Coal spraying nozzle for coal gasification device and combustion device

A gasification device and combustion device technology, applied in the field of coal material nozzles, can solve problems such as wear, serious erosion, long-term stable operation, and short service life, so as to optimize the working conditions, reduce benefit loss, and save repairs The effect of fees

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

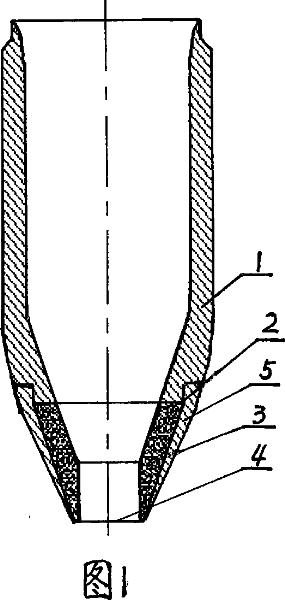

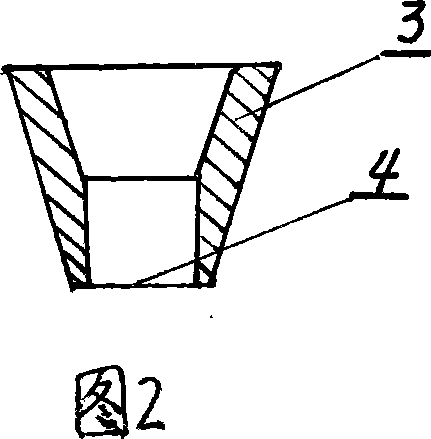

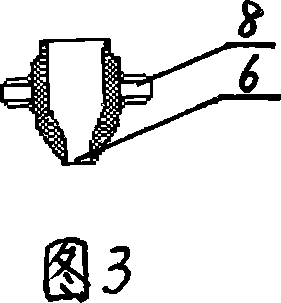

[0023] The invention adopts INCONEL600 and YRS188 imported materials, processed, assembled and welded. The coal nozzle has a central oxygen nozzle 6 inside and an outer oxygen nozzle 7 outside. The center oxygen nozzle 6 and the coal nozzle 1 of the present invention, the coal nozzle 1 of the present invention and the outer oxygen nozzle 7 pass through an inner support plate 8 respectively. , The outer support plate 9 is connected and positioned. The front part of the coal material nozzle is a conical body 2, and the front part of the conical body 2 is connected with a support body 5 embedded with an inner bushing 3. The front port of the inner bushing 3 is a nozzle opening 4, and the inner bushing 3 is a tapered ceramic tube made of high-temperature-resistant, wear-resistant, and erosion-resistant ceramic materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com