Screw nail

A screw and screw rod technology, applied in the direction of screws, threaded fasteners, connecting components, etc., can solve problems such as insufficient continuation function, and achieve the effects of labor-saving operation, stable locking, and rapid chip removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Specific embodiments of the present invention are described below in conjunction with accompanying drawing:

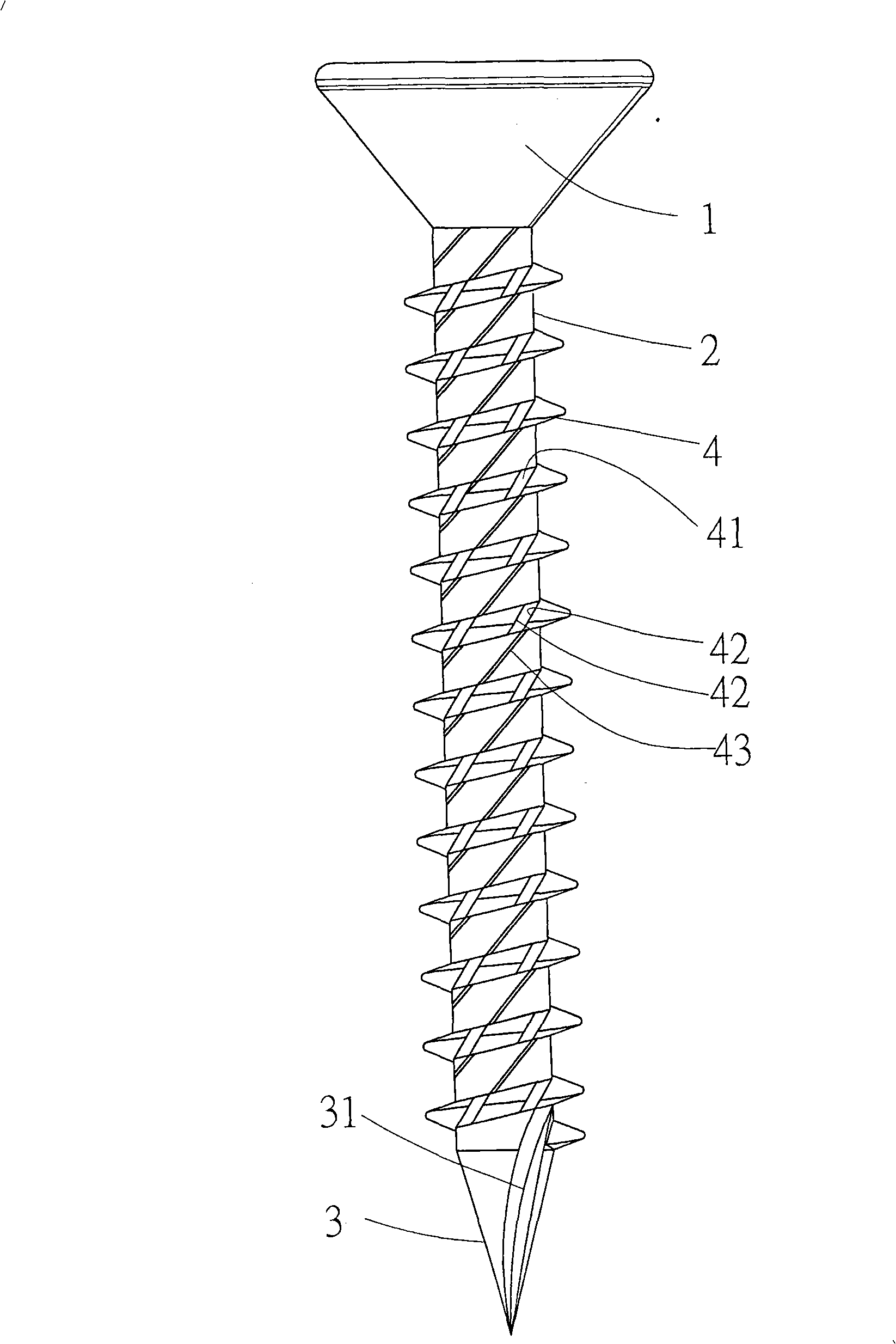

[0024] First, please also see Figure 1 to Figure 3 As shown, the screw of the present invention is divided into a nail head 1, a nail shank 2 and a nail tip 3, and the nail shank 2 spirals upwards along the nail tip 3 to the place below the nail head 1 to be provided with a thread 4, and the nail The tip 3 can also be provided with a V-shaped cutting groove 31 .

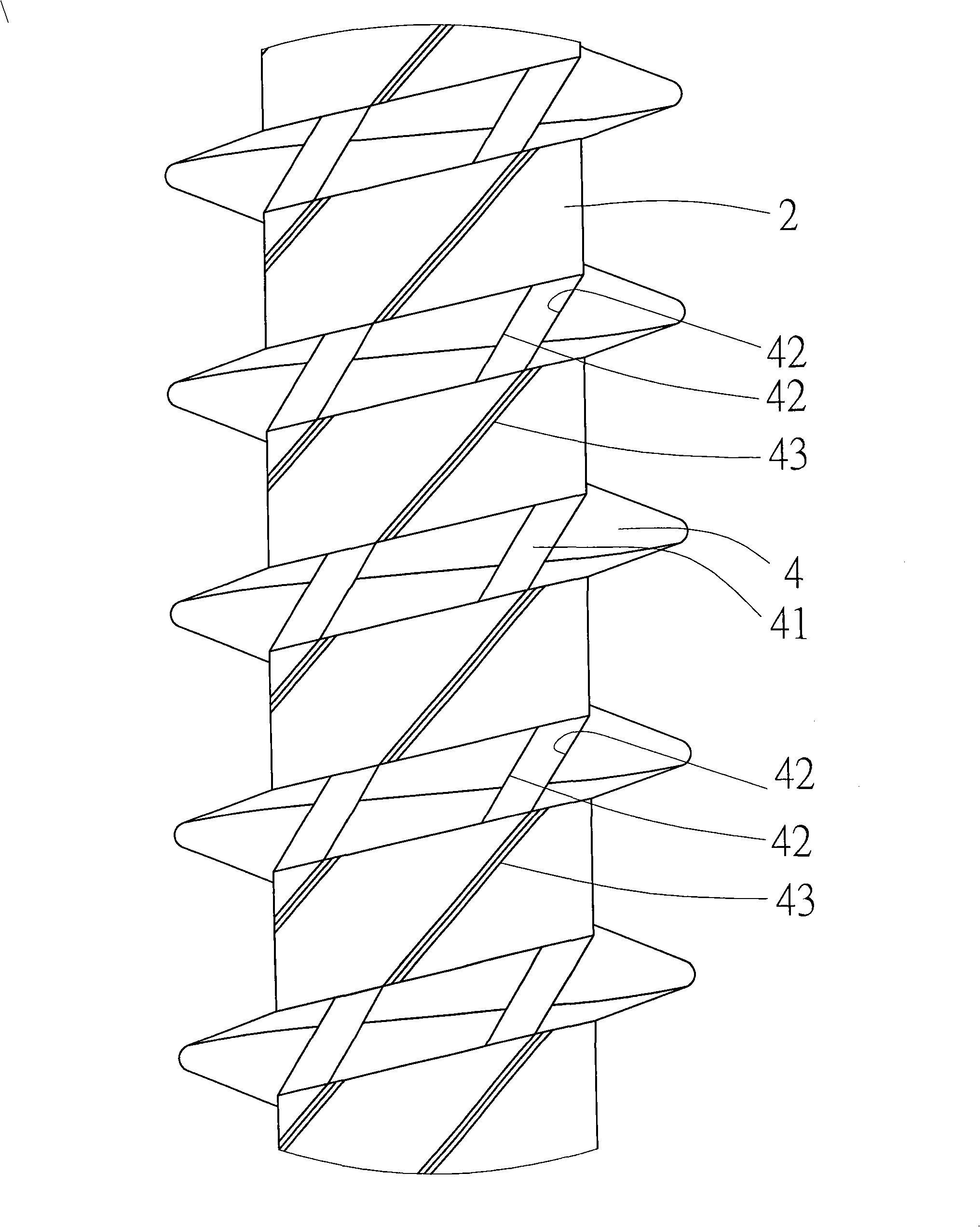

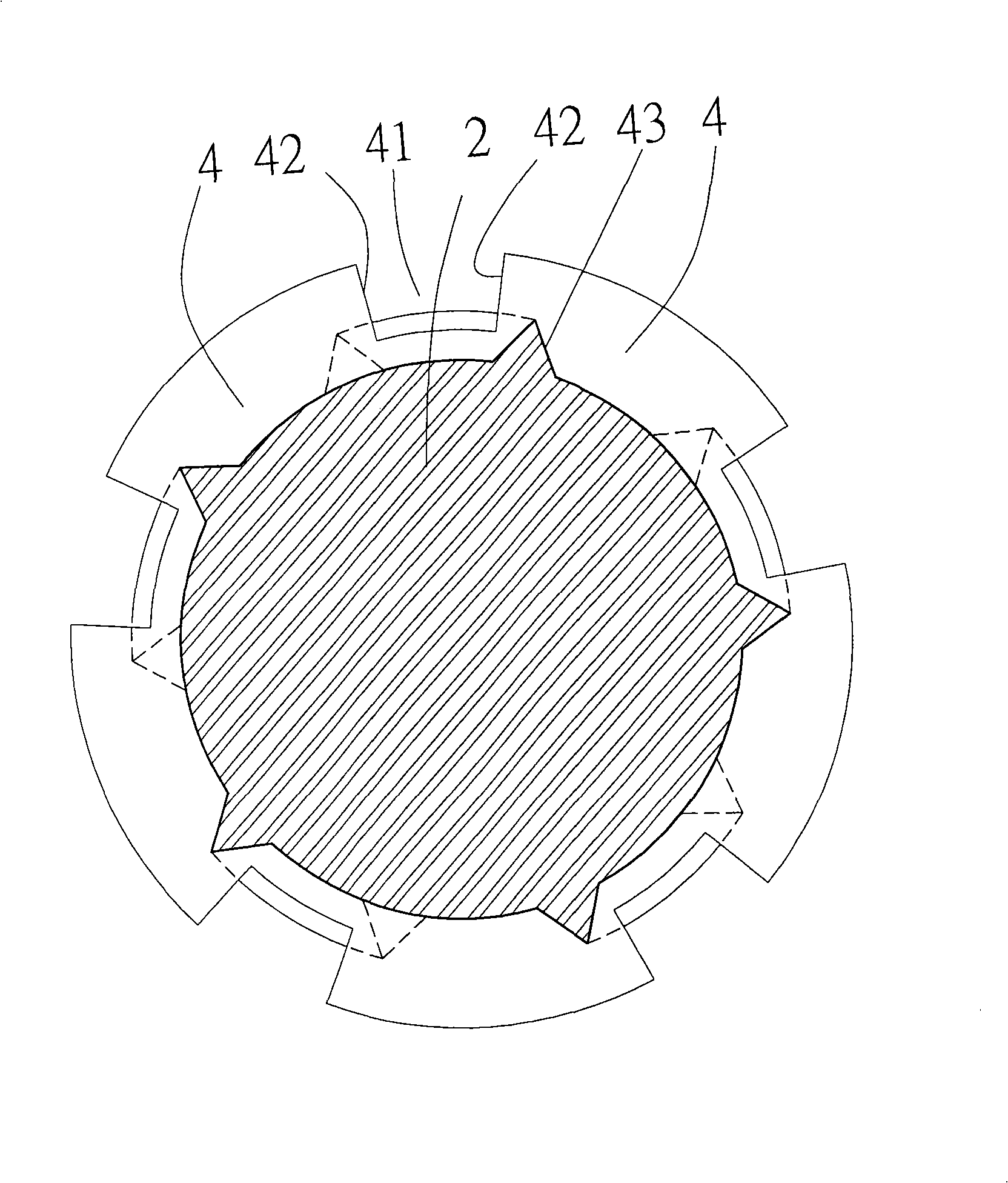

[0025] Number groove 41 is provided with number groove 41 on the number tooth pattern 4 of nail bar 2, and the two sidewalls of each groove 41 are parallel to each other, and the sidewall of each groove 41 forms auxiliary cutter 42 with tooth pattern 4 joints, and A guiding rib 43 is connected between the groove 41 of each upper thread 4 and the corresponding groove 41 of the lower thread 4 .

[0026] In addition, the recessed depth of the aforementioned groove 41 can be lower than the highest point...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com