Swinging type squeezing system

A technology of oscillating oil cylinder and barrel, which is applied in the field of oscillating extrusion system of horizontal extrusion casting machine, which can solve problems such as instability, easy occurrence of entrained air, difficulty in guaranteeing dimensional accuracy in the thickness direction of castings, etc., and realize automation, The effect of large receiving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

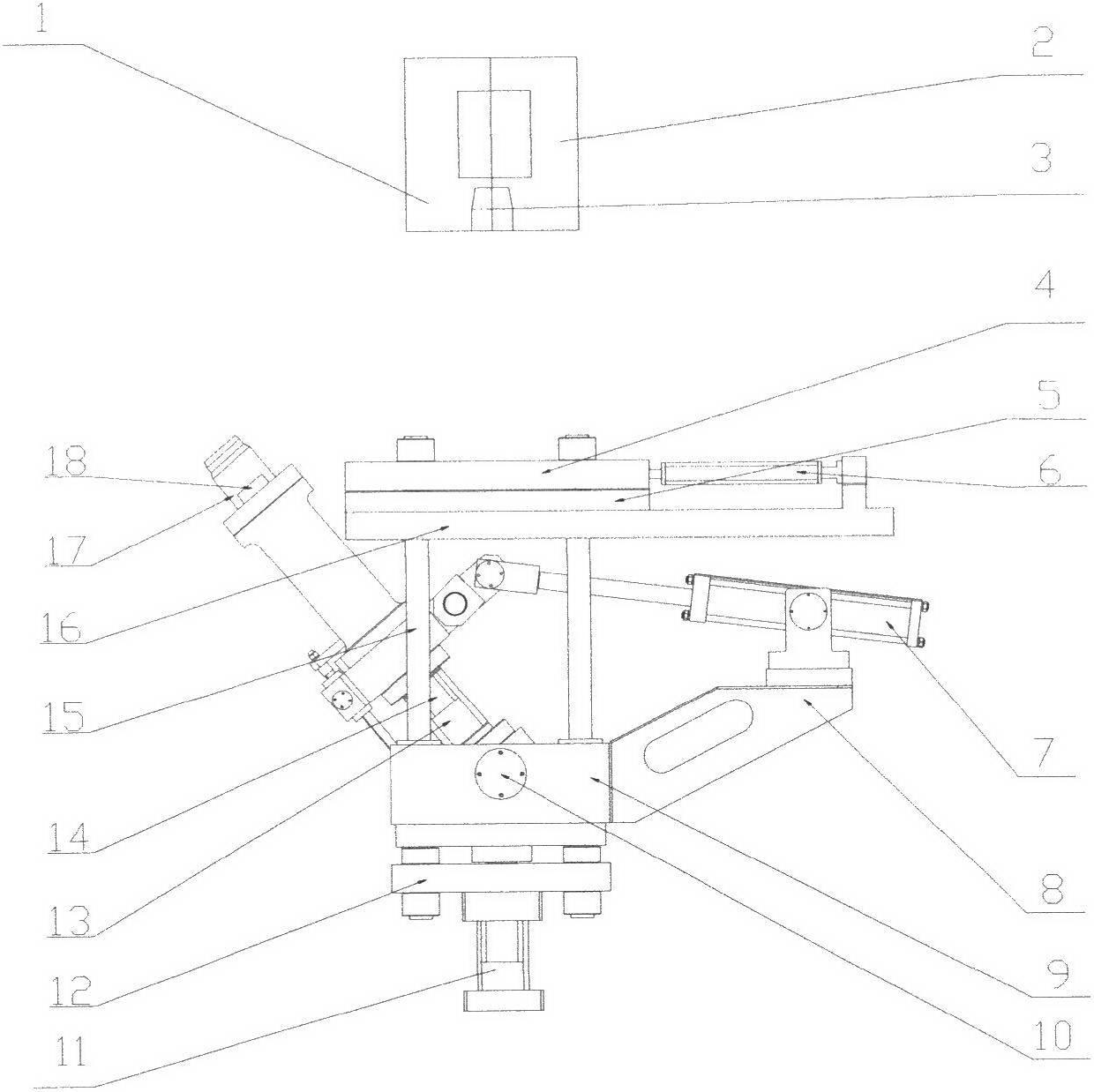

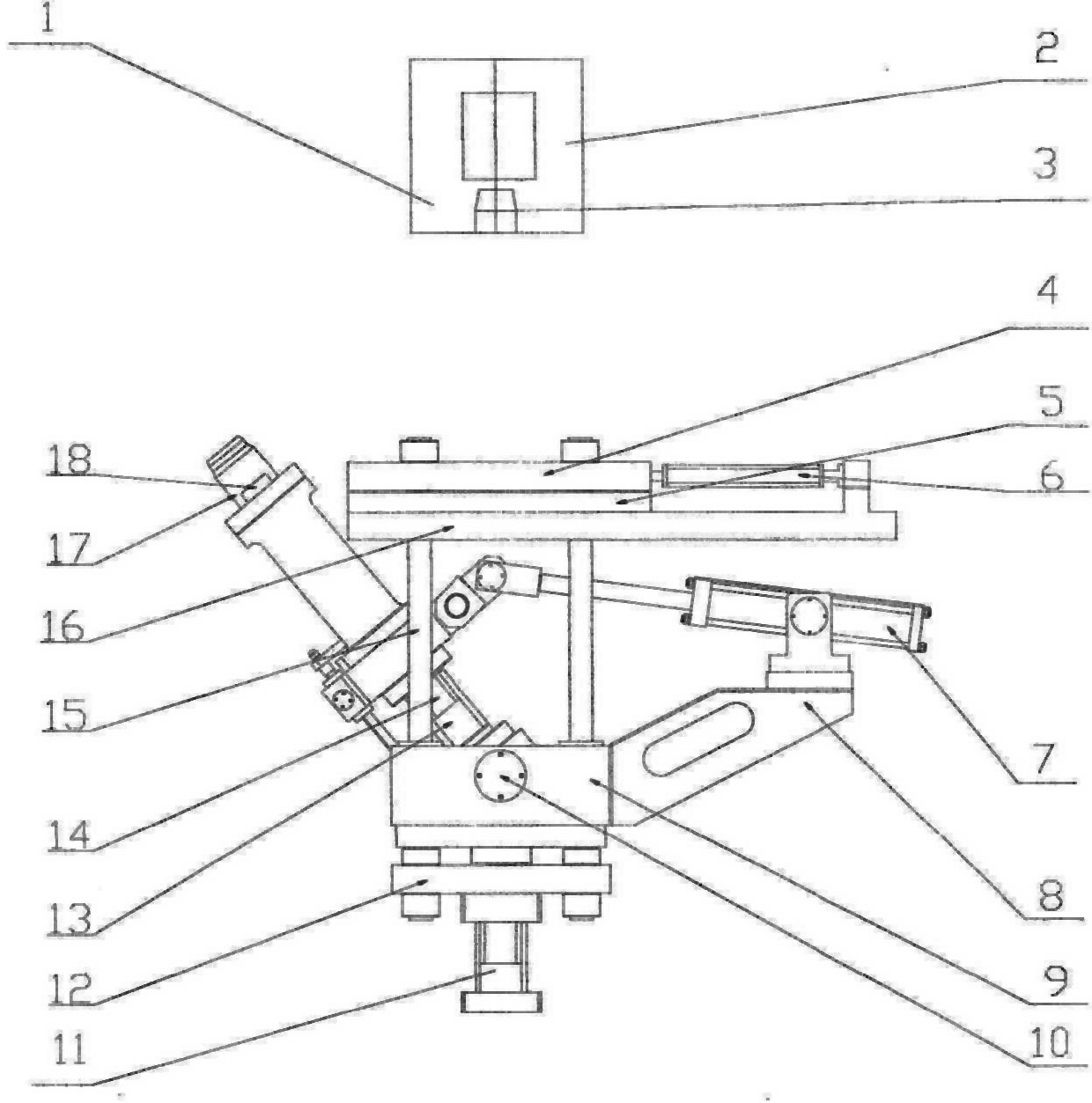

[0019] As shown in the figure, the fixed mold 1 and the movable mold 2 are arranged above the extrusion system. When the squeeze casting machine closes the mold, the fixed mold 1 and the movable mold 2 fit together to form a circular sprue sleeve 3 . There is a suspension frame directly below the sprue bushing. The suspension frame is composed of a fixed upper beam 4, a pull rod 15, and a lifting seat plate 12. The pull rod 15 is provided with an extruded seat plate 9, and the extruded seat plate 9 is set on the pull rod 15. Can move up and down along the pull rod 15, the extruding seat plate 9 is provided with a rotating shaft 10, an angle bracket 8, an extruding oil cylinder 13 is arranged on the rotating shaft 10, a barrel 17 is arranged on the extruding oil cylinder 13, a punch 18 is arranged in the barrel 17, The barrel swing oil cylinder 7 is arranged on the corner support 8, and the barrel swing oil cylinder 7 is connected with the barrel 17. Lifting oil cylinder 11 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com