Patents

Literature

121results about How to "Evenly divided" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

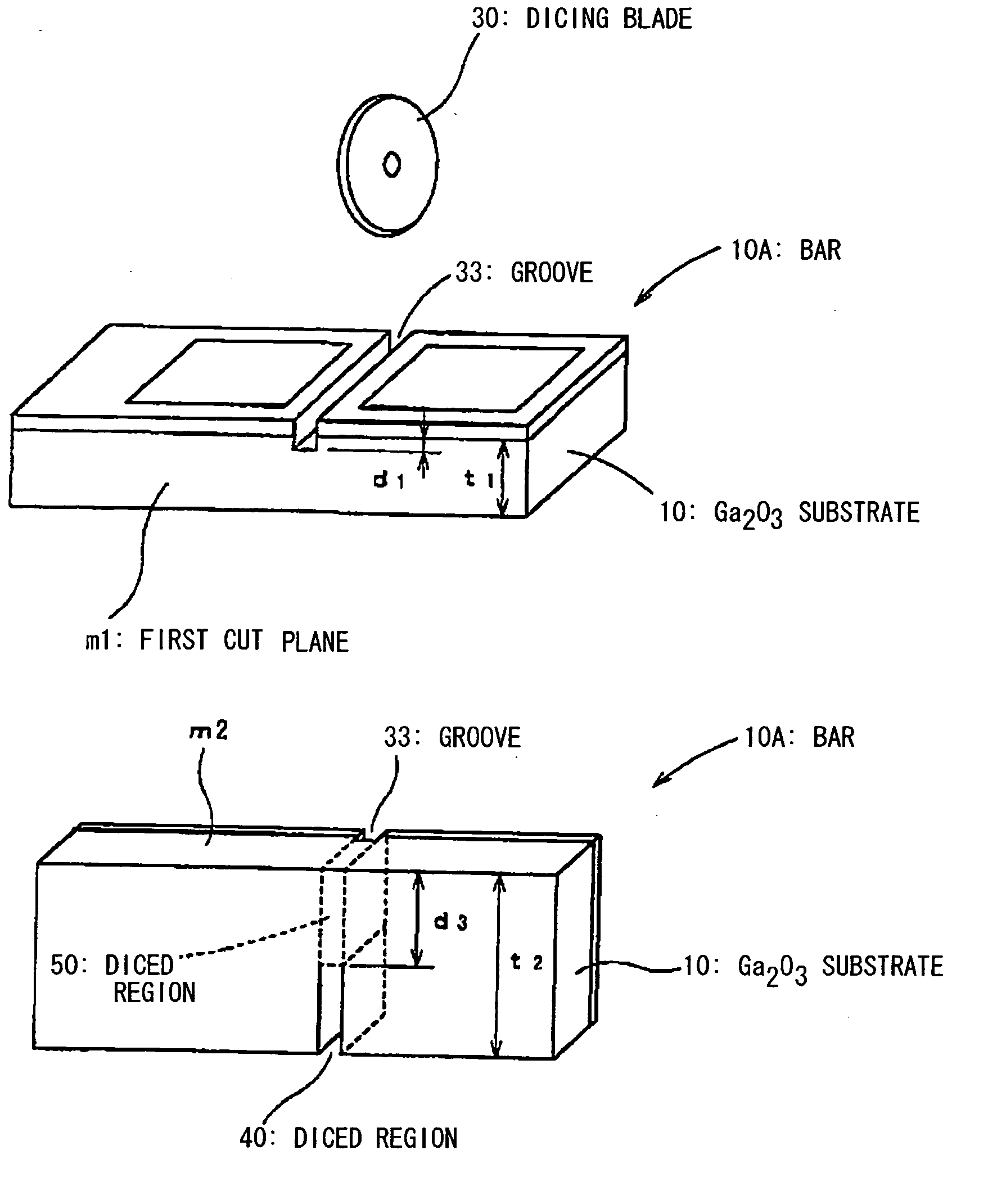

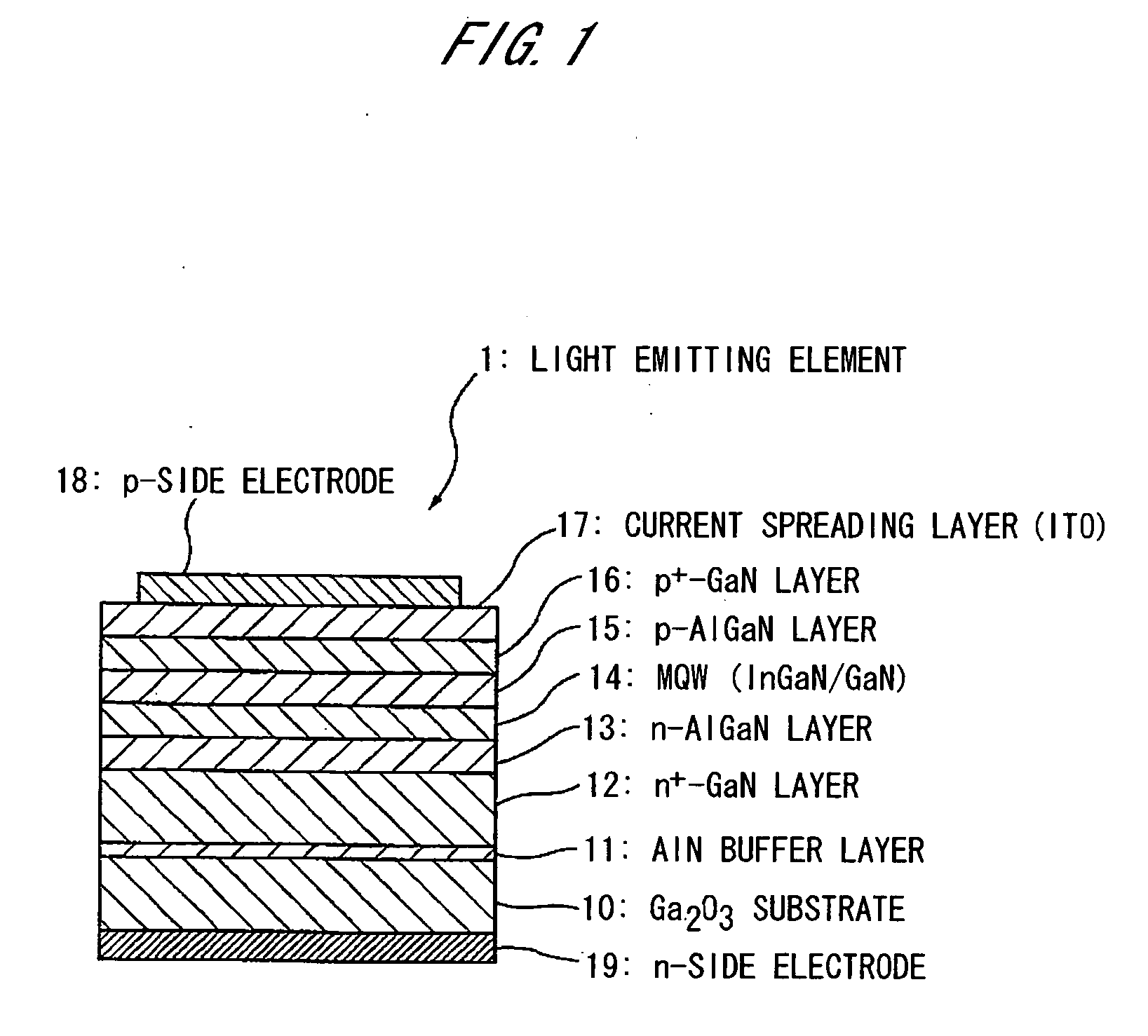

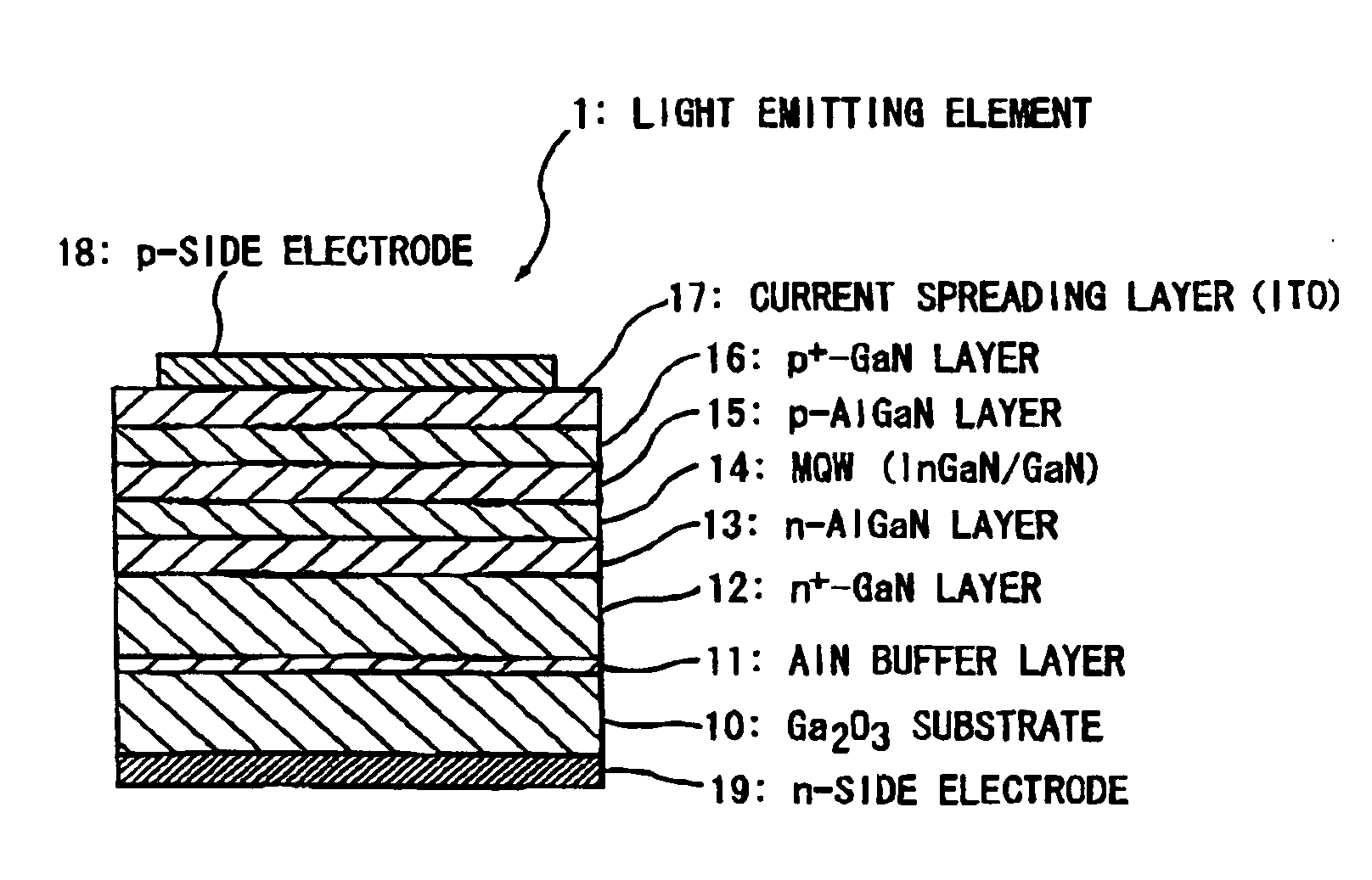

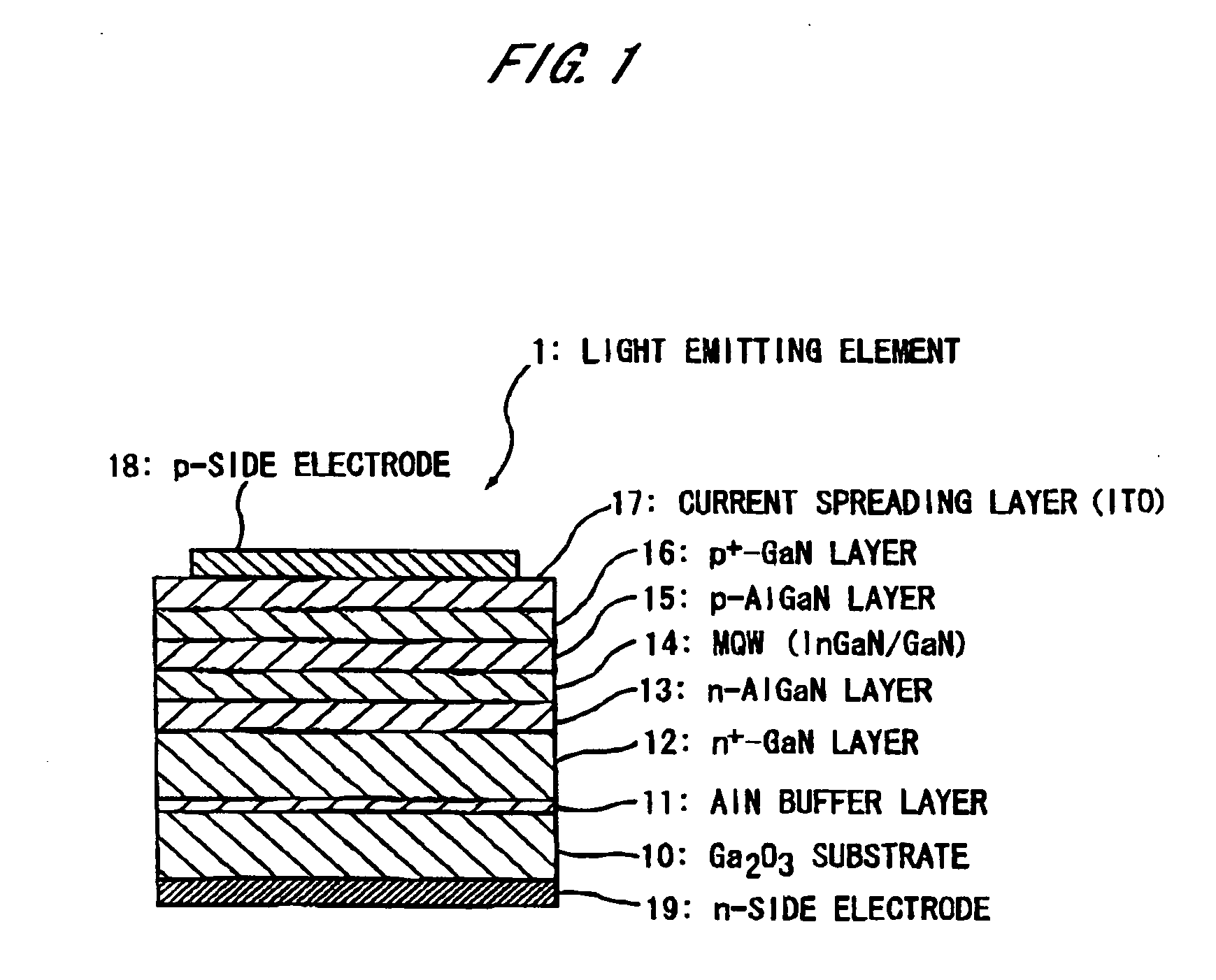

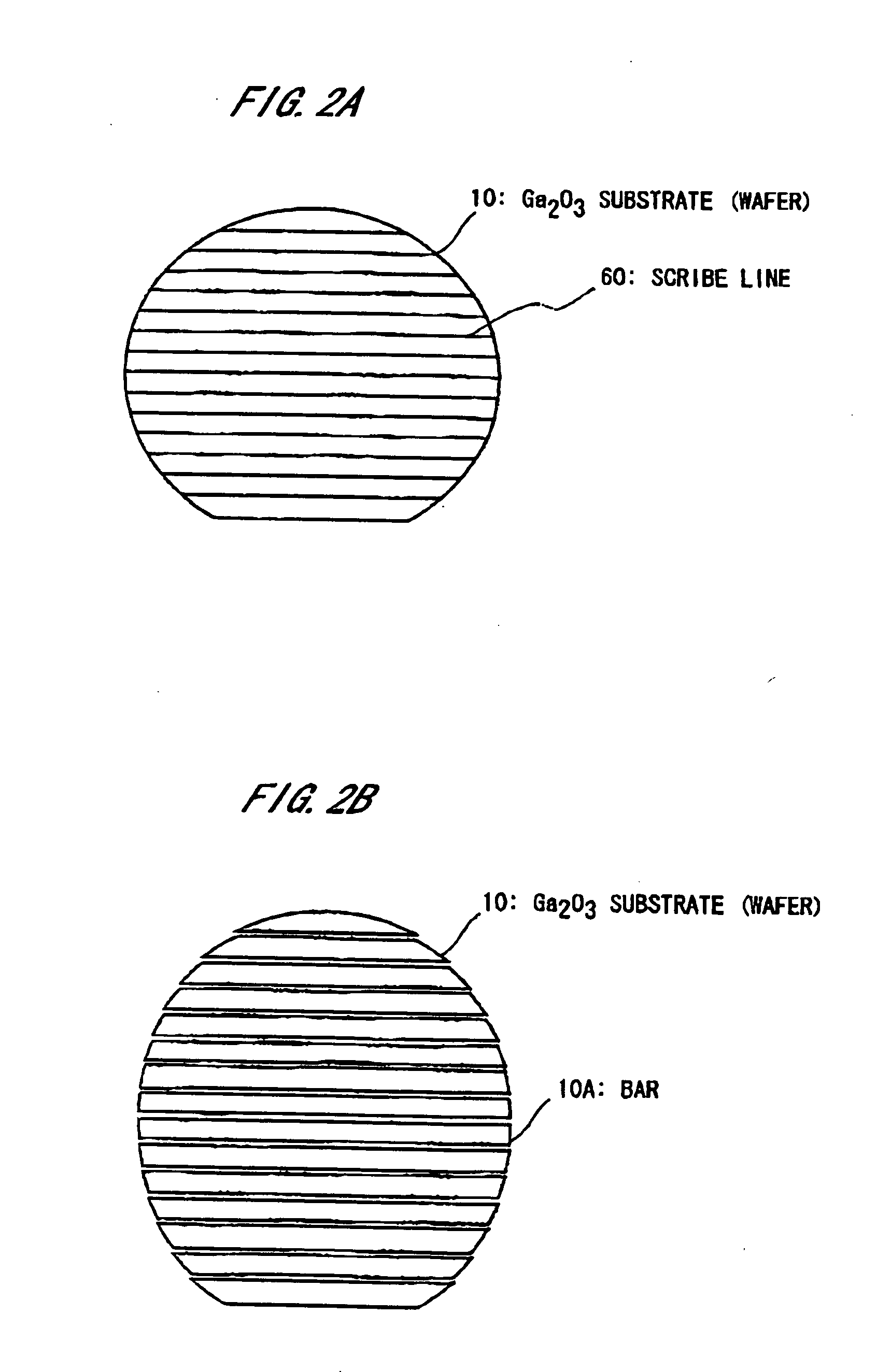

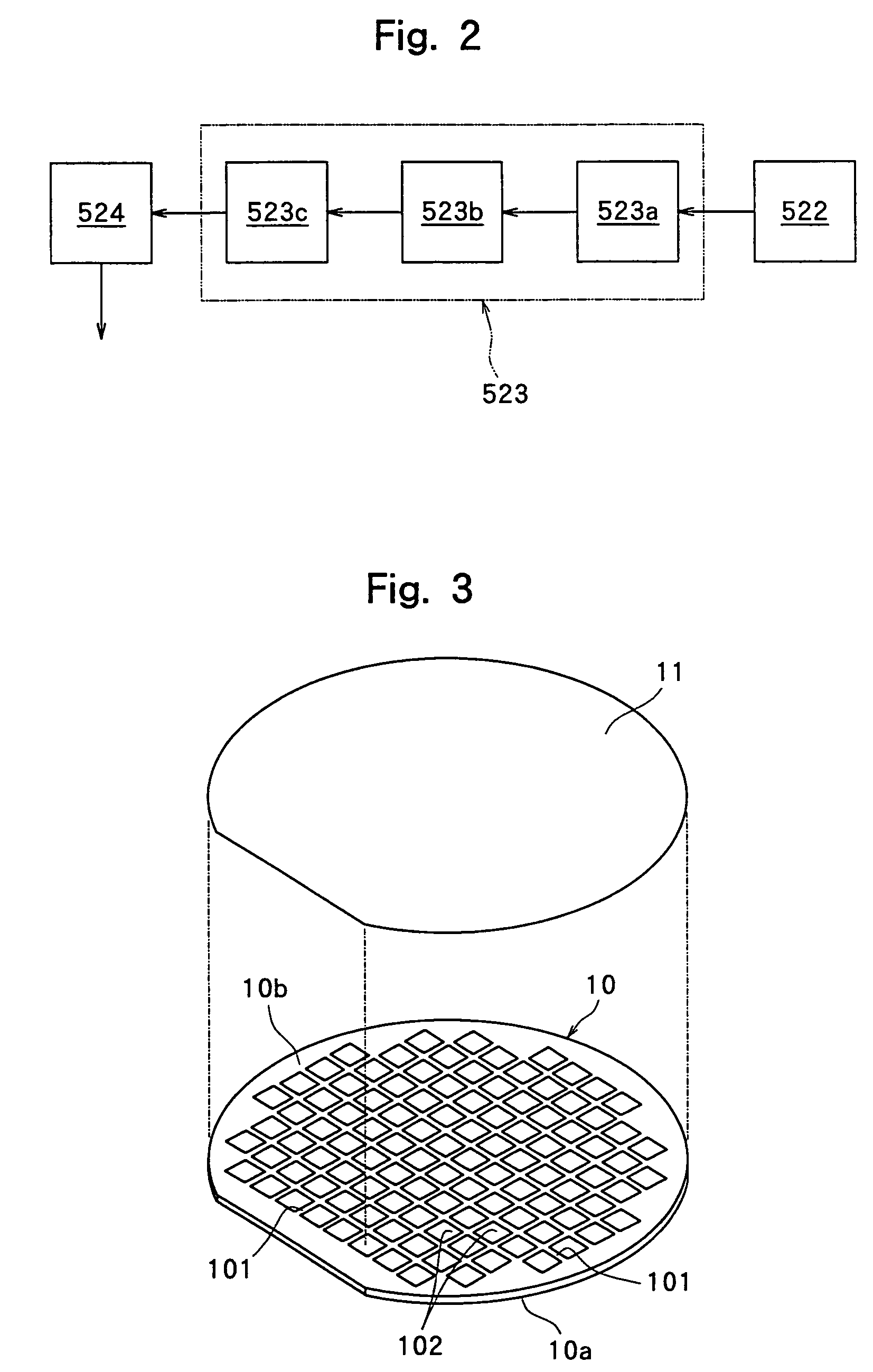

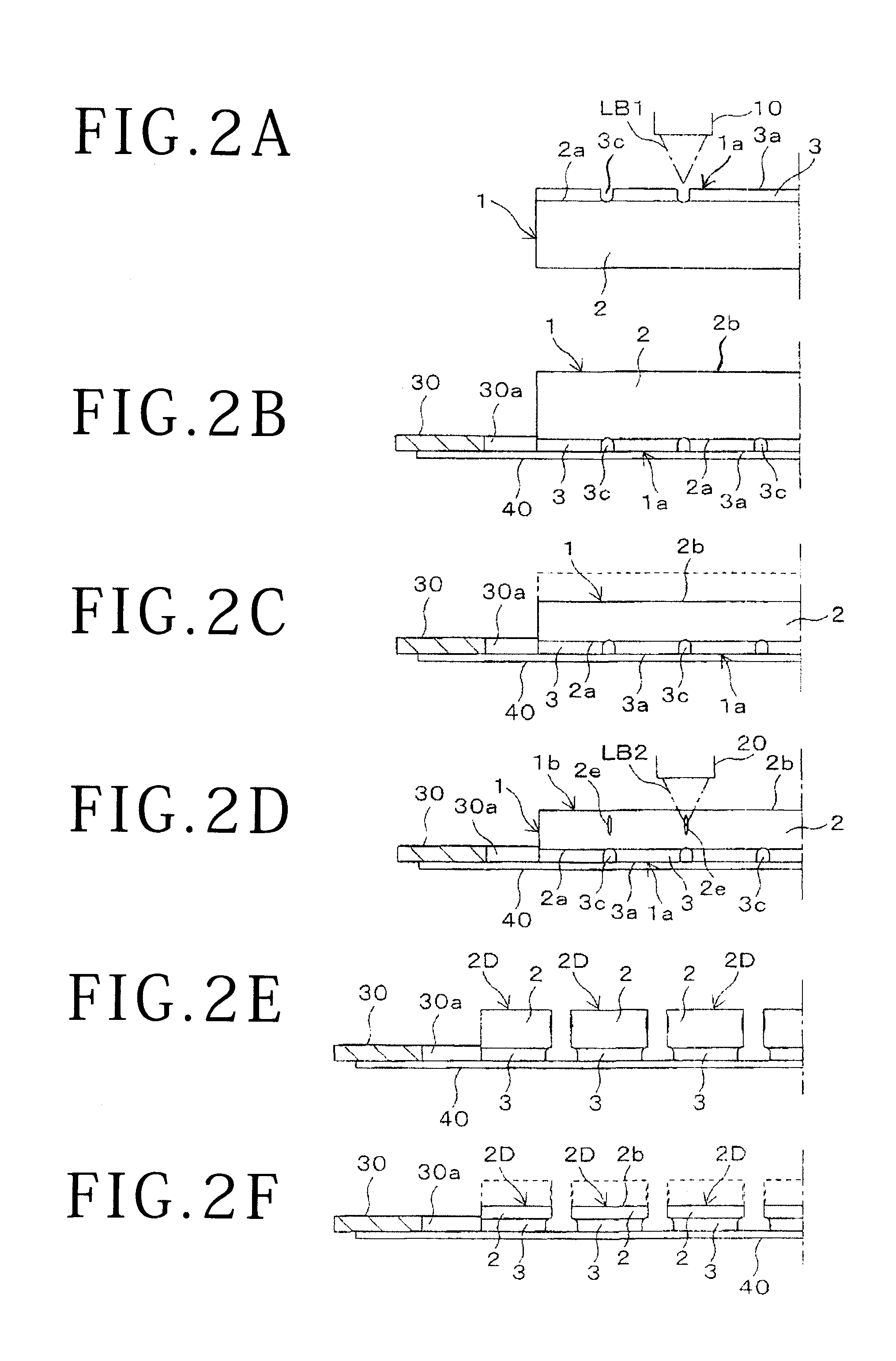

Semiconductor element and method of making same

InactiveUS20070134833A1Improve production yieldHigh product yieldSemiconductor/solid-state device manufacturingSemiconductor devicesGallium oxideSemiconductor components

A method of making a semiconductor element which has a substrate formed of gallium oxide and a semiconductor layer formed on the substrate. The method has: a first dividing step that the substrate with the semiconductor layer formed thereon is divided into a strip bar along a first cleaved surface of the substrate; and a second dividing step that the strip bar is divided in a direction perpendicular to the first cleaved surface.

Owner:TOYODA GOSEI CO LTD +1

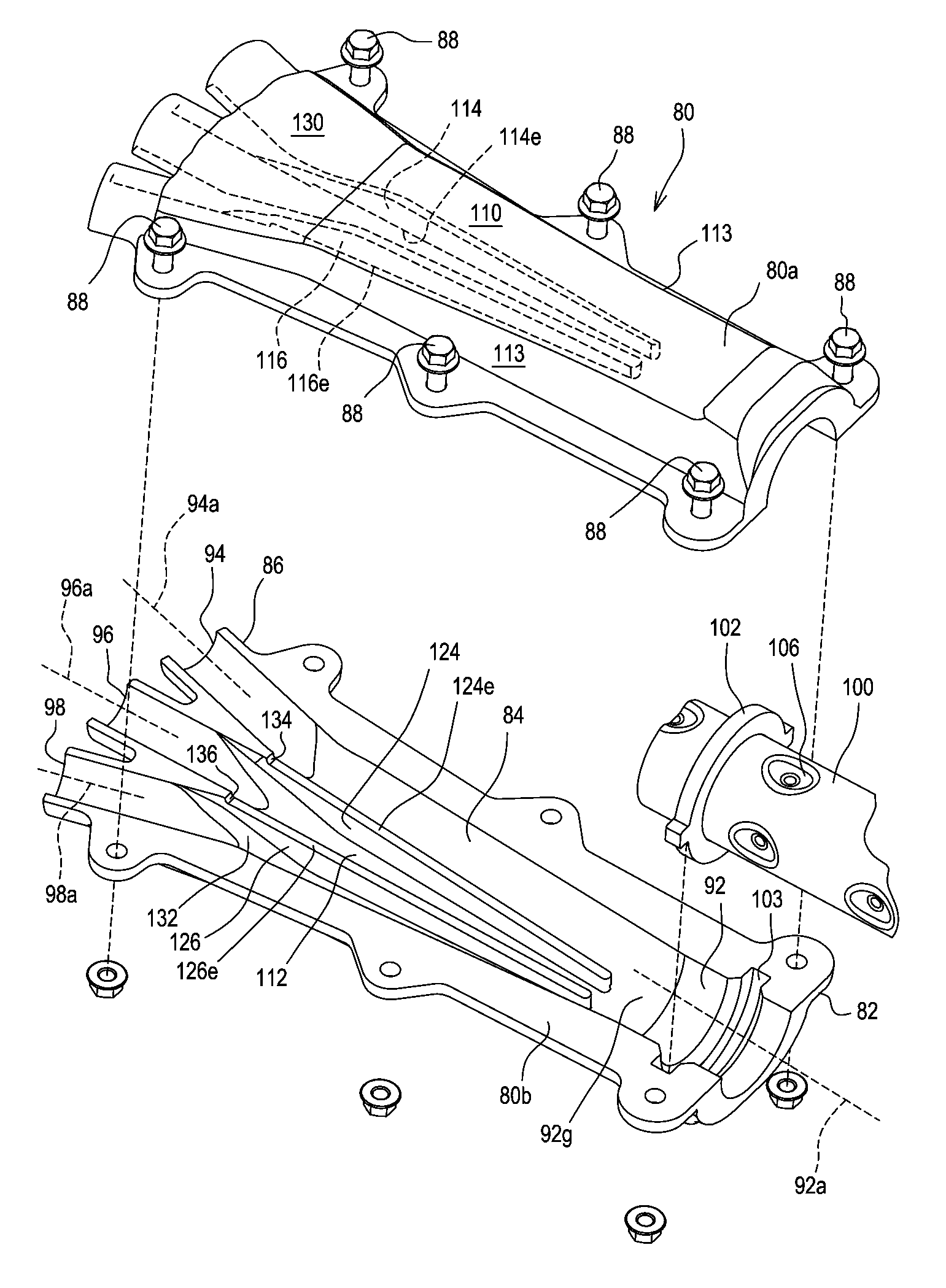

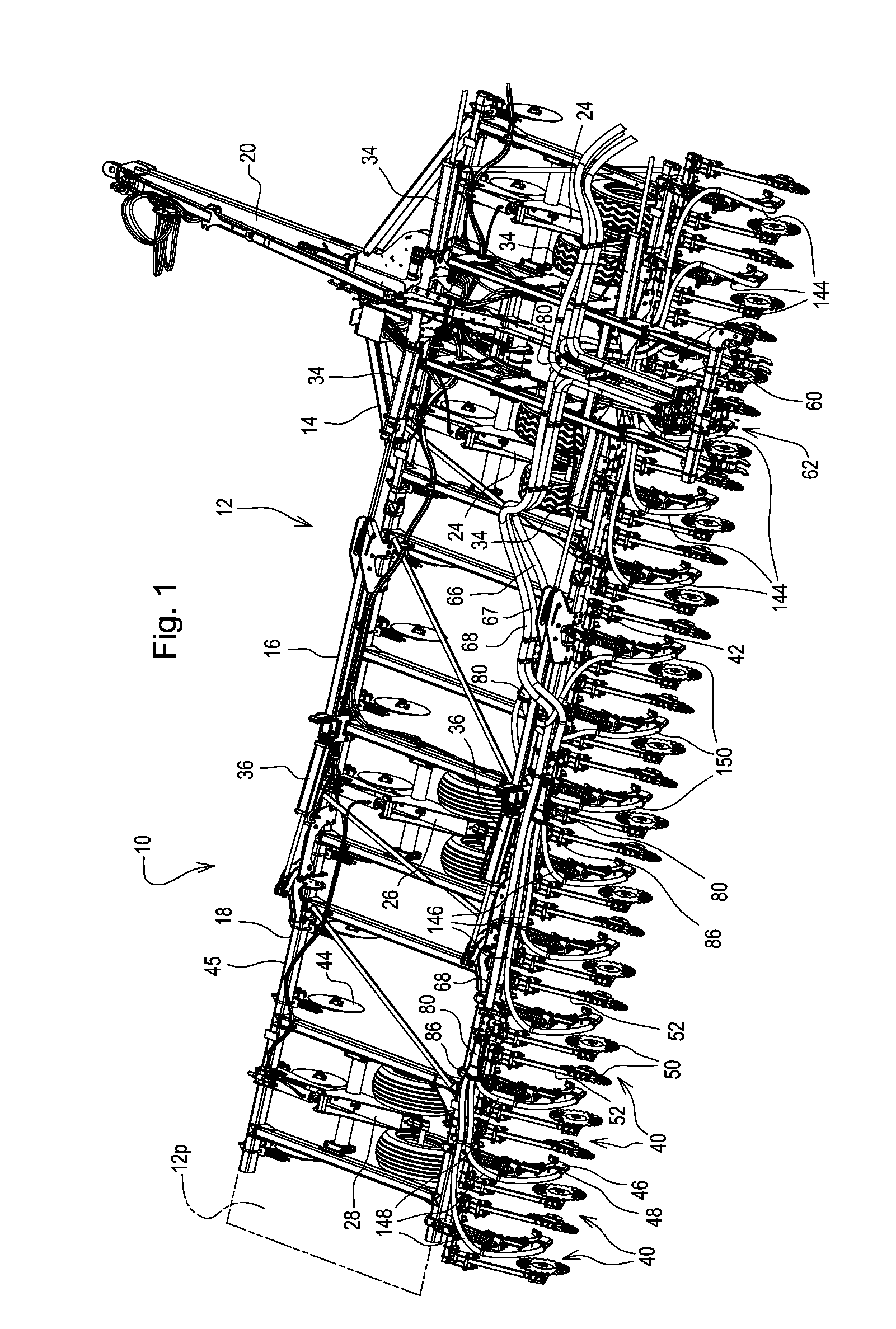

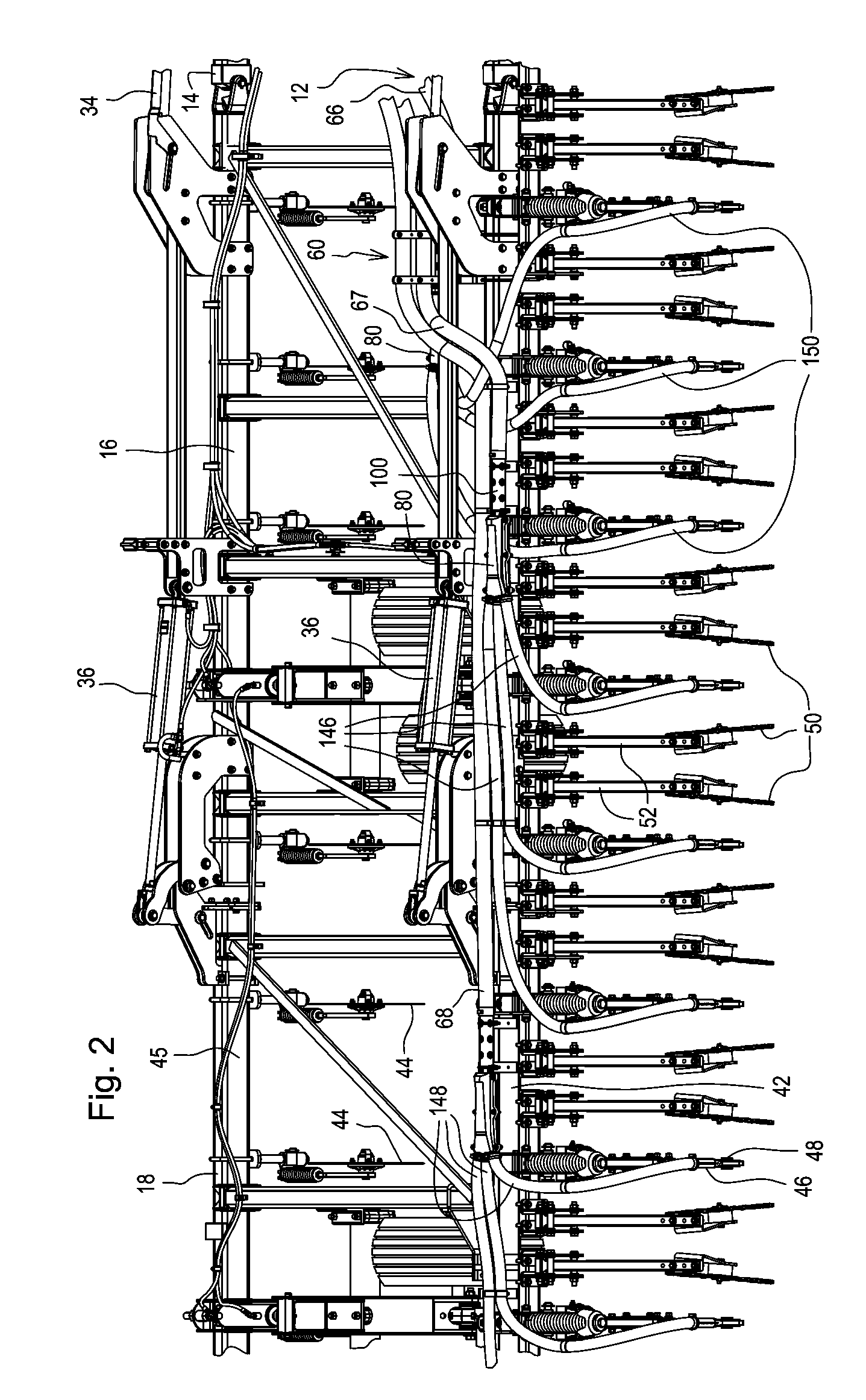

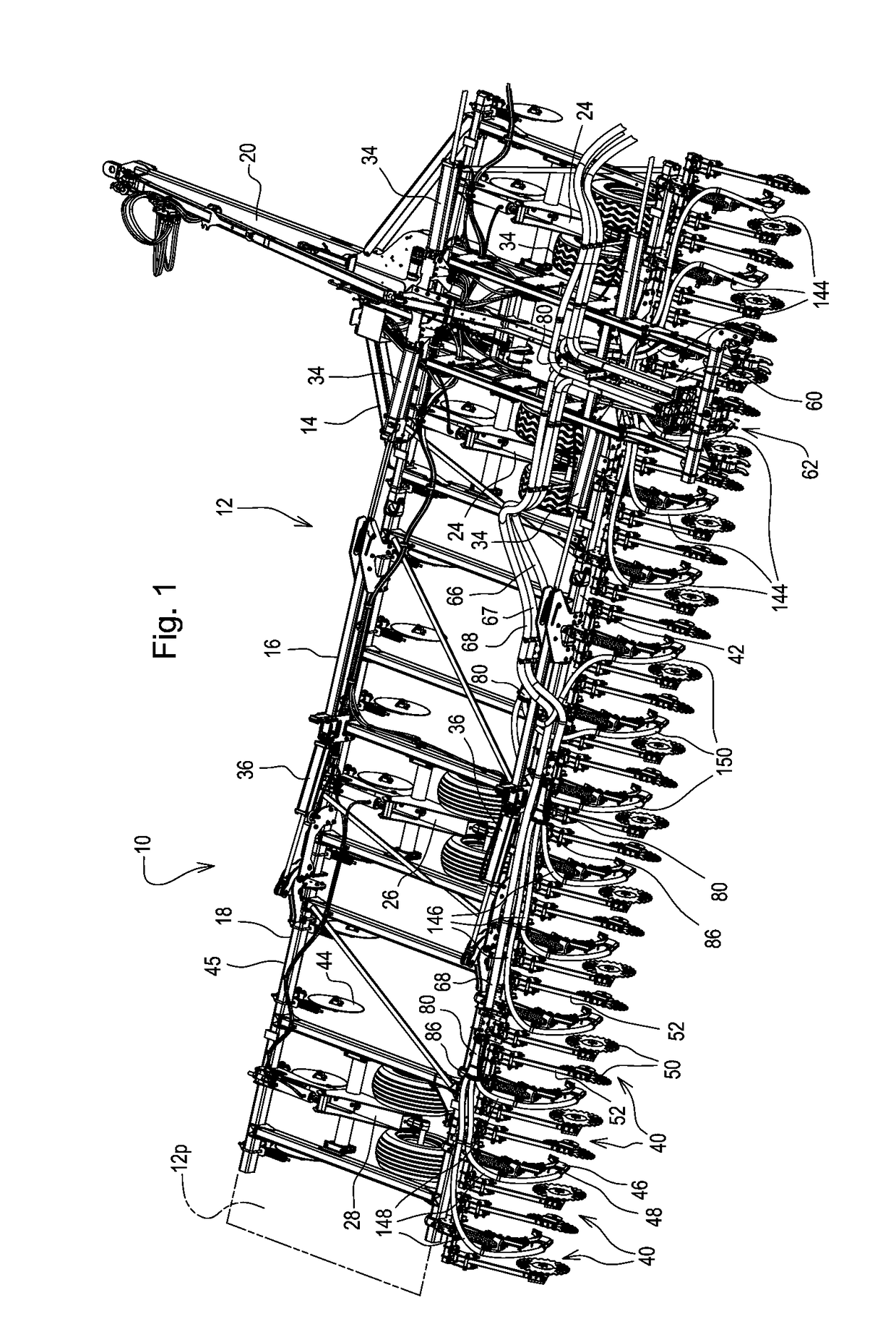

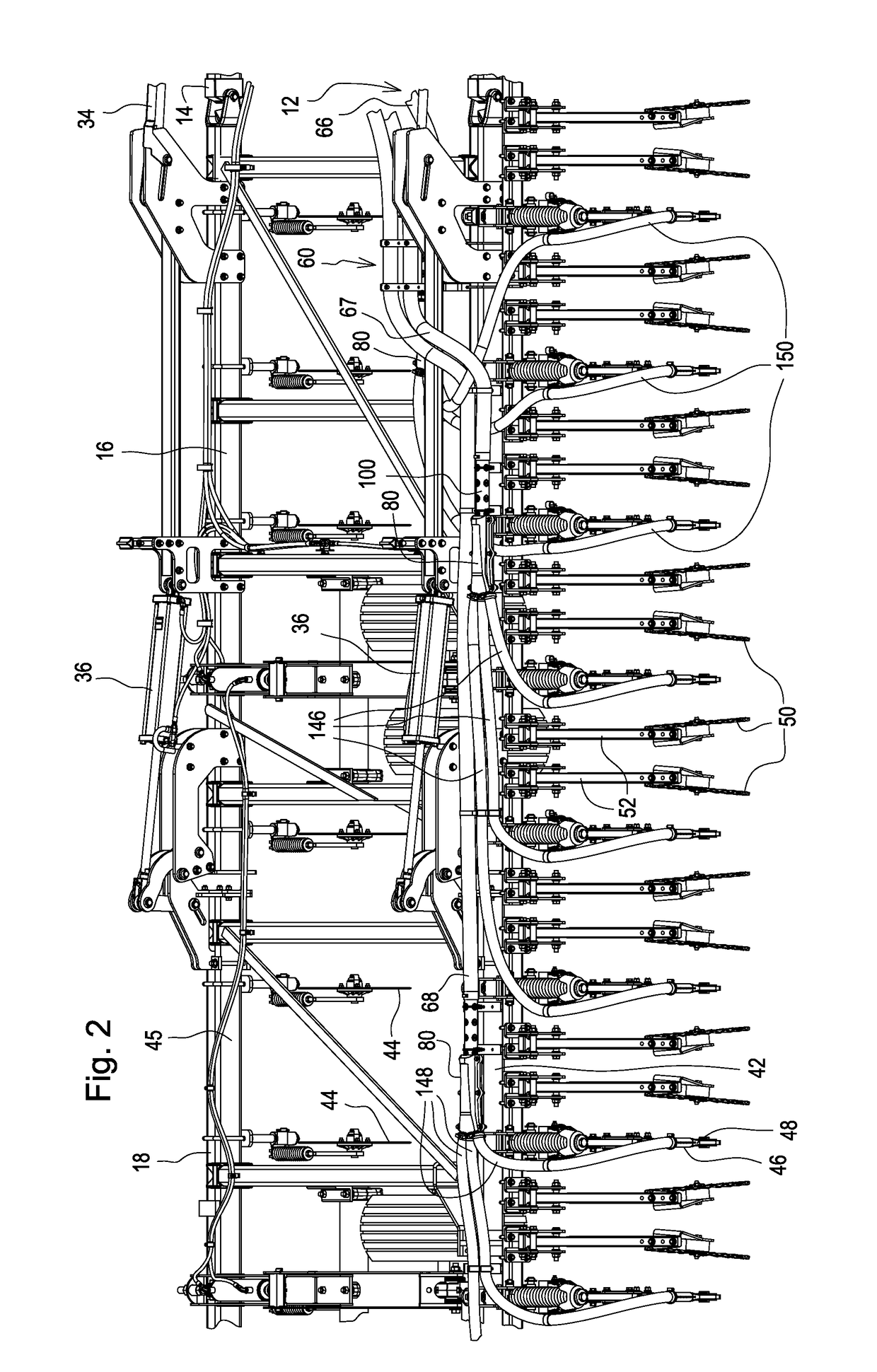

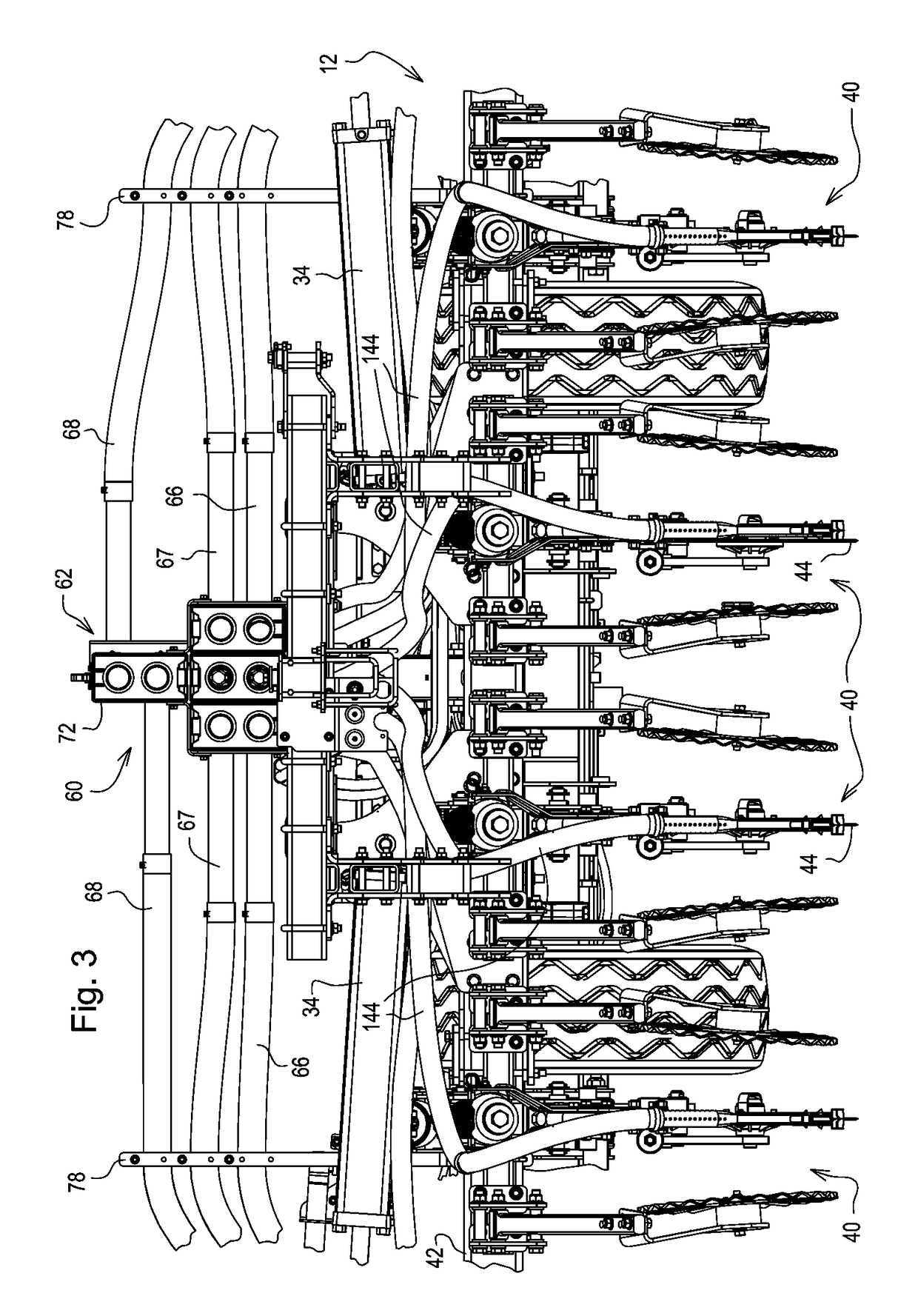

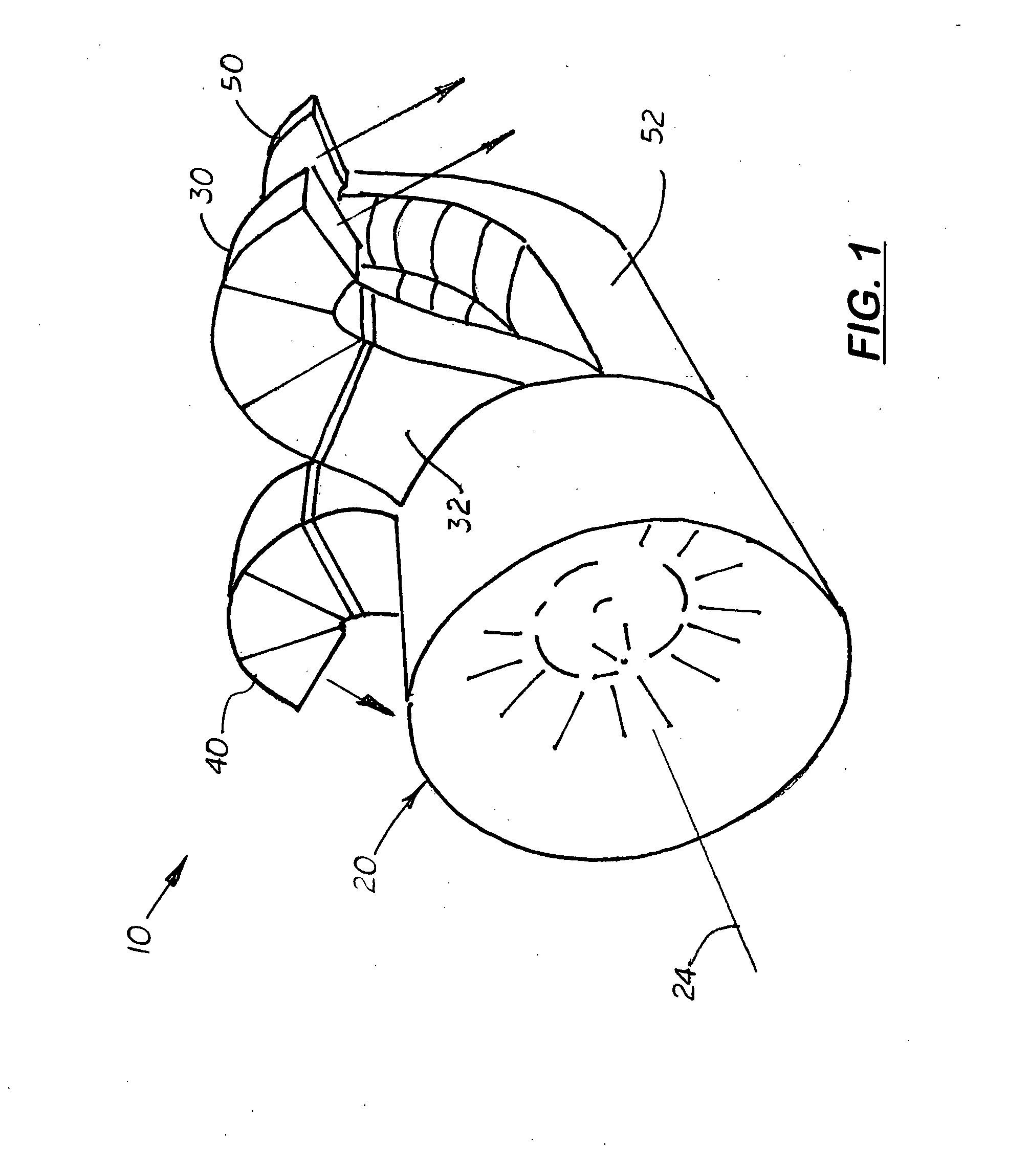

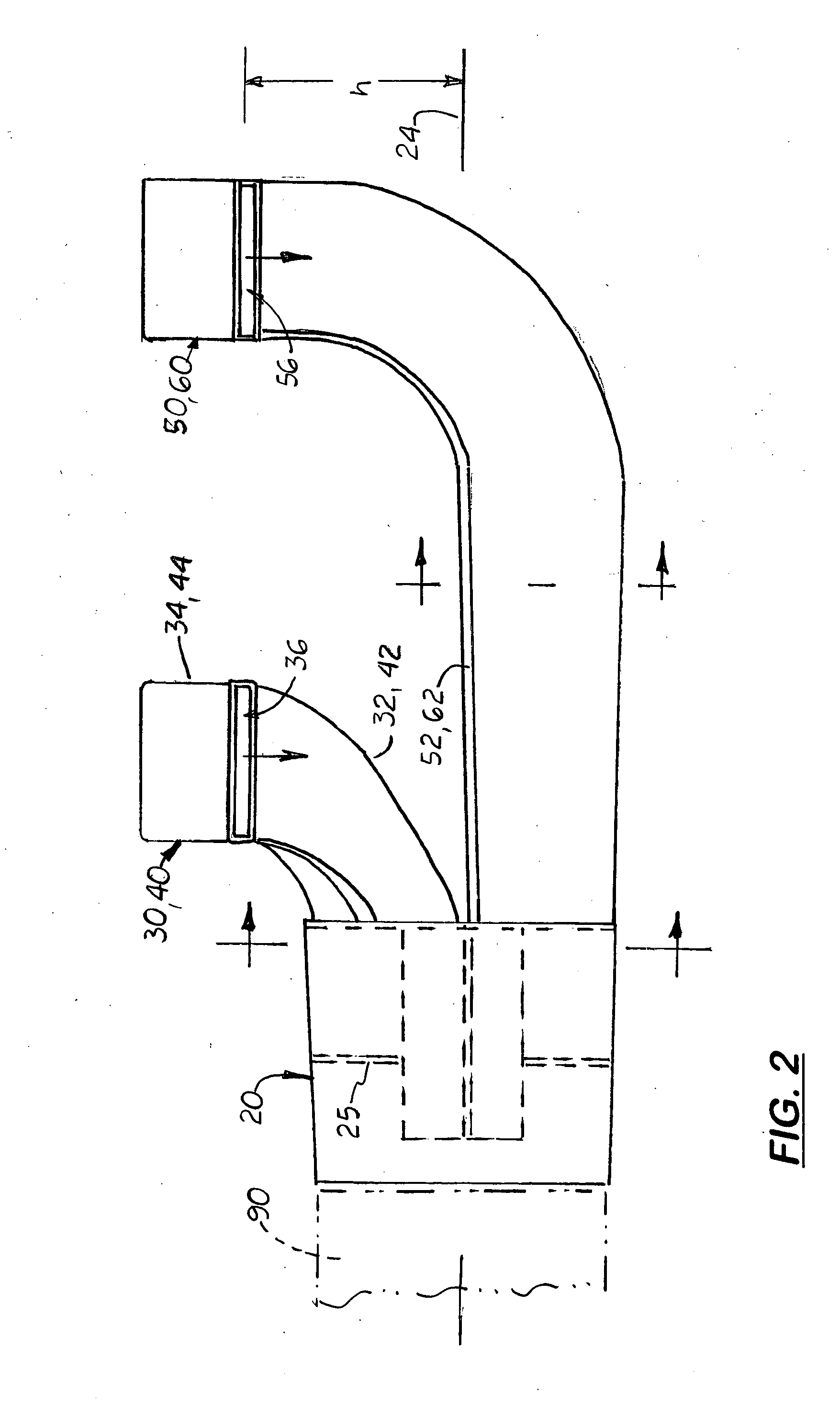

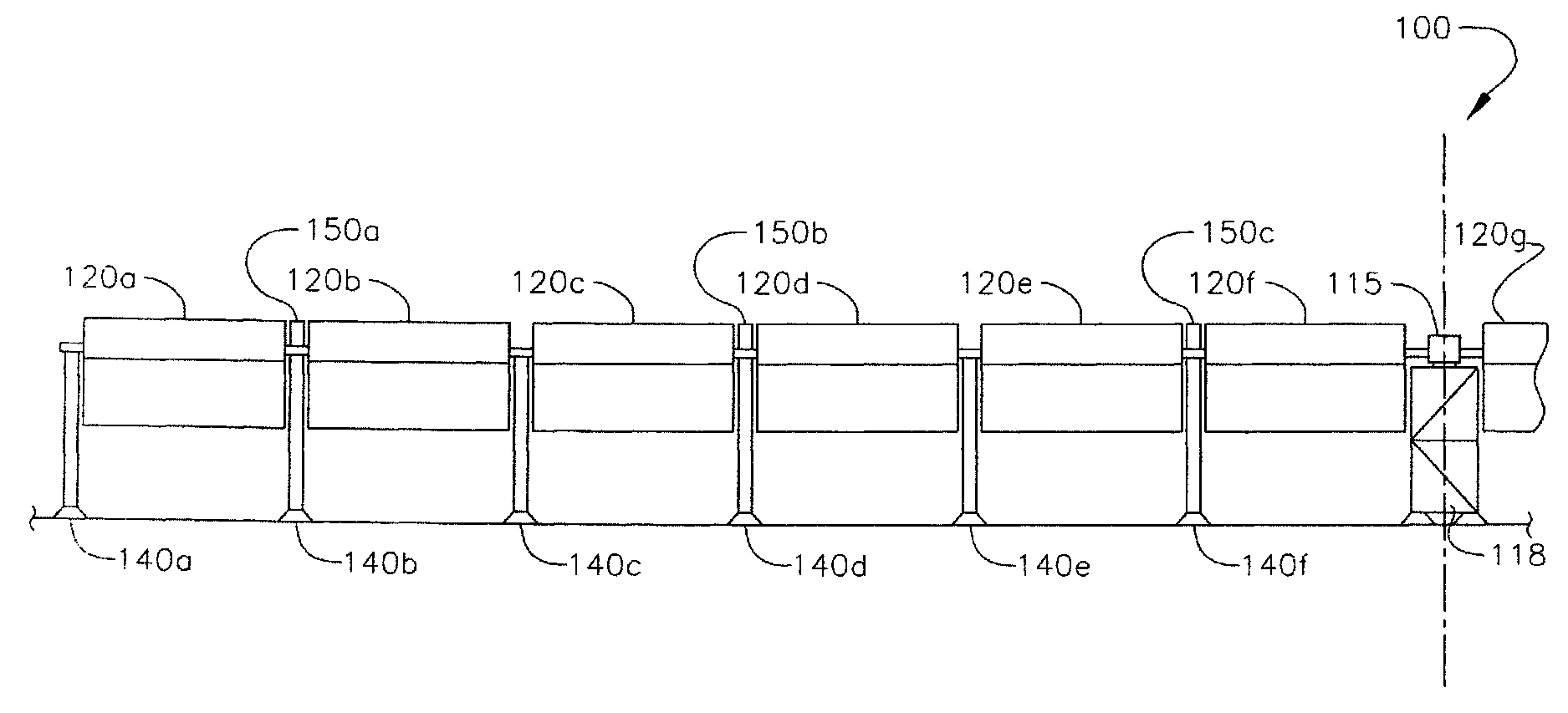

Commodity Splitter for an Air Delivery System

ActiveUS20110311322A1Streamline in appearanceEasily mountSowingPotato plantersAirflowPressure balance

Owner:DEERE & CO

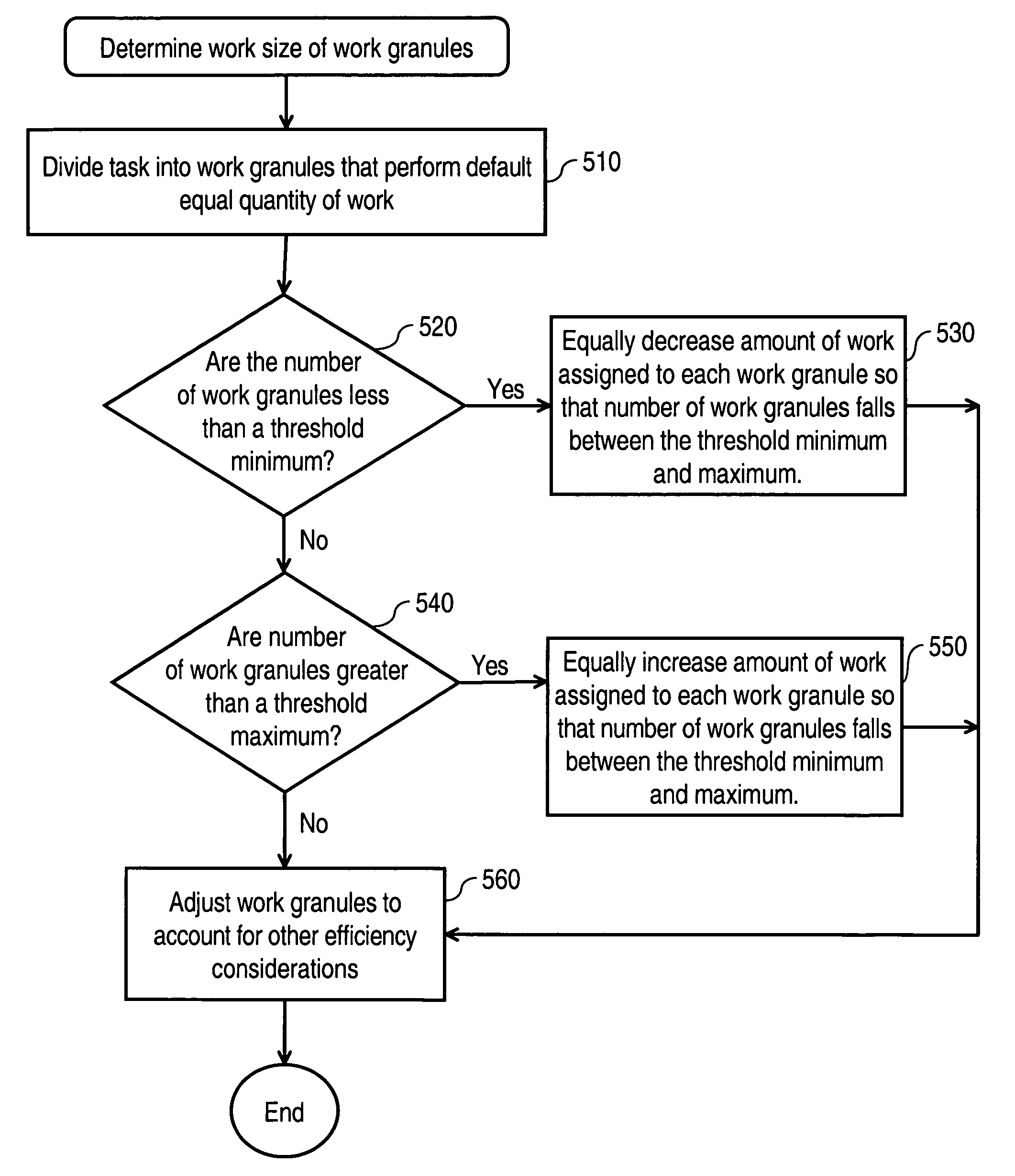

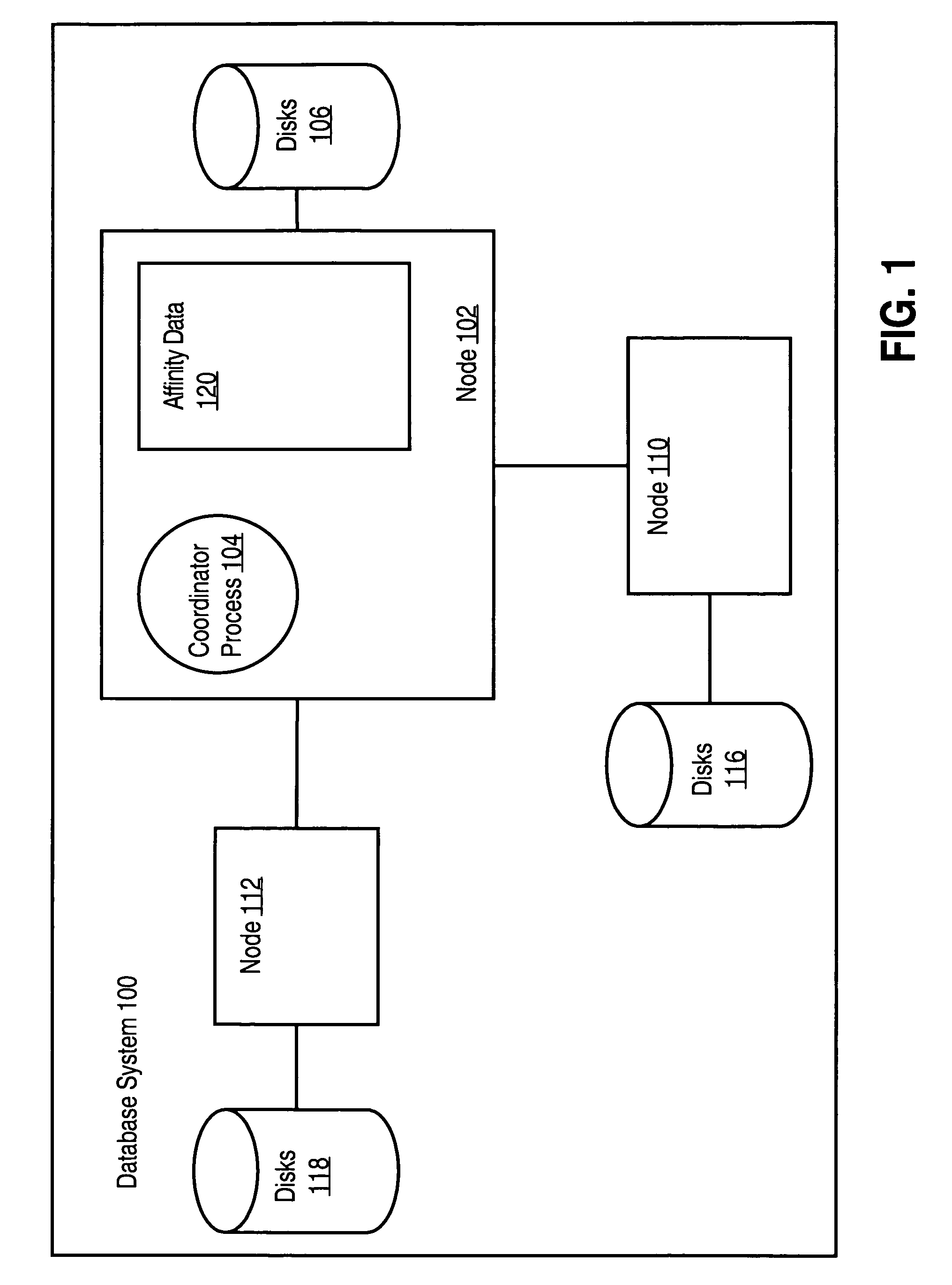

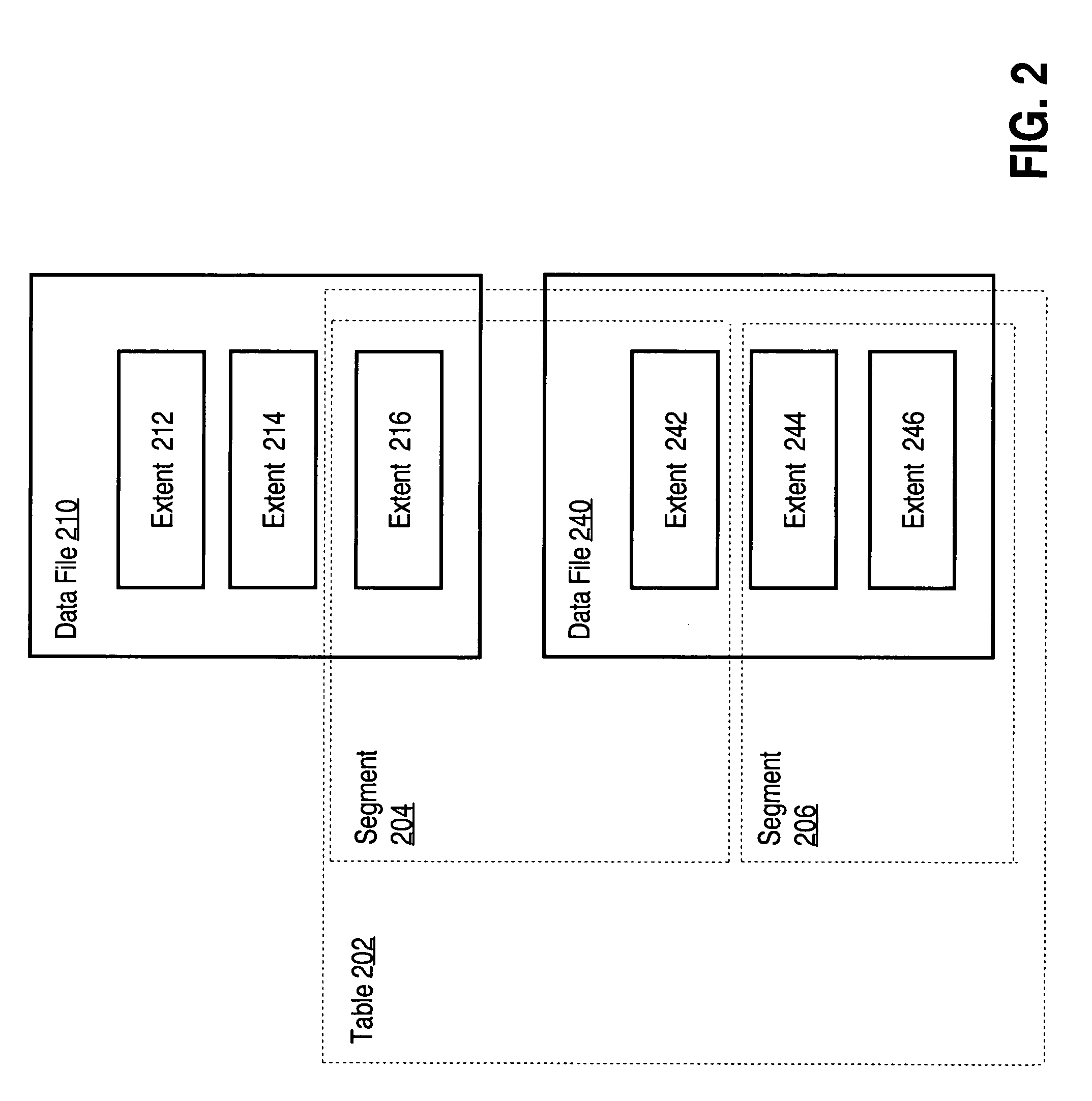

Managing parallel execution of work granules according to their affinity

InactiveUS7386849B2Evenly dividedData processing applicationsResource allocationWorkloadEfficiency factor

A method and apparatus are provided for managing work granules being executed in parallel. A task is evenly divided between a number of work granules. The number of work granules falls between a threshold minimum and a threshold maximum. The threshold minimum and maximum may be configured to balance a variety of efficiency factors affected by the number of work granules, including workload skew and overhead incurred in managing larger number of work granules. Work granules are distributed to processes on nodes according to which of the nodes, if any, may execute the work granule efficiently. A variety of factors may used to determine where a work granule may be performed efficiently, including whether data accessed during the execution of a work granule may be locally accessed by a node.

Owner:ORACLE INT CORP

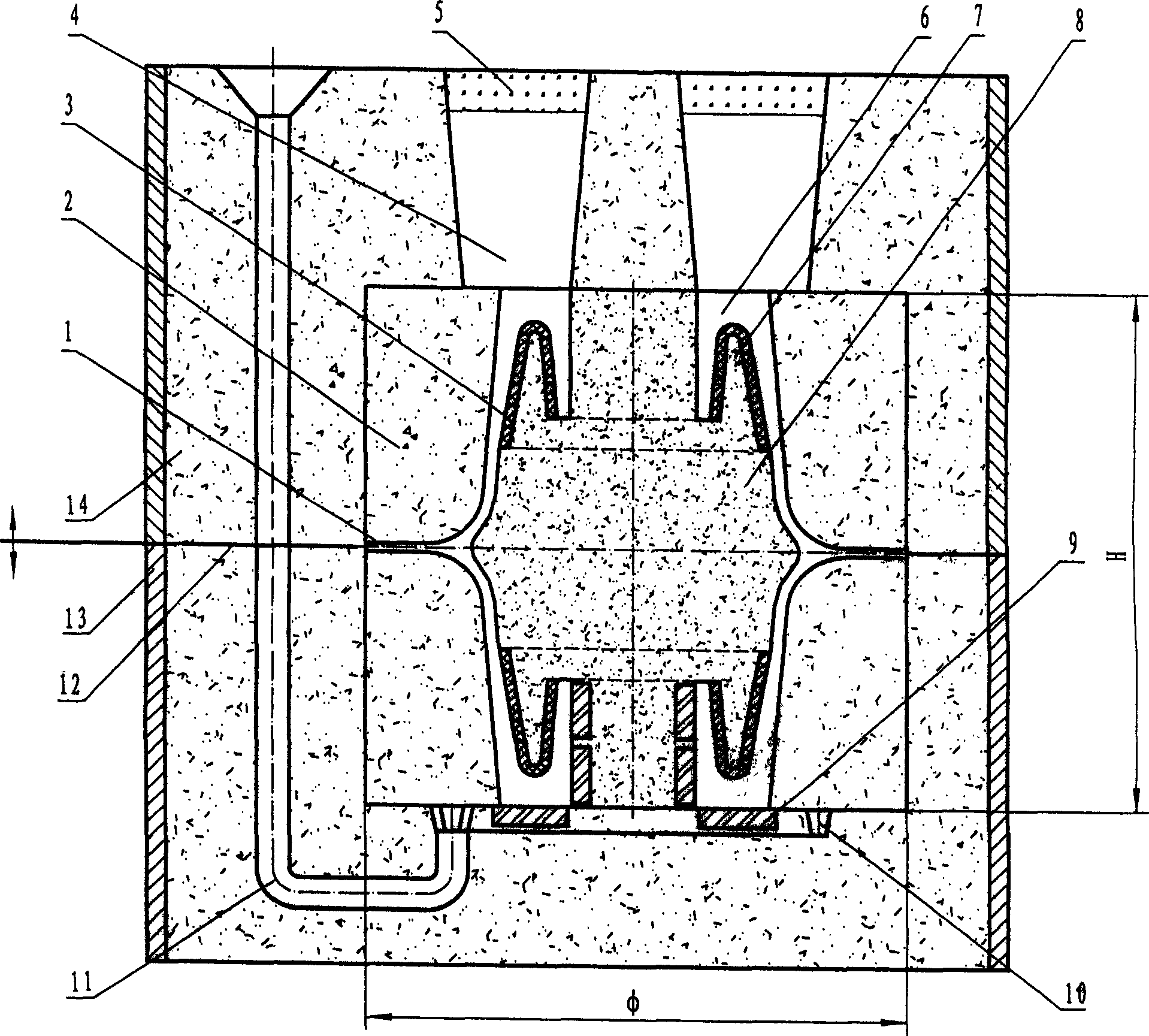

Vacuum pump impeller integral casting process

The present invention provides an integral casting process of vacuum pump blade wheel. It uses copper alloy to make the integral pattern prepared by using intermediate partition board, blade and wheel hub undergo the processes of numerically-controlled processing and moulding treatment. Its sand core is placed in lower mold, on the sand core of internal cavity place a ceramic core is set, upper blade wheel and upper wheel hub top portion are equipped with riser, undersurface of lower wheel hub and shaft hole place are equipped with external chill, the internal running channel set in lower blade bottom end is communicated with straight running channel in the mold. The molten metal can be fed into internal running channel via straight running channel, then passed through the lower blade bottom end and introduced into mold cavity to make bottom casting operation, when the molten metal is reached to riser top from bottom to top, an exothermic mixture is added into riser interior, after the casting is cooled, the molding box is opened, sand is removed and the casting is undergone the process of heat treatment.

Owner:遵义拓特铸锻有限公司

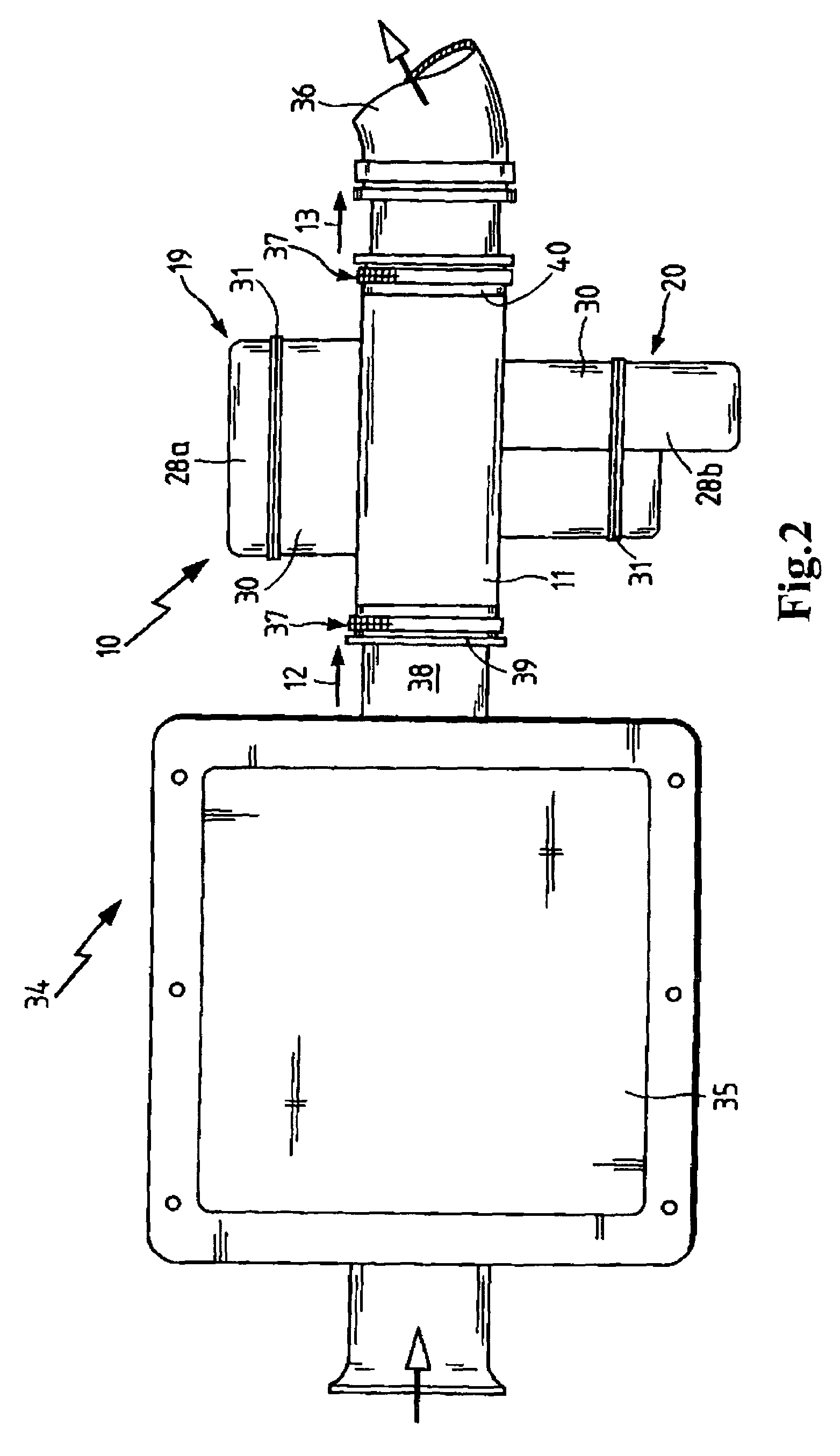

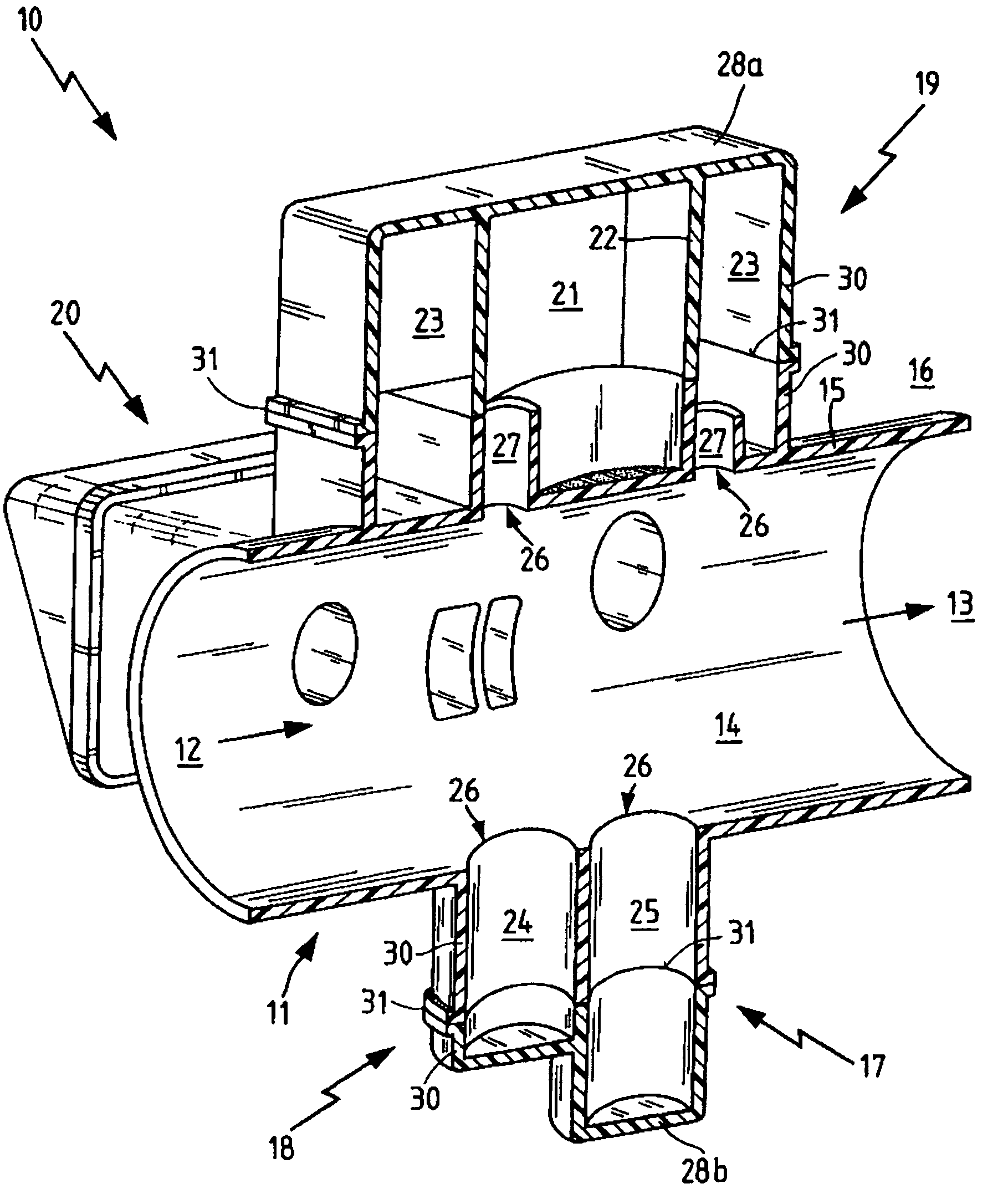

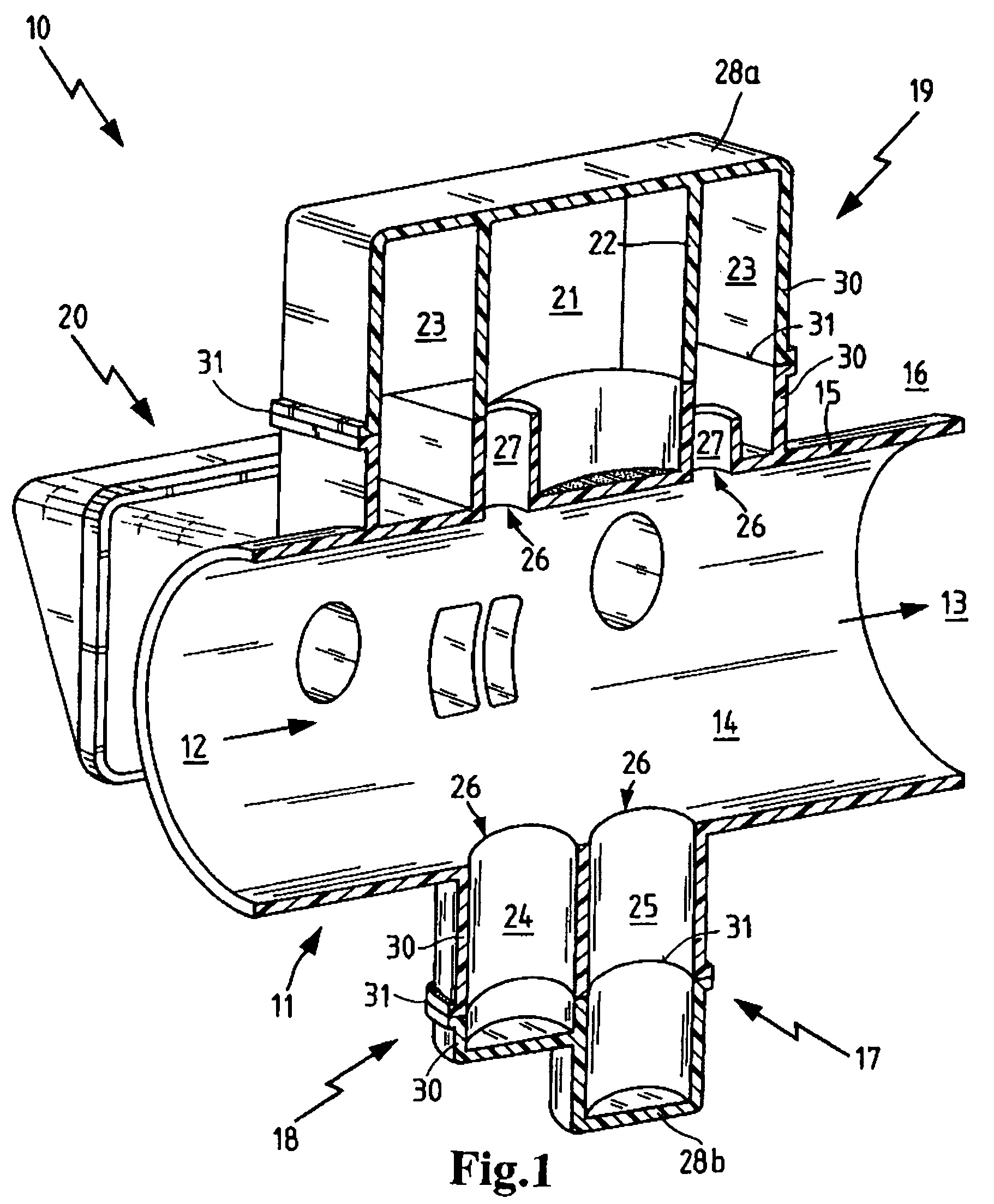

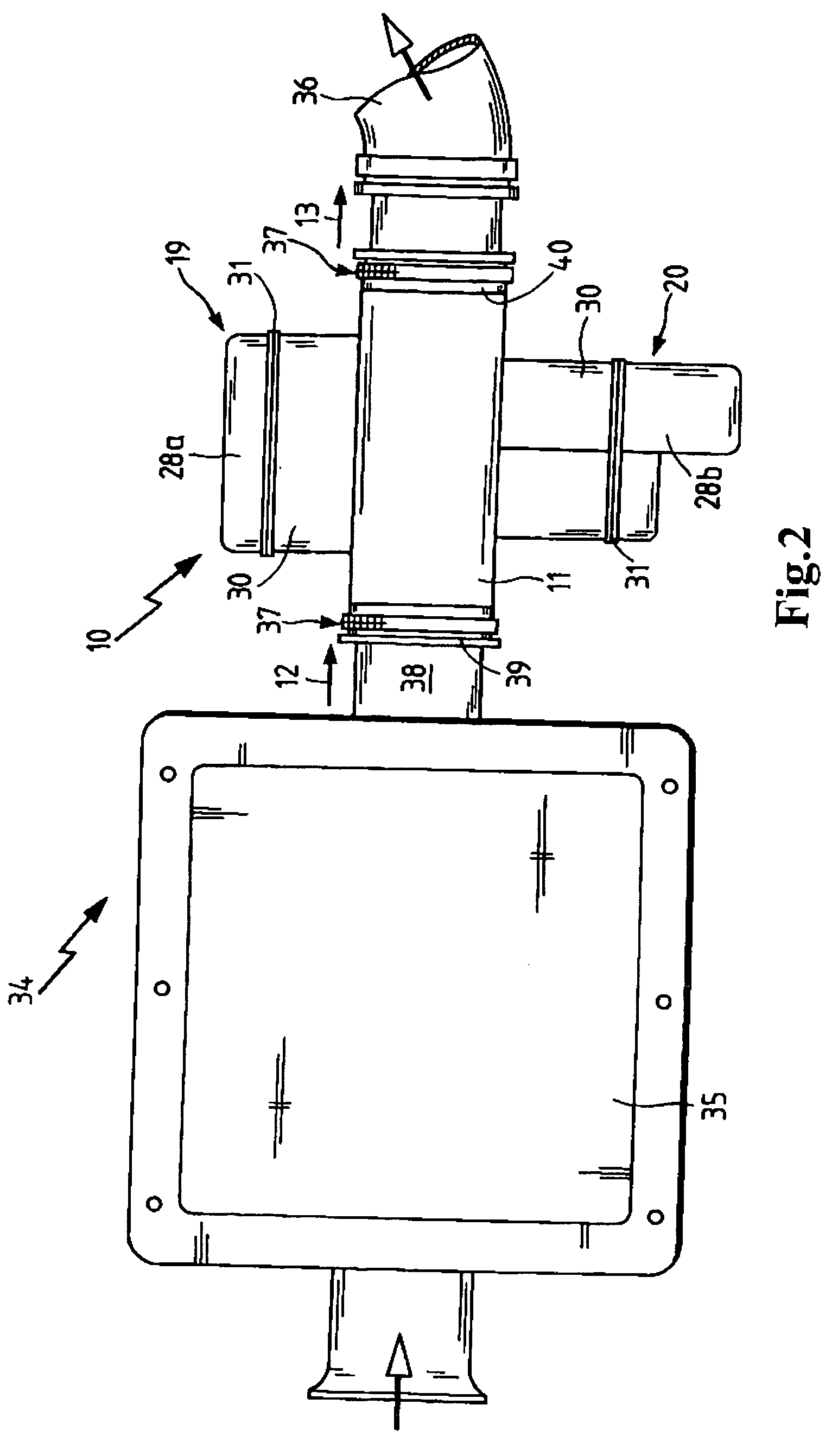

Intake noise suppressor

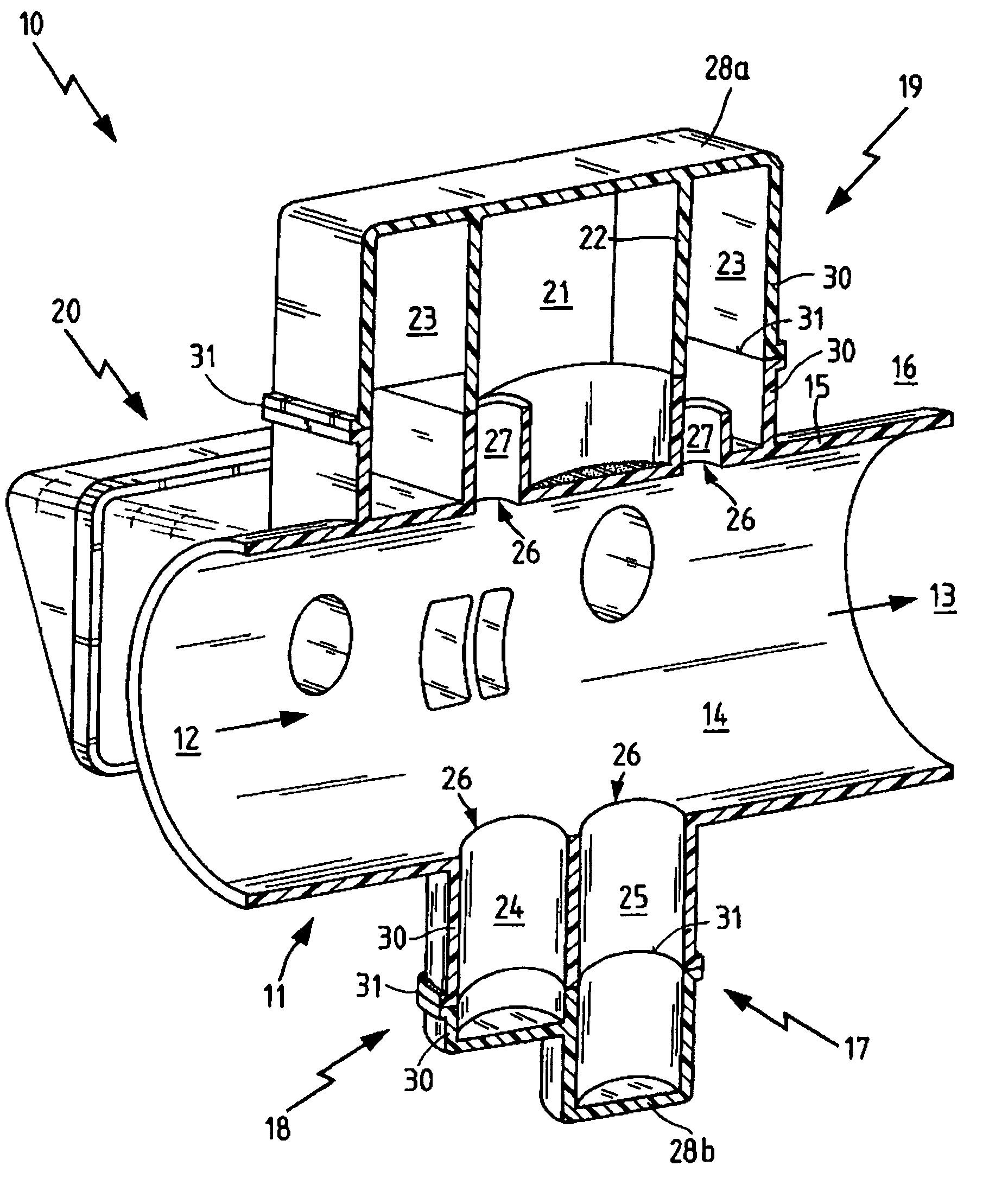

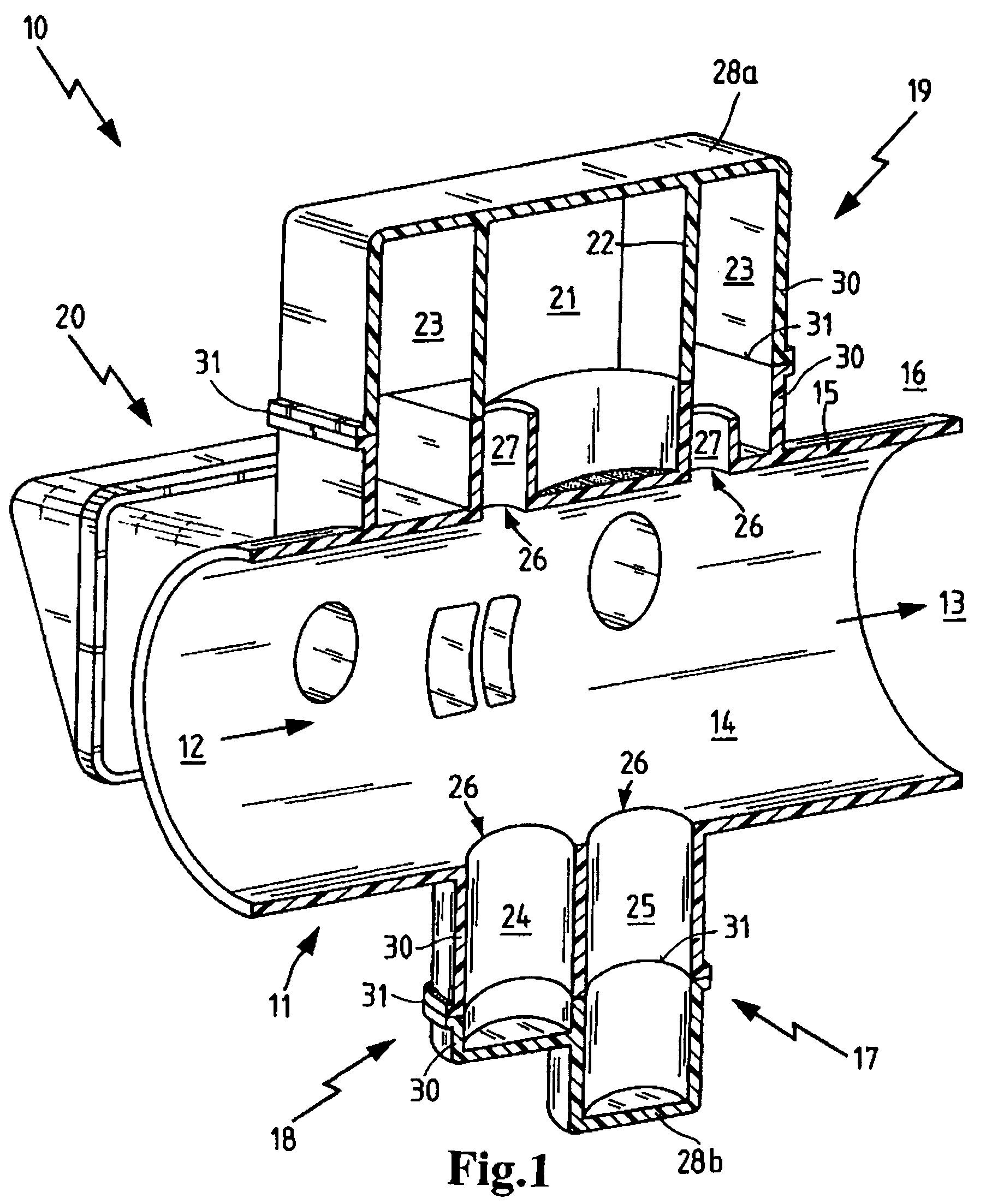

ActiveUS7198017B2Manufactured easily and reliably and economicallyGood static stabilityExhaust apparatusSilencing apparatusSuppressorEngineering

An intake manifold 10 in the air intake tract of an internal combustion engine which has a main flow cross section 14 between an oncoming flow side 12 and an outgoing flow side 13. At least one resonator chamber 23 is arranged on the circumference of the main flow cross section 14 in communication with the main flow cross section 14. The resonator chamber 23 is surrounded by side walls 30 and closed by a cover 28, with the side walls 30 of the resonator chamber 23 and the wall 15 forming the main flow cross section 14 being manufactured together in one piece. A parting plane 31 situated between the cover 28 and the side walls 30 of the resonator chamber 23 is arranged outside of the wall 15 forming the main flow cross section 14.

Owner:MANN HUMMEL GMBH

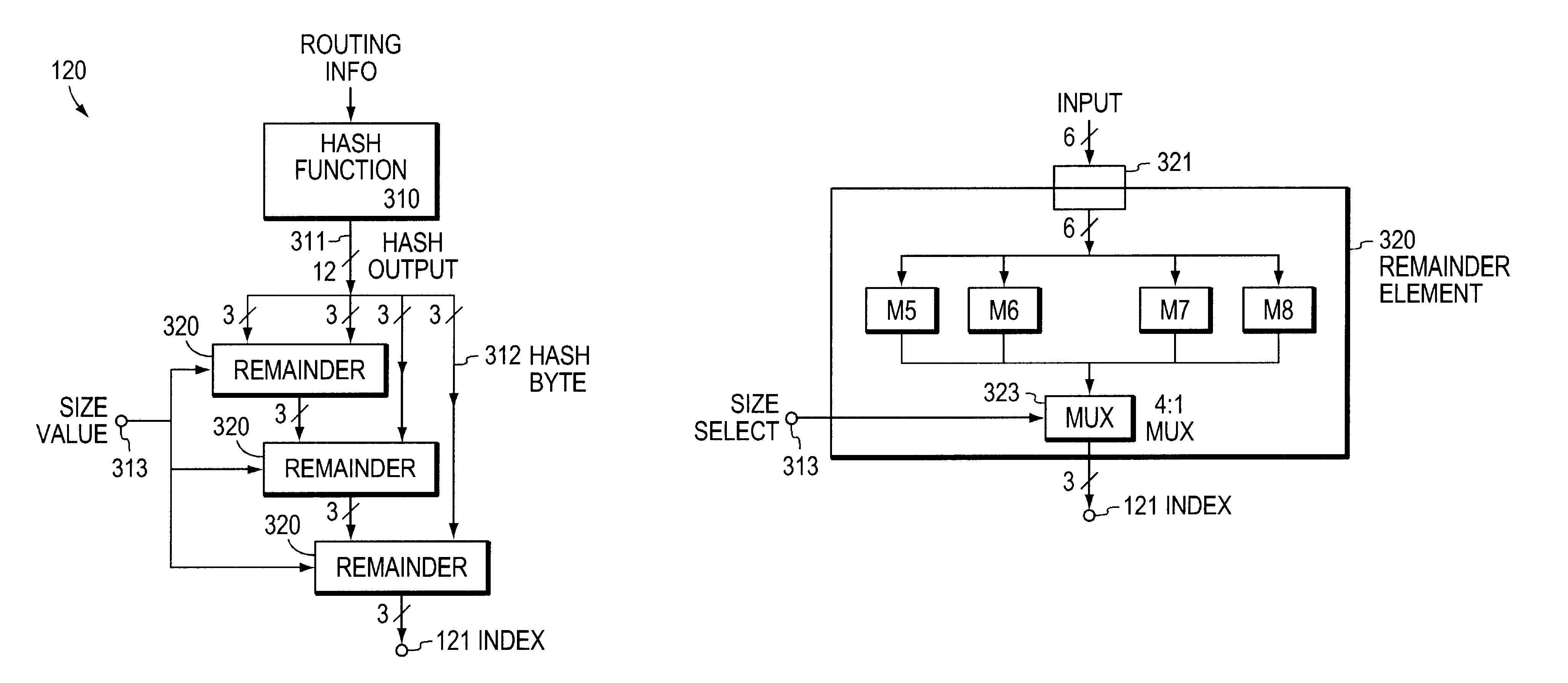

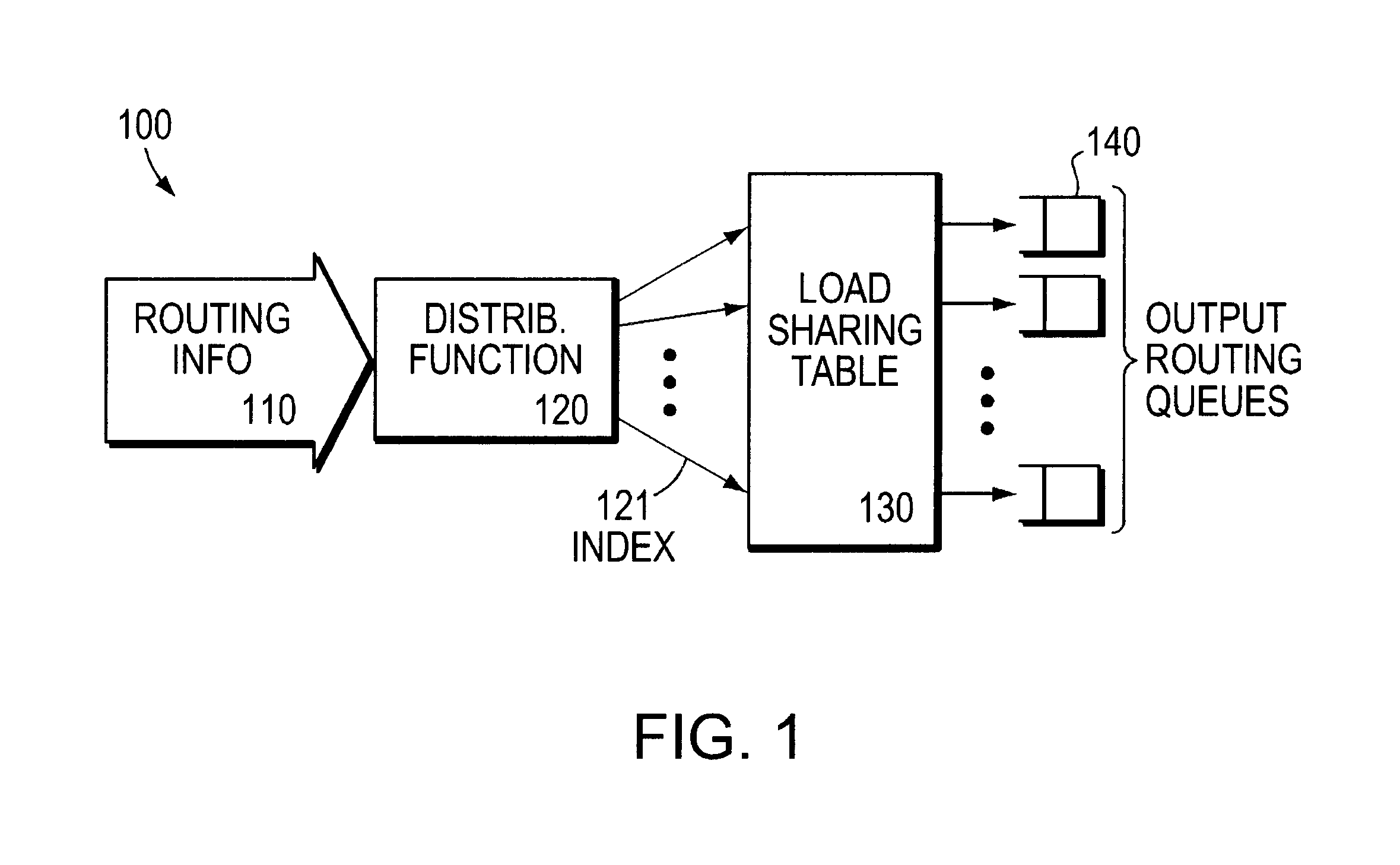

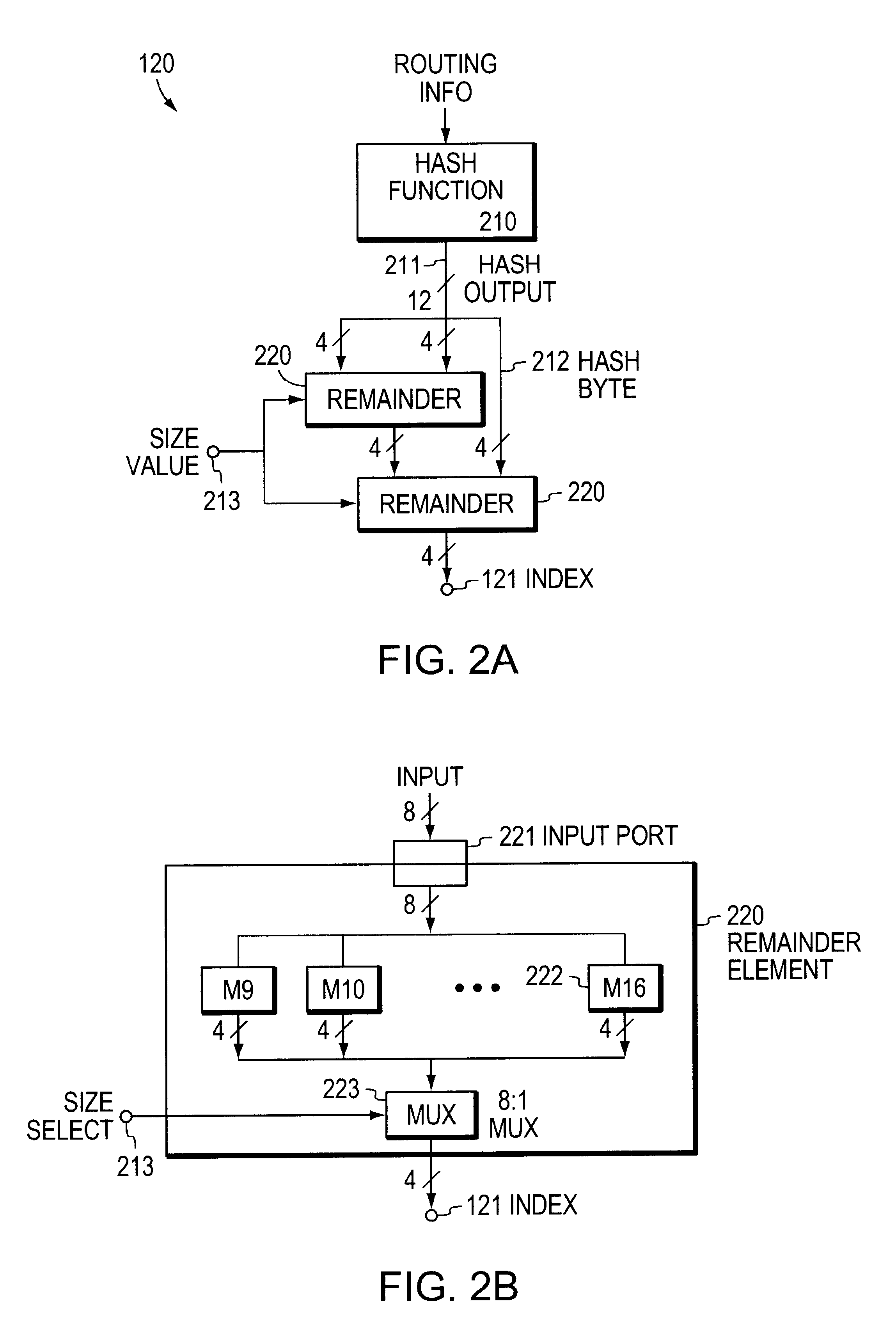

Load sharing across flows

InactiveUS6603765B1Equally distributedReduce the amount requiredData switching by path configurationSecuring communicationTraffic loadDistributed computing

The invention provides a system and method for sharing packet traffic load among a plurality of possible paths. Each packet is associated with a flow, and a hash value is determined for each flow, so as to distribute the sequence of packets into a set of hash buckets. The hash value has a relatively large number of bits, but is divided by the number of possible paths so as to achieve a relatively small modulus value; the modulus value is used to index into a relatively small table associating one selected path with each entry. The modulus value is determined by a relatively small amount of circuitry, simultaneously for a plurality of moduli, and one such modulus value is selected in response to the number of possible paths.

Owner:CISCO TECH INC

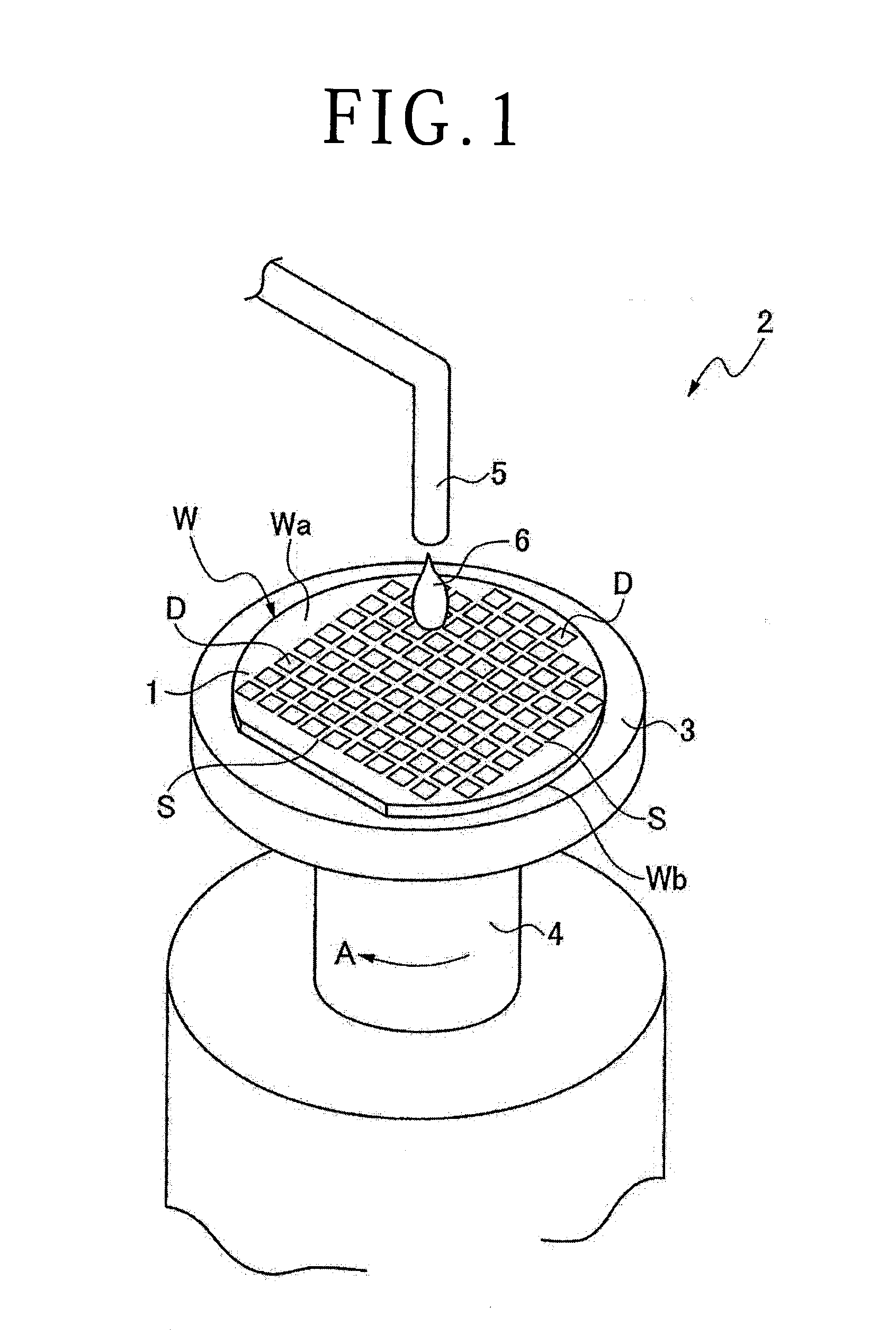

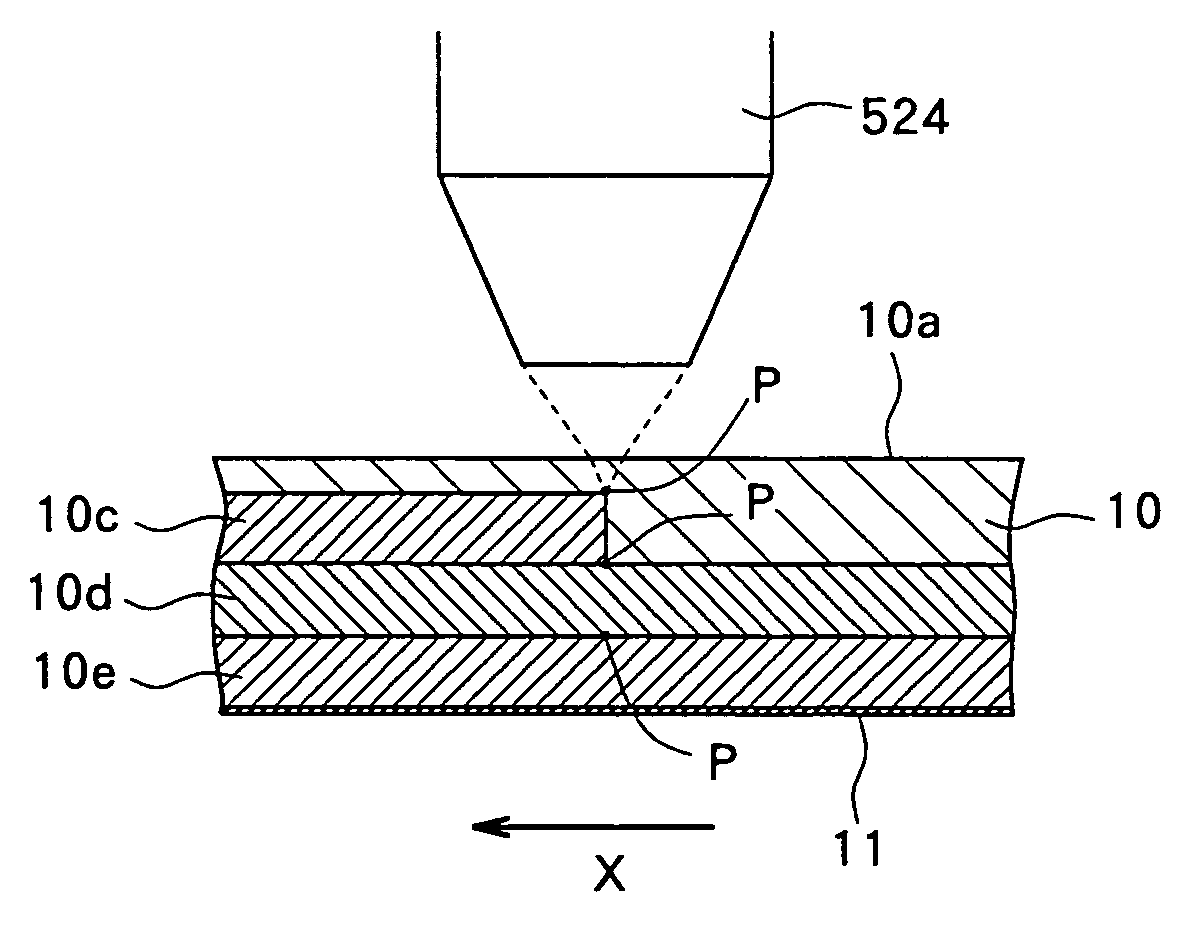

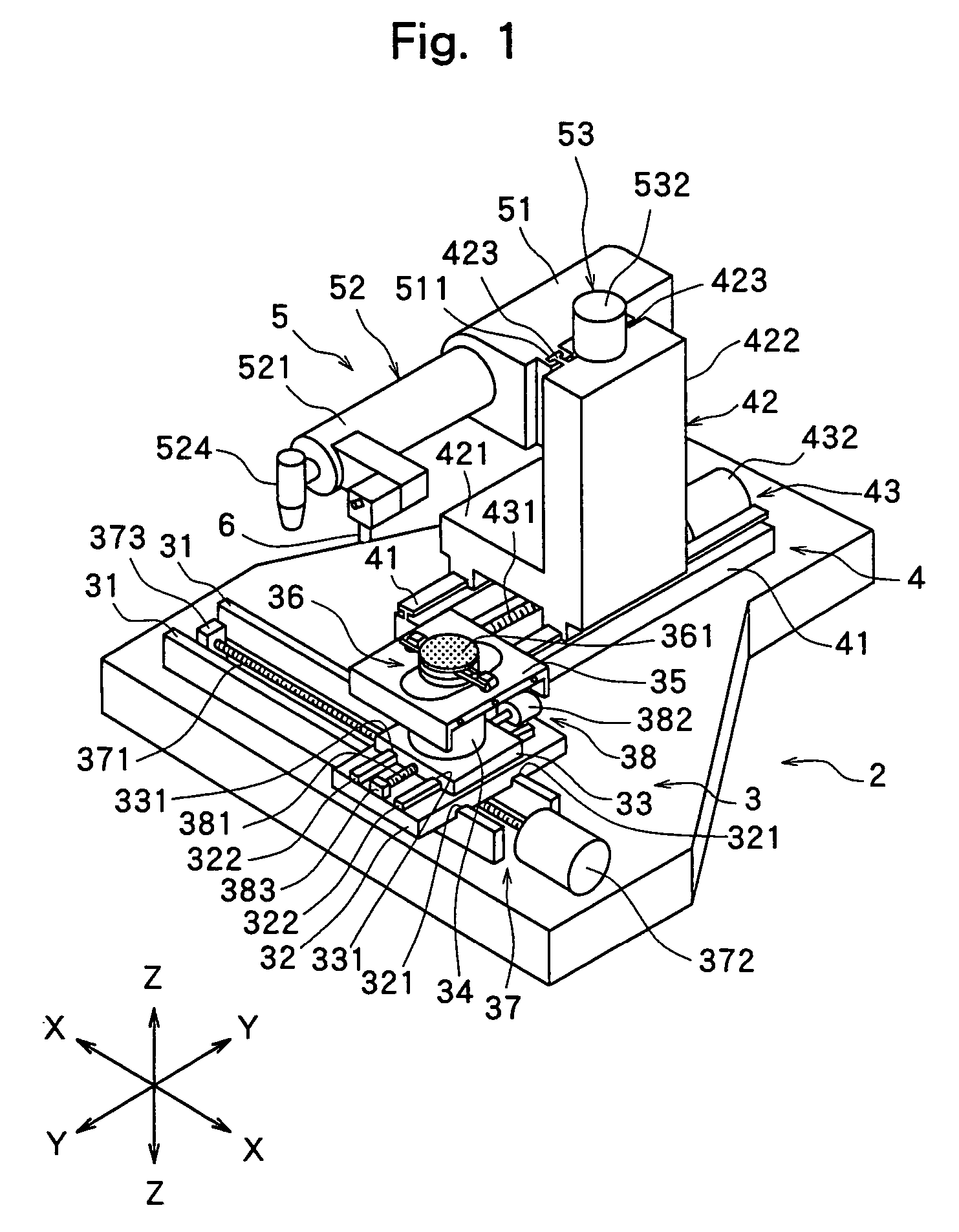

Method of dividing wafer

InactiveUS20160307851A1Effective divisionEasy to disassembleSemiconductor/solid-state device detailsSolid-state devicesEngineeringWater soluble

A method of dividing a wafer includes a protective film forming step of forming a water-soluble protective film on a front side of the wafer, a mask forming step of forming an etching mask on the front side of the wafer by partly removing the water-soluble protective film along the streets, a plasma etching step of performing a plasma etching on the wafer along the streets through the etching mask in the form of the water-soluble protective film, and a protective film removing step of removing the water-soluble protective film by supplying cleaning water to the water-soluble protective film. After plasma etching, i.e. in removing the protective film, the water-soluble protective film can easily be removed from the front side of the wafer simply by supplying the cleaning water from a water supply unit to the water-soluble protective film.

Owner:DISCO CORP

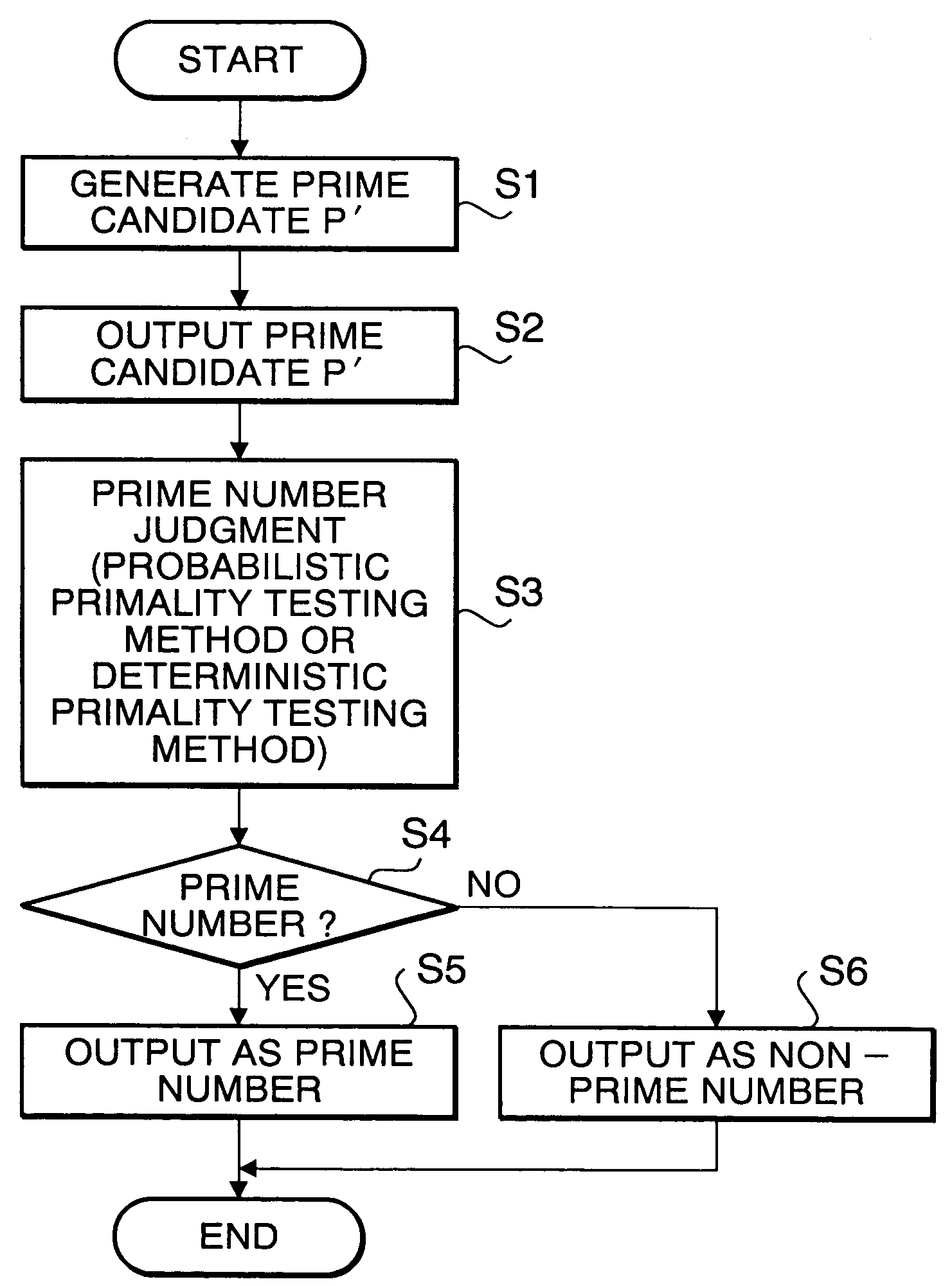

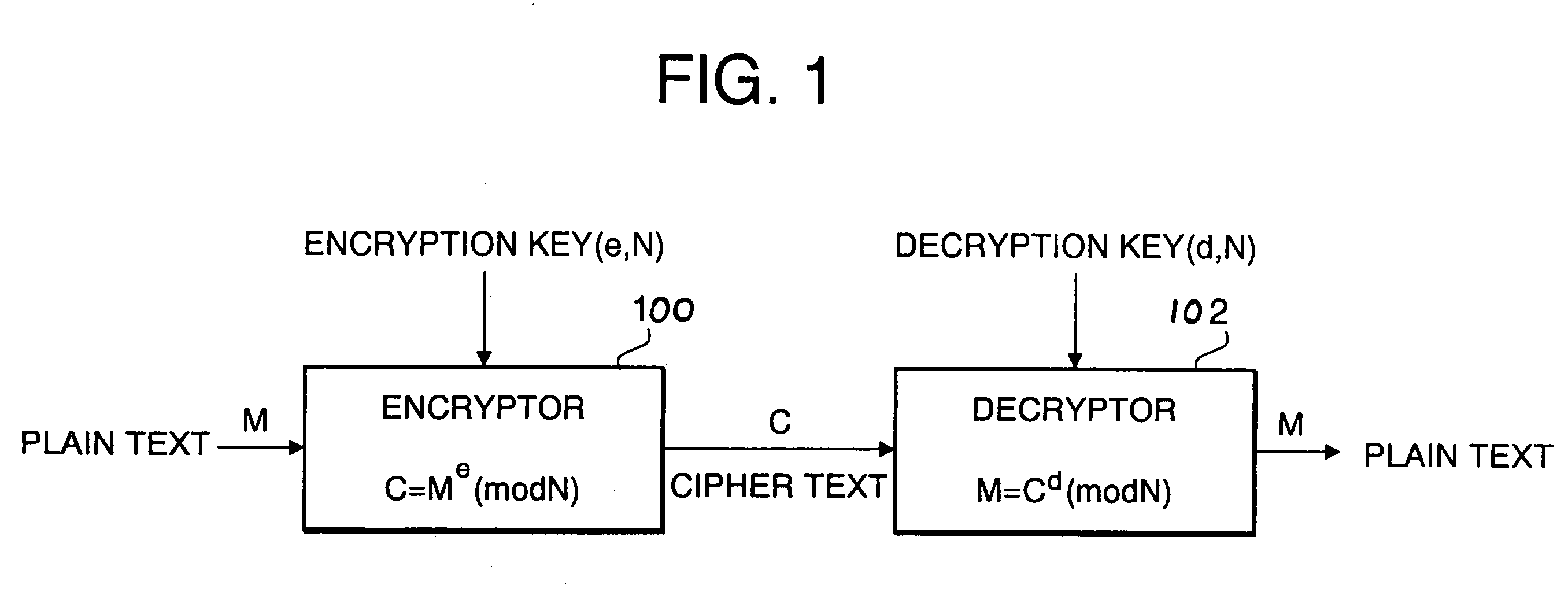

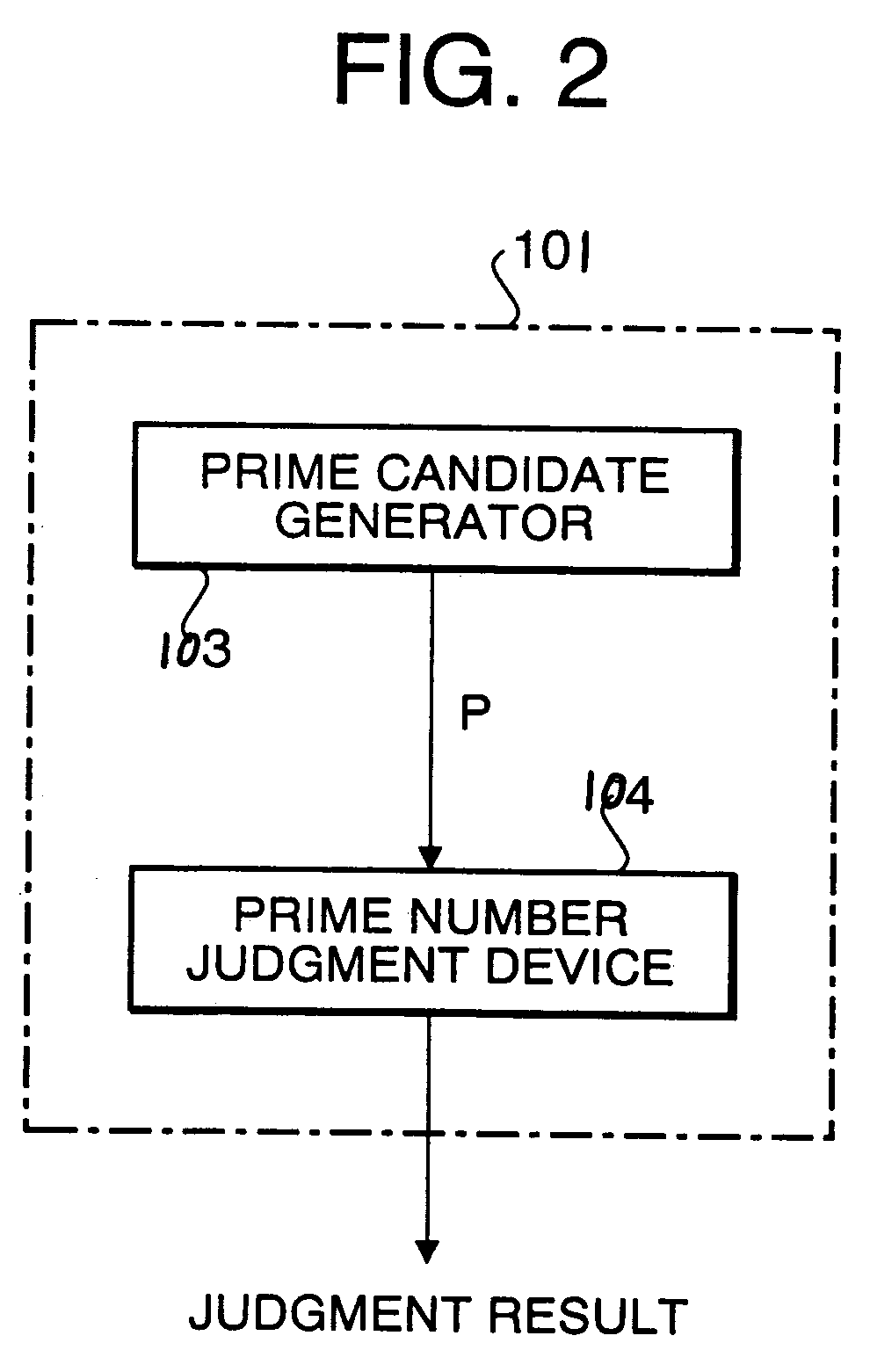

Prime number generation method, prime number generation apparatus, and cryptographic system

InactiveUS7043018B1Generate efficientlyTime that would be wasted in useless prime number judgment is savedKey distribution for secure communicationRandom number generatorsCryptosystemRandom number generation

A prime number generation method for efficiently generating prime numbers that are highly resistant to the P−1 and P+1 methods. These prime numbers are used in a cryptosystem. Prime candidates are first generated, and the generated prime candidates are subjected to prime number judgment by either a probabilistic primality testing method or a deterministic primality testing method. A prime candidate P′ is generated using odd random numbers, a judgment is made as to whether or not that prime candidate P′ satisfies the expression P′≡0, ±1 (mod pi) (where 3≦i≦n) for prime numbers from p3 to pn (where pn is the n'th prime). When that expression is satisfied, that prime candidate P′ is excluded. Only those prime candidates P′ that do not satisfy that condition are subjected to the prime number judgment.

Owner:MURATA MASCH LTD +1

Intake noise suppressor

ActiveUS20060027204A1Reduce complexitySimple designExhaust apparatusSilencing apparatusSuppressorEngineering

An intake manifold 10 in the air intake tract of an internal combustion engine which has a main flow cross section 14 between an oncoming flow side 12 and an outgoing flow side 13. At least one resonator chamber 23 is arranged on the circumference of the main flow cross section 14 in communication with the main flow cross section 14. The resonator chamber 23 is surrounded by side walls 30 and closed by a cover 28, with the side walls 30 of the resonator chamber 23 and the wall 15 forming the main flow cross section 14 being manufactured together in one piece. A parting plane 31 situated between the cover 28 and the side walls 30 of the resonator chamber 23 is arranged outside of the wall 15 forming the main flow cross section 14.

Owner:MANN HUMMEL GMBH

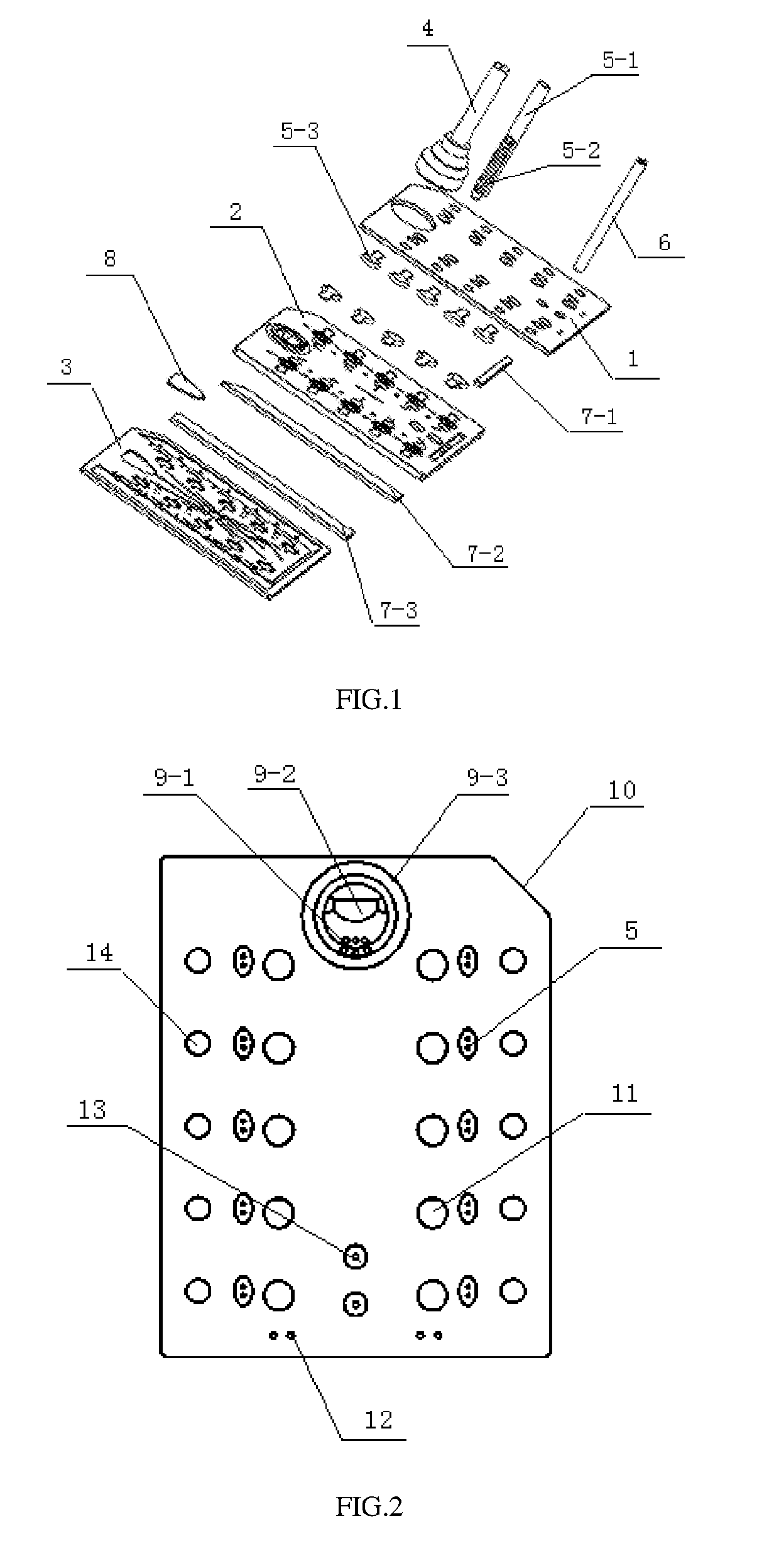

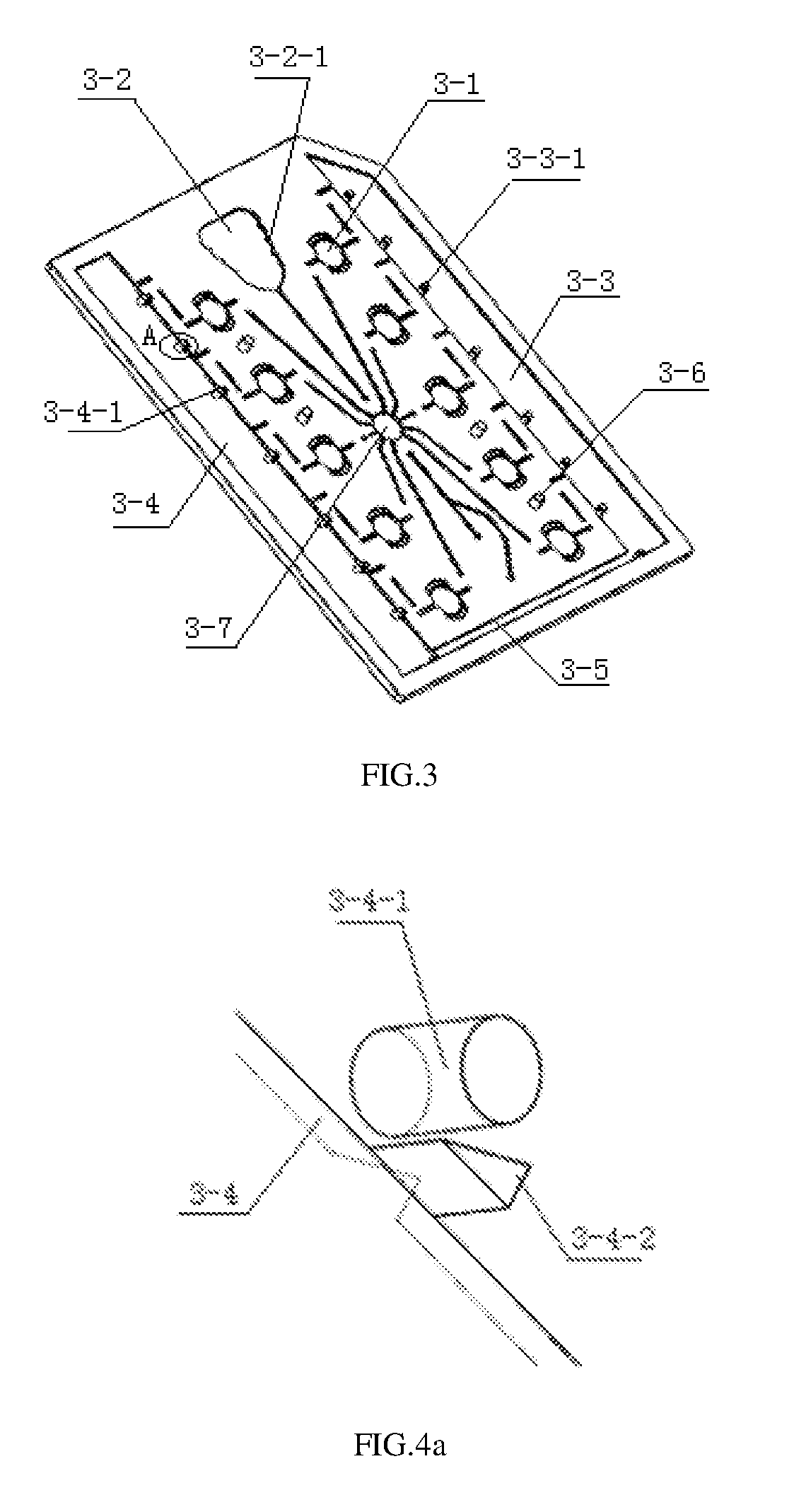

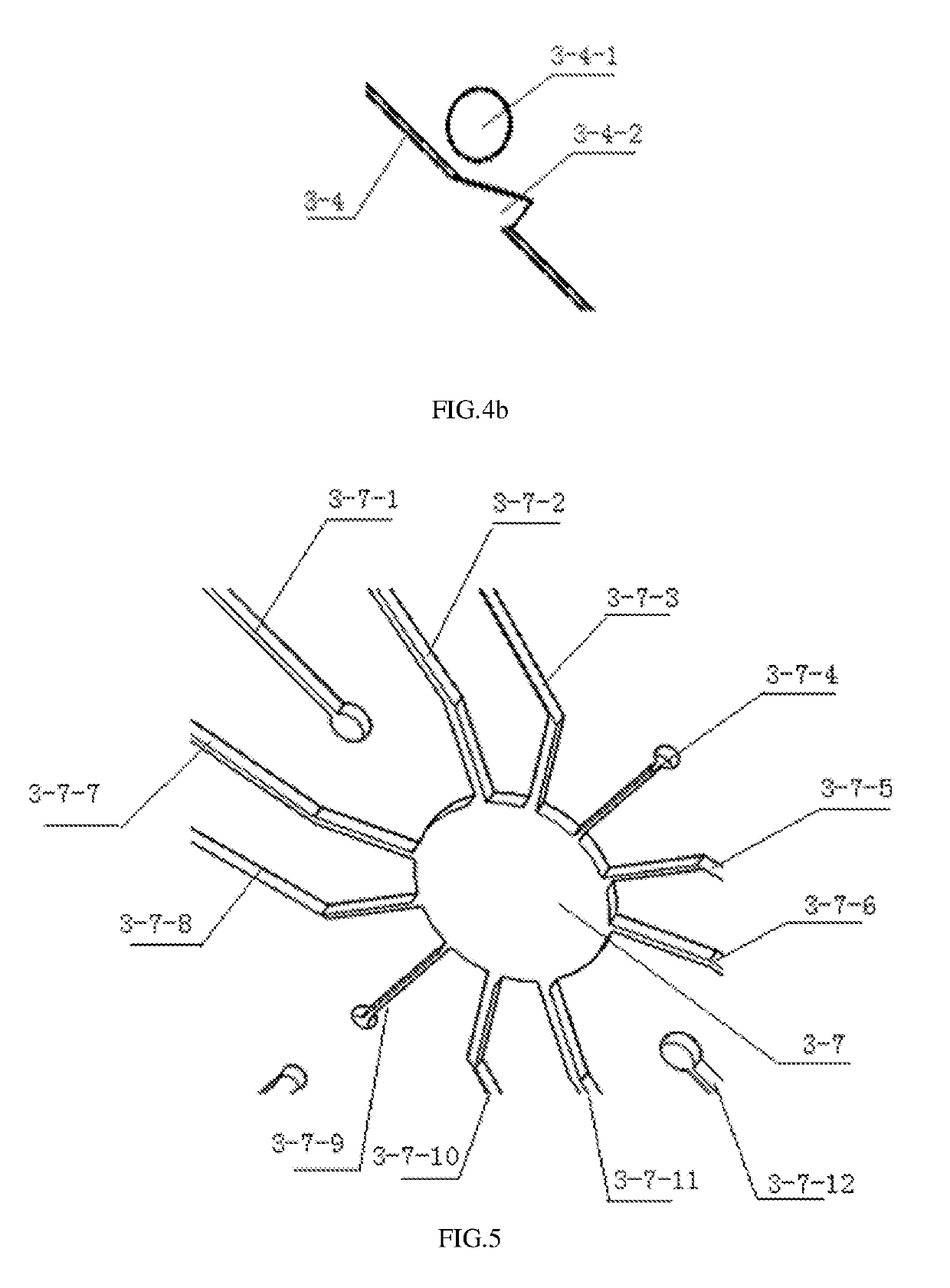

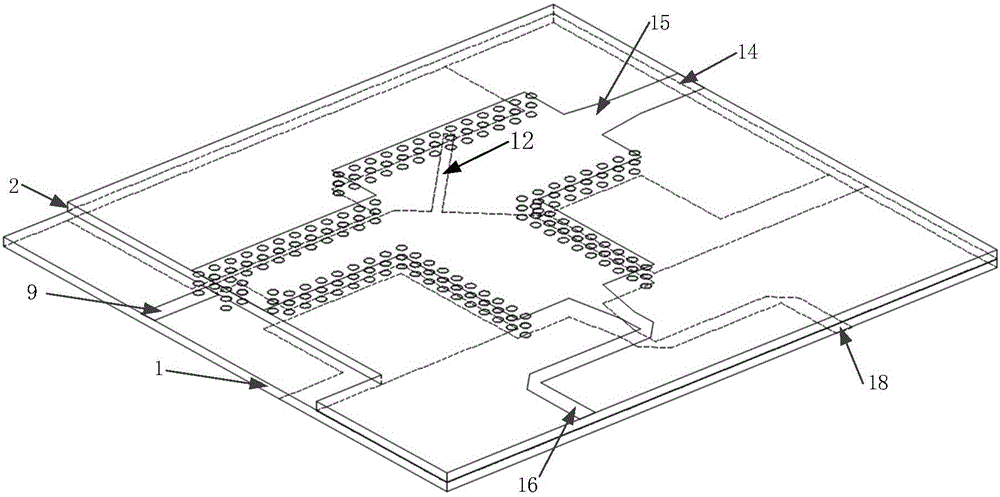

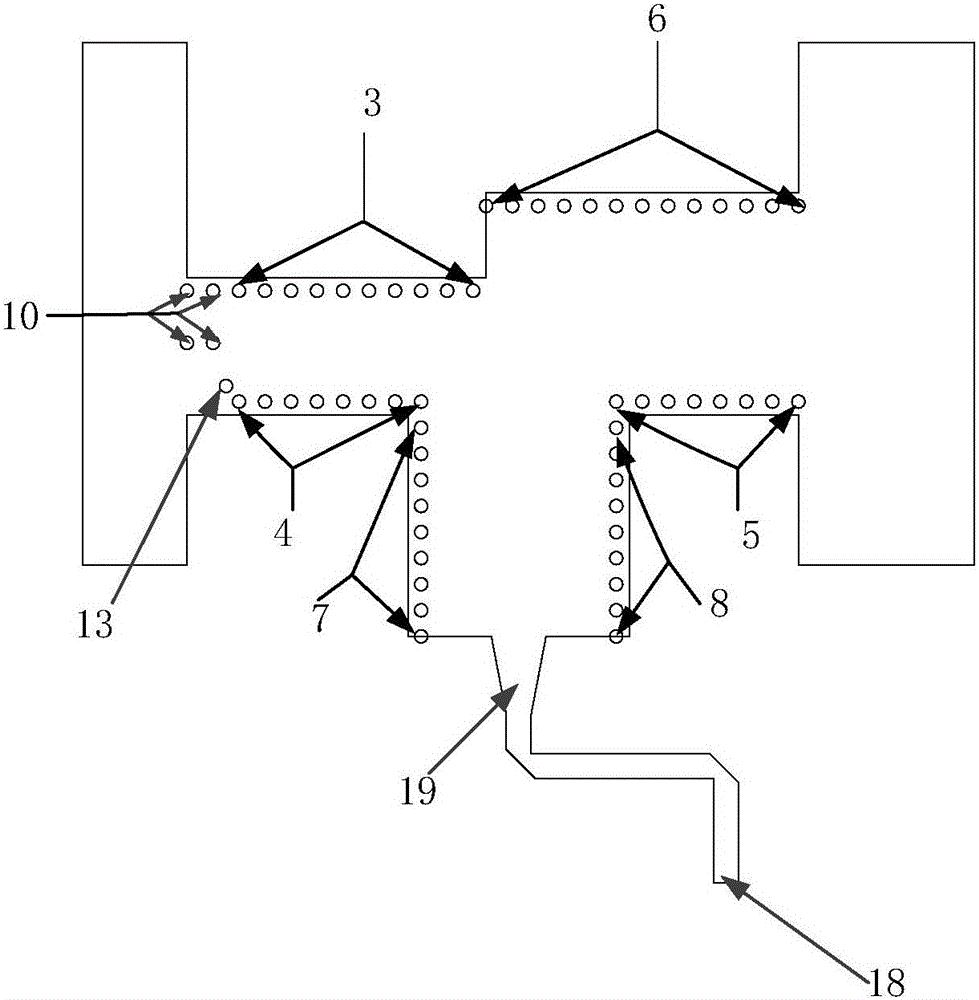

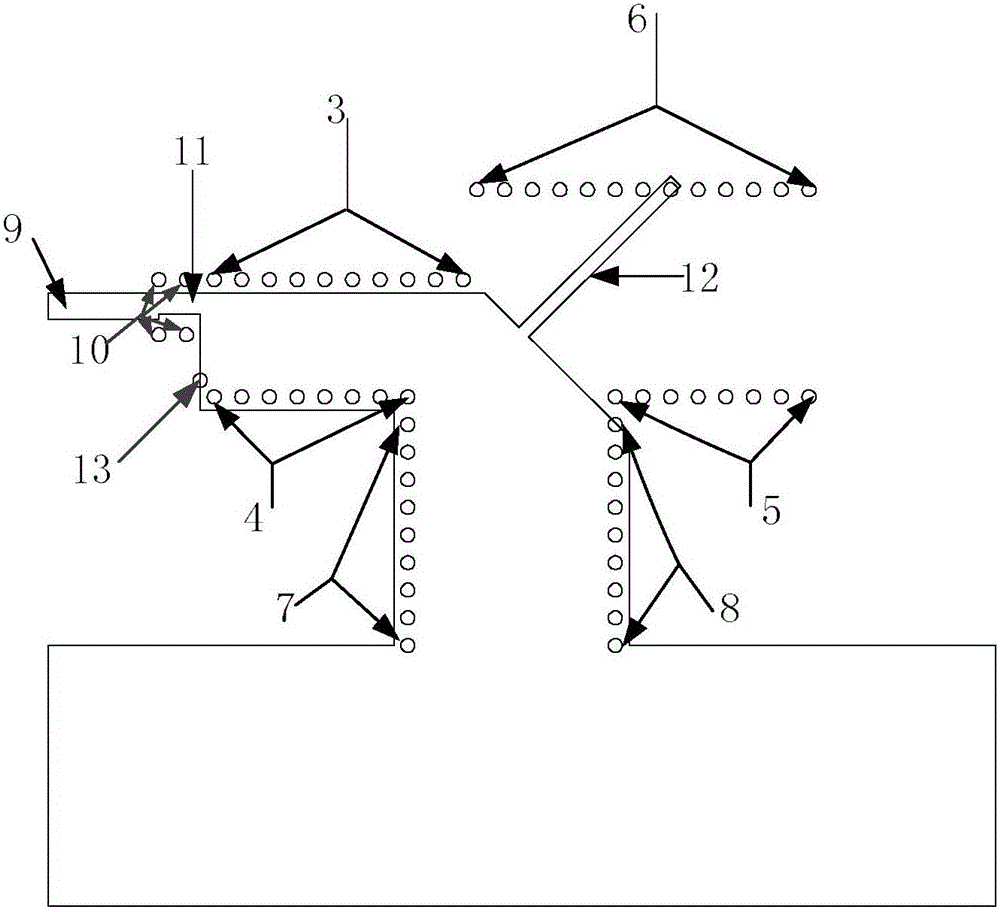

Multi-flux micro-fluidic chip based on active fluid flow control

ActiveUS20190137488A1Improve fluxImprove throughputValve arrangementsLaboratory glasswaresMicrofluidic chipMicro fluidic

Provided is a multi-flux micro-fluidic chip including a chip body. The chip body includes a fluid inflow cavity communicated with an external air path, reaction-quantification cavities, waste liquid cavities, and a fluid path distribution cavity disposed at a middle position of the chip body. The two or more reaction-quantification cavities are distributed on two sides of the fluid path distribution cavity in rows to form the first and second row of reaction-quantification cavities respectively; and they are communicated with a fluid outlet of the fluid path distribution cavity through fluid path branches, and a fluid inlet of the fluid path distribution cavity through fluid path branches, and a fluid inlet of the fluid path distribution cavity is communicated with a fluid outlet of the fluid inflow cavity and an external fluid path, which making it possible to detect multiple items simultaneously and greatly improving the flux of the micro-fluidic chip.

Owner:NANJING LANSION BIOTECH CO LTD

Commodity splitter for an air delivery system

ActiveUS8469636B2Easy to installMore appearancePotato plantersBulk conveyorsEdge spaceMechanical engineering

Owner:DEERE & CO

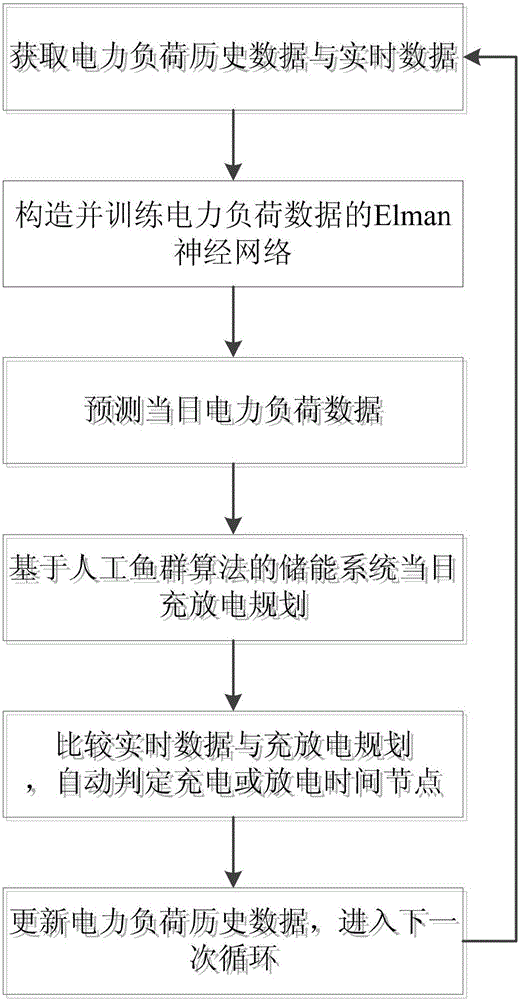

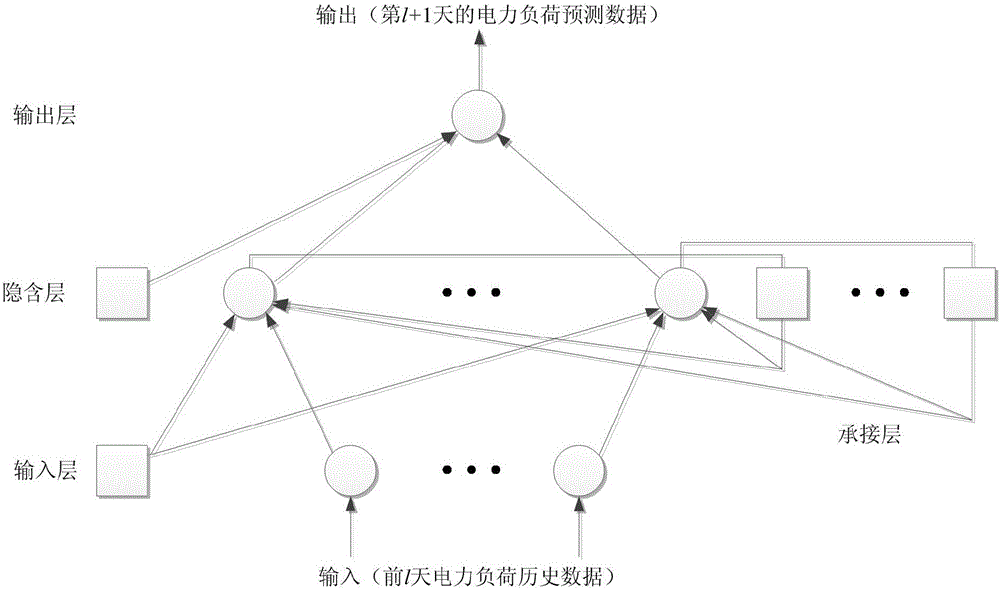

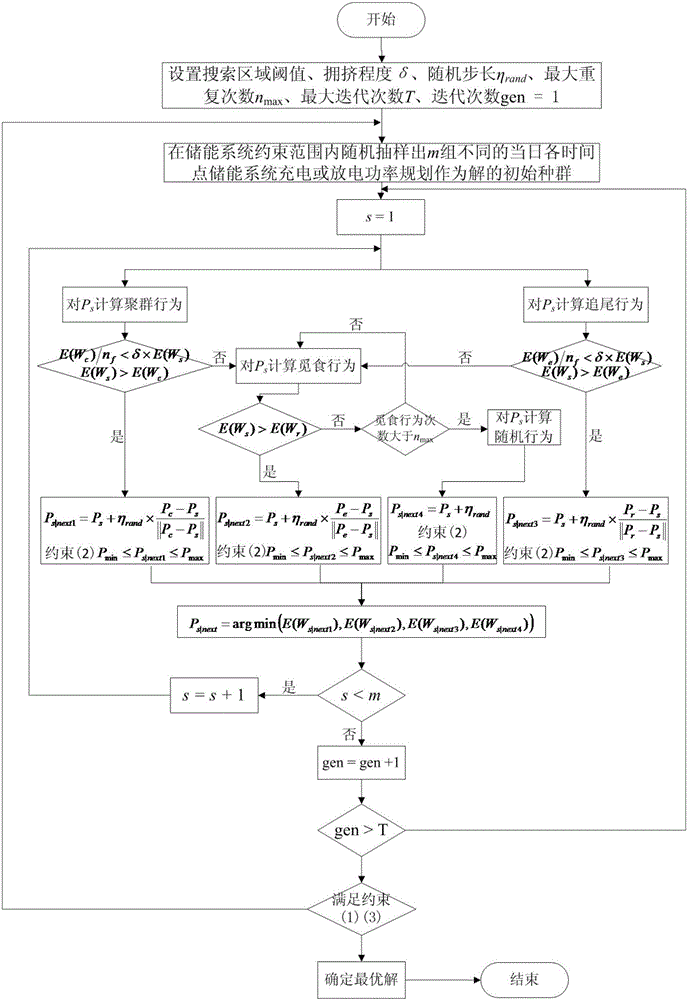

Intelligent energy storage system grid-connected real-time control method based on artificial fish swarm algorithm

ActiveCN105162151AImprove utilization efficiencyAutomatic charging and dischargingAc network load balancingNeural learning methodsReal-time dataCharge discharge

An intelligent energy storage system grid-connected real-time control method based on an artificial fish swarm algorithm adopts an Elman neural network to predict intraday power load real time data on the base of power load historical data, then utilizes the artificial fish swarm algorithm to plan the optimal charge-discharge time and the optimal power of intraday power load prediction data, and performs comparison with the electric power real time data through an intelligent electric meter, so as to determine the optimal charge-discharge time node. The invention achieves automatic grid-connected discharge in the peak of power utilization and achieves charge in the low ebb of power utilization, achieves peak load shifting on the user side, and improves the utilization efficiency of electric power resources.

Owner:STATE GRID CORP OF CHINA +2

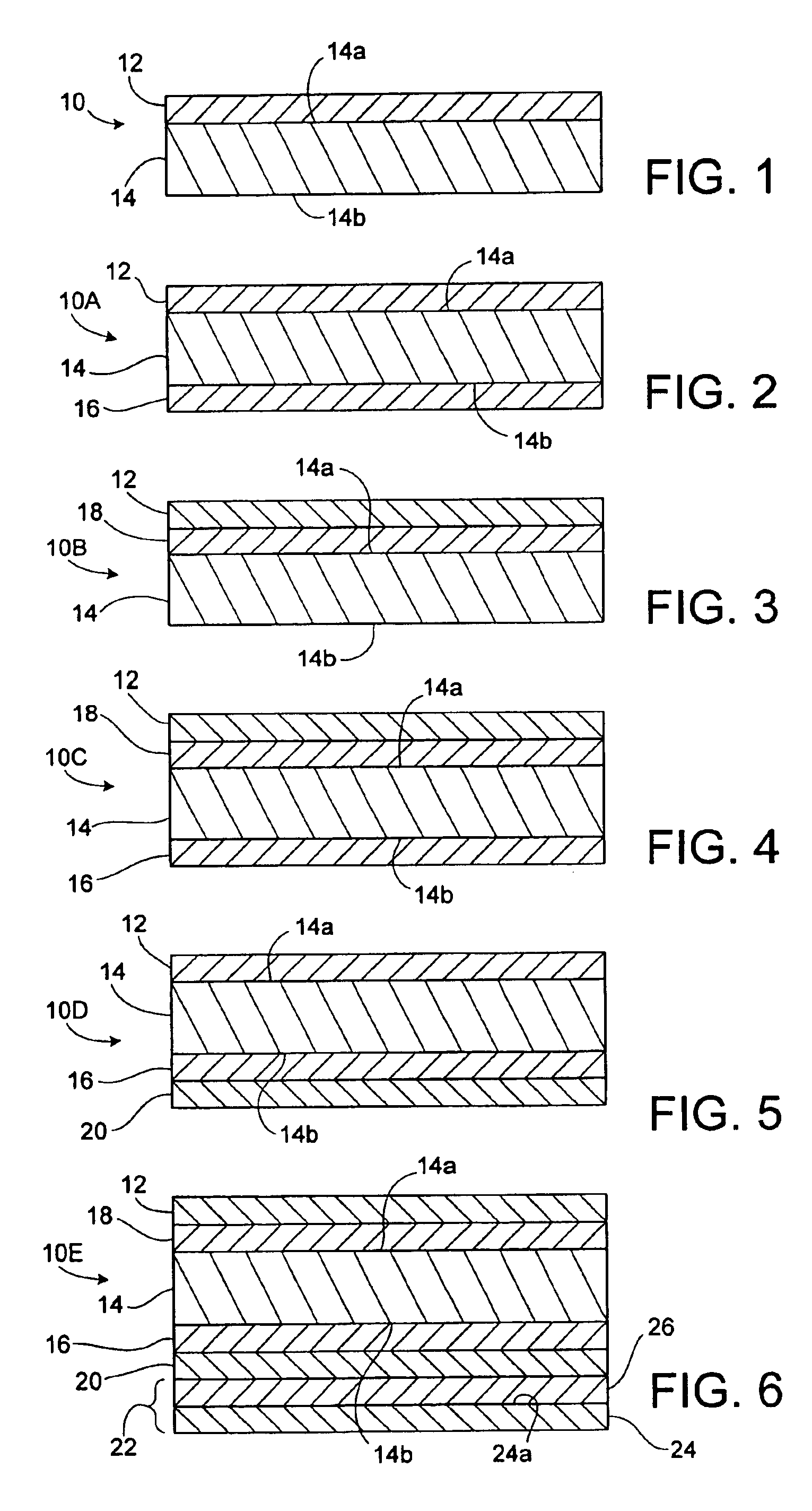

Water-absorbent film construction

InactiveUS6846531B2Practical to useHigh strengthSynthetic resin layered productsCellulosic plastic layered productsOptoelectronicsPolymer

Owner:AVERY DENNISON CORP

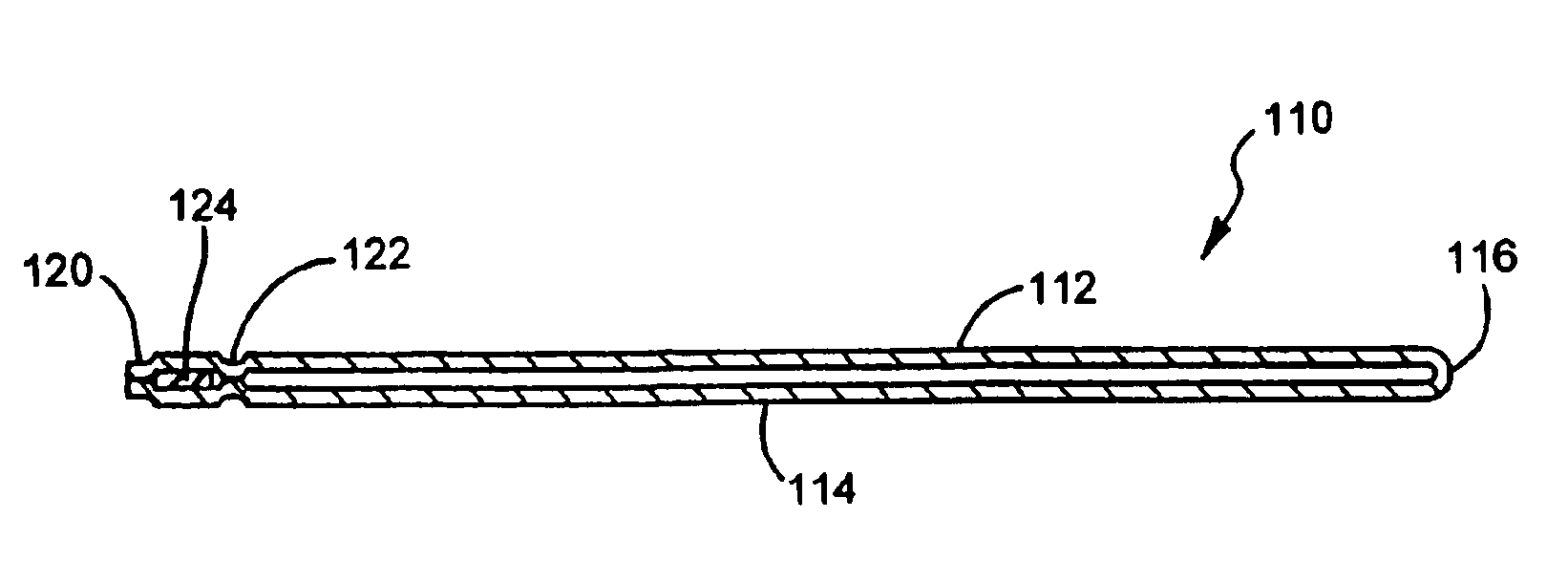

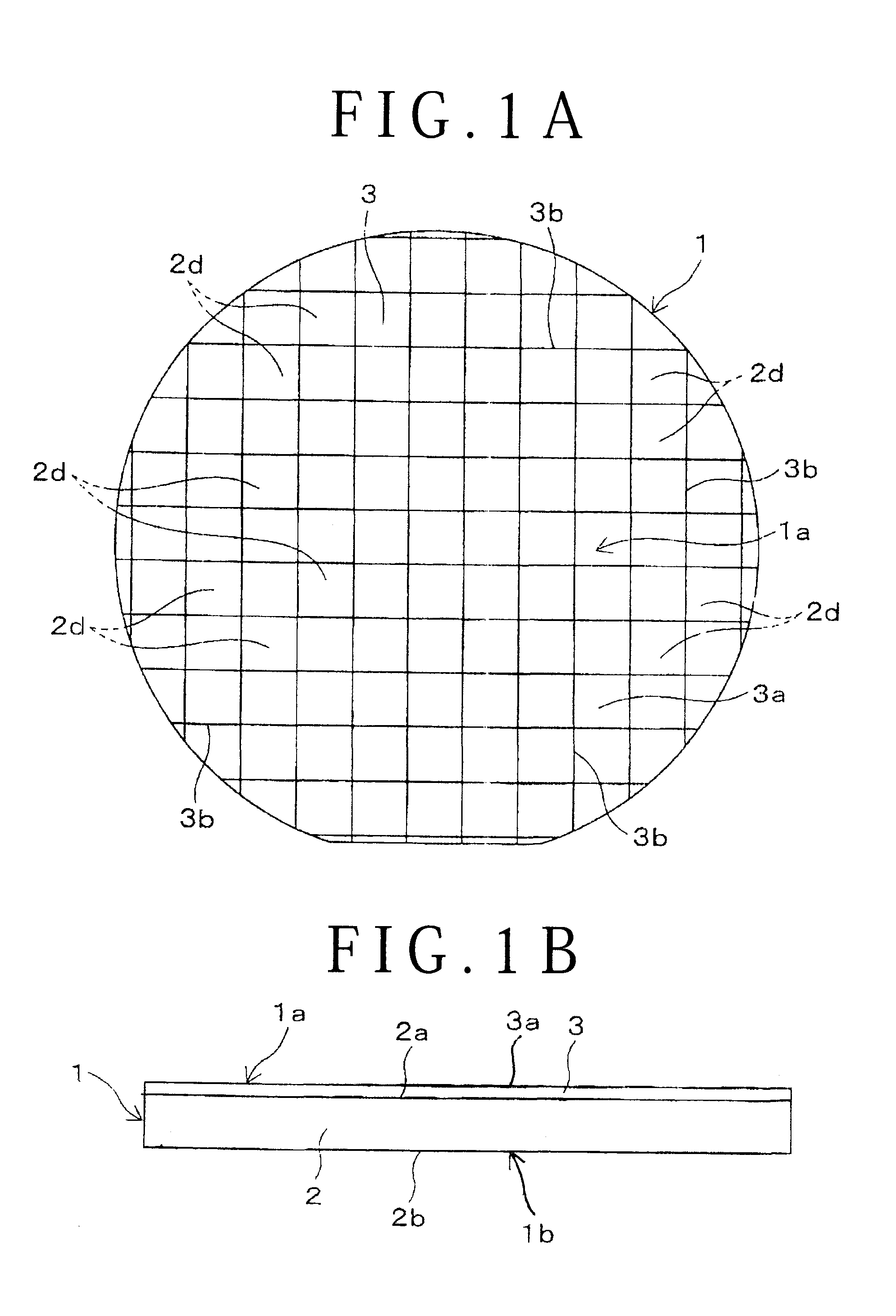

Semiconductor element and method of making same

InactiveUS20100270548A1High product yieldReduce stressSemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringGallium oxide

A semiconductor element includes a substrate including gallium oxide and having a predetermined plane direction, and a semiconductor layer formed on the substrate, in which, the semiconductor element is in chip form and further includes a first end face formed along a cleaved surface of the substrate and a second end face formed perpendicular to the first end face, wherein the first end face has a stronger cleavage property than the second end face.

Owner:KOHA CO LTD

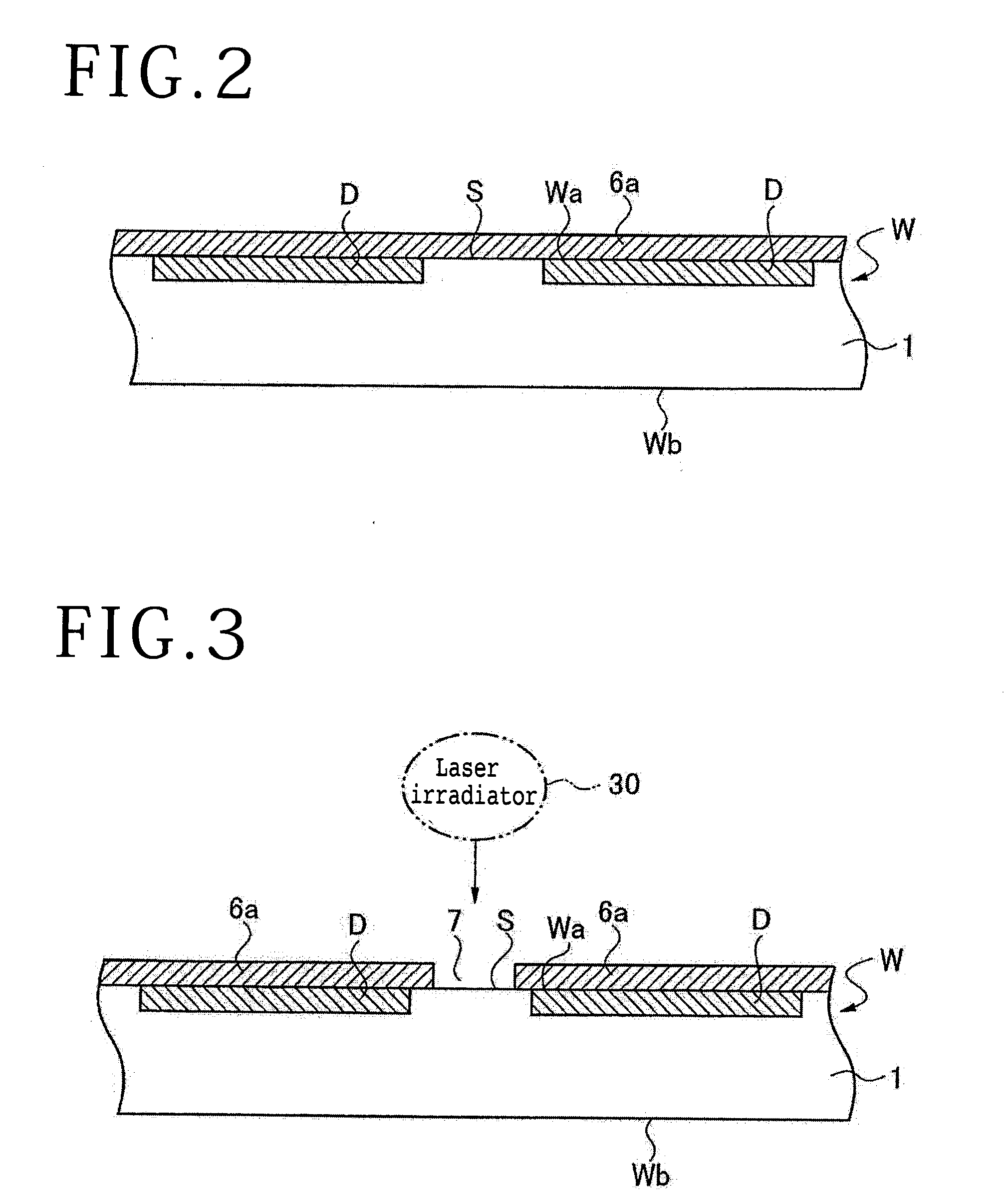

Method of dividing a non-metal substrate

ActiveUS7179721B2Evenly dividedSemiconductor/solid-state device manufacturingWelding/soldering/cutting articlesOptoelectronicsLaser beams

A method of dividing a non-metal substrate having a first surface and a second surface formed parallel to the first surface, comprising:a deteriorated layer forming step for forming a deteriorated layer in the inside of the non-metal substrate along dividing lines by applying a laser beam capable of passing through the non-metal substrate from the first surface side with its converging point on the inside thereof; anda deteriorated layer exposing step for exposing the deteriorated layer to the first surface by grinding the first surface side of the non-metal substrate having the deteriorated layer formed therein.

Owner:DISCO CORP

Novel planar Magic-T based on folded substrate integrated waveguide

The invention discloses a novel planar Magic-T based on a folded substrate integrated waveguide. The folded substrate integrated waveguide is used to realize an H-surface power divider, a T-shaped junction of a conventional trough line excitation substrate integrated waveguide, and the planar Magic-T is realized. The leakage loss is less, the power capacity is higher, and the bandwidth is larger. By means of the open-circuit and short-circuit characteristics of the folded substrate integrated waveguide and the conventional substrate integrated waveguide, a relatively high isolation degree between two input ports is realized, and the unbalance degrees of amplitudes and phases between two output ports are very small, so that the performance of the Magic-T is improved, the design process is simplified, and the Magic-T is easy to apply to a higher frequency band. The overlapping of T-shaped junction of an H-surface and an E surface enables a high integration level of the structure, and the requirements of planarization, miniaturization and high performance in modern radio communication are met.

Owner:NANJING UNIV OF POSTS & TELECOMM

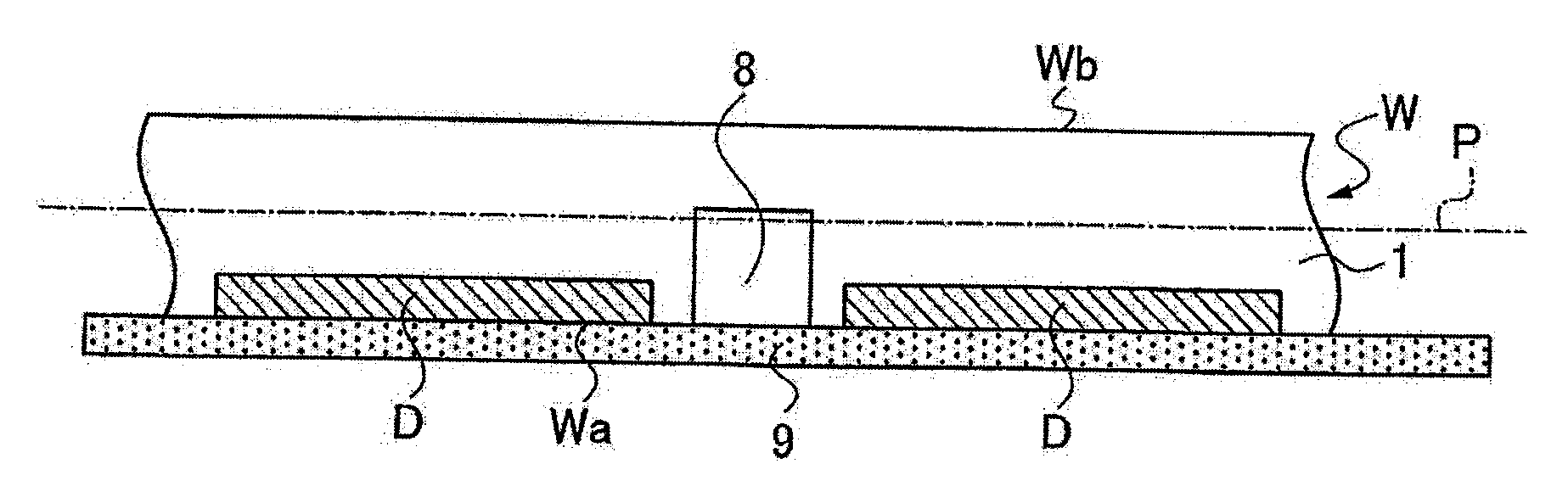

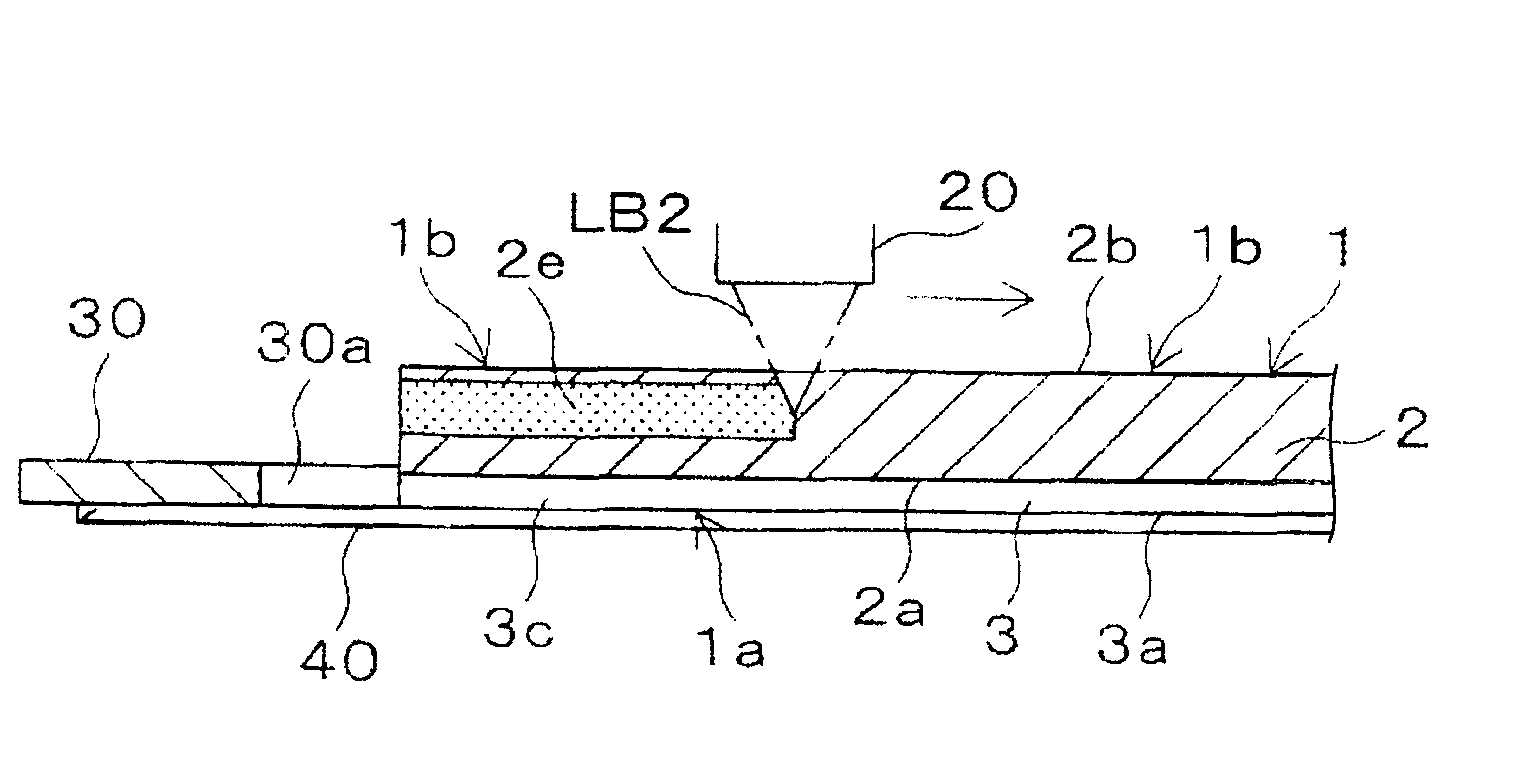

Workpiece dividing method

ActiveUS20120100696A1High molding strengthEvenly dividedSemiconductor/solid-state device manufacturingOptoelectronicsLaser beams

A workpiece has a substrate and a film formed on the front side of the substrate. A first laser beam applied to the film from the front side of the workpiece along streets formed on the film, thereby forming a plurality of laser processed grooves along the streets. An adhesive tape is attached to the front side of the workpiece. Thereafter, a second laser beam is applied to the substrate from the back side of the workpiece along the streets, with the focal point of the second laser beam set inside the substrate, forming a plurality of modified layers along the streets. Thereafter, the adhesive tape is expanded to divide the substrate along the streets, thereby obtaining a plurality of individual devices. The back side of the substrate of each device is then ground to remove the modified layers and reduce the thickness of each device to a predetermined thickness.

Owner:DISCO CORP

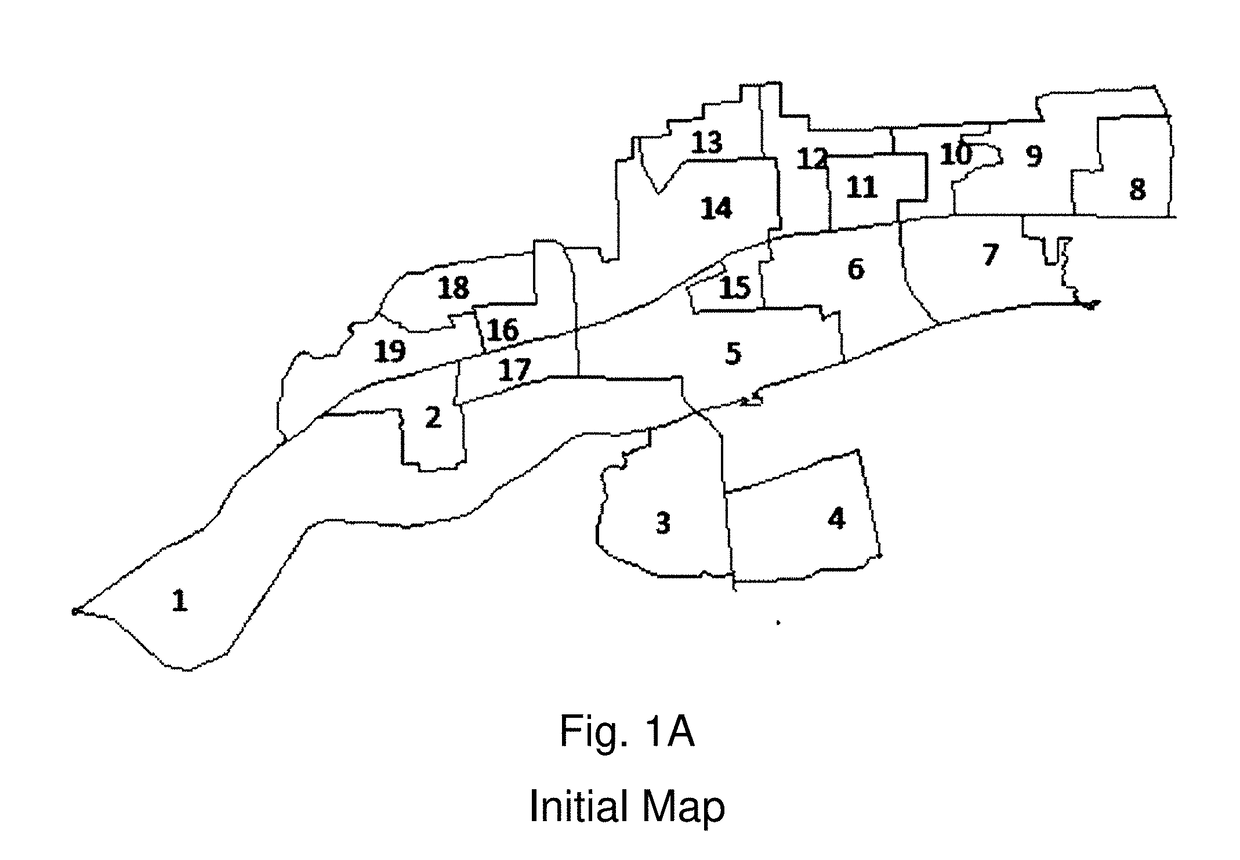

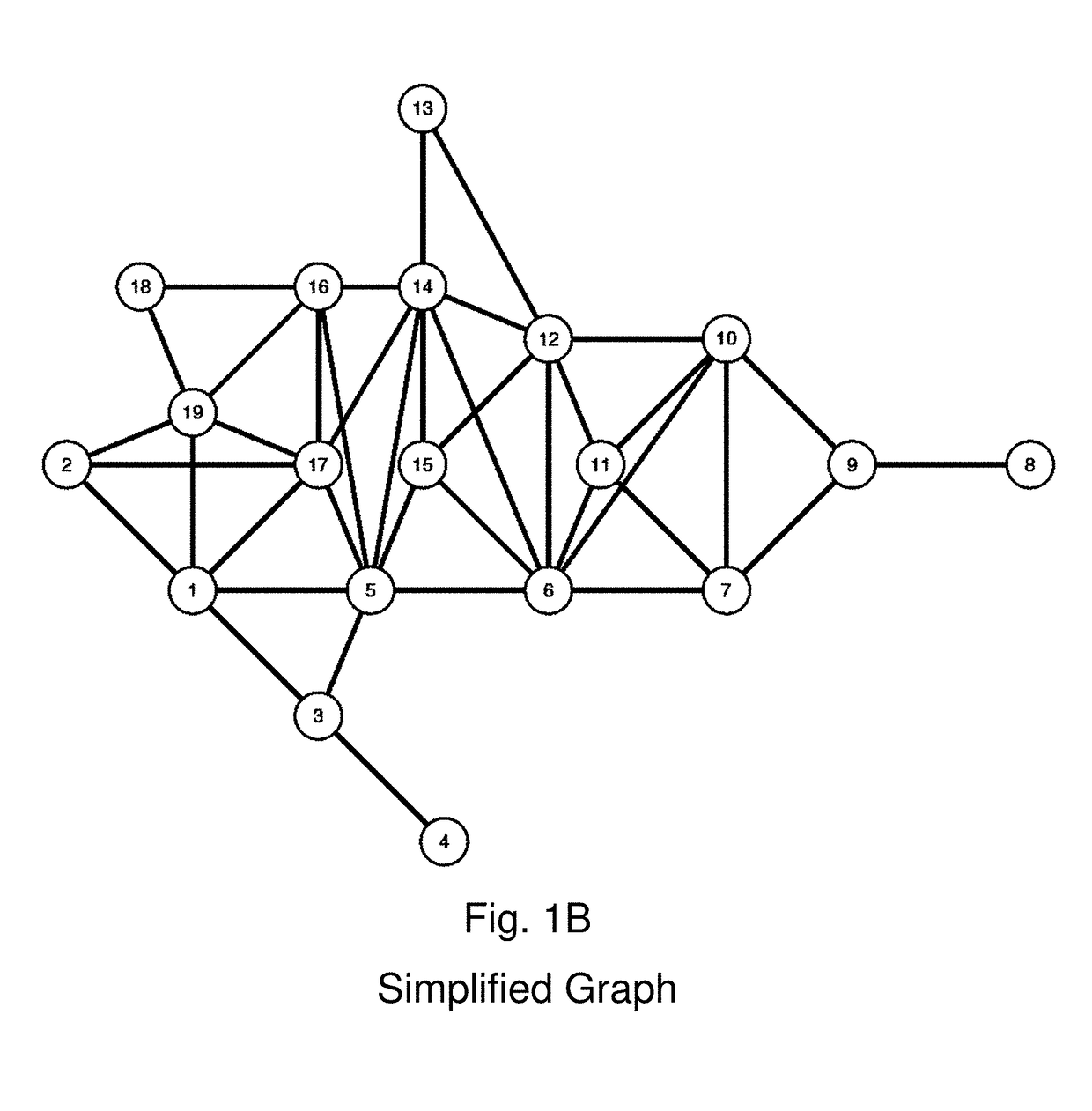

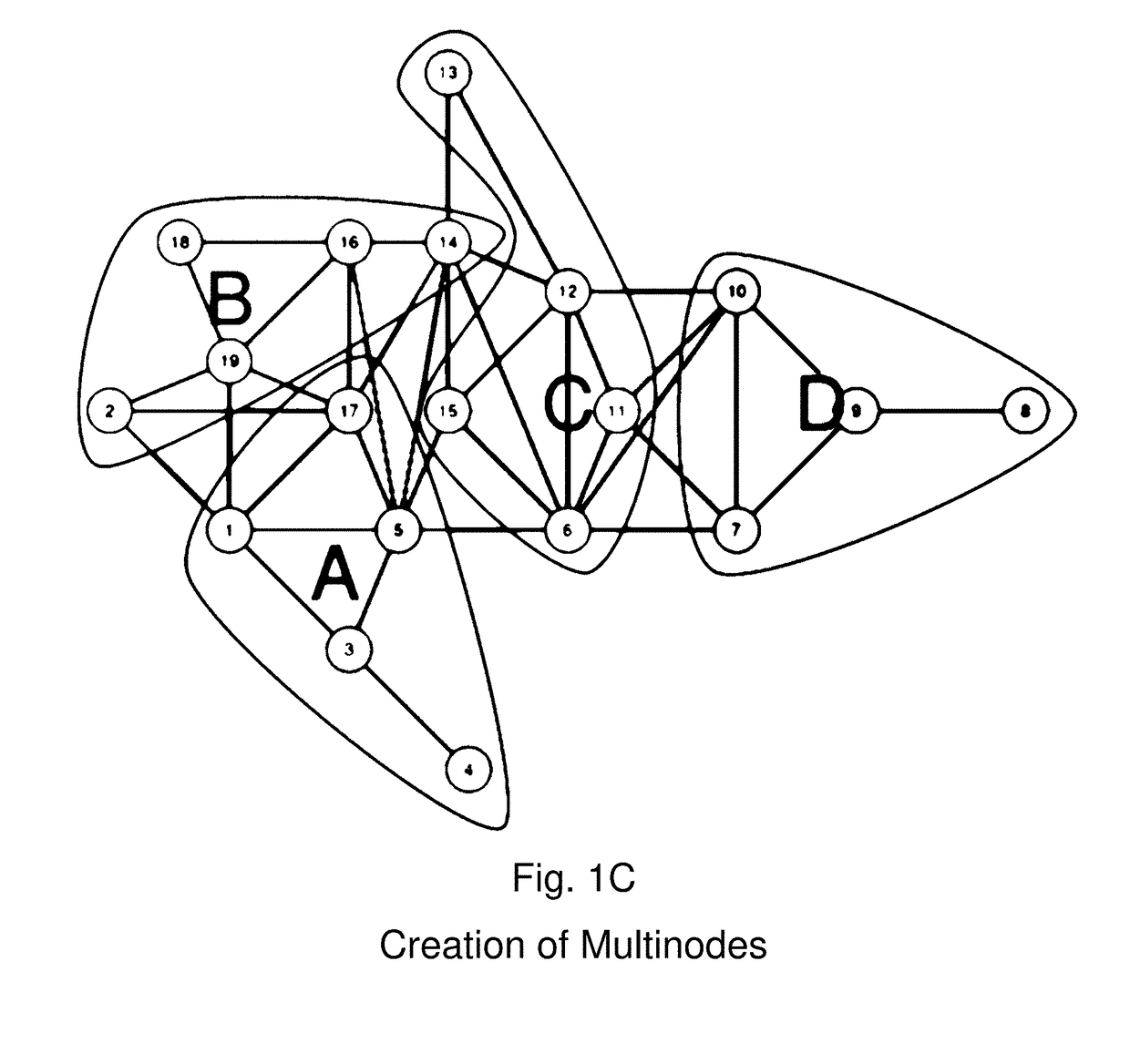

Neutral radistricting using a multi-level weighted graph partitioning algorithm

InactiveUS20180342030A1Improve efficiencyAvoid issuingForecastingComplex mathematical operationsGeographic regionsData set

A system and method for partitioning a map into a plurality of disjoint regions each representing a respective continuous bounded geographic region, comprising: receiving a data set representing a geographic region having geographic variations, and a partitioning objective; partitioning the data so that the partitioning objective is met, using a distinct condition, to produce a plurality of partitioned geographic regions, dependent on at least the geographic variations and characteristics of the data and the initial condition. A plurality of initial conditions or distinctness criteria applied to the partitioning as the distinct criterion, to produce a plurality of different maps. The plurality of maps may then be compared according to a fitness criterion.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

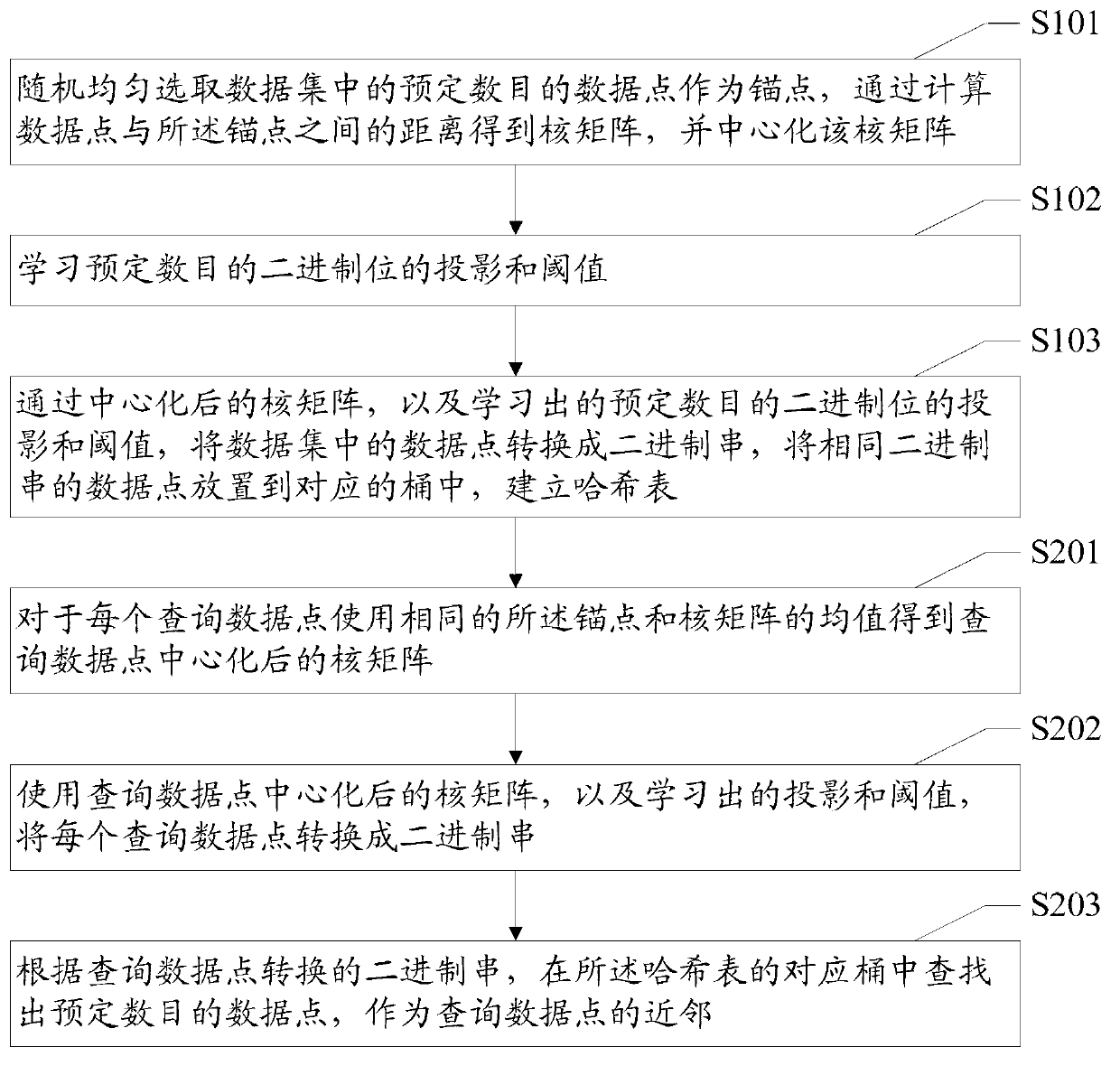

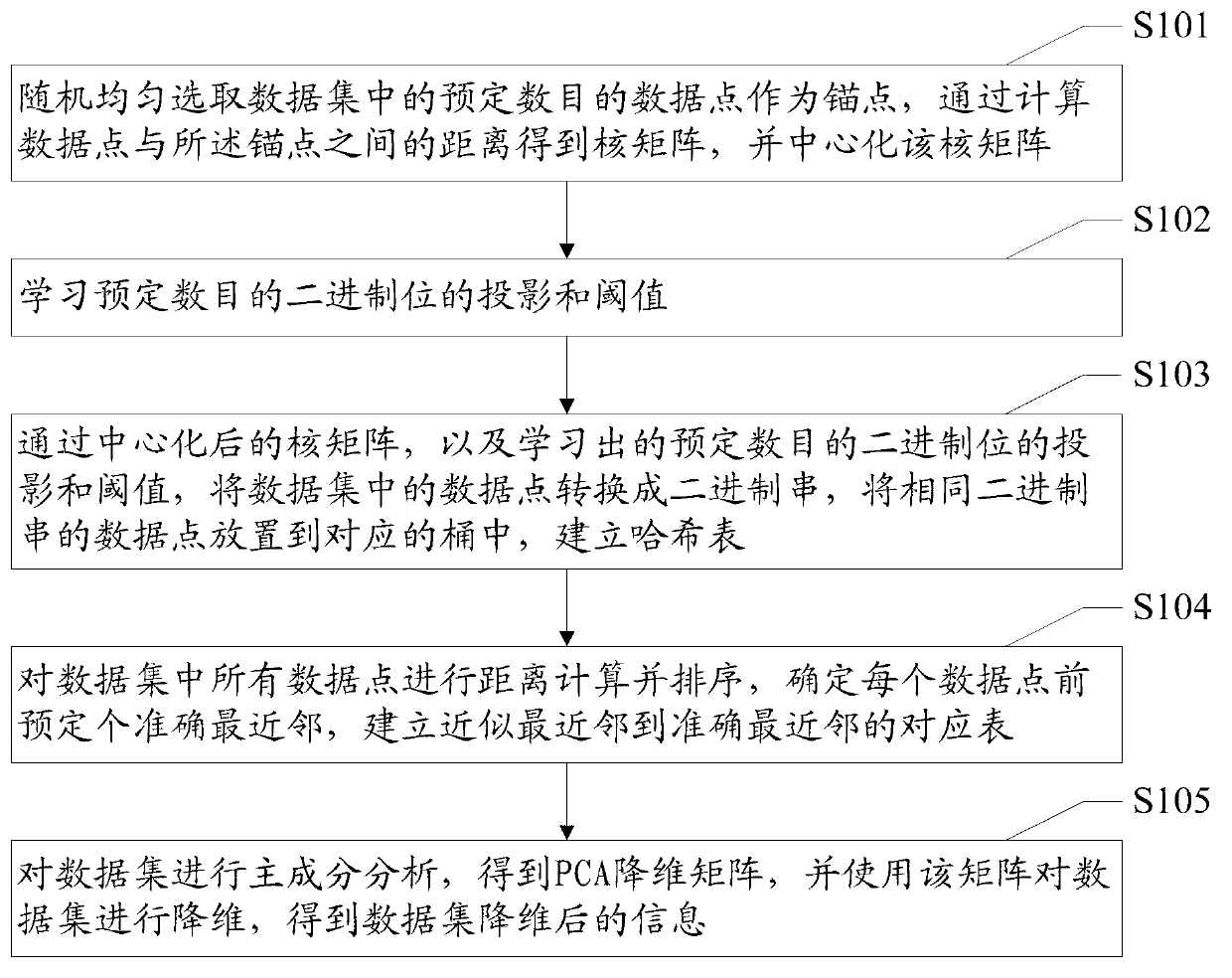

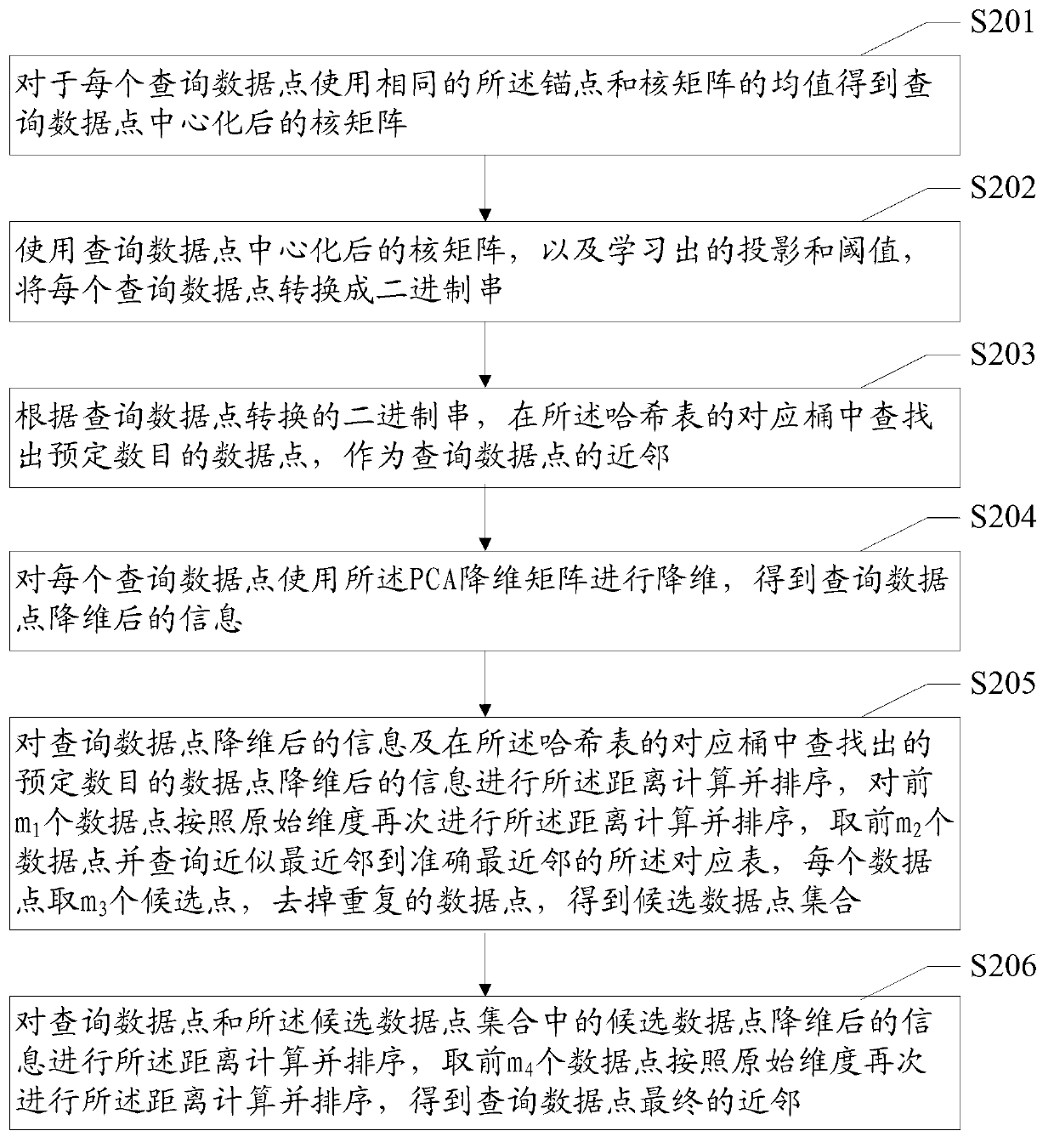

Neighbor searching method and neighbor searching system

InactiveCN103020321AEvenly dividedImprove accuracySpecial data processing applicationsOffline learningAlgorithm

The invention discloses a neighbor searching method and a neighbor searching system. The neighbor searching method includes offline learning and online searching. A learning function of data point number in small regions on two sides of a Hash hyperplane is minimized to enable the Hash hyperplane to penetrate through a data sparse region, and accordingly high accuracy in neighbor searching can be guaranteed. An approximate balance barrel regular term is added to a learning function through approximate balance barrel conditions to enable more balanced data point partition by the Hash hyperplane, and accordingly high searching speed in neighbor searching is guaranteed. Regardless of a small quantity of data or massive data, high-accuracy and high-speed neighbor searching can be realized by the neighbor searching method and the neighbor searching system.

Owner:GUANGDONG TUTUSOU NETWORK TECH

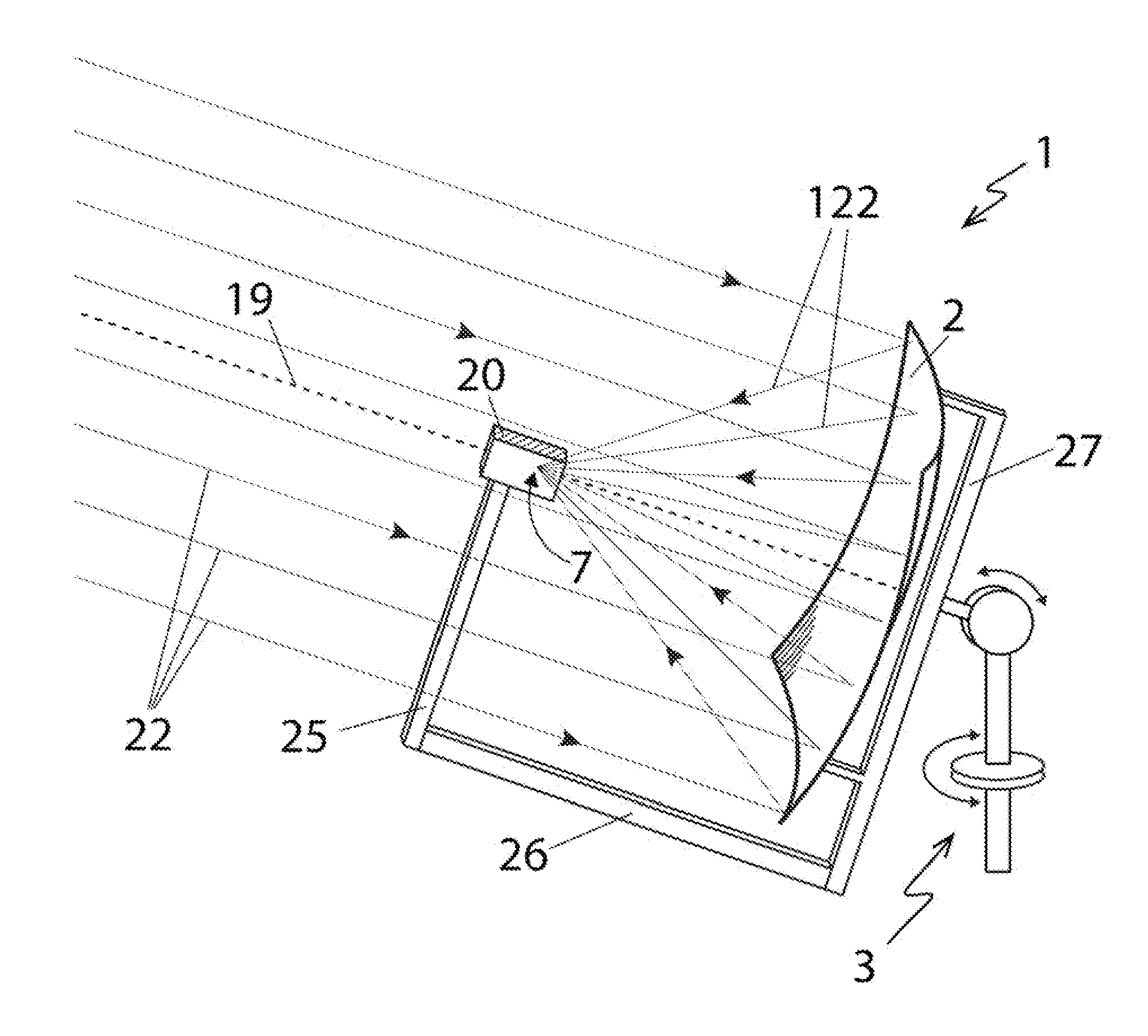

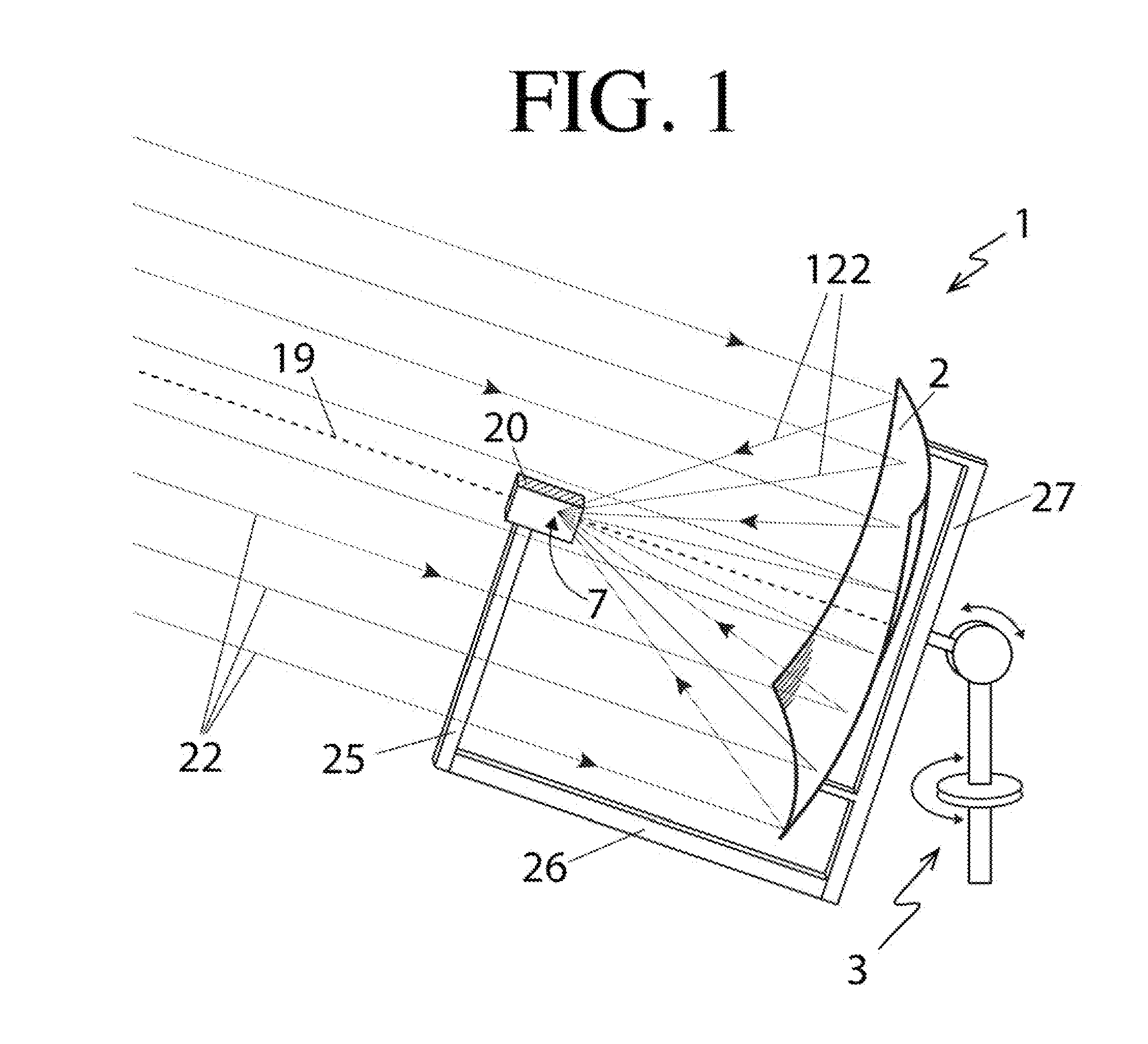

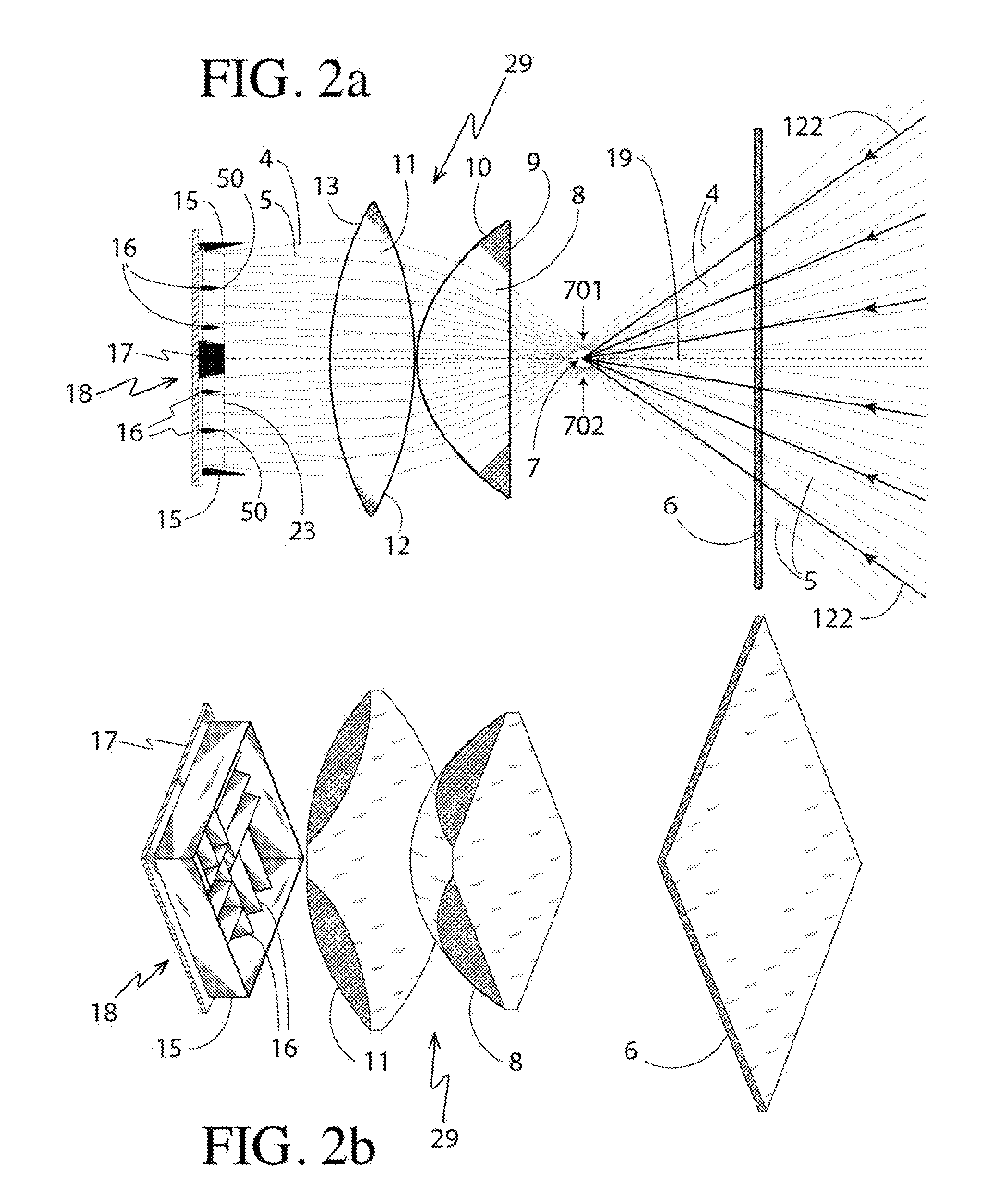

Solar generator with large reflector dishes and concentrator photovoltaic cells in flat arrays

ActiveUS20150303867A1Avoid pollutionEvenly dividedPhotovoltaic supportsPV power plantsElectricitySolar generator

An apparatus is disclosed for generation of electricity using sunlight focused onto multi junction photovoltaic cells having high conversion efficiency. The apparatus includes a large paraboloidal mirror of back-silvered glass, turned to the sun throughout the day, so as to provide an intense focus. Multiple photovoltaic cells are provided at the focus. The optics are configured to distribute sunlight without significant loss into separate regions matched to the photovoltaic cell size. A secondary optical system takes strongly focused sunlight near the focus of a single paraboloidal mirror and distributes it equally between the cells, and regions of equally concentrated sunlight are matched to cell size and are substantially co-planar, so that the cells may be grouped on flat circuit cards.

Owner:THE ARIZONA BOARD OF REGENTS ON BEHALF OF THE UNIV OF ARIZONA

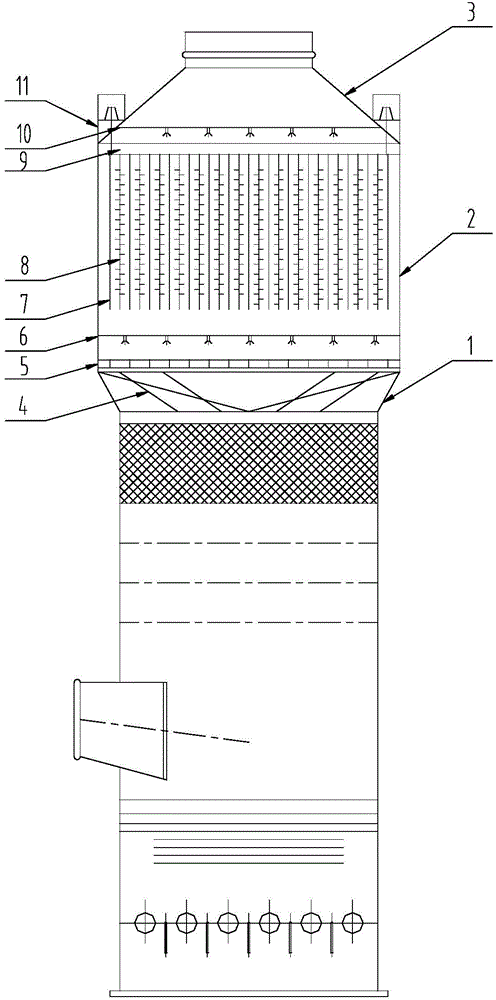

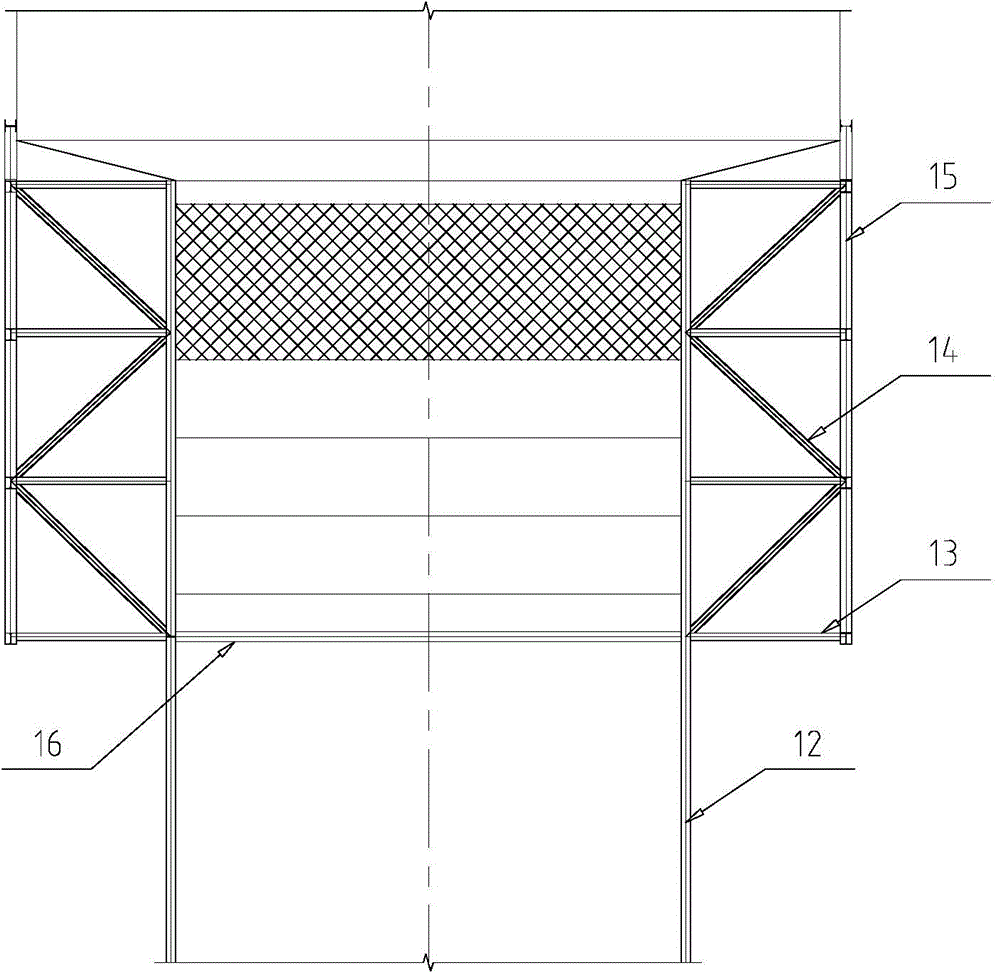

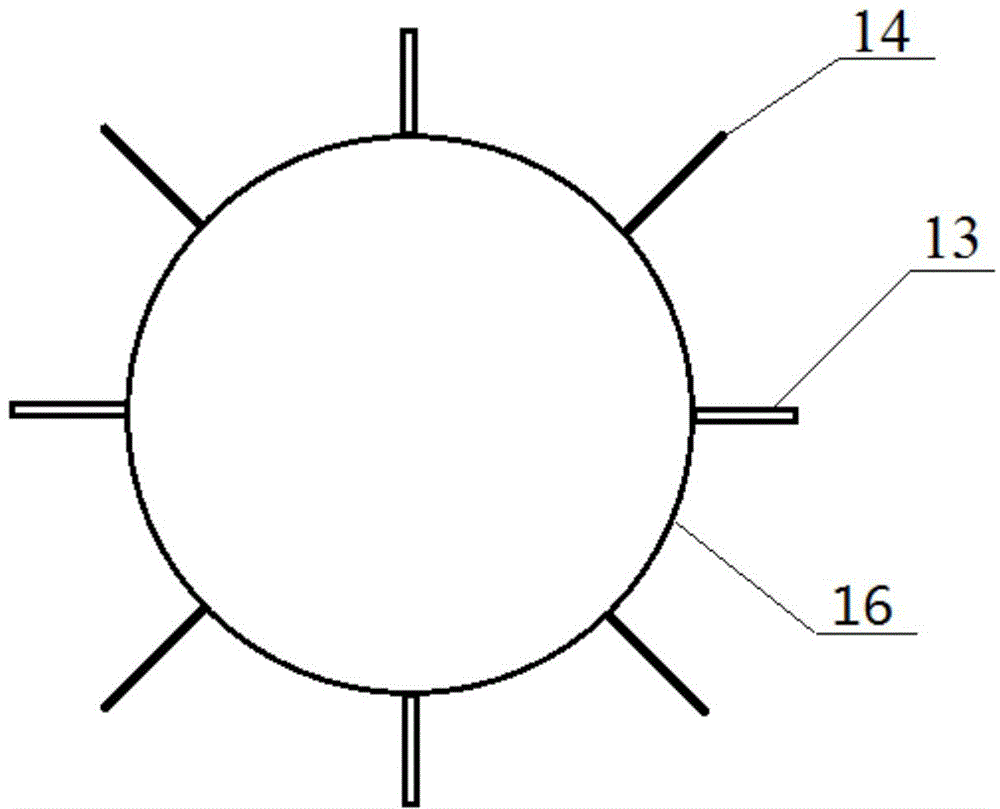

Overhead type rectangular wet electric precipitator

ActiveCN104437870ARealize modular productionEasy to makeElectrostatic separation housingExternal electric electrostatic seperatorTowerPetroleum engineering

The invention provides an overhead type rectangular wet electric precipitator. The main body section of the electric precipitator is of a rectangular cylindrical structure and comprises a spray washing system, an anode module, a cathode module, a spray humidification system and a uniform distribution device; the electric precipitator is also provided with a shell self-supporting structure which comprises an inner column, an outer column, a main truss, an auxiliary truss and an annular truss; the inner column provided with the main truss is adhered to the outer wall of an absorption tower, and the top end of the main truss is used for supporting the wet electric precipitator; the main truss and the auxiliary truss are spaced from each other and are connected mutually to transfer load; the top end of the outer column provided with the auxiliary truss is used for supporting the wet electric precipitator; the annular truss is attached to the outer wall of the absorption tower; the inner column is arranged on the annular truss. Uniform partition in the precipitator can be realized, the cathode system and the anode system are produced in a modularized manner; the self-supporting structure does not need to occupy land and has no influence on the mounting and the overhauling of the original absorption tower; the effective dust collection area is increased, and the dust removal efficiency is improved.

Owner:SHANGHAI LONGKING ENVIRONMENTAL PROTECTION

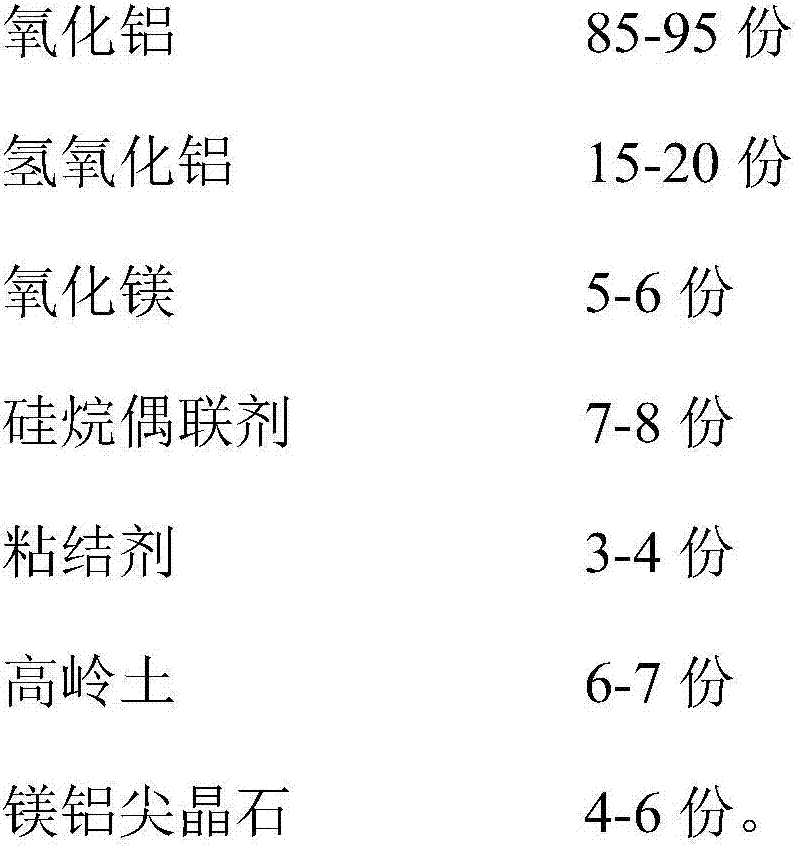

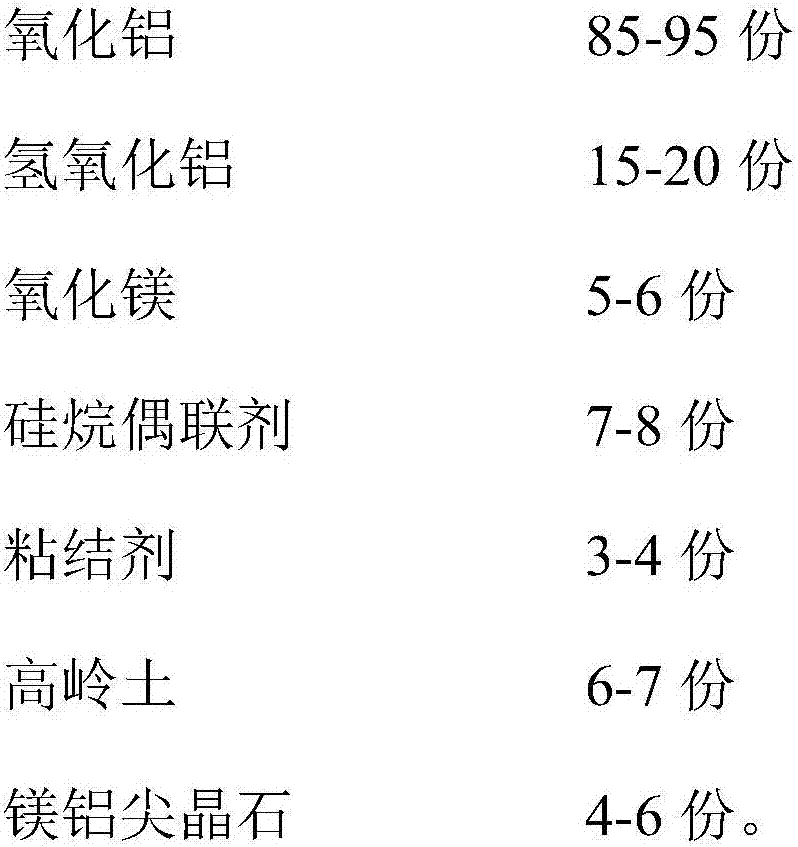

Alumina ceramic and preparation method thereof

The invention discloses alumina ceramic and a preparation method thereof; in one aspect of the alumina ceramic, the surface of inorganic powder is coated with a binder through silane coupling agent, mobility and uniformity of the inorganic powder are enhanced, and the binder may break down and disperse from inside with the formation of zero or few holes and cracks during degumming; in second aspect, aluminum hydroxide, silane coupling agent and binder may break down and produce alumina and silica to fill possibly produced holes and cracks, and product compactness is enhanced; in third aspect, binding force between alumina and magnesia may increase under the induction of magnesium aluminate spinel; under the joint action of the three aspects, the alumina ceramic has increased hardness and strength. The growth of alumina grains is jointly inhibited under the cooperation of the magnesium aluminate spinel and magnesia at the premise of improving the hardness and strength of the alumina ceramic, inter-grain gaps are eliminated, the defects are lessened, stress concentration points are decreased, and the ductility of the alumina ceramic is improved.

Owner:JINGDEZHEN CERAMIC INSTITUTE

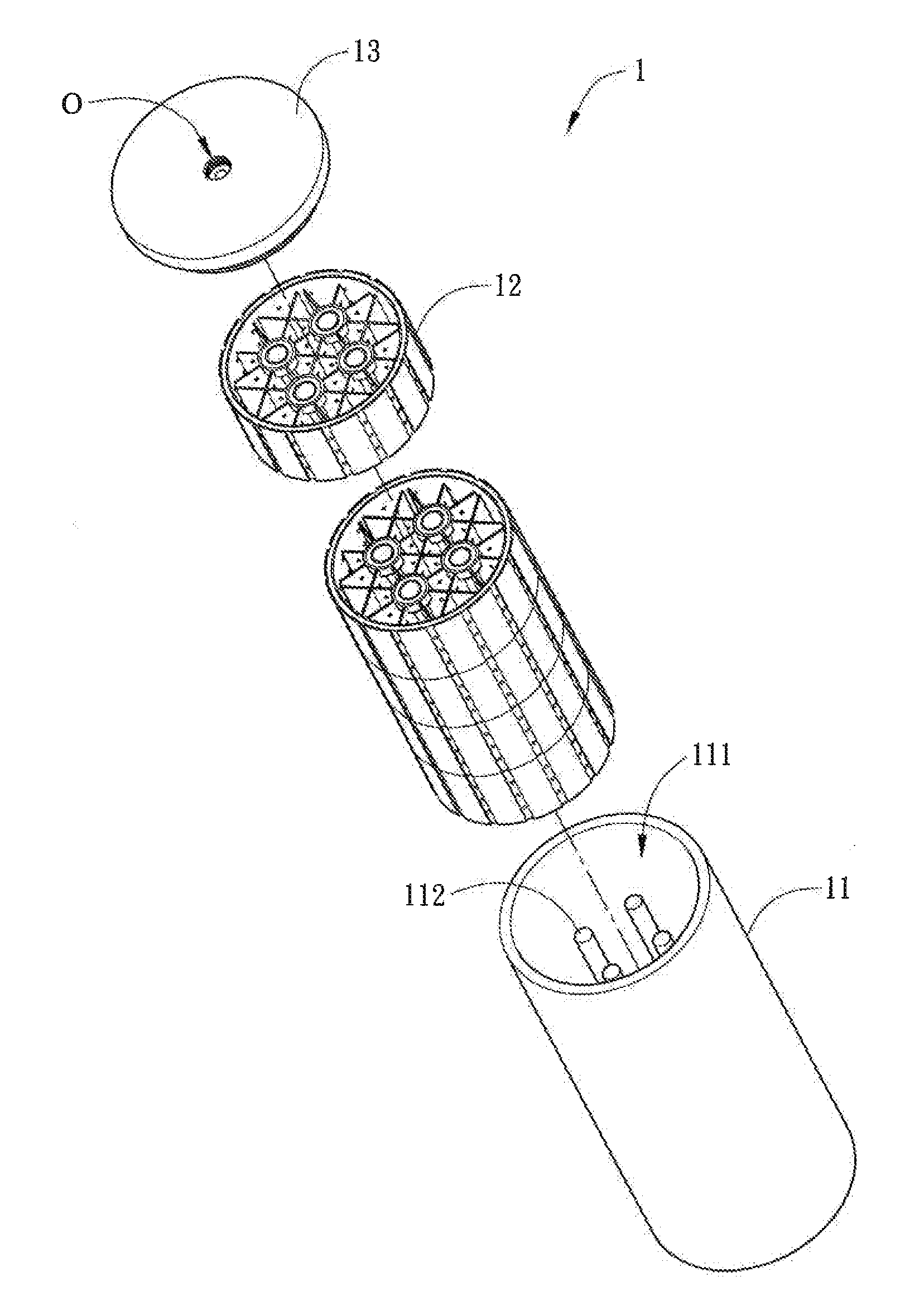

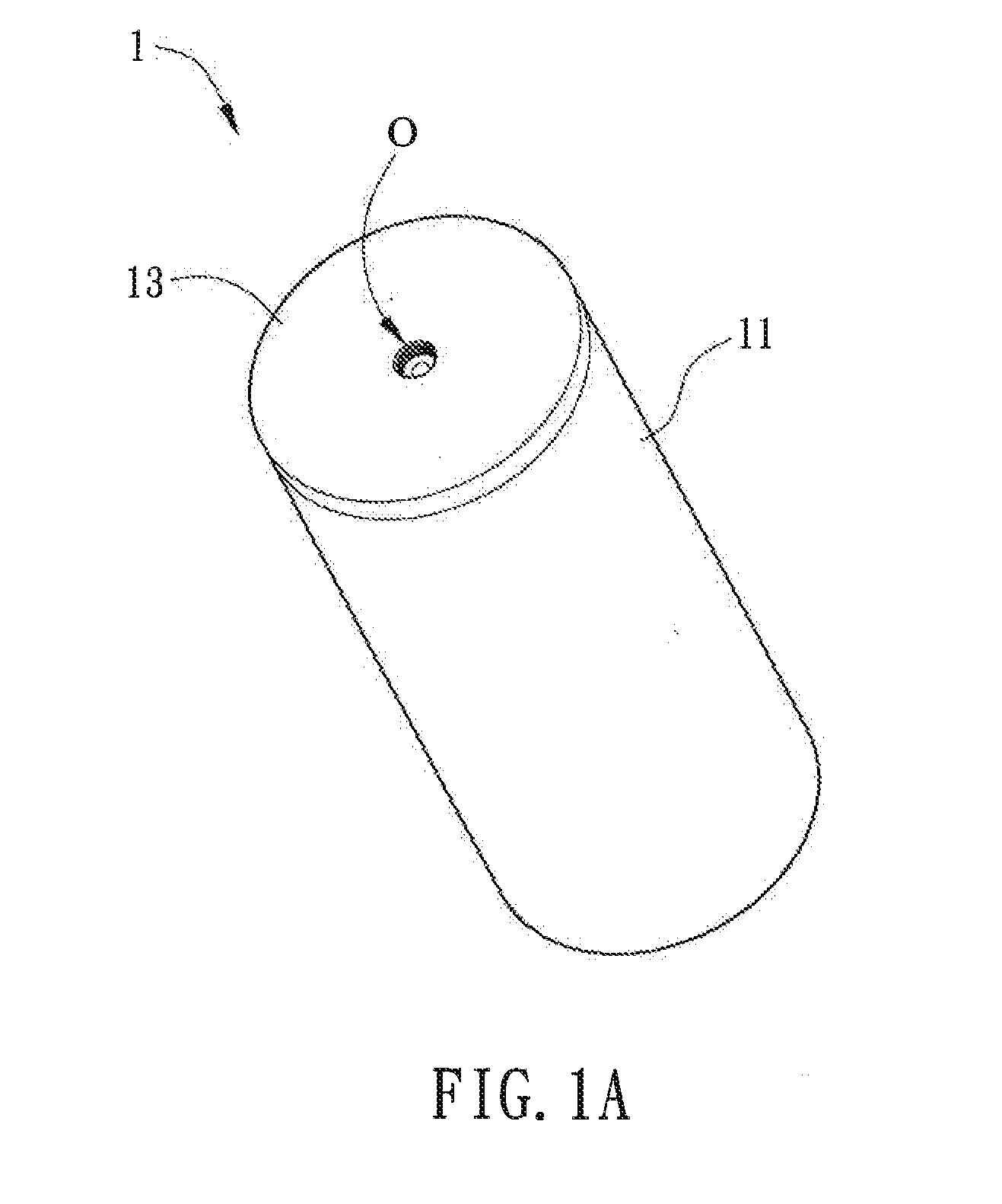

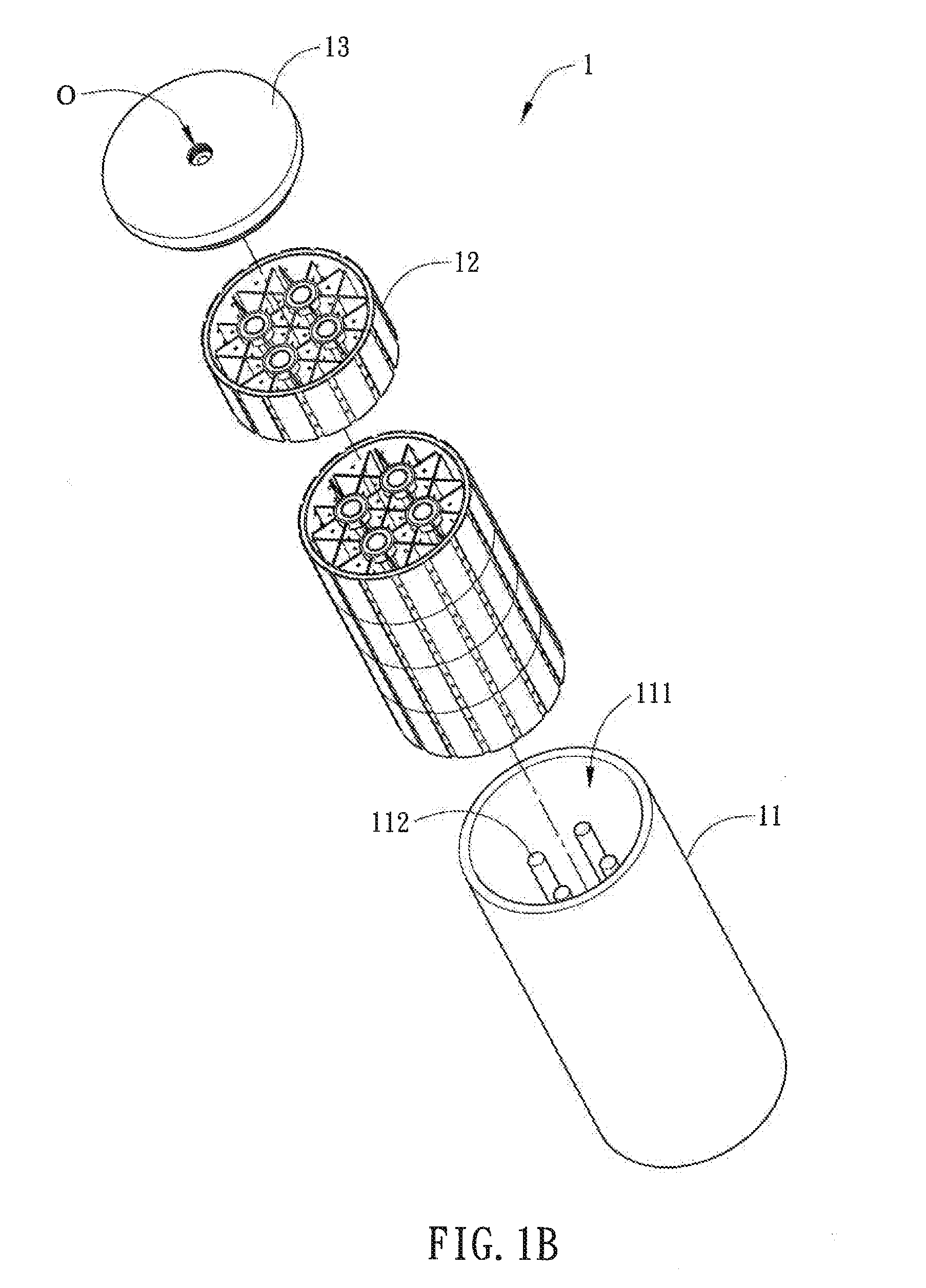

Hydrogen storage apparatus

InactiveUS20140061066A1Fast heat conductionImprove efficiencyOther accessoriesContainer/bottle contructionInterior spaceElectrical and Electronics engineering

A hydrogen storage apparatus includes a canister and at least one hydrogen storage unit. The canister has at least a hollow rod. The hydrogen storage unit is disposed in the canister. The hydrogen storage unit includes a housing, a heat-dissipating channel and a plurality of heat-dissipating partitions. The periphery of the housing is configured with a plurality of grooves, and each groove has a plurality of first holes. The heat-dissipating channel is located within the housing. Each heat-dissipating partition has a plurality of second holes and connects to the housing and heat-dissipating channel. The heat-dissipating partitions divide the space inside the housing. The first holes and the second holes connect to the inner space of the housing.

Owner:NAT CENT UNIV

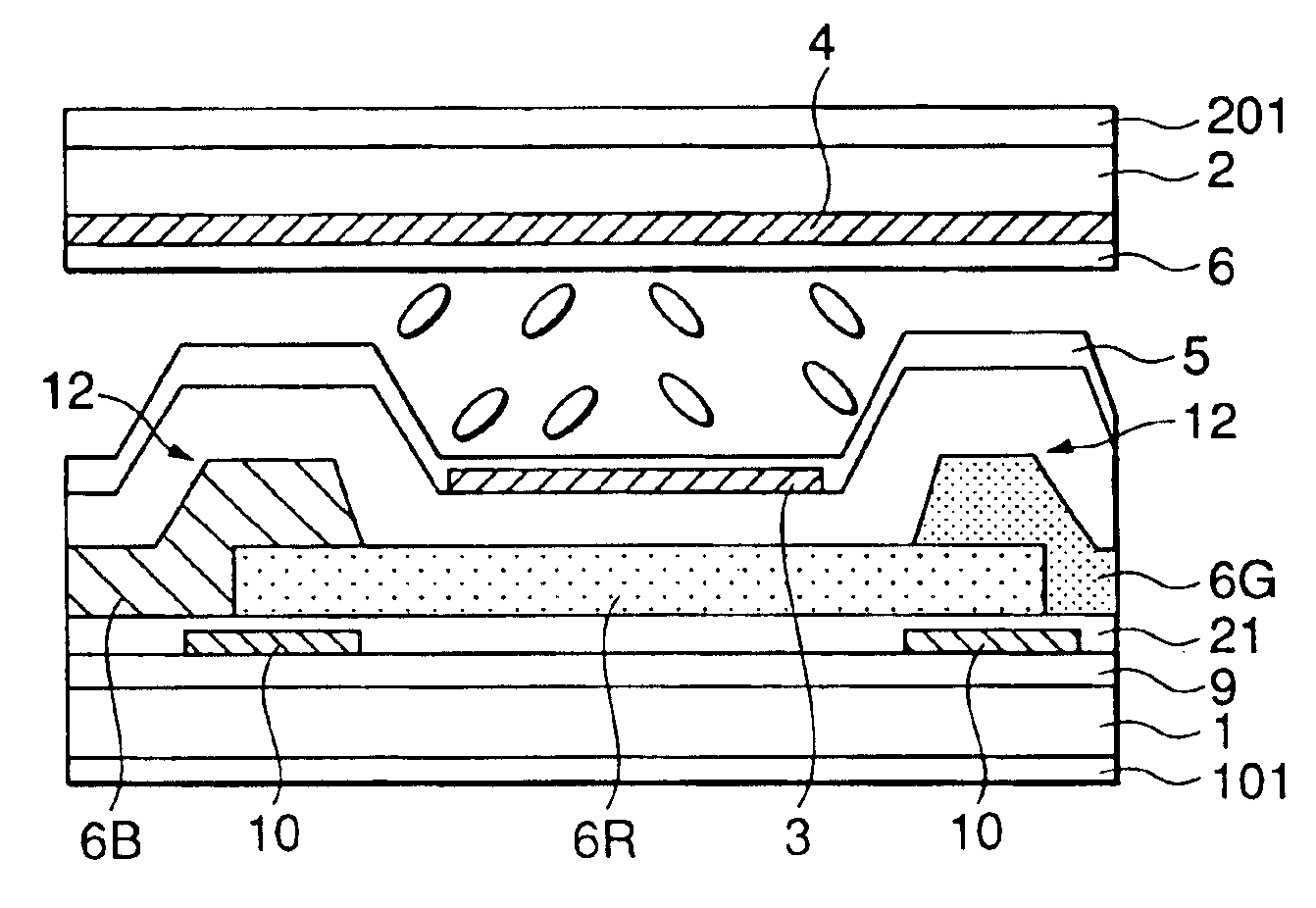

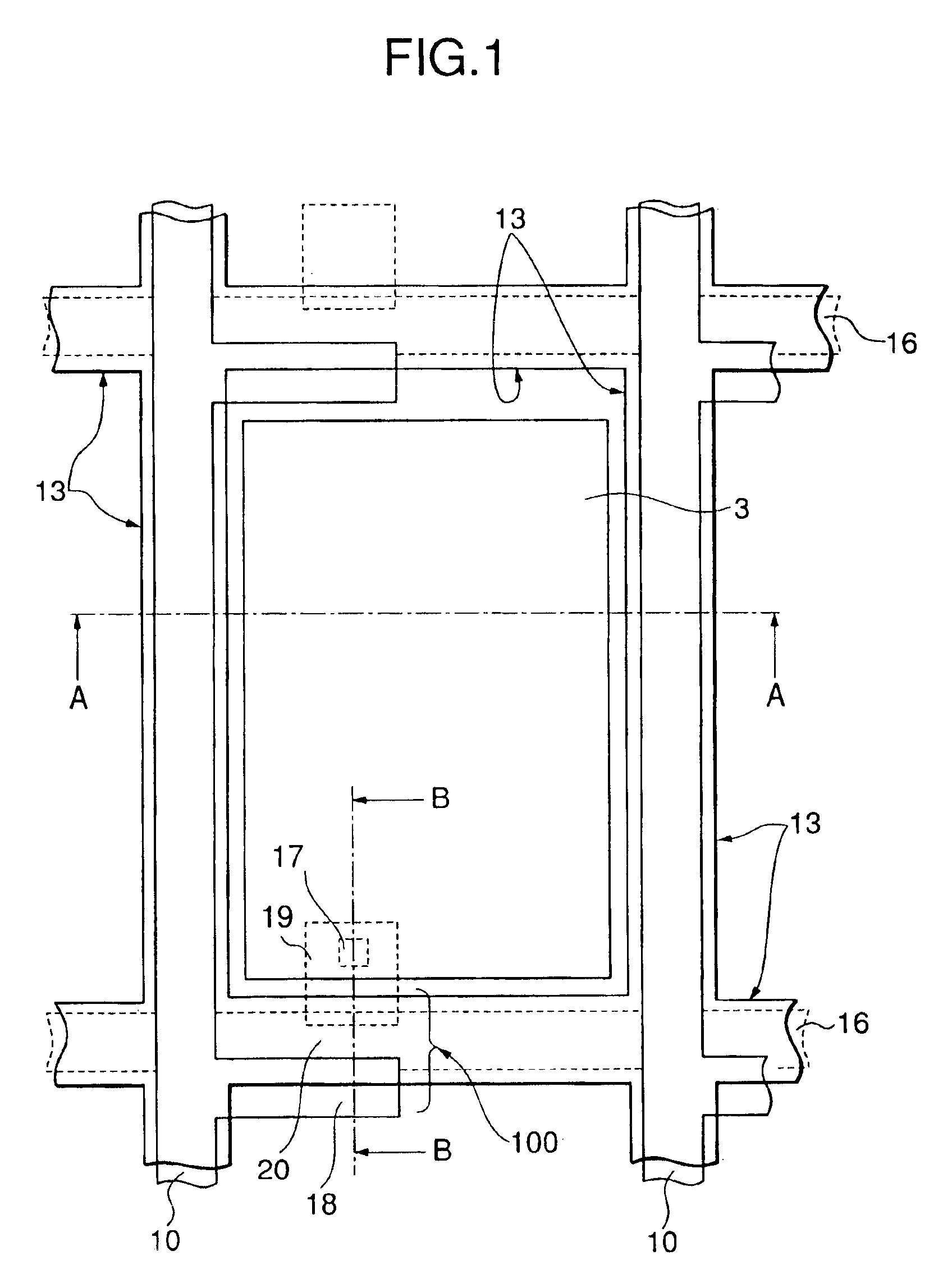

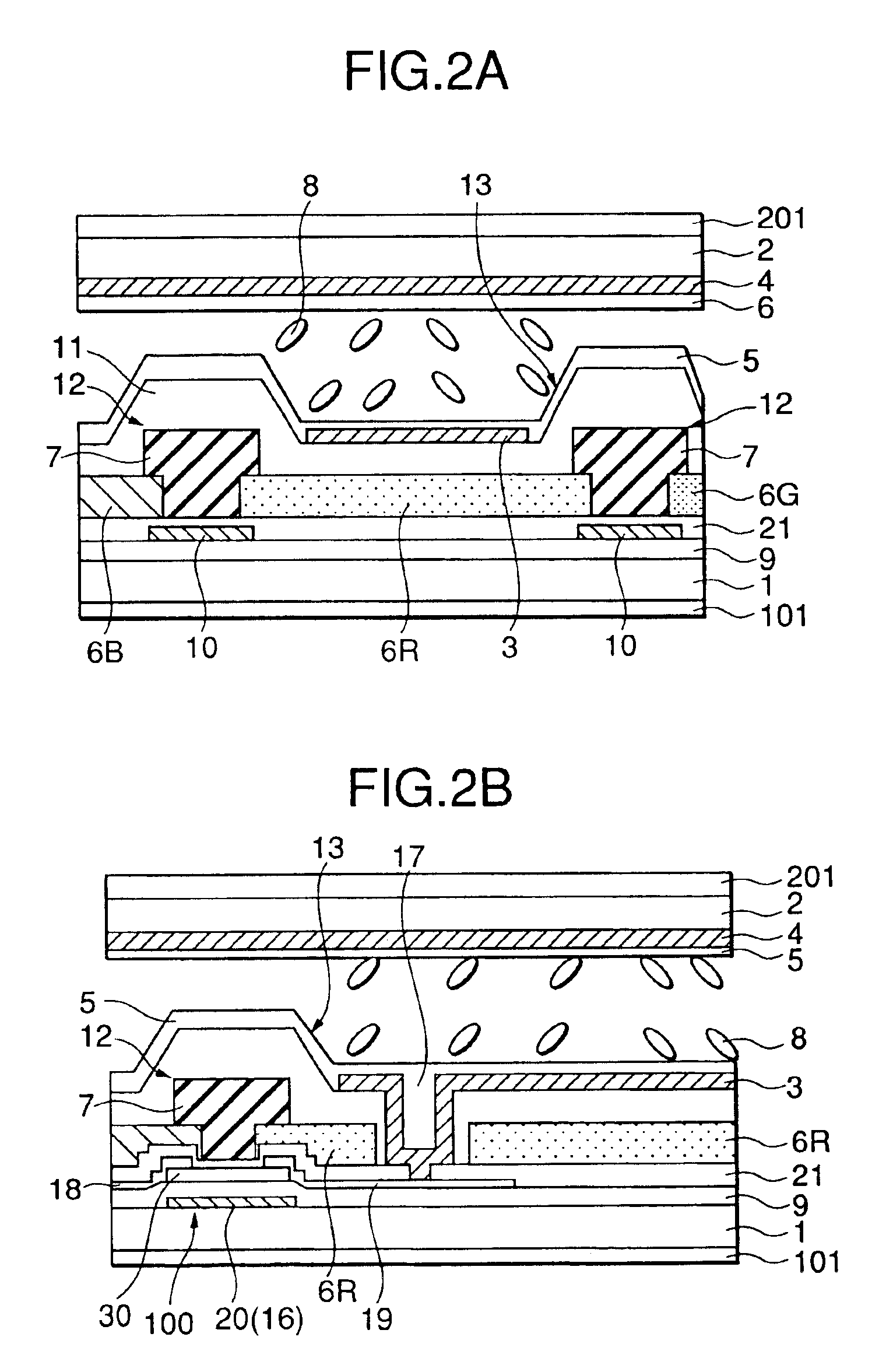

Orientation division type liquid crystal display, fabrication method thereof and image display method

InactiveUS6927822B2Expand field of viewClarifyNon-linear opticsIdentification meansLiquid-crystal displayActive matrix

In an orientation division type liquid crystal display device for widen a viewing angle of a display pixel of an active matrix type liquid crystal color display device having a COT structure, pixel color layers (6B, 6R, 6G) as color filters and pixel electrodes 3 are formed on a substrate on the side of the pixel electrodes and slopes 13 are provided along four side peripheries of each pixel electrode. Liquid crystal molecules 8 between each pixel electrode of the pixel electrode substrate and a common electrode of an opposing substrate are controlled in orientation direction along the slopes to divide it to a plurality of directions to thereby widen a viewing angle of a pixel display. The slope is formed on a step portion 12 formed by a BM layer formed on at least one of a gate electrode, a drain electrode and a source electrode formed in a periphery of the pixel electrode or at least one of a gate wiring and a drain wiring formed in the periphery or a step portion formed by partially overlapping peripheral portions of the adjacent pixel color layers.

Owner:GOLD CHARM LTD

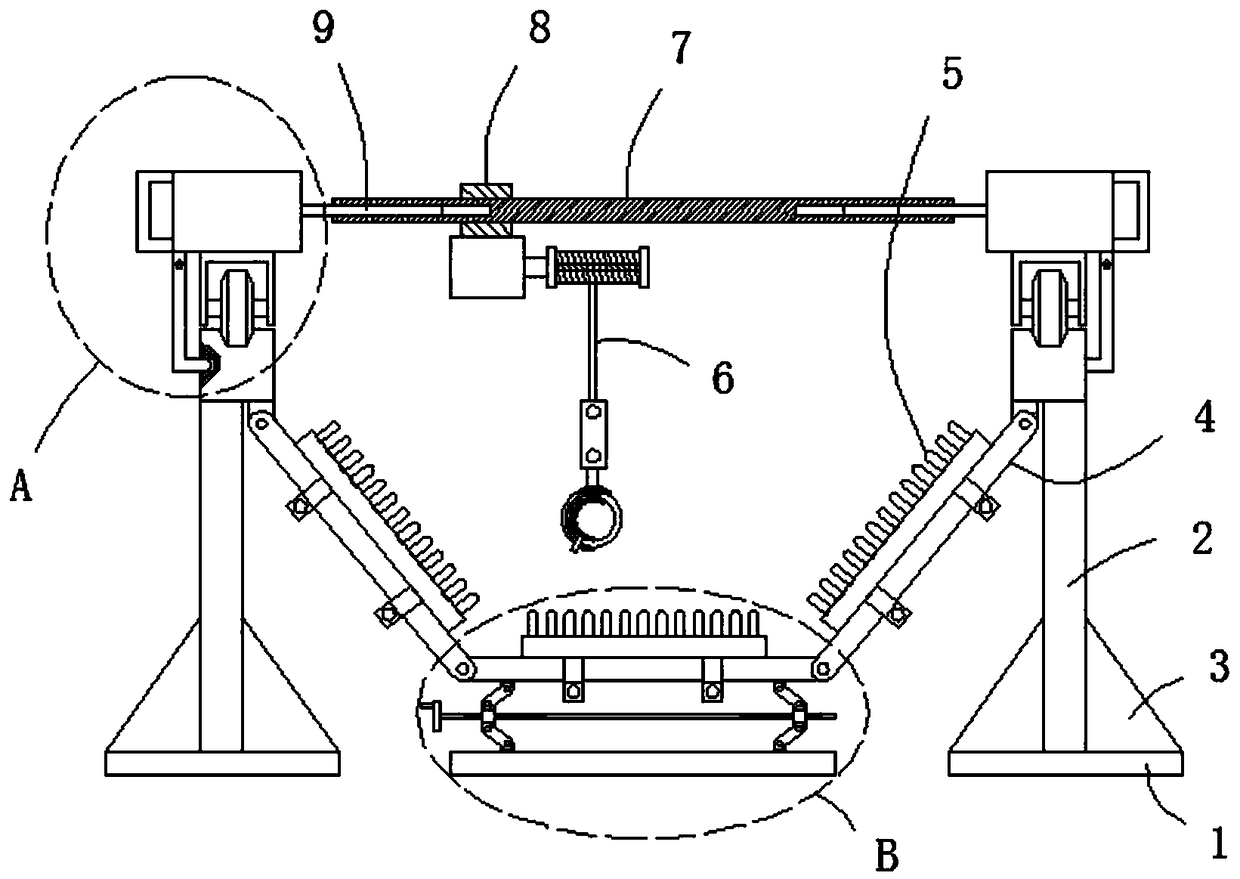

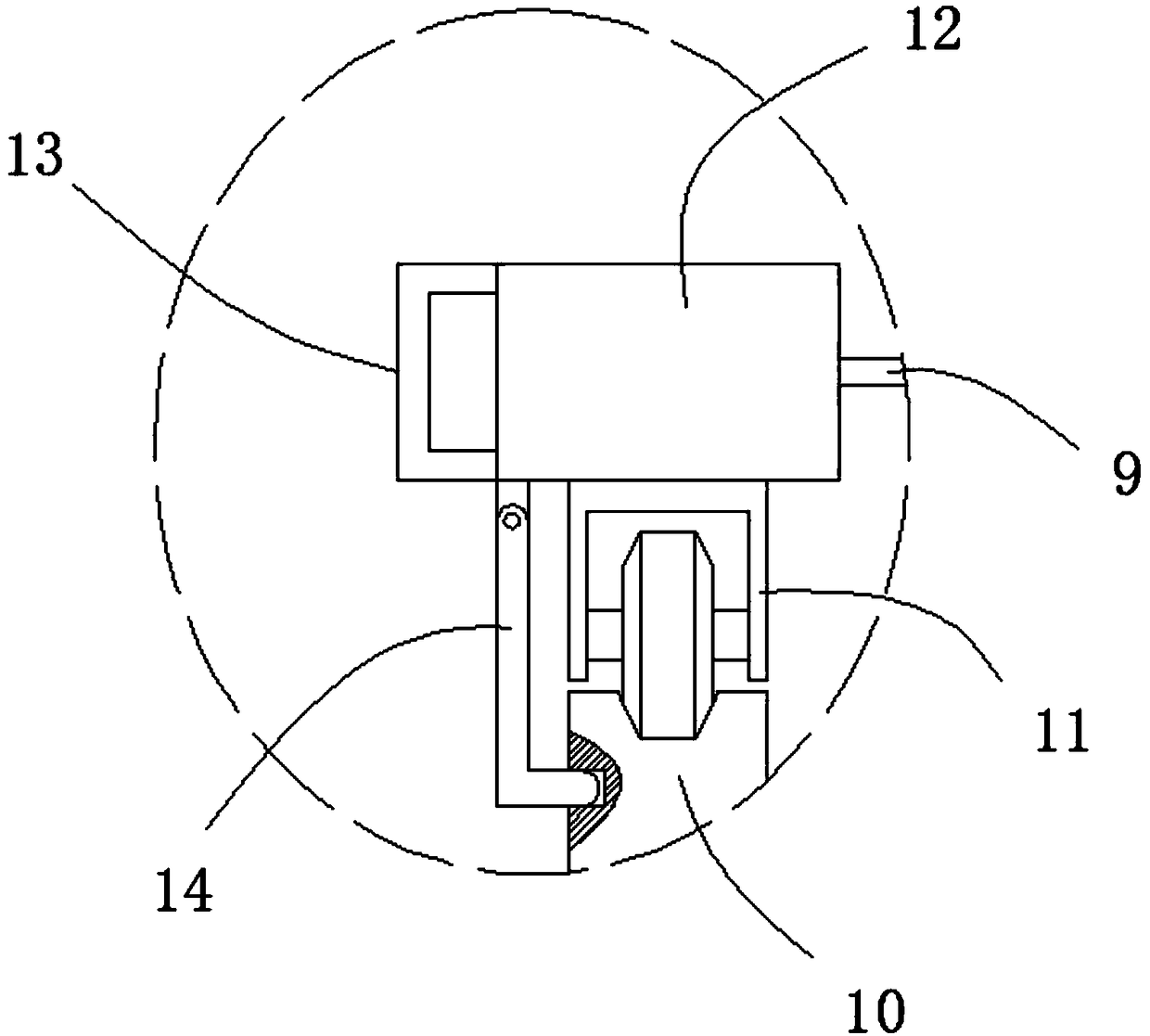

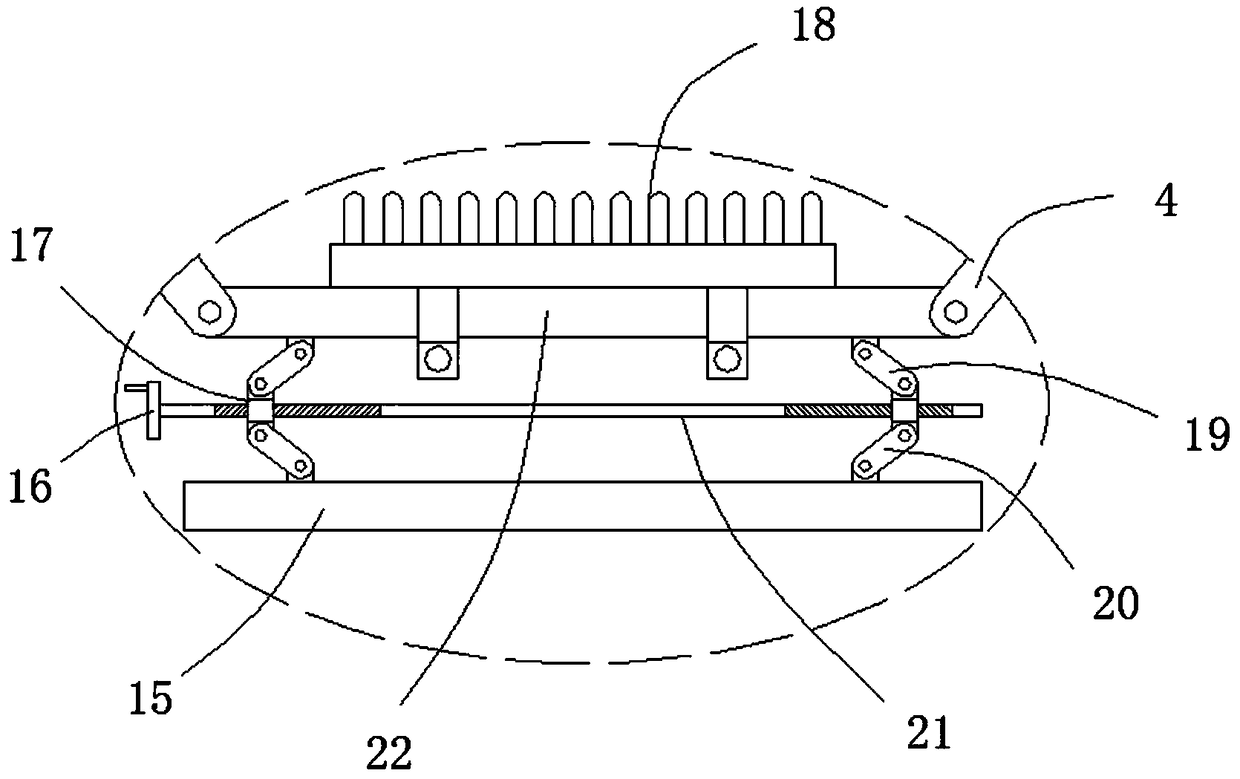

Prefabricated box girder steel bar binding and positioning jig frame

ActiveCN109483727AStable structureOperational securityCeramic shaping apparatusBuilding material handlingEngineeringRebar

The invention discloses a prefabricated box girder steel bar binding and positioning jig frame which comprises first bottom plates and a second bottom plate. The two first bottom plates are arranged,and multiple supporting pillars which are arranged at equal intervals are welded to the tops of the first bottom plates. Fixing bars are fixed to the tops of the supporting pillars. Rolling grooves are formed in the tops of the fixing bars, and moving blocks are arranged above the fixing bars. Wheels are arranged at the bottoms of the moving blocks, and the wheels are installed in the rolling grooves in a rolling manner. A first casing pipe is arranged between the two moving blocks, and first sliding rods are connected in the two ends of the first casing pipe in a sliding and sleeved manner. The ends, back to each other, of the two first sliding rods are fixed to the moving blocks on the two sides, a sliding block is connected to the outer portion of the first casing pipe in a sliding andsleeving manner, and a lifting device is installed at the bottom of the sliding block. By means of the prefabricated box girder steel bar binding and positioning jig frame, position adjustment can beconducted on a steel bar, the labor intensity is greatly lowered, and operation convenience is improved.

Owner:CHINA CONSTR SENVENTH ENG BUREAU INSTALLATION ENG

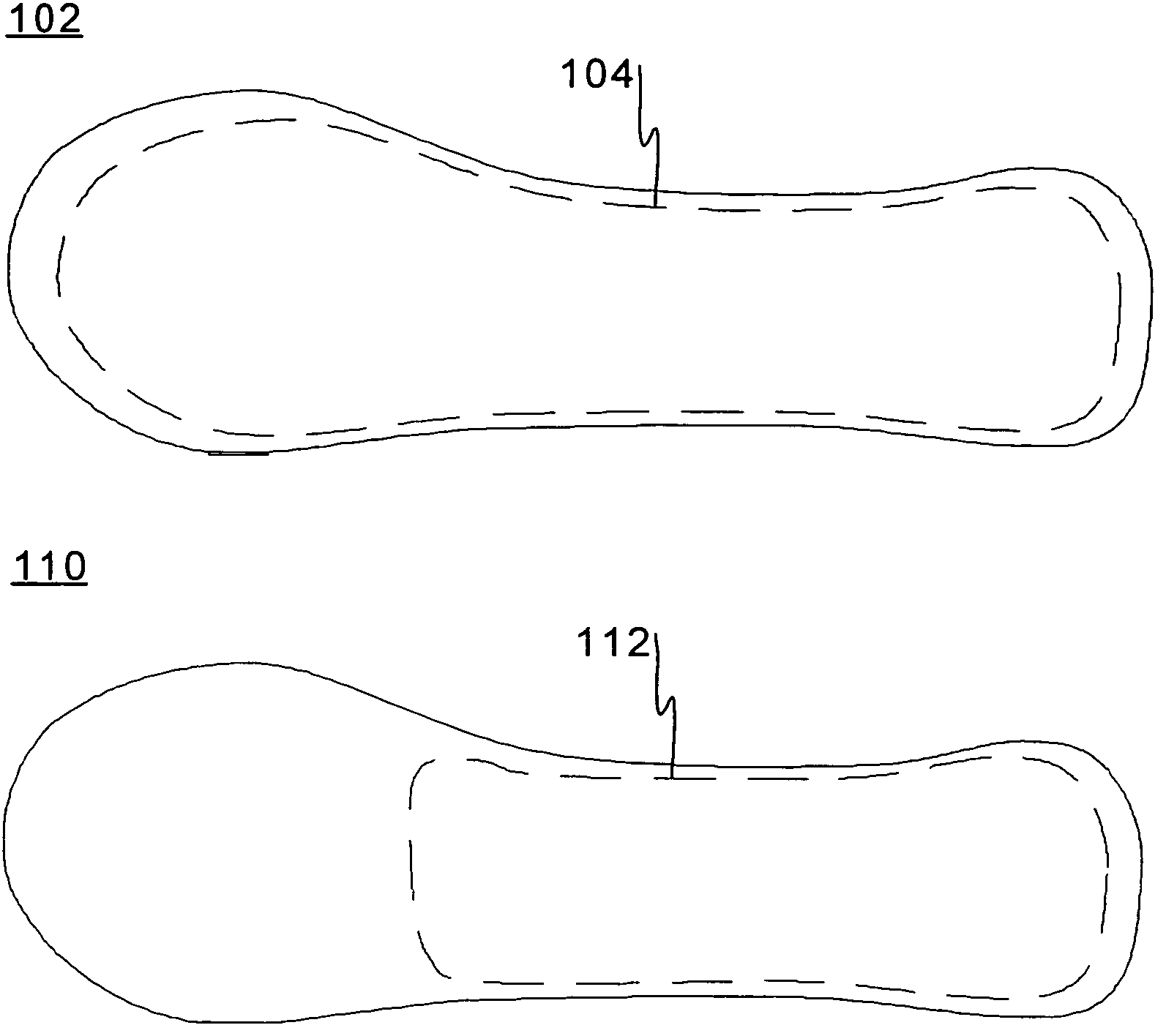

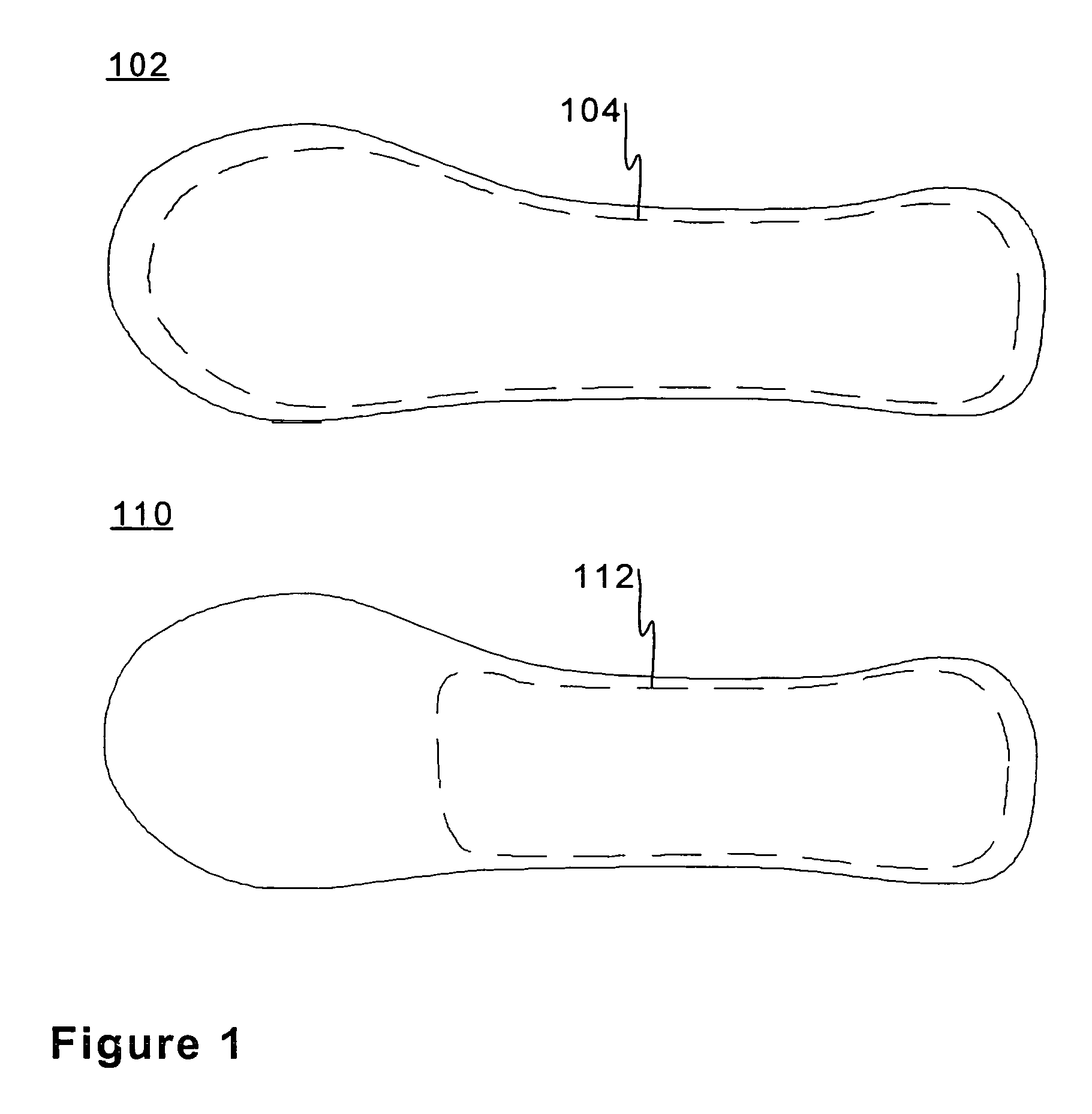

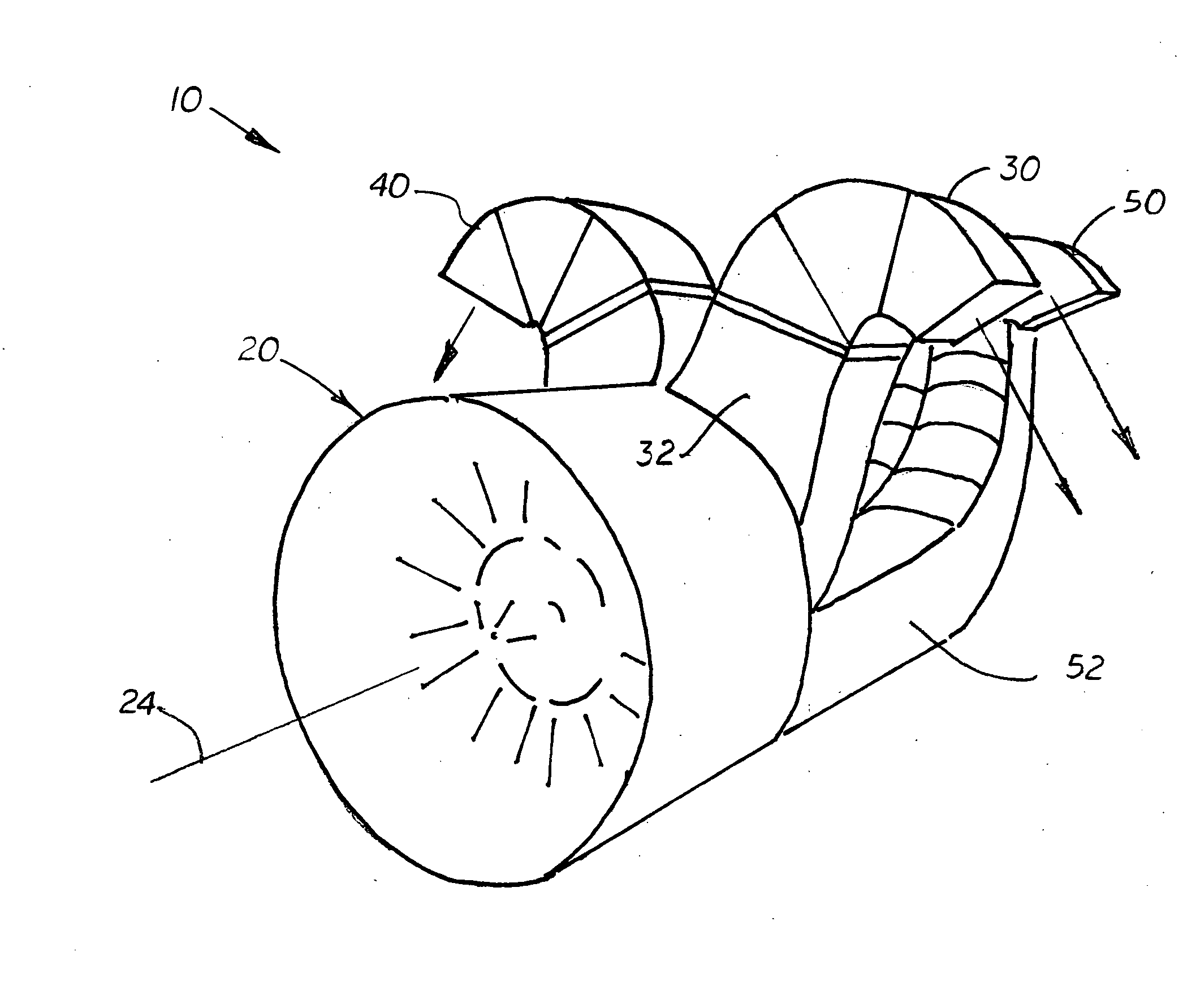

Individually formed footwear and a related method

ActiveUS7793433B2Reduce lossesReduces ovepronation and oversupinationFoot measurement devicesSolesCompanion animalBiomedical engineering

Individually formed footwear such as shoes and insoles for correcting the feet position and alleviate related problems. The shoe or insole comprises at least one layer made of thermoplastic material, which material is advantageously chosen from a group of ABS, PVC, A-PET and PETG. A method for providing such footwear to a client at a retail store is likewise presented.

Owner:FOOTBALANCE SYST

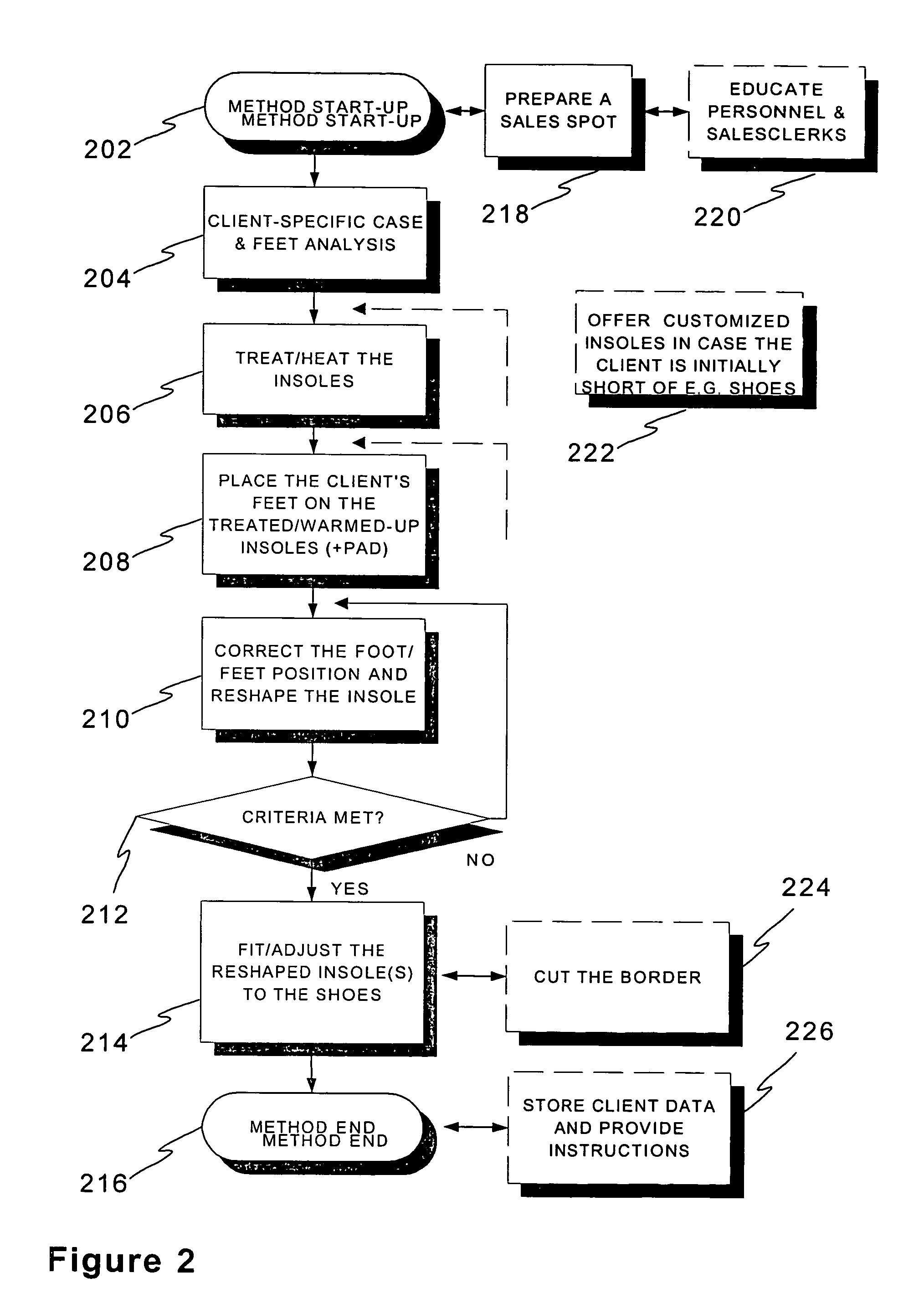

Aircraft engine balanced thrust vectoring system

InactiveUS20090001216A1Simple thrust vectoringHover stabilityVertical landing/take-off aircraftsThrust vectoringLow volume

A balanced thrust vectoring system for an aircraft designed to provide even weight distribution, simple thrust vectoring, and hover stability. The system includes a main diverter that connects to a jet output port. Located inside the diverter is a 4 way splitter that divides the diverter into four equal volumes. Attached to the diverter and adjacent to the two upper volumes are two front upward extending ducts. Attached to the diverter and adjacent to the two lower volumes are two rear upward extending ducts. Each duct includes an upper bend that and diagonally aligned nozzle opening. Each duct has only two bends which help vector the exhaust downward in an efficient manner. The diameter of each duct is consistent to allow their entire length to maximize air flow.

Owner:KIRSTEIN JOSHUA M

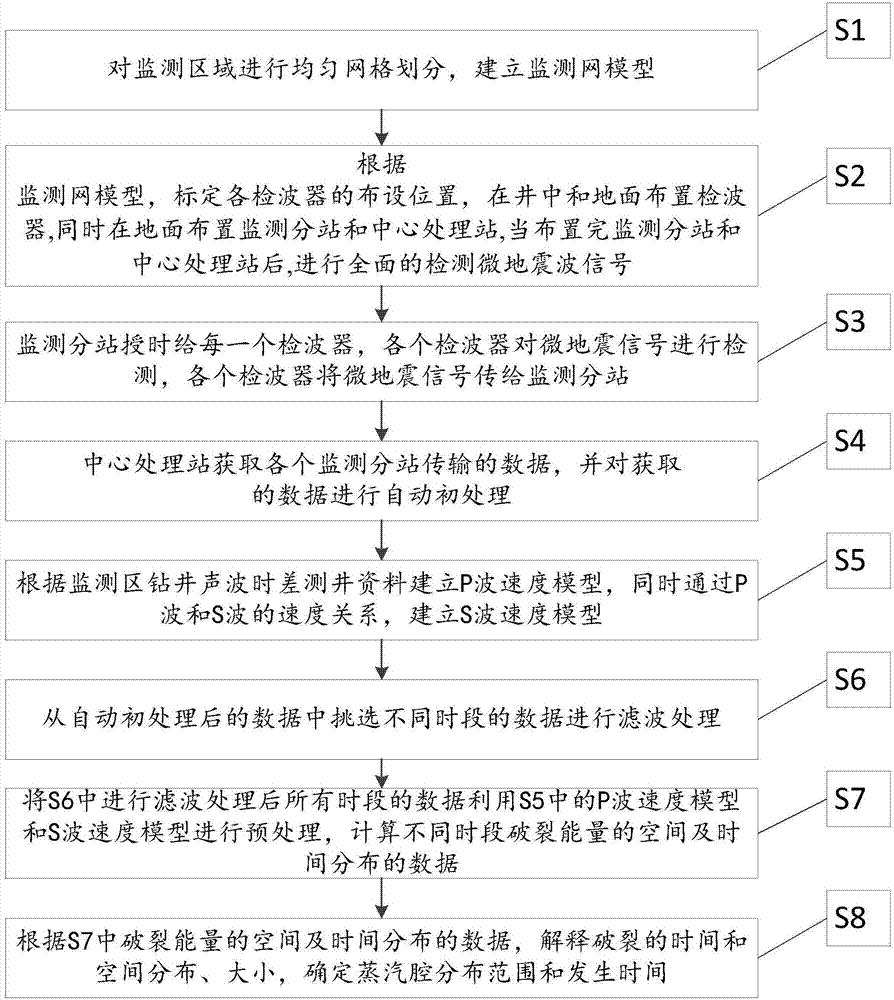

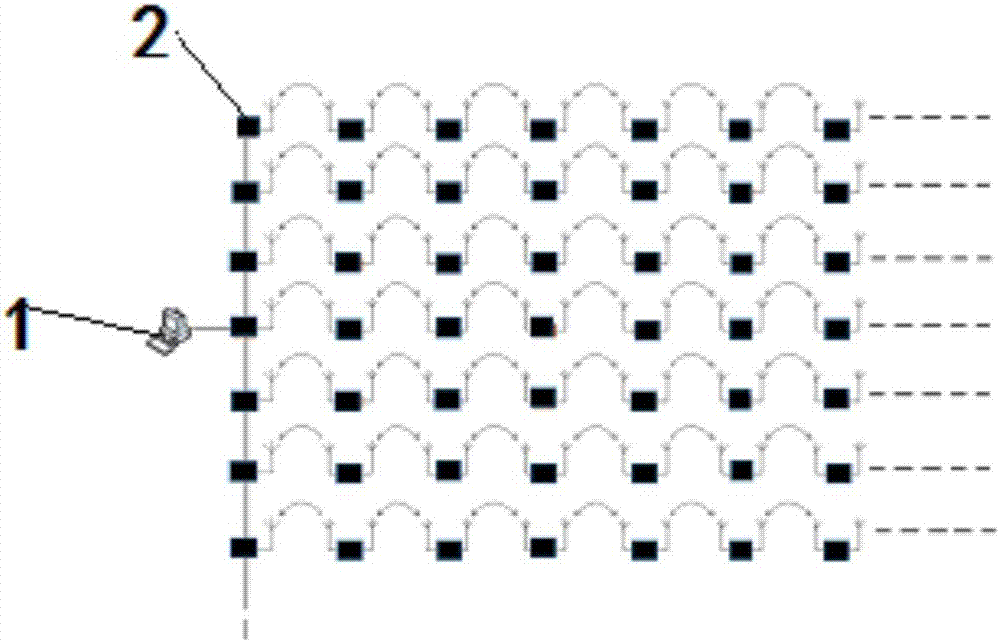

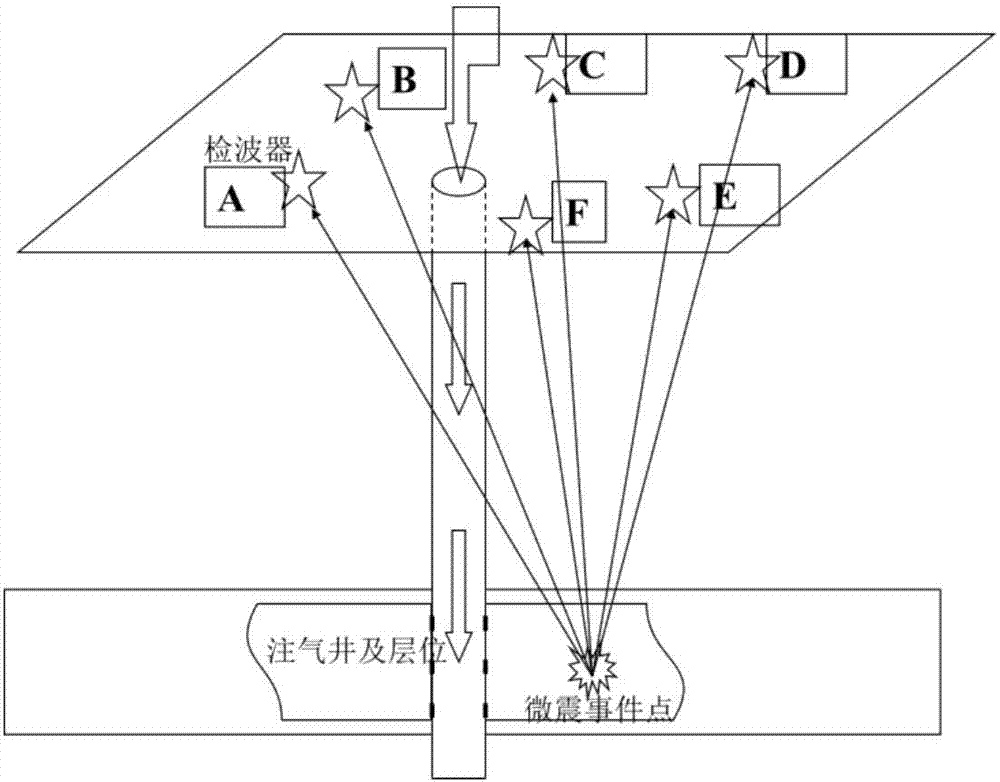

Microseismic wave monitoring method and system based on steam-assisted gravity oil drainage

ActiveCN106873028AReduce noiseReduced shieldingSeismic signal receiversSeismic signal processingTime distributionContinuous monitoring

The invention relates to a microseismic wave monitoring method and system based on steam-assisted gravity oil drainage, and the method comprises the steps: arranging a detection device nearby a monitoring region, and starting the detection of a microseismic event; enabling a microseismic signal to be processed initially in an automatic manner after a monitoring substation receives the microseismic signal, and then transmitting the microseismic signal to a central processing station; enabling the central processing station to carry out the analysis and calculation of the data, and obtaining the spatial and time distribution data of the microseismic fracture energy; explaining the occurrence time, spatial distribution and size of the fracture, and determining the distribution range and occurrence time and time of a steam cavity. The invention also relates to a system, and the system comprises a ground monitoring module and an underground monitoring module. The ground monitoring module and the underground monitoring module are respectively used for receiving and processing the microseismic signal data received on the ground and in the observation well. According to the invention, the method effectively improves the event positioning precision under the complex stratum conditions. A microseismic monitoring positioning terminal is simple and reasonable in structural design, and can achieve the real-time and continuous monitoring of the microseismic signal.

Owner:克拉玛依市海晟达石油科技有限公司

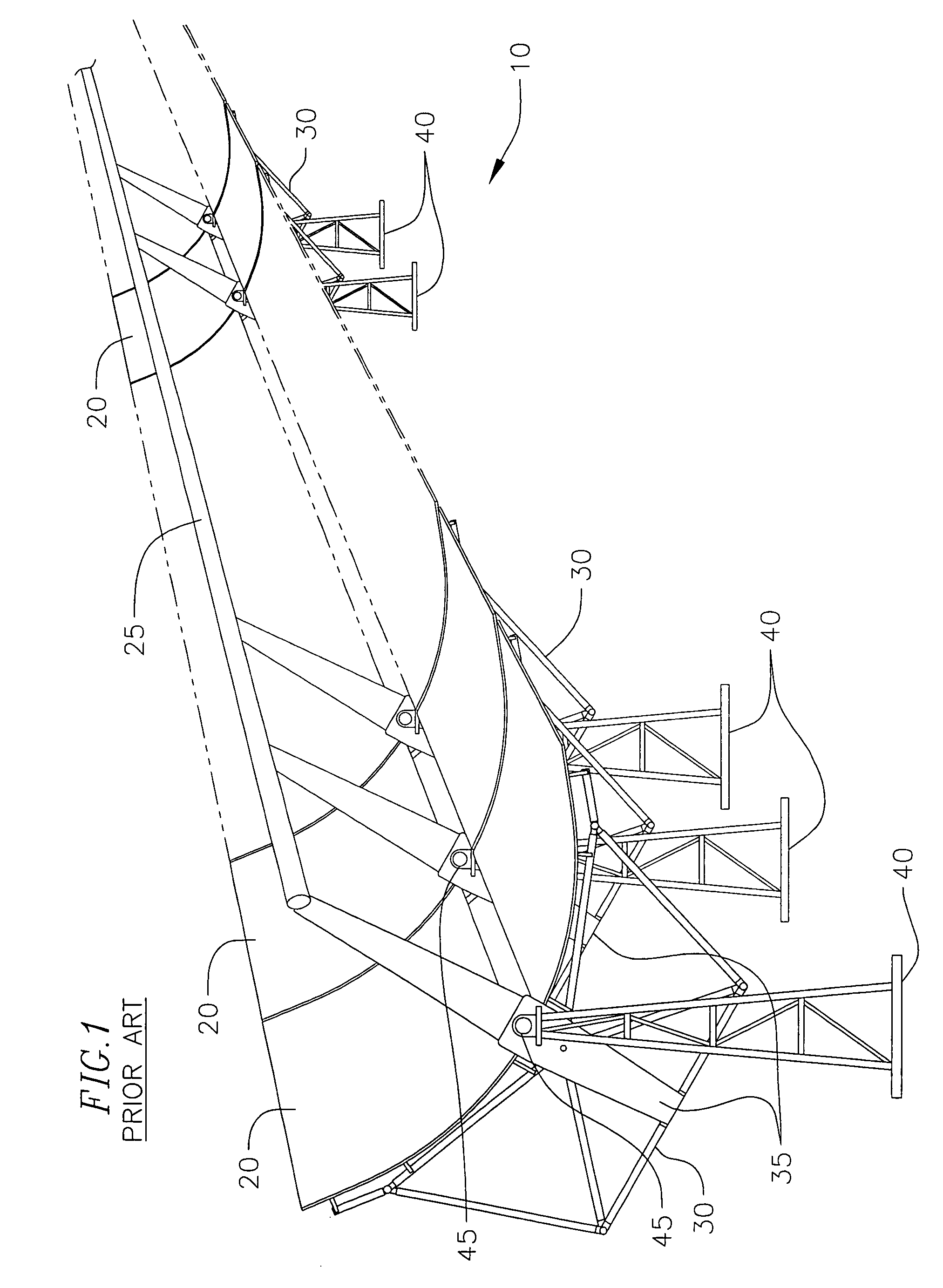

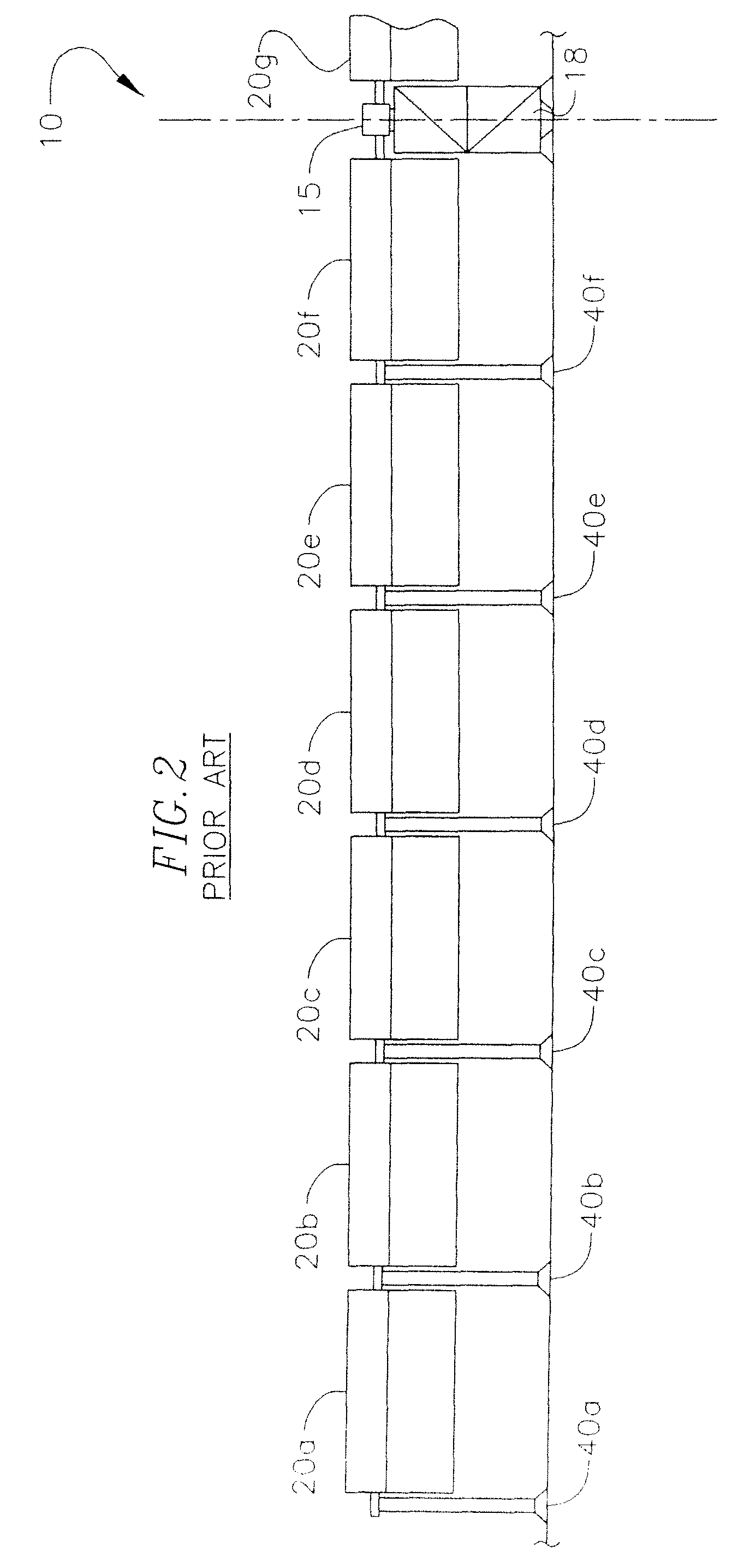

Multiplexed torque brake system for a solar concentrator assembly

InactiveUS8671931B2Design economyReduce design loadSolar heating energySolar heat devicesEngineeringDesign load

A multiplexed torque brake (MTB) system for preventing the accumulation of torsional forces at a center drive and thereby significantly reducing the design load requirements for trough frames of a corresponding solar concentrator assembly (SCA). In one embodiment, an MTB system for an SCA having a plurality of solar reflector frames spaced along a length of the SCA includes a plurality of brake mechanisms arranged at locations spaced apart from each other along the length of the SCA, each of the brake mechanisms coupled to a corresponding one of a plurality of supporting pylons and configured to constrain the solar reflector frames from rotating when subjected to torsional loads, the brake mechanisms adapted to transfer the torsional loads to the corresponding supporting pylons.

Owner:GOSSAMER SPACE FRAMES

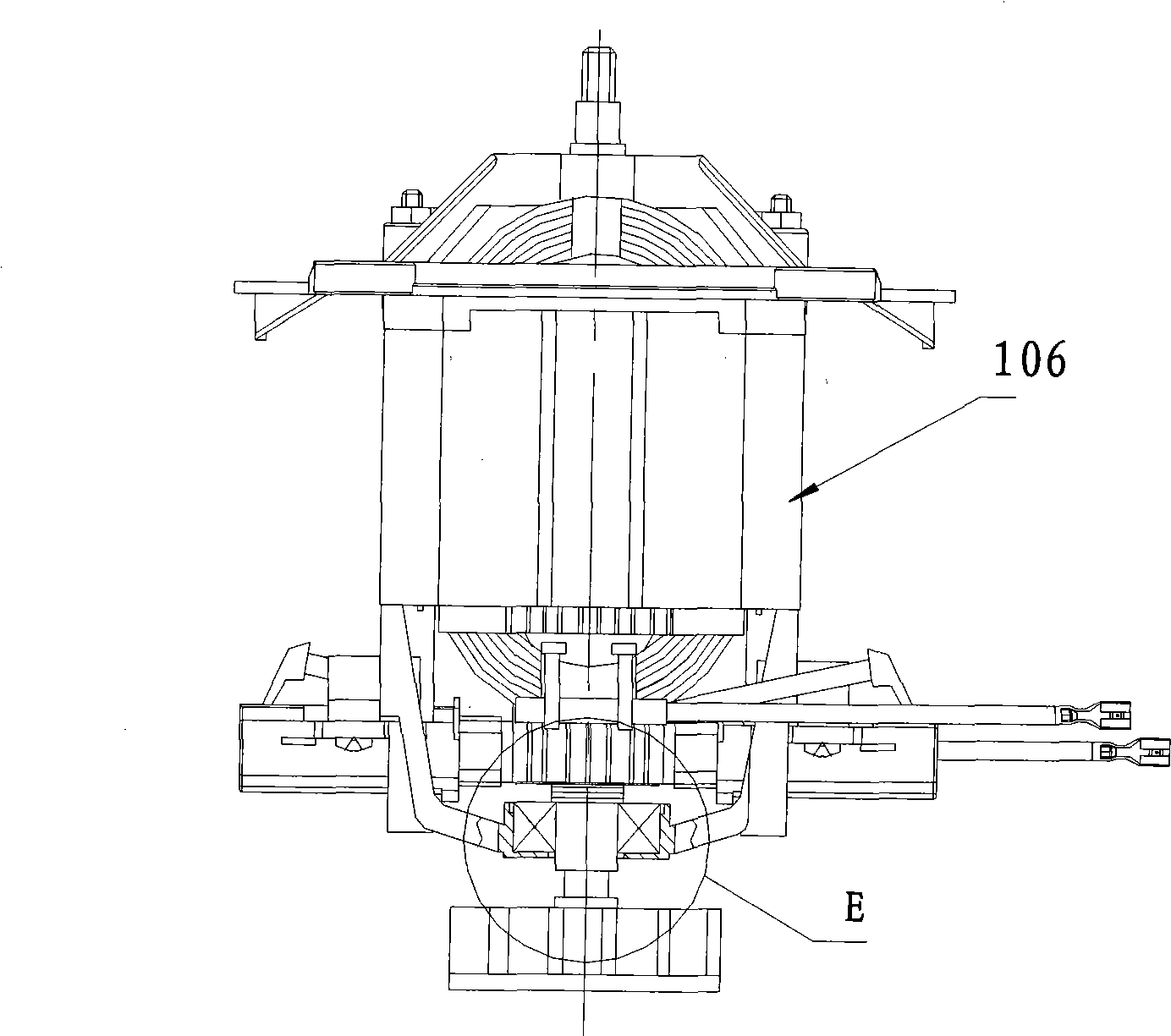

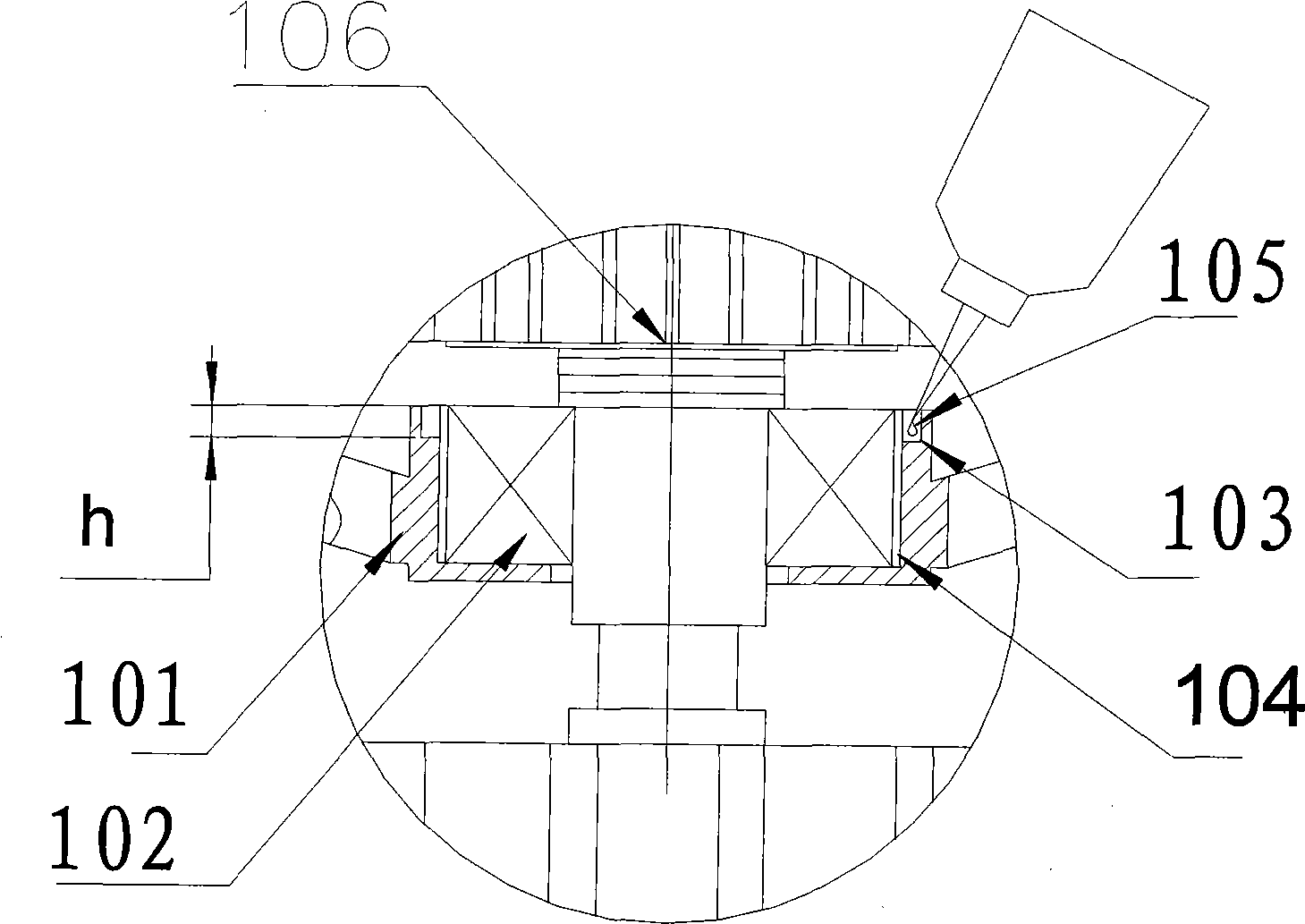

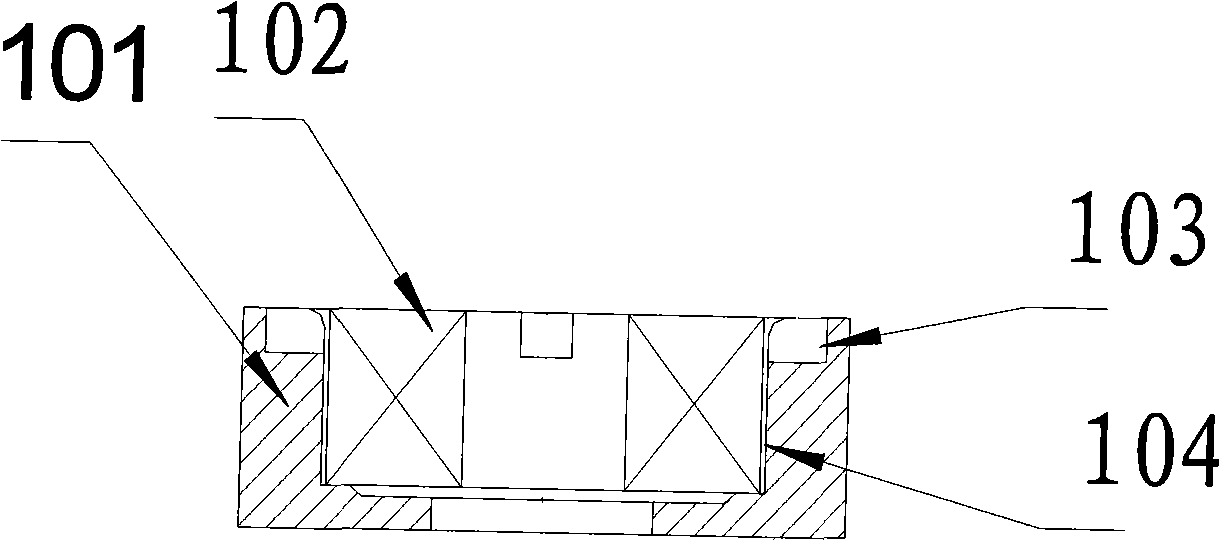

Method and structure for glue injection and holding when assembling bearing for motor

ActiveCN101499689AEvenly dividedAvoid damageManufacturing dynamo-electric machinesSupports/enclosures/casingsEngineeringMechanical engineering

The invention provides a method for glue-injection and solidification during the assembly of the bearing of a motor, comprising the steps as follows: two to four glue injection gaps (103) are arranged with equal intervals at the internal side of the end cover of the motor with a clearance fit bearing chamber (101) and at the upper edge of the ring wall of the bearing chamber (101); the motor end cover which is assembled in the bearing (102) is assembled on the motor (106), and all assembly and correction procedures are completed; gluewater (105) is dripped through all glue injection gaps (103) at the circumferential edge of the bearing chamber by each blowhole on the end cover; after the gluewater in the glue injection gaps (103) is completed infiltrated into the clearance (104) between the bearing chamber and the bearing external ring, all the extra gluewater remains in the glue injection gaps and is solidified. Compared with the prior art, the method has the technical effects that: due to the liquidity of the gluewater, the gluewater can be excellently ensured to be uniformly shared in the clearance between the bearing chamber and the bearing external ring, the solidification between the bearing and the bearing chamber is achieved, the damage of gluewater infiltrated inside the bearing to the bearing is avoided, simultaneously, the degree of adaptability of the motor and the bearing is improved, and the noise and vibration of the motor are greatly reduced.

Owner:DONGMING MOTOR ELECTRICSHENZHEN CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com