Press-shooting system for novel extrusion casting machine

A squeeze casting machine and injection rod technology, which is applied in the field of casting machinery, can solve the problems of large space occupied by the injection system, poor stability of the injection process, and difficulty in the thickness and size of castings, achieving automation, high speed, height reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

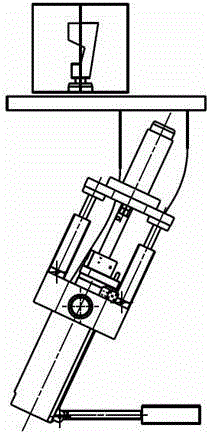

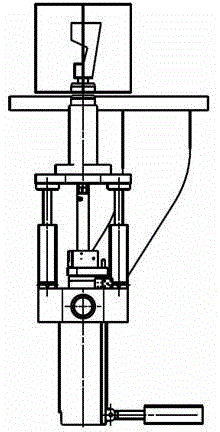

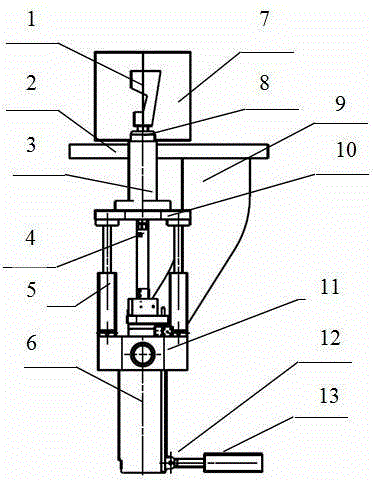

[0020] Such as figure 1 As shown, the fixed template 2 and the movable mold 7 are located above the injection mechanism. When the squeeze casting machine closes the mold, the fixed template 2 and the movable mold 7 are pasted together to form a closed mold cavity space, and there is a circle below Shaped sprue sleeve 8. A rotating bracket 9 is fixed on the fixed template 2, and the injection mechanism is hung on the rotating bracket 9 through an intermediate rotating shaft 11. The injection rod 4 is connected to the bottom of the barrel 3, and the oil cylinder 6 is connected to the bottom of the injection rod 4. The injection rod 4 is used to complete the filling. There is a square barrel fixing plate 10 at the bottom of the barrel 3, and the barrel fixing plate 10 Two barrel piston pressure rods are connected below, and the effect of the piston pressure rod is to lift and lower the barrel, and the lifting and lowering of the barrel 3 are realized by moving up and down of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com