Vacuum pump impeller integral casting process

The technology of vacuum pump and impeller is applied in the field of integral casting process of vacuum pump impeller, which can solve the problems of lack of metal liquid feeding, uneven blade equalization, many consumables, etc. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

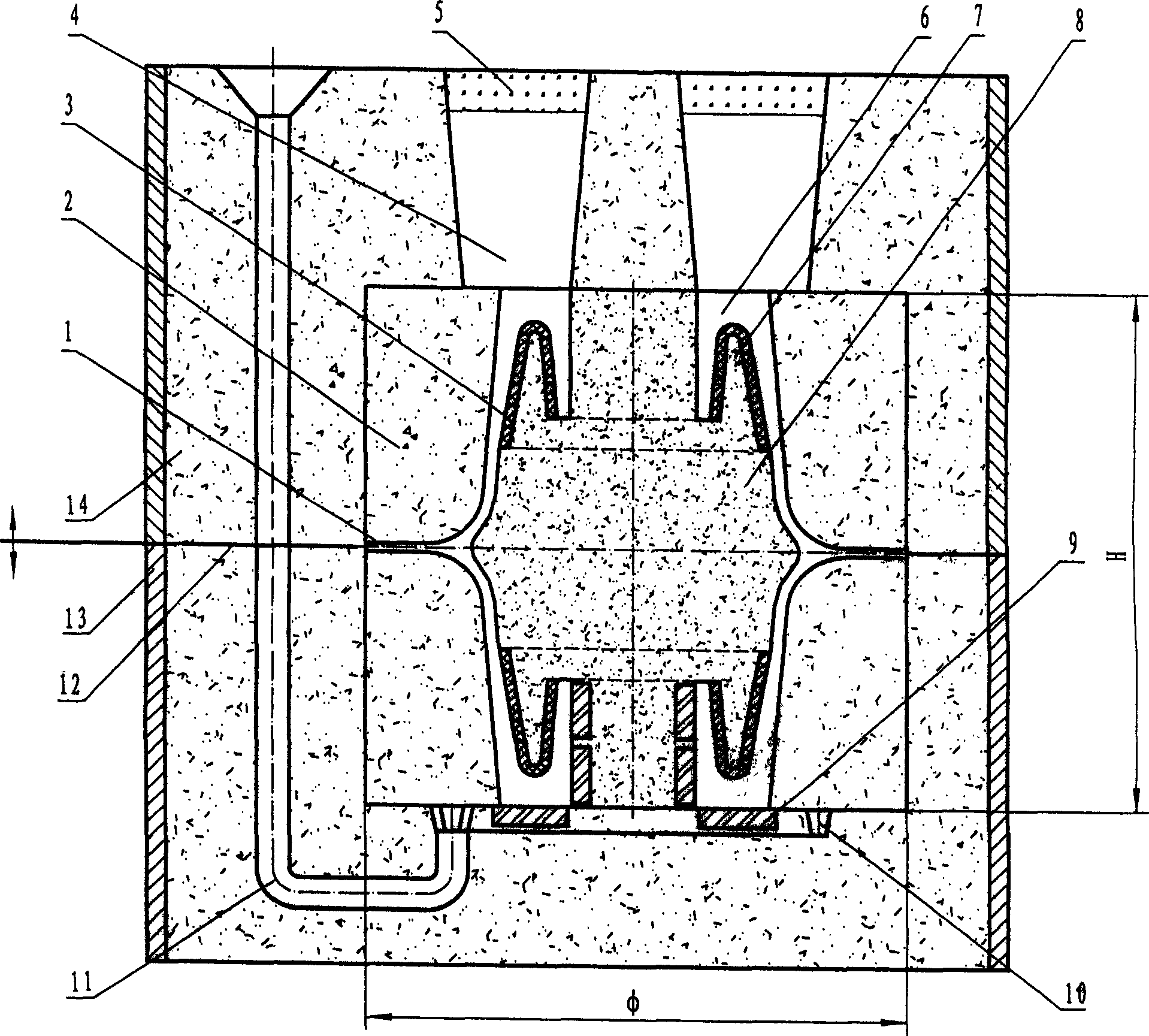

[0011] The integral casting process of the vacuum pump impeller of the present invention will be further described in detail below in conjunction with the examples of the above-mentioned drawings. The overall casting process of the vacuum pump impeller of the present invention is based on the conventional core box preparation, sand mixing molding, pouring, sand cleaning, removal of the pouring riser, and heat treatment, and the vacuum pump impeller φ (diameter) × H (height) = φ720 × H730 (mm), 18 to 20 blades each on the upper and lower sides, the alloy material adopts ZG0Cr18Ni9 as an embodiment of the present invention, and the integral casting process of the vacuum pump impeller of the present invention is described in detail.

[0012] The vacuum pump impeller of the present invention belongs to the upper and lower symmetrical components. Copper alloy is used to set the parting surface along the 1 / 2 thickness of the middle partition, and the upper and lower molds of the int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com