Thick gauge q450nqr1 steel plate and its rough rolling method

A thick-gauge, steel plate technology, applied to weathering steel and its rolling, thick-gauge Q450NQR1 steel plate and its rough rolling, to achieve the effect of large margin, improved grain uniformity, and good application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1—5

[0043] The Q450NQR1 billets of Examples 1-5 were smelted according to the chemical composition in Table 1, and the thicknesses of the billets of Examples 1-5 were 200mm, 230mm, 230mm, 230mm, and 230mm respectively.

[0044] Billet chemical composition % of table 1 embodiment 1-5

[0045]

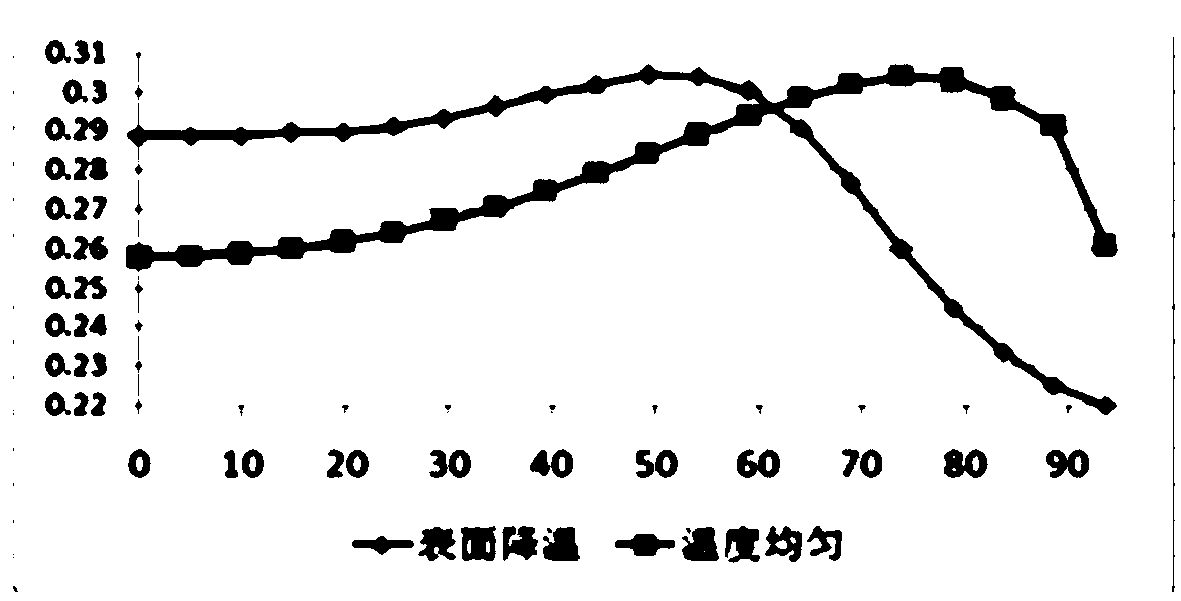

[0046] All odd and even passes are used for full descaling, and the rolling rate is shown in Table 2. The rough rolling compression ratio is not changed, and the rough rolling descaling water is fully opened for odd and even passes. The surface temperatures of Examples 1-5 are respectively 910, 930, 930, 940, and 920; the cooling depths are respectively 10mm, 18mm, 16mm, 18mm, and 20mm to control the temperature difference between the surface layer and the core between 30 and 200°C.

[0047] The rolling parameter of table 2 embodiment 1-5

[0048]

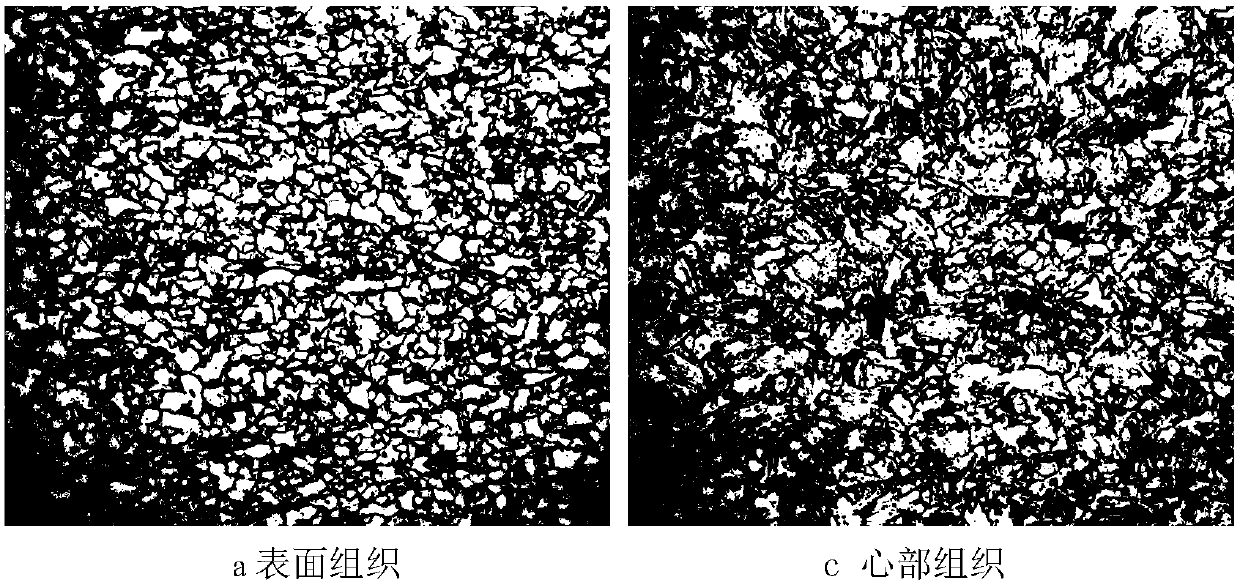

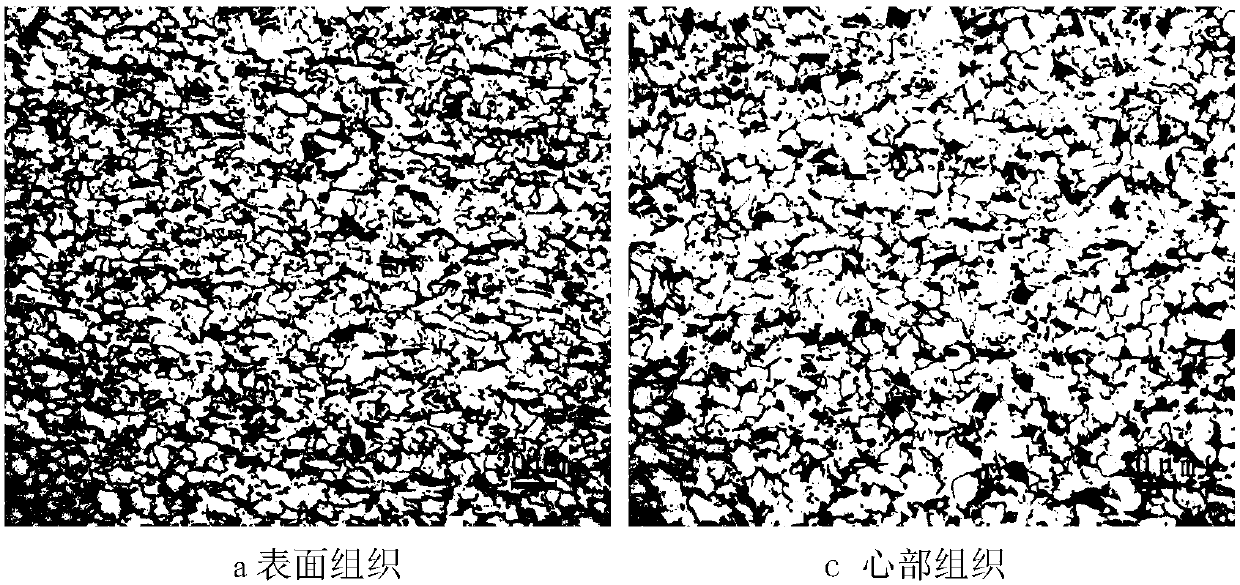

[0049] The finished product thicknesses of Examples 1-5 obtained by rolling are respectively 12 mm. The surface and core grain size is d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com