Aluminum alloy and preparation method thereof

A technology for aluminum alloy and aluminum alloy products, applied in the field of aluminum alloy manufacturing, can solve the problems of high tendency of casting mold mucous membrane, bad defects of aluminum alloy products, large energy consumption, etc. Mechanical strength, good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

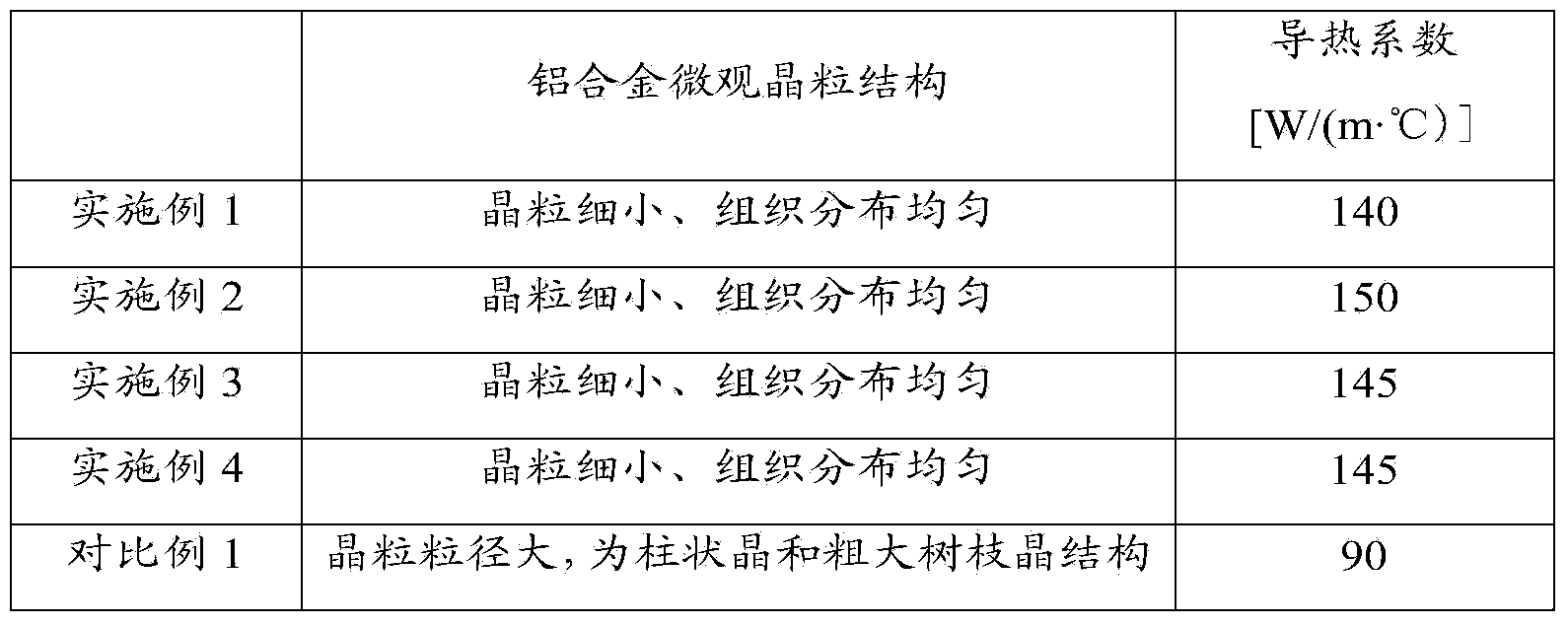

Embodiment 1

[0026] The preparation method of aluminum alloy is as follows:

[0027] (A) Injecting the first aluminum liquid with a pressure of 0.6 MPa and a temperature of 630°C into a cooling mold with a temperature of 10°C for cooling and molding, and the cooling time is 7s to form a first semi-solid blank;

[0028] (B) Turning the first semi-solid blank to remove the scale on the surface, then putting it into the second aluminum liquid at 650°C for stirring to obtain the second semi-solid slurry;

[0029] (C) sending the second semi-solid slurry into the injection chamber for injection molding to obtain an aluminum alloy product.

Embodiment 2

[0031] The preparation method of aluminum alloy is as follows:

[0032] (A) The first aluminum liquid with a pressure of 0.8MPa and a temperature of 650°C is injected into a cooling model with a cooling medium of 25°C circulating cooling water using a light cylinder for cooling and molding, and the advancing speed of the electronic control valve is 200mm / s , the flow rate of the first aluminum liquid is 6L / s, and the cooling time in the cooling model is 13s to form the first semi-solid billet;

[0033] (B) Turning the first semi-solid billet to remove the 0.5mm scale on the surface, the turning rate is 600rad / min, and then the NC equipment is automatically inserted into the second aluminum liquid at 680°C and stirred for 10s to obtain The second semi-solid slurry, wherein the stirring rate is 600rad / min, and the quality of the first semi-solid blank is 2.5% of the total mass of the target product aluminum alloy product;

[0034] (C) sending the second semi-solid slurry into t...

Embodiment 3

[0036] The preparation method of aluminum alloy is as follows:

[0037] (A) The first aluminum liquid with a pressure of 0.7MPa and a temperature of 640°C is injected into a cooling model with a cooling medium of 10°C circulating cooling water using a light cylinder for cooling and molding. The propulsion rate of the light cylinder is 250mm / s, The flow rate of the first aluminum liquid is 8.5L / s, and the cooling time in the cooling model is 13s to form the first semi-solid billet;

[0038] (B) Turn the first semi-solid billet to remove the 0.8mm oxide scale on the surface, the turning rate is 800rad / min, then put it into the second aluminum liquid at 650°C and stir for 20s to obtain the second semi-solid Slurry, wherein the stirring rate is 800rad / min and eccentric stirring is adopted, the eccentric distance is 0.2mm, and the quality of the first semi-solid blank is 3% of the total mass of the target aluminum alloy product;

[0039] (C) sending the second semi-solid slurry in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com