silk are changed, the integrity of a biofilm is damaged, the internal pores of the biofilm are enlarged, the dense degree of the biofilm can be quantitatively and uniformly adjusted according to the actual situation, on the basis of not influencing the normal use of the biofilm, the internal porosity of the biofilm is improved, the adhesion capacity of the biofilm is reduced, and the separation of the aged biofilm is promoted so as to provide the combined filler which is easy to adjust, promotes demolding and has efficient degradation capacity for sewage treatment.

Owner:刘日山

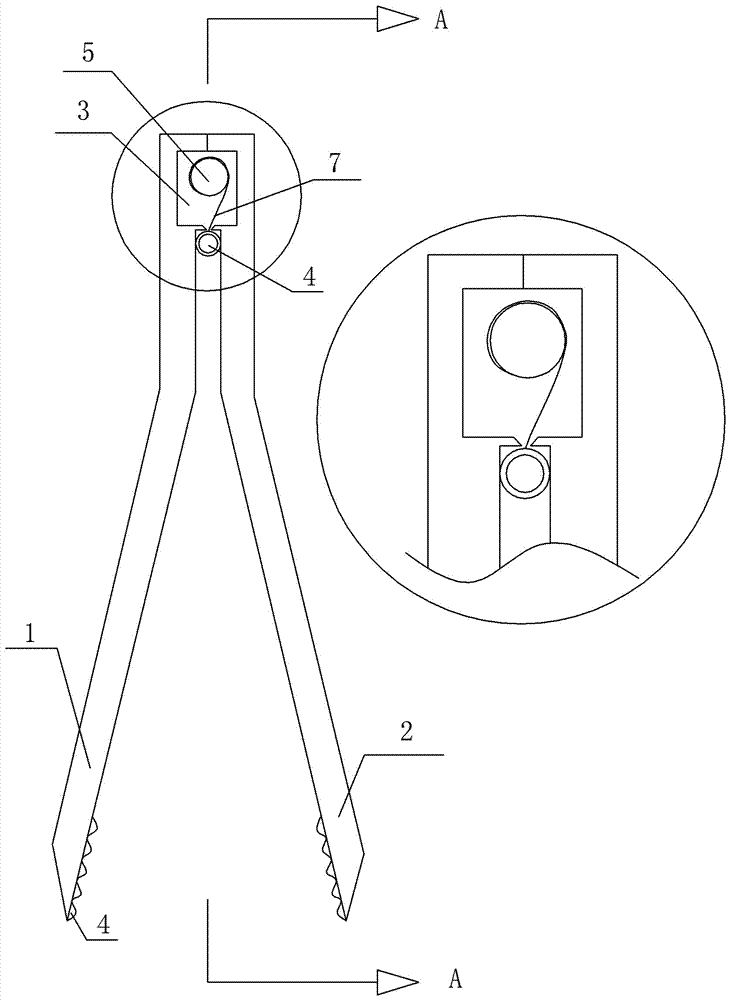

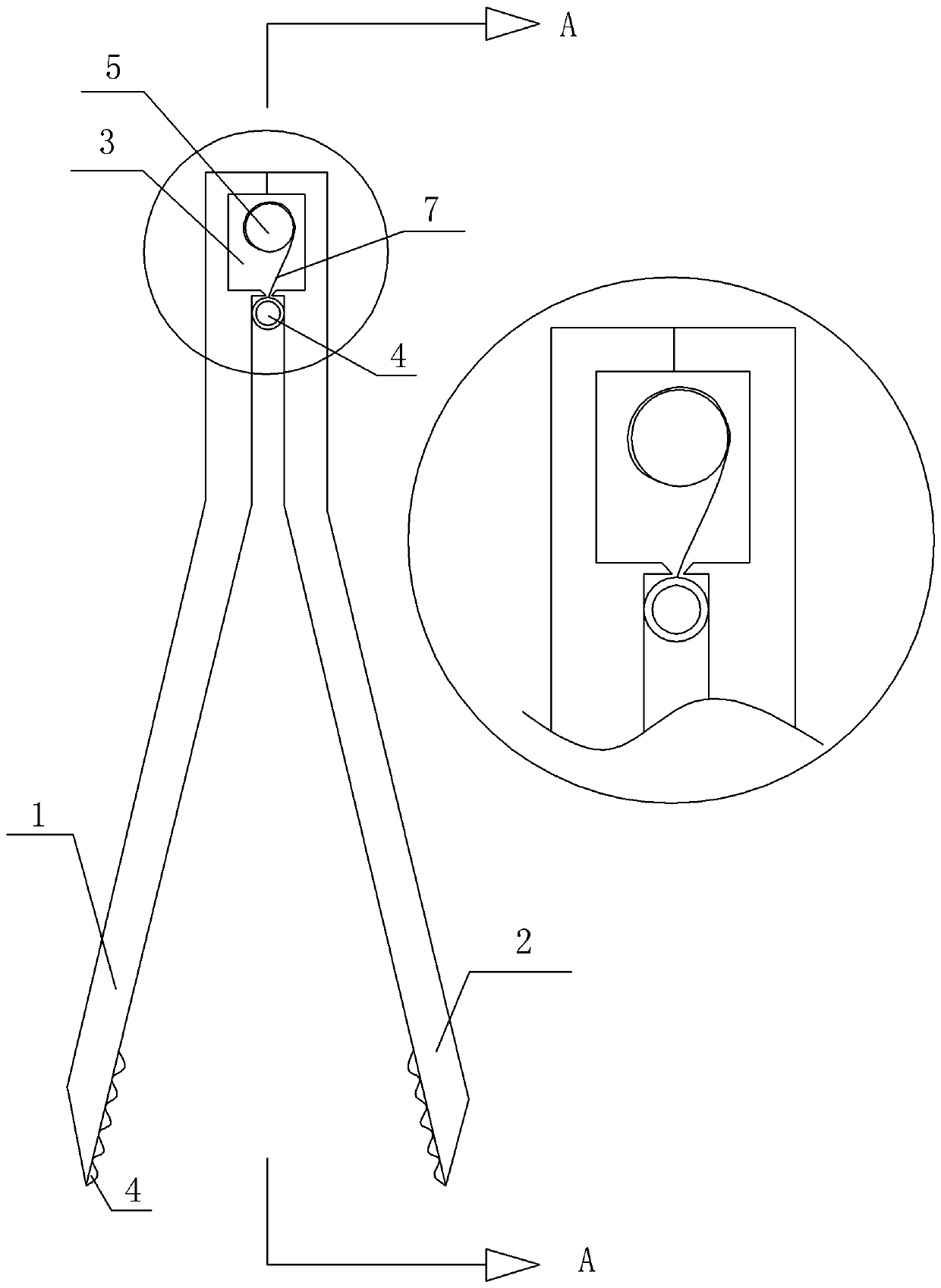

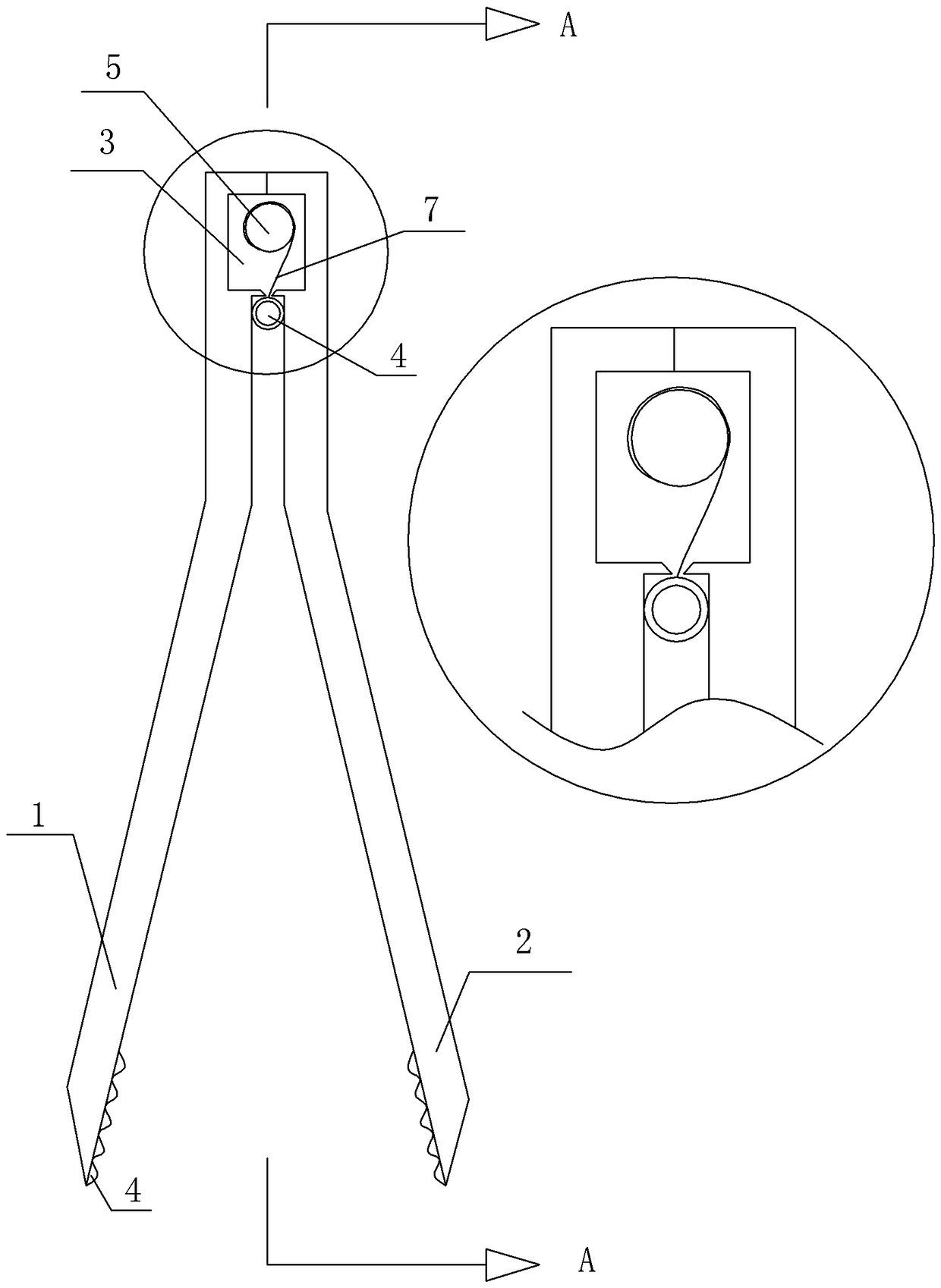

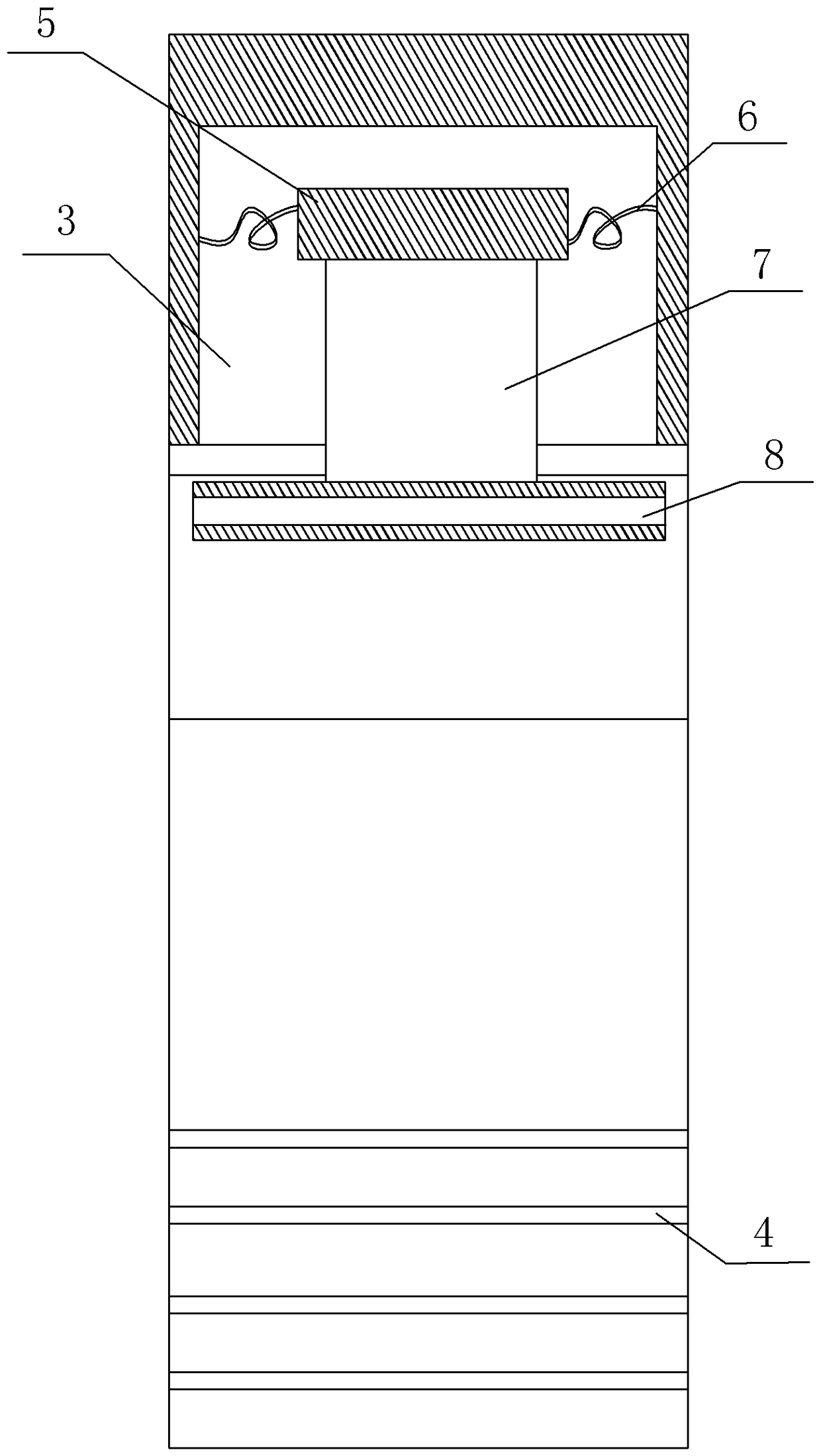

Tweezers and disinfecting device thereof

ActiveCN107414692AIncrease intensitySolve the problem that the spacing is small and cannot be cleanedMetal-working hand toolsChemicalsMedical equipmentEngineering

The invention relates to the field of medical equipment and cleaning, and particularly relates to a pair of tweezers and a disinfecting device thereof. The pair of tweezers comprises a first clamping arm and a second clamping arm, wherein a first cavity is formed in one end of the first clamping arm, a second cavity is formed in one end of the second clamping arm, one end of the first clamping arm is fixedly connected with one end of the second clamping arm, and the first cavity communicates with the second cavity; rotating rods and torsion springs are arranged in the first cavity and the second cavity, cleaning cloth is arranged on the circumferential walls of the rotating rods, and one end of the cleaning cloth is fixedly connected with the circumferential walls of the rotating rods; and a circular post is located between the first clamping arm and the second clamping arm, and the other end of the cleaning cloth is fixedly connected with the circumferential wall of the circular post. By adopting the technical scheme, the problem of incapability of cleaning due to small spacing between the first clamping arm and the second clamping arm is effectively solved, and additionally, the force of the pair of tweezers can be increased by the circular post, so that the pair of tweezers is easy to control when in use, and the use comfort is increased.

Owner:宁波隆锐机械制造有限公司

Method for disinfection of tweezers

ActiveCN107583070ARealize moving up and downPrevent rustCleaning using toolsCleaning using liquidsMedical equipmentBiochemical engineering

The invention specifically relates to a method for disinfection of tweezers, belonging to the field of medical equipment and cleaning thereof. The method comprises the following steps: step 1, preparing disinfection equipment; step 2, fixing tweezers; step 3, fixing a ring column; step 4, cleaning and disinfecting the tweezers; step 5, relieving the spacing of the ring column; step 6, drying the tweezers; and step 7, taking off the tweezers. With the method in the invention, tweezers can be thoroughly cleaned and disinfected.

Owner:宁波隆锐机械制造有限公司

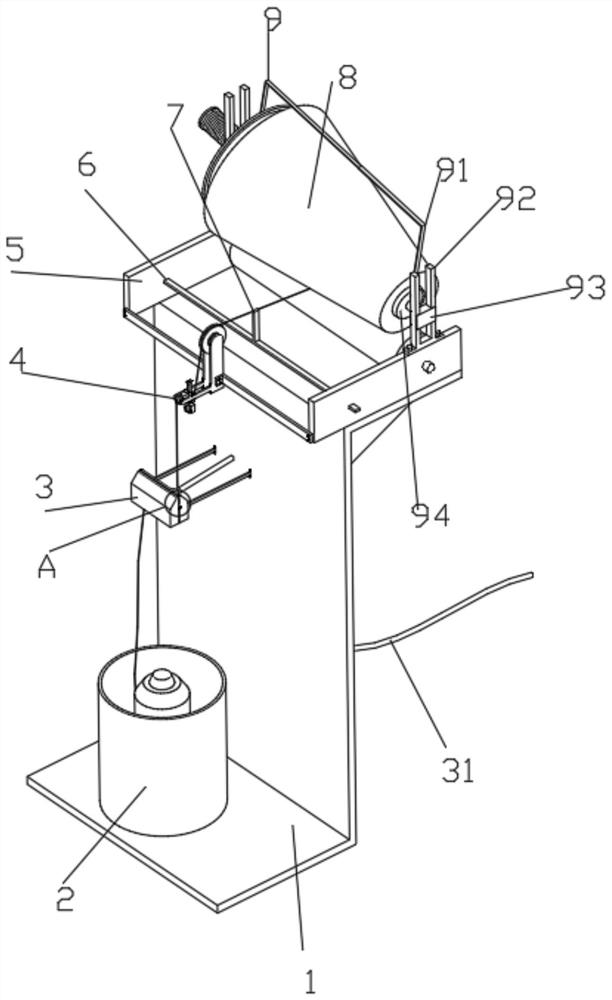

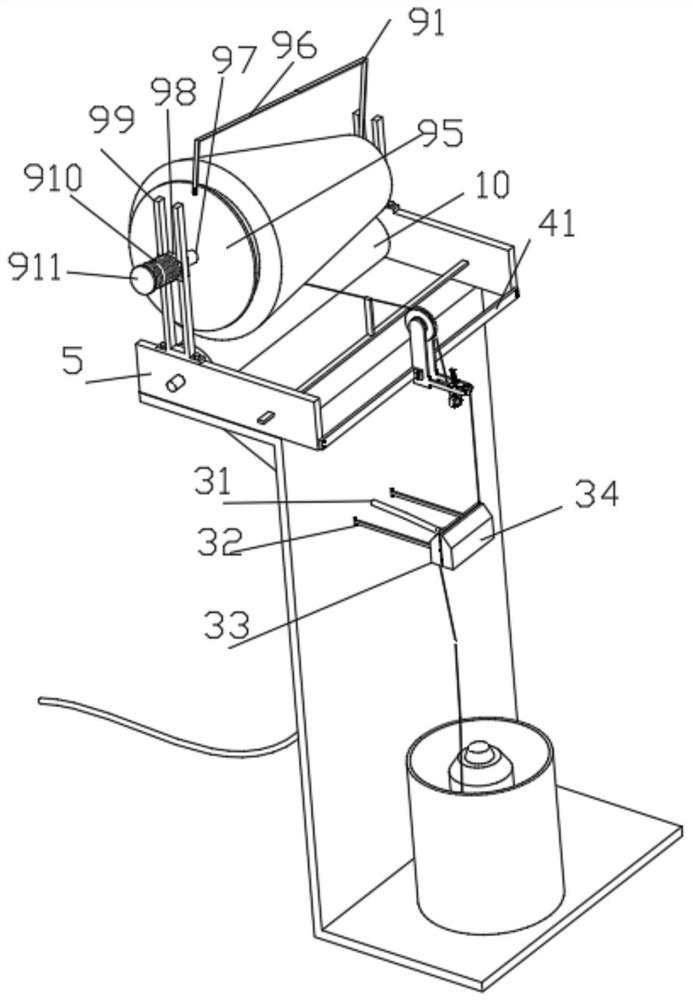

Wool-like yarn and processing technology and device

ActiveCN113564765AImprove the overall textureEnhance the three-dimensional senseContinuous wound-up machinesYarnWoolPolymer chemistry

The invention discloses a wool-like yarn and a processing technology and device, and relates to the technical field of textile production. The wool-like yarn is formed by blending FDY polyester filament yarn and Dacron DTY, the weight content of the FDY polyester filament yarn accounts for 50%-70%, and the weight content of the Dacron DTY accounts for 30%-50%. According to the mode, the wool-like yarn is formed by blending the FDY polyester filament yarn and the polyester DTY, and the wool-like yarn has softness and antibiosis of the FDY polyester filament yarn; the wool-like yarn further has filament light and bone feeling of the polyester DTY, and the whole texture is high; meanwhile, the wool-like yarn is subjected to sanding treatment through the reprocessing technology, the stereoscopic impression of the wool-like yarn is improved, the texture of the wool-like yarn can reach the wool texture, the wool-like yarn is soft and comfortable, wool can be replaced, and the cost is low; and meanwhile, a two-for-one twister performs alarm treatment, yarn breakage detection is convenient, and factories can master production conditions timely.

Owner:常熟市天润蒸纱有限公司

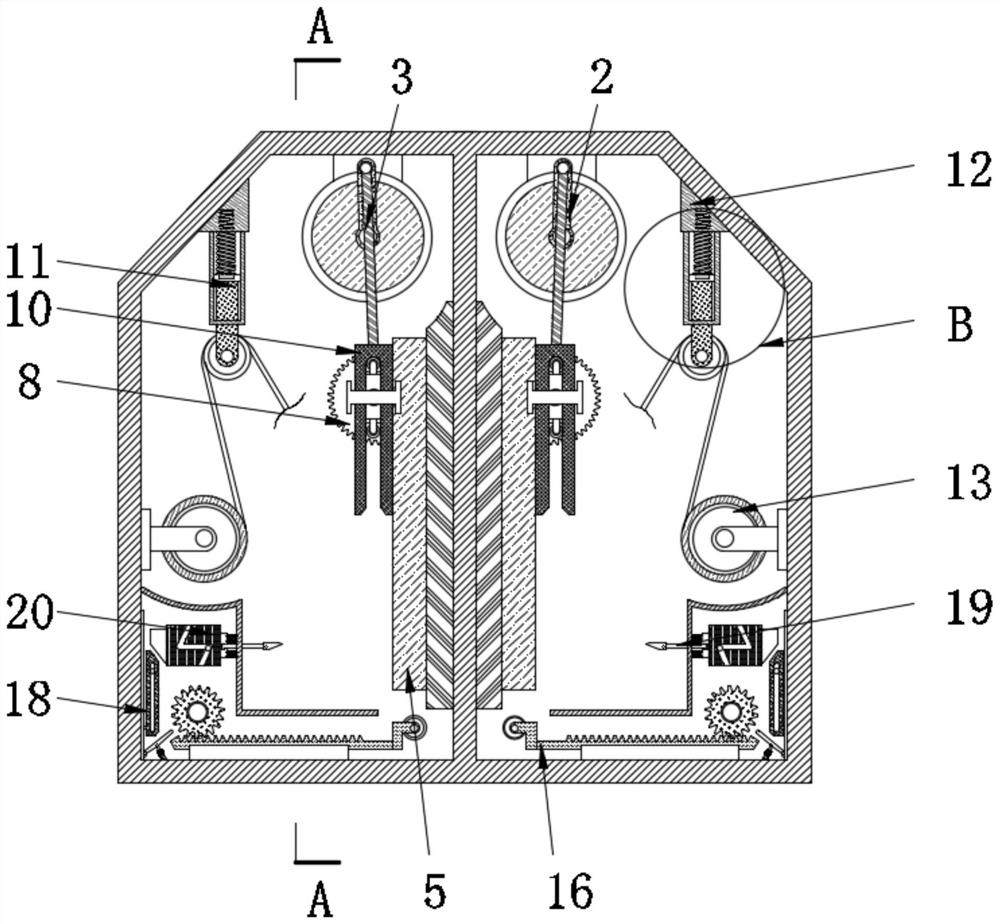

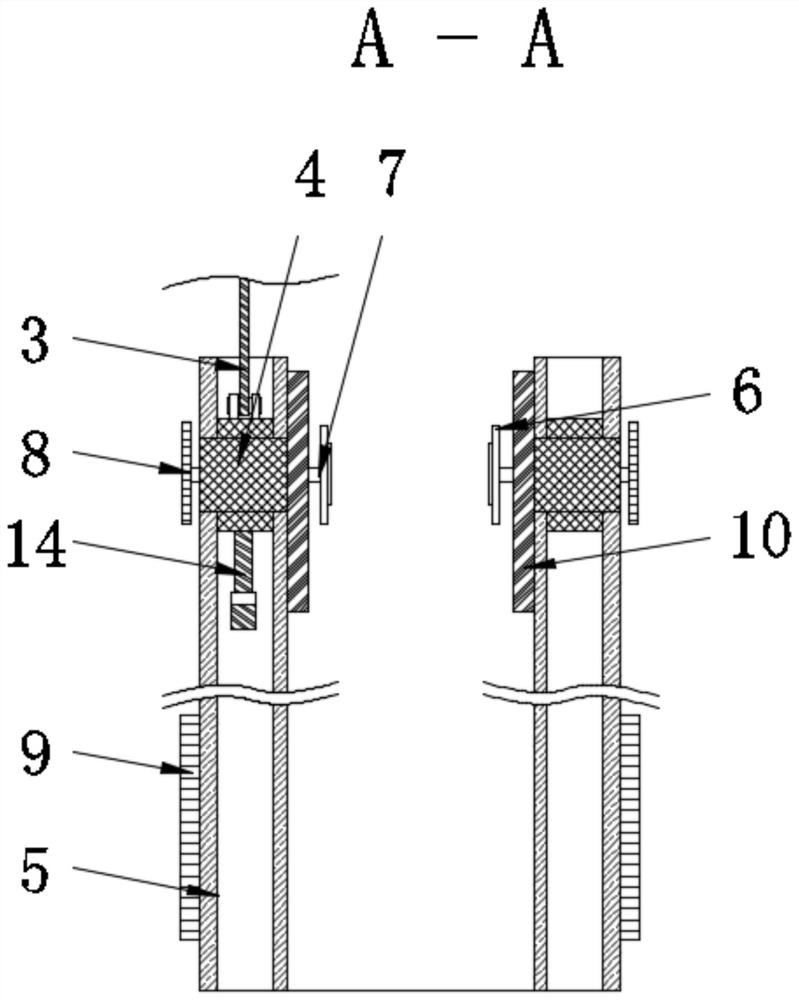

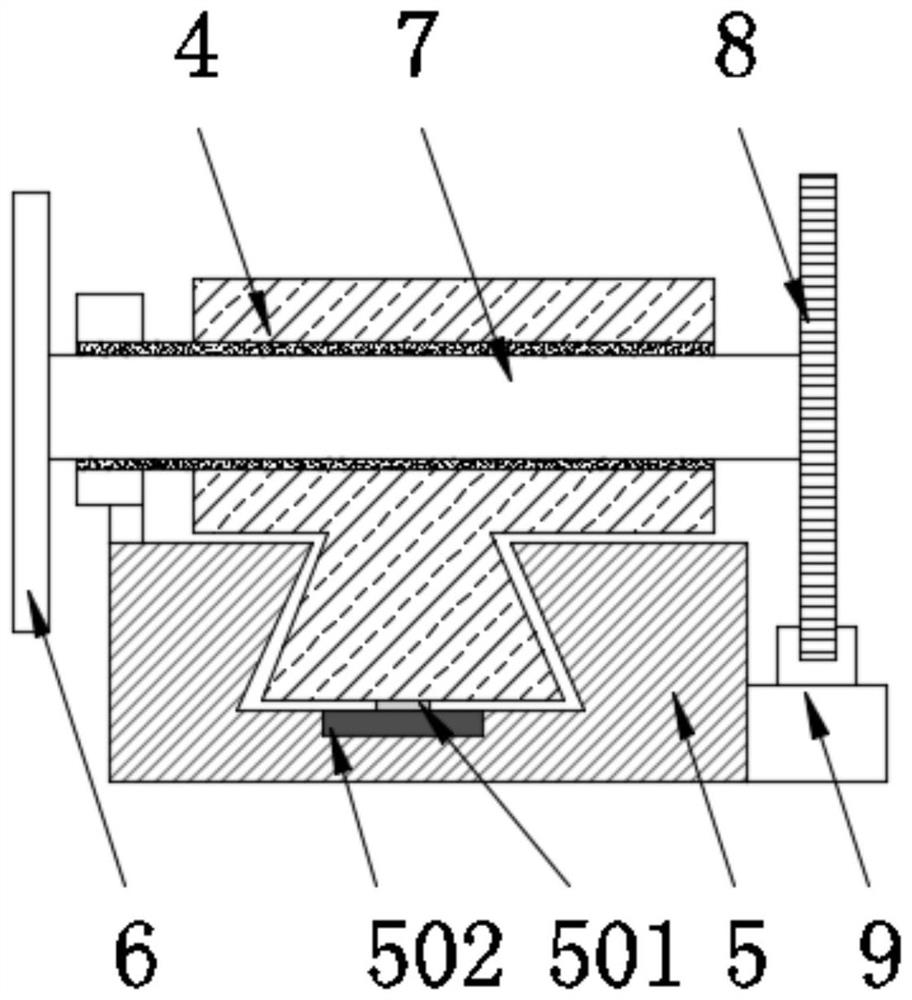

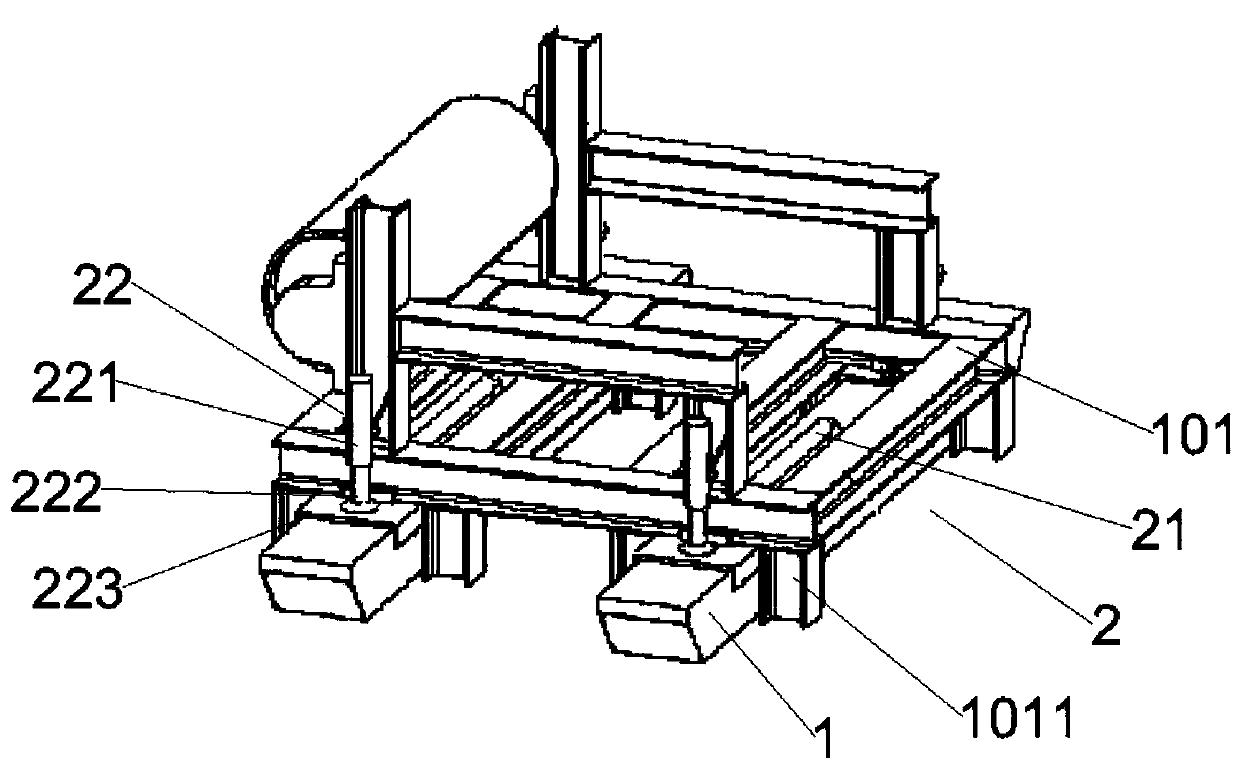

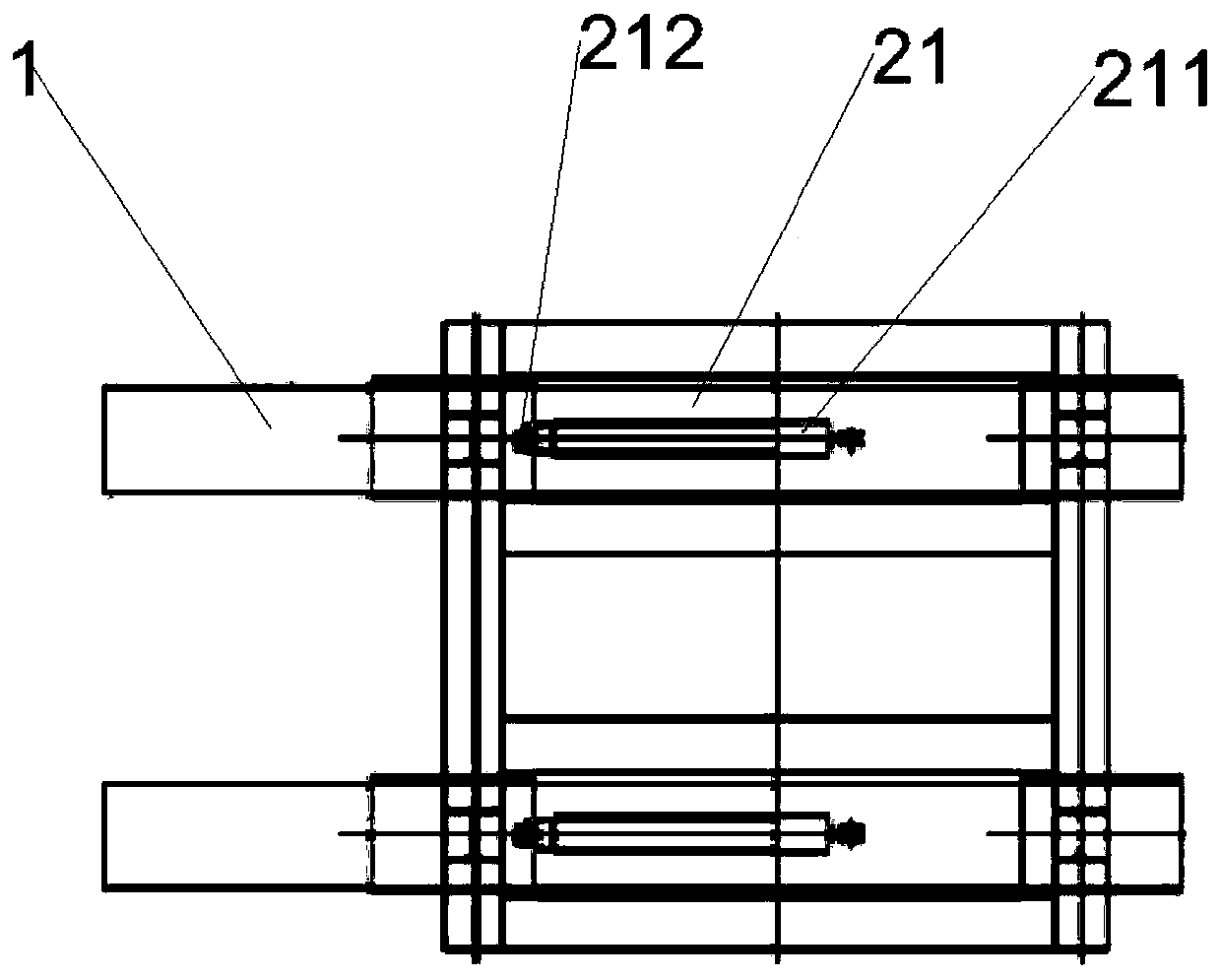

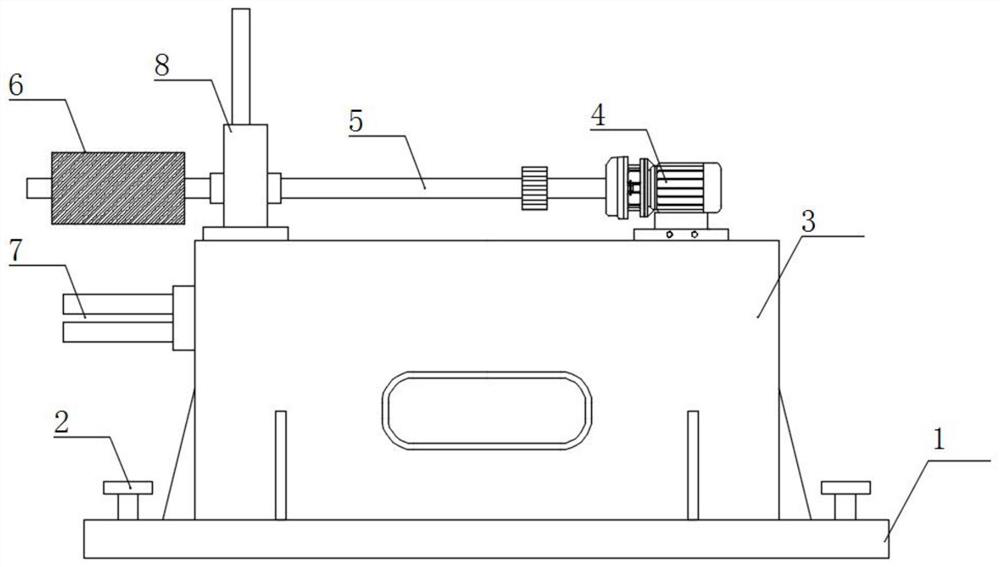

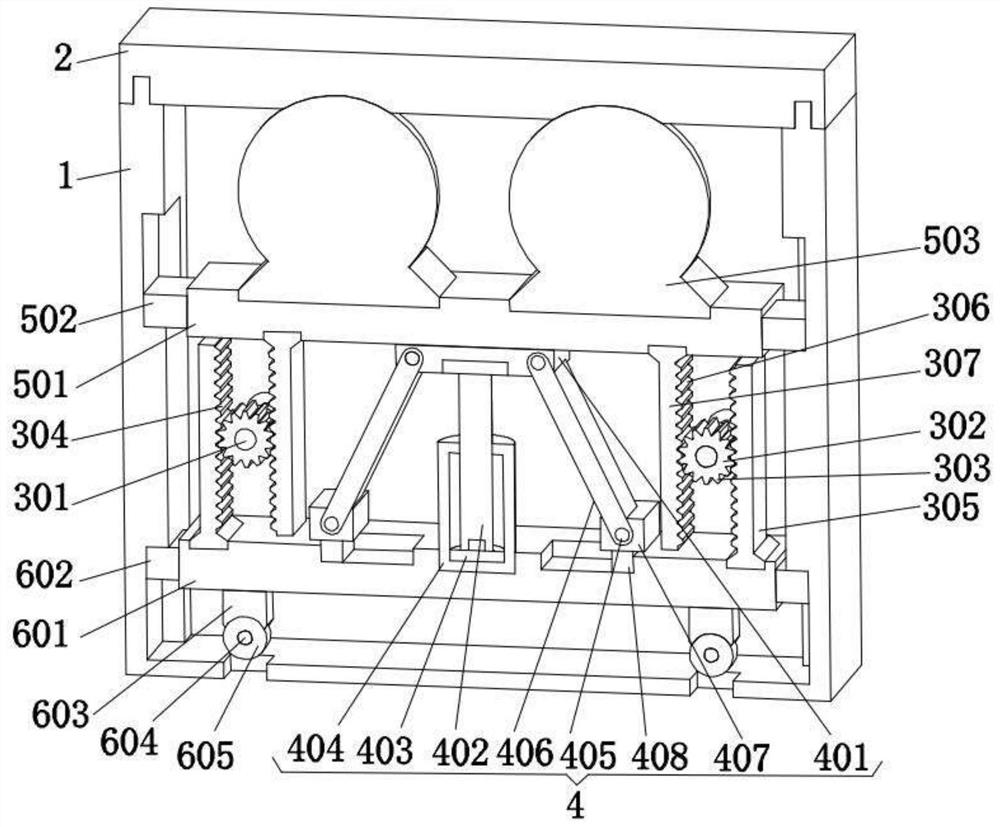

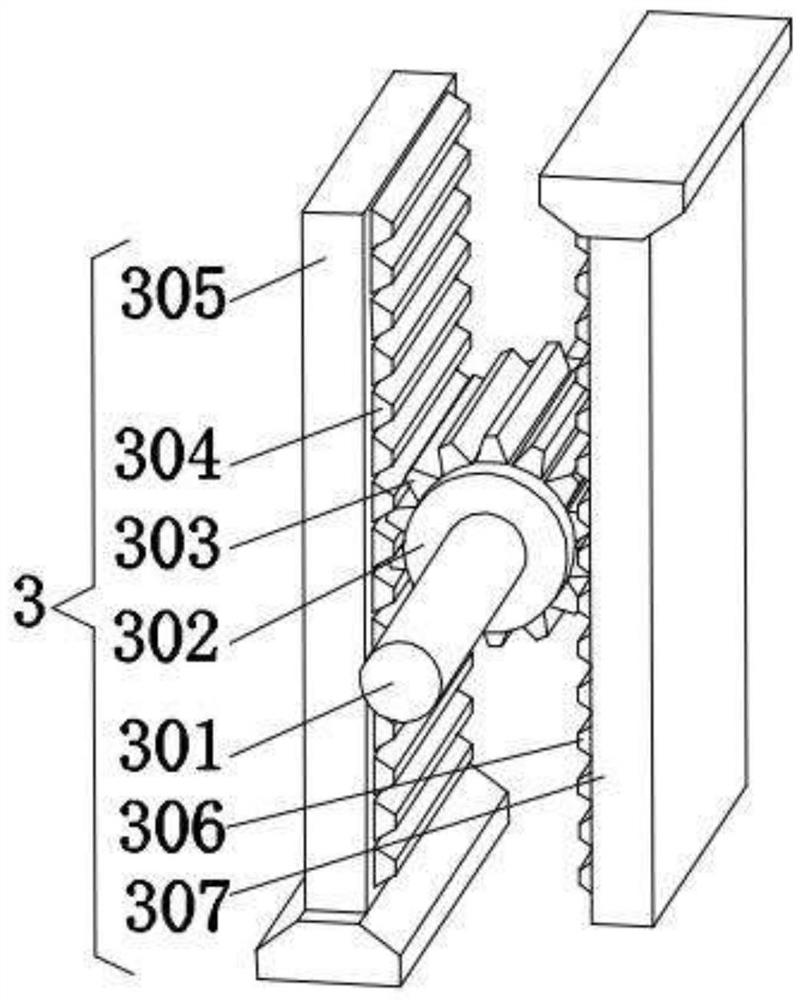

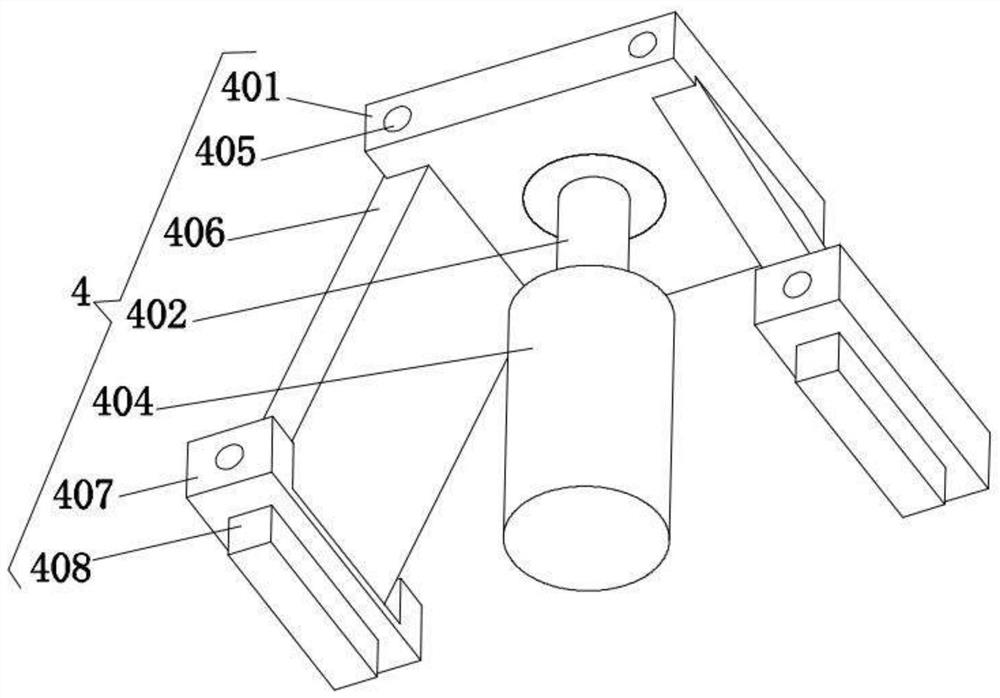

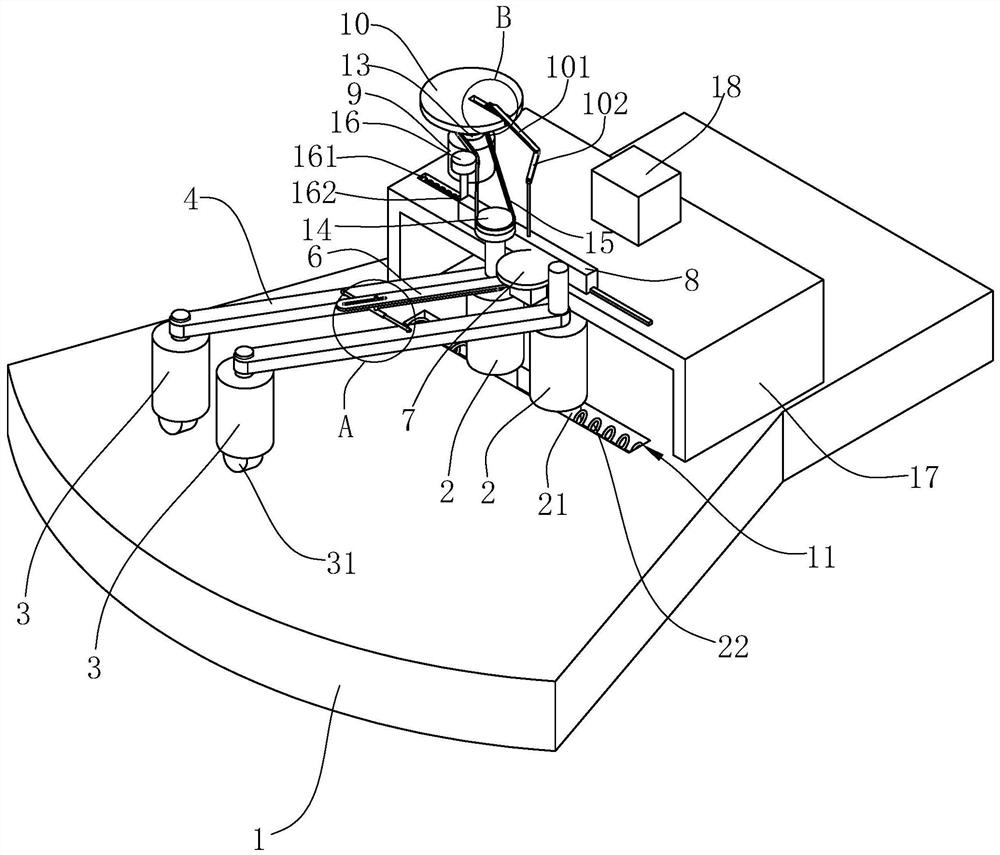

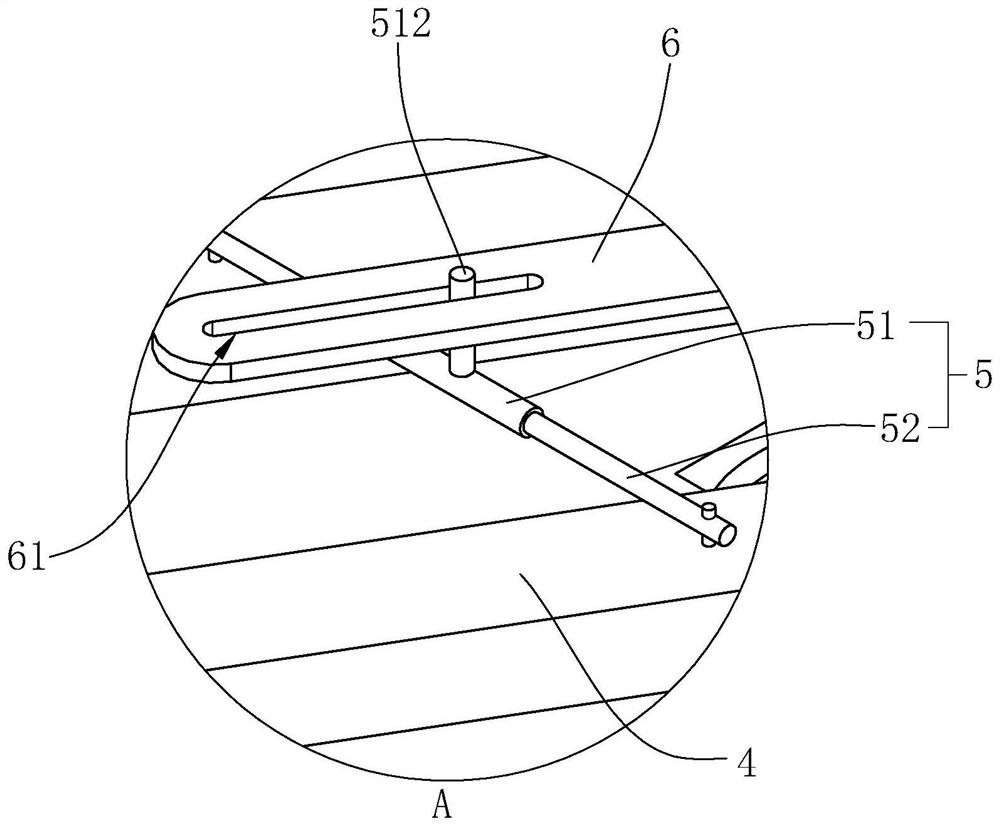

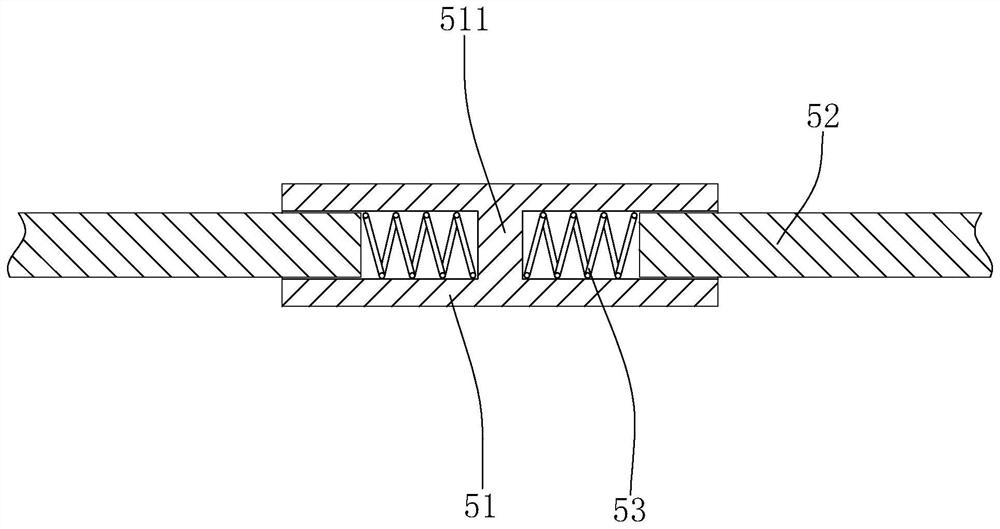

Self-adaptive elastic laminating device for carton forming

ActiveCN112026160AMake sure to move in syncAvoid wrinklesBox making operationsPaper-makingCartonEngineering

The invention provides a self-adaptive elastic laminating device for carton forming. A movable rod is movably connected to the tail end of a main rod, and a moving seat is movably arranged at the bottom end of the movable rod and slidably mounted in a clamping plate. A sticking roller frame is arranged on the outer side of the moving seat and slidably mounted in a fixed seat, and a laminating roller is arranged below the sticking roller frame. The main rod drives the moving seat at the bottom end of the movable rod to move up and down in a guide rail. When the clamping plate in the moving seatdrives a carton to move downwards, the positions of a metal sheet and a variable resistor are adjusted by movement of the moving seat in the guide rail, so that current in a coil connected with the variable resistor in series is adjusted. Therefore, a magnetic field generated by the coil pushes a magnet to push the sticking roller frame to move downwards, and synchronous movement of the stickingroller frame and the moving seat is guaranteed. Thus, a film on the surface of the sticking roller is in an elastic tensioning state, and the wrinkling phenomenon is avoided.

Owner:佛山市南海威肯包装机械有限公司

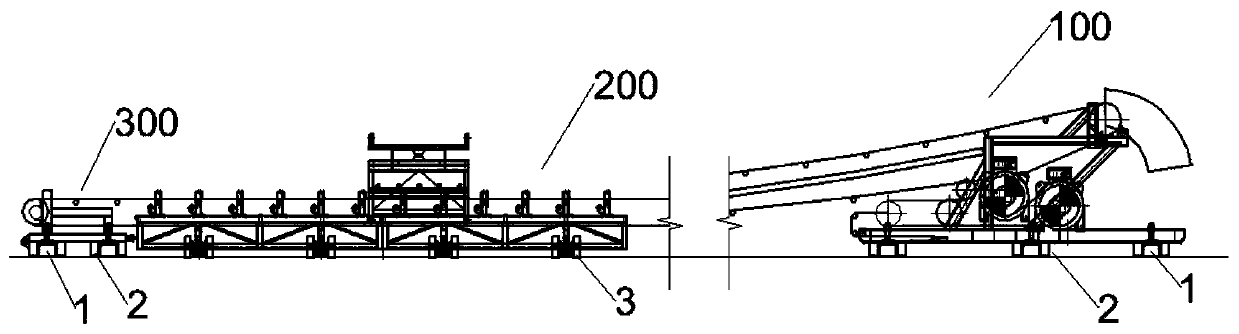

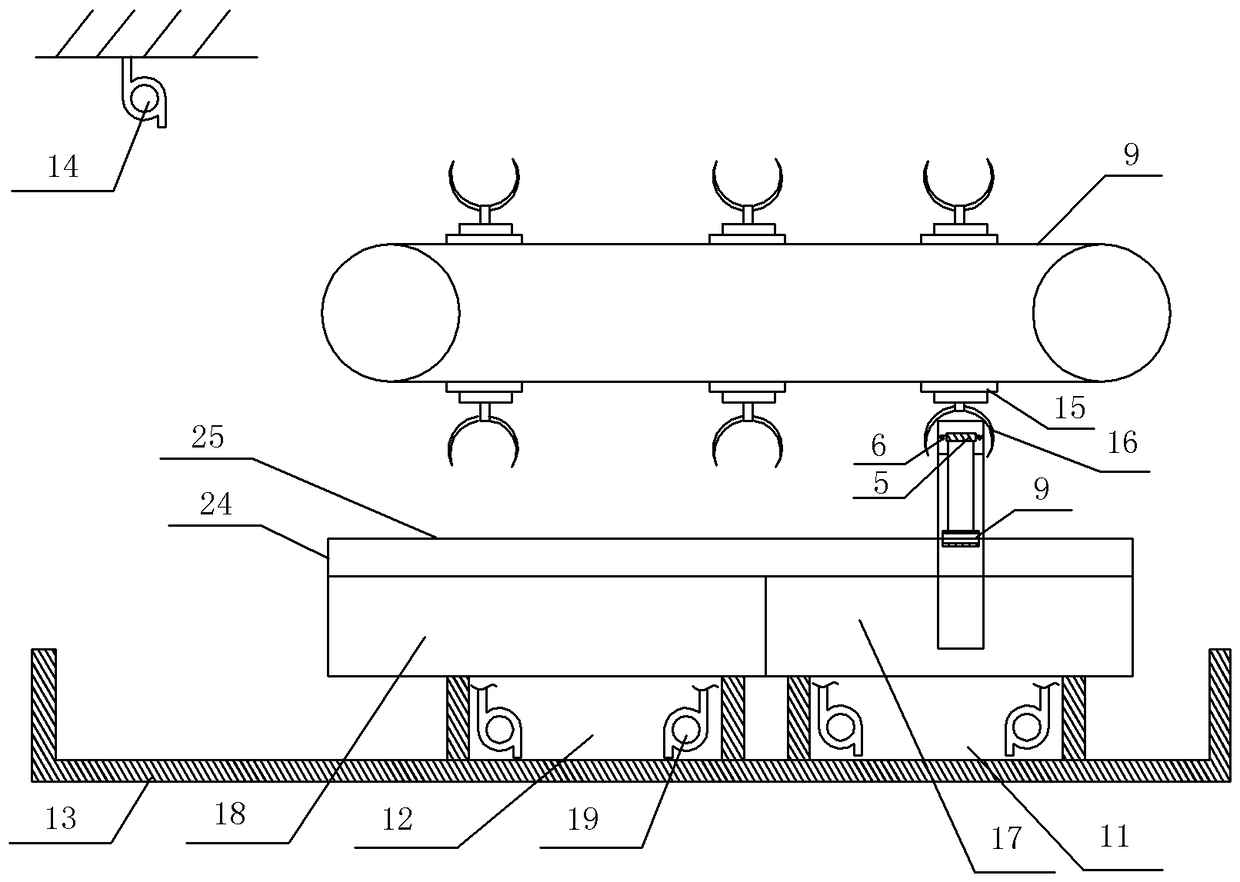

Automatic moving belt conveyor

PendingCN109879002AImprove stabilityAchieving autonomous mobilitySupporting framesBelt conveyorEngineering

The invention discloses an automatic moving belt conveyor. The conveyor comprises a machine head part (100), a middle part (200) and a machine tail part (300), wherein the machine head part (100) andthe machine tail part (300) are both provided with first sliding shoes (1), the middle part (200) is provided with second sliding shoes (4), the machine head part (100) and the machine tail part (300)both comprise first automatic moving mechanisms (2) which are arranged on the first sliding shoes (1), the first automatic moving mechanisms (2) are used for pushing the machine head part (100) and the machine tail part (300) to move in the direction of the first sliding shoes (1), the middle part (200) comprises second automatic moving mechanisms (3) which are arranged on the second sliding shoes (4), and the second automatic moving mechanisms (3) are used for pushing the middle part (200) to move in the direction of the second sliding shoes (4). The automatic moving belt conveyor realizes autonomous movement of the conveyor and autonomous leveling after movement, and is good in stability, ingenious and simple in structure, low in economic cost and wide in adaptability.

Owner:新疆金能矿业有限公司

Magnetorheological damper capable of recovering heat energy and chemically generating power under power loss state

InactiveCN108757816AEfficient deliveryIncrease transfer speedSpringsNon-rotating vibration suppressionElectricityChemical reaction

The invention discloses a magnetorheological damper capable of recovering heat energy and chemically generating power under a power loss state. The magnetorheological damper comprises an outer cylinder barrel, a left end cover and a right end cover; chemical reaction chambers are formed at the inner sides of the left end cover and the right end cover; electrode bars are arranged in the chemical reaction chambers; an electrolyte containing cavities is arranged in the outer cylinder barrel; electrolyte is filled in the electrolyte containing cavity; a middle connection rod is arranged between aleft piston and a right piston; an inner cylinder is arranged on the middle connection rod; an excitation coil is arranged at the outer side of the inner cylinder; magnetorheological liquid is filledbetween the inner cylinder and a sealing ring and a middle cavity; an external power connector is arranged at the outer side of the outer cylinder barrel; and two ends of the excitation coil are connected with the external power connector and the electrode bars through leads. According to the magnetorheological damper, automatic compensation and power supply can be carried out under the power lossstate so as to continuously generate damp, and damping effect of magnetorheological liquid can be effectively enhanced so as to greatly improve the stability and reliability of the whole magnetorheological damper.

Owner:CHONGQING UNIV OF TECH

Punching and discharging all-in-one machine

PendingCN111633245ASimple structureLow costPositioning apparatusMetal working apparatusPunchingStructural engineering

The invention belongs to the technical field of machining, and discloses a punching and discharging all-in-one machine. The punching and discharging all-in-one machine comprises a base and a rack, wherein a punching mechanism is installed in the middle of the top of the rack; moving devices are installed at the positions, positioned on the two sides of the punching mechanism, of the top of the rack; lifting air cylinders are installed at the bottoms of the two moving devices; an upper pressing plate is connected to the bottoms of the two lifting air cylinders; a guide hole and two limiting grooves are formed in the upper pressing plate; the two limiting grooves are symmetrically positioned in the two sides of the guide hole; a movable lower pressing plate is arranged at the top of the base; limiting blocks are vertically fixed to the two sides of the lower pressing plate; and the limiting blocks correspond to the limiting grooves. According to the punching and discharging all-in-one machine, an automatic discharging structure of a workpiece is arranged, and therefore automatic discharging can be effectively formed after punching of the workpiece is completed; and the automatic discharging structure is composed of the movable lower pressing plate and a plurality of discharging rollers, and the punching and discharging all-in-one machine has the beneficial effects of being simplein structure and low in cost.

Owner:镇江市惠灵顿膜业有限公司

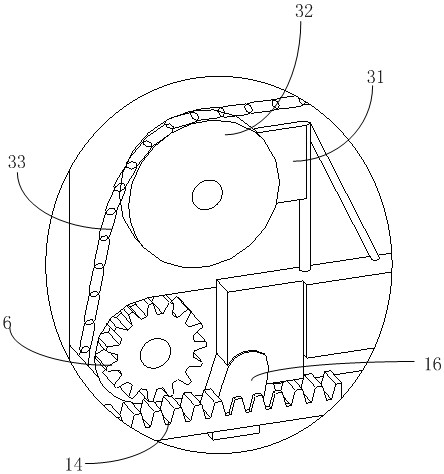

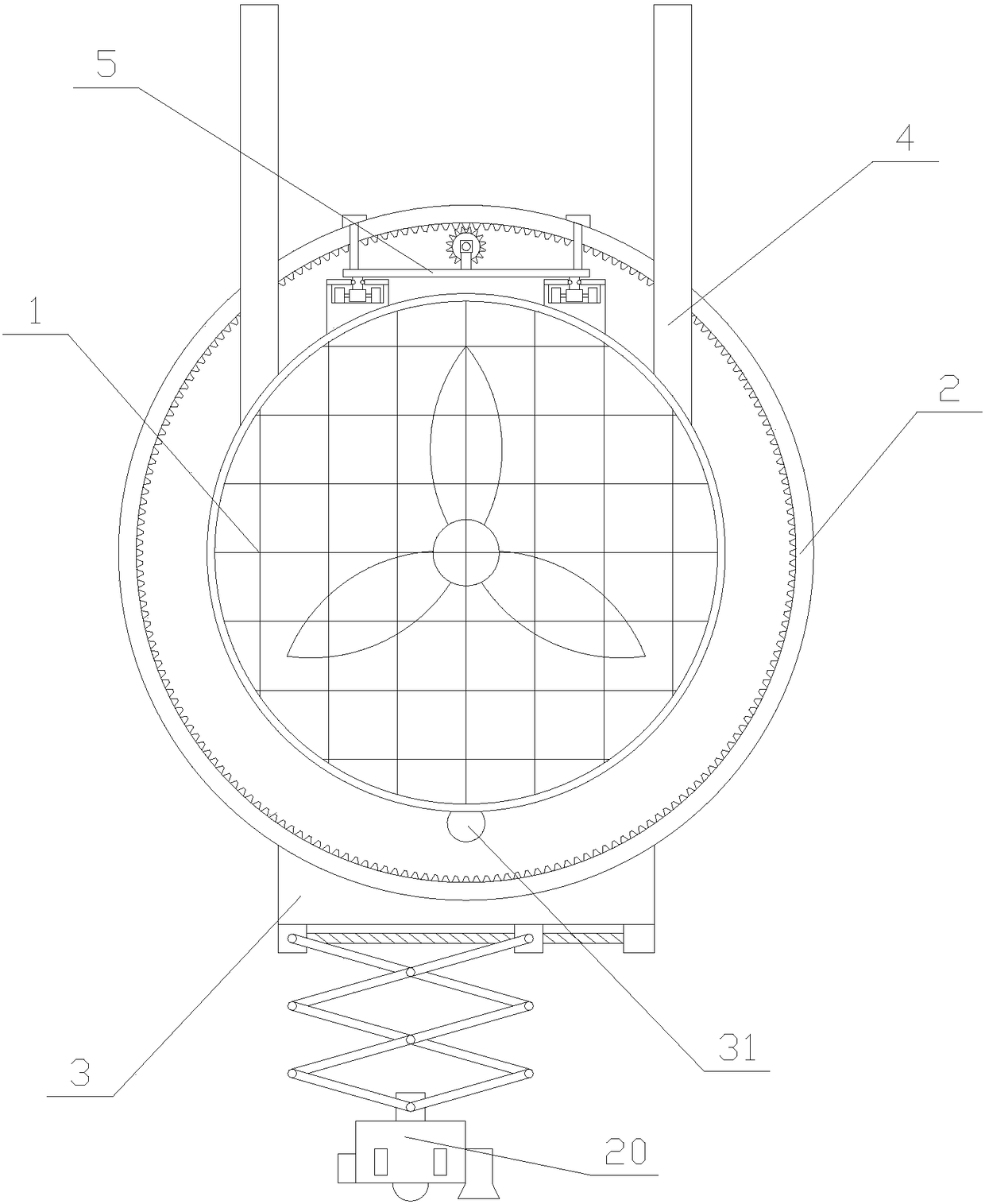

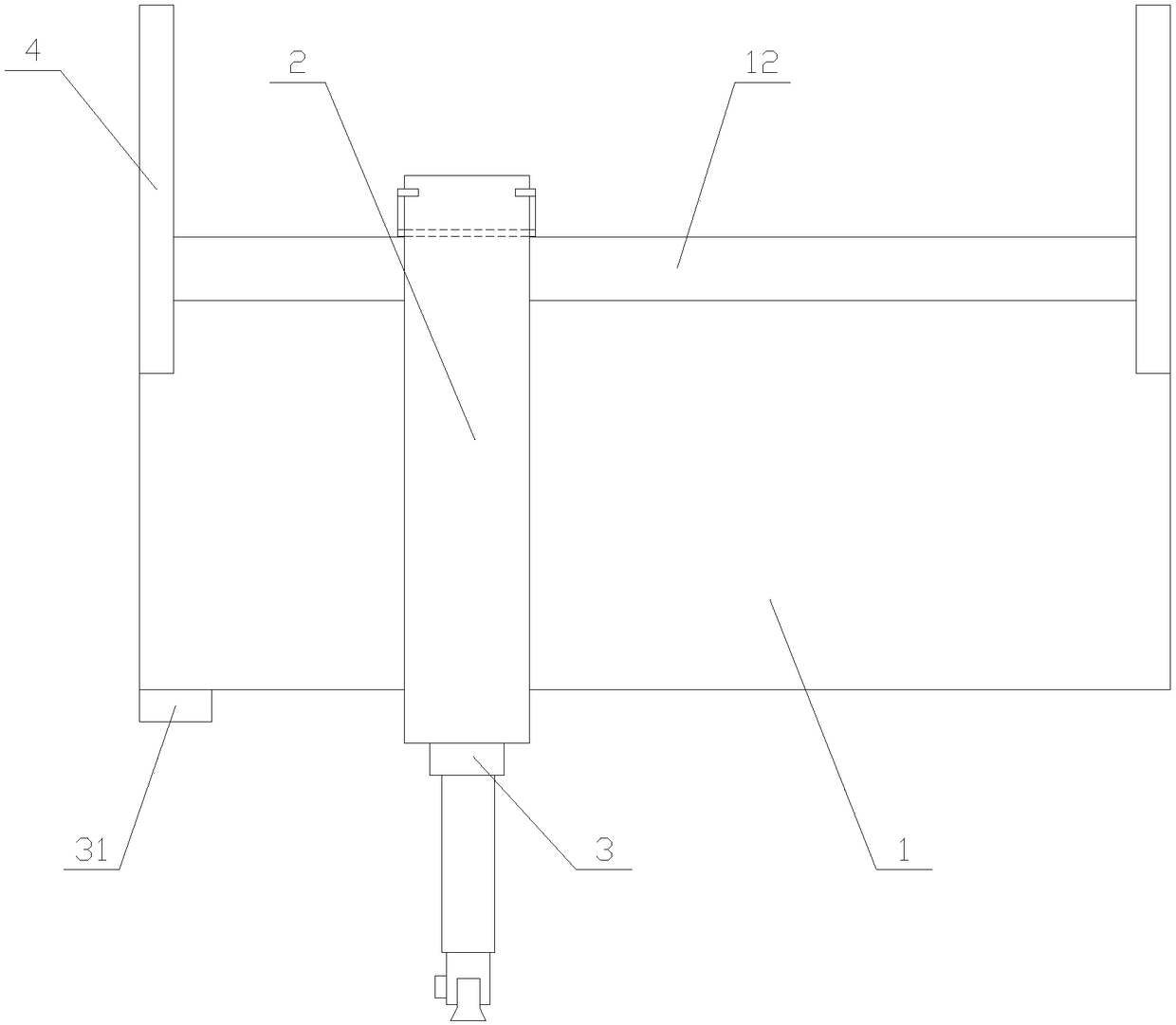

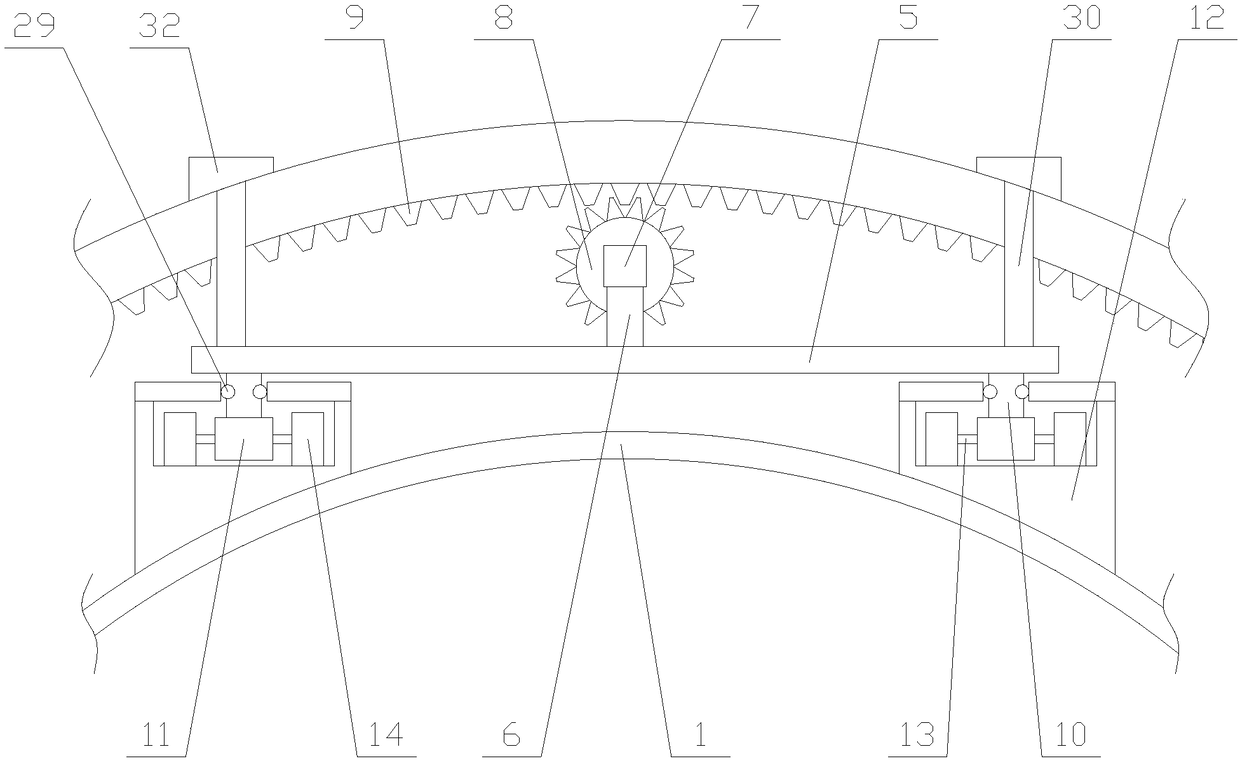

Poultry loading and unloading mechanism

ActiveCN112141758ARealize automatic loading and unloadingReduce labor intensityControl devices for conveyorsSupporting framesDrive wheelGear wheel

Owner:潍坊振兴农牧机械有限公司

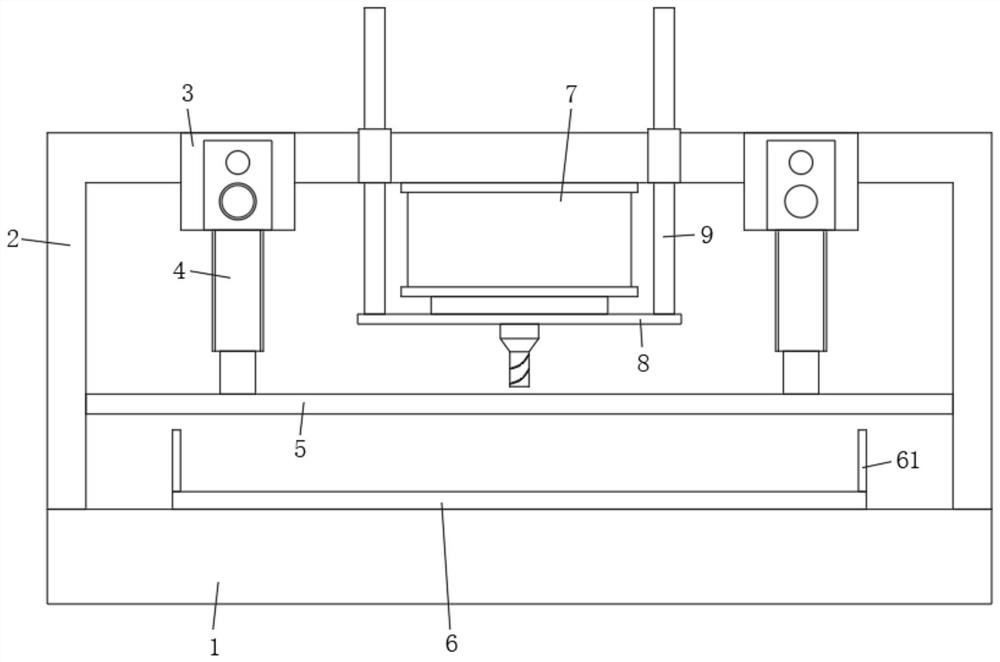

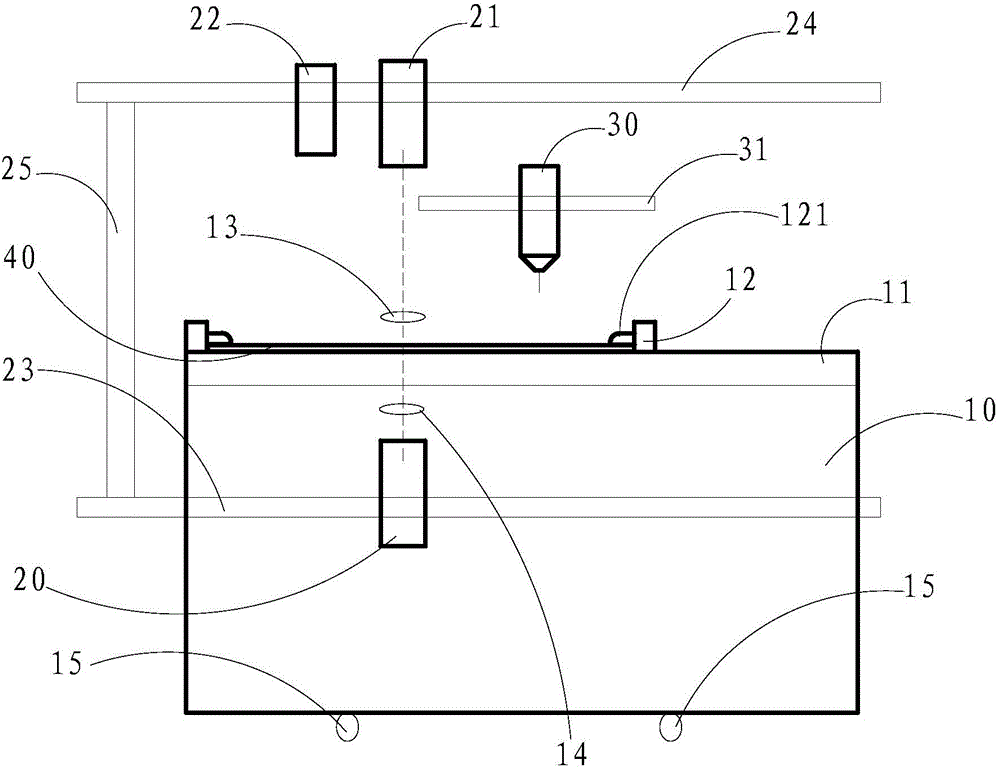

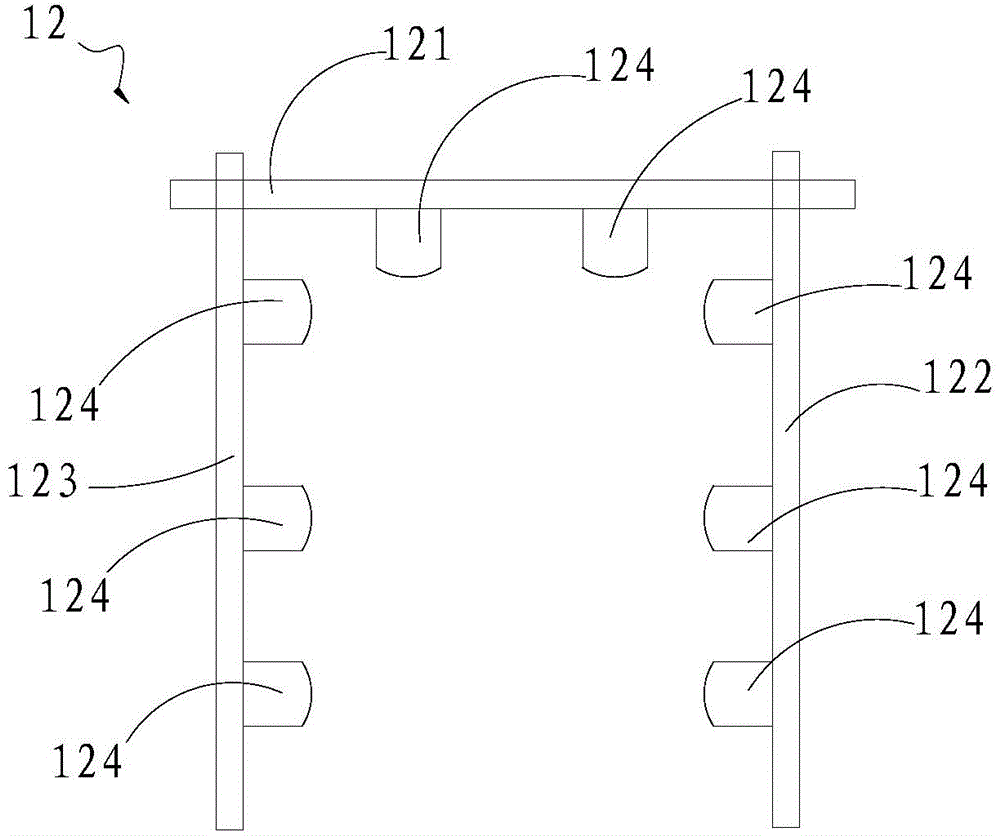

X-Ray drilling device

ActiveCN104476612ASimple structureHigh degree of automationPrinted circuitsMetal working apparatusEngineeringX-ray

The invention relates to an X-Ray drilling device. The X-Ray drilling device comprises a worktable, a first guide rail and a first drive mechanism, wherein the worktable is connected with a first pressing structure; the first drive mechanism is used for driving the worktable to move along the first guide rail; the second guide rail and a third guide rail are both arranged in a manner of being vertical to the first guide rail and are respectively positioned on the two sides of the first pressing structure; a second drive mechanism is used for driving an X-Ray transmitter to move along the second guide rail and driving an X-Ray receiver to move along the third guide rail; a drilling mechanism is connected with a fourth guide rail; the third drive mechanism is used for driving the drilling mechanism to move along the fourth guide rail. Therefore, the X-Ray drilling device disclosed by the invention is simple in structure, overcomes the limitation that a plate edge is only drilled in the prior art, can be used for implementing steps of punching and drilling at any position on a PCB, and is high in automation degree, accurate in drilling position and beneficial for improving the work efficiency of plate drilling.

Owner:GUANGZHOU FASTPRINT CIRCUIT TECH +2

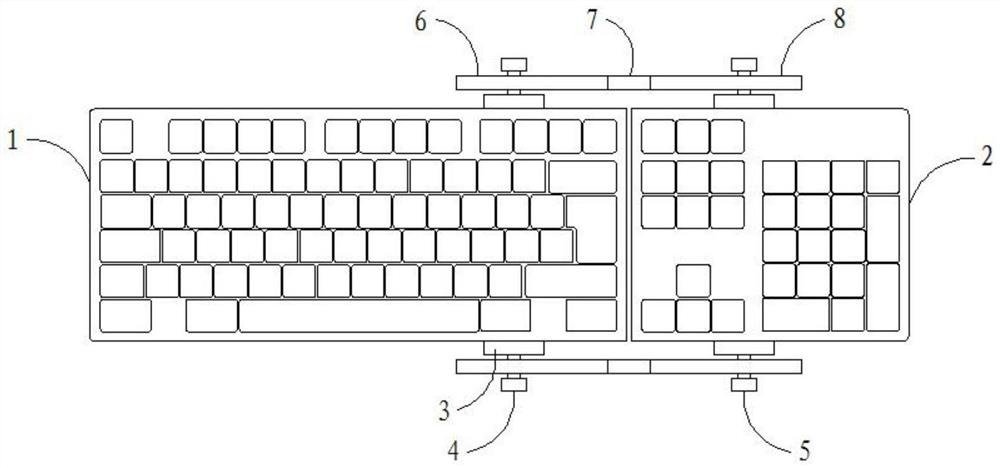

Keyboard with rest reminding function and working method of keyboard

PendingCN113284754AWith rest reminder functionEasy to carry and useElectric switchesComputer hardwareEngineering

The invention relates to a keyboard, in particular to a keyboard with a rest reminding function and a working method of the keyboard. The first keyboard and the second keyboard are internally provided with dip angle adjusting structures which are connected through a second folding connecting structure and used for synchronously adjusting dip angles, and the first keyboard is internally provided with a main control chip; the main control chip is connected with a voice acquisition module used for acquiring voice information of a user, the main control chip is connected with a voice key which is arranged on the first keyboard and used for controlling the voice acquisition module, and the main control chip is connected with a communication module used for communicating with a computer client; and the main control chip is connected with setting keys, a display screen, a prompt module and an indicator light module which are arranged on the first keyboard. According to the technical scheme, the defects that in the prior art, the folding function and the rest reminding function are not achieved, and synchronous inclination angle adjustment on the two sides cannot be achieved after folding can be effectively overcome.

Owner:HEFEI MADAO INFORMATION TECH CO LTD

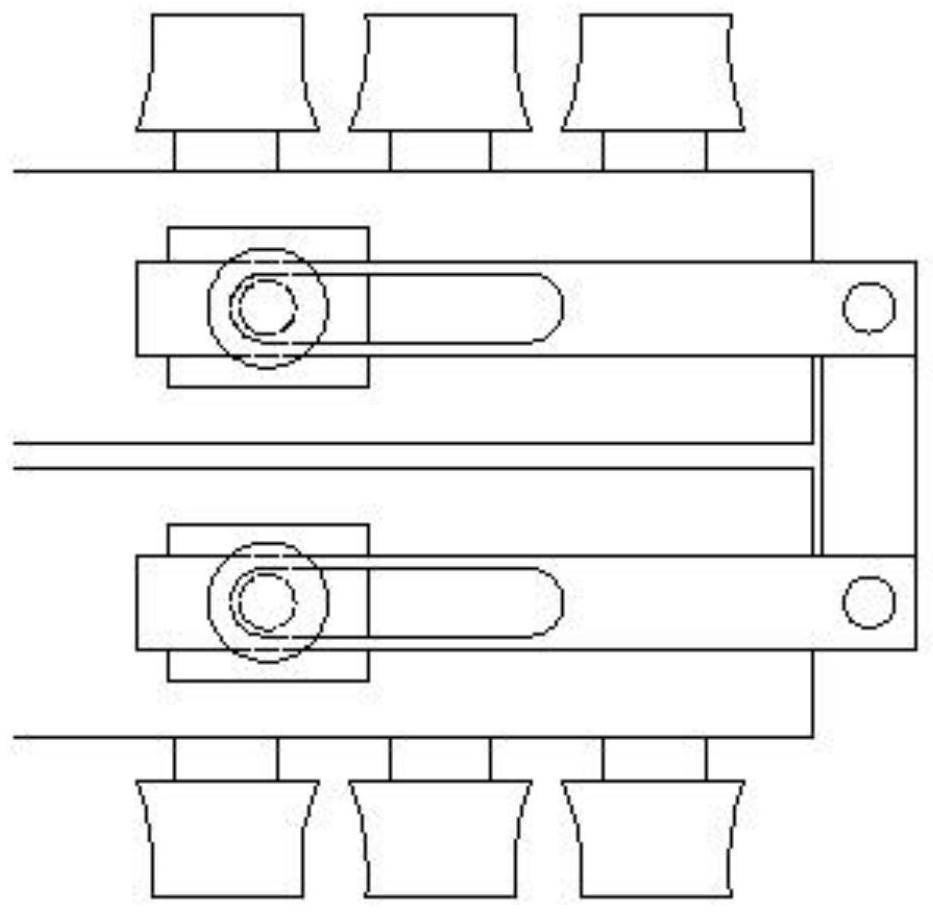

Stainless steel band cold-rolling mill

PendingCN113492161APlay a stabilizing roleGuaranteed normal operationElectric machineryStructural engineering

The invention discloses a stainless steel band cold-rolling mill, and particularly relates to the field of cold-rolling mills. The stainless steel band cold-rolling mill comprises a base, a control box is fixedly mounted at the top of the base, a driving motor is fixedly mounted on one side of the top surface of the control box, and a blocking assembly is fixedly mounted on the other side of the top surface of the control box. An output shaft of the driving motor is fixedly provided with a driving rod, and the other end of the driving rod penetrates through the blocking assembly and is fixedly provided with a tension roller. According to the stainless steel band cold-rolling mill, the driving rod is stabilized through the blocking assembly, shaking and breaking caused by the fact that the driving rod is too long are avoided, normal operation of the machine is guaranteed, adjustment of the height of the tension roller is facilitated by matching with adjustment of a baffle, and therefore the adaptation range of the device is widened.

Owner:无锡市冶龙机械有限公司

Wide-detection-range underground pipe gallery inspection device based on Internet of Things

InactiveCN108107053AKeep abreast of the operation statusSmooth motionAnalysing gaseous mixturesSensing radiation from moving bodiesEngineeringInternet of Things

The invention relates to a wide-detection-range underground pipe gallery inspection device based on Internet of Things. The wide-detection-range underground pipe gallery inspection device based on Internet of Things comprises a blower fan, a circular ring, a driving mechanism, a telescopic mechanism, a detection mechanism, a rotating block, and four suspension rods; the driving mechanism comprisesa translation assembly, a bottom plate, and a rotating assembly; the rotating assembly comprises a supporting block, a first motor, and a driving gear; the translation assembly comprises two translation units; the telescopic mechanism comprises a telescopic assembly and a moving assembly; the telescopic assembly comprises a moving block, a fixing block, a telescopic support, a hinge joint block,and two connecting rods. In applications of the wide-detection-range underground pipe gallery inspection device based on Internet of Things, the circular ring is driven by the driving mechanism to move and rotate, so that it is convenient for detection of the wide-detection-range underground pipe gallery inspection device from different positions and angles, and detection range is widened; and inaddition, a detecting block is driven by the telescopic mechanism to move, so that the detecting block is capable of moving close to gallery internal wall and performing detecting, detection range iswidened, and the operation situations of galleries can be obtained timely.

Owner:南京卓茨机电科技有限公司

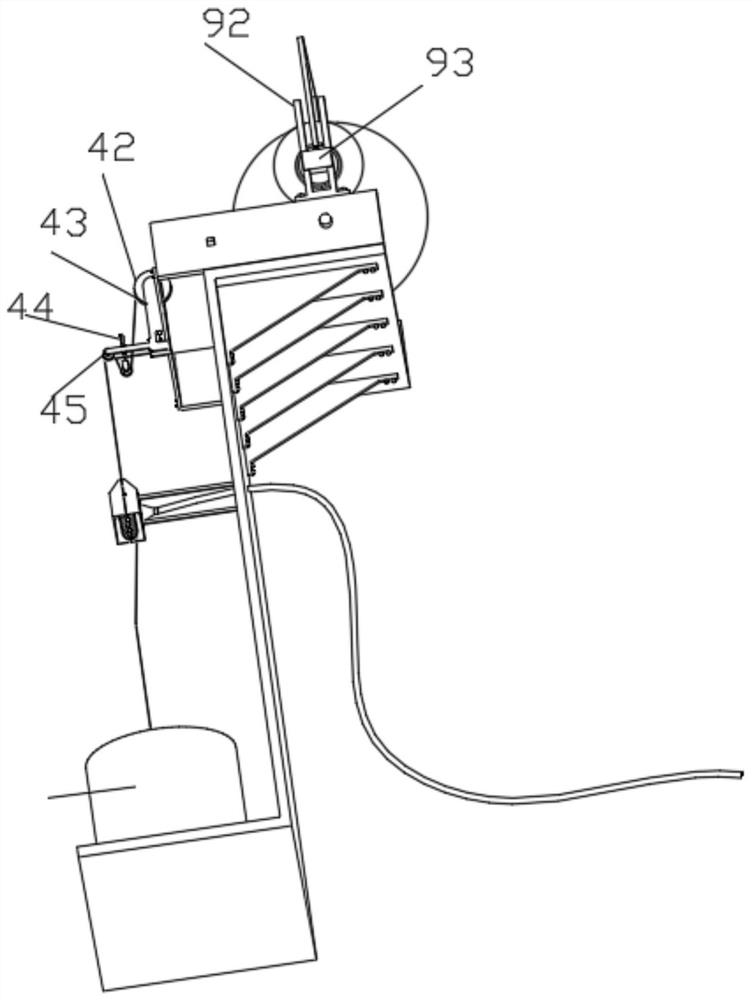

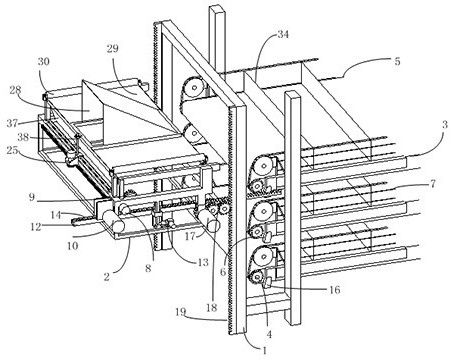

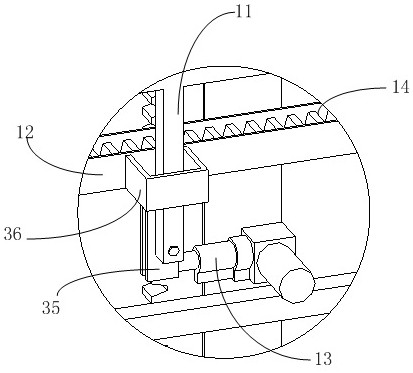

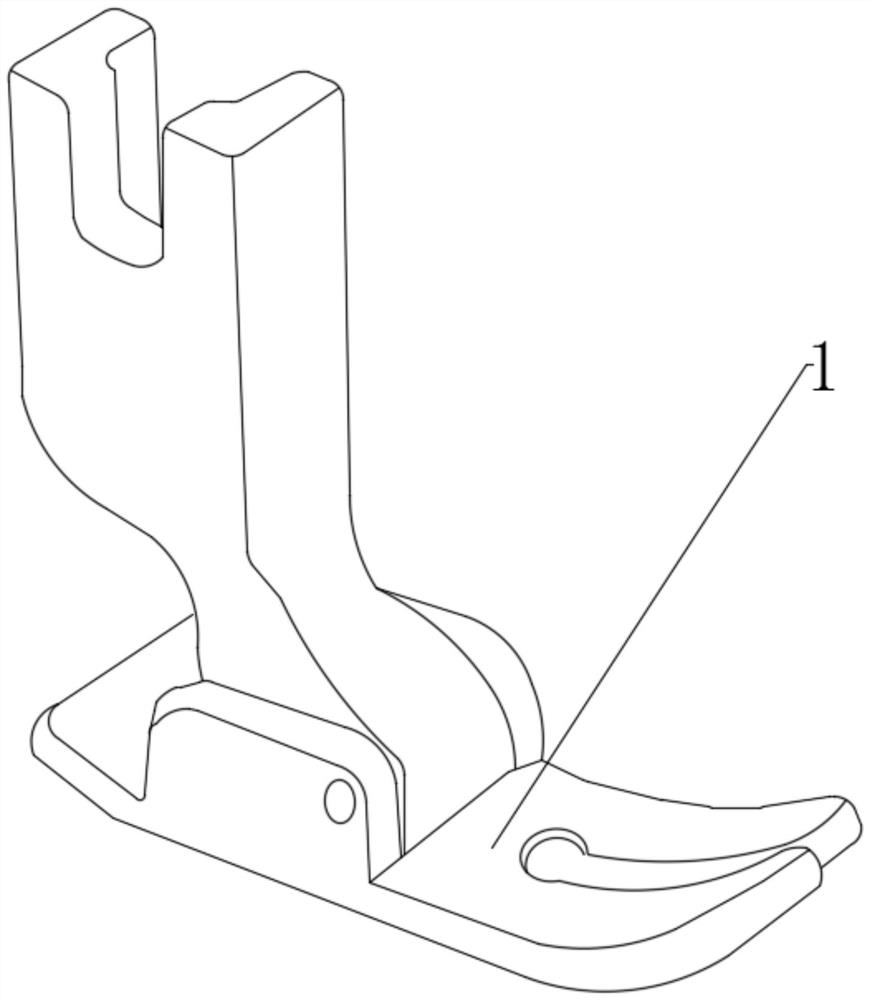

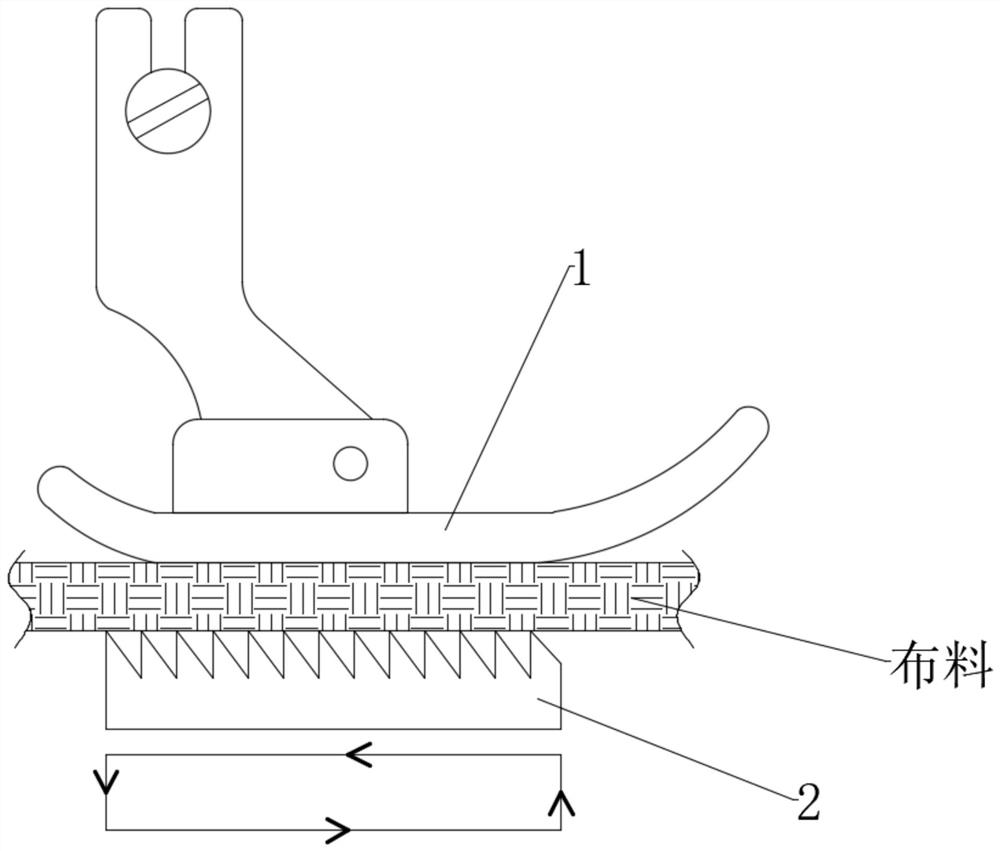

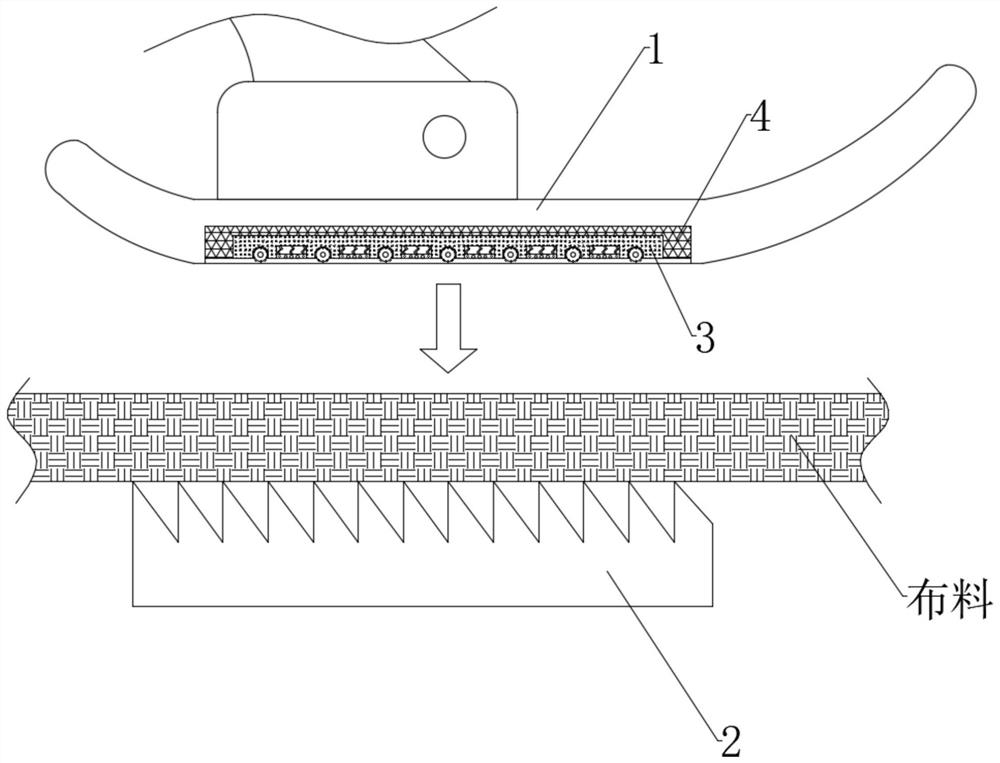

Magnetic guide synchronous type sewing machine feeding mechanism and using method thereof

The invention discloses a magnetic guide synchronous type sewing machine feeding mechanism and a using method thereof, and belongs to the field of sewing machines. An elastically connected material pressing plate is arranged below an existing presser foot body, a magnetic feed dog is used for attracting out the material pressing plate to press cloth, and when the feed dog moves forwards, the material pressing plate synchronously pushes cloth forwards along with the feed dog under the action of magnetic attraction, so that dislocation of the upper layer and the lower layer of smooth cloth is effectively reduced; meanwhile, the contact area of the cloth and the material pressing plate is reduced through a rolling cylinder on the material pressing plate, and friction resistance of the upper layer of cloth is reduced; when the feed dog feeds the cloth forwards, the rolling cylinder is driven to roll on the upper-layer cloth to achieve the effect of pushing the cloth forwards, so that the synchronous feeding effect is effectively improved; and in addition, an elastic pressing plate further presses the cloth downwards through the magnetic attraction effect to compensate for the defect of insufficient pressing force, and an elastic connecting rod can limit excessive pressing of the elastic pressing plate to prevent the pressing force from being too large.

Owner:杨俊波

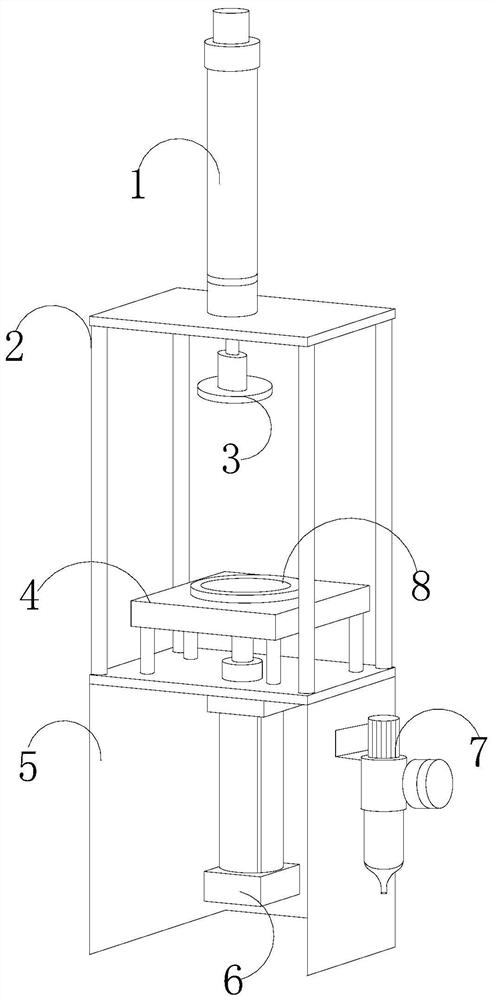

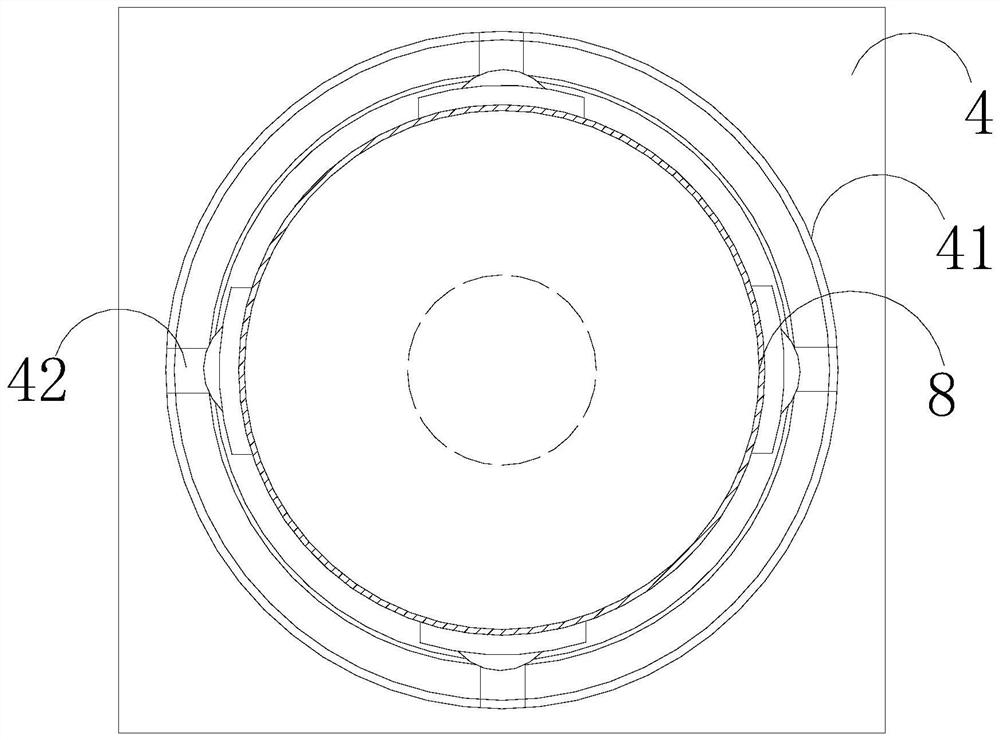

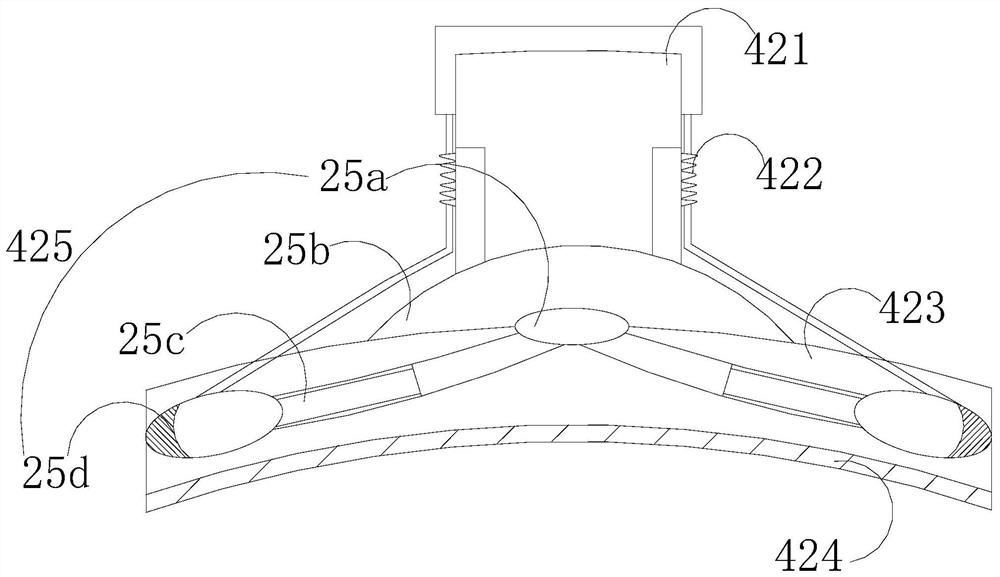

Semiconductor wafer expander

InactiveCN112864070AEvenly heatedReduce wearSolid-state devicesSemiconductor/solid-state device manufacturingCircular discWafering

The invention discloses a semiconductor wafer expander, which structurally comprises a first air cylinder, racks, an upper disc, a supporting base, a fixed frame, a second air cylinder, a heater and a heating disc, wherein the four racks are welded to the fixed frame, a rectangular plate is welded to the upper ends of the racks, the first air cylinder is installed above the rectangular plate, the first air cylinder is mechanically connected with the upper disc, and the upper disc is vertically opposite to the heating disc and the supporting base. According to the invention, a position correcting device is matched with a heating disc, the position correcting device drives a position correcting disc to continuously move towards the center position of the heating disc through an arranged telescopic air cylinder, and a wafer deviating from the central position of the heating disc is adjusted to the middle position in the synchronous movement of the position correcting disc, so that a film is uniformly heated.

Owner:陶汉成

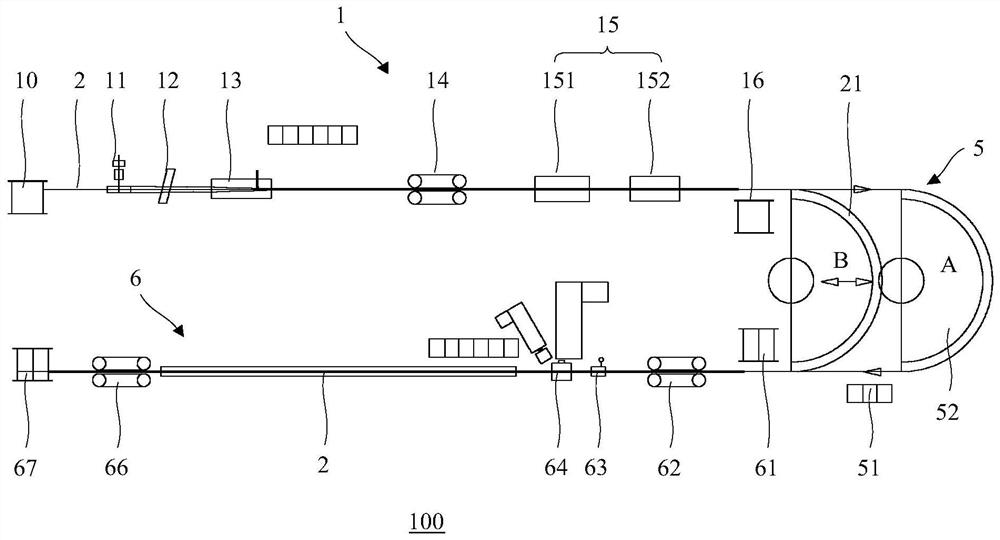

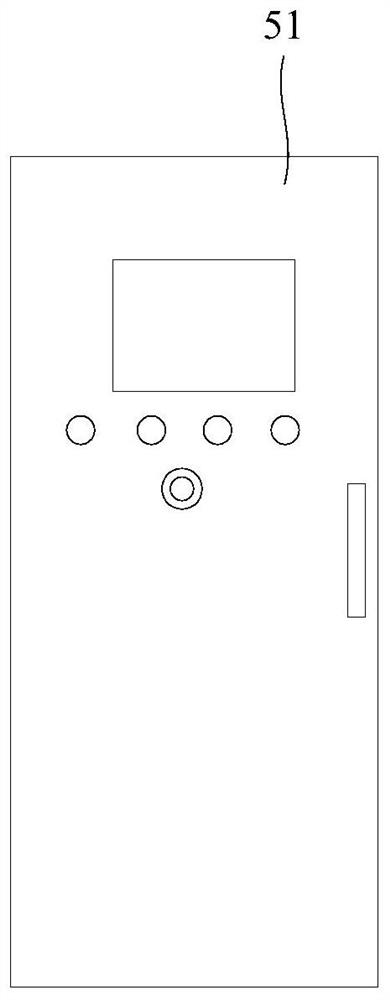

Cable Sheath Production Line

ActiveCN112233861BEasy to operateCompact structureCable/conductor manufactureSmall footprintElectric cables

The invention provides a cable sheath production line. The cable sheath production line includes a metal sheath installation component, a non-metallic sheath installation component and a transfer storage unit. The metal sheath installation component, the transfer storage unit and the non-metal sheath installation component are arranged in sequence along the feeding direction of the cable semi-finished product. The transfer storage line unit is set outside the same end of the metal sheath installation component and the non-metal sheath installation component, and there is a distance between the metal sheath installation component and the non-metal sheath installation component, so that the cable semi-finished product is installed on the metal sheath The part between the component and the non-metallic sheath installation component forms a curved arc-shaped storage part, and the flow transfer storage unit can move relative to the metal sheath installation component and the non-metallic sheath installation component to change the length of the storage part, and Make the semi-finished cable move synchronously in the metal sheath installation assembly and the non-metal sheath installation assembly. The equipment in the invention has compact structure, small occupied area and high production efficiency.

Owner:ZHONGTIAN TECH SUBMARINE CABLE CO LTD

Multifunctional measuring equipment for road and bridge construction

InactiveCN113739012AGood protectionEasy to storeOptical rangefindersStands/trestlesMeasuring equipmentStructural engineering

The invention providers multifunctional measuring equipment for road and bridge construction, which comprises a placement box; a sealing plate is detachably mounted at the upper end of the placement box; an adjusting mechanism is detachably mounted in the placement box; a distance measuring mechanism is detachably mounted at the upper end of the adjusting mechanism; a bearing mechanism is detachably mounted at the lower end of the adjusting mechanism; and the lower end surface of the bearing mechanism is detachably installed with a moving mechanism. According to the multifunctional measuring equipment for the road and bridge construction provided by the invention, the extension and storage of the distance measuring mechanism and the moving mechanism can be realized, the operation is convenient, the supporting effect of the distance measuring mechanism and the moving mechanism at different heights can be met, the practicability is extremely high, the application range is wide, and the popularization and the utilization are convenient.

Owner:王荣成

Stretching device capable of continuously stretching PVC (polyvinyl chloride) film

ActiveCN114524313AShorten the timeMake sure to move in syncFlat articlesLaser beam welding apparatusPolyvinyl chlorideEngineering

The invention discloses a PVC film sustainable stretching device which comprises a drying chamber, two transmission rollers are further arranged in the drying chamber, a conveying belt is correspondingly installed between the two transmission rollers, the conveying belt corresponds to the transmission rollers in width, and a feeding roller corresponding to the conveying belt in position and height is further installed on the left side of the drying chamber. The feeding roller can convey the PVC film to the conveying belt, and the PVC film is conveyed forwards along with the conveying belt. The whole structure is arranged in the drying chamber, in the stretching and transferring process after clamping and fixing, the stretched PVC film is dried and cured through the time difference, and time is saved; the transmission chain wheels are connected and installed on the transmission rollers on the two sides, the transmission chain is installed on the transmission chain wheels, the reciprocating type stretching mechanism is installed on the transmission chain, synchronous movement of the reciprocating type stretching mechanism and the transmission rollers can be guaranteed, and continuous feeding of PVC films can be achieved through the additionally-arranged feeding rollers.

Owner:江苏永润包装材料有限公司

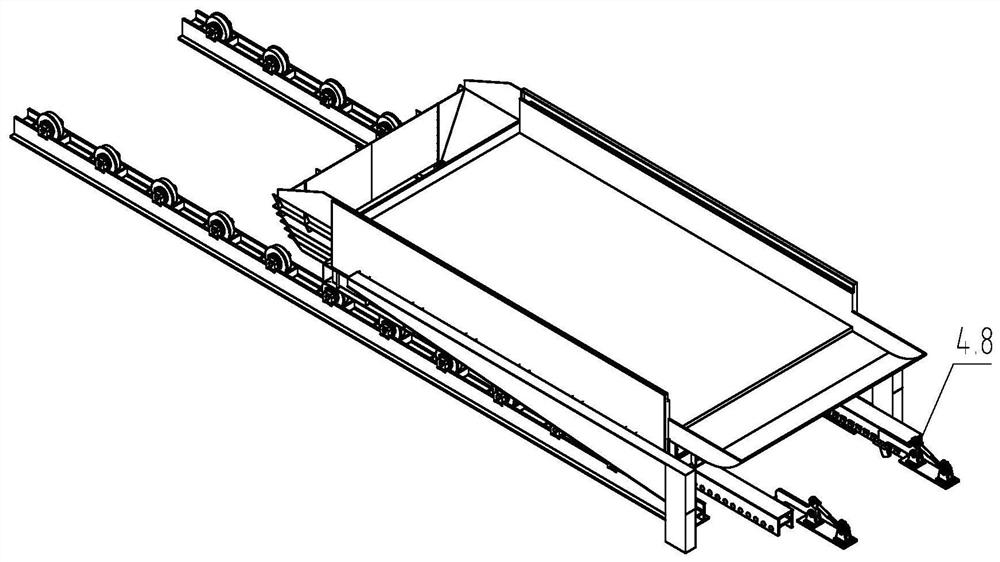

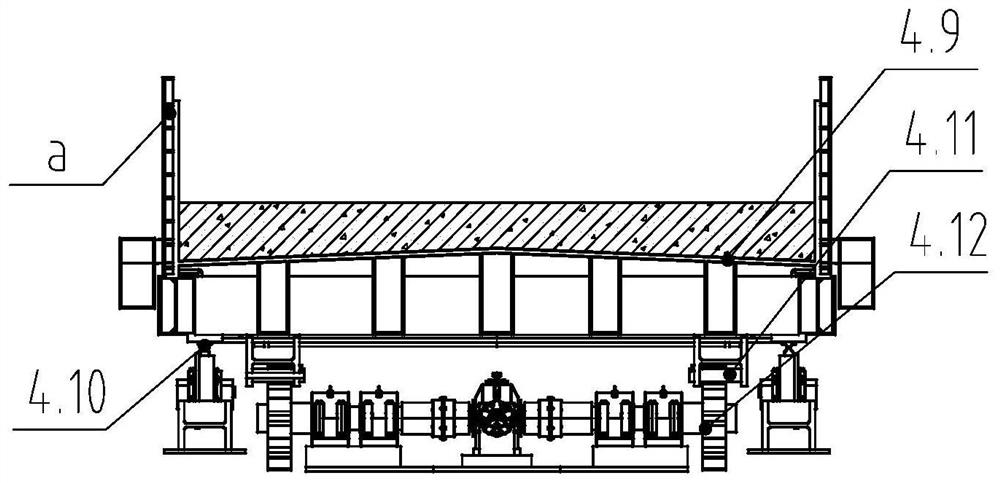

Movable slag bed

PendingCN113046501ASave lengthSave extra spaceRecycling and recovery technologiesMetallurgical slagSupporting system

The invention relates to the field of metallurgical slag treatment, in particular to a movable slag bed. The movable slag bed comprises a movable slag bed body, a slag bed feed opening, a ground supporting system, a movable slag bed ground driving device and a movable slag bed locking device. According to the technical scheme, the operation mode that the movable slag bed is matched with a fixed slag pot tipping device is adopted, the length and the area of a plant can be greatly saved, and the manufacturing and using cost is reduced. The slag bed can move back and forth among a slag receiving position, a metallurgical slag crushing position and a large slag cleaning position, and the slag tank tipping device is fixedly mounted, so that compared with an original fixed slag bed technical scheme, the length and the occupied area of the plant can be greatly saved, meanwhile, equipment operation is more flexible, and large slag cleaning operation is easy.

Owner:北京清皓源技术有限公司

A kind of tweezers and its disinfection device

ActiveCN107414692BIncrease intensityImprove comfortMetal-working hand toolsChemicalsMedicineEngineering

The invention relates to the field of medical equipment and cleaning, and particularly relates to a pair of tweezers and a disinfecting device thereof. The pair of tweezers comprises a first clamping arm and a second clamping arm, wherein a first cavity is formed in one end of the first clamping arm, a second cavity is formed in one end of the second clamping arm, one end of the first clamping arm is fixedly connected with one end of the second clamping arm, and the first cavity communicates with the second cavity; rotating rods and torsion springs are arranged in the first cavity and the second cavity, cleaning cloth is arranged on the circumferential walls of the rotating rods, and one end of the cleaning cloth is fixedly connected with the circumferential walls of the rotating rods; and a circular post is located between the first clamping arm and the second clamping arm, and the other end of the cleaning cloth is fixedly connected with the circumferential wall of the circular post. By adopting the technical scheme, the problem of incapability of cleaning due to small spacing between the first clamping arm and the second clamping arm is effectively solved, and additionally, the force of the pair of tweezers can be increased by the circular post, so that the pair of tweezers is easy to control when in use, and the use comfort is increased.

Owner:宁波隆锐机械制造有限公司

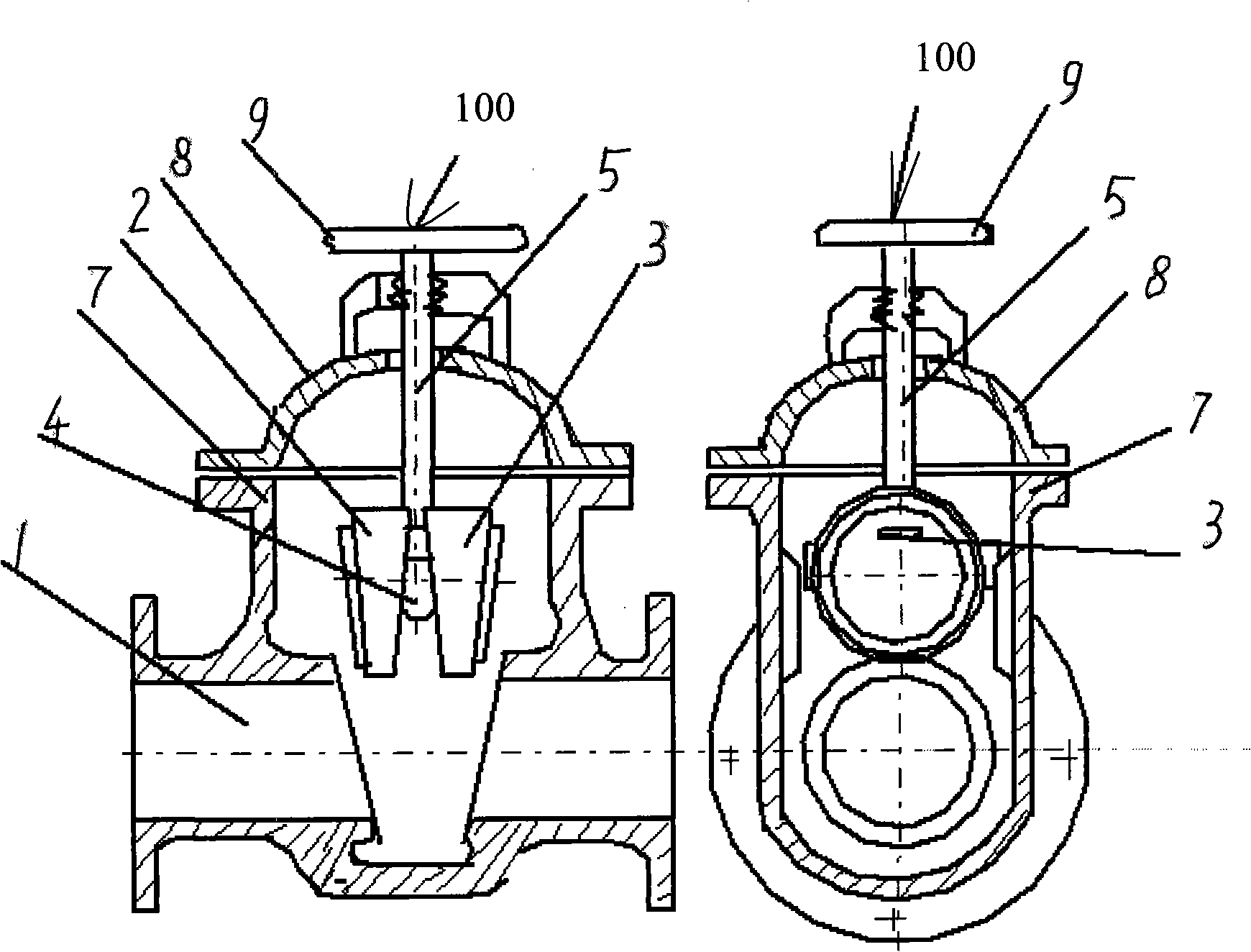

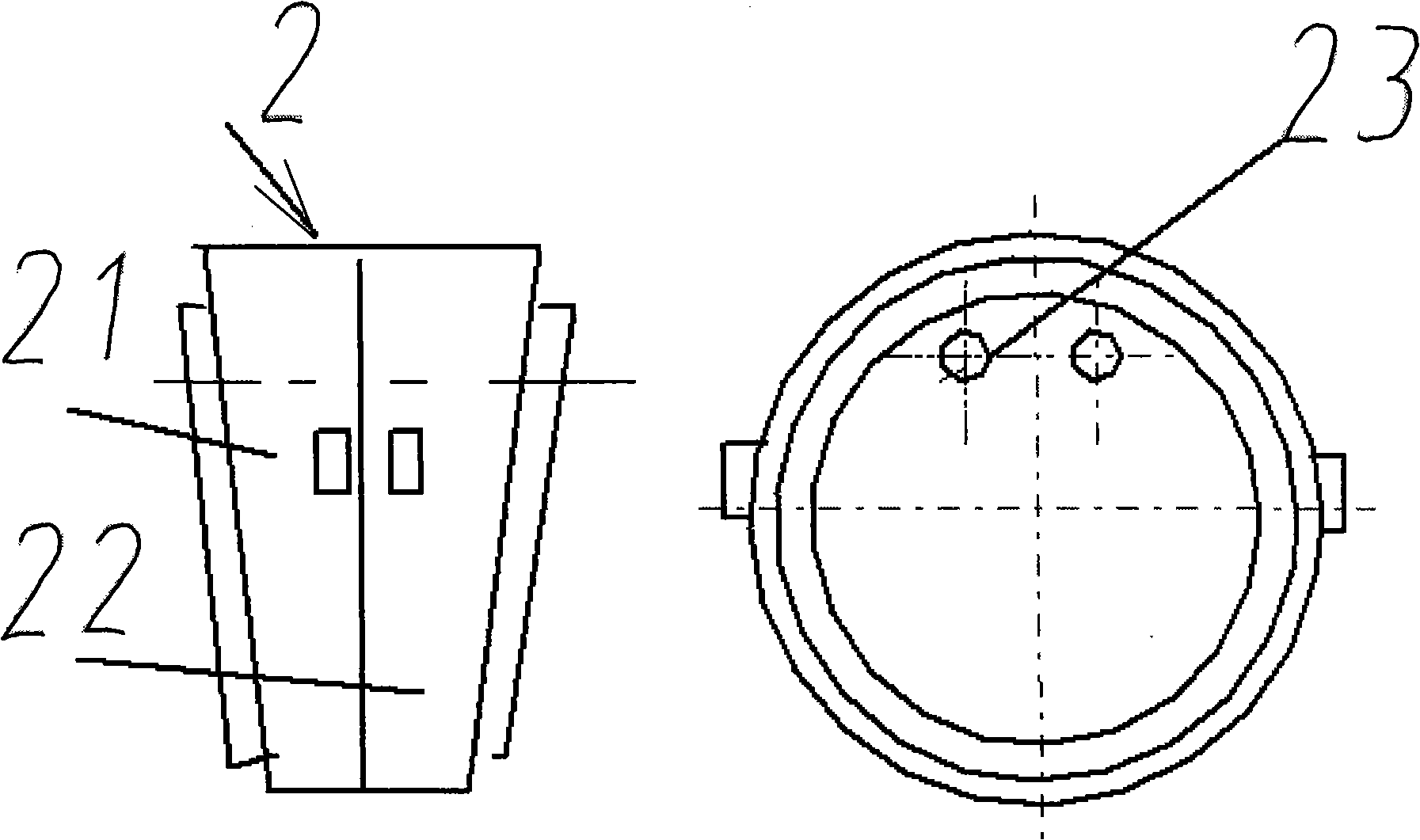

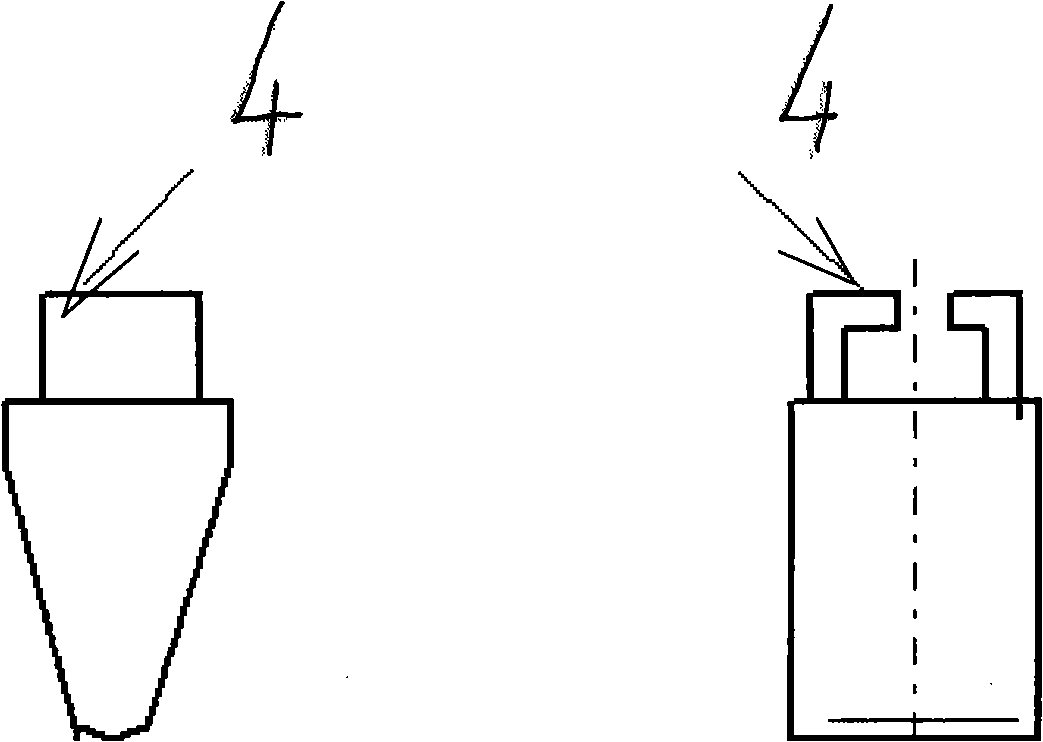

Method for preventing shutter malposition of gate valve

InactiveCN101303084AMake sure to move in syncNot easy to misplaceOperating means/releasing devices for valvesSlide valveEngineeringGate valve

The invention provides a method for preventing malposition of the flashboards of a gate valve, which comprises the steps as follows: A: associated elements are arranged between the flashboards for blocking a flow passage of the gate valve; B: the flashboards provided with the associated elements are assembled with block pieces and valve rods to form a valve spool; C: the valve spool obtained in step B is installed into a valve body matched with the valve spool; and D: a valve cover and a spider handle thereof, which are corresponding to the valve body, are installed. The method has advantages that: the associated elements are arranged between two relatively independent flashboards to guarantee the synchronous movement of the two flashboards without making any malposition or separation, therefore can guarantee the reasonable positions of the block pieces so as to prolong the service life of the gate valve, besides, the associated elements are arranged between the flashboards, thus being favorable for improving the integrity of the valve spool, simplifying the operation process for dismantling and installing the valve spool when maintaining pipelines, and promoting working efficiency.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

Feeding device for metal band sawing machine

InactiveCN112247270AIncrease cutting diversityMake sure to move in syncMetal sawing devicesEngineeringBar stock

The invention relates to a feeding device for a metal band sawing machine. The feeding device comprises a base, wherein a pair of driving rollers and a pair of guide rollers are arranged on the base;the axes of the driving rollers and the axes of the guide rollers extend in the vertical direction, and the driving rollers and the guide rollers rotate around the respective axes; the lower ends of the driving rollers move oppositely or reversely in the horizontal direction; the two guide rollers are rotationally arranged on the base around the axis of one driving roller respectively; and the distance between the axes of the guide rollers is always equal to the distance between the axes of the driving rollers. The driving rollers and the guide rollers are used for controlling rotation and feeding of bars, and thus machining of the bars at different cutting angles is achieved.

Owner:安徽运杰机械设备制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com