Patents

Literature

48results about How to "Not easy to wrap" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Camptothecin-adriamycin prodrug and preparation method and application thereof

ActiveCN106831805ASynergisticLow toxicityOrganic active ingredientsOrganic chemistryCarrying capacityNanoparticle

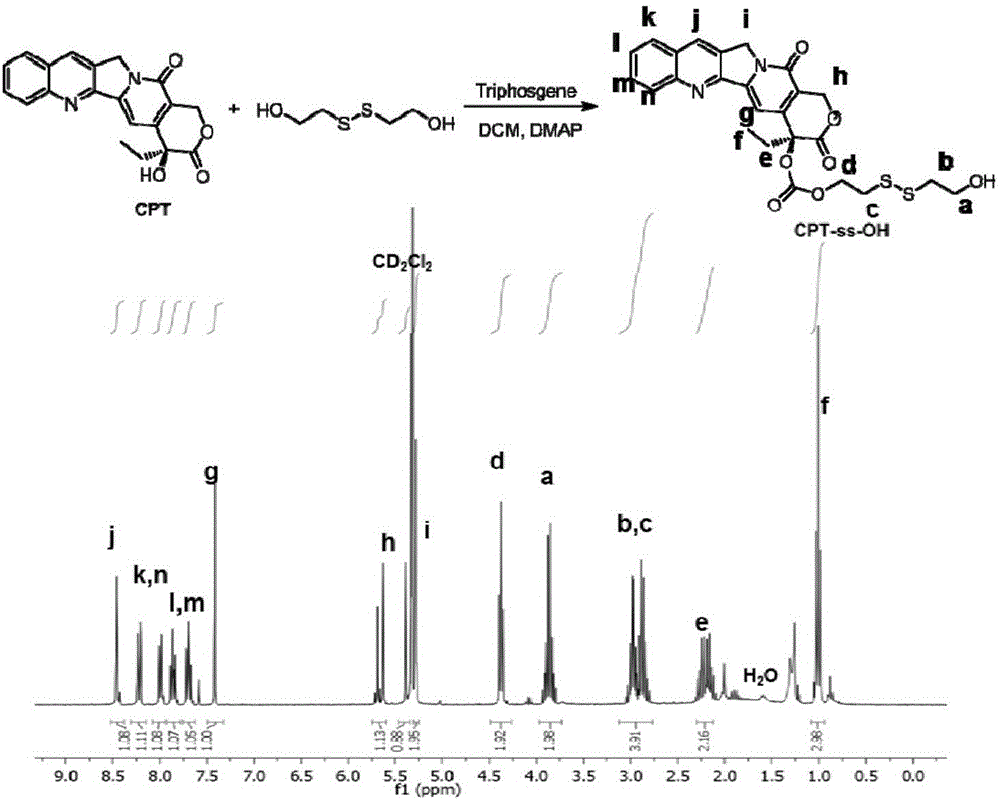

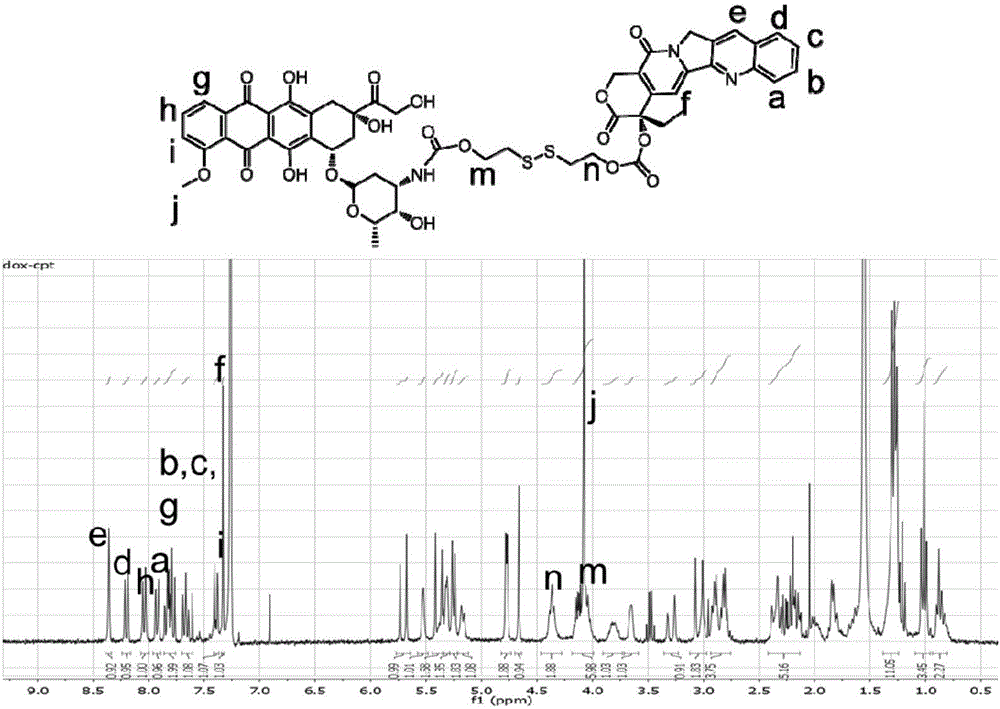

The invention provides camptothecin-adriamycin prodrug. A structural formula of the prodrug is shown as a formula (I), wherein R1 is camptothecin or derivative group thereof, R2 is one of -CH2- or -O-, R3 is one of -CH2- or -O-, X is one of S or -CH2-, and n1 and n2 are numbers of repeated units, and are integers from 0 to 10. The prodrug can be easily wrapped by amphiphilic polymer to form nanoparticles. The nanoparticles are high in drug carrying efficiency and drug carrying capacity and capable of quickly releasing unmodified camptothecin and adriamycin in the presence of glutathione, and the nanoparticles can be effectively taken in by tumor cells to kill the same. The invention further provides a preparation method of the prodrug, a preparation of the prodrug and application of the prodrug in preparing cancer treating drug.

Owner:YANTAI LANNACHENG BIOTECHNOLOGY CO LTD

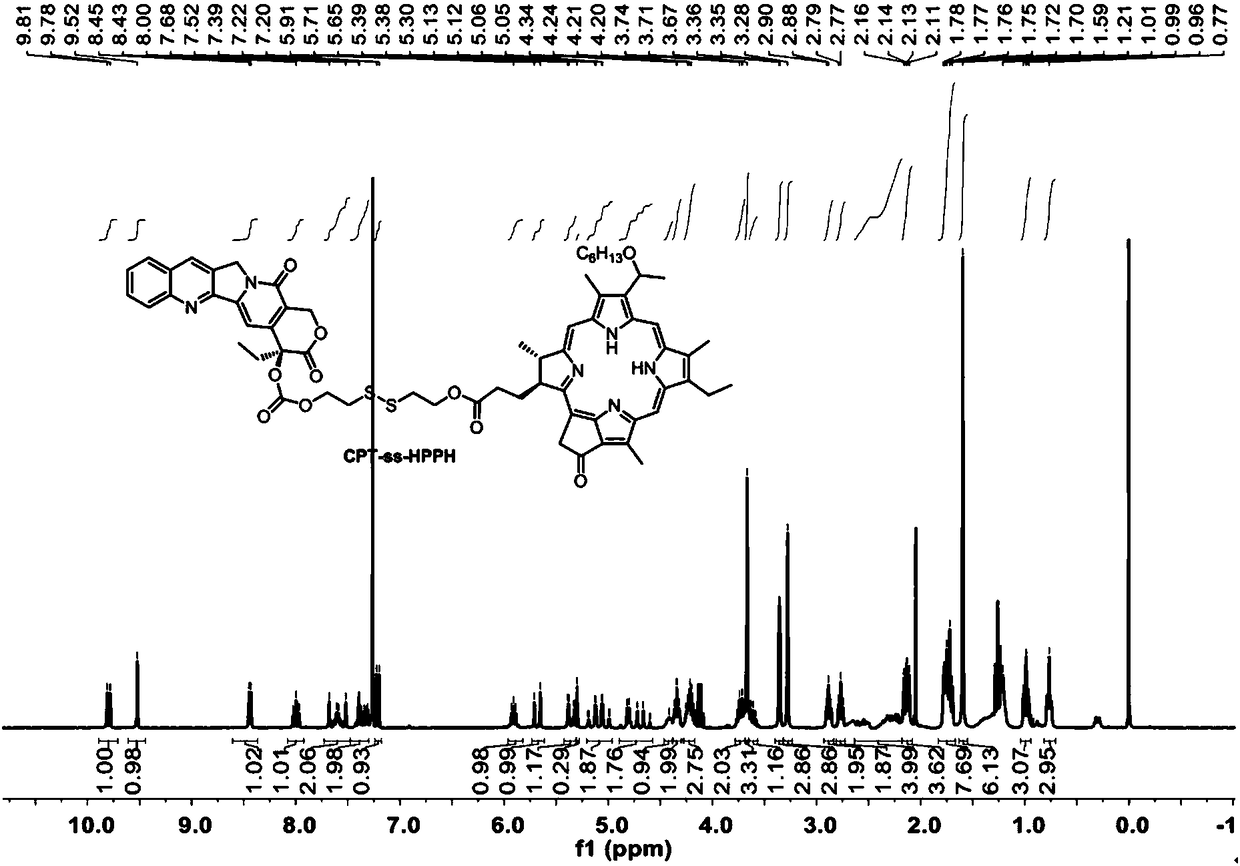

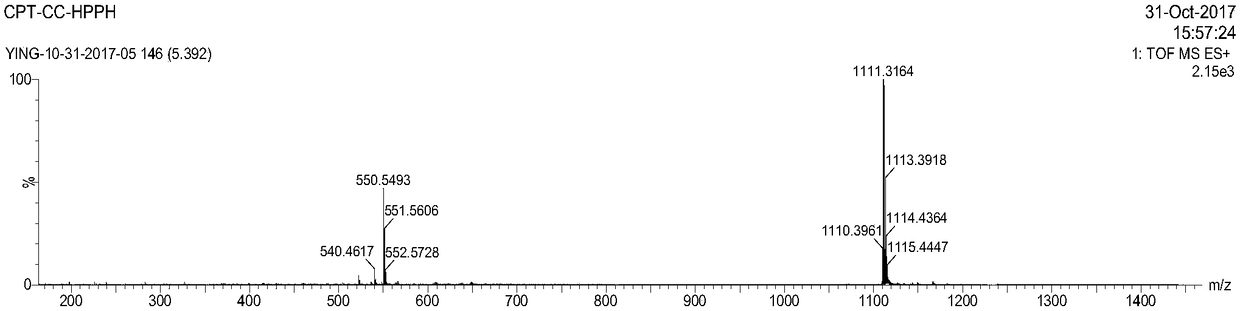

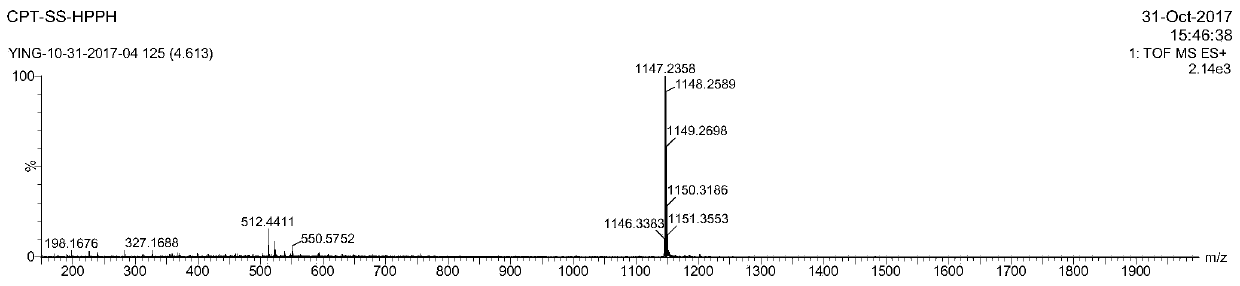

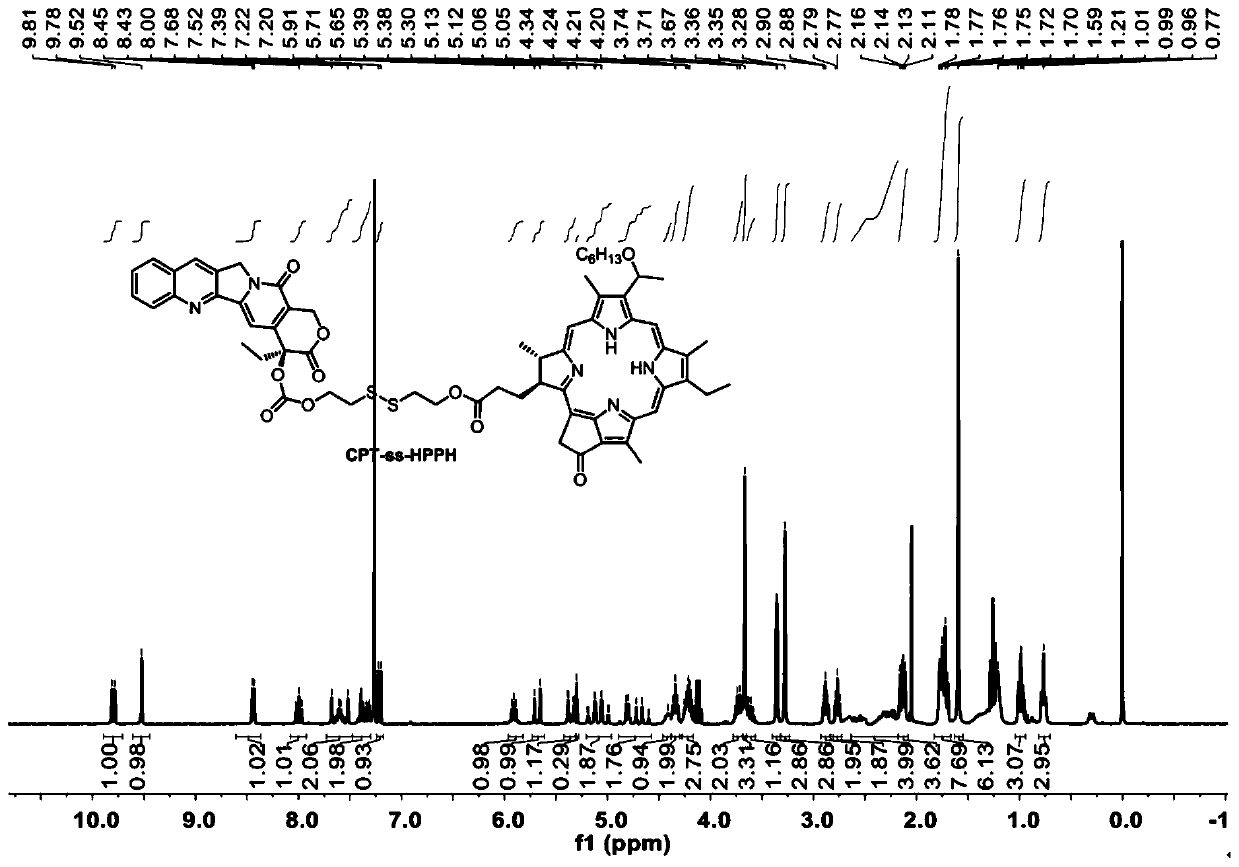

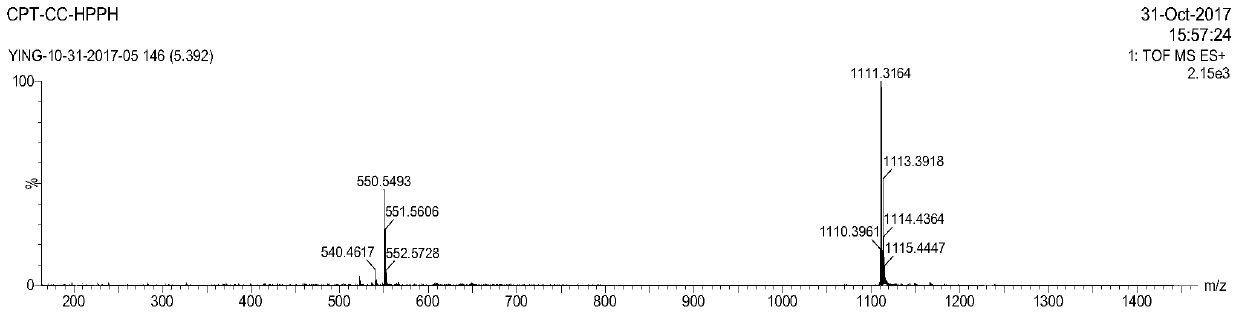

Heterodimer multifunctional prodrug based on camptothecin and preparation method and application of heterodimer multifunctional prodrug

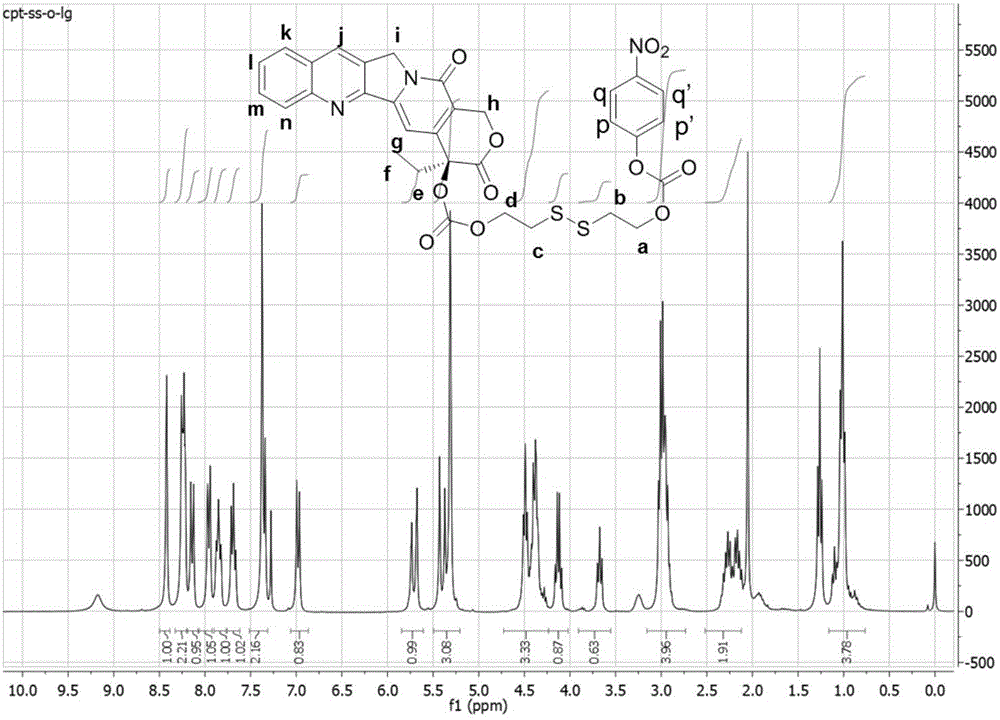

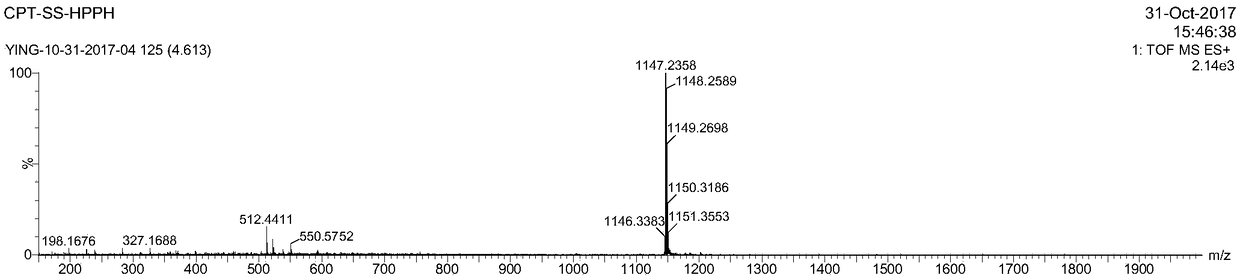

ActiveCN108409756ASelective releaseFacilitated releaseOrganic active ingredientsOrganic chemistryNanoparticleFast release

The invention provides a heterodimer multifunctional prodrug based on camptothecin. The heterodimer multifunctional prodrug is loaded with the camptothecin and 2-(1-hexyloxy ethyl)-2-devinyl-pyropheophorbide-a (HPPH), the prodrug is a camptothecin-HPPH prodrug formed by the camptothecin and the HPPH through a connecting group, and the structural formula of the prodrug is as shown in formula (I), wherein R is the connecting group and is one of -SS-, -CH2CH2- or -S(CH3)C(CH3)S-; R1 is the camptothecin group. The prodrug has the advantages that the prodrug can be easily wrapped by amphiphilic polymer to form nano particles, and the formed nano particles are high in drug loading efficiency and drug loading capacity and can fast release the unmodified camptothecin and HPPH in the presence of glutathione; meanwhile, the nano particles can be effectively absorbed by tumor cells to kill the tumor cells. The invention further provides a preparation method and preparation of the prodrug and application of the prodrug in the preparation of drugs for treating cancer.

Owner:SHANGHAI THERANOSTICS BIOTECH CO LTD

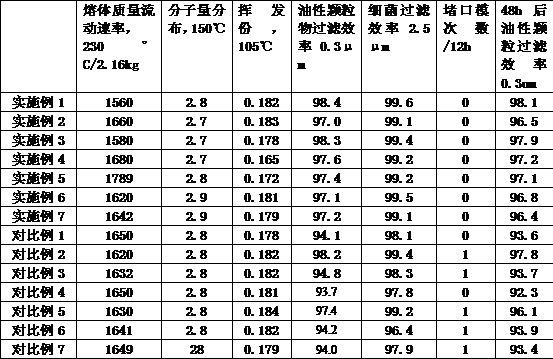

Melt-blown material with high oily particle filtering efficiency, and preparation method and application of melt-blown material

PendingCN111909455AImprove liquidityImprove filtration efficiencyFiltration separationProtective garmentPolymer scienceFluoropolymer

The invention discloses a melt-blown material with high oily particle filtering efficiency, and a preparation method and application of the melt-blown material. The melt-blown material comprises the following raw materials in parts by weight: ultra-high-flowability polypropylene, an antioxidant and a compound electret, wherein the compound electret is composed of, in parts by weight, tourmaline powder, a fluorine-containing polymer and an oleophobic agent. The melt-blown material and the preparation method and application thereof are directed at the defects that a die head is easy to block inthe extrusion process of an existing melt-blown material, the filtering efficiency of oily particles is low, filtering efficiency retention time is short and the like, and overcome the problems that the material has non-uniform filtering efficiency in different equipment and mouth dies and is large in effect difference.

Owner:DONGGUAN HONOUR E P

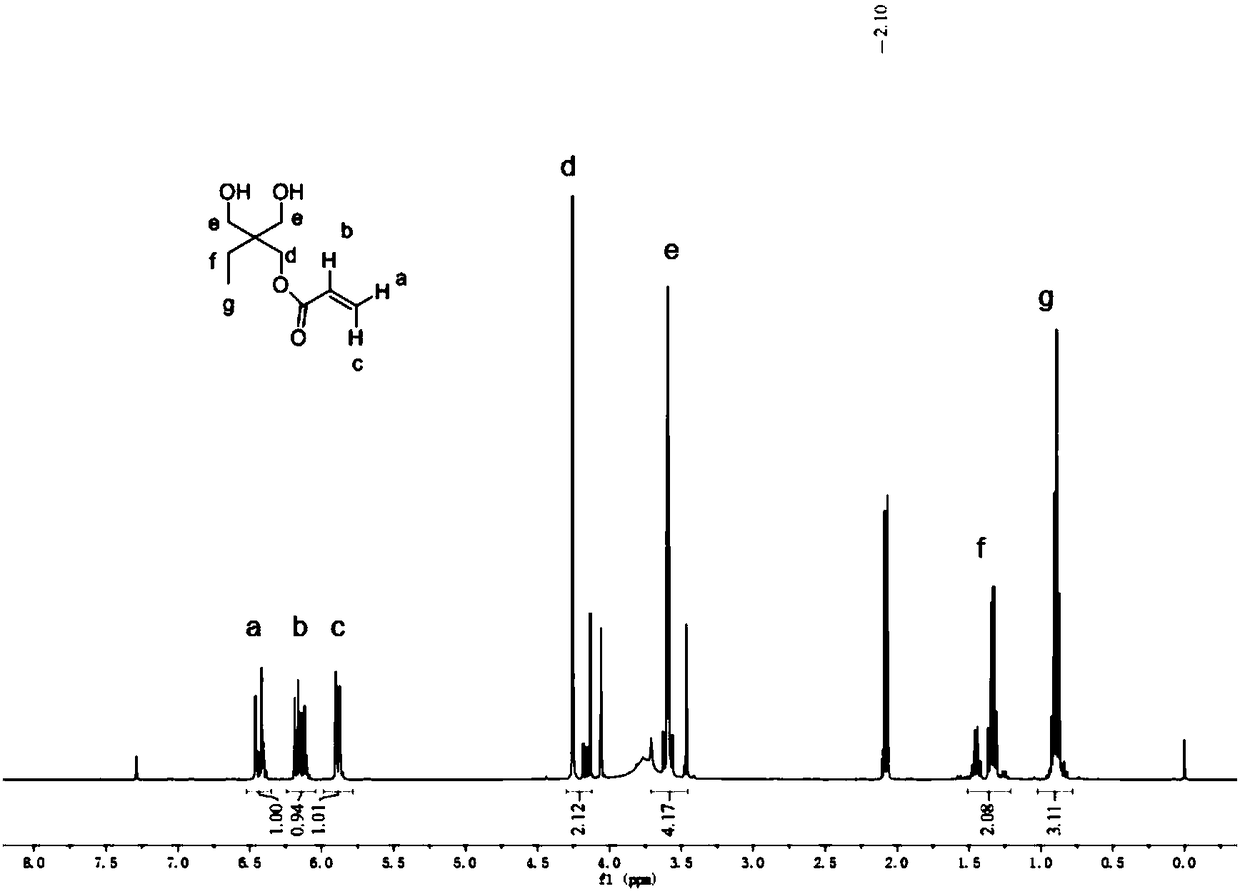

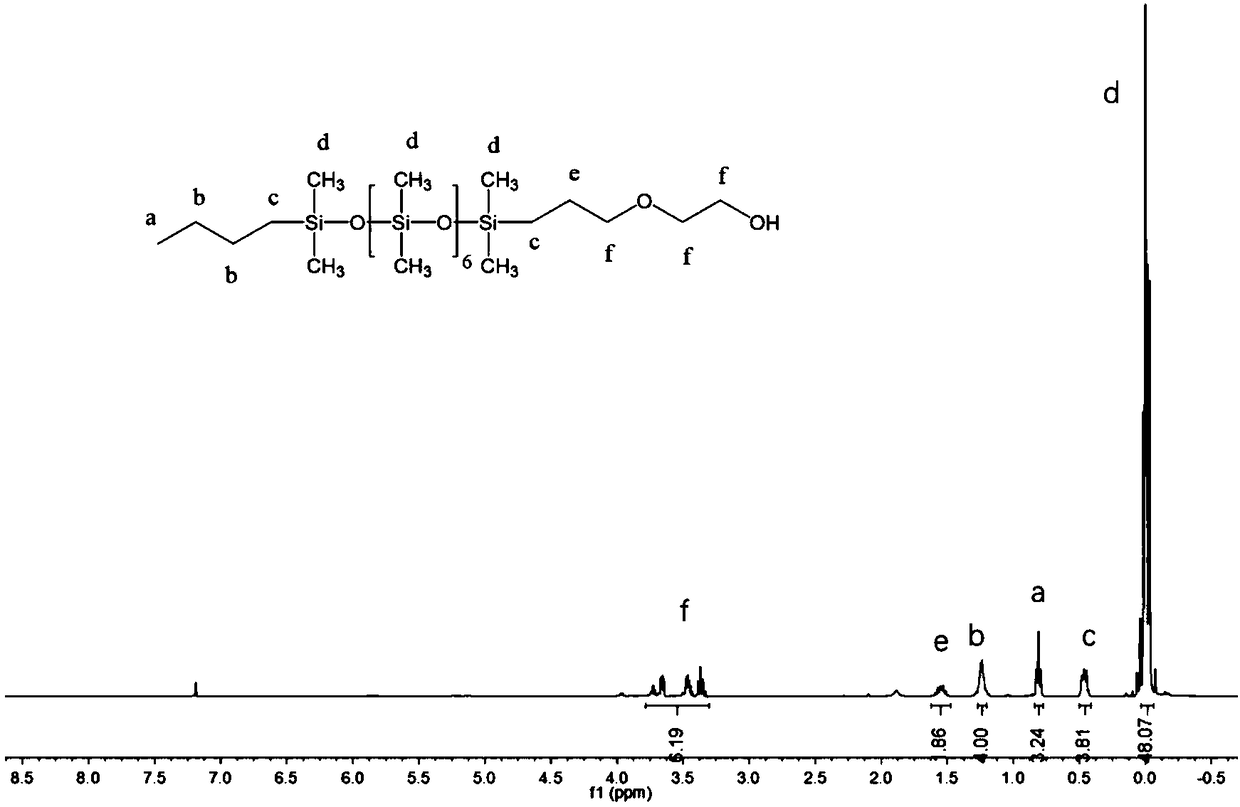

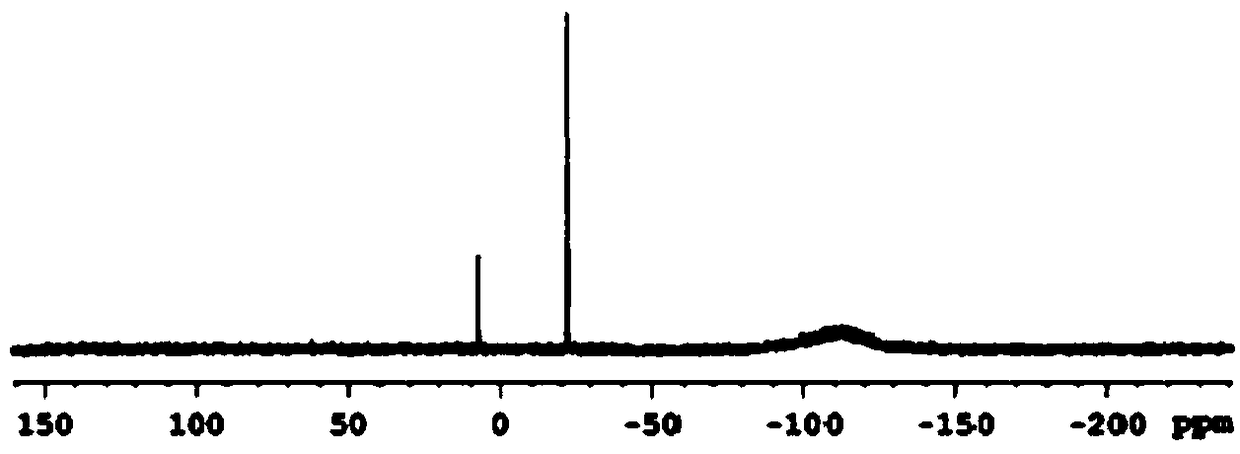

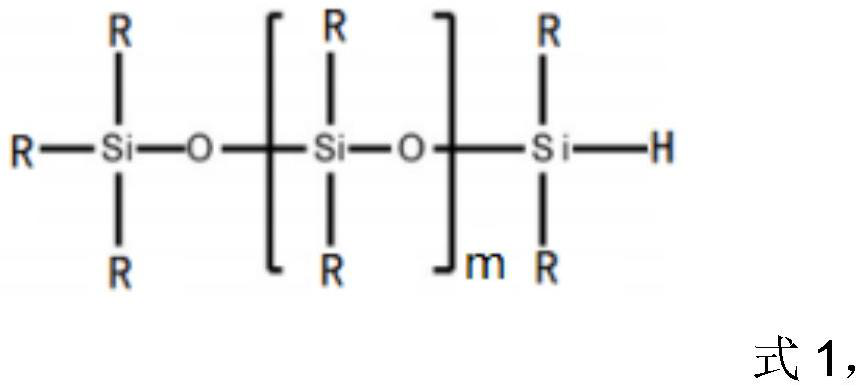

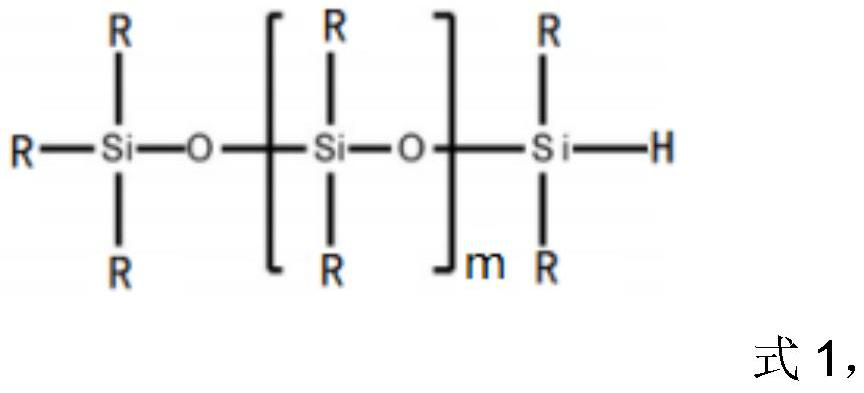

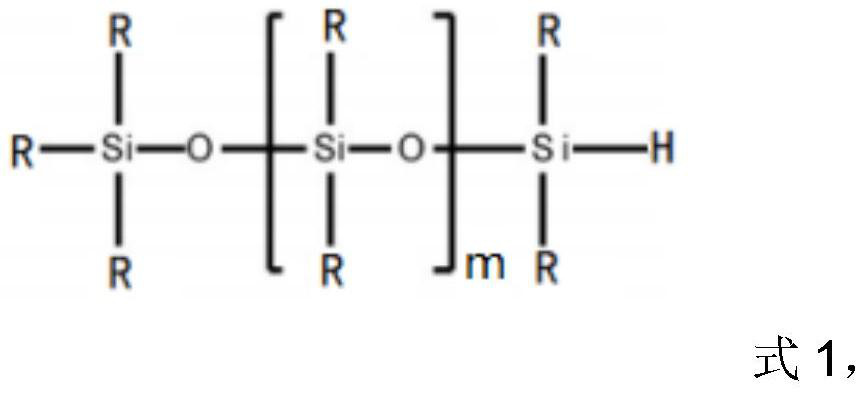

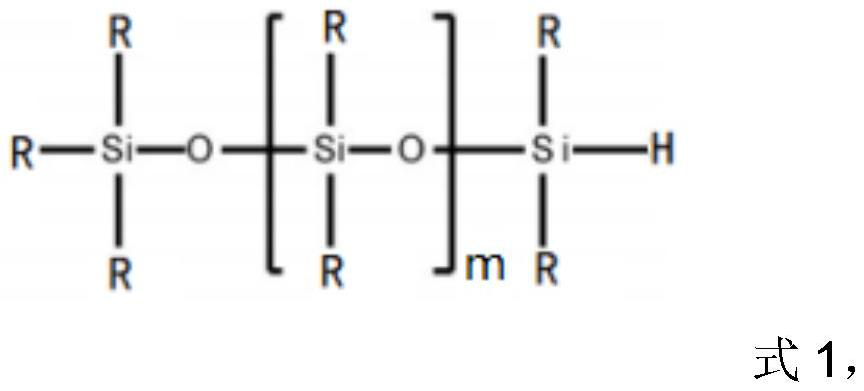

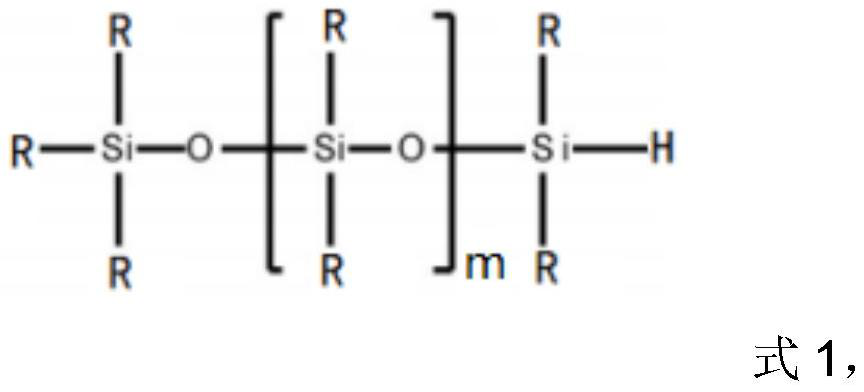

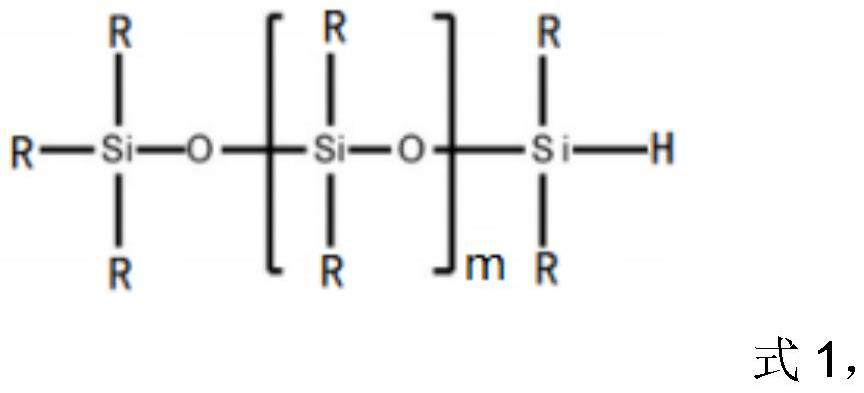

Method for preparing photopolymerizable organosilicon polyurethane acrylate aqueous oligomer and composition thereof

The invention discloses a method for preparing a photopolymerizable organosilicon polyurethane acrylate aqueous oligomer and a composition thereof. The method is based on the shortcomings of the current photopolymerizable organosilicon polyurethane acrylate aqueous oligomer, and the method comprises the following steps: synthesizing 2,2-bis(hydroxymethyl) butyl acrylate (HBA), and introducing thematerial into the oligomer molecule to make the polymer side chain is rich in unsaturated carbon-carbon double bonds; synthesizing one-terminated hydroxypolydimethylsiloxane (Si-OH), and introducing the substrate to the end of a main chain of the aqueous polyurethane acrylate oligomer so that the substrates facilitate enrichment on the surface of the material. Through the above molecular design, the problems of poor water resistance and low hardness of the aqueous photocurable material caused by the low double bond content and low crosslink density of the photocurable material are effectivelysolved, and the disadvantages that silicone chain is easily wrapped by the crosslinked network when is in the middle of the main chain so that the silicone is not enriched at the surface of the material, so that the surface hydrophobicity of the material can be effectively increased.

Owner:安庆北化大科技园有限公司

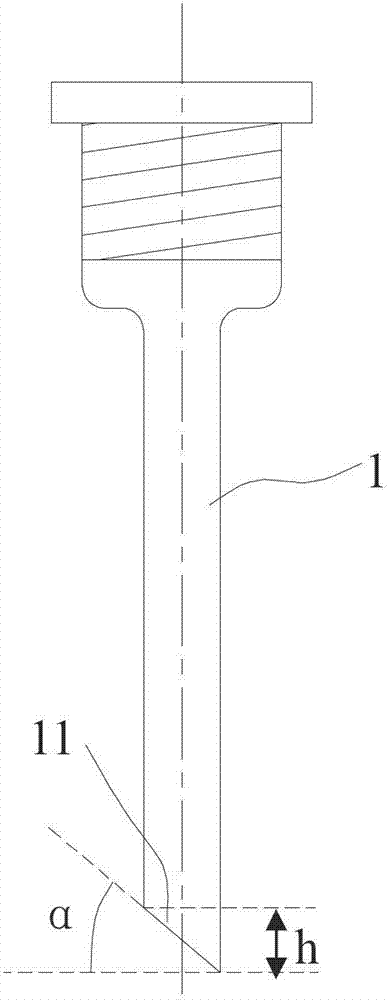

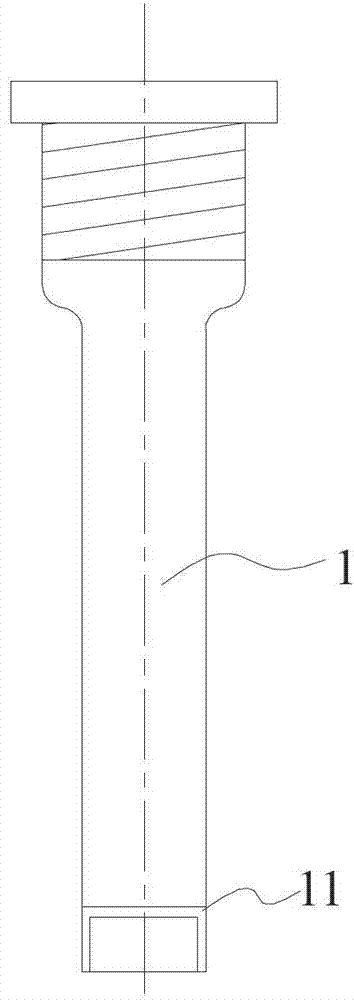

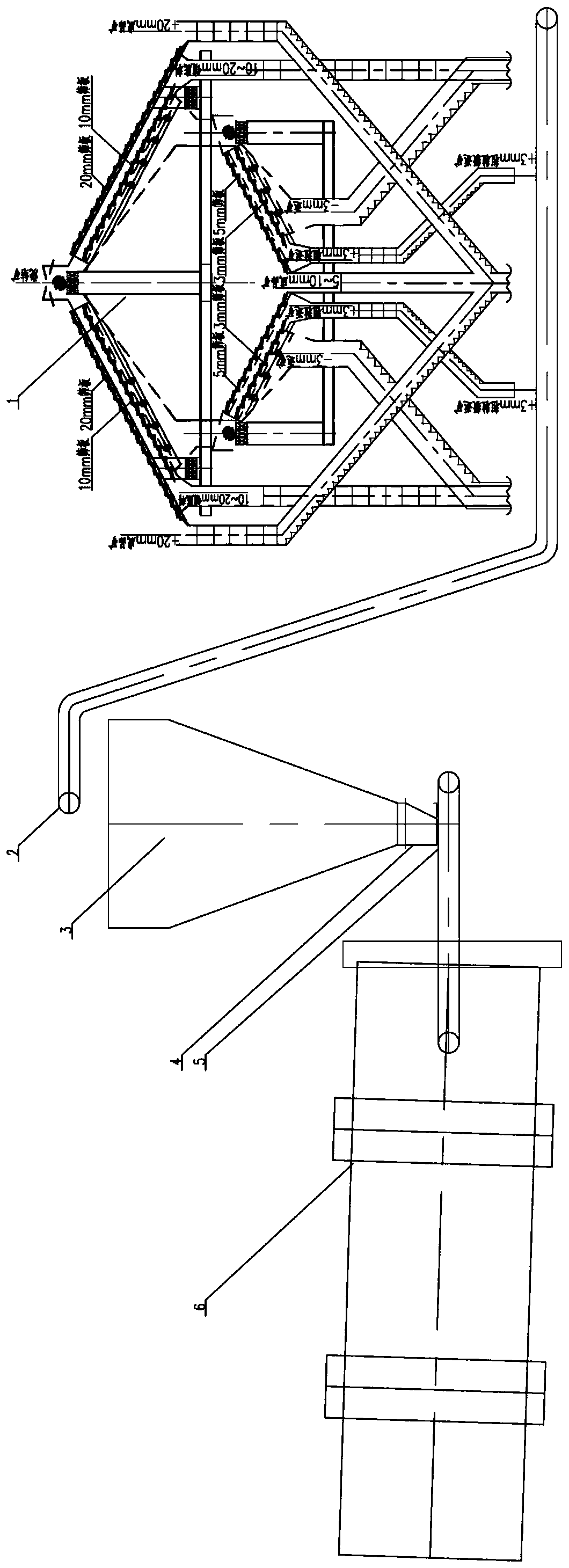

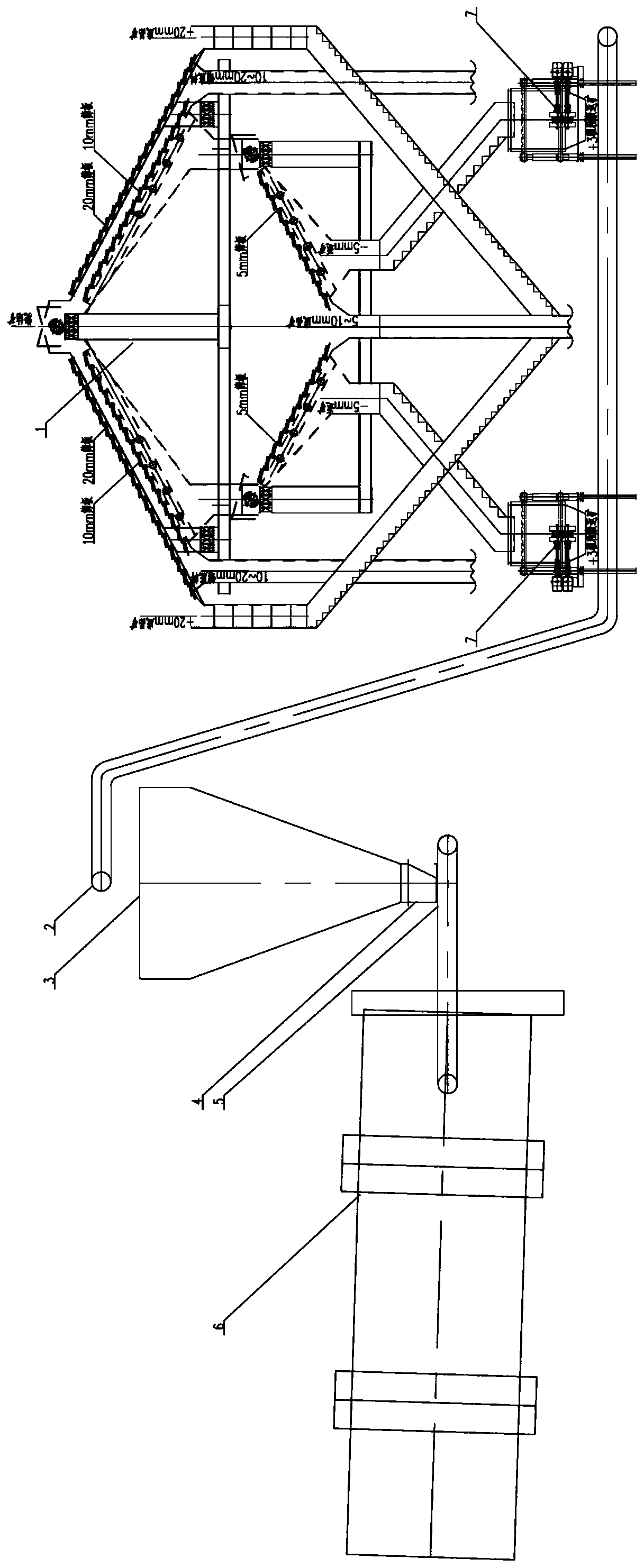

Sealant overflow process of photovoltaic assembly framing

ActiveCN102903794AOverflow evenlyEasy to wrapLiquid surface applicatorsFinal product manufactureEngineeringSealant

The invention discloses a sealant overflow process of photovoltaic assembly framing. The sealant overflow process comprises the steps of: (1) injecting a sealant into a mounting groove of the frame by an injection head, wherein the injection head is provided with a tip consisting of a platform and a bevel surface on the outlet thereof, the platform and the bevel surface have an included angle beta of 75 to 80 degrees, and the height h of the bevel surface is equal to 7 to 8mm; (2) placing a laminated plate on the lifting platform of a frame loading machine, and pressing the frame from four corners of the frame by using a press block of the frame loading machine to inlay the mounting groove of the frame into the edge of the laminated plate so as to result in sealant overflowing, and framing to obtain the photovoltaic assembly; and (3) continuously conveying the photovoltaic assembly to a sealed chamber through the conveying belt of a plurality of automatic line units to cure the sealant. The sealant overflow process provided by the invention can realize a good sealant overflowing effect, thereby ensuring the insulation sealing property of the photovoltaic assembly, greatly reducing the sealant removal frequency, and improving the photovoltaic assembly production efficiency.

Owner:HEFEI & SOLAR TECH

Thermosetting acrylic coating

InactiveCN1508203AReduce reactivityWill not be deformed by heatCoatingsPolymer scienceAcrylic coating

The invention discloses a thermosetting a crylic acid coating roll-coated on aluminum foil surface and painting the aluminum foil surface. It is made from thermosetting a crylic acid resin 50-60shares, butoxy amino resin 15-20shares, pigment 5-28shares, solvent 5-10shares, levelling agent 0.2-0.4share, defoaming agent 0.2-0.4share, adhesion accelerant 0-3shares, and wet dispersing agent 0-4shares. The pigment is titanium pigment or flashlight aluminum powder; the solvent is xylene, S-100 high boiling arene solvent, butyl glycol ether or ethylene glycol ethyl ether acetic acid. It has wide application range.

Owner:WUXI ACRYL TECH

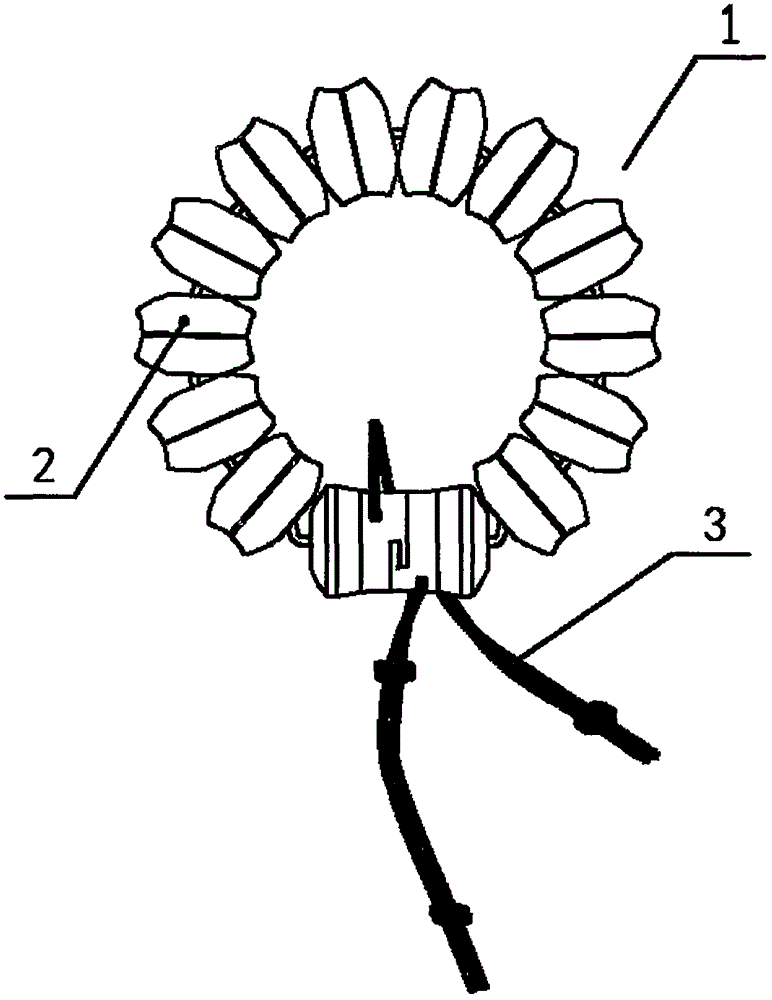

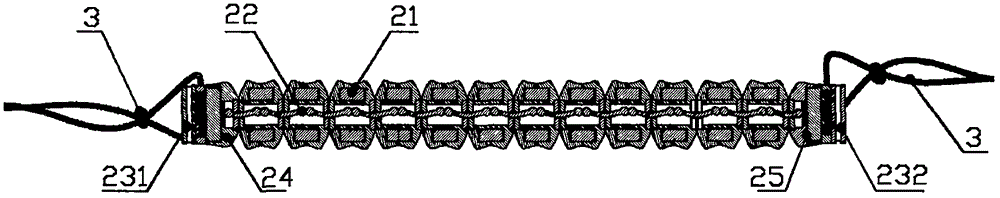

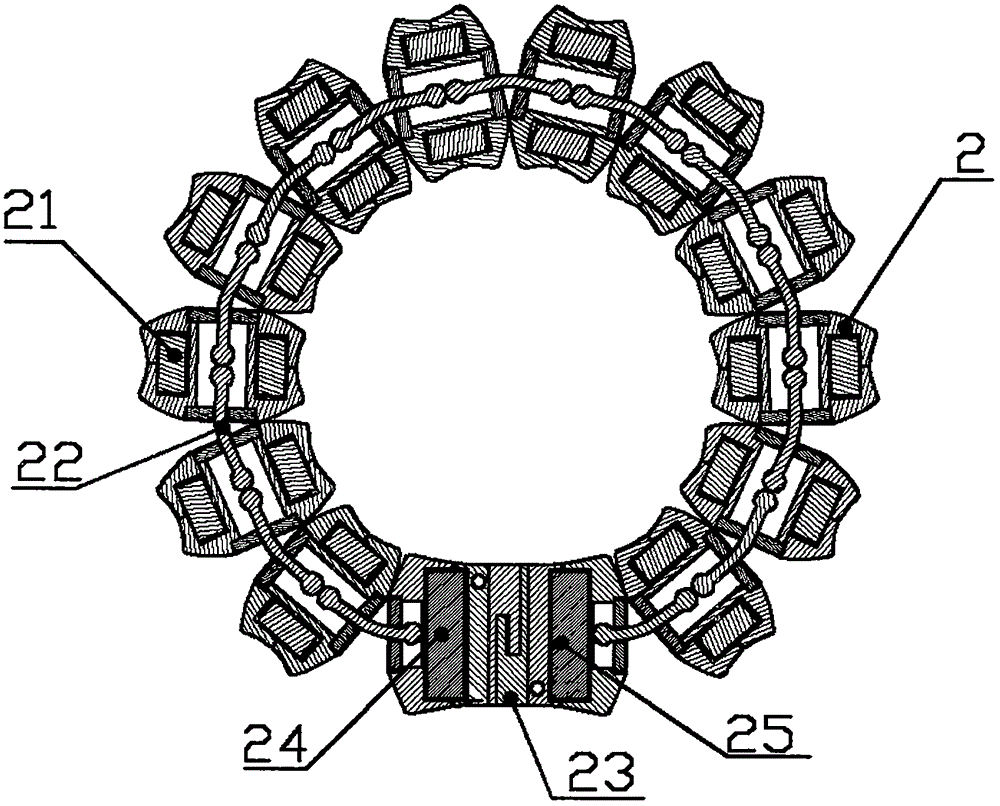

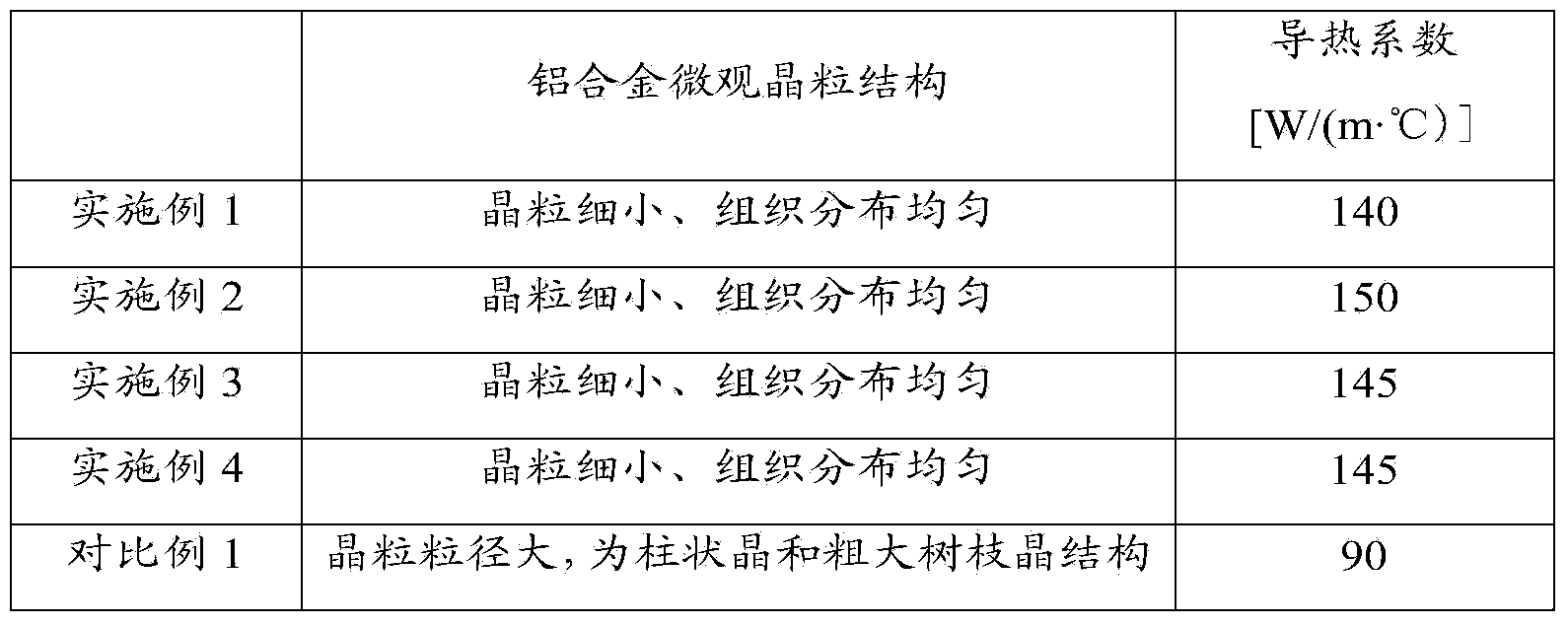

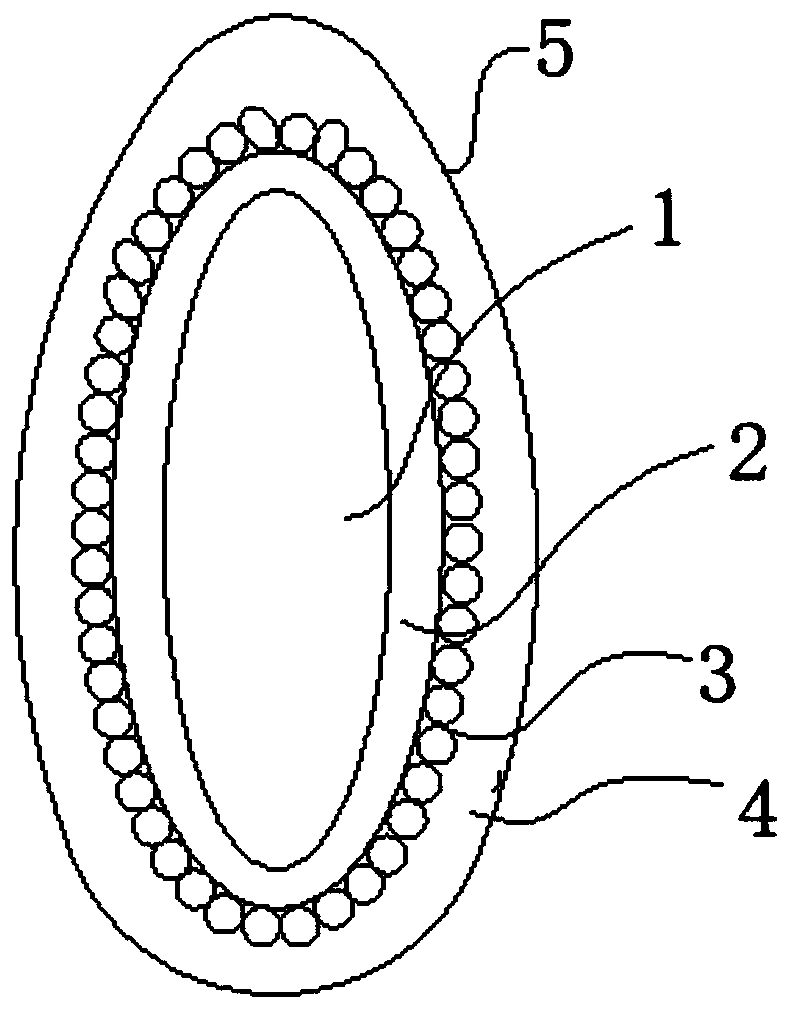

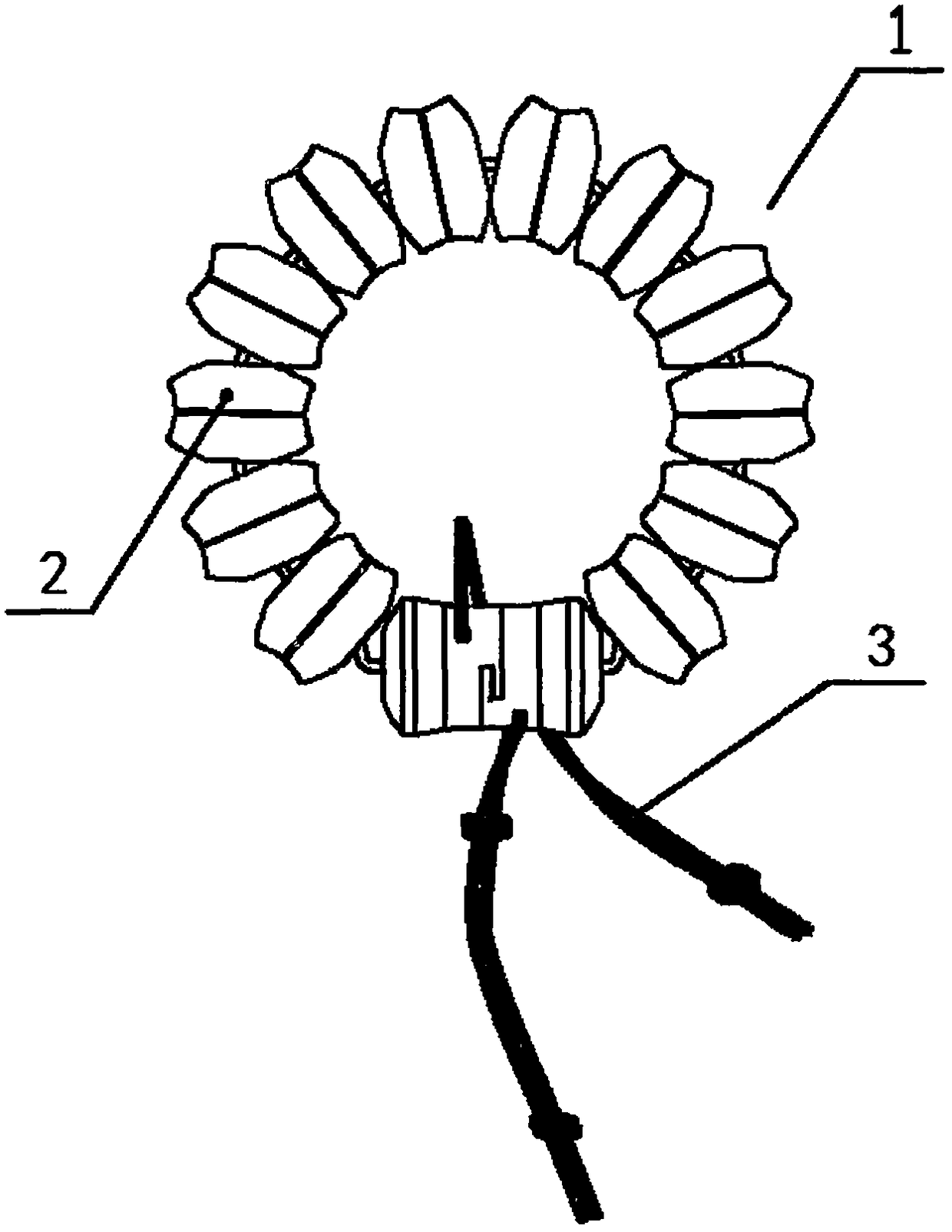

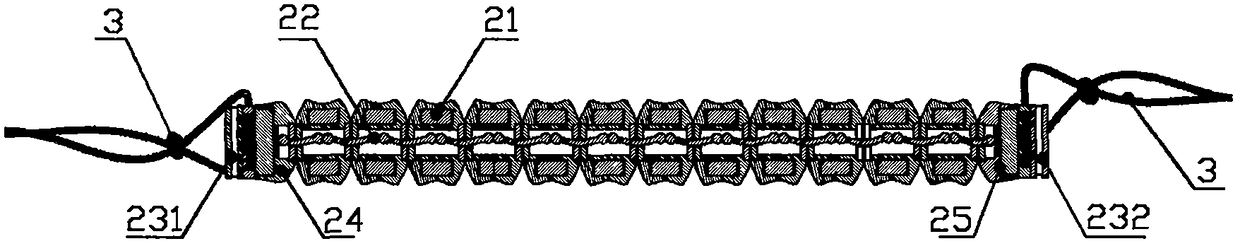

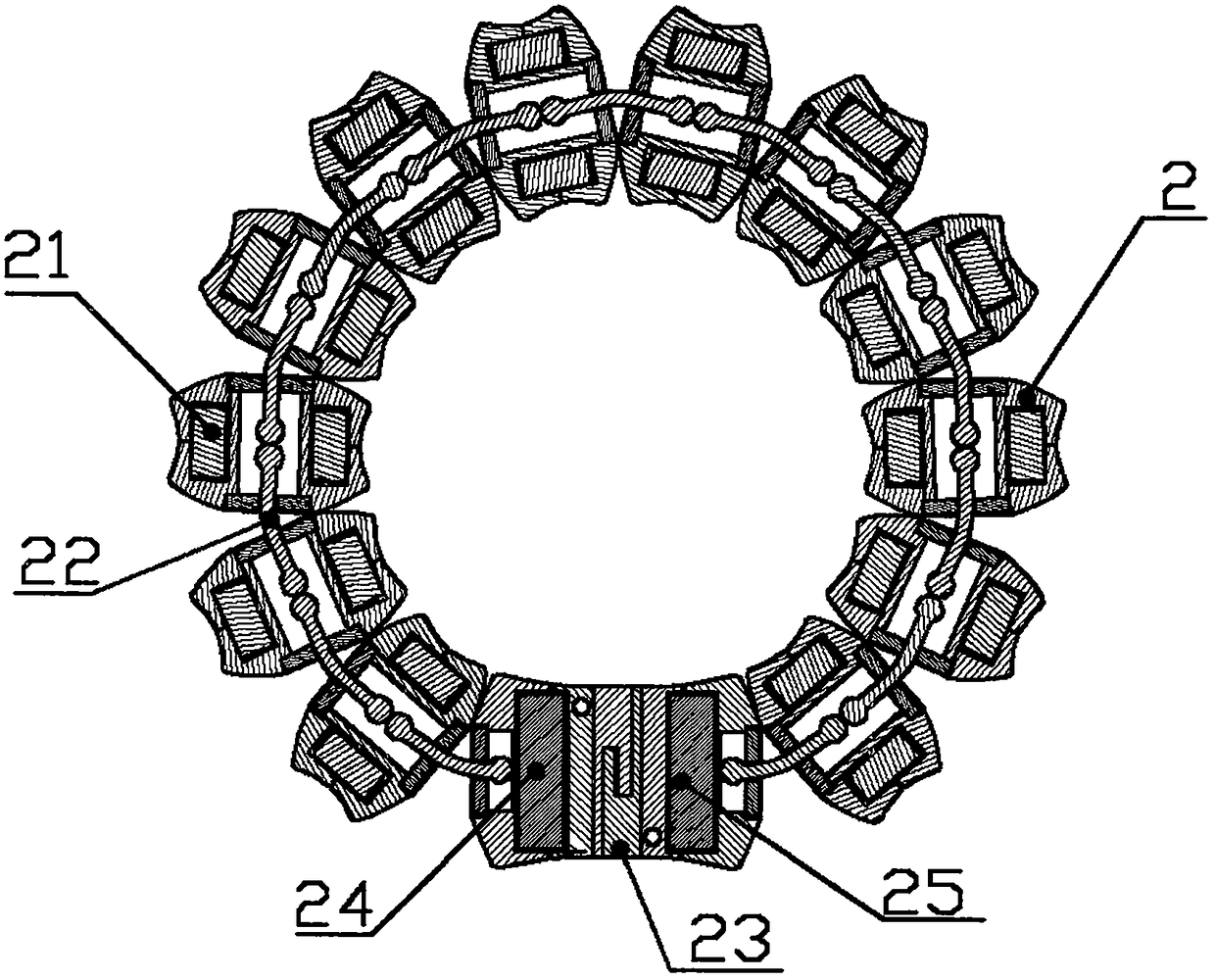

Implanting instrument capable of preventing gastroesophageal reflux

ActiveCN105997296ALess discomfortReduce frictionAnti-incontinence devicesSurgeryMagnetic chainSphincter

The invention relates to an implanting instrument capable of preventing gastroesophageal reflux. The implanting instrument comprises a magnetic chain and auxiliary lines, the magnetic chain comprises multiple magnetic devices, multiple connecting units and a lock catch device, each magnetic device comprises one or more annular magnets and a shell, and the internal circumferential face of each shell is an internal concave cambered surface; the adjacent magnetic devices are movably connected through one connecting unit, and each connecting unit comprises a connecting part and limiting parts arranged at the ends of the connecting part; the lock catch device comprises a first lock catch device body and a second lock catch device body, the magnetic chain is further provided with a starting magnetic device and a tail end magnetic device, the first lock catch device body and the second lock catch device body are arranged on a shell of the starting magnetic device and a shell of the tail end magnetic device respectively, and when the first lock catch device body and the second lock catch device body are combined, a closed annular magnetic chain ring is formed by the magnetic chain. According to the implanting instrument capable of preventing the gastroesophageal reflux, the design is reasonable, and the shape formed by connecting the magnetic chain in series is closer to a circle, so that the implanting instrument is more attached to the outer wall of esophagus after being implanted to the outer side of lower esophageal sphincter, and the effect of strengthening the LES through the instrument is exerted more sufficiently.

Owner:NINGBO SHENGJIEKANG BIOTECH

Process for producing memantine hydrochloride

ActiveCN103965058AHigh yieldLess side effectsOrganic compound preparationAmino compound preparationMemantine HydrochlorideHydrolysis

The invention belongs to the technical field of medicine, and in particular relates to a process for producing memantine hydrochloride. The process for producing the memantine hydrochloride comprises the steps of performing acetyl amination reaction on 1-bromo-3,5-dimethyladamantane and acetonitrile at 5-10 DEG C under the action of concentrated sulfuric acid to obtain 1-acetamino-3,5-dimethyladamantane; performing hydrolysis reaction on the 1-acetamino-3,5-dimethyladamantane and polyol which does not contain an ether bond under an alkali condition to obtain 1-amino-3,5-dimethyladamantane; and acidifying the 1-amino-3,5-dimethyladamantane with hydrochloric acid, and performing re-crystallization to obtain the high-purity memantine hydrochloride. The process for producing the memantine hydrochloride, disclosed by the invention, has the advantage that the product yield of the memantine hydrochloride is increased by controlling process parameters and changing process conditions based on an existing synthetic process.

Owner:CHENGDU YILUKANG MEDICAL TECH & SERVICE

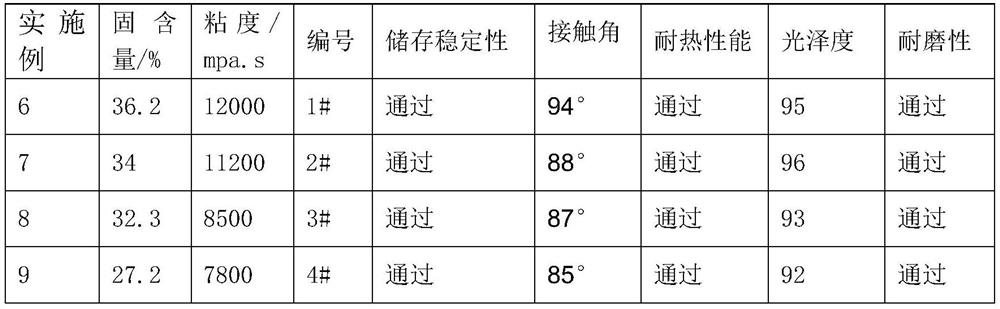

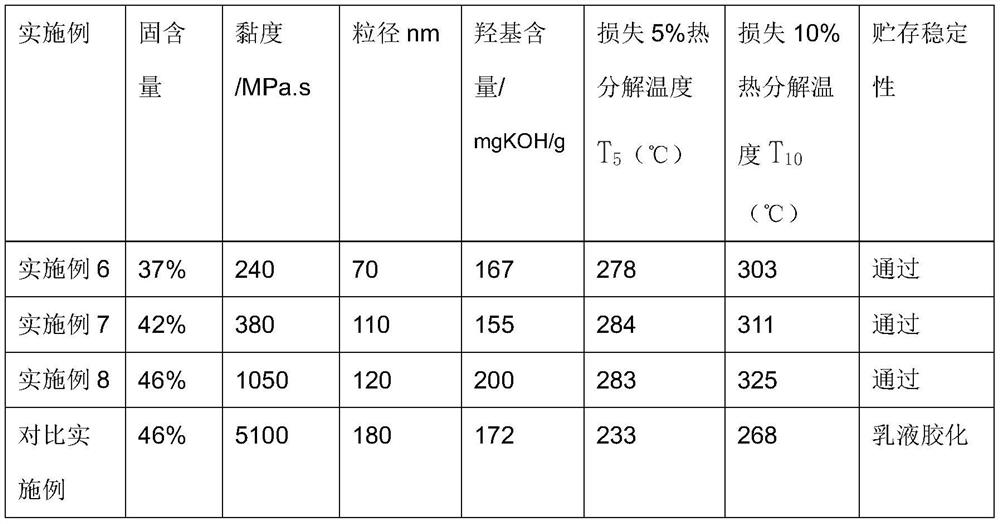

Hydroxyl silicone oil modified polyurethane resin, coating and preparation method of hydroxyl silicone oil modified polyurethane resin

InactiveCN112940211AHigh reactivityImprove high temperature resistancePolyurea/polyurethane coatingsPolyesterPolymer science

The present invention discloses a Hydroxyl silicone oil modified polyurethane resin, a coating and a preparation method of hydroxyl silicone oil modified polyurethane resin. The preparation method of the resin comprises the following steps: mixing polyester polyol, polyisocyanate, hydroxyl silicone oil and a solvent, then carrying out heating reaction, adding a chain extender A and a cosolvent, then adding a chain extender B, carrying out constant-temperature reaction, carrying out neutralization, then carrying out cooling, adding water and a chain extender C for reaction, and removing the solvent after the reaction is completed to obtain hydroxyl silicone oil modified waterborne polyurethane resin, wherein the hydroxyl silicone oil includes a polysiloxane having a hydroxyl group attached to silicon at only one end. The polyurethane coating prepared by the invention has good glossiness and heat resistance.

Owner:SHENZHEN ANPIN SILICONE MATERIAL

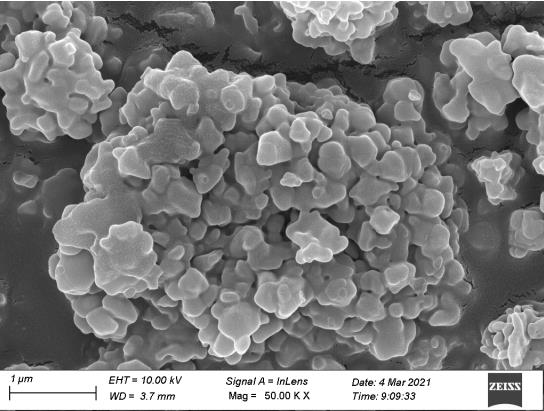

Organosilicon modified acrylic acid secondary dispersion and preparation method thereof

The invention discloses an organic silicon modified acrylic acid secondary dispersion and a preparation method thereof. The dispersion is prepared from 15-25 parts by weight of a (methyl) acrylate monomer, 0.5-3 parts by weight of a monomer containing carboxyl, 8-15 parts by weight of hydroxyl (methyl) acrylate and 2-6 parts by weight of an organic silicon modified monomer. The organic silicon modified acrylic acid secondary dispersion is high in organic silicon grafting rate and good in emulsion stability, the phenomena of floating oil, gel, phase separation and the like are avoided after the dispersion is placed for 6 months, and a cured paint film has excellent scratch resistance, weather resistance, aging resistance, hydrophobicity, heat resistance and the like.

Owner:惠州市安品新材料有限公司

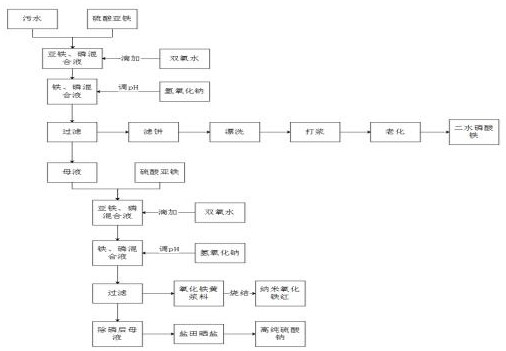

Sewage treatment and slag recycling process for production of iron phosphate by sodium method

ActiveCN113072048AEffective precipitationHigh recovery rateMaterial nanotechnologyFerric oxidesPhosphatePhosphoric acid

The invention belongs to the technical field of chemical engineering, and particularly discloses a sewage treatment and slag recycling process for producing iron phosphate by a sodium method. The method comprises the steps of adding ferrite and an oxidizing agent into the sodium system ferric phosphate production sewage, and initially adjusting the pH value with alkali liquor to obtain a reaction solution; filtering the reaction liquid to obtain first-stage slag and first-stage mother liquor, adding ferrite and an oxidizing agent into the first-stage mother liquor, then adjusting the pH value of the first-stage mother liquor by using alkali liquor, and filtering to obtain second-stage filter residues and second-stage mother liquor; rinsing, slurrying and aging the first-stage slag to obtain iron phosphate dihydrate, and rinsing, drying and sintering the second-stage slag to obtain nano iron oxide red; and carrying out MVR evaporation or salt pan salt drying on the second-stage mother liquor to obtain high-purity sodium sulfate. According to the method, chemical substances such as phosphorus and iron in the iron phosphate production sewage can be recycled and changed into high-added-value products, so that the sewage treatment cost is reduced, zero discharge of the sewage is realized, resources are saved, and circular economic development of industrial production is realized.

Owner:HUBEI HONGRUN HIGH-TECH NEW MATERIALS CO LTD

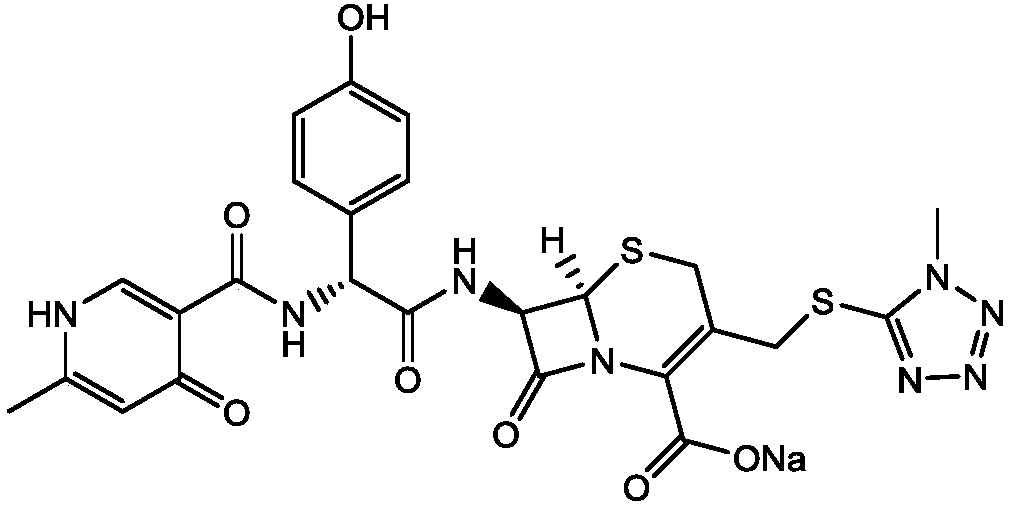

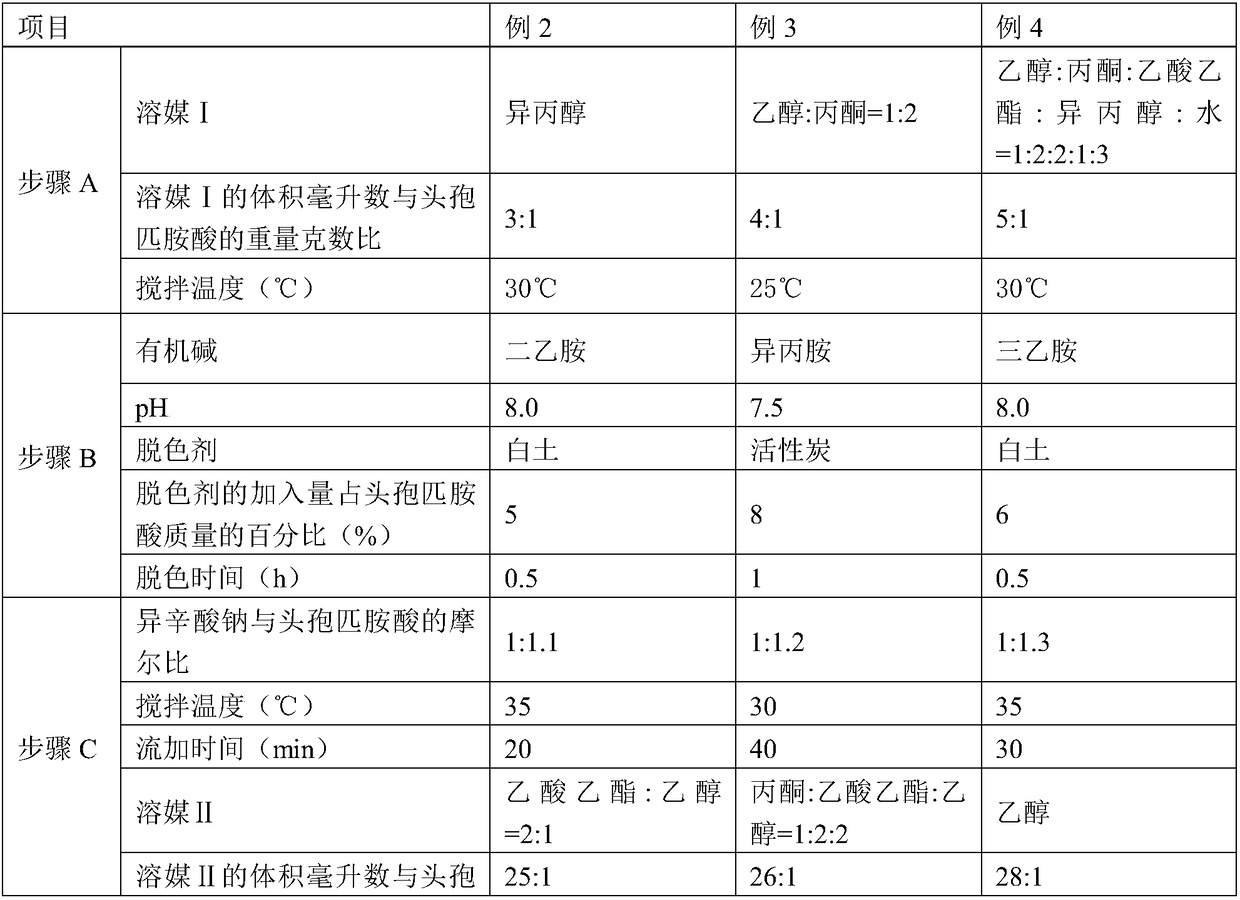

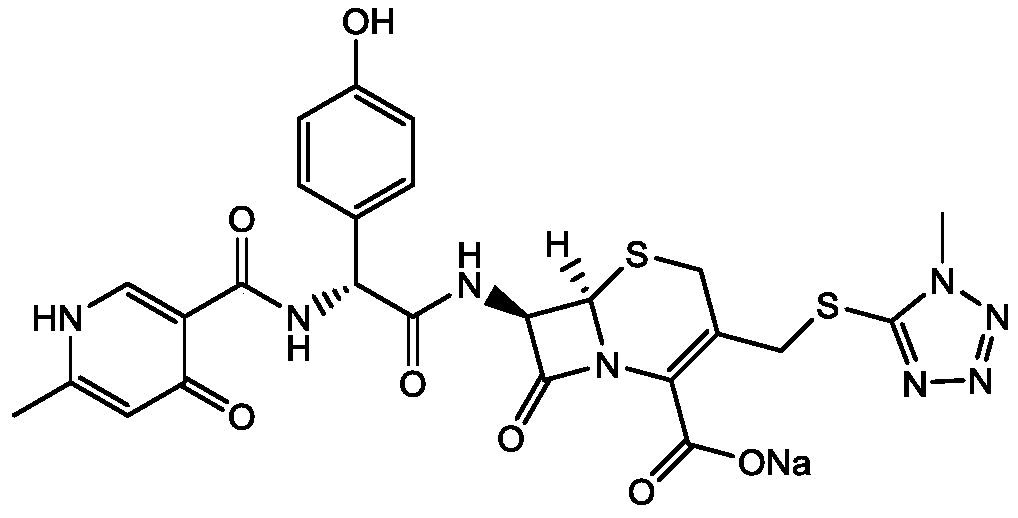

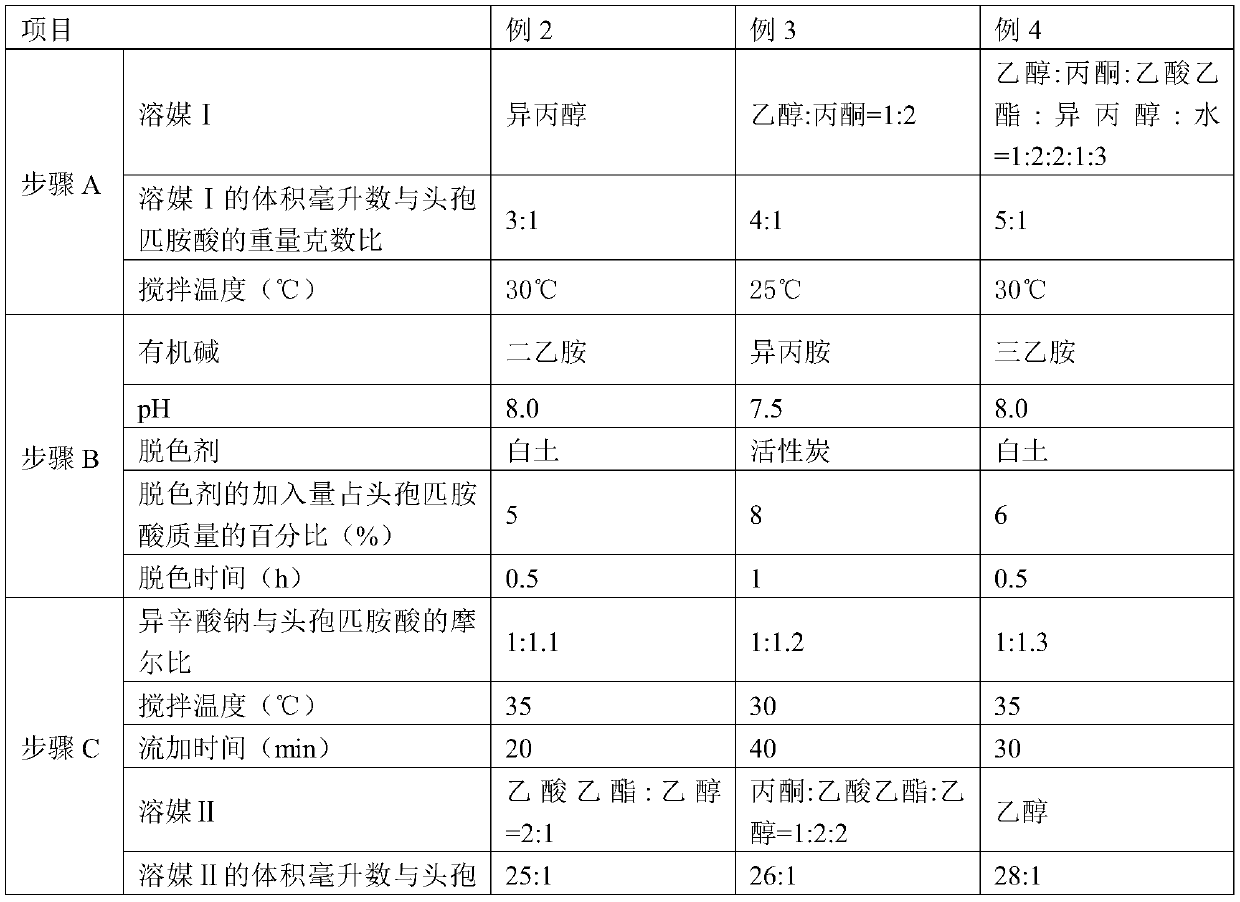

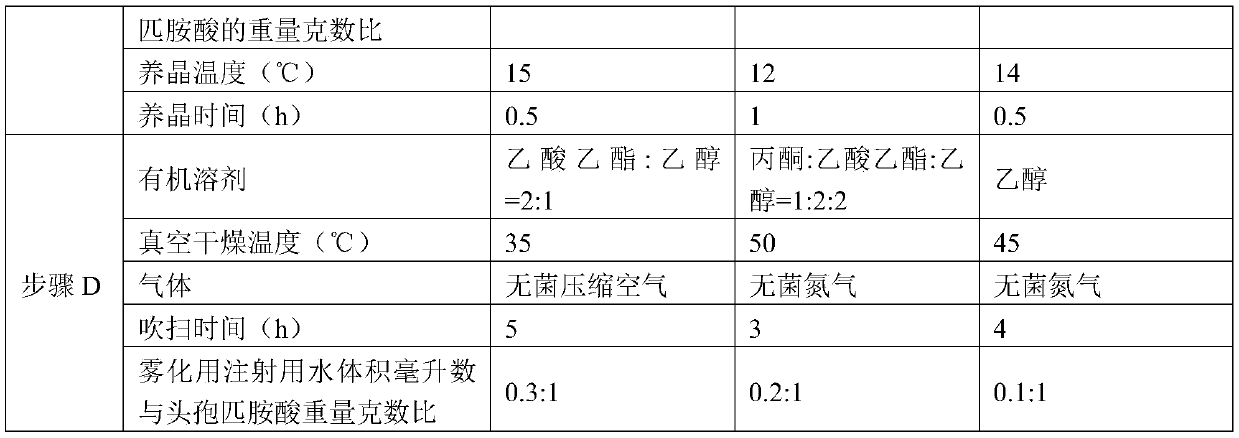

Preparation method of cefpiramide sodium

The invention discloses a preparation method of cefpiramide sodium, belonging to the field of chemical pharmacy. The preparation method comprises the following steps: preparing a cefpiramide amine salt by using a cefpiramide acid as a raw material, carrying out salt formation and crystallization, drying, and driving atomized water for injection by using gas to blow before drying. The preparation method can reduce the solvent residue in the product, is simple, energy-saving and environmentally-friendly and is suitable for large-scale industrial production; and the prepared cefpiramide sodium has the advantages of high purity and good stability.

Owner:NORTH CHINA PHARMA HEBEI HUAMIN PHARMA

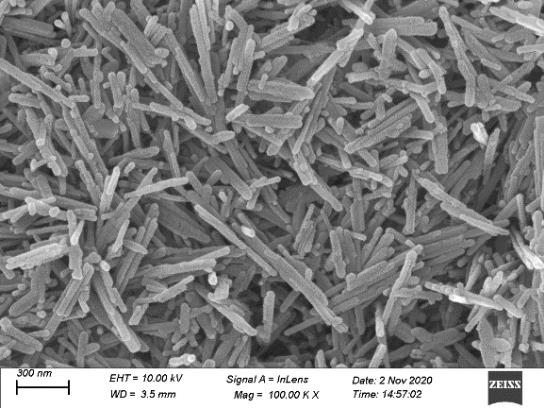

Preparation method of high-density nickel-cobalt-manganese hydroxide

PendingCN112591807AImprove securityImprove cycle performanceSecondary cellsPositive electrodesDiaphragm pumpPhysical chemistry

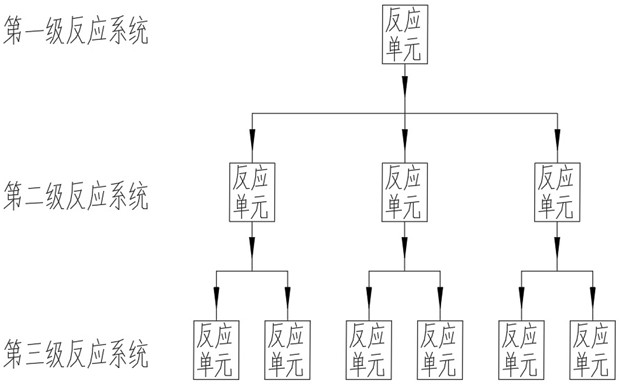

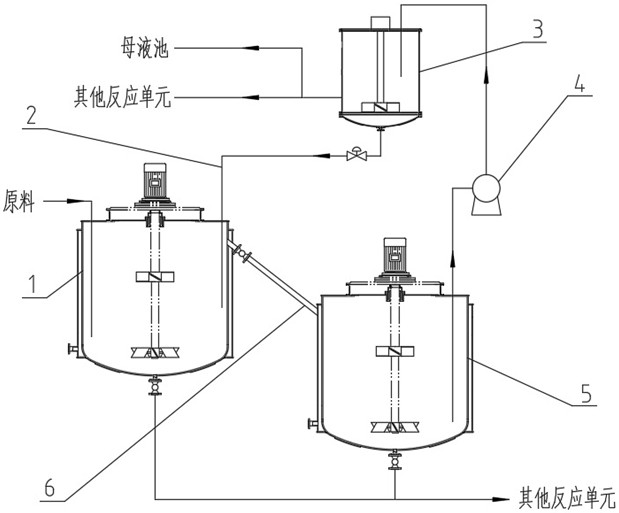

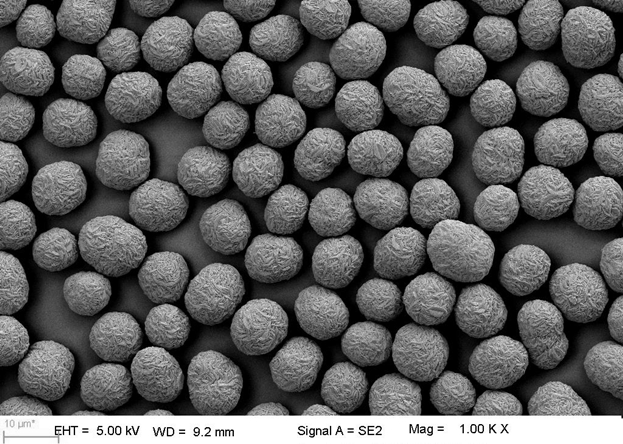

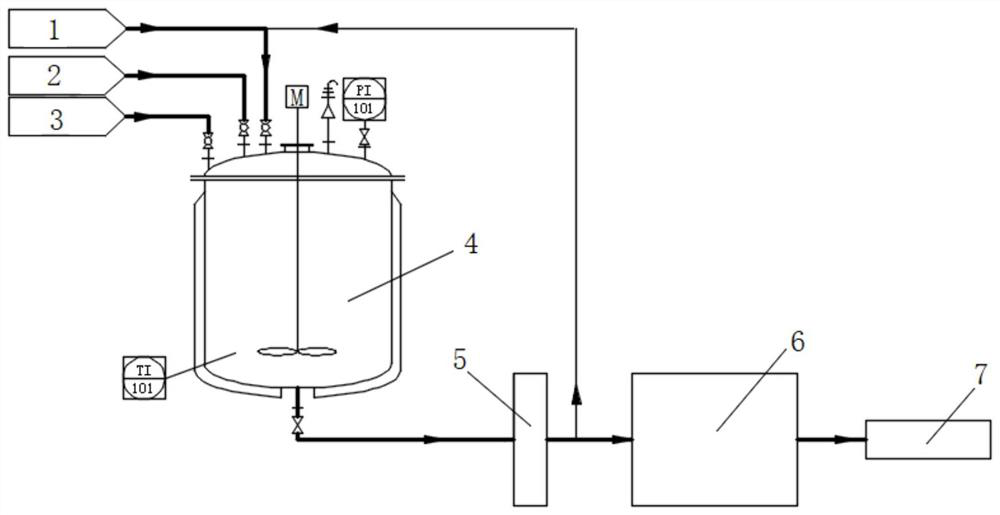

The invention relates to a preparation method of high-density nickel-cobalt-manganese hydroxide. The preparation method comprises three stages of reaction systems, each stage of reaction system comprises one or more than one reaction unit, and each reaction unit comprises a reaction kettle, an overflow pipe, an intermediate tank, a diaphragm pump, a thickener and a return pipe which are connectedin sequence; the invention provides the preparation method of high-density nickel-cobalt-manganese hydroxide, and aims to solve the problems that in the current process of preparing a precursor through coprecipitation, small and micro particles cannot be eliminated, particle size distribution is wide, large particles are prone to breakage, morphology consistency is poor, and the impurity sodium-sulfur content is high. The precursor particles prepared by the method have the characteristics of higher consistency, no small-particle and micro-powder phenomena, centralized particle size distribution, higher tap density, extremely compact particles, low possibility of breakage, low sodium-sulfur content and the like, so that the subsequently prepared positive electrode material has higher safetyperformance, cycle performance and higher specific capacity.

Owner:HUAYOU NEW ENERGY TECH (QUZHOU) CO LTD +1

Preparation method of polyacrylonitrile fiber

ActiveCN112831859AImprove spinnabilityNot easy to plug holesMonocomponent synthetic polymer artificial filamentArtifical filament manufacturePolymer scienceSpinning

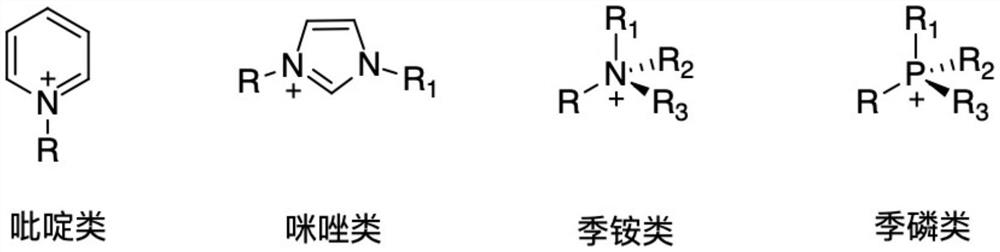

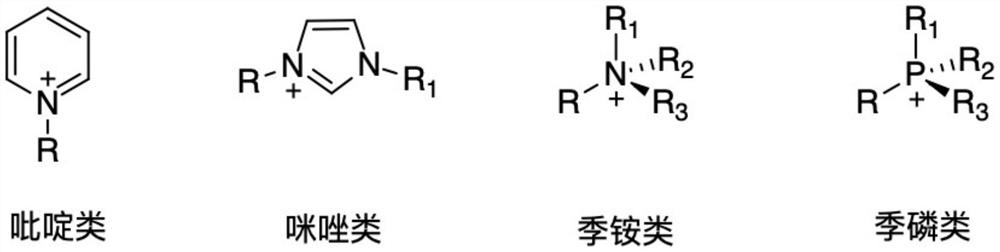

The invention discloses a preparation method of a polyacrylonitrile fiber. Polyacrylonitrile is firstly swelled and dissolved in an ionic liquid and a high-boiling-point (150-190 DEG C) solvent in a certain proportion under the conditions of high temperature and high pressure, then a volatile or low-boiling-point (30-60 DEG C) solvent is added to obtain a homogeneous spinning solution, then spinning and traction splitting are carried out to prepare the polyacrylonitrile fiber, and the polyacrylonitrile fiber has the advantages that the solvent is not prone to being wrapped in the fiber, and the fiber defect is improved; and the prepared fiber has the technical effects of denser density and thinner diameter.

Owner:SHANDONG RENFENG SPECIAL MATERIALS

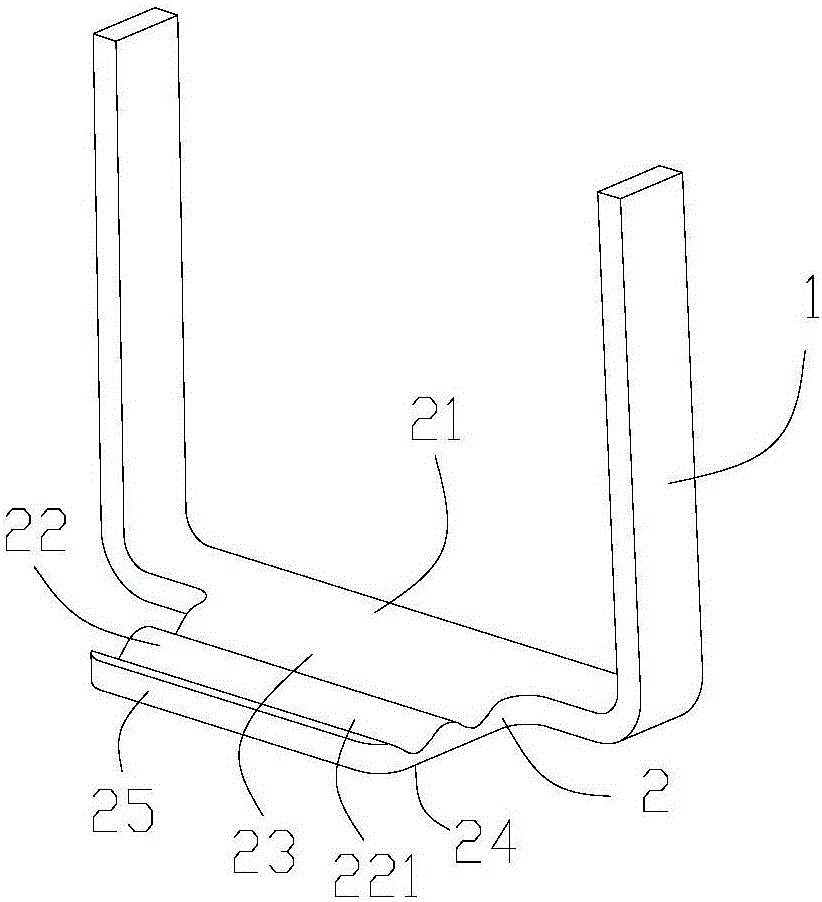

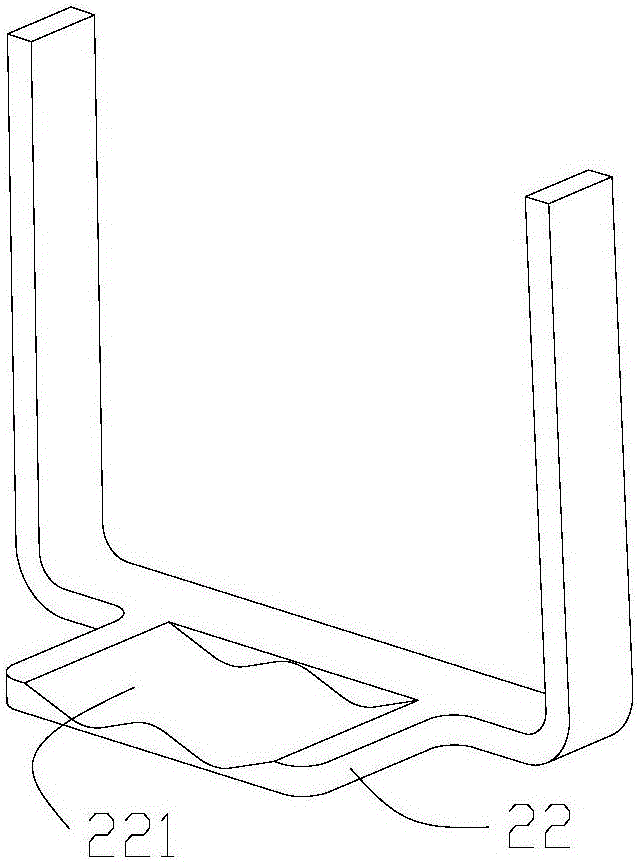

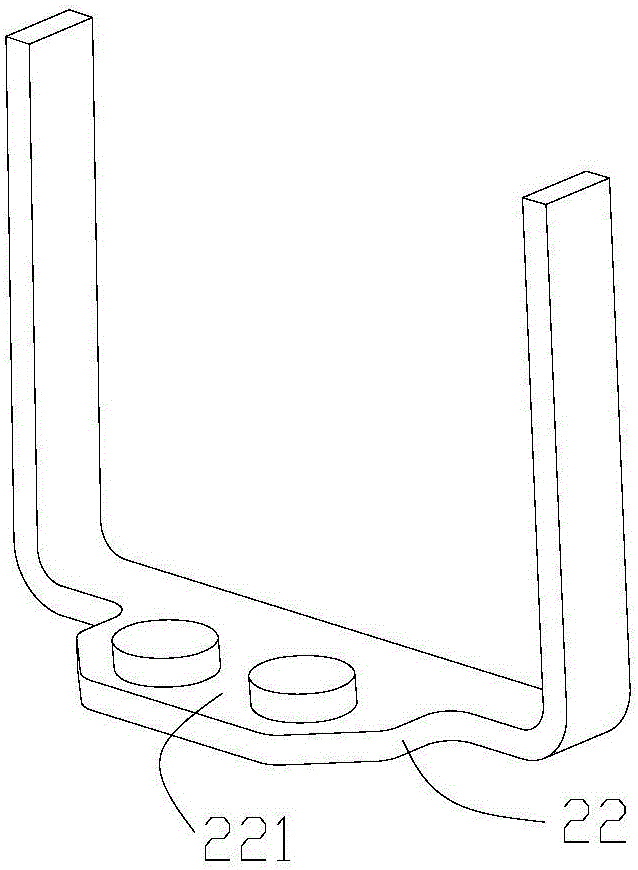

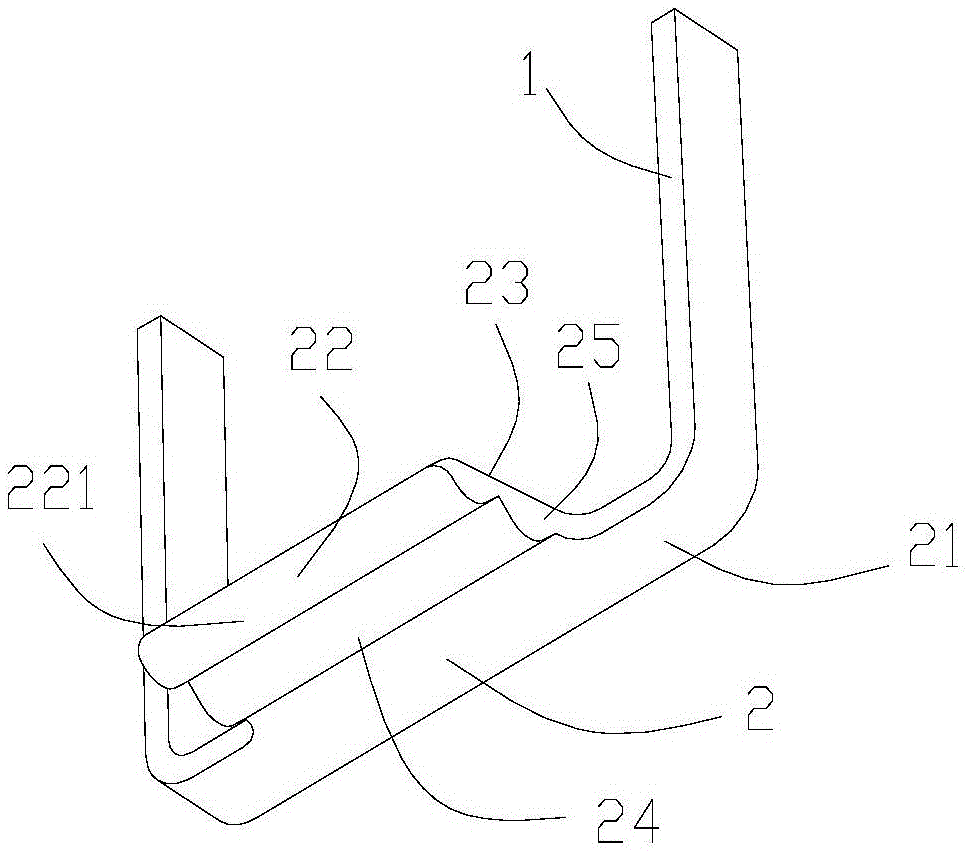

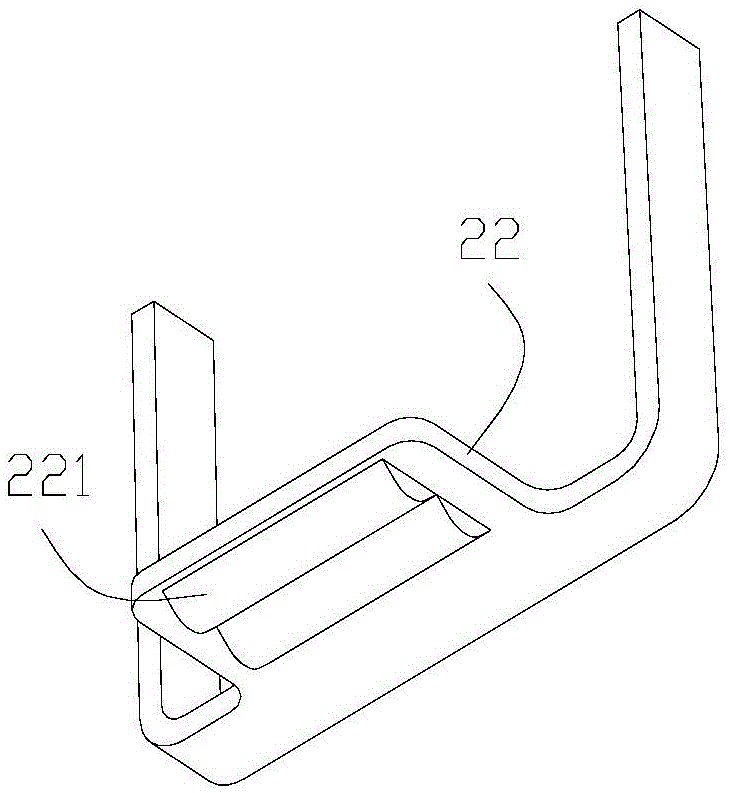

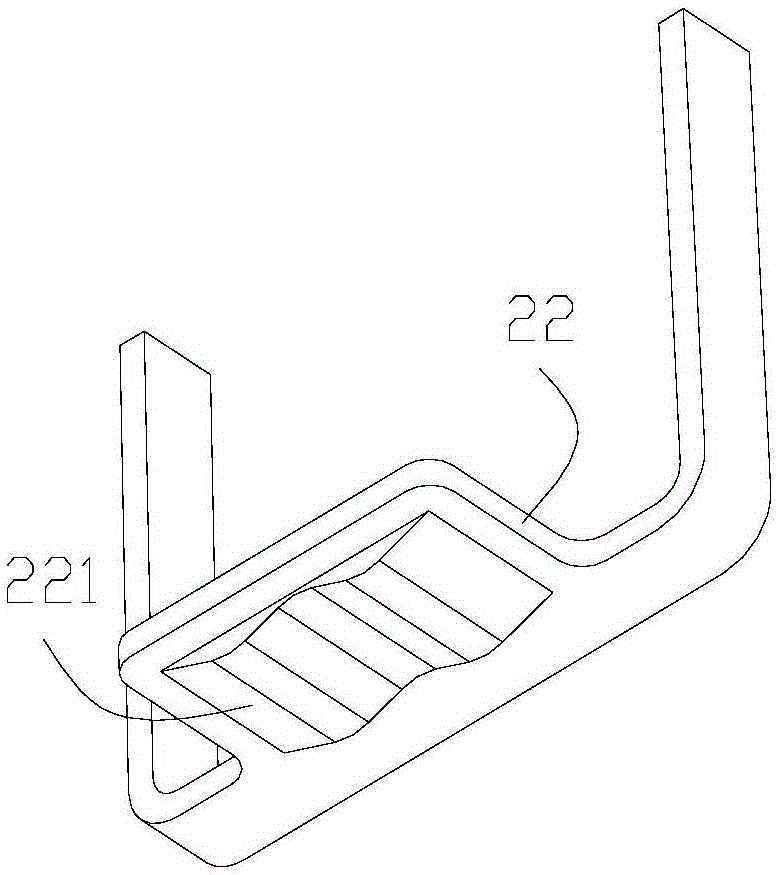

Prepuce stitching staple and circumcision anastomat adopting same

The invention provides a prepuce stitching staple. The staple comprises staple legs and a crossbeam, the crossbeam is composed of a staple bridge and an auxiliary piece, and the inner surface of the crossbeam is a non-planar surface. According to the prepuce stitching staple, the staple is formed under the drive of an advancing component of an instrument, tissues can be closed tightly, the stitching can be completed, the area of the crossbeam which is composed of the staple bridge and the auxiliary piece is large, and the inner surface of the crossbeam is the non-planar surface, so that the prepuce stitching staple is not prone to being wrapped by the tissues, therefore after the wound is healed, the prepuce stitching staple can fall off automatically under the action of long-time slow peristalsis of the tissues.

Owner:北京天钥医疗器械有限公司

Thermosetting acrylic coating for coating surface of aluminium foil

The invention discloses a thermosetting a crylic acid coating roll-coated on aluminum foil surface and painting the aluminum foil surface. It is made from thermosetting a crylic acid resin 50-60shares, butoxy amino resin 15-20shares, pigment 5-28shares, solvent 5-10shares, levelling agent 0.2-0.4share, defoaming agent 0.2-0.4share, adhesion accelerant 0-3shares, and wet dispersing agent 0-4shares. The pigment is titanium pigment or flashlight aluminum powder; the solvent is xylene, S-100 high boiling arene solvent, butyl glycol ether or ethylene glycol ethyl ether acetic acid. It has wide application range.

Owner:WUXI ACRYL TECH

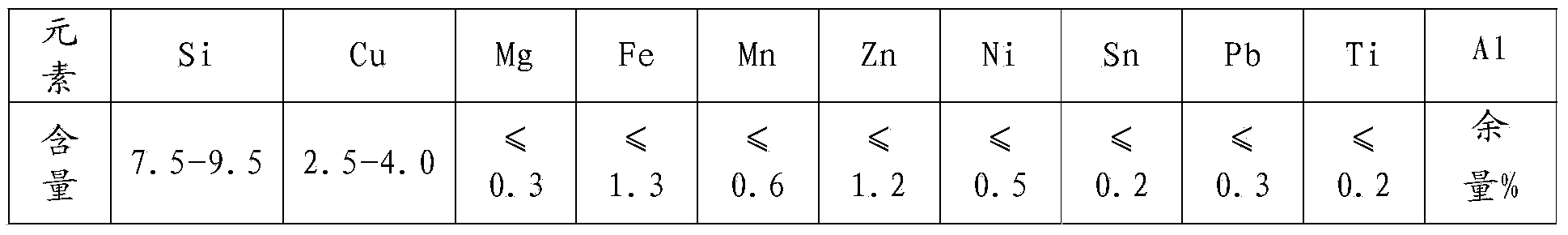

Aluminum alloy and preparation method thereof

The invention relates to the field of aluminum alloy manufacturing, and particularly relates to an aluminum alloy and a preparation method thereof. The preparation method of the aluminum alloy comprises the following steps: (A) injecting first molten aluminum with a pressure of 0.6-0.8 MPa and a temperature of 630-650 DEG C into a cooling model at a temperature of 10-25 DEG C to cool, so that a first semisolid blank is formed; (B) after the first semisolid blank is turned, putting the obtained substance into second molten aluminum at a temperature of 650-680 DEG C to stir, so that second semisolid slurry is obtained; and (C) feeding the second semisolid slurry into an injection chamber, so that a product is obtained. Compared with common die casting methods in the prior art, the preparation method of the aluminum alloy disclosed by the invention can obtain fine grain structures without the addition of a grain refiner, and structures of columnar crystals and oversize dendrites in traditional casting are eliminated, so that products are uniform in grain and better in effect, and the moulding temperature of the products is about 100 DEG C lower than the temperature of common die casting materials.

Owner:FUJIAN KINRUI HIGH TECH CO LTD

Polystyrene foam filling method for composite material honeycomb sandwich structure

The invention relates to a polystyrene foam filling method for a composite material honeycomb sandwich structure. The polystyrene foam filling method comprises the following steps of paving a layer of strip-shaped polystyrene foam on the die-attaching side of a honeycomb core, heating and extruding the strip-shaped polystyrene foam into a filling cavity of the honeycomb core, and paving a single-layer isolating membrane between the honeycomb core and a die; filling the non-die-attaching side of the honeycomb core with powdery polystyrene foam, and laying multiple layers of isolating membranes; and putting a forming die into curing forming equipment for heating and curing the polystyrene foam. According to the polystyrene foam filling method for the composite material honeycomb sandwich structure, residual stress generated by curing shrinkage of the polystyrene foam due to the fact that a composite material honeycomb sandwich structure workpiece is subjected to the procedures of pre-bonding and foaming in sequence, only the foaming face on one side is bound, and the other side is not bound can be eliminated; air wrapping in the filling cavity of the honeycomb core in the polystyrene foam filling process is avoided, and the filling quality and efficiency are improved; and the honeycomb core is independently formed, a pre-bonding process is cancelled, and the manufacturing cost of the composite material honeycomb sandwich structure is reduced.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

Method for improving dephosphorization effect of titanium-containing high-phosphorus molten iron in converter dephosphorization period

ActiveCN113337662AGood dephosphorization effectImprove slag rateManufacturing convertersProcess efficiency improvementSlagTitanium

The invention discloses a method for improving the dephosphorization effect of titanium-containing high-phosphorus molten iron in the converter dephosphorization period. The method comprises the following steps of: (1) pouring slags and remaining slags when tapping at the converter smelting end point of the last melt; (2) after the slag splashing furnace protection of the last melt is finished, sequentially adding a first batch of lime and scrap steel, preheating, and adding molten iron; (3) after ignition, respectively adding light-burned dolomite and a second batch of lime, maintaining high oxygen supply intensity, gradually reducing the lance position from the oxygen lance position to the lowest lance position, and adding sintering return mine; and (4) when the first batch of slag charge is molten, slagging, adding the second batch of slag charge, raising the lance position, reducing the oxygen supply intensity, stopping smelting, turning down the furnace, measuring the temperature and sampling. The method solves the problems that in the converter dephosphorization period of the titanium-containing high-phosphorus molten iron, the slags are excessively sticky, the slag-steel separation effect is poor and the lime is prone to being wrapped by the slags, resulting in the low utilization rate and the poor dephosphorization effect; and the influence of generation of a large amount of TiO2 in the slags in the early stage on the slag structure and the dephosphorization effect is controlled, so that the dephosphorization rate in the dephosphorization period is improved to reach over 65%.

Owner:SHOUGANG SHUICHENG IRON & STEEL GRP

Layered chocolate shelled melon seeds and processing method thereof

PendingCN111543613ARich tasteImprove experienceFood ingredient as antioxidantEdible seed preservationHorticultureFood processing

The invention discloses layered chocolate shelled melon seeds and a processing method thereof, and belongs to the field of food processing. According to the layered chocolate shelled melon seeds, theouter surface of baked shelled melon seeds is coated with a chocolate inner layer, a popping candy layer and a chocolate outer layer from inside to outside; the popping candy layer is embedded betweenthe two chocolate layers, so that the fixing effect is good, the popping candy layer is not easy to fall off, the taste of the shelled melon seeds is enriched, the taste of the popping candy is three-dimensional when the popping candy jumps in the mouth, and the aftertaste is more lasting in the specific reaction process. The problem that existing chocolate shelled melon seeds are monotonous in taste and lack of three-dimensional taste is solved.

Owner:CHACHA FOOD CO LTD +1

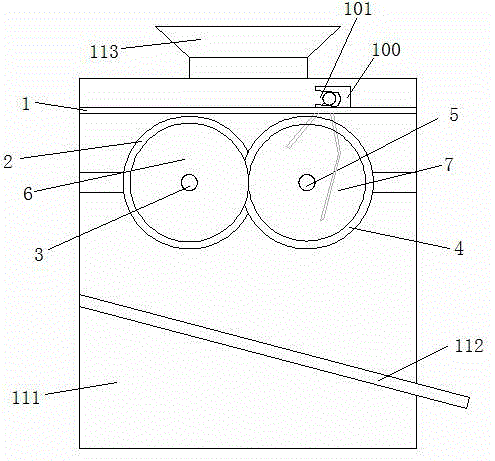

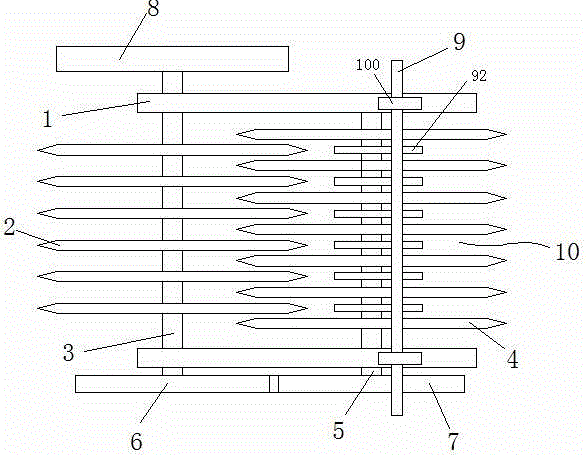

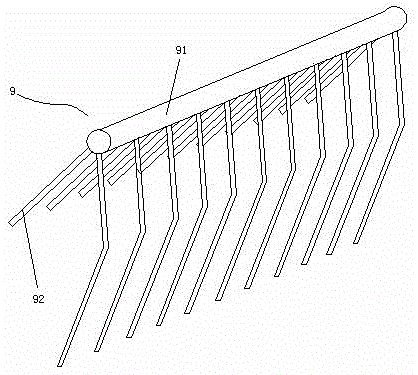

Kelp slitter

The invention discloses a kelp slitter. A bracket in the kelp slitter is fixedly connected into a box; a guide plate is aslant positioned below the bracket; a first blade shaft and a second blade shaft are both rotationally arranged on the box, and are parallel to each other; a plurality of second slitting blades are fixedly connected to the second blade shaft at equal intervals; cutter tanks are formed between two adjacent second slitting blades; a plurality of first slitting blades are fixedly connected to the first blade shaft at equal intervals, and one sides, opposite to the cutter tanks, of all the first slitting blades are positioned in the cutter tanks; a first transmission gear and a second transmission gear are fixedly connected to the first blade shaft and the second blade shaft respectively; the first transmission gear and the second transmission gear are meshed; a transmission belt wheel is fixedly connected to the first blade shaft, and is connected with a motor rotating shaft through a transmission belt; shielding bodies are positioned on the bracket; and one ends of the shielding bodies extend into the cutter tanks. The kelp slitter is simple in structure and safe in use; kelp is not easy to wrap the blades; and the slitting efficiency is high.

Owner:ZHENJIANG SHILONG FOOD MACHINERY CO LTD

Modified acrylic resin emulsion and preparation method thereof

PendingCN113105592AImprove hydrophobicityImprove scratch resistanceCoatingsMethacrylatePolymer science

The invention discloses modified acrylic resin and a preparation method thereof. The modified acrylic resin is prepared by reacting the following raw materials in parts by weight: 25-45 parts of a (methyl) acrylate monomer, 0.5-3 parts of a monomer containing carboxyl, 0.5-2 parts of a hydrophilic functional monomer and 2-6 parts of polysiloxane with unsaturated groups capable of free radical polymerization. According to the invention, the modified acrylic resin is high in silicone oil grafting rate and good in emulsion stability, the phenomena of floating oil, gelation, phase separation and the like are avoided after the modified acrylic resin is placed for 6 months, and a cured paint film has excellent scratch resistance, weather resistance, aging resistance, hydrophobicity, heat resistance and the like.

Owner:SHENZHEN ANPIN SILICONE MATERIAL

A kind of camptothecin-based heterodimer multifunctional prodrug and its preparation method and application

ActiveCN108409756BLow toxicityFacilitated releaseOrganic active ingredientsOrganic chemistryDimerPharmaceutical drug

The invention provides a heterodimer multifunctional prodrug based on camptothecin. The heterodimer multifunctional prodrug is loaded with the camptothecin and 2-(1-hexyloxy ethyl)-2-devinyl-pyropheophorbide-a (HPPH), the prodrug is a camptothecin-HPPH prodrug formed by the camptothecin and the HPPH through a connecting group, and the structural formula of the prodrug is as shown in formula (I), wherein R is the connecting group and is one of -SS-, -CH2CH2- or -S(CH3)C(CH3)S-; R1 is the camptothecin group. The prodrug has the advantages that the prodrug can be easily wrapped by amphiphilic polymer to form nano particles, and the formed nano particles are high in drug loading efficiency and drug loading capacity and can fast release the unmodified camptothecin and HPPH in the presence of glutathione; meanwhile, the nano particles can be effectively absorbed by tumor cells to kill the tumor cells. The invention further provides a preparation method and preparation of the prodrug and application of the prodrug in the preparation of drugs for treating cancer.

Owner:SHANGHAI THERANOSTICS BIOTECH CO LTD

Prepuce stitching nail and circumcision anastomat with the same

Owner:北京天钥医疗器械有限公司

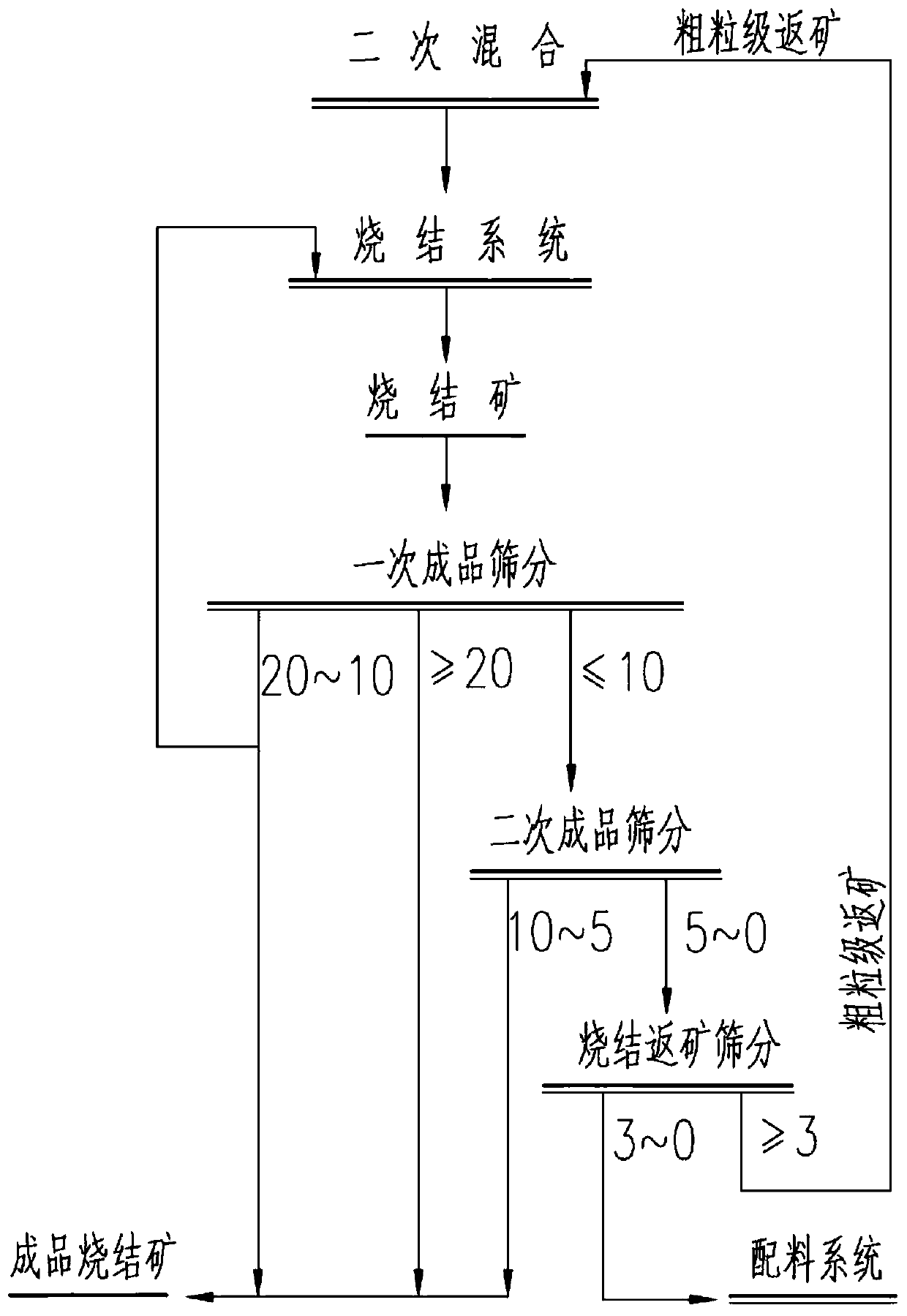

Sintering method and system adopting sintering return ore as embedded material

The invention relates to a sintering method and system adopting a sintering return ore as an embedded material. The method at least comprises the steps of preparing the embedded material, directly conveying the obtained embedded material to the tail part of a secondary mixing machine in a sintered material pelleting workshop, and uniformly mixing. The system comprises a return ore coarse grain screening unit and a conveying unit, wherein the return ore coarse grain screening unit is used for further screening and grading the separated sintering return ore so as to obtain a coarse grain-gradedreturn ore; and the conveying unit is used for directly feeding the coarse grain-graded return ore obtained through screening to the tail end of a secondary cylinder mixing machine. By adopting the adding system using the sintering return ore as the embedded material designed by the process and the device provided by the invention, the coarse grain-graded return ore is directly added to the tail end of the secondary cylinder mixing machine, so that internal transfer and cycle facility construction and equipment investment can be reduced, and the operation and maintenance cost is further saved;meanwhile, the coarse grain-graded return ore does not participate in the pelleting process, so that mixture pellets are protected, the filling rate of the mixing machine is reduced, the processing efficiency in unit volume is improved, and a mixture pelleting effect is improved; and in addition, the sintering return ore is not easy to be wrapped by adhered particles and is uniformly embedded into the mixture so as to achieve a material layer support effect, so that the air permeability of a material layer can be improved, and a sintering effect can be improved.

Owner:HUATIAN ENG & TECH CORP MCC

A kind of preparation method of cefpiramide sodium

The invention discloses a preparation method of cefpiramide sodium, which belongs to the field of chemical pharmacy, and comprises the steps of preparing cefpiramide salt by using cefpiramide as raw material, forming salt and crystallizing, drying, and using gas to drive the atomized cefpiramide before drying. Purging with water for injection; the invention can reduce the solvent residue in the product, and the prepared cefpiramide sodium has the advantages of high purity and good stability, the preparation method is simple, energy-saving and environment-friendly, and is suitable for large-scale industrial production.

Owner:NORTH CHINA PHARMA HEBEI HUAMIN PHARMA

Method for recovering organic tin acetate from waste floccules in sucralose production

PendingCN113717215AReduce concentrationGood dispersionEsterified saccharide compoundsTin organic compoundsPtru catalystSucrose

The invention relates to a method for recovering organic tin acetate from waste floccules in sucralose production, which comprises the steps of distillation, neutralization, centrifugation, water separation, acylation and extraction, and is characterized in that between the distillation step and the neutralization step, a black brown floccule obtained by distillation is mixed with and dissolved in a protonic solvent according to a volume ratio of 10: (1-5); and crude dibutyltin oxide obtained through centrifugation in the neutralization step is dried at 40-100 DEG C to obtain dried crude dibutyltin oxide. The method has the advantages that the black brown floccule is dissolved with the protic solvent, the dispersion effect of the dibutyltin oxide in water can be promoted, the treated dibutyltin oxide powder is uniform in particle, the appearance of the product is similar to that of a pure product in color, the impurity content is low, and the production efficiency can reach the standard of a normal catalyst and is relatively stable; and the method is easy to operate, the reaction efficiency and the material utilization rate of the whole production process are optimized, and the economic benefits of enterprises are obviously increased.

Owner:ANHUI JINGHE IND

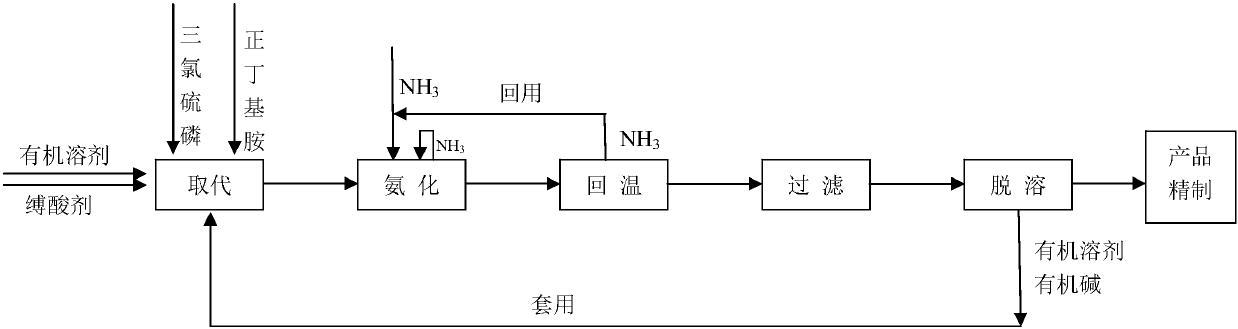

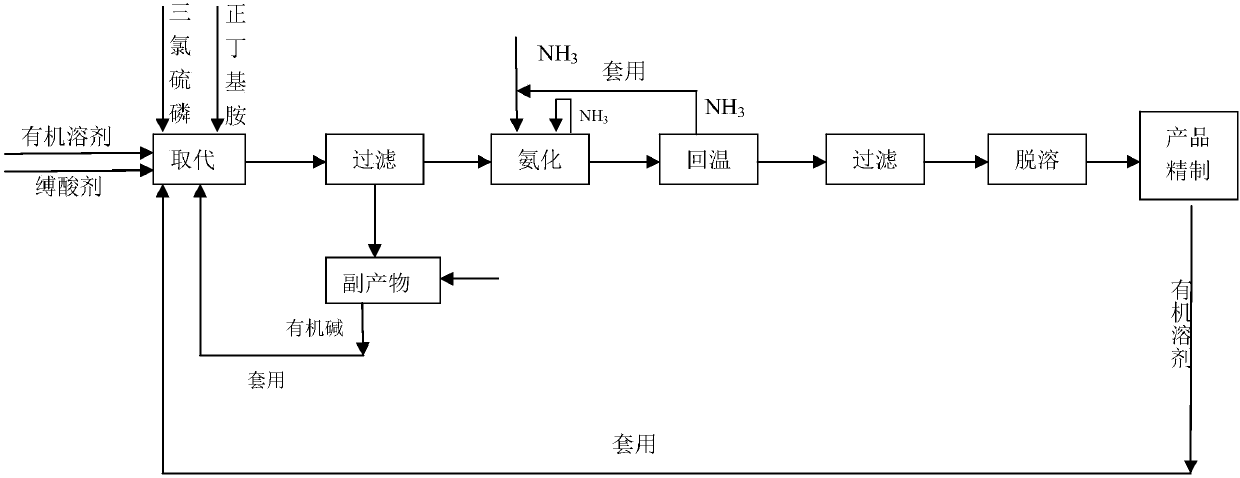

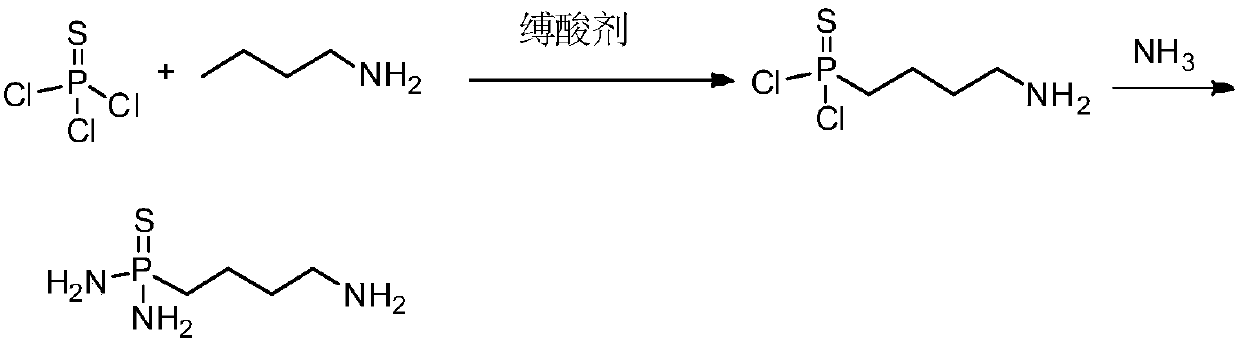

A clean production process for preparing n-n-butylthiophosphoric triamide

ActiveCN105399768BQuality improvementAvoid pollutionGroup 5/15 element organic compoundsOrganic solventN-(n-butyl) thiophosphoric triamide

The invention relates to a clean production process for preparing N-n-butyl thiophosphoric triamide, which mainly includes substitution, ammoniation, temperature return, filtration, desolventization and product purification processes, and N-n-butyl thiophosphoric triamide The organic solvent and ammonia produced in the production process of amide have been recycled, and ammonium chloride is a kind of chemical fertilizer raw material, which can be used in the production of chemical fertilizer. The process of the invention reduces production cost and reduces environmental pollution, and is a clean production process of N-n-butylthiophosphoric triamide with high yield, excellent product quality and no pollution.

Owner:江西吉翔医药化工有限公司

Implantable device for anti-gastroesophageal reflux

ActiveCN105997296BLess discomfortReduce frictionAnti-incontinence devicesSurgerySphincterImplanted device

Owner:NINGBO SHENGJIEKANG BIOTECH

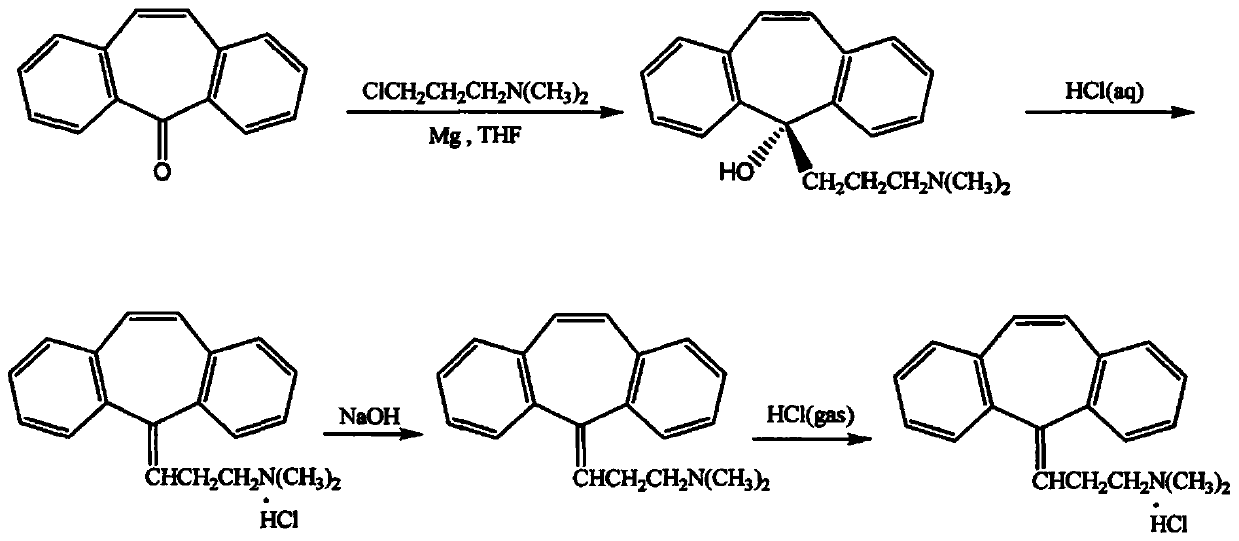

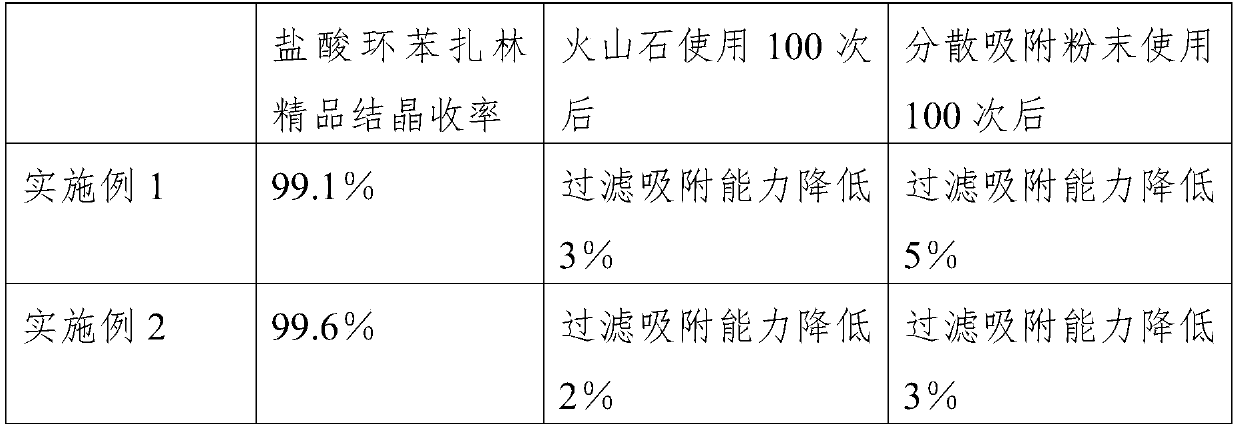

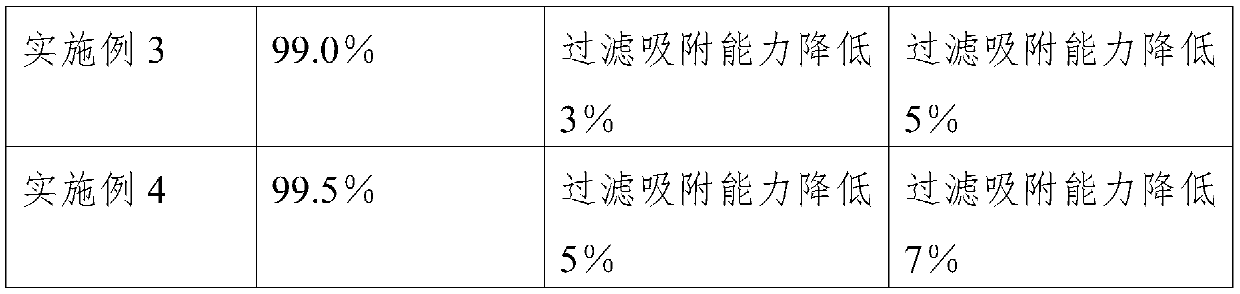

Refining method of cyclobenzaprine hydrochloride

InactiveCN111333518ANot easy to wrapHigh purityAmino compound purification/separationPhysical chemistryOrganosolv

The invention discloses a refining method of cyclobenzaprine hydrochloride, and concretely relates to the field of medicines. The refining method comprises the following preparation steps: S1, in an extraction process in the later period of cyclobenzaprine hydrochloride processing, adding dispersed adsorption powder into a mixed solution of cyclobenzaprine hydrochloride, stirring by adopting a paddle stirrer, and precipitating to obtain a cyclobenzaprine hydrochloride crude product; S2, adding an organic solvent into the cyclobenzaprine hydrochloride crude product, performing recrystallization, dissolving and stirring in a steam pressurizing manner, and keeping constant temperature for later use; and S3, filtering and adsorbing the mixed solution obtained in step S2 through vesuvianite, and filtering to obtain a white refined cyclobenzaprine hydrochloride product. By adding the dispersed adsorption powder, crystals can be dispersed and fluffy, impurity byproducts are not wrapped, crystal discharging is fine and uniform, impurities and redundant metal ions can be adsorbed, and the cyclobenzaprine hydrochloride fine product with high purity and extraction rate is obtained.

Owner:CP PHARMA QINGDAO CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com