Patents

Literature

45results about How to "Dense structure of casting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

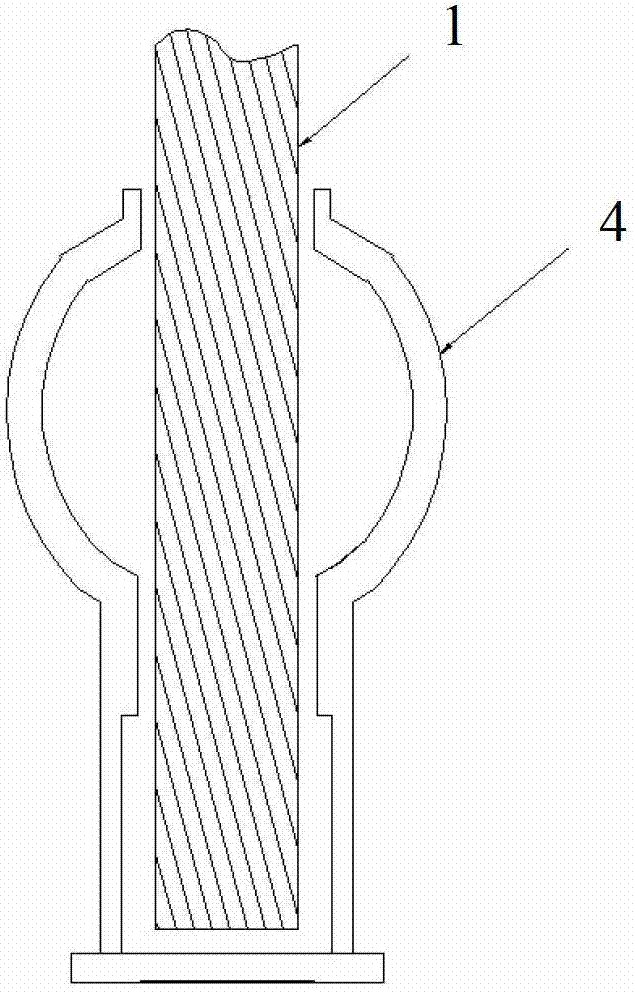

Vacuum pump impeller integral casting process

The present invention provides an integral casting process of vacuum pump blade wheel. It uses copper alloy to make the integral pattern prepared by using intermediate partition board, blade and wheel hub undergo the processes of numerically-controlled processing and moulding treatment. Its sand core is placed in lower mold, on the sand core of internal cavity place a ceramic core is set, upper blade wheel and upper wheel hub top portion are equipped with riser, undersurface of lower wheel hub and shaft hole place are equipped with external chill, the internal running channel set in lower blade bottom end is communicated with straight running channel in the mold. The molten metal can be fed into internal running channel via straight running channel, then passed through the lower blade bottom end and introduced into mold cavity to make bottom casting operation, when the molten metal is reached to riser top from bottom to top, an exothermic mixture is added into riser interior, after the casting is cooled, the molding box is opened, sand is removed and the casting is undergone the process of heat treatment.

Owner:遵义拓特铸锻有限公司

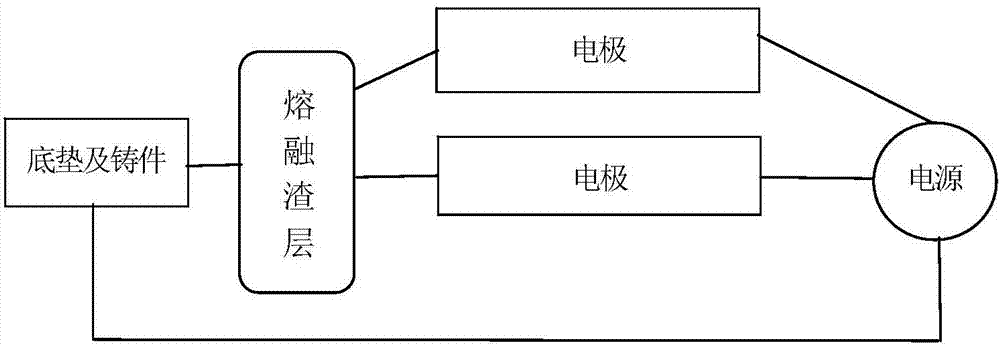

Electroslag smelting casting method of fixed blades of water turbine

The invention relates to an electroslag smelting casting method of fixed blades of a water turbine. Consumable electrodes are prepared by adopting a voltaic arc furnace refining method and the fixed blades are prepared by adopting an electroslag smelting casting process through a mould. The chemical components of the consumable electrodes are controlled as follows: C is 0.14-0.19 percent, Si is less than or equal to 0.6 percent, Mn is 1.5-1.9 percent, P is less than or equal to 0.035 percent, S is less than or equal to 0.035 percent, V is 0.02-0.15 percent, Nb is 0.015-0.06 percent, Ti is 0.15-0.25 percent, Al is more than or equal to 0.015 percent, O is less than or equal to 0.0040 percent, N is less than or equal to 0.0080 percent, H is less than or equal to 0.00035 percent, and the balance is Fe. The electroslag smelting casting system and the electroslag guide are controlled as follows: CaF2 is 60-80 percent, Al2O3 is 40-20 percent, or less MgO and CaO (the total is less than or equal to 20 percent); and the electroslag amount is usually 1.5-5 percent of the weight of a casting. The invention has less amount of oxide and sulfide, small size, even distribution, clean casting base body, high cooling speed, large crystallization temperature gradient at the front of solid and fluid, compact casting texture, high size precision and little distortion, and can greatly improve the product property of the refined casting.

Owner:SHENYANG RES INST OF FOUNDRY

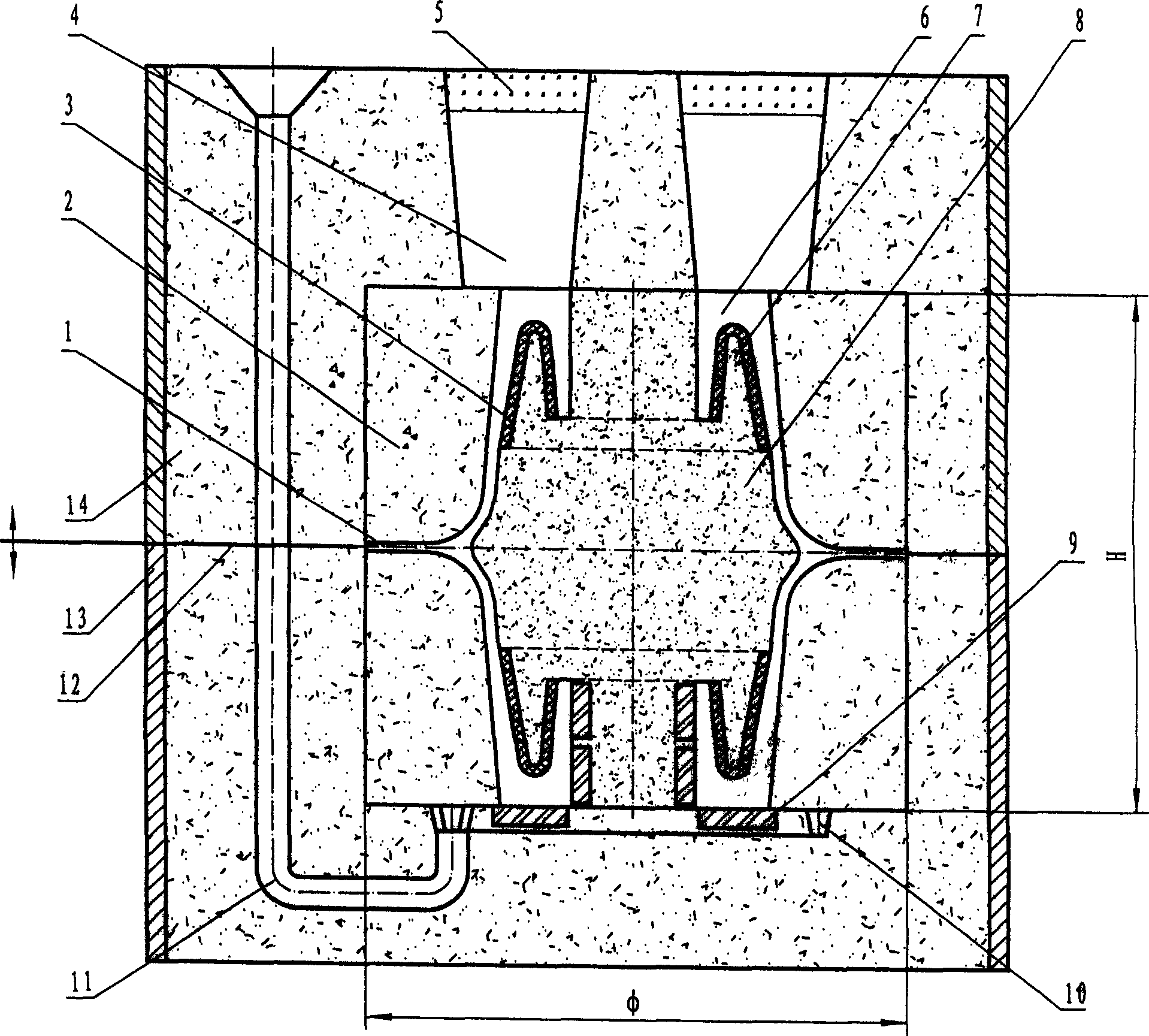

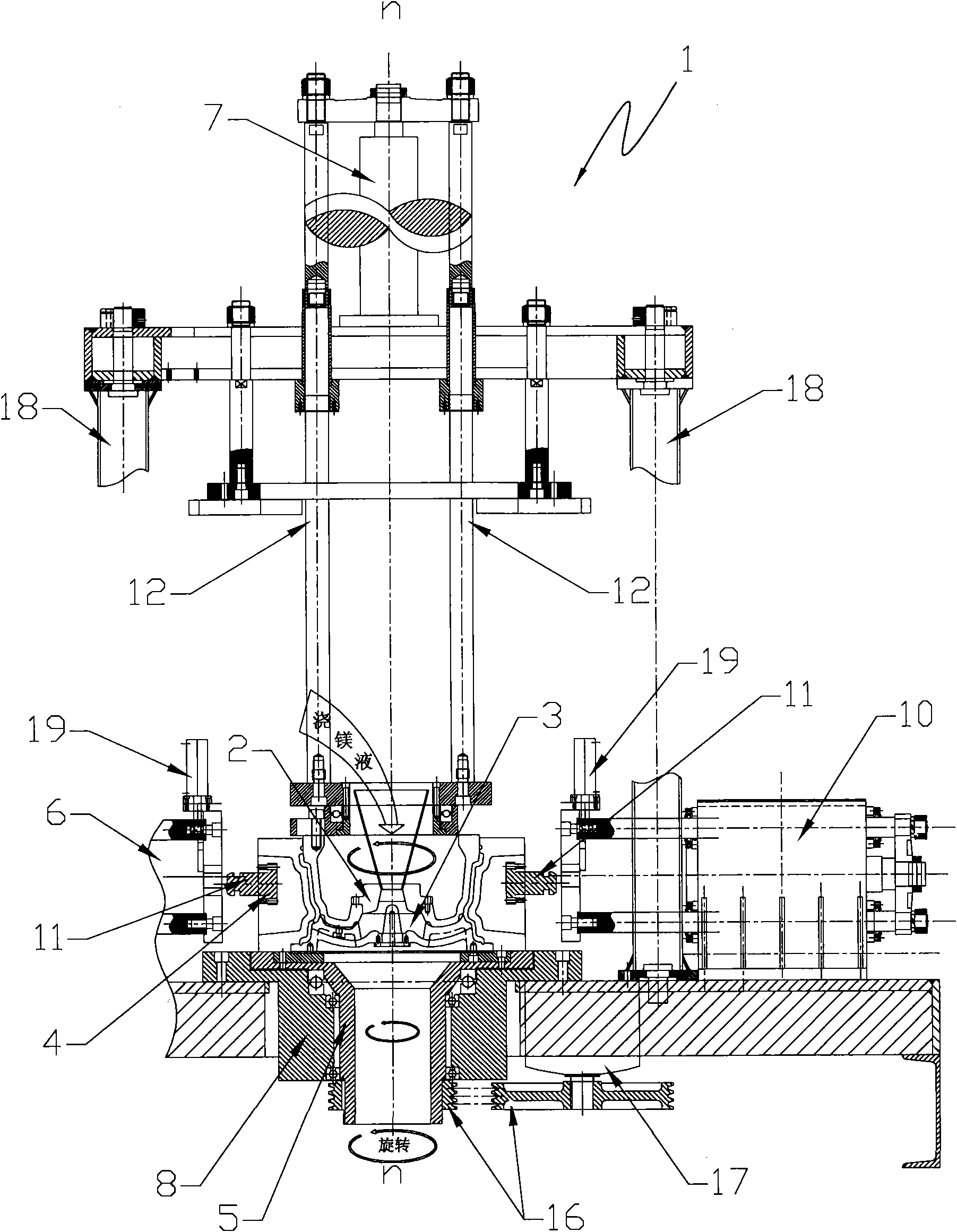

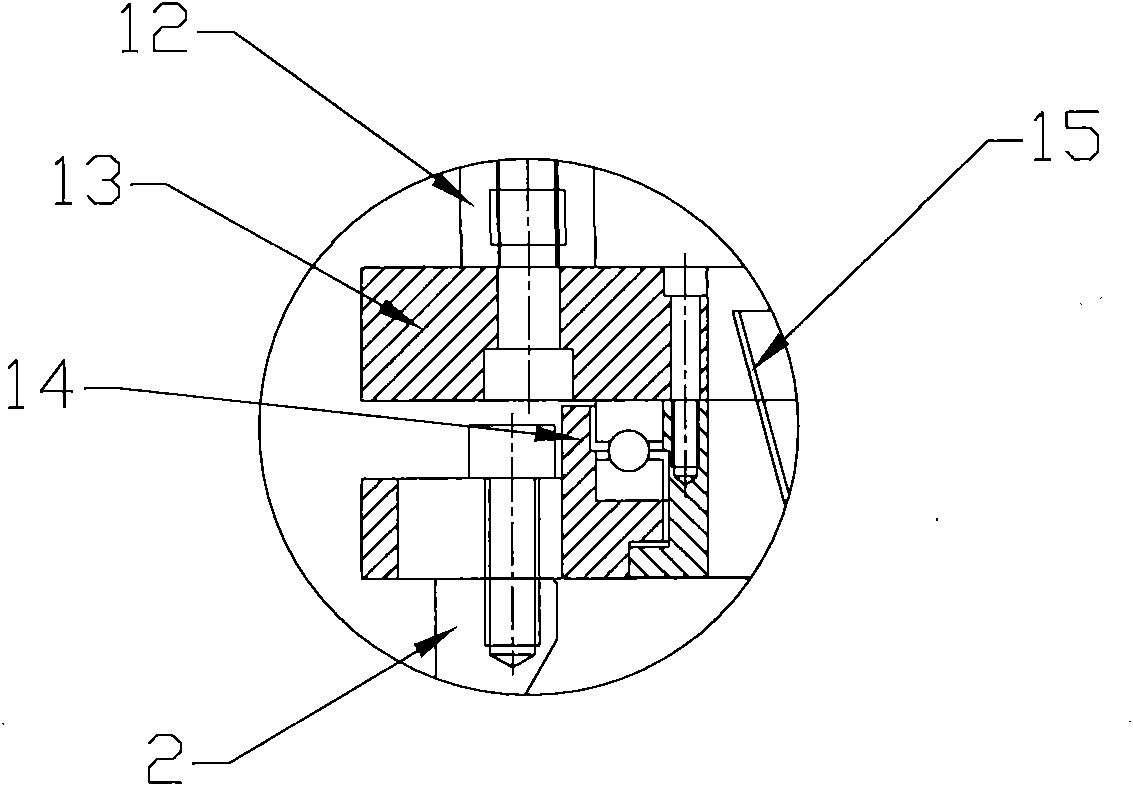

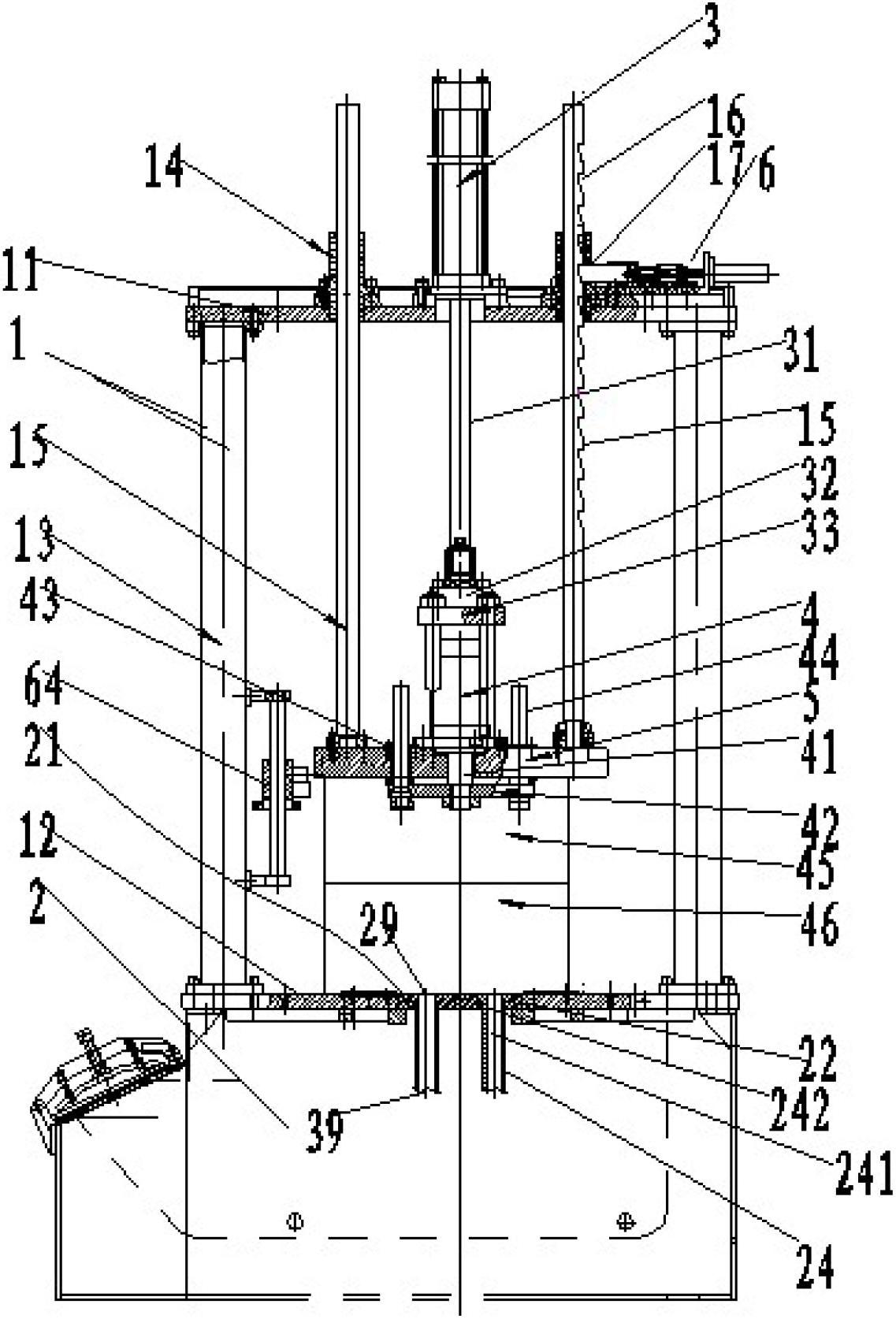

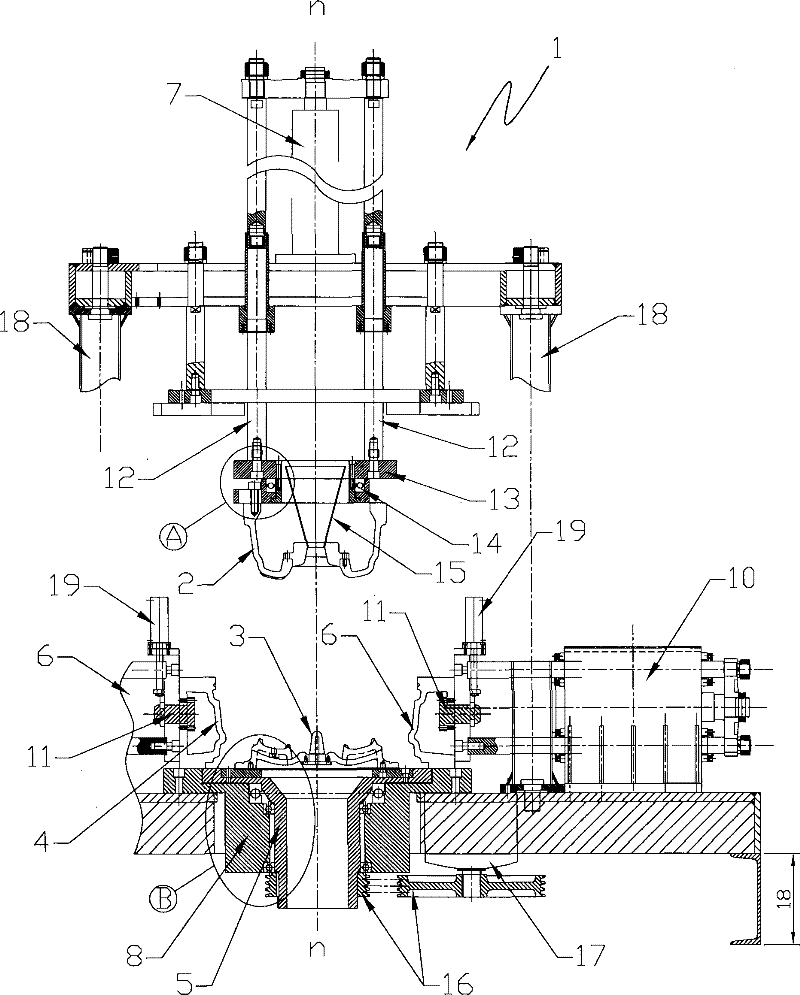

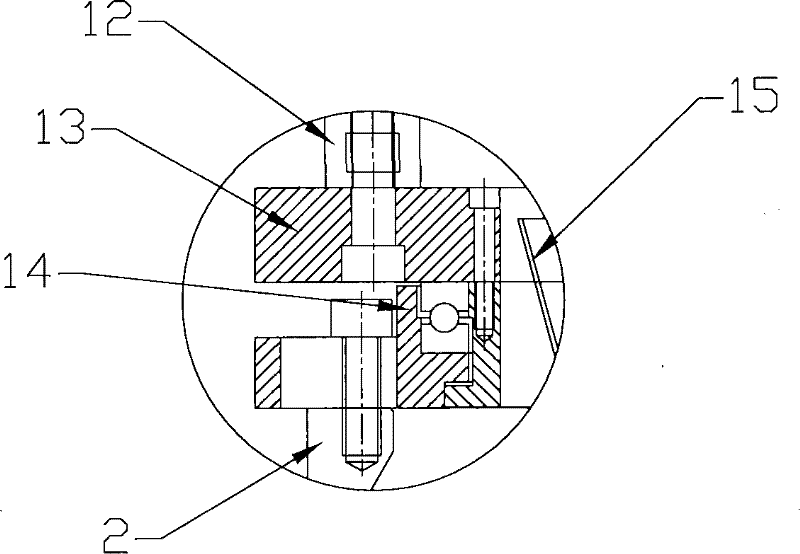

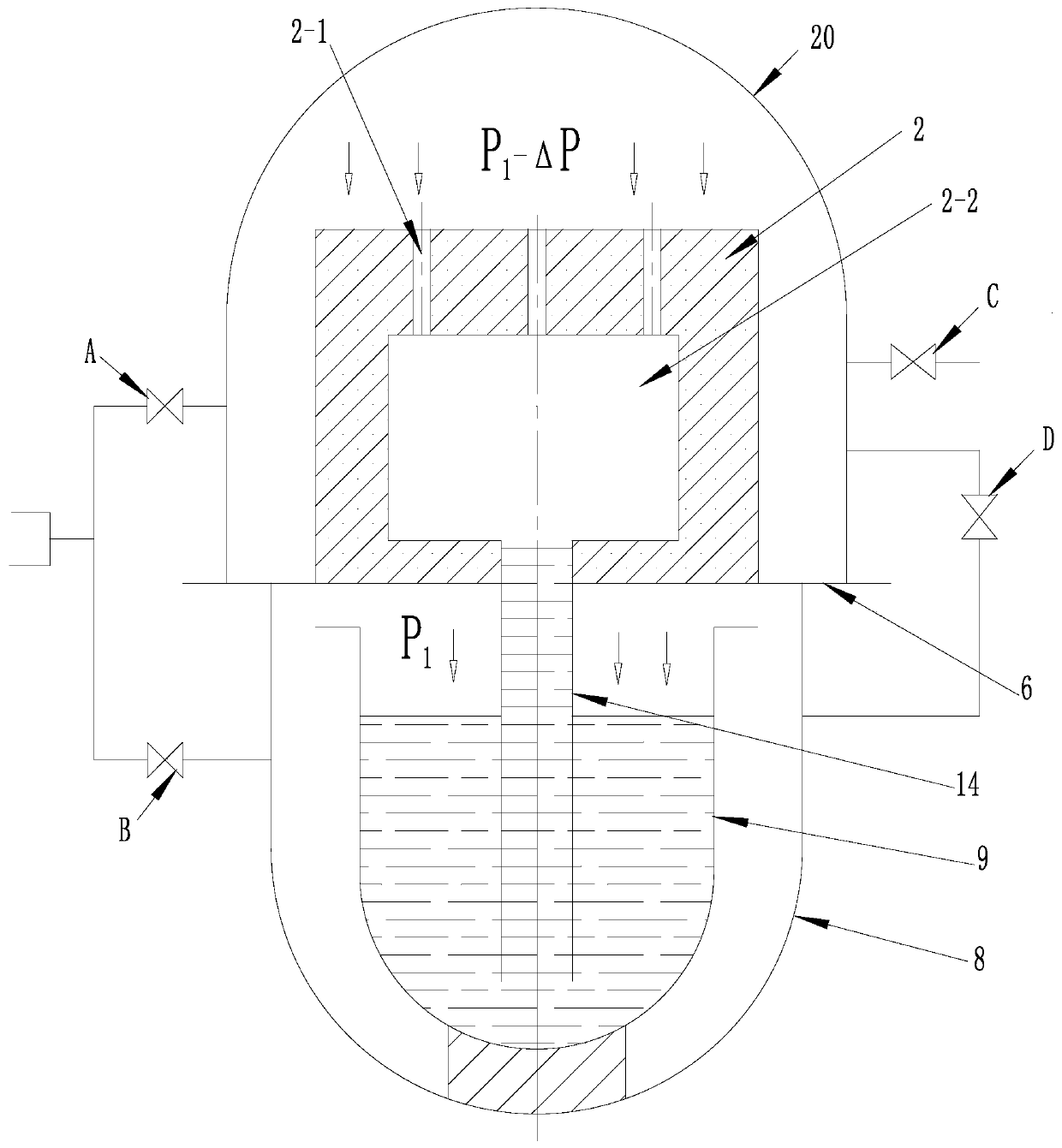

System for casting and pouring propeller of ship

The invention discloses a system for casting and pouring a propeller of a ship, comprising a sealing pressure tank (11), a steel ladle (10) which is arranged inside the sealing pressure tank (11) and used for containing high temperature molten steel (8), a liquid lifting tube (7) extending inside the steel ladle (10), a gas injection mechanism communicated with the sealing pressure tank (11), as well as a sand mold (2) and a mud core (3) that are arranged on the top of the sealing pressure tank (11); the sand mold (2) and the mud core (3) form a die cavity (14) and a shrink head (1), and the top of the liquid lifting tube (7) is communicated with the die cavity (14). By adopting the structure, the system for casting and pouring the propeller of the ship has stable liquid metal stamping, good formability and compact structure of cast parts as well as high mechanical property, so that the quality of the cast parts of the propeller of the ship can be ensured; the consumption of the metal liquid is reduced, and the yield of the metal liquid is increased, so that the system is applicable to the casting mold of various materials in batches.

Owner:WUHU FUJIHENG MACHINERY

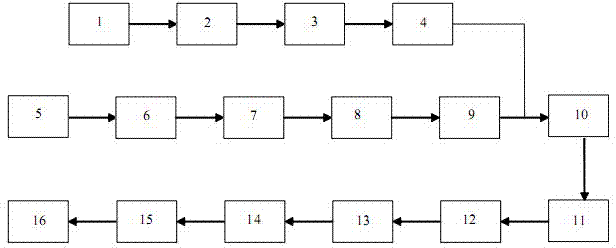

Process for casting heat-resistant steel or wear-resistant alloy steel by evaporative pattern casting (EPC)

InactiveCN103084542AReduce internal defectsDense structure of castingFoundry mouldsFoundry coresAdhesiveGraphite

The invention discloses a process for casting heat-resistant steel or wear-resistant alloy steel by evaporative pattern casting (EPC). The process comprises the following steps of: purchasing raw materials, blending the materials, performing steelmaking, manufacturing a pattern, preparing a coating, brushing the coating, drying, pouring, testing, thermally processing, polishing, and packaging and warehousing. The invention further provides ingredients of the raw materials. The ingredients respectively are 0.3-0.8% of copper, 0.1-0.3% of molybdenum and 0.2-0.5% of chromium; molybdenum is added together with waste steel in a melting process; and copper is added together with molten iron into ladles in a tapping process. The invention also provides a preparation method of the coating. The coating comprises the following components in percentages by weight: 50-80% of fireproof material, 0.5-4% of adhesive, 1-3% of suspending agent, 0.5-3% of sodium dihydrogen phosphate and the balance of water, wherein the fireproof material is composed of bauxite, alundum powder, graphite powder or mullite powder. By adopting the method disclosed by the invention, effects of low cost, short processing period and good quality are achieved, the process of the method is reasonable, and the preparation effects of the raw materials and the coating are good, so the method is applicable to mass production and large-scale production.

Owner:CHAOHU LETTER BUILDING MATERIALS MACHINERY & EQUIP LIMITED

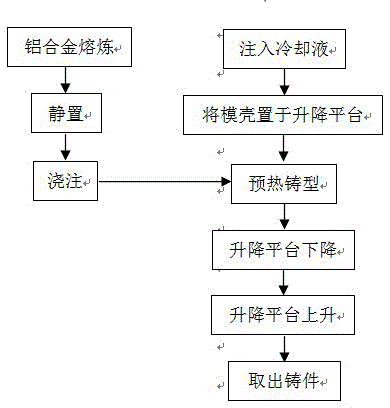

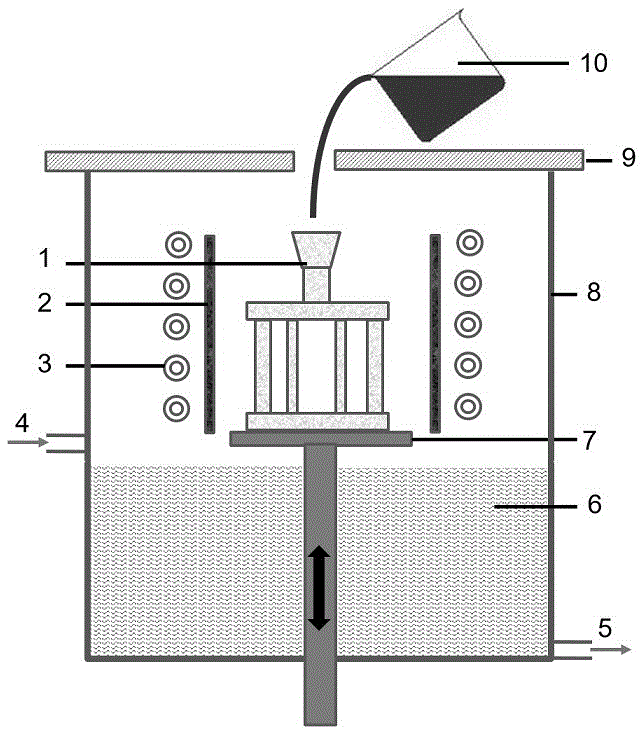

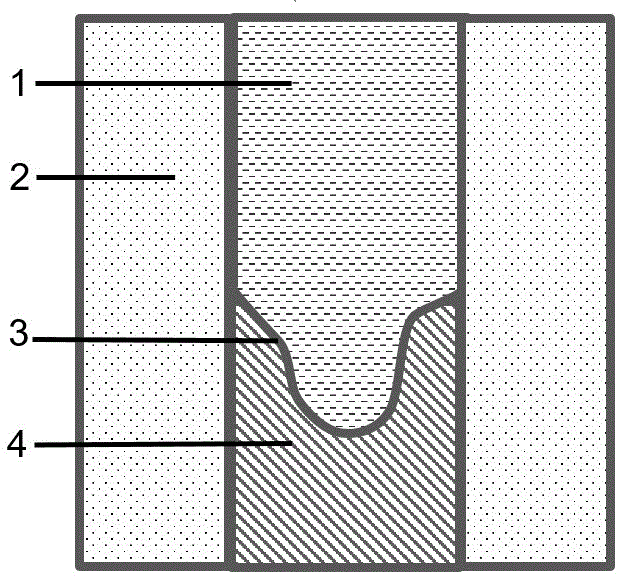

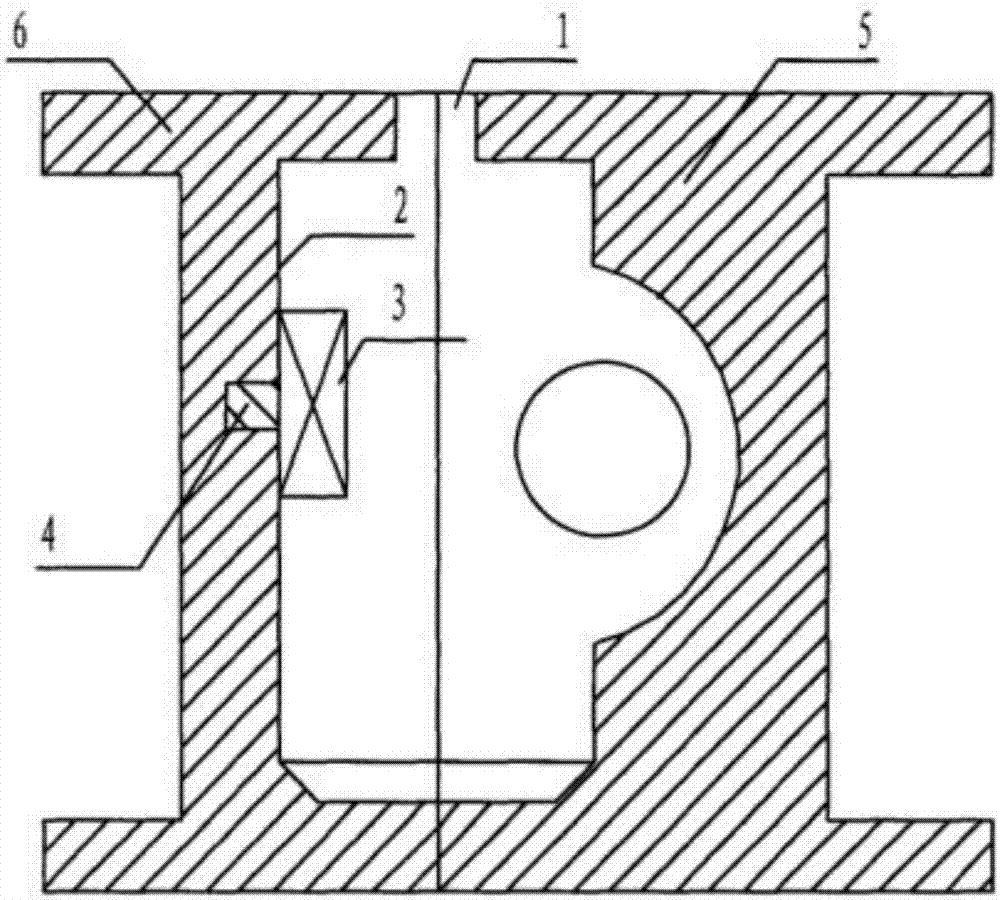

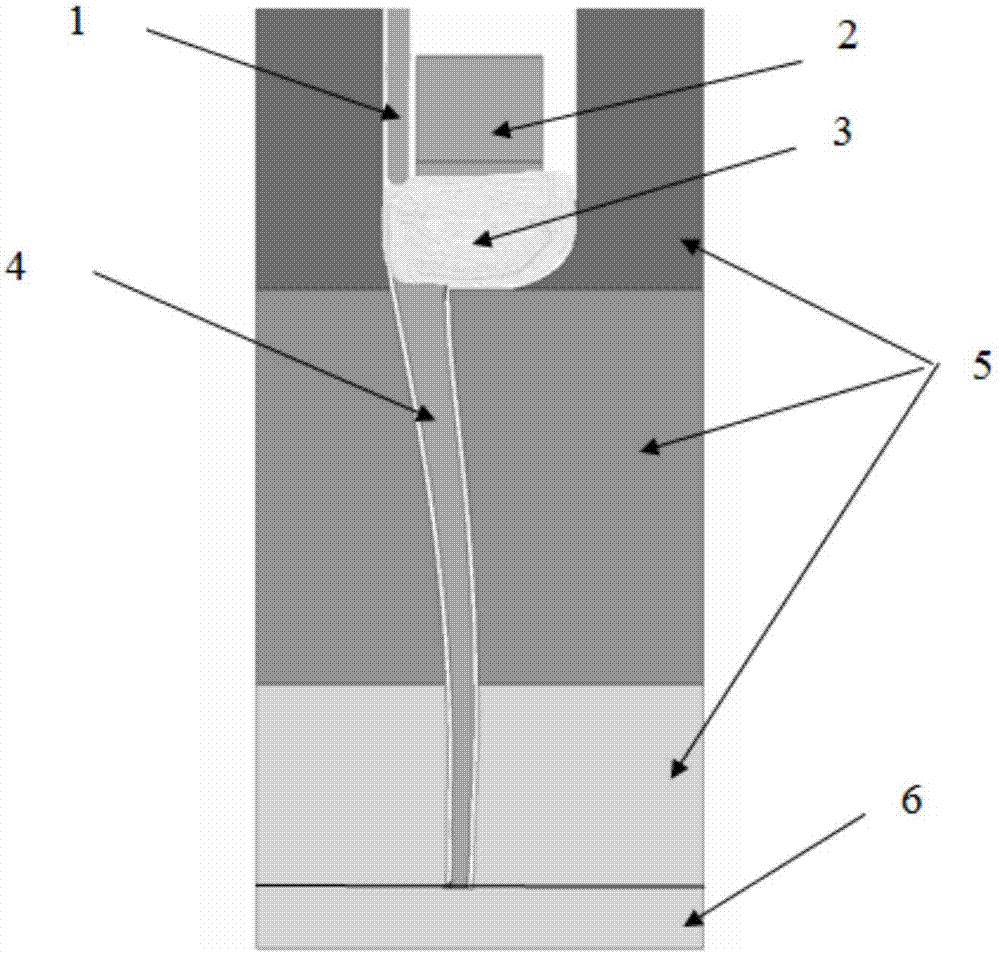

Aluminum alloy investment casting method and investment casting device adopting near liquidus pouring

InactiveCN105598372ADense structure of castingEliminate casting stressFoundry mouldsFoundry coresInvestment castingMelt temperature

The invention discloses an aluminum alloy investment casting method adopting near liquidus pouring. The method comprises the following steps: preheating a mould shell to be close to the liquidus, performing near liquidus temperature pouring, and meanwhile, reducing the pouring temperature, and pouring after the melt temperature is higher than the temperature of the liquidus; after finishing pouring, immersing the mould shell into the cooling liquid at a certain speed, thereby effectively and accurately controlling a solidification process of the casting; quickening the cooling of the casting, thereby acquiring the high-quality aluminum alloy casting with uniform structure and small grain. In the casting solidification process, the temperature gradient can be accurately controlled, the lower part of the casting is firstly soaked into the cooling liquid and the upper part is still in the heating atmosphere and under the molten state, so that the casting can be solidified from bottom to top, the solidified part is subjected to full liquid feeding, the casting is compact in structure, and meanwhile, the casting stress in the solidification process of each part of the casting is eliminated. The method provided by the invention is fit for common aluminum alloy casting and large-size, thin-wall and complex aluminum alloy investment casting.

Owner:NANCHANG HANGKONG UNIVERSITY

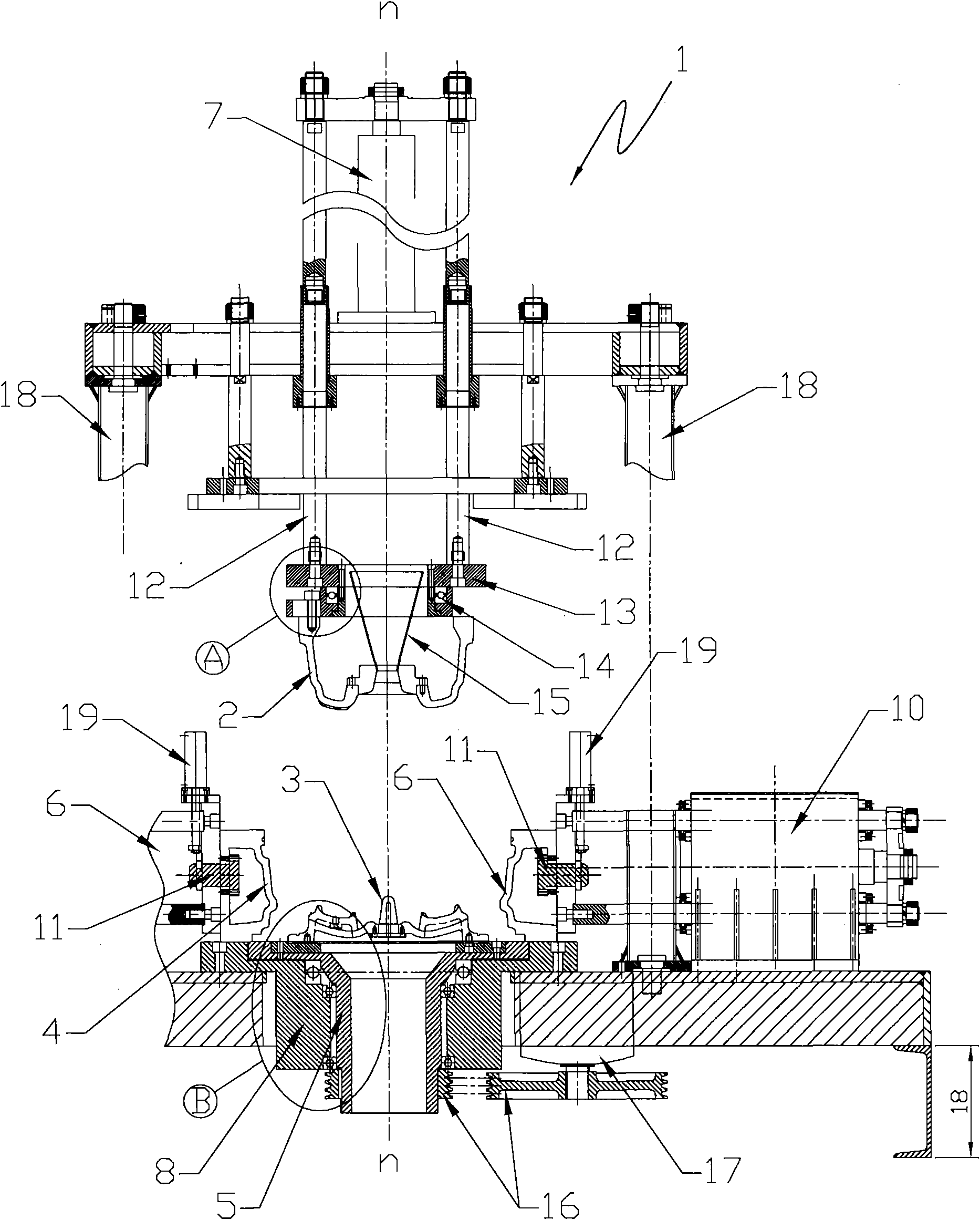

Centrifugal casting method and device of magnesium alloy hub

The invention relates to a centrifugal casting method of a magnesium alloy hub, which belongs to the technical field of casting. The prior gravity and low-pressure casting method for casting the magnesium alloy hub exists the easily occurred casting defects of incompleteness of mould filling, shrinkage cavity, cold shut, hot cracking, shrinkage cracking, and the like. An upper die, a side die and a lower die of a die are matched and then held into a whole, then gravity center casting is carried out for the matched die, the die is enabled to rotate around the axes thereof for a set time and then stop before cast magnesium melt solidifies, the cast mode can be divided into casting before die rotating and casting after die rotating according to the technological requirements of concrete products, and the die is opened to take out a cast after the magnesium alloy melt solidifies. With the method, the magnesium melt in the die can rapidly fill shrinkage towards peripheral parts under the action of centrifugal force to enable cast products to be full and compact, and the method has the advantages of low production rejection rate, compact structure of casts, improvement of quality of workpieces, and the like.

Owner:SHANGHAI MERIDIAN MAGNESIUM PROD CO LTD

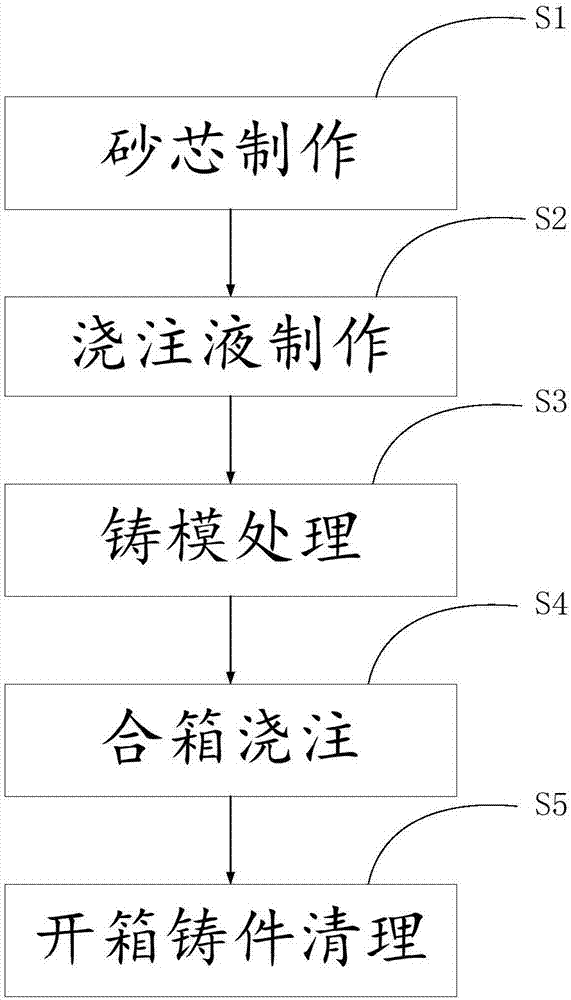

Manufacturing technology of gearbox body casting

InactiveCN107363227ADense structure of castingReduce the occurrence of pinholes in castingsFoundry mouldsFoundry coresDesign technologyMetal

The invention provides a manufacturing technology of a gearbox body casting, and belongs to the technical field of metal casting. The manufacturing method comprises the following steps: S1, sand core manufacturing, specifically, manufacturing the sand core of a gearbox body by combining refractory mortar coated sand with a sand core box mold, and baking the sand core for later use; S2, casting liquid preparation, wherein the adopted casting alloy material is ZAlSi7MgA; S3, casting mold processing, specifically, the casting mold processing is preheating a casting outer mold and assembling the sand core prepared in the step S1 in the inner cavity of the casting mould to form a casting model; S4, mold closing and casting, specifically, pouring the casting liquid prepared in the step S2 into the casting model prepared in the step S3; and S5, mold opening and casting cleaning, wherein the mold opening and casting cleaning comprise the steps of cutting, rough grinding and fine grinding. According to the manufacturing technology of gearbox body casting, through reasonable designed technology parameters, a casting structure is compact, and the occurrence of casting pin holes is reduced.

Owner:江苏雷科德轨道交通科技有限公司

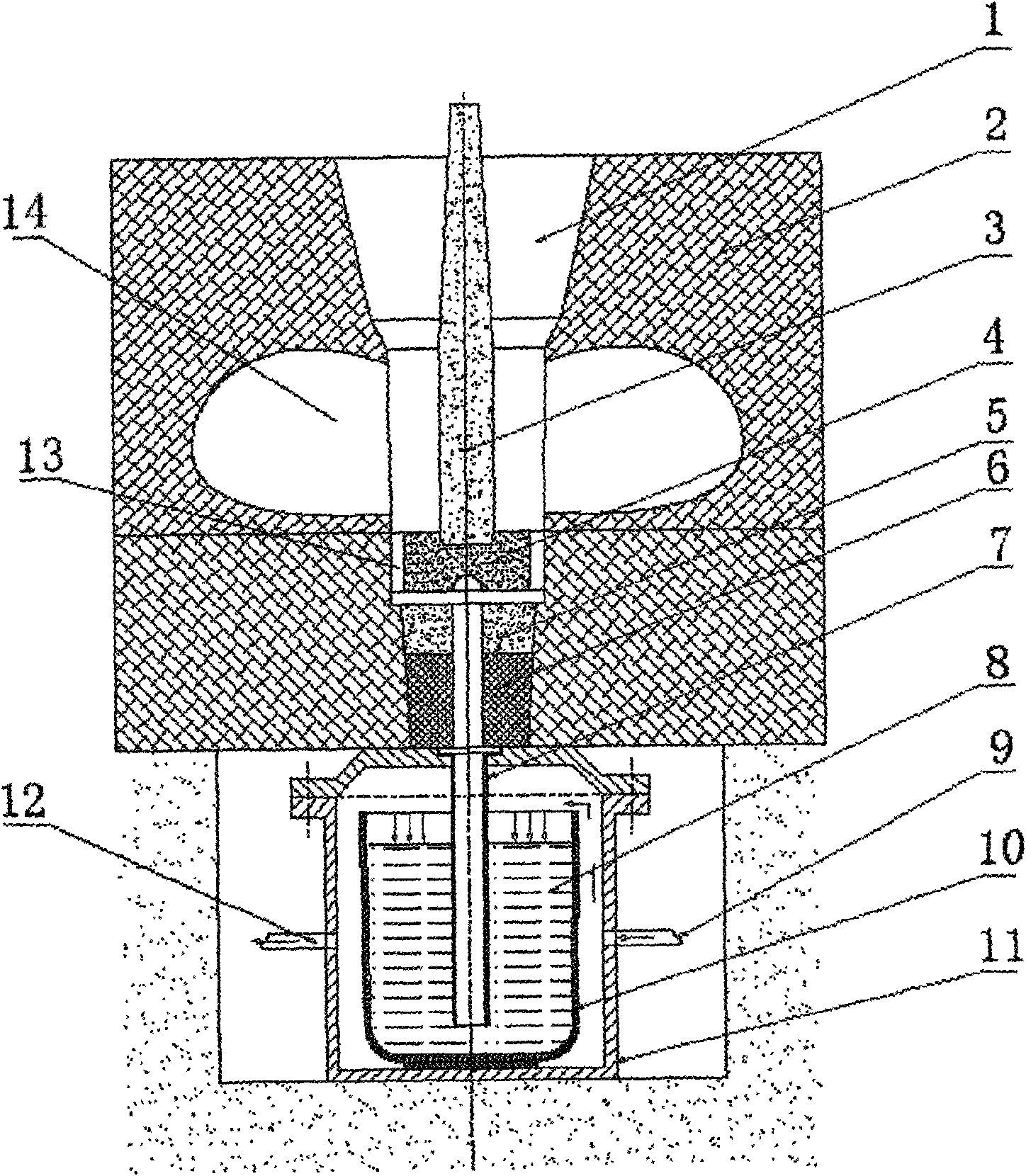

Fired mold low-pressure casting process of integral type compressor impeller

InactiveCN103658536AReduce labor intensityIncrease pressureFoundry mouldsFoundry coresImpellerStaining

The invention provides a fired mold low-pressure casting process of an integral type compressor impeller. The process comprises the following steps of preparing coating with silica sol binder for fired mold casting, wherein a fireproofing surface layer and a second layer are made of fused alumina powder and sand, and a reinforced layer is made of mullite powder and sand special for fired mold casting; when coating the coating on the reinforced layer, adopting a two-time slurry staining method, i.e. firstly staining thin coating and secondly staining thick coating; and after dewaxing a shell, roasting at the low temperature of 500 DEG C, storing, and roasting at high temperature before pouring, wherein the temperature of high-temperature roasting is 1000 DEG C, the heat preservation time is 4h, and the temperature of the shell during pouring is 100-150 DEG C. The prepared shell is high in strength, low-pressure pouring can be carried out by utilizing a single shell, the pouring temperature of molten aluminum is 670-680 DEG C, the mold-filling pressure is 0.03 MPa, the mold-filling time is 10s, the solidification holding pressure is 0.35 MPa, and the holding pressure time is 5min. The integral type compressor impeller produced by adopting the fired mold low-pressure casting process is good in mold-filling and feeding effect, compact in casting tissue, good in product mechanical property and inner quality, high in production efficiency, and low in labor intensity, and has no need to be modeled through binning.

Owner:SHANDONG JIANZHU UNIV

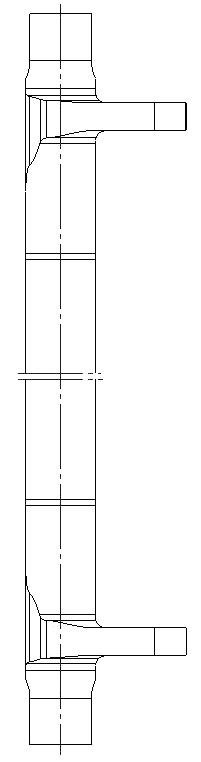

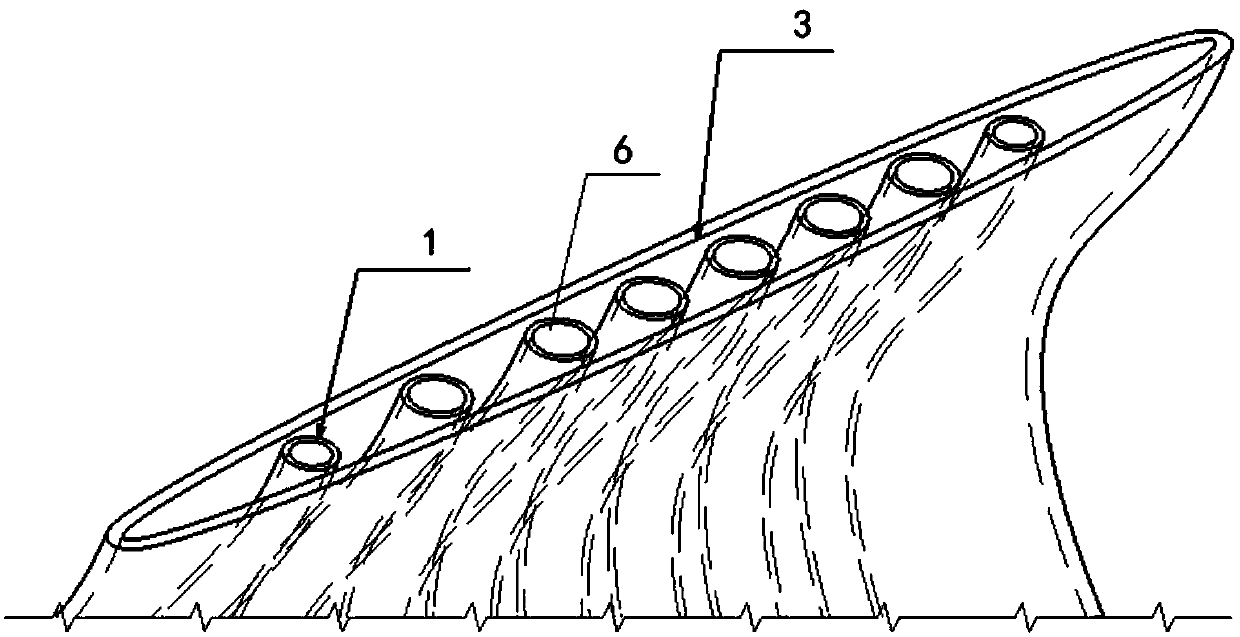

Method for low-pressure casting thin-wall long-sized castings and equipment used by same

The invention relates to a method for low-pressure casting thin-wall long-sized castings and equipment used by the same, wherein metal materials are firstly smelted, a furnace body is closed, a mould is prepared, dry compressed air is filled into an airtight container, under the action of gas pressure, liquid metal rises along a multitube and multi-sprue riser tube and stably enters a mould cavity through a sprue, and the gas pressure on the liquid level in a crucible is kept; and after the casting is completely solidified, the gas pressure on the liquid level is relieved to enable the unsolidified liquid metal in the riser tube to flow back into the crucible, and then the casting is taken out. The method for producing the thin-wall long-sized casting has the advantages that mold-filling is stable, a product is well molded, the mold-filling of liquid metal is carried out under the pressure, the liquid metal has good liquidity and is convenient to cast the thin-wall casting of the kind the casting is crystallized and solidified under the pressure and has a compact structure, so the mechanical property is improved, a pouring system is simple, casting heads are reduced, mechanization and automation are realized, the labor intensity of workers is reduced, a mould with multi-cavities is realized, the production efficiency is improved and the like.

Owner:烟台路通精密科技股份有限公司

Electroslag casting production method for waterwheel blade green compact

An electroslag casting production method for a waterwheel blade green compact is characterized by comprising the following steps: confirming the outline of the blade green compact according to the intelligent three-dimensional expanded size of a water turbine blade; producing a crystallizer and a consumable electrode of the blade green compact; preparing the qualified blade green compact of the electroslag casting water turbine by optimizing electroslag casting process parameters and the anti-cracking heat treatment process. The method has the advantages that the detects of the conventional blade green compact of the water turbine can be overcome; a near-net forming green compact producing process is provided for the water turbine blade formed through heated-die pressing process; the produced blade green compact material is high in degree of purity, uniform in chemical constituents, compact in structure, free of defects such as looseness, slag inclusion and hole shrinkage, favorable in mechanical property, and higher in fatigue resistance performance, anti-cracking performance and expansibility, and can reach the mechanical property of forge pieces made of the same material and meet the requirements of flaw detection indexes.

Owner:SHENYANG RES INST OF FOUNDRY

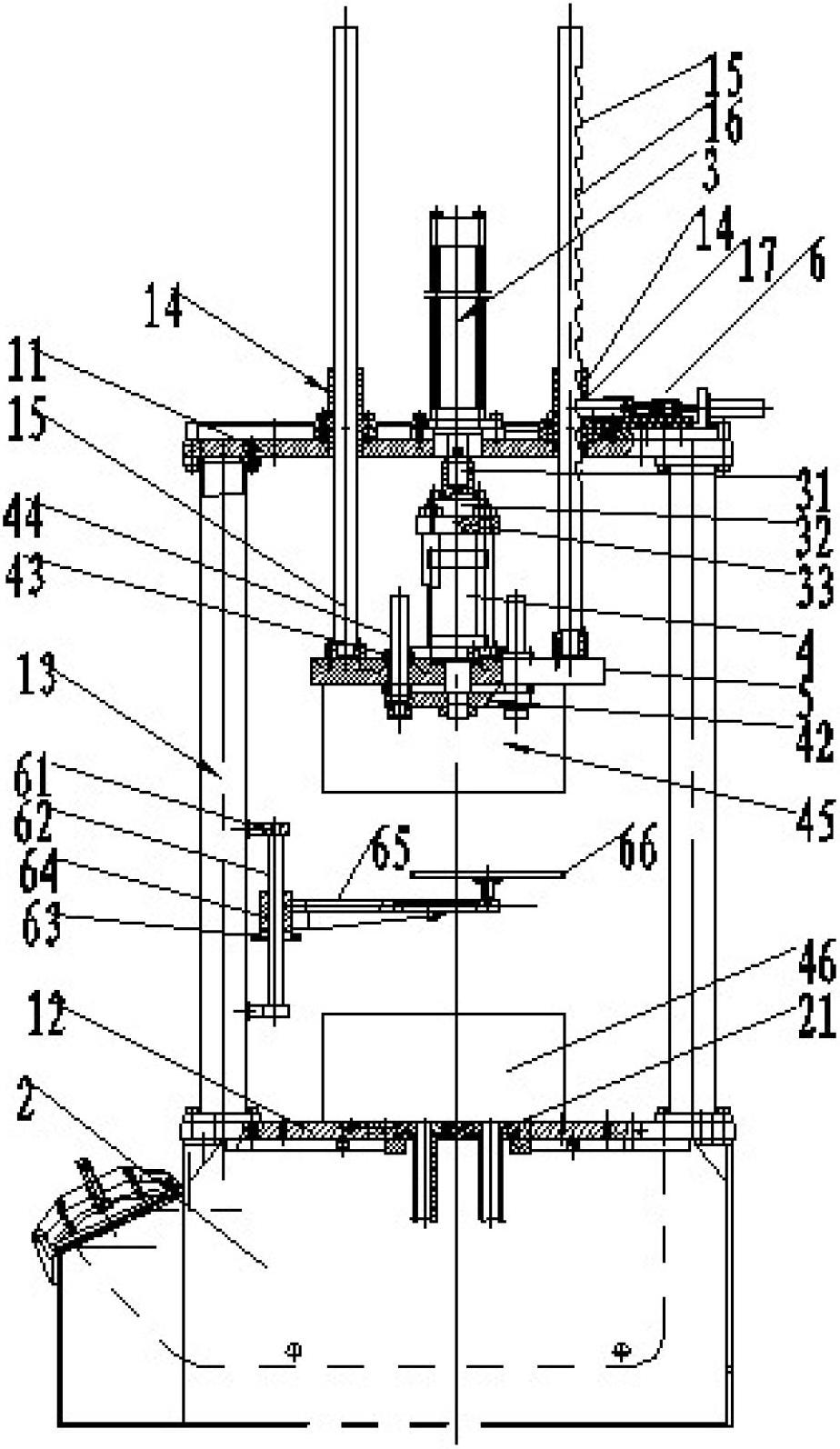

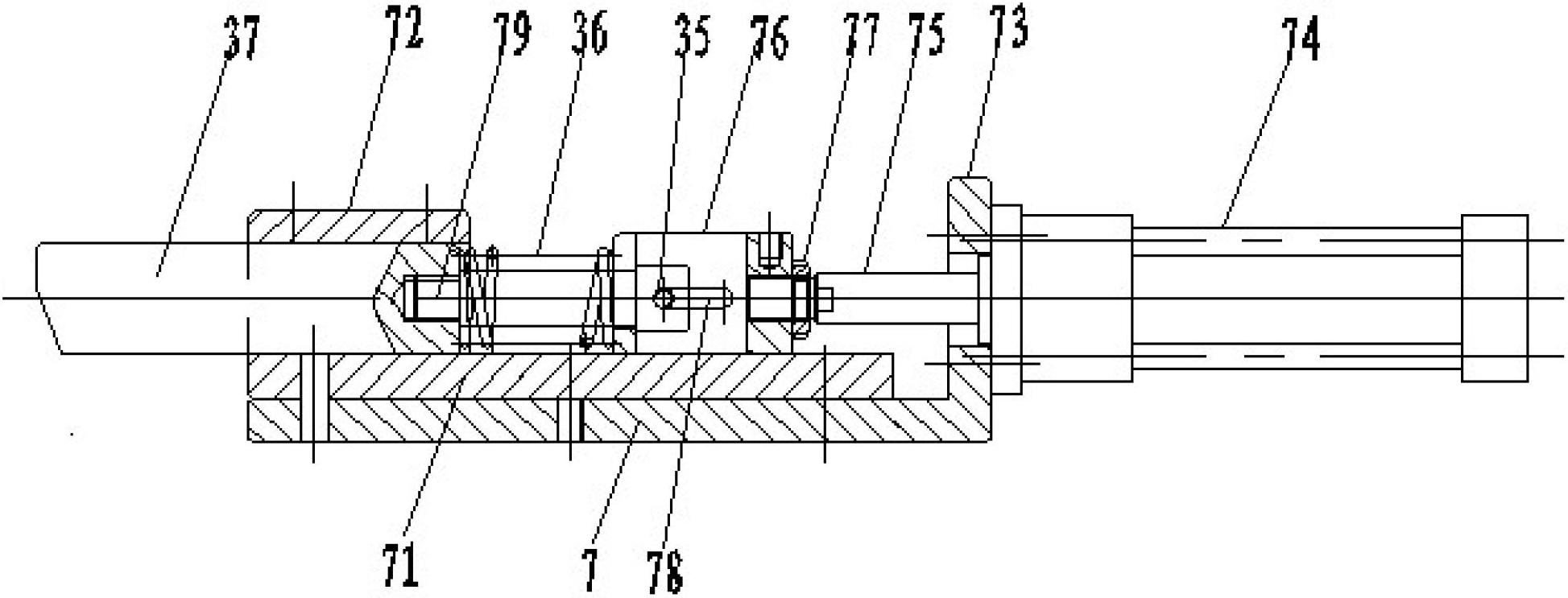

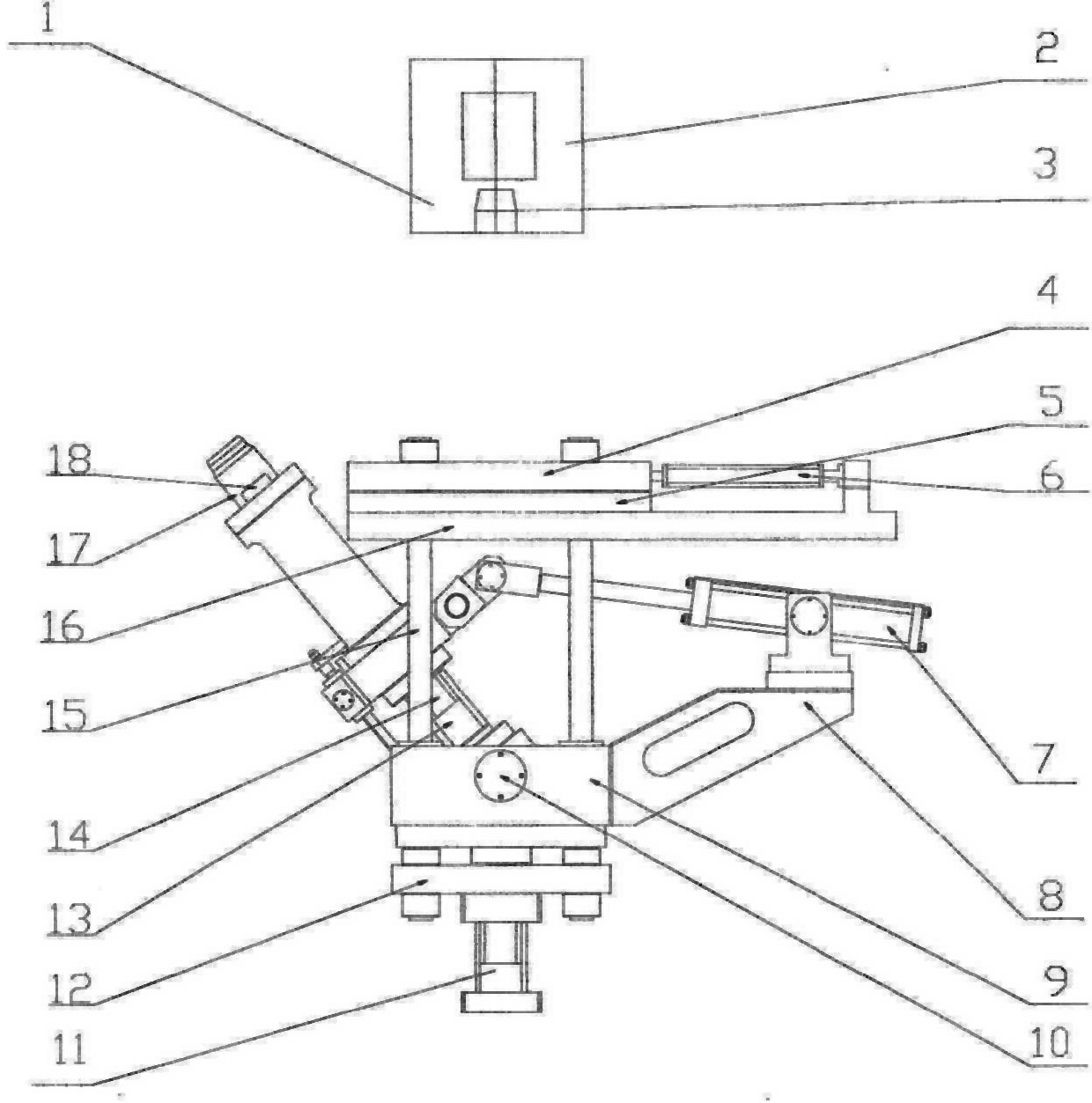

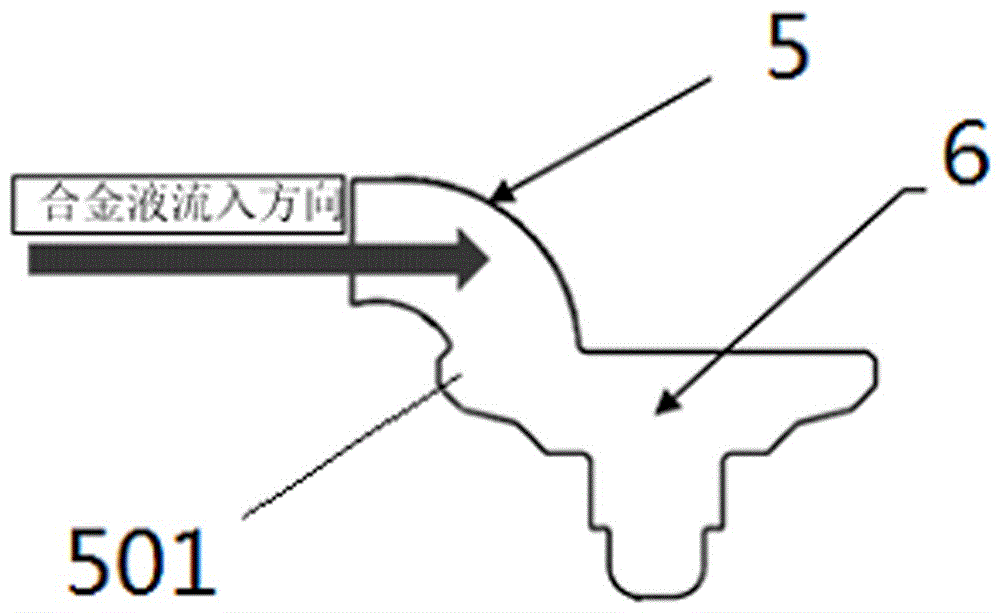

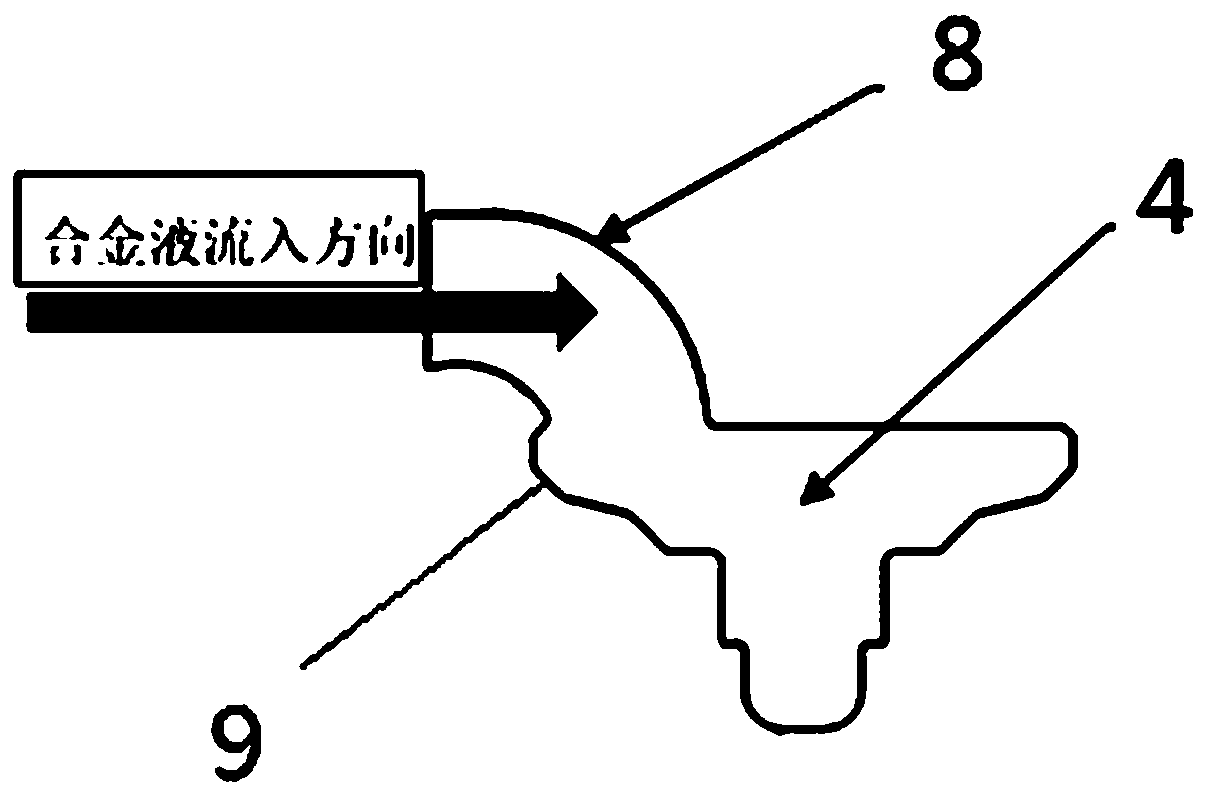

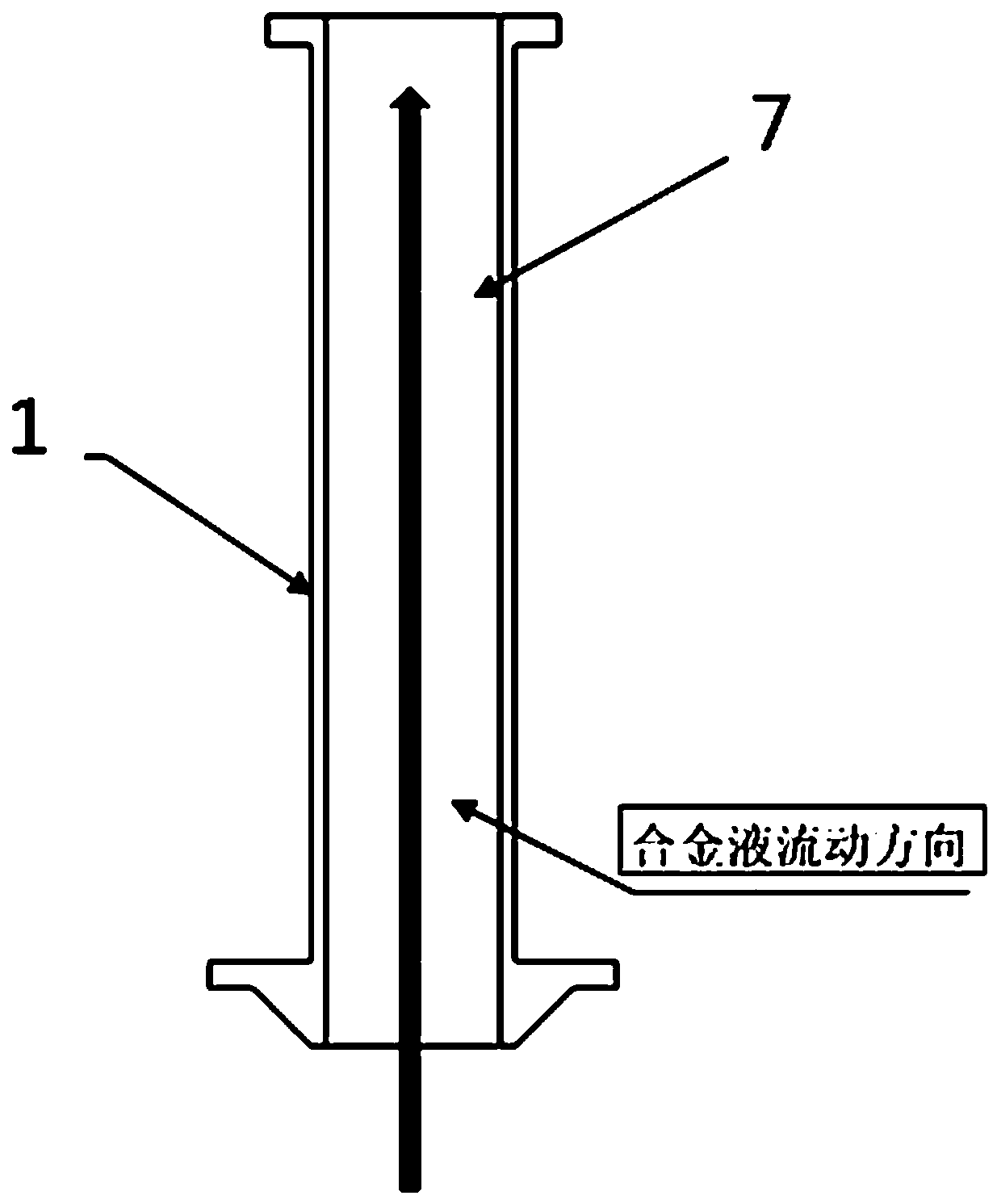

Swinging type squeezing system

The invention provides a swinging type squeezing system. A sprue sleeve commonly consisting of a movable die and a fixed die of a die is located on the main axis of a squeezing system of a squeezing casting machine; and a material cylinder is arranged right under the die splitting face of the die. Main movement realized by the material cylinder is in swinging type; the material cylinder is fed in an inclined manner, the entrapping of air is difficult to occur; the material cylinder aligns to the sprue sleeve, so that the material sleeve is lifted up and is abutted against the sprue sleeve; a punching head in the material cylinder is raised to push a metal liquid to enter into a die cavity from bottom to top; and meanwhile, air in the die cavity is raised and externally overflows through an exhaust channel, so as to form a casting piece. When the thickness of the fixed die is changed, the position of the material cylinder in a horizontal direction can be adjusted, so that the material cylinder can accurately align to the sprue sleeve. With the adoption of the swinging type squeezing system provided by the invention, the problems that squeezing, casting and feeding are inconvenient and unstably, the size precision of the casting piece in a thickness direction is difficult to ensure and the automation degree of the equipment is low can be solved.

Owner:SUZHOU SANJI FOUNDRY EQUIP

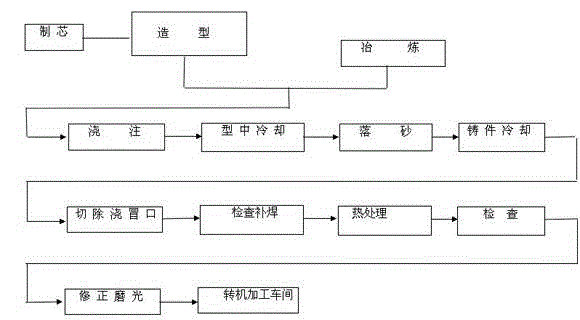

A casting method of an ultrafine high-nickel-content air tube

InactiveCN104525869AAvoid problemsQuality improvementFoundry mouldsFoundry coresMaterials scienceMetal

The invention discloses a casting method of an ultrafine high-nickel-content air tube. The method comprises following four steps: core preparing, moulding, pouring and sand knock-out. The method is mainly characterized in that: a pouring process of the method adopts a top pouring manner, a product is turned transversely by 90 degrees and poured, the problem that high-nickel-content tubes having a diameter of 26 mm, an inner diameter of 14 mm and a wall thickness of 4 mm are difficult to cast and mould is overcome by controlling the pouring temperature, speed and time, a process yield of the method is high, moulding operation is convenient, the consumption amount of metal liquids is small, the production cost is reduced, and requirements on the large-scale production efficiency are satisfied.

Owner:西峡飞龙特种铸造有限公司

Electroslag fusion casting manufacture method of rotating wheel blanks of impact type hydraulic generator

ActiveCN102756111AImprove qualityEasy for CNC machiningFurnace typesHeat treatment furnacesElectricityManufacturing technology

The invention relates to the manufacture field of impact type rotating wheels, and in particular relates to an electroslag fusion casting manufacture method of rotating wheel blanks of an impact type hydraulic generator. The electroslag fusion casting manufacture method is an electroslag fusion casting technology for impact type rotating wheel integral casting blanks and individual rotating wheel water tank blanks. According to the method, self-consumable electrodes and the electroslag fusion casting technology are adopted; the rotating wheel integral casting blanks are produced by rotating wheel integral casting circular type blank crystallizers under an integral structure or an individual combined structure; and the individual rotating wheel water tank blanks are produced by rotating wheels water tank crystallizers under the integral structure or the individual combined structure. With the adoption of the method, the shortcomings of the current production technology of high water head impact type rotating wheel blanks can be solved; the near net forming impact type rotating wheel integral casting blank manufacture technology and the individual rotating wheel water tank blank manufacture technology are adopted; the produced rotating wheel blanks and the water tank blanks are high in fatigue resistance, high in crack generation and expansion resistance, long in service lives and high in use safety; and the quality and performance of the produced rotating wheel blanks and the water tank blanks are in line with those of forged blanks obtained by using the same materials; and the method has the advantages of low production cost, short production period and the like.

Owner:沈阳市盛华特种铸造有限公司

MW grade wind-powered torsion shaft and preparation technology thereof

The invention aims to provide a torsion shaft for an aerogenerator, and an electroslag refusion casting method thereof, and the torsion shaft combines technical advantages of arc metallurgy and technical advantages of electroslag refusion casting (ESRC). A casting produced by adopting the preparation technology of the MW grade wind-powered torsion shaft provided in the invention has the advantages of uniform and compact crystal tissue, high purity, less nonmetallic inclusions, possessing of excellent compactness and fatigue resistance, reaching of forging flaw detection quality standards, realization of near net-shape forming, and low cost. The internal quality of the produced torsion shaft is obviously better than that of torsion shafts produced through sand casting.

Owner:SHENYANG RES INST OF FOUNDRY

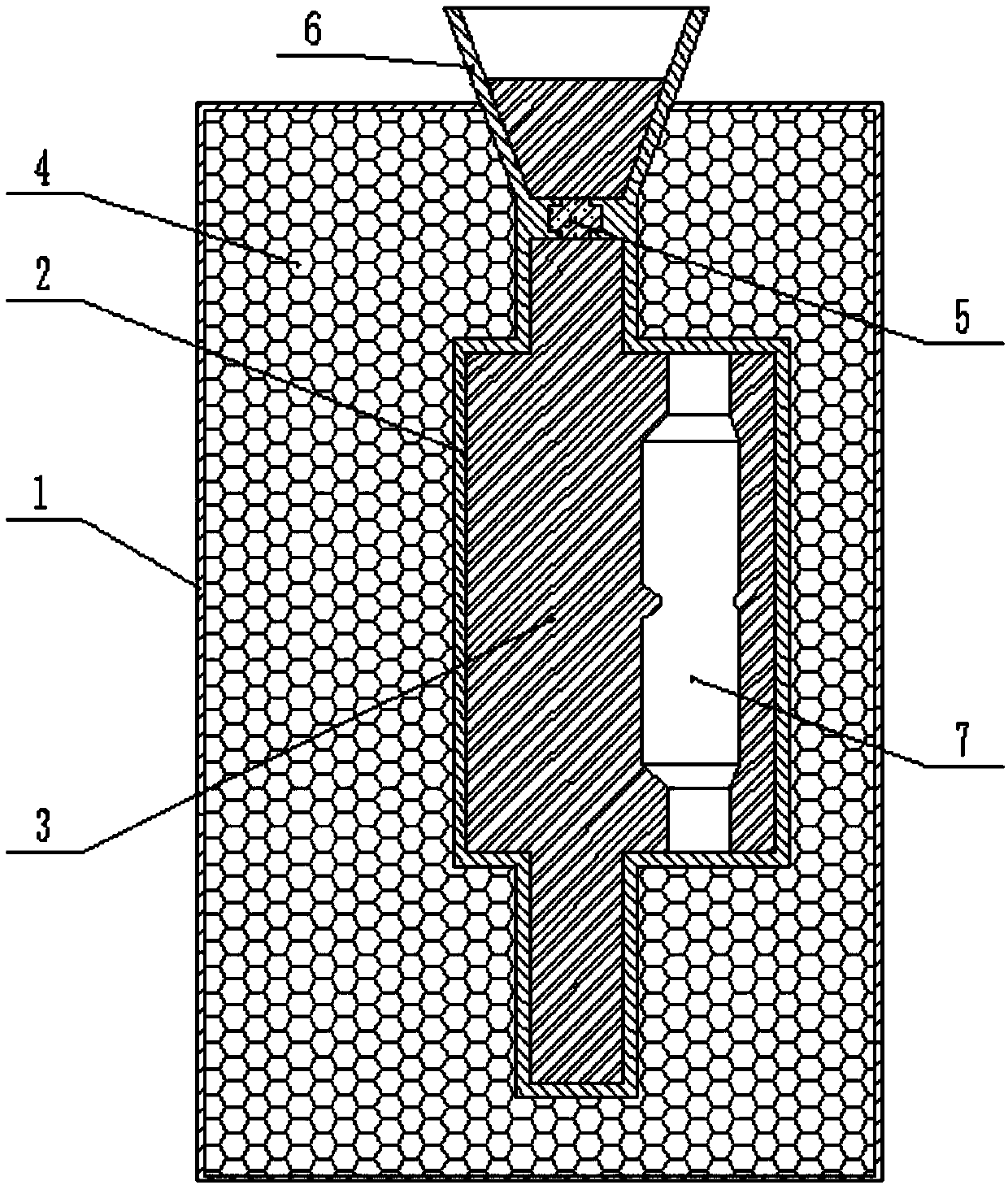

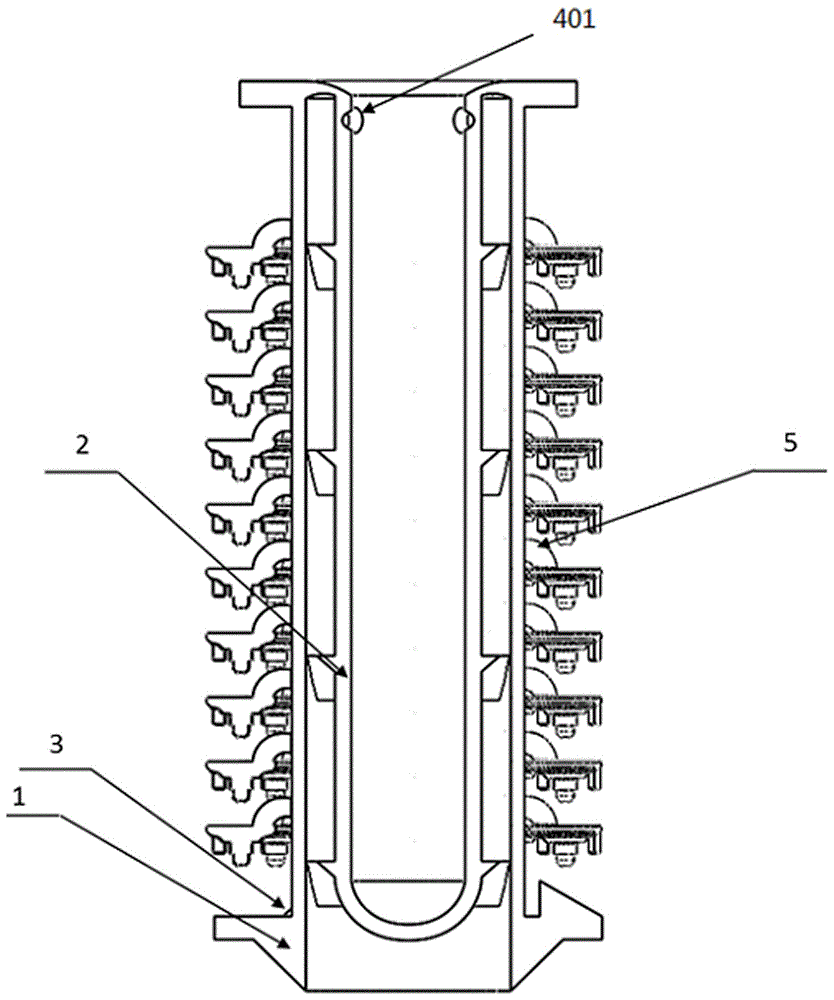

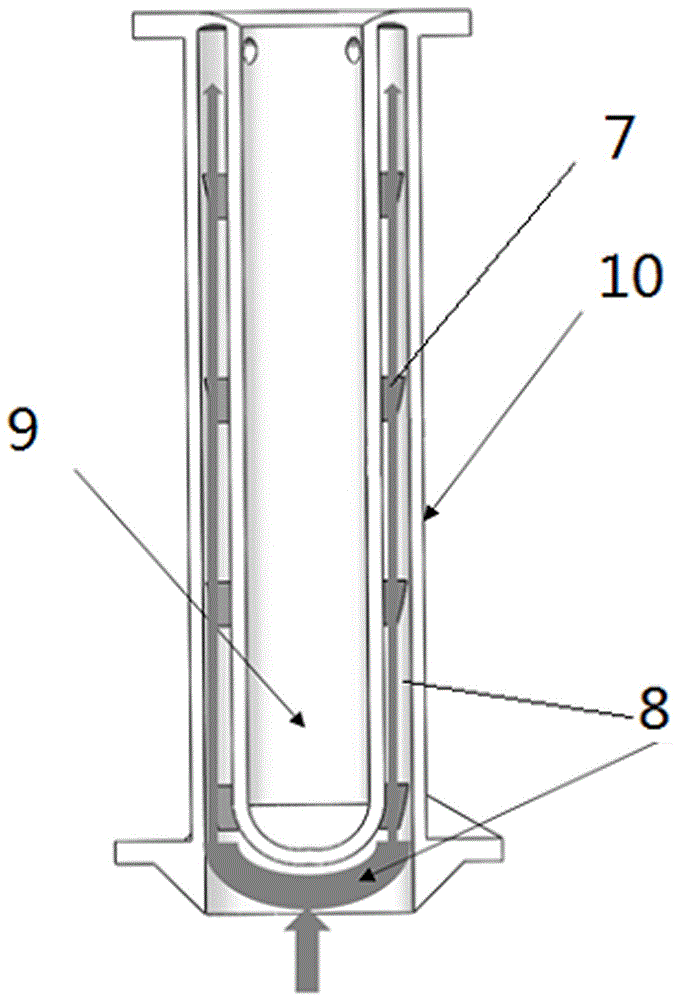

Turbine runner three-dimensional curved surface blade electroslag smelting casting direct forming method

The invention relates to the field of electroslag smelting casting production of turbine runner blade castings, in particular to a turbine runner three-dimensional curved surface blade electroslag smelting casting direct forming method. Electroslag smelting casting is used for completing secondary refining purification and casting near net forming of consumable electrode materials. The specific process comprises the following steps that 1) the structure form of a casting blank crystallizer is of an assembled type or a split type; 2) consumable electrodes in the smelting casting process consistof two parts, namely the fixed electrodes and the movable electrodes; and 3) a power supply mode adopts an alternating current single-electrode series loop and double-electrode series loop mixed power supply mode, by means of a power loop formed between double-electrode series electrodes, the slag layer temperature of an electroslag smelting casting area is increased, the metal fluidity of the area is improved, the solidification speed of the area is controlled, and blade smelting casting forming is achieved. The technology provided by the invention is applicable to manufacturing of the castings of tubular turbine generator runner blades or mixed-flow turbine generator runner blades or axial flow turbine generator runner blades.

Owner:沈阳市盛华特种铸造有限公司

Casting process for producing precoated sand shell core rotor with steel shots as filling material

InactiveCN109676087ASpeed up coolingDense structure of castingFoundry mouldsFoundry coresFilling materialsCooling speed

The invention discloses a casting process for producing a precoated sand shell core rotor with steel shots as a filling material, and relates to the technical field of casting. The casting process comprises the following steps that firstly, a shell core and a built-in core are manufactured through precoated sand, the shell core is combined into a precoated sand shell, and the built-in core is placed in the precoated sand shell; secondly, the precoated sand shell is placed in a container, the container is filled with the steel shots, thus, the precoated sand shell is wrapped with the steel shots, and finally the steel shots are compacted through vibration; thirdly, a pouring cup and a riser are arranged at the top of the precoated sand shell; fourthly: molten iron of nodular cast iron is injected into the precoated sand shell smoothly through the pouring cup, and casting molding is conducted; and fifthly, after the molten iron is completely cured, the casting rotor is obtained. The functions of rapid heat absorption and heat transfer chilling of the steel shots are used for increasing the cooling speed of the molten iron, the cooling speed of the cast iron eutectic stage is changed,an as-cast microstructure of the cast iron can be changed in a large range, and thus casting structure is dense.

Owner:济宁市兖州区联诚机械零部件有限公司 +1

Engine aluminum cylinder body low-pressure casting method

The invention discloses an engine aluminum cylinder body low-pressure casting method. Casting of an engine aluminum cylinder body is achieved through core manufacturing, molten aluminum processing and low-pressure casting. Compared with high-pressure casting having the defects that casting inner air holes can be generated easily, the organization is loose and insufficient casting exists, low-pressure casting has the advantages that the casting technology parameters of low-pressure casting can be adjusted at will within any technological range, it can be guaranteed that liquid metal is stable in model filling, the writhe, the impact and the splashing caused in the model filling process of the molten metal can be reduced or avoided, and therefore less oxidizing slag is formed, the defects of castings are avoided or reduced, and the quality of the castings is improved; model filling can be performed on the molten metal under the action of pressure, the fluidity of the molten metal can be improved, the forming performance of the castings is good, the castings with the contours clear and the surface smooth and clean can be formed easily, and large thin-wall castings can be formed more easily.

Owner:台州艾锐思汽车部件有限公司

Solidification contraction-free high-hardness casting magnesium alloy and process thereof

The invention discloses a solidification contraction-free high-hardness casting magnesium alloy and a process thereof. The alloy comprises the following components in percentage by weight: 0.6-0.8wt.%of Li, 2.0-3.0wt.% of Sb, 5.0-8.0wt.% of In, 4.0-6.0wt.% of Bi, 1.0-2.0wt.% of Pb, 3.0-5.0wt.% of Ge, 1.2-1.5wt.% of Si, 5.0-8.0wt.% of Sn and the balance of magnesium. By adopting the magnesium alloy, casting defects are effectively eliminated, formation of casting pores and looseness is reduced, and excellent mechanical properties of a cast alloy part are achieved. Therefore, the invention provides a lightening solving scheme of a magnesium alloy substitution product, and updating and industry updating requirements of novel materials in China are effectively promoted in the implementation and industrialization process.

Owner:GUANGZHOU YUZHI TECH CO LTD

Vacuum casting process

InactiveCN105541087AGood effectReduce gasGlass shaping apparatusGlass productionSlagUltimate tensile strength

The invention discloses a vacuum casting process. The process comprises the following steps: A. molten metal or colored glaze liquid is melted in a smelting furnace; B. the molten metal or the colored glaze liquid are precipitated, and the middle part without dross and sand is taken; C. a mold is placed in a vacuum chamber, and the vacuum chamber is enclosed; D. air in the mold is extracted, and a certain negative pressure is caused in the mold; E. the molten metal or the colored glaze liquid is poured into a pouring ladle, after air in the molten metal or the colored glaze liquid floats upward and is discharged, an opening at the bottom of the pouring ladle is opened for casting; F. after casting, the molten metal or the colored glaze liquid is solidified, and air exhaust for the mold is stopped. Compared with the traditional casting process, the vacuum casting process has the advantages of few defects such as pores and slag inclusion, compact texture, high mechanical property, low manufacture cost, etc., and is especially good for obviously increasing density, intensity and toughness of aluminium alloy, and reducing pores.

Owner:鹤山市凤台菱精密铸造有限公司

Anti-segregation refining agent for casting high-lead bronze and production method thereof

ActiveCN106702197BReduce lead segregation tendencyDense structure of castingRare-earth elementNitrogen

The invention discloses an anti-segregation refining agent for casting high-lead bronze. The anti-segregation refining agent for casting high-lead bronze is composed of, by weight, 15-16% of Ni, 10-11% of P, 30-32% of rare earth elements, 5-6% of Zn, 6.8-7.2% of Si, 0.28-0.33% of Mg, 0.10-0.15% of Ti, 0.10% or less of Fe, 0.05% or less of Mn, less than 1.0% of impurities and the balance Cu. Oxidative slagging is reduced by spraying a covering agent after precise matching, high-purity nitrogen and refining agent powder spraying are adopted for powder spraying refining, and ingredients are adjusted through supplementing or diluting, so that the lead segregation phenomenon is avoided, a high-lead bronze casting is uniform in lead granule distribution, fine in metallographic grain and tight in structure, the requirements of markets and casting enterprises are met, and the quality of bronze castings in China is effectively improved.

Owner:新乡市海山机械有限公司

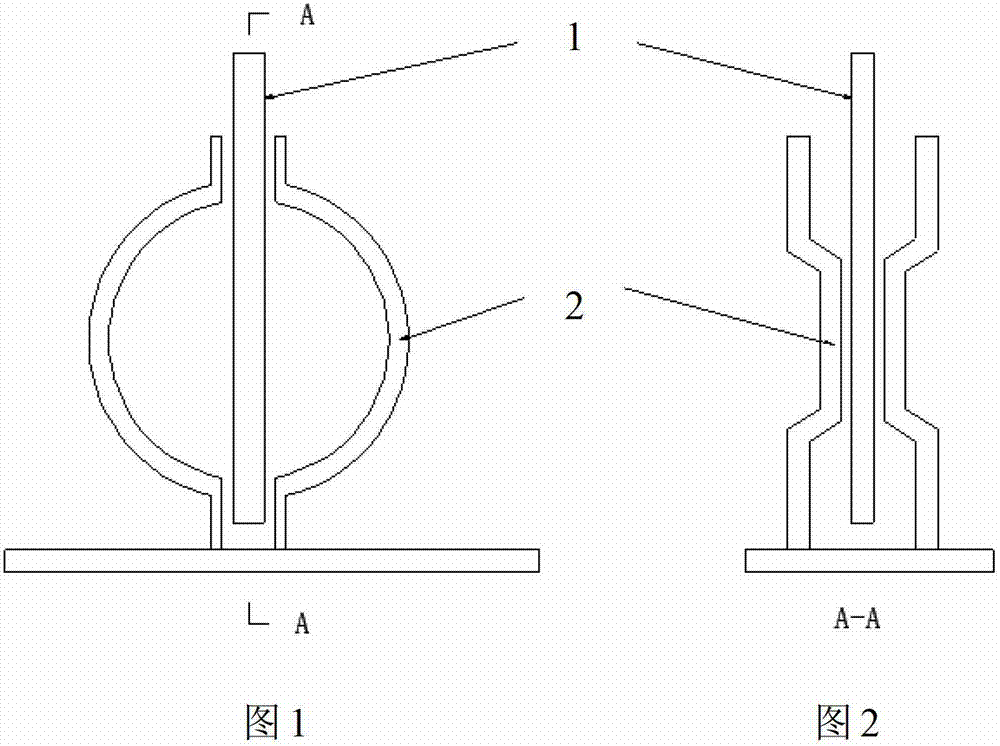

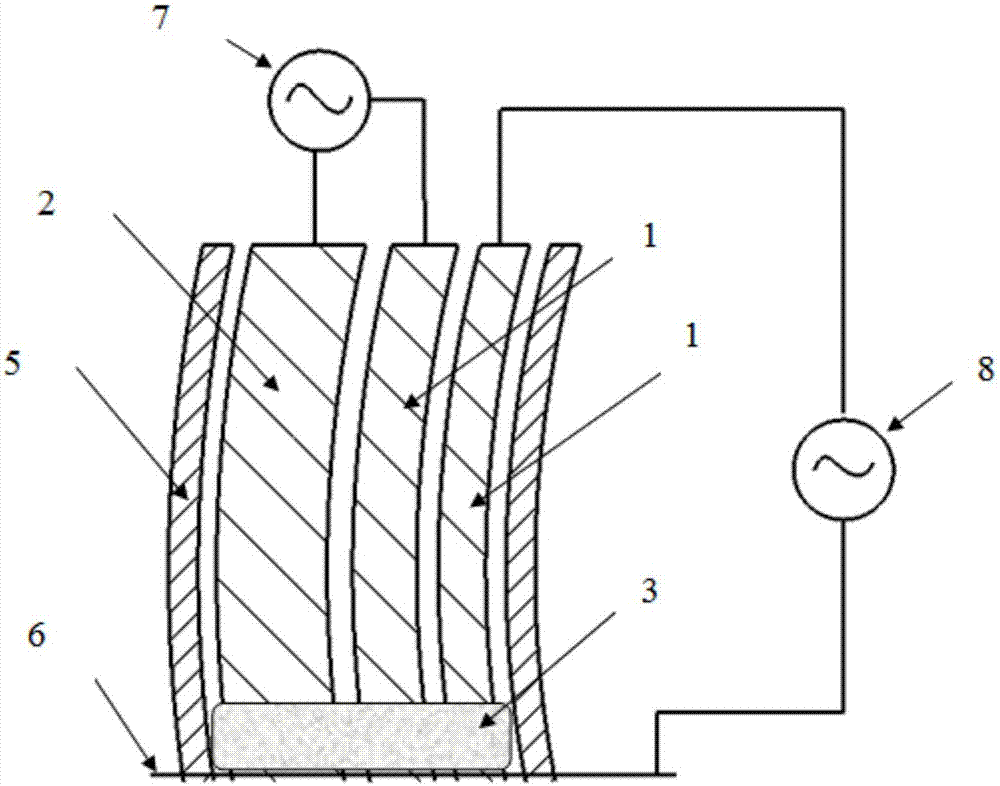

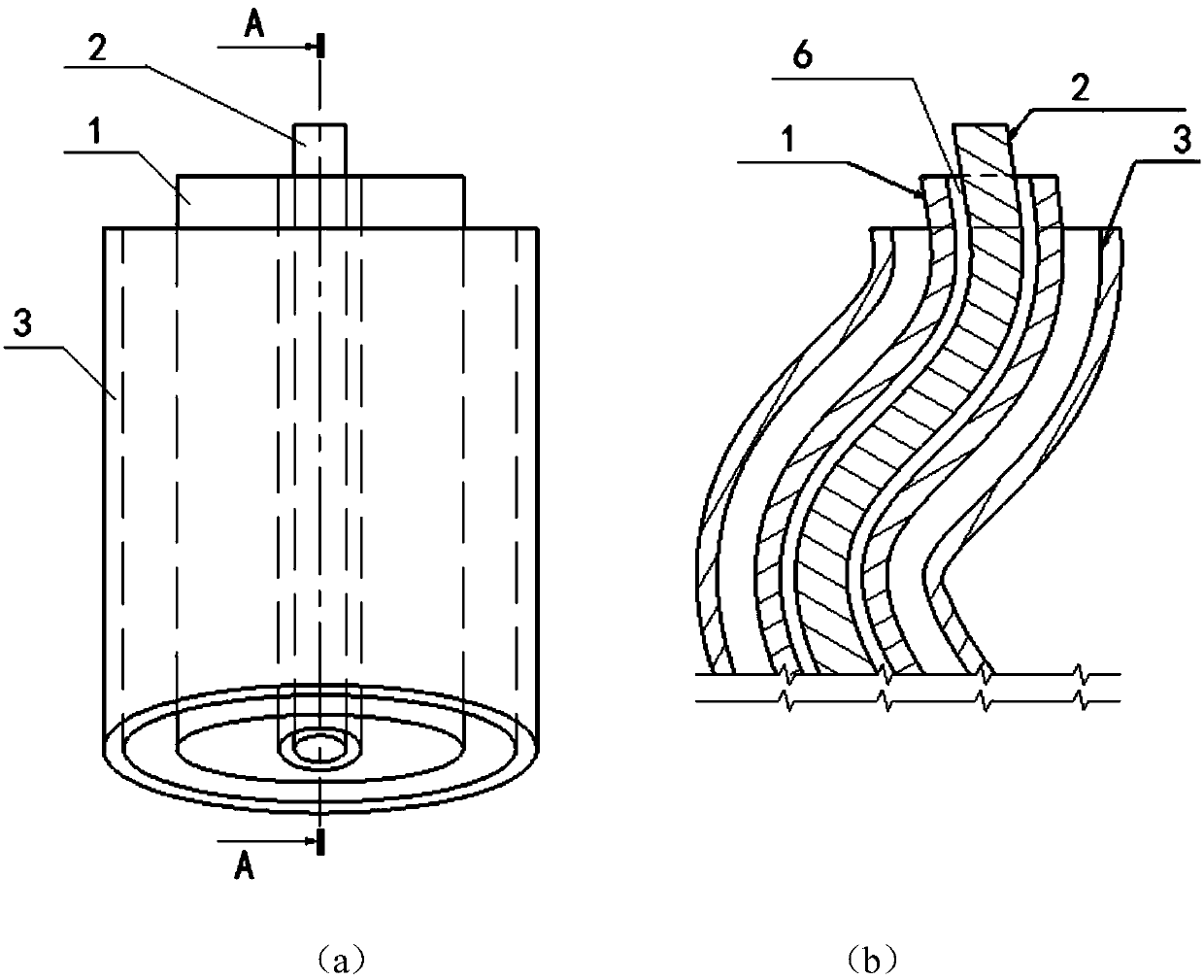

Double-layer hollow cylinder fusion mold shell structure for heat-resistant alloy vacuum suction casting technology

The invention relates to a double-layer hollow cylinder fusion mold shell structure for a heat-resistant alloy vacuum suction casting technology. The double-layer hollow cylinder fusion mold shell structure is characterized in that the mold shell structure is of a double-layer structure, the outer layer is an outer shell, the inner layer is of a hollow cylinder structure, and the hollow cylinder is connected with the outer shell through middle connecting pieces; a molten steel flow channel is formed between the hollow cylinder and the outer shell, and connected with mold shell castings through pouring gates, wherein the mold shell castings are arranged on the outer side of the outer shell; and a platform is arranged at the upper end of the mold shell structure, and a reinforcing structure is arranged at the lower end of the mold shell structure. A mold shell with the structure is applied to the heat-resistant alloy vacuum suction casting technology and is high in safety factor. The castings are dense in organization, small in size of crystal grains and small in number of shrinkage cavity and shrinkage porosity defects, the yield rate is likely to be above 90%, and the casting energy sources are saved by above 80%.

Owner:SHANGHAI SINOTEC

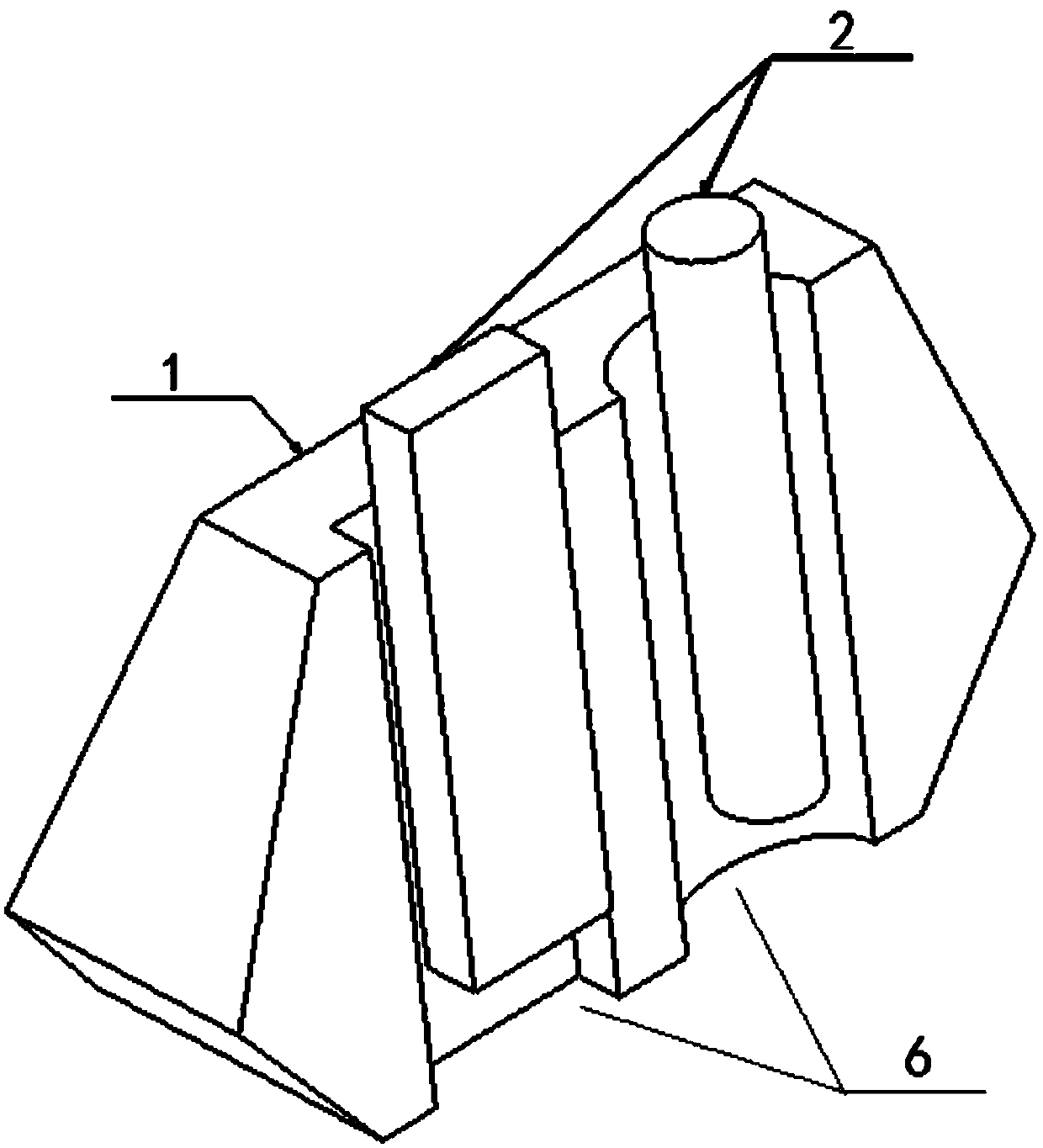

Casting process for integrally casting a vacuum pump impeller by using large nodular cast iron

InactiveCN112916804AHigh dimensional accuracyEvenly dividedFoundry mouldsFoundry coresImpellerSpiral blade

The invention relates to the technical field of casting of equipment parts, and discloses a casting process for integrally casting a vacuum pump impeller by using large nodular cast iron. The casting process comprises the following steps that S1, a blade of the vacuum pump impeller is segmented, and a structure for splicing a required integral spiral blade is designed on each section of the blade of the vacuum pump impeller, and then a forming mold for forming foam patterns of each section of the blade of the vacuum pump impeller is machined by adopting existing equipment. According to the casting process for integrally casting the vacuum pump impeller by using the large nodular cast iron, the nodular cast iron is integrally casted, a sand box is opened after a casting is completely cooled, and heat treatment is carried out after sand cleaning and casting head removal, such that the vacuum pump impeller integral casting which is compact in internal structure and meets the requirement on dimensional accuracy is obtained, the impeller is high in size precision, uniform in equal division and free of welding seams, an inner cavity of a hub is free of sand burning and sintering, the casting structure is compact, the welding stress influence is eliminated, and operation is stable.

Owner:HAIAN HAITAI CASTING

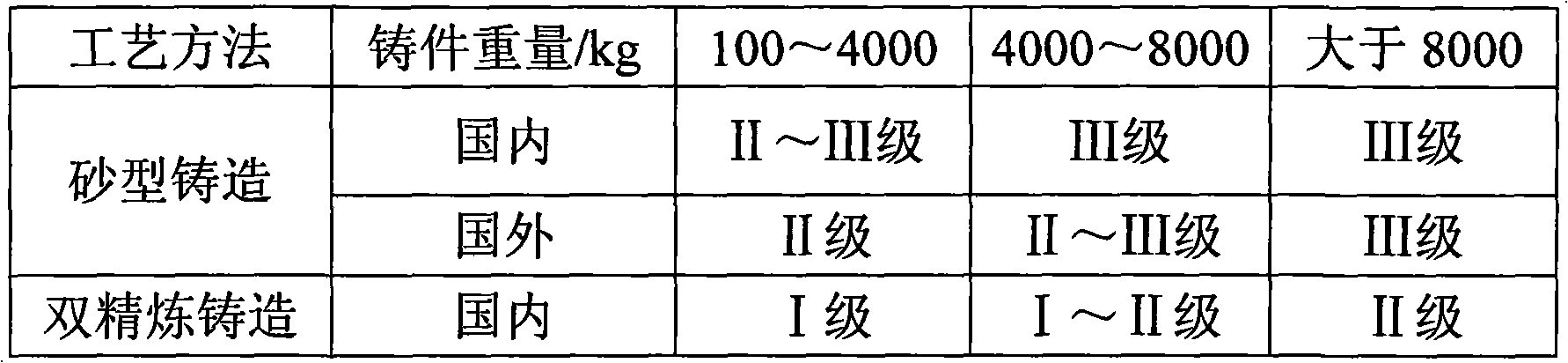

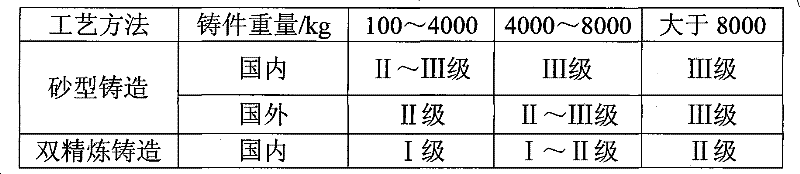

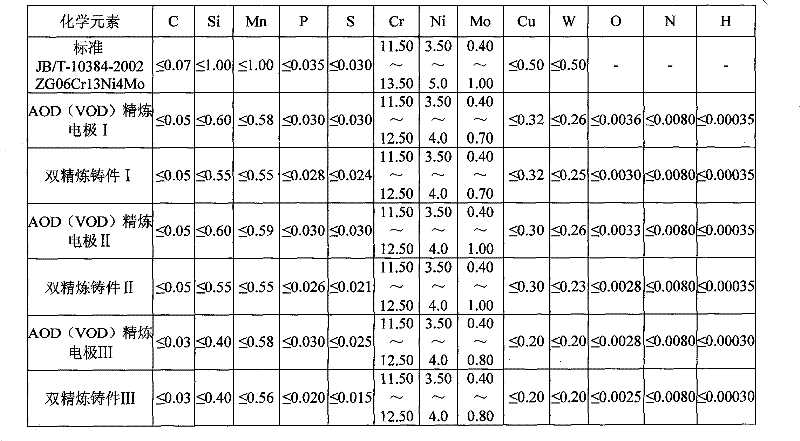

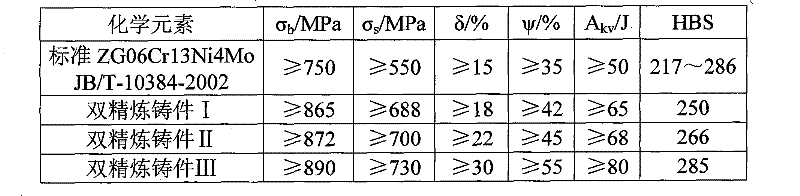

Turbine wicket gate double-refining casting technique

ActiveCN101450376BQuality improvementReduce in quantityFurnace typesHeat treatment furnacesHydraulic turbinesRaw material

The invention provides a hydraulic turbine guiding blade double refining casting process, which adopts an AOD or VOD refining method to prepare a raw material consumable electrode, and the weight percentages of chemical compositions of the prepared raw material consumable electrode are : less than or equal to 0.05 percent of C, less than or equal to 0.6 percent of Si, less than or equal to 0.58 percent of Mn, less than or equal to 0.03 percent of P, less than or equal to 0.03 percent of S, 11.5 to13.5 percent of Cr, 3.5 to 5.0 percent of Ni, 0.4 to 1.0 percent of Mo, less than or equal to 0.5 percent of Cu, less than or equal to 0.008 percent of N, less than or equal to 0.00035 percent of H and the balance Fe. Then a prepared consumable electrode is made into a hydraulic turbine stainless guiding blade component by electroslag smelting casting method; and the double refining casting process can refine and purify steel liquid completely and effectively so as to remove the gas and non-metallic inclusions in steel greatly. The crystal structure of the casting is uniform and compact, and has low sulfur and phosphorus content, less non-metallic inclusions, higher toughness, anti-fatigue performance and good welding performance.

Owner:SHENYANG RES INST OF FOUNDRY

Electroslag casting manufacturing method of hydraulic turbine blade compact

An electroslag casting production method for a waterwheel blade green compact is characterized by comprising the following steps: confirming the outline of the blade green compact according to the intelligent three-dimensional expanded size of a water turbine blade; producing a crystallizer and a consumable electrode of the blade green compact; preparing the qualified blade green compact of the electroslag casting water turbine by optimizing electroslag casting process parameters and the anti-cracking heat treatment process. The method has the advantages that the detects of the conventional blade green compact of the water turbine can be overcome; a near-net forming green compact producing process is provided for the water turbine blade formed through heated-die pressing process; the produced blade green compact material is high in degree of purity, uniform in chemical constituents, compact in structure, free of defects such as looseness, slag inclusion and hole shrinkage, favorable in mechanical property, and higher in fatigue resistance performance, anti-cracking performance and expansibility, and can reach the mechanical property of forge pieces made of the same material and meet the requirements of flaw detection indexes.

Owner:SHENYANG RES INST OF FOUNDRY

Centrifugal casting method and device of magnesium alloy hub

The invention relates to a centrifugal casting method of a magnesium alloy hub, which belongs to the technical field of casting. The prior gravity and low-pressure casting method for casting the magnesium alloy hub exists the easily occurred casting defects of incompleteness of mould filling, shrinkage cavity, cold shut, hot cracking, shrinkage cracking, and the like. An upper die, a side die anda lower die of a die are matched and then held into a whole, then gravity center casting is carried out for the matched die, the die is enabled to rotate around the axes thereof for a set time and then stop before cast magnesium melt solidifies, the cast mode can be divided into casting before die rotating and casting after die rotating according to the technological requirements of concrete products, and the die is opened to take out a cast after the magnesium alloy melt solidifies. With the method, the magnesium melt in the die can rapidly fill shrinkage towards peripheral parts under the action of centrifugal force to enable cast products to be full and compact, and the method has the advantages of low production rejection rate, compact structure of casts, improvement of quality of workpieces, and the like.

Owner:SHANGHAI MERIDIAN MAGNESIUM PROD CO LTD

Electroslag casting manufacturing method and device for special-shaped castings with three-dimensional changes

ActiveCN107649664BSolve the process bottleneck of melting and castingSolve process bottlenecksElectrode materialCasting

The invention relates to the field of manufacturing three-dimensionally changed special-shaped castings through electroslag smelting casting, in particular to a method and device for manufacturing a three-dimensionally changed special-shaped casting through electroslag smelting casting. Electroslag smelting casting is used for completing secondary refining purification and casting near-net formingof consumable electrode materials. The method for manufacturing the three-dimensionally changed special-shaped casting through electroslag smelting casting comprises the specific processes that (1) acasting blank crystallizer adopts a combined structural form or a split type structural form; and (2) consumable electrodes in the smelting casting process are composed of two parts, namely the guiding electrode and the supplementary electrodes; the guiding electrode is followed and fixed relative to the crystallizer and internally provided with guiding channels; the supplementary electrodes aremovable and are arranged in the guiding channels; and the working form of the electrodes in the smelting casting process is as follows: the supplementary electrodes are continuously supplemented to the molten electroslag position through the guiding channels, and thus the smelting casting process is completed. Therefore, the method and device for manufacturing the three-dimensionally changed special-shaped casting through electroslag smelting casting is mainly suitable for casting of the three-dimensionally changed special-shaped casting.

Owner:沈阳市盛华特种铸造有限公司

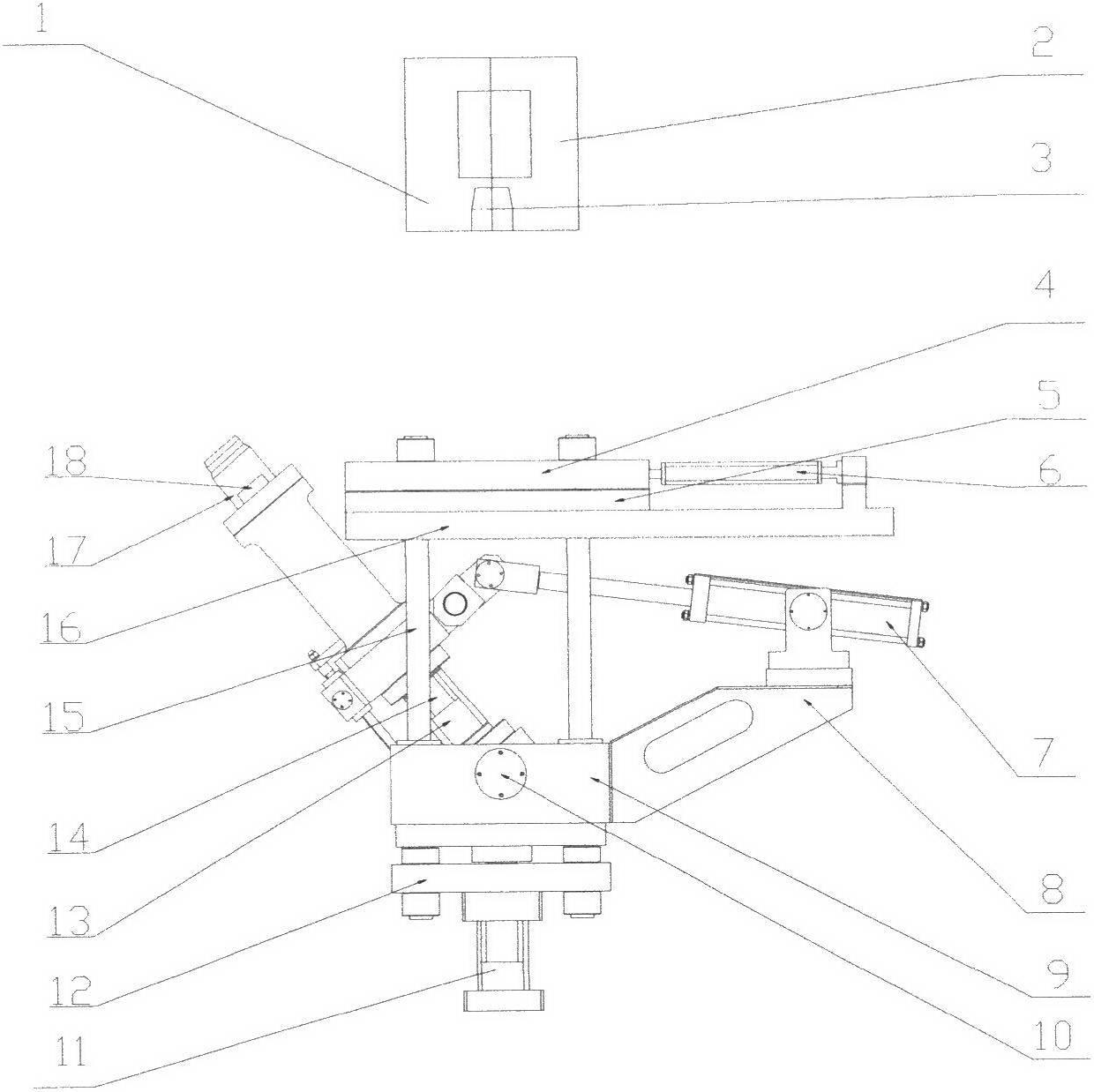

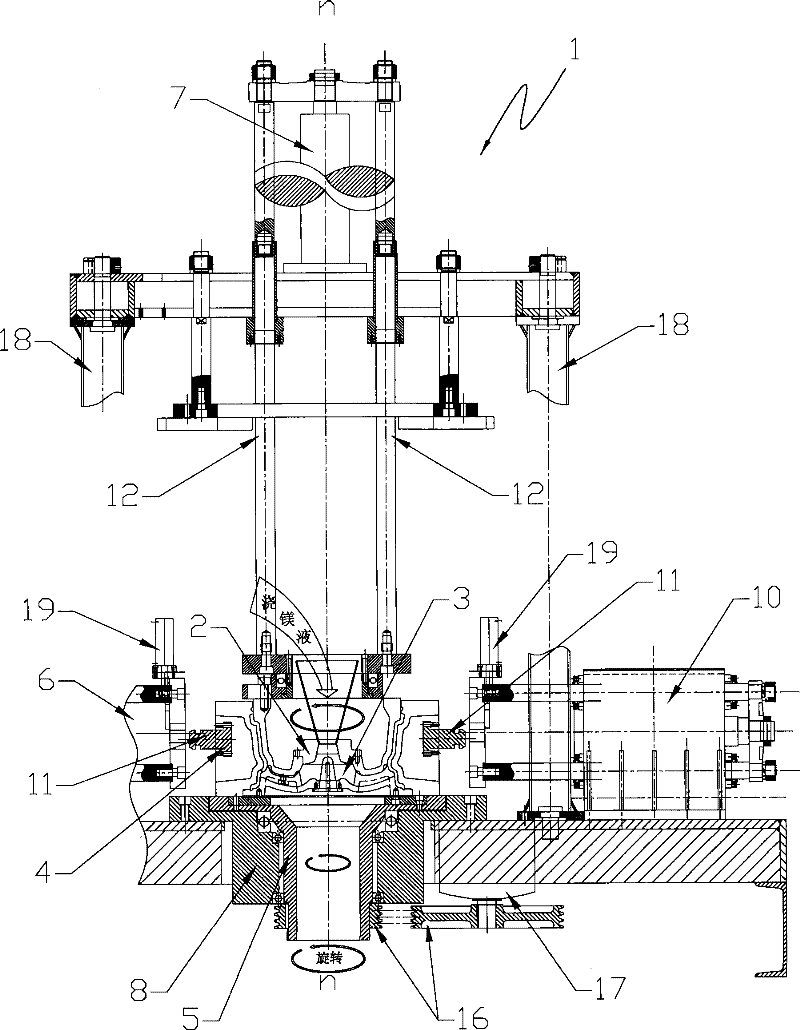

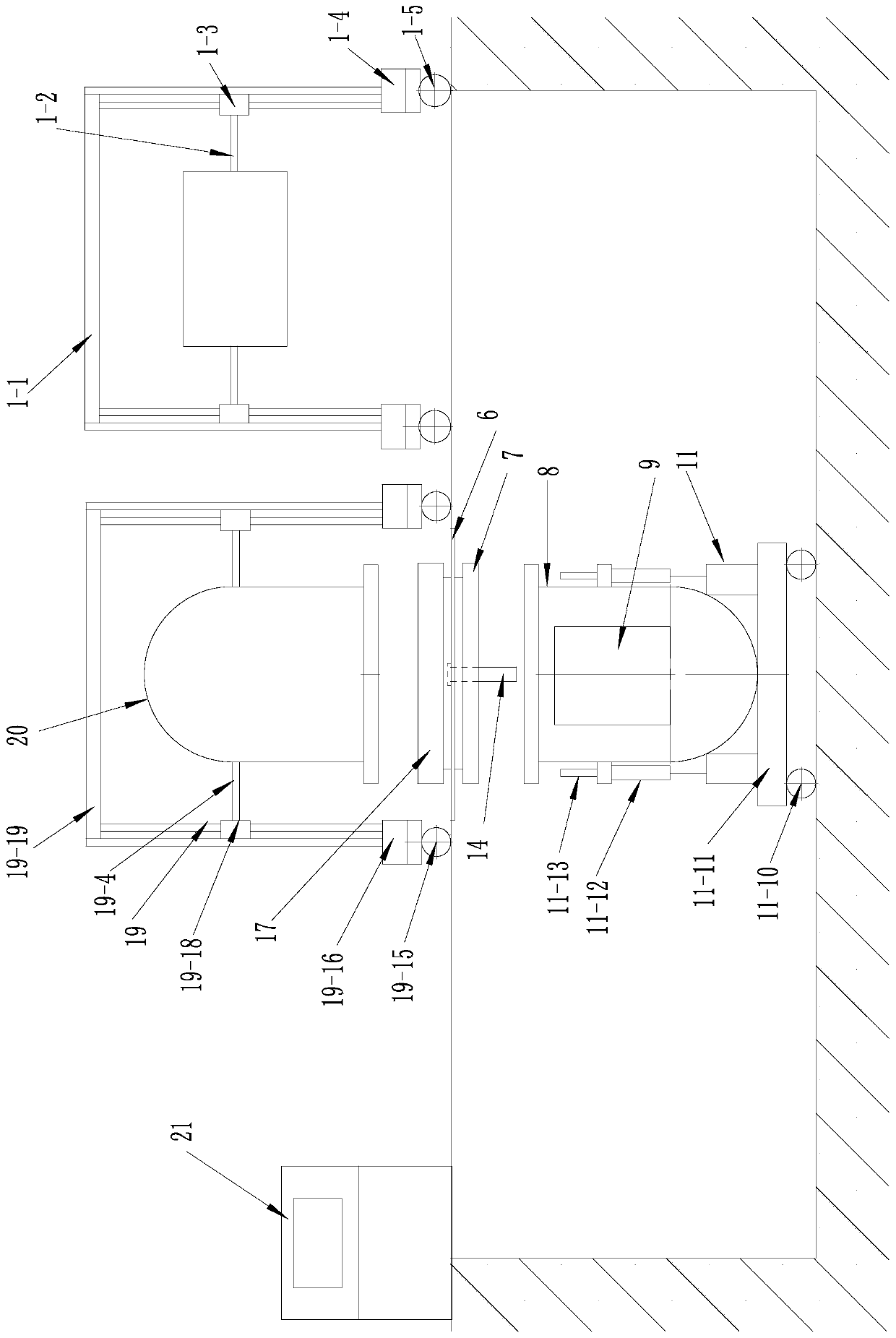

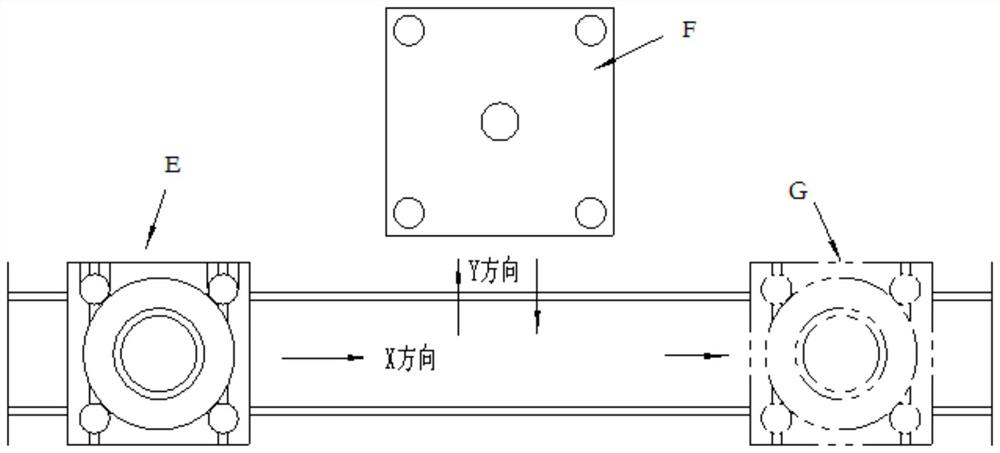

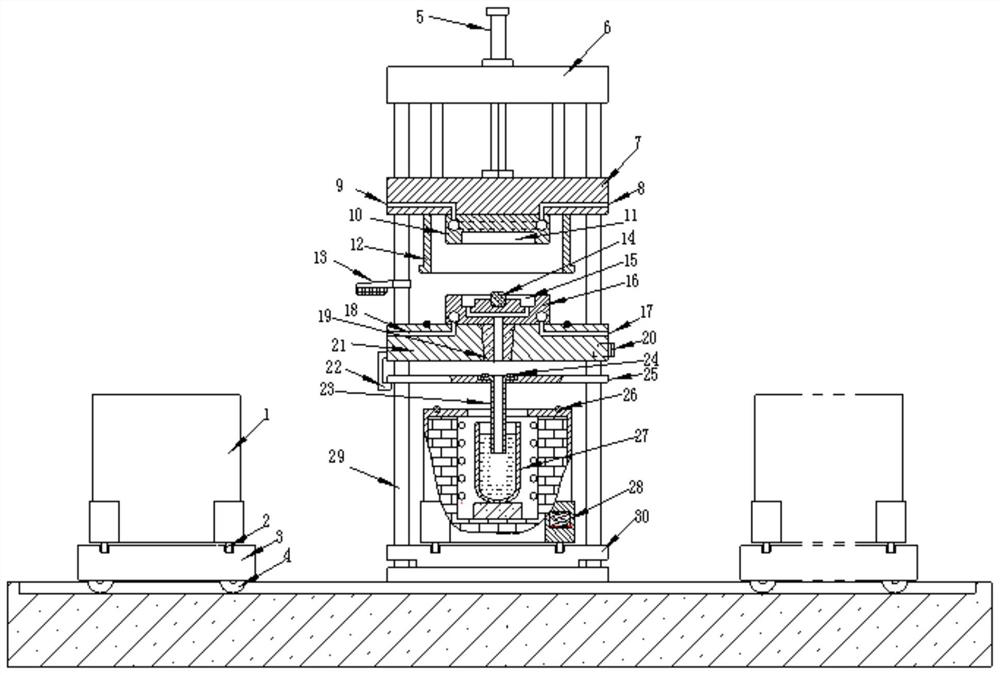

A kind of magnesium alloy differential pressure casting method

The invention discloses a magnesium alloy differential pressure casting machine and a casting method, relates to a casting machine and a casting method and aims at solving the problems that the defects of shrinkage porosity and cavity, secondary oxidization slag inclusion and the like exist in castings obtained through an existing magnesium alloy casting manner, the mechanical performance of the castings is reduced, and due to barometric pressure casting, magnesium combustion cannot be avoided or controlled. The magnesium alloy differential pressure casting machine comprises an upper tank, a lower tank, a casting die, a magnesium alloy heat preservation furnace, a middle partition plate, a liquid elevating pipe, an upper tank motion control frame and a lower tank motion control frame. Theupper tank is arranged on the upper tank motion control frame capable of driving the upper tank to move transversely and vertically. The lower tank is arranged on the lower tank motion control frame capable of driving the lower tank to move vertically and transversely. The casting die is arranged in the upper tank and placed on the middle partition plate, and the magnesium alloy heat preservationfurnace is arranged in the lower tank. The method mainly comprises the first step of preparation, the second step of casting die positioning, the third step of lower tank positioning, the fourth stepof upper tank positioning and the fifth step of alloy liquid pouring. The magnesium alloy differential pressure casting machine and the casting method are used for magnesium alloy casting.

Owner:HARBIN INST OF TECH

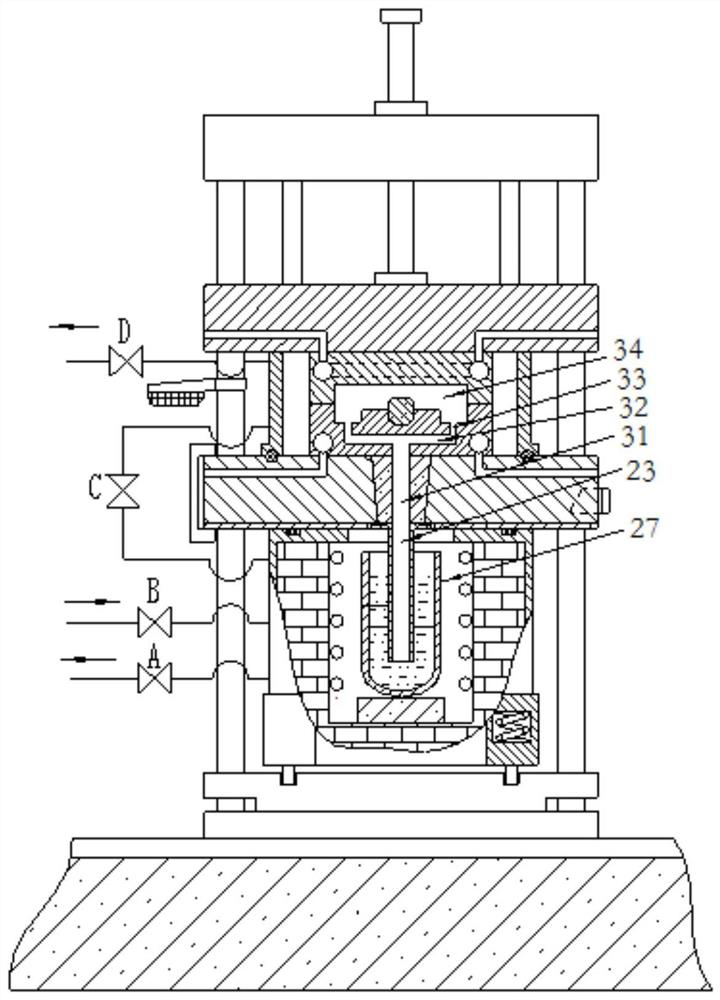

A semi-continuous anti-gravity pouring method for an aluminum alloy automobile frame

The invention discloses a semi-continuous anti-gravity pouring method for an aluminum alloy automobile frame with a complex structure, which relates to the technical field of metal processing. The invention aims to solve the problem that the performance of the casting is low due to the gas brought in by the aluminum liquid during the die-casting of the existing aluminum alloy automobile frame, and at the same time, the traditional low-pressure and differential-pressure equipment has low production efficiency and cannot meet the needs of mass production. The pouring method includes aluminum alloy smelting treatment; casting mold pretreatment; the lower tank moves horizontally; the lower tank moves to the pouring station; The invention is used for processing aluminum alloy automobile frame with complex structure.

Owner:HARBIN INST OF TECH +1

A high-strength vermicular graphite cast iron high-pressure valve body material

InactiveCN103741017BMeet the use requirementsHigh tensile strengthChemical compositionThermal fatigue

The invention discloses a high-strength vermicular graphite cast iron high-pressure valve body material which comprises the following chemical components in percentage by weight: 3.5-4.0% of C, 1.8-2.7% of Si, 0.4-0.8% of Mn, less than or equal to 0.02% of S, less than or equal to 0.06% of P, 0.4-0.7% of Mo, 0.40-0.60% of Cu, 0.1-0.2% of Ti, 0.08-0.15% of V, 0.013-0.022% of Mg, 0.021-0.045% of Re and the balance of iron. A composite vermicular agent accounting for 0.8-1.5% of the total mass of the iron liquid is adopted for vermicular treatment, and a 75 ferrosilicon inoculant accounting for 0.3-0.6% of the total mass of the iron liquid is adopted for inoculation treatment; the tensile strength of the vermicular graphite cast iron material is greater than or equal to 600MPa, the elongation is greater than or equal to 3.5%, the density is high, the heat conduction and dispersion property and the thermal fatigue resistance are good, and the casting technology is simple; a high-pressure valve body casting produced by use of the high-strength vermicular graphite cast iron material can perfectly meet the using requirements of a high-pressure valve body of a large type excavator while the cost is low.

Owner:SHANDONG JIANZHU UNIV

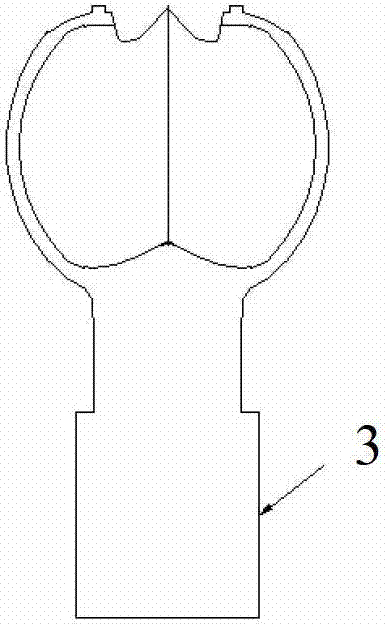

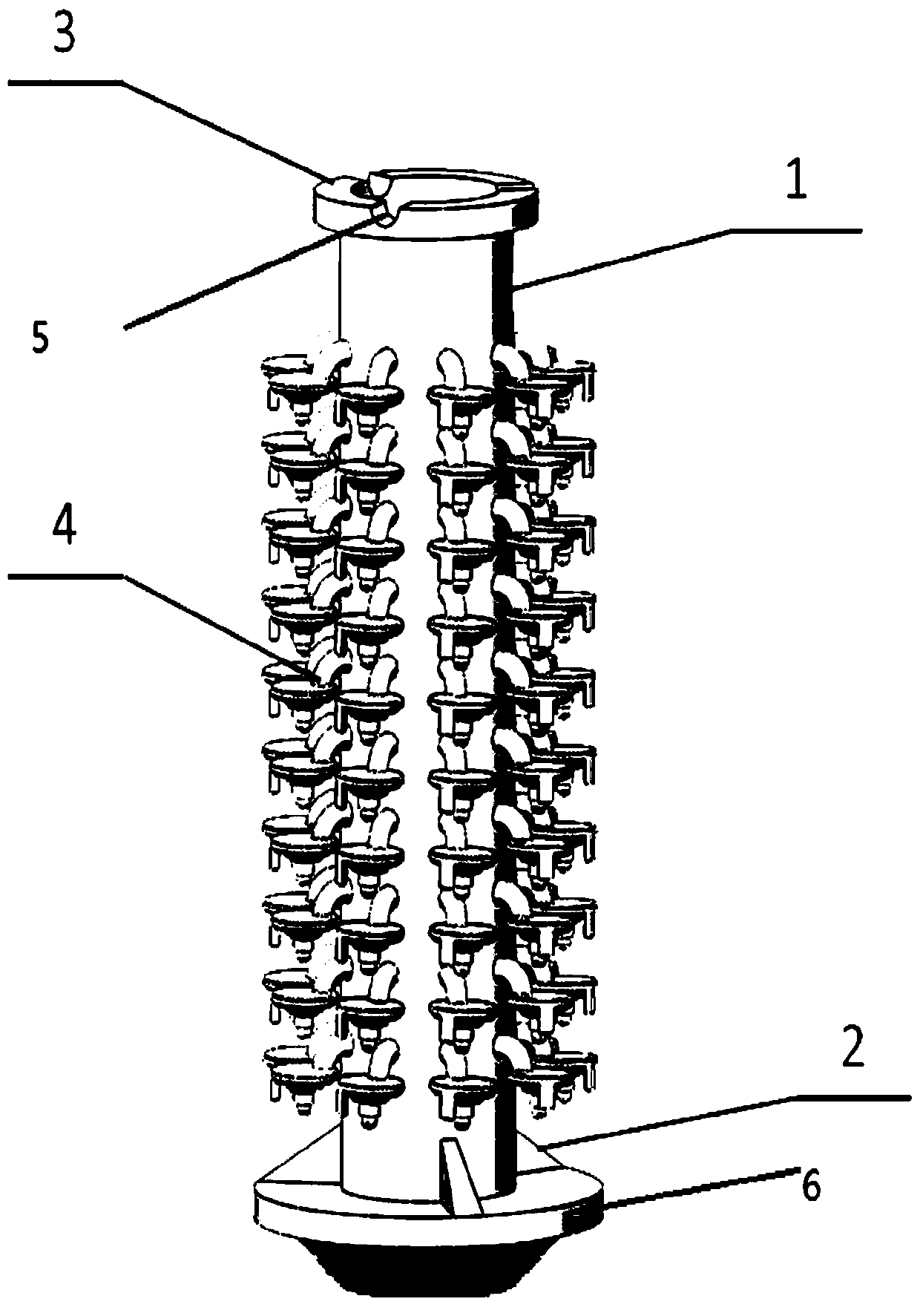

Hollow through-hole investment mold shell structure for vacuum suction casting process of high temperature resistant alloy

The invention provides a hollow through hole fired mold shell structure. The hollow through hole fired mold shell structure is characterized in that a main body of the mold shell structure is of a hollow through hole structure, and the upper portion of the hollow through hole is provided with a platform protruding outwards and venting holes; a base is arranged on the lower portion of the hollow through hole; reinforcing connecting pieces are arranged between the base and the outer wall of the hollow through hole; mold shell castings are evenly distributed on the outer wall of the hollow through hole; the mold shell castings are connected with the hollow through hole through a pouring gate system; and the pouring gate system comprises an elbow pouring gate, a mold filling pouring gate and a feeding pouring gate. By arranging the venting holes and all the components again, the hollow through hole fired mold shell structure has greater functional characteristics. By applying the hollow through hole structure and the reinforcing structures, the effects that an alloy solution ascends in the mold filling stage and the alloy solution in the hollow through hole flows back rapidly in the pressure relief stage are guaranteed, and the hollow through hole fired mold shell structure has outstanding beneficial effects.

Owner:SHANGHAI SINOTEC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com