Cold-rolled weathering resistant steel and preparation method thereof

A technology of weathering steel and continuous cold rolling, applied in the field of cold-rolled weathering steel and its preparation, can solve the problems of increased cost of cold-rolled steel plates, reduced welding performance, difficult control of production process, etc. The effect of good atmospheric corrosion resistance and weldability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with examples.

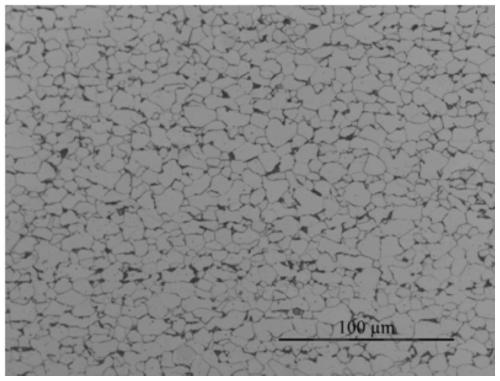

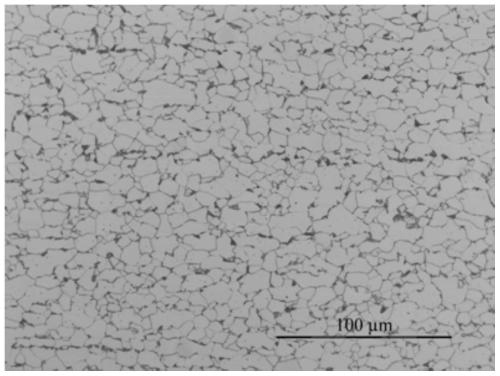

[0033] The chemical composition and weight percentage of the cold-rolled weathering steel of each embodiment and comparative example are as shown in table 1:

[0034] The chemical composition is shown in Table 1: the rest are unavoidable impurities and Fe

[0035]

[0036]

[0037] After continuous casting of molten steel, it undergoes hot rolling, pickling, five-stand full six-high continuous cold rolling, continuous annealing, and tempering preparation. The main process parameters are shown in Table 2.

[0038] Table 2 Production Process Parameters

[0039]

[0040] The properties of each embodiment and comparative example are shown in Table 3.

[0041] The mechanical properties of each embodiment of table 3

[0042]

[0043]

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com