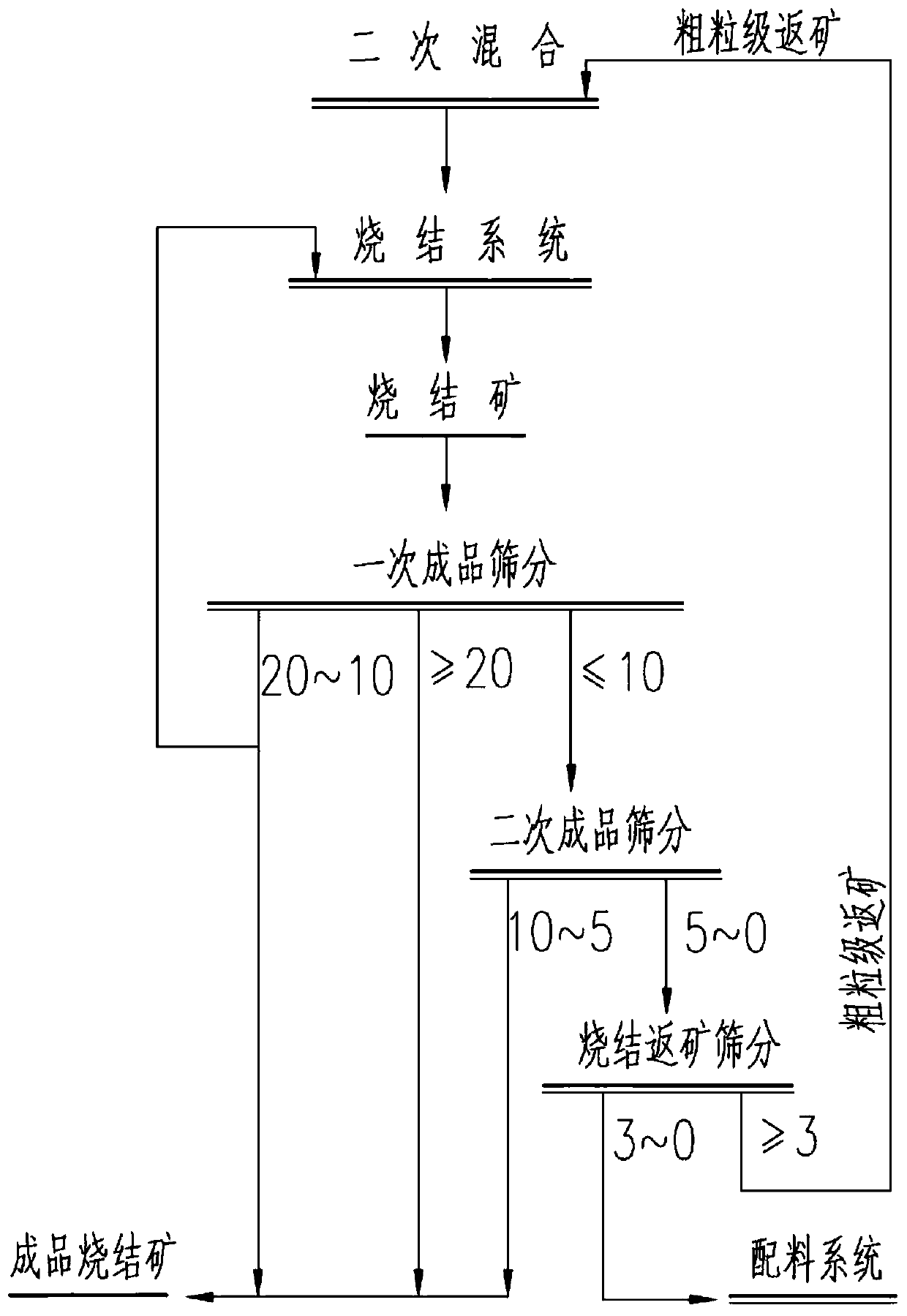

Sintering method and system adopting sintering return ore as embedded material

A technology of sintering, returning to ore and sintering method, which is applied in the field of metallurgical technology and equipment, can solve the problems of increased air flow resistance of material layer, insufficient effective air volume of material surface, increased air leakage of sintering machine, etc., so as to reduce filling rate, reduce civil engineering and equipment Investment, quick results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

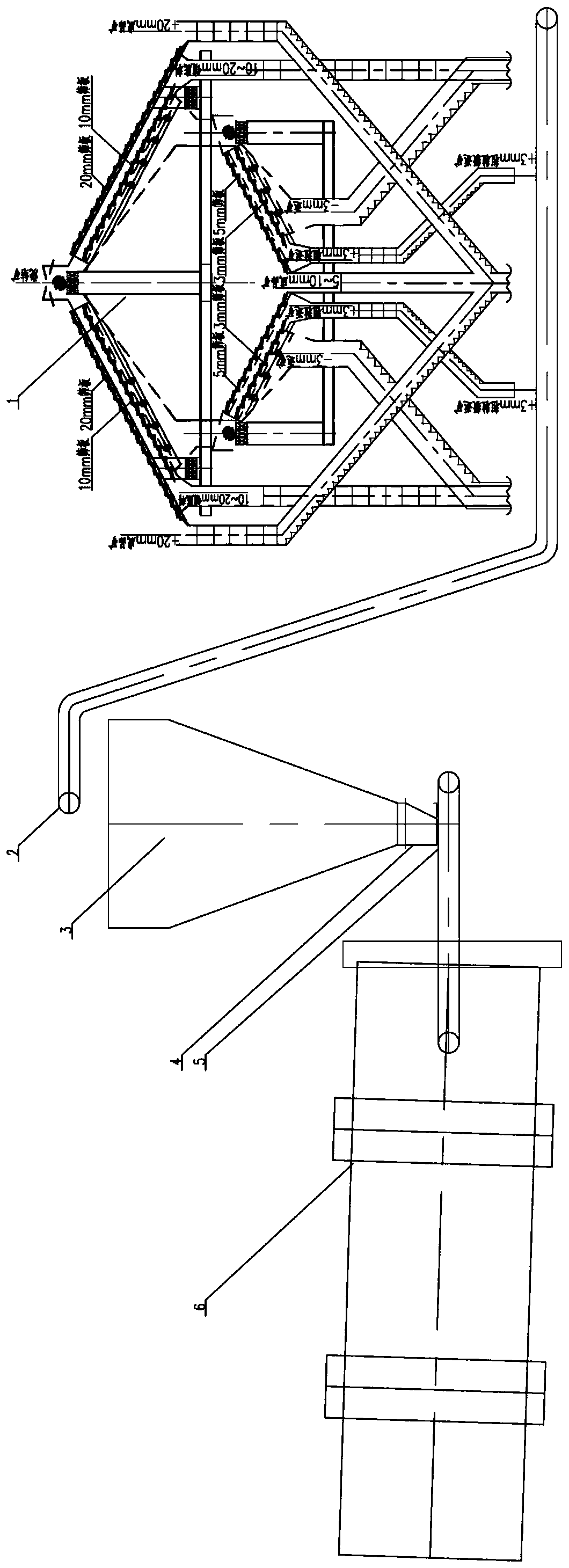

[0034] This embodiment is a new sintering project.

[0035] Such as figure 2 Shown, including: finished product sizing screen 1, from top to bottom in the finished product sizing screen 1, including: 20mm sieve plate; 10mm sieve plate, 5mm sieve plate and 3mm sieve plate; +3mm material diameter set at the outlet There is a belt conveyor 2; the discharge port of the belt conveyor 2 is provided with a storage bin 3; a dragging feed valve 4 is set at the discharge port of the storage bin 3; a pull-type electronic belt scale 5 is set below the dragging feed valve 4; The output end of the electronic belt scale 5 is set in the secondary cylinder mixer 6. The above-mentioned sieve diameter can also be adjusted according to the on-site production situation

[0036] Such as figure 2 As shown, the coarse-grained return ore obtained by screening, that is, the embedded material, is transported to the embedded material storage bin by the belt conveyor; the under-screened product is returned ...

Embodiment 2

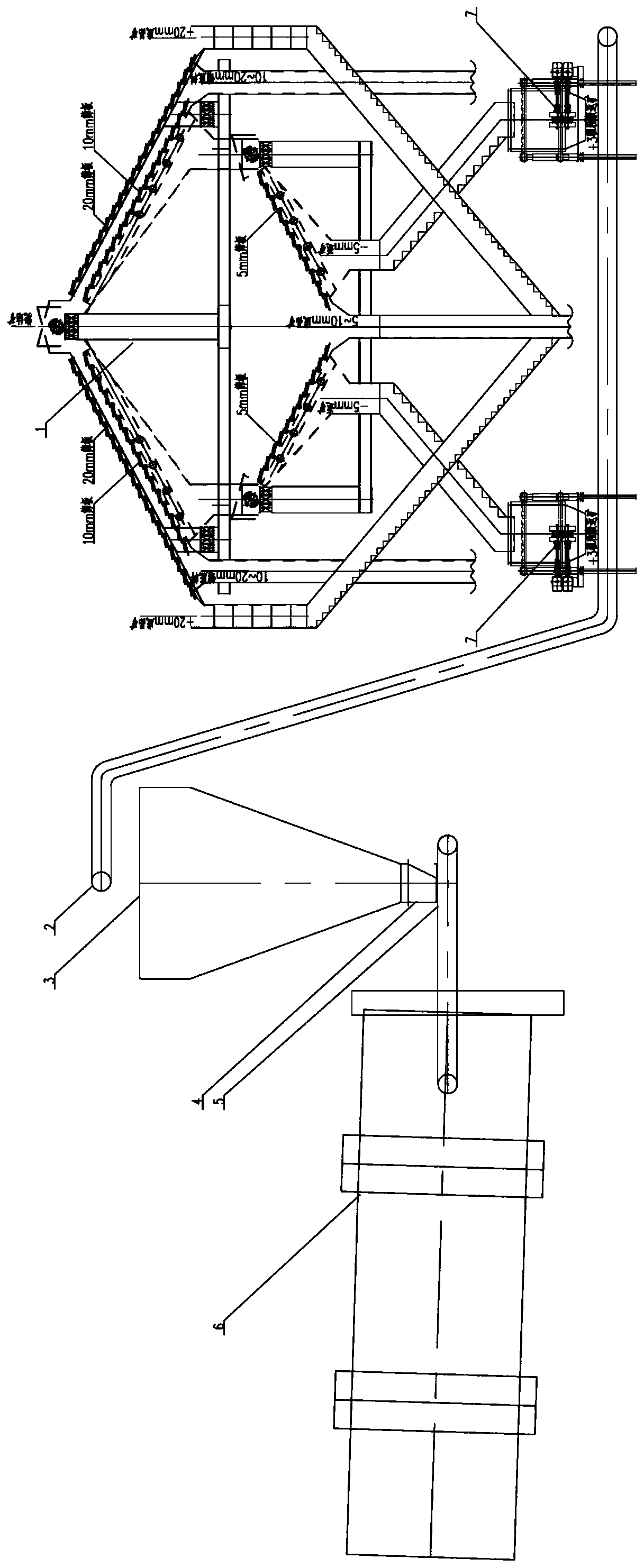

[0038] This embodiment is a transformation project.

[0039] Such as image 3 Shown, including: finished product sizing screen 1, from top to bottom in the finished product sizing screen 1, including: 20mm sieve plate; 10mm sieve plate and 5mm sieve plate; 5mm material diameter outlet set +3mm sintering return Sieve 7; the sintering return ore screen 7 is equipped with a belt conveyor 2 at the outlet; the outlet of the belt conveyor 2 is equipped with a storage bin 3; at the outlet of the storage bin 3, a drag feeding valve 4 is set; A pull-type electronic belt scale 5 is arranged under the valve 4; the output end of the pull-type electronic belt scale 5 is arranged in the secondary cylinder mixer 6. The above-mentioned sieve diameter can also be adjusted according to on-site production conditions.

[0040] Such as image 3 As shown, the coarse-grained return ore obtained by screening, that is, the embedded material, is transported to the embedded material storage bin by the bel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com