A high-strength corrosion-resistant explosion-proof pneumatic cylinder and its preparation method

A pneumatic cylinder and corrosion-resistant technology, applied in the field of high-strength corrosion-resistant explosion-proof pneumatic cylinder and its preparation, can solve the problems of easy existence of holes, porosity, segregation, affecting the internal structure and mechanical properties of the final product, etc. Defects, dense organization, and the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

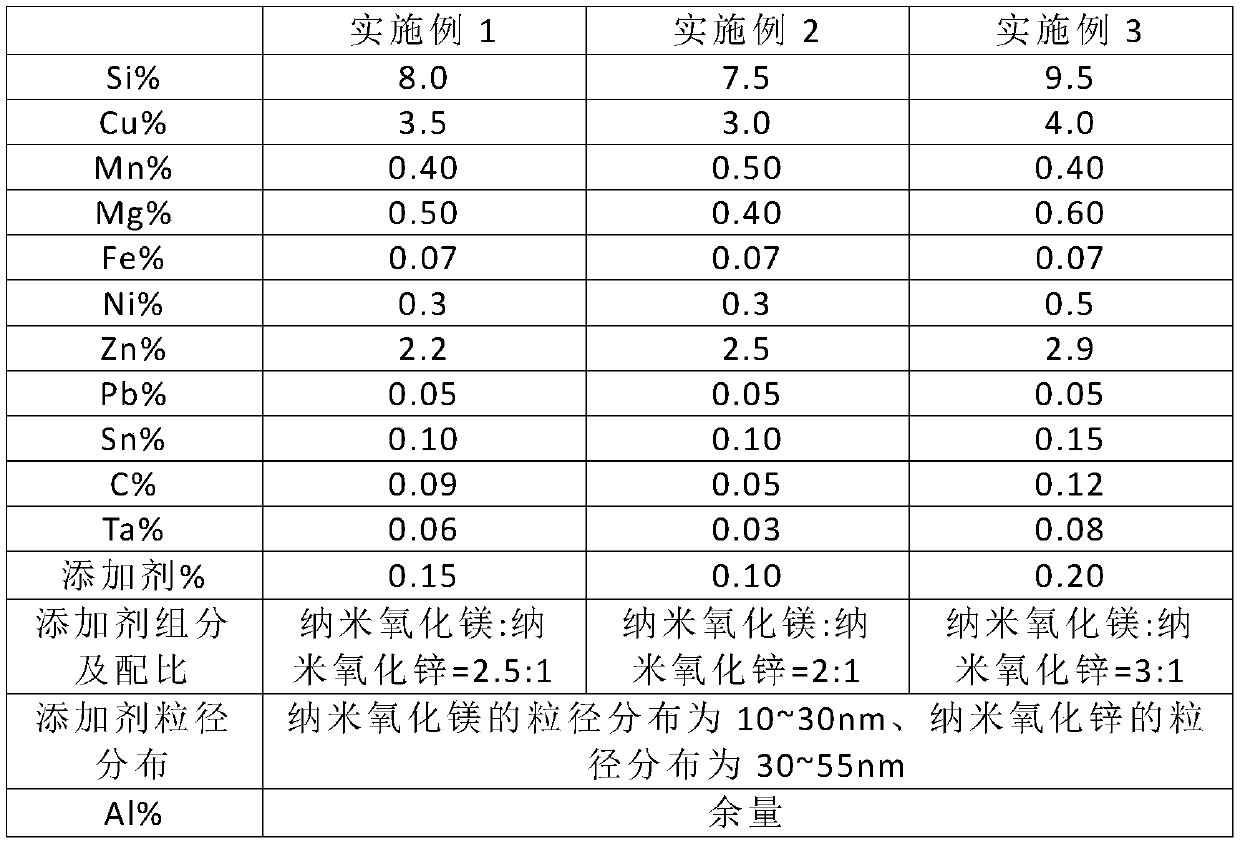

[0025] The components and weight percentages of the aluminum alloys used in the high-strength corrosion-resistant explosion-proof pneumatic cylinders in Examples 1 to 3 are shown in the following table:

[0026] Table 1: Components and weight percentages of aluminum alloys used in pneumatic cylinders in Examples 1 to 3

[0027]

Embodiment 4

[0029] The preparation method of the high-strength corrosion-resistant explosion-proof pneumatic cylinder in this embodiment comprises the following steps:

[0030] (1) Smelting molten aluminum: prepare raw materials according to the aluminum alloy in Example 1, melt the raw materials into molten aluminum, add additives to the molten aluminum, and stir evenly.

[0031] (2) Die-casting molding: the aluminum liquid is made into semi-solid droplets with a particle size distribution of 2-6 μm by spraying method to form a semi-solid slurry at a temperature of 610°C, and the semi-solid slurry is kept warm and immediately heated at a temperature of 610°C The lower injection is injected into the extrusion die-casting machine, and the finished product of the pneumatic cylinder is obtained by die-casting. The injection speed is 0.4m / s, the pressure of pressurized casting is 60MPa, and the pressurization time is 50s.

[0032] (3) Post-treatment: Cool the pressurized casting to 520°C for ...

Embodiment 5

[0034] The preparation method of the high-strength corrosion-resistant explosion-proof pneumatic cylinder in this embodiment comprises the following steps:

[0035] (1) Smelting molten aluminum: prepare raw materials according to the aluminum alloy in Example 1, melt the raw materials into molten aluminum, add additives to the molten aluminum, and stir evenly.

[0036] (2) Die-casting molding: the aluminum liquid is sprayed into semi-solid droplets with a particle size distribution of 2-6 μm to form a semi-solid slurry at a temperature of 590°C, and the semi-solid slurry is immediately pressed at a temperature of 590°C Injection into extrusion die-casting machine, die-casting molding, that is, the finished product of the pneumatic cylinder, the injection speed is 0.3m / s, the pressure of pressurized casting is 80MPa, and the pressurization time is 30s.

[0037] (3) Post-treatment: cool the pressurized casting to 525°C for solution treatment for 2 hours, then cool down to 250°C ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com