Patents

Literature

37results about How to "Improve grain uniformity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

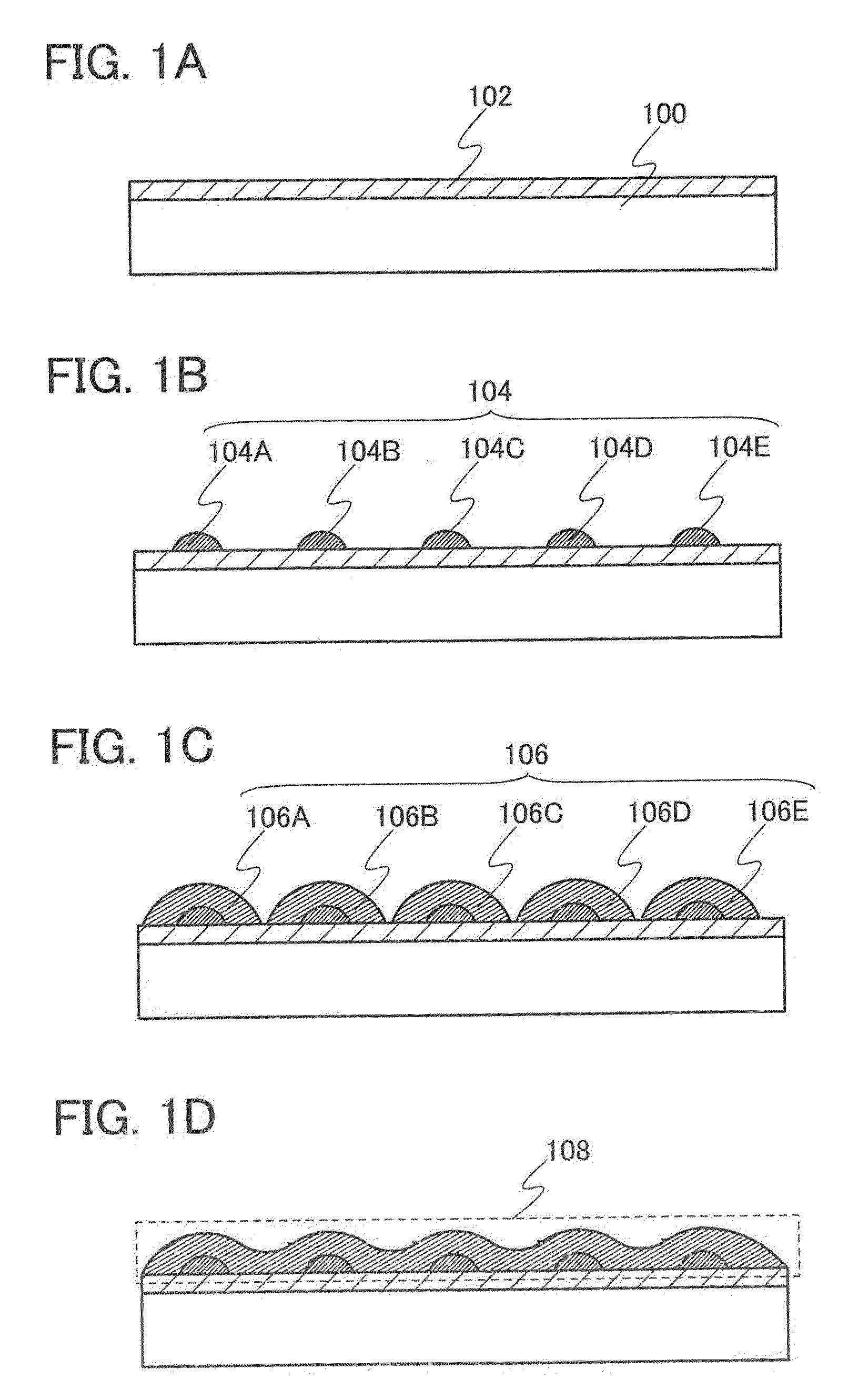

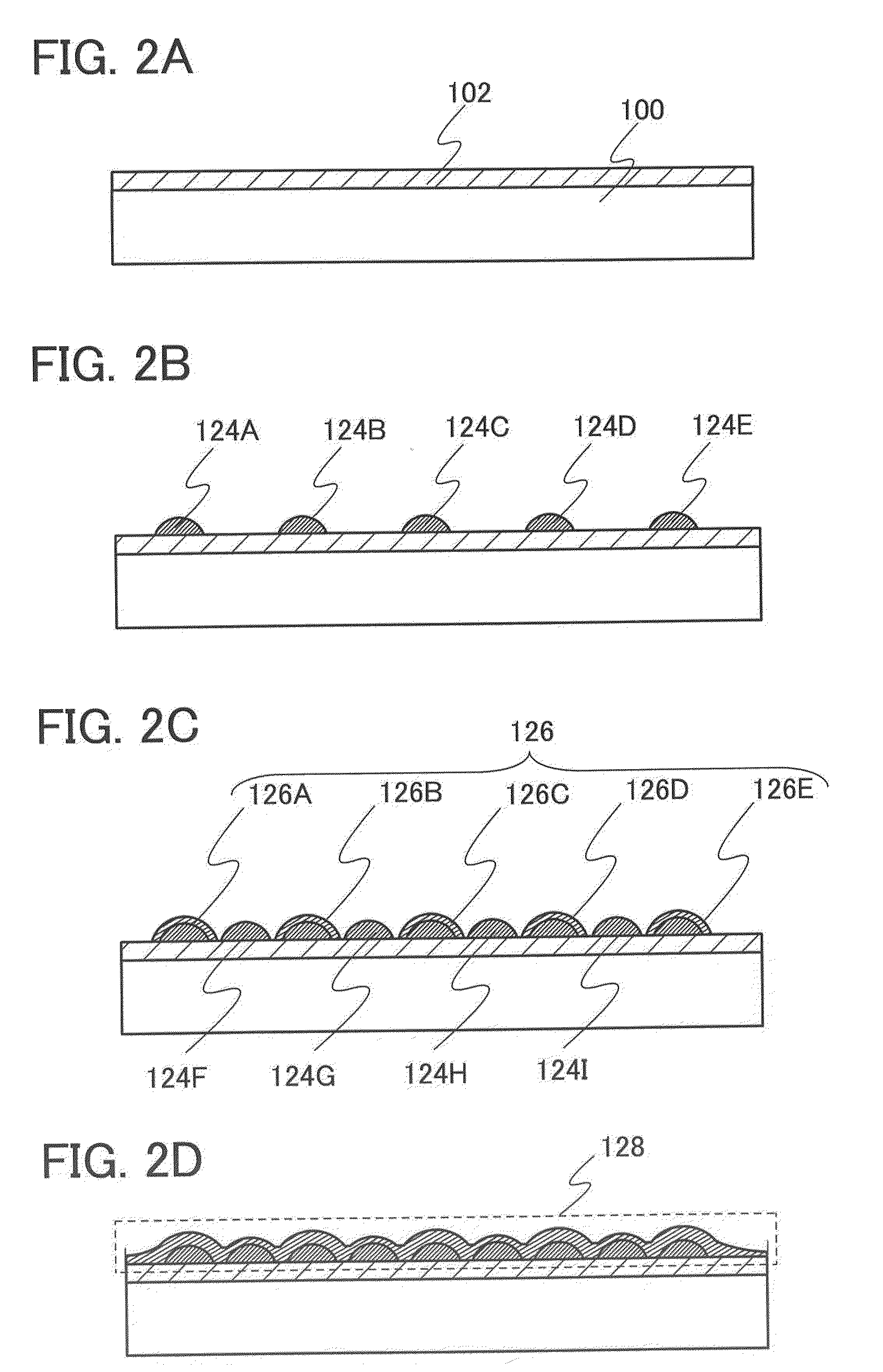

Method for Manufacturing Crystalline Semiconductor Film and Method for Manufacturing Thin Film Transistor

InactiveUS20100216285A1Improve grain uniformityHigh carrier mobilityPolycrystalline material growthSolid-state devicesSemiconductor materialsFlow ratio

A crystalline semiconductor film is manufactured by a first step in which a crystalline semiconductor film is formed on and in contact with an insulating film and a second step in which the crystalline semiconductor film is grown in a condition where a generation frequency of nuclei is lower than in the first step. The second step is conducted in a condition where a flow ratio of a semiconductor material gas to a deposition gas is lower than in the first step. Thus, a crystalline semiconductor film whose crystal grains are large and uniform can be obtained and plasma damage to a base film of the crystalline semiconductor film can be reduced compared with a crystalline semiconductor film in a conventional method.

Owner:SEMICON ENERGY LAB CO LTD

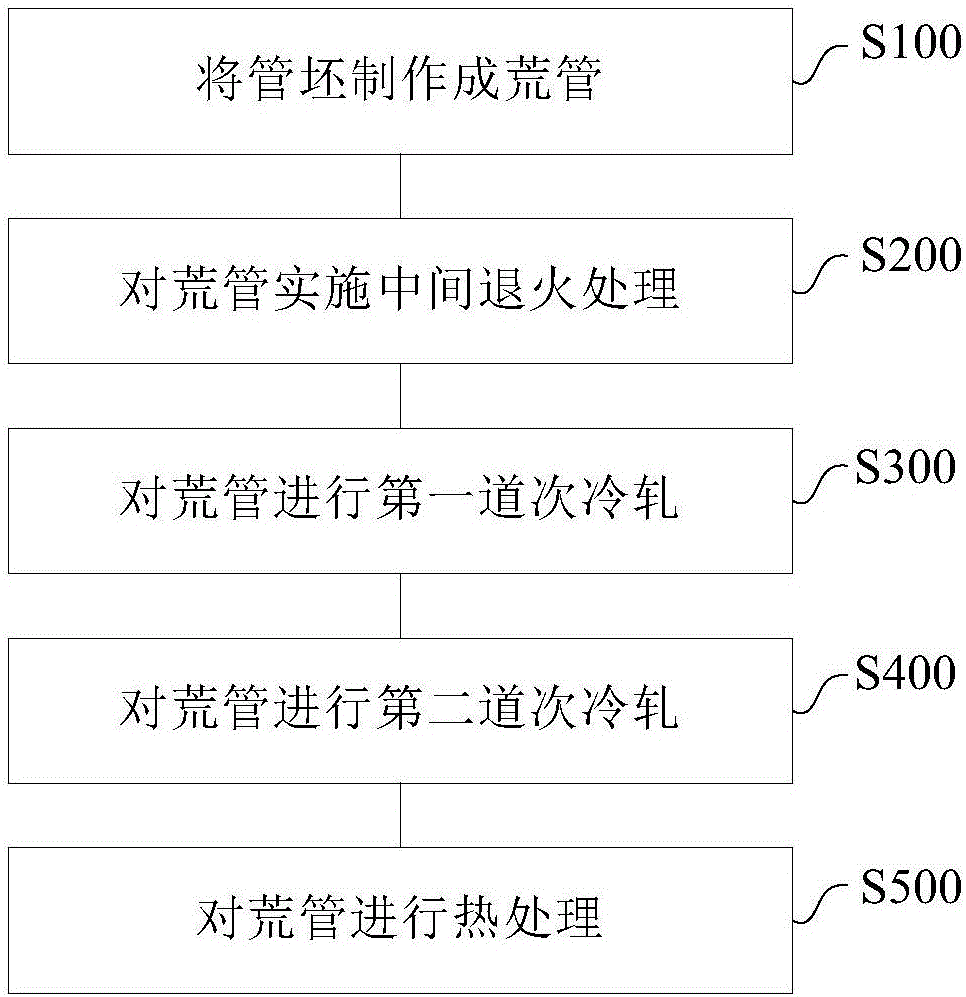

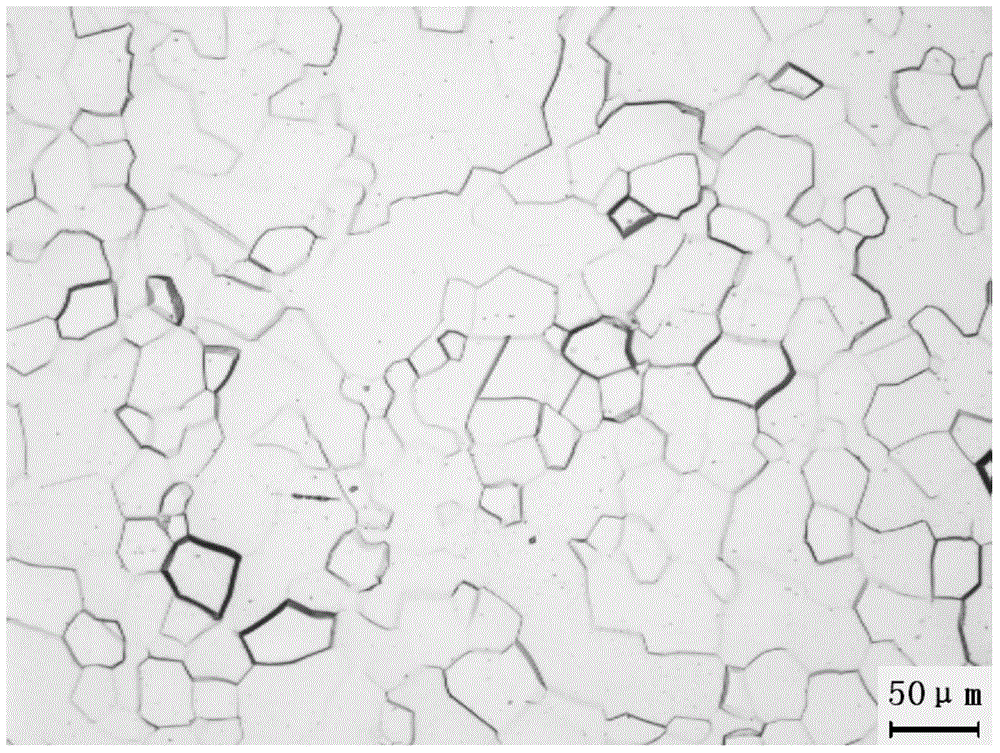

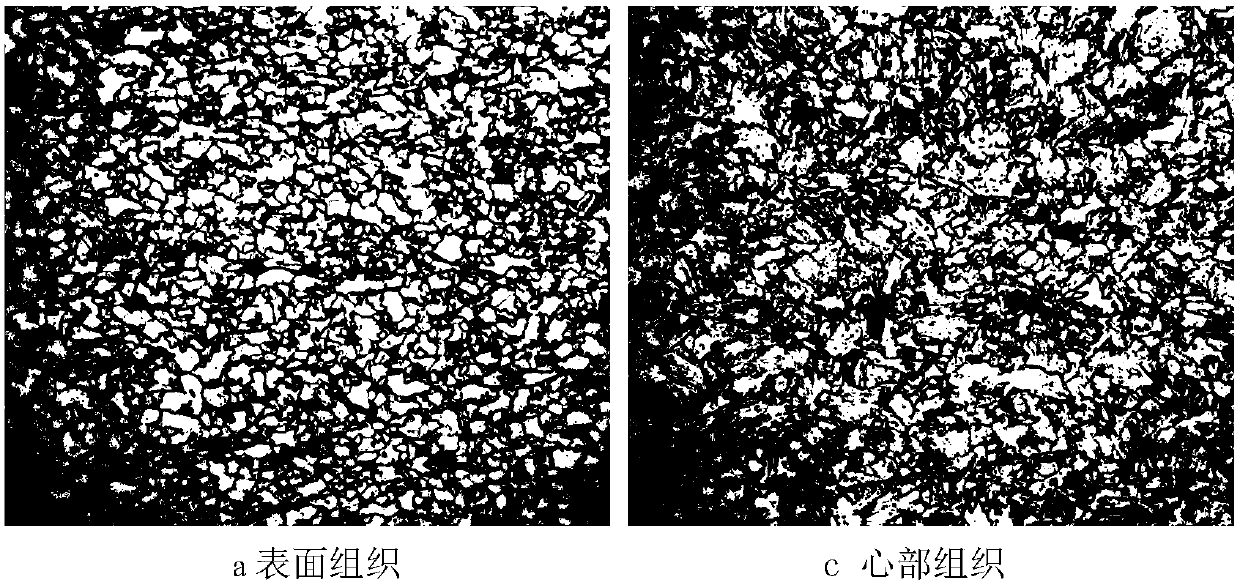

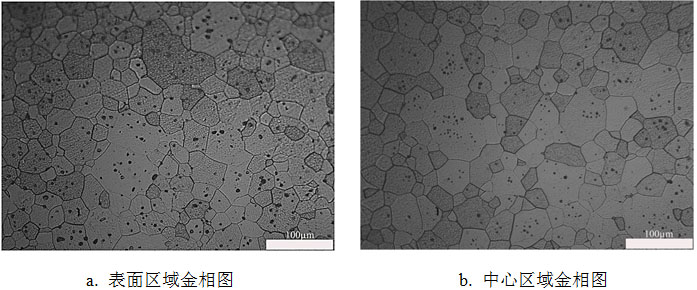

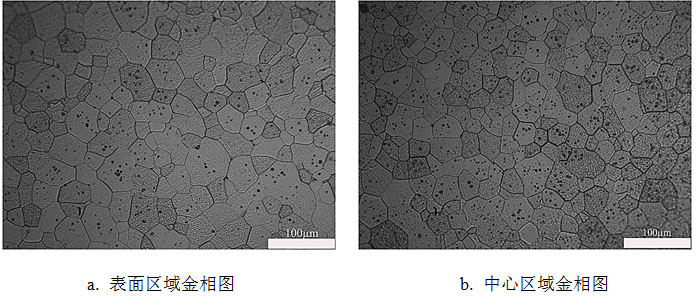

Manufacturing method of wolfram-contained austenite stainless steel seamless tube

InactiveCN106702259AImprove grain uniformityImprove room temperature performanceFurnace typesMetal rolling arrangementsHeat treatedAustenitic stainless steel

The invention discloses a manufacturing method of a wolfram-contained austenite stainless steel seamless tube. The method comprises following steps: 11, a tube blank is manufactured into a pierced billet, in the process of manufacturing the pierced billet, the extrusion ratio of extrusion to the pierced billet ranges from 6 to 12, and the extrusion speed ranges from 130 to 180mm / s; 12, the pierced billet is subject to first-pass cold rolling, and the pass deformation amount of the first-pass cold rolling ranges from 40% to 60%; 13, intermediate annealing treatment is applied to the pierced billet subject to first-pass cold rolling, the annealing temperature ranges from 1120 DEG C to 1200 DEG C, and heat preservation is carried out for 30 min to 60 min; 14, second-pass cold rolling is applied to the pierced billet subject to intermediate annealing treatment, and the pass deformation amount of the second-pass cold rolling is controlled to range from 35% to 50%; 15, the pierced billet subject to second-pass cold rolling is subject to heat treatment, temperature of heat treatment ranges from 1150 DEG C to 1250 DEG C, and heat preservation is carried out for 30 min to 60 min. The manufacturing method solves the problem that the product quality of a wolfram-contained austenite stainless steel seamless tube manufactured at present is poor.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

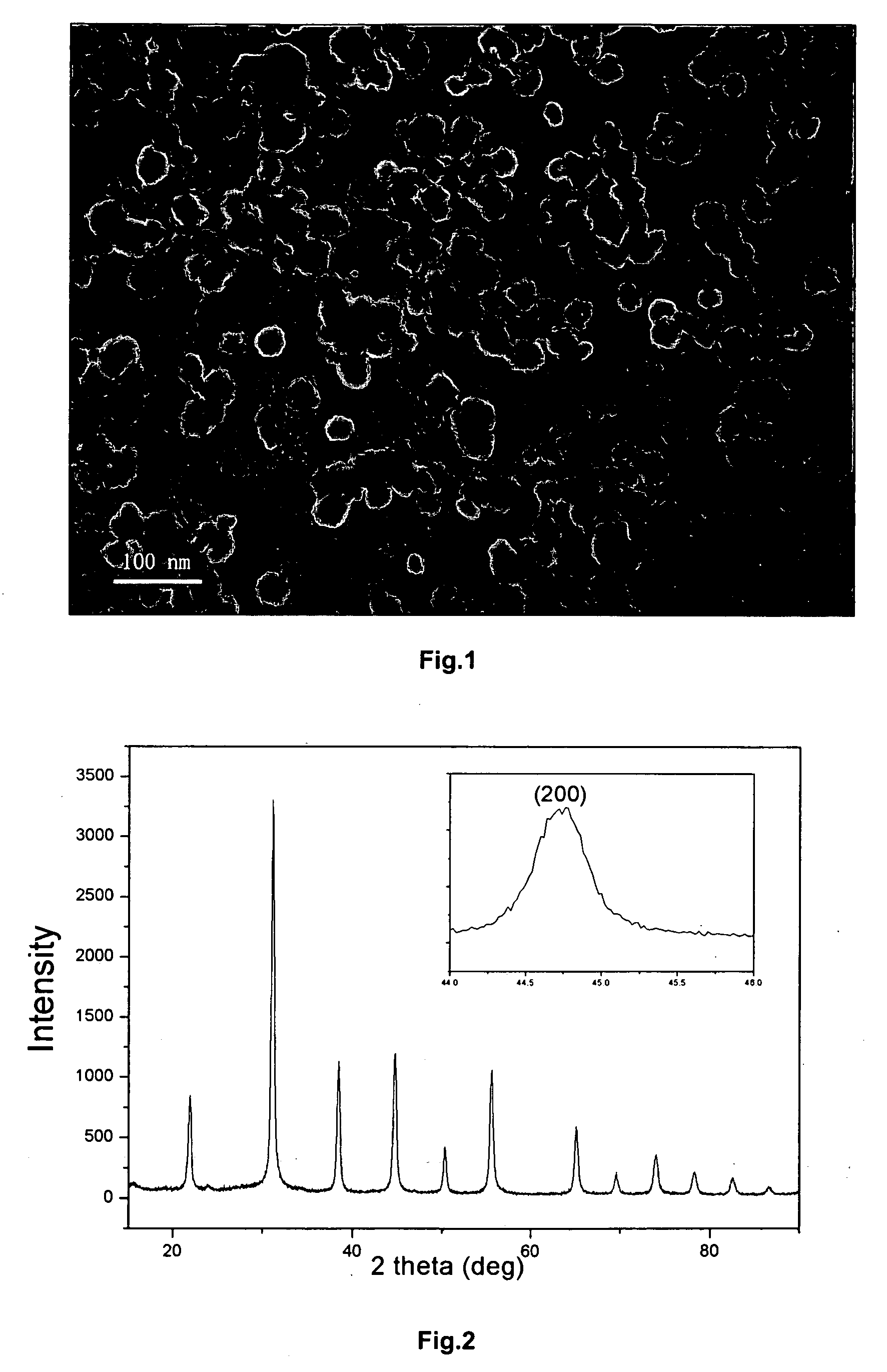

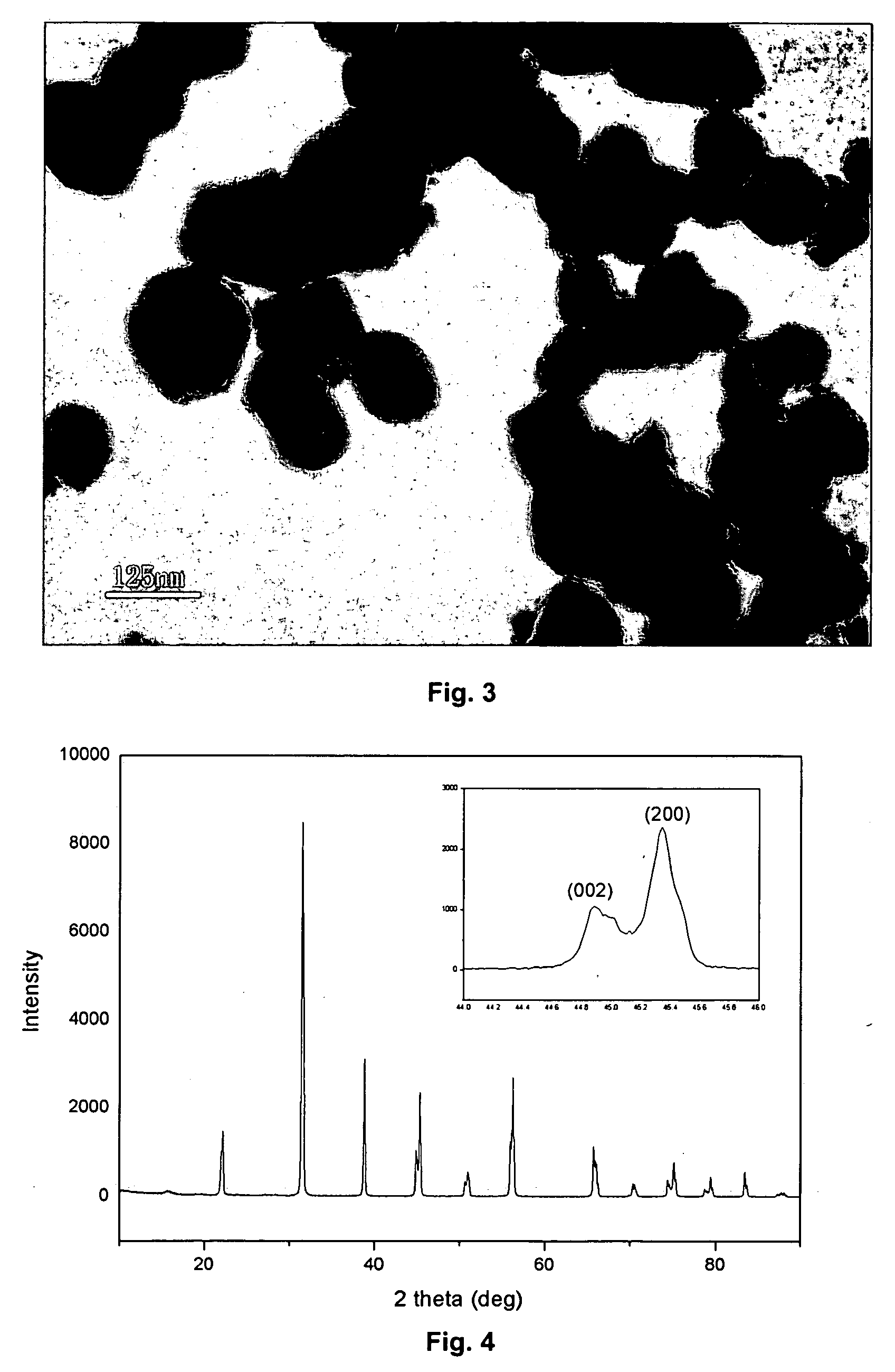

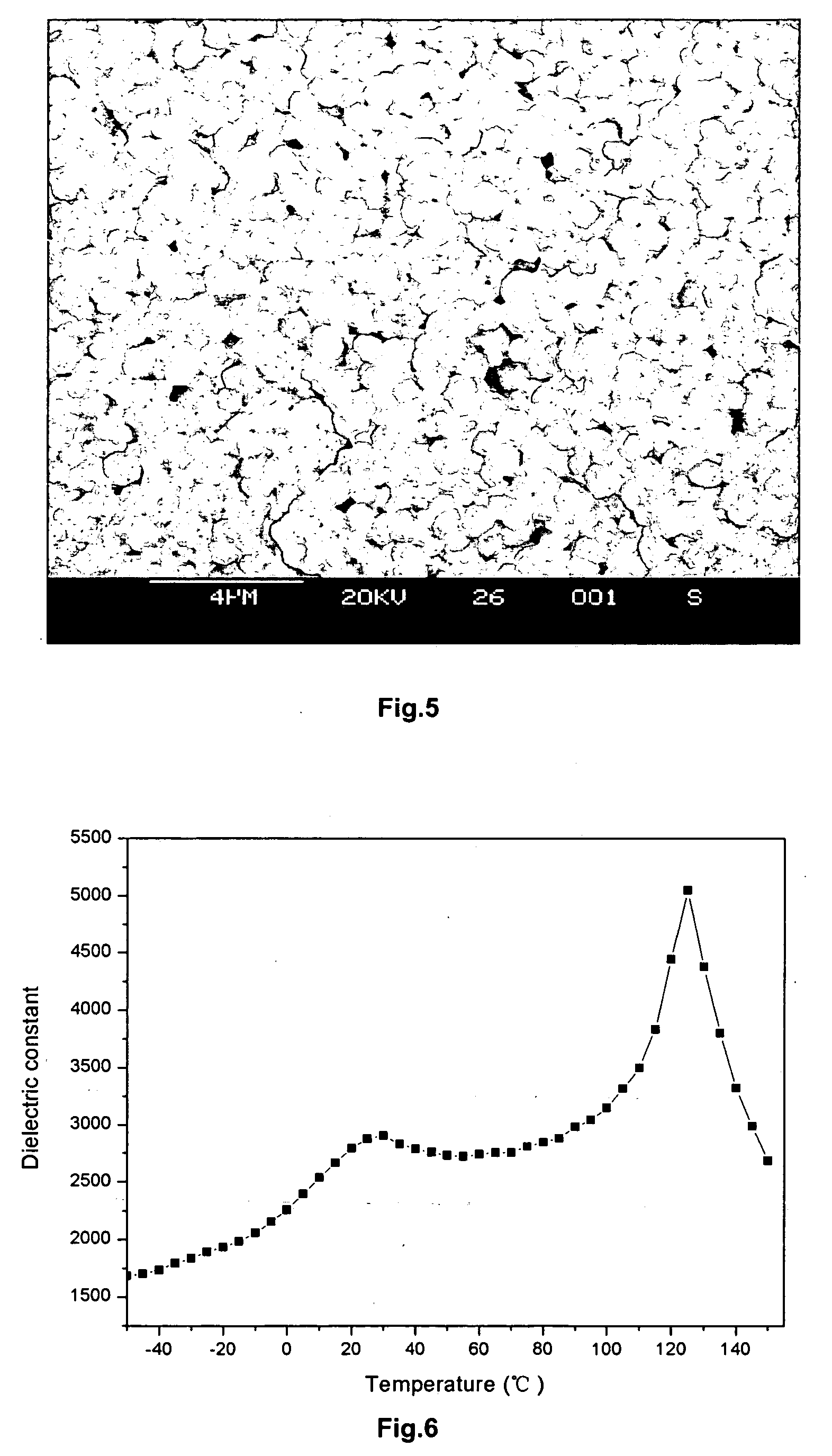

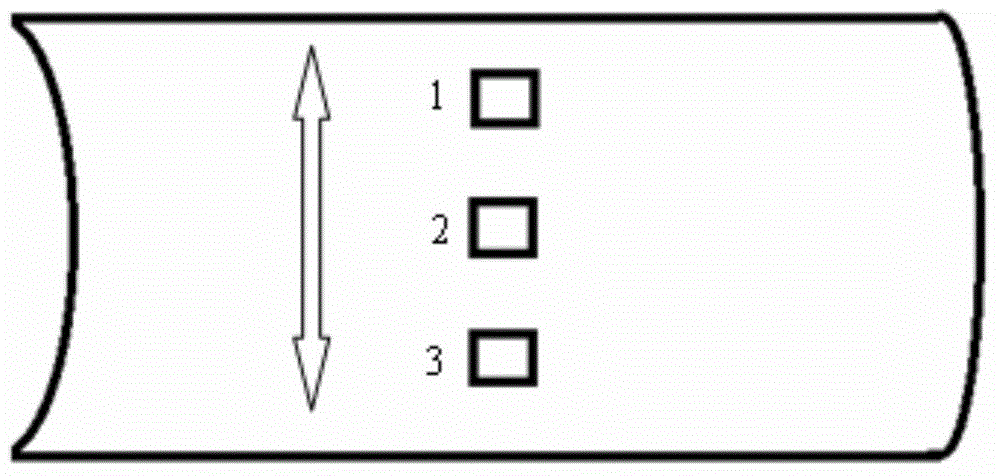

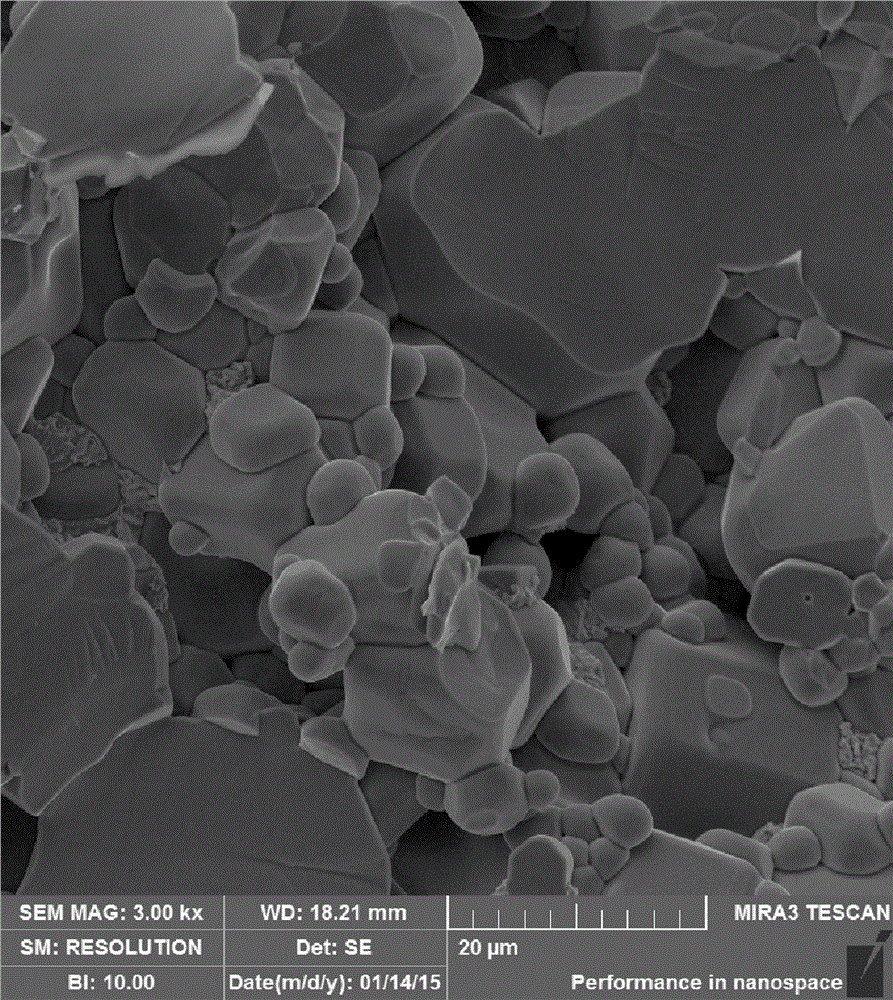

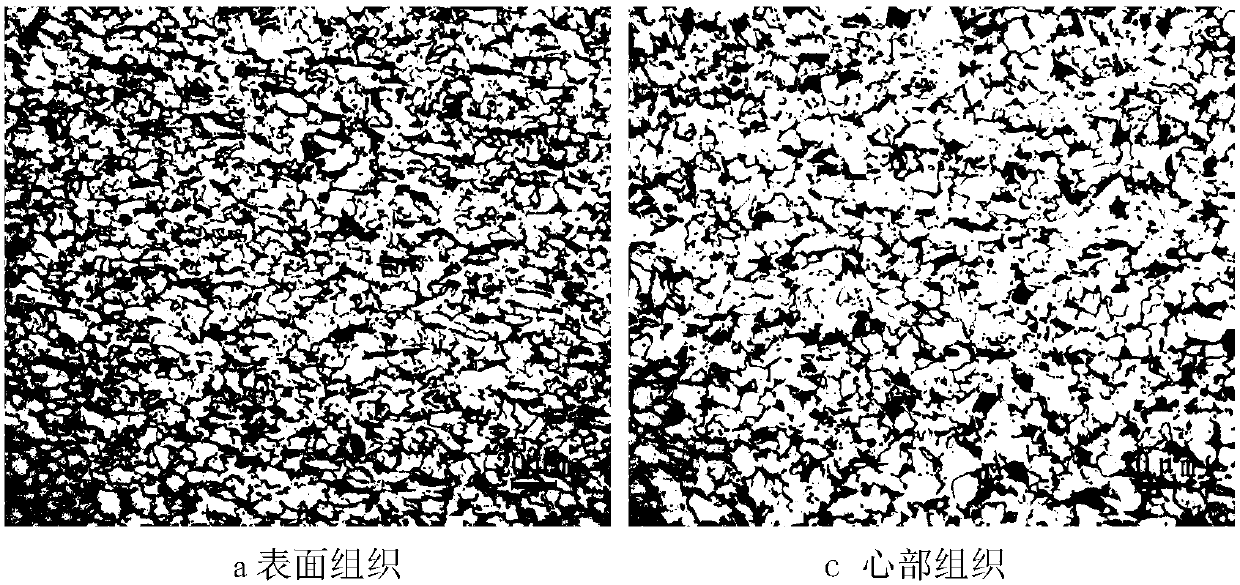

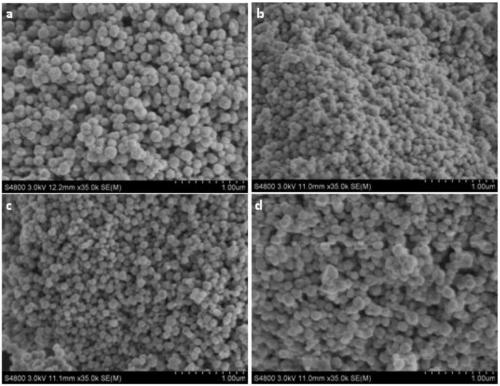

High-gravity reactive precipitation process for the preparation of barium titanate powders

InactiveUS20050019248A1High yieldShort timeMaterial nanotechnologyAlkaline earth titanatesBarium titanateOrganic base

The invention relates to a process for the preparation of fine barium titanate (BaTiO3) powders. The process comprises introducing an aqueous solution (I) containing salts of barium and titanium, and an aqueous basic solution (II) containing an inorganic or organic base separately and simultaneously into a high-gravity reactor with the high-gravity level of 1.25G to 12,500G and performing the reaction of the solution (I) with the solution (II) at a temperature of from 60 to 100° C. The solution (I) is preheated to a temperature ranging from 60° C. to 65° C. and the solution (II) is preheated to a temperature ranging from 60° C. to 100° C. respectively prior to the reaction, in which the Ba / Ti molar ratio in the solution (I) is more than 1 and the concentration of the base in the solution (II) is such that the reaction mixture is maintained at a constant OH− concentration, preferably a pH value of about 14. The reaction product is separated by filtering and washed with deionized water to remove the impurity ions and excessive barium ions, and then dried to obtain BaTiO3 powders. Said powders consist essentially of crystalline, primary particles having a uniform particle size ranging from 5 to 200 nm, an approximately spherical morphology and a high sintering activity.

Owner:BEIJING UNIV OF CHEM TECH

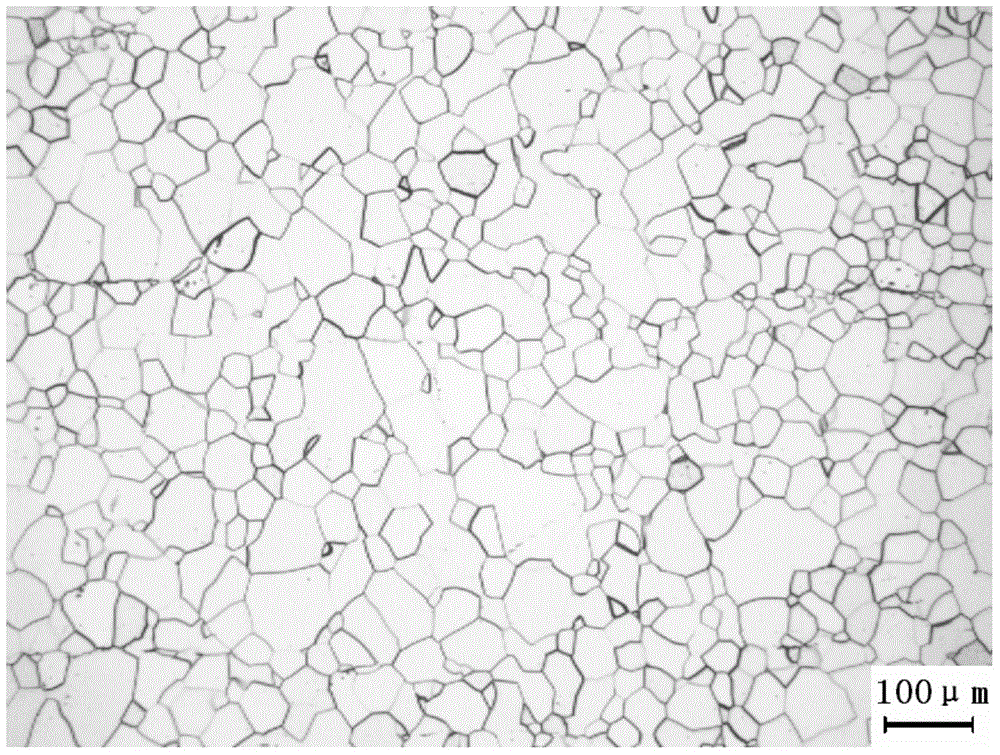

Continuous annealing method of pure titanium roll

InactiveCN104060205AGuaranteed annealing qualityImprove grain uniformityFurnace typesHeat treatment furnacesTitaniumContinuous annealing

The invention discloses a continuous annealing method of a pure titanium roll, and the method comprises the following steps: (1) a to-be-annealed titanium roll continuously, from head to tail, passes through a preheating section, a heating section and a soaking section of an annealing furnace in a speed of 2-5m / min in a form of a titanium belt, the titanium belt passes through the preheating section at the temperature of 250 to 350 DEG C, the titanium belt passes through the heating section at the temperature of 700 to 750 DEG C, and the total time for the titanium belt to pass through the annealing furnace is 4-10min; and (2) the titanium belt annealed by the annealing furnace is cooled in a manner of mist cooling. The continuous annealing method can significantly shorten the production cycle, improve production efficiency, and ensure the annealing quality of the titanium roll, improve annealed structure grain uniformity of the titanium roll, and ensure continuous production of a continuous titanium roll annealing-shot blasting-pickling process.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

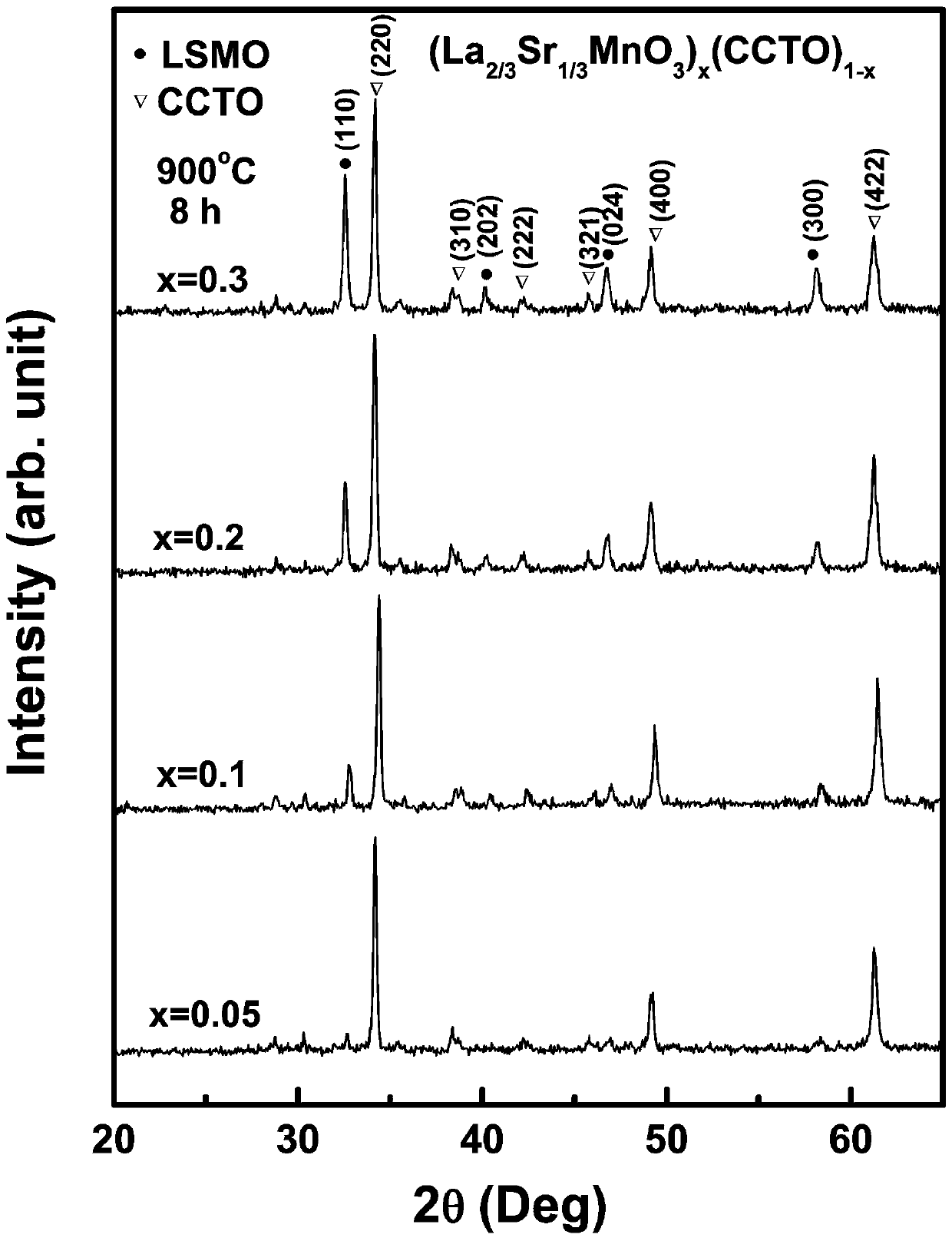

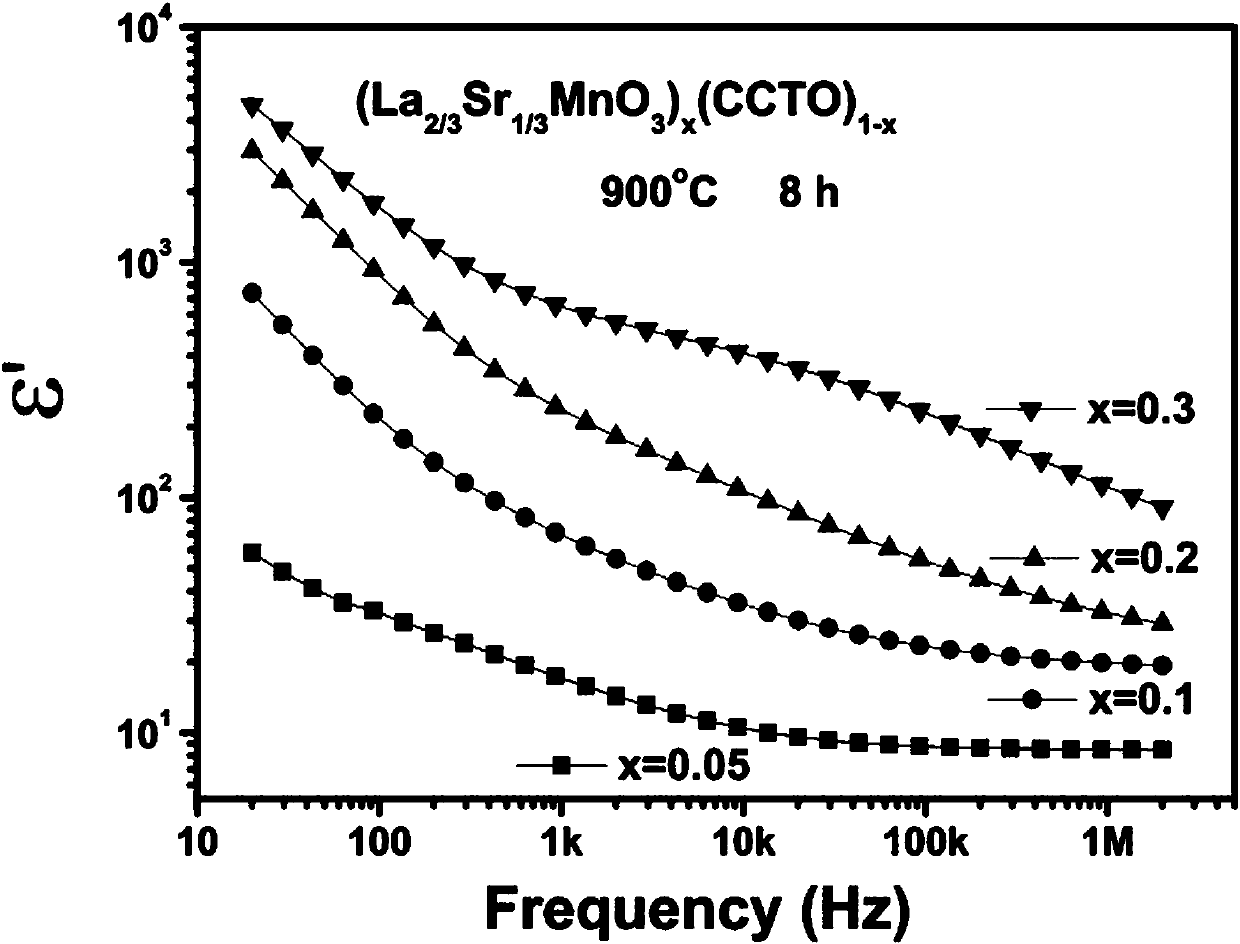

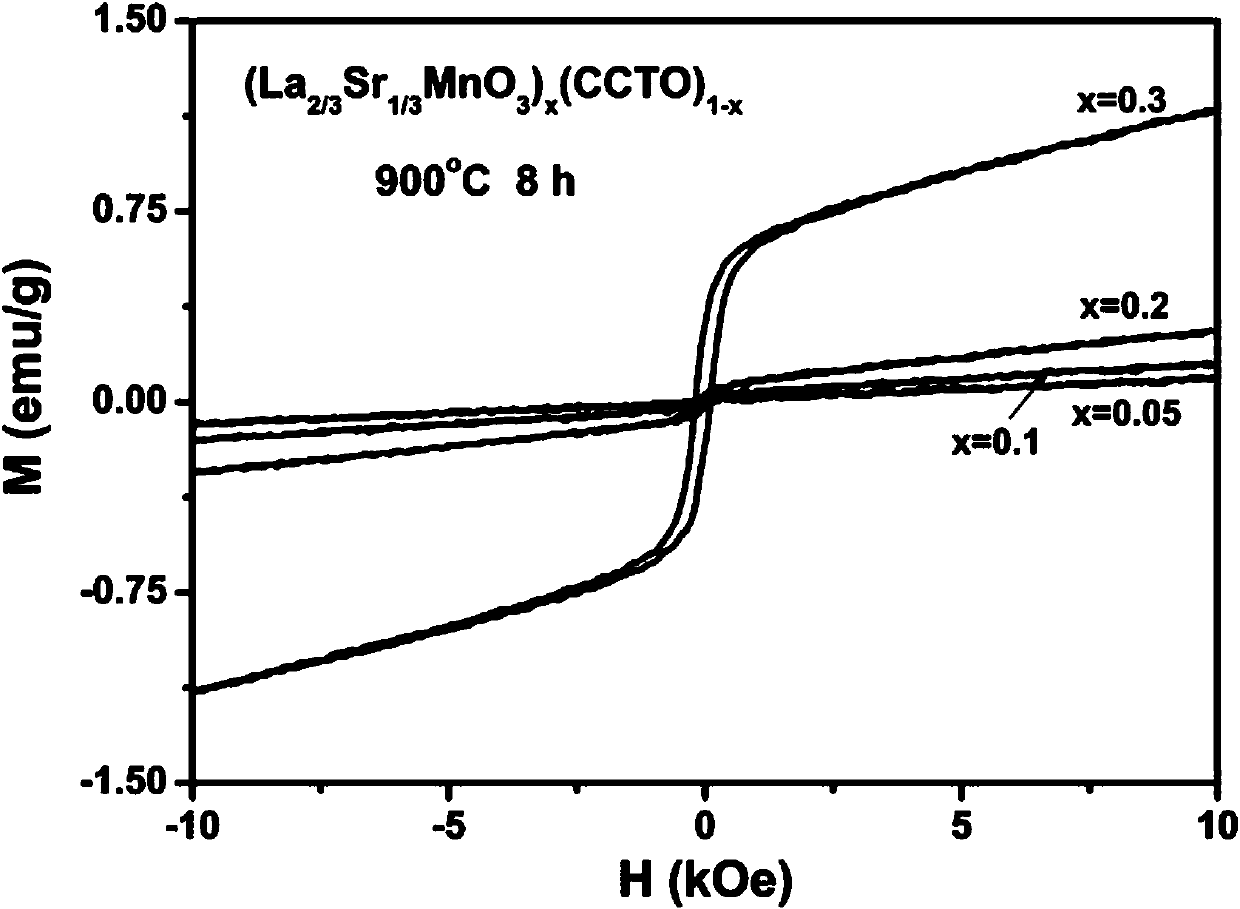

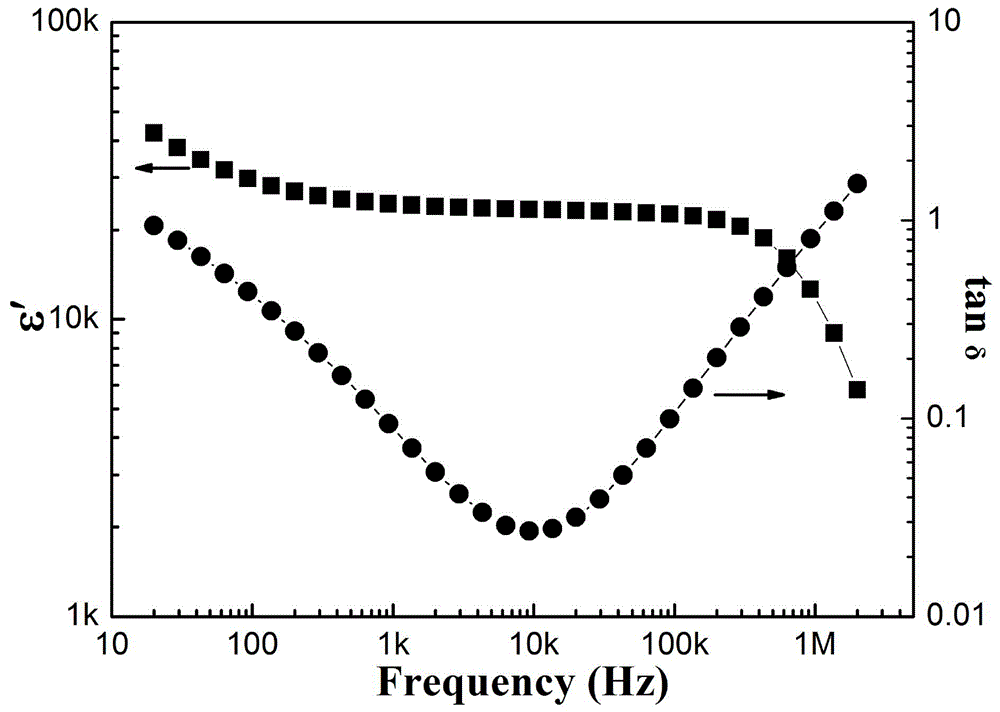

Method for preparing lanthanum strontium manganite/copper calcium titanate composite magnetoelectric ceramic material by virtue of sol-gel method

InactiveCN107759216AImprove uniformityImprove featuresInductances/transformers/magnets manufactureLanthanum strontium manganiteAdhesive

The invention belongs to the technical field of ceramic synthesis and provides a method for preparing a strontium lanthanum manganate / copper calcium titanate composite magnetoelectric ceramic materialby virtue of a sol-gel method. The method comprises the steps of respectively preparing lanthanum strontium manganite (LSMO) precursor powder, copper calcium titanate and CCTO precursor powder by virtue of the sol-gel method, mixing the LSMO precursor powder with the CCTO precursor powder, adding an adhesive, uniformly mixing, pressing to form a ceramic blank, and sintering a ceramic blank, so asto obtain a strontium lanthanum manganate / copper calcium titanate (LSMO-CCTO) composite magnetoelectric ceramic sample. The method has the beneficial effects that the raw materials are low in cost; components in the reaction process are controllable, and an impure phase is avoided; the gelling time is short; a preparation process is simple, and the dielectric property and magnetism of the ceramicsample have very strong regularity; a ceramic wafer is high in density and grain uniformity; and the process is simple and easy for industrial production, the prepared ceramic sample is high in density and grain uniformity and excellent in magnetoelectric performance.

Owner:TAIYUAN UNIV OF TECH

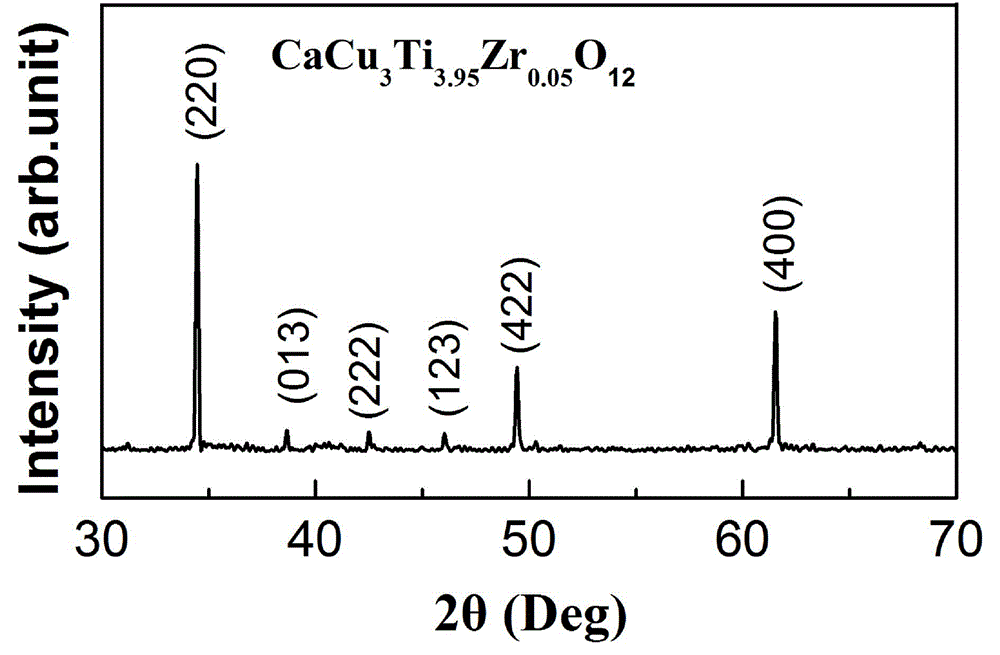

Preparation method for CaCu3Ti4-xZrxO12 ceramic with high dielectric constant and low dielectric loss

The invention discloses a preparation method for a Zr-doping CaCu3Ti4O12 ceramic material with a high dielectric constant and low dielectric loss by utilization of a sol-gel method, and belongs to the dielectric material synthesis technology field. The concrete method is as follows: a sol-gel method is employed, calcium nitrate, cupric nitrate, zirconium oxynitrate and butyl titanate are employed as raw materials, absolute ethyl alcohol is employed as a solvent, nitric acid is employed to adjust the pH of a solution, the raw materials are weighed according to chemical element mol ratios, sol is prepared and placed in a water-bath kettle, stirring is carried out continuously until xerogel is formed, organic matters are removed, CaCu3Ti4-xZrxO12 precursor powder is obtained, then calcining, crushing, grinding, sieving and granulation are carried out, then a ceramic body with a thickness of 1mm and with a diameter of 12mm is prepared, then the ceramic body is placed in a sintering furnace, sintering and thermal insulation are carried out, and finally a CaCu3Ti4-xZrxO12 ceramic sample can be obtained. The method is simple in technology and is easy for industrial production. The prepared ceramic sample has a high density, good particle uniformity and has an enough high dielectric constant and low dielectric loss.

Owner:TAIYUAN UNIV OF TECH

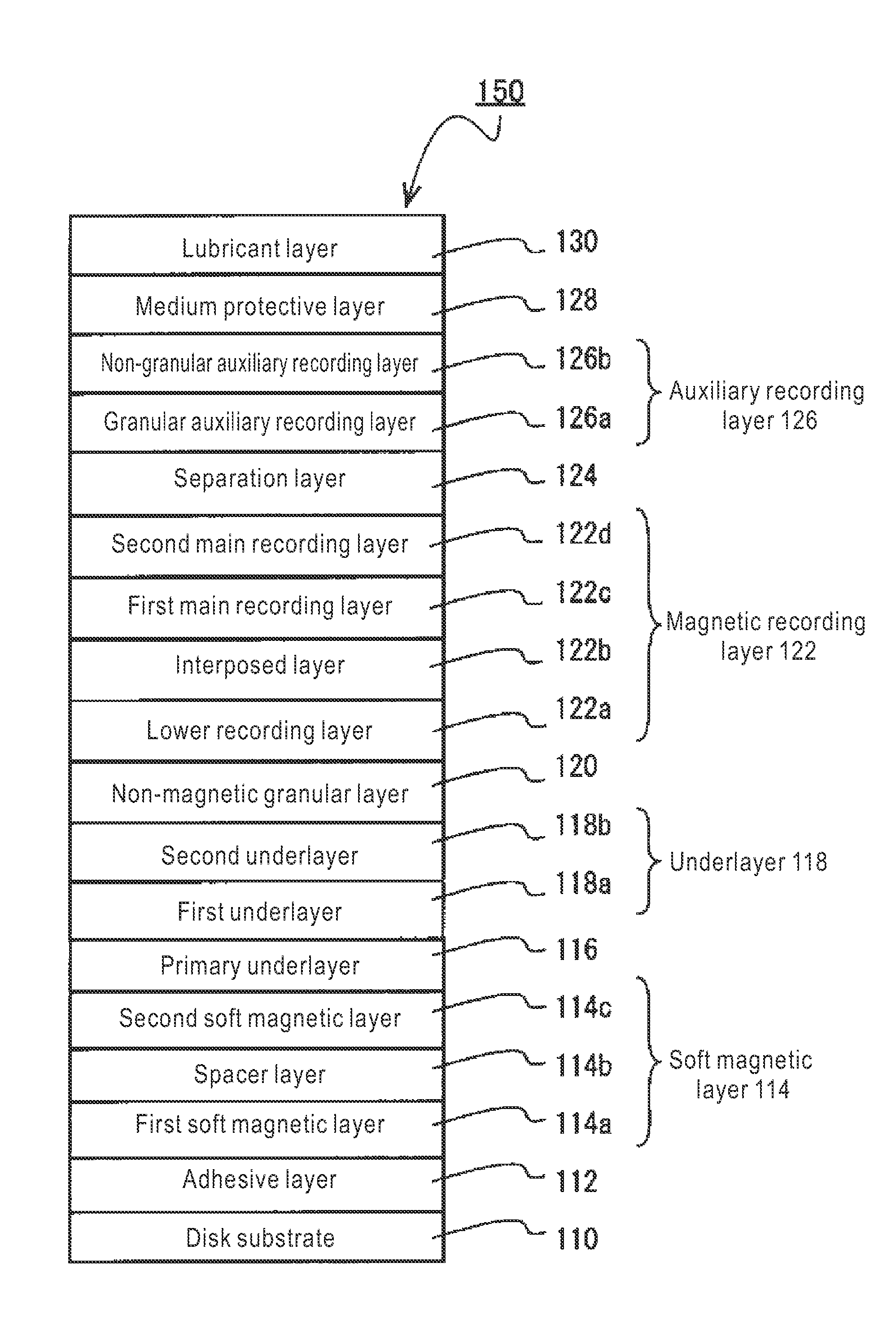

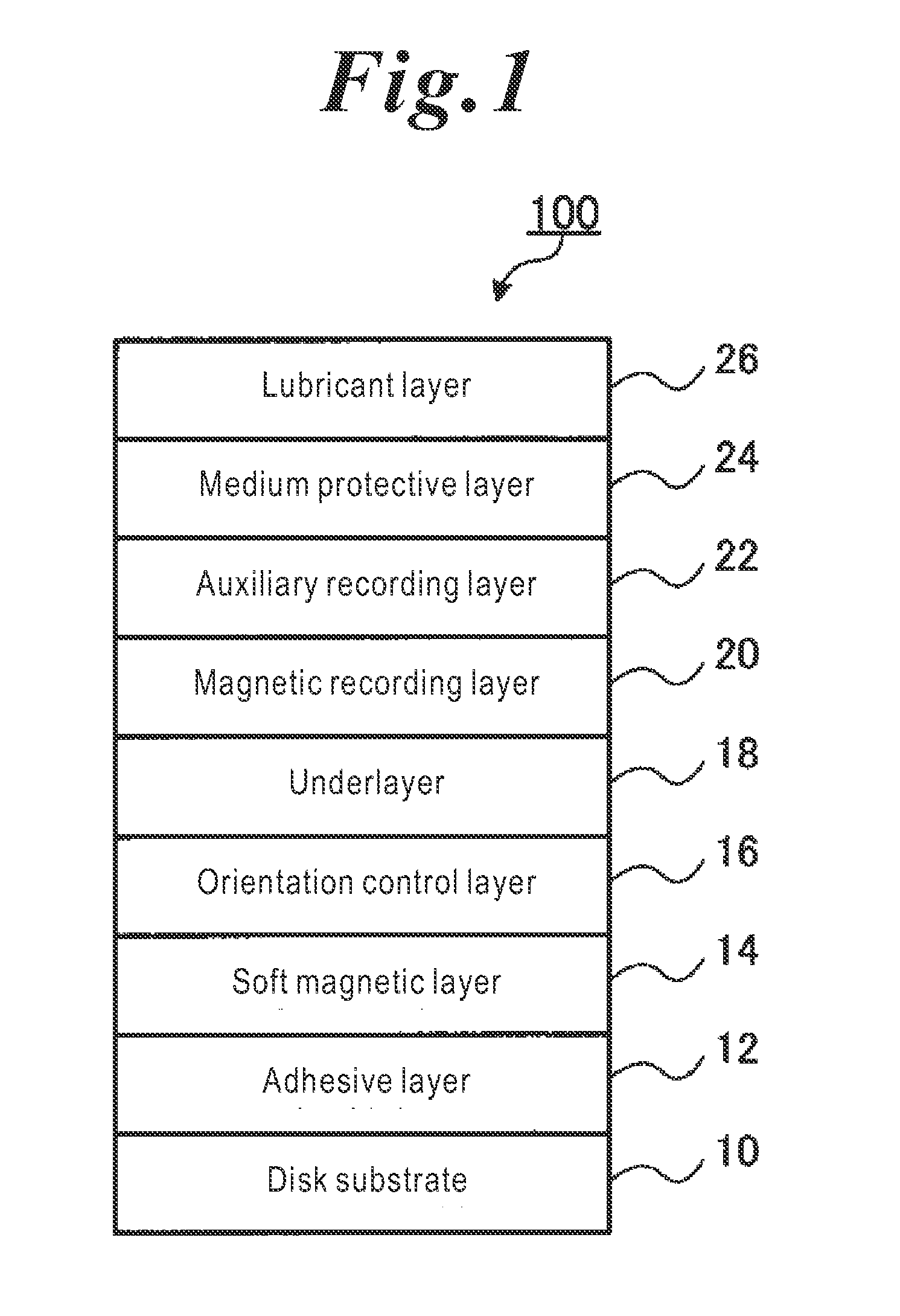

Magnetic disk and method for manufacturing same

ActiveUS8877359B2Reduce noiseImprove recording densityRecord information storageCoating by sputteringOxygenNon magnetic

Owner:WESTERN DIGITAL TECH INC

After-forging grain-refining strength-toughening treatment process of 1Mn18Cr18N steel guard ring for generating set

ActiveCN101255490AReduce intensityFine and uniform grain stateControllabilityUltimate tensile strength

The invention discloses a fine grains strengthening-toughening process after forging a 1Mn18Cr18N steel shroud ring rolling piece for manufacturing a generating set, comprising the steps of: cold pre-deforming and solution heat treating the rough machined 1Mn18Cr18N steel shroud ring rolling piece, and sampling testing the solution heat treating effect. According to the invention, austenitic steel forging piece which is essentially coarse grains and can not refine grains by heat treatment has fine and uniform grains before cold deformation strengthening, thus to greatly improve the strength, plasticity and toughness of the forging piece, as well as strengthen the quality controllability.

Owner:DEYANG WANXIN POWER STATION PROD DEV

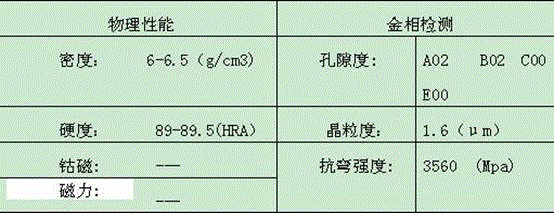

High-strength metal ceramic used for cutting nonferrous metal sheet and preparation method thereof

ActiveCN106756411AHigh hardnessLight weightTransportation and packagingMetal-working apparatusAviationAlcohol

The invention discloses high-strength metal ceramic used for cutting a nonferrous metal sheet and a preparation method thereof. The preparation method includes the following steps that a, original TiC powder, original Mo powder, original Ni powder and NbC powder are taken and ground through a ball milling medium for 48-64 h, and then slurry is obtained, specifically, the average fisher particle size of the original TiC powder is not greater than 1.0 [mu]m, and the mass ratio of the original TiC powder is 44%-46%; the average fisher particle size of the original Mo powder is not greater than 1.0 [mu]m, and the mass ratio of the original Mo powder is 14%-16%; the average fisher particle size of the original Ni powder is not greater than 1.0 [mu]m, and the mass ratio of the original Ni powder is 38%-40%; the average fisher particle size of the NbC powder is not greater than 1.0 [mu]m, and the mass ratio of the NbC powder is 0.8%-1.2%; the ball milling medium comprises hard alloy bar balls and absolute ethyl alcohol, or comprises hard alloy bar balls and No.120 aviation gasoline; b, the slurry obtained through the step a enters a stainless steel container through a stainless steel screen; and c, after the slurry is subjected to standing in the stainless steel container for 24 hours and under the condition that the ball milling medium comprises the hard alloy bar balls and the absolute ethyl alcohol, the absolute ethyl alcohol on the upper layer of the slurry is taken out.

Owner:株洲精特硬质合金有限公司

Preparation method of narrow-hardenability pinion steel

ActiveCN102400052BImprove hardenabilityHardenability improved and stabilizedManufacturing convertersProcess efficiency improvementWear resistanceImpurity

The invention provides a narrow-hardenability pinion steel which comprises the following components in percentage by weight: 0.18%-0.22% of C, 0.20%-0.30% of Si, 0.90%-1.15% of Mn, less than or equal to 0.030% of P, less than or equal to 0.030% of S, 1.00%-1.35% of Cr, 0.04%-0.08% of Ti, 0.004%-0.005% of B, 0.025%-0.038% of W, less than or equal to 11.5*10<-6> of [O], less than or equal to 1.5*10<-6> of [H], 35*10<-6>-45*10<-6> of [N] and the balance of Fe and inevitable impurities. The invention provides a preparation method of the narrow-hardenability pinion steel. The preparation method comprises the following steps: 1) primary smelting based on a top-bottom blowing converter; 2) ladle deoxidizing and alloying; 3) LF (ladle furnace) refining; 4) RH refining; and 5) continuous casting. Compared with the prior art, the narrow-hardenability pinion steel provided by the invention has the characteristics of better wear resistance and high temperature resistance, higher hardenability andnarrower jominy hardenability.

Owner:WANGUAN SMELTING MOLD CASTING

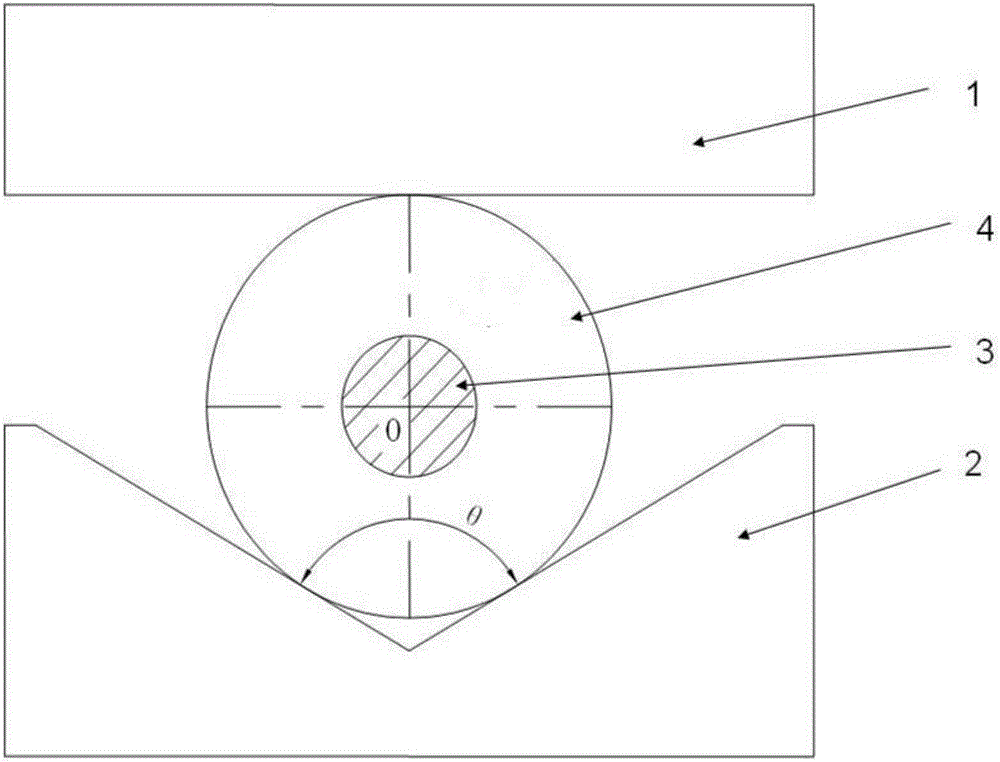

V-anvil with flat upper layer dabber swaging and turning method

InactiveCN106825375AImprove the circumferenceImprove uniformityForging/hammering/pressing machinesEngine componentsReduction rateTurn angle

The invention discloses a method for elongating and turning over a mandrel with an upper flat and a lower V anvil. The divergence angle η of the large deformation zone is determined according to the reduction rate ΔH and the V anvil angle θ; there are two strong zones and one weak zone under the flat anvil, and a reasonable overturning process should give full play to the single anvil reduction effect so that the strong and weak zones can be reasonably matched. The deformation of the outer layer of the forging is equivalent to the deformation of the layer near the mandrel, thereby improving the uniformity of the overall deformation of the forging, so the theoretical flip angle ω should be η / 2; after rounding the number of flips n, it can be changed from 360° / n Obtain the actual flip angle ω t ; Considering that the deformation uniformity and compaction effect are poor during sequential turning, n turning should be divided into multiple groups for pressing, and each group is pressed symmetrically along the circumference. The flipping method of the invention can significantly improve the deformation uniformity in the circumferential and radial directions of the circular section of the forging, and improve the compaction effect of the forging.

Owner:TSINGHUA UNIV

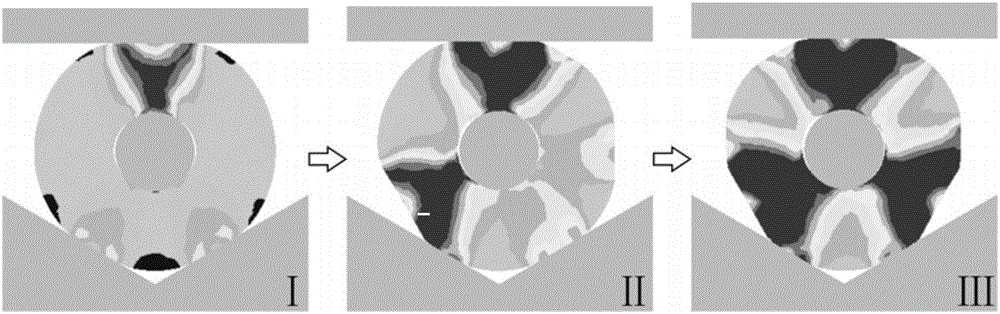

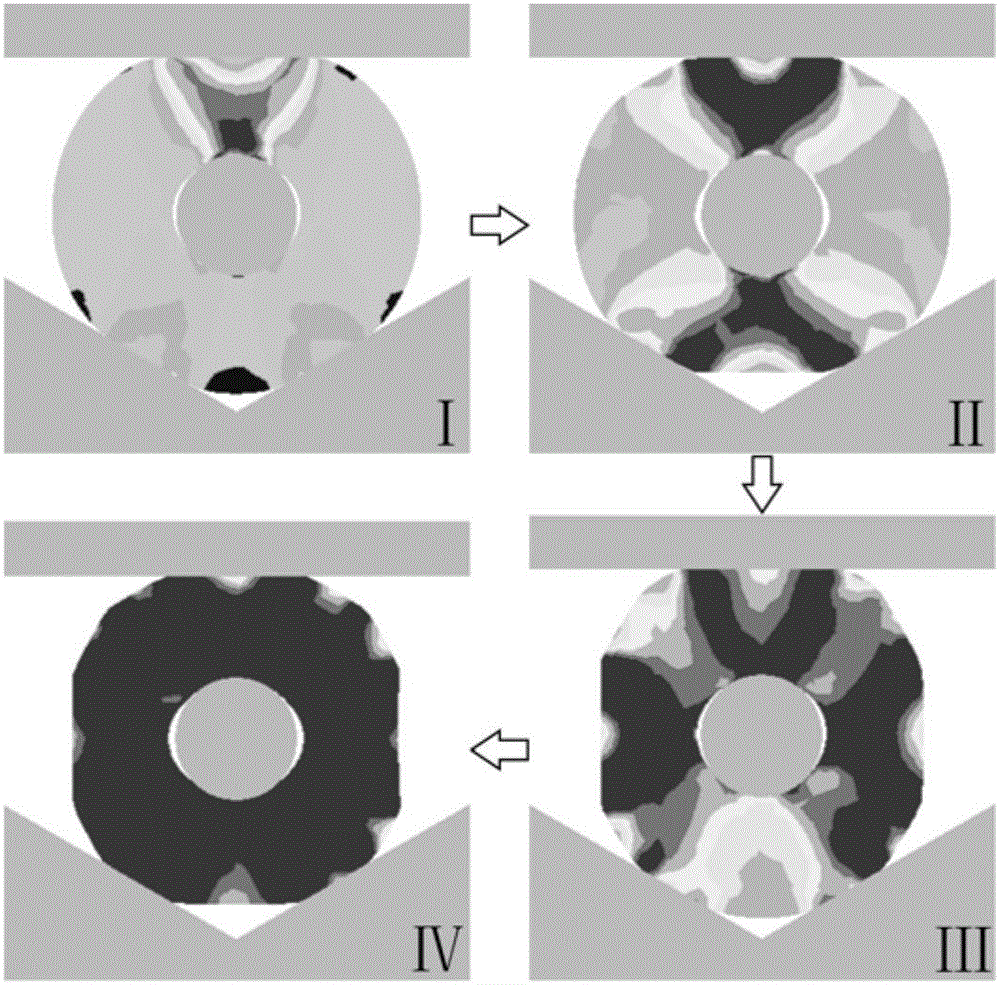

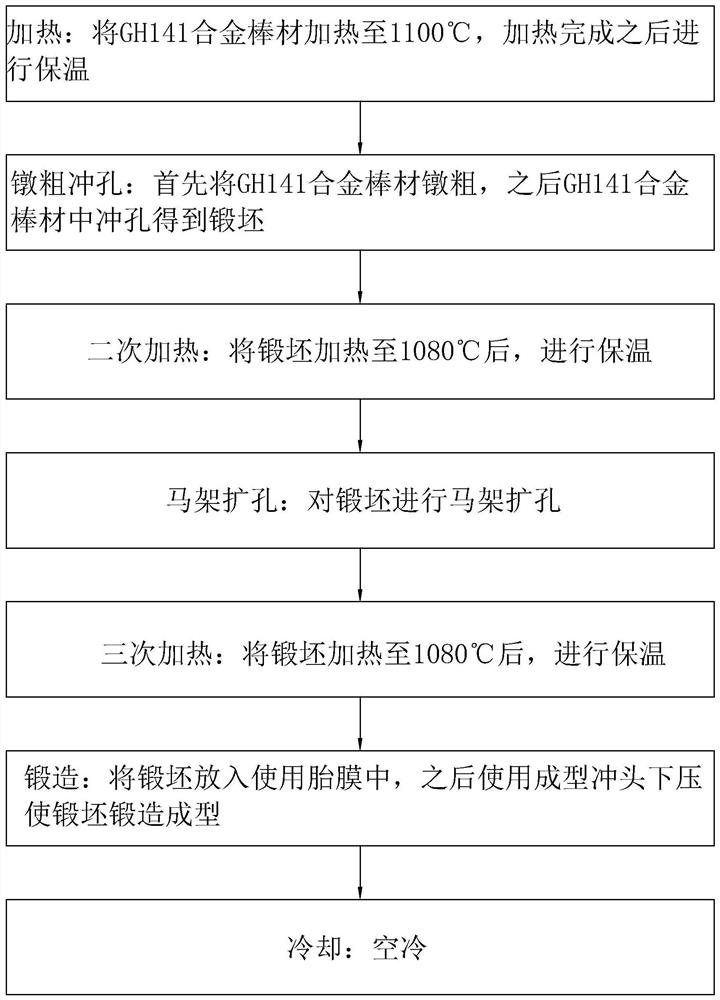

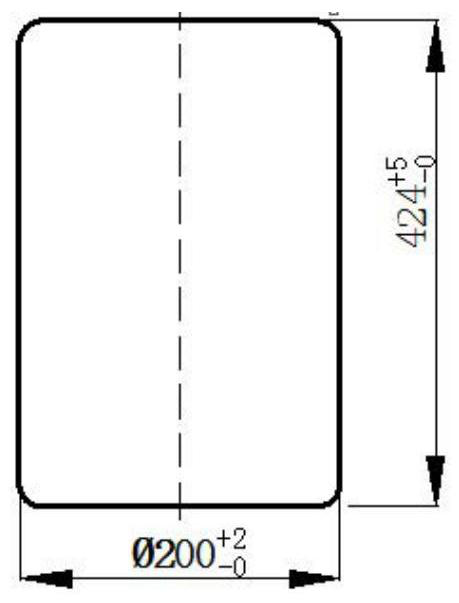

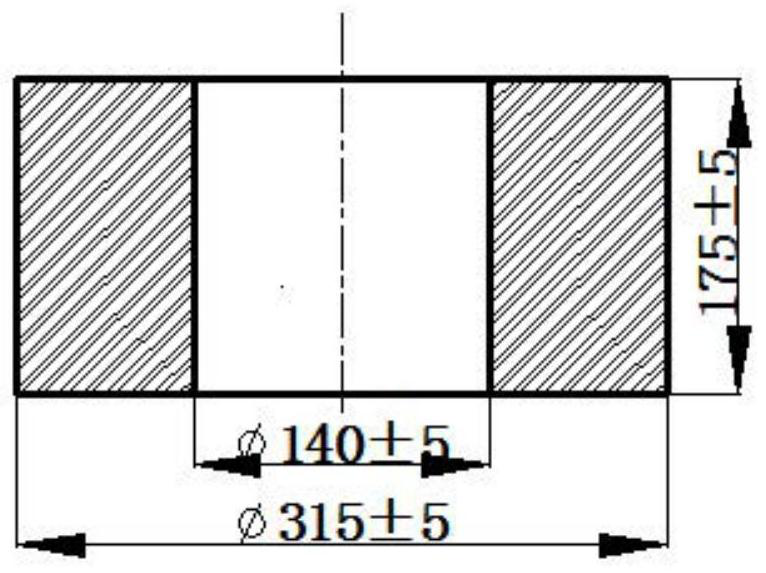

Forging method achieving uniformity of crystal particles of GH141 abnormally-shaped annular forged piece

InactiveCN111659846AImprove mixed crystal defectsIncrease profitMetal-working apparatusEngine componentsPunchingEngineering

The invention discloses a forging method achieving the uniformity of crystal particles of a GH141 abnormally-shaped annular forged piece, and belongs to the technical field of forging technologies. According to the technical scheme, the forging method is characterized by comprising the following steps that S1, heating is conducted, specifically, a GH141 alloy bar is heated to enable the temperature to be 1100 DEG C, and heat preservation is conducted after heating is accomplished; S2, upsetting operation and punching operation are conducted, specifically, the GH141 alloy bar is subjected to upsetting operation, and then the GH141 alloy bar is subjected to punching operation, so that a forged blank is obtained; S3, heating is conducted for the second time, specifically, after the forged blank is heated to enable the temperature to be 1080 DEG C, heat preservation is conducted; S4, mandrel supporter hole enlarging operation is conducted, specifically, the forged blank is subjected to mandrel supporter hole enlarging operation; S5, heating is conducted for the third time, specifically, after the forged blank is heated to enable the temperature to be 1080 DEG C, heat preservation is conducted; S6, forging is conducted, specifically, the forged blank is put into a used blank membrane (2), and then a forming punch (1) is utilized to downwards press the forged blank so that the forgedblank can be forged and formed; and S7, cooling operation is conducted, specifically, air cooling operation is conducted. The forging method has the advantage that the degree of the uniformity of thecrystal particles of the GH141 abnormally-shaped annular forged piece is improved.

Owner:WUXI PAIKE HEAVY CASTING & FORGING

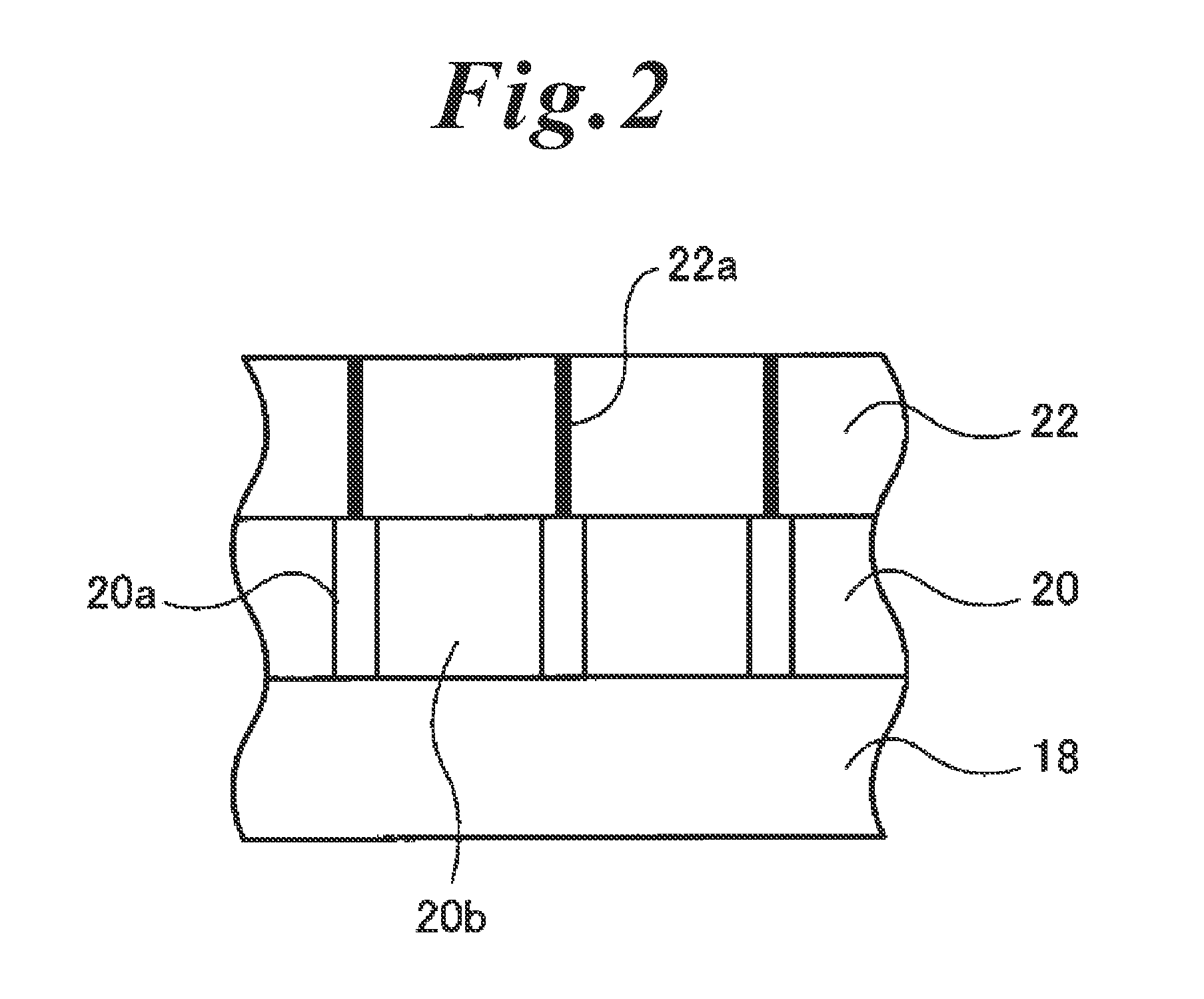

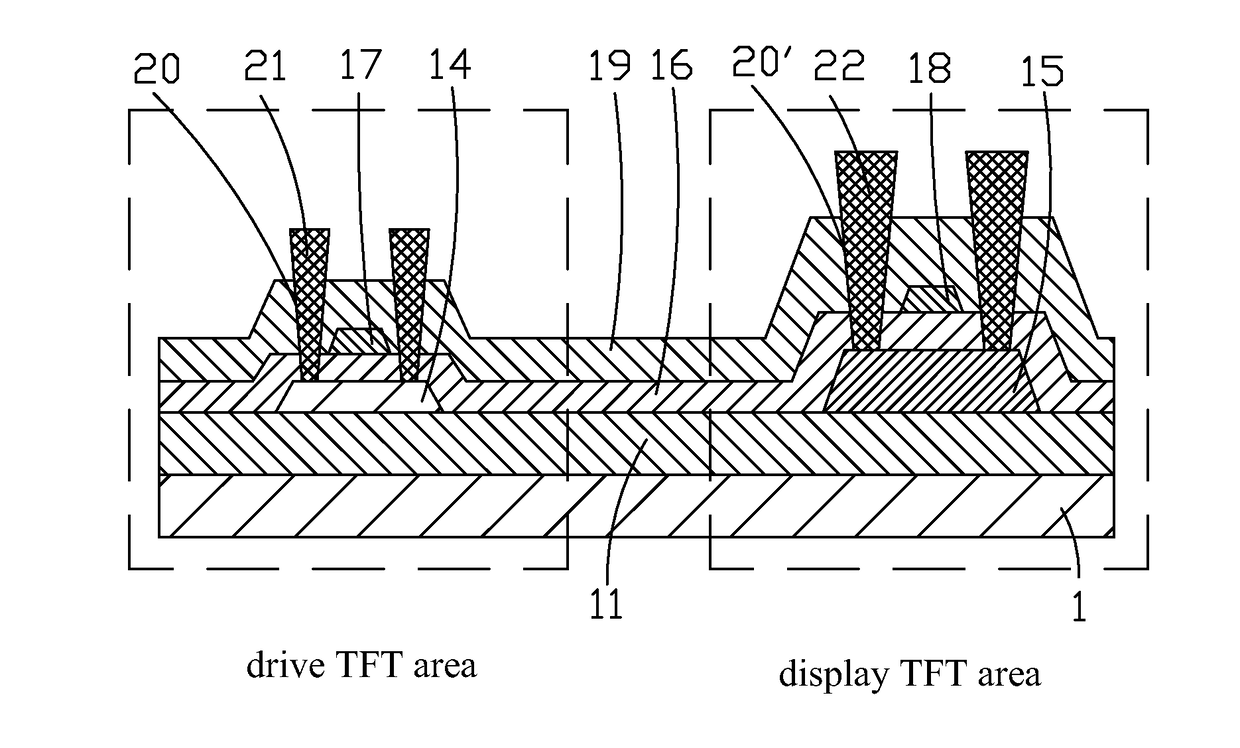

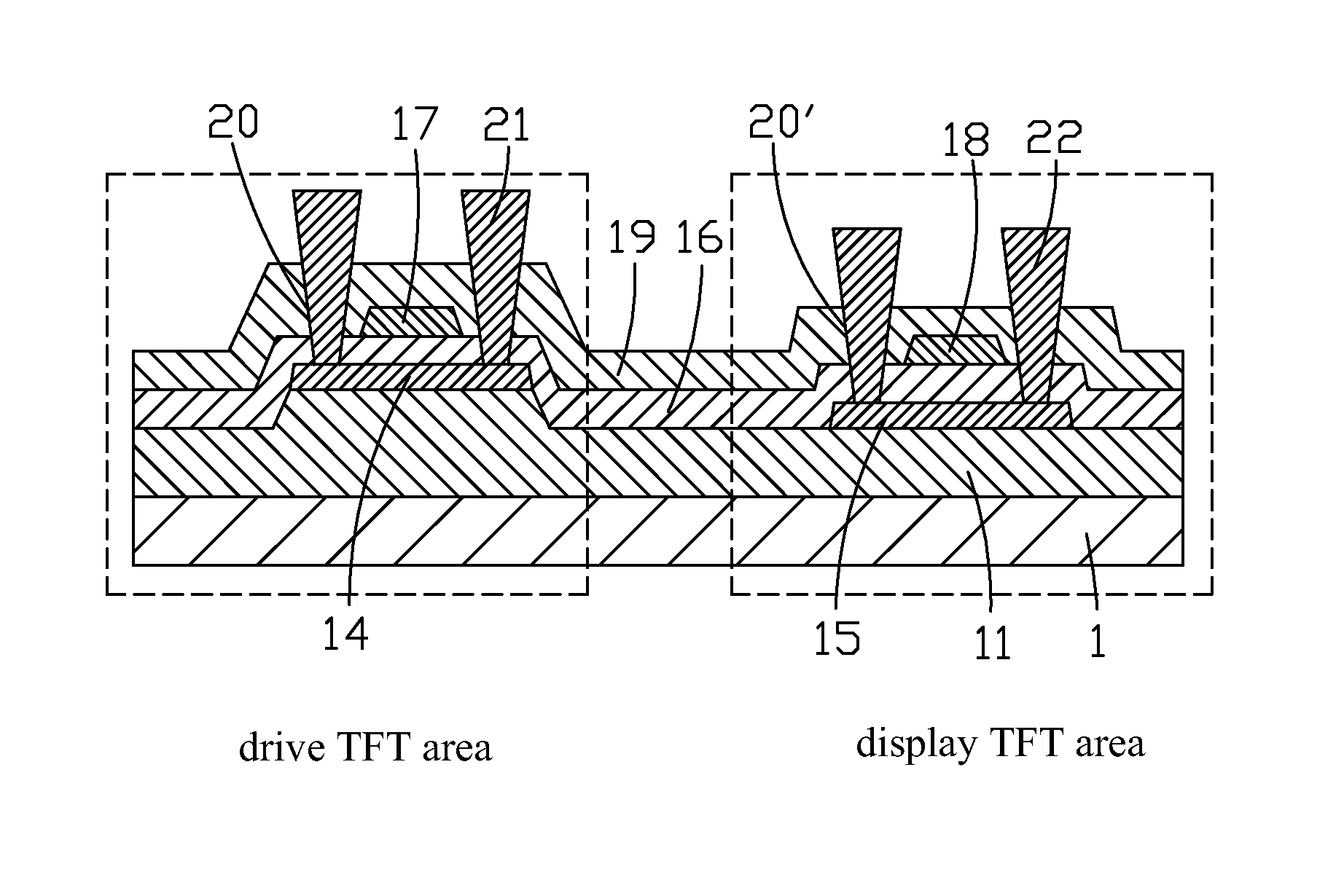

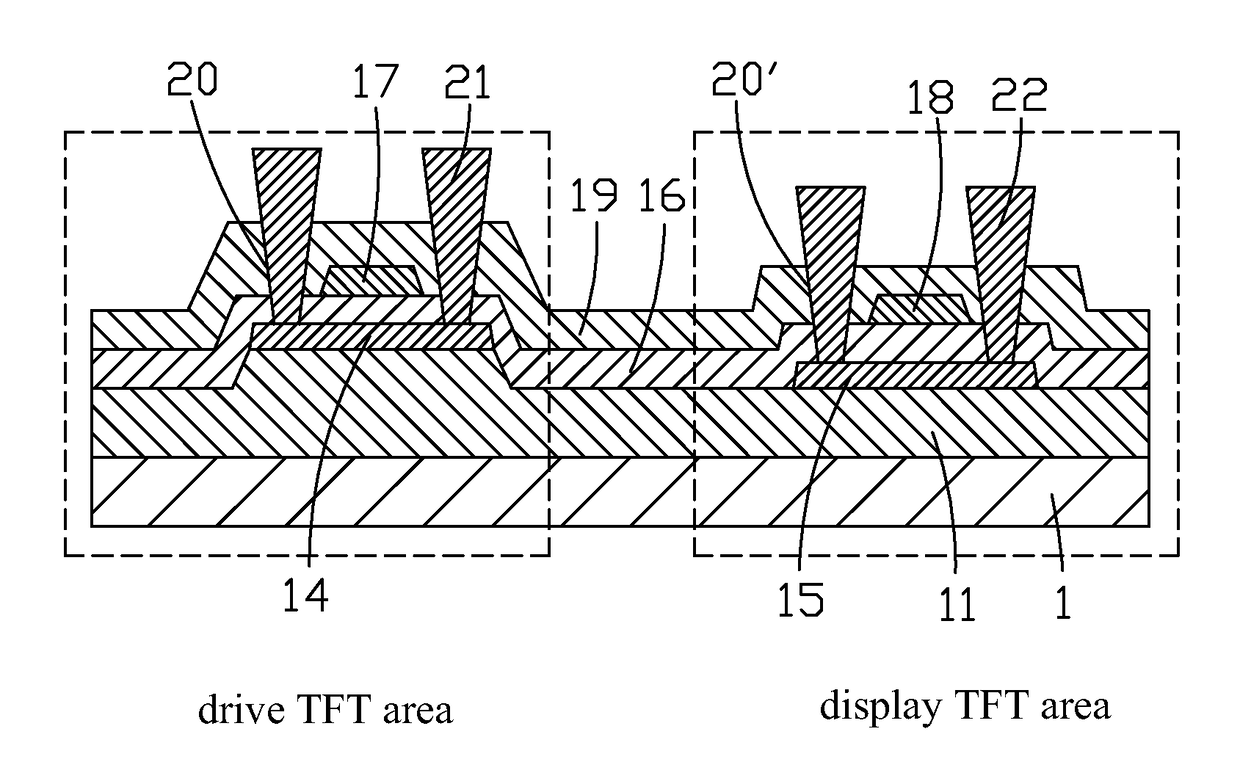

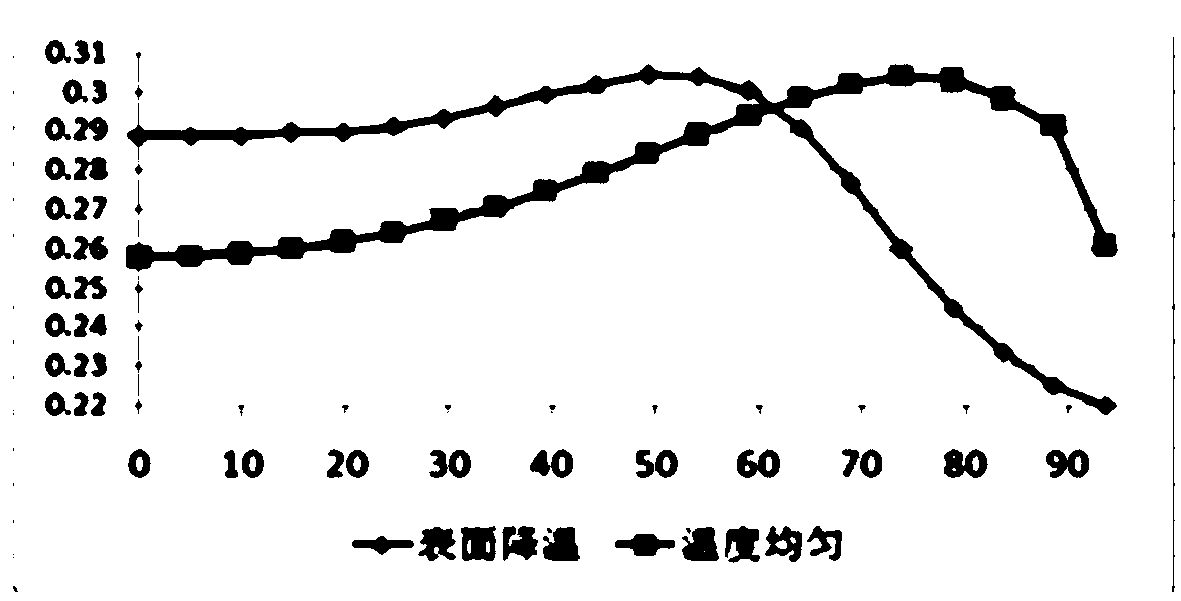

Low temperature poly-silicon TFT substrate structure and manufacture method thereof

InactiveUS20170098667A1High electron mobilityImprove uniformityTransistorSolid-state devicesCrystalliteElectron mobility

The present invention provides a Low Temperature Poly-silicon TFT substrate structure and a manufacture method thereof. By providing the amorphous silicon layers in the drive TFT area and the display TFT area with different thicknesses, of which the thickness of the amorphous silicon layer in the drive TFT area is smaller, and the thickness of the amorphous silicon layer in the display TFT area is larger, and thus, in the Excimer Laser Annealing process, different crystallization results are generated with the amorphous silicon layers in the drive TFT area and the display TFT area under the function of the laser with the same energy to achieve the control to the grain diameters of the crystals. The polysilicon layer with larger lattice dimension is formed in the drive TFT area in the crystallization process to raise the electron mobility. The fractured crystals of polysilicon layer in the display TFT area can be obtained in the crystallization process for ensuring the uniformity of the grain boundary and raising the uniformity of the current. Accordingly, the electrical property demands for the different TFTs can be satisfied to raise the light uniformity of the OLED.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

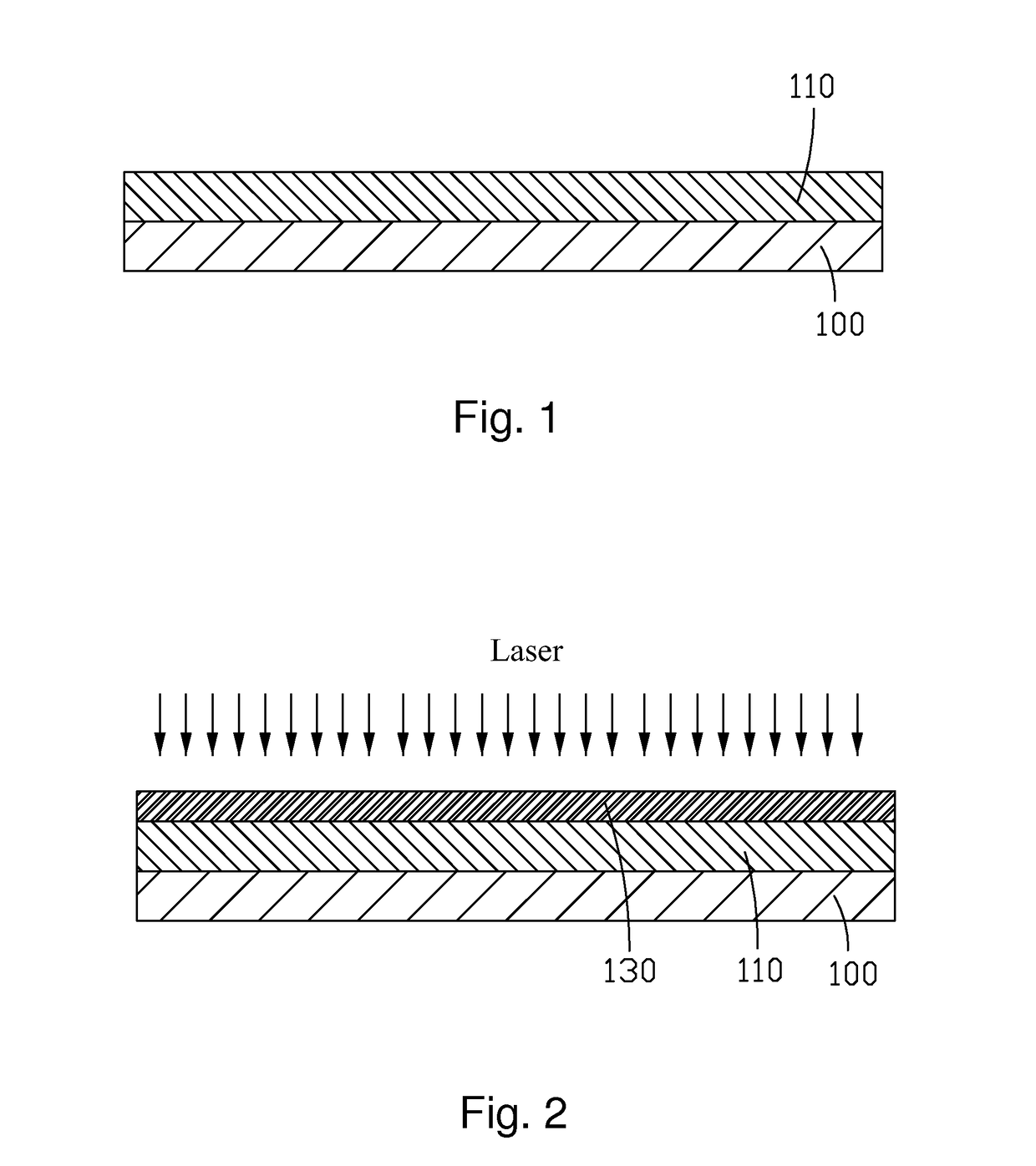

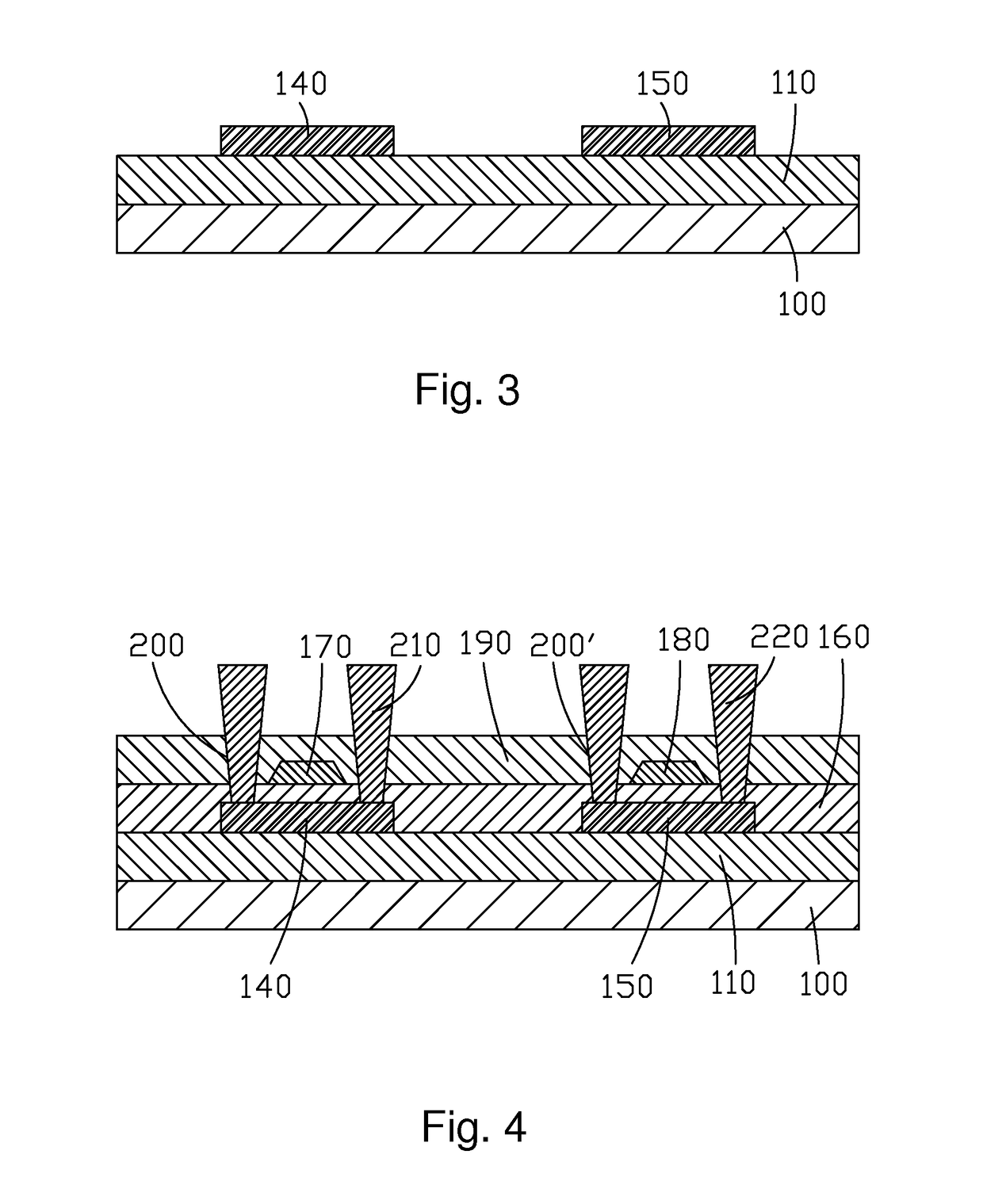

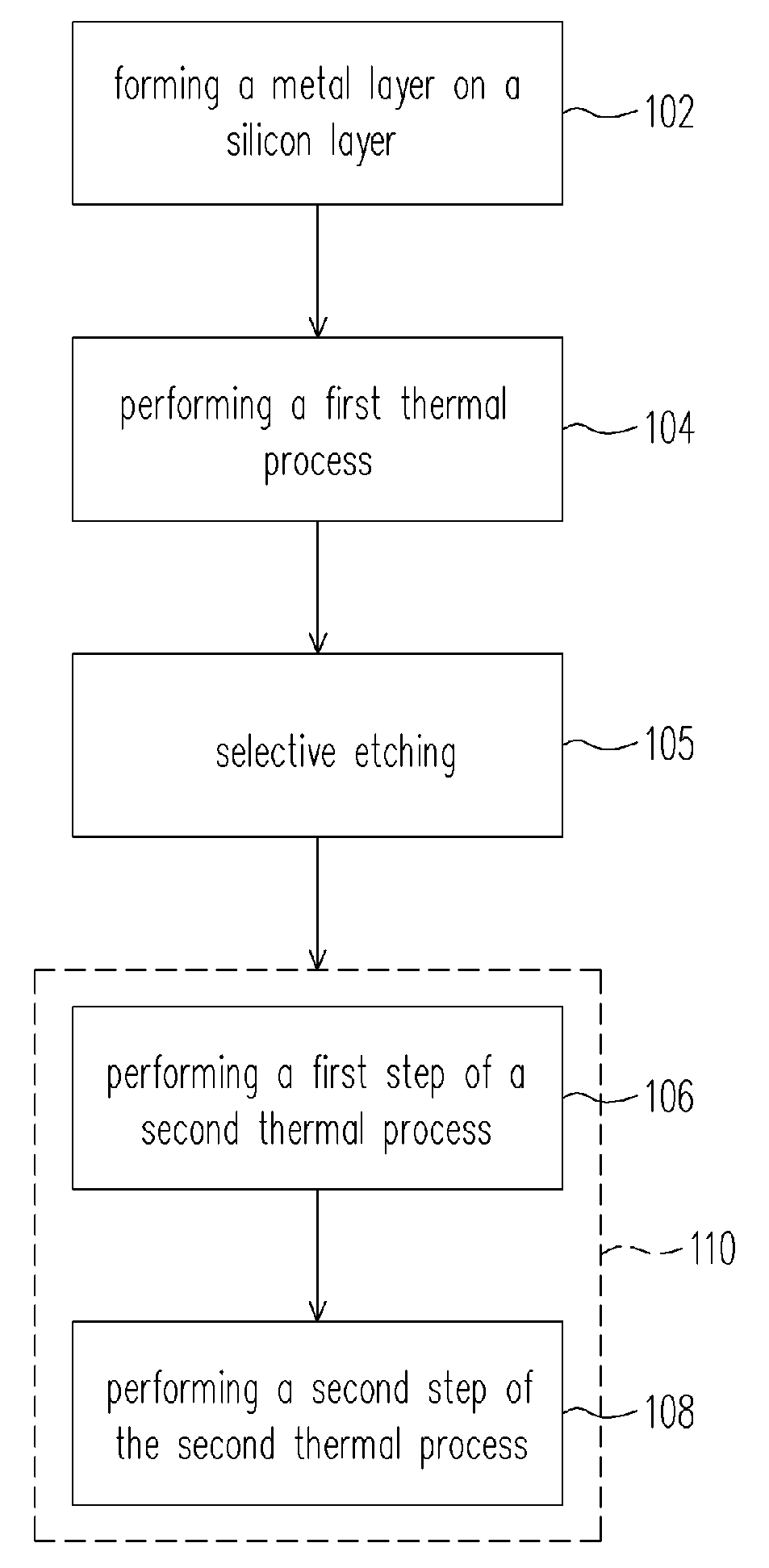

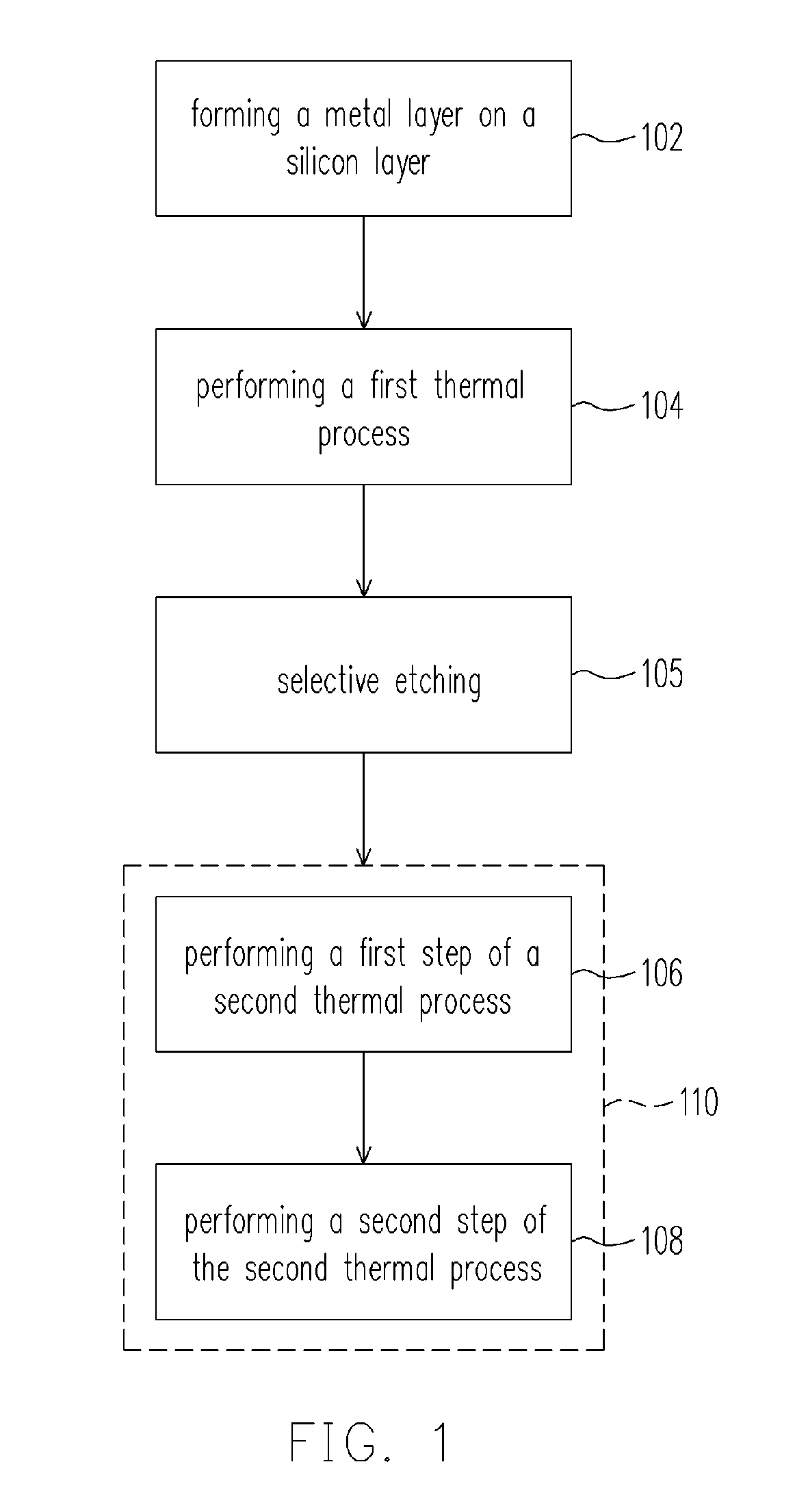

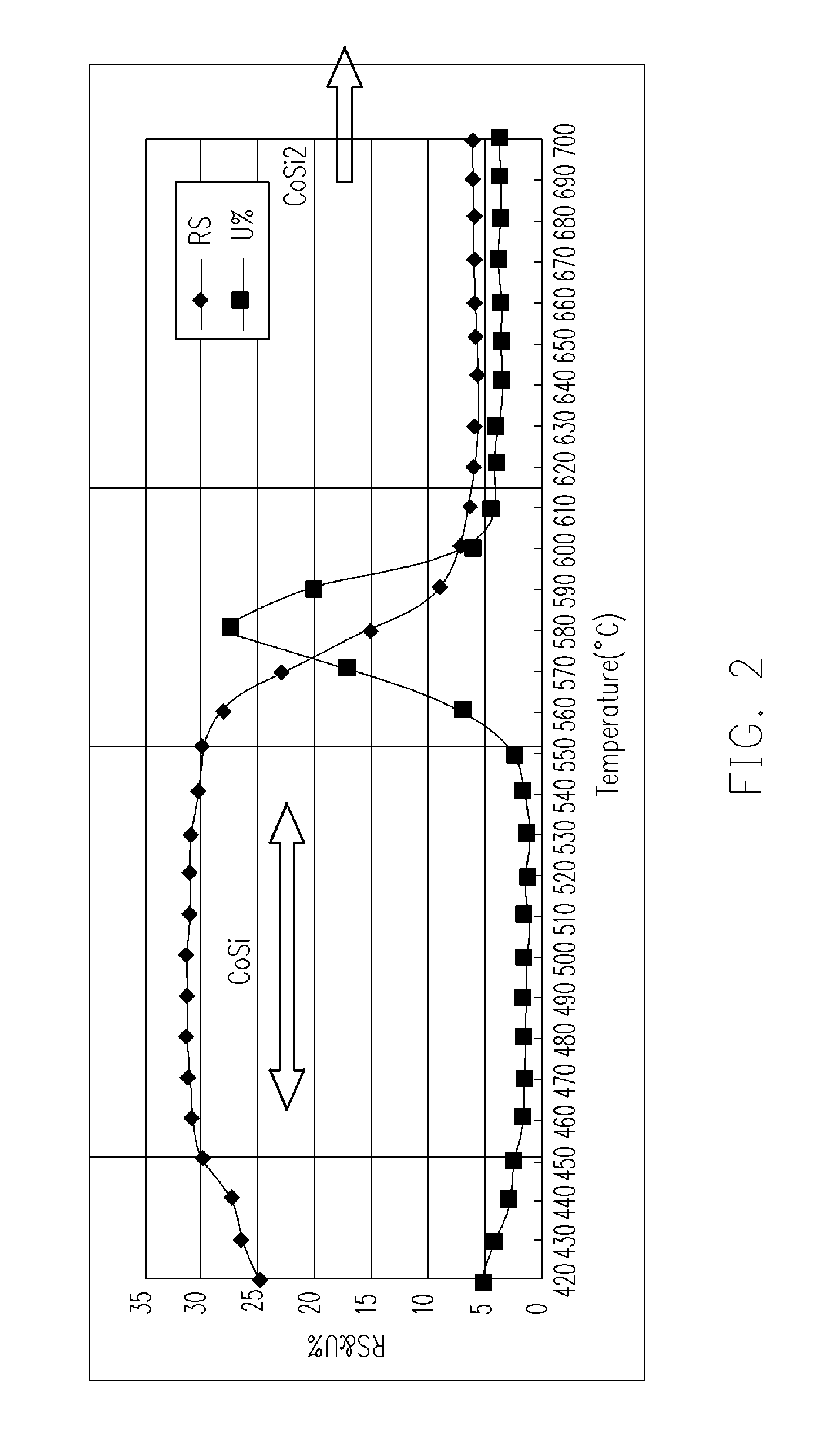

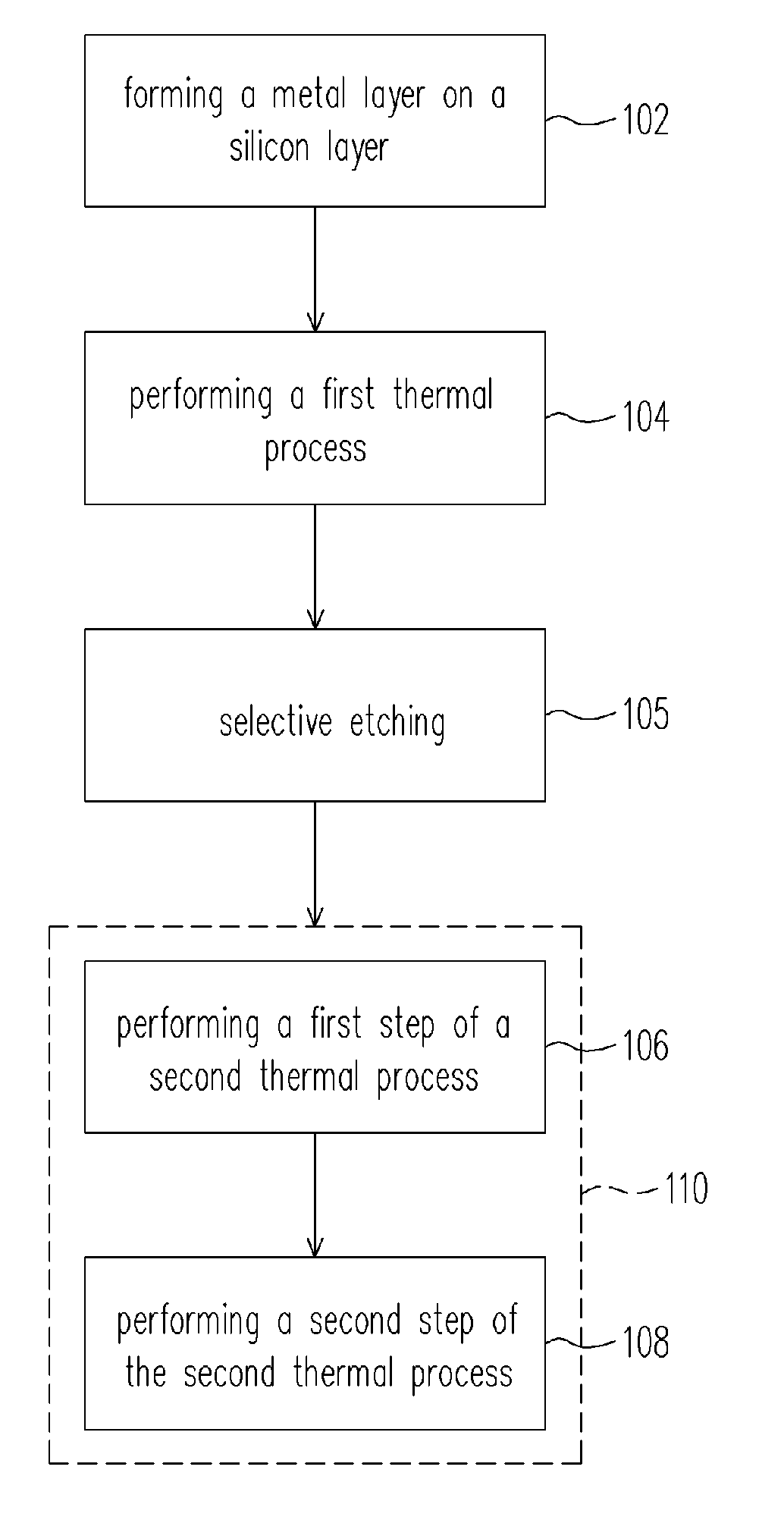

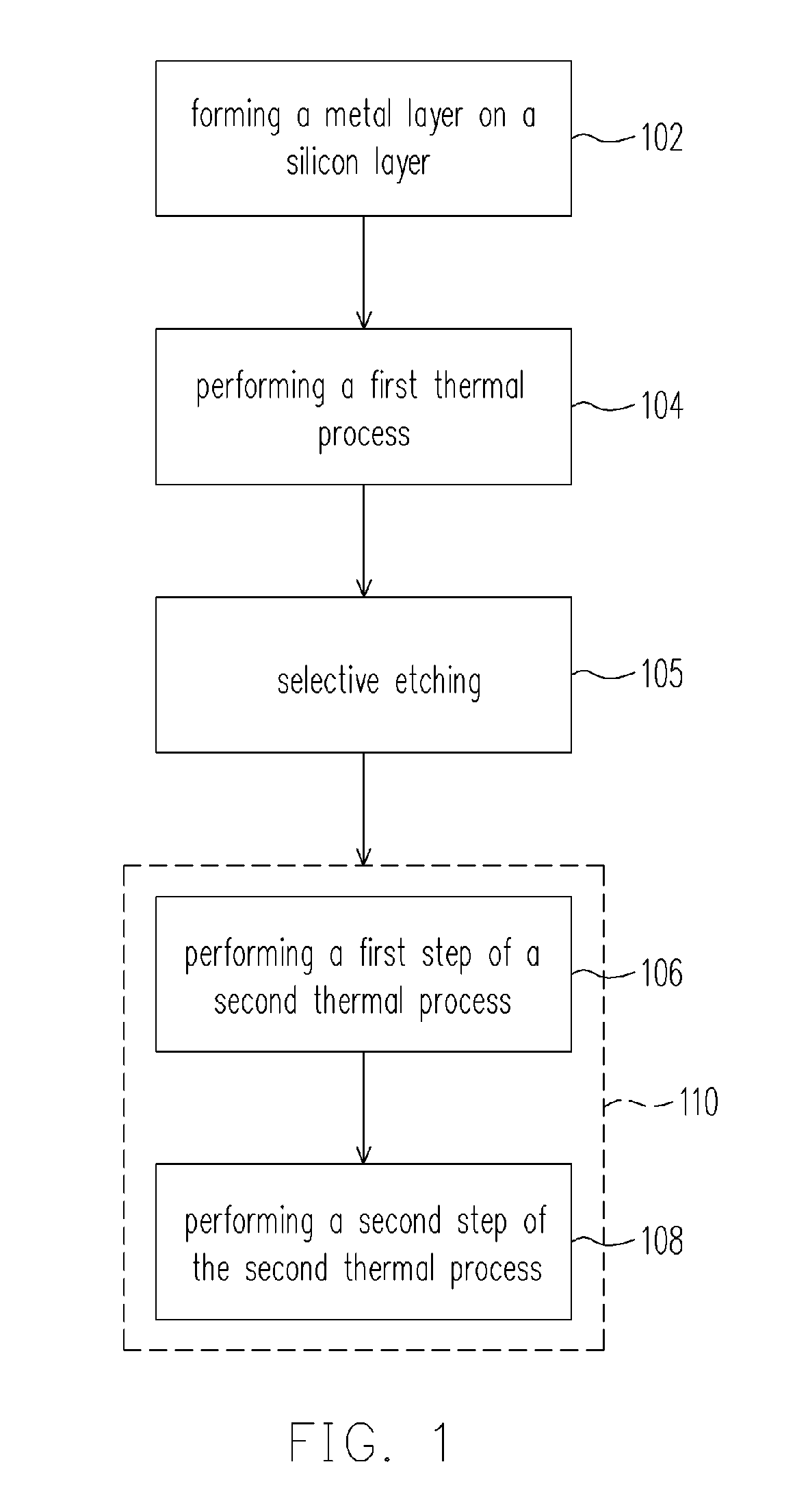

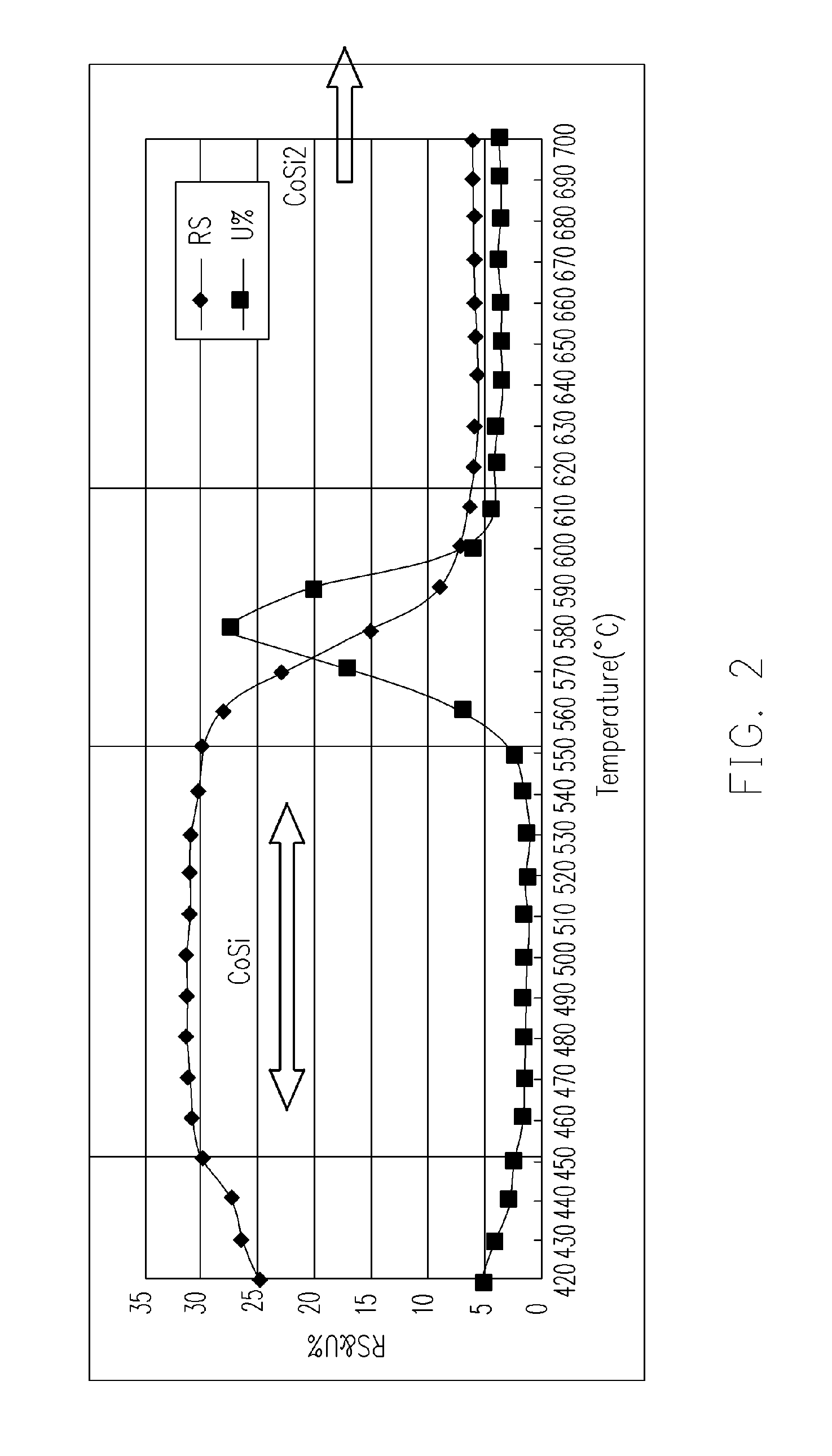

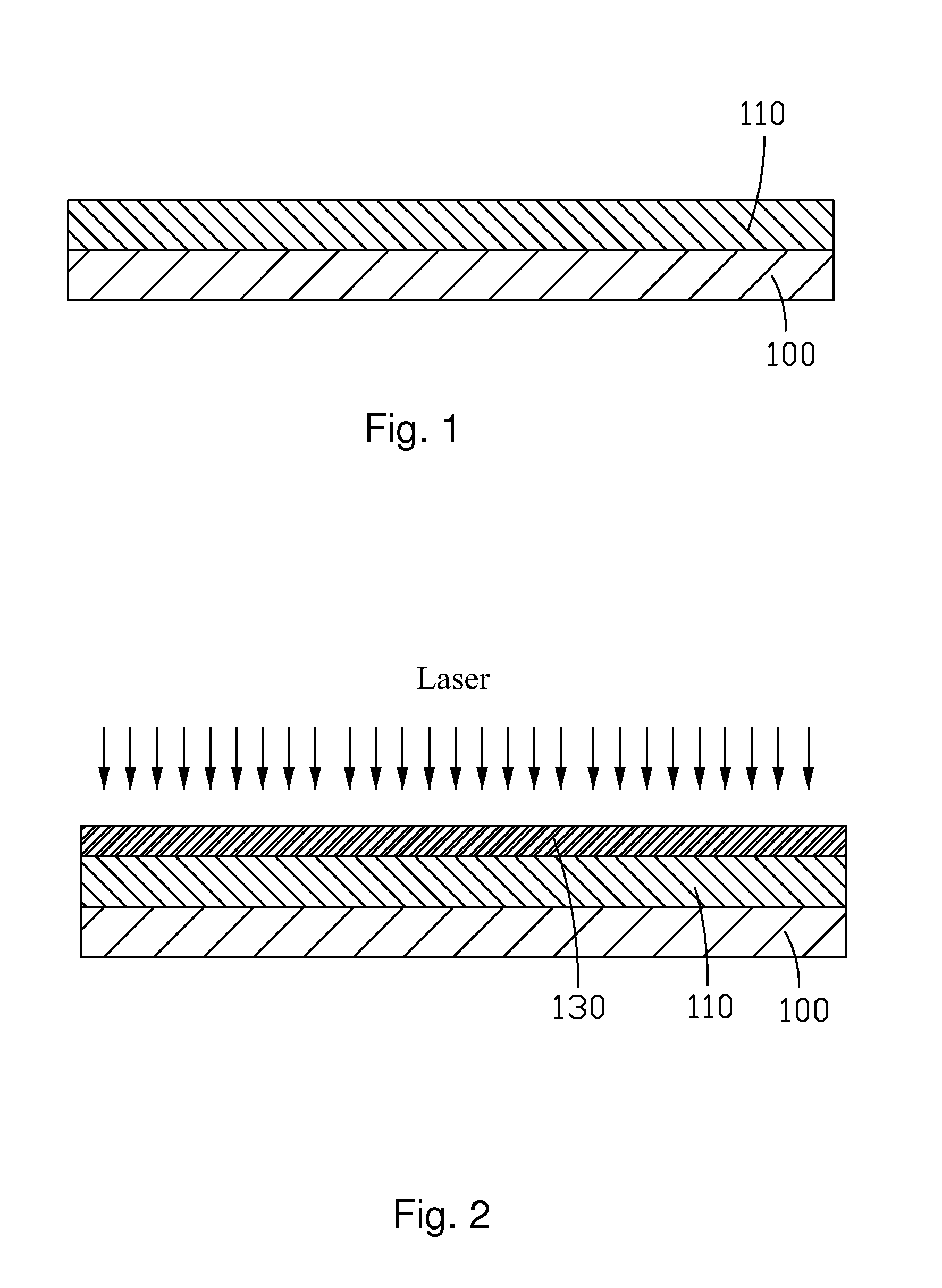

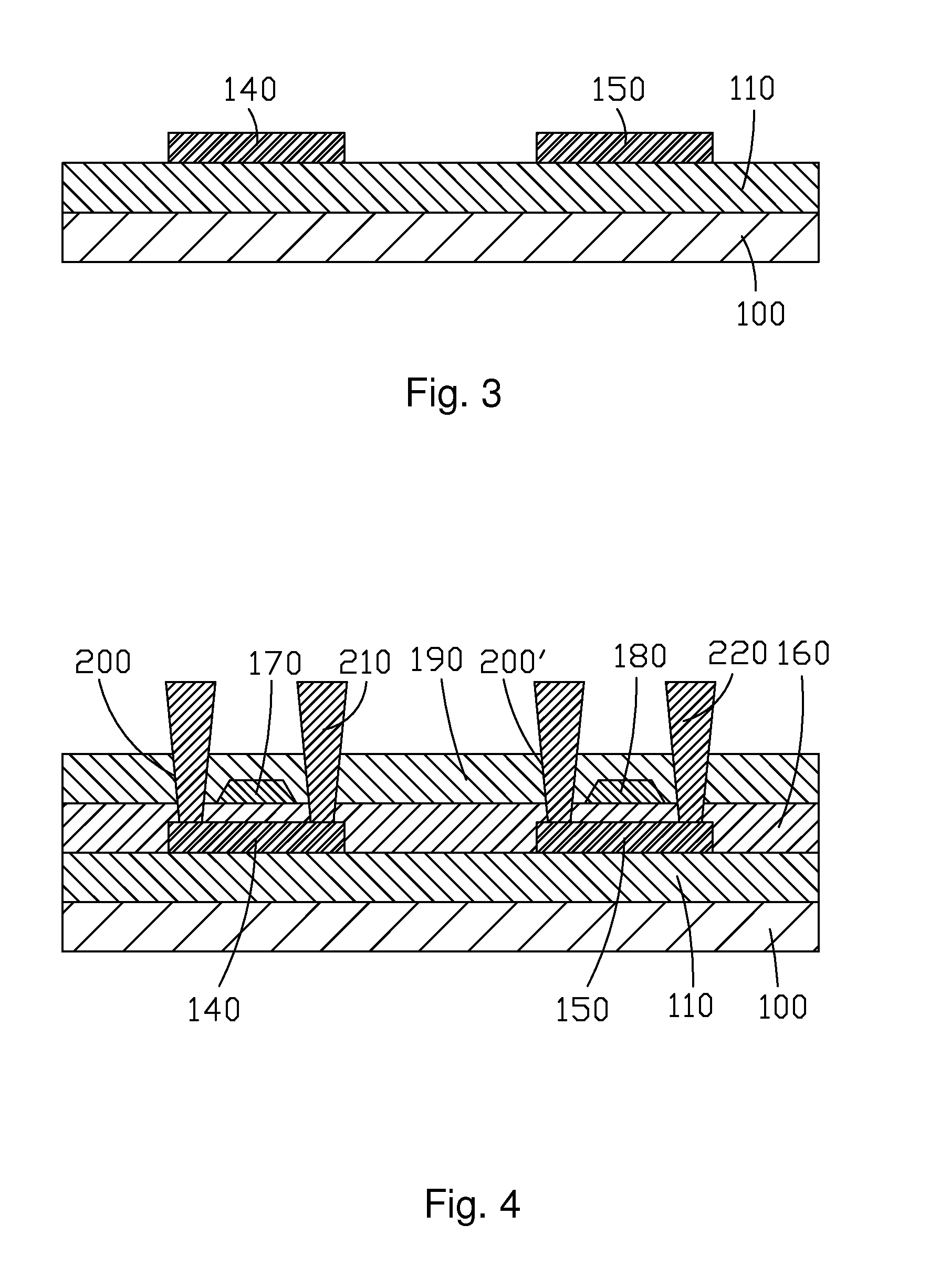

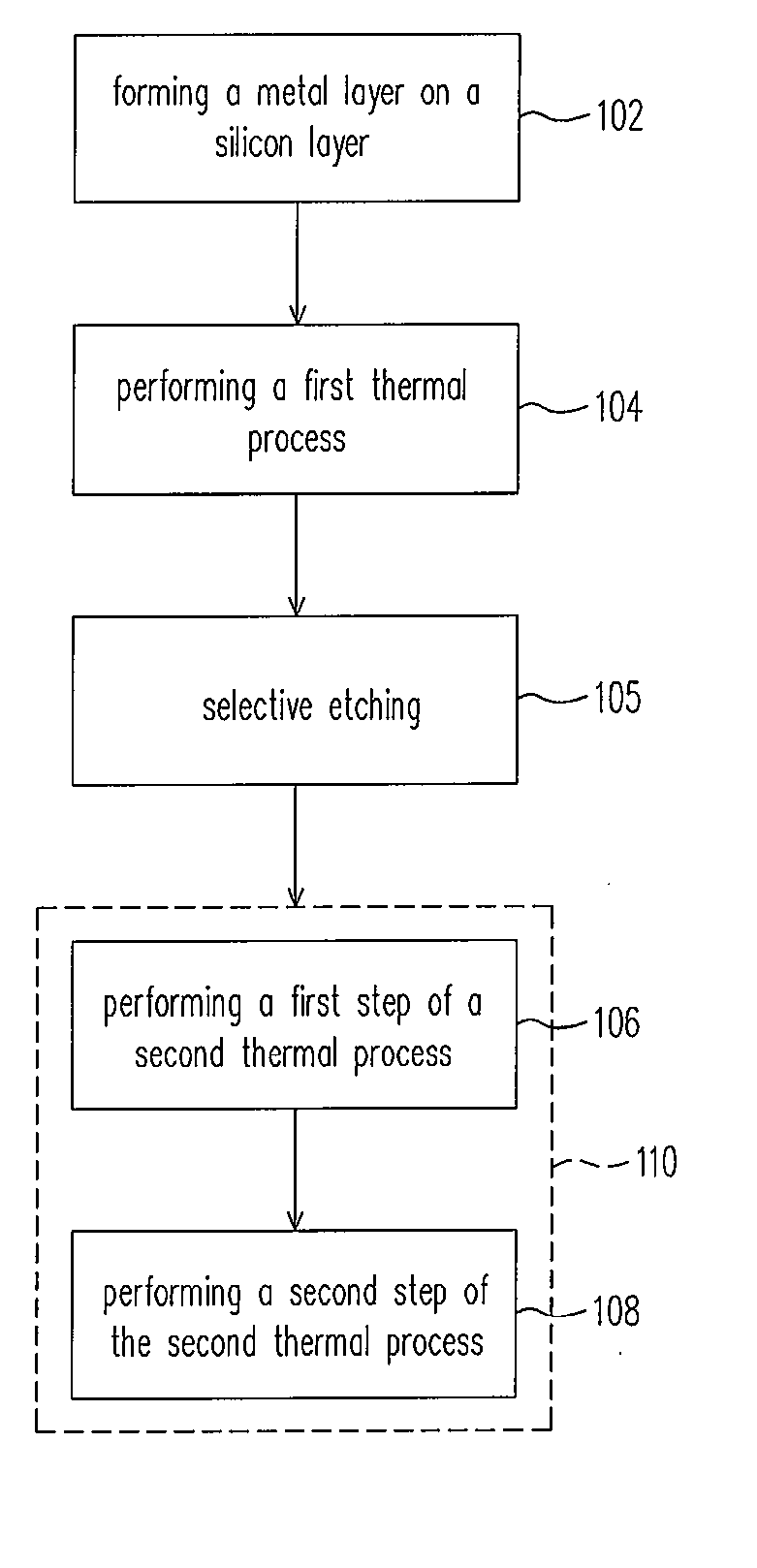

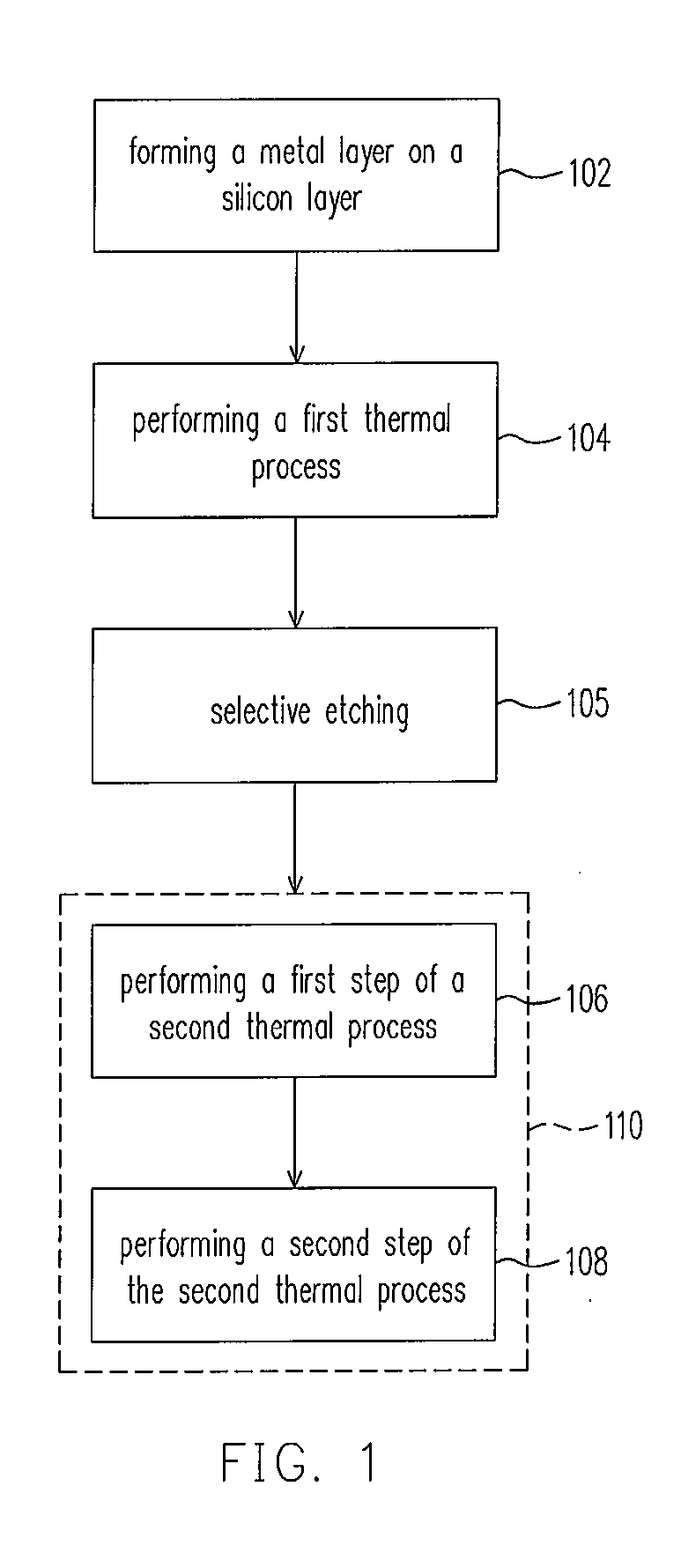

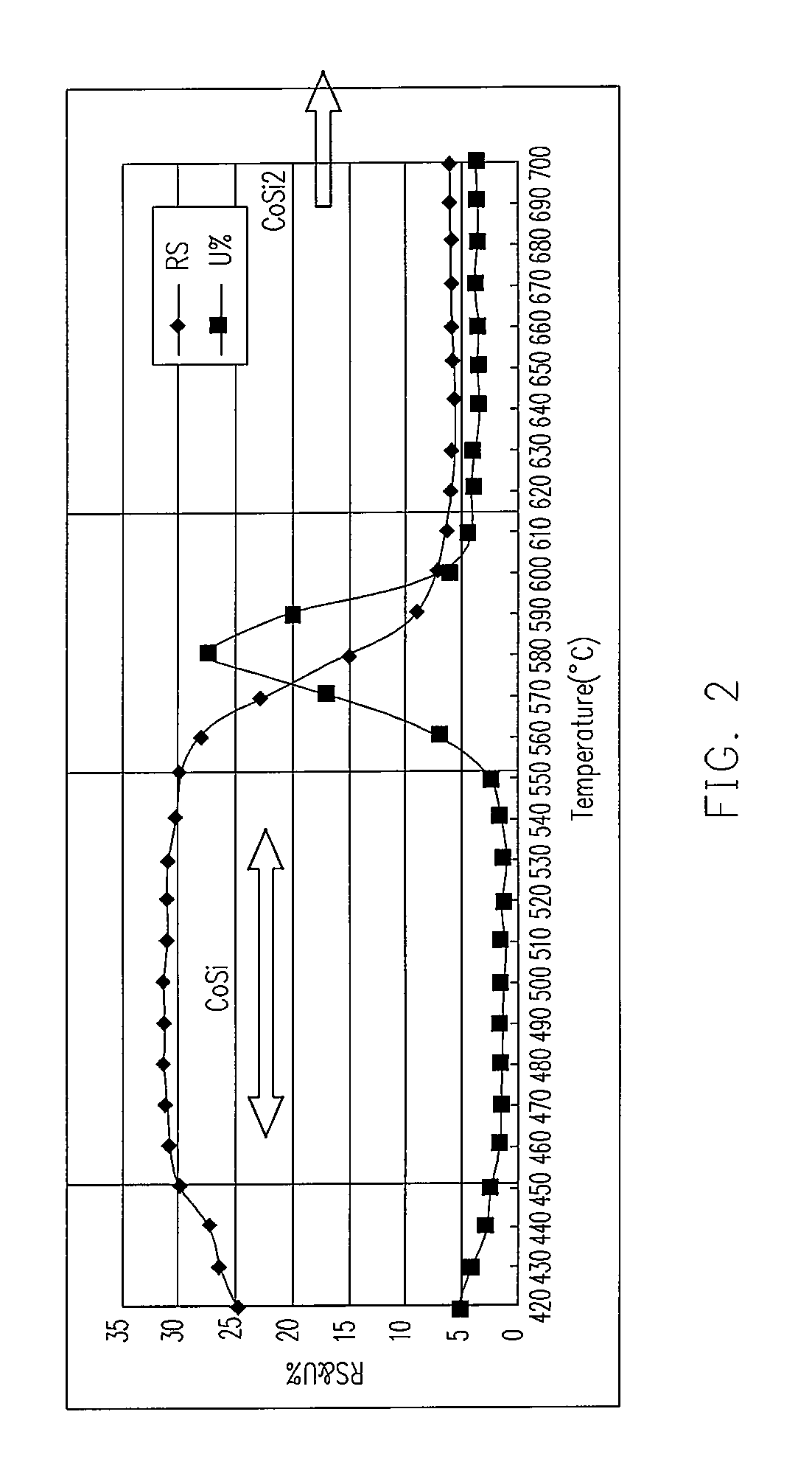

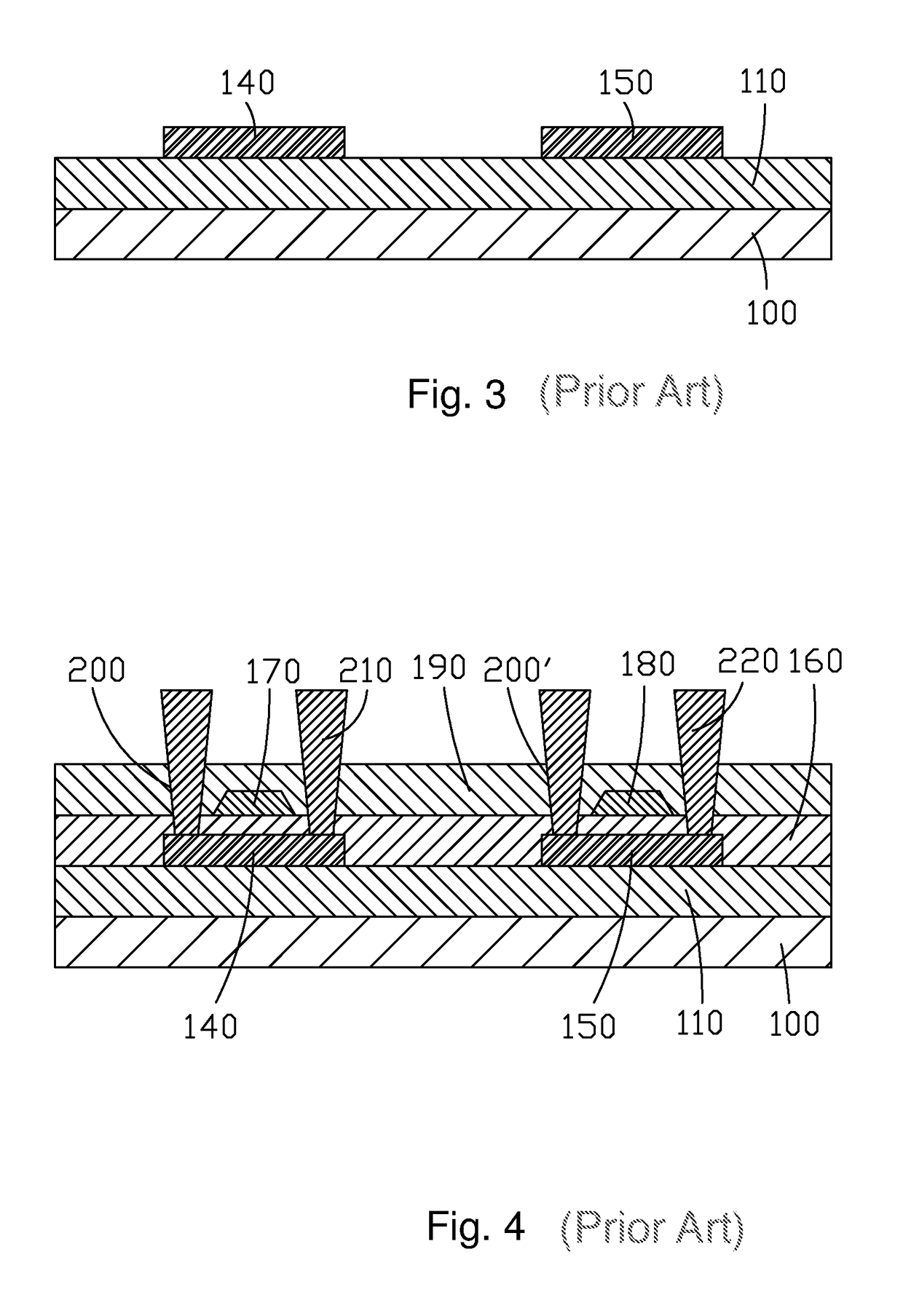

Salicide process

ActiveUS7238611B2Avoid roughnessImprove grain uniformitySemiconductor/solid-state device manufacturingSemiconductor devicesPlatinumSalicide

A salicide process is provided. A metal layer selected from a group consisting of titanium, cobalt, platinum, palladium and an alloy thereof is formed over a silicon layer. A first thermal process is performed. Next, a second thermal process is performed, wherein the second thermal process includes a first step performed at 600˜700 degrees centigrade for 10˜60 seconds and a second step performed at 750˜850 degrees centigrade for 10˜60 seconds. If the metal layer is selected from a group consisting of nickel and an alloy thereof is formed on a silicon layer, the first step of the second thermal process is performed at 300˜400 degrees centigrade for 10˜60 seconds and the second step of the second thermal process is performed at 450˜550 degrees centigrade for 10˜60 seconds.

Owner:MARLIN SEMICON LTD

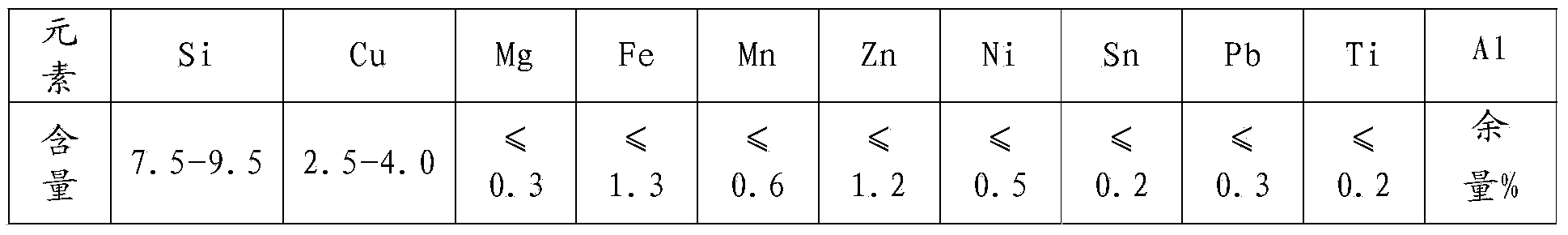

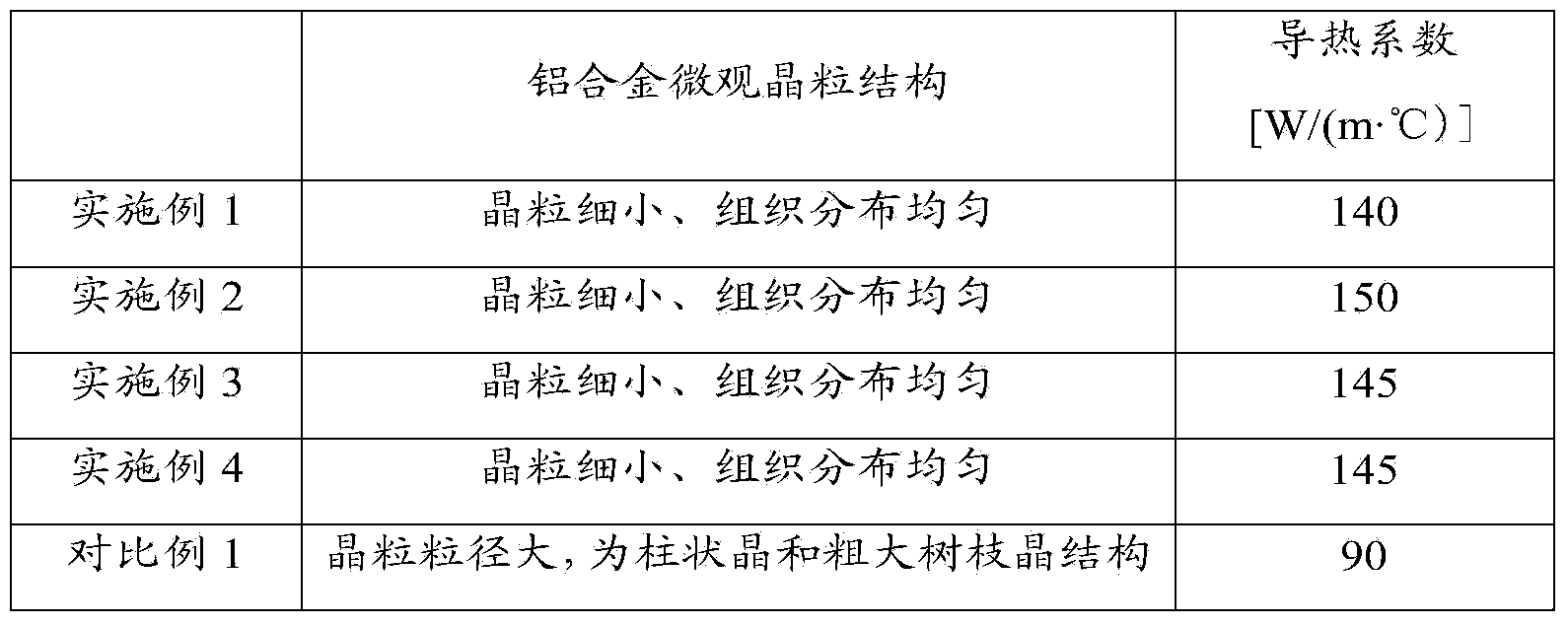

Aluminum alloy and preparation method thereof

The invention relates to the field of aluminum alloy manufacturing, and particularly relates to an aluminum alloy and a preparation method thereof. The preparation method of the aluminum alloy comprises the following steps: (A) injecting first molten aluminum with a pressure of 0.6-0.8 MPa and a temperature of 630-650 DEG C into a cooling model at a temperature of 10-25 DEG C to cool, so that a first semisolid blank is formed; (B) after the first semisolid blank is turned, putting the obtained substance into second molten aluminum at a temperature of 650-680 DEG C to stir, so that second semisolid slurry is obtained; and (C) feeding the second semisolid slurry into an injection chamber, so that a product is obtained. Compared with common die casting methods in the prior art, the preparation method of the aluminum alloy disclosed by the invention can obtain fine grain structures without the addition of a grain refiner, and structures of columnar crystals and oversize dendrites in traditional casting are eliminated, so that products are uniform in grain and better in effect, and the moulding temperature of the products is about 100 DEG C lower than the temperature of common die casting materials.

Owner:FUJIAN KINRUI HIGH TECH CO LTD

Honey paste processing technology

The invention belongs to the technical field of honey processing and provides a honey paste processing technology. The technology comprises (1) preparing a liquid seed crystal, (2) preparing a solid seed crystal, (3) preparing a raw material seed crystal, (4), carrying out mixing, (5) carrying out pulsed laser processing and (6) carrying out vacuuming. Through use of the raw material seed crystalsprepared from the liquid and solid seed crystals, adjustment of parameters such as moisture content, a crystallization temperature and a mass ratio in the preparation of liquid and solid seed crystals and use of pulsed laser and photothermal conversion, the solution close to a light focus is instantaneously evaporated and the honey is concentrated. Simultaneously, a shock wave is generated to partially shake the honey liquid and promote the formation of a crystallization nucleus, thereby improving the crystal grain uniformity and the delicateness and optimizing the honey quality. The honey paste has a thick and pure taste and satisfies the market demands.

Owner:MINGGUANG HAOHAO BEES

Manufacture method for large-size 5N high-purity aluminum target material

ActiveCN110328237AImprove grain uniformitySimple processTemperature control deviceMeasuring devicesCooling curveTemperature curve

The invention relates to a manufacture method for a large-size 5N high-purity aluminum target material. When large-size 5N high-purity aluminum is rolled to a certain thickness, in the width direction, temperatures, ranging from T1 to Tn, of rollers are detected every 100 mm to 300 mm, or temperatures of the 5N high-purity aluminum target material are detected every 100 mm to 300 mm in the width direction; and according to the temperature curve chart, a specific working roller cooling curve is set, uniformity of the rolling temperature of the rollers and the 5N high-purity aluminum target material can be ensured in the subsequent rolling pass process, and therefore uniformity, in the width direction, of the large-size 5N high-purity aluminum target material is ensured. The large-size 5N high-purity aluminum target material manufactured through the manufacture method is good in crystal grain uniformity, simple in technological process, short in production period, high in production efficiency and high in finished product rate and has production and market competitive advantages.

Owner:中铝东南材料院(福建)科技有限公司 +1

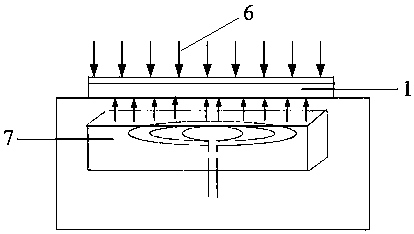

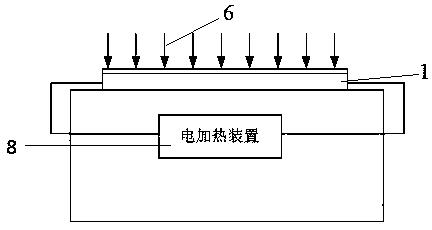

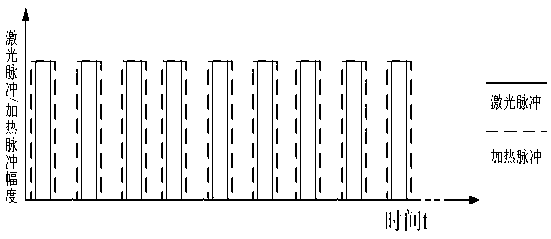

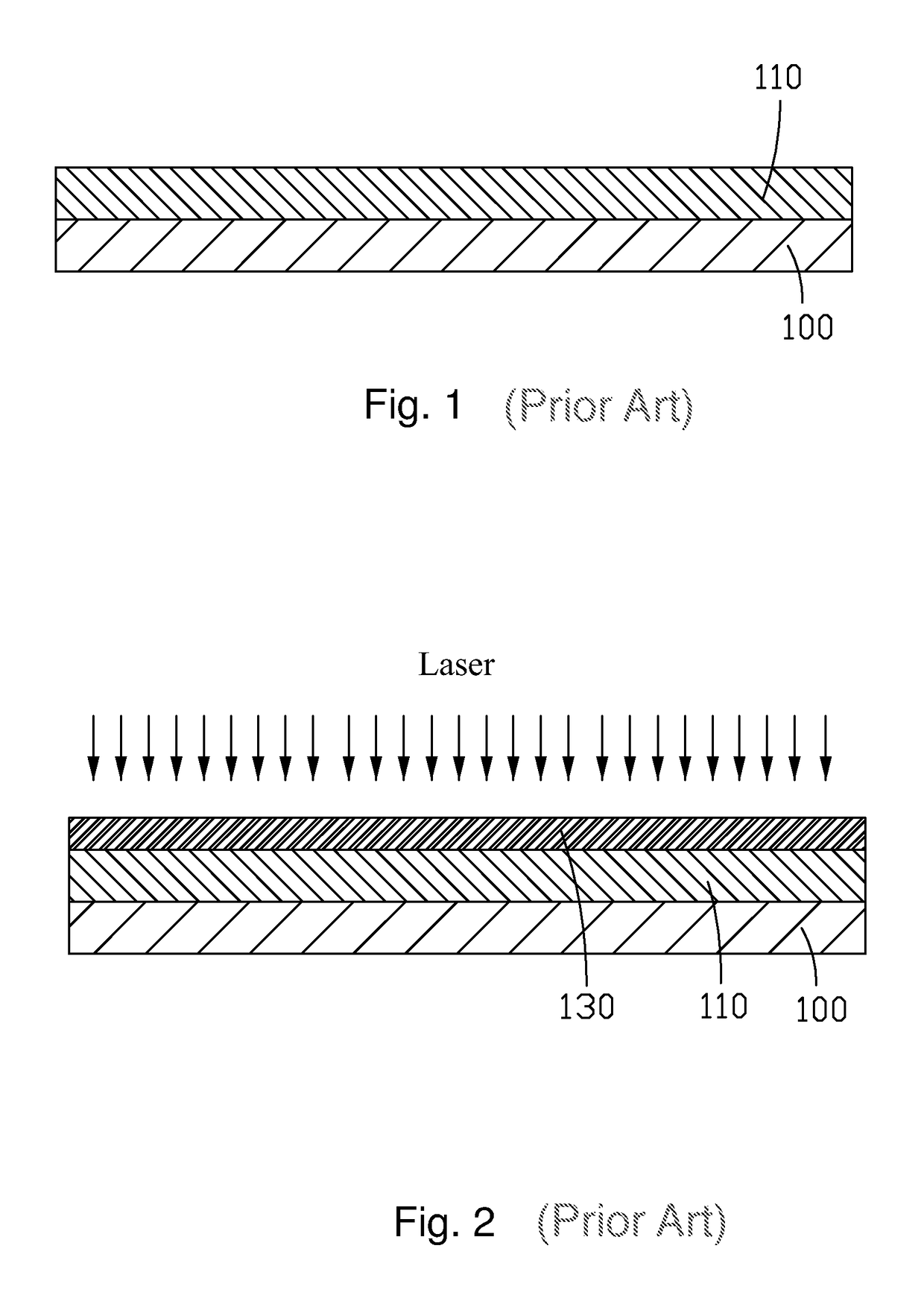

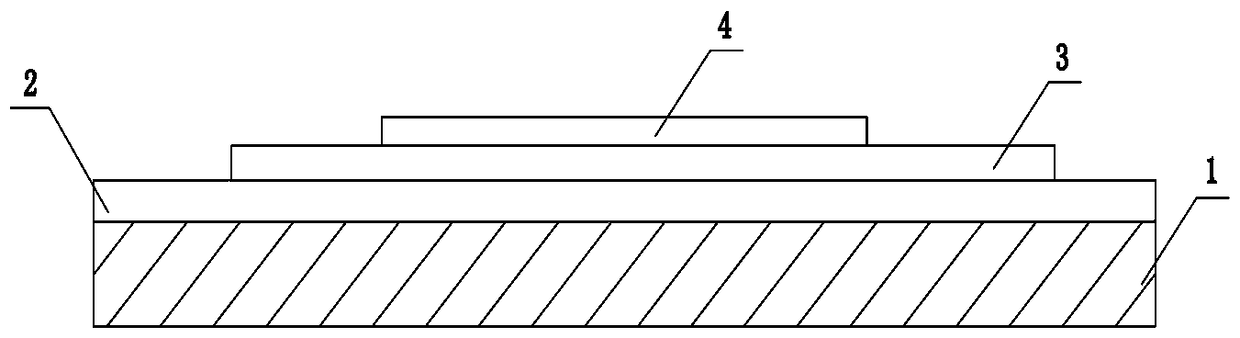

Method for preparing polycrystalline silicon thin film by laser crystallization and product and thin film transistor obtained

ActiveCN108172503AReduce the temperatureImprove grain uniformityTransistorSemiconductor/solid-state device manufacturingSilicon oxideHeat sensitive

The invention relates to the technical field of TFT thin film transistors, in particular to a method for preparing a polycrystalline silicon thin film by laser crystallization and a product and a thinfilm transistor obtained. The preparation steps are as follows: S1, forming a thermistor layer on a glass substrate; S2, forming an amorphous silicon layer on the thermistor layer; and S3, irradiating the amorphous silicon film layer in S2 with laser pulse, and heating the thermistor layer by electric heating or electromagnetic heating to convert the amorphous silicon layer into a polycrystallinesilicon layer. There is a process of forming an isolation layer on the glass substrate before S1, and the isolation layer is made of silicon oxide and / or silicon nitride. The polycrystalline siliconthin film obtained has the characteristics of high grain uniformity, high consistency of grain density, high grain migration rate and high stability. The thin film transistor obtained has the characteristics of no spot, uniform brightness and good electrical performance.

Owner:TRULY HUIZHOU SMART DISPLAY

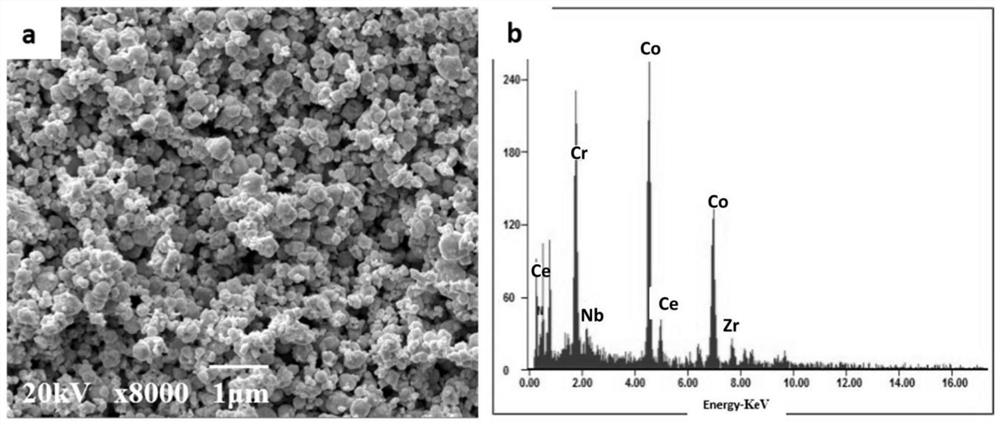

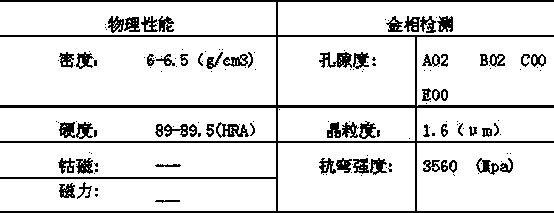

Alloy reinforced titanium carbonitride-based composite material and preparation method thereof

The invention relates to an alloy reinforced titanium carbonitride-based composite material. The alloy reinforced titanium carbonitride-based composite material is characterized by being composed of atitanium-based base material and an alloy composite material, wherein the titanium-based base material is composed of TiCN and WC powder, and the alloy composite material is alloy phase composite powder composed of beta-Co, Cr, Ce, Nb and Zr. The titanium carbonitride-based composite material is spherical, excellent in interface bonding degree, and good in structural crystal face and grain uniformity. In the preparation process in line with a method, the segregation of Co and carbide is effectively inhibited, the agglomeration of alloy phases is inhibited, and the prepared titanium carbonitride-based composite material is good in uniformity and has few defects. The bending strength of the prepared titanium carbonitride-based composite material reaches 3000 MPa on average, and the averagefracture toughness can reach 13MPa.m<1 / 2>.

Owner:CHONGQING UNIV OF ARTS & SCI

Salicide process

ActiveUS20060234485A1Avoid roughnessImprove grain uniformitySemiconductor/solid-state device manufacturingSemiconductor devicesSalicidePlatinum

A salicide process is provided. A metal layer selected from a group consisting of titanium, cobalt, platinum, palladium and an alloy thereof is formed over a silicon layer. A first thermal process is performed. Next, a second thermal process is performed, wherein the second thermal process includes a first step performed at 600˜700 degrees centigrade for 10˜60 seconds and a second step performed at 750˜850 degrees centigrade for 10˜60 seconds. If the metal layer is selected from a group consisting of nickel and an alloy thereof is formed on a silicon layer, the first step of the second thermal process is performed at 300˜400 degrees centigrade for 10˜60 seconds and the second step of the second thermal process is performed at 450˜550 degrees centigrade for 10˜60 seconds.

Owner:MARLIN SEMICON LTD

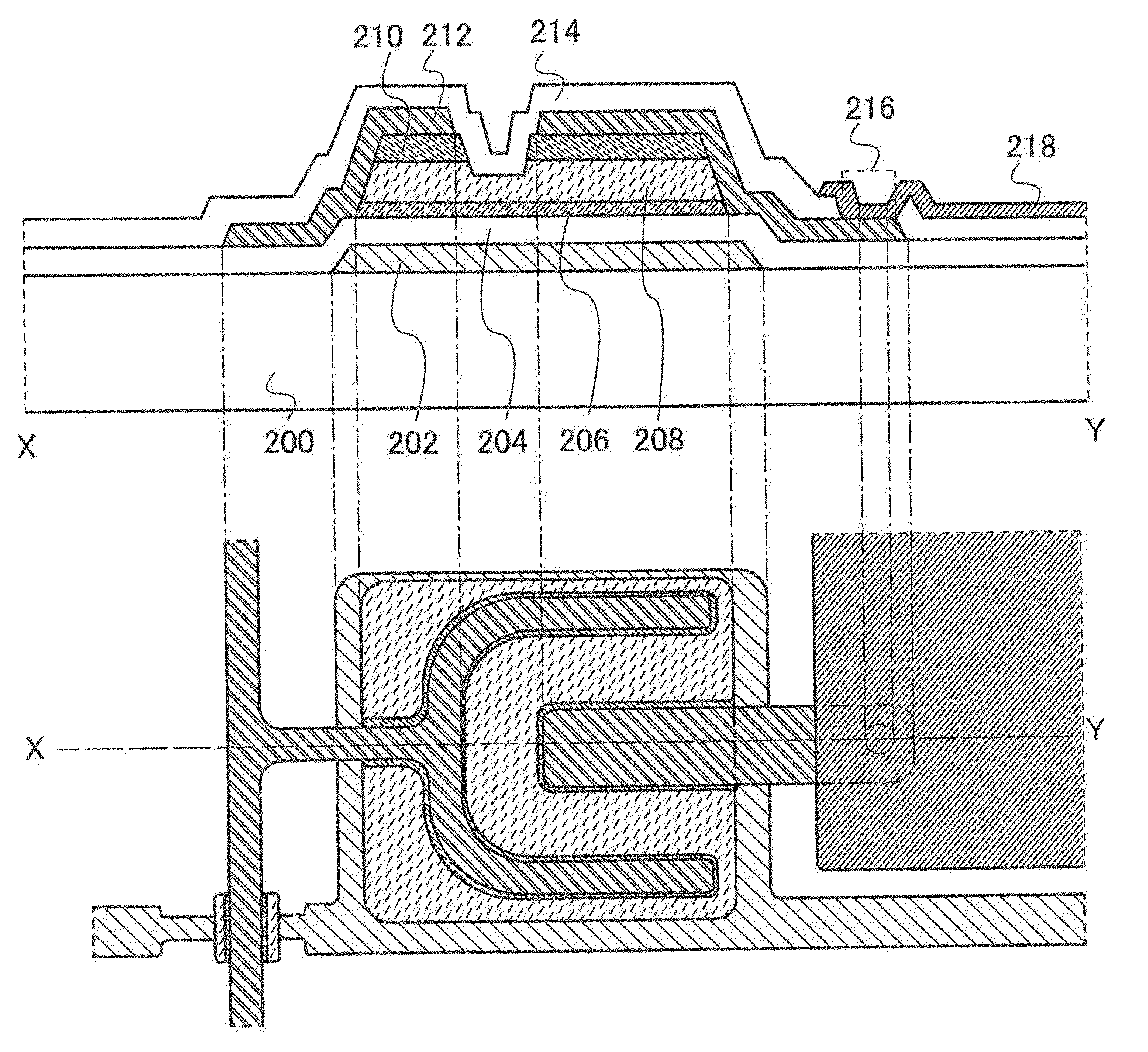

Low temperature poly-silicon TFT substrate structure and manufacture method thereof

ActiveUS20170033134A1High electron mobilityImprove uniformityTransistorSolid-state devicesEngineeringElectric properties

The present invention provides a Low Temperature Poly-silicon TFT substrate structure and a manufacture method thereof. By providing the buffer layers in the drive TFT area and the display TFT area with different thicknesses, of which the thickness of the buffer layer in the drive TFT area is larger, and the thickness of the buffer layer in the display TFT area is smaller, different temperature grades are formed in the crystallization process of the polysilicon to achieve the control to the grain diameters of the crystals. The polysilicon layer with larger lattice dimension is formed in the drive TFT area in the crystallization process to raise the electron mobility. The fractured crystals of polysilicon layer in the display TFT area can be obtained in the crystallization process for ensuring the uniformity of the grain boundary and raising the uniformity of the current. Accordingly, the electrical property demands for different TFTs can be satisfied to raise the light uniformity of the OLED.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

Salicide process

ActiveUS20070048986A1Avoid roughnessImprove grain uniformitySemiconductor/solid-state device manufacturingSemiconductor devicesSalicideAlloy

A salicide process is provided. A metal layer selected from a group consisting of nickel and an alloy thereof is formed on a silicon layer, the first step of the second thermal process is performed at 300˜400 degrees centigrade for 10˜60 seconds and the second step of the second thermal process is performed at 450˜550 degrees centigrade for 10˜60 seconds.

Owner:MARLIN SEMICON LTD

Low temperature poly-silicon TFT substrate structure and manufacture method thereof

ActiveUS9881946B2Improve uniformityHigh electron mobilityTransistorSolid-state devicesEngineeringElectron mobility

The present invention provides a Low Temperature Poly-silicon TFT substrate structure and a manufacture method thereof. By providing the buffer layers in the drive TFT area and the display TFT area with different thicknesses, of which the thickness of the buffer layer in the drive TFT area is larger, and the thickness of the buffer layer in the display TFT area is smaller, different temperature grades are formed in the crystallization process of the polysilicon to achieve the control to the grain diameters of the crystals. The polysilicon layer with larger lattice dimension is formed in the drive TFT area in the crystallization process to raise the electron mobility. The fractured crystals of polysilicon layer in the display TFT area can be obtained in the crystallization process for ensuring the uniformity of the grain boundary and raising the uniformity of the current. Accordingly, the electrical property demands for different TFTs can be satisfied to raise the light uniformity of the OLED.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

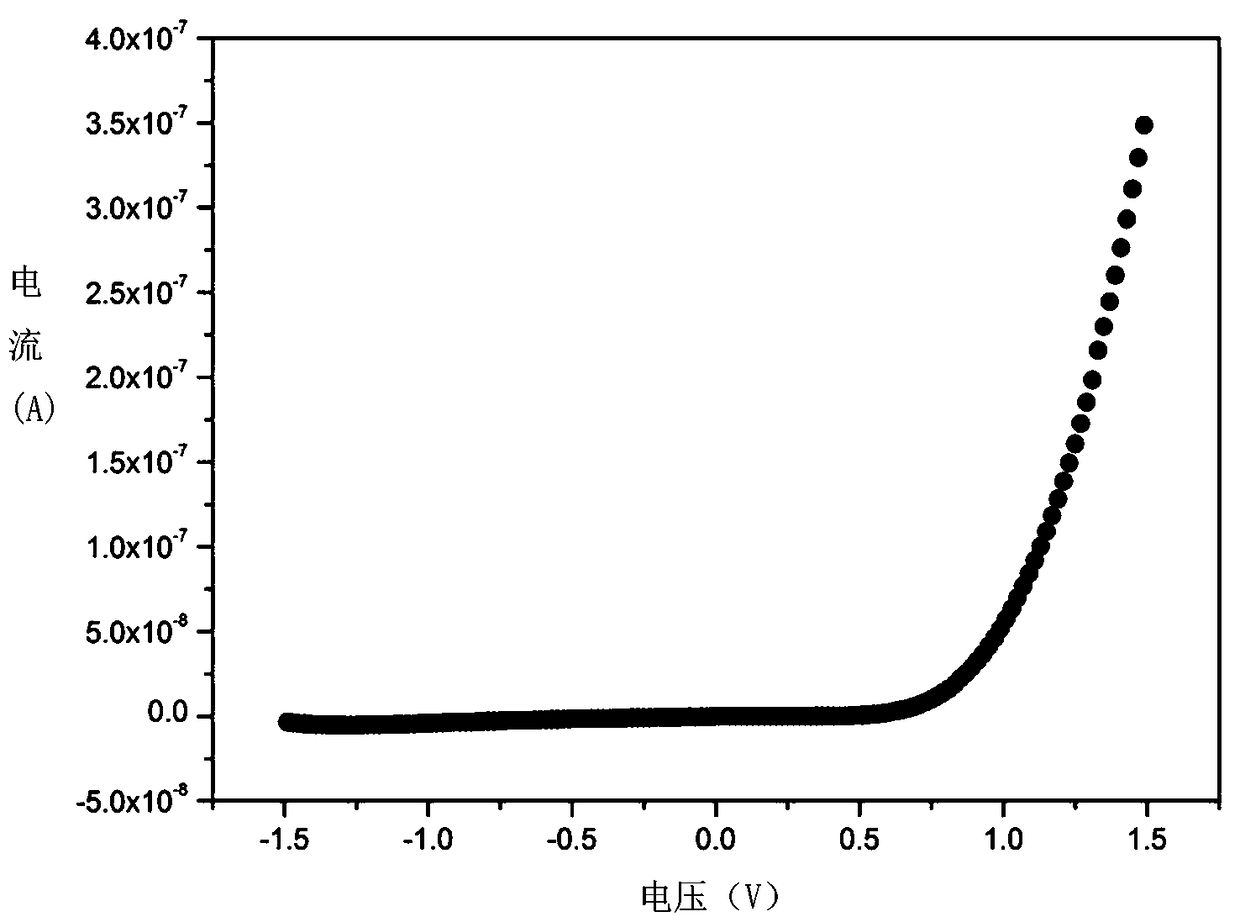

Flexible zinc oxide schottky diode and its preparation method

ActiveCN105977383BImprove grain uniformityLess intergranular interfaceSolid-state devicesSemiconductor/solid-state device manufacturingPhysical chemistryElectrical performance

The invention provides a flexible zinc oxide Schottky diode and a preparation method thereof. The sol-gel method is used to form a flexible zinc oxide Schottky diode on an ITO conductive layer with a flexible substrate with reagents such as zinc nitrate organic solution and polytetravinylphenol organic solution. A better flexible polytetravinylphenol hybrid zinc oxide film, and a thermal evaporation coating method is used to evaporate a precious metal layer on the surface of the polytetravinylphenol hybrid zinc oxide film to obtain a flexible zinc oxide Schottky diode. The polytetravinylphenol hybridized zinc oxide film prepared by the method has high flexibility, so that the prepared diode has good mechanical bending performance and stable electrical performance, and the method has simple process and easy-to-obtain raw materials.

Owner:HENAN UNIVERSITY

Thick gauge q450nqr1 steel plate and its rough rolling method

ActiveCN106350735BImprove tissue performanceImprove grain uniformityMetal rolling arrangementsSheet steelImpurity

The invention relates to weathering steel and a rolling method thereof, in particular to a thick-gauge Q450NQR1 steel plate and a rough rolling method thereof, and belongs to the technical field of steel and iron. The rough rolling method of the thick-gauge Q450NQR1 steel plate is characterized in that the steel plate is prepared from the following chemical ingredients in percentage by weight: 0.05 to 0.08 percent of C, 0.25 to 0.40 percent of Si, 0.8 to 1.45 percent of Mn, at most 0.018 percent of P, at most 0.008 percent of S, 0.32 to 0.38 percent of Cr, 0.12 to 0.20 percent of Ni, 0.20 to 0.25 percent of Cu, 0.05 to 0.06 percent of V, 0.03 to 0.045 percent of Nb and the balance of Fe and unavoidable impurities, wherein the rough rolling method uses odd-even pass whole-course whole-number scale removal; all scale removal water in odd-even passes is in the boiling state; the rolling is performed at a low speed. The difficult problem of original crystalline grain nonuniformity in the cooling process is solved; the cost is low.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP +1

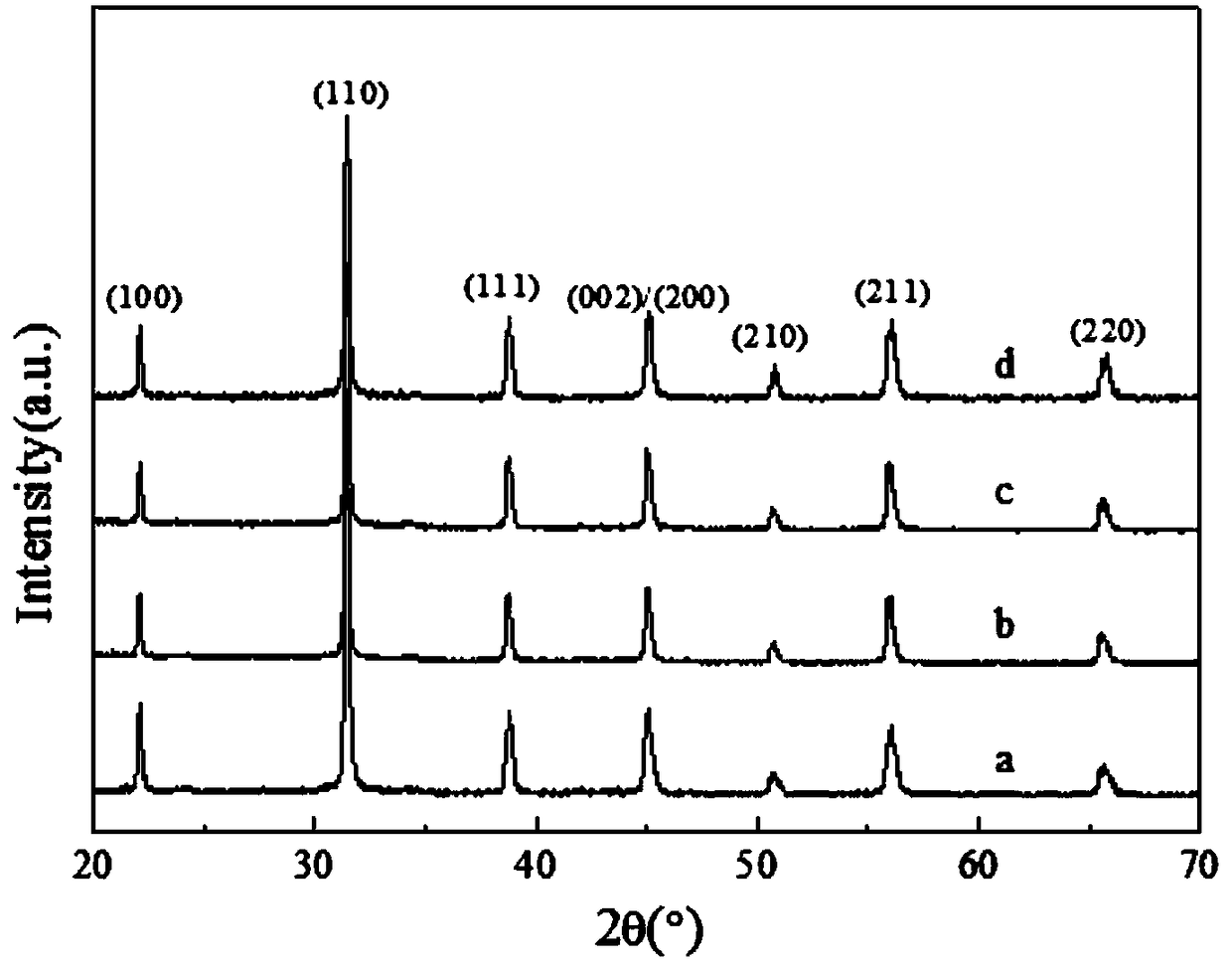

A kind of sol-hydrothermal preparation process of tetragonal barium titanate powder

ActiveCN107151029BHigh purityHigh crystallinityAlkaline earth titanatesFixed capacitor dielectricAcetic acidAlcohol

Owner:CHANGAN UNIV

A preparation method of large-size 5n high-purity aluminum target

ActiveCN110328237BImprove grain uniformitySimple processTemperature control deviceMeasuring devicesCooling curveWork roll

The invention relates to a method for preparing a large-size 5N high-purity aluminum target. When the large-size 5N high-purity aluminum is rolled to a certain thickness, the temperature T1~Tn of the roll is detected every 100~300mm along the width direction, or Detect the temperature of the 5N high-purity aluminum target at every interval (100~300mm) along the width direction, and then set a specific work roll cooling curve according to the temperature curve, so that the rolling temperature can be guaranteed during the subsequent rolling pass The uniformity of the large-size 5N high-purity aluminum target is guaranteed to be uniform in the width direction. The large-sized 5N high-purity aluminum target prepared by the invention has good crystal grain uniformity, simple process, short production cycle, high production efficiency and high yield, and has advantages in production and market competition.

Owner:CHINALCO SOUTHEAST MATERIALS (FUJIAN) TECH CO LTD +1

After-forging grain-refining strength-toughening treatment process of 1Mn18Cr18N steel guard ring for generating set

The invention discloses a post-forging fine grain strengthening and toughening treatment process for manufacturing a 1Mn18Cr18N steel retaining ring forging for a generator set. The post-forging fine-grain strengthening and toughening treatment process of 1Mn18Cr18N steel retaining ring forgings for generator sets includes pre-cooling and deformation of steel retaining ring forgings that have been roughly machined, solution heat treatment, and sampling to detect the effect of solution heat treatment. Adopting the invention can make the austenitic steel forgings with coarse grains in essence and cannot be refined by heat treatment have fine and uniform grains before cold deformation strengthening, thereby greatly improving the strength and ductility of the forgings, and at the same time, the quality controllability powerful.

Owner:DEYANG WANXIN POWER STATION PROD DEV

A method for improving grain uniformity of molybdenum and its alloy sputtering targets

ActiveCN109355632BAvoid uniformityUniform temperatureVacuum evaporation coatingSputtering coatingHydrogen atmosphereThin membrane

The invention relates to a method for improving molybdenum and alloy sputtering target material grain uniformity. The method comprises the steps that firstly, molybdenum powder with the fisher particle size being 2.0 to 4.5 micrometers is subject to ball grinding and grading, and the content of particles, below one micrometers, in the molybdenum powder is below 5%, the content of particles, below0.5 micrometer, in the molybdenum powder is below 1%, and the molybdenum powder is mixed with alloy powder with the fisher particle size being 5 to 20 micrometers evenly to obtain mixed powder; secondly, the mixed powder is subjected to cold isostatic pressing forming, and a pressing plate blank is obtained; thirdly, the pressing plate blank is sintered at the temperature of 1750 to 2150 DEG C andis subjected to heat preservation for 2 to 8 hours, and a sintering blank is obtained; fourthly, the sintered blank is rolled and deforms to obtain a rolled blank, the cogging temperature ranges from1350 to 1500 DEG C, and the final rolling temperature ranges from 1100 to 1400 DEG C; fifthly, the rolled blank is annealed for one to four hours in the vacuum or hydrogen atmosphere at the temperature of 1050 to 1250 DEG C, and the sputtering target material is obtained. Through the method, the grain uniformity in the molybdenum and alloy sputtering target material small area and between the areas can be improved, the sputter coating microcosmic and whole uniformity can be ensured, and the quality, the service life and the product consistency of related electronic element function films canbe improved.

Owner:ZHENGZHOU UNIV

High-strength cermet for cutting non-ferrous metal sheet and preparation method thereof

ActiveCN106756411BHigh hardnessLight weightTransportation and packagingMetal-working apparatusMass ratioGasoline

The invention discloses a high-strength cermet for cutting non-ferrous metal sheets and a preparation method thereof, wherein the preparation method comprises the following steps: a. taking primary TiC powder, primary Mo powder, primary Ni powder and NbC powder and passing them through a ball milling medium After grinding for 48h-64h, the slurry is obtained, wherein the average Fischer particle size of the primary TiC powder is ≤1.0 μm, and the mass ratio is 44%-46%, and the average Fischer particle size of the primary Mo powder is ≤1.0 μm, and the mass ratio is 14% %-16%, the average Fischer particle size of primary Ni powder is ≤1.0μm, and the mass proportion is 38%-40%, the average Fischer particle size of NbC powder is ≤1.0μm, and the mass proportion is 0.8%-1.2%, the ball milling medium It is cemented carbide baseball and absolute ethanol, or the ball milling medium is cemented carbide baseball and No. 120 aviation gasoline; b, the slurry after step a is made to enter the stainless steel container through a stainless steel screen; c, the slurry is placed on the stainless steel After standing still in the container for 24 hours, and when the ball milling medium is cemented carbide baseball and absolute ethanol, the absolute ethanol on the upper layer of the slurry is taken out.

Owner:株洲精特硬质合金有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com