Aircraft with aft split-level multi-deck fusealge and method for remoulding aircraft

An aircraft and fuselage technology, applied in the field of split-level cabin floor structure, can solve problems such as reducing passenger comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

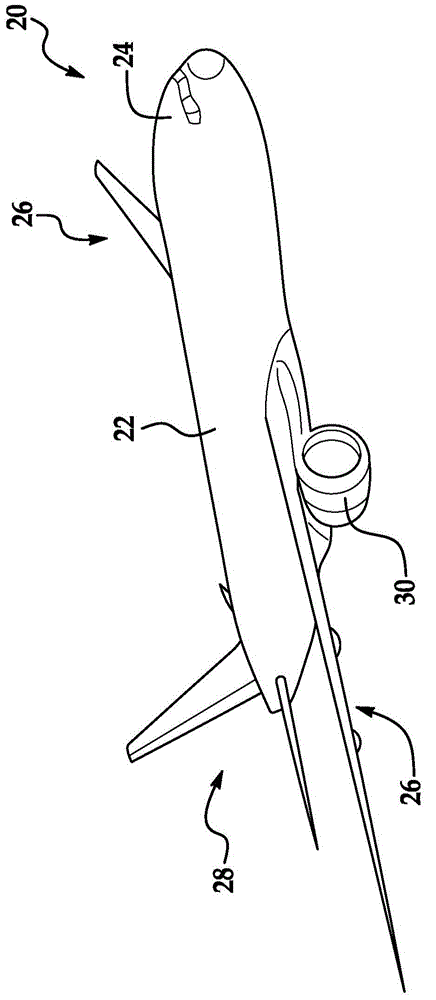

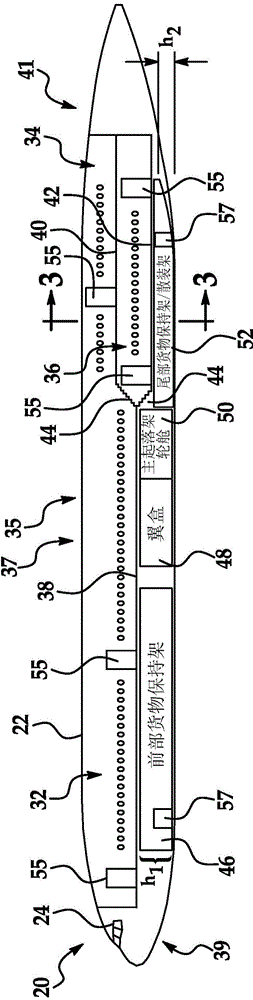

[0041] first reference Figure 1 to Figure 3 , aircraft 20 includes a generally cylindrical fuselage 22 to which wing assemblies 26 and tail assemblies 28 are attached. In the illustrated example, aircraft 20 is propelled by jet engines 30 mounted on wing assemblies 26, as figure 1Best seen. Aircraft 20 may carry any of various types of payload, including cargo and passengers. As used herein, the term "passenger" is intended to include all forms of passengers, including crew members, pilots, entourage and service personnel.

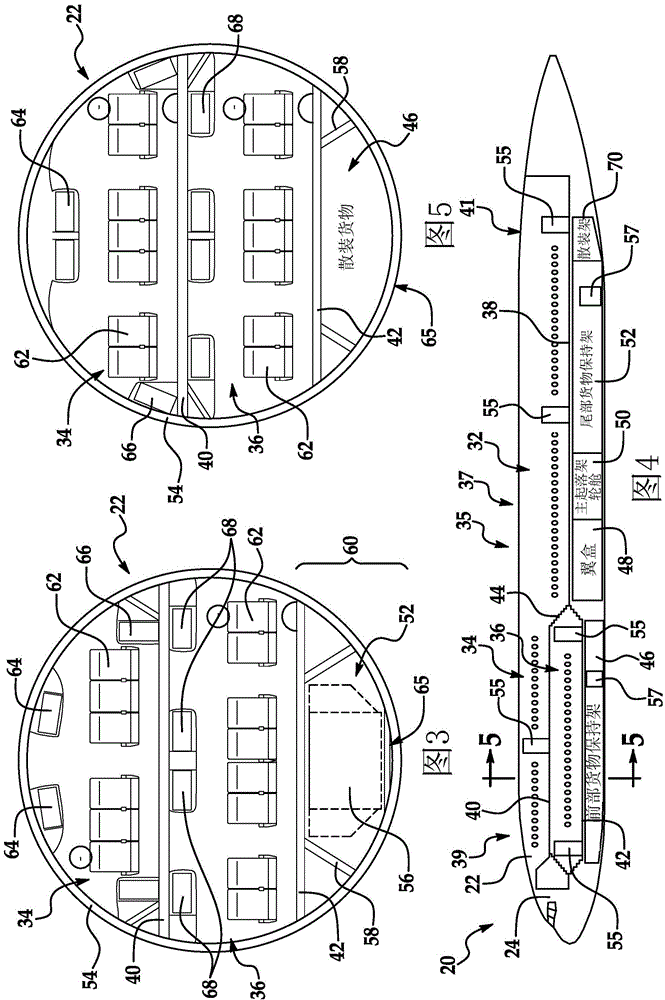

[0042] Now especially with reference to figure 2 with image 3 , the fuselage 22 broadly includes a crew cockpit 24 positioned forward and a split-level cabin layout 35 comprising: a first main-level cabin 32 positioned immediately behind the cockpit 24; and an upper Second cabin 34 and lower third cabin 36, they are positioned between main cabin 32 and tail assembly 28 ( figure 1 )between. Passenger compartments 32, 34 and 36 include passenger co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com